Teco EQ7 Catalog

Features and Benefits

State of the art engineering and robust, best-in-class performance.

CONTROL FEATURES

z Four selectable control modes – Volts/Hertz, Dynamic Torque, Sensorless Vector, Closed Loop Vector

z Provides drive solutions for today's demanding motor driven machinery

ADVANCED SPEED AND TORQUE CONTROL CAPABILITIES

z High levels of torque boost attainable

z Power loss ride through

z Torque limit adjustable features

ADVANCED TUNING FEATURES

z High level of detail and information regarding applied motors

z Motor types range from variable torque to full flux vector motors

PID LOOP CONTROL FEATURES

z Process or Dancer control

z Loss of feedback detection

z Sleep-wake mode

z High and low feedback alarms

z Wide variety of process set point signals to choose from

CLOSED LOOP SPEED CONTROL

z 100 Hz speed loop bandwidth

z Full-quadrature encoder feedback with marker pulse

z Range: 20 – 60,000 counts/ revolution

z Loss of encoder signal detection with alternative operation selection

z PI speed loop with adjustable gains and notch filtering

EXTENSIVE INPUT/ OUTPUT CAPABILITIES

z Forward and Reverse inputs plus seven assignable digital inputs

z Over 50 settings available; each assignable as normally open or normally closed state

z Three analog inputs; 0 to ±10V or 0 to 10V, 4 to 20 ma, 0 to ±10V signals

z Assignable frequency reference, PID set point or feedback, torque reference, torque gain plus

many choices

z Two analog outputs: selectable as 0 to 10V or 4 to 20ma output, scaling, plus over a dozen configuration

choices such as output frequency, current, voltage, torque plus more.

z Four transistor type outputs; over 50 settings available; each assignable as normally open or normally

closed state

z Two assignable contact outputs; over 50 settings as with the transistor outputs

z Pulse train input

MONITORING AND DIAGNOSTICS

z Extensive monitoring capabilities

z Detailed status information for all recorded faults (up to 4)

z Cumulative operating time displays for component maintenance

z Output frequency reduction to avoid overload trips and transistor junction over temperature

Applications

Application Type V/F Mode

Fans and Blowers X

Centrifugal Pumps X X

Mixers X X

Conveyors X X X

Hoist / Elevator X X

Stamping / Punch Press X X

Dynamometers X X

Extruders X X

Web / Roll Processes X

Torque Regulation X

Direct Torque Control X

Indexing Operations X X

Positioning * X

* Requires External Positioning Controller Interface

Dynamic

Torque Mode

Sensorless

Vector Mode

Closed-Loop

Vector Mode

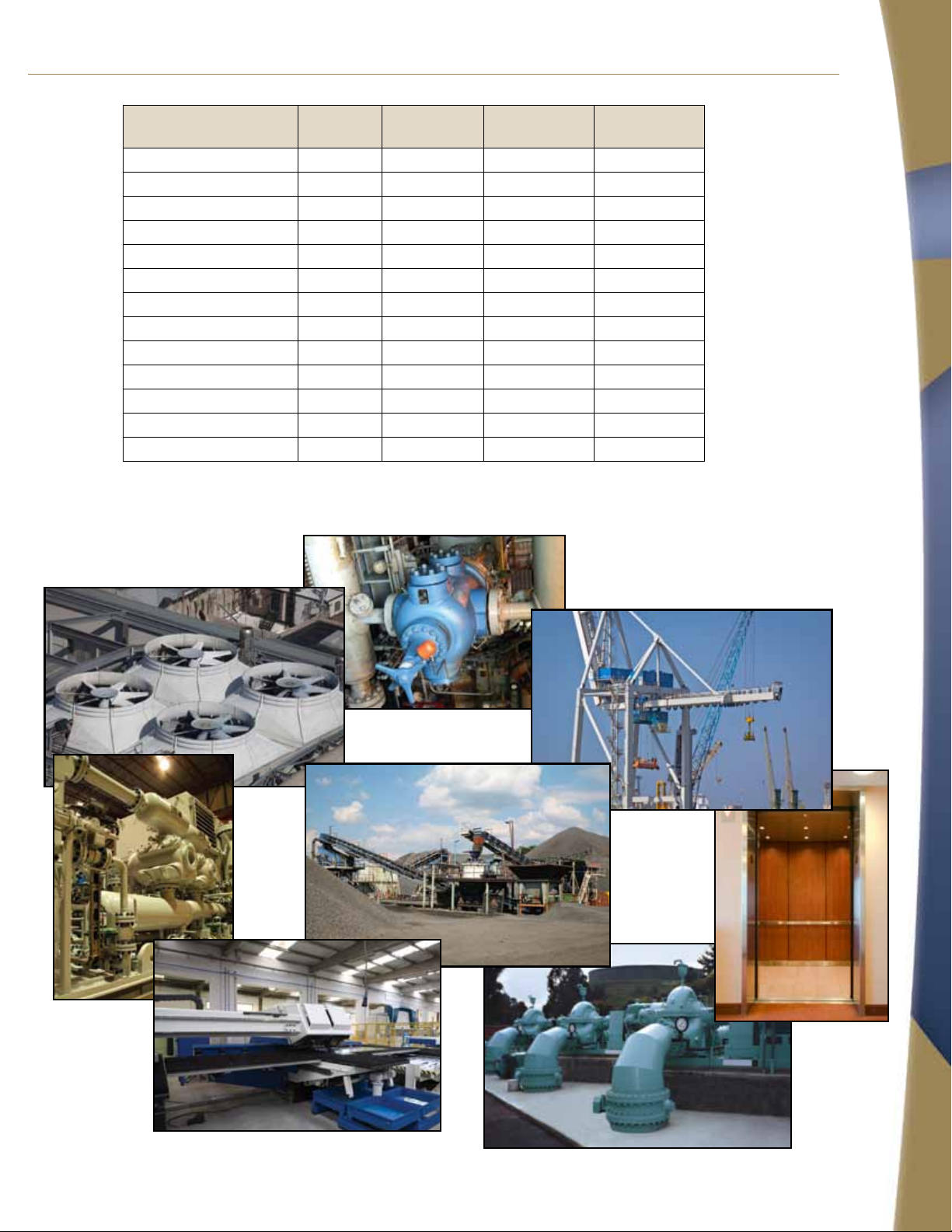

Keypad Panel Functions and Operations

FEATURES:

• LED and LCD display for

user-friendly monitoring

• Extensive monitoring

and diagnostics

• Configuration menus including

a Quick-start menu

• Stores configuration settings

for easy download

Type Item Description (information, condition, status)

Hz Output frequency, frequency command

A Output current

V Output voltage

Unit of

Number

Displayed

on LED

Monitor

Operating

Status

Source of

Operation

% Calculated torque, load factor, speed

r/min Motor speed, set motor speed, load shaft speed, set load shaft speed

m/min Line speed, set line speed

kW Input power, motor output

X10 Data greater than 99,999

min Constant feeding rate time, constant feeding rate time setting

sec Timer

PID PID process value

FWD Running (forward rotation)

REV Running (reverse rotation)

STOP No output frequency

REM Remote mode

LOC Local mode

COMM Communication enabled (RS-485 (standard,optional) eld bus option)

JOG Jogging mode

HAND Keypad eective (lights also in local mode)

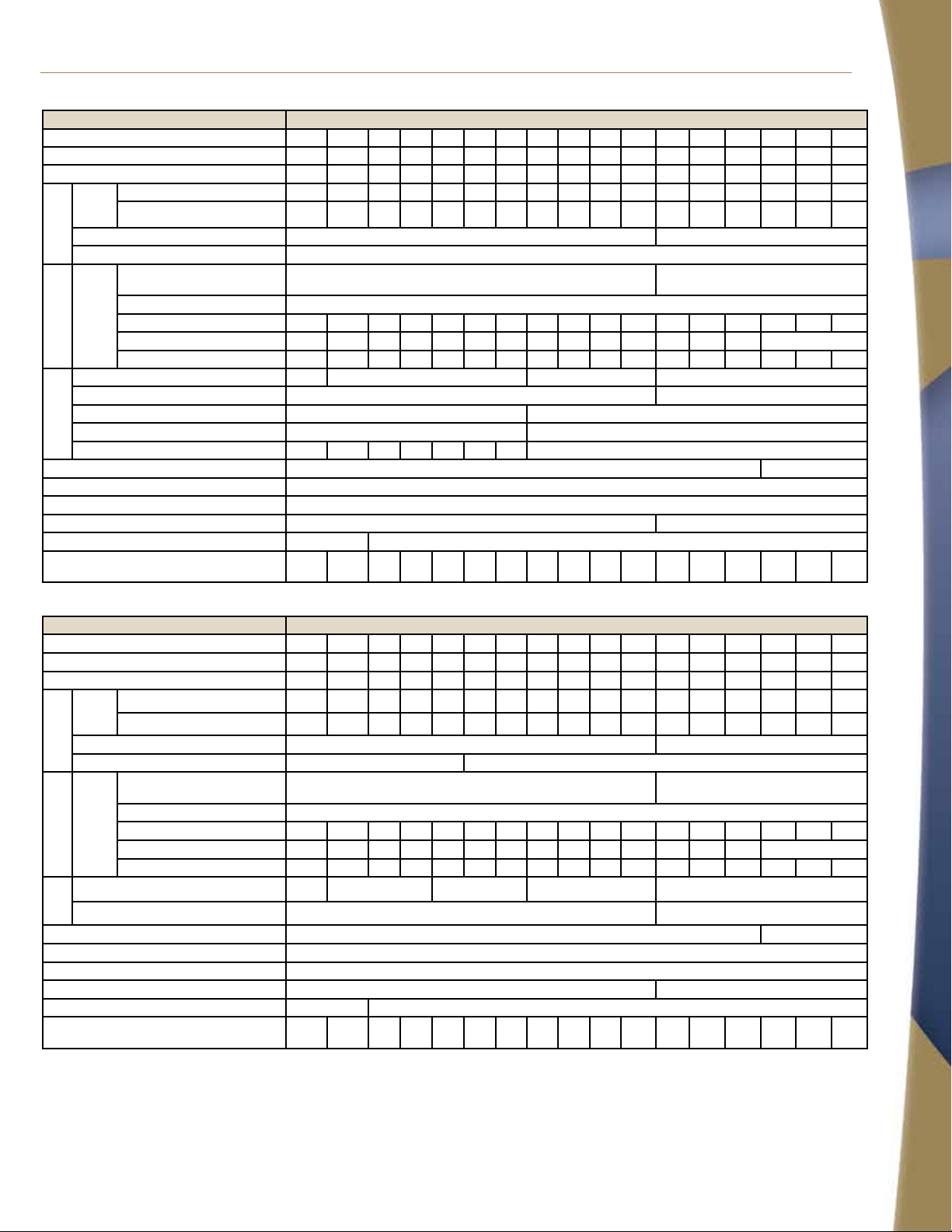

Constant Torque/ Variable Torque - 230V Series

Constant Torque

Item Specifications

Model EQ7-2XXX-C 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125 150

Nominal applied motor hp

Nominal applied motor hp

Three

phase

*9

input

Rated voltage

Output ratings

Overload Capability 150%-1 min, 200% -3.0 s

Three

phase

input

Input ratings

Torque *7 [%] 150% 100% 20% 10 to 15%

Braking transistor Built-in -

Built-in braking resistor Built-in -

Braking

Braking time [s] 5 s -

%ED 3 5 3 2 3 3 2 -

DC reactor (DCR) Option As standard

Keypad Multi-function keypad

Applicable Safety Standards UL508C, C22.2 No.14, EN61800-5-1:2007, EN61800-5-2:2007 SIL2, EN ISO13849-1:2008 PL=d Cat.3, EN954-1:1996 Cat.3

Enclosure (IEC60529) IP20, UL open type, NEMA 1 (Option) IP00, UL open type, NEMA 1 (Option)

Cooling method Natural Cooling Fan cooling

Weight/ Mass [lbs(kg)]

*1

for three phase input 1 2 3 5 7.5 7.5 10 15 20 25 30 40 50 60 75 100 125

*1

for single phase input 0.5 1 1.5 3 3 3 5 7.5 10 10 15 20 25 30 30 40 40

Rated capacity *2 [kVa] 2 3.2 4.4 7.2 11 11 15 20 25 30 36 47 58 72 86 113 138

Rated current [A] 5 8 11 18 27 27 37 49 63 76 90 119 146 180 215 283 346

*3

[V] Three-phase, 200 to 240V (with AVR function) Three-phase 200 to 230V (with AVR function)

Voltage, frequency Three-phase, 200 to 240V, 50/60Hz

Voltage, frequency variations Voltage +10 to -15% (Interphase voltage unbalance: 2% or less),

Three-phase, 200 to 220V, 50Hz

Three-phase, 200 to 230V, 60Hz

*5

Frequency +5 to -5%

Input current with DCR 3 5.5 7.7 13 18.5 18.5 25.1 37.6 50.2 62.7 75.3 100 120 145 178 246 291

Input current without DCR 4.7 8.5 11.9 20 28.4 28.4 38.6 54.8 72.4 87.7 101 136 167 203 -

*6

Required capacity with DCR

[kVa] 1.2 2.2 3.1 5.2 7.4 7.4 10 15 20 25 30 40 48 58 71 98 116

*8

4.4

6.2

6.6

6.6

14.3

14.3

14.3

12.8

20.9

20.9

22

55.1

70.6

92.6

94.8

(2.0)

(2.8)

(3.0)

(3.0)

(6.5)

(6.5)

(6.5)

(5.8)

(9.5)

(9.5)

(10)

(25)

(32)

(42)

(43)

137

(62)

231

(105)

Variable Torque mode

Item Specifications

Model EQ7-2XXX-C 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125 150

Nominal applied motor hp *1 for three phase input 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150

Nominal applied motor hp *1 for single phase input 0.5 1 1.5 3 3 5 7.5 10 10 15 20 25 30 30 40 40 50

Three

Rated capacity *2 [kVa] 2 3.2 4.4 7.2 11 13 18 24 30 35 46 58 72 86 113 138 165

phase

*9

Rated current [A]

input

Rated voltage

Output ratings

Overload Capability 150%-1 min, 200% -3.0 s 120%-1 min

*3

[V] Three-phase, 200 to 240V (with AVR function) Three-phase 200 to 230V (with AVR function)

Voltage, frequency Three-phase, 200 to 240V, 50/60Hz

Three

Voltage, frequency variations Voltage +10 to -15% (Interphase voltage unbalance: 2% or less),

phase

Input current with DCR 3 5.5 7.7 13 18.5 25.1 37.6 50.2 62.7 75.3 100 120 145 178 246 291 358

input

Input ratings

Input current without DCR 4.7 8.5 11.9 20 28.4 38.6 54.8 72.4 87.7 101 136 167 203 244 -

Required capacity with DCR

Torque *7 [%] 150% 100% 70% 15% 7 to 12%

Braking transistor Built-in -

Braking

DC reactor (DCR) Option As standard

Keypad Multi-function keypad

Applicable Safety Standards UL508C, C22.2 No.14, EN61800-5-1:2007, EN61800-5-2:2007 SIL2, EN ISO13849-1:2008 PL=d Cat.3, EN954-1:1996 Cat.3

Enclosure (IEC60529) IP20, UL open type, NEMA 1 (Option) IP00, UL open type, NEMA 1 (Option)

Cooling method Natural Cooling Fan cooling

Weight/ Mass [lbs(kg)]

(*1) 4-pole standard motor

(*2) Rated capacity is calculated by assuming the output rated voltage as 230V for 230V series and 460V for 460V series.

(*3) Output voltage cannot exceed the power supply voltage. At single-phase input use, the output voltage may be lower than three-phase input.

(*4) To use the inverter with the carrier frequency of 3 kHz or more at ambient temperature of 40C (104F) or higher, please consult the instruction manual for modified amp ratings

at these conditions

(*5) Voltage unbalance[%] = (Max.voltage [V] - Min. voltage [V ]/Three-phase average voltage [V]x67(See IEC61800-3.) If this value is 2 to 3%, use an optional AC reactor (ACR).

(*6) Required when a DC reactor (DCR) is used.

(*7) Without external braking resistor condition. Average braking torque for the motor running alone. (It varies with the efficiency of the motor.)

(*8) For inverters of 100 hp or above, the DC reactor is provided as separate standard component. be sure to connect it to those inverters.

(*9) For single-phase input installations, please consult factory.

*4

5 8 11 18 27 31.8 46.2 59.4 74.8 88 115 146 180 215 283 346 415

Three-phase, 200 to 220V, 50Hz

Three-phase, 200 to 230V, 60Hz

*5

Frequency +5 to -5%

*6

[kVa] 1.2 2.2 3.1 5.2 7.4 10 15 20 25 30 40 48 58 71 98 116 143

*8

4.4

6.2

6.6

6.6

14.3

14.3

14.3

12.8

20.9

20.9

22

55.1

70.6

92.6

94.8

(2.0)

(2.8)

(3.0)

(3.0)

(6.5)

(6.5)

(6.5)

(5.8)

(9.5)

(9.5)

(10)

(25)

(32)

(42)

(43)

137

(62)

231

(105)

Loading...

Loading...