Page 1

Page 2

Preface

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily

injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

This icon indicates information which, if not followed, can result in the inverter not operating to full efficiency,

as well as information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

The EQ7 product is designed to drive a three-phase induction motor. Read through this instruction manual to

become familiar with proper handling and correct use. Improper handling might result in incorrect operation,

shorter life cycle, or failure of this product as well as the motor.

Have this Instruction Manual delivered to the end user of this product. Keep this Instruction Manual in a safe

place accessible by only people in connection with the VFD until this product is no longer being used.

Read this Instruction Manual in conjunction with EQ7 User Manual.

All EQ7 documentation is subject to change without notice

Available Documentation:

1. EQ7 Quick Setting Guide

2. EQ7 Instruction Manual

3. EQ7 User Manual

Safety Precautions

Read this instruction manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all

safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to ignore the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

Icons

The following icons are used throughout this quick start manual.

i

Page 3

Table of Contents

Safety and Conformity ......................................................................................................... iv

Application ............................................................................................................................................................. iv

Installation .............................................................................................................................................................. iv

Wiring ..................................................................................................................................................................... v

Operation ............................................................................................................................................................... vi

Maintenance, Inspection and Part Replacements ................................................................................................. vii

Conformity with UL standards and CSA standards (cUL –listed for Canada) ....................................................... viii

1. Drive Model Identification, Installation and Wiring Practices ....................................... 1-1

1.1 Drive Models Constant Torque (CT) / Variable Torque (VT) HP Ratings ....................................................... 1-2

1.2 Installation and wiring practices ....................................................................................................................... 1-3

1.3 Precautions in running Inverters ...................................................................................................................... 1-11

1.4 Precautions in using special motors ................................................................................................................ 1-11

2. Mounting and Wiring the Inverter.................................................................................... 2-1

2.1 Operating Environment .................................................................................................................................... 2-1

2.2 Installing the Inverter ....................................................................................................................................... 2-1

2.3 Wiring ............................................................................................................................................................... 2-4

2.4 Mounting and Connecting the Keypad ............................................................................................................ 2-27

2.5 Input Power and Motor Connection ................................................................................................................. 2-28

3. Operation using the Keypad ............................................................................................ 3-1

3.1 LED Monitor, LCD Monitor, and Keys ............................................................................................................. 3-1

3.2 Overview of Operating Modes ......................................................................................................................... 3-3

3.3 Running Mode ................................................................................................................................................. 3-4

3.4 Programming Mode ......................................................................................................................................... 3-8

4. Function Codes / Parameters ......................................................................................... 4-1

4.1 Function Code Tables ..................................................................................................................................... 4-1

4.2 Details of Function Codes ............................................................................................................................... 4-25

5. Check Motor Rotation and Direction ............................................................................... 5-1

6. Speed Reference Command Configuration .................................................................... 6-1

6.1 Reference from the Keypad ............................................................................................................................. 6-1

6.2 Reference from an Analog Signal (0-10V / 4-20mA) / Speed Pot ................................................................... 6-2

6.3 Reference from Serial Communication – RS485 ............................................................................................ 6-4

ii

Page 4

7. Operation Method Configuration (Run / Stop) ............................................................... 7-1

7.1 Run / Stop from the Keypad ............................................................................................................................ 7-1

7.2 Run / Stop from External Switch / Contact or Pushbutton .............................................................................. 7-2

7.3 Run / Stop from Serial Communication – RS485 ............................................................................................ 7-4

8. Motor and Application Specific Settings ........................................................................ 8-1

8.1 Set Motor Nameplate Data .............................................................................................................................. 8-1

8.2 Acceleration and Deceleration Time................................................................................................................ 8-2

8.3 Torque Boost Setting ....................................................................................................................................... 8-3

8.3 Load Selection / Auto Torque Boost / Auto Energy Saving Operation ............................................................ 8-4

8.4 Reset EQ7 back to Factory Default ................................................................................................................. 8-6

9. Using PID Control for Constant Flow / Pressure Applications ..................................... 9-1

9.1 What is PID Control ......................................................................................................................................... 9-1

9.2 Connect Transducer Feedback Signal ........................................................................................................... 9-2

9.3 Setpoint Scaling / Transducer Feedback Scaling ............................................................................................ 9-4

10. Troubleshooting ............................................................................................................. 10-1

10.1 Protective Functions ...................................................................................................................................... 10-1

10.2 Before Proceeding with Troubleshooting ..................................................................................................... 10-2

10.3 If Neither an Alarm Nor “Light Alarm” Indication( ) Appears on the LED Monitor .................................. 10-5

10.4 If an Alarm Code Appears on the LED Monitor ............................................................................................. 10-12

10.5 If the “Light Alarm” Indication ( ) Appears on the LED Monitor .............................................................. 10-25

10.6 If an Abnormal Pattern Appears on the LED Monitor .................................................................................... 10-26

10.7 If the inverter is running on Single-Phase Power .......................................................................................... 10-27

11. Specifications ................................................................................................................. 11-1

11.1 Drive Ratings ................................................................................................................................................. 11-1

11.2 Common Specifications ................................................................................................................................. 11-7

11.3 External Dimensions, Drive, Panel Cutting, DCR, Keypad ........................................................................... 11-12

iii

Page 5

Application

• The EQ7 drive is designed to drive a three-phase induction motor. Do not use it for single-phase

motors or for other purposes.

Fire or an accident could occur.

• The EQ7 drive may not be used for a life-support system or other purposes directly related to the

human safety.

• Though the EQ7 drive is manufactured under strict quality control, install safety devices for

applications where serious accidents or property damages are foreseen in relation to the failure of

it.

An accident could occur.

• Install the inverter on a base made of metal or other non-flammable material.

Otherwise, a fire could occur.

• Do not place flammable object nearby.

Doing so could cause fire.

• Inverters with a capacity of 50 HP or above, whose protective structure is IP00 (Open Chassis),

involve a possibility that a human body may touch the live conductors of the main circuit terminal

block. Inverters to which an optional DC reactor is connected also involve the same. Install such

inverters in an inaccessible place.

Otherwise, electric shock or injuries could occur.

• Do not support the inverter by its front cover during transportation.

Doing so could cause a drop of the inverter and injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter or from accumulating on the heat sink.

• When changing the positions of the top and bottom mounting bases, use only the specified screws.

Otherwise, a fire or an accident might result.

• Do not install or operate an inverter that is damaged or lacking parts.

Doing so could cause fire, an accident or injuries.

Installation

iv

Page 6

Wiring

• If no zero-phase current (earth leakage current) detective device such as a ground-fault relay is

installed in the upstream power supply line in order to avoid the entire power supply system's

shutdown undesirable to factory operation, install a residual-current-operated protective device

(RCD)/earth leakage circuit breaker (ELCB) individually to inverters to break the individual inverter

power supply lines only.

Otherwise, a fire could occur.

• When wiring the inverter to the power source, insert a recommended molded case circuit breaker

(MCCB) or residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB)

(with overcurrent protection) in the path of each pair of power lines to inverters. Use the

recommended devices within the recommended current capacity.

• Use wires of the specified size.

• Tighten terminals with specified torque.

Otherwise, a fire could occur.

• When there is more than one combination of an inverter and motor, do not use a multi-conductor

cable for the purpose of running the leads together.

• Do not connect a surge absorber to the inverter's output (secondary) circuit.

Doing so could cause a fire.

• Be sure to connect an optional DC reactor (DCR) when the capacity of the power supply

transformer exceeds 500 kVA and is 10 times or more the inverter rated capacity.

Otherwise, a fire could occur.

• Ground the inverter in compliance with the national or local electric code.

• Be sure to ground the inverter's grounding terminals G.

Otherwise, an electric shock or a fire could occur.

• Qualified electricians should carry out wiring.

• Be sure to perform wiring after turning the power OFF.

Otherwise, an electric shock could occur.

• Be sure to perform wiring after installing the inverter unit.

Otherwise, an electric shock or injuries could occur.

• Ensure that the number of input phases and the rated voltage of the product match the number of

phases and the voltage of the AC power supply to which the product is to be connected.

Otherwise, a fire or an accident could occur.

• Do not connect the power supply wires to output terminals (U, V, and W).

• When connecting a DC braking resistor (DBR), never connect it to terminals other than terminals

P(+) and DB.

Doing so could cause fire or an accident.

• In general, the insulation of the control signal wires are not specifically designed to withstand a high

voltage (i.e., reinforced insulation is not applied). Therefore, if a control signal wire comes into direct

contact with a live conductor of the main circuit, the insulation may break down, which would

expose the signal wire to the high voltage of the main circuit. Make sure that the control signal wires

will not come into contact with live conductors of the main circuit.

Doing so could cause an accident or an electric shock.

v

Page 7

• Before changing the switches or touching the control circuit terminal symbol plate, turn OFF the

power and wait at least five minutes for inverters of 40 HP or below, or at least ten minutes

for inverters of 50 HP or above. Make sure that the LED monitor and charging lamp are turned

OFF. Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage

between the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• The inverter, motor and wiring generate electric noise. This may cause the malfunction of nearby

sensors and devices. To prevent malfunctioning, implement noise control measures.

Otherwise an accident could occur.

• Be sure to mount the front cover before turning the power ON. Do not remove the cover when the

inverter power is ON.

Otherwise, an electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If the auto-reset function has been selected, the inverter may automatically restart and drive the

motor depending on the cause of tripping. Design the machinery or equipment so that human safety

is ensured at the time of restarting.

Otherwise, an accident could occur.

• If the stall prevention function (current limiter), automatic deceleration (anti-regenerative control), or

overload prevention control has been selected, the inverter may operate with

acceleration/deceleration or frequency different from the commanded ones. Design the machine so

that safety is ensured even in such cases.

• If any of the protective functions have been activated, first remove the cause. Then, after checking

that the all run commands are set to OFF, release the alarm. If the alarm is released while any run

commands are set to ON, the inverter may supply the power to the motor, running the motor.

Otherwise, an accident could occur.

• If you enable the "Restart mode after momentary power failure" (Function code F14 = 3 to 5), then

the inverter automatically restarts running the motor when the power is recovered.

Design the machinery or equipment so that human safety is ensured after restarting.

• If the user configures the function codes wrongly without completely understanding this Instruction

Manual and the EQ7 DRIVE User's Manual, the motor may rotate with a torque or at a speed not

permitted for the machine.

An accident or injuries could occur.

• Even if the inverter has interrupted power to the motor, if the voltage is applied to the main circuit

input terminals L1/R, L2/S and L3/T, voltage may be output to inverter output terminals U, V, and W.

• Even if the run command is set to OFF, voltage is output to inverter output terminals U, V, and W if

the servo-lock command is ON.

• Even if the motor is stopped due to DC braking or preliminary excitation, voltage is output to inverter

output terminals U, V, and W.

An electric shock may occur.

• The inverter can easily accept high-speed operation. When changing the speed setting, carefully

check the specifications of motors or equipment beforehand.

Otherwise, injuries could occur.

Operation

vi

Page 8

• Do not touch the heat sink and braking resistor because they become very hot.

Doing so could cause burns.

• The DC brake function of the inverter does not provide any holding mechanism.

Injuries could occur.

• Ensure safety before modifying the function code settings.

Run commands (e.g., "Run forward" FWD), stop commands (e.g., "Coast to a stop" BX), and

frequency change commands can be assigned to digital input terminals. Depending upon the

assignment states of those terminals, modifying the function code setting may cause a sudden

motor start or an abrupt change in speed.

• When the inverter is controlled with the digital input signals, switching run or frequency command

sources with the related terminal commands (e.g., SS1, SS2, SS4, SS8, Hz2/Hz1, Hz/PID, IVS, and

LE) may cause a sudden motor start or an abrupt change in speed.

• Ensure safety before modifying customizable logic related function code settings (U codes and

related function codes) or turning ON the "Cancel customizable logic" terminal command CLC.

Depending upon the settings, such modification or cancellation of the customizable logic may

change the operation sequence to cause a sudden motor start or an unexpected motor operation.

An accident or injuries could occur.

• Before proceeding to the maintenance/inspection jobs, turn OFF the power and wait at least five

minutes for inverters of 40 HP or below, or at least ten minutes for inverters of 50 HP or

above. Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure,

using a multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+)

and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, an electric shock or injuries could occur.

• Never modify the inverter.

Doing so could cause an electric shock or injuries.

• Treat the inverter as an industrial waste when disposing of it.

Otherwise injuries could occur.

GENERAL PRECAUTIONS

Drawings in this manual may be illustrated without covers or safety shields for explanation of detail

parts. Restore the covers and shields in the original state and observe the description in the manual

before starting operation.

Maintenance, inspection and parts replacement

Disposal

vii

Page 9

Conformity with UL standards and CSA standards (cUL-listed for Canada)

1. Solid state motor overload protection (motor protection by electronic thermal overload relay) is provided in each

model.

Use function codes F10 to F12 to set the protection level.

2. Use Cu wire only.

3. Use Class 1 wire only for control circuits.

4. Short circuit rating

"Suitable For Use On A Circuit Of Delivering Not More Than 100,000 rms Symmetrical Amperes, 240 Volts

Maximum for 230 V class input 40 HP or below, 230 Volts maximum for 230 V class input 50 HP or above

when protected by Class J Fuses or a Circuit Breaker having an interrupting rating not less than 100,000 rms

Symmetrical Amperes, 240 Volts Maximum." Models FRN; rated for 230 V class input.

"Suitable For Use On A Circuit Of Delivering Not More Than 100,000 rms Symmetrical Amperes, 480 Volts

Maximum when protected by Class J Fuses or a Circuit Breaker having an interrupting rating not less than

100,000 rms Symmetrical Amperes, 480 Volts Maximum." Models FRN; rated for 460 V class input.

"Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection

must be provided in accordance with the National Electrical Code and any additional local codes."

5. Field wiring connections must be made by a UL Listed and CSA Certified closed-loop terminal connector sized

for the wire gauge involved. Connector must be fixed using the crimp tool specified by the connector

manufacturer.

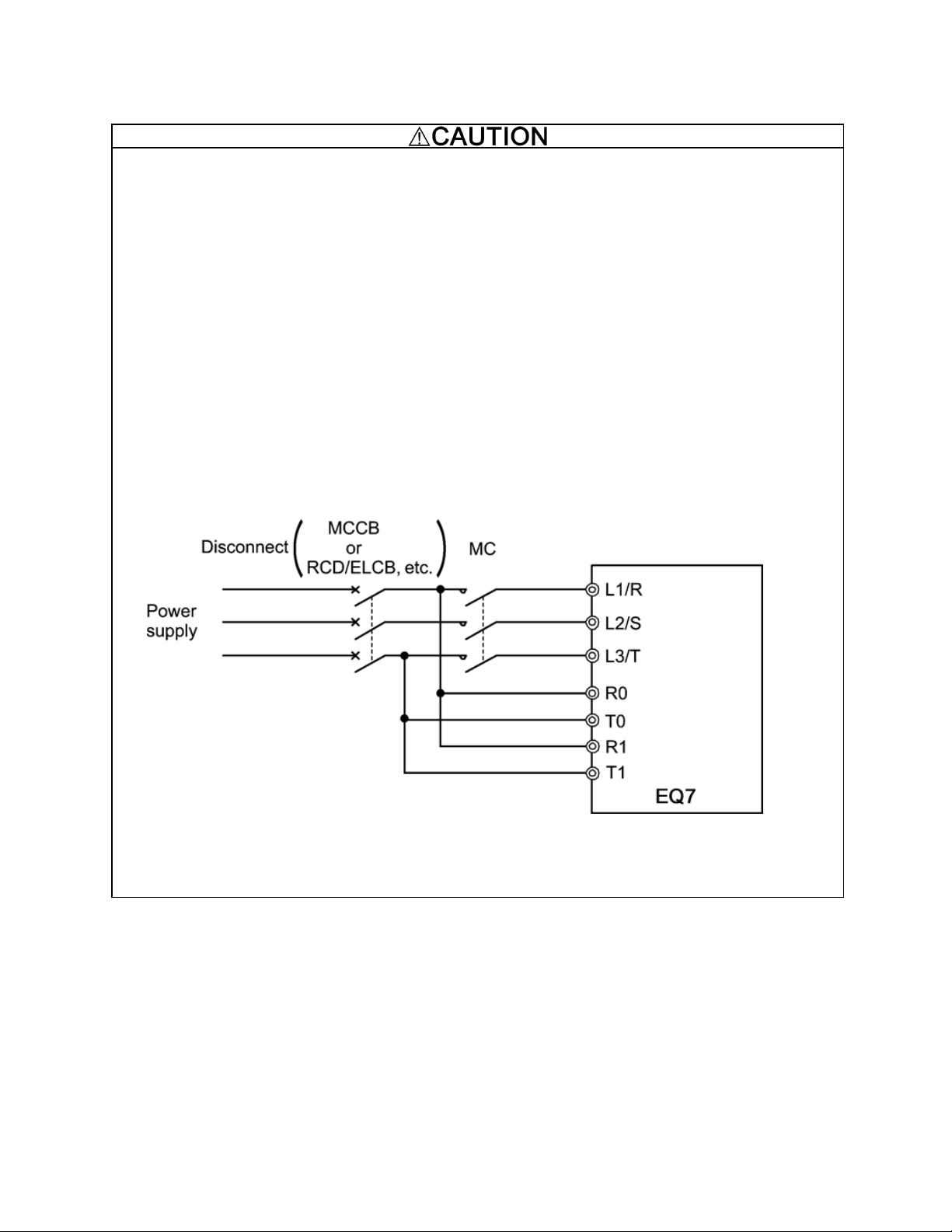

6. All circuits with terminals L1/R, L2/S, L3/T, R0, T0, R1, T1 must have a common disconnect and be connected

to the same pole of the disconnect if the terminals are connected to the power supply.

7. When using the inverter as a UL Enclosed Type (UL TYPE1), purchase Type 1 kit (option) and mount it on the

inverter as instructed.

UL/cUL-listed inverters are subject to the regulations set forth by the UL standards and CSA standards (cULlisted for Canada) by installation within precautions listed below.

viii

Page 10

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

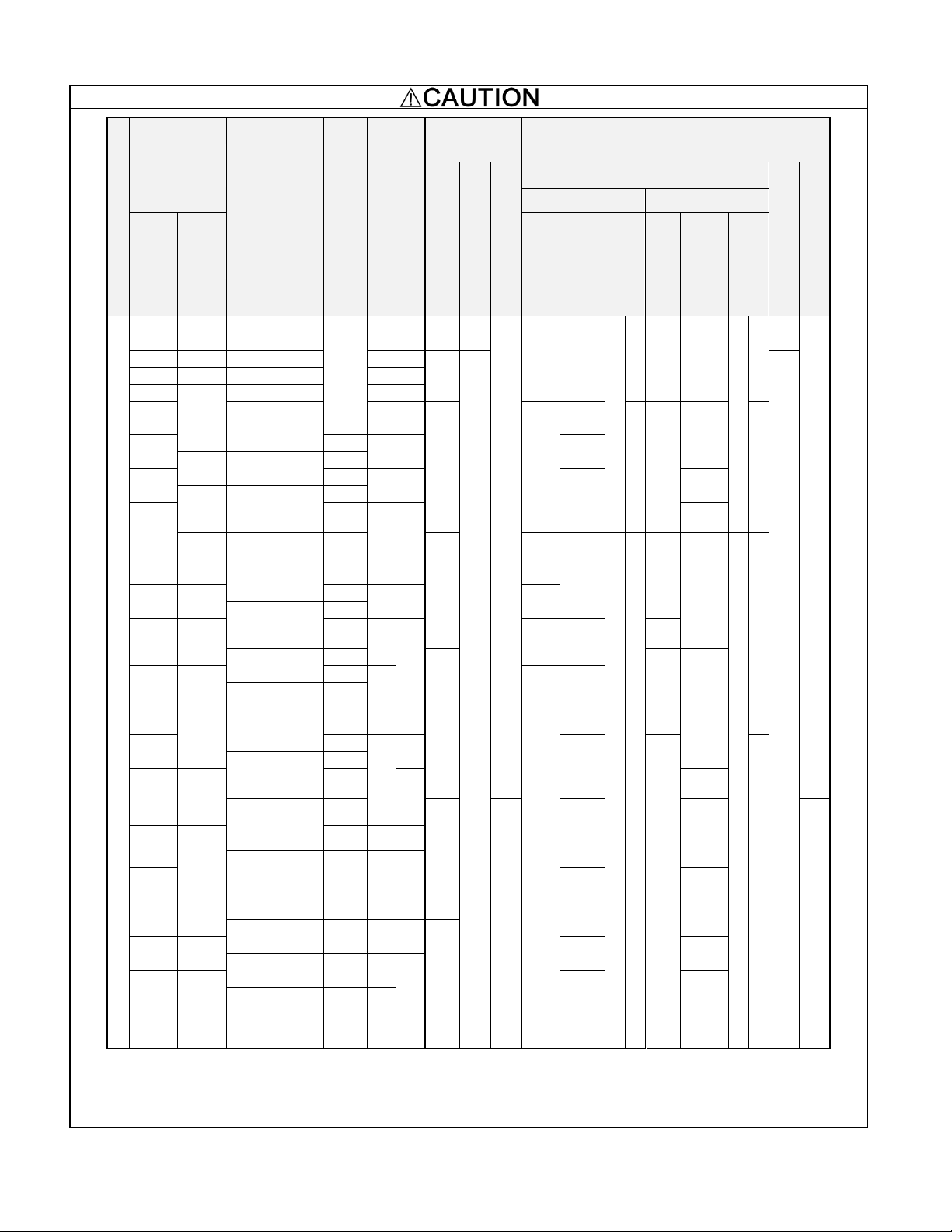

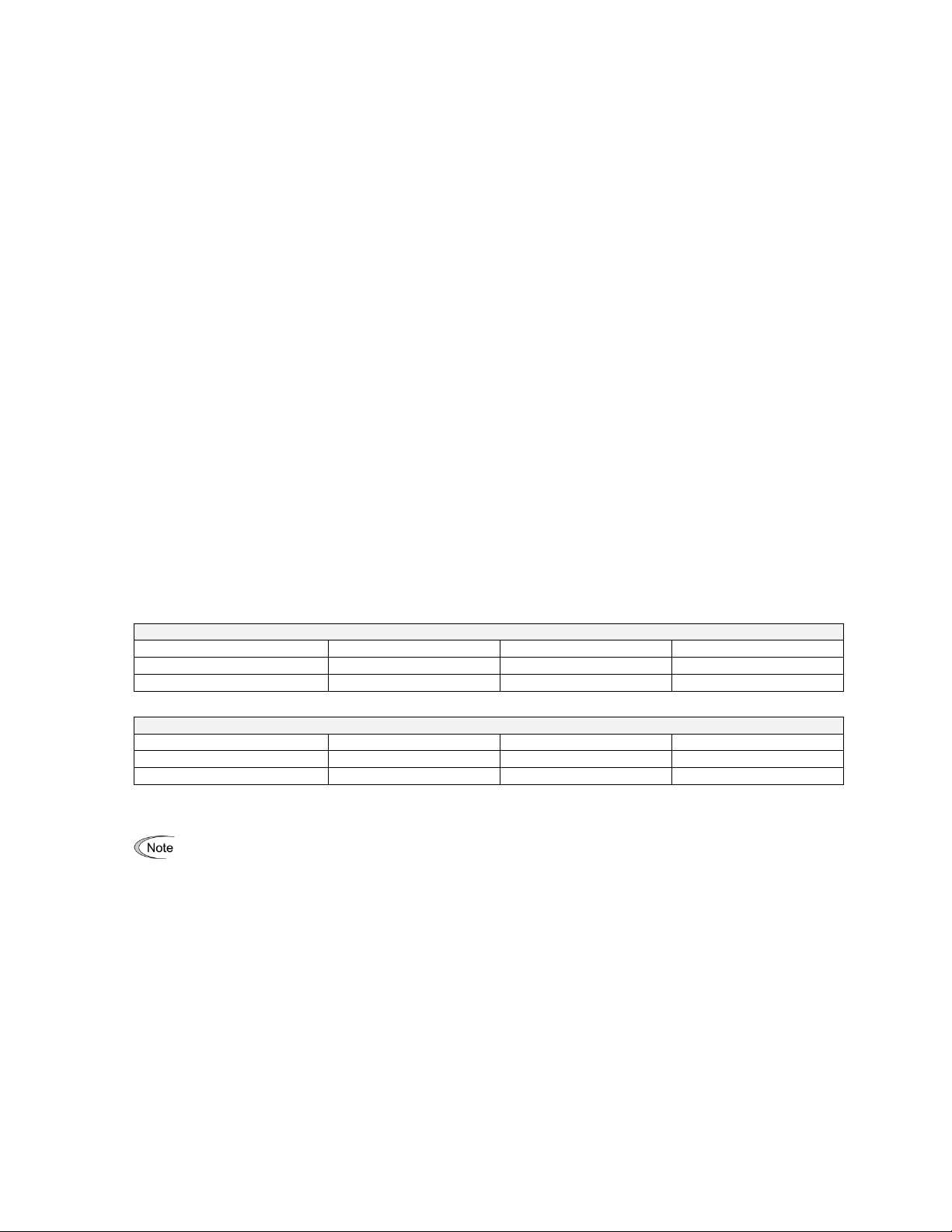

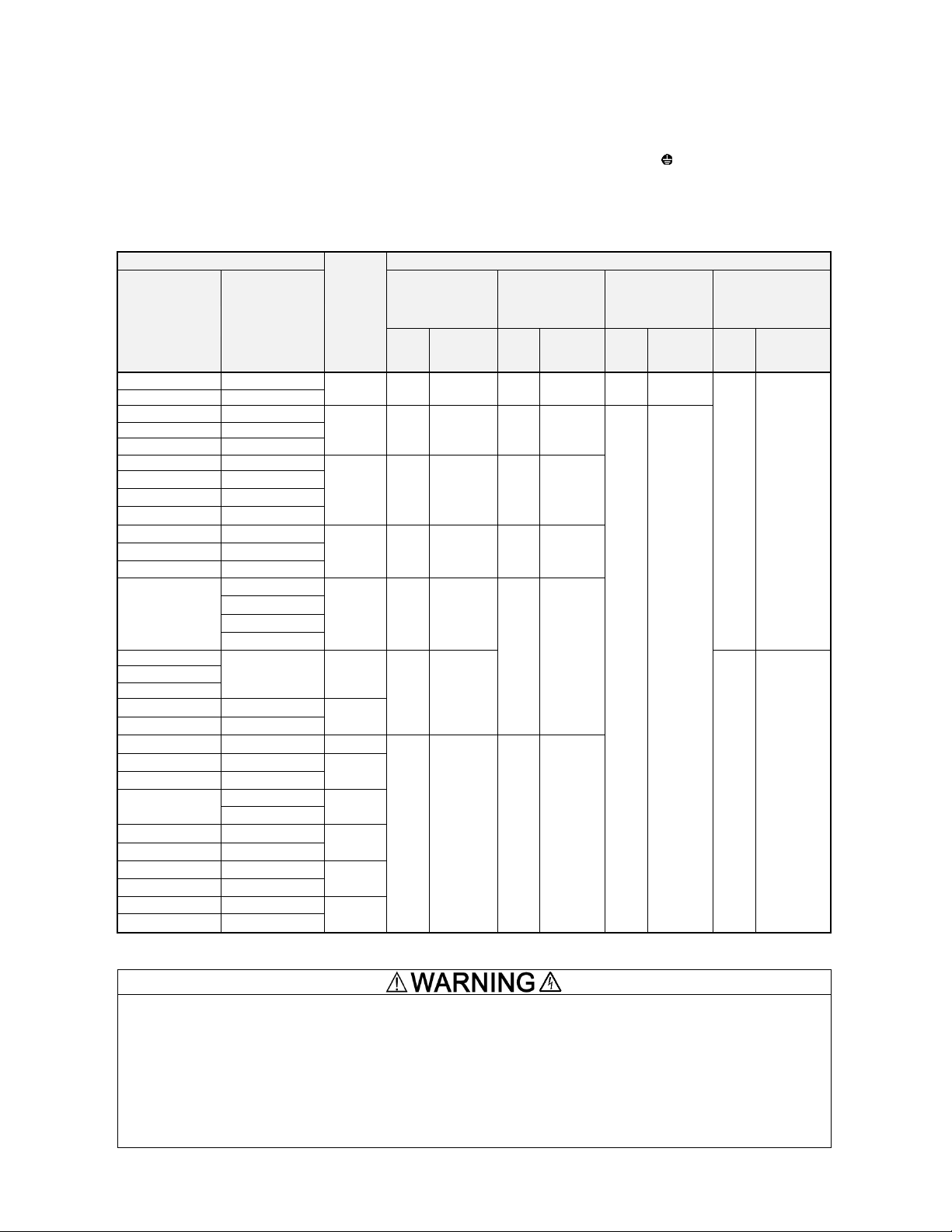

8. Install UL certified fuses or circuit breaker between the power supply and the inverter, referring to the table below.

Power supply voltage

Nominal

applied motor

(HP)

Inverter type

CT/VT mode

Class J fuse size (A)

Circuit breaker trip size (A)

Required

torque

lb-in (Nm)

Wire size

AWG (mm

2

)

Main terminal

Aux. control power

supply

Aux. Fan power supply

Main terminal

Aux. control power

supply

Aux. fan power supply

L1/R, L2/S, L3/T

U, V, W

Three-

phase

Single-

phase

60C (140F)

Cu wire

75C (167F)

Cu wire

Remarks

60C (140F)

Cu wire

75C (167F)

Cu wire

Remarks

230 V

0.5

0.25

EQ7-20P5-C

CT/

VT

10

5

10.6

(1.2)

-

-

14

(2.1)

14

(2.1)

*1

-

14

(2.1)

14

(2.1)

*1

-

-

-

1

0.5

EQ7-2001-C

15

10

2

1

EQ7-2002-C

20

15

15.9

(1.8)

10.6

(1.2)

14

(2.1)

*1

*2

3

1.5

EQ7-2003-C

30

20

5

3

EQ7-2005-C

40

30

10

(5.3)

10

(5.3)

12

(3.3)

12

(3.3)

7.5

EQ7-2007-C

60

50

30.9

(3.5)

-

8

(8.4)

*2

*3

-

8

(8.4)

*2

*3

EQ7-2010-C

CT

10

5

VT

75

75

EQ7-2015-C

CT

15

7.5

VT

100

100

6

(13.3)

-

EQ7-2020-C

CT

20

10

VT

150

125

4

(21.2)

6

(13.3)

-

EQ7-2025-C

CT

51.3

(5.8)

3

(26.7)

-

4

(21.2)

-

25

VT

175

150

1

(42.4)

3

(26.7)

3

(26.7) 4 (21.2)

EQ7-2030-C

CT

30

15

VT

200

175

-

2

(33.6)

*2

*3

2

(33.6) 3 (26.7)

EQ7-2040-C

CT

40

20

VT

250

200

2/0

(67.4)

-

2

(33.6)

*2

*3

EQ7-2050-C

CT

119.4

(13.5)

1

(42.4)

50

25

VT

350

250

3/0

(85)

1/0

(53.5)

EQ7-2060-C

CT

238.9

(27)

10.6

(1.2)

4/0

(107.2)

14

(2.1)

60

30

VT

400

300

4/0

(107.2)

EQ7-2075-C

CT

75

VT

450

350

2/0×2

(67.4×2)

EQ7-2100-C

CT

100

VT

500

3/0×2

(85×2)

3/0×2

(85×2)

40

EQ7-2125-C

CT

424.7

(48)

125

VT

600

400

4/0×2

(107.2×2

)

4/0×2

(107.2×2

)

EQ7-2150-C

CT

150

50

VT

700

500

300×2

(152×2)

300×2

(152×2)

Note 1: Control circuit terminals Tightening torque: 6.1 b-in (0.7 Nm), Recommended wire size: AWG 19 or 18 (0.65 to 0.82 mm2)

*1 No terminal end treatment is required for connection.

*2 Use 75 C (167 F) Cu (Copper) wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is necessary.

ix

Page 11

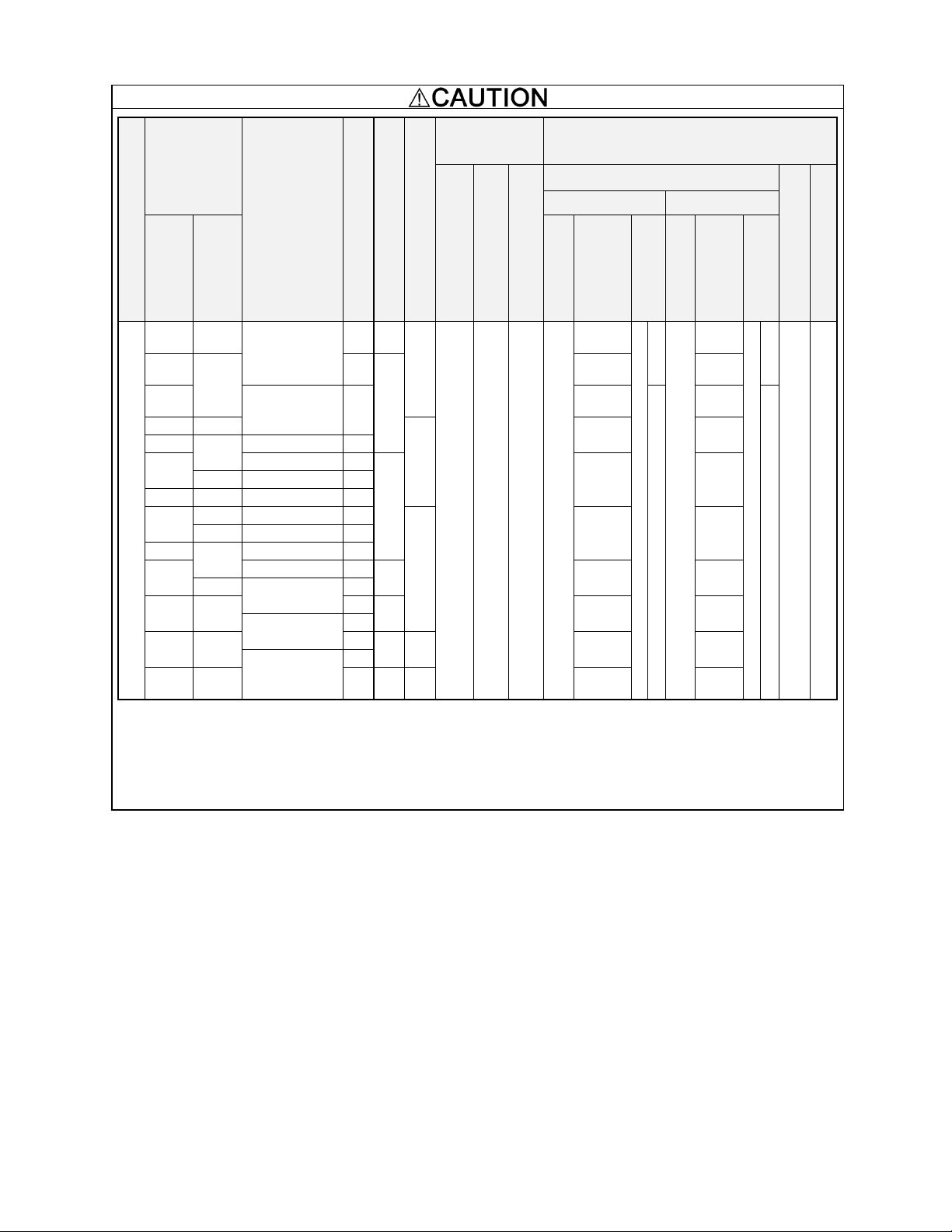

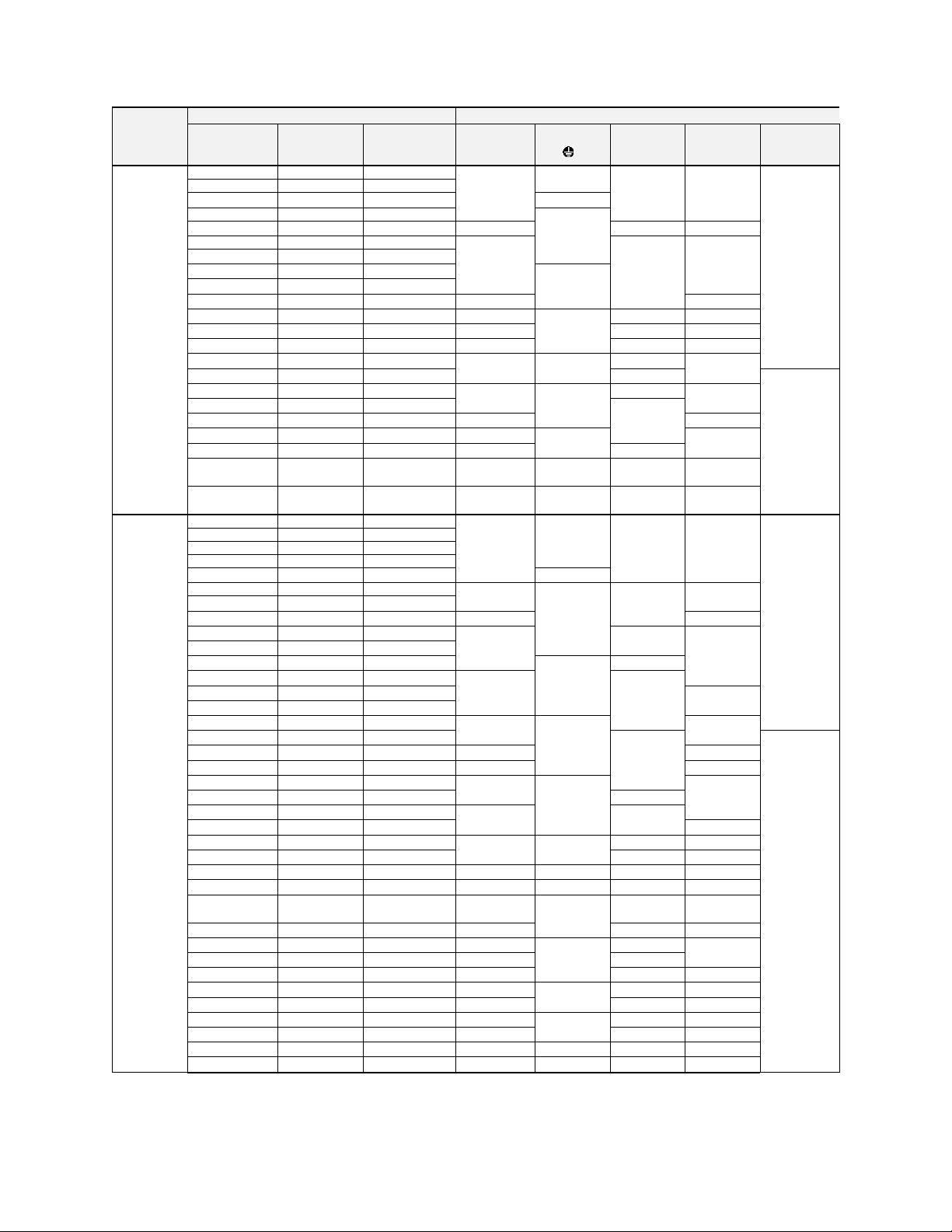

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

Power supply voltage

Nominal applied

motor

(HP)

Inverter type

CT/VT mode

Class J fuse size (A)

Circuit breaker trip size (A)

Required

torque

b-in (Nm)

Wire size

AWG (mm

2

)

Main terminal

Aux. control power supply

Aux. Fan power supply

Main terminal

Aux. control power supply

Aux. fan power supply

L1/R, L2/S, L3/T

U, V, W

Three-

phase

Single-

phase

60 C (140 F)

Cu wire

75 C (167 F)

Cu wire

Remarks

60 C (140 F)

Cu wire

75 C (167 F)

Cu wire

Remarks

460 V

0.5

0.25

EQ7-40P5-C

CT/

VT

3

5

10.6

(1.2)

-

-

14

(2.1)

14

(2.1)

*1

-

14

(2.1)

14

(2.1)

*1

-

-

-

1

0.5

EQ7-4001-C

6

2

1

EQ7-4002-C

10

10

15.9

(1.8)

10.6

(1.2)

14

(2.1)

*1

*2

3

1.5

EQ7-4003-C

15

15

5

3

EQ7-4005-C

20

20

7.5

EQ7-4007-C

30

30

30.9

(3.5)

-

12

(3.3)

*2

*3

-

12

(3.3)

*2

*3

EQ7-4010-C

CT

10

VT

40

40

10

(5.3)

5

EQ7-4015-C

CT

15

VT

60

50

8

(8.4)

10

(5.3)

7.5

EQ7-4020-C

CT

20

VT

70

60

8

(8.4)

10

EQ7-4025-C

CT

51.3

(5.8)

6

(13.3)

6

(13.3)

-

-

6

(13.3)

6

(13.3)

-

-

25

VT

90

75

EQ7-4030-C

CT

30

15

VT

100

100

4

(21.2)

EQ7-4040-C

CT

40

20

VT

125

125

3

(26.7)

4

(21.2)

4

(21.2)

EQ7-4050-C

CT

119.4

(13.5)

2

(33.6)

2

(33.6)

50

25

VT

175

2

(33.6)

3

(26.7)

EQ7-4060-C

CT

60

30

VT

200

150

-

2

(33.6)

*2

*3

EQ7-4075-C

CT

75

VT

250

200

1/0

(53.5)

-

*2

*3

EQ7-4100-C

CT

100

40

VT

175

1/0

(53.5)

EQ7-4125-C

CT

238.9

(27)

10.6

(1.2)

2/0

(67.4)

4/0

(107.2)

14

(2.1)

*1

*2

125

50

VT

300

200

EQ7-4150-C

CT/VT

350

250

150

1/0×2

(53.5×2

)

1/0×2

(53.5×2)

60

EQ7-4200-C

CT/VT

400

300

200

2/0×2

(67.4×2)

EQ7-4250-C

CT/VT

500

350

424.7

(48)

250

75

3/0×2

(85×2)

3/0×2

(85×2)

EQ7-4300-C

CT/VT

600

500

300

100

4/0×2

(107.2×

2)

250×2

(127×2)

EQ7-4350-C

CT/VT

700

350

250×2

(127×2)

300×2

(152×2)

EQ7-4450-C

CT

700

Note 1: Control circuit terminals Tightening torque: 6.1 lb-in (0.7 Nm), Recommended wire size: AWG 19 or 18 (0.65 to 0.82 mm2)

*1 No terminal end treatment is required for connection.

*2 Use 75 C (167 F) Cu (Copper) wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is necessary.

x

Page 12

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

Power supply voltage

Nominal applied

motor

HP

Inverter type

CT//VT mode

Class J fuse size (A)

Circuit breaker trip size (A)

Required

torque lb-in

(Nm)

Wire size

AWG (mm

2

)

Main terminal

Aux. control power supply

Aux. Fan power supply

Main terminal

Aux. control power supply

Aux. fan power supply

L1/R, L2/S, L3/T

U, V, W

Three-

phase

Single-

phase

60 C (140 F)

Cu wire

75 C (167 F)

Cu wire

Remarks

60 C (140 F)

Cu wire

75 C (167 F)

Cu wire

Remarks

460 V

350

-

EQ7-4450-C

CT

800

600

424.7

(48)

10.6

(1.2)

10.6

(1.2)

-

300×2

(152×2)

-

*2

*3

-

350×2

(177×2)

-

*2

*3

14

(2.1)

*1

*2

14

(2.1)

*1

*2

450

125

VT

1000

400×2

(203×2)

400×2

(203×2)

400

EQ7-4500-C

CT

250×2

(127×2)

*2

*4

300×2

(152×2)

*2

*4

450

-

800

300×2

(152×2)

350×2

(177×2)

-

150

EQ7-4600-C

CT

500

EQ7-4500-C

VT

1200

400×2

(203×2)

400×2

(203×2)

-

EQ7-4600-C

CT - 150

EQ7-4700-C

CT

600

200

EQ7-4600-C

VT

1200

500×2

(253×2)

500×2

(253×2)

-

EQ7-4700-C

CT

-

200

EQ7-4800-C

CT

700

EQ7-4700-C

VT

1400

600×2

(304×2)

600×2

(304×2)

-

EQ7-4800-C

CT

800

250

VT

1600

350×3

(177×3)

400×3

(203×3)

EQ7-4900-C

CT

900

300

VT

2000

1400

500×3

(253×3)

600×3

(304×3)

EQ7-41000-C

CT

1000

400

VT

2200

1600

600×3

(304×3)

500×4

(253×4)

Note: Control circuit terminals Tightening torque: 6.1 lb-in (0.7 Nm), Recommended wire size: AWG 19 or 18 (0.65 to 0.82 mm2)

*1 No terminal end treatment is required for connection.

*2 Use 75 C (167 F) Cu (Copper) wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is necessary.

*4 It is showing the wire size for UL Open Type.

See additional material INR-SI47-1365-JE for UL Enclosed Type (Pack with TYPE1 kit).

xi

Page 13

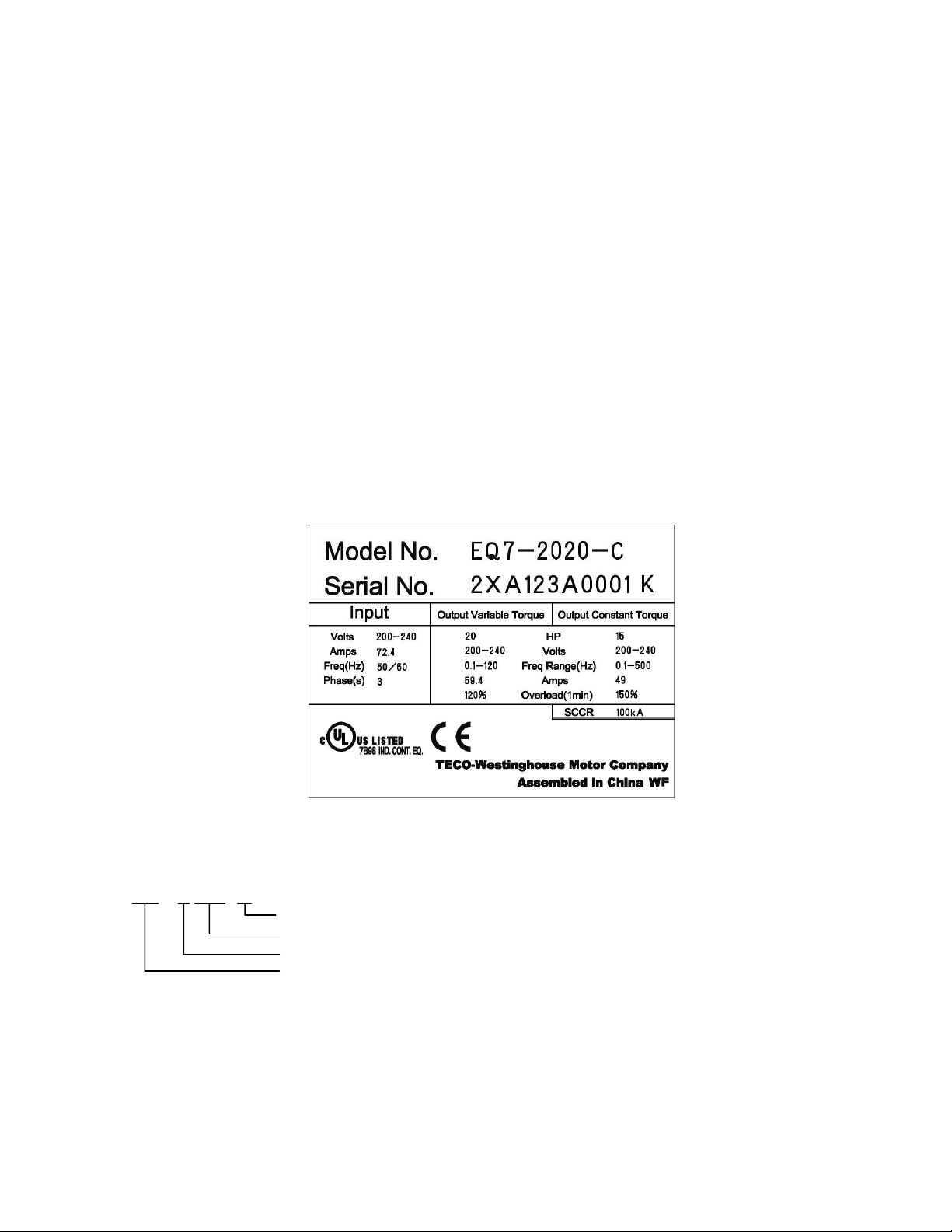

Chapter 1 Drive Model Identification

EQ7 – X XXX - X

C = Chassis; IP20 or IP00

HP Rating (Variable Torque)

2 = 230V, 4 = 460V

Product Type

It is essential to verify the EQ7 drive nameplate and make sure that the EQ7 drive has the correct rating so it can be

used in your application with the proper sized AC motor.

Unpack the EQ7 drive and check the following:

(1) The EQ7 drive and quick start guide (this document) are contained in the package. The EQ7 DRIVE-2100-C /

EQ7 DRIVE-4100-C and higher rated types come with a DC reactor (DCR). Be sure to connect the DCR.

(2) The EQ7 drive has not been damaged during transportation there should be no dents or parts missing.

(3) The EQ7 drive is the type you ordered. You can check the type and specifications on the main nameplate. (Main

and sub nameplates are attached to the EQ7 drive and are located as shown below.)

(4) Check that the input voltage range meets the input power requirements.

(5) Ensure that for variable torque applications the motor rated current matches the variable torque FLA or for

constant torque applications it matches the constant torque FLA. Verify that the output voltage rating on the EQ7

drive label meets the motor requirements (nameplate).

TYPE: Type of inverter

Figure 1.1 Nameplate

1-1

Page 14

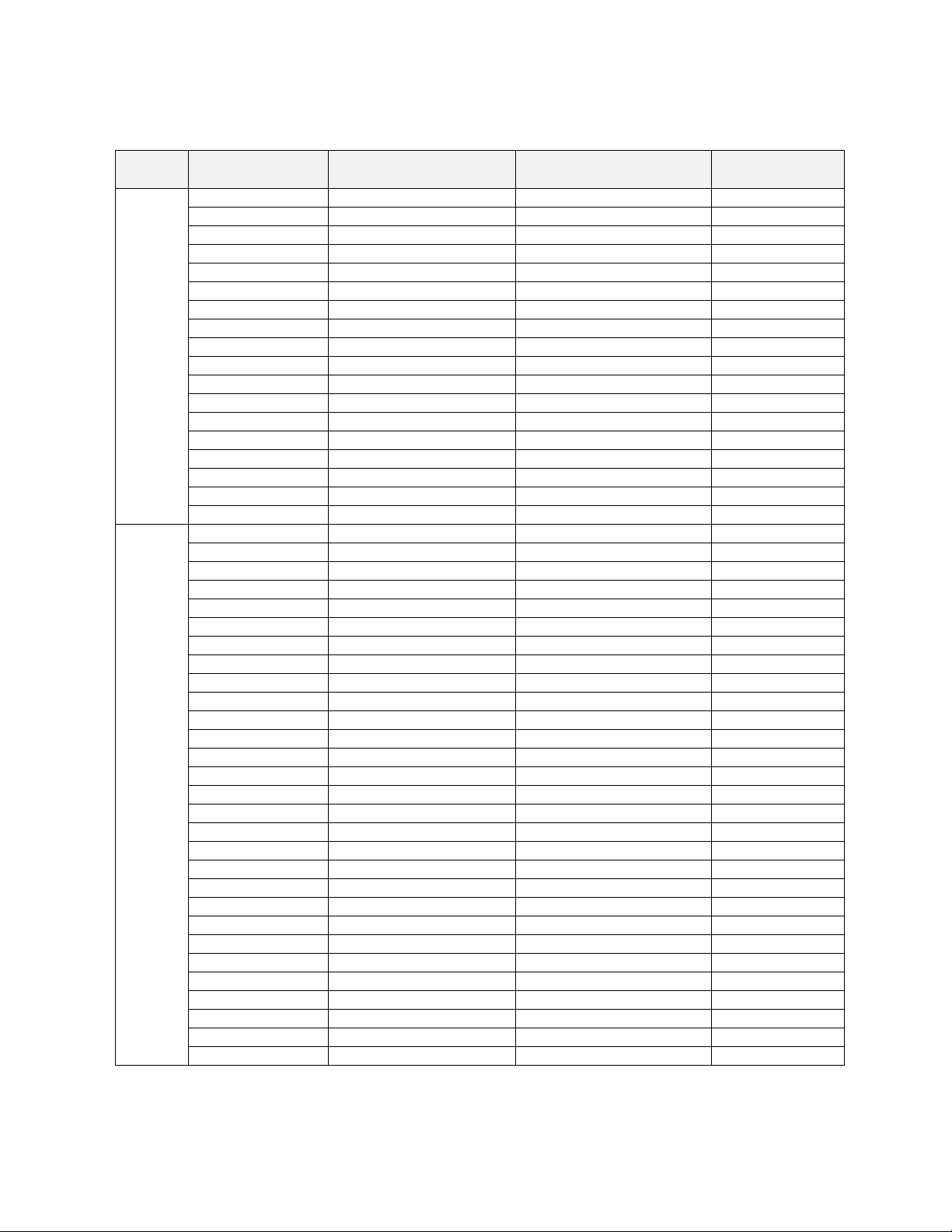

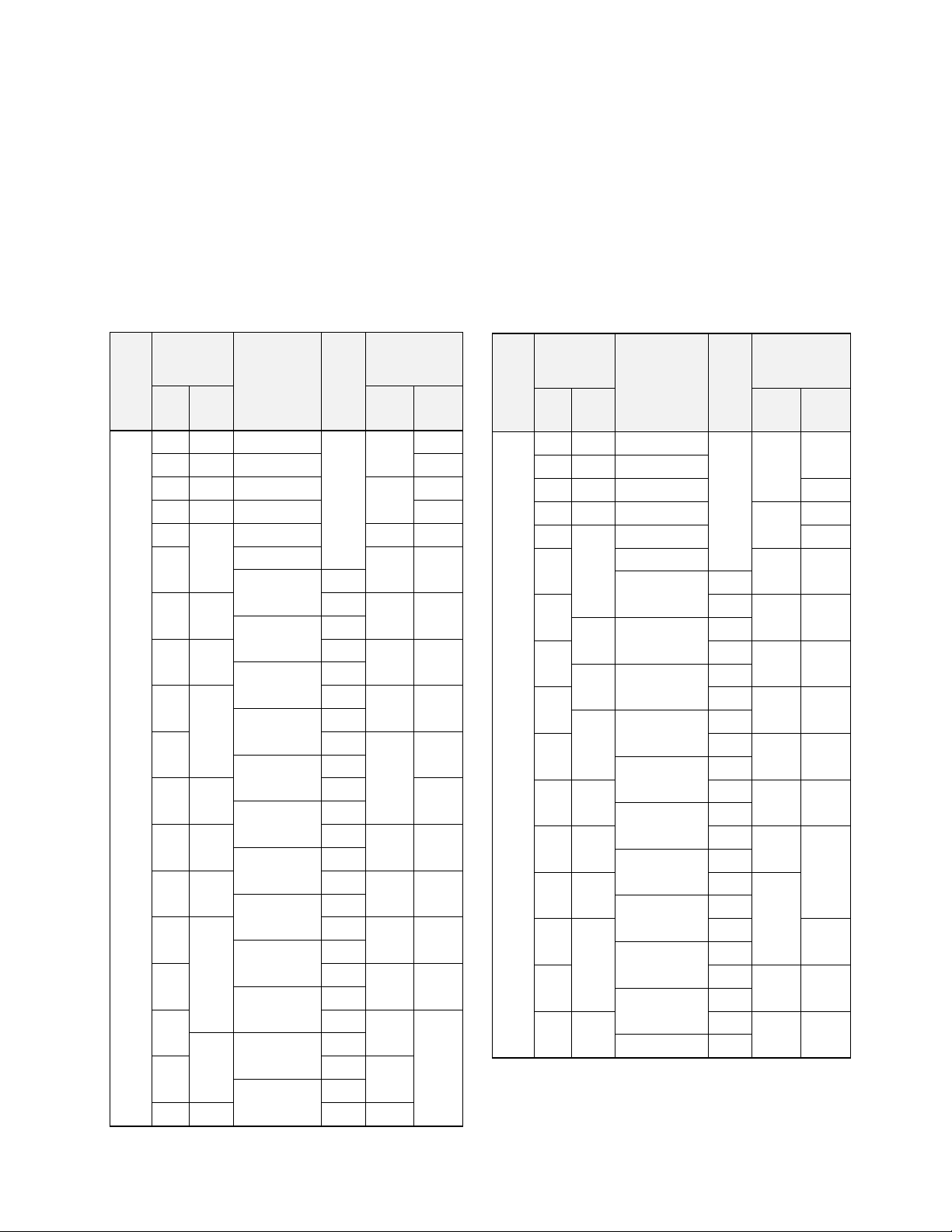

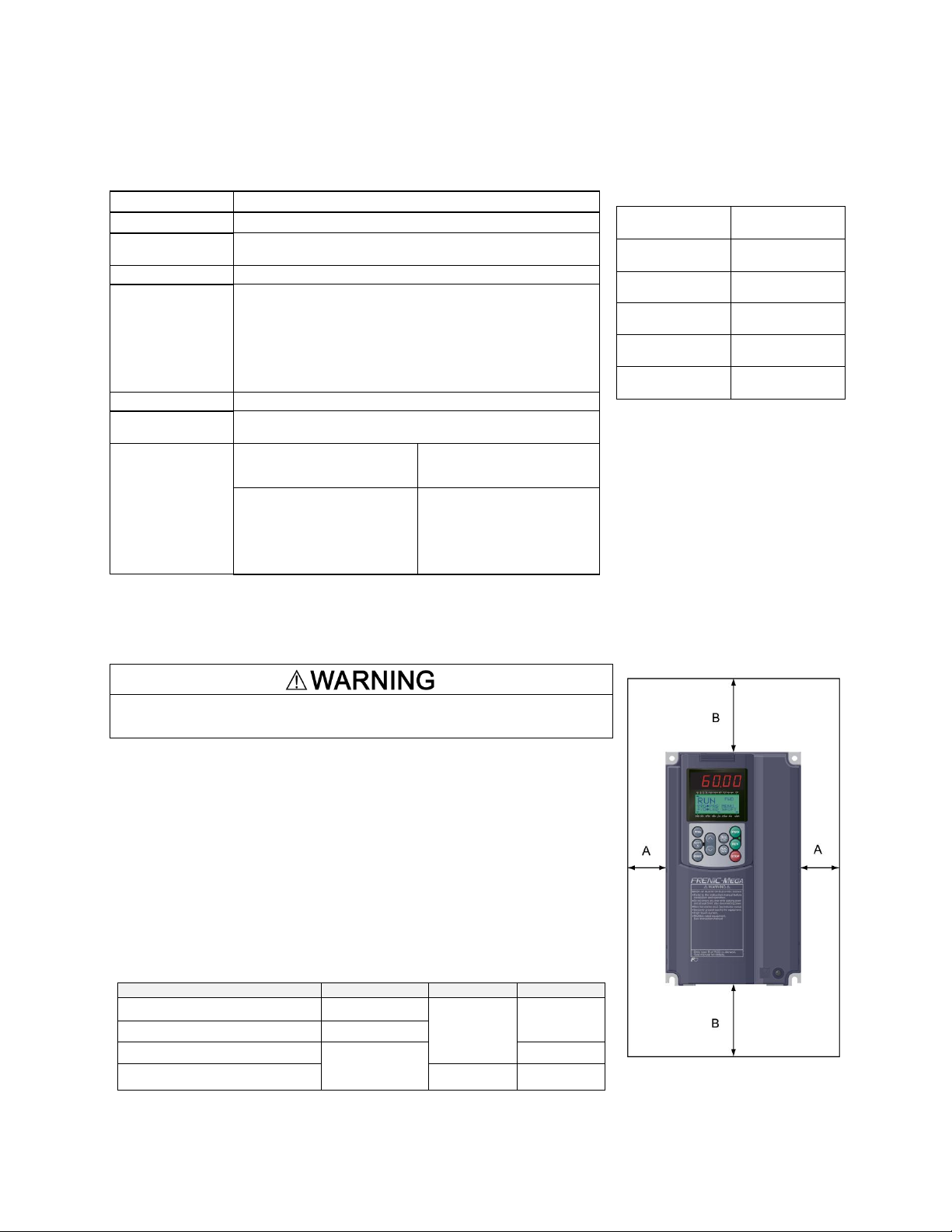

1.1 Drive Models Constant Torque (CT) / Variable Torque (VT) HP Ratings

Voltage

EQ7 DRIVE

Variable Torque HP

Constant Torque HP

Frame /

Enclosure

230V

EQ7-20P5-C

0.5

0.5

Plastic

EQ7-2001-C

1 1 Plastic

EQ7-2002-C

2 2 Plastic

EQ7-2003-C

3 3 Plastic

EQ7-2005-C

5 5 Plastic

EQ7-2007-C

7.5

7.5

Plastic

EQ7-2010-C

10

7.5

Plastic

EQ7-2015-C

15

10

Plastic

EQ7-2020-C

20

15

Plastic

EQ7-2025-C

25

20

Plastic

EQ7-2030-C

30

25

Plastic

EQ7-2040-C

40

30

Plastic

EQ7-2050-C

50

40

Sheet Metal

EQ7-2060-C

60

50

Sheet Metal

EQ7-2075-C

75

60

Sheet Metal

EQ7-2100-C

100

75

Sheet Metal

EQ7-2125-C

125

100

Sheet Metal

EQ7-2150-C

150

125

Sheet Metal

460V

EQ7-40P5-C

0.5

0.5

Plastic

EQ7-4001-C

1 1 Plastic

EQ7-4002-C

2 2 Plastic

EQ7-4003-C

3 3 Plastic

EQ7-4005-C

5 5 Plastic

EQ7-4007-C

7.5

7.5

Plastic

EQ7-4010-C

10

7.5

Plastic

EQ7-4015-C

15

10

Plastic

EQ7-4020-C

20

15

Plastic

EQ7-4025-C

25

20

Plastic

EQ7-4030-C

30

25

Plastic

EQ7-4040-C

40

30

Plastic

EQ7-4050-C

50

40

Sheet Metal

EQ7-4060-C

60

50

Sheet Metal

EQ7-4075-C

75

60

Sheet Metal

EQ7-4100-C

100

75

Sheet Metal

EQ7-4125-C

125

100

Sheet Metal

EQ7-4150-C

150

125/150*

Sheet Metal

EQ7-4200-C

200

200*

Sheet Metal

EQ7-4250-C

250

250*

Sheet Metal

EQ7-4300-C

300

300*

Sheet Metal

EQ7-4350-C

350

350*

Sheet Metal

EQ7-4450-C

400/450

350

Sheet Metal

EQ7-4500-C

500

400/450*

Sheet Metal

EQ7-4600-C

600

500*

Sheet Metal

EQ7-4700-C

700

600*

Sheet Metal

EQ7-4800-C

800

700*

Sheet Metal

EQ7-4900-C

900

800

Sheet Metal

EQ7-41000-C

1000

900

Sheet Metal

This table shows the Variable Torque and Constant Torque ratings for all EQ7 drive models.

* The HP ratings marked with (*) are suitable for constant torque V/F Control. Refer to EQ7 Instruction Manual

chapter 11 for constant torque vector control HP ratings.

Table 1.1

1-2

Page 15

1.2 Installation and wiring practices

Environments

Possible problems

Sample measures

Applications

Highly concentrated

sulfurizing gas or

other corrosive gases

Corrosive gases cause parts

inside the inverter to corrode,

resulting in an inverter

malfunction.

Any of the following measures may be

necessary.

-Mount the inverter in a sealed panel

with IP6X or air-purge mechanism.

-Place the panel in a room free from

influence of the gases.

Paper manufacturing, sewage

disposal, sludge treatment,

tire manufacturing, gypsum

manufacturing, metal

processing, and a particular

process in textile factories.

A lot of conductive

dust or foreign

material (e.g., metal

powders or shavings,

carbon fibers, or

carbon dust)

Entry of conductive dust into

the inverter causes a short

circuit.

Any of the following measures may be

necessary.

-Mount the inverter in a sealed panel.

-Place the panel in a room free from

influence of the conductive dust.

Wiredrawing machines, metal

processing, extruding

machines, printing presses,

combustors, and industrial

waste treatment.

A lot of fbrous or

paper dust

Fibrous or paper dust

accumulated on the heat sink

lowers the cooing effect.

Entry of dust into the inverter

causes the electronic circuitry

to malfunction.

Any of the following measures may be

necessary.

-Mount the inverter in a sealed panel

that shuts out dust.

-Ensure a maintenance space for

periodical cleaning of the heat sink in

panel engineering design.

-Employ external cooling when

mounting the inverter in a panel for

easy maintenance and perform

periodical maintenance.

Textile manufacturing and

paper manufacturing.

High humidity or dew

condensation

In an environment where a

humidifier is used or where the

air conditioner is not equipped

with a dehumidifier, high

humidity or dew condensation

results, which causes a shortcircuiting or malfunction of

electronic circuitry inside the

inverter.

- Put a heating module such

as a space heater in the panel.

Outdoor installation.

Film manufacturing line,

pumps and food processing.

V bration or shock

exceeding the

specified level

If a large vibration or shock

exceeding the specified level is

applied to the inverter, for

example, due to a carrier

running on seam joints of rails

or blasting at a construction

site, the inverter structure gets

damaged.

-Insert shock-absorbing materials

between the mounting base of the

inverter and the panel for safe

mounting.

Installation of an inverter

panel on a carrier or selfpropelled machine.

Ventilating fan at a

construction site or a press

machine.

Fumigation for export

packaging

Halogen compounds such as

methyl bromide used in

fumigation corrodes some

parts inside the inverter.

-When exporting an inverter built in a

panel or equipment, pack them in a

previously fumigated wooden crate.

-When packing an inverter alone for

export, use a laminated veneer lumber

(LVL).

Exporting.

Mounting of the EQ7 drive is extremely important for accessibility as well as for the environment. Various EQ7 drive

models are available and the mounting dimensions (footprint) may be different. Install the EQ7 drive in an

environment that satisfies the requirements.

TECO-Westinghouse Motor Company strongly recommends installing inverters in a panel for safety reasons, in

particular, when installing the ones that have an enclosure rating of IP00.

When installing the EQ7 drive in a place out of the specified environmental requirements, it is necessary to derate the

inverter or consider the panel engineering design suitable for the special environment or the panel installation

location. For details consult your TECO-Westinghouse Motor Company representative. The special environments

listed below require using the specially designed panel or considering the panel installation location.

Installation environment

Table 1.2: Installation environment

1-3

Page 16

Storage environment

Inverter 7.5 HP and larger

Motor Insulation Level

1000 V

1300 V

1600 V

460 VAC Input Voltage

66 ft (20 m)

328 ft (100 m)

1312 ft (400 m)*

230 VAC Input Voltage

1312 ft (400 m)*

1312 ft (400 m)*

1312 ft (400 m)*

Inverter 5 HP and smaller

Motor Insulation Level

1000 V

1300 V

1600 V

460 VAC Input Voltage

66 ft (20 m)

165 ft (50 m)*

165 ft (50 m)*

230 VAC Input Voltage

328 ft (100 m)*

328 ft (100 m)*

328 ft (100 m)*

• When a motor protective thermal O/L relay is inserted between the inverter and the motor, the thermal

O/L relay may malfunction (particularly in the 460 V series), even when the cable length is 165 ft (50 m) or

less. To correct, insert a filter or reduce the carrier frequency. (Use function code F26 "Motor sound".)

• For the vector control mode, wiring length is 328 ft (100 m) or less.

The storage environment in which the inverter is stored after purchase is different from the operation environment.

For details, refer to the EQ7 DRIVE User's Manual, Chapter 2.

Wiring precautions

(1) Route the wiring of the control circuit terminals as far from the wiring of the main circuit as possible. Otherwise

electric noise may cause malfunctions.

(2) Place the control circuit wires inside the inverter to keep them away from the live parts of the main circuit (such as

the terminal block of the main circuit).

(3) If more than one motor is to be connected to a single inverter, the wiring length should be the sum of the length of

the wires to the motors.

(4) Drive output terminals (U, V, W)

1) Connect these terminals to a 3-phase motor in the correct phase sequence. If the direction of motor rotation is

incorrect, exchange any two of the U, V, and W phases.

2) Do not connect a power factor correction capacitor or surge suppressor to the inverter output.

3) If the cable from the inverter to the motor is very long, a high-frequency current may be generated by stray

capacitance between the cables and result in an overcurrent trip of the inverter, an increase in leakage current,

or a reduction in current indication precision.

When a motor is driven by a PWM-type inverter, the motor terminals may be subject to surge voltage

generated by inverter element switching. If the motor cable (with 460 V series motors, in particular) is particularly

long, surge voltage will deteriorate motor insulation. To prevent this, use the following guidelines:

* For this case the cable length is determined by secondary effects and not voltage spiking.

(5) When an output circuit filter is inserted in the secondary circuit or the wiring between the inverter and the

motor is long, a voltage loss occurs due to reactance of the filter or wiring so that the insufficient voltage may cause

output current oscillation or a lack of motor output torque. To avoid it, select the constant torque load by setting the

function code F37 (Load Selection/Auto Torque Boost/Auto Energy Saving Operation 1) to "1" and keep the inverter

output voltage at a higher level by configuring H50/H52 (Non-linear V/f Pattern, Frequency) and H51/H53 (Non-linear

V/f Pattern, Voltage).

1-4

Page 17

Precautions for connection of peripheral equipment

3)61800 (IEC 67×

(V) voltage average phase-Three

(V) voltage Min - (V) voltageMax

=(%) unbalance Voltage -

DCR models

Input power factor

Remarks

DCR2/4-/A/B

Approx. 90% to 95%

The last letter identifies the capacitance.

DCR2/4-C

Approx. 86% to 90%

Exclusively designed for inverters of 50 HP or above.

For selecting DCR models, refer to Chapter 11 "SPECIFICATIONS."

(1) Phase-advancing capacitors for power factor correction

Do not mount a phase-advancing capacitor for power factor correction in the inverter's input (primary) or output

(secondary) circuit. Mounting it in the input (primary) circuit takes no effect. To correct the inverter power factor,

use an optional DC reactor (DCR). Mounting it in the output (secondary) circuit causes an overcurrent trip,

disabling operation.

An overvoltage trip that occurs when the inverter is stopped or running with a light load is assumed to be due to

surge current generated by open/close of phase-advancing capacitors in the power system. An optional DC/AC

reactor (DCR/ACR) is recommended as a measure to be taken at the inverter side.

Input current to an inverter contains a harmonic component that may affect other motors and phase-advancing

capacitors on the same power supply line. If the harmonic component causes any problems, connect an optional

DCR/ACR to the inverter. In some cases, it is necessary to insert a reactor in series with the phase-advancing

capacitors.

(2) Power supply lines (Application of a DC/AC reactor)

Use an optional DC reactor (DCR) when the capacity of the power supply transformer is 500 kVA or more and is

10 times or more the inverter rated capacity or when there are thyristor-driven loads. If no DCR is used, the

percentage-reactance of the power supply decreases, and harmonic components and their peak levels increase.

These factors may break rectifiers or capacitors in the converter section of the inverter, or decrease the

capacitance of the capacitors.

If the input voltage unbalance rate is 2% to 3%, use an optional AC reactor (ACR).

(3) DC reactor (DCR) for correcting the inverter input power factor (for suppressing harmonics)

To correct the inverter input power factor (to suppress harmonics), use an optional DCR. Using a DCR increases

the reactance of inverter’s power source so as to decrease harmonic components on the power source lines and

correct the power factor of the inverter.

(4) PWM converter for correcting the inverter input power factor

Using a PWM converter (High power-factor, regenerative PWM converter) corrects the inverter power factor up to

nearly 100%. When combining an inverter with a PWM converter, disable the main power down detection by

setting the function code H72 to "0." If the main power loss detection is enabled (H72 = 1 by factory default), the

inverter interprets the main power as being shut down, ignoring an entry of a run command.

1-5

Page 18

(5) Molded case circuit breaker (MCCB) or residual-current-operated protective device (RCD)/earth leakage circuit

Power

supply

voltage

Nominal

applied

motor

(HP)

Inverter type

CT/VT

mode

Rated current of

MCCB and

RCD/ELCB (A)

Three

-

phase

Single-

phase

w/ DCR

w/o

DCR

230 V

0.5

0.25

EQ7-20P5-C

CT/VT

5

5

1

0.5

EQ7-2001-C

10 2 1

EQ7-2002-C

10

15 3 1.5

EQ7-2003-C

20

5

3

EQ7-2005-C

20

30

7.5

EQ7-2007-C

30

50

EQ7-2010-C

CT

10

5

VT

40

75

EQ7-2015-C

CT

15

7.5

VT

50

100

EQ7-2020-C

CT

20

10

VT

75

125

EQ7-2025-C

CT

25

VT

100

150

EQ7-2030-C

CT

30

15

VT

175

EQ7-2040-C

CT

40

20

VT

150

200

EQ7-2050-C

CT

50

25

VT

175

250

EQ7-2060-C

CT

60

30

VT

200

300

EQ7-2075-C

CT

75

VT

250

350

EQ7-2100-C

CT

100

VT

350

--

40

EQ7-2125-C

CT

125

VT

400

EQ7-2150-C

CT

150

50

VT

350

Power

supply

voltage

Nominal

applied

motor

(HP)

Inverter type

CT/VT

mode

Rated current of

MCCB and

RCD/ELCB (A)

Three

-

phase

Single-

phase

w/ DCR

w/o

DCR

460 V

0.5

0.25

EQ7-40P5-C

CT/VT

5

5

1

0.5

EQ7-4001-C

2

1

EQ7-4002-C

10 3 1.5

EQ7-4003-C

10

15

5 3 EQ7-4005-C

20

7.5

EQ7-4007-C

15

30

EQ7-4010-C

CT

10

VT

20

40

5

EQ7-4015-C

CT

15

VT

30

50

7.5

EQ7-4020-C

CT

20

VT

40

60

10

EQ7-4025-C

CT

25

VT

40

75

EQ7-4030-C

CT

30

15

VT

50

100

EQ7-4040-C

CT

40

20

VT

75

125

EQ7-4050-C

CT

50

25

VT

100

EQ7-4060-C

CT

60

30

VT

150

EQ7-4075-C

CT

75

VT

125

200

EQ7-4100-C

CT

100

40

VT

175

--

EQ7-4125-C

CT

breaker (ELCB)

Install a recommended MCCB or RCD/ELCB (with overcurrent protection) in the primary circuit of the inverter to

protect the wiring. Since using an MCCB or RCD/ELCB with a lager capacity than recommended ones breaks the

protective coordination of the power supply system, be sure to select recommended ones. Also select ones with

short-circuit breaking capacity suitable for the power source impedance.

Molded Case Circuit Breaker (MCCB) and Residual-Current-Operated Protective Device (RCD)/Earth Leakage

Circuit Breaker (ELCB)

1-6

Page 19

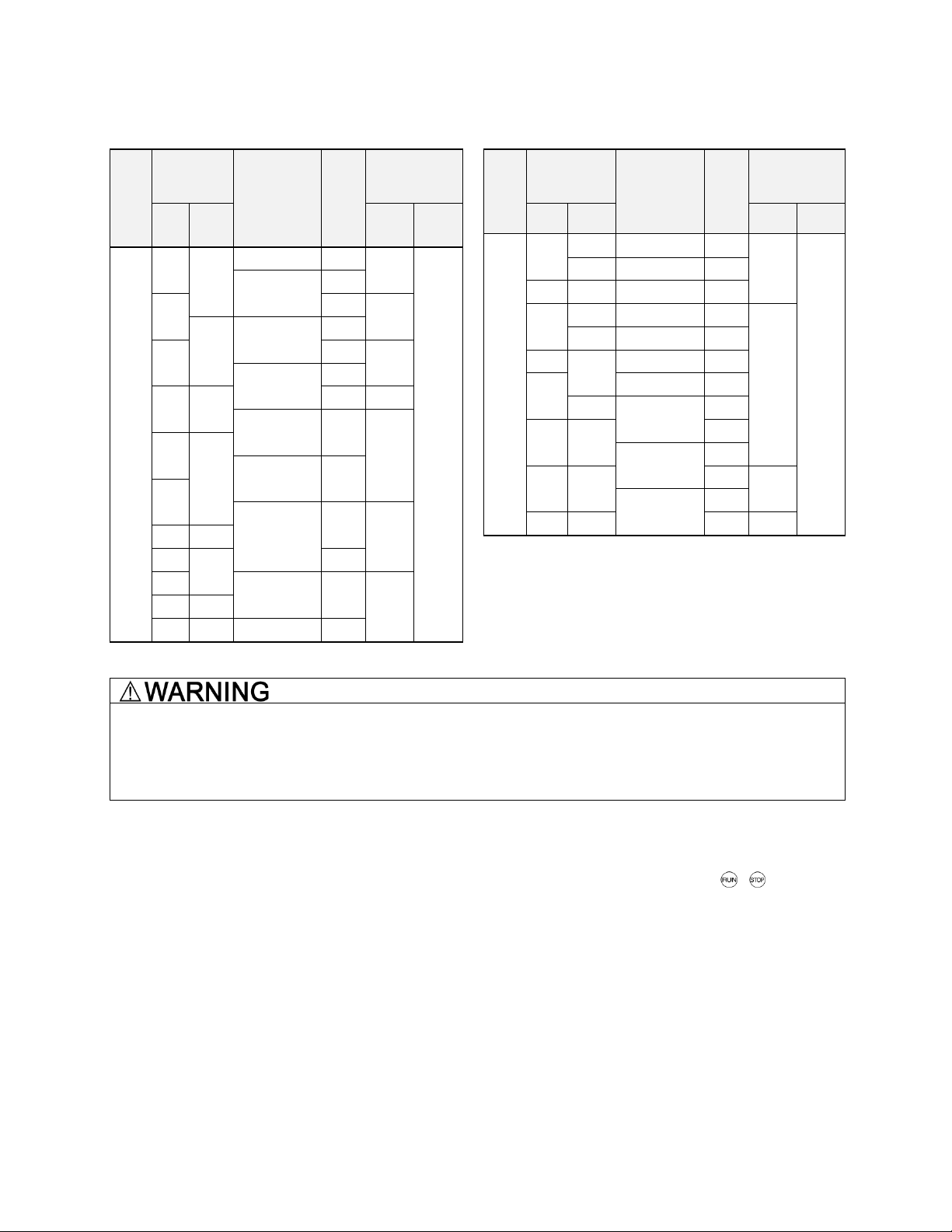

Molded Case Circuit Breaker (MCCB) and Residual-

Power

supply

voltage

Nominal

applied

motor

(HP)

Inverter type

CT/VT

mode

Rated current of

MCCB and

RCD/ELCB (A)

Three

-

phase

Single-

phase

w/ DCR

w/o

DCR

460 V

125

50

EQ7-4125-C

VT

200

--

EQ7-4150-C

CT

150

CT/VT

250

60

EQ7-4200-C

CT

200

CT/VT

300

EQ7-4250-C

CT

250

75

CT/VT

350

EQ7-4300-C

CT/VT

500

300

100

EQ7-4350-C

CT/VT

350

EQ7-4450-C

CT

600

350

-

450

125

VT

400

EQ7-4500-C

CT

800

450

-

-

150

EQ7-4600-C

CT

Power

supply

voltage

Nominal

applied

motor

(HP)

Inverter type

CT/VT

mode

Rated current of

MCCB and

RCD/ELCB (A)

Three-

phase

Single-

phase

w/ DCR

w/o

DCR

460 V

500

150

EQ7-4500-C

VT

800

--

-

EQ7-4600-C

CT - 150

EQ7-4700-C

CT

600

200

EQ7-4600-C

VT

1200

-

EQ7-4700-C

CT

-

200

EQ7-4800-C

CT

700

EQ7-4700-C

VT

-

EQ7-4800-C

CT

800

250

VT

EQ7-4900-C

CT

900

300

VT

1400

EQ7-41000-C

CT

1000

400

VT

1600

If no zero-phase current (earth leakage current) detective device such as a ground-fault relay is installed in the

upstream power supply line in order to avoid the entire power supply system's shutdown undesirable to factory

operation, install a residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB)

individually to inverters to break the individual inverter power supply lines only.

Otherwise, a fire could occur.

Current-Operated Protective Device (RCD)/Earth

Leakage Circuit Breaker (ELCB)

(6) Magnetic contactor (MC) in the inverter input (primary) circuit

Avoid frequent ON/OFF operation of the magnetic contactor (MC) in the input circuit; otherwise, the inverter failure

may result. If frequent start/stop of the motor is required, use FWD/REV terminal signals or the / keys on the

inverter's keypad.

The frequency of the MC's ON/OFF should not be more than once per 30 minutes. To assure 10 -year or longer

service life of the inverter, it should not be more than once per hour.

1-7

Page 20

• From the system's safety point of view, it is recommended to employ such a sequence that shuts down

the magnetic contactor (MC) in the inverter input circuit with an alarm output signal ALM issued on

inverter's programmable output terminals. The sequence minimizes the secondary damage even if the

inverter breaks.

When the sequence is employed, connecting the MC's primary power line to the inverter's auxiliary

control power input makes it possible to monitor the inverter's alarm status on the keypad.

• The breakdown of a braking unit or misconnection of an external braking resistor may trigger that of the

inverter's internal parts (e.g., charging resistor). To avoid such a breakdown linkage, introduce an MC

and configure a sequence that shuts down the MC if a DC link voltage establishment signal is not

issued within three seconds after the MC is switched on.

For the braking transistor built-in type of inverters, assign a transistor error output signal DBAL on

inverter's programmable output terminals to switch off the MC in the input circuit.

(7) Magnetic contactor (MC) in the inverter output (secondary) circuit

If a magnetic contactor (MC) is inserted in the inverter's output (secondary) circuit for switching the motor to a

commercial power or for any other purposes, it should be switched on and off when both the inverter and motor

are completely stopped. This prevents the contact point from getting rough due to a switching arc of the MC. The

MC should not be equipped with any main circuit surge killer.

Applying a commercial power to the inverter's output circuit breaks the inverter. To avoid it, interlock the MC on the

motor's commercial power line with the one in the inverter output circuit so that they are not switched ON at the

same time.

(8) Surge absorber/surge killer

Do not install any surge absorber or surge killer in the inverter's output (secondary) lines.

Noise reduction

If noise generated from the inverter affects other devices, or that generated from peripheral equipment causes the

inverter to malfunction, follow the basic measures outlined below.

(1) If noise generated from the inverter affects the other devices through power wires or grounding wires:

- Isolate the grounding terminals of the inverter from those of the other devices.

- Connect a noise filter to the inverter power wires.

- Isolate the power system of the other devices from that of the inverter with an insulated transformer.

- Decrease the inverter's carrier frequency (F26).

1-8

Page 21

(2) If induction or radio noise generated from the inverter affects other devices:

Problem

Measures

An earth leakage circuit

breaker* that is

connected to the input

(primary) side has

tripped.

*With overcurrent

protection

1) Decrease the carrier frequency.

2) Make the wires between the inverter and motor shorter.

3) Use an earth leakage circuit breaker with lower sensitivity than the one currently

used.

4) Use an earth leakage circuit breaker that features measures against the high

frequency current component.

An external thermal relay

was activated.

1) Decrease the carrier frequency.

2) Increase the current setting of the thermal relay.

3) Use the electronic thermal overload protection built in the inverter, instead of the

external thermal relay.

- Isolate the main circuit wires from the control circuit wires and other device wires.

- Put the main circuit wires through a metal conduit pipe, and connect the pipe to the ground near the inverter.

- Install the inverter into the metal panel and connect the whole panel to the ground.

- Connect a noise filter to the inverter's power wires.

- Decrease the inverter's carrier frequency (F26).

(3) When implementing measures against noise generated from peripheral equipment:

- For inverter's control signal wires, use twisted or shielded-twisted wires. When using shielded-twisted wires,

connect the shield of the shielded wires to the common terminals of the control circuit.

- Connect a surge absorber in parallel with magnetic contactor's coils or other solenoids (if any).

Leakage current

A high frequency current component generated by insulated gate bipolar transistors (IGBTs) switching on/off inside the

inverter becomes leakage current through stray capacitance of inverter input and output wires or a motor. If any of the

problems listed below occurs, take an appropriate measure against them.

Selecting inverter capacity

(1) To drive a general-purpose motor, select an inverter according to the nominal applied motor rating listed in the

standard specifications table. When high starting torque is required or quick acceleration or deceleration is

required, select an inverter with one rank higher capacity than the standard.

(2) Special motors may have larger rated current than general-purpose ones. In such a case, select an inverter that

meets the following condition.

Inverter rated current > Motor rated current

1-9

Page 22

1.3 Precautions in running inverters

Precautions for running inverters to drive motors or motor-driven machinery are described below.

Motor temperature

When an inverter is used to run a general-purpose motor, the motor temperature becomes higher than when it is

operated with a commercial power supply. In the low-speed range, the motor cooling effect will be weakened, so

decrease the output torque of the motor when running the inverter in the low-speed range.

Motor noise

When a general-purpose motor is driven by an inverter, the noise level is higher than that when it is driven by a

commercial power supply. To reduce noise, raise carrier frequency of the inverter. Operation at 60 Hz or higher can

also result in higher noise level.

Machine vibration

When an inverter-driven motor is mounted to a machine, resonance may be caused by the natural frequencies of the

motor-driven machinery. Driving a 2-pole motor at 60 Hz or higher may cause abnormal vibration. If it happens, do any

of the following:

- Consider the use of a rubber coupling or vibration-proof rubber.

- Use the inverter's jump frequency control feature to skip the resonance frequency zone(s).

- Use the vibration suppression related function codes that may be effective. For details, refer to the description of

H80 in Chapter 4 "FUNCTION CODES" of the user manual.

1.4 Precautions in using special motors

When using special motors, please read the following section:

Explosion-proof motors

When driving an explosion-proof motor with an inverter, use a combination of a motor and an inverter that has been

approved in advance.

Submersible motors and pumps

These motors have a larger rated current than general-purpose motors. Select an inverter with rated output current

that is greater than that of the motor. These motors differ from general-purpose motors in thermal characteristics.

Decrease the thermal time constant of the electronic thermal overload protection to match the motor rating.

Brake motors

For motors equipped with parallel-connected brakes, their power supply for braking must be supplied from the inverter

input (primary) circuit. If the power supply for braking is mistakenly connected to the inverter's output (secondary)

circuit, the brake may not work when the inverter output is shut down. Do not use inverters for driving motors

equipped with series-connected brakes.

Geared motors

If the power transmission mechanism uses an oil-lubricated gearbox or speed changer/reducer, then continuous

operation at low speed may cause poor lubrication. Avoid such operation.

Synchronous motors

It is necessary to take special measures suitable for this motor type. Contact your TECO-Westinghouse Motor

Company representative for details.

Single-phase motors

Single-phase motors are not suitable for inverter-driven variable speed operation.

1-10

Page 23

High-speed motors

If the reference frequency is set to 120 Hz or higher to drive a high-speed motor, test-run the combination of the

inverter and motor beforehand to check it for the safe operation.

Precautions for use on single-phase power

An inverter is a device that converts alternating current of the input line to direct current via the ac-to-dc rectifier and

then converts it to alternating current via the dc-to-ac switching inverter circuit in order to output the required

alternating current. The EQ7 drive is designed to connect to the three-phase power and this manual stipulates the

specifications for the use on the three-phase power.

If the inverter designed for connection to three-phase power runs on single-phase power, ripples (voltage fluctuation)

on the DC link bus voltage rectified from the input power become larger than those in the inverter running on threephase power. The DC-voltage ripple affects the inverter output; that is, ripples could be superimposed on the output

voltage or current, making control hard.

Accordingly, the inverter may not work in full performance or function correctly. To use the EQ7 drive on single-phase

power, therefore, you need to take the following into account.

Output current

Select the inverter capacity to keep the output current within the specified level, referring to chapter 11. Output current

exceeding the limit extremely increases voltage ripples on the DC link bus, impeding normal operation or resulting in

an inverter breakdown.

Wiring

When connecting 230 V inverters of 60 HP or above or 460 V ones of 125 HP or above to single-phase power, use L1

and L3 phases since cooling fans and magnetic contactors inside the inverter are supplied with power via L1 and L3.

Using L2 does not work cooling fans or magnetic contactors, causing abnormal heat, in the worst case, resulting in an

inverter breakdown.

Connecting peripheral devices

For the specifications of circuit breakers and fuses to apply, refer to pages 1-6 and 1-7.

Configuring function codes

(1) Cancel the input phase loss protection of the protection/maintenance function with function code H98 (Bit 1 = 0).

This is because the inverter judges single-phase power as a phase loss.

(2) Limit the drive mode to the VT / CT-V mode (Function code F80 = 0 or 1).

(3) Do not use "Vector control without speed sensor" or torque control. (Function codes F42 5, H18 = 0)

(4) "V/f control with slip compensation inactive" is recommended (F42 = 0). Any other drive control calculates the

motor model using the motor parameters inside the inverter. As ripples on the DC link bus voltage become larger,

therefore, calculation causes some errors so that the inverter may not provide the desired performance. Consider

this problem before use. In particular, when using "Vector control with speed sensor" (F42 = 6), dancer control

(J01 = 3), or brake signals (J68, J69, J70, etc.), assure the operation and safety of those speed sensors.

1-11

Page 24

Item

Specifications

Site location

Indoors

Surrounding/ambient

temperature

-10 to +50 C (14 to 122 F) (Note 1)

Relative humidity

5 to 95% (No condensation)

Atmosphere

The inverter must not be exposed to dust, direct sunlight,

corrosive gases, flammable gases, oil mist, vapor or water drops.

Pollution degree 2 (IEC60664-1) (Note 2)

The atmosphere can contain a small amount of salt.

(0.01 mg/cm2 or less per year)

The inverter must not be subjected to sudden changes in

temperature that will cause condensation to form.

Altitude

3300 ft (1000 m) max. (Note 3)

Atmospheric

pressure

86 to 106 kPa

Vibration

Inverters of

100 HP or below (230 V series)

125 HP or below (460 V series)

Inverters of

125 HP or above (230 V series)

150 HP or above (460 V series)

0.12 inch (3 mm)

(Max. amplitude)

0.12 inch (3 mm)

(Max. amplitude)

2 to less than 9 Hz

2 to less than 9 Hz

9.8 m/s2

9 to less than 20 Hz

2 m/s2

9 to less than 55 Hz

2 m/s2

20 to less than 55 Hz

1 m/s2

55 to less than 200 Hz

1 m/s2

55 to less than 200 Hz

Install the inverter on a base made of metal or other non-flammable material.

Install the inverter on a base made of metal or other non-flammable material.

Otherwise, a fire could occur.

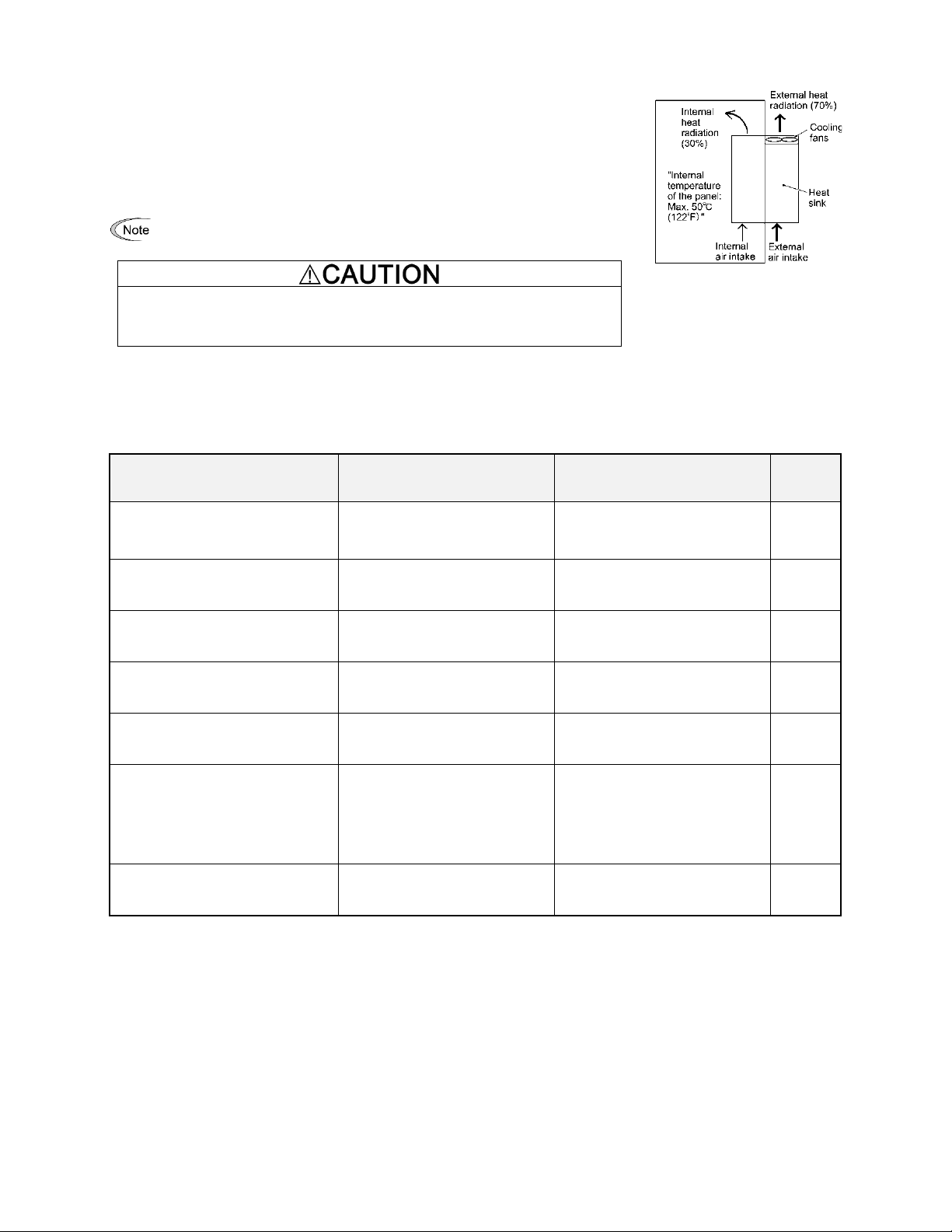

(2) Clearances

Ensure that the minimum clearances indicated in Figure 2.1 and Table 2.3 are

maintained at all times. When mounting the inverter in the panel of your system,

take extra care with ventilation inside the panel as the surrounding temperature

easily rises. Do not mount the inverter in a small panel with poor ventilation.

When mounting two or more inverters

When mounting two or more inverters in the same unit or panel, install them side

by side. When one must be mounted above the other, be sure to separate them

with a partition plate, or the like, so that any heat radiating from an inverter will not

affect the one/s above.

As long as the surrounding temperature is 40°C (104°F) or lower, inverters of 40

HP or below can be mounted side by side without any clearance between them.

Table 2.3 Clearances

inch (mm)

Inverter capacity

A B C

0.5 to 2 HP

2.0 (50)

3.9 (100)

0

3 to 40 HP

0.39 (10)

50 to 450 HP

2.0 (50)

3.9 (100)

500 to 1000 HP

5.9 (150)

5.9 (150)

C: Space required in front of the inverter unit

Table 2.2 Output Current Derating

Factor in Relation to Altitude

Altitude

Output current

derating factor

3300 ft (1000 m)

or lower

1.00

3300 to 4900 ft

(1000 to 1500 m)

0.97

4900 to 6600 ft

(1500 to 2000 m)

0.95

6600 to 8200 ft

(2000 to 2500 m)

0.91

8200 to 9800 ft

(2500 to 3000 m)

0.88

(Note 1) When inverters (40 HP or

below) are mounted side-by-side without

any clearance between them, the

surrounding temperature should be within

the range from -10 to +40 C (14 to 104 F).

This specification also applies to the

inverters (40 HP) equipped with a NEMA1

kit.

(Note 2) Do not install the inverter in an

environment where it may be exposed to

lint, cotton waste or moist dust or dirt

which will clog the heat sink of the

inverter. If the inverter is to be used in

such an environment, install it in a

dustproof panel.

(Note 3) If you use the inverter in an

altitude above 3300 ft (1000 m), you

should apply an output current derating

factor as listed in Table 2.2.

Figure 2.1 Mounting Direction and

Required Clearances

Chapter 2 Mounting and Wiring the Inverter

2.1 Operating Environment

Install the inverter in an environment that satisfies the requirements listed in Table 2.1.

Table 2.1 Environmental Requirements

2.2 Installing the Inverter

(1) Mounting base

2-1

Page 25

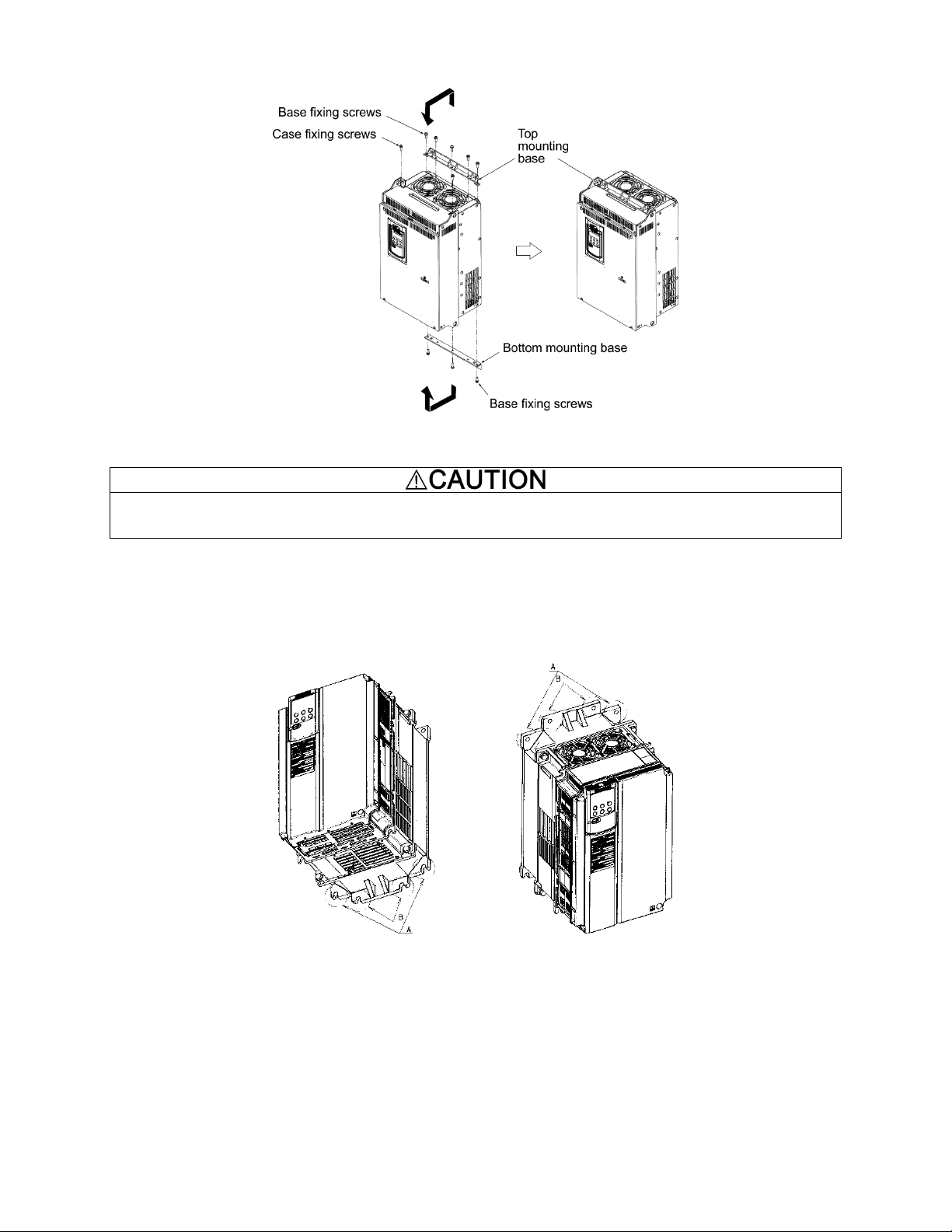

When employing external cooling

In external cooling, the heat sink, which dissipates about 70% of the total heat (total

loss) generated into air, is situated outside the equipment or the panel. The external

cooling, therefore, significantly reduces heat radiating inside the equipment or panel.

To employ external cooling for inverters (except DCR built-in type) of 40 HP or below,

use the mounting adapter for external cooling (option); for those of 50 HP or above,

simply change the positions of the mounting bases.

The DCR built-in type of 40 HP or below cannot employ external cooling.

Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign

materials from getting into the inverter or from accumulating on the heat sink.

Otherwise, a fire or accident could occur.

Figure 2.2 External Cooling

Inverter type

Base fixing screw

(Screw size and q'ty)

Case fixing screw

(Screw size and q'ty)

Tightening

torque

lb-in (Nm)

EQ7-2050-C /EQ7-2060-C

EQ7-4050-C

EQ7-4100-C

M6 20

5 pcs for upper side,

3 pcs for lower side

M6 20

2 pcs for upper side

51.3

(5.8)

EQ7-2075-C / EQ7-4100-C

EQ7-4125-C

M6 20

3 pcs each for upper and lower

sides

M6 12

3 pcs for upper side

51.3

(5.8)

EQ7-2125-C

EQ7-4150-C / EQ7-4200-C

M5 12

7 pcs each for upper and lower

sides

M5 12

7 pcs for upper side

31.0

(3.5)

EQ7-4250-C / EQ7-4300-C

M5 16

7 pcs each for upper and lower

sides

M5 16

7 pcs for upper side

31.0

(3.5)

EQ7-2150-C

EQ7-4350-C / EQ7-4450-C

M5 16

8 pcs each for upper and lower

sides

M5 16

8 pcs for upper side

31.0

(3.5)

EQ7-4500-C / EQ7-4600-C

EQ7-4700-C / EQ7-4800-C

M5 16

2 pcs each for upper and lower

sides

M6 20

6 pcs each for upper and lower

sides

M5 16

2 pcs each for upper and lower

sides

M6 20

6 pcs each for upper and lower

sides

31.0

(3.5)

51.3

(5.8)

EQ7-4900-C / EQ7-41000-C

M8 20

8 pcs each for upper and lower

sides

M8 20

8 pcs each for upper and lower

sides

119

(13.5)

To utilize external cooling for inverters of 50 HP or above, change the positions of the top and bottom mounting bases

from the edge to the center of the inverter as shown in Figure 2.3.

Screws differ in size and count for each inverter. Refer to the table below.

Table 2.4 Screw Size, Count and Tightening Torque

1) Remove all base fixing screws and case fixing screws from the top of the inverter.

2) Move the top mounting base to the center of the inverter and secure it to the case fixing screw holes with the base

fixing screws. (After changing the position of the top mounting base, some screws may be left unused.)

3) Remove the base fixing screws from the bottom of the inverter, move the bottom mounting base to the center of the

inverter, and secure it with the base fixing screws, just as in step 2). (Inverters of 450 HP or below have no case

fixing screws on the bottom.)

2-2

Page 26

When changing the positions of the top and bottom mounting bases, use only the specified screws.

Otherwise, a fire or accident could occur.

Figure 2.3 Changing the Positions of the Top and Bottom Mounting Bases

(3) Mounting notes

The EQ7-2007-C / EQ7-4007-C through EQ7-2040-C / EQ7-4040-C should be mounted with four screws or bolts using

screw holes A or B shown below. Note that, at each of the top and bottom of the inverter, the two screws or bolts should

be located in a bilaterally symmetrical position.

2-3

Page 27

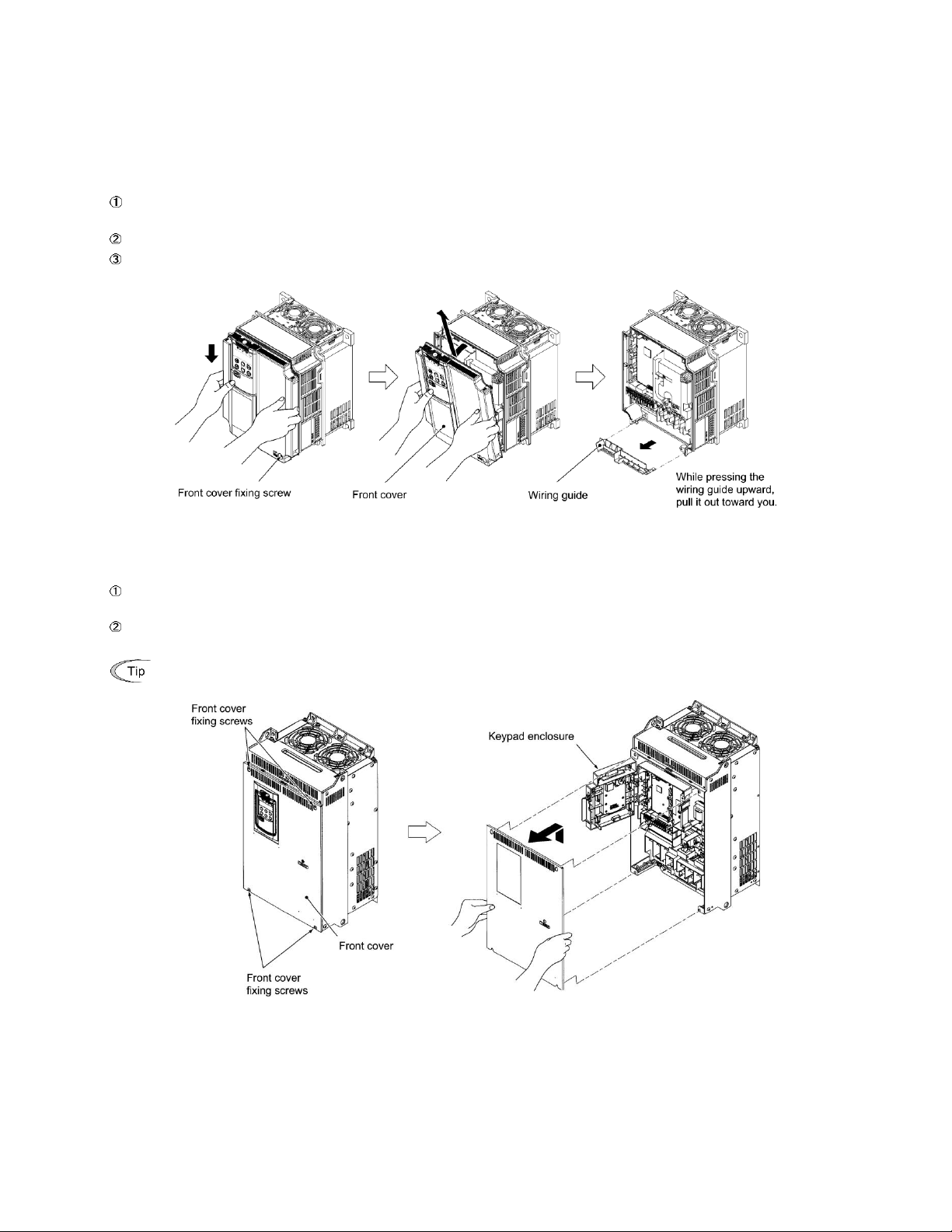

To expose the control printed circuit board (control PCB), open the keypad enclosure.

2.3 Wiring

Follow the procedure below. (In the following description, the inverter has already been installed.)

2.3.1 Removing and mounting the front cover and the wiring guide

(1) For inverters of 40 HP or below

First loosen the front cover fixing screw, slide the cover downward holding both sides, tilt it forward, and then pull it

upward, as shown below.

While pressing the wiring guide upward, pull it out and forward.

After carrying out wiring (see Sections 2.3.2 through 2.3.6), put the wiring guide and the front cover back into place

in the reverse order of removal.

Figure 2.4 Removing the Front Cover and the Wiring Guide (e.g EQ7-4020-C)

(2) For inverters of 50 to 1000 HP

Loosen the four front cover fixing screws, hold the cover with both hands, slide it upward slightly, and pull it forward,

as shown below.

After carrying out wiring (see Sections 2.3.2 through 2.3.6), align the screw holes provided in the front cover with the

screws on the inverter case, and then put the front cover back into place in the reverse order of removal.

Figure 2.5 Removing the Front Cover (e.g. EQ7-4050-C)

2-4

Tightening torque: 15.9 lb-in (1.8 Nm) (M4)

31.0 lb-in (3.5 Nm) (M5)

Page 28

Inverter type

Refer to:

Screw specifications

Three-phase

230 V

Three-phase

460 V

Main circuit

terminals

Grounding

terminals

Auxiliary control

power input

terminals

[R0, T0]

Auxiliary fan

power input

terminals

[R1, T1]

Screw

size

Tightening

torque

lb-in (N·m)

Screw

size

Tightening

torque

lb-in (N·m)

Screw

size

Tightening

torque

b-in (N·m)

Screw

size

Tightening

torque

lb-in (N·m)

EQ7-20P5-C

EQ7-40P5-C

Figure A

M3.5

10.6 (1.2)

M3.5

10.6 (1.2)

--

--

--

--

EQ7-2001-C

EQ7-4001-C

EQ7-2002-C

EQ7-4002-C

Figure B

M4