TecMate Optimate 7 Ampmatic, TM254, TM255, Optimate 6 Ampmatic, TM180 EU Instructions For Use Manual

...Page 1

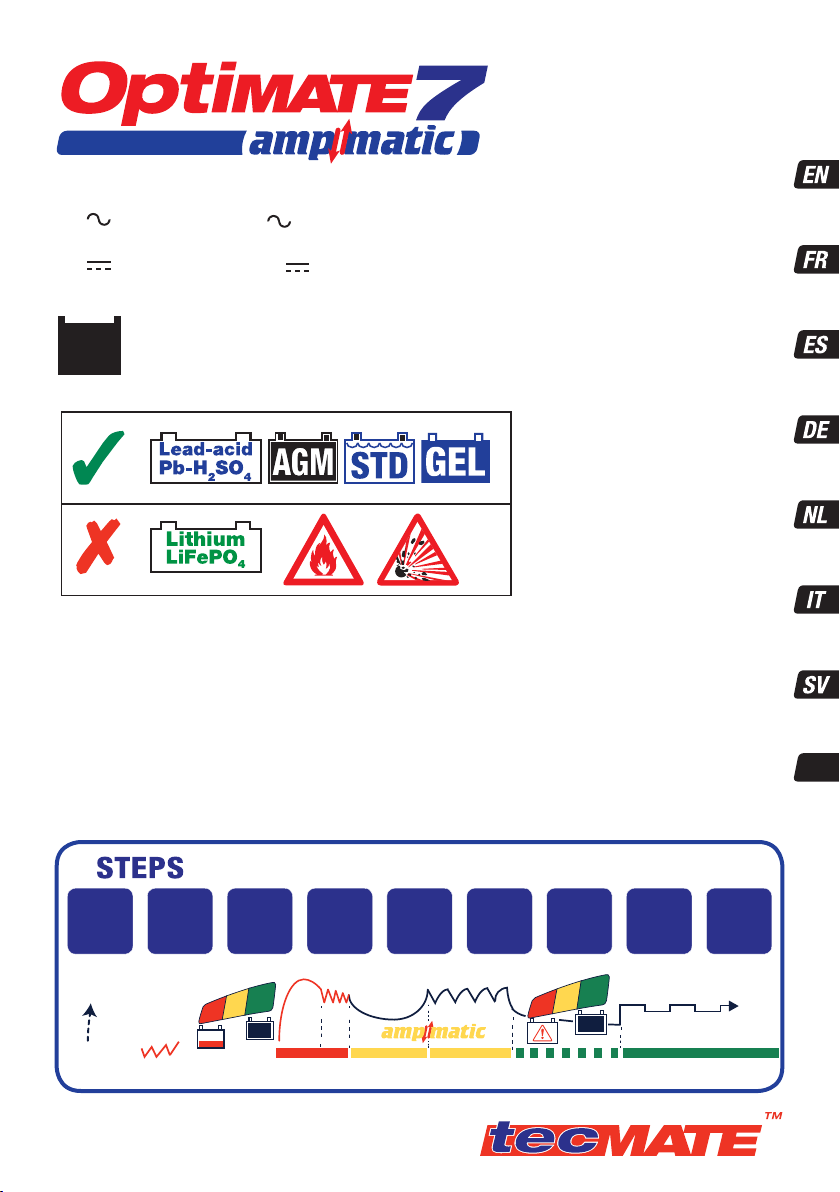

MODEL: TM254 / TM255

AC: 100 – 240V 50-60Hz

0.66A @ 240V / 1.59A @ 100V

DC: 120W ¨ 12V 10A

Thermally adjusted

INSTRUCTIONS FOR USE

IMPORTANT: Read completely

before charging

MODE D’EMPLOI

IMPORTANT: à lire avant

d’utiliser l’appareil

+-

1 x 12V

STD / AGM-MF / GEL

3 - 400Ah (max. Ah rating

based on 48 hour charge).

Automatic charger for 12V lead-acid batteries

Chargeur automatique pour batteries 12V plomb-acide

Cargador automático para baterías 12V plomoácido

Automatische Ladegerät für 12V Blei-Säure Batterien

Automatische lader voor 12V loodzuur accu’s

Caricabatterie automatico per batterie 12V piombo-acido

Automatisk diagnostisk laddare för 12V blybatterier

Automatick. nab.ječka pro 12V olovo/kyselinov. baterie

9

1

Low Volt

Start (0.5V)

2

Pulse

Wake up

3

TEST before

charge

4

SAVE

sulphated

battery

5

Pulse

SAVE

6

Controlled

CHARGE

MODO DE EMPLEO

IMPORTANTE: a leer antes de

utilizar el aparato

ANWENDUNGSVORSCHRIFTEN

WICHTIG: Vollständig vor der

Benutzung lesen

GEBRUIKSAANWIJZING

BELANGRIJK: Lees volledig voor

gebruik

ISTRUZIONI PER L’USO

IMPORTANTE: da leggere prima

di utilizzare l’apparecchio

INSTRUKTIONER

VIKTIGT: läs följande fullständiga

instruktioner för användningen

innan du använder laddaren

INSTRUKCE PRO POUŽIT.

DŮLEŽIT: Přečtěte si pozorně

před použit.m

7

OPTIMIZE

8

TEST after

CHARGE

9

OptiMate

‘365’

maintenance

CZ

2V

0.5V

0.5V

1.START 3.

TM254_TM255-IN1-170302

copyright @ 2016 TecMate International

2.

PULSE

TEST

14.4V

24-7-365

4&5.SAVE 6.CHARGE 7.OPTIMIZE 8.FINAL TEST 9.MAINTAIN

13.6V

Page 2

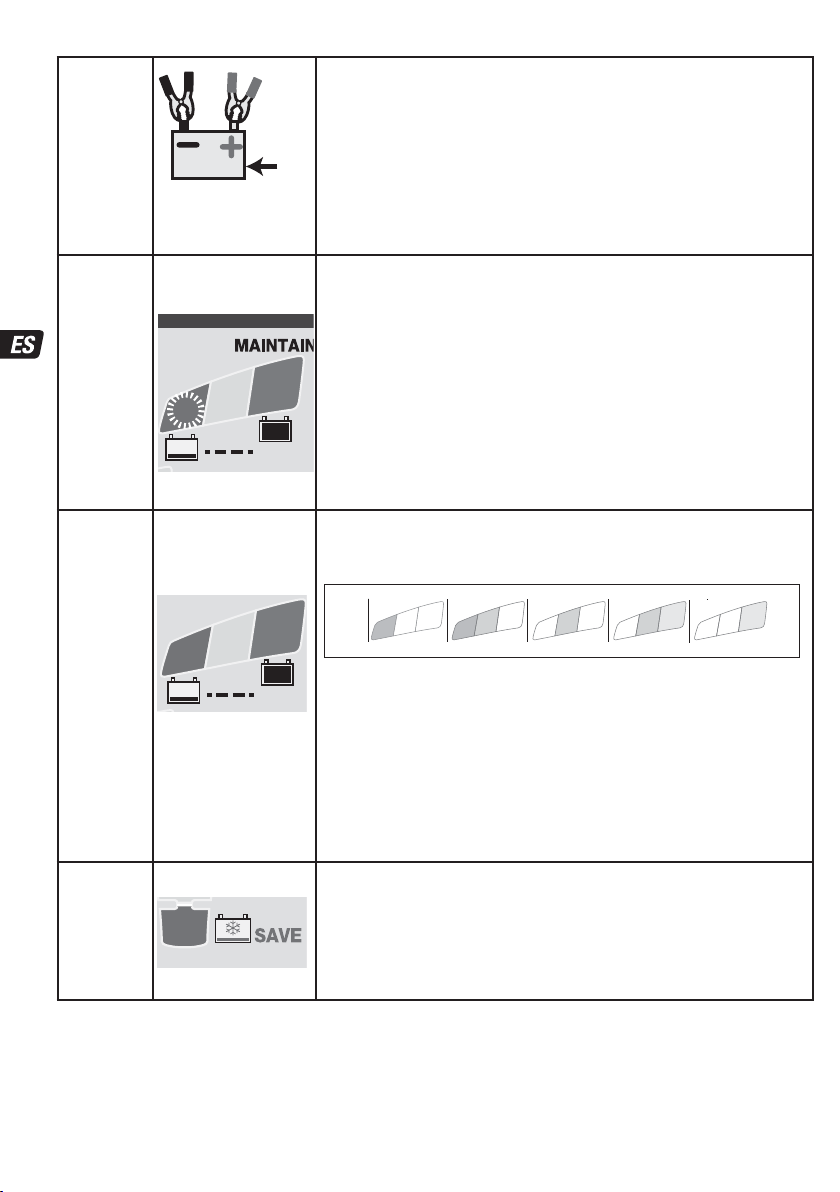

LEDs

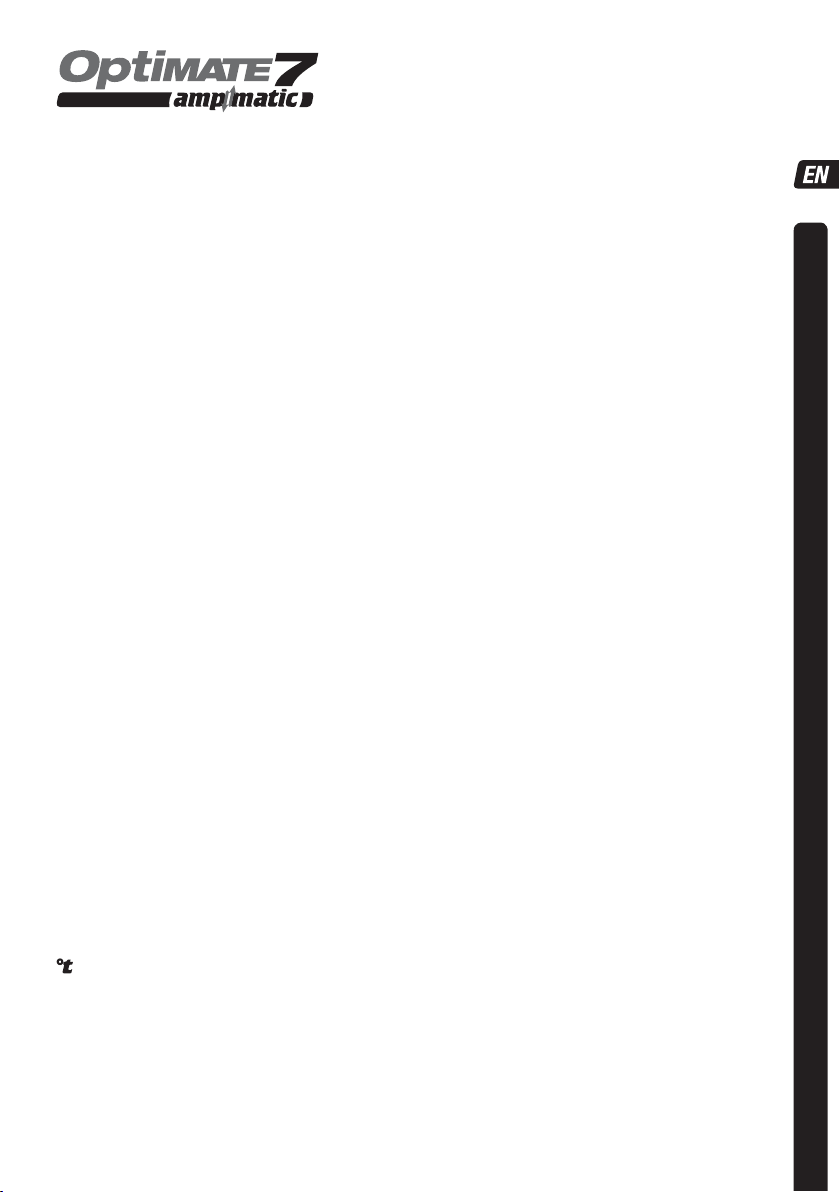

CONNECT

TEST

10s

°t

1

SAVE

15m - 2h

2

12V

CHARGE

72h max

5

4

3

8

TEST

OPTIMIZE

10m - 36h

7

6

TEST

30m - 12h

MAINTAIN

365

TEST LEDs

0

0

80 100%604020AGM

7

8

8

7

6

7

100% 806040STD

6

Page 3

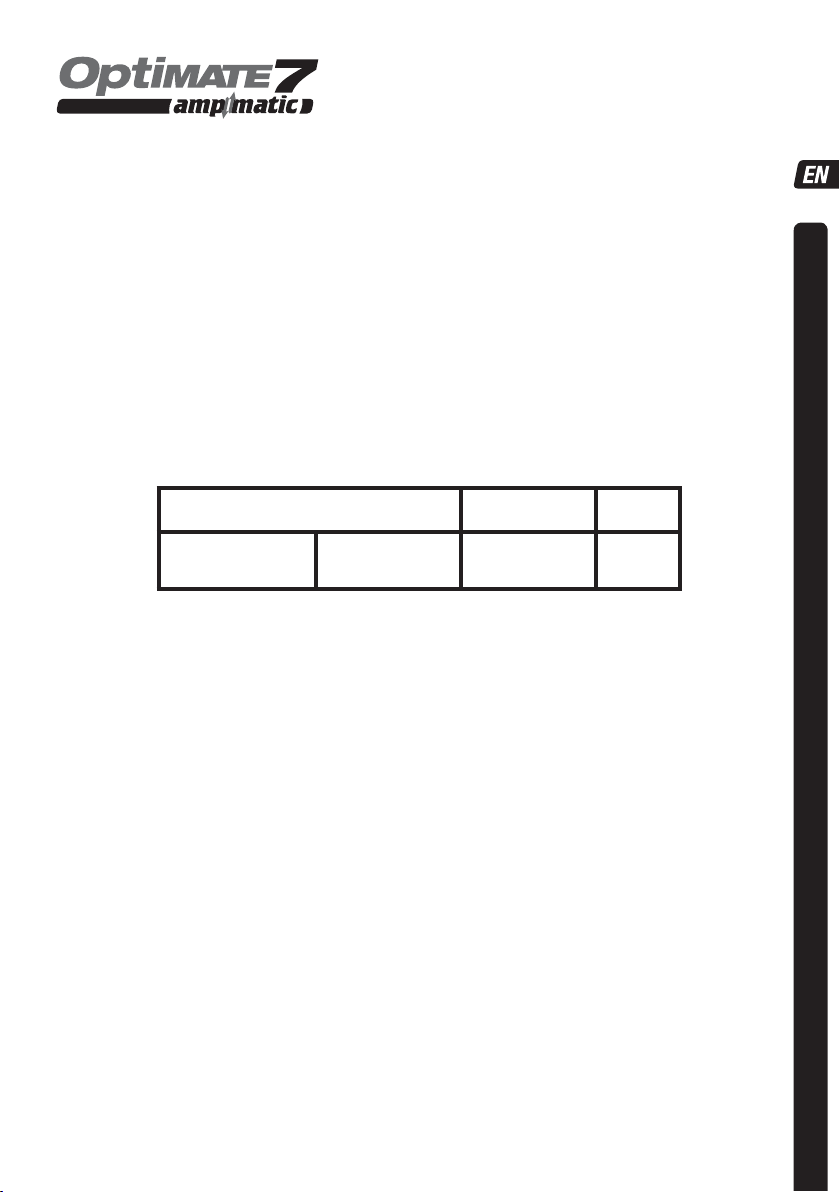

IMPORTANT SAFETY

INSTRUCTIONS FOR CANADA & USA

THIS PORTION OF THE MANUAL CONTAINS IMPORTANT SAFETY INSTRUCTIONS FOR

THE OPTIMATE 7 BATTERY CHARGER. IT IS OF THE UTMOST IMPORTANCE THAT

EACH TIME, BEFORE USING THE CHARGER, YOU READ AND EXACTLY FOLLOW THESE

INSTRUCTIONS. SAVE THESE INSTRUCTIONS.

Automatic charger for 12V lead-acid batteries

DO NOT USE FOR NiCd, NiMH, Li-Ion OR NON-RECHARGEABLE BATTERIES.

1. CAUTION : CLASS II APPLIANCE. DO NOT CONNECT TO GROUND.

2. Do not expose charger to rain or snow.

3. Use of an attachment not recommended or sold by the battery charger manufacturer may result in a risk of fire, electric shock,

or injury to persons.

4. To reduce risk of damage to electric plug and cord, pull by plug rather than cord when disconnecting charger.

5. An extension cord should not be used unless absolutely necessary. Use of improper extension cord could result

in a risk of fire and electric shock. If extension cord must be used make sure that :

a) pins on plug of extension cord are the same number, size and shape as those of plug on charger.

b) the extension cord is properly wired and in good electrical condition, and

c) the conductor wire size is large enough for the AC ampere rating of the charger as specified in the table below.

AC INPUT RATING IN AMPERES

Equal to or greater than But less than

2A 3A 25 (17.6)

6. Do not operate charger with damaged cord or plug – replace the cord or plug immediately.

7. Do not operate charger if it has received a sharp blow, been dropped,or otherwise damaged in any way;

take it to a qualified serviceman.

8. Do not disassemble charger; take it to a qualified serviceman when service or repair is required.

Incorrect reassembly may result in a risk of electric shock or fire.

9. To reduce risk of electric shock, unplug the charger from outlet before attempting any maintenance or cleaning.

Turning off controls will not reduce this risk.Clean only with slightly moist,not wet, cloth.Do not use solvents.

10. WARNING - RISK OF EXPLOSIVE GASES.

a) WORKING IN VICINITY OF A LEAD-ACID BATTERY IS DANGEROUS. BATTERIES GENERATE EXPLOSIVE GASES

DURING NORMAL BATTERY OPERATION. FOR THIS REASON, IT IS OF UTMOST IMPORTANCE THAT YOU FOLLOW THE

INSTRUCTIONS EACH TIME YOU USE THE CHARGER.

b) To reduce risk of battery explosion, follow these instructions and those published by the battery manufacturer

and manufacturer of any equipment you intend to use in vicinity of the battery. Review cautionary marking on

these products and on engine.

11. PERSONAL PRECAUTIONS.

a) Someone should be within range of your voice OR close enough to come to your aid when you work near a lead-acid battery.

b) Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

c) Wear complete eye protection and clothing protection. Avoid touching eyes while working near battery.

d) If battery acid contacts or enters eye, flood eye with cold running water for at least 10 minutes and get medical

attention immediately. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters

an eye, immediately flood eye with running cold water for at least 10 minutes and get medical attention immediately.

e) NEVER smoke or allow a spark or flame in vicinity of battery or engine.

f) Be extra cautious to reduce risk of dropping a metal tool onto battery. It might spark or short-circuit battery or other electrical

part that may cause explosion.

g) Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a lead-acid

battery. A lead-acid battery can produce a short-circuit current high enough to weld a ring or the like to metal,

causing a severe burn.

i) NEVER charge a frozen battery.

LENGTH OF CORD,

FEET (m)

50 (15.2)

100 (30.5)

AWG SIZE

OF CORD

18

18

14

SAFETY US & CAN

3

Page 4

12. PREPARING TO CHARGE

a) If necessary to remove battery from vehicle to charge,always remove grounded terminal from battery first.

Make sure all accessories in the vehicle are off, so as not to cause an arc.

b) Be sure area around battery is well ventilated while battery is being charged. Gas can be forcefully

blown away by using a piece of cardboard or other non-metallic material as a fan.

c) Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes.

d) Add distilled water in each cell until battery acid reaches level specified by battery manufacturer. This helps purge

excessive gas from cells. Do not overfill. For a battery without cell caps, such as valve regulated lead acid (VRLA) or absorbed glass

mat (AGM) batteries, carefully follow manufacturer’s recharging instructions.

e) Study all battery manufacturer’s specific precautions such as removing or not removing cell caps while charging

and recommended rates of charge.

SAFETY US & CAN

Determine voltage of battery by referring to vehicle or battery user’s manual and BEFORE MAKING

f)

THE BATTERY CONNECTIONS, MAKE SURE THAT THE VOLTAGE OF THE BATTERY YOU ARE GOING TO

CHARGE MATCHES THE OUTPUT VOLTAGE OF THE CHARGER.

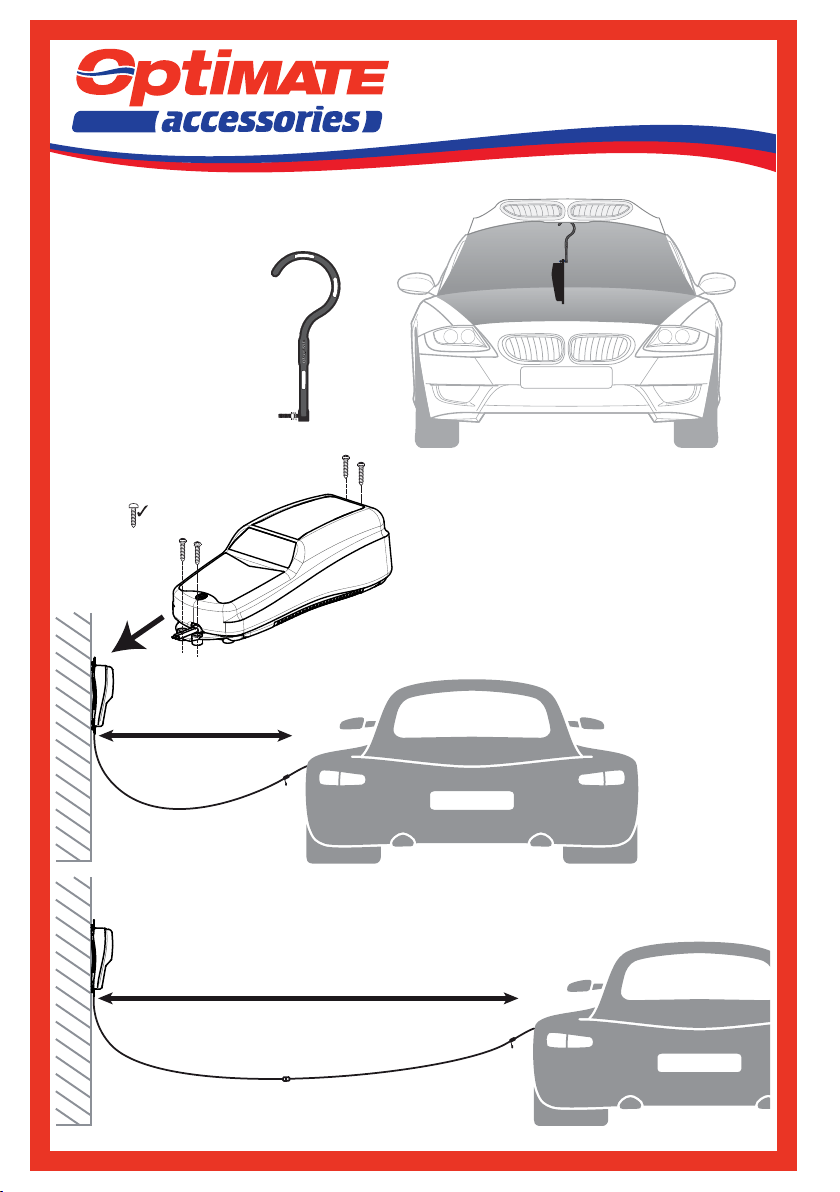

13. CHARGER LOCATION.

a) Locate charger as far away from battery as DC cables permit.

b) Never place charger directly above batterv being charged; gases from battery will corrode and damage the charger.

c) Never allow battery acid to drip on charger when reading gravity or filling battery. Do not operate charger in a closed-in area or

restrict ventilation in any way.

d) Do not set a battery on top of charger. IMPORTANT : Place charger on a hard flat surface or mount onto a vertical surface. Do not

place on plastic, leather or textile surface.

14. DC CONNECTION PRECAUTIONS

a) Connect and disconnect DC output clips only after setting any charger switches to off position and removing AC

cord from electric outlet. Never allow clips to touch each other, however should this happen no damage will result to

the charger circuit & the automatic charging programme will just reset to «start».

b) Attach clips to battery and chassis as indicated in 15(e), 15(f), and 16(b) through 16(d).

NOTE : This battery charger has an automatic safety feature that will prevent it from operating if the

battery has been inversely connected.

disconnect the battery clips, then reconnect correctly according to the instructions below.

15. FOLLOW THESE STEPS WHEN BATTERY IS INSTALLED IN VEHICLE. A SPARK NEAR A BATTERY MAY CAUSE BATTERY

EXPLOSION. TO REDUCE RISK OF A SPARK NEAR BATTERY :

a) Position AC and DC cords so as to reduce risk of damage by hood, door or moving engine part.

b) Stay clear of fan -blades, belts,pulleys,and other parts that can cause injury to persons.

c) Check polarity of battery posts.POSITIVE (POS, P, +) battery post usually has larger diameter than NEGATIVE (NEG,

N,–) post.

d) Determine which post of battery is grounded (connected) to the chassis. If negative post is grounded to chassis

(as in most vehicles), see (e). If positive post is grounded to the chassis, see (f).

e) For negative-grounded vehicle, connect POSITIVE (RED) clip from battery charger to POSITIVE (POS, P, + )

ungrounded post of battery. Connect NEGATIVE (BLACK) clip to vehicle chassis or engine block away from battery.

Do not connect clip to carburetor, fuel lines, or sheet-metal body parts. Connect to a heavy gage metal part of the

frame or engine block.

f) For positive-grounded vehicle, connect NEGATIVE (BLACK) clip from battery charger to NEGATIVE (NEG. N , -)

ungrounded post of battery. Connect POSITIVE (RED) clip to vehicle chassis or engine block away from battery.

Do not connect clip to carburetor, fuel lines, or sheet-metal body parts. Connect to a heavy gage metal part of the

frame or engine block.

g) When disconnecting charger, turn switches to off, disconnect AC cord,remove clip from vehicle chassis,and then

remove clip from battery terminal.

h) See operating instructions for length of charge information.

16. FOLLOW THESE STEPS WHEN BATTERY IS OUTSIDE VEHICLE. A SPARK NEAR THE BATTERY MAY CAUSE BATTERY

EXPLOSION. TO REDUCE RISK OF A SPARK NEAR BATTERY :

a) Check polarity of battery posts. POSITIVE (POS, P, +) battery post usually has a larger diameter than NEGATIVE

(NEG,N, -) post.

This battery charger has an automatic safety feature that will prevent it from operating if the

b)

Set charger switches to off position and/or remove AC cord from electrical outlet,

battery has been inversely connected. The charger does not allow charge current unless a voltage of

at least 2V is sensed.

c) Connect POSITIVE (RED) charger clip to POSITIVE (POS, P, +) post of battery.

d) Connect NEGATIVE (BLACK) charger clip to NEGATIVE (NEG, N, -) battery post of the battery.

e) Do not face battery when making final connection.

f) When disconnecting charger, always do so in reverse sequence of connecting procedure & break first connection

while as far away from battery as practical.

g) A marine (boat) battery must be removed & charged on shore. To charge it on board requires equipment specially

designed for marine use.

4

Page 5

AUTOMATIC DIAGNOSTIC CHARGER FOR 12V LEAD-ACID BATTERIES.

DO NOT USE FOR NiCd, NiMH, Li-Ion OR NON-RECHARGEABLE BATTERIES.

IMPORTANT: READ THE FOLLOWING INSTRUCTIONS BEFORE USING THE CHARGER

This appliance can be used by children aged from 8 years and above and persons with reduced

physical,sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

SAFETY WARNING AND NOTES: Batteries emit EXPLOSIVE GASES - prevent flame or sparks near batteries. Disconnect

AC power supply before making or breaking DC/battery connections. Battery acid is highly corrosive. Wear protective clothing and

eyewear and avoid contact. In case of accidental contact, wash immediately with soap and water. Check that the battery posts are

not loose; if so, have the battery professionally assessed. If the battery posts are corroded, clean with a copper wire brush; if greasy

or dirty clean with a rag damped in detergent.

are in good, undamaged condition. If the input cable is damaged, it is essential to have it replaced

without delay by the manufacturer, his authorised service agent or a qualified workshop, to avoid

Protect your charger from acid and acid fumes and from damp and humid conditions both during use and in storage.

danger.

Damage resulting from corrosion, oxidation or internal electrical short-circuiting is not covered by warranty. Distance the charger

from the battery during charging to avoid contamination by or exposure to acid or acidic vapours. If using it in the horizontal

orientation, place the charger on a hard, flat surface, but NOT on plastic, textile or leather. Use the fixing holes provided in the

enclosure base to attach the charger to any convenient, sound vertical surface.

EXPOSURE TO LIQUIDS: This charger is designed to withstand exposure to liquids accidentally spilled or splashed onto the

casing from above, or to light rainfall. Prolonged exposure to falling rain is inadvisable and longer service life will be obtained by

minimizing such exposure.Failure of the charger due to oxidation resulting from the eventual penetration of liquid into the electronic

components, connectors or plugs,is not covered by warranty.

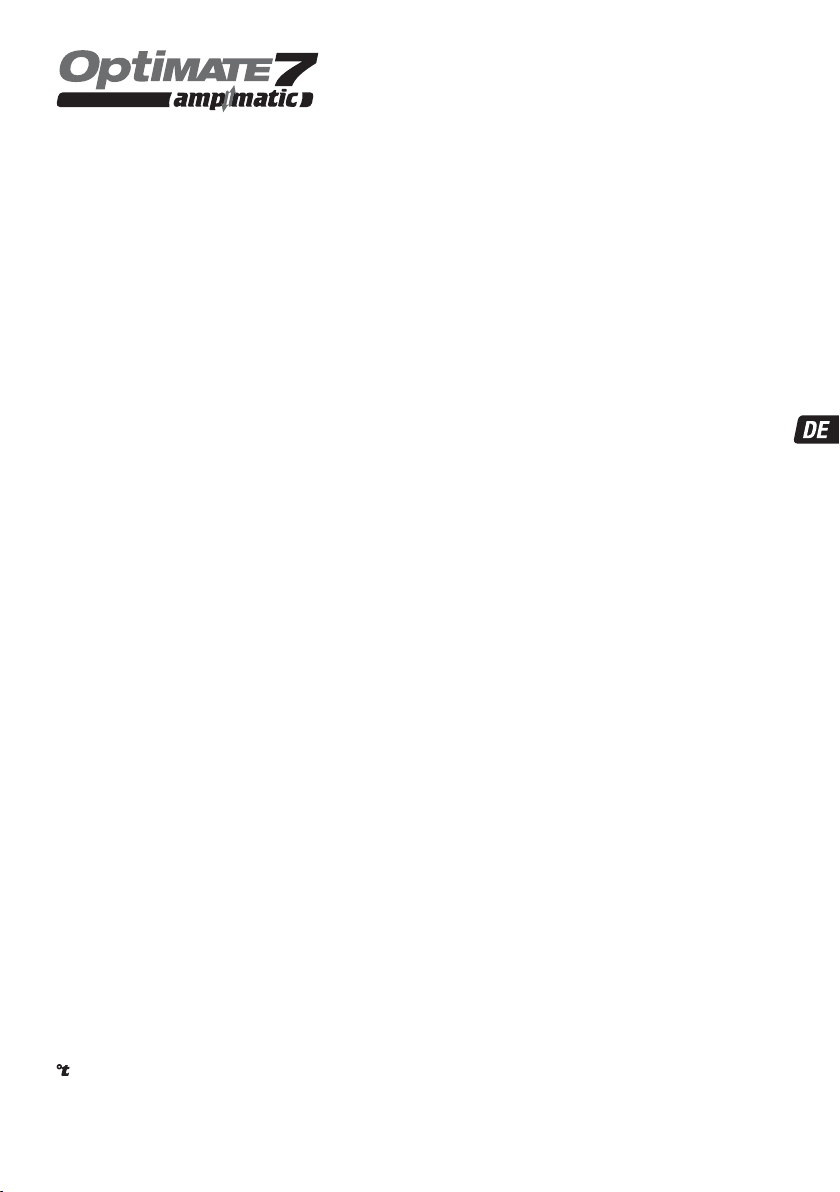

CONNECTING THE CHARGER TO THE BATTERY

1. Disconnect AC power supply before making or breaking DC / battery connections.

2. If charging a battery in the vehicle with the battery clips, before making connections, first check that the battery clips can be

safely and securely positioned clear from surrounding wiring, metal tubing or the chassis. Make connections in the following

First connect to the battery terminal not connected to the chassis (normally positive), then

order:

connect the other battery clip (normally negative) to the chassis well away from the battery and

fuel line. Always disconnect in reverse sequence.

3. When charging a battery out of the vehicle with the battery clips, place it in a well ventilated area. Connect the charger to the

battery: RED clamp to POSITIVE (POS, P or +) terminal and BLACK clamp to NEGATIVE (NEG, N or –) terminal. Make sure the

connections are firm and secure. Good contact is important.

4. If the battery is deeply discharged (and possibly sulphated), remove from the vehicle and inspect the battery before

connecting the charger for a recovery attempt. Visually check the battery for mechanical defects such as a bulging or

cracked casing, or signs of electrolyte leakage. If the battery has filler caps and the plates within the cells can be seen from the

outside, examine the battery carefully to try to determine if any cells seem different to the others (for example, with white

matter between the plates, plates touching). If mechanical defects are apparent do not attempt to charge the battery, have the

battery professionally assessed.

5. If the battery is new, before connecting the charger read the battery manufacturer’s safety and operational instructions

carefully. If applicable, carefully and exactly follow acid filling instructions.

PROCEEDING TO CHARGE:

CHARGING TIME : Charge time on a flat but otherwise undamaged battery: a 100Ah 12V should take no more than about 12

hours to progress to the self-discharge check. Deep-discharged batteries may take significantly longer, a full charge may not be

achieved within the 72 hour charge safety limit. In this case.

: The charge voltage is inversely regulated according to ambient temperature i.e. voltage is increased at lower temperature,

decreased at higher temperature. Adjustment: -0.004V / cell / °C above or below 20°C (68°F).

POWER ON: LED #1 - Confirms AC power supply to the charger.

HIGH and LOW intensity indication: The"POWER ON" LED #1 will indicate brightly when current is delivered to the battery.

The "POWER ON" LED #1 will reduce intensity to a low level to indicate low power "ECO" mode. This will occur if there is no battery

connected, or when a battery is connected and the program finds itself in the voltage retention test mode or the 'rest' periods of

Maintenance Charge mode.

REVERSE POLARITY PROTECTION: LED #2 - Lights when the battery connections are incorrect. The charger is

protected so no damage will result, and the output will remain disabled until the connections are corrected.

Use the charger only if the input and output leads and connectors

electronically

SAFETY

5

Page 6

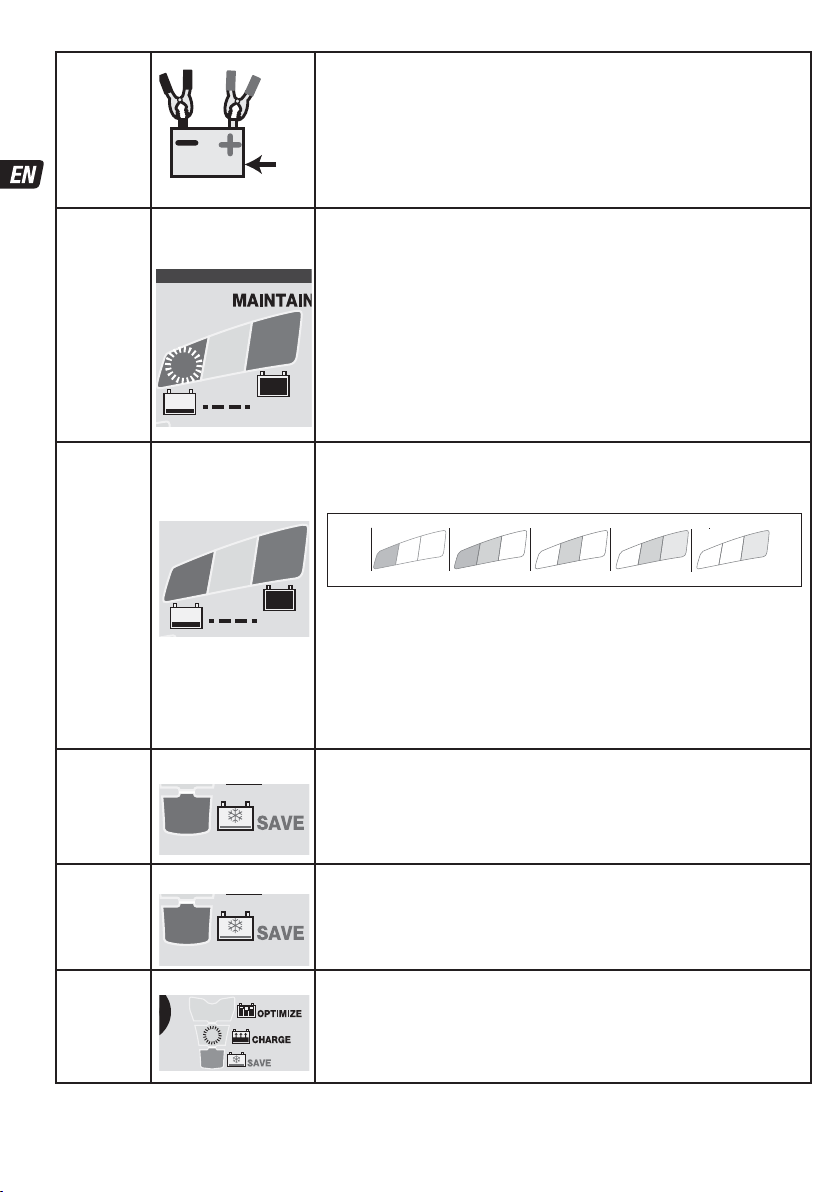

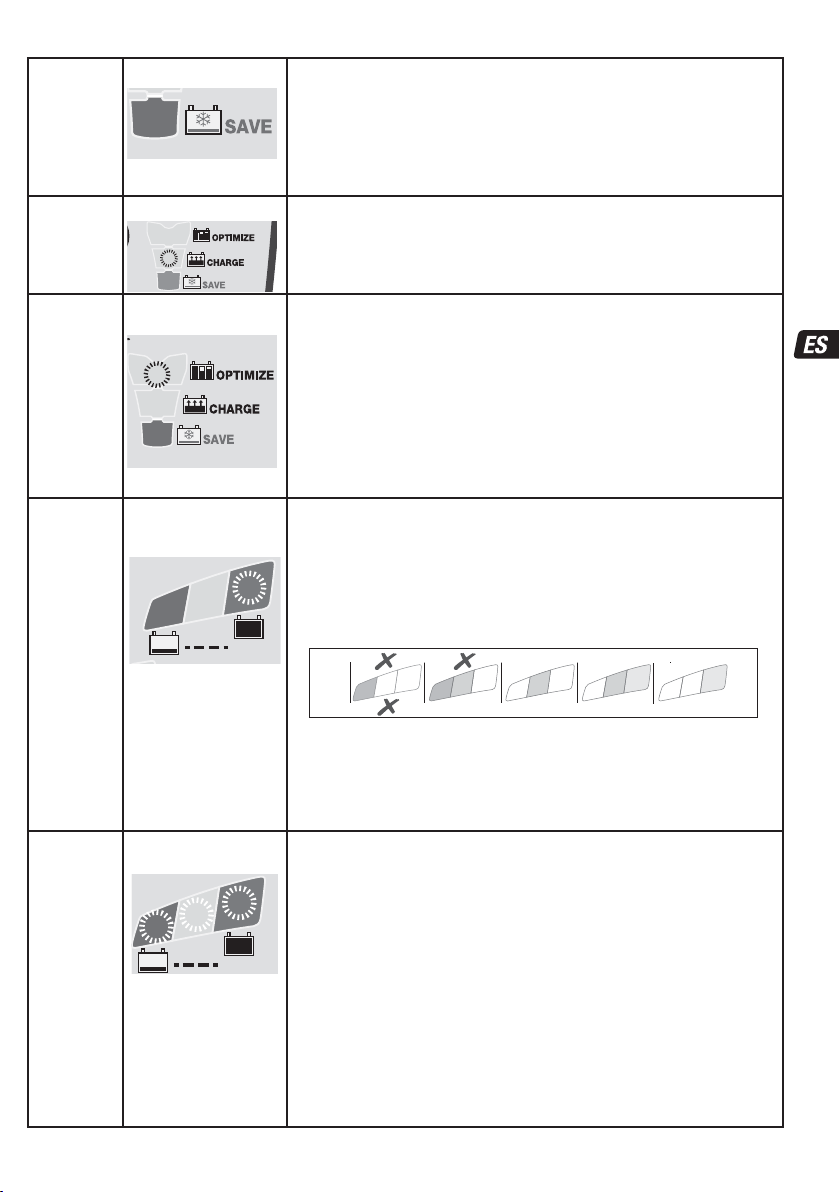

STEP 1

Low Volt

START -

Bat ≥ 0.5V

STEP 2

Pulse

wake up

STEP 3

TEST

before

charge

STEP 4

ADVANCED

SAVE

STEP 5

PULSE

SAVE

STEP 6

CHARGE

LED #8 FLASHING

7

8

TEST

TEST LEDs

6 : GREEN

7 : YELLOW

8 : RED

7

8

TEST

LED #3 : RED

3

LED #3 : RED

3

LED #4 : YELLOW

4

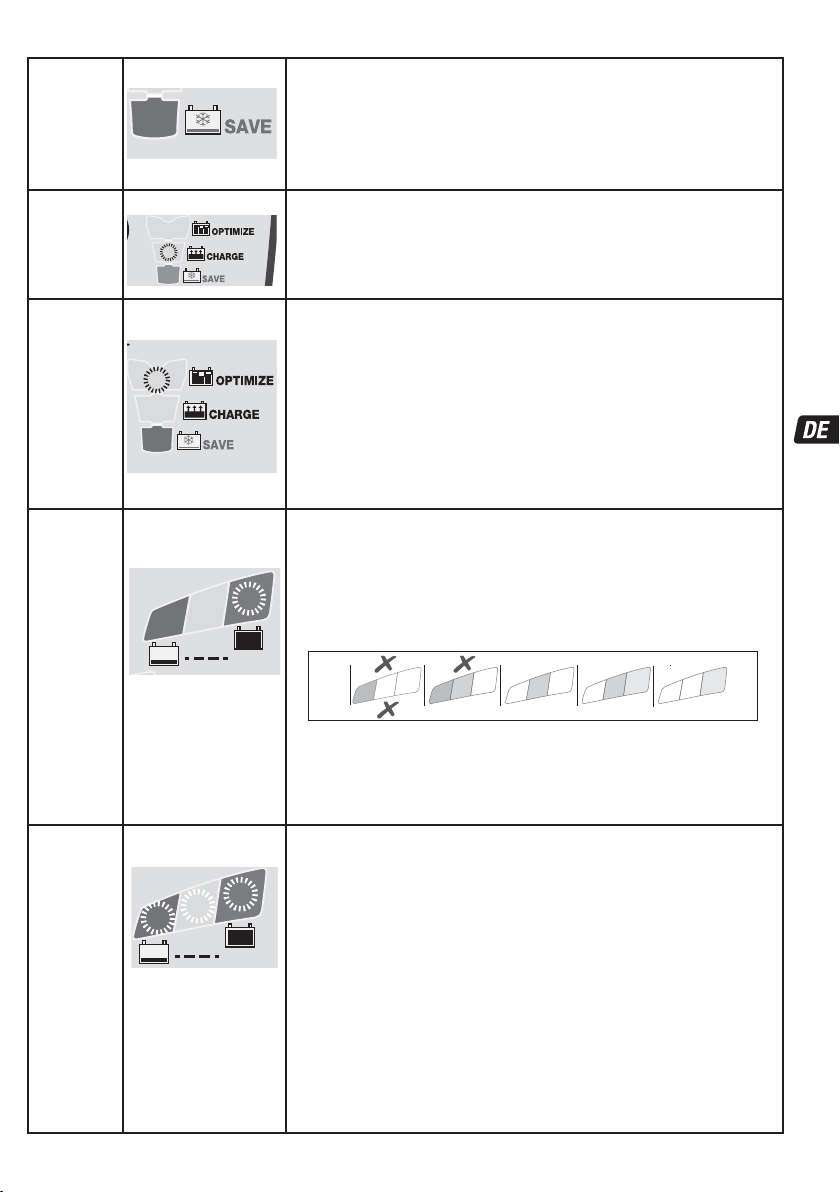

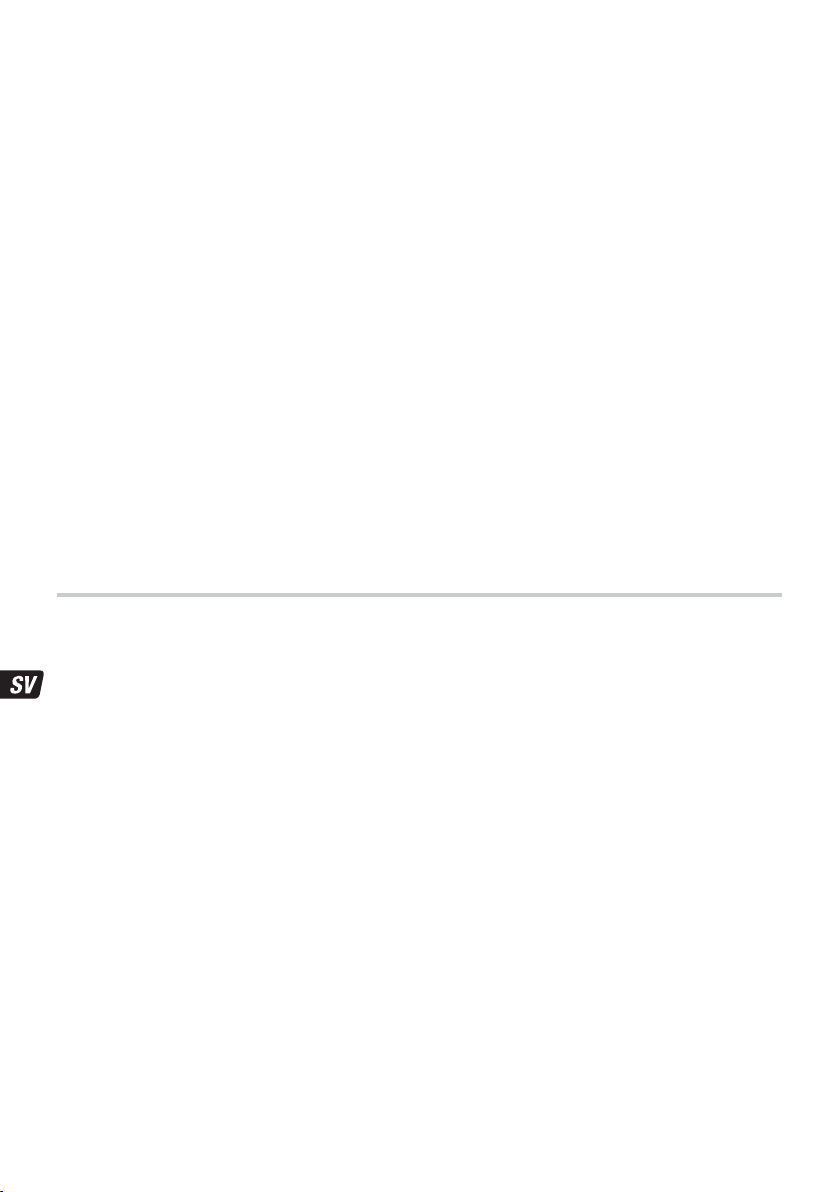

STD: Battery voltage check - OptiMate 7 Ampmatic automatically activates

if connected battery voltage is at least 0.5 Volt.

Batteries measuring below 2 Volts at connection will proceed to

STEP 2 for 'Pulse wake up' that includes a battery short circuit test.

V

Batteries measuring 2 Volts or more will proceed directly to STEP 3.

Pulse wake up - LED #8 (red) flashing: OptiMate 7 Ampmatic is injecting a

test signal to see if the battery is recoverable.

Once the voltage holds above 2 Volts and no short circuit has been detected the

program will commence to STEP 3.

If flashing continues the following conditions may prevent the charge program from

progressing:

1) Vehicle circuitry remains connected to the battery.

6

NOTE: If the battery under charge is in a low voltage or suphated state,

for the most effective charge and test results disconnect the battery

from the vehicle circuitry and then charge.

2) Battery has multiple short circuited cells. The battery has permanent damage and

should be replaced.

TEST LEDs #6/7/8 indicate the battery condition prior to charging. Consult the table

below to match TEST LED indication to an estimated state of charge percentage

(SOC%). Charging commences after 10 seconds.

0

6

Decisions made during the test:

Charge voltage during STEP 6 and 7 is adjusted according to the measured ambient

temperature.

STEP 7 OPTIMIZE minimum charge time is set according to the test result, varying

between 10 minutes for a battery with 80% or higher state of charge to 120 minutes for

a battery with 40% or less state of charge.

Severity of discharge is determined; a battery with 60% or more charge progresses

directly to STEP 6 where-as a severely discharged battery progresses to STEP 4 and 5.

Severely discharged batteries will undergo a longer test (up to 12 hours) during STEP 8.

Charge time: maximum 2 hours.

Output voltage increases to a maximum of 22V with current limited to 0.4A, but only if

no vehicle electronics have been detected, otherwise it moves directly to STEP 5.

IMPORTANT: Read section VERY FLAT NEGLECTED BATTERIES below.

CHARGE TIME : min 15 minutes, max. 2 hours.

Current is delivered in pulses to prepare the battery to accept normal charge.

This step is particularly effective for recovery of factory activated / “hi-performance”

pure lead or cyclic cell AGM batteries.

The ampmatic™ charge current monitoring and control program automatically

determines the most efficient rate of charge current for the connected battery,

according to its state of charge, state of health, and electrical storage capacity.

8

0

Engages if the battery was diagnosed as sulphated,

Engages if the battery state of charge was 40% or less OR

battery has sufficiently recovered during ADVANCED SAVE.

Engages if the battery state of charge was 50% or higher (as tested in

STEP 3) or once the battery has been sufficiently recovered during STEP 5.

7

8

unable to accept or hold charge.

7

6

7

80 100%604020AGM

6

100% 806040STD

6

Page 7

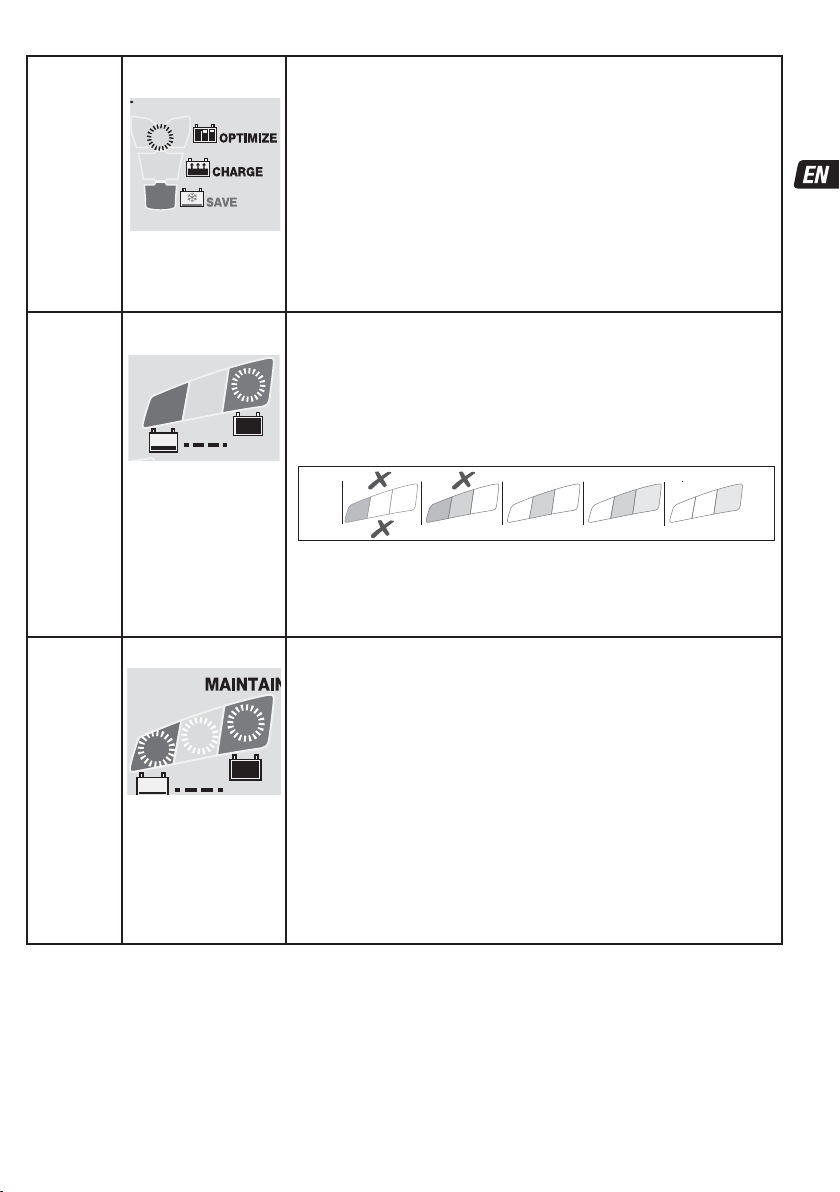

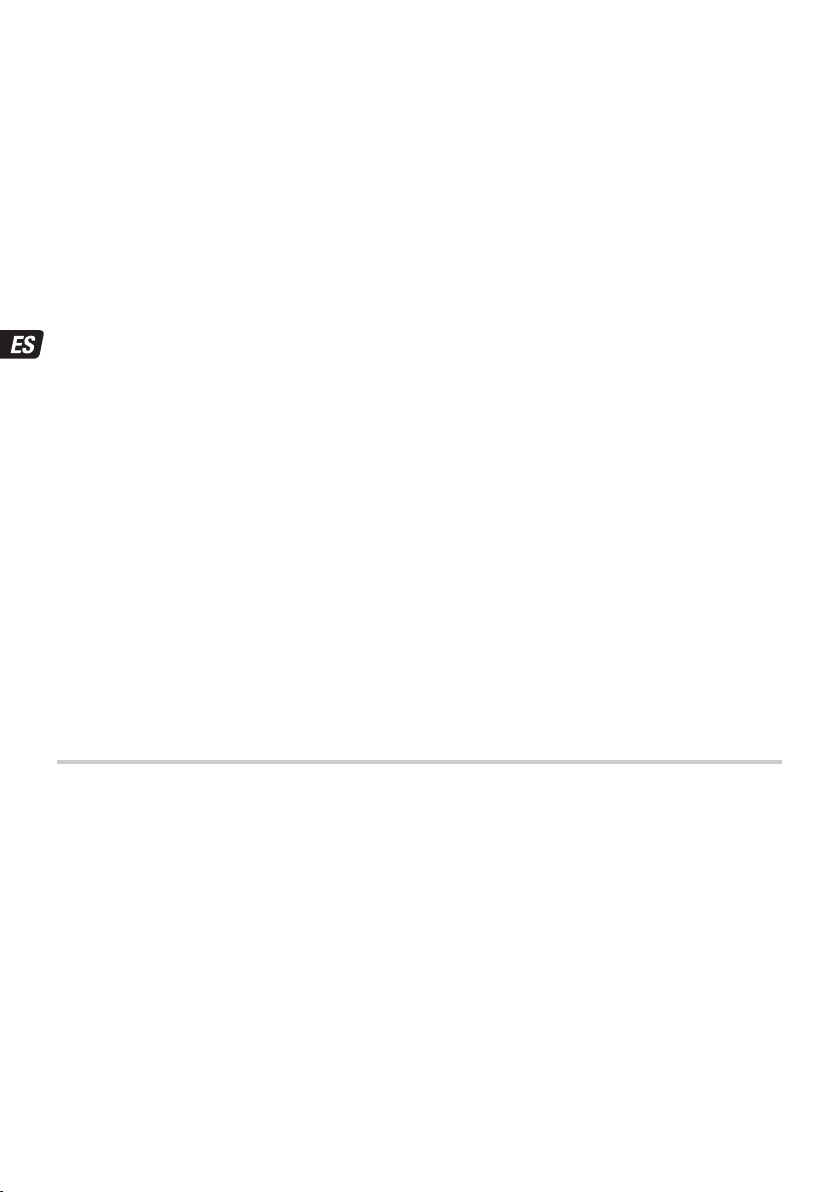

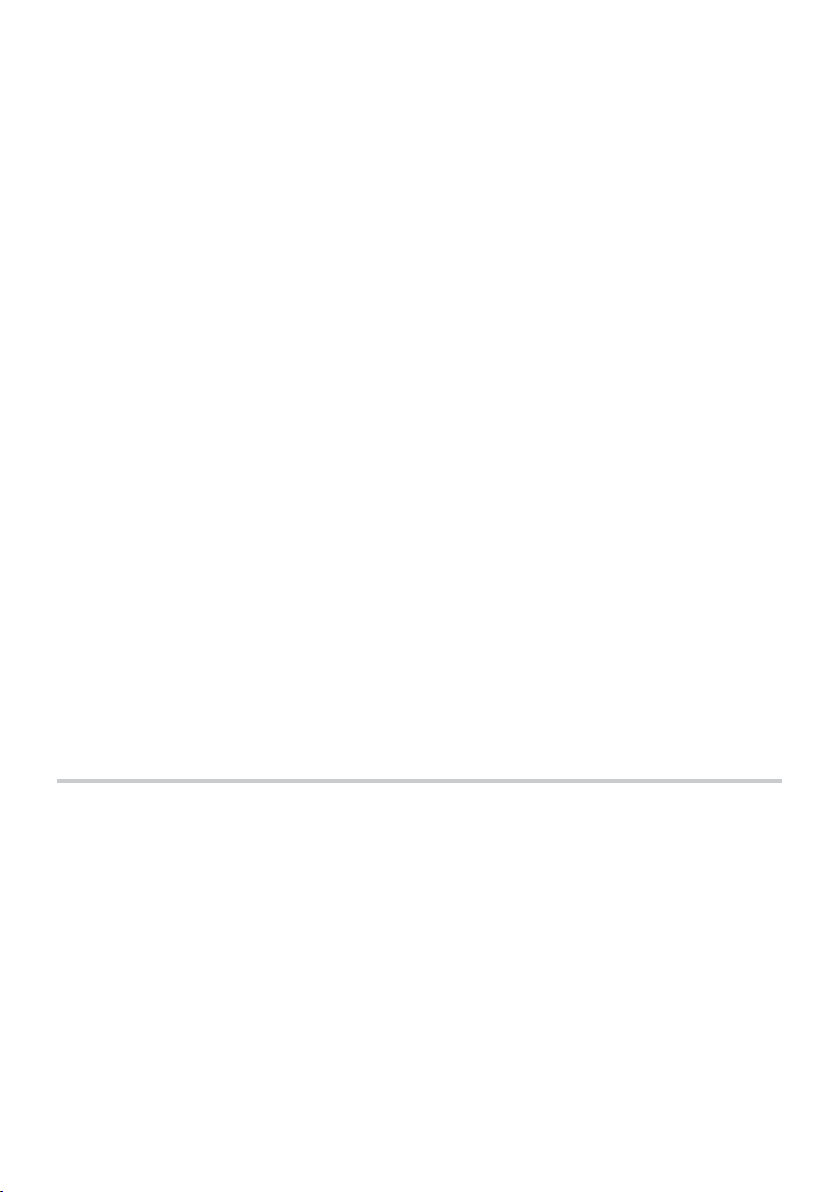

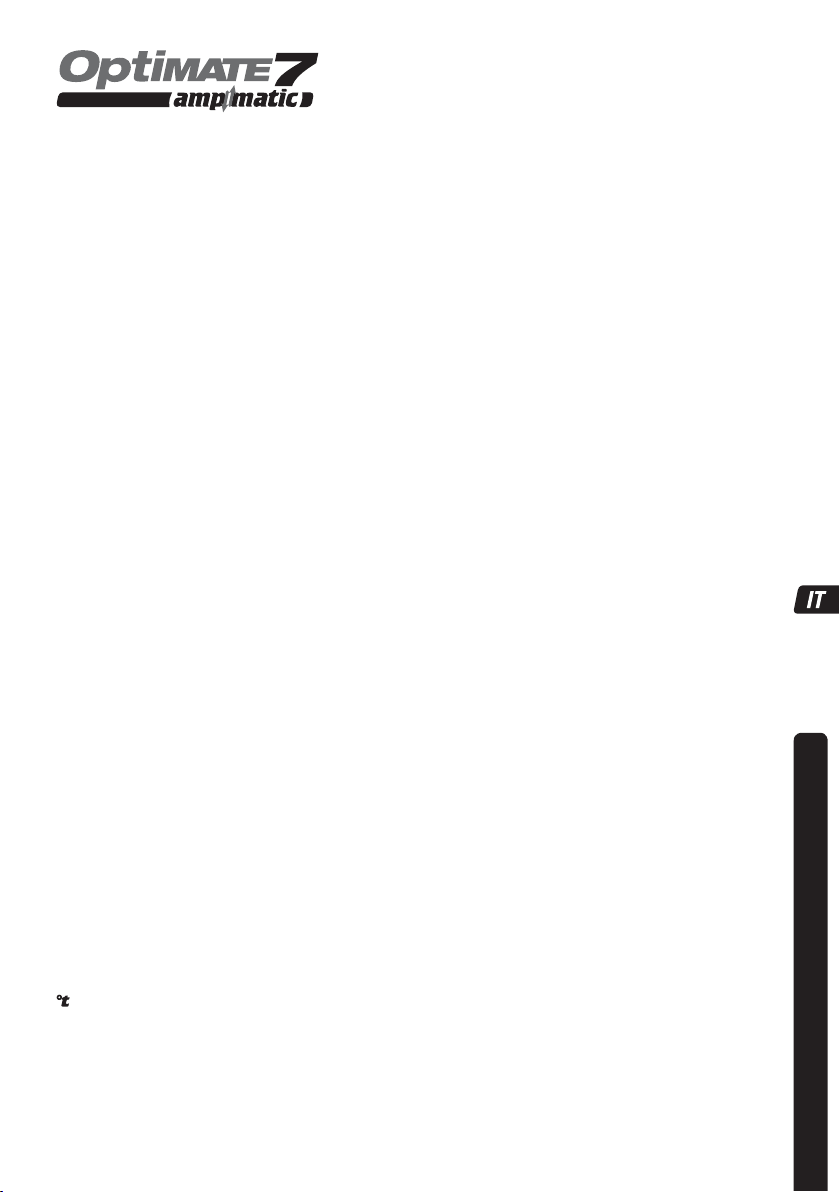

STEP 7

OPTIMIZE

STEP 8

TEST after

charge

STEP 9

OPTIMATE

'365'

Maintenance

LED #5 : YELLOW

5

LED #6 FLASHING

6

TEST

LED #6 / 7 / 8 ON

6

7

8

TEST

For batteries with a good

state of health LED #6

(green) will remain on.

Exception: STD wet cell

batteries with filler caps

have a lower fully charged

voltage: LED #6 remains

on together with LED #7.

Engages when the voltage has reached 14.4V for the first time during

CHARGE mode.

The ampmatic™ current control program now delivers pulses of current to equalise

the individual cells within the battery and optimizes charge level.

Charging should complete within the minimum charge time set during STEP 3, but if

the battery requires further charging the program will extend OPTIMIZE mode up to a

maximum of 1/2 the charge time the battery remained in STEP 6.

NOTE: Charge time is usually extended if there is higher than expected current draw by

connected circuitry or battery health is less than optimal.

TIP: If the battery under charge was in a low voltage or suphated state, for the most

effective charge and test results disconnect the battery from the vehicle circuitry and

then charge.

For safety reasons there is an overall charge time limit of 72 hours for

STEP 4, 5 and 6.

TEST after charge : Delivery of current to the battery is interrupted for

30 minutes** to allow the program to determine the battery’s ability to

retain charge.

IF the result in STEP 3 was RED (LED #8) or RED & YELLOW (LED #7 & 8), indicating

**

a deep discharged battery) the voltage retention test is extended to 12 hours to confirm

battery health.

The TEST result (indicated on LED # 6, 7, 8) is adjusted in real time according to the

measured battery voltage.

0

7

8

0

The TEST will be interrupted if LED #8 (red) lights. A significant problem exists if the

battery is unable to retain sufficient charge during this voltage retention test. Consult

the table above to match TEST LED indication to an estimated state of charge

percentage (SOC%).

More information is provided in the section “NOTES ON TEST RESULTS”.

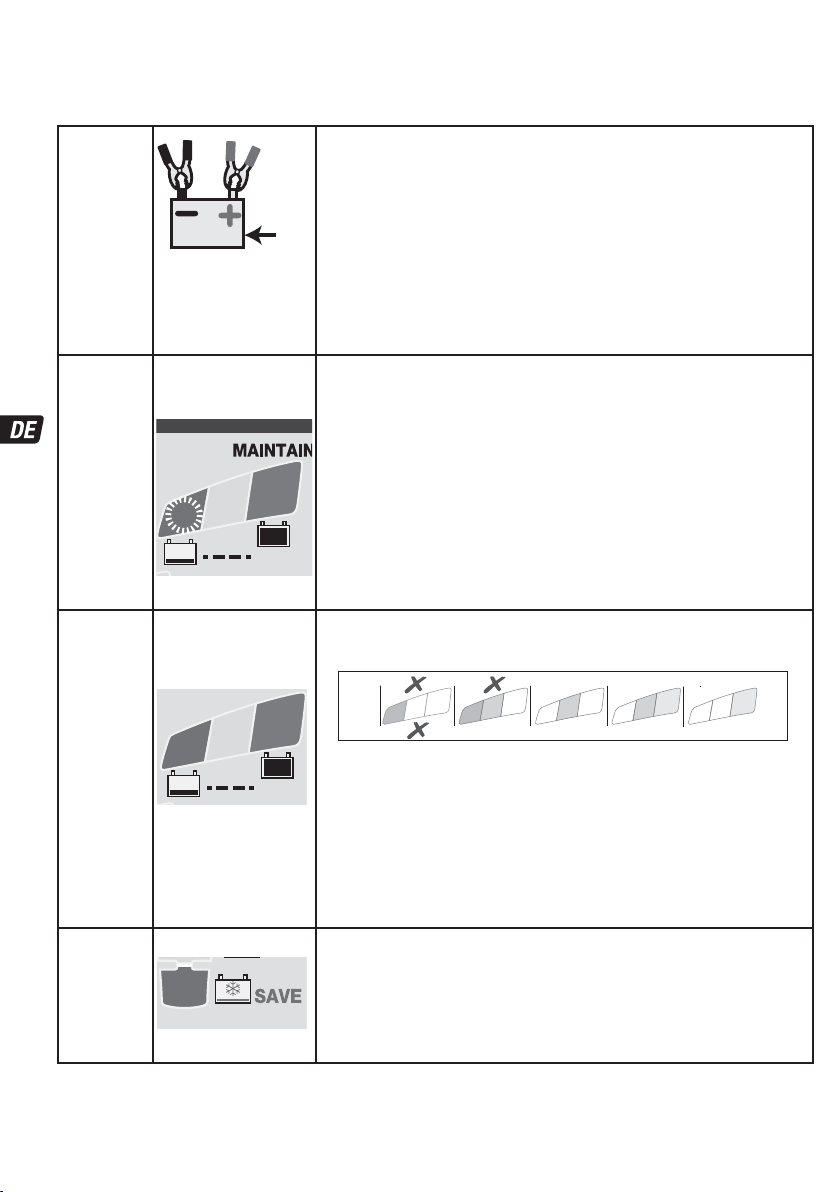

MAINTENANCE CHARGE: LED #6 / 7 / 8 steady on

Float voltage setting: 13.6V nominal at 20°C (68°F) The float voltage is inversely

regulated according to ambient temperature; i.e., voltage is increased at lower

temperature, decreased at higher temperature.

Adjustment: -0.004V / cell / °C above or below 20°C (68°F).

STD maintenance mode consists of 30 minute float charge periods followed by and

alternating with 30 minute ‘rest’ periods, during which there is no charge delivered.

This “50% duty cycle” prevents loss of electrolyte in sealed batteries and minimizes

gradual loss of water from the electrolyte in batteries with filler caps, and thereby

contributes significantly to optimizing the service life of irregularly or seasonally used

batteries.

During “float charge” a continuous LOW CURRENT PULSE IS DELIVERED TO PREVENT

SULFATION, further extending battery power and life.

If the OptiMate senses the battery has lost charge the program will revert back to

CHARGE step.

according to state of charge measured during STEP 8.

8

7

80 100%604020AGM

6

7

100% 806040STD

6

VERY FLAT NEGLECTED BATTERIES: If the battery is deeply discharged (and possibly sulfated), remove from the vehicle or

equipment and inspect the battery before connecting the charger for a recovery attempt.

The charger’s TURBO recovery mode cannot engage if it senses that the battery is still connected to a circuit which effectively

offers a lower electrical resistance than the battery on its own. However, if the deep-discharged battery is not removed for recovery, neither

battery nor vehicle or equipment electronics will be damaged. Pay particularly close attention to the following A battery left

deep-discharged for an extended period may develop permanent damage in one or more cells. Such batteries may heat up excessively

during high current charging.

Monitor the battery temperature during the first hour, then hourly there-after. Check for unusual signs, such as bubbling or leaking

electrolyte, heightened activity in one cell compared to others, or hissing sounds. If at any time the battery is uncomfortably hot to touch or

you notice any unusual signs, DISCONNECT THE CHARGER IMMEDIATELY.

7

Page 8

NOTES ON TEST RESULTS:

1. For any test result other than green #6 (or green #6 and yellow #7 together if the battery is a STD type with filler caps), disconnect

the battery from the electrical system it supports, and reconnect the OptiMate. If a better test result is now obtained, this suggests

that the power losses are partly due to an electrical problem in the electrical system and not in the battery itself. If the poor result

persists, you are advised to take the battery to a professional service workshop equipped with professional equipment for a more

thorough investigation.

If the red LED #8 alone, or the yellow #7 and red LED #8 indicate together (or yellow LED alone for a sealed battery), a significant

2.

problem exists. The red / yellow+red LEDs mean that after being charged the battery’s voltage is not being sustained or that despite

recovery attempts the battery was irrecoverable. This may be due to a defect in the battery itself, such as a short-circuited cell or

total sulphation, or, in the case of a battery still connected to the electrical system it supports, the red LED #8 may be signalling a

loss of current through deteriorated wiring or a degraded switch or contact, or in-circuit current-consuming accessories. A sudden

load being switched on while the charger is connected can also cause the battery voltage to dip significantly.

GOOD TEST RESULT, but the battery cannot deliver sufficient power: a) Permanent damage within the battery may be causing

3.

excessive self discharge that is not detected within the test period. Disconnect OptiMate from the battery. After at least 48 hours

reconnect and observe the result during the TEST BEFORE CHARGE. b) Long term vibration may have caused hairline cracks or poor

connections in inter cell connectors within the battery. A high loss of voltage occurs across such cracks or poor connections when

power demand is high (e.g. cranking the engine).

MAINTAINING A BATTERY FOR EXTENDED PERIODS: The OptiMate will maintain a battery whos basic condition is good,

for months at a time. At least once every two weeks, check that the connections between the charger and battery are secure, and,

in the case of batteries with filler caps on each cell, disconnect the battery from the charger, check the level of the electrolyte and if

necessary, top up the cells (with distilled water, NOT acid), then reconnect. When handling batteries or in their vicinity, always take

care to observe the SAFETY WARNINGS above.

ECO POWER SAVING MODE WHEN THE CHARGER IS CONNECTED TO AC SUPPLY:

The power converter switches to ECO mode when the charger is not connected to a battery resulting in a very low power draw of

less than 0.5W, equivalent to power consumption of 0.012 kWh per day. When a battery is connected to the charger power

consumption depends on the current demand of the battery and its connected vehicle / electronic circuitry. After the battery has

been charged and the charger is in long term maintenance charge mode (to keep the battery at 100% charge) the total power

consumption is estimated to be 0.024kWh or less per day.

LIMITED WARRANTY

TecMate (International) SA, B-3300 Tienen, Belgium, offers this limited warranty to the original purchaser at retail of this

product. This limited warranty is not transferable. TecMate (International) warrants this battery charger for three years from

date of purchase at retail against defective material or workmanship. If such should occur the unit will be repaired or replaced

at the option of the manufacturer. It is the obligation of the purchaser to forward the unit together with proof of purchase (see

NOTE), transportation or mailing costs prepaid, to the manufacturer or its authorized representative. This limited warranty is

void if the product is misused, subjected to careless handling, or repaired by anyone other than the factory or its authorized

representative. The manufacturer makes no warranty other than this limited warranty and expressly excludes any implied

warranty including any warranty for consequential damages.

THIS IS THE ONLY EXPRESS LIMITED WARRANTY AND THE MANUFACTURER NEITHER ASSUMES NOR AUTHORIZES ANYONE TO

ASSUME OR MAKE ANY OTHER OBLIGATION TOWARDS THE PRODUCT OTHER THAN THIS EXPRESS LIMITED WARRANTY. YOUR

STATUTORY RIGHTS ARE NOT AFFECTED.

NOTE: Details at www.tecmate.com/warranty.

OptiMate 7 and the names of other battery care products mentioned in these instructions such as BatteryMate, TestMateand

TestMate mini, are registered trademarks of TecMate International NV.

WARRANTY in Canada, USA, Central America and South America:

TecMate North America, Oakville, ON, Canada, as a wholy owned subsidiary of TecMate International, assumes the

responsibility for product warranty in these regions.

More information on TecMate products can be found at www.tecmate.com.

8

Page 9

INSTRUCTIONS IMPORTANTES CONCERNANT LA SÉCURITÉ

CONSERVER CES INSTRUCTIONS. CE MANUEL CONTIENT DES INSTRUCTIONS

IMPORTANTES CONCERNANT LA SÉCURITÉ ET LE FONCTIONNEMENT DU

CHARGEUR OPTIMATE 7.

CHARGEUR AUTOMATIQUE POUR BATTERIES 12V PLOMB-ACIDE

NE CONVIENT PAS POUR LES BATTERIES NiCd, NiMH, Li-Ion OU NON RECHARGEABLES.

AVERTISSEMENT :

N’utiliser l’appareil qu’à l’intérieur. Ne pas exposer à la pluie ou à la neige. Appareil de Classe II.

a) CONSERVER CES INSTRUCTIONS. CE MANUEL CONTIENT DES INSTRUCTIONS IMPORTANTES CONCERNANT LA SÉCURITÉ ET

LE FONCTIONNEMENT.

b) IL EST DANGEREUX DE TRAVAILLER A PROXIMITÉ D’UNE BATTERIE AU PLOMB. LES BATTERIES PRODUISENT DES GAZ

EXPLOSIFS EN SERVICE NORMAL. IL EST AUSSI IMPORTANT DE TOUJOURS RELIRE LES INSTRUCTIONS AVANT D’UTILISER LE

CHARGEUR ET DE LES SUIVRE À LA LETTRE.

c) POUR RÉDUIRE LE RISQUE D’EXPLOSION, LIRE CES INSTRUCTIONS ET CELLES QUI FIGURENT SUR LA BATTERIE.

d) NE JAMAIS FUMER PRÈS DE LA BATTERIE OU DU MOTEUR ET ÉVITER TOUTE ÉTINCELLE OU FLAMME NUE À PROXIMITÉ DE

CES DERNIERS.

e) UTILISER LE CHARGEUR POUR CHARGER UNE BATTERIE AU PLOMB UNIQUEMENT. CE CHARGEUR N’EST PAS CONÇU POUR

ALIMENTER UN RÉSEAU ÉLECTRIQUE TRÈS BASSE TENSION NI POUR CHARGER DES PILES SÈCHES. LE FAIT D’UTILISER LE

CHARGEUR POUR CHARGER DES PILES SÈCHES POURRAIT ENTRAÎNER L’ÉCLATEMENT DES PILES ET CAUSER DES BLESSURES

OU DES DOMMAGES.

f) NE JAMAIS CHARGER UNE BATTERIE GELÉE.

g) S’IL EST NÉCESSAIRE DE RETIRER LA BATTERIE DU VÉHICULE POUR LA CHARGER, TOUJOURS DÉBRANCHER LA BORNE DE

MISE À LA MASSE EN PREMIER. S’ASSURER QUE LE COURANT AUX ACCESSOIRES DU VÉHICULE EST COUPÉ AFIN D’ÉVITER LA

FORMATION D’UN ARC.

h) PRENDRE CONNAISSANCE DES MESURES DE PRÉCAUTION SPÉCIFIÉES PAR LE FABRICANT DE LA BATTERIE, P. EX., VÉRIFIER

S‘IL FAUT ENLEVER LES BOUCHONS DES CELLULES LORS DU CHARGEMENT DE LA BATTERIE, ET LES TAUX DE CHARGEMENT

RECOMMANDÉS.

i) SI LE CHARGEUR COMPORTE UN SÉLECTEUR DE TENSION DE SORTIE, CONSULTER LE MANUEL DE L’USAGER DE LA VOITURE

POUR DÉTERMINER LA TENSION DE LA BATTERIE ET POUR S’ASSURER QUE LA TENSION DE SORTIE EST APPROPRIÉE. SI LE

CHARGEUR N’EST PAS MUNI D’UN SÉLECTEUR, NE PAS UTILISER LE CHARGEUR À MOINS QUE LA TENSION DE LA BATTERIE NE

SOIT IDENTIQUE À LA TENSION DE SORTIE NOMINALE DU CHARGEUR.

j) NE JAMAIS PLACER LE CHARGEUR DIRECTEMENT SOUS LA BATTERIE À CHARGER OU AU-DESSUS DE CETTE DERNIÈRE. LES

GAZ OU LES FLUIDES QUI S’ÉCHAPPENT DE LA BATTERIE PEUVENT ENTRAÎNER LA CORROSION DU CHARGEUR OU

L’ENDOMMAGER. PLACER LE CHARGEUR AUSSI LOIN DE LA BATTERIE QUE LES CABLES C.C. LE PERMETTENT.

k) NE PAS FAIRE FONCTIONNER LE CHARGEUR DANS UN ESPACE CLOS ET/OU NE PAS GÊNER LA VENTILATION.

l) METTRE LES INTERRUPTEURS DU CHARGEUR HORS CIRCUIT ET RETIRER LE CORDON C.A. DE LA PRISE AVANT DE METTRE

ET D’ENLEVER LES PINCES DU CORDON C.C. S’ASSURER QUE LES PINCES NE SE TOUCHENT PAS.

m) SUIVRE LES ÉTAPES SUIVANTES LORSQUE LA BATTERIE SE TROUVE DANS LE VÉHICULE.

UNE ÉTINCELLE PRÈS DE LA BATTERIE POURRAIT PROVOQUER L’EXPLOSION DE CETTE DERNIÈRE. POUR RÉDUIRE LE RISQUE

D’ÉTINCELLE À PROXIMITÉ DE LA BATTERIE :

(i) PLACER LES CORDONS C.A. ET C.C. DE MANIÈRE À ÉVITER QU’ILS SOIENT ENDOMMAGÉS PAR LE CAPOT,

UNE PORTIÈRE OU LES PIÈCES EN MOUVEMENT DU MOTEUR ;

(ii) FAIRE ATTENTION AUX PALES, AUX COURROIES ET AUX POULIES DU VENTILATEUR AINSI QU’À

TOUTE AUTRE PIÈCE SUSCEPTIBLE DE CAUSER DES BLESSURES ;

(iii) VÉRIFIER LA POLARITÉ DES BORNES DE LA BATTERIE. LE DIAMÈTRE DE LA BORNE POSITIVE

(POS, P, +) EST GÉNÉRALEMENT SUPÉRIEUR À CELUI DE LA BORNE NÉGATIVE (NÉG, N, –) ;

(iv) DÉTERMINER QUELLE BORNE EST MISE À LA MASSE (RACCORDÉE AU CHÂSSIS). SI LA BORNE

NÉGATIVE EST RACCORDÉE AU CHÂSSIS (COMME DANS LA PLUPART DES CAS), VOIR LE POINT (v). SI LA

BORNE POSITIVE EST RACCORDÉE AU CHÂSSIS, VOIR LE POINT (vi) ;

SÉCURITÉ US & CAN

9

Page 10

(v) SI LA BORNE NÉGATIVE EST MISE À LA MASSE, RACCORDER LA PINCE POSITIVE (ROUGE) DU

CHARGEUR À LA BORNE POSITIVE (POS, P, +) NON MISE À LA MASSE DE LA BATTERIE. RACCORDER LA

PINCE NÉGATIVE (NOIRE) AU CHÂSSIS DU VÉHICULE OU AU MOTEUR, LOIN DE LA BATTERIE. NE PAS

RACCORDER LA PINCE AU CARBURATEUR, AUX CANALISATIONS D’ESSENCE NI AUX PIÈCES DE LA

CARROSSERIE EN TÔLE. RACCORDER À UNE PIÈCE DU CADRE OU DU MOTEUR EN TÔLE DE FORTE

ÉPAISSEUR ;

(vi) SI LA BORNE POSITIVE EST MISE À LA MASSE, RACCORDER LA PINCE NÉGATIVE (NOIRE) DU

CHARGEUR À LA BORNE NÉGATIVE (NÉG, N, –) NON MISE À LA MASSE DE LA BATTERIE. RACCORDER

LA PINCE POSITIVE (ROUGE) AU CHÂSSIS DU VÉHICULE OU AU MOTEUR, LOIN DE LA BATTERIE. NE

PAS RACCORDER LA PINCE AU CARBURATEUR, AUX CANALISATIONS D’ESSENCE NI AUX PIÈCES DE LA

CARROSSERIE EN TÔLE. RACCORDER À UNE PIÈCE DU CADRE OU DU MOTEUR EN TÔLE DE FORTE ÉPAISSEUR ;

(vii) BRANCHER LE CORDON D’ALIMENTATION C.A. DU CHARGEUR ;

(viii) POUR INTERROMPRE L’ALIMENTATION DU CHARGEUR, METTRE LES INTERRUPTEURS HORS

CIRCUIT, RETIRER LE CORDON C.A. DE LA PRISE, ENLEVER LA PINCE RACCORDÉE AU CHÂSSIS ET EN

SÉCURITÉ US & CAN

DERNIER LIEU CELLE RACCORDÉE À LA BATTERIE.

n) SUIVRE LES ÉTAPES SUIVANTES LORSQUE LA BATTERIE EST À L’EXTÉRIEUR DU VÉHICULE.

UNE ÉTINCELLE PRÈS DE LA BATTERIE POURRAIT PROVOQUER L’EXPLOSION DE CETTE DERNIÈRE. POUR RÉDUIRE LE RISQUE

D’ÉTINCELLE À PROXIMITÉ DE LA BATTERIE :

(i) VÉRIFIER LA POLARITÉ DES BORNES DE LA BATTERIE. LE DIAMÈTRE DE LA BORNE POSITIVE

(POS, P, +) EST GÉNÉRALEMENT SUPÉRIEUR À CELUI DE LA BORNE NÉGATIVE (NÉG, N, –) ;

(ii) RACCORDER UN CÂBLE DE BATTERIE ISOLÉ No 6 AWG MESURANT AU MOINS 60 CM DE

LONGUEUR À LA BORNE NÉGATIVE (NÉG, N, –) ;

(iii) RACCORDER LA PINCE POSITIVE (ROUGE) À LA BORNE POSITIVE (POS, P, +) DE LA BATTERIE ;

(iv) SE PLACER ET TENIR L’EXTRÉMITÉ LIBRE DU CÂBLE AUSSI LOIN QUE POSSIBLE DE LA BATTERIE,

PUIS RACCORDER LA PINCE NÉGATIVE (NOIRE) DU CHARGEUR À L’EXTRÉMITÉ LIBRE DU CÂBLE ;

(v) NE PAS SE PLACER FACE À LA BATTERIE POUR EFFECTUER LE DERNIER RACCORDEMENT ;

(vi) RACCORDER LE CORDON D’ALIMENTATION C.A. DU CHARGEUR À LA PRISE ;

(vii) POUR INTERROMPRE L’ALIMENTATION DU CHARGEUR, METTRE LES INTERRUPTEURS HORS

CIRCUIT, RETIRER LE CORDON C.A. DE LA PRISE, ENLEVER LA PINCE RACCORDÉE AU CHÂSSIS ET EN

DERNIER LIEU CELLE RACCORDÉE À LA BATTERIE. SE PLACER AUSSI LOIN QUE POSSIBLE DE LA BATTERIE

POUR DÉFAIRE LA PREMIÈRE CONNEXION.

10

Page 11

CHARGEUR AUTOMATIQUE À FONCTION DIAGNOSTIC POUR BATTERIES 12V PLOMB-ACIDE

NE CONVIENT PAS POUR LES BATTERIES NiCd, NiMH, Li-Ion OU NON RECHARGEABLES.

IMPORTANT : LIRE ENTIÈREMENT LES INSTRUCTIONS SUIVANTES AVANT D’UTILISER LE CHARGEUR

Cet appareil n'est pas destiné à être utilisé par des personnes (y compris des enfants) possédant des

capacités physiques, sensorielles ou mentales réduites, ou manquant d'expérience et de connaissance,

sauf si elles bénéficient d'une surveillance ou ont reçu des instructions concernant l'utilisation de

l'appareil d'une personne responsable de leur sécurité. Les enfants doivent faire l'objet d'une surveillance

pour s'assurer qu'ils ne jouent pas avec l'appareil.

AVERTISSEMENT DE SÉCURITÉ et REMARQUES

flammes ou les étincelles à proximité

Avant d’établir ou de rompre les connexions de courant continu à la batterie, déconnecter l’alimentation secteur. L’acide des

batteries est un puissant corrosif. Porter des vêtements et lunettes protecteurs et éviter tout contact. En cas de contact accidentel,

laver immédiatement à l’eau et au savon. S’assurer que les bornes des batteries ne sont pas branlantes ; le cas échéant la batterie

doit subir une évaluation professionnelle. Si les bornes sont corrodées, nettoyer à l’aide d’une brosse de cuivre ; si elles sont

grasses ou sales, nettoyer à l’aide d’un torchon trempé dans du détergent. Utiliser uniquement le chargeur si les câbles et

connecteurs d’entrée et de sortie sont en bon état et non endommagés. Si le câble d’entrée est endommagé, il est essentiel de le

faire remplacer par le constructeur, son agent de service autorisé ou un atelier qualifié, pour éviter tout danger. Protéger le chargeur

contre les acides et fumées acides, l’humidité et un environnement humide, aussi bien durant l’usage que l’entreposage. Les dégâts

résultant de la corrosion, de l’oxydation ou de courts-circuits internes ne sont pas couverts par la garantie. Durant le chargement,

éloigner le chargeur de la batterie pour éviter la contamination par l’acide ou les vapeurs acides ou l’exposition à ceux-ci. En cas

d’utilisation horizontale, placer le chargeur sur une surface dure et plane, PAS en plastique, tissu ou cuir. Utiliser les trous de fixation

de la base pour fixer le chargeur sur toute surface verticale appropriée et solide.

.

: Les batteries émettent des GAZ EXPLOSIFS - il faut interdire les

EXPOSITION AUX LIQUIDES : Ce chargeur est conçu pour résister à l’exposition aux liquides qui tomberaient accidentellement

sur le boîtier, ou à une pluie légère. Une exposition prolongée à des liquides tombants ou à la pluie est à déconseiller. Une durée de

vie supérieure résultera d’une telle précaution. Une panne due à l’oxydation résultant d’une pénétration de liquide dans les

composants électroniques,bloc connecteurs ou fiches,ne sera pas couverte par la garantie.

BRANCHEMENT DU CHARGEUR A LA BATTERIE

1. Débranchez l'alimentation secteur avant d'effectuer un branchement CC/batterie ou de le débrancher.

2. Si vous chargez une batterie installée dans le véhicule avec les pinces pour batterie, avant les branchements, vérifiez d'abord

que les pinces pour batterie peuvent être positionnées en toute sécurité loin du câblage voisin, d'un tube métallique ou du

châssis. Respectez l'ordre qui suit : branchez d'abord la borne de la batterie non raccordée au châssis (normalement positive)

puis, branchez l'autre pince pour batterie (normalement négative) au châssis à un endroit bien éloigné de la batterie et du

conduit de carburant. Débranchez toujours dans l'ordre inverse.

3. Lorsque vous chargez une batterie hors du véhicule avec les pinces pour batterie, placez-la dans un endroit bien ventilé.

Branchez le chargeur à la batterie : La pince ROUGE sur la borne POSITIVE (POS, P ou +) et la pince NOIRE sur la borne

NÉGATIVE (NEG, N ou –).Vérifiez que les branchements sont bien fixés. Un bon contact est important.

4. Si la batterie est complètement déchargée (et probablement sulfatée), retirez-la du véhicule et inspectez la batterie

avant de brancher le chargeur pour une tentative de récupération. Vérifiez visuellement la batterie à la recherche de

défauts mécaniques tels qu'un gonflement ou un boîtier craquelé ou encore de signes de fuite d'électrolyte. Si la batterie

présente des bouchons de remplissage et que les plaques des cellules sont visibles de l'extérieur, examinez soigneusement la

batterie pour tenter de déterminer si certaines cellules semblent différentes des autres (par exemple, de la matière blanche

entre les plaques, les plaques qui entrent en contact). Si vous avez détecté des défauts mécaniques, ne chargez pas la batterie

et faites-la examiner par un professionnel.

5. Si la batterie est neuve, avant de brancher le chargeur, lisez attentivement les instructions d'utilisation et de sécurité fournies

par le fabricant de la batterie. Si besoin est, suivez attentivement et exactement les instructions relatives au remplissage de

l'acide.

COMMENCER LA CHARGE

TEMPS DE CHARGE : Le temps de charge d’une batterie déchargée mais non endommagée est légèrement inférieur à 25% de la

puissance nominale de la batterie en Ah, ce qui signifie qu’une batterie de 100Ah aurait besoin de moins de 12h pour aboutir à

l’essai de décharge. Ce temps peut être considérablement plus élevé pour les batteries profondément déchargées.

MARCHE : LED #1 - Confirme la présence d’alimentation AC vers le chargeur.

Indication d’intensité FORTE ou FAIBLE: la diode #1 « POWER ON » brillera fortement lorsque le courant est débité vers la batterie.

La diode #1 réduit son intensité à un niveau bas pour indiquer le mode d'énergie bas « ÉCO ». Cela se produit si aucune batterie

n'est branchée ou lorsqu'une batterie est branchée et que le programme se trouve en mode Test de conservation de la tension

initiale et étendue ou en mode Périodes de repos de la charge d'entretien.

PROTECTION POLARITÉ INVERSE : LED #2 - s’allume lorsque les connexions à la batterie sont erronnées. Le chargeur bénéficie

d’une protection électronique évitant l’endommagement, il n’y a aucun courant de sortie aussi longtemps que les connexions ne

sont pas corrigées.

11

Page 12

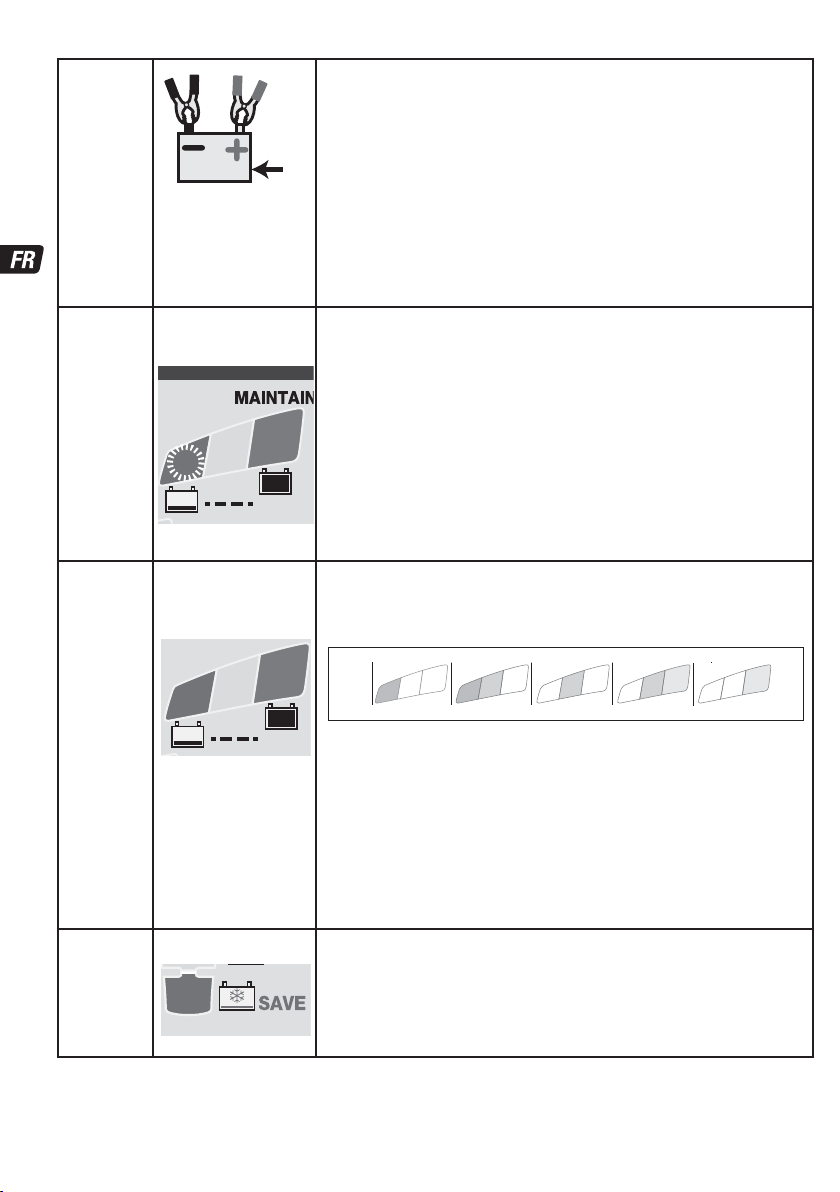

ÉTAPE1

Démarrage à

basse

tension (Bat

≥ 0,5 V)

STD : vérification de la tension de la batterie – le mode STD s’active si la

tension de la batterie connectée est d’au moins 0,5 V.

Les batteries pour lesquelles la mesure est inférieure à 2 Volts au moment de la

connexion, passeront à

ÉTAPE 2 pour y subir les «Pulsations de réactivation»; cette étape comporte un

V

test de mise en court-circuit de la batterie.

Les batteries pour lesquelles la mesure est de 2 Volts ou plus, passeront

directement à ÉTAPE 3.

ÉTAPE 2

Pulsations

de

réactivation

ÉTAPE 3

TEST

avant la

charge

ÉTAPE 4

RÉCUPÉRATION

Turbo

LED #8 CLIGNOTANT

6

7

8

TEST

LED TEST

Nº6: VERTE

Nº7: JAUNE

Nº8: ROUGE

6

7

8

TEST

LED #3 : ROUGE

3

Pulsations de réactivation - LED n°8 (rouge) clignotant: le dispositif

OptiMate 7 Ampmatic envoie un signal de test pour vérifier si la batterie est

récupérable.

Si la tension se maintient au-dessus de 2 volts, et si aucun court-circuit n'a été détecté,

le programme commencera à ÉTAPE 3. Si le clignotement se poursuit, les situations

suivantes peuvent empêcher le programme de charge de se poursuivre:

1) Une connexion subsiste entre le faisceau électrique du véhicule et la batterie.

REMARQUE: Si la batterie en charge se trouve dans un état de basse

tension ou un état sulfaté, déconnecter la batterie du faisceau électrique

du véhicule et la charger ensuite pour obtenir une charge optimale et

des résultats de test effectifs.

2) La batterie possède de multiples cellules en court-circuit. La batterie a subi des

dommages permanents et doit être remplacée.

LES LED TEST nº6/7/8 indiquent l'état de la batterie avant le début de la charge.

Reportez-vous au tableau ci-dessous ou à la page 2 pour obtenir les indications des

LED TEST qui correspondent à un pourcentage de l'état de charge estimé (% de l'état

de charge, SOC).

0

8

0

Décisions prises pendant l'essai:

La tension de charge pendant les ÉTAPES 6 et 7 est réglée en fonction de la mesure de

la température ambiante.

ÉTAPE 7 OPTIMISATION le temps de charge minimum du mode OPTIMISATION est

défini en fonction des résultats et varie de 10 min pour une batterie chargée à 80 % ou

plus d'état de charge à 120 min pour une batterie dont l'état de charge est de 40 % ou

moins.

L'importance de la décharge fait l'objet d'une détermination, une batterie dont la

charge est de 60% ou plus passe directement à ÉTAPE 6, tandis qu'une batterie

fortement déchargée passe à ÉTAPE 4 et 5. Les batteries fortement déchargées

subiront un test plus long (jusqu'à 12 heures) pendant ÉTAPE 8.

Se déclenche si la batterie s’avère sulfatée, incapable de recevoir

Temps de charge: 2heures maximum.

La tension de sortie augmente jusqu'à un maximum de 22V, avec un courant limité à

0,4A, mais uniquement si aucun composant électronique du véhicule n'a été détecté,

sinon elle passe à l'étape suivante. IMPORTANT: veuillez lire la section BATTERIES NON

ENTRETENUES TRÈS FAIBLES ci-dessous.

7

8

ou de maintenir la charge.

7

80 100%604020AGM

6

7

100% 806040STD

6

12

Page 13

ÉTAPE 5

RÉCUPÉRATION

par

impulsions

ÉTAPE 6

CHARGE

LED #3 : ROUGE

3

LED #4 : JAUNE

4

Se déclenche si l’état de charge de la batterie est à 40% ou moins OU si

la batterie a suffisamment récupéré au cours de la RÉCUPÉRATION TURBO. Temps de

charge : minimum 15 minutes, maximum 2 heures. Une nouvelle charge est appliquée; le

courant est envoyé par impulsions pour préparer la batterie à recevoir la charge. Ce mode

est particulièrement efficace pour initialiser la récupération de batteries activées en usine /

‘haute performance’, pur plomb ou de type AGM à cellules cylindiques.

Le mode de CHARGE s’enclenche si la batterie est d’au moins 50 % (selon les

résultats du test de l’ÉTAPE 3), ou si elle est suffisamment restaurée au cours de

l’ÉTAPE 5.

Le mode de commande et de surveillance du courant de charge ampmatic™

determine automatiquement le taux de charge le plus efficace pour la batterie connectée,

en fonction de l’état de charge, de l’état de santé et de la capacité de stockage électrique

de celle-ci.

ÉTAPE 7

OPTIMISATION

ÉTAPE 8

TEST après

la charge

ÉTAPE 9

Entretien

OptiMate

'365'

LED #5 : JAUNE

5

LED #6 CLIGNOTANTE

6

TEST

LED #6 / 7 / 8

ALLUMÉES

6

7

8

TEST

Pour des batteries en bon état, la

LED nº6 (verte) reste allumée.

Exception: les batteries à

électrolyte liquide standard avec

bouchons de remplissage

présentent une tension inférieure

lorsqu'elles sont complètement

chargées: la LED nº6 reste

allumée, de même que la LED nº7.

Le mode d’OPTIMISATION de charge démarre lorsque la tension atteint pour la

première fois 14.4V durant la phase de charge principale. Le mode de commande et

de surveillance du courant de charge ampmatic™ délivre des impulsions de courant

pour égaliser chaque cellule de la batterie et optimiser le niveau de charge. La charge doit

être terminée en respectant le temps de charge minimum établi à l'ÉTAPE 3. Si la batterie

nécessite plus de charge, le programme prolongera le mode d’OPTIMISATION de charge

pendant un maximum de 2 heures.

REMARQUE : le temps de charge est habituellement étendu si la consommation électrique

de la batterie par circuit raccordé est supérieure aux estimations ou si l'état général de la

batterie n'est pas optimal.

Pour des raisons de sécurité, il y a une limite de charge absolue de 72 heures pour les

ÉTAPES 4, 5 et 6.

TEST APRES CHARGE : L’alimentation de la batterie est interrompue

pendant 30 minutes** afin de permettre au programme de déterminer

** SI le résultat à l'ÉTAPE3 était ROUGE (LED nº8) ou ROUGE et JAUNE (LED nº7 et 8),

indiquant une batterie complètement déchargée avant la connexion, le test de rétention de

tension est étendu à 12heures en vue de confirmer l'état de la batterie.

Le résultat du TEST (indiqué par les LED nº 6, 7 et 8) est réglé en temps réel en fonction de

la tension mesurée sur la batterie.

0

0

Le TEST est interrompu si la LED nº 8 (rouge) s’allume. Un problème significatif existe

si la batterie est incapable de retenir suffisamment de charge pendant le test. Reportezvous au tableau « AVERTISSEMENTS ANTICIPÉS DES PROBLÈMES DE BATTERIE » à la page

2 pour obtenir les indications des LED TEST qui correspondent à un pourcentage de l'état

de charge estimé (% de l'état de charge, SOC). Pour de plus amples informations,

reportez-vous à la section « NOTES CONCERNANT LES RÉSULTATS DES TESTS ».

Réglages de la tension d’annonciation : tension nominale de 13,6 V à 20 °C (68 °F).

La tension d’annonciation est inversement régulée en fonction de la température

ambiante (elle augmente, par exemple, en cas de température inférieure, et diminue

en cas de température supérieure). Réglage : -0,04 V/cellule/°C au-dessus ou en

dessous de 20 °C (68 °F).

Le CYCLE DE CHARGE DE MAINTENANCE consiste en périodes de charge flottante de

30 minutes suivies par et alternant avec des périodes de repos de 30 minutes durant

lesquelles aucun courant de charge n’est délivré. Ce cycle à 50% de charge évite la perte

d’électrolyte dans les batteries scellées et réduit au minimum la perte progressive d’eau

des batteries à bouchons de remplissage, ce qui contribue de manière significative à

l’optimisation de la durée utile de batteries utilisées de manière irrégulière ou saisonnière.

Durant les périodes de charge flottante, un petit courant pulsé est continuellement délivré

pour prévenir la sulfatation, optimisant encore la puissance et la durée de vie

de la batterie.

la capacité de la batterie à retenir la charge.

8

Si le OptiMate capte une perte de charge de la batterie,

le programme passe à nouveau en modeCHARGE.

7

8

CHARGE DE MAINTENANCE: LED nº6/7/8 fixes

en fonction de l’état de charge mesuré à l’ÉTAPE 8.

7

7

80 100%604020AGM

6

100% 806040STD

6

13

Page 14

BATTERIES DÉGRADÉES ET TRÈS FAIBLES: Si la batterie est complètement déchargée (et peut-être même sulfatée),

retirez-la du véhicule ou de ’equipment et examinez-la avant de la connecter au chargeur pour une tentative de

récupération.

Le mode récupération TURBO du chargeur ne peut pas s’engager s’il détecte une connexion entre la batterie et le circuit

câblé du véhicule ce qui permet une résistance électrique plus faible qu’avec la batterie seule. Cependant, si la batterie

complètement déchargée n’est pas retirée pour récupération, ni la batterie, ni le véhicule ou l’equipment

Tenir spécialement compte de ce qui suit: Les cellules d’une batterie restée en décharge profonde durant une longue période

peuvent être endommagées à titre permanent. Ces batteries peuvent chauffer excessivement durant la charge à courant élevé.

Vérifier la température de la batterie durant la première heure, puis chaque heure suivante. Vérifier la présence de signes inhabituels

comme des bulles ou fuites d’électrolyte, une activité plus importante d’une cellule par rapport aux autres, ou des sifflements. Si à

un moment quelconque, la batterie devient trop chaude au toucher ou si vous constatez des signes inhabituels, DÉCONNECTER

IMMÉDIATEMENT LE CHARGEUR.

ne seront endommagés.

REMARQUES SUR LES RÉSULTATS DU TEST:

1. Pour tout résultat différent d’une LED #6 verte, déconnecter la batterie du système électrique du véhivcule et reconnecter le

OptiMate. Si on obtient ensuite un meilleur résultat, cela indique que les pertes de puissance sont dues en partie à un problème du

système électrique et non à la batterie. Si les mauvais résultats persistent, il est conseillé d’amener la batterie dans un atelier

professionnel équipé d’appareils de test professionnels pour procéder à une analyse approfondie.

2. Si la LED #8 rouge seule, ou la LED #7 jaune et la LED #8 rouge s’allument en même temps, un problème signifi catif existe. Les

rouge (ou LED jaune + rouge seul pour batterie scellée) signifie qu’après la charge la tension de la batterie n’est pas maintenue ou

que malgré des tentatives de récupération, la batterie est irrécupérable. Ceci peut être dû à une panne de la batterie comme une

cellule court-circuitée ou une sulfatation totale, ou, dans le cas d’une batterie toujours connectée au système électrique supporté, le

LED #8 rouge peut signaler la perte de courant via un câblage détérioré ou un commutateur ou un contact dégradé, ou la présence

d’accessoires consommateurs de courant au sein du circuit. Une consommation soudaine, comme l’allumage des phares du

véhicule lorsque le chargeur est connecté, peut également entraîner une chute de tension significative sur la batterie.

3. BONS RESULTATS DE TEST, mais la batterie ne peut fournir assez de puissance : a) Un dommage permanent dans la batterie peut causer

une décharge excessive non détectable pendant la période de test. Déconnectez l’OptiMate de la batterie. Après au moins 48 heures

reconnectez l’OptiMate et observez le résultat pendant le TEST AVANT LA CHARGE; b) Des vibrations prolongées peuvent causer des

fissures fines dans les connecteurs intercellulaires de la batterie. Une perte de tension élevée survient uniquement lorsque la

demande en énergie est élevée (p. ex. démarrer le moteur).

MAINTENANCE D’UNE BATTERIE DURANT DES PÉRIODES PROLONGÉES: Le OptiMate maintiendra une batterie dont

l'état est bon, en toute sécurité durant plusieurs mois. Vérifier au moins une fois par quinzaine la sécurité des connexions entre

chargeur et batterie. Dans le cas de batteries équipées de bouchons de remplissage sur chaque cellule, déconnecter la batterie du

chargeur, vérifier le niveau d’électrolyte et faire l’appoint si nécessaire (en eau distillée, PAS en acide), puis reconnecter. Lors de

la manipulation de batteries ou à proximité de celles-ci, toujours respecter les AVERTISSEMENTS DE SÉCURITÉ ci-dessus.

MODE ÉCONOMIE D’ÉNERGIE LORSQUE LE CHARGEUR EST CONNECTÉ A L’ALIMENTATION SECTEUR :

Le convertisseur d'énergie se désactive et passe en mode ECO lorsque le chargeur est déconnecté de la batterie, la puissance

demandée diminue jusque 0.5W, l'équivalent d'une consommation d'énergie de 0,012 kWh par jour. Lorsqu'une batterie est

branchée au chargeur, la consommation d'énergie dépend de la demande en courant de la batterie et du véhicule/des circuits

électroniques raccordés. Une fois que la batterie est chargée et que le programme de charge est en mode de charge d'entretien à

long terme (pour garder la batterie chargée à 100 %), la consommation d'énergie totale est estimée à 0,024 kWh ou moins par jour.

GARANTIE LIMITÉE

TecMate International SA, B-3300 Tienen, Belgique, consent la présente garantie au premier client utilisateur de ce produit,

sans possibilité de transfert. TecMate (International) garantit ce chargeur pendant trois ans à compter de la date d’achat au

détail contre les défauts de composants ou d’assemblage. Le cas échéant, le chargeur sera réparé ou remplacé à la discrétion

du fabricant. L’acheteur doit expédier, à ses frais, l’appareil ainsi qu’une preuve d’achat (voir "NOTE") au fabricant ou à son

représentant agréé. Cette garantie limitée devient nulle si l’appareil est utilisé ou manipulé de façon inadéquate ou s’il a été

réparé par toute personne physique ou morale autre que le fabricant ou un représentant agréé. Le fabricant n’offre aucune

autre garantie que la présente, et exclut expressément toute garantie contre les dommages conséquentiels.

CECI EST LA SEULE GARANTIE EXPRESSÉMENT CONSENTIE PAR LE FABRICANT. CELUI-CI N’ASSUME ET N’AUTORISE

QUICONQUE A ASSUMER OU ETABLIR TOUTE AUTRE OBLIGATION LIÉE À CE PRODUIT, AUTRE QUE CETTE GARANTIE LIMITÉE

EXPRESSÉMENT CONSENTIE. VOS DROITES STATUTAIRES NE SONT PAS AFFECTÉES.

NOTE: Voir www.tecmate.com/warranty ou contactez warranty@tecmate.com

OptiMate 7 et les noms des autresappareilsmentionnés dans ce texte tels queBatteryMate, TestMate et TestMate mini, sont des

marques déposées de TecMate International SA.

Vous trouverez plus d'informations sur les produits TecMate sur www.tecmate.com.

Garantie applicable en Amérique du Nord (Canada et USA), Amérique Centrale et Amérique du Sud

TecMate North America, Oakville, ON, Canada, en tant que filiale de TecMate (International) S.A., assume toute obligation

légale de garantie et service après-vente pour les produits distribués en Amérique du Nord (Canada et USA), Amérique Centrale

et Amérique du Sud.

Vous trouverez plus d'informations sur les produitsTecMate sur www.tecmate.com.

14

Page 15

CARGADOR DE DIAGNÓSTICO AUTOMÁTICO PARA BATERÍAS DE PLOMO ÁCIDO DE 12 V.

NO UTILIZAR CON BATERÍAS DE NiCd, NiMH, Li-Ion O BATERÍAS NO RECARGABLES.

IMPORTANTE: LEA COMPLETAMENTE LAS SIGUIENTES INSTRUCCIONES ANTES DE UTILIZAR EL

CARGADOR

Este aparato no puede ser utilizado por que lo utilicen personas (incluidos niños) con capacidades físicas,

sensoriales o mentales disminuidas, o bien con falta de experiencia y conocimientos, a menos que una

persona responsable de su seguridad las supervise o les dé instrucciones sobre el uso del aparato. Es

necesario supervisar a los niños para asegurarse de que no juegan con el aparato.

AVISOS Y PRECAUCIONES DE SEGURIDAD:

chispas cerca de las baterías. Desconecte de la red CA antes de realizar o deshacer conexiones en la batería. El ácido de la

batería es altamente corrosivo. Utilice ropa y gafas de protección y evite el contacto con el ácido. En caso de contacto accidental,

enjuague inmediatamente la zona afectada con agua y jabón. Compruebe que los polos de la batería no estén sueltos, y si lo están,

lleve la batería a un servicio técnico. Si los bornes presentan corrosión, límpielos con un cepillo de hilo de cobre, y si presentan

grasa o suciedad, límpielos con un trapo humedecido en detergente. Utilice el cargador solamente si los cables y conectores de

entrada y salida se encuentran en buenas condiciones y sin daños. Si el cable de entrada está dañado, es fundamental que el

fabricante, el servicio técnico autorizado o un taller capacitado lo sustituyan sin demora para evitar riesgos. Proteja el cargador del

ácido y de las emisiones de gases de ácido y de ambientes húmedos o superficies mojadas durante su utilización y

almacenamiento. La garantía no cubre daños derivados de la corrosión, oxidación o cortocircuitos eléctricos internos. Coloque el

cargador a una distancia adecuada de la batería durante la recarga para evitar la contaminación o la exposición al ácido o vapores

de ácido. Si se utiliza en posición horizontal, coloque el cargador en una superficie dura y plana, PERO NUNCA sobre plástico, tela o

piel. Utilice los orificios de fijación de la base de la carcasa para fijar el cargador en una superficie cómoda y totalmente horizontal.

Las baterías emiten GASES EXPLOSIVOS, evite la posibilidad de llamas o

EXPOSICIÓN A LÍQUIDOS: Este cargador fue desarrollado para resistir a líquidos que hubieran sido derramados de form

accidental o a intemperies ligeras. No obstante, no se recomiendan las exposiciones prolongadas, que podrían menguar la duración

de vida del cargador. Los desgastes, resultado de la oxidación debida al ataque eventual de líquidos en los componentes

electrónicos, los conectadores o enchufes no se cubren por la garantía.

CONEXIÓN DEL CARGADOR A LA BATERÍA

1. Desconecte la alimentación CA antes de efectuar o deshacer las conexiones en la batería.

2. Si se va a cargar una batería montada en el vehículo con las pinzas, compruebe primero que las pinzas se pueden colocar de

forma segura y correcta, lejos del cableado, los tubos metálicos o del chasis, antes de efectuar las conexiones. Realice las

conexiones en este orden: realice primero la conexión al terminal de la batería que no está conectado con el chasis

(normalmente positivo), luego conecte la otra pinza de batería (normalmente negativa) al bastidor a una distancia sufi ciente de

la batería y de la tubería de combustible. Desconecte siempre realizando los pasos anteriores en orden inverso.

3. Cuando cargue una batería fuera del vehículo con las pinzas, colóquela en un lugar bien ventilado. Conecte el cargador a la

batería: pinza ROJA con el terminal POSITIVO (POS, P o +) y pinza NEGRA con el terminal NEGATIVO (NEG, N o –). Asegúrese de

que las conexiones son firmes y seguras. Es importante que hagan bien contacto.

4. Si la batería está excesivamente descargada (y posiblemente sulfatada), retírela del vehículo e inspecciónela antes de

conectar el cargador para intentar recuperarla. Examine visualmente la batería en busca de desperfectos mecánicos, como

combas o fisuras en la carcasa, o indicios de fugas de electrólito. Si la batería tiene tapones de llenado y se pueden ver desde

fuera las placas del interior de las células, examine detenidamente la batería para comprobar si hay células que parezcan

distintas de las demás (por ejemplo, con materia blanca entre las placas o placas en contacto). Si se han detectado

desperfectos mecánicos, no intente cargar la batería, encargue su evaluación a personal cualificado.

5. Si la batería es nueva, lea atentamente las instrucciones de seguridad y uso del fabricante de la misma antes de conectar el

cargador. En su caso, siga estrictamente las instrucciones de llenado de ácido.

INICIAR LE CARGA

TIEMPO DE CARGA : El tiempo de carga para una batería de 100 Ah no debería tardar más de 12 horas en realizar la

comprobación de autodescarga.

: La tensión de carga se regula inversamente a la temperatura ambiente: cuando la temperatura es menor, se aumenta la tensión

y, cuando la temperatura es mayor, se disminuye la tensión. Ajuste: -0,004 V / célula / °C por encima o por debajo de 20 °C (68 °F).

POTENCIA ACTIVADA: LED #1 - Este LED confirma la alimentación AC hacia el cargador.

Indicación con intensidad FUERTE o DÉBIL: El led #1 (alimentación) brillará fuertemente cuando se entregara una corriente a la

batería. El led #1 reducirá su intensidad a un nivel bajo para indicar el modo «ECO» de baja potencia. Esto ocurrirá si no hay ninguna

batería conectada, o si hay una batería conectada y el programa está en el modo de prueba de retención de tensión Inicial y

Prolongado, o en los demás períodos del modo de Carga de mantenimiento.

PROTECCIÓN DE POLARIDAD INVERTIDA: LED #2 - Se enciende cuando las conexiones de la batería son incorrectas. El cargador

cuenta con una protección electrónica, por lo tanto no se producirá ningún daño, y la corriente de salida permanecerá desactivada

hasta que se corrijan las conexiones.

15

Page 16

PASO1

Arranque de

baja tensión

(Bat. ≥ 0,5 V)

STD: comprobación de la tensión de la batería: el modo STD se activa si la

tensión de la batería conectada es de al menos 0,5 voltios.

Con las baterías inferiores a 2 voltios en la conexión pasarán al

PASO 2 para pulso de encendido, que incluye una prueba de cortocircuito.

V

En las baterías de 2 o más voltios se procederá directamente al PASO 3.

PASO 2

Pulso de

encendido

PASO 3

PRUEBA

antes de la

carga

PASO 4

RECUPERACIÓN

avanzada

- batería

sulfatada

PARPADEO

LED #8

7

8

TEST

LED DE PRUEBA

N.º6: VERDE

N.º7: AMARILLO

N.º8: ROJO

7

8

TEST

LED #3 : ROJO

3

Pulso de encendido - LED #8 parpadeo (rojo) : OptiMate 7 Ampmatic está

enviando una señal de prueba para ver si la batería se puede recuperar.

Si la tensión es superior a 2 voltios y no se ha detectado ningún cortocircuito, el

programa procederá al PASO 3.

Si el parpadeo continúa, las siguientes condiciones pueden impedir que el programa de

carga siga adelante:

1) La red eléctrica del vehículo sigue conectada a la batería.

6

NOTA: Si la batería que se está cargando presenta una baja tensión o

está sulfatada, para obtener unos mejores resultados de la prueba y que

la carga resulte más efectiva, desconecte la batería de la red eléctrica

del vehículo y luego cárguela.

2) La batería tiene múltiples células cortocircuitadas. La batería tiene un daño

permanente y debe ser sustituida.

Los LED DE PRUEBA n.º 6, 7 y 8 indican el estado de la batería antes de cargarla.

Consulte la tabla que figura más abajo o en la página 2 para asociar la indicación de los

LED DE PRUEBA al estado de porcentaje de carga estimado (SOC%).

0

6

Decisiones tomadas durante la prueba:

PASO 7 OPTIMIZACIÓN: el tiempo de carga mínimo se define según el resultado de la

prueba, y oscila entre 10 minutos para una batería con un estado de carga del 80 %

o más, y 120 minutos para una batería con un estado de carga del 40 % o menos.

La temperatura ambiente se mide para determinar los parámetros de la tensión de

carga. La carga comienza transcurridos 10 segundos.

Se determina el grado de descarga; una batería con un 60% o más de carga pasa

directamente al PASO 6, mientras que una batería con muy poca carga pasa a los PASOS

4 y 5. Las baterías con muy poca carga serán sometidas a una prueba más larga (de

hasta 12 horas) durante el PASO 8.

Tiempo de carga: 2 horas como máximo.

La tensión de salida aumenta hasta un máximo de 22V con la corriente limitada a 0,4A,

pero solo si no se ha detectado el sistema electrónico del vehículo. En caso contrario,

salta al siguiente paso. IMPORTANTE: lea la sección BATERÍAS DESCUIDADAS MUY

DESCARGADAS, que se incluye más adelante.

8

0

Se activa si se diagnostica que la batería está sulfatada

7

8

o es incapaz de aceptar o retener una carga.

7

80 100%604020AGM

6

7

100% 806040STD

6

16

Page 17

PASO 5

RECUPERACIÓN

Pulso

PASO 6

CARGA

PASO 7

OPTIMIZACIÓN

PASO 8

PRUEBA tras

la carga

PASO 9

Manteni-

miento

OptiMate

'365'

LED #3 : ROJO

3

LED #4 : AMARILLO

4

LED #5 : AMARILLO

5

LED #6

PARPADEO

6

TEST

LED #6 / 7 / 8

ACTIVADO

6

7

8

TEST

Para las baterías en buen estado,

el LED n.º6 (verde) permanecerá

activado.

Excepción: las baterías de célula

húmeda estándar con tapones de

relleno poseen una tensión de

carga completa menor, por lo que

tanto el LED n.º 6 como el LED

n.º7 permanecerán activados.

Se activa si el estado de carga de la batería es de un 40% o inferior

O si la batería se ha recuperado lo suficiente durante la RECUPERACIÓN TURBO.

Tiempo de carga: mínimo 15 minutos, máximo 2 horas.

Se aplicará una carga de reacondicionamiento; se suministra corriente por impulsos para

preparar la batería para que acepte una carga normal. Este modo es especialmente eficaz

para la recuperación de baterías activadas de fábrica / baterías «de alto rendimiento» de

plomo puro o baterías AGM con células cíclicas.

El modo CARGA se activa si el estado de carga de la batería es 50 %

o superior (prueba en el PASO 3), o una vez que la batería

se haya recuperado lo suficiente durante el PASO 5.

El programa de control de corriente ampmatic™ suministra impulsos de corriente

para ecualizar las células individuales dentro de la batería y optimiza el nivel de carga.

El modo OPTIMIZACIÓN comienza cuando el voltaje alcanza

los 14,4 V por primera vez durante el modo CARGA.

El programa de control de corriente ampmatic™ suministra impulsos de corriente

para ecualizar las células individuales dentro de la batería y optimiza el nivel de carga.

La carga se debe completar dentro del tiempo de carga mínimo establecido durante el

PASO 3, pero si la batería necesita más carga, el programa ampliará el modo

OPTIMIZACIÓN hasta un máximo de 2 horas. OBSERVACIÓN: el tiempo de carga se suele

ampliar si el consumo de corriente de los circuitos conectados es superior al esperado o

si el estado de la batería es inferior al óptimo.

Por razones de seguridad hay un límite temporal de carga general de 72 horas

para los PASOS 4, 5 y 6.

PRUEBA después de la CARGA: el suministro de corriente

se interrumpe durante 30 minutos** para que el programa pueda

determinar la capacidad de retención de carga de la batería.

** SI el resultado del PASO 3 ha sido ROJO (LED n.º 8) o ROJO Y AMARILLO (LED n.º 7

y 8), que indica que la batería está muy descargada antes de la conexión, la prueba de

retención de tensión se ampliará a 12 horas para comprobar el estado de la batería.

El resultado de la PRUEBA (que se indica en los LED n.º6, 7 y 8) se ajustará en tiempo

real de acuerdo con la tensión que se mida en la batería.

0

8

0

La PRUEBA se interrumpirá si se ilumina el LED n.º8 (rojo). Existe un problema

importante si la batería no puede retener suficiente carga durante la prueba de retención

de tensión. Consulte la tabla «ADVERTENCIA PRECOZ DE PROBLEMAS CON LA BATERÍA»

en la página 2 para asociar la indicación de los LED de PRUEBA al estado de porcentaje

de carga estimado (SOC%). Se proporciona más información en la sección

«OBSERVACIONES SOBRE LOS RESULTADOS DE LA PRUEBA».

CARGA DE MANTENIMIENTO: LED n.º 6 / 7 / 8 fijos

según el estado de carga medido durante el PASO 8.

Configuración de tensión flotante: 13,6V nominales a 20°C (68°F). La tensión flotante

se regula inversamente a la temperatura ambiente: la tensión aumenta cuando la

temperatura es menor y disminuye cuando la temperatura es mayor. Ajuste:

–0,04V / célula / °C por encima o por debajo de 20°C (68°F).

El modo de mantenimiento estándar consiste en periodos de carga flotante de 30

minutos seguidos por periodos alternos de «descanso» de 30 minutos durante los que no

se suministra corriente. Este «ciclo de trabajo del 50 %» evita la pérdida de electrolito en

baterías selladas y minimiza la pérdida gradual de agua del electrolito en baterías con

tapones de relleno, y por tanto, contribuye de forma significativa a optimizar la vida útil

de baterías usadas de forma irregular o en determinados periodos.

Durante la «carga flotante», se suministra de forma continua un IMPULSO DE BAJA

CORRIENTE PARA IMPEDIR LA SULFATACIÓN, lo que aumenta la potencia y la vida útil de

la batería.

Si OptiMate detecta que la batería ha perdido carga, el programa volverá al PASO

CARGA.

7

8

7

80 100%604020AGM

6

7

100% 806040STD

6

17

Page 18

BATERÍAS INUTILIZADAS O MUY DESCARGADAS: Si la batería está excesivamente descargada (y posiblemente

sulfatada), retírela del vehículo e inspecciónela antes de conectar el cargador para intentar recuperarla.

El modo de recuperación TURBO del cargador no puede activarse si detecta que la batería está todavía conectada a un

circuito de cableado del vehículo o el equipamiento, que ofrece de forma efectiva una resistencia eléctrica inferior a la batería

misma. Sin embargo, si la batería muy descargada no se retira para su recuperación, no se dañará ni la batería ni la electrónica del

vehículo o el equipamiento. Preste especial atención a los siguientes puntos: Una batería que haya permanecido descargada

durante un periodo largo puede desarrollar daños permanentes en una o más células. Esas baterías pueden calentarse en exceso

durante la fase de alta tensión. Pare inmediatamente la carga de la batería si está demasiado caliente al tacto.

Controle la temperatura de la batería durante la primera hora, a partir de entonces, contrólela cada hora. Permanezca atento a

señales inusuales, como pueden ser el burbujeo o la fuga de electrolito, una mayor actividad en una célula en comparación con las

otras o sonidos silbantes. Si en cualquier momento la batería está demasiado caliente o nota cualquier señal que no sea normal,

DESCONECTE EL CARGADOR INMEDIATAMENTE.

OBSERVACIONES SOBRE LOS RESULTADOS DE LA PRUEBA:

1. Con cualquier resultado de prueba distinto a #6 verde, desconecte la batería del sistema eléctrico al que está conectado y vuelva

a conectar el OptiMate. si obtiene mejores resultados esta vez, esto sugiere que las pérdidas de corriente son debidas en parte a un

problema eléctrico en el sistema eléctrico y no en la propia batería. Si los resultados bajos persisten, se recomienda que llevar la

batería a un taller profesional equipado con equipos profesionales para que realicen un diagnóstico más exhaustivo.

2. Si se ilumina únicamente el LED #8 rojo, o bien el LED #7 amarillo y el LED #7 rojo al mismo tiempo, esto indica que existe un

problema importante. Los LED #7 y #8 amarillo + rojo, (o el LED #7 amarillo en una batería sellada) quieren decir que tras la carga

no se mantiene el voltaje de la batería o que a pesar de los intentos de recuperación, la batería es irrecuperable. Esto puede deberse

a un defecto propio de la batería, tal como un cortocircuito en una celda o un sulfatado total, o en el caso de una batería conectada

al sistema eléctrico al que suministra corriente, el LED #7 rojo puede indicar una pérdida de corriente por un cable o contacto

defectuoso, o un accesorio del circuito que esté consumiendo corriente. Una carga repentina como por ejemplo el encendido de las

luces mientras el cargador está conectado, también puede hacer que el voltaje de la batería baje de forma significativa.

3. RESULTADO SATISFACTORIO DE LA PRUEBA, pero la batería no puede suministrar sufi ciente potencia: a) Este test de retención de voltaje

es signifi cativo pero no siempre conclusivo. El estado de una batería a ciclo profundo se podrá determinar de forma más precisa a medio de

un comprobador TestMate

produce una gran pérdida de tensión solo cuando la demanda de potencia es alta (p.ej., arranque del motor).

™. b) La vibración a largo plazo podría provocar grietas finas en los conectores entre las células de la batería. Se

MANTENIMIENTO DE LA BATERÍA EN PERÍODOS PROLONGADOS DE TIEMPO: El OptiMate mantendrá una batería

cuyo estado es bueno, en total seguridad durante varios meses.

Al menos una vez cada dos semanas, compruebe que las conexiones entre el cargador y la batería está correctas, y en el caso de

baterías con un tapón en cada celda, desconecte la batería del cargador, compruebe el nivel de electrolito y si es necesario, rellene