Page 1

ORDER NO. EMID0207013C0

A5

PCM KEYBOARD

SX-KN7000P

SX-KN7000PC

SX-KN7000EX

SX-KN7000EF

SX-KN7000EH

SX-KN7000EQ

SX-KN7000EG

SX-KN7000EB

SX-KN7000EV

SX-KN7000GN

SX-KN7000GM

SX-KN7000GH

SX-KN7000GT

SX-KN7000GU

(P) U.S.A.

(PC) Canada

(EX) Norway, Sweden, Denmark, Finland, Spain, Portugal, Greece,

Poland, Czech,South Africa

(EF) France

(EH) Netherlands

(EQ) Germany

(EG) Austria, Switzerland, Italy

(EB) Great Britain

(EV) Belgium

(GN) Australia, New Zealand

(GM) Malaysia, Singapore

(GH) Hong Kong

1

Page 2

(GT) Taiwan

(GU) Thailand, Indonesia, Dubai, Brazil, Philippines, Barkley(special)

SPECIFICATIONS

SPECIFICATIONS

KEYBOARD

SOUND GENERATOR

MAX. POLYPHONY

61 KEYS (WITH INITIAL

TOUCH)

PCM

128 NOTES

2

Page 3

SOUNDS NUMBER OF SOUNDS:

1236 SOUNDS (1187

SOUNDS + 2 ORGAN

DRAWBARS + 2 ORGAN

TABS + 3 ACCORDION

REGISTERS + 41 DRUM

KITS)

SOUND GROUP:

PIANO, GUITAR,

STRINGS &

VOCAL,BRASS, MALLET

& ORCH PERC, WORLD,

ORGAN &

ACCORDION,SAX &

WOODWIND, PAD ,

SYNTH, BASS, DRUM

KITS, DIGITAL

DRAWBAR, ORGAN

TABS, ACCORDION

REGISTER

SOUND EXPLORER:

Supported

EFFECT PART:

SUSTAIN, DIGITAL

EFFECT, SOUND DSP

GLOBAL:

REVERB, CHORUS,

MULTI, MIC

WHEEL

PITCH BEND,

MODULATION

PART SELECT

RIGHT 1, RIGHT 2, LEFT

TRANSPOSE +/-12 NOTES

RHYTHMS NUMBER OF RHYTHMS:

220 RHYTHMS × 4

VARIATIONS

RHYTHM GROUP:

8 & 16 BEAT, ROCK &

POP, BALLAD, JAZZ &

SWING, MODERN

DANCE, MARCH &

WALTZ, 60s & 70s,SOUL &

R&B, COUNTRY &

WESTERN, ORGANIST,

BALL ROOM, LATIN &

WORLD, ENTERTAINER,

MOVIE & SHOW,

FAVORITES

Supported

3

Page 4

CONTROLS

MAIN VOLUME, APC/

SEQUENCER VOLUME,

LINE IN VOLUME, SD

VOLUME, BALANCE,

MUTE, CONDUCTOR,

START/STOP, INTRO &

ENDING 1, INTRO &

ENDING 2, FILL IN 1, FILL

IN 2, COUNT INTRO,

SYNCHRO&

BREAK,TEMPO/

PROGRAM, TAP TEMPO,

FADEIN/OUT, SPLIT

POINT

PERFORMANCE PADS 20 PRESET BANKS × 6

PADS WITH SOLO

USER BANK × 3,

COMPILE BANKS × 2,

CONTROL PRESET × 1

STOP, AUTO SETTING

AUTO PLAY CHORD

MODE: BASIC,

FINGERED, PIANIST

MEMORY, ON BASS,

CHORD FINDER, LEFT

HOLD

MUSIC STYLE ARRANGER

SOUND ARRANGER

MUSIC STYLIST

ONE TOUCH PLAY

TECHNI-CHORD

PANEL MEMORY

13 BANKS × 8, SET,

Supported

Supported

Supported

Supported

Supported

NEXT BANK, BANK VIEW,

CUSTOM PANEL

SEQUENCER 16 TRACKS

RESOLUTION: 1/96 PER

BEAT

STORAGE CAPACITY:

APPROX.40000 NOTES

(10 SONG MAX.)

INPUT MODES: EASY

RECORD, REALTIME

RECORD, STEP RECORD

FUNCTIONS: RECORD&

EDIT, COPY &

PASTE,RANGE EDIT

4

Page 5

COMPOSER 8 PARTS: BASS,

ACCOMP 1 - 5, DRUMS 1,

2

STORAGE CAPACITY:

APPROX. 13000 NOTES

INPUT MODES: EASY

COMPOSER, REALTIME

RECORD, STEP RECORD

FUNCTIONS: PATTERN

COPY, CUSTOM STYLE

COPY, SEQ TO

COMPOSERCOPY, LOAD

SINGLE COMPOSER

MEMORY: 3 BANKS

DISK DRIVE 3.5 inch DISK DRIVE for

2HD (1.44MB), 2DD

(720KB)

LOAD, SAVE, DIRECT

PLAY, SONG MEDLEY,

DISK TOOLS,

PREFERENCES, STYLE

CONVERT, CUSTOM

STYLE LOAD/SAVE

SD CARD

LOAD, SAVE,

FAVORITES SONGS,

TECHNICS SONG

MEDLEY, SD-AUDIO

PLAY, SD-SOUND PLAY,

CUSTOM STYLE LOAD/

SAVE, SD CARD TOOLS,

SD PREFERENCES

SOUND SETTING

PART SETTING, MIXER,

MASTER TUNING, KEY

SCALING, TECHNI-

CHORD, SOUND LOAD

OPTION, APC REVERB

SETTING, MONITOR

SETTING, SEPARATE

SETTING

SOUND EDIT EASY EDIT, TONE,

PITCH, FILTER,

AMPLITUDE, LFO,

EFFECT, CONTROLLER

MEMORY: 40, 1 USER

DRUM KIT

5

Page 6

REVERB & EFFECT

MIC REVERB & EFFECT,

SOUND LOAD OPTION,

ALLOCATION, MIXER,

SOUND DSP, MULTI,

CHORUS, REVERB,

EQUALIZER

CONTROL

INITIAL, OVERALL

TOUCH SENSITIVITY,

FOOT CONTROLLERS,

PANEL MEMORY MODE,

MUSIC STYLE

ARRANGER MODE, FADE

IN/OUT SETTING

CUSTOMIZE

HOME PAGE SETTING,

FAVORITE SETTING,

DISPLAY TIME OUT,

WALL PAPER SETTING,

MIDI SETTING LOAD

OPTION, DATA

PROTECTION,

LANGUAGE SELECT,

DISK PREFERENCE,

VIDEO OUT MODE

SETTING

MIDI

PART SETTING,

CONTROL MESSAGES,

REALTIME MESSAGES,

COMMON SETTING,

INPUT/OUTPUT SETTING,

MIDI PRESETS, MODE

SETTING, PROGRAM

CHANGE MIDI OUT,

PANEL MEMORY

OUTPUT, COMPUTER

CONNECTION

DISPLAY LCD

PAGE, CONTRAST, EXIT,

DISPLAY HOLD

HELP

DEMO

Supported

Supported

6

Page 7

TERMINALS

OUTPUT

SPEAKERS

POWER REQUIREMENT 75 W

DIMENSIONS (W×H×D)

NET WEIGHT

ACCESSORIES

PHONES, FOOT SW 1, 2,

FOOT CONTROLLER,

EXP PEDAL, MAIN OUT (R

/MONO,L), SUB OUT (1,2)

AUX IN (R/MONO,L), LINE

IN (R/MONO,L), USB,

VIDEO OUT, MIDI (IN/

BASS PEDAL,

OUT,THRU), MIC

66 W (18 W × 2 FOR MID/

HIGH, 30 W × 1 FOR

BASS)

12 cm × 2, 6.5 cm × 2

FOR MID/HIGH, 14 cm × 1

FOR BASS

AC120/220/240V 50/60 Hz

AC120V 60 Hz (NORTH

AMERICA AND MEXICO)

AC230-240V 50/60 Hz

(EUROPE, AUSTRALIA

AND NEW ZEALAND

114 cm × 17 cm × 41 cm

(44-7/8” × 6-11/16” × 16-1/

8”)

17.6 kg (38.8 lbs)

AC CORD, MUSIC

STAND, STYLE CONVERT

DISK, INITIAL DATA

DISK, CD-ROM(AUDIO

RECORDER, SONG

MANAGER, USB DRIVER),

SD CARD

1. Warning

1

7

Page 8

To prevent the risk of fire, smoke, or electrical shock and to ensure safe operation,

please be sure to follow the safety guidelines below.

1. At places where special caution is required, the necessary safety precautions are

clearly labeled or printed, for example, on the cabinet, or on the part concerned.

Please follow these safety precautions, and also those listed in the Owner'sManual.

2. Parts which have a ; mark in the circuit diagram or in the parts list are essential

for safety. When replacing these parts, be sure to use onlythe specified parts.

3. Use the specified types for internal wiring (double-insulated wiring, etc.).

4. When replacing parts on the AC primary side (power transformer, electric switch,

electrical cord, noise-prevention condenser, etc.), wind the lead wire and secure it

by soldering.

5. Do not let the wiring come into contact with heat-emitting devices (fuse resistor,

radiator plate, etc.).

6. When replacing the wiring, make sure that it is not in contact with the unfinished or

rough edge of a part.

7. When replacing the power cord (except for the plug-in type), tug it from various

directions to confirm that it does not slip out of place.

8. Spacing

If soldering was done on the AC primary circuit, confirm that the interval between

the soldered terminals or between the terminal and surrounding metallic parts is at

least the minimum required (between the primary circuit and the chassis: atleast6.5

mm; between primary circuit terminals: at least 4.0 mm; between primary circuit

terminals and secondary circuit terminals: at least 6.5 mm.).

2. Safety Precaution

2.1. Safety Precaution

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only the manufacturer’s recommended components for

safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation

papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the

following insulation resistance test to prevent the customer from being exposed to

a shock hazard.

8

Page 9

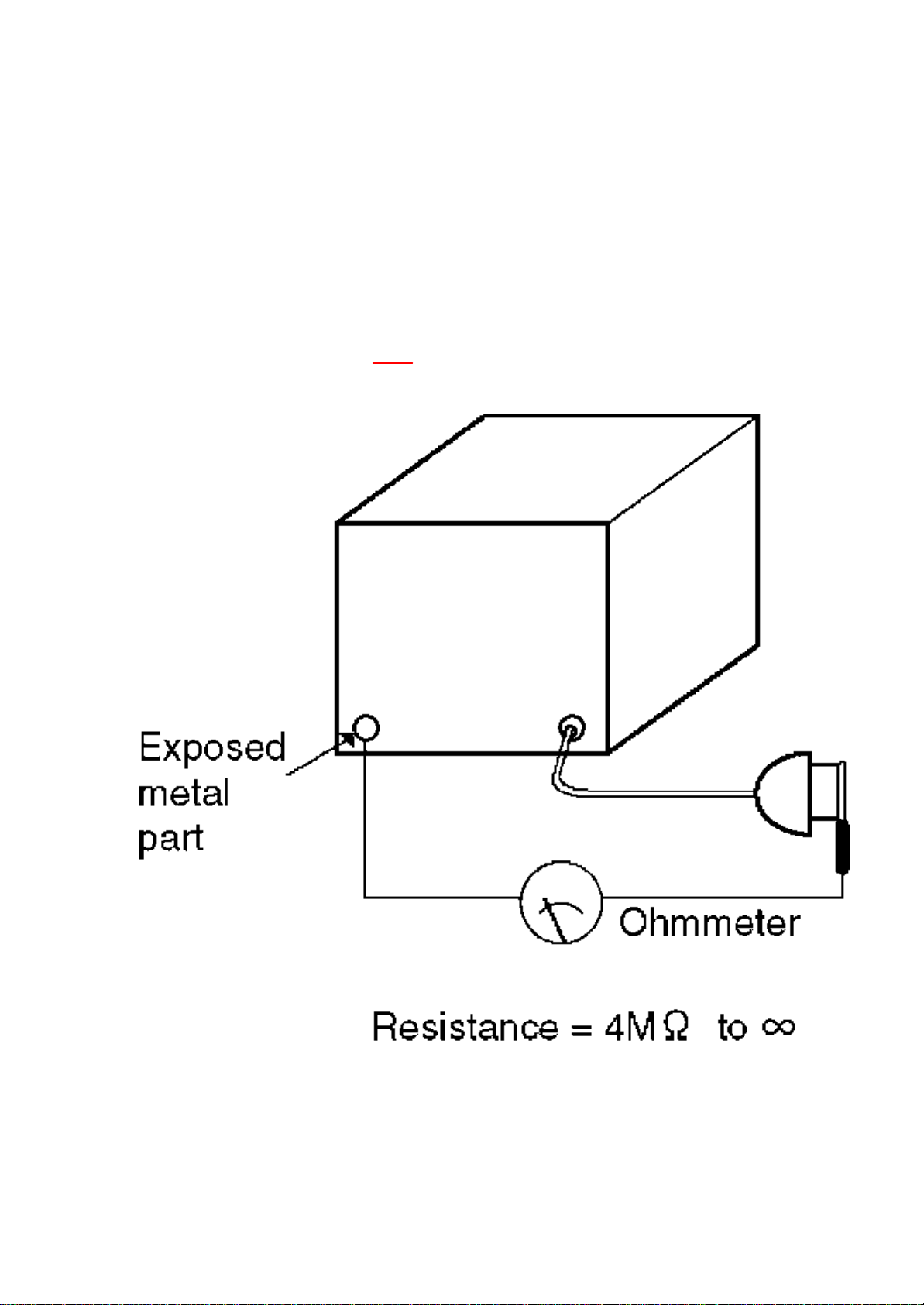

2.2. Insulation Resistance Test

1. Unplug the power cord and short the prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and

each exposed metal cabinet part, such as screw heads, connectors, control shafts,

handle brackets, etc. Measurements should range from 4 MOhm to infinity for

allexposedparts. (refer to Fig.1 )

Fig.1

3. OWNERS MANUAL

9

Page 10

4. MIDI Implementation Chart

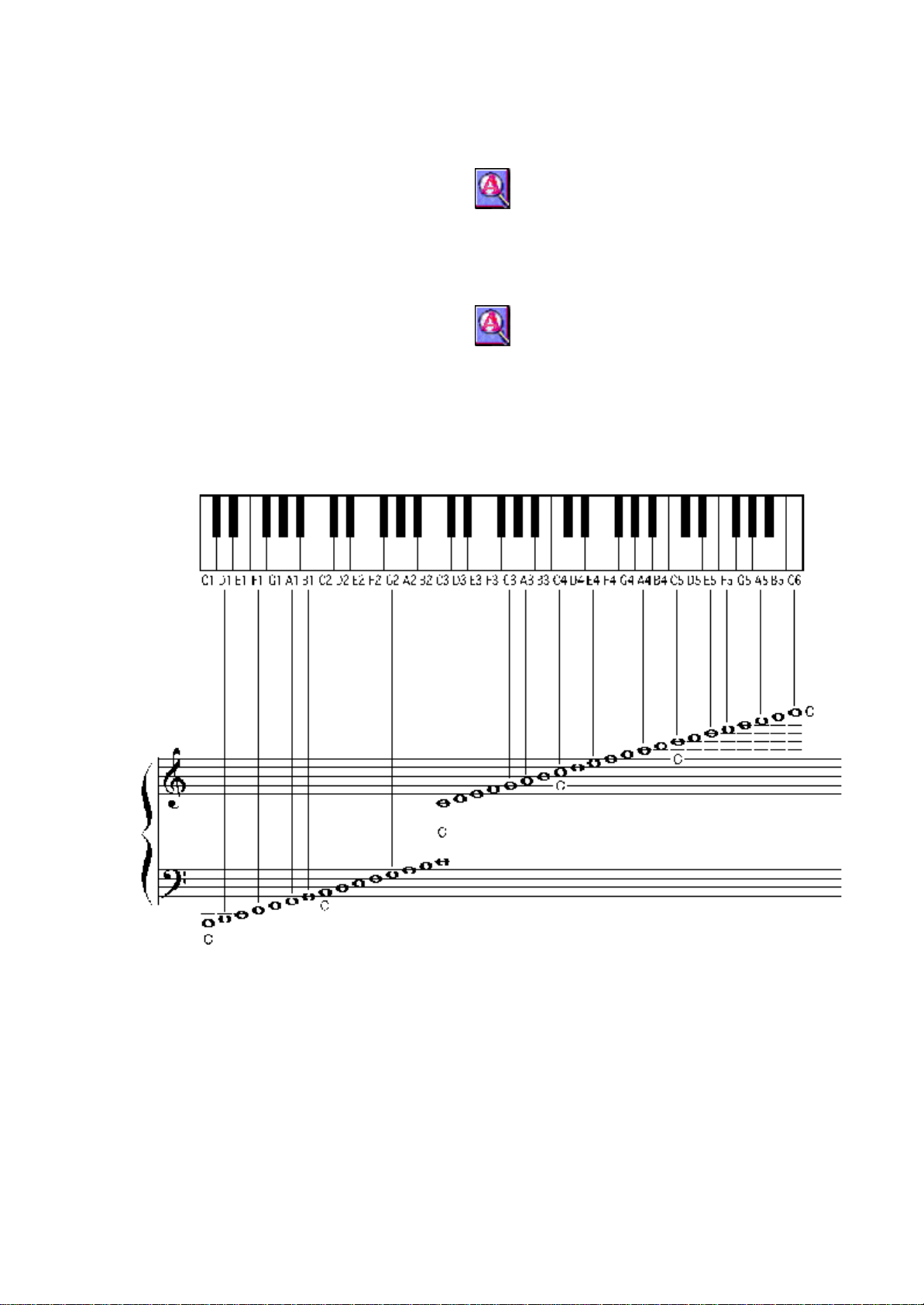

5. Keyboard Ranges

This keyboard features Touch Response, by which you control the volume by playing

the keys harder or softer.

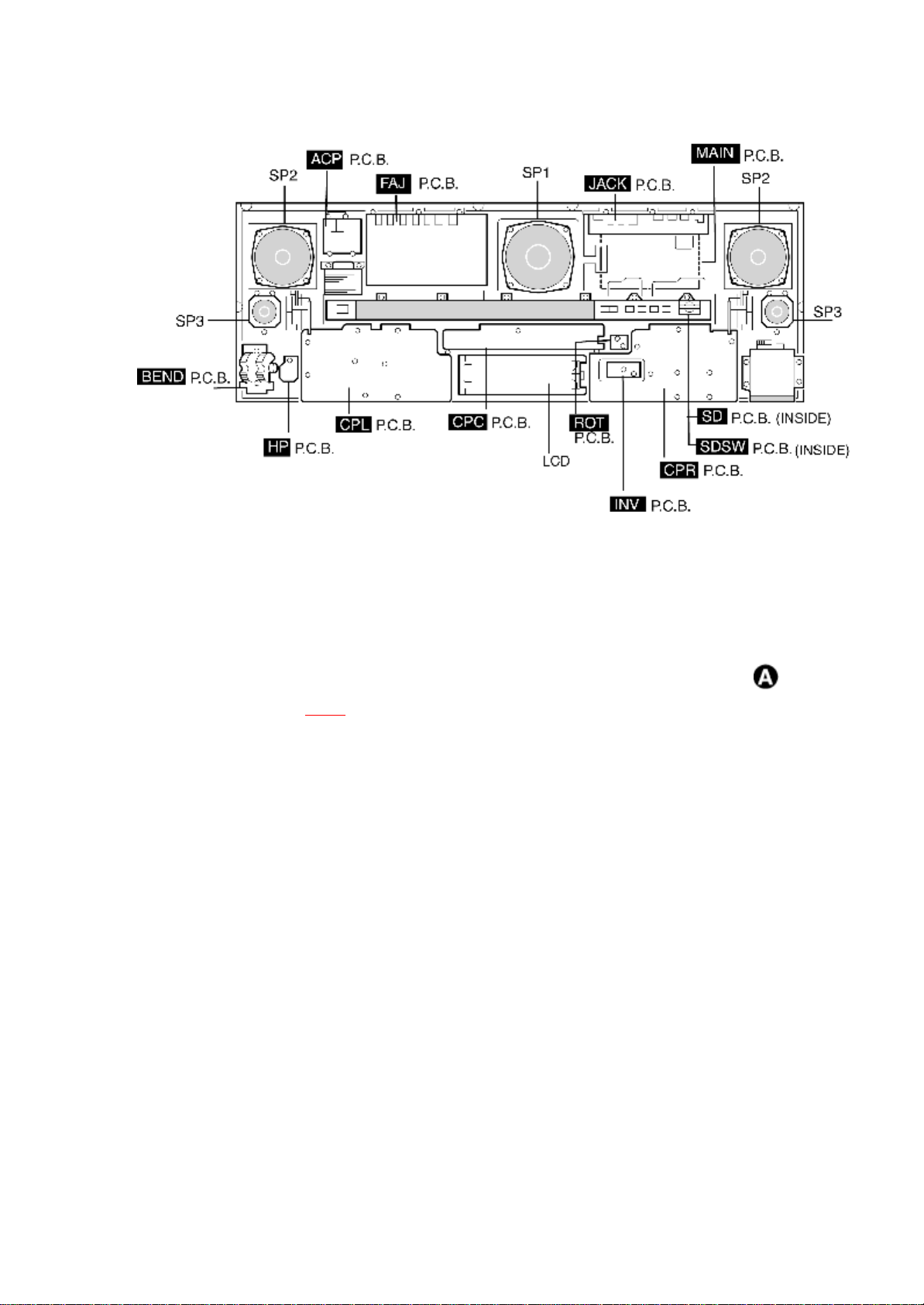

6. Parts Location

10

Page 11

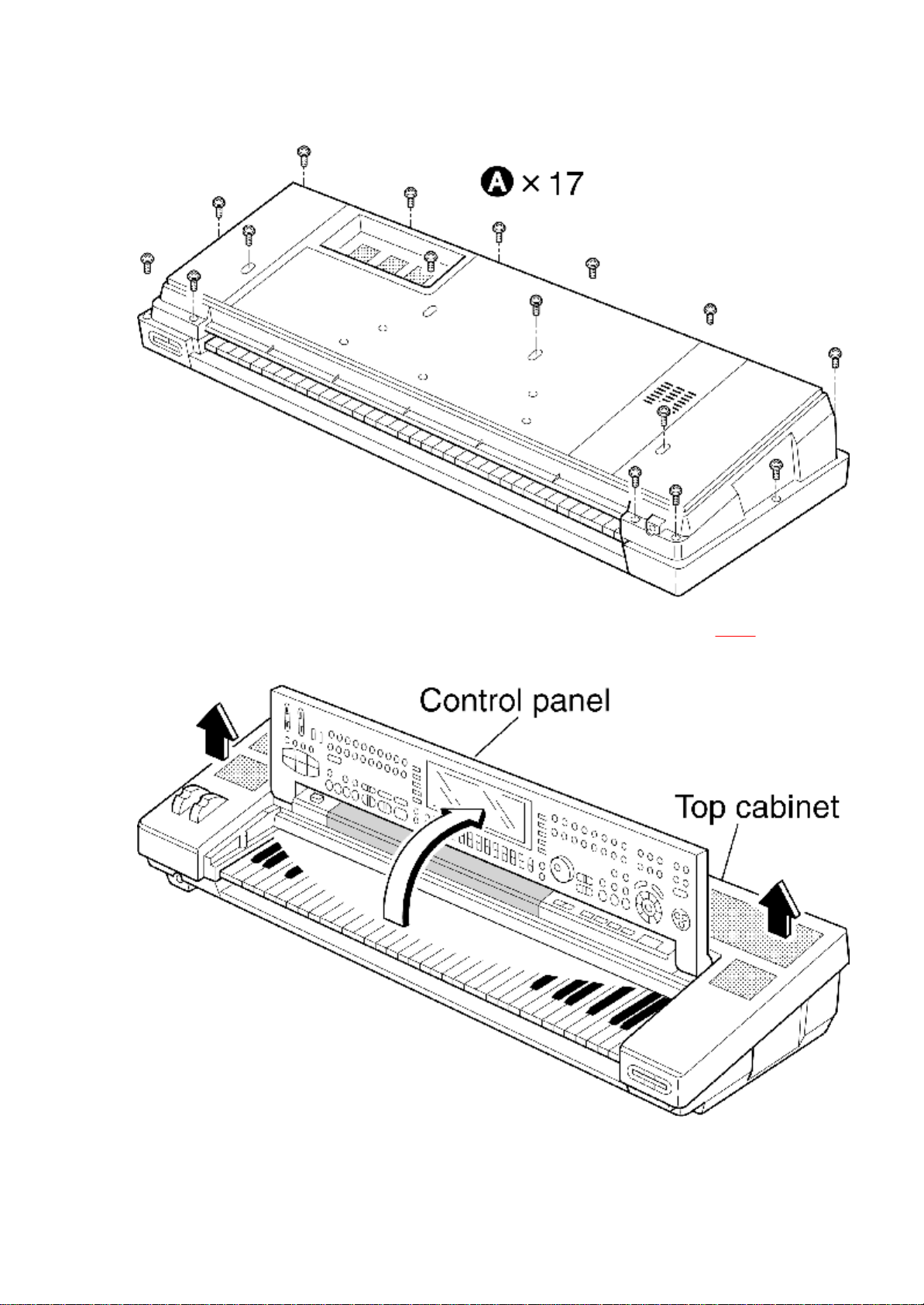

7. Disassembly Instructions

7.1. Removing the top cabinet

1. Turn the keyboard cabinet upside down, and remove the bottom screws ( 17

pcs.) as shown in Fig.2 .

2. Place the keyboard bottomside down, and open the top cabinet .

Fig.2

11

Page 12

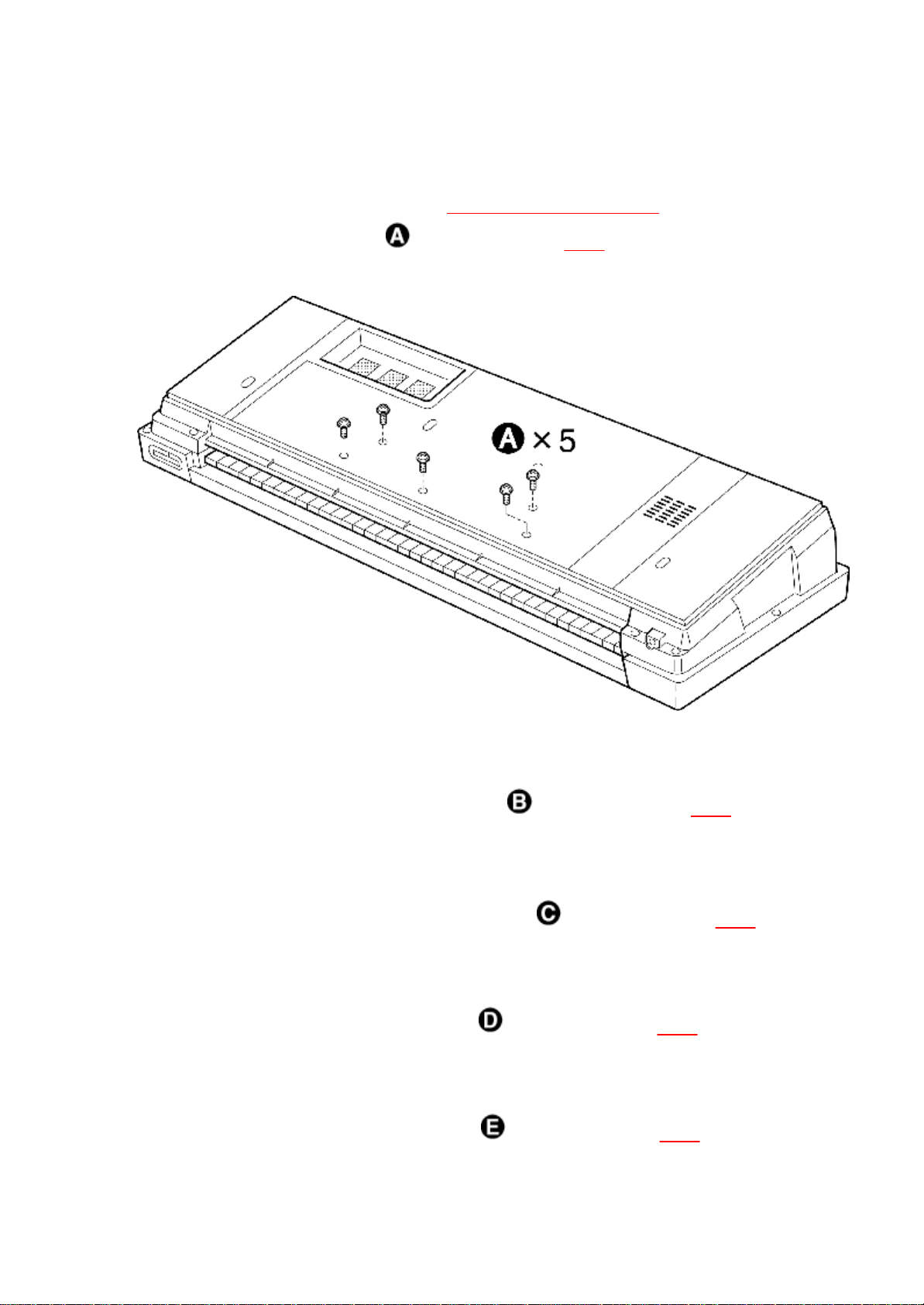

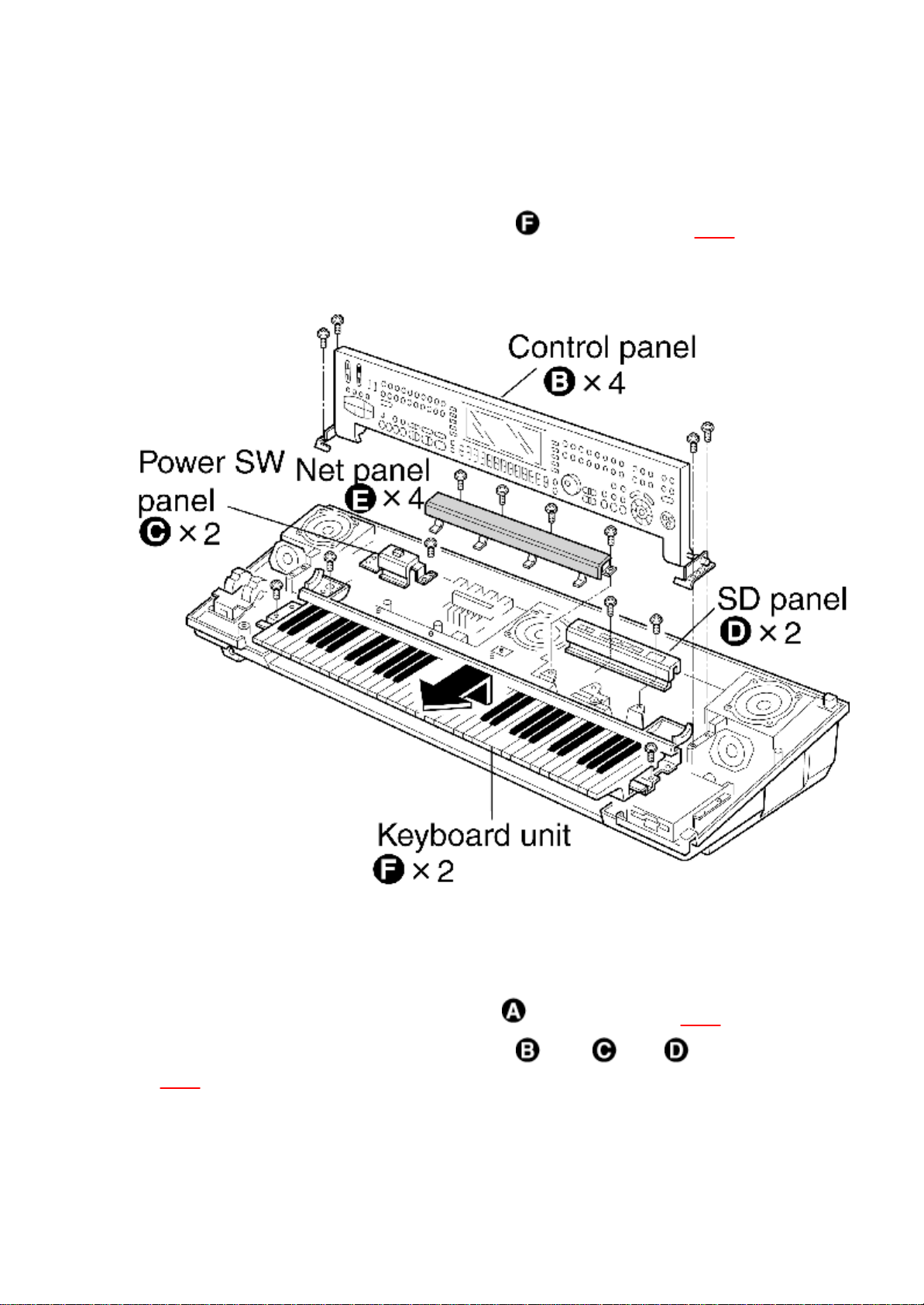

- The control panel is set up, and remove the top cabinet as shown in Fig.3 .

Fig.3

7.2. Removing the control panel, power SW panel, SD panel,

12

Page 13

net panel and keyboard unit

- Remove the top cabinet (see step “Removing the top cabinet ”).

- Remove the bottom screws( 5pcs.) as shown in Fig.4

Fig.4

Control panel

1. Place the keyboard bottomside down.

2. Remove the control panel holding screws ( 4pcs.) as shown in Fig.7 .

Power SW panel

- Remove the power SW panel holding screws ( 2pcs.) as shown in Fig.7 .

SD panel

- Remove the SD panel holding screws ( 2pcs.) as shown in Fig.7 .

Net panel

- Remove the net panel holding screws ( 4pcs.) as shown in Fig.7 .

13

Page 14

Keyboard unit

- Remove the keyboard unit holding screws ( 2pcs.) as shown in Fig.7 .

Fig.5

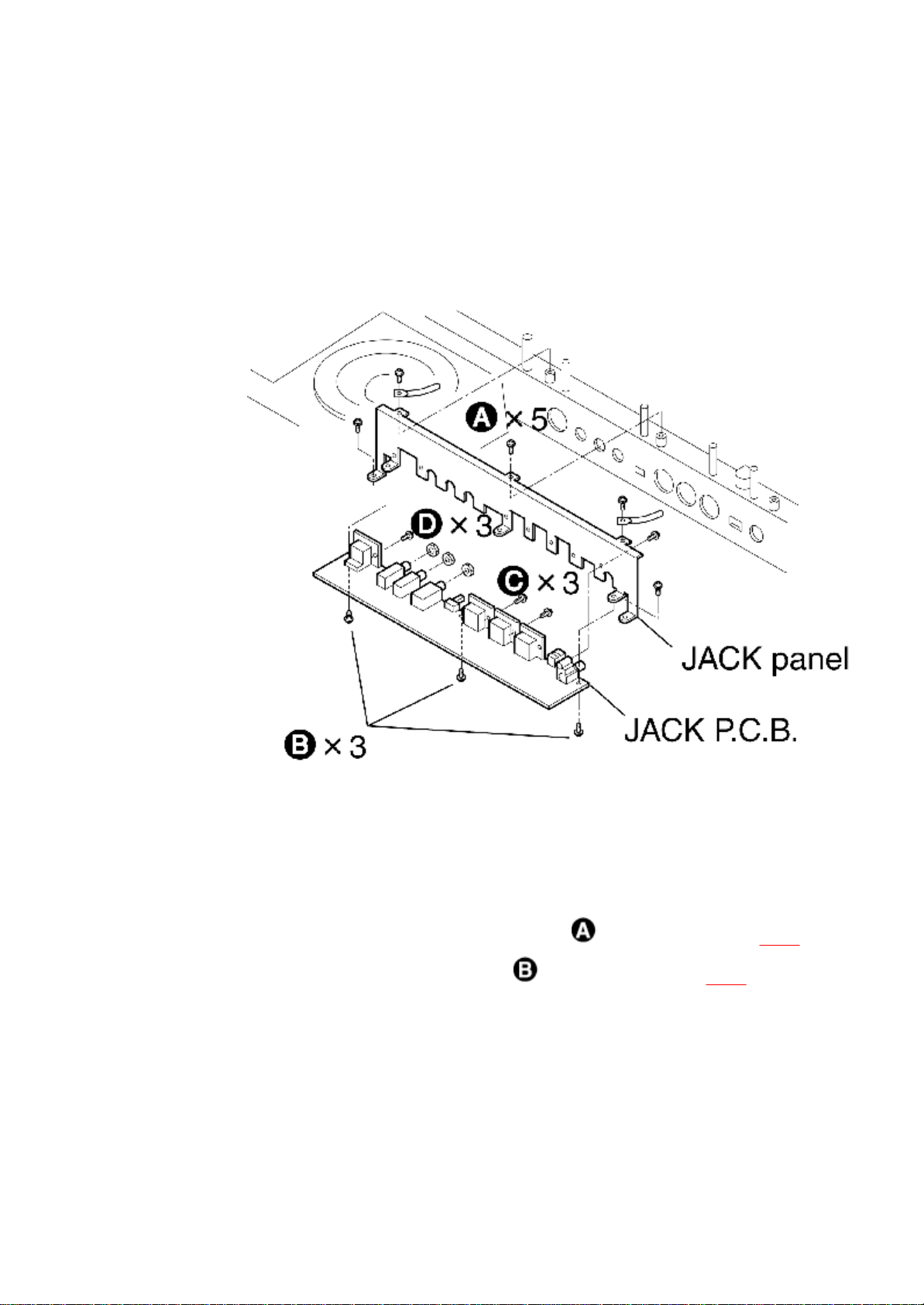

7.3. Removing the JACK and MAIN printed circuit boards

JACK P.C.B.

1. Remove the jack panel mounting screws ( 5pcs.) as shown in Fig.6 .

2. Remove the JACK P.C.B. mounting screws ( 3 pcs., 3pcs, 3pcs.)as shown in

Fig.6 .

Fig.6

14

Page 15

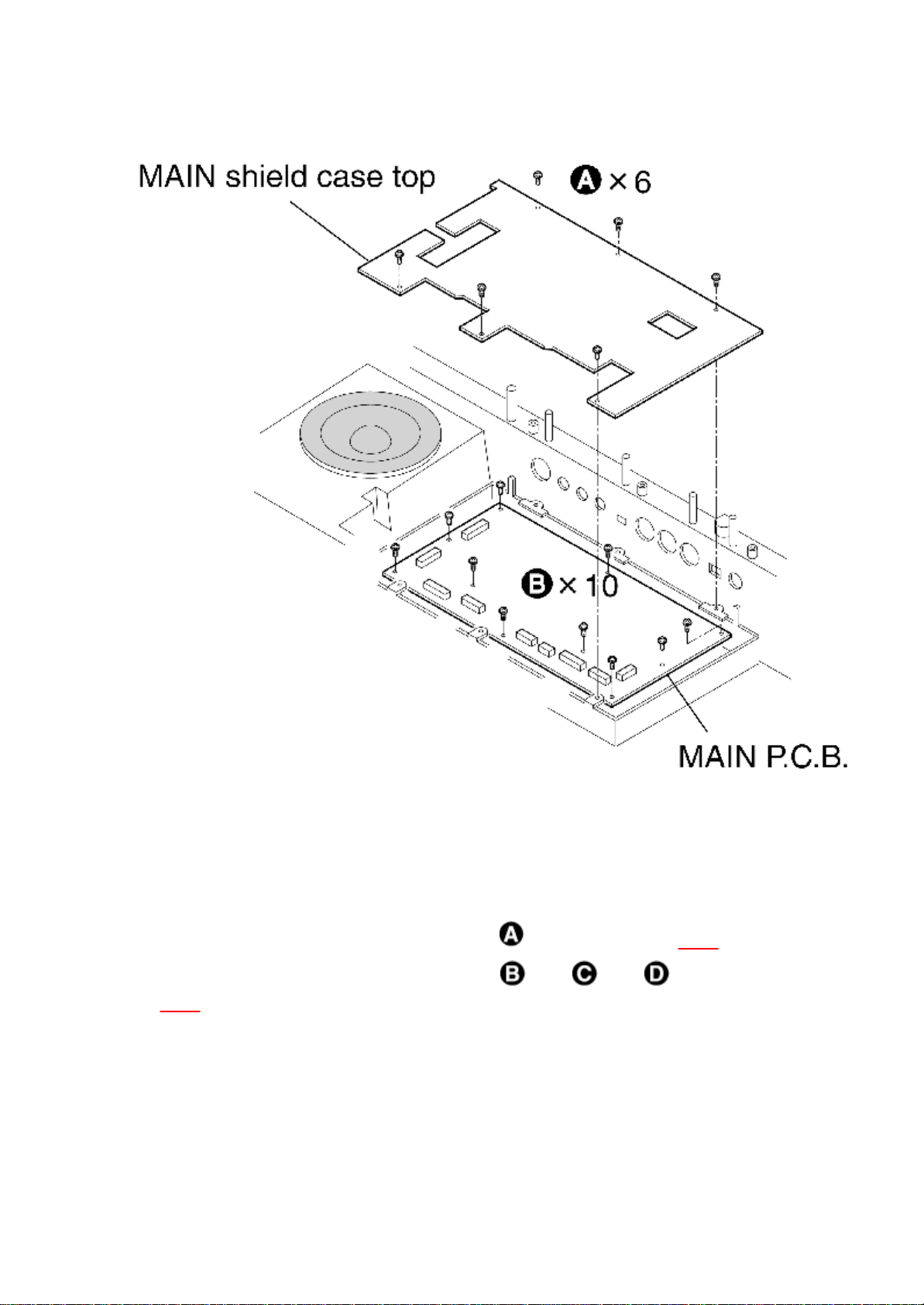

MAIN P.C.B.

1. Remove the main shild top case mounting screws ( 6 pcs.) as shown in Fig.7 .

2. Remove the MAIN P.C.B. mounting screws ( 10pcs.) as shown in Fig.7 .

Fig.7

15

Page 16

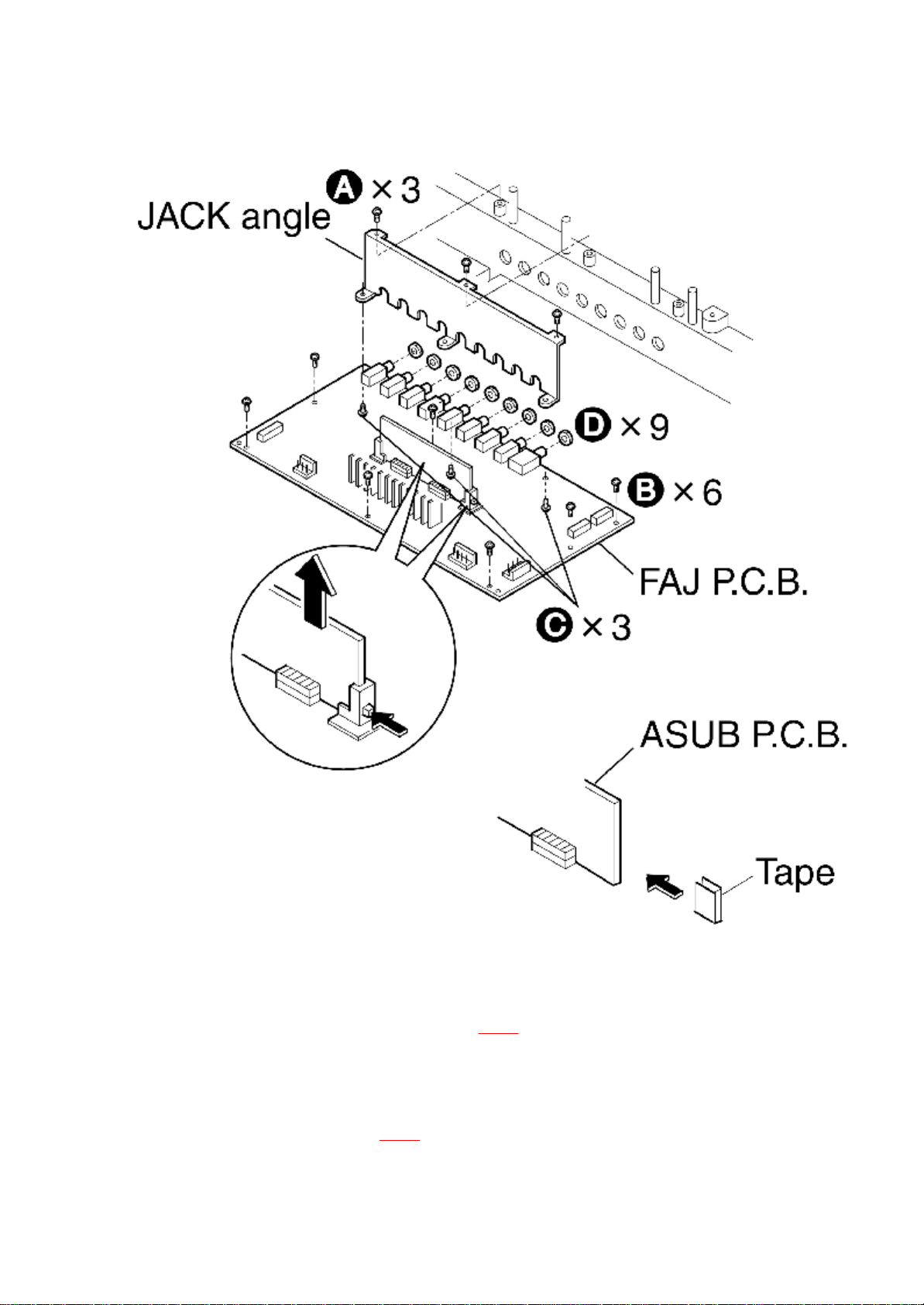

7.4. Removing the FAJ printed circuit board

FAJ P.C.B.

1. Remove the FAJ angle mounting screws ( 3pcs.) as shown in Fig.8 .

2. Remove the FAJ P.C.B. mounting screws ( 6pcs., 3pcs, 9pcs.)as shown in

Fig.8 .

Fig.8

16

Page 17

ASUB P.C.B. disasemble

- Push the board holder libs as shown in Fig.8 .

ASUB P.C.B. asemble

- Paste the tape as shown in Fig.8

17

Page 18

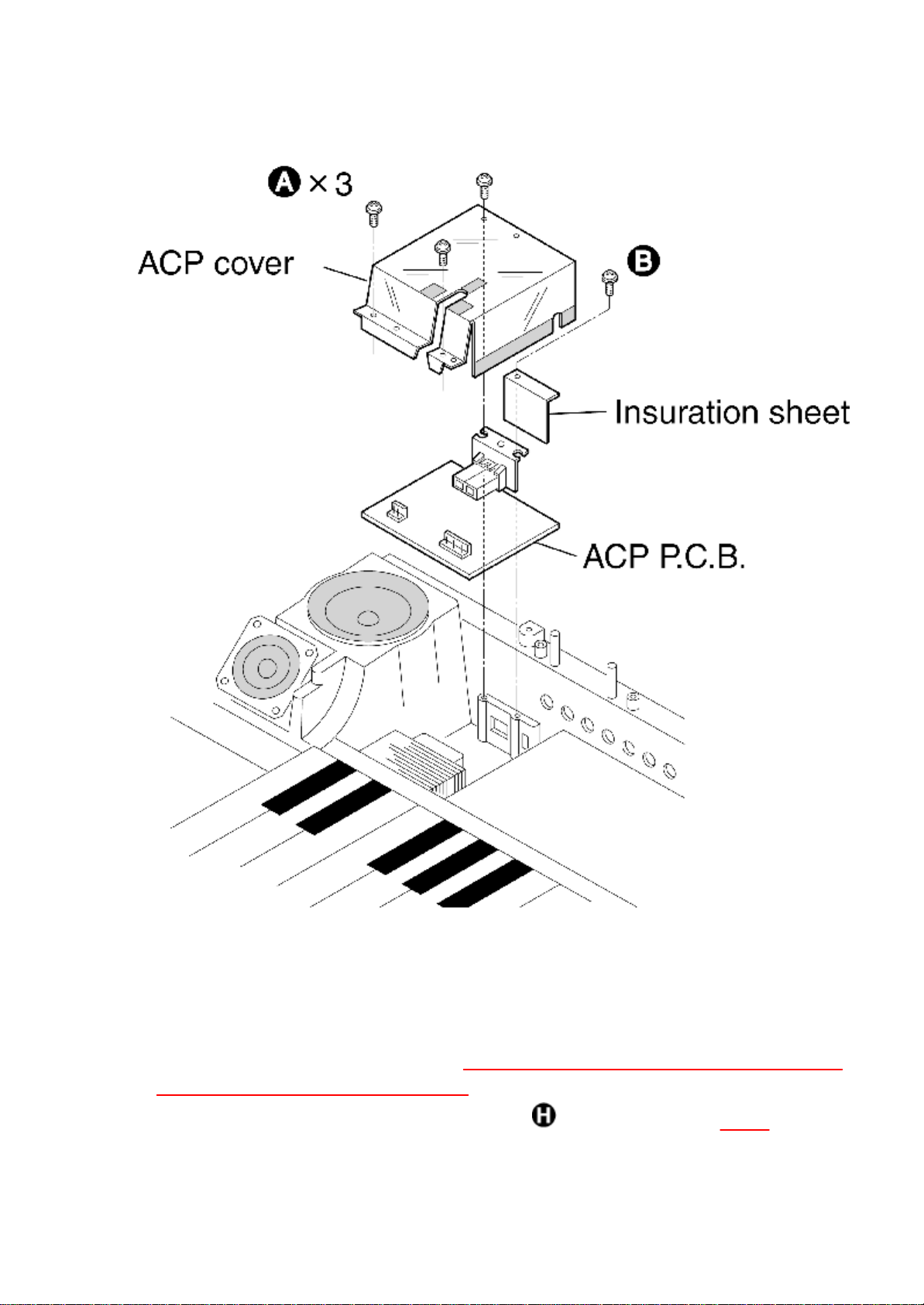

7.5. Removing the ACP printed circuit board

ACP P.C.B.

1. Remove the ACP cover mounting screws ( 3pcs.) as shown in Fig.9 .

2. Remove the ACP P.C.B.and insuration sheet mounting screw ( pc.) as shown in

Fig.9 .

Fig.9

18

Page 19

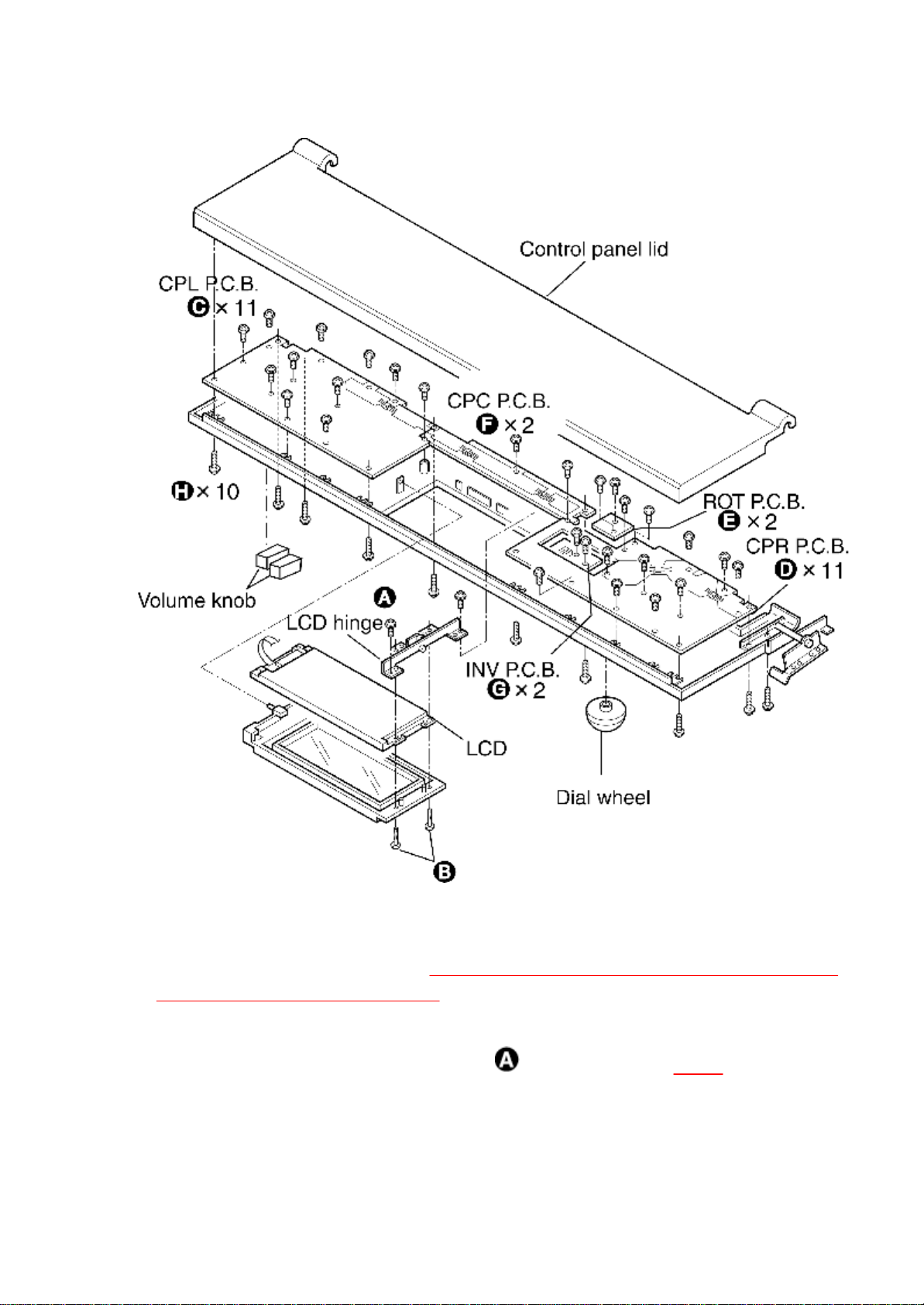

7.6. Removing the LCD, CPL, CPC, CPR, ROT and INV

printed circuit boards

- Remove the control panel (see step “Removing the control panel, power SW panel,

SD panel, net panel and keyboard unit ”).

- Remove the control panel lid holding screws ( 10pcs.)as shown in Fig.10 .

19

Page 20

LCD

1. Remove the LCD hinge holding screws ( 2pcs.) as shown in Fig.10 .

2. Remove the LCD holding screws ( 2pcs.) as shown in Fig.10 .

CPL P.C.B.

1. Pull off the SLIDE VOLUME knob as shown in Fig.10 .

2. Remove the CPL P.C.B. mounting screws ( 11 pcs.) as shown in Fig.10 .

CPR P.C.B.

- Remove the CPR P.C.B. mounting screws ( 11 pcs.) as shown in Fig.10 .

ROT P.C.B. , CPC P.C.B. and INV P.C.B.

1. Pull off the TEMPO/PROGRAM dial as shown in Fig.10 .

2. Remove the ROT P.C.B. mounting screws ( 2 pcs.) as shown in Fig.10 .

3. Remove the CPC P.C.B. mounting screws ( 2pcs.) as shown in Fig.10 .

4. Remove the INV P.C.B. mounting screws ( 2 pcs.) as shown in Fig.10 .

Fig.10

20

Page 21

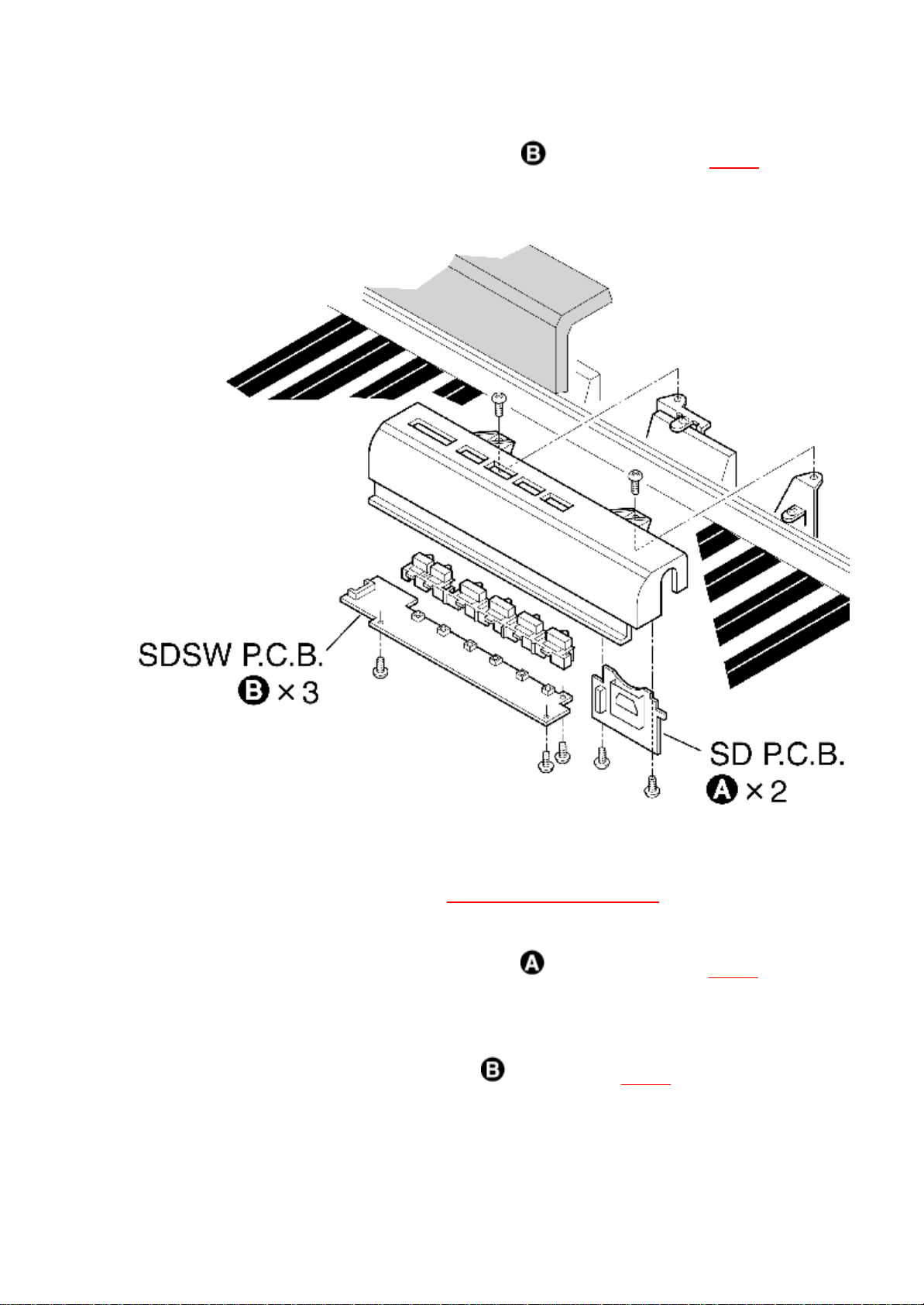

7.7. Removing the SD and SDSW printed circuit boards

- Remove the SD panel (see step “Removing the control panel, power SW panel, SD

panel, net panel and keyboard unit ”).

SD P.C.B.

- Remove the SD P.C.B. mounting screws ( 2pcs.) as shown in Fig.11 .

SDSW P.C.B.

21

Page 22

- Remove the SDSW P.C.B. mounting screws ( 3 pcs.) as shown in Fig.11 .

Fig.11

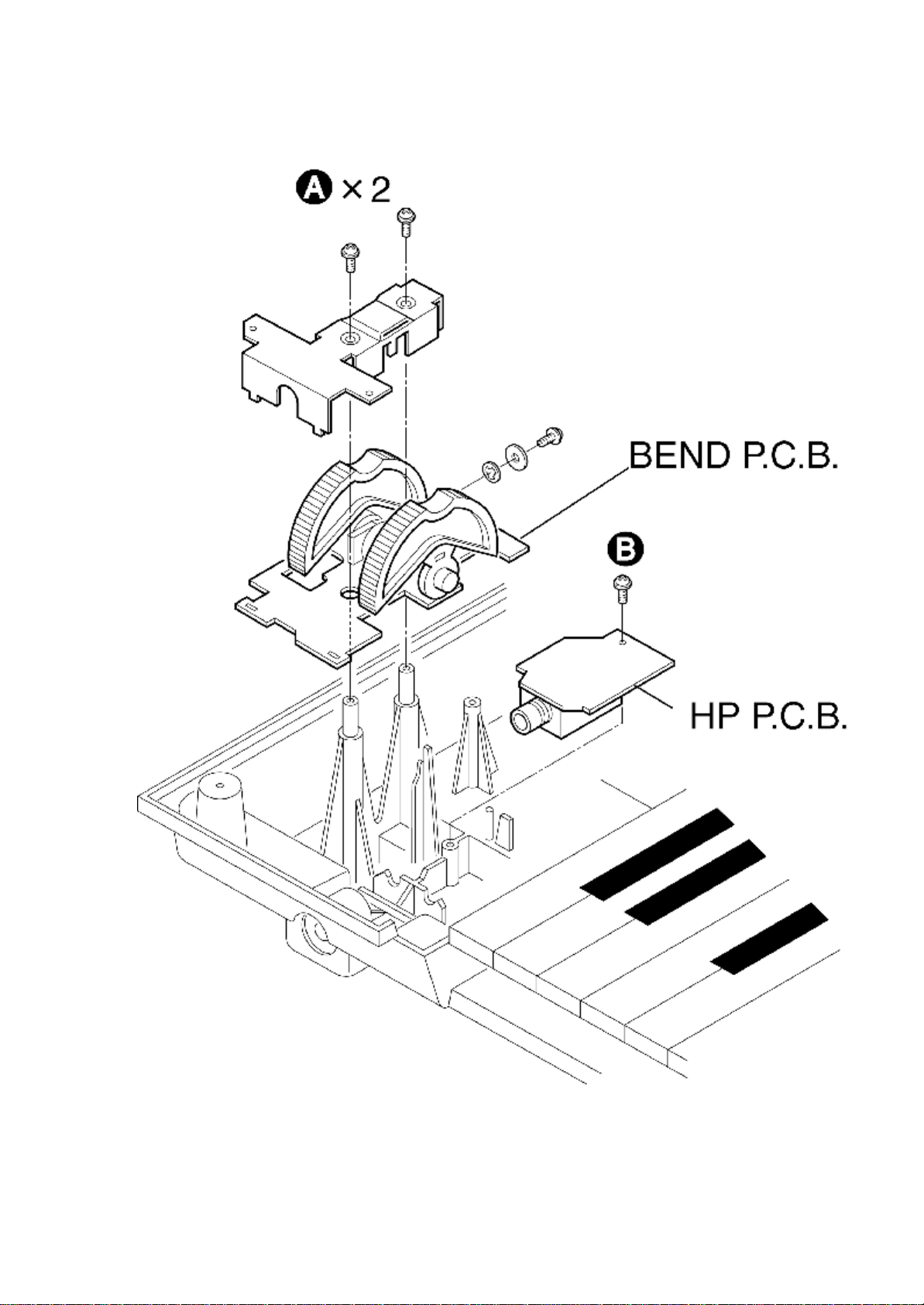

7.8. Removing the BEND and the HP P.C.B.

- Remove the top cabinet (see step “Removing the top cabinet ”).

BEND P.C.B.

- Remove the BEND P.C.B. mounting screws ( 2 pcs.) as shown in Fig.12 .

HP P.C.B.

- Remove the HP P.C.B. mounting screw( ) as shown in Fig.12 .

Fig.12

22

Page 23

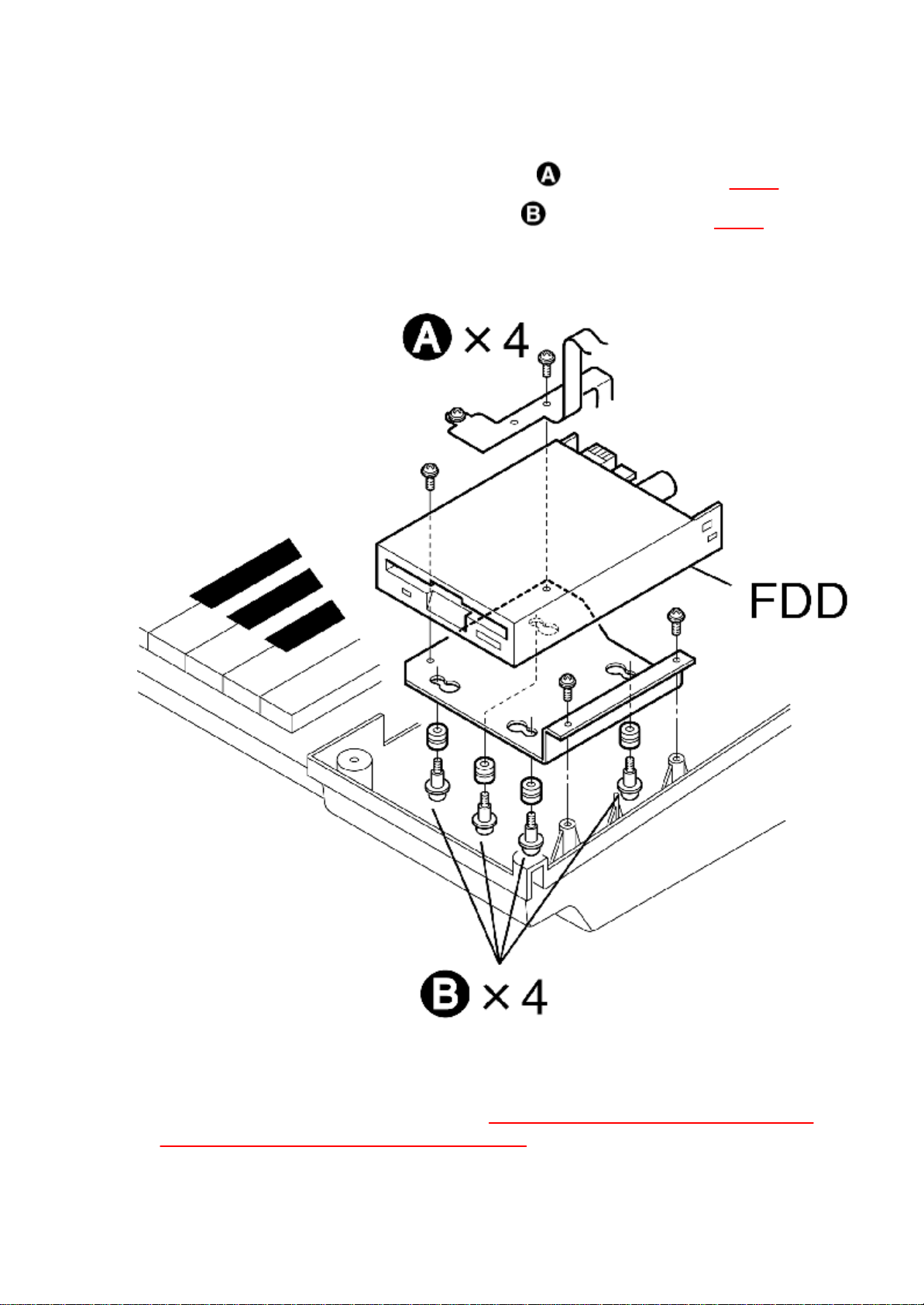

7.9. Removing the Disk Drive Unit

23

Page 24

1. Remove the Disk Drive unit mounting screws ( 4 pcs. ) as shown in Fig.13 .

2. Remove the Disk Drive unit holding screws ( 4 pcs. ) as shown in Fig.13 .

Fig.13

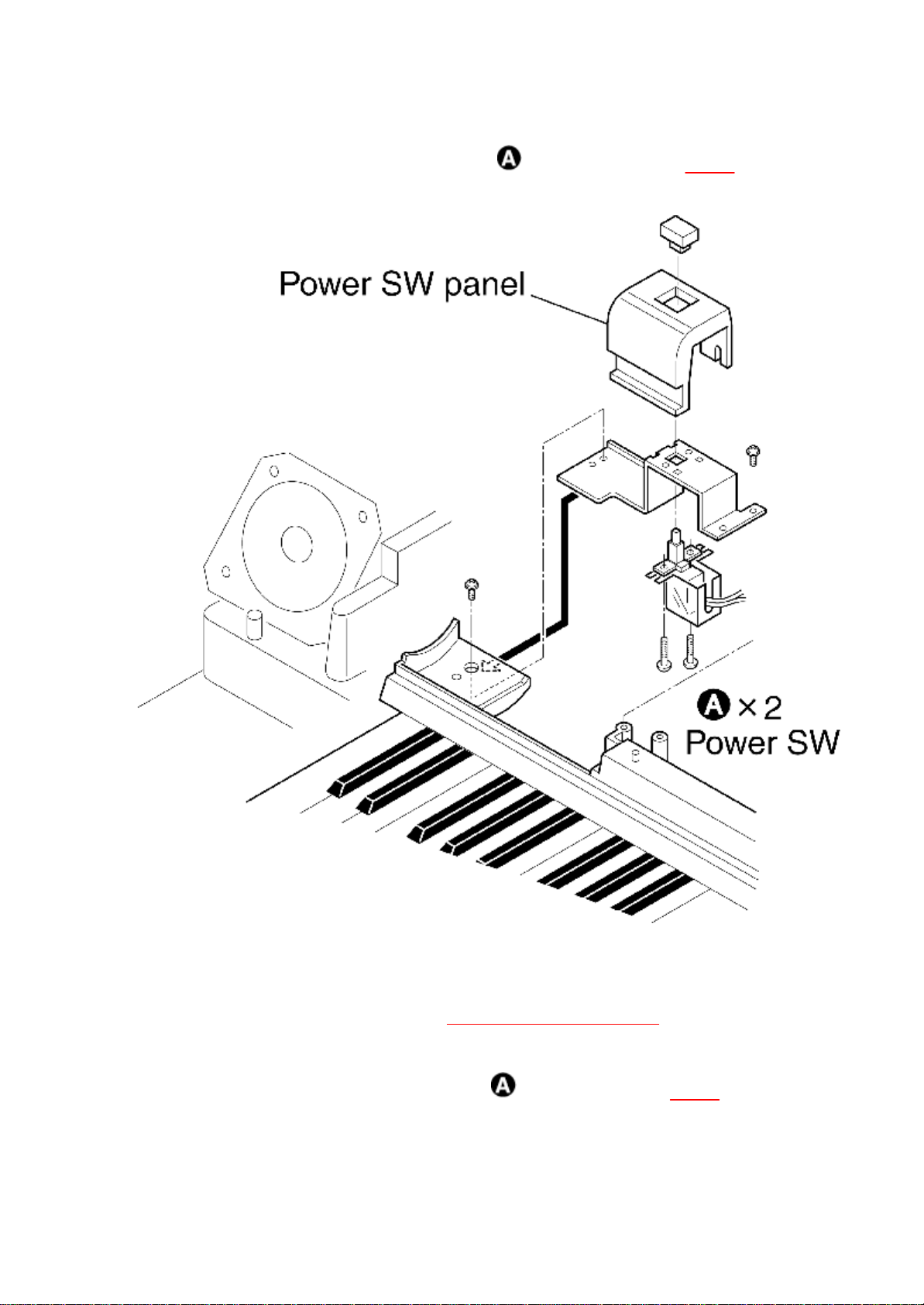

7.10. Removing the Power SW

1. Remove the Power SW panel (see step “Removing the control panel, power SW

panel, SD panel, net panel and keyboard unit ”).

24

Page 25

2. Remove the power SW mounting screws ( 2pcs. ) as shown in Fig.14 .

Fig.14

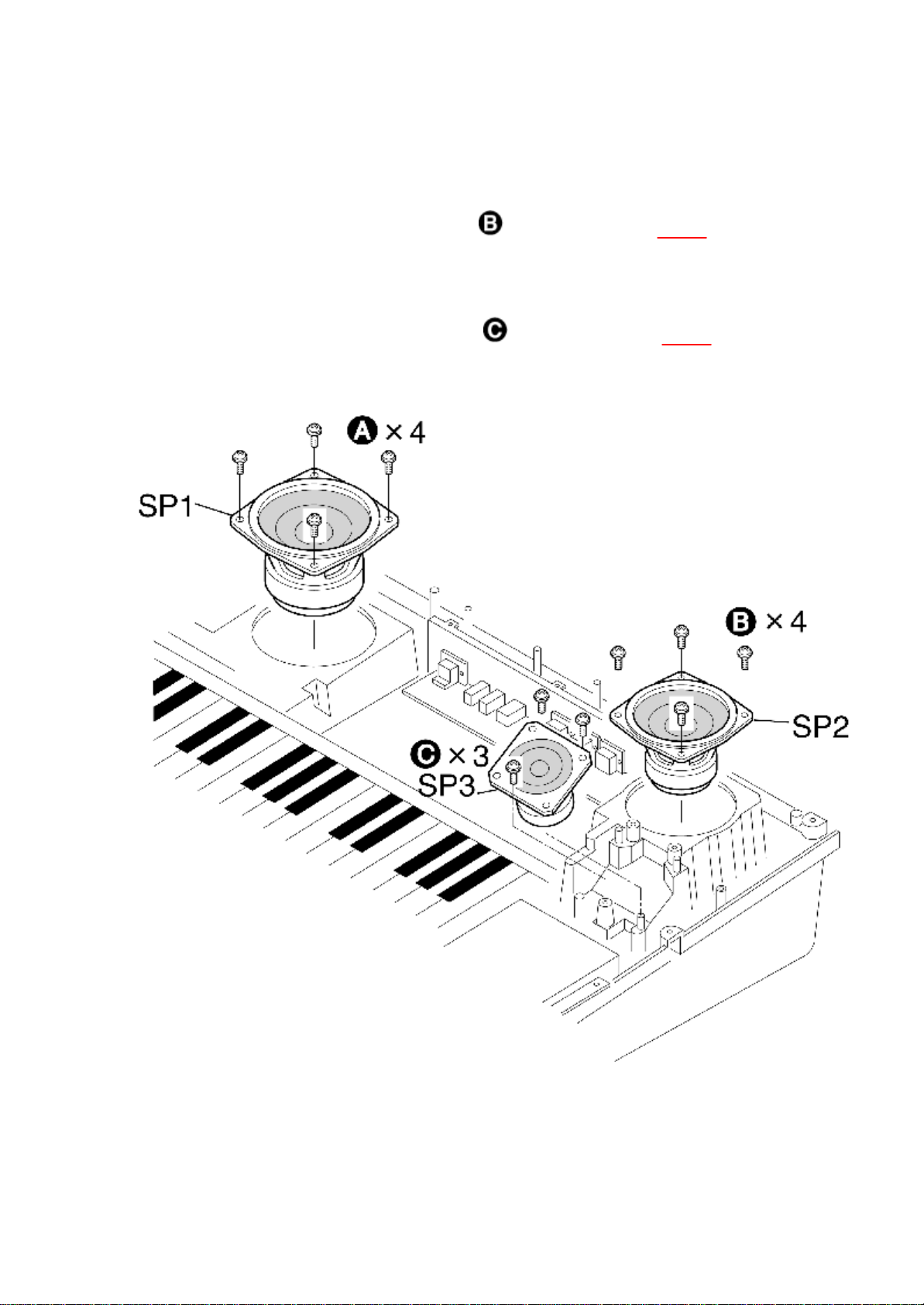

7.11. Removing the 14cm SP, 12cm SP and 6.5cm SP

- Remove the top cabinet (see step “Removing the top cabinet ”).

14 cm SP

- Remove the 14 cm SP@holding screws ( 4pcs.) as shown in Fig.15 .

25

Page 26

12 cm SP

- Remove the 12 cm SP holding screws ( 4pcs.) as shown in Fig.15 .

6.5 cm SP

- Remove the 6.5 cm SP holding screws ( 4pcs.) as shown in Fig.15 .

Fig.15

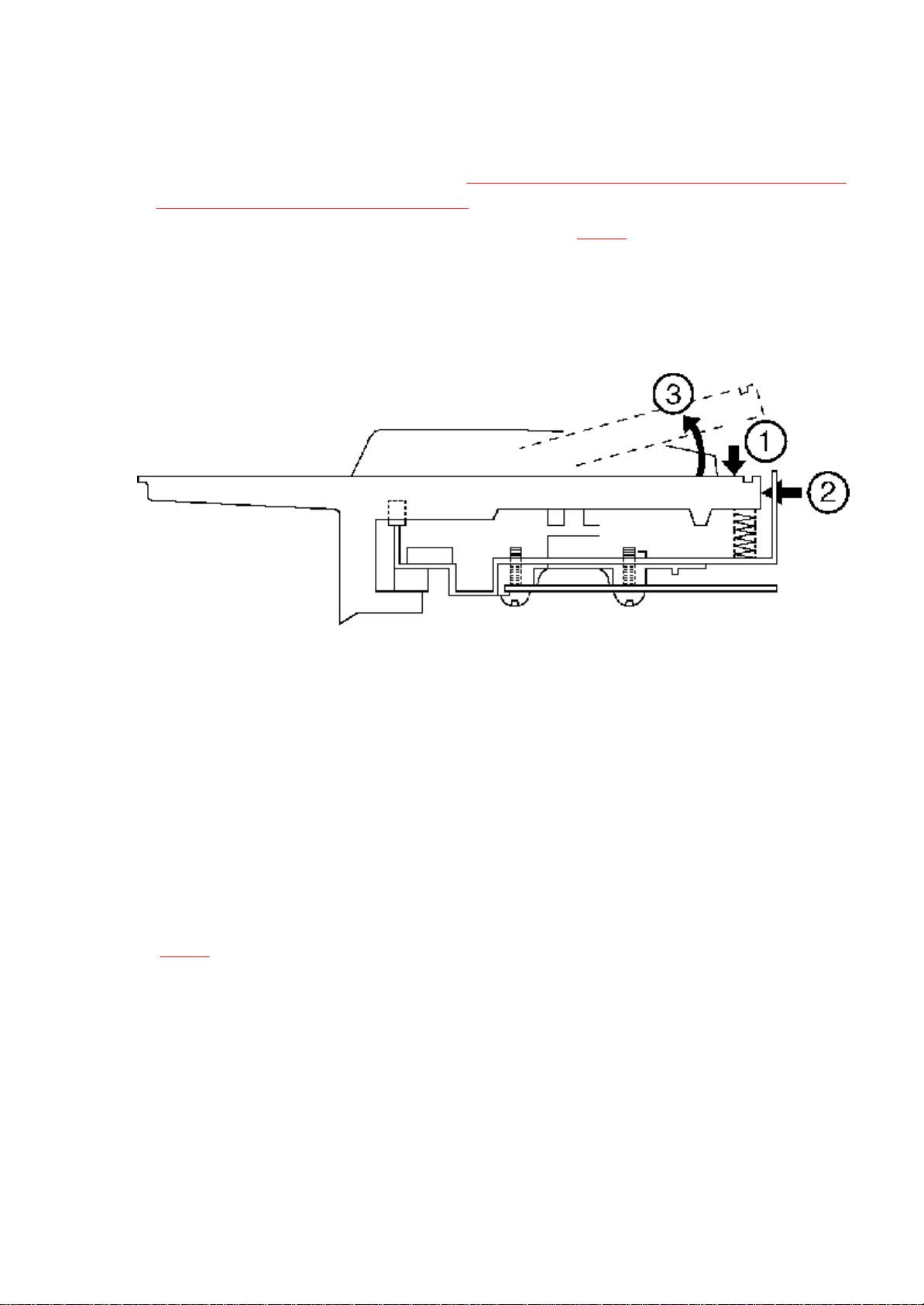

7.12. Removing the keys

26

Page 27

- Remove the keyboard unit (see step “Removing the control panel, power SW panel,

SD panel, net panel and keyboard unit ”).

1. Press downward on the rear of the key as shown in Fig.16 .

2. While pressing downward on the rear of the key, push the key forward and release it

from the chassis.

3. Lift the key and remove it from the chassis.

Fig.16

NOTE:

To remove a black key, the white key to either side of it should be removed first.

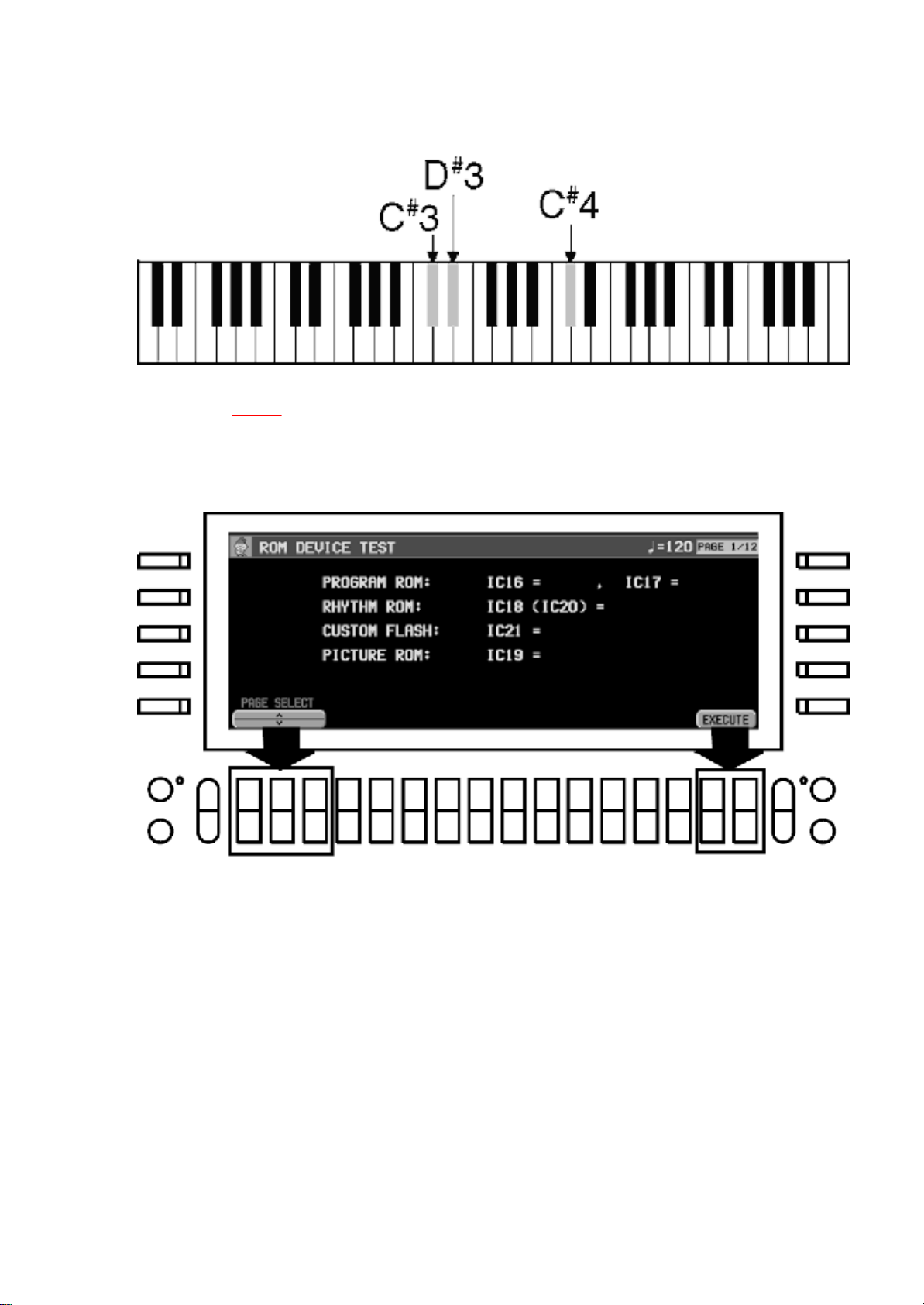

8. Service Diagnostic Function

The service diagnostic function makes it possible to determine whether the various

test modes pass or fail. The test modes are completely independent of one another.

Select a test mode as necessary, and run the test.

To set to the service diagnostic mode:

1. Press and hold the C#3, D#3, C#4 keys, and then turn on the power switch. (refer to

Fig.20 )

Fig.20

27

Page 28

2. After the service diagnostic screen is displayed on the LCD, release the three keys.

(refer to Fig.21 )

3. Use the corresponding buttons below the “page select” display to select the

respective test.

Fig.21

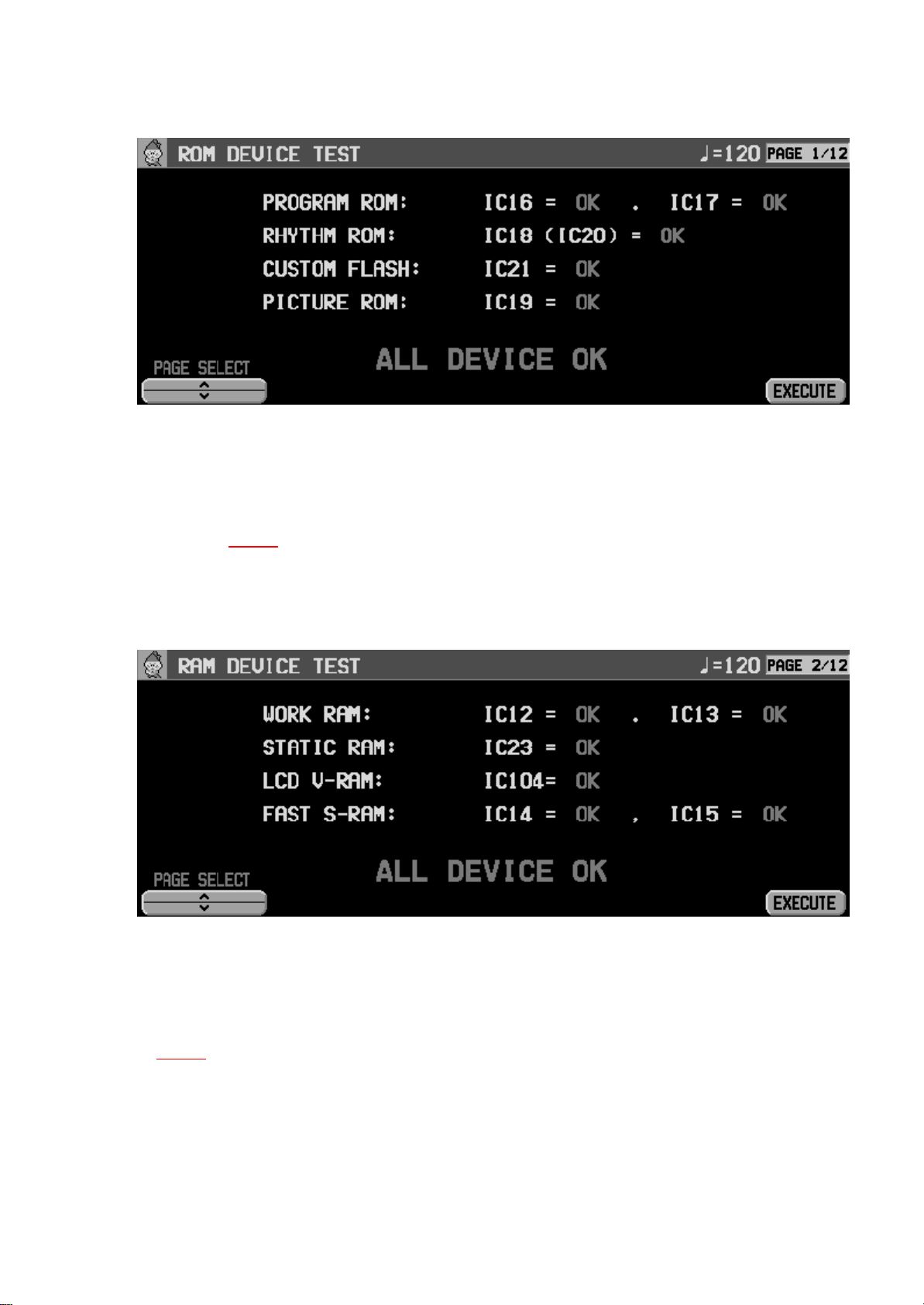

8.1. ROM device test

Fig.22

28

Page 29

- Press the EXECUTE button to begin the test.

- The test result (OK or NG) is displayed within twenty seconds. If the test result is

NG, not only the respective IC, but also a break or short circuit in the ADDRESS/

DATA BUS as well as in any of the strobe signal lines may be the causeof thefailure.

(refer to Fig.22 )

8.2. RAM device test

Fig.23

- Press the EXECUTE button to begin the test.

- The test result (OK or NG) is displayed within a few seconds. If the test result is NG,

not only the respective IC, but a break or short circuit in the ADDRESS/DATA BUS

as well as in any of the strobe signal lines may be the causeofthe failure. (refer to

Fig.23 )

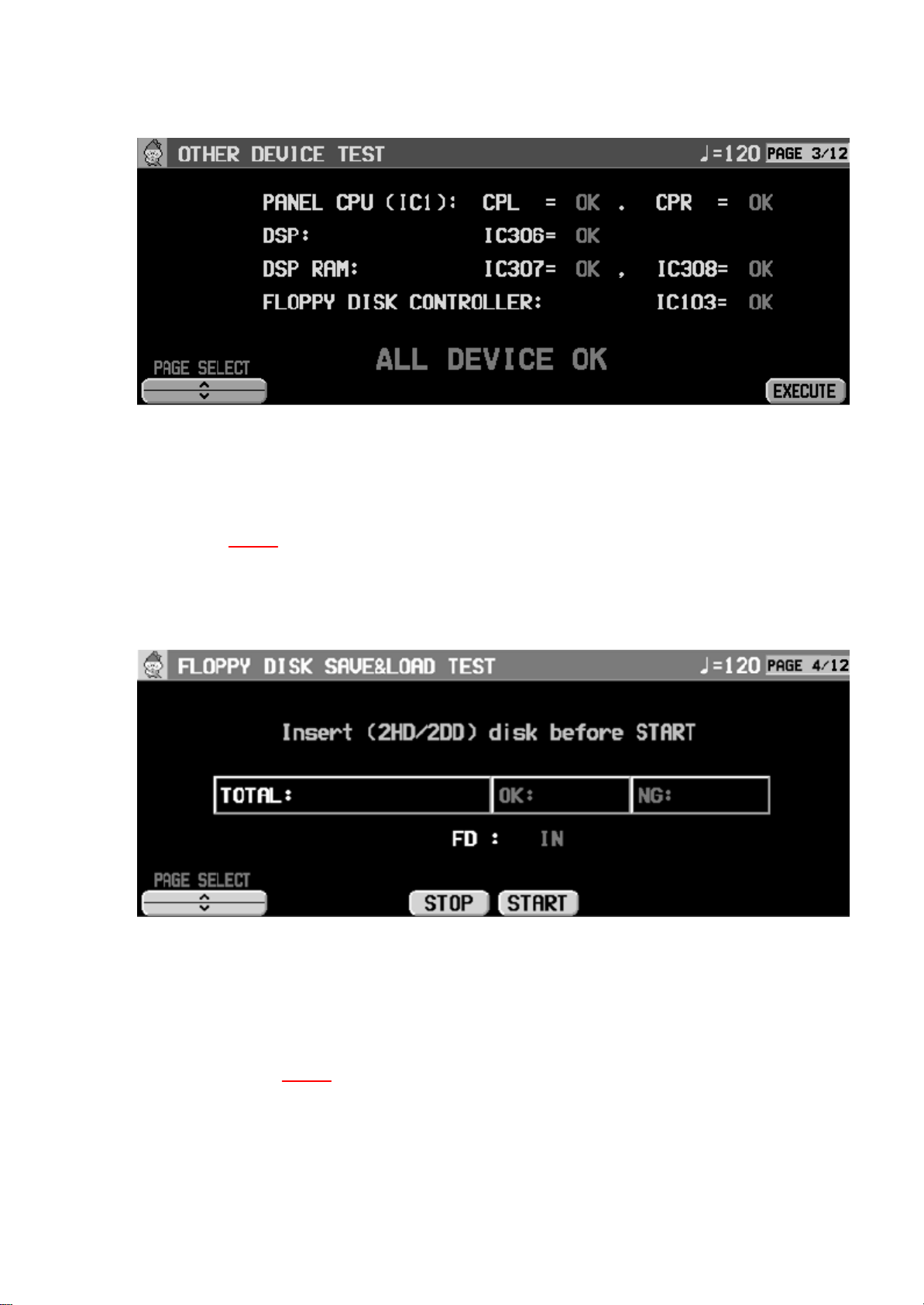

8.3. Other device test

Fig.24

29

Page 30

- Press the EXECUTE button to begin the test.

- The test result (OK or NG) is displayed with in a few seconds. If the test result is

NG, not only the respective IC, but also a break or short circuit in the ADDRESS/

DATA BUS as well as in any of the strobe signal lines may be thecause of thefailure.

(refer to Fig.24 )

8.4. Floppy Disk SAVE/LOAD test

Fig.25

- Insert a formatted floppy disk into the Disk Drive. Press the START button to begin

the test.

- The test is carried out repeatedly. Data is saved and loaded, and then the two data

sets are compared. The number of times that the test results in OK or NG are

counted and displayed on the LCD. To interrupt the test, press the STOP

button.(referto Fig.25 )

- Even when the Floppy Disk Drive is functioning properly, the test can result in NG.

If this happens frequently, clean the magnetic heads of the Floppy Disk Drive with a

30

Page 31

cleaning disk. Then, change the disk used in testing with another disk

andreperformthe test. If the trouble is not solved, it is likely that the Disk Drive unit

or some other part of the hardware is broken.

8.5. Panel SW & LED test

Fig.26

- Press all the buttons on the Control Panel and confirm that the corresponding LED

lights.

- If an LED fails to light, the cause may be a defective switch or a break in the

surrounding circuit, etc.

- After all the buttons have been pressed, all the PANEL MEMORY LEDs light. If all

switches are OK, “ALL DEVICE OK” is shown on the LCD. (If a switch is defective,

nothing is shown.) (refer to Fig.26 )

- To light all the LEDs, press and hold the DEMO button. If an LED fails to light, the

LED may be defective or there may be a break in the surrounding circuit.

8.6. LCD module test (LCD adjustment and confirmation)

Fig.27

31

Page 32

- Press the RGBWB, CROSSTALK, SAMPLE, CONTRAST or VIDEO OUT button to

begin the respective test. (refer to Fig.27 )

RGBWB:

All the dots light in red, green, blue, white, and finally black. The display can be held

by pressing the DISPLAY HOLD button.

CROSSTALK:

An H pattern is shown. LCD crosstalk can be evaluated. To exit this test, press the

EXIT button.

SAMPLE:

Several display patterns shown during normal use are shown. The display can be

held by pressing the DISPLAY HOLD button.

CONTRAST:

The test pattern is shown. Adjust the contrast by the CONTRAST control on the

right of the LCD. To exit this test, press the EXIT button.

VIDEO OUT :

Check each display mode of PAL and NTSC. To exit this test, press the EXIT button.

- If the correct display is not shown during these tests, the LCD or LCD drive circuit

may be defective.

8.7. In & Out interface test

Fig.28

32

Page 33

- The operation status of each input action part can be confirmed. If the part is

operating properly, “OK” is shown, excluding the Expression Pedal. (refer to Fig.28

)

- When a keyboard key is pressed, the corresponding pitch and velocity aftertouch is

displayed (only as long as the key is depressed).

- The respective statuses for other input action parts are displayed. (Analog parts are

shown as numerical values from 0 to 255, and switches are shown as ON or OFF.)

- If the display fails to change when the part is operated, or if the change is abnormal,

it may indicate a defective part.

8.8. MIDI IN/OUT test

Fig.29

- First, set the COMPUTER terminal switch to MIDI.

- Use a MIDI cable to directly connect the MIDI IN and MIDI OUT terminals.

- When a keyboard key is pressed, the transmitted and received data are compared

33

Page 34

and the MIDI terminal operation is indicated as being OK or NG. (refer to Fig.29 )

- If NG is shown, check both the IN and OUT terminals, as well as the circuit.

8.9. WAVE ROM test

Fig.30

- Press the EXECUTE button to start the test.

- The test result (OK or NG) is displayed within thirty seconds. If the test result is NG,

not only the respective IC, but also a break or short circuit in the ADDRESS/DATA

BUS as well as in any of the strobe signal lines may be the causeofthe failure. (refer

to Fig.30 )

8.10. SOUND SYSTEM test

Fig.31

- Use the button in the SOUND GROUP to select an item from 1 to 6 (refer to Fig.31

and Fig.32 ). Press a keyboard key.

34

Page 35

Fig.32

1. Generate a full amplitude sine wave in the pitch of each key. (No touch, fixed stereo

center).

If no sound is generated or if the sound is distorted, the sound generator ROM

corresponding to the key position is defective.

2. For confirming the output pathway from the sound generator. (Fixed scale, no touch)

The Lch and Rch sound outputs are confirmed separately.

3. Generate a full amplitude sine wave in the pitch of each key +2 octaves. (No touch,

fixed stereo center)

By generating a sound frequency outside the normal keyboard zone, you can

confirm whether or not there is an abnormality in the sound output frequency zone.

4. Generates a full amplitude sine wave in the pitch of each key -2 octaves. (No touch,

fixed stereo center)

By generating a sound frequency outside the normal keyboard zone, you can

confirm whether or not there is an abnormality in the sound output frequency zone.

5. Generate a sine wave in the pitch of each key with touch.

You can confirm if the volume changes depending on the touch.

6. Generate a full amplitude sine wave in the pitch of each key at a -16 dB volume. (No

touch, fixed stereo center)

You can confirm the same sound output as in 1, at a lower volume.

8.11. SD test

Fig.33

35

Page 36

Load/save test

- Insert the SD card. Press the START button to begin the test.

- The test is carried out repeatedly. Data is saved and loaded, and then the two data

sets are compared. The number of times that the test results in OK or NG are

counted and displayed on the LCD. To interrupt the test, press the STOP

button.(referto Fig.25 )

Audio test

- Insert the SD card. Press the START button to begin the test.

8.12. WAVE EXPANSION BOARD test

Fig.34

- Insert the SY-EW01,EW02,,EW03 or EW04 board.

36

Page 37

- Press the EXECUTE button to start the test.

- The test result (OK or NG) is displayed . If the test result is NG, not only the

respective IC, but also a break or short circuit in the ADDRESS/DATA BUS as well

as in any of the strobe signal lines may be the causeof the failure. (referto Fig.30 )

9. Precautions before Servicing the Main Circuit

This model employs a FLASH ROM (EEPROM) for the PROGRAM ROMs and the

CUSTOM DATA ROM. If changing any of these ICs, service the MAIN CIRCUIT as

explained here following.

9.1. About the FLASH ROM

The FLASH ROM can be electrically erased and rewritten. This model is designed so

that the repair technician can easily write and change programs and data in the FLASH

ROM, by using a floppy disk. (refer to Fig.33 )

Fig.33

37

Page 38

9.2. Notes on replacing FLASH ROMs

The replacement parts include a FLASH ROM with a available memory and the

PROGRAM DISKs which contains the program to be written into the PROGRAM

ROMs. After replacing the PROGRAM ROM, always write the program into it from the

38

Page 39

PROGRAM DISKs includedinthe replacement parts. For details on programming, see

“After replacing the PROGRAM ROM (IC16/IC17) ” .

The CUSTOM DATA ROM stores RHYTHM & ACCOMP data for the RHYTHM GROUP/

CUSTOM function. The initial RHYTHM & ACCOMP data is factory-set in the CUSTOM

DATA ROM at the time of shipping. The CUSTOM DATA ROM can also store

COMPOSERdatathat the user creates. However, user-data is lost when the CUSTOM

DATA ROM is replaced. After replacing the CUSTOM DATA ROM, default the data in it

with the INITIAL DATA DISK attached to this product. For details on defaulting, see

“After replacing the CUSTOM DATA ROM (IC18) ”.

9.3. About the replacement parts

The same FLASH ROM with a available memory can be used for the PROGRAM ROMs

(IC16/IC17). Moreover, the included PROGRAM DISKs contains all programs.

Therefore, the replacement parts can be used for IC16 and IC17.

9.4. How to write program/data into FLASH ROMs

9.4.1. After replacing the PROGRAM ROM (IC16/IC17)

1. Set the PROGRAM DISK 1 included in the replacement parts into the Floppy Disk

Drive.

2. Hold down the PANEL MEMORY buttons 1 , 2 , 3 and 4. And turn on the power

switch. (refer to Fig.34 )

Fig.34

39

Page 40

3. Check “Flash Memory Update” is displayed on the LCD, and release the PANEL

MEMORY buttons.

The program will be written into the FLASH ROM automatically. Replace the floppy

disk when instructed.

4. When the operation is complete, “Completed!!” will be displayed on the LCD.

5. Turn the power switch off and then turn it on again. Check the instrument is

functioning properly.

9.4.2. After replacing the CUSTOM DATA ROM (IC18)

1. With the normal display displayed on the LCD, set the INITIAL DATA DISK included

with the model into the Floppy Disk Drive.

The normal display automatically changes to the DISK MENU display.

2. Select “LOAD” to change to the file select display.

3. Move the highlighting cursor to “CTMINI” in “No. 01” and select “LOAD”.

“PLEASE WAIT...” will appear on the LCD and the model will start defaulting data in

the CUSTOM DATA ROM.

40

Page 41

4. When the operation is complete, “Completed!!” will be displayed on the LCD.

METER

READING

5. Turn the power switch off and then back on again. Check the instrument is

functioning properly.

10. Measurements and Adjustments

ADJUSTMENT

TOUCH SENSOR

MEASURING

CONDITIONS

any position Oscilloscope MKB3 P.C.B. VR1 CN11-3pin 5.0V

1. Press one of the any keys hardly and check the CN11-3 pin voltage.

The voltage will increase and become steady.

2. Adjust the voltage to 5.0V with VR1 at that time.

EQUIPMENT

ADJUSTMENT

P.C.B.

ADJ. POINT CONNECT

METER TO

11. Precautions before Servicing

11.1. Precautions for measuring of the output waveforms

1. The waveform was measured with a “National Digital Storage Oscilloscope VP5730A”. Therefore the waveforms of musical tone signals shown may differ

somewhat due to the difference in the timing of triggering.

2. Since the 1/10 test probe is used, the indicated voltage value on the bottom part of

each waveform illustration is 1/10 of the actual value (e.g. 0.2 V/cm should be 2.0 V/

cm).

3. To measure the waveforms, first set this unit to the service diagnostic mode (refer

to “WAVE ROM test ”). The WAVE ROM output will then be output as a sine wave to

facilitate the servicingcheck.

11.2. Important safety notice

- Components identified by a mark have special characteristics impotant for safety.

- When replacing any of these components, use only manufacture’s specified parts.

11.3. Symbolic Marks

The symbolic marks for resistors and capacitors which used in this circuits are

classified as following Table-1 and Table-2 .

11.3.1. RESISTORS

41

Page 42

- Resistors without symbolic mark are FIXED CARBON FILM RESISTORS (ERD-type).

- All resistors are 1/4 WATT, ±5 % TOLERANCE unless otherwise designated in

schematic diagrams.

Table-1

SYMBOL

Fixed Carbon Film Resistors

“FLAME-PROOF” (ERD—F—type)

Fixed Wire Wound Resistors

“FLAME-PROOF” (ERF—type)

Fixed Metal Oxide Film Resistors

“FLAME-PROOF” (ERG—type)

Fixed Metal Film Resistors

“FLAME-PROOF” (ERX—type)

Fixed Metal Film Resistors (Precision and

High Stability)

(ERO—type)

Fuse Type Fixed Metal Oxide Film

Resistors

“FLAME-PROOF” (ERQ—type)

Fuse Type Fixed Carbon Film Resistors

“FLAME-PROOF” (ERD2FC—type)

SPECIFICATION

11.3.2. CAPACITORS

- Capacitors without symbolic mark are POLYESTER CAPACITORS. (ECQM-type,

ECQG-type, ±10% Tolerance)

- Polarized capacitors without symbolic mark are Aluminum Electrolytic Capapcitors.

(ECEA-type, ±20% Tolerance)

Table-2

42

Page 43

SYMBOL

SPECIFICATION TYPE

Non-Polarized Electrolytic

Capacitors

ECEA_KN_type

Non-Polarized Electrolytic (for

Network system)

Tantalum Solid Electrolytic

Capacitors

Metalized Plastic Film

Capacitors (TF Series)

Temperature Compensating

Ceramic Capacitors

High-Dielecytric Constant

Ceramic Capacitors

Axial Lead Ceramic

Capacitors

Metalized Polyester Film

Capacitors for Across the Line

Aluminum Electrolytic

Capacitors for Smoothing

Circuit

Multilayer Ceramic Chip

Capacitors

ECEA_Y_type

ECS_type

ECQV_type

ECC_type

ECK_type

ECR_type

ECB_type

ECQ_EW_type

ECES_type

ECUV_type

12. MEASURING CONDITION

43

Page 44

44

Page 45

13. SCHEMATIC DIAGRAM

45

Page 46

14. Printed Circuit Board

15. Block Diagram

16. Wiring Connection Diagram

17. Replacement Parts List

Notes:

*Important safety notice:

Components identified by mark have special characteristics important for safety.

Funrthermore, special parts which have purposes of fire-retardant (resistors), highquality sound (capacitors),low -noise(resistors), etc. are used.

When replacing any of components, be sure to use only manufacture’s specified parts

shown in the parts list.

*Warning: This product uses a laser diode. Refer to caution statements.

*ACHTUNG:Die lasereinheit nicht zerlegen.Die lasereinheit darf nur gegen einc vom

hersteller spezifizierte einheit ausgetauscht werden.

*Capacity values are in microfarads (uF) unless specified otherwise, P=Pico-farads

(pF) F=Farads (F)

46

Page 47

*Resistance values are in ohms, unless specified otherwise, 1K=1,000 (OHM), 1M=

1,000K (OHM)

*The marking <RTL> indicates that the Retention Time is limited for this item. After the

discontinuation of this assembly in production, it will no longer be available.

*Since SW consists of buttons and P.C.B.’s, we do not supply it as an individual part

(refer to “Manual Keyboard Parts and Control Panel Parts Location ”.).

*[SPC] in Remarks columns parts that are supplied by SPC..

*“<IA>”-“<IG>”, marks in Remarks indicate languages of instruction manuals. [<IA> :

English, <IB> : French, <IC> : Germany, <ID> :Spanish, <IE> : Danish, <IF> :

Netherlands, <IG> : Italian, ]

Ref. No. Part No. Part Name & Description

1 QAQG102AA TOP CASE UNIT 1 P

1 QAQG102AB TOP CASE UNIT 1 EXCEP P

2 QMGG071AA TOP CASE CUSHION 7

3 QYKG326BA NET PANEL ASSY 1

4 XTW3+10Q SCREW 79

5 QYAG3009AB ASSEMBLED MUSIC RACK 1

6 RFKJXKN7000E BOTTOM CASE ASS'Y 1

6 RFKJXKN7000P BOTTOM CASE ASS'Y 1

7 SHGG3130A FOOT 4

8 QLZG022A CORE 3

9 QLZG017A CORE B 7

10 XTW3+14Q SCREW 4

11 K2AA2G000003 AC IN COVER 1 EXCEPT P PC

11 K2AB2G000003 AC IN COVER 1 P PC

12 XYN4+F20 SCREW 4 P PC

12 XYN4+F25 SCREW 4 EXCEPT P PC

13 XTW3+16JFZ SCREW 21

14 QMAG0292AA MAIN LID 1

15 QMRG2061AAK INSULATION SHEET 1 EXCEPT GM GU GT

15 QMRG2063AAK INSULATION SHEET 1 GM GU GT

16 QMRG2120AA ACP COVER 1

17 QQLG241AA CAUTION LABEL 1 P PC

17 QQLG251AA CAUTION LABEL 1 EB

18 QQLG253AA FAJ JACK LABEL 1

19 QQLG254AA MAIN JACK LABEL 1

20 XTV3+10G-M SCREW 14

21 XYE3+FJ10 SCREW 30

22 QLZG025A CORE 1

23 QLZG026A CORE 1

24 QMRG5300AA BBD SHEET 7

25 QSCG138A SHIELD SHEET 1

26 XTW3+10TFZ SCREW 22

27 XTV3+12G SCREW 2

28 SBCG110B POWER BUTTON 1

29 QGPG0166AA P.SW PANEL 1

30 QMRG2123AA P.SW COVER 1

31 QGPG0163AA CONTROL PANEL 1 P

31 QGPG0163AB CONTROL PANEL 1 EXCEPT P

32 QGUG1440AD1K BUTTON 1

Pcs

Remarks

47

Page 48

Ref. No. Part No. Part Name & Description

33 QGUG1536BA BUTTON A -1 2

34 QGUG1536CA BUTTON A -2 1

35 QGUG1536EA BUTTON A -4 1

36 QGUG1536FA BUTTON A -5 1

37 QGUG1537CA BUTTON B 1

38 QGUG1538BA BUTTON C-1 2

39 QGUG1538CA BUTTON C-2 1

40 QGUG1539AA BUTTON D 8

41 QGUG1540BA BUTTON E 3

42 QGUG1541AA BUTTON F 2

43 QGUG1542AA BUTTON G 2

44 QGUG1543BA BUTTON H 2

45 QGUG1544AA BUTTON I 2

46 QGUG1547BA BUTTON L 1

47 QGUG1548AA BUTTON M 1

48 QGUG3002BC DIAL WHEEL 1

49 QGUG1536DA BUTTON A -3 1

50 QGUG1537DA BUTTON B-1 1

51 QGUG1538AA BUTTON C 2

52 QGUG1538CB BUTTON C-3 1

53 QMRG7146AA BUTTON ORNAMENT O 1

54 QGUG1549BA BUTTON N 1

55 QMRG7147AA BUTTON ORNAMENT Q 1

56 QGUG1550AA BUTTON P 1

57 QSLG025AA LCD 1 L5DCDPH00001

58 QMFG1294AA HINGE FELT 2

59 QKWG046AA LCD WINDOW 1

60 QGUG1551AA BUTTON R 1

61 QGUG1552BA BUTTON S 1

62 QHDG052AB SCREW 4

63 QMGG072AA CUSHION 8

64 QMGG072AB CUSHION 2

65 QMRG2121AA WIRING COVER A 1

66 QMRG2122AA WIRING COVER B 1

67 QMRG2127BA DIFFUSSION SHEET 1

68 QMRG5297AA URETHANE FOAM 1

69 QMRG7145AA LCD COVER 1

70 QMRG7148AA BUTTON LIGHTING CHIP 1

71 QMRG7149AA LIGHTING ON/OFF LEVER 1

72 XTB23+10JFZ SCREW 2

73 XTV3+10G-M SCREW 2

74 XTV3+14G SCREW 10

75 QMEG013AA EARTH SPRING A 1

76 QMEG014AA EARTH SPRING B 1

77 QMRG2128AA PROTECT SHEET 1

78 QMRG5298AA BUTTON CUSHION A 1

79 QMRG5299AA BUTTON CUSHION B 2

80 SBNG7070C SLIDE VOL KNOB 2

81 QGKG0183AA FRONT ORNAMENT 1 P

81 QGKG0183AB FRONT ORNAMENT 1 EXCEPT P

82 XTV3+6J MIDI JACK SCREW 5

83 XYE3+FJ10 SCREW 1

84 SBNG4050B BENDER WHEEL 2

85 SHGG5010A TUBE 2

Pcs

Remarks

48

Page 49

Ref. No. Part No. Part Name & Description

86 QMFG4076AAK CUSHION 2

87 QHQG009AA NUT 2

88 SUSG570A SPRING 1

89 XYE3+FJ10 SCREW 3

90 XNS12FZ NUT 9

91 QMEG011AA THERMISTOR SPRING 1

92 QWZG010AA THERMISTOR TUBE 1 FAJ

93 XTV3+10C SCREW 1

94 XYE3+FJ10 SCREW 3

95 XNS12FZ NUT 3

96 XTW3+10TFZ MIDI JACK SCREW 6

97 XTB3+10GFZ VIDEO OUT(1) 1

98 QMFG4107AA CUSHION 1

99 QMGG029AA FLOATING RUBBER 4

100 QAUG033AA FDD UNIT 1

101 QMFG4207AA CUSHION 1

102 QHDG043AA SCREW 4

103 XYN3+F8 SCREW 1

104 XTT4+20CFZ SCREW 32

105 RFKNSXKN7000 SP BOX LID ASS'Y 1

106 QKUG1052AAZ SP BOX LID (B) 2

107 QMRG5277AA SP LID CUSSION (A) 8

108 QMRG5278AA SP LID CUSSION (B) 4

109 QMRG5279AA SP LID CUSSION (C) 2

110 QMRG5280AA SP LID CUSSION (D) 1

111 QMRG5284AA SP LID CUSSION (H) 2

112 QMRG5285AA SP LID CUSSION (I) 2

113 QMRG7141AA BASS PORT COVER 1

114 QGPG0164AA SD PANEL 1

115 QGKG0184BA SD CARD LID 1

116 QGUG1553AA BUTTON V 1

117 QMRG5276BA SD LID CUSSION 2

118 QMRG7144AA EDGE PANEL 1

119 QMBG033AA SD LID SPRING 1

120 QHDG064AA SCREW 5

121 QHDG065AA SCREW 1

122 QWZG011AA LED TUBE 1

123 QGPG0167BA CP LID 1 P

123 QGPG0167BB CP LID 1 EXCEPT P

130 QMRG5297AA URETANE FORM 1

131 QMRG5301AA ORNAMENT CAP 1

132 QMRG5302AA ACOUSTIC MATERIAL 1

133 QMRG5303AA CORE HOLDING TAPE 1

134 QMRG5304AA CORE HOLDING SHEET 1

135 QMRG5305AA URETAN SHEET 1

136 QMRG5306AA PEF SHEET 1

137 QMRG5307AA URETANE FORM 4 GU GM GT

138 QQLG167AA VOLT ADJ LABEL 1

139 QKCG003 CP HING (R) 1

140 QKCG004 CP HING (L) 1

141 QKCG005 LCD HING 1

142 QMRG5243AB URETANE FORM 4

143 QMRG5247AB URETANE FORM 1

144 QEXGRA01010U CONNECTION WITH WIRE 1

Pcs

Remarks

49

Page 50

Ref. No. Part No. Part Name & Description

201 XYE3+FJ10 SCREW 2

202 QMWG6009BAK 13KEYS RUBBER SWITCH 1

203 QMWG6010BA 12KEYS RUBBER SWITCH 4

204 QMFG4176AAK CUSHION 1

205 QMRG2074AAK HOLDING SHEET 1

206 QMWG5003CA AFTER TOUCH SENSOR 1

207 XTW3+10T SCREW 37

208 SHGG9052A KEY GUIDE RUBBER 61

209 QMFG1120CA FELT 1

210 STBG1101B WHITE KEY(C F) 10

211 STBG1111B WHITE KEY(D) 5

212 STBG1121B WHITE KEY(E B) 10

213 STBG1131B WHITE KEY(G) 5

214 STBG1141B WHITE KEY(A) 5

215 STBG1151B WHITE KEY(CC) 1

216 STBG2071AK BLACK KEY 25

A1 QQFGKN7000AA FAN BAG 1 P

A1 QQFGKN7000BA FAN BAG 1 PC

A1 QQFGKN7000CA FAN BAG 1 EX

A1 QQFGKN7000DA FAN BAG 1 EQ

A1 QQFGKN7000EA FAN BAG 1 EB

A1 QQFGKN7000FA FAN BAG 1 EG

A1 QQFGKN7000GA FAN BAG 1 EF

A1 QQFGKN7000HA FAN BAG 1 EH

A1 QQFGKN7000JA FAN BAG 1 EV

A1 QQFGKN7000KA FAN BAG 1 GU GM GH GT

A1 QQFGKN7000LA FAN BAG 1 GN

A1-1 QQTG0671A INSTRUCTION MANUAL 1 P <IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 PC<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 EX<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 GN<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 GM<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 GH<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 GU<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 GT<IA>

A1-1 QQTG0671A INSTRUCTION MANUAL 1 EB<IA>

A1-1 QQTG0672A INSTRUCTION MANUAL 1 PC<IB>

A1-1 QQTG0672A INSTRUCTION MANUAL 1 EG<IB>

A1-1 QQTG0672A INSTRUCTION MANUAL 1 EV<IB>

A1-1 QQTG0672A INSTRUCTION MANUAL 1 EF<IB>

A1-1 QQTG0673A INSTRUCTION MANUAL 1 EQ<IC>

A1-1 QQTG0673A INSTRUCTION MANUAL 1 EG<IC>

A1-1 QQTG0673A INSTRUCTION MANUAL 1 EV<IC>

A1-1 QQTG0674A INSTRUCTION MANUAL 1 EX<ID>

A1-1 QQTG0675A INSTRUCTION MANUAL 1 EX<IE>

A1-1 QQTG0676A INSTRUCTION MANUAL 1 EH<IF>

A1-1 QQTG0676A INSTRUCTION MANUAL 1 EV<IF>

A1-1 QQTG0677A INSTRUCTION MANUAL 1 EG<IG>

A1-2 QQCG0428A REFERENCE GUIDE(ENGLISH) 1

A1-3 QQTG0678A INSTALL MANUAL 1

A2 QAQG2043AA PACKAGED FD 1

A3 K2CB2CB00006 AC CORD 1

A3 QJAG027AB AC CORD 1

Pcs

P PC

EX EQ EG EF

Remarks

50

Page 51

Ref. No. Part No. Part Name & Description

A3 QJAG027AB AC CORD 1

A3 QJAG028AB AC CORD 1

A3 RJA0035-2X AC CORD 1

A4 QFVG2044A PACKAGED CD-ROM 1

A5 K2DA42E00001 ATTACHMENT PLUG 1

P1 QPGG0522AA CARTON BOX 1

PCB1 SXPG238611 MAIN PCB 1 <RTL>

PCB2 SXPG232411A MKB1 PCB 1 <RTL>

PCB3 SXPG232411B MKB2 PCB 1 <RTL>

PCB4 SXPG232511 MKB3 PCB 1 <RTL>

PCB5 SXPG232941 ACP PCB 1 <RTL>EX EB EQ EG

PCB5 SXPG232941 ACP PCB 1 <RTL>EF EH EV GN GH

PCB5 SXPG232951 ACP PCB 1 <RTL>P PC

PCB5 SXPG232961 ACP PCB 1 <RTL>GM GU GT

PCB6 SXPG238711A FAJ PCB 1 <RTL>

PCB7 SXPG238711B JACK PCB 1 <RTL>

PCB8 SXPG238811B INV PCB 1 <RTL>

PCB9 SXPG238811A ASUB PCB 1 <RTL>

PCB10 SXPG238811C SD PCB 1 <RTL>

PCB11 SXPG238911A CPL PCB 1 <RTL>

PCB12 SXPG238911B CPC PCB 1 <RTL>

PCB13 SXPG239011A CPR PCB 1 <RTL>

PCB14 SXPG239011B ROT PCB 1 <RTL>

PCB15 SXPG239011E BEND PCB 1 <RTL>

PCB16 SXPG239011D HP PCB 1 <RTL>

PCB17 SXPG239011C SDSW PCB 1 <RTL>

Pcs

EH EV GU GM GT

EB GH

GN

GM GU GT

Remarks

<MAIN P.C.B.>

PCB1 SXPG238611 MAIN PCB 1 <RTL>

C1 ECJ1VB1C104K 0.1U 1 [SPC]

C2 ECJ1VB1C104K 0.1U 1 [SPC]

C3 ECJ1VB1C104K 0.1U 1 [SPC]

C4 ECJ1VB1A224K 0.22U 1 [SPC]

C5 ECJ1VB1C104K 0.1U 1 [SPC]

C6 ECJ1VB1C104K 0.1U 1 [SPC]

C7 ECJ1VB1C104K 0.1U 1 [SPC]

C8 ECJ1VB1C104K 0.1U 1 [SPC]

C9 ECJ1VB1C104K 0.1U 1 [SPC]

C10 ECJ1VB1C104K 0.1U 1 [SPC]

C11 ECJ1VB1C104K 0.1U 1 [SPC]

C12 ECJ1VB1C104K 0.1U 1 [SPC]

C13 ECJ1VB1C104K 0.1U 1 [SPC]

C14 ECJ1VB1H103K 0.01U 1 [SPC]

C15-18 ECJ1VB1C104K 0.1U 4 [SPC]

C19 ECJ1VG1H150J 15P 1 [SPC]

C20 ECJ1VB1C104K 0.1U 1 [SPC]

C21 ECJ1VG1H150J 15P 1 [SPC]

C22-26 ECJ1VB1C104K 0.1U 5 [SPC]

C28,29 ECJ1VB1C104K 0.1U 2 [SPC]

C30 ECJ1VG1H471J 470P 1 [SPC]

C31-43 ECJ1VB1C104K 0.1U 13 [SPC]

C44-47 ECJ1VG1H101J 100P 4 [SPC]

51

Page 52

Ref. No. Part No. Part Name & Description

C49 ECJ1VB1C104K 0.1U 1 [SPC]

C101,02 ECJ1VB1C104K 0.1U 2 [SPC]

C108 ECJ1VB1C104K 0.1U 1 [SPC]

C110 ECJ1VB1C104K 0.1U 1 [SPC]

C111 ECJ1VG1H470J 47P 1 [SPC]

C112 ECJ1VG1H100D 10P 1 [SPC]

C113 ECJ1VB1C104K 0.1U 1 [SPC]

C114-19 ECJ1VG1H470J 47P 6 [SPC]

C120,21 ECJ1VG1H100D 10P 2 [SPC]

C122 ECJ1VG1H470J 47P 1 [SPC]

C123,24 ECJ1VG1H100D 10P 2 [SPC]

C125 ECJ1VB1C104K 0.1U 1 [SPC]

C126-28 ECJ1VG1H100D 10P 3 [SPC]

C129 EEVHB0J470R 6V 47U 1 [SPC]

C130 ECJ1VG1H100D 10P 1 [SPC]

C131 ECJ1VG1H101J 100P 1 [SPC]

C132 ECJ1VG1H470J 47P 1 [SPC]

C133 ECJ1VG1H100D 10P 1 [SPC]

C134-37 ECJ1VB1C104K 0.1U 4 [SPC]

C138 ECJ1VG1H221J 220P 1 [SPC]

C139-44 ECJ1VB1C104K 0.1U 6 [SPC]

C145,46 ECJ1VG1H470J 47P 2 [SPC]

C147-49 ECJ1VB1C104K 0.1U 3 [SPC]

C150 ECJ1VG1H471J 470P 1 [SPC]

C151 ECJ1VB1H103K 0.01U 1 [SPC]

C152-55 ECJ1VB1C104K 0.1U 4 [SPC]

C156 ECJ1VG1H101J 100P 1 [SPC]

C157 ECJ1VB1C104K 0.1U 1 [SPC]

C158-65 ECJ1VG1H101J 100P 8 [SPC]

C166 ECJ1VB1C104K 0.1U 1 [SPC]

C201 ECJ1VG1H100D 10P 1 [SPC]

C202 ECJ1VG1H221J 220P 1 [SPC]

C203 ECJ1VG1H100D 10P 1 [SPC]

C204-07 ECJ1VB1C104K 0.1U 4 [SPC]

C208-12 ECJ1VG1H101J 100P 5 [SPC]

C213-28 ECJ1VB1C104K 0.1U 16 [SPC]

C229 ECJ1VG1H221J 220P 1 [SPC]

C231-49 ECJ1VB1C104K 0.1U 19 [SPC]

C301-03 ECJ1VB1C104K 0.1U 3 [SPC]

C304 EEVHB0J101P 6V 100U 1 [SPC]

C305 EEVHB1C100R 16V 10U 1 [SPC]

C306-29 ECJ1VB1C104K 0.1U 24 [SPC]

C330 EEVHB0J101P 6V 100U 1 [SPC]

C331,32 ECJ1VB1C104K 0.1U 2 [SPC]

C333,34 ECJ1VG1H471J 470P 2 [SPC]

C335 EEVHB0J470R 6V 47U 1 [SPC]

C336-40 ECJ1VB1C104K 0.1U 5 [SPC]

C341 EEVHB1C100R 16V 10U 1 [SPC]

C342 ECJ1VB1C104K 0.1U 1 [SPC]

C343,44 EEVHB1C100R 16V 10U 2 [SPC]

C345 ECJ1VG1H102J 0.001U 1 [SPC]

C346 EEVHB1C100R 16V 10U 1 [SPC]

C347-51 ECJ1VB1C104K 0.1U 5 [SPC]

C354,55 ECJ1VB1A224K 0.22U 2 [SPC]

Pcs

Remarks

52

Page 53

Ref. No. Part No. Part Name & Description

C358 ECJ1VB1H472K 0.0047U 1 [SPC]

C359,60 ECJ1VB1C104K 0.1U 2 [SPC]

C363 ECJ1VB1C104K 0.1U 1 [SPC]

C364,65 ECJ1VG1H681J 680P 2 [SPC]

C366,67 ECJ1VG1H102J 0.001U 2 [SPC]

C368,69 ECJ1VB1C104K 0.1U 2 [SPC]

C370,71 ECJ1VG1H102J 0.001U 2 [SPC]

C372-74 ECJ1VB1C104K 0.1U 3 [SPC]

C375,76 ECJ1VG1H102J 0.001U 2 [SPC]

C377-80 ECJ1VG1H221J 220P 4 [SPC]

C381,82 ECJ1VG1H151J 150P 2 [SPC]

C383-85 ECJ1VB1C104K 0.1U 3 [SPC]

C401 ECJ1VG1H220J 22P 1 [SPC]

C403 ECJ1VG1H030C 3P 1 [SPC]

C405 ECJ1VG1H030C 3P 1 [SPC]

C406,07 ECJ1VB1C104K 0.1U 2 [SPC]

C408 EEVHB0G101 4V 100U 1 [SPC]

C409 EEVHB1C100R 16V 10U 1 [SPC]

C410-33 ECJ1VB1C104K 0.1U 24 [SPC]

C434,35 EEVHB1C100R 16V 10U 2 [SPC]

C436,37 ECJ1VB1C104K 0.1U 2 [SPC]

C438 ECJ1VG1H681J 680P 1 [SPC]

C439,40 EEVHB1H1R0R 50V 1U 2 [SPC]

C441,42 ECJ1VG1H102J 0.001U 2 [SPC]

C443,44 ECJ1VG1H151J 150P 2 [SPC]

C445,46 EEVHB1H1R0R 50V 1U 2 [SPC]

C447 ECJ1VB1C104K 0.1U 1 [SPC]

C448,49 ECJ1VG1H471J 470P 2 [SPC]

C450-54 ECJ1VB1C104K 0.1U 5 [SPC]

C455 EEVHB1C100R 16V 10U 1 [SPC]

C456-58 ECJ1VB1C104K 0.1U 3 [SPC]

C459 ECJ1VG1H330J 33P 1 [SPC]

C460 EEVHB1H2R2R 50V 2.2U 1 [SPC]

C461,62 EEVHP1H1R0R 50V 1U 2 [SPC]

C464 ECJ1VG1H680J 68P 1 [SPC]

C465 ECJ1VB1C104K 0.1U 1 [SPC]

C466 ECJ1VG1H150J 15P 1 [SPC]

C467 ECJ1VG1H102J 0.001U 1 [SPC]

C468 ECJ1VB1C104K 0.1U 1 [SPC]

C469 ECJ1VG1H102J 0.001U 1 [SPC]

C470,71 EEVHB1H1R0R 50V 1U 2 [SPC]

C472-75 ECJ1VB1C104K 0.1U 4 [SPC]

C476 ECJ1VB1A224K 0.22U 1 [SPC]

C477-84 ECJ1VG1H102J 0.001U 8 [SPC]

CN101 K1KA15A00116 CONNECTOR 1 [SPC]

CN102 K1KA14A00197 CONNECTOR 1 [SPC]

CN103 K1KA08A00293 CONNECTOR 1 [SPC]

CN104 K1KA05A00257 CONNECTOR 1 [SPC]

CN105 K1MN20A00045 CONNECTOR 1 [SPC]

CN106 TJSF43711 CONNECTOR 1 K1KA11B00040[SPC]

CN201 K1KA16A00172 CONNECTOR 1 [SPC]

CN202,03 QJTG02840AA CONNECTOR 2 K1MM40A00002[SPC]

CN204 K1KA80A00100 CONNECTOR 1 [SPC]

CN205 QJTG02840AA CONNECTOR 1 K1MM40A00002[SPC]

Pcs

Remarks

53

Page 54

Ref. No. Part No. Part Name & Description

CN206 K1KA80A00100 CONNECTOR 1 [SPC]

CN207 QJTG02840AA CONNECTOR 1 K1MM40A00002[SPC]

CN208,09 K1KA80A00100 CONNECTOR 2 [SPC]

CN301 K1KA12A00227 CONNECTOR 1 [SPC]

CN302 TJSF34113A CONNECTOR 1 K1KA13A00049[SPC]

CN401 K1KA11A00102 CONNECTOR 1 [SPC]

CN402 K1KA10A00317 CONNECTOR 1 [SPC]

D1 MA2J11100L DIODE 1 [SPC]

D2 MA2J11100L DIODE 1 [SPC]

D3 MA2J11100L DIODE 1 [SPC]

D101 MA2J11100L DIODE 1 [SPC]

D102 MA2J11100L DIODE 1 [SPC]

D103 MA2J11100L DIODE 1 [SPC]

D104 MA2J11100L DIODE 1 [SPC]

D201-08 MA2J11100L DIODE 8 [SPC]

D301 MA2J11100L DIODE 1 [SPC]

D302 MA3X152D0L DIODE 1 [SPC]

D303 MA2J11100L DIODE 1 [SPC]

D304,05 MA3X152E0L DIODE 2 [SPC]

D306 MA8039H DIODE 1 MAZ80390H[SPC]

D401 MA2Z30400L DIODE 1 [SPC]

IC1 TC74VHC138F IC 1 C0JBAN000074[SPC]

IC2 TC74VHC139F IC 1 C0JBAN000176[SPC]

IC3 TC74VHC139F IC 1 C0JBAN000176[SPC]

IC4 MN103002A 32 BIT MICRO CONTROLLER 1 [SPC]

IC5 TC7SH02FU IC 1 C0JBAD000071[SPC]

IC6 C0ZBZ0000667 SPECTRAM SPREAD 1 [SPC]

IC7 C0JBAE000140 2 INPUT OR GATE 1 [SPC]

IC8 TC7W08FU IC 1 C0JBAA000207[SPC]

IC9 TC74VHC08F IC 1 C0JBAA000090[SPC]

IC10 C0JBAA000102 INVERTER AND GATE 1 [SPC]

IC11 C0JBAF000162 IC 1 [SPC]

IC12,13 C3ABMG000166 16M BIT PYNAMIC RAM 2 [SPC]

IC14,15 C3BBHG000048 1MFASTSRAM 2 [SPC]

IC16,17 RFKFXKN7000 FLASH MEMORY 1 [SPC]

IC18 C3CBND000046 IC 1 [SPC]

IC19 C3CBMD000098 IC 1 [SPC]

IC21 C3FBMD000050 IC 1 [SPC]

IC22 TC7W08FU IC 1 C0JBAA000207[SPC]

IC23 C3BBJG000011 IC 1 [SPC]

IC25 JVAHC174AFEL IC 1 C0JBAF000303[SPC]

IC26 TC7SH32FUTL IC 1 C0JBAE000093[SPC]

IC101 C0JBAB000164 IC 1 [SPC]

IC102 C0JBAZ000529 IC 1 [SPC]

IC103 C1DB00000607 FDC 1 [SPC]

IC104 C0HBA0000117 LCD CONTROLLER 1 [SPC]

IC105 TC7S14F IC 1 C0JBAZ000514[SPC]

IC106 C0JBAZ000853 IC 1 [SPC]

IC201 C1BB00000709 TONE GENERATOR 1 [SPC]

IC202 TC74VHC139F IC 1 C0JBAN000176[SPC]

IC203 C3CBQD000002 IC 1 [SPC]

IC204 C3CBQD000001 IC 1 [SPC]

IC205 C1BB00000709 TONE GENERATOR 1 [SPC]

IC206 TC74VHC139F IC 1 C0JBAN000176[SPC]

Pcs

Remarks

54

Page 55

Ref. No. Part No. Part Name & Description

IC207 C3CBQD000004 IC 1 [SPC]

IC208 C3CBQD000003 IC 1 [SPC]

IC209 C0JBAE000140 2 INPUT OR GATE 1 [SPC]

IC301 TC7SH32FUTL IC 1 C0JBAE000093[SPC]

IC302 TC74VHC245F IC 1 C0JBAZ000505[SPC]

IC303 TC74VHC574F IC 1 C0JBAF000183[SPC]

IC304 TC74VHC245F IC 1 C0JBAZ000505[SPC]

IC305 C0JBAZ000874 IC 1 [SPC]

IC306 S21065LKS240 IC 1 C2HBBY000012[SPC]

IC307,08 KM416S1120DT IC 2 C3ABMG000039[SPC]

IC309 PCM1800E-T1 IC 1 C0FBAJ000004[SPC]

IC310 PCM69BU-T1 IC 1 C0FBBZ000012[SPC]

IC311 C0FBBK000025 IC 1 [SPC]

IC312-16 M5218AFPE3 IC 5 C0ABBB000163[SPC]

IC318 MN1382CTX IC 1 MN1382CP[SPC]

IC401 MN102H60KTA IC 1 [SPC]

IC402 MN67737DB1 IC 1 [SPC]

IC403 S29L331AFSTB IC 1 C3EBEG000021[SPC]

IC404 C0JBAR000155 IC 1 [SPC]

IC405 TC7W00FUTL IC 1 C0JBAC000113[SPC]

IC406 PCM1716ET2 IC 1 C0FBBK000009[SPC]

IC407 C2CBGF000150 USB MICRO CONTROLLER 1 [SPC]

IC408 C2BBGE000618 USB AUDIO 1 [SPC]

IC409 M5218AFPE3 IC 1 C0ABBB000163[SPC]

IC410 PCM1800E-T1 IC 1 C0FBAJ000004[SPC]

IC411 C0JBAZ000529 IC 1 [SPC]

IC412 C0JBAS000075 IC 1 [SPC]

IC413 C0JBAF000162 IC 1 [SPC]

IC414 C3FBKD000162 IC 1 [SPC]

JP1 ERJ3GEY0R00V 0 1 [SPC]

JP3 ERJ3GEY0R00V 0 1 [SPC]

JP7 ERJ3GEY0R00V 0 1 [SPC]

JP10 ERJ3GEY0R00V 0 1 [SPC]

JP12,13 ERJ3GEY0R00V 0 2 [SPC]

JP402 ERJ3GEY0R00V 0 1 [SPC]

L101 J0JBC0000023 COIL 1 [SPC]

L103 J0JBC0000023 COIL 1 [SPC]

L401 G1C6R8J00003 COIL 1 [SPC]

Q1 2SB0709ARL TRANSISTOR 1 [SPC]

Q2 2SD0601AQL TRANSISTOR 1 [SPC]

Q3 UN5216 TRANSISTOR 1 UNR521600L[SPC]

Q101 2SD0601AQL TRANSISTOR 1 [SPC]

Q102,03 UN511NTX TRANSISTOR 2 UNR511N00L[SPC]

Q104 UN5216 TRANSISTOR 1 UNR521600L[SPC]

Q105,06 2SB0709ARL TRANSISTOR 2 [SPC]

Q302 2SB0709ARL TRANSISTOR 1 [SPC]

Q303,04 2SD0601AQL TRANSISTOR 2 [SPC]

Q305 2SB970-QRSTX TRANSISTOR 1 2SB09700WL[SPC]

Q306 2SD0601AQL TRANSISTOR 1 [SPC]

Q307,08 B1CFDC000004 TRANSISTOR 2 [SPC]

Q309 2SD0601AQL TRANSISTOR 1 [SPC]

Q401 2SD0601AQL TRANSISTOR 1 [SPC]

Q402 2SB970-QRSTX TRANSISTOR 1 2SB09700WL[SPC]

R1 ERJ3GEYJ101V 100 1 [SPC]

Pcs

Remarks

55

Page 56

Ref. No. Part No. Part Name & Description

R2 ERJ3GEYJ102V 1K 1 [SPC]

R3 ERJ3GEYJ472V 4.7K 1 [SPC]

R4 ERJ3GEYJ102V 1K 1 [SPC]

R5,R6 ERJ3GEYJ104V 100K 2 D0GB104JA002[SPC]

R7-10 ERJ3GEYJ472V 4.7K 4 [SPC]

R11,12 ERJ3GEYJ470V 47 2 [SPC]

R13 ERJ3GEYJ472V 4.7K 1 [SPC]

R14 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R15-17 ERJ3GEYJ470V 47 3 [SPC]

R18 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R19-21 ERJ3GEYJ472V 4.7K 3 [SPC]

R22 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R23 ERJ3GEYJ471V 470 1 [SPC]

R24 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R25,26 ERJ3GEYJ472V 4.7K 2 [SPC]

R27 ERJ3GEYJ102V 1K 1 [SPC]

R28-31 ERJ3GEYJ472V 4.7K 4 [SPC]

R32 ERJ3GEYJ101V 100 1 [SPC]

R33 ERJ3GEY0R00V 0 1 [SPC]

R34 ERJ3GEYJ470V 47 1 [SPC]

R35 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R36 ERJ3GEYJ470V 47 1 [SPC]

R37 ERJ3GEYJ331V 330 1 [SPC]

R38 ERJ3GEYJ472V 4.7K 1 [SPC]

R40 ERJ3GEY0R00V 0 1 [SPC]

R42 ERJ3GEY0R00V 0 1 [SPC]

R101-05 ERJ3GEYJ470V 47 5 [SPC]

R106 ERJ3GEYJ102V 1K 1 [SPC]

R107 ERJ3GEYJ101V 100 1 [SPC]

R108 ERJ3GEYJ105V 1M 1 [SPC]

R109 ERJ3GEYJ471V 470 1 [SPC]

R110 ERJ3GEYJ105V 1M 1 [SPC]

R111 ERJ3GEYJ101V 100 1 [SPC]

R112 ERJ3GEYJ470V 47 1 [SPC]

R113 ERJ3GEYJ101V 100 1 [SPC]

R114 ERJ3GEYJ151V 150 1 [SPC]

R115 ERJ3GEYJ101V 100 1 [SPC]

R116,17 ERJ3GEYJ105V 1M 2 [SPC]

R118 ERJ3GEYJ221V 220 1 [SPC]

R119 ERJ3GEYJ102V 1K 1 [SPC]

R120 ERJ3GEYJ101V 100 1 [SPC]

R121 ERJ3GEYJ152V 1.5K 1 [SPC]

R122,23 ERJ3GEYJ101V 100 2 [SPC]

R124-31 ERJ3GEYJ103V 10K 8 D0GB103JA002[SPC]

R132,33 ERJ3GEYJ470V 47 2 [SPC]

R134,35 ERJ3GEYJ103V 10K 2 D0GB103JA002[SPC]

R136 ERJ3GEYJ101V 100 1 [SPC]

R137,38 ERJ3GEYJ472V 4.7K 2 [SPC]

R139 ERJ3GEYJ470V 47 1 [SPC]

R140-42 ERJ3GEYJ472V 4.7K 3 [SPC]

R146 ERJ3GEYJ472V 4.7K 1 [SPC]

R147 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R148 ERJ3GEY0R00V 0 1 [SPC]

R150,51 ERJ3GEYJ470V 47 2 [SPC]

Pcs

Remarks

56

Page 57

Ref. No. Part No. Part Name & Description

R152 ERJ3GEYJ472V 4.7K 1 [SPC]

R201 ERJ3GEYJ105V 1M 1 [SPC]

R202,03 ERJ3GEYJ470V 47 2 [SPC]

R205-17 ERJ3GEYJ470V 47 13 [SPC]

R218 ERJ3GEY0R00V 0 1 [SPC]

R219-32 ERJ3GEYJ470V 47 14 [SPC]

R234-58 ERJ3GEYJ470V 47 25 [SPC]

R301,02 ERJ3GEYJ472V 4.7K 2 [SPC]

R303 ERJ3GEYJ101V 100 1 [SPC]

R304 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R305,06 ERJ3GEYJ333V 33K 2 D0GB333JA002[SPC]

R308 ERJ3GEYJ105V 1M 1 [SPC]

R309 ERJ3GEYJ104V 100K 1 D0GB104JA002[SPC]

R310 ERJ3GEYJ473V 47K 1 D0GB473JA002[SPC]

R311 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R313 ERJ3GEYJ470V 47 1 [SPC]

R314-16 ERJ3GEYJ101V 100 3 [SPC]

R317 ERJ3GEYJ153V 15K 1 [SPC]

R318 ERJ3GEYJ471V 470 1 [SPC]

R319,20 ERJ3GEYJ682V 6.8K 2 D0GB682JA002[SPC]

R321-24 ERJ3GEYJ681V 680 4 D0GB681JA002[SPC]

R325,26 ERJ3GEYJ682V 6.8K 2 D0GB682JA002[SPC]

R327 ERJ3GEYJ471V 470 1 [SPC]

R328-37 ERJ3GEYJ682V 6.8K 10 D0GB682JA002[SPC]

R338,39 ERJ3GEYJ103V 10K 2 D0GB103JA002[SPC]

R340 ERJ3GEYJ682V 6.8K 1 D0GB682JA002[SPC]

R341 ERJ3GEYJ153V 15K 1 [SPC]

R342,43 ERJ3GEYJ103V 10K 2 D0GB103JA002[SPC]

R344 ERJ3GEYJ682V 6.8K 1 D0GB682JA002[SPC]

R345 ERJ3GEYJ153V 15K 1 [SPC]

R346,47 ERJ3GEYJ473V 47K 2 D0GB473JA002[SPC]

R351 ERJ3GEYJ471V 470 1 [SPC]

R352,53 ERJ3GEYJ101V 100 2 [SPC]

R354 ERJ3GEYJ471V 470 1 [SPC]

R355 ERJ3GEYJ472V 4.7K 1

R356 ERJ3GEYJ562V 5.6K 1 D0GB562JA002[SPC]

R357 ERJ3GEYJ102V 1K 1 [SPC]

R358 ERJ3GEYJ473V 47K 1 D0GB473JA002[SPC]

R359,60 ERJ3GEYJ472V 4.7K 2 [SPC]

R361,62 ERJ3GEYJ470V 47 2 [SPC]

R401-03 ERJ3GEYJ394V 390K 3 [SPC]

R404 ERJ3GEYJ104V 100K 1 D0GB104JA002[SPC]

R405,06 ERJ3GEY0R00V 0 2 [SPC]

R407 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R408,09 ERJ3GEYJ220V 22 2 [SPC]

R410,11 ERJ3GEYJ103V 10K 2 D0GB103JA002[SPC]

R412 ERJ3GEYJ220V 22 1 [SPC]

R413 ERJ3GEYJ221V 220 1 [SPC]

R414,15 ERJ3GEYJ471V 470 2 [SPC]

R416 ERJ3GEYJ105V 1M 1 [SPC]

R417 ERJ3GEYJ221V 220 1 [SPC]

R420-23 ERJ3GEYJ220V 22 4 [SPC]

R424,25 ERJ3GEYJ104V 100K 2 D0GB104JA002[SPC]

R426 ERJ3GEYJ220V 22 1 [SPC]

Pcs

Remarks

[SPC]

57

Page 58

Ref. No. Part No. Part Name & Description

R427 ERJ3GEYJ394V 390K 1 [SPC]

R428 ERJ3GEYJ220V 22 1 [SPC]

R429 ERJ3GEYJ101V 100 1 [SPC]

R430-32 ERJ3GEYJ472V 4.7K 3 [SPC]

R433 ERJ3GEYJ101V 100 1 [SPC]

R434-37 ERJ3GEY0R00V 0 4 [SPC]

R438 ERJ3GEYJ102V 1K 1 [SPC]

R439 ERJ3GEYJ472V 4.7K 1 [SPC]

R440,41 ERJ3GEYJ682V 6.8K 2 D0GB682JA002[SPC]

R442 ERJ3GEYJ103V 10K 1 D0GB103JA002[SPC]

R443,44 ERJ3GEYJ333V 33K 2 D0GB333JA002[SPC]

R445,46 ERJ3GEY0R00V 0 2 [SPC]

R447,48 ERJ3GEYJ330V 33 2 D0GB330JA002[SPC]

R449 ERJ3GEYJ471V 470 1 [SPC]

R450 ERJ3GEY0R00V 0 1 [SPC]

R451 ERJ3GEYJ472V 4.7K 1 [SPC]

R452 ERJ3GEYJ152V 1.5K 1 [SPC]

R453,54 ERJ3GEYJ102V 1K 2 [SPC]

R455,56 ERJ3GEYJ822V 8.2K 2 D0GB822JA002[SPC]

R458 ERJ3GEYJ473V 47K 1 D0GB473JA002[SPC]

R459 ECJ1VG1H102J 0.001U 1 [SPC]

R460,61 ERJ3GEYJ472V 4.7K 2 [SPC]

R462 ERJ3GEYJ470V 47 1 [SPC]

R463 ERJ3GEYJ471V 470 1 [SPC]

R464 ERJ3GEYJ220V 22 1 [SPC]

R465,66 ERJ3GEYJ103V 10K 2 D0GB103JA002[SPC]

R467 ERJ3GEYJ471V 470 1 [SPC]

R469 ERJ3GEYJ394V 390K 1 [SPC]

R470 ERJ3GEYJ224V 220K 1 D0GB224JA002[SPC]

X1 VSX0917 OSCILATOR 1 H0J160500026[SPC]

X102 H0J177500018 17.73MHZ OSCILATOR 1 [SPC]

X103 H0J240500016 24MHZ OSCILATOR 1 [SPC]

X104 H0J143500039 14.32MHZ OSCILATOR 1 [SPC]

X105 H1A5005B0014 50MHZ OSCILATOR 1 [SPC]

X201 H0J169300002 OSCILATOR 1 [SPC]

X301 H1A3005B0005 OSCILATOR 1 [SPC]

X401 H0J327200034 OSCILATOR 1 [SPC]

X402 H2D225500001 OSCILATOR 1 [SPC]

Z1,Z2 EXBV8V472JV 4.7K X 4 2 [SPC]

Z3 EXBV8V470JV 47 X 4 1 [SPC]

Z6-13 EXBV8V472JV 4.7K X 4 8 [SPC]

Z14 EXBV8V101JV 100 X 4 1 [SPC]

Z15-24 EXBV8V472JV 4.7K X 4 10 [SPC]

Z101,02 EXBV8V470JV 47 X 4 2 [SPC]

Z103 EXBV8V102JV 1K X 4 1 [SPC]

Z104 EXBV8V101JV 100 X 4 1 [SPC]

Z105,06 EXBV8V221JV 220 X 4 2 [SPC]

Z107,08 EXBV8V101JV 100 X 4 2 [SPC]

Z109-12 EXBV8V470JV 47 X 4 4 [SPC]

Z114 EXBV8V470JV 47 X 4 1 [SPC]

Z115-17 EXBV8V472JV 4.7K X 4 3 [SPC]

Z201,02 EXBV8V223JV 22K X 4 2 [SPC]

Z203-05 EXBV8V470JV 47 X 4 3 [SPC]

Z206,07 EXBV8V472JV 4.7K X 4 2 [SPC]

Pcs

Remarks

58

Page 59

Ref. No. Part No. Part Name & Description

Z208-10 EXBV8V470JV 47 X 4 3 [SPC]

Z211 EXBV8V101JV 100 X 4 1 [SPC]

Z212-46 EXBV8V470JV 47 X 4 35 [SPC]

Z301-03 EXBV8V101JV 100 X 4 3 [SPC]

Z304-07 EXBV8V221JV 220 X 4 4 [SPC]

Z308 EXBV8V472JV 4.7K X 4 1 [SPC]

Z309-12 EXBV8V221JV 220 X 4 4 [SPC]

Z313 EXBV8V472JV 4.7K X 4 1 [SPC]

Z314 EXBV8V470JV 47 X 4 1 [SPC]

Z315,16 EXBV8V101JV 100 X 4 2 [SPC]

Z317,18 EXBV8V472JV 4.7K X 4 2 [SPC]

Z401 EXBV8V470JV 47 X 4 1 [SPC]

Z402 EXBV8V101JV 100 X 4 1 [SPC]

Z403 EXBV8V103J 10K X 4 1 D0GZ103J0001[SPC]

<FAJ P.C.B.>

PCB6 SXPG238711A FAJ PCB 1 <RTL>

C501,02 ECEA1HSN010 50V 1U 2

C503 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C504 ECA0JAK470XH 6V 47U 1

C505,06 ECA1CAK100XB 16V 10U 2

C507 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C508 F1D1H470A006 47P 1

C509,10 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C511 F1D1H221A012 220P 1

C512 ECEA1HSN010 50V 1U 1

C513,14 ECQV1H683JZ3 0.068U 2

C515 ECEA1CKN100B 16V 10U 1

C516,17 ECQM1H224JZ 0.22U 2

C518 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C520 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C521,22 ECQB1H223JF3 0.022U 2

C523 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C524,25 ECBT1H150JC5 15P 2

C526 ECEA1CKN100B 16V 10U 1

C527 ECQV1H104JZ 0.1U 1

C528 ECQV1H154JZ3 0.15U 1

C529 ECQV1H104JZ 0.1U 1

C530 ECQV1H154JZ3 0.15U 1

C531,32 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C533 ECEA1CKN100B 16V 10U 1

C534 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C535 ECQV1H683JZ3 0.068U 1

C536 ECQV1H154JZ3 0.15U 1

C537 ECQV1H683JZ3 0.068U 1

C538 ECQV1H154JZ3 0.15U 1

C539 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C540 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C541 ECEA1CKN100B 16V 10U 1

C542 ECQB1H333JF3 0.033U 1

C543 ECQB1H153JF3 0.015U 1

C544 ECQB1H333JF3 0.033U 1

C545 ECQB1H153JF3 0.015U 1

Pcs

Remarks

59

Page 60

Ref. No. Part No. Part Name & Description

C546,47 F1D1H101A012 100P 2

C548,49 ECEA1CKN100B 16V 10U 2

C550-53 ECQB1H223JF3 0.022U 4

C554,55 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C556,57 F1D1H470A006 47P 2

C558,59 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C560,61 ECEA1CKN100B 16V 10U 2

C562,63 ECBT1H150JC5 15P 2

C564 ECBT1H220JC5 22P 1

C565,66 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C567 ECBT1H220JC5 22P 1

C568,69 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C570,71 ECQB1H473JF3 0.047U 2

C572 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C573-75 ECQB1H473JF3 0.047U 3

C576 ECBT1C472KR5 0.0047U 1 F1D1C472A010

C577 ECQB1H223JF3 0.022U 1

C578,79 ECQV1H104JZ 0.1U 2

C580 ECEA1HSN010 50V 1U 1

C581,82 ECBT1C472KR5 0.0047U 2 F1D1C472A010

C584-86 F1D1H470A006 47P 3

C587-89 F1D1H221A012 220P 3

C590,91 ECEA1CKN100B 16V 10U 2

C592,93 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C594,95 F1D1H470A006 47P 2

C596 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C597,98 ECBT1C472KR5 0.0047U 2 F1D1C472A010

C599,00 ECA1EM102 25V 1000P 2

C601-05 ECQV1H105JZ3 1U 5

C606-15 F1D1H101A012 100P 10

C616 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C618 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C620 ECA1CAK101XB 16V 100U 1

C622-26 QCBG1H473ZFA 0.047U 5 F1E1H473A001

C630,31 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C641-44 QCBG1H473ZFA 0.047U 4 F1E1H473A001

C645 ECQE1A104M6 0.1 1

C646 ECA1EAM101XB 16V 100U 1

C647 ECA1HAK010XI 50V 1U 1

C648 ECA1EAM101XB 16V 100U 1

C649 ECA1CAK100XB 16V 10U 1

C652-55 ECA1EM472 25V 4700P 4

C656,57 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C658,59 F1D1H102A012 0.001U 2

C660,61 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C662,63 ECA0JAM102XB 6V 1000P 2

C664,65 ECA1CAK101XB 16V 100U 2

C667,68 EECS5R5V105 5.2V 1F 2

CN501 SJPG1JS130A CONNECTOR 1

CN502 SJPG1JS120A CONNECTOR 1

CN503 SJPG1JS130A CONNECTOR 1

CN504 SJPG1JS050A CONNECTOR 1

CN505,06 QJTG04309AA CONNECTOR 2

CN507 SJPG1300A CONNECTOR 1

Pcs

Remarks

60

Page 61

Ref. No. Part No. Part Name & Description

CN508 SJPG1320A CONNECTOR 1

CN641 SJPG7JS030A CONNECTOR 1

D501-07 RVD1SS133TA DIODE 7 B0AACK000004

D509 10 AK03WK DIODE 2 B0JAMD000005

D511 MA4150-M DIODE 1 MAZ41500M

D512 RVD1SS133TA DIODE 1 B0AACK000004

D641 MA4082-MTA DIODE 1 MAZ40820MF

D642 MA4033M DIODE 1 MAZ40330M

D643 MAZ40560MF DIODE 1

D644,45 ERA1502V5 DIODE 2 B0EAKM000061

D646-49 SVDS3V40 DIODE 4 B0EAKM000066

D650,51 MAZ40560MF DIODE 2

D654,55 AK03WK DIODE 2 B0JAMD000005

D656 MA2051LF DIODE 1 MAZ2051000LF

D657 MA2062LF DIODE 1 MAZ2062000LF

D658 AK03WK DIODE 1 B0JAMD000005

FP501,02 K5G202AA0003 FUSE 2

FP503 K5G302AA0003 FUSE 1

FP504,05 K5G3113A0001 FUSE 2

FP641 K5G202AA0003 FUSE 1

FP642,43 K5G402AA0003 FUSE 2

IC501-14 NJM4558L IC 14

IC641 AN6913 IC 1 AN6913-NT

IC643 KIA7915PI IC 1 C0CABLG00006

IC644 KIA7815PI IC 1 C0CAALG00016

IC701 PC900V IC 1 B3PAE0000002

JK501 QJJG010AA JACK HEADPHONE 1 1

JK502-09 QJJG019AA JACK 8

JK709 SJSG1390A JACK 1 K1CB108B0027

JP502 RWDJ06-150 JUMPER 1

L501-04 QLQGT3T131LA COIL 4

L505-08 QLBG005A COIL 4

L509 QLQGT3T131LA COIL 1

L510-12 QLQGT1D600LA COIL 3

L643-49 QLBG005A COIL 7

L650,51 G0C121Z00001 COIL 2

Q501 2SC1815TPE2 TRANSISTOR 1 B1AACF000023

Q502,03 2SJ498CDTA TRANSISTOR 2

Q504 2SD592AR TRANSISTOR 1 2SD0592AR

Q505 2SB621A-R TRANSISTOR 1 2SB0621AH

Q506 2SD592AR TRANSISTOR 1 2SD0592AR

Q507 2SB621A-R TRANSISTOR 1 2SB0621AH

Q508 SLA5007 TRANSISTOR 1 B1MADFC00001

Q509 2SJ425 TRANSISTOR 1 B1DCFG000001

Q510 2SK1188 TRANSISTOR 1 B1DAKG000001

Q511 DTC114YSA TRANSISTOR 1

Q512 2SA1015TPE2 TRANSISTOR 1 B1ACCF000016

Q513 2SC1815TPE2 TRANSISTOR 1 B1AACF000023

Q514 2SA1015TPE2 TRANSISTOR 1 B1ACCF000016

Q515,16 2SC1815TPE2 TRANSISTOR 2 B1AACF000023

Q641 2SA1643LF645 TRANSISTOR 1 B1BCED000002

Q642 2SC1815TPE2 TRANSISTOR 1 B1AACF000023

Q643 2SA1643LF645 TRANSISTOR 1 B1BCED000002

Pcs

Remarks

61

Page 62

Q643

2SA1643LF645

TRANSISTOR

1

B1BCED000002

62

Page 63

Ref. No. Part No. Part Name & Description

Q644 2SC1815TPE2 TRANSISTOR 1 B1AACF000023

Q645,46 2SA1015TPE2 TRANSISTOR 2 B1ACCF000016

Q647,48 2SC1815TPE2 TRANSISTOR 2 B1AACF000023

R501 ERDS2FJ472 4.7K 1

R502 ERDS2FJ104 100K 1

R503,04 ERDS2FJ222 2.2K 2

R505 ERDS2FJ104 100K 1

R506 ERDS2FJ152 1.5K 1

R507 ERDS2FJ103 10K 1

R508 ERDS2FJ683 68K 1

R509 ERDS2FJ222 2.2K 1

R510,11 ERDS2FJ683 68K 2

R512,13 ERDS2FJ223 22K 2

R514,15 ERDS2FJ154 150K 2

R516,17 ERDS2FJ683 68K 2

R518,19 ERDS2FJ332 3.3K 2

R520,21 ERDS2FJ153 15K 2

R522 ERDS2FJ104 100K 1

R523,24 ERDS2FJ821 820 2

R525,26 ERDS2FJ333 33K 2

R527,28 ERDS2FJ103 10K 2

R529,30 ERDS2FJ681 680 2

R531 ERDS2FJ104 100K 1

R532,33 ERDS2FJ683 68K 2

R534 ERDS2TJ682T 6.8K 1

R535 ERDS2FJ393 39K 1

R536,37 ERDS2FJ333 33K 2

R538 ERDS2FJ104 100K 1

R539 ERDS2TJ682T 6.8K 1

R540 ERDS2FJ393 39K 1

R541,42 ERDS2FJ223 22K 2

R543 ERDS2FJ153 15K 1

R544,45 ERDS2FJ122 1.2K 2

R546-48 ERDS2FJ153 15K 3

R549,50 ERDS2FJ103 10K 2

R551,52 ERDS2FJ153 15K 2

R553,54 ERDS2FJ123 12K 2

R555,56 ERDS2FJ681 680 2

R557,58 ERDS2FJ473 47K 2

R559,60 ERDS2FJ222 2.2K 2

R561,62 ERDS2TJ682T 6.8K 2

R563-66 ERDS2FJ473 47K 4

R567,68 ERDS2FJ154 150K 2

R569,70 ERDS2FJ821 820 2

R571 ERDS2FJ222 2.2K 1

R572,73 ERDS2FJ102 1K 2

R574,75 ERDS2FJ104 100K 2

R576 ERDS2FJ222 2.2K 1

R577,78 ERDS2FJ220 22 2

R579,80 ERDS2FJ102 1K 2

R581,82 ERDS2FJ104 100K 2

R583,84 ERDS2TJ183 18K 2

R585-87 ERDS2FJ473 47K 3

R588,89 ERG1SJ680 68 2

Pcs

Remarks

63

Page 64

Ref. No. Part No. Part Name & Description

R590-92 ERDS2FJ102 1K 3

R593,94 ERDS2TJ183 18K 2

R595 ERDS2TJ682T 6.8K 1

R596,97 ERDS2FJ103 10K 2

R598,99 ERDS2FJ563 56K 2

R600 ERDS2FJ332 3.3K 1

R601,02 ERDS2FJ473 47K 2

R603 ERDS2TJ272T 2.7K 1

R604,05 ERDS2FJ473 47K 2

R606 ERDS2FJ332 3.3K 1

R607,08 ERDS2FJ222 2.2K 2

R609 ERDS2FJ473 47K 1

R610 ERDS2TJ105T 1M 1

R611 ERDS2FJ473 47K 1

R612,13 ERDS2TJ105T 1M 2

R614 ERDS2FJ473 47K 1

R615,16 ERDS2FJ821 820 2

R617 ERDS2FJ472 4.7K 1

R618 ERDS2FJ222 2.2K 1

R619,20 ERDS2FJ472 4.7K 2

R621,22 ERDS2TJ105T 1M 2

R623 ERDS2FJ222 2.2K 1

R624-27 ERDS2TJ105T 1M 4

R628,29 ERDS2FJ101 100 2

R630 ERDS2FJ332 3.3K 1

R631,32 ERDS2FJ103 10K 2

R633 ERDS2FJ472 4.7K 1

R634,35 ERDS2FJ101 100 2

R636 ERDS2FJ473 47K 1

R637 ERDS2FJ332 3.3K 1

R638-40 ERDS2FJ101 100 3

R641 ERG1SJ102 1W 1K 1

R642 ERDS2FJ331 330 1

R643 ERDS2FJ271 270 1

R644,45 ERDS2FJ103 10K 2

R646 ERDS2FJ102 1K 1

R647 ERDS2FJ681 680 1

R648,49 ERX1SJR33 1W 0.33 2

R650 ERDS2FJ471 470 1

R651,52 ERDS2FJ331 330 2

R653 ERDS2FJ471 470 1

R654 ERDS2FJ473 47K 1

R655 ERDS2TJ823T 82K 1

R656 ERDS2FJ473 47K 1

R657 ERDS2TJ823T 82K 1

R658,59 ERDS2FJ103 10K 2

R660 ERDS2FJ470 47 1

R661 ERDS2FJ330 33 1

R662,63 ERDS2FJ151 150 2

R664,65 ERDS2FJ680 68 2

R666,67 ERD2FCJ6R8 1/4W 6.8 FUSE TYPE 2

R668,69 ERDS2FJ473 47K 2

R670 ERDS2FJ152 1.5K 1

R671-73 ERDS2FJ101 100 3

Pcs

Remarks

64

Page 65

R671-73

ERDS2FJ101

100

3

65

Page 66

Ref. No. Part No. Part Name & Description

R674 ERDS2FJ473 47K 1

R675,76 ERDS2FJ103 10K 2

R677 ERDS2TJ105T 1M 1

R678 ERDS2FJ102 1K 1

R679 ERTD2ZHK153T 15K 1

R680 ERDS2FJ273 27K 1

R681-83 ERDS2FJ102 1K 3

<JACK P.C.B.>

PCB7 SXPG238711B JACK PCB 1 <RTL>

C701,02 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C705-07 QCBG1H473ZFA 0.047U 3 F1E1H473A001

C709-16 QCBG1H473ZFA 0.047U 8 F1E1H473A001

CN701 K1MN20A00047 CONNECTOR 1

CN702 QJSG022AA CONNECTOR 1 K1FB104B0023

D701 RVD1SS133TA DIODE 1 B0AACK000004

D702 RVD1SS133TA DIODE 1 B0AACK000004

D703 RVD1SS133TA DIODE 1 B0AACK000004

D704 RVD1SS133TA DIODE 1 B0AACK000004

D705 RVD1SS133TA DIODE 1 B0AACK000004

D707 RVD1SS133TA DIODE 1 B0AACK000004

D708 RVD1SS133TA DIODE 1 B0AACK000004

IC701 PC900V IC 1 B3PAE0000002

JK701 K4BK01H00001 VIDEO OUT 1

JK702 QJJG020AA MIDI THRU 1

JK703 QJJG020AA MIDI OUT 1

JK704 QJJG020AA MIDI IN 1

JK706 QJJG010AA JACK 1

JK707 QJJG019AA JACK 1

JK708 QJJG019AA JACK 1

JK709 SJSG1390A FC 1 K1CB108B0027

L701 QLQGT3T131LA COIL 1

L703 QLQGT3T131LA COIL 1

L704 QLQGT3T131LA COIL 1

L705 QLQGT3T131LA COIL 1

L706 QLQGT3T131LA COIL 1

L708 QLQGT3T131LA COIL 1

L709 QLQGT3T131LA COIL 1

L710 QLQGT3T131LA COIL 1

L711 QLQGT3T131LA COIL 1

Q701 2SA1015TPE2 TRANSISTOR 1 B1ACCF000016

R701 ERDS2FJ221 22 1

R703 ERDS2FJ220 22 1

R704 ERDS2FJ221 22 1

R706 ERDS2FJ220 22 1

R707 ERDS2FJ221 220 1

R708 ERDS2FJ331 330 1

R709 ERDS2FJ332 3.3K 1

R711 ERDS2FJ102 1K 1

R712 ERDS2FJ152 1.5K 1

R713-18 ERDS2FJ102 1K 6

SW701 QSSGT016AA SW 1 K0D112B00112

Pcs

Remarks

66

Page 67

Ref. No. Part No. Part Name & Description

<INV P.C.B.>

PCB8 SXPG238811B INV PCB 1 <RTL>

C801 ECUV1C104KBV 0.1U 1 ECJ1VB1C104K

C802 ECEA1AKS221 6V 220U 1

C803 ECQV1H104JZ 0.1U 1

C804 ECCW3F180JGE 18P 1

C805 ECUV1C104KBV 0.1U 1 ECJ1VB1C104K

CN801 K1MN20B00049 CONNECTOR 1

CN802 SJPG1JS140A CONNECTOR 1

CN803 RJP4G27ZA CONNECTOR 1 K1KA04A00063

CN804 K1KA02B00124 CONNECTOR 1

L803 QLBG005A COIL 1

L804 QLQGT1B101KA COIL 1 G0C101K00030

Q801,02 2SD0592ARA TRANSISTOR 2

R801,02 ERJ3GEYJ472V 4.7K 2

T801 QTDG005A TRANSFORMER 1 G4F1A0000003

Z801-03 EXBV8V220JV 22X4 3

<ASUB P.C.B.>

PCB9 SXPG238811A ASUB PCB 1 <RTL>

C820 ECJ1VB1H102K 0.001U 1

C821 ECUV1H080DCV 8P 1 ECJ1VC1H080D

C822 ECUV1C104KBV 0.1U 1 ECJ1VB1C104K

C823 ECUV1H471KBV 470P 1 ECJ1VB1H471K

C824 ECJ1VC1H151J 150P 1

C825 ECUV1H471KBV 470P 1 ECJ1VB1H471K

C826-28 ECJ1VC1H151J 150P 3

C829,30 ECEA1EKA470B 25V 47U 2

C831,32 ECJ1VC1H151J 150P 2

C833 ECUV1H471KBV 470P 1 ECJ1VB1H471K

C836-38 ECJ1VC1H151J 150P 3

C841 ECEA1CKS100 16V 10U 1

CN820,21 QJUG05309AA CONNECTOR 2

D820-25 MA2J11100L DIODE 6

D826 MA8062LTX DIODE 1 MAZ80620LL

IC820 TC7WU04FU IC 1 C0JBAB000339

Q820 2SB0709ARL TRANSISTOR 1

Q821 2SD0601AQL TRANSISTOR 1

Q822 2SB0709ARL TRANSISTOR 1

Q823 2SD0601AQL TRANSISTOR 1

Q824 2SB0709ARL TRANSISTOR 1

Q825 2SD0601AQL TRANSISTOR 1

Q826-28 2SB0709ARL TRANSISTOR 3

Q829 2SD0601AQL TRANSISTOR 1

Q830 2SB0709ARL TRANSISTOR 1

Q831 2SD0601AQL TRANSISTOR 1

Q832 2SB0709ARL TRANSISTOR 1

Q833 2SD0601AQL TRANSISTOR 1

Q834,35 2SB0709ARL TRANSISTOR 2

Q836 2SD0601AQL TRANSISTOR 1

Q837 2SB0709ARL TRANSISTOR 1

Q838 2SD0601AQL TRANSISTOR 1

Pcs

Remarks

67

Page 68

Ref. No. Part No. Part Name & Description

Q839,40 2SB0709ARL TRANSISTOR 2

Q841,42 2SD0601AQL TRANSISTOR 2

Q843 2SB0709ARL TRANSISTOR 1

Q844 2SD0601AQL TRANSISTOR 1

Q845 2SB0709ARL TRANSISTOR 1

Q846 2SD0601AQL TRANSISTOR 1

Q847,48 2SB0709ARL TRANSISTOR 2

Q849 2SD0601AQL TRANSISTOR 1

Q850-52 2SB0709ARL TRANSISTOR 3

Q853,54 2SD0601AQL TRANSISTOR 2

Q855 2SB0709ARL TRANSISTOR 1

Q856 2SD0601AQL TRANSISTOR 1

Q857 2SB0709ARL TRANSISTOR 1

Q858 2SD0601AQL TRANSISTOR 1

Q859 2SB0709ARL TRANSISTOR 1

Q860,61 2SD0601AQL TRANSISTOR 2

R820 ERJ3GEYJ102V 1K 1

R821,22 ERJ3GEYJ332V 3.3K 2 D0GB332JA002

R823 ERJ3GEYJ102V 1K 1

R824,25 ERJ3GEYJ471V 470 2

R826 ERJ3GEYJ472V 4.7K 1

R827 ERJ3GEYJ152V 1.5K 1

R828 ERJ3GEYJ471V 470 1

R829 ERJ3GEYJ472V 4.7K 1

R830 ERJ3GEYJ822V 8.2K 1 D0GB822JA002

R831 ERJ3GEYJ821V 820 1

R833 ERD2FCVG471T 1/4W 470 FUSE TYPE 1

R834 ERJ3GEYJ332V 3.3K 1 D0GB332JA002

R835 ERJ3GEYJ153V 15K 1

R836 ERJ3GEYJ332V 3.3K 1 D0GB332JA002

R838-40 ERD2FCVG471T 1/4W 470 FUSE TYPE 3

R841,42 ERJ3GEYJ472V 4.7K 2

R843 ERJ3GEYJ332V 3.3K 1 D0GB332JA002

R844,45 ERJ3GEYJ472V 4.7K 2

R846 ERJ3GEYJ153V 15K 1

R847 ERJ3GEYJ332V 3.3K 1 D0GB332JA002

R848,49 ERD2FCVG471T 1/4W 470 FUSE TYPE 2

R850 ERD2FCG101 100 1

R851-54 ERJ3GEYJ472V 4.7K 4

R855 ERD2FCG101 100 1

R857 ERD2FCVG471T 1/4W 470 FUSE TYPE 1

R858 ERJ3GEYJ332V 3.3K 1 D0GB332JA002

R859 ERJ3GEYJ153V 15K 1

R860 ERJ3GEYJ332V 3.3K 1 D0GB332JA002

R861,62 ERD2FCVG471T 1/4W 470 FUSE TYPE 2

R863-66 ERJ3GEYJ472V 4.7K 4

R867 ERD2FCG101 100 1

R868,69 ERJ3GEYJ821V 820 2

R870,71 ERJ3GEYJ471V 470 2

Pcs

Remarks

<ACP P.C.B.>

68

Page 69

Ref. No. Part No. Part Name & Description

PCB5 SXPG232941 ACP PCB 1 <RTL>EF EH EV GN GH

PCB5 SXPG232951 ACP PCB 1 <RTL>P PC

PCB5 SXPG232961 ACP PCB 1 <RTL>GM GU GT

C1 F1B2E4720001 4700P 1

C2 ECQU2A104MN 0.1 1

F1 XBA1C20NB100 FUSE 2A 1

F1 XBA2C12TB0L FUSE T1.25A 1

F2 XBA2C08TB0L FUSE T800MA 1

F2 XBA2C08TB0L FUSE T800MA 1

F2 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

F3 XBA2C08TB0L FUSE T800MA 1

JK1 SJVD0203B JACK AC IN 1

L1 QLQGT2T100LA 10UHX2 1

S1 SSRG100A SW VOLTAGE SELECTOR 1

S1 SSRG100A SW VOLTAGE SELECTOR 1

S1 SSRG100A SW VOLTAGE SELECTOR 1

Pcs

(P PC)

(GU GT GM)

K5D801BLA001 (GU)

K5D801BLA001 (GT)

K5D801BLA001 (GM)

K5D801BLA001 (EX)

K5D801BLA001 (EB)

K5D801BLA001 (EQ)

K5D801BLA001 (EG)

K5D801BLA001 (EF)

K5D801BLA001 (EH)

K5D801BLA001 (EV)

K5D801BLA001 (GN)

K5D801BLA001 (GH)

K0ZZ00000503 (GU)

K0ZZ00000503 (GT)

K0ZZ00000503 (GM)

Remarks

<CPL P.C.B.>

PCB11 SXPG238911A CPL PCB 1 <RTL>

C1101-03 QCBG1H473ZFA 0.047U 3 F1E1H473A001

C1105 ECA0JAK221XH 6V 220U 1

C1106 QCBG1H473ZFA 0.047U 1 F1E1H473A001

C1108,09 QCBG1H473ZFA 0.047U 2 F1E1H473A001

C1110 ECA0JAK470XH 6V 47U 1

C1111-16 QCBG1H473ZFA 0.047U 6 F1E1H473A001

CN1101 K1KA07C00007 CONNECTOR 1

CN1102 K1KA04B00032 CONNECTOR 1

CN1104 SJPG2JS130A CONNECTOR 1

CN1105 K1KA12C00012 CONNECTOR 1

CN1106 K1KA06C00008 CONNECTOR 1

D1101 RVD1SS133TA DIODE 1 B0AACK000004

D1102 RVD1SS133TA DIODE 1 B0AACK000004

D1103 RVD1SS133TA DIODE 1 B0AACK000004

D1104 RVD1SS133TA DIODE 1 B0AACK000004

D1105 RVD1SS133TA DIODE 1 B0AACK000004

D1106 RVD1SS133TA DIODE 1 B0AACK000004

D1107 RVD1SS133TA DIODE 1 B0AACK000004

D1108 RVD1SS133TA DIODE 1 B0AACK000004

D1109 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1110 LN382GPXVTX3 LED 1 LNJ382GKGX02

69

Page 70

D1110

LN382GPXVTX3

LED1LNJ382GKGX02

70

Page 71

Ref. No. Part No. Part Name & Description

D1111 LN382GPXVTX3 LED 1 LNJ382GKGX02

D1112 LN382GPXVTX3 LED 1 LNJ382GKGX02

D1113 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1114 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1115 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1116 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1117 RVD1SS133TA DIODE 1 B0AACK000004

D1118 RVD1SS133TA DIODE 1 B0AACK000004

D1119 RVD1SS133TA DIODE 1 B0AACK000004

D1120 RVD1SS133TA DIODE 1 B0AACK000004

D1121 RVD1SS133TA DIODE 1 B0AACK000004

D1122 RVD1SS133TA DIODE 1 B0AACK000004

D1123 RVD1SS133TA DIODE 1 B0AACK000004

D1124 RVD1SS133TA DIODE 1 B0AACK000004

D1125 LN382GPXVTX3 LED 1 LNJ382GKGX02

D1126 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1127 LN382GPXVTX3 LED 1 LNJ382GKGX02

D1128-32 LN282RPXVTX3 LED 5 LNJ282RKRX02

D1133-40 RVD1SS133TA DIODE 8 B0AACK000004

D1141-48 LN282RPXVTX3 LED 8 LNJ282RKRX02

D1149-56 RVD1SS133TA DIODE 8 B0AACK000004

D1157-64 LN282RPXVTX3 LED 8 LNJ282RKRX02

D1165-72 RVD1SS133TA DIODE 8 B0AACK000004

D1173 LN382GPXVTX3 LED 1 LNJ382GKGX02

D1174 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1175-79 LN382GPXVTX3 LED 5 LNJ382GKGX02

D1180 LN282RPXVTX3 LED 1 LNJ282RKRX02

D1181-94 RVD1SS133TA DIODE 13 B0AACK000004

IC1101 M37471M2196S IC 1 C2BBDB000023

IC1102 HD74LS138P DECODER 1 C0JACN000001

IC1103 HD74LS07P IC 1 C0JACB000006

Q1101-08 2SA830STPB TRANSISTOR 8

R1101 ERDS2FJ102 1K 1

R1103,04 ERDS2FJ102 1K 2

R1105 ERDS2FJ104 100K 1

R1106,07 ERDS2FJ101 100 2

R1108 ERDS2FJ103 10K 1

R1109 ERDS2FJ333 33K 1

R1110 ERDS2FJ103 10K 1

R1112-27 ERDS2FJ103 10K 16

R1128-33 ERDS2FJ680 68 6

SW1102-38 EVQ21405R PUSH SWITCH 37 EVQ21405RJ

SW1139-42 EVQ21507K PUSH SWITCH 4

SW1143 EVQ21405R PUSH SWITCH 1 EVQ21405RJ

SW1144 EVQ21507K PUSH SWITCH 1

SW1145 EVQ21405R PUSH SWITCH 1 EVQ21405RJ

SW1146 EVQ21507K PUSH SWITCH 1

SW1147,48 EVQ21405R PUSH SWITCH 2 EVQ21405RJ

SW1149 JSE0013 PUSH SWITCH 1 K0L1BA000007

SW1150-54 EVQ21405R PUSH SWITCH 5 EVQ21405RJ

VR1102 EVD07205B24G VOLUME 1 D2B6A24B0003

VR1103 QRVG30P02B53 VOLUME 1 D2B6C53B0003

VR1104 QRVG20N01B14 VOLUME 1 D2B4A14B0003

VR1105 D2B4C53A0002 VOLUME 1

Pcs

Remarks

71

Page 72

Ref. No. Part No. Part Name & Description

X1101 EFOEC4004T3 4MHZ CERAMIC OSCILATOR 1

<CPC P.C.B.>

PCB12 SXPG238911B CPC PCB 1 <RTL>

CN1107 K1KA12C00012 CONNECTOR 1

CN1108 K1KA06C00008 CONNECTOR 1

D1195-02 RVD1SS133TA DIODE 8 B0AACK000004