Page 1

Table Of Contents

COVER

1 Note

2 Handling Precautions for

Traverse Deck

2.1 Handling of traverse

deck (optical pickup)

2.2 Grounding for

electrostatic breakdown

prevention

2.2.1 Human body

grounding

2.2.2 Work table grounding

3 Precaution of Laser Diode

4 Location of Controls

5 Operation Checks and

Component

ReplacementProcedures

5.1 Checking for the main P.

C.B.

5.2 Checking for the CD

servo P.C.B.

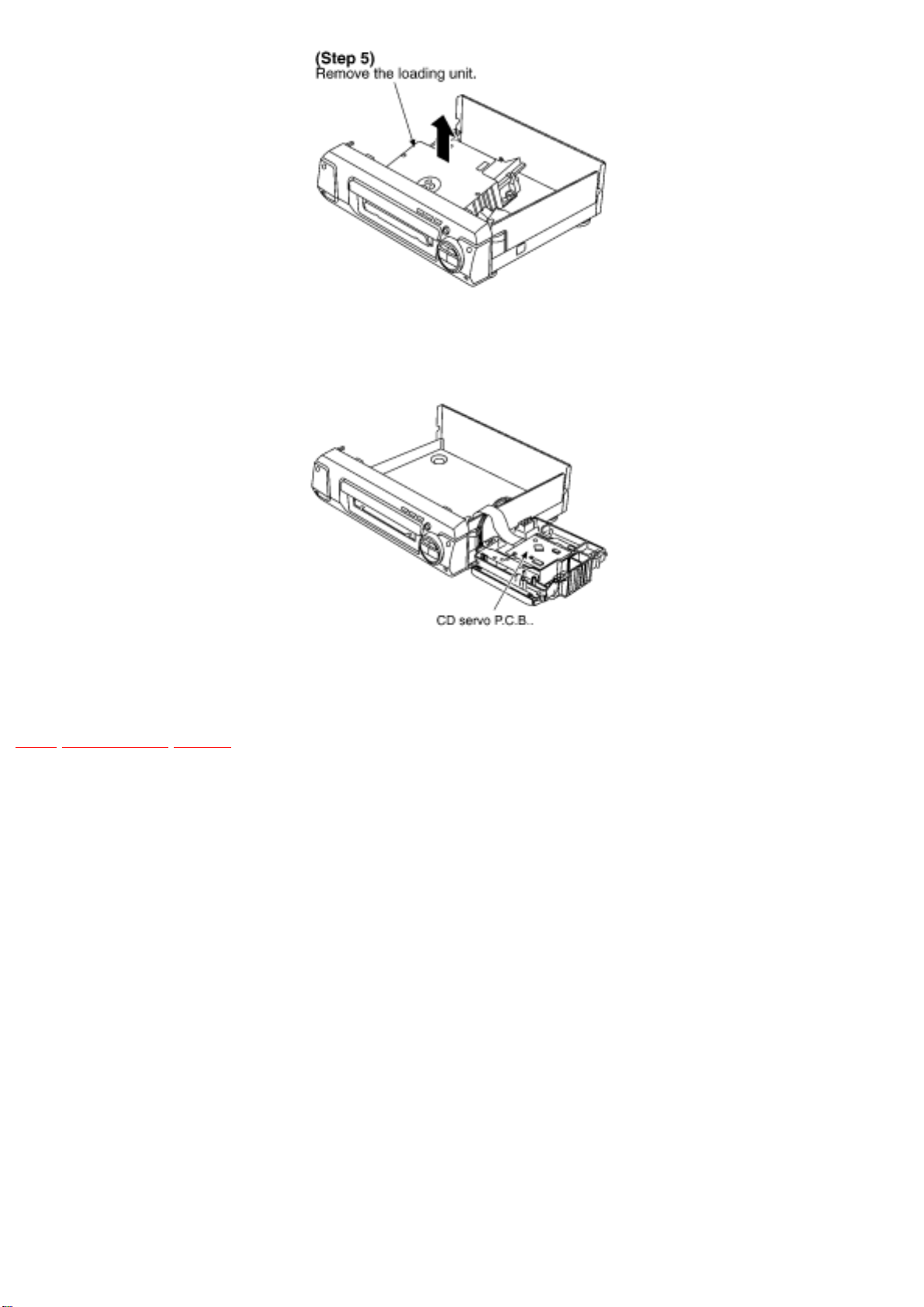

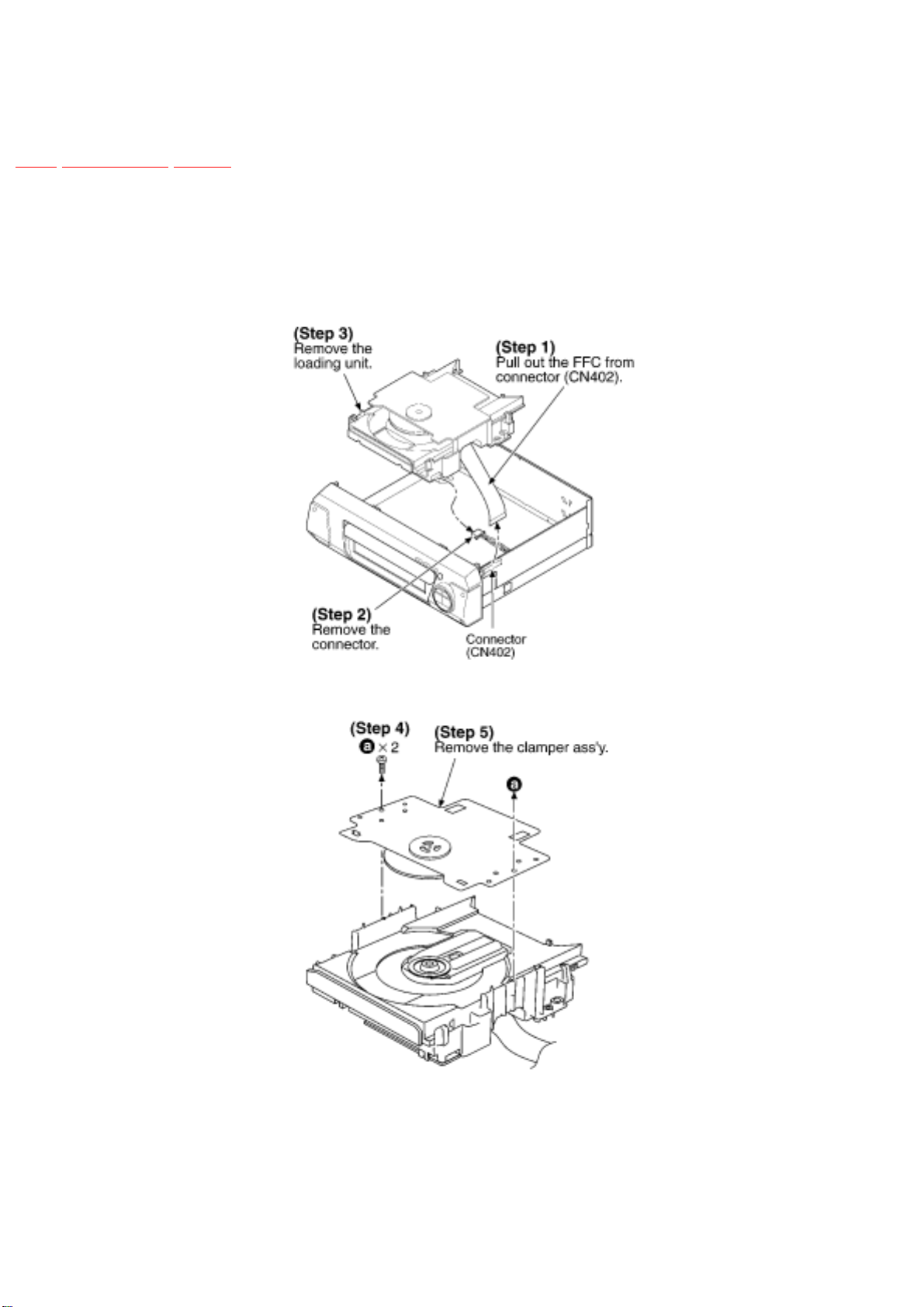

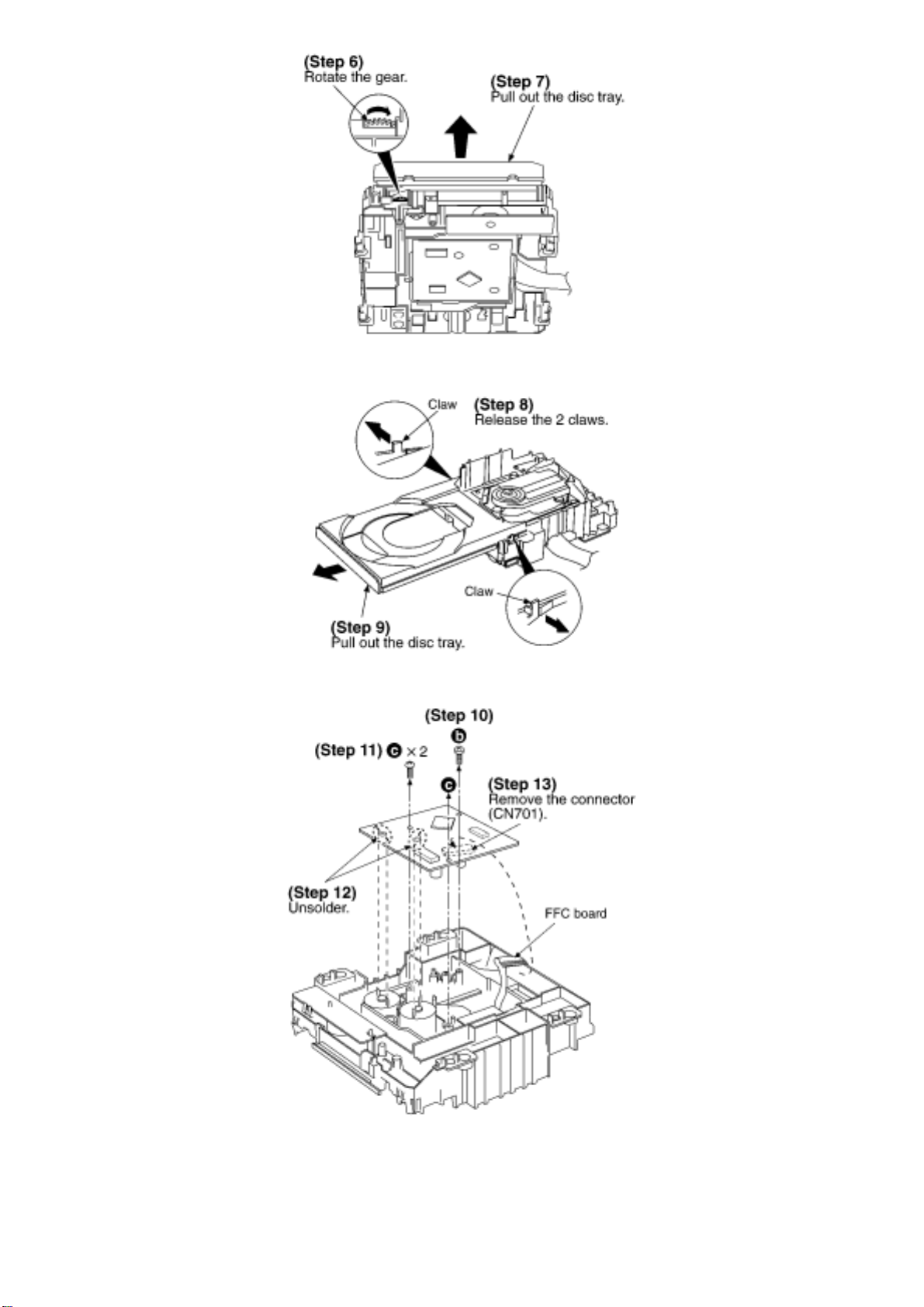

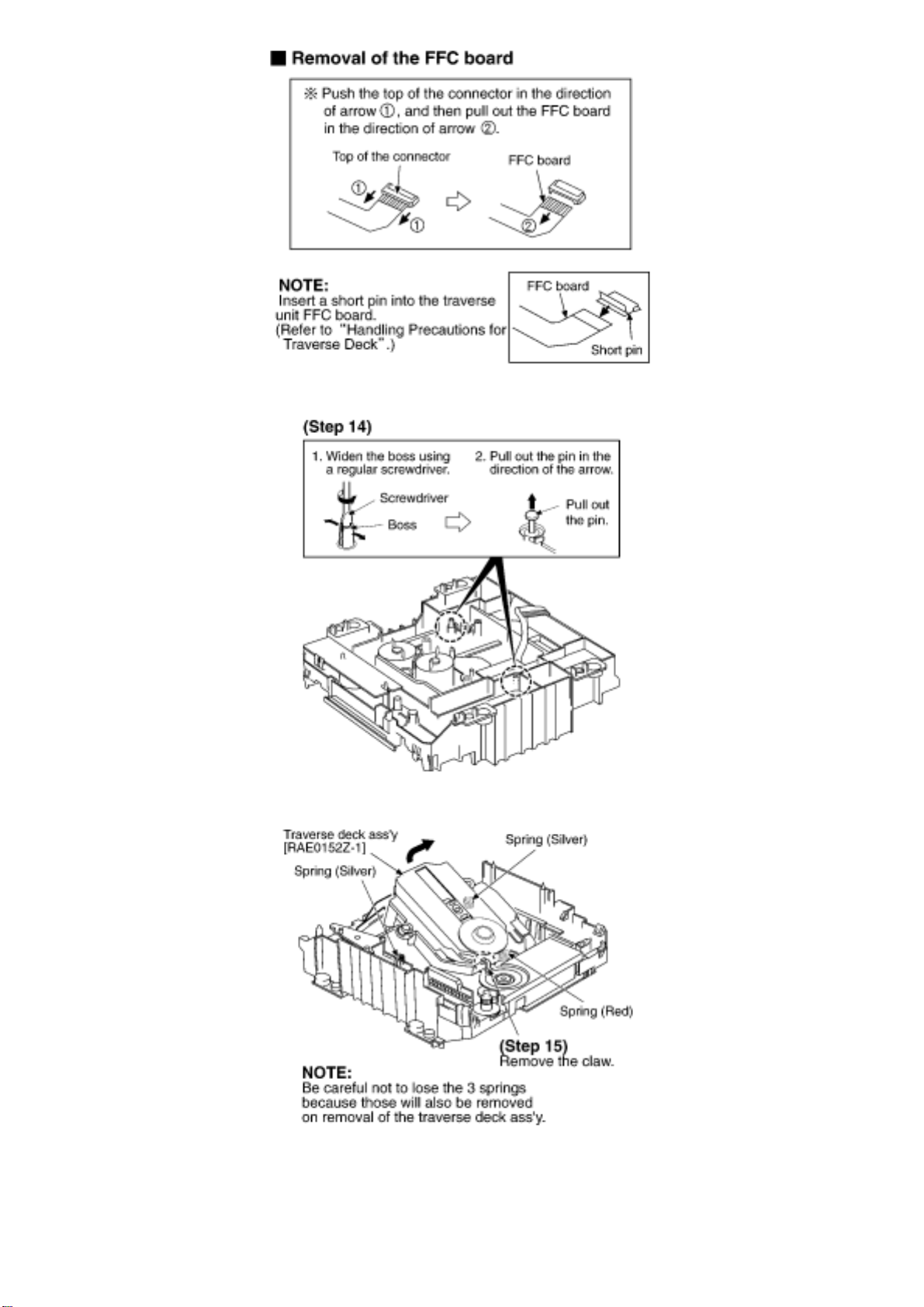

5.3 Replacement for the

traverse deck ass’y

5.4 Replacement for the

belt, loading motor ass’y and

loading switch

6 Error Code Display and

Servo Adjustment Function

6.1 Error Code Display

Procedure

6.1.1 Automatic Adjustment

Results

6.1.2 Checking the

mechanism switches

6.2 Servo Adjustment

Procedure

6.3 Error code based on

troubleshooting

7 To Supply Power Source

8 Schematic Diagram Notes

9 Schematic Diagram

10 Printed Circuit Board

Diagram

11 Type Illustration of ICs,

Transistors and Diodes

12 Wiring Connection

Diagram

13 Block Diagram

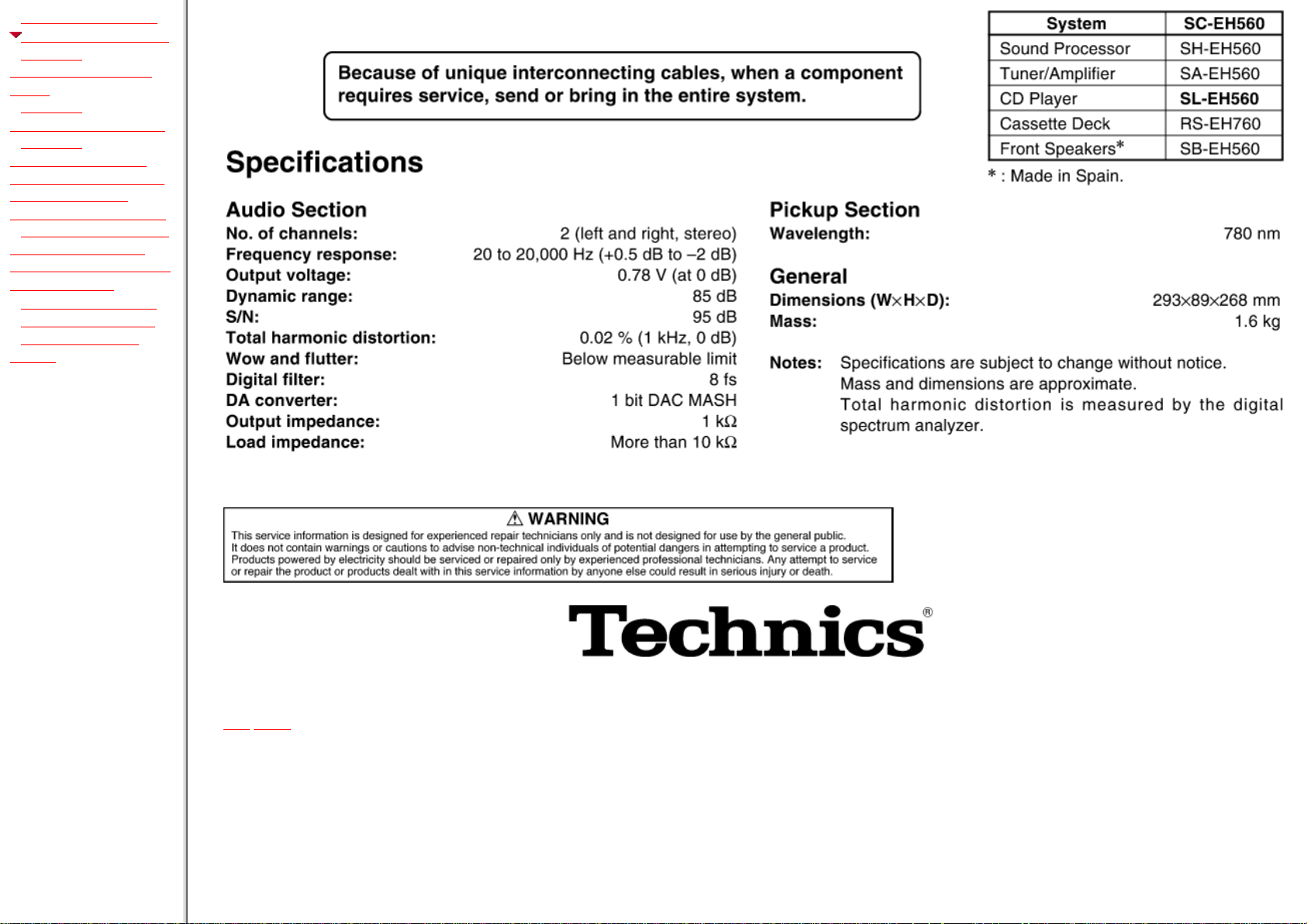

Service Manual

TOP NEXT

AD0002042C2

Compact Disc Player

SL-EH560

Traverse Deck:RAE0152Z-1 Mechanism series

Colour

(S)..........Silver Type

Area

(E)..........Europe.

Page 2

14 Troubleshooting Guide

15 Terminal Function of ICs

15.1 IC451

(M38504M6200F):System

Control

15.2 IC701

(AN8839NSBE2):Servo Amp

15.3 IC702

(MN662790RSA1):Servo

Processor/Digital Signal

Processor/Digital

Filter/D/A converter

15.4 IC703 (AN8739SBE2):

Focus Coil/Tracking

Coil/Traverse Motor/

SpindleMotor Drive

16 Replacement Parts List

17 Cabinet Parts Location

18 Loading Unit Parts

Location

© 2000 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

•@

TOP NEXT

Page 3

Table Of Contents

COVER

1 Note

2 Handling Precautions for Traverse Deck

2.1 Handling of traverse deck (optical pickup)

2.2 Grounding for electrostatic breakdown prevention

2.2.1 Human body grounding

2.2.2 Work table grounding

3 Precaution of Laser Diode

4 Location of Controls

5 Operation Checks and Component ReplacementProcedures

5.1 Checking for the main P.C.B.

5.2 Checking for the CD servo P.C.B.

5.3 Replacement for the traverse deck ass’y

5.4 Replacement for the belt, loading motor ass’y and loading switch

6 Error Code Display and Servo Adjustment Function

6.1 Error Code Display Procedure

6.1.1 Automatic Adjustment Results

6.1.2 Checking the mechanism switches

6.2 Servo Adjustment Procedure

Page 4

6.3 Error code based on troubleshooting

7 To Supply Power Source

8 Schematic Diagram Notes

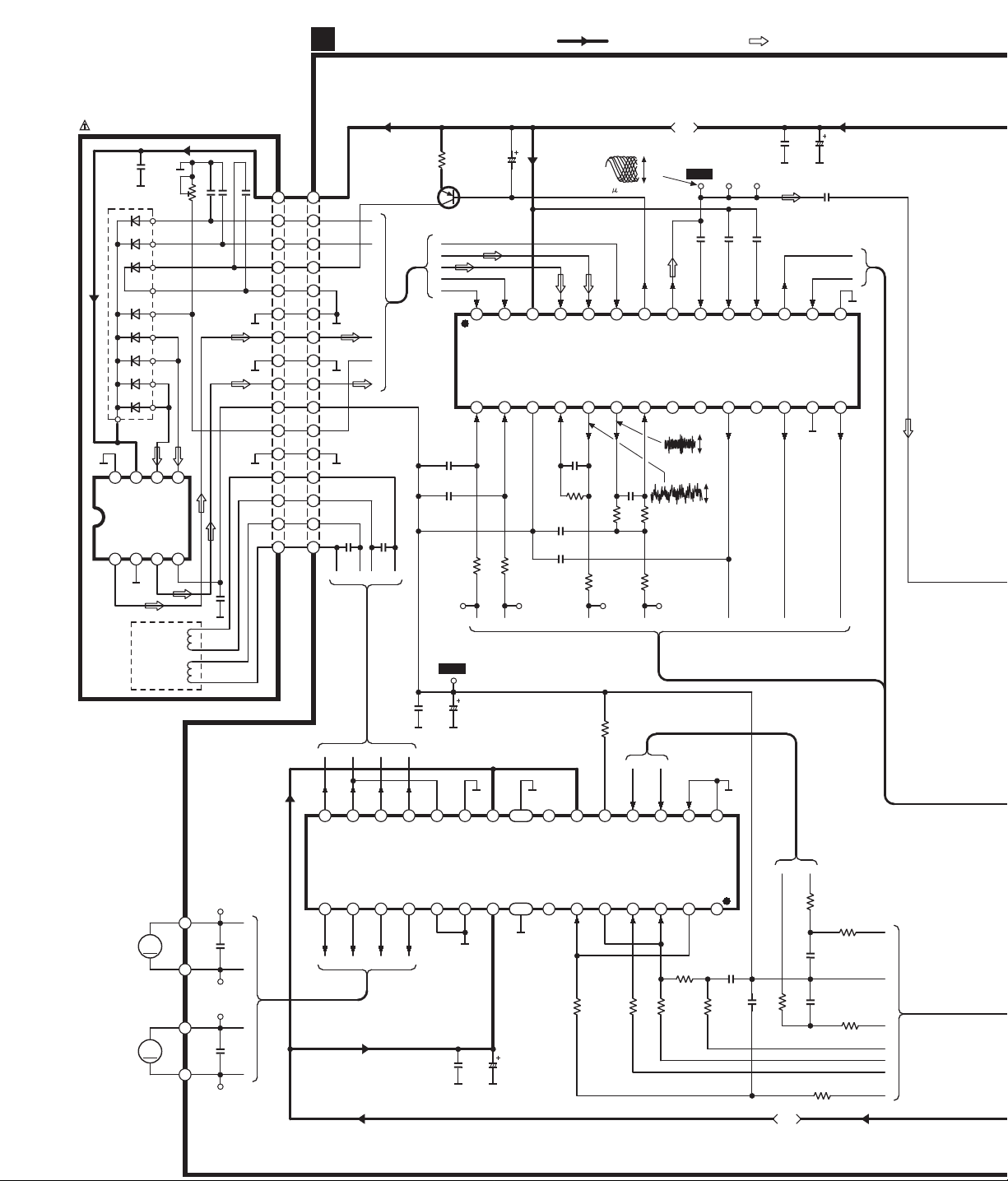

9 Schematic Diagram

10 Printed Circuit Board Diagram

11 Type Illustration of ICs, Transistors and Diodes

12 Wiring Connection Diagram

13 Block Diagram

14 Troubleshooting Guide

15 Terminal Function of ICs

15.1 IC451 (M38504M6200F):System Control

15.2 IC701 (AN8839NSBE2):Servo Amp

15.3 IC702 (MN662790RSA1):Servo Processor/Digital Signal Processor/Digital Filter/D/A converter

15.4 IC703 (AN8739SBE2):Focus Coil/Tracking Coil/Traverse Motor/SpindleMotor Drive

16 Replacement Parts List

17 Cabinet Parts Location

18 Loading Unit Parts Location

Page 5

Service Manual

TOP NEXT

AD0002042C2

Compact Disc Player

SL-EH560

Traverse Deck:RAE0152Z-1 Mechanism series

Colour

(S)..........Silver Type

Area

(E)..........Europe.

Page 6

© 2000 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

•@

TOP NEXT

Page 7

1 Note

TOP PREVIOUS NEXT

Refer to the service manual for Model No. SA-EH560 (OREDER No. AD0002043C2) for

information on Packaging.

•@

TOP PREVIOUS NEXT

Page 8

2 Handling Precautions for Traverse Deck

TOP PREVIOUS NEXT

The laser diode in the traverse deck (optical pickup) may break down due to potential difference

caused by static electricity of clothes or human body.

So be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

2.1 Handling of traverse deck (optical pickup)

2.2 Grounding for electrostatic breakdown prevention

2.2.1 Human body grounding

2.2.2 Work table grounding

•@

TOP PREVIOUS NEXT

Page 9

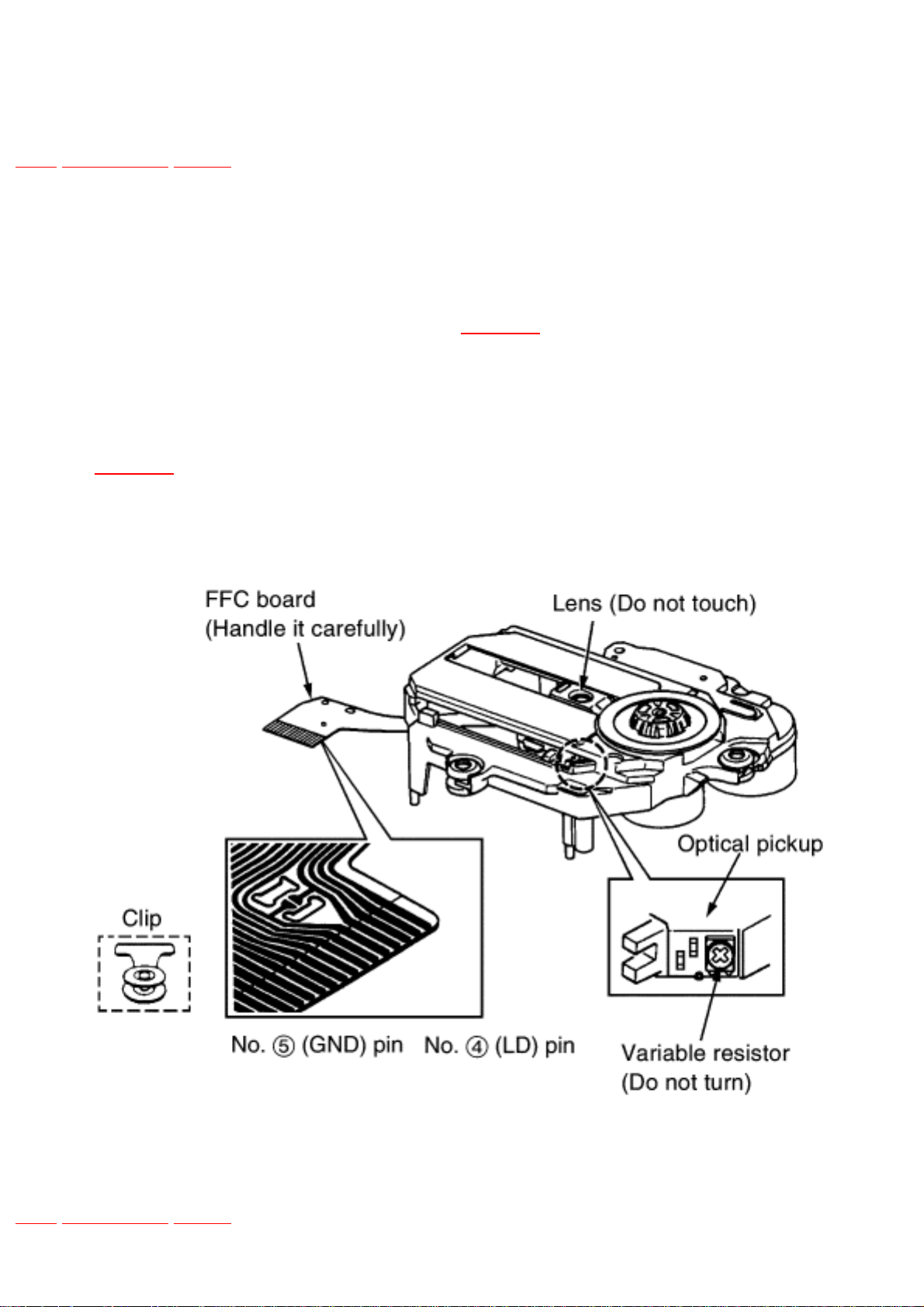

2.1 Handling of traverse deck (optical pickup)

TOP PREVIOUS NEXT

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive

to electrical shock.

2. To protect the laser diode against electrostatic breakdown, short the flexible board (FFC

board) with a clip or similar object. Refer to

3. Take care not to apply excessive stress to the flexible board (FFC board).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted. Refer

to

Fig. 2-1.

Fig. 2-1.

Fig. 2-1.

•@

TOP PREVIOUS NEXT

Page 10

2.2 Grounding for electrostatic breakdown

prevention

TOP PREVIOUS NEXT

2.2.1 Human body grounding

2.2.2 Work table grounding

•@

TOP PREVIOUS NEXT

Page 11

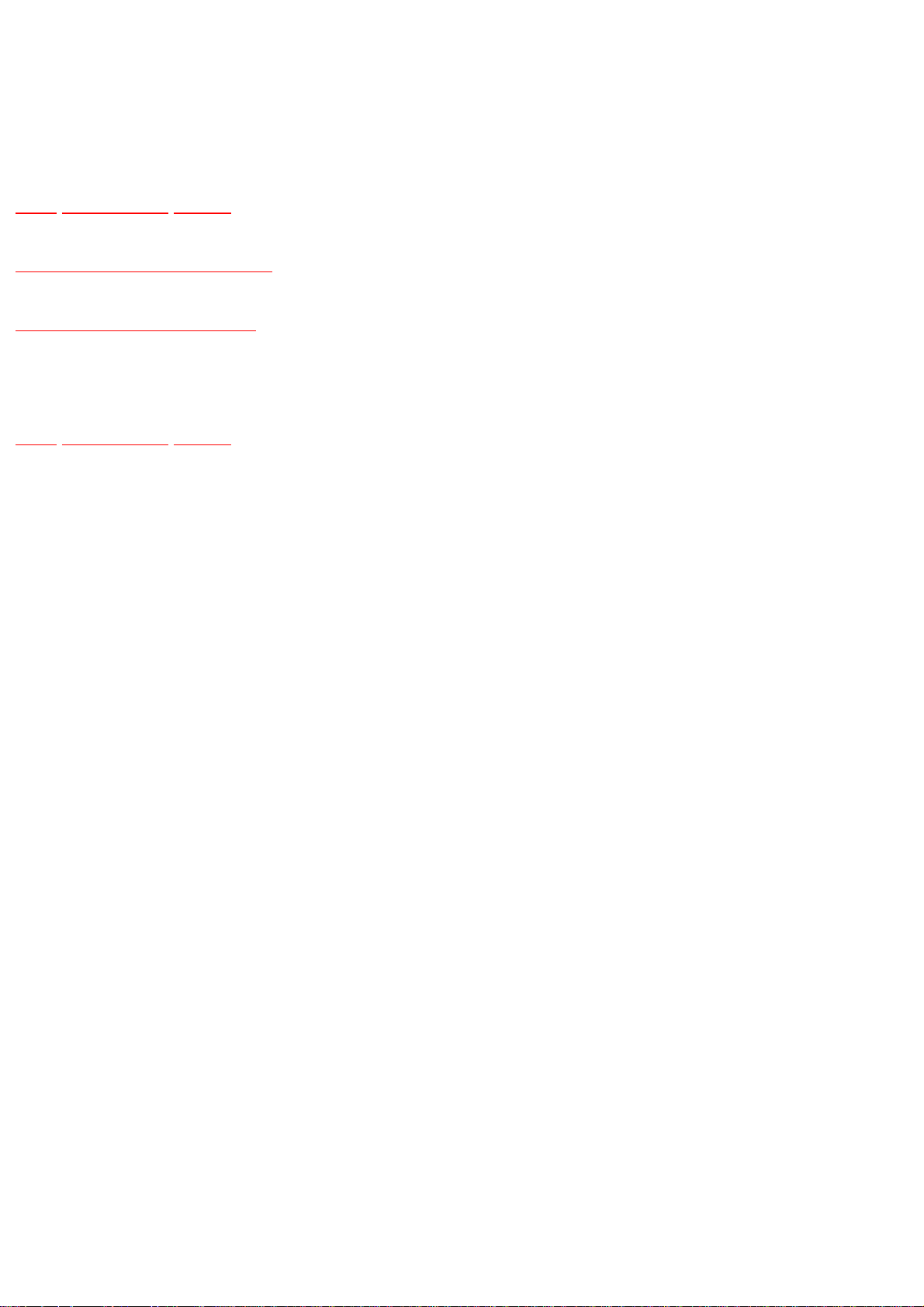

2.2.1 Human body grounding

TOP PREVIOUS NEXT

Use the anti-static wrist strap to discharge the static electricity from your body. Refer to Fig. 2-2.

Fig. 2-2.

•@

TOP PREVIOUS NEXT

Page 12

2.2.2 Work table grounding

TOP PREVIOUS NEXT

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is

placed, and ground the sheet. Refer to Fig. 2-3.

Fig. 2-3.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap.

So take care not to let your clothes tough the traverse deck (optical pickup).

•@

TOP PREVIOUS NEXT

Page 13

3 Precaution of Laser Diode

TOP PREVIOUS NEXT

CAUTION:

This product utilizes a laser diode with the unit turned on, invisible laser radiation is emitted from the pickup lens.

Wave length: 780 nm

Maximum output radiation power from pickup: 100μW/VDE

Laser radiation from pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at the pickup lens for a long time.

Page 14

•@

TOP PREVIOUS NEXT

Page 15

4 Location of Controls

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 16

5 Operation Checks and Component

Replacement/Procedures

TOP PREVIOUS NEXT

This section describes procedures for checking the operation of the major printed circuit boards and

replacing the main components.

For reassembly after operation checks or replacement, reverse the respective procedures. Special

reassembly procedures are described only when required.

/

5.1 Checking for the main P.C.B.

5.2 Checking for the CD servo P.C.B.

5.3 Replacement for the traverse deck ass’y

5.4 Replacement for the belt, loading motor ass’y and loading switch

•@

TOP PREVIOUS NEXT

Page 17

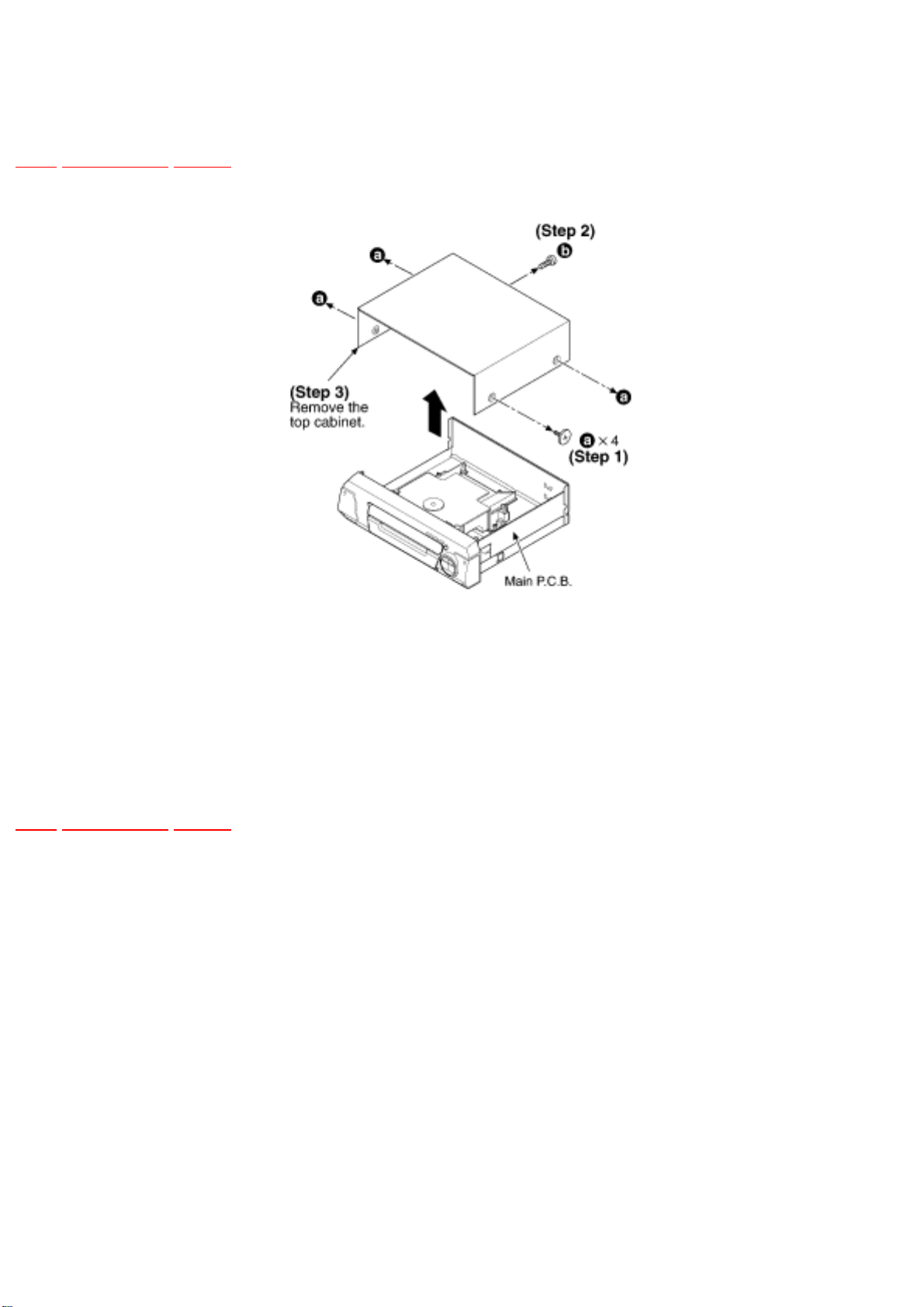

5.1 Checking for the main P.C.B.

TOP PREVIOUS NEXT

Check the main P.C.B. as shown above.

/

•@

TOP PREVIOUS NEXT

Page 18

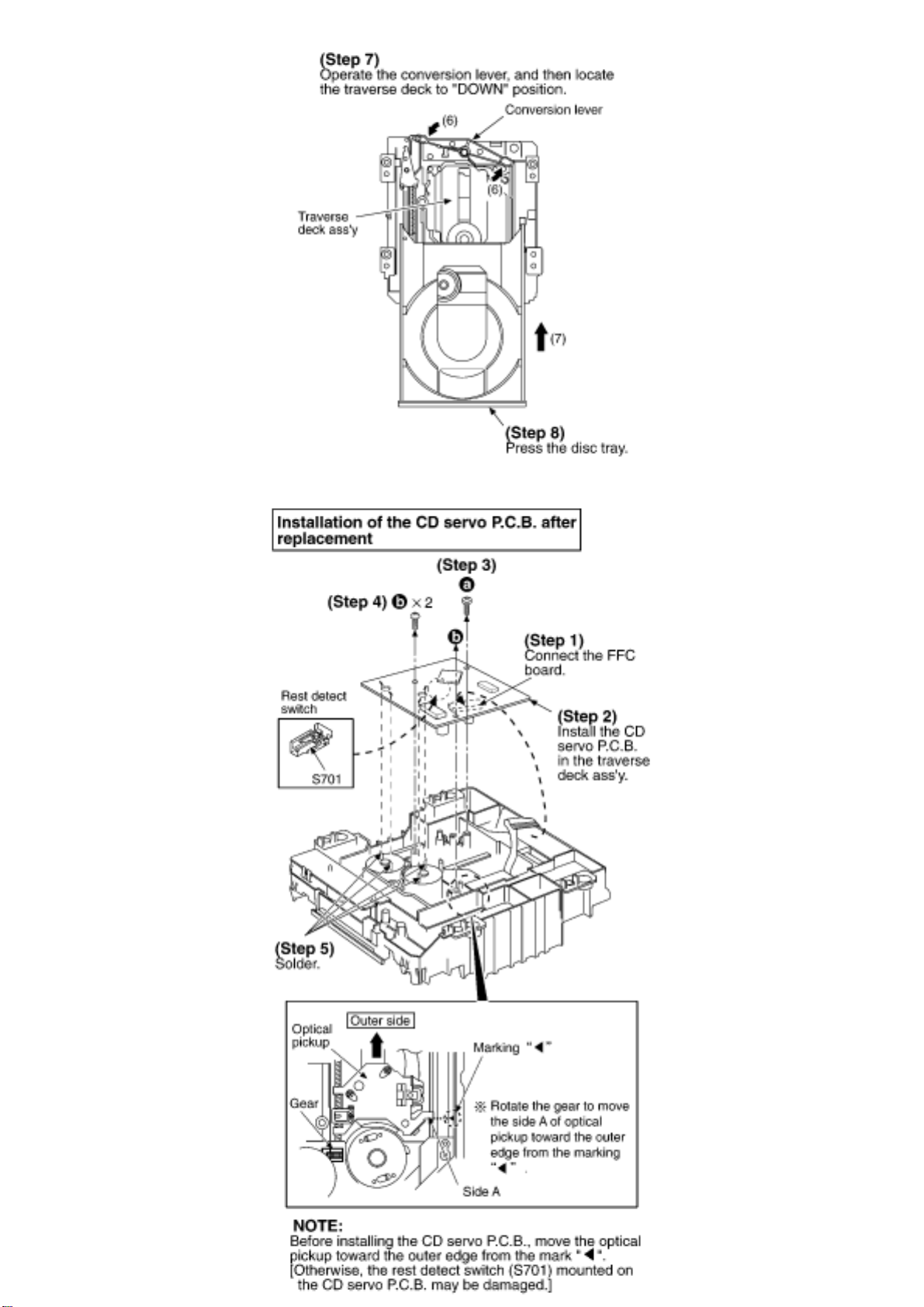

5.2 Checking for the CD servo P.C.B.

TOP PREVIOUS NEXT

Follow the (Step 1) - (Step 3) of item 5.1.

Page 19

Check the CD servo P.C.B. as shown below.

•@

TOP PREVIOUS NEXT

Page 20

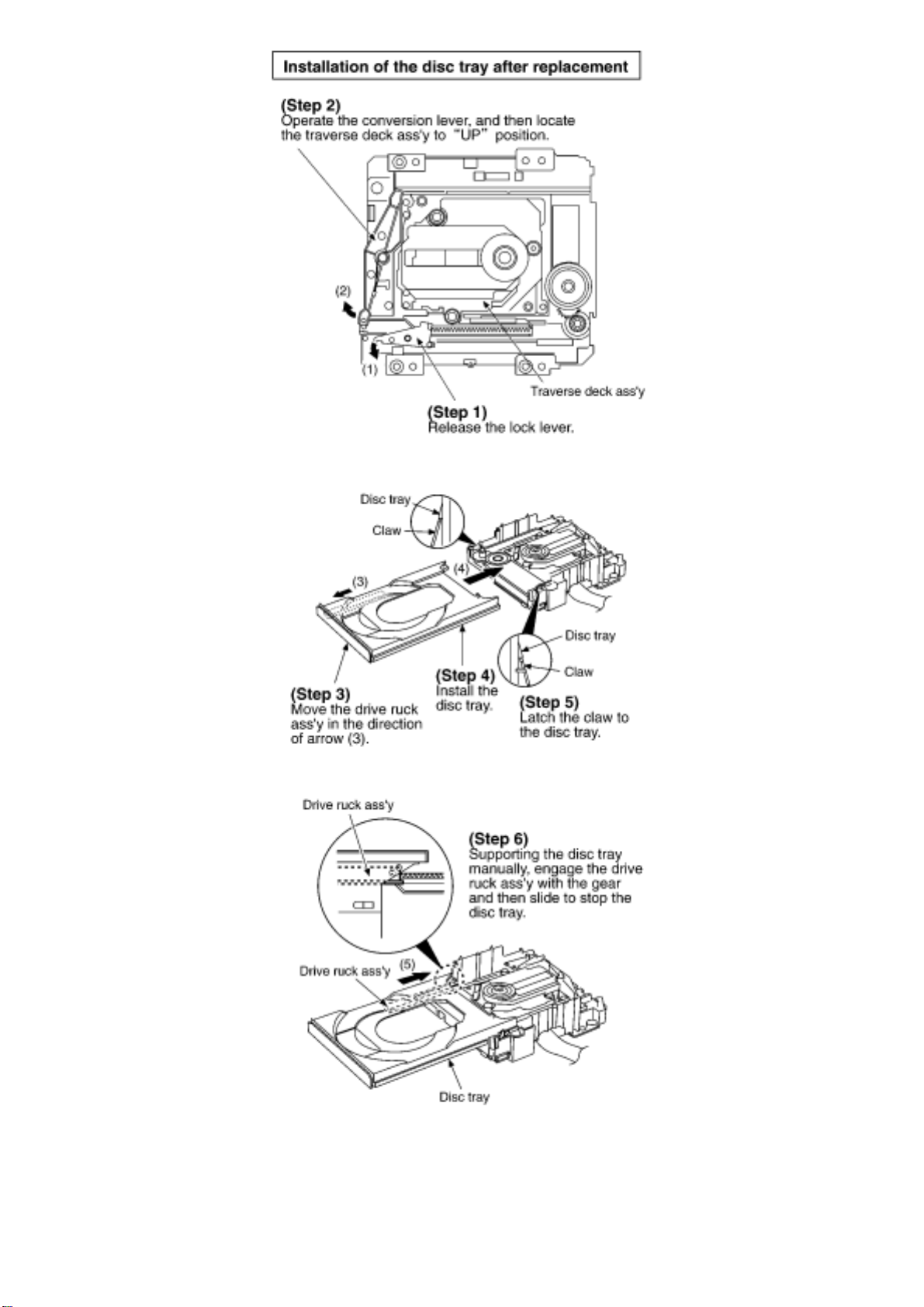

5.3 Replacement for the traverse deck ass’y

TOP PREVIOUS NEXT

Follow the (Step 1) - (Step 3) of item 5.1.

Follow the (Step 1) - (Step 5) of item 5.2.

Page 21

Page 22

Page 23

Page 24

Page 25

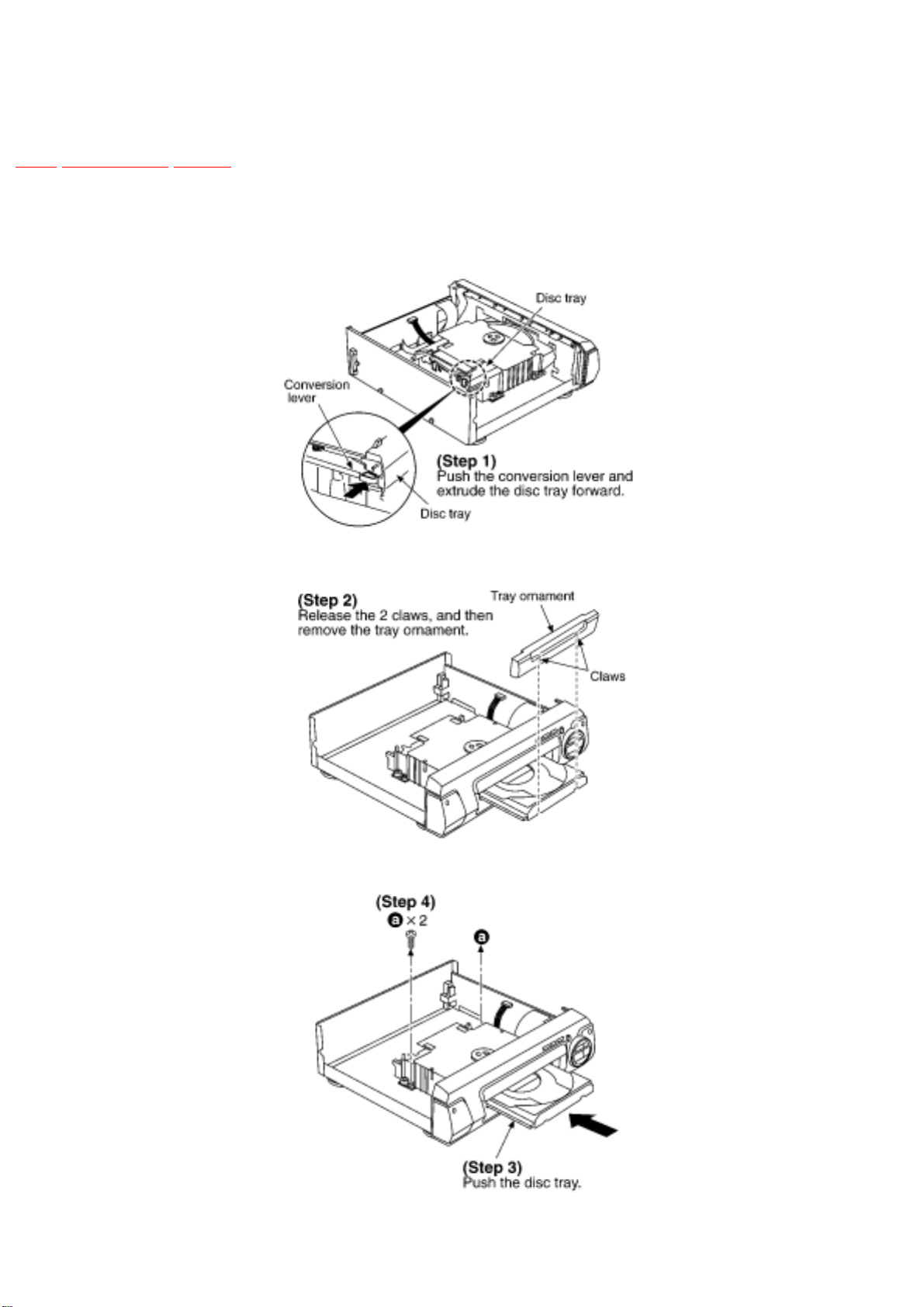

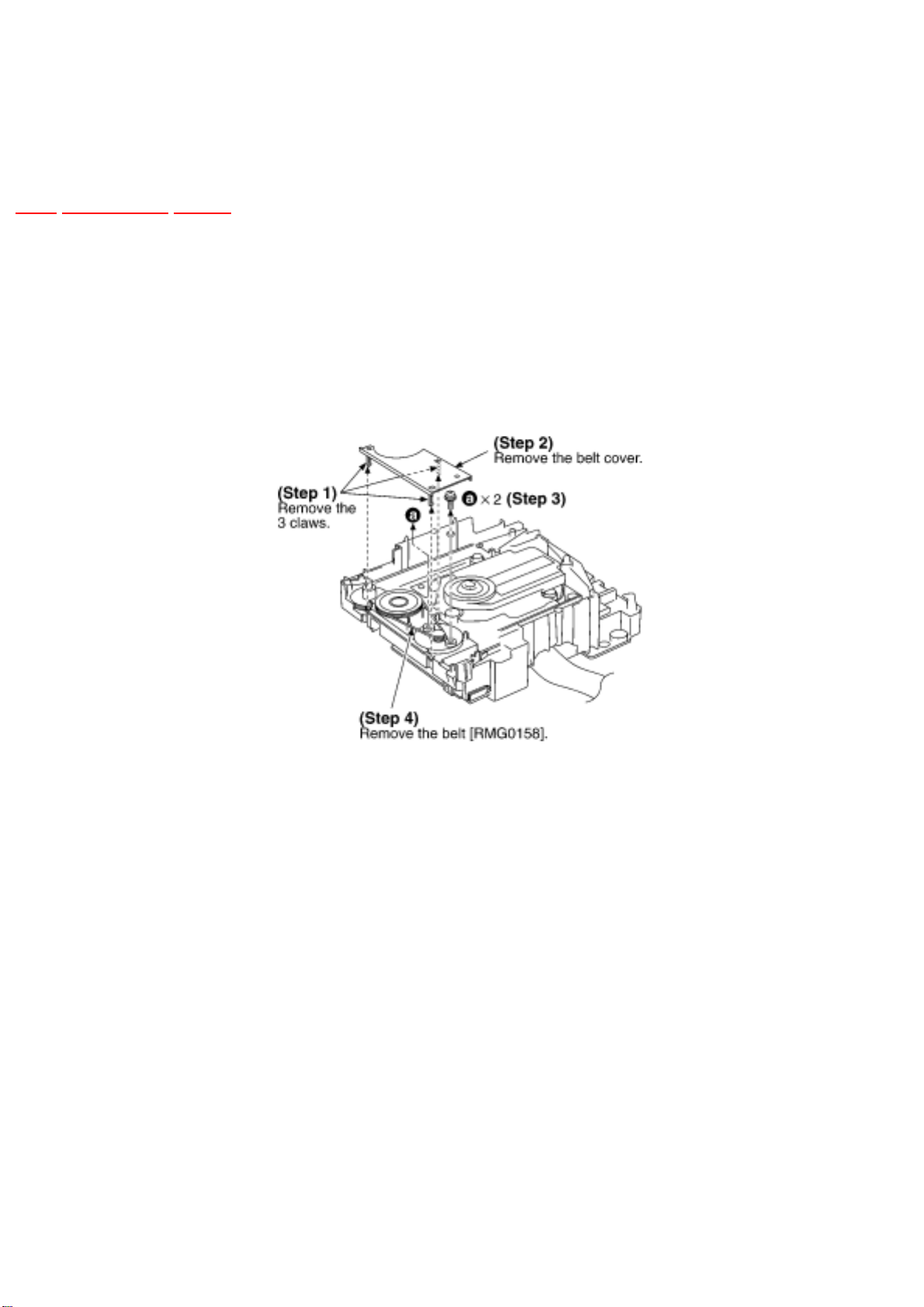

5.4 Replacement for the belt, loading motor

ass’y and loading switch

TOP PREVIOUS NEXT

Follow the (Step 1) - (Step 3) of item 5.1.

Follow the (Step 1) - (Step 5) of item 5.2.

Follow the (Step 1) - (Step 9) of item 5.3.

Page 26

•@

TOP PREVIOUS NEXT

Page 27

6 Error Code Display and Servo Adjustment

Function

TOP PREVIOUS NEXT

This unit has an error code display function, so that if the unit operates incorrectly, the fault is

displayed using an error code on the FL display of the Tuner/Amplifier (SA-EH560). It also has a

servo adjustment function for displayingthe status of servo system functions (Focus, Tracking, CLV

servo) on the FL display of the Tuner/Amplifier. The system control IC and FL display are part of the

Tuner/Amplifier so make sure the system has been connected properly beforeusing these functions.

Use these two functions for guidance during fault diagnosis and repair.

Note:

Check beforehand for scratching or soiling of the test disc (SZZP1054C), and soiling or other

problems with the pickup lens.

6.1 Error Code Display Procedure

6.1.1 Automatic Adjustment Results

6.1.2 Checking the mechanism switches

6.2 Servo Adjustment Procedure

6.3 Error code based on troubleshooting

•@

TOP PREVIOUS NEXT

Page 28

6.1 Error Code Display Procedure

TOP PREVIOUS NEXT

6.1.1 Automatic Adjustment Results

6.1.2 Checking the mechanism switches

•@

TOP PREVIOUS NEXT

Page 29

6.1.1 Automatic Adjustment Results

TOP PREVIOUS NEXT

1. Turn on the power.

2. Load the test disc (SZZP1054C).

3. Hold down the REPEAT button for at least 2 seconds, and then press the STOP button for at

least 2 seconds while continuing to hold down the REPEAT button.

4. A servo section error code is displayed. Refer to

this error code display as a guideline for finding the malfunction point in the servo circuitry. If

the errorcode E00 is displayed, the unit is OK.

•@

TOP PREVIOUS NEXT

Error code based on troubleshooting . Use

Page 30

6.1.2 Checking the mechanism switches

TOP PREVIOUS NEXT

1. Press the F.SKIP button.

2. A mechanism OK/NG error code is displayed. Refer to Table 6-1. This error code can be used diagnose whether the mechanism is OK or not. If there are multiple errors, these can be

displayedsuccessively by pressing the F.SKIP button.

3. Remove the disc and turn off the power. (The error code display mode is canceled.)

Table 6-1.

•@

TOP PREVIOUS NEXT

Page 31

6.2 Servo Adjustment Procedure

TOP PREVIOUS NEXT

1. Turn on the power.

2. Load the test disc (SZZP1054C).

3. Hold down the REPEAT button for at least 2 seconds, and then press the PAUSE button for at least

2 seconds while continuing to hold down the REPEAT button.

4. Press the PLAY button, and play for 10 seconds.

5. Servo adjustment results are displayed. Refer to

adjustment results, refer to

Fig. 6-2.

Fig. 6-1.

Fig. 6-2.

Fig. 6-1. For further information about servo

Page 32

6. Remove the disc and turn off the power.

•@

TOP PREVIOUS NEXT

Page 33

6.3 Error code based on troubleshooting

TOP PREVIOUS NEXT

This unit is satisfactory if the error code is E00 and E02 .

Before testing, check that the test disc is free of scratches and optical pickup is clean.

Symptom Probable

FL

error

code/

display

E01 Focus and

tracking

offset

adjustments

not

completed

in the

specified

time period.

cause

Clocks X1

IN and X2

OUT, power

supply VDD

and reset/

RST, all on

IC702.

MDATA,

MCLK,

MLD and

SENSE

signals to/

from

mechanism

controller.

Signal to check Normal voltage and waveform values

Signal

name

MDATA IC702-8

MCLK IC702-7

MLD IC702-9

SENSE IC702-

/RST IC702-

X1 IN IC702-

Location PLAY STOP

pin

pin

pin

- -

10 pin

3.4 V 3.4 V

18 pin

58 pin

0 V

3.4 V

3.4 V

E03,

E05,

E07,

E09,

E0B,

E0D,

E0F

Disc play

unstable.

Scratches or

contaminants

on disc

surface.

Focus and

Tracking

servo circuit

(check

waveforms,

voltages and

part values.)

Spindle

driver circuit.

Optical

pickup.

X2 OUT IC702-

59 pin

FE IC702-

32 pin

1.7 V

Page 34

TE IC702-

33 pin

1.7 V

E04,

E06,

E0C,

E0E,

Best Eye

(PD

balance)

adjustment

not

completed

in the

specified

time period.

Scratches or

contaminants

on disc

surface.

Focus and

Tracking

servo circuit

(check

waveforms,

voltages and

part values.)

Optical

pickup.

FOD IC702-

28 pin

TRD IC702-

27 pin

KICK IC702-

26 pin

/FLOCK IC702-

11 pin

/RFDET IC702-

38 pin

RF TJ701

STAT IC702-

17 pin

FBAL IC702-

30 pin

RF IC701-8

pin

1.7 V 1.7 V

1.7 V 1.7 V

- -

- -

0 V 3.3 V

1.0 V

3.3 V 0 V

1.7 V 1.7 V

1.0 V

FE IC702-

32 pin

/TLOCK IC702-

12 pin

OFT IC702-

36 pin

1.7 V

- -

0 V 0 V

Page 35

E08,

E0A

Focus and

Tracking

gain

adjustment

not

completed

in specified

time period.

Scratches or

contaminants

on disc

surface.

Focus and

Tracking

servo circuit

(check

waveforms,

voltages and

part values.)

Optical

pickup.

FE IC702-

32 pin

TE IC702-

33 pin

1.7 V

1.7 V

•@

TOP PREVIOUS NEXT

/TLOCK IC702-

12 pin

OFT IC702-

36 pin

- -

0 V 0 V

Page 36

7 To Supply Power Source

TOP PREVIOUS NEXT

This unit is designed to operate on power supplied from system connected./When a component requires

service, use the system connections to supply power source./For system connections, refer to Fig.7-1.

Fig. 7-1.

•@

TOP PREVIOUS NEXT

Page 37

8 Schematic Diagram Notes

TOP PREVIOUS NEXT

This schematic diagram may be modified at any time with the development of new technology.

Notes:

S601:

CD edit switch (EDIT)

S602:

Repeat switch (REPEAT)

S603:

Random play switch (RANDOM)

S611:

Disc tray open/close switch/(

OPEN/CLOSE)

S612:

Pause switch (

)

S613:

F.Skip/search switch (

)

S614:

Page 38

Play switch (

)

S615:

Stop switch (

)

S616:

R.Skip/search switch (

)

S701:

Rest detect switch in OFF position

S790:

Disc tray close detect switch in OFF position

S791:

Disc tray open detect switch in OFF position

Indicated voltage values are the standard values for the unit measured by the DC electronic circuit

tester (high-impedance) with the chassis taken as standard. Therefore, there may exist some errors in

the voltage values, depending on theinternal impedance of the DC circuit tester.

No mark

: CD Stop

( )

: CD Play [1 kHz, L+R, 0 dB]

Important safety notice:

Page 39

Components identified by mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound

(capacitors), low-noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacturer’s specified parts shown in the

parts list.

Caution!

IC and LSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

Cover the parts boxes made of plastics with aluminum foil.

Ground the soldering iron.

Put a conductive mat on the work table.

Do not touch the legs of IC or LSI with the fingers directly.

Voltage and signal line

: Positive voltage line

: CD signal line

•@

TOP PREVIOUS NEXT

Page 40

9 Schematic Diagram

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 41

10 Printed Circuit Board Diagram

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 42

11 Type Illustration of ICs, Transistors and

Diodes

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 43

12 Wiring Connection Diagram

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 44

13 Block Diagram

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 45

14 Troubleshooting Guide

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 46

15 Terminal Function of ICs

TOP PREVIOUS NEXT

15.1 IC451 (M38504M6200F):System Control

15.2 IC701 (AN8839NSBE2):Servo Amp

15.3 IC702 (MN662790RSA1):Servo Processor/Digital Signal Processor/Digital Filter/D/A converter

15.4 IC703 (AN8739SBE2):Focus Coil/Tracking Coil/Traverse Motor/SpindleMotor Drive

•@

TOP PREVIOUS NEXT

Page 47

15.1 IC451 (M38504M6200F):/System Control

TOP PREVIOUS NEXT

Pin No. Terminal Name I/O Function

1 Vcc I Power supply terminal

2 VREF I Reference voltage input

3 AVSS - GND terminal

4 SYNC I Power failure detect signal input

5 SUBQ I Sub-code Q data signal input

6 SQCK O Sub code Q resistor clock signal output

7 BLKCK I Block clock signal input

8 CD REQ I Serial communication signal to Sound Processor (Request signal input)

9 B CS O Serial communication signal to Sound Processor (Chip select signal output)

10 B CLK O Serial communication signal to Sound Processor (Clock signal output)

11 DATA O O Serial communication signal to Sound Processor (Data signal output)

12 DATA I I Serial communication signal to Sound Processor (Data signal input)

13 TEST I Test mode select signal input/(Connected to VCC via resistor)

14 RESTSW I Rest switch signal input

15 CNVSS - Connected to VSS

16 SERVO RST O Reset signal output for CD servo IC

17 E-CS - EEPROM serial communication signal

(Not used, open)

18 RESET I Reset signal input

19 X IN I Oscillator connected terminal (8 MHz)

20 X OUT O

21 VSS - GND terminal

22 LED ORG O ORANGE LED signal output

23 E-CLK - Serial communication signal to EEPROM

(Clock signal output) (Not used, open)

24 E-DATA O Serial communication signal to EEPROM

(Data signal output)

25 LED GRN O GREEN LED signal output

26 MSEL I Function select signal input/(Connected to VCC via resistor)

27 MDATA O Command data output

28 MCLK O Command clock output

29 MLD O Command load output

Page 48

30 STAT I Status signal input

31 HALH - CD mechanism motor speed control signal output (Not used, open)

32 PLG - CD mechanism solenoid control signal output (Not used, open)

33 CW O CD mechanism motor control signal output (forward direction)

34 CCW O CD mechanism motor control signal output (reverse direction)

35 PSTN - Position sensor detect signal input

(Not used, open)

36 SW1 - Disc tray position 1 detect signal input

(Not used, open)

37 SW2 - Disc tray position 2 detect signal input

(Not used, open)

38 SW3 I Disc tray open detect signal input

39 SW5 - Bottom switch detect signal input

(Not used, open)

40 KEY2 I Operation key signal input

41 KEY1 I Operation key signal input

42 SW4 I Disc tray close detect signal input

•@

TOP PREVIOUS NEXT

Page 49

15.2 IC701 (AN8839NSBE2):/Servo Amp

TOP PREVIOUS NEXT

Pin No. Terminal Name I/O Function

1 PDE I Tracking signal input terminal 1 (E ch)

2 PDF I Tracking signal input terminal 2 (F ch)

3 Vcc I Power supply terminal

4 PDA I Focus signal input terminal 1 (A ch)

5 PDB I Focus signal input terminal 2 (B ch)

6 LPD I Laser PD signal

7 LD O Laser power auto control output

8 RF O RF amp terminal

9 RFIN I AGC input terminal

10 CSBRT I OFTR capacitor connection terminal

11 CEA I HPF-AMP capacitor connection terminal

12 BDO O Dropout detection control

13 LDON I LD APC ON/OFF (H: ON)

14 GND - GND terminal

15 /RFDET O RF detect signal output (L: detect)

16 PDOWN - Power down terminal

17 OFTR O Off track detection (H: detect)

18 NC - Not used, open

19 ENV O Envelope signal output

20 NC - Not used, open

21

22 TEN I Tracking error signal input

23 TEOUT O Tracking error signal output

24 FEOUT O Focus error signal output

•@

25 FEN I Focus error signal input

26 VREF O Reference voltage output

27 TBAL I Tracking balance adj. input

28 FBAL I Focus balance adj. input

Page 50

15.3 IC702 (MN662790RSA1):/Servo Processor/

Digital Signal Processor/Digital Filter//D/A

converter

TOP PREVIOUS NEXT

Pin No. Terminal Name I/O Function

1 BCLK - Serial bit clock output (Not used, open)

2 LRCK - L/R discriminating signal output

(Not used, open)

3 SRDATA - Serial data signal output (Not used, open)

4 DVDD1 I Power supply terminal

5 DVSS1 - GND terminal

6 TX O Digital audio interface signal output

7 MCLK I Command clock signal input

8 MDATA I Command data signal input

9 MLD I Command load signal input

10 SENSE - Sense signal (Not used, open)

11 /FLOCK - Optical servo condition (focus)

(Not used, open)

12 /TLOCK - Optical servo condition (tracking)

(Not used, open)

13 BLKCK O Sub-code block clock signal output

(f=75 Hz)

14 SQCK I Sub-code Q resistor clock signal input

15 SUBQ O Sub-code Q data signal output

16 DMUTE - Muting input (Not used, connected to GND)

17 STAT O Status signal output

18 /RST I Reset signal input (L: reset)

19 SMCK - System clock (Not used, open)

20 CSEL I Frequency control terminal of crystal oscillator (Connected to VDD)

21 TRV - Traverse servo control signal output

(Not used, open)

22 TVD O Traverse drive signal output

23 PC O Turntable motor drive signal output (L: ON)

24 ECM O Turntable motor drive signal output

(Forced mode)

Page 51

25 ECS O Turntable motor drive signal output

(Servo error signal)

26 KICK - Kick pulse output (Not used, open)

27 TRD O Tracking drive signal output

28 FOD O Focus drive signal output

29 VREF I D/A drive output normal voltage input

30 FBAL O Focus balance adj. output

31 TBAL O Tracking balance adj. output

32 FE I Focus error signal input

33 TE I Tracking error signal input

34 RFENV I RF envelope signal input

35 VDET I Oscillator detect signal input (H: detect)

36 OFT I Off track signal input (H: Off track)

37 TRCRS I Track cross signal input

38 /RFDET I RF detect signal input (L: detect)

39 BDO I Dropout detection signal input (H: dropout)

40 LDON O Laser power control signal output (H: ON)

41 PLLF2 - PLL loop filter terminal (Not used, open)

42 DSLF2 I/O DSL loop filter terminal

43 WVEL - Double velocity status signal output

(Not used, open)

44 ARF I RF signal input

45 IREF I Reference current input

46 DRF I DSL bias terminal

47 DSLF I/O DSL loop filter terminal

48 PLLF I/O PLL loop filter terminal

49 VCOF - VCO loop filter terminal

(Not used, connected to GND)

50 AVDD2 I Power supply terminal

51 AVSS2 - GND terminal

52 EFM - EFM signal (Not used, open)

53 PCK - PLL extract clock (Not used, open)

54 VCOF2 - VCO loop filter terminal

(Not used, connected to GND)

55 SUBC - Sub-code serial output clock

(Not used, open)

56 SBCK - Sub-code serial input data

(Not used, connected to GND)

57 VSS - GND terminal

Page 52

58 X1 IN I Crystal oscillator terminal (f=33.8688 MHz)

59 X2 OUT O

60 VDD I Power supply terminal

61 BYTCK - Byte clock signal (Not used, open)

62 /CLDCK - Sub-code frame clock signal

(Not used, open)

63 FCLK - Crystal frame clock (Not used, open)

64 IPFLAG - Interpolation flag terminal (Not used, open)

65 FLAG - Flag terminal (Not used, open)

66 CLVS - Turntable servo phase synchro signal

(Not used, open)

67 CRC - Sub-code CRC check terminal

(Not used, open)

68 DEMPH - De-emphasis ON signal (Not used, open)

69 RESY - Re-synchronizing signal of frame sync.

(Not used, open)

•@

70 IOSEL I I/O select signal input (Connected to VDD)

71 /TEST I Test terminal

(Not used, connected to power supply)

72 AVDD1 I Power supply terminal

73 OUTL O L ch audio signal output

74 AVSS1 - GND terminal

75 OUTR O R ch audio signal output

76 RSEL I Polarity direction control terminal of RF signal (Not used, connected to power supply)

77 IOVDD I Power supply terminal

78 PSEL - Test terminal (Connected to GND)

79 MSEL - Output frequency select signal input

(Not used, connected to GND)

80 SSEL I SUBQ output mode select signal input

(Connected to VDD)

TOP PREVIOUS NEXT

Page 53

15.4 IC703 (AN8739SBE2):/Focus Coil/Tracking

Coil//Traverse Motor/Spindle/Motor Drive

TOP PREVIOUS NEXT

Pin No. Terminal Name I/O Function

1 /RST - Not used, open

2 NC - Not used

3 IN2 I Motor driver 2 input

4 PC2 I Turntable motor drive signal input (L: ON)

5 NC - Not used

6 IN1 I Motor driver 1 input

7 PVCC1 I Driver power supply terminal 1

8 PGND1 - Driver GND terminal 1

9 NC - Not used, connected to GND

10 D1- O Motor driver 1 output terminal (-)

11 D1+ O Motor driver 1 output terminal (+)

12 D2- O Motor driver 2 output terminal (-)

13 D2+ O Motor driver 2 output terminal (+)

14 D3- O Motor driver 3 output terminal (-)

15 D3+ O Motor driver 3 output terminal (+)

16 D4- O Motor driver 4 output terminal (-)

17 D4+ O Motor driver 4 output terminal (+)

18 NC - Not used

19 PGND2 - Driver GND terminal 2

20 PVCC2 I Driver power supply terminal 2

21 VCC I Power supply terminal

22 VREF I Reference voltage input terminal

•@

23 IN4 I Motor driver 4 input

24 IN3 I Motor driver 3 input

25 RSTIN I Reset terminal

(Not used, connected to GND)

26 NC - Not used, connected to GND

Page 54

16 Replacement Parts List

TOP PREVIOUS NEXT

Notes:

Important safety notice:

Components identified by

mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound

(capacitors), low-noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacture’s specified parts shown in the

parts list.

The marking [RTL] indicates that Retention Time is Limited for this item. After the discontinuation

of this assembly in production, the item will continue to be available for a specific period of time.

The retention period of availabilityis dependent on the type of assembly, and in accordance with the

laws governing part and product retention. After the end of this period, the assembly will no longer

be available.

All parts are supplied by MESA.

Ref. No. Part No. Part Name& Description Pcs Remarks

1 RKM0400-1S TOP CABINET 1

2 RHD30007-S SCREW 4

3 XTBS3+8JFZ1 SCREW 1

4 REX0976 CONNECTOR ASS’Y(6P) 1

5 RGK1136-1S TRAY ORNAMENT 1

6 RKA0105-K RUBBER 4

7 RKA0106-N FOOT RING 4

8 RYP0897A-1S FRONT PANEL ASS’Y 1

8-1 RGB0025-A TECHNICS BADGE 1

9 XTBS3+8JFZ1 SCREW 3

10 XTB3+8FFZ SCREW 2

11 REZ1199 FFC 1

Page 55

101 RFKJXDT07-K LOADING CHASSIS ASS’Y 1

101-1 RDG0142 GEAR 1

101-2 RDG0193 GEAR 1

101-3 RDP0065 PULLEY 1

102 REM0019 MOTOR ASS’Y 1

103 RMK0255 BELT COVER 1

104 RGQ0144-K DISC TRAY 1

105 RAE0152Z-1 TRAVERSE DECK ASS’Y 1

105-1 SHGD113-1 FLOATING RUBBER 3

105-2 SNSD38 SCREW 2

105-3 RAF0150A-1 OPTICAL PICK-UP 1

105-4 RDG0247 DRIVE GEAR 1

105-5 RDG0248 GEAR 1

105-6 RXQ0339 TRAVERSE MOTOR 1

105-7 RXQ0304-1 PLATE 1

105-8 XQN17+CG5 SCREW 1

105-9 XQN2+CQ5 SCREW 1

105-10 XQS17+A35FZ SCREW 2

106 RMS0350-1 PIN(A) 1

107 RMS0627 PIN(B) 1

108 RME0109 SPRING(A) 2

109 RME0142 SPRING(B) 1

110 RMR0698-K1 TRAVERSE CHASSIS 1

111 XTV2+6G SCREW 2

112 RME0063 SPRING 1

113 RMM0079-1 SLIDE PLATE(1) 1

114 RML0178-1 LEVER 1

115 RFKNLPG440-K GEAR ASS’Y 1

116 RHD20009-1 SCREW 1

117 RME0087 SPRING 1

118 RML0349 LEVER 1

119 RMM0059-1 SLIDE PLATE(2) 1

120 RMR0334 HOLDER 1

121 RHM245ZA MAGNET 1

Page 56

122 RXQ0380 HOLDER 1

123 XTN26+6G SCREW 3

124 RMA0793-1 DISC CLAMPER ASS’Y 1

125 XYN2+F6FZ SCREW 2

126 RMG0158 BELT 1

127 XTN2+6G SCREW 1

C4 ECBT1E103ZF 25V 0.01U 1

C5 RCE1AKA101BG 10V 100U 1

C6 ECA1CM471 16V 470U 1

C7 ECBT1E103ZF 25V 0.01U 1

C9 ECEA1AKS221 10V 220U 1

C10 ECEA1AKS221 6.3V 220V 1

C11 ECBT1H102KB5 50V 1000P 1

C12 ECBT1C103MS5 16V 0.01U 1

C151,52 ECBT1H102KB5 50V 1000P 2

C401 RCE1HKA3R3BG 50V 3.3U 1

C402 ECBT1E103ZF 25V 0.01U 1

C403 ECBT1H102KB5 50V 1000P 1

C404,05 ECBT1E103ZF 25V 0.01U 2

C406 ECEA1AKS221 6.3V 220V 1

C407 ECEA1AKS221 10V 220U 1

C408 ECBT1H101KB5 50V 100P 1

C410 EEAFC0J101B 6.3V 100U 1

C411 ECBT1H104ZF5 50V 0.1U 1

C413,14 ECBT1H471KB5 50V 470P 2

C415,16 ECBT1E103ZF 25V 0.01U 2

C452 ECBT1E103ZF 25V 0.01U 1

C701 ECEA0JKA330I 6.3V 33U 1

C702 ECUZNE104MBN 25V 0.1U 1

C703 ECEA0JKS101 6.3V 100U 1

C704 ECUZNE104MBN 25V 0.1U 1

C706 ECUV1H272KBN 50V 2700P 1

C707 ECUV1E273KBN 25V 0.027U 1

C710 ECUV1H121KCN 50V 120P 1

C711,12 ECUWNE104ZFN 25V 0.1U 2

C713 ECUZNE104MBN 25V 0.1U 1

Page 57

C714 ECEA0JKS101 6.3V 100U 1

C715 ECUV1H272KBN 50V 2700P 1

C716 ECUV1H821KBN 50V 820P 1

C717 ECUWNE104ZFN 25V 0.1U 1

C718 ECUV1E104KBN 25V 0.1U 1

C721,22 ECUV1H030CCN 50V 3P 2

C723 ECEA1AKS221 10V 220U 1

C724 ECUZNE104MBN 25V 0.1U 1

C725,26 ECUE1H102KBN 50V 1000P 2

C727,28 ECEA1HKS010 50V 1U 2

C730 ECUWNE104ZFN 25V 0.1U 1

C731,32 ECEA1AKS221 6.3V 220U 2

C733 ECUZNE104MBN 25V 0.1U 1

C734 ECEA1AKS221 10V 220U 1

C735-37 ECUWNE104ZFN 25V 0.1U 3

C738 ECUE1H103KBN 50V 0.01U 1

C739 ECUE1H152KBN 50V 1500P 1

C742 ECUV1E273KBN 25V 0.027U 1

C743 ECUWNE104ZFN 25V 0.1U 1

C744 ECUE1E822KBN 25V 8200P 1

C745 ECUV1E104KBN 25V 0.1U 1

C747 ECUV1H181KCN 50V 180P 1

C749 ECUE1H222KBN 50V 2200P 1

C750,51 ECUZNE104MBN 25V 0.1U 2

C752 ECUE1H102KBN 50V 1000P 1

C753 ECUV1H471KBM 50V 470P 1

C754 ECUE1H471KBN 50V 470P 1

C760 ECUV1E104KBN 25V 0.1U 1

C790 ECA1AKF820 10V 82U 1

CN402 RJS1A6723-Q CONNECTOR(23P) 1

CN405 RJP6G18ZA CONNECTOR(6P) 1

CN701 RJU035T016-1 CONNECTOR(16P) 1

CN702 RJS1A6723-1Q CONNECTOR(23P) 1

CP790 RJP6G17ZA CONNECTOR(6P) 1

Page 58

D3 MA4082LTA DIODE 1

D10 MA165 DIODE 1

D12-14 MA165 DIODE 3

D401-04 MA165 DIODE 4

D406,07 MA165 DIODE 2

D606 SML79455C LED 1

D801 MA165 DIODE 1

IC2 UPC29M33HB IC 1

IC451 M38504M6200F IC 1

IC452 TC74HCT7007A IC 1

IC701 AN8839NSBE2 IC 1

IC702 MN662790RSA IC 1

IC703 AN8739SBE2 IC 1

IC790 TA7291S IC 1

JK401 RJT065K20 SYSTEM CONNECTOR(20P) 1

L701,02 RLBN102V-Y COIL 2

PCB1 REP2822A-2M MAIN PCB ASS’Y 1 [RTL]

Q2,Q3 2SD1862QRTV6 TRANSISTOR 2

Q4 2SB621A-R TRANSISTOR 1

Q5 2SC3311ATA TRANSISTOR 1

Q401 UN4214TA TRANSISTOR 1

Q402-04 2SC3311ATA TRANSISTOR 3

Q701 2SB709S TRANSISTOR 1

Q702 DTC143XUA106 TRANSISTOR 1

Q801,02 UN411FTA TRANSISTOR 2

R5 ERDS2FJ271 1/4W 270 1

R6 ERDS2FJ6R8 1/4W 6.8 1

R7,R8 ERDS2FJ1R2 1/4W 1.2 2

R9 ERQ16NKWR33E 1/6W 0.33 1

R10 ERDS2FJ471 1/4W 470 1

R11 ERDS2FJ222 1/4W 2.2K 1

Page 59

R21,22 ERDS2FJ100 1/4W 10 2

R31 ERDS2FJ100 1/4W 10 1

R155,56 ERDS2FJ473 1/4W 47K 2

R157,58 ERDS2FJ221 1/4W 220 2

R401 ERDS2FJ681 1/4W 680 1

R402 ERDS2FJ104 1/4W 100K 1

R403 ERDS2FJ472 1/4W 4.7K 1

R404 ERDS2FJ222 1/4W 2.2K 1

R405 ERDS2FJ104 1/4W 100K 1

R406 ERDS2FJ101 1/4W 100 1

R407 ERDS2FJ471 1/4W 470 1

R408 ERDS2FJ222 1/4W 2.2K 1

R409 ERDS2FJ471 1/4W 470 1

R411 ERD16TJ000T 1/4W 0 1

R413 ERDS2FJ101 1/4W 100 1

R414-16 ERDS2FJ222 1/4W 2.2K 3

R419,20 ERDS2FJ102 1/4W 1K 2

R421,22 ERDS2FJ103 1/4W 10K 2

R424 ERDS2FJ472 1/4W 4.7K 1

R426 ERDS2FJ472 1/4W 4.7K 1

R429 ERDS2FJ103 1/4W 10K 1

R432 ERDS2FJ472 1/4W 4.7K 1

R433 ERDS2FJ103 1/4W 10K 1

R434,35 ERDS2FJ101 1/4W 100 2

R436,37 ERDS2FJ472 1/4W 4.7K 2

R438 ERDS2FJ102 1/4W 1K 1

R439 ERDS2FJ223 1/4W 22K 1

R440 ERDS2FJ473 1/4W 47K 1

R441 ERDS2FJ472 1/4W 4.7K 1

R442 ERDS2FJ103 1/4W 10K 1

R444 ERDS2FJ472 1/4W 4.7K 1

R445 ERDS2FJ473 1/4W 47K 1

R448,49 ERDS2FJ102 1/4W 1K 2

R451-55 ERDS2FJ332 1/4W 3.3K 5

R610 ERDS2FJ151 1/4W 150 1

R611 ERDS2FJ821 1/4W 820 1

R612 ERDS2FJ102 1/4W 1K 1

Page 60

R620 ERDS2FJ821 1/4W 820 1

R621 ERDS2FJ102 1/4W 1K 1

R622 ERDS2FJ122 1/4W 1.2K 1

R623 ERDS2FJ152 1/4W 1.5K 1

R624 ERDS2FJ182 1/4W 1.8K 1

R701 ERJ6GEYJ4R7V 1/10W 4.7 1

R702 ERJ6GEYJ103V 1/10W 10K 1

R704 ERJ6GEYJ102V 1/10W 1K 1

R705 ERJ6GEYJ154V 1/10W 150K 1

R706 ERJ6GEYJ102V 1/10W 1K 1

R707 ERJ6GEYJ393V 1/10W 39K 1

R708 ERJ6GEYJ223V 1/10W 22K 1

R709 ERJ6GEYJ683Z 1/10W 68K 1

R711 ERJ6GEYJ823 1/10W 82K 1

R712 ERJ8GEYJ221V 1/8W 220 1

R714 ERJ6GEYJ682V 1/10W 6.8K 1

R715 ERJ6GEYJ102V 1/10W 1K 1

R717,18 ERJ6GEYJ102V 1/10W 1K 2

R721 ERJ6GEYJ101V 1/10W 100 1

R723 ERJ6GEYJ682V 1/10W 6.8K 1

R724 ERJ6GEYJ183V 1/10W 18K 1

R725 ERJ6GEYJ391V 1/10W 390 1

R727-29 ERJ6GEYJ392V 1/10W 3.9K 3

R731 ERJ6GEYJ682V 1/10W 6.8K 1

R735,36 ERJ6GEYJ101V 1/10W 100 2

R741 ERJ6GEYJ473V 1/10W 47K 1

R742 ERJ6GEYJ224Z 1/10W 220K 1

R744 ERJ6GEYJ124V 1/10W 120K 1

R749 ERJ6GEYJ472V 1/10W 4.7K 1

R753 ERJ6GEYJ100 1/10W 10 1

R802 ERDS2FJ103 1/4W 10K 1

RJ701 ERJ6GEY0R00V CHIP JUMPER 1

RJ702-10 ERJ8GEY0R00A CHIP JUMPER 9

RJ712-14 ERJ8GEY0R00A CHIP JUMPER 3

RJ716 17 ERJ8GEY0R00A CHIP JUMPER 2

RJ721 22 ERJ6GEY0R00V CHIP JUMPER 2

Page 61

•@

RJ724 ERJ6GEY0R00V CHIP JUMPER 1

RJ726-28 ERJ6GEY0R00V CHIP JUMPER 3

RJ731-36 ERJ6GEY0R00V CHIP JUMPER 6

RJ750 ERJ6GEY0R00V CHIP JUMPER 1

S601-03 EVQ11G05R SW,PUSH 3

S611-16 EVQ11G05R SW,PUSH 6

S701 RSH1A043-U SW,REST 1

S790,91 RSH1A005 SW,OPEN/CLOSE DET. 2

X401 RSXY8M00D01T OSCILLATOR 1

X701 RSXB33M8J01T OSCILLATOR 1

TOP PREVIOUS NEXT

Page 62

17 Cabinet Parts Location

TOP PREVIOUS NEXT

•@

TOP PREVIOUS NEXT

Page 63

18 Loading Unit Parts Location

TOP PREVIOUS

•@

TOP PREVIOUS

Page 64

Page 65

Page 66

Page 67

Page 68

OPTICAL PICKUP

SEMICONDUCTOR

LASER

+B2

PHOTO DETECTOR

EE

D

C

A

B

D

C

F F

Q701

LASER

POWER

DRIVE

+B2

6

7

4

13

5

1

2

VREF.

AN8839NSBE2

SERVOAMP

LPD

LD

PDA

LDON

PDB

PDE

VREF.

PDF

IC701

E

F

VREF.

VREF.

VREF.

VREF.

VREF.

VREF.

VREF.

A

B

ECH

VCBA

FCH

(RF)

TJ701

89

RF RFIN CSBRT CEA

BDO

DET.

RF

DET.

ACH

SUB-

VCBA

TRACTER

BCH

VREF.

TBAL

FBAL

27

28

SUBTRACTER

TEIN

22

VREF.

VREF.

PDOWN

Vref.

VREF.

2316

+B2

10

OFTR

DET.

TEOUT

+B2

11

3

TENV

ENV

OFTR

BDO

/RFDET

FE IN

FE OUT

V

VREF

GND

19

RFENV

17

OFT

12

BDO

15

/RFDET

25

24

FE

CC

3

+B2

26

VREF

14

VREF

FOCUS COIL

TRACKING COIL

M701

TRAVERSE

MOTOR

M702

SPINDLE

MOTOR

F+

F-

T+

T-

M

M

AN8739SBE2

FOCUS COIL / TRACKING

COIL / TRAVERSE MOTOR /

SPINDLE MOTOR DRIVE

IC703

TRV+

TRV-

SP+

SP-

LDON

FBAL

TBAL

22

D4+

17

FOCUS

D4-

16

D3+

15

D3-

14

D1+

11

D1-

10

D2+

13

D2-

12

8

PGND1

19

PGND2

COIL

DRIVE

TRACKING

COIL

DRIVE

TRAVERSE

MOTOR

DRIVE

SPINDLE

MOTOR

DRIVE

RESET

SIGNAL

GENERATOR

/RST

VREF

IN3

IN4

IN1

IN2

PC2

PVcc1

PVcc2

24

23

6

3

4

7

+B1

20

TE

VREF

TRD

FOD

TVD

ECS

ECM

PC

1

Page 69

MN662790RSA1

SERVOPROCESSOR / DIGITAL SIGNAL PROCESSOR

+B2

DIGITAL FILTER / D/A CONVERTER

+B2

IC702

70

+B2

66

67

13

BLKCK

62

56

SBCK

55

SUBC

68

Q702

SWITCH-

ING

80

14

15

53

48

52

41

47

+B2

SQCK

SUBQ

SPEED

DSLF2

46

44

+B2

76

78

MLD

MCLK MCLK

MDATA

+B2

STAT

9

7

8

45

17

79

54

49

61

IOSEL

CLVS

CRC

BLKCK

/CLDCK

SBCK

SUBC

DEMPH

SSEL

SQCK

SUBQ

PCK

PLLF

EFM

PLLF2

DSLF

DRF

ARF

RSEL

PSEL

MLD

MDATA

IREF

STAT

MSEL

VCOF2

VCOF

BYTCK

BUFFER

SUBCODE

DSL / PLL VCO

MICRO COMPUTER

VCO

GENERATOR

PITCH CONTROL

78

PSEL

BUFFER

CD-TEXT

EFM DEMODULATION /

SYNC INTERPOLATION

SUBCODE DEMODULATION

INTERFACE

TIMING

79 80

MSEL

SSEL

16k

CIRC ERROR

CORRECTION/

72

450 60

DVDD1

AVDD2

DIGITAL DEEMPHASIS

SRAM

DEINTERLEAVE

77 71

DD

V

AVDD1

VCC5V

DIGITAL FILTER

8 TIMES OVERSAMPLING/

DIGITAL AUDIO

INTERFACE

DIGITAL AUDIO

INTERFACE

INTERPORATION/

SOFT MUTING/

DIGITAL

ATTENUATION

SERVOCPU

5745157

DVss1

AVss1

/TEST

PWM

1 BIT DAC

PWM LOGICS

PWM

(R)

(L)

AVss2

D/A

OUTPUT

PORT

Vss

CONVERTER

75

OUTR

OUTL

FLAG

IPFLAG

TX

ECM ECM

ECS ECS

PC PC

LRCK

SRDATA

BCLK

DMUTE

DSLF2 DSLF2

KICK

TRV

VREF VREF

TVD TVD

TRD TRD

FOD FOD

TBAL TBAL

FBAL FBAL

/TLOCK

/FLOCK

RCH

73

65

64

6

24

25

23

2

3

1

16

42

26

21

29

22

27

28

31

30

12

11

A/D

CONVERTER

CSEL

FCLK

20

X2

59 59

X1

FE

32 33 34

TE

SMCK

19

63

RFENV

INPUT PORT

TRCRS

VDET

37 35 39

BDO

SERVOTIMING

GENERATOR

/RFDET

38 36

OFT

10 43 40

SENSE

WVEL

LDONLDON

/RST

18

+B2

X701

(33.8688MHz)

FE

TE

RFENV

BDO

/RFDET

OFT

/RST

Page 70

+B1

+B2

+B3

UPC29M33HB

Q4,5

REGULA TOR

IC2

REGULA TOR

+B3

Q2,3

REGULA TOR

Q401

RESET +B3

D402

Q402

+B3

INTER-

FACE

+10V

Q403,

404

INTER-

FACE

RCH

(8MHz)

X401

JK401

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20 NC

SYNC1

CD REQ

CT.GND

CS

+B(10V)

D.GND

SCLK

DATA

NC

V.GND

TO SOUND

NC

PROCESSOR

BLOCK

DIAGRAM/

NC

TO CASSETTE

DECK BLOCK

NC

DIAGRAM

NC

NC

CDRCH

OUT

A.GND

CDLCH

OUT

NC

SPEED

SERVORST

MCLK

MDATA

MLD

SUBQ

BLKCK

STAT

+B2

SQCK

TC74HCT7007A

IC452

CONVERTER

(3.3V To5V)

1

11

13

S701

(REST)

14

GND

47

16

28

27

29

+B3

Vcc

7

21

1

2 4

SPEED

SERVORST

MCLK

MDATA

MLD

Y3A3

Y0A0

Y4A4

Y5A5

VCC

VREF

SUBQ

5

7

89

2

10

12

15

VSS

BLKCK

STAT

3

18

AVSS

CNVSS

1430

REST

SW

6

RESET

MSEL

SQCK

26

(S601~603,611~616)

8

9

CD REQ

M38504M6200F

IC451

SYSTEM CONTROL

KEY2

KEY1

40

41

KEY MATRIX

TA7291S

IC790

MOTORDRIVE

M

LOADING

MOTOR

BCS

(OPEN

3

7

S790

DET.)

13

SYNC

38

+B1

10

TEST

SW3

S791

(CLOSE

DET.)

5

2,4,6,8

B CLK

1

9

11

12

19

20

XIN

CCW

Q801,

802

XOUT

25

LED GRN

22

LED

DRIVE

LED ORG

()

+B3

D606

DATA I

DATA O

SW4

CW

42

33

34

NOTE:

SIGNAL LINE

: CD SIGNAL

Page 71

SCHEMATIC DIAGRAM-1

NOTE:

The number which noted at the connectors

on the schematic diagram as

"SCHEMATICDIAGRAM-1" or

"SCHEMATICDIAGRAM-2"

indicates the schematic diagram

serial number located on the left corner

in the schematic diagram.

OPTICAL PICKUP

0.1

8

3

LD

11

12

2

10

5

4

9

6

1 2 3 4

Vcc

BIN

GND

NBOUT

GND

NAOUT

8 7 6 5

TRACKING

COIL

FOCUS

COIL

AIN

VREF

1K

680P

680P

0.1

0.047

1

2

3

4

5

6

7

8

9

VREF

10

11

13

14

15

Vcc

PDF

PDE

LD

GND

GND

NB

GND

NA

LPD

GND

T+

T

F+

F

CD SERVO CIRCUIT

A

CN701

1

C751

D

0.1

CB A

A

B

C

D

E

C750

0.1

2

3

4

5

6

7

8

9

10

11

1212

13

14

15

1616

Q701

2SB709STX

LASER POWER

DRIVE

4.7

R701

(2.5V)

3.4V

3V

0.3V

(1.8V)

D

E

C

A

B

1.7V 3.4V1.7V 1.7V 1.7V

PDE

FBAL

1.7V 1.7V 1.7V 1.7V 1.7V 1.7V 1.7V 1.7V 0V 3.3V

C712

0.1

C711

0.1

22K

R708

TP42 TP40

I

VREF

:POSITIVE VOLTAGELINE :CD SIGNAL LINE

5V

3.4V

C707

(2.3V)

CSBRT

ENV

TP30

0.027

0.1

C704

1.8V 0V

CEA

NC

BDO

OFTR

C703

6.3V100

C716

820P

(3.3V)

0V

LDON

PDOWN

1413121110987654321

GND

/RFDET

1516171819202122232425262728

(0V)

B

A

PDA

FEN

C747

180P

R744

120K

R706

PLAY

0.5 s. 0.2V/DIV.

(0.2V)0V(2.5V)3V(1.5V)

LPD

PDB

FEOUT

TEOUT

10K

R702

1K

TP33 TP32

C710

120P

R705

R704

150K

1K

C701

6.3V33

IC701

AN8839NSBE2

SERVOAMP

Vcc

PDF

TBAL

VREF

C749

2200P

C742

0.027

39K

R707

HGFEDC

0.8V

P-P

1V 0.7V 2.1V

LD

RF

TEN

NC

PLAY

2ms. 0.1V/DIV.

PLAY

2ms. 0.1V/DIV.

(RF)

TJ701

0.1

C702

RFIN

NC

0.6V

P

-

0.2V

P

TP29

C706

P

-

P

2700P

M702

SPINDLE

MOTOR

M701

TRAVERSE

MOTOR

M

M

TP36

C737

TP35

TP38

C736

TP37

0.1

C713

C714

BADC

(0.4V) (0.2V) (0.1V) (0.4V)0V(0.2V)

0V 0V 0V 0V 7.8V 7.8V 1.7V 1.7V 1.7V

14 15 16 17 18 19 20

D3

D2+

13 12 11 10 9 8 7

A

0.1

B

C

0.1

D

0V 0V 0V 0V

(0.1V) (0.7V) (0.6V)

AB CD

D3+

D2

D4

D1+

D4+

D1

NC

NC

6.3V100

0.1

C735

PGND2

PGND1

C734

IC703

AN8739SBE2

FOCUS COIL/

TRACKING COIL/

TRAVERSEMOTOR/

SPINDLE MOTOR DRIVE

NC

GND

PVcc2

NC

GND

PVcc1

7.8V

R723

10V220

100

R736

BA

21 22 23 24 25 26

IN3

VREF

NC

R735

100

IN4

PC2

(0V)

R724

18K

RSTIN

NC

IN2

1.7V1.7V3.3V1.7V1.7V

R725

390

1K

R715

Vcc

IN1

6 5 4 3 2 1

6.8K

NC

/RST

C715

2700P

C738

0.01

R729

3.9K

7.7V

7.8V

R727

C752

C739

AB

3.9K

1000P

1500P

R731

6.8K

R749

4.7K

R728

3.9K

C

A

B

D

E

F

G

Page 72

SCHEMATIC DIAGRAM-2

2.4V

P-P

F=33.8688MHz

C722

3P

X701

(33.8688MHz)

C721

3P

68K

R709

R714

C744

6.8K

R741

8200P

47K

R711

C717

82K

0.1

C760

0.1

C723

C724

10V220

3.4V

1.6V

1.6V

3.4V

(1.2V)

1.7V

1.7V

1.7V

R742

220K

1.7V

220

R712

0.1

:POSITIVE VOLTAGELINE :CD SIGNAL LINE

5V

3.4V

TP23

C725

C726

1000P

1000P

C727

50V1

C728

50V1

C732

6.3V220

0.1

C745

C733

A

B

C

D

G

H

I

J

K

TP21

0.1

5V

3.4V

A

B

PLAY

T 13.3ms.

PLAY

T 26.6ms.

L702

2.9V

0V

3.3V

0V

3.4V(0V)

2.2V

P-P

PSEL

PC

1.7V

3.4V

SSEL

MSEL

BCLK

LRCK

SRDATA

DVDD1

DVss1

MCLK

MDATA

SENSE

/FLOCK

/TLOCK

BLKCK

SQCK

SUBQ

DMUTE

SMCK

CSEL

TRV

TVD

2122232425262728293031323334353637383940

MLD

STAT

/RST

TX

R717

1K

R718

1K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

3.4V

1.7V

3.4V

0V

3.4V

0V

2.9V

3.3V(0.2V)

0V(3.3V)

3.4V

3.4V

TP11

TP10

TP9

100

R721

C731

6.3V220

C730

0.1

470P

C754

3.4V

CRC

300mV

P

1.7V

DEMPH

-

P

0.8V

P-P

1.7V

1.7V

RESY

FETERFENV

1.7V

3.4V

IOSEL

TBAL

1.7V

61

62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CLVS

FCLK

FLAG

BYTCK

DD

V

60

X2 OUT

59

X1 IN

58

Vss

57

SBCK

56

SUBC

55

VCOF2

54

PCK

53

EFM

52

AVss2

51

AV

DD2

50

VCOF

49

0V

PLLF

48

DSLF

47

DRF

46

1V

IREF

45

ARF

44

WVEL

43

DSLF2

42

PLLF2

41

LDON

0V(3.3V)

/CLDCK

BDO

0V

IPFLAG

F=33.8688MHz

IC702

MN662790RSA1

SERVO PROCESSOR/

DIGITALSIGNALPROCESSOR/

DIGITALFILTER/

D/A CONVERTER

PLAY

0.5 s. 0.2V/DIV.

VDET

OFT

TRCRS

/RFDET

0V

3.3V(0V)

3.1V

1.6V

DD1

OUTL

/TEST

AV

PLAY

T 13.3ms.

PLAY

F=75Hz

FOD

FBAL

VREF

1.7V

1.7V

1kHz, 0dB

1.6V

AVss1

TRD

1.7V

PLAY

3.1V

OUTR

3.3V

0V

KICK

1.7V

3.4V

RSEL

3.3V

0V

ECS

1.7V

IOVDD

ECM

4.7K

C718

3.4V

10K

TP16

0V

Q702

DTC143XUA106

SWITCHING

0.1

PLAY

2ms. 0.1V/DIV.

S701

(REST)

7.8V

0.6V

P-P

TP1

TP2 TP5

1

SUBC

RESTSW

2ms. 0.1V/DIV.

D

TP3

10

R753

TP4

32 4 5 6 7 8 9 10 11 12 13

/RST

STAT

SBCK

SUBQ

SQCK

BLKCK

F

GEDCBAABC EFGHI

DGHIJK

TP12TP8TP7TP6

NC

NC

D

To MAIN CIRCUIT(CN402)

on SCHEMATIC DIAGRAM-5

SPEED

MLD

PLAY

0.2V

P-P

P.GND

C743

0.1

+B(1)

AB

TP17

L701

TX

CLDCK

C

TP14TP13

TP15 TP19 TP22

MCLK

MDATA

TP20

D.GND

+B(2)

C753

470P

Rch OUT

5V

3.4V

A.GND

2321 2220191817161514

B

A

CN702

Lch OUT

Page 73

SCHEMATIC DIAGRAM-3

:POSITIVE VOLTAGELINE

LOADING MOTOR CIRCUIT

B

IC790

TA7291S

MOTOR DRIVE

C790

10V82

M

LOADING

MOTOR

S790

MAIN CIRCUIT

D

7.8V

123456789

5V7.8V0.6V7.8V7.8V0.6V7.8V5V

CP790

S791

(OPEN DET.)

(CLOSE DET.)

CN405

1

1

2

2

3

3

4

4

5

5

6

6

4.8V

A

B

C

D

OPERATION CIRCUIT

C

R624

)

/

S616

(

1.8K

S615

()

R623

R610

1.5K

S614

150

R622

1.2K

()

S613

D606

SML79455C

()

Q801,802

UN411FTA

LED DRIVE

W401A

1

1

2

2

3

3

4

4

5

5

6

6

7

7

A

B

C

D

E

4.8V

R802

W401B

10K

R620

R621

)

/

(

1K

()

S612

S603

(RANDOM)

Q801

Q802

(0V)

4.5V

4.8V

4.8V

(4.5V)

0V

820

S611

R612

1K

CLOSE)

( OPEN/

S602

(REPEAT)

4.7K

4.7K

R611

820

S601

(EDIT)

(4.5V)

0V

10K

(0V)

10K

4.5V

D801

MA165TA

Page 74

SCHEMATIC DIAGRAM-4

:POSITIVE VOLTAGELINE

0.01

C415

Q402

2SC3311ATA

INTERFACE

R440

47K

1.4V

0.5V

10K

R442

Q401

UN4214TA

RESET

10K

0V

47K

D401

MA165TA

1

R401

680

3

2.1V 2V 4.7V 4.8V 0V 4.7V 1.4V 0.4V 1V 3.3V 3.3V 0V 4.8V 4.8V 1.6V 4.8V 4.8V

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

21

Vss

X OUT

F=8MHz

CLK

-

LED ORG

E

22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

0V 0V 4.5V 0V 0V 4.8V 4.8V 0V 5V 5V 4.8V 4.8V 4.8V 4.8V

(4.5V) (0V) (4.8V)

0

R411

R402

100K

C401

50V3.3

X401

(8MHz)

2

R406

100

Q403

2SC3311ATA

INTERFACE

1K

R438

1V

D403

MA165TA

4.7V

1.4V

P-P

100

R413

EDC

R439

C402

XIN

DATA

E

0.2V

22K

0.01

F=8MHz

100P

C408

4.7K

R437

D404

MA165TA

R451

RESET

LED GRN

R429

3.3K

1.8V

P-P

10K

R436

4.7K

0.5V

47K

R445

Q404

2SC3311ATA

INTERFACE

AB

3.3K

2.2K

R455

R404

CS

E

PLAY

SERVORST

T 13.3ms.

MSEL

MDATA

2.2K

2.2K

R414

R415

R452

3.3K

R453

3.3K

R454

3.3K

CDE

0V

R403

CNVss

MCLK

R416

4.7K

R444

4.7K

RESTSW

MLD

2.2K

R405

3.3V

0V

R441

4.7K

100K

TEST

STAT

7.8V

4.8V

A

B

C

A

B

ABC

DATA I

DATA O

PLAY

5V

0V

T 20ms.

HALH

PLG

PLAY

PLAY

5V

T 26.6ms.

T 26.6ms.

B CLK

T 20ms.

CW

AD CB

0V

ABC D

(0.2V) (4.8V) (3.3V)

(0.2V)

4.8V

3.3V 0V 0V 0V 0V 4.8V

8

7 6 5 4 3 2 1

IC452

TC74HCT7007A

3.3V TO 5V

CONVERTER

A

B

470

R407

R408

BCS

PLAY

CCW

5V

CD REQ

0V

PSTN

BLKCK

PLAY

F=75Hz

SW1

2.2K

SQCK

SW2

R409

0V

470

5V

3.3V

0V

Y5 A5Y4 A4Y3 A3 Vcc

A

(0.2V)

SYNC

SUBQ

PLAY

T 26.6ms.

SW3

SW5

F=75Hz

Y0 A0Y1 A1Y2 A2GND

B

R435

100

R434

100

R449

1K

C416

D407

MA165TA

AVss

KEY2

1K

R419

R420

BA

PLAY

5V

0V

F=75Hz

14131211109

0V0V

D402

MA165TA

R448

1K

0.01

D406

MA165TA

R433 10K

IC451

M38504M6200F

SYSTEM CONTROL

C411

Vcc

VREF

5V

0V

KEY1

SW4

C414

470P

C413

470P

1K

R422

R421

C

D

E

10K

10K

0.1

R424

4.7K

R432

4.7K

0V

C452

3.3V

0.01

C410

6.3V100

Page 75

SCHEMATIC DIAGRAM-5

MAIN CIRCUIT

D

:POSITIVE VOLTAGELINE :CD SIGNAL LINE

Q4

2SB621ARSTA

REGULATOR

C11

1000P

Q5

2SC3311ATA

REGULATOR

D12 D13 D14

D12-14

MA165TA

D10

MA165TA

7.4V

2.8V

R10

470

7.4V

R5

270

C5

10V100

C152

C151

1000P

1000P

+10V

C6

16V470

47K

R156

47K

R155

C7

R158

R157

0.01

220

220

10.4V

JK401

SYNC

1

CD REQ

2

CT.GND

3

CS

4

+B(10V)

5

D.GND

6

SCLK

7

DATA

8

NC

9

V.GND

10

NC

11

NC

12

NC

13

NC

14

NC

15

CD Rch OUT

16

A.GND

17

CD Lch OUT

18

NC

19

NC

20

ToMAIN CIRCUIT of

SOUND PROCESSOR &

MAIN CIRCUIT of

CASSETTE DECK

R7

INGNDOUT

7.8V3.4V

10V220

1.2

R8

1.2

Q2,3

2SD1862QRTV6

REGULATOR

7.8V

7.8V4.8V

IC2

UPC29M33HB

REGULATOR

2 3 1

R11

C12

0.01

2.2K

C10

6.3V220

C9

3.3V

Q2

8V 10.2V

8.2V

Q3

8V

8.2V

10.2V

R9

1/6W0.33

C4

0.01

R6

6.8

D3

MA4082LTA

E

D

C

A

B

A

B

C405

0.01

C406

6.3V220

3.4V

7.8V

D.GND

C

B

A

D

A

B

E

C

D

A

B

R21

R426

10

4.7K

R31

R22

A.GNDCT.GND

10

10

C403

1000P

C404

0.01

CN402

C407

10V220

E1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

REST SW

SUBC

/RST

STAT

SBCK

SUBQ

SQCK

BLKCK

NC

NC

SPEED

MLD

MDATA

MCLK

P.GND

+B(1)

TX

CLDCK

D.GND

+B(2)

Rch IN

A.GND

Lch IN

A

To CD SERVO CIRCUIT(CN702)

on SCHEMATIC DIAGRAM-2

Page 76

A

B

C

DE

This printed circuit board diagram may be modified at any time with the development of new technology.

F

1

TP30

C702

TP29

R707

R736

5

R702

R708

20

(RF)

TJ701

RJ709

1

28

C711

C712

C713

RJ703

6

8

10

11

12

14

13

15

16

C714

14

15

71013

RJ722

RJ710

4

9

2

7

R701

RJ750

3

5

RJ727

RJ702

RJ712

CN701

1

B

Q701

C734

C701

C

C750

E

VREF

C751

C735

CD SERVO P.C.B.

A

TP1

RJ704

TP15

C721

C722

C724

IC702

20

(SPINDLE

R714

TP36

M702

MOTOR)

TP16

RJ734

X701

6061

21

C717

C744

C723

55

25

R731

R723

C737

RJ707

RJ708

50

35

30

C738

M

C703

R711

R709

R712

R742

RJ721

R741

45

41

40

TP42

S701

(REST SW)

R724

R735

R725

TP35

Q702

E

C760

C718

C742

R715

C715

C704

RJ724

C716

B

C

TP32

TP33

C752

26

RJ701

R749

R727

25

1

C707

R705

R704

C749

14

15

R728

R729

5

C706

R706

TP40

C739

21

10

IC701

20 25

C710

C747

R744

RJ728

IC703

TP20

TP19

2

RJ714

3

4

TP37

5

(REP2772A-N)

TP23

C753

TP22

CN702

23

22

21

20

19

18

RJ706

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

(TRAVERSE MOTOR)

TP13

RJ735

RJ705

C743

TP2

M

M701

TP5

C730

TP21

C731

R721

L702

C732

L701

TP7

TP4

TP12TP14

C725

R718

C754

RJ726

TP6

C726

TP8

RJ713

R717

TP3

RJ731

80

1

C733

RJ716

TP11

RJ717

75

5

TP17

C728

C727

TP9

R753

TP38

70

10

TP10

C736

65

15

RJ732

C745

RJ733

RJ736

6

LOADING MOTOR P.C.B.

B

1

CP790

1

S790 S791

2

3

4

5

6

7

(REP1960A)

LOADING

MOTOR

M

2

IC790

3

C790

4

5

6

7

8

9

8

ELECTRICAL PARTS LOCATION

Ref. No. Lo. No.

CD SERVO P.C.B.

A

IC701

IC702

IC703

Q701

Q702

L701

L702

X701

S701

CN701

CN702

M701

M702

TJ701

TJ702

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP19

TP20

TP21

TP22

TP23

TP29

TP30

TP32

TP33

TP35

TP36

TP37

TP38

TP40

TP42

R701

R702

R704

R705

R706

R707

R708

R709

R711

R712

R714

R715

R717

R718

R721

R723

R724

R725

R727

R728

R729

R731

R735

R736

R741

R742

R744

R749

LOADING MOTOR P.C.B.

B

IC790

S790

S791

2D

3B

4D

3D

2C

3B

3B

2C

3C

3D

3A

4A

4C

2D

3C

4B

4A

4B

4B

4B

4B

4B

3B

3B

3B

3B

4B

4A

4A

4B

4B

3B

2A

1A

2B

2A

1A

2D

1D

3C

3C

4C

4B

5A

5B

3D

3C

2D

3D

3C

3C

3C

3D

3D

2C

2C

2C

2B

3C

2B

2B

3B

4C

3C

4C

4C

4C

4C

3C

3C

4D

2C

2C

3D

4C

7D

7B

7B

Ref. No. Lo. No.

R753

RJ701

RJ702

RJ703

RJ704

RJ705

RJ706

RJ707

RJ708

RJ709

RJ710

RJ712

RJ713

RJ714

RJ716

RJ717

RJ721

RJ722

RJ724

RJ726

RJ727

RJ728

RJ731

RJ732

RJ733

RJ734

RJ735

RJ736

RJ750

C701

C702

C703

C704

C706

C707

C710

C711

C712

C713

C714

C715

C716

C717

C718

C721

C722

C723

C724

C725

C726

C727

C728

C730

C731

C732

C733

C734

C735

C736

C737

C738

C739

C742

C743

C744

C745

C747

C749

C750

C751

C752

C753

C754

C760

CP790

C790

4B

2C

2D

3D

4B

4A

3A

4C

5C

2D

2D

3D

4B

2A

3B

4B

2C

2D

1C

3B

2D

3D

2B

3B

3B

1C

4A

4B

2D

2D

2D

1C

1C

1C

1C

3D

2D

3D

3D

4D

4C

2C

2C

3C

2B

2B

2C

2B

2B

2B

2B

2B

2B

2B

3B

3B

4D

4D

4B

4C

4C

4C

3C

3A

2C

3B

3D

3C

4D

4D

4C

2A

2B

2C

7B

7D

Page 77

A

B

C

DE

F

1

2

A.GND

D.GND

3

CT.GND

4

5

6

7

8

MAIN P.C.B.

D

R448

J

J

J

IC2

2

3

1

C12

C10

R11

R10

J

J

J

J

R438

C408

R436

J

C415

CN405

1

2

3

4

5

6

C416

C403

R451

R455

J

J

J

J

J

J

CN402

23

21

19

17

15

13

11

9

7

5

3

1

R155

R156

J

22

20

18

16

14

12

10

8

6

4

2

R157

R158

J

J

R449

Q5

R441

J

R22

C9

Q4

B

B

D10

C

C

E

E

D14 D13

R439

Q404

B

C

R444

E

B

C

R437

E

Q402

R424

J

J

J

C413

C414

R432

R405

J

D406

R433

D407

C410

R453

R454

R452

C151

C152

C404

C407

To SOUND PROCESSOR &

CASSETTE DECK

JK401

151719

R31

R445

R442

Q403

J

J

J

J

42

C5

C11

D404

B

C

E

R5

J

D12

D403

C7

C6

R9

D3

R6

R440

J

J

R420

R419

J

IC451

1

5 101520

R434

X401

J

C411

R435

R408

C402

ECB

R404

Q401

C401

R402

J

J

J

J

J

C405

C406

R426

810 14

R407

IC452

R409

R406

R8

R422

1

2

3

D401

157

Q3

C4

R7

Q2

213

2225303540

21

R403

J

R421

J

R21

B

C

E

B

C

E

J

J

J

R414

R401

R416

C452

R429

135791113

246810E11214161820

D402

4567

W401A

R413

R411

J

R415

10V

ELECTRICAL PARTS LOCATION

Ref. No. Lo. No.

MAIN P.C.B.

D

IC2

IC451

IC452

Q2

Q3

Q4

Q5

Q401

Q402

Q403

Q404

D3

D10

D12

D13

D14

D401

D402

D403

D404

D406

D407

X401

CN402

CN405

W401A

JK401

E1

R5

R6

R7

R8

R9

R10

R11

R21

R22

R31

R155

R156

R157

R158

R401

R402

R403

R404

R405

R406

R407

R408

R409

R411

R413

R414

2B

6C

7C

3C

3C

3B

3B

6C

3B

3B

3B

2C

3B

3B

3B

3B

6C

2C

3C

3B

6B

6B

6C

8B

5B

5C

2C

2C

2B

2C

3C

3C

2C

3B

3B

2C

2B

2B

2B

2B

2B

2B

6C

6C

7C

6C

5B

7C

7C

6B

7C

5C

5C

6C

Ref. No. Lo. No.

R415

R416

R419

R420

R421

R422

R424

R426

R429

R432

R433

R434

R435

R436

R437

R438

R439

R440

R441

R442

R444

R445

R448

R449

R451

R452

R453

R454

R455

C10

C11

C12

C151

C152

C401

C402

C403

C404

C405

C406

C407

C408

C410

C411

C413

C414

C415

C416

C452

6C

6C

5C

5C

5C

5C

4B

7B

5C

5B

6B

6C

6B

4B

3B

3B

3B

3C

3B

3B

3B

3B

2B

6B

6B

6B

6B

6B

6B

C4

3C

C5

2B

C6

2C

C7

2C

C9

2B

3B

3B

3B

7B

7B

6C

6C

6B

7B

7B

7B

7B

4B

6B

6B

5B

5B

5B

6B

7C

(REP2822A-2M)

Page 78

A

B

C

DE

F

1

2

3

OPERATION P.C.B.

C

D606

S614

D801

( )

S615

( )

( )

S613

( )

J

R623

R622

R624

( )

E

E

Q802

S612

( )

Q801

C

C

B

B

R621

S616

R802

R610

J

R620

S602

(REPEAT)

S603

(RANDOM)

J

J

J

J

S611

( OPEN/

CLOSE)

R612

R611

W401B

S601

(EDIT)

1

2

3

4

5

6

7

ELECTRICAL PARTS LOCATION

Ref. No. Lo. No.

OPERATION P.C.B.

C

Q801

Q802

D606

D801

S601

S602

S603

S611

S612

S613

S614

S615

2B

2B

2C

2B

3C

3C

4C

2C

2B

2C

2B

2B

Ref. No. Lo. No.

S616

W401B

R610

R611

R612

R620

R621

R622

R623

R624

R802

2C

2C

2C

3C

3C

2C

2B

2B

2C

2C

1C

4

5

J

6

7

8

(REP2822A-2M)

Page 79

OPTICAL PICKUP

LOADING

B

MOTOR P.C.B.

CN701

1

2

.

.

.

.

.

RED MARK

CD SERVO P.C.B.

A

.

M702

.

.

(SPINDLE

.

.

.

.

MOTOR)

15

16

M701

(TRAVERSE

MOTOR)

CN702

22

.

.

.

.

.

.

.

.

.

2

23

.

.

.

.

.

.

.

.

.

.

1

To SOUND PROCESSOR &

CASSETTE DECK

CP790

MAIN P.C.B.

D

OPERATION P.C.B.

C

1

.

.

.

.

6

WHITE

1

.

.

.

.

6

1

.

.

.

.

6

W401A

1

.

.

.

.

.

7

1 . . . . 6

CN405

7 . . . . . 1

W401B

CN402

. . . . . . . . . .

23

. . . . . . . . .

22

1

2

Page 80

No.1

1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

20

21

40

41

60

61

80

E

C

B

AN8839NSBE2

M38504M6200F

28PIN

42PIN

AN8739SBE2 TC74HCT7007A

26

21

1

6

20

14

7

13

1

7

M662790RSA1 TA7291S

14

8

1

9

UPC29M33HB

1

3

MA4082LTA

A

A

Anode

2SB709STX

DTC143XUA106

C

2

B

E

E

C

B

2SC3311ATA

UN411FTA

UN4214TA

2SB621ARSTA

2SD1862QRTV6

B

C

E

A

A

Anode

MA165TA

Ca

Ca

Cathode

SML79455C

Ca

Ca

Cathode

A

Anode

A

Cathode

Ca

Anode

Ca

A

A

Page 81

D FE H

RANDOM REPEAT EDIT

OPEN/CLOSE

J K ML

0

MN

D Random play button (RANDOM)

I

E Repeat button (REPEAT)

F CD edit button (EDIT)

H Disc tray open/close button (< OPEN/CLOSE)

I Skip/search buttons (4, 5)

»

g

J Disc tray

K Stop button (∫)

L Pause button (;)

M Play button and indicator (!)

The color of the indicator depends on the operation taking place.

If stopped: orange

If playing: green

If paused: flashes

Loading...

Loading...