Page 1

ORDER

NO.

SD7702-1182

Direct drive automatic Turntable System

Specifications

Turntable section

Type:

Drive method:

Motor:

Turntable platter:

Turntable speeds:

Pitch controls:

Wow and flutter:

Rumble:

Tonearm section

Type:

Effective length: 230 mm (9

Overhang:

Technics

bypanasonic

Specifications are subject to change without notice for further improvement.

Weights and dimensions shown are approximate.

Direct Drive Automatic Turntable System,

Automatic start, Automatic return, Automatic

shut

-

off and MEMO-REPEAT play Manual

play

Direct Dr~ve

Back Electromotive Force Frequency

Generator servo DC motor

employing one chip

Alurr~inum die-cast, 33 cm (13")

33-113 and 45 r.p.m.

Individual adjustment controls. 10%

adjustment range

0.025%

-

-

W.R.M.S (JIS C5521)

k0.035% Weighted zero to peak

(DIN 45507)

50 dB (Dl N 45539A)

73 dB (DIN 45539B)

Universal tubular arm, staticbalanced type

1 5 mm

-

(

19/32")

Panasonic Company

Division of Matsushita Electric

Corporation of America Hawaii 96817 Ontario, Canada

One Panasonic Wav. Secaucus,

IC

1/16',)

New Jersey 07094.

Friction:

Effective mass: 22 g (6.0 g cartridge weight 1.75 g stylus

Tracking error angle:

Offset angle:

Adjustable stylus

pressure range:

Cartridge weight range: 5 to 11 g

Head shell weight: 9.5 g

General

Power supply: AC 120V.50or60Hz

Power consumption: 6 W

Dimensions: 12.5 x 45.3 x 36.9 cm

(HxWxD)

Wegiht:

Matsushita Electric of Hawaii, Inc. Matsushita Electric of Canada Ltd.

320 Waiakarr~ilo Road, Honolulu,

7 mg (horizontally and vertically)

pressure)

Within

+3O at the point of 145

(5-45164") from the

center

within

21.5O

0 to 3 g (stylus pressure direct reading

tv

pe)

14-15/16 x 17-12/16 x 14-9/16 inches)

9.0 kg

i

+lo

at the point of 55 mm

(2-311 6") from the

center

I

(1 9.8 ibs.)

40

Ronson Drive, Rexdale,

mm

1

I

M9W

1

B5

Page 2

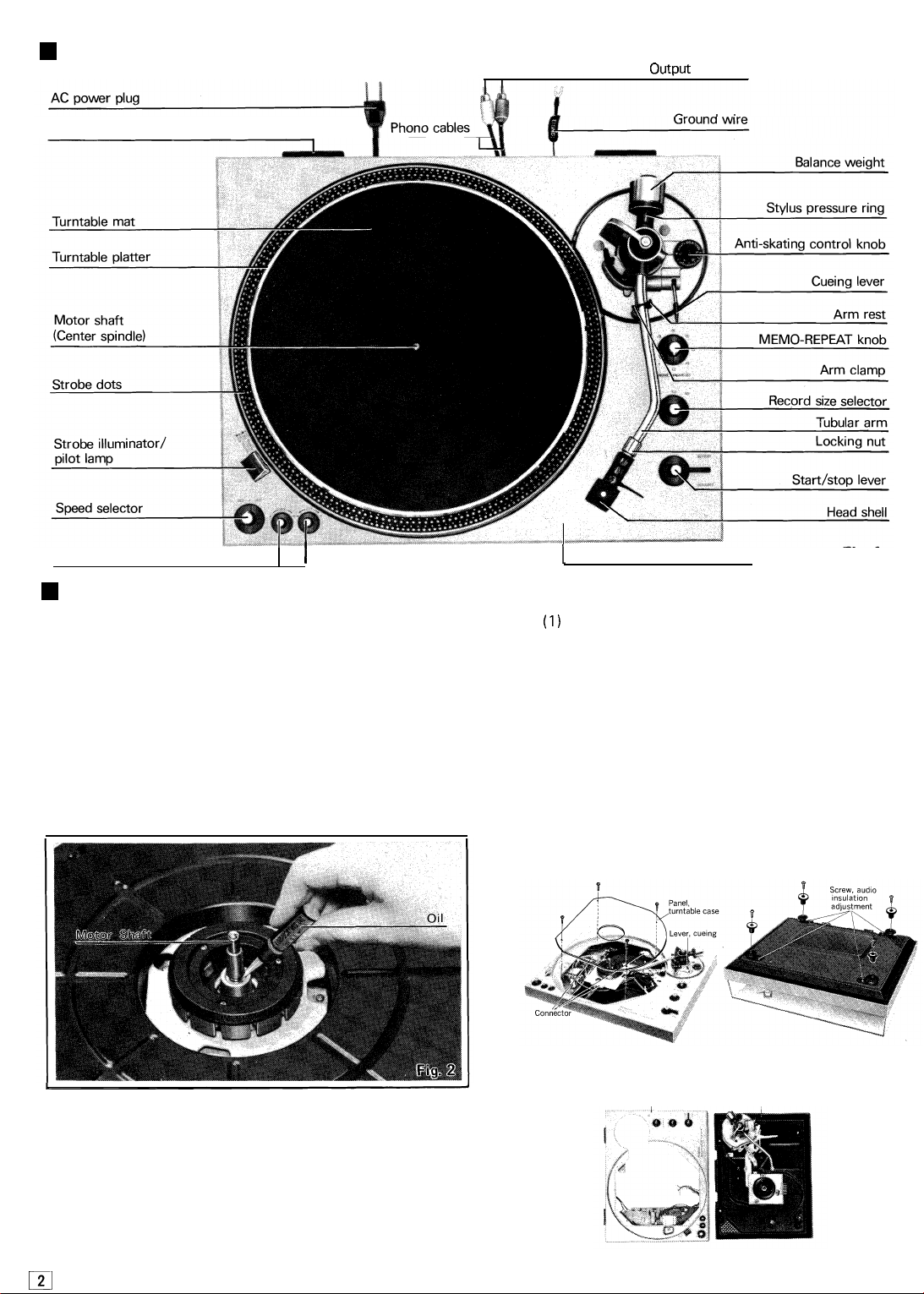

Parts identification

Hinge

Output terminals

Pitch control knobs

1

Assembly and set-up

Apply two or three drops of oil to the motor shaft

using the furnished oil container.

Although the unit has been lubricated before shipping

from the factory, apply a few drops of oil to the

motor shaft for assurance. After that, application of

two or three drops of oil once every

operation or so is sufficient. The time interval is

much longer than that of the former type motors

(200 - 500 hours), so do not apply too much oil, nor

more frequently than necessary. Never use any other

type of oil.

(See Fig.

2)

2000 hours'

.

Fig.

1

(1)

For removal of the cover, take off 4 vis-screws

from the panel cover.

(2)

Draw out three connectors.

(3)

For separation of the body from the main

base, turn the cueing lever upward, move the

-

arm in inboard direction, then lift up the

tone

body.

Note:

The turntable horizontaliy to the panel face is

already adjusted before shipment.

If deviated, correct it by means of the adjust

screws using a 5mm box spanner.

Turntable base

1

1.

2.

3.

4.

5.

6.

121

SL-1600

Remove the cartrige.

Fix the tone arm to the arm rest.

Remove the turntable.

Turn the player set upside down with good care

not to damage the acryl cover.

Take off 4 vis-screws from the back panel.

Place the player set face upward holding it with

both hands so that the body is not separated from

the main body.

Turntable

base Main base

Page 3

H

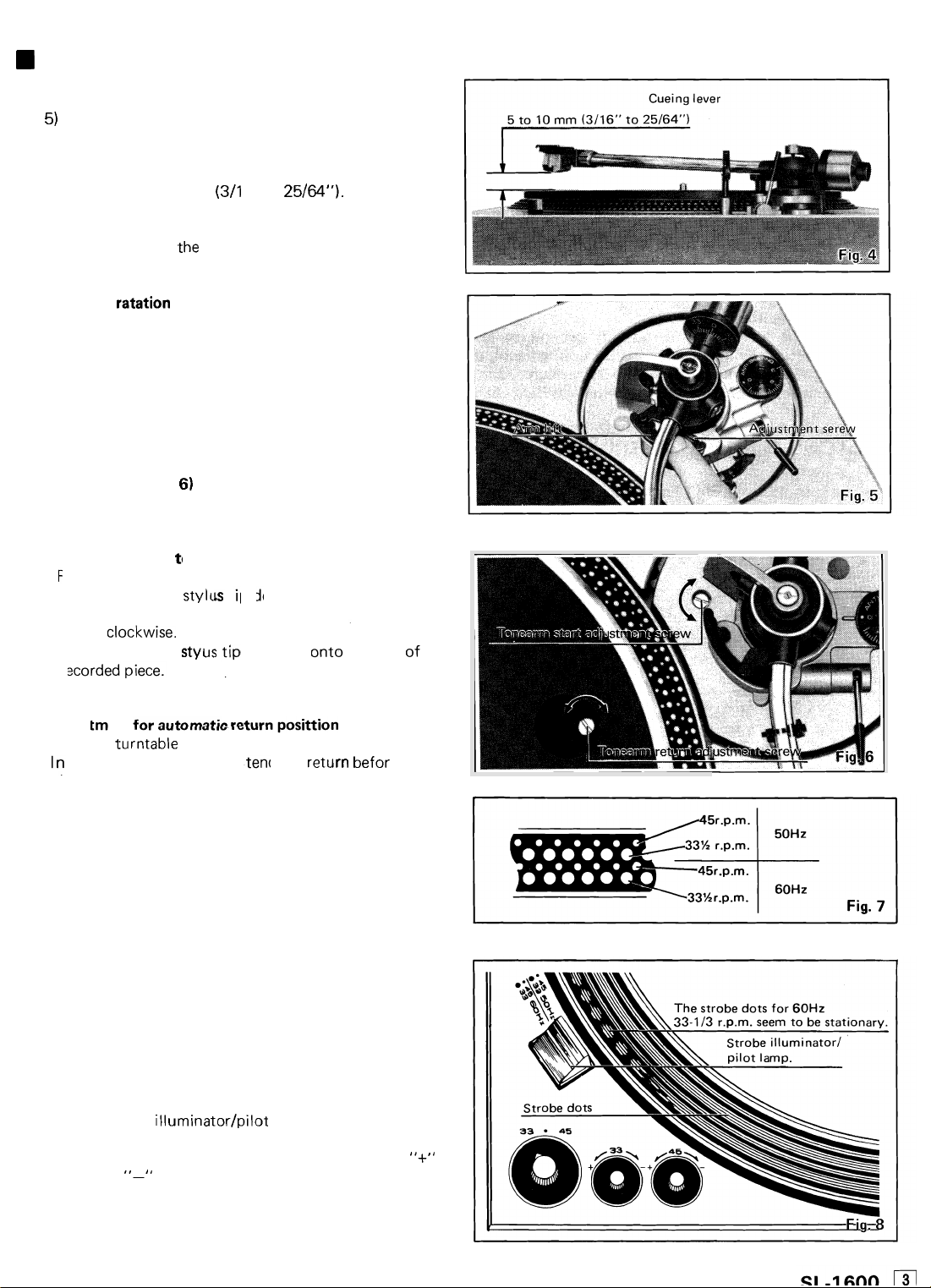

Adjustments

Adjustment of the arm lift height

(See Figs. 4 and

5)

The arm lift height (distance between the stylus tip

and record surface when cueing lever is raised) has

been adjusted at the factory before shipping to ap

proximately 5 to

If the clearance becomes too narrow or too wide be

cause of the physical size of the different cartridges

on the market turn

counterclockwise, at the same time pushing the arm

lift down.

Clockwise ratation

-

distance between the record and stylus tip is reduc

ed.

Counterclockwise rotation

-

distance between the record and stylus tip increases.

Note:

As the adjusting screw has a hexagon head, be sure to

make the adjustment while depressing the arm lift.

Adjustments for automatic start and automatic return

positions (See Fig.

Should the tonearm not function correctly, make

adjustments according to the follwing procedures.

Adjustment for automatic start position

(Remove the rubber cap.)

In cases where the

record.

-

Move

C~OCKW~S~.

In cases where the styus tip descends onto halfway of

a recorded piece.

-

Move counterclockwise

10

mm

(311

6

"

to

25/64").

.the adjustment screw clockwise or

6)

styl~s tip descends outside of the

-

-

-

Adjustment for automatic return posittion

(Remove l~rntable sheet.)

n cases where the tonearm tends to

playing has finished.

-

Move clockwise.

In cases where the tonearm fails to return after the

last groove of the record.

-

Move counterclockwise.

Speed adjustment (with pitch control knobs)

Figs. 7.8 and

Strobe dots are set on the tapered rim of the turn

table platter according to the power frequency and

the number of revolutions of the records. Make

adjustment, referring to strobe dot indication. (See

Fig. 7)

1.

Set the speed selector to the number of revolutions to

be adjusted. (See Fig.

2.

Release the arm clamp and raise the cueing lever

3.

Move the tonearm to a slight extent towards the

turntable platter.

The strobe

luminating the strobe dots.

4.

While turning the pitch control knobs either to

side or

strobe dots of the turntable look as if they were

stationary.

9)

8)

illuminator/pilot lamp will be lit for it

"-"

side, adjust to such an extent that the

retclrn befor the

(See

-

-

"+"

Page 4

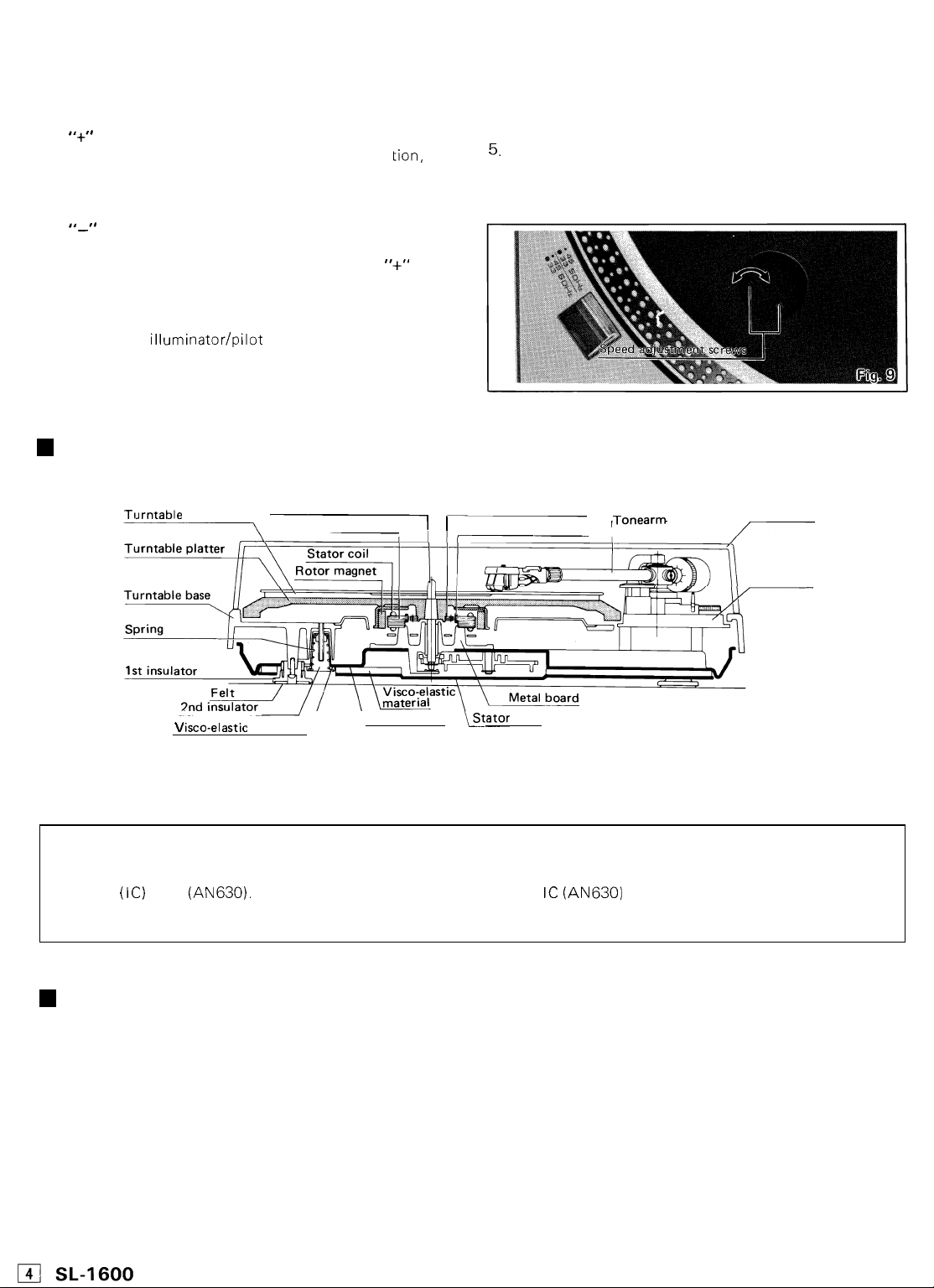

The state under which the strobe dots seem to be

stationary represents the correct number of revolu

tions.

"+"

direction

This increases the speed of the turntable rota

the strobe dot pattern seems to flow in the same

direction as the rotational direction of the turntable

platter.

"-"

direction

This decreases the speed of the turntable rotation,

resulting in a state opposite to that in the

tion.

Note:

Strobe dot pattern.

The strobe

the commercially available power source. The frequency

of such power source, when actually measured, has a

fluctuation of about 0.2%. As such a fluctuation of the

illuminator/pilot lamp of this unit employs

tion, and

"+"

direc

-

-

power source affects the strobe illuminator, the strobe

dot pattern also seems to fluctuate to a certain extent.

But the unit is not affected by

power source, since a D.C. motor is employed.

5,

If the desired speed can not be obtained by the variable

pitch controls, turn the speed adjusting screws with a

screw driver for further adjustments. (See Fig.

-

the fluctuations of the

Cross section of motor portion and double insulator

9)

Turntable mat

V

isco-elastic material

Motor shaft (Center spindle)

Stator

\

Main base \tator frame

Operation principles of the

This unit, like the SL 1300 has a rational motor structure, and its drive control circuit is the B.F.G. type (Back

TECHNICAL EXPLANATION electromotive force frequency generator) which is constructed on a single integrated

circuit

(IC) chip (AN630). The following is a block diagram of the IC (AN6303 for which the operating principle will

be briefly explained

Position detecting rotor

I

I

Position detecting coil

I-

SL-1600

Tonearm

Dust cover

Arm base

Operating principle

The back electromotive force, which is generated by the

drive coil winding according to the rotation of the

motor, is detected and converted to a frequency signal

that is proportional to the numder of revolutions.

Conversion is performed by a wave

logic circuit (This is referred to as the B.F.G. method).

This frequency signal is compared with a standard signal

by means of a frequency

which converts

constant number of revolutions. After removing un

necessary

-

shaping circuit and a

-

voltage conversion circuit

it

to a voltage signal in order maintain a

frequency components, with

active filter, from this voltage signal, it controls the cur

rent flow in three differential switching circuits. As a

result, the flow of current in the drive coil winding is

always constant maintaining the correct rotational spe

ed. Control of the rotational speed can be performed by

means of adjusting the standard signal generator circuit

according to the rotational speed adjustment cricuit.

-

-

the operational-amplifier

-

-

Page 5

Explanation of each part

1.

B.F.G. METHOD (BACK ELECTROMOTIVE

FORCE FREQUENCY GENERATOR)

Making use of the back electromotive force that is

generated in the drive coil winding of the motor as a

frequency generator, the frequency of the frequency

generator is converted to the number of revolutions for

the turntable.

After shaping the wave form of this back electromotive

it

force,

generated that is proportional to the number of revolu

tions.

drive coil winding, frequency generator coil windings

and magnets are not necessary, yielding a motor struc

ture that is very compact.

2.

FREOUENCY-VOLTAGE CONVERSION CIRCUIT

Being composed of a

a pulse generating circuit and a sampling integration cir

cuit, the B.F.G. output frequency is converted to a vol

tage, and control output voltage is generated in order to

maintain the rotational speed of the turntable at a cons

tant level.

is composed logically, and a frequency is

This is the use of the B.F.G. Making use of the

trapezoidal

wave generating circult.

3.

OPERATION CONTROL CIRCUIT

The operation control circuit functions as a control out

put voltage control keeping the rotational speed of the

turntable constant with regard to the start of turntable

operation and the operation of the mechanism. With

this circuit, transient response characteristics and start

ing characteristics are very good.

-

-

-

-

-

4.

OPERATIONAL AMPLIFIER (OP AMP) ACTIVE

FILTER

Because of using an operational amplifier in the active

filter, an ideal filter operation is possible.

As a result, such high performance as a signal

(SN) ratio of

0.03%

of

5.

DRIVE CIRCUIT

By incorporating a large copacity power transistor in the

integrated circuit, a starting torque of

obtained. By means of this large starting torgue, prompt

starts have been realized.

6.

THREE DIFFERENTIAL SWITCHING CIRCUITS

By means of the signal from the position signal coil, the

starting circuit power transistor selector operates,

obtaining smooth rotation.

60

dB (I EC-B) and a wow-and-flutter level

(WRMS) have been achieved.

-to-

1

kg-cm can be

-

-

noise

Block diagram

Page 6

RECT

AN630

with the development of new technology)

(This schematic diagram may be modified at any time

Schematic Di agra

-

-

-

-

-

____

-

-

-

-

-

-

-

-

IZOY

AC

152

-

RECT

SVDMI

I

--------------------

I

I

IS

position.

Power swltch 1s off

Speed selector swltch

2:

-

1, S2

S2

1. S1:

2.

NOTES:

position.

r.p.m

1/3

33

chassls with a standard tester that has an

from the

The voltage values entered are the values measured

3.

rotational

at a

100Kfl/V

of

r.p.m.

1/3

33

resistance

internal

speed of

Page 7

SWITCH

POWER

Circuit Board Wiring View

Page 8

EXPLODED

VIEW

OF

TURNTABLE

Page 9

EXPLODED

VIEW

OF

TURNTABLE

Page 10

ECEA50ZR22

ECEA50ZR33

ECQMlH104KZ

ECEA50M2R2R

ECEA50MR33R

ECQM1 H472KZ

ECQMlH223KZ

ECQM1 H823KZ

ECQFlA473MD

ECQUlA473MC

table Mat, Set for [MC]

SFTE170-01A

Name Plate, Set for [MC]

SFNN 16OMO1

Clarnper, AC Power Cord

Spacer. AC Power Cord

REPLACEMENT PARTS LIST

H

1%. Metallic

1%. Metallic

5%. Metallic

5%. Carbon

k

L

*

*

2.7R. 1W.

47KR. 1/4W,

ERD25TJ330

ERXIANJ2R7

ER025CKF3902 39KR. 1/4W.

ER025C KF6202 68KR. 1/4W.

ERD25TJ473

5%. Carbon

5%, Carbon

5%. Carbon

5%. Metall~c

*

*

*

*

120KR. 1/4W.

1KR. 1/4W.

1.5R. 1W.

56KR. 114W.

ERD25TJ102

ERD25TJ124

ERD25TJ563

ERXlANJlR5

Page 11

Page 12

Loading...

Loading...