Page 1

ORDER

NO

.

AD

0303062

C

0

A

2

Service

Man

ual

Turntable

System

SL

-

1210

M

5

GE

SL

-

1210

M

5

GEB

SL

-

1210

M

5

GGN

SL

-

1210

M

5

GPP

Colour

Black

Type

:

SL

-

1210

M

5

G

Specifications

TURNTABLE

SECTION

Type

:

Offset

angle

:

Friction

:

Tracking

errar

angle

:

22

°

Guartz

direct

drive

Manual

turntable

Direct

drive

Brushless

DC

motor

Aluminum

diecast

Diameter

33.2

cm

(

13

-

5

/

64

”

)

Mass

1.7

kg

(

3.74

lb

.

)

33

-

1

/

3

r

/

min

,

45

r

/

min

±

8

%

,

±

16

%

(

two

settings

)

1.5

kg

-

cm

(

1.3

lb

-

in

)

0.7

s

.

tram

standstill

to

33

-

1

/

3

r

/

min

Electronic

brake

0.01

%

WRMS

*

0.025

%

WRMS

(

JIS

C

5521

)

±

0.035

%

peak

(

IEC

98

A

Weighted

)

-

56

dB

(

IEC

98

A

Unweighted

)

-

78

dB

(

IEC

98

A

Weighted

)

*

This

rating

refers

to

turntable

assembly

alone

,

excluding

effects

of

record

,

cartridge

or

tonearm

,

but

including

platter

.

Measured

by

obtaining

signal

tram

built

-

in

frequency

generator

of

motor

assembly

.

Less

than

7

mg

(

lateral

,

vertical

)

Within

2

°

32

’

[

at

th

è

outer

groove

of

30

cm

(

12

”

)

record

]

Within

0

°

32

’

[

at

th

è

inner

groove

of

30

cm

(

12

”

)

record

]

0

-

4

g

3.5-13

g

11

-

20.5

g

(

including

headshell

)

9.5

-

13

g

17

-

20.5

g

(

including

headshell

)

3.5

-

6.5

g

11

-

14

g

(

including

headshell

)

Drive

method

:

Motor

:

Turntable

platter

:

Stylus

pressure

adjustment

range

:

Applicable

cartridge

weight

range

:

Turntable

speeds

:

Variable

range

pitch

:

Starting

torque

:

Build

-

up

characteristics

:

Braking

System

:

Wow

and

flutter

:

(

with

auxiliary

weight

)

;

(

with

shell

weight

)

;

Headshell

weight

:

7.5

g

GENERAL

Power

supply

:

Rumble

:

AC

110

-

127

V

/

220-240

V

,

50

Hz

(

E,EB

,

GN

)

AC

120

V

,

60

Hz(PP

)

15

W(E,EB

,

GN

)

14.5

W(PP

)

45.3

x

17.2

x

35.5

cm

(

17

-

27

/

32

”

x

6

-

25

/

32

”

x

13-31/32

”

)

11.7

kg

(

25.74

lb

)

Power

consumption

:

Dimensions

(

WxHxD

)

:

TONEARM

SECTION

Type

:

Effective

length

:

Arm

height

adjustment

range

:

Overhang

:

Effective

mass

:

Universal

230

mm

(

9

-

1

/

16

”

)

0-6

mm

15

mm

(

19

/

32

”

)

12

g

(

without

cartridge

)

Mass

:

Note

:

Specifications

are

subjecttochange

without

notice

.

Mass

and

dimensions

are

approximate

.

Techmcs

Page 2

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

A

WARNING

This

Service

information

is

designed

for

experienced

repair

technicians

only

and

is

not

designed

for

use

by

th

è

generai

public

.

It

does

not

contain

warnings

or

cautionstoadvise

non

-

technical

individuals

of

potential

dangersinattempting

to

Service

a

product

.

Products

powered

by

electricity

shouldbeserviced

or

repaired

only

by

experienced

professional

technicians

.

Any

attempt

to

Service

or

repair

th

è

productorproducts

dealt

with

in

this

Service

information

by

anyone

else

could

resultinserious

injury

or

death

.

CONTENTS

Page

Page

1

Accessories

2

Controls

3

Turntable

System

pitch

adj

.

slider

replacement

instructions

.

4

4

Safety

Precaution

5

Caution

for

AC

Mains

Lead

6

Operation

Checks

and

Component

Replacement

Procedures

7

6.1

.

Checking

for

th

è

main

P

.C.B.

and

power

supply

P

.

C

.B.

—

7

6.2

.

Checking

for

th

è

pitch

control

(1)

P

.C.B.

6.3

.

Replacement

for

th

è

drive

coil

ass

’

y

and

FG

coil

ass

’

y

—

•

9

6.4

.

Replacement

for

th

è

tonearm

unit

6.5

.

Replacement

for

th

è

parts

mounted

onspeed

selector

P

.C.

B

.

and

power

switch

6.6

.

Replacement

for

th

è

LED

and

Stylus

illuminator

switch

-

12

7

Cautions

in

handling

of

thèblue

LED

8

Type

lllustration

of

IC

’

s

,

Transistors

and

Diods

9

Measurements

and

Adjustments

9.1

.

The

stateofset

and

th

è

use

apparatus

9.2

.

Measurements

and

Adjustments

9.3

.

Alignment

points

10

Schematic

Diagram

10.1

.

Schematic

Diagram

Notes

10.2

.

Schematic

Diagram

11

Printed

Circuit

Board

Diagram

12

Block

Diagram

13

Wiring

Connection

Diagram

14

Replacement

Parts

List

15

Cabinet

Parts

Location

15.1

.

Cabinet

15.2

.

Tonearm

16

Packaging

2

15

3

15

15

5

15

6

16

16

17

8

19

21

10

22

23

12

27

27

14

28

14

29

1

Accessories

•

Disc

slip

sheet

set

(

RGS

0005

Z

-

1

)

.

.

.

1

pc

.

•

Overhang

gauge

(

SFK

0135

-

01

)

..

.

1

pc

.

Teclmics

SDYmioe

.i.

-

Disc

slip

sheet

-

Transparent

sheet

•

Auxiliary

weight

(

SFPWG

17202

)

..

.

1

pc

.

•

Nuts

(

RHN

26003

)

..

.

2

pcs

.

•

Screws

(

short

) (

SFCZV

8801

-

1

)

..

.

2

pcs

.

•

Screws

(

long

)

(

SFPEV

9801

-

1

)

..

.

2

pcs

.

•

Washers

(

SFPEW

9601

)

...

2

pcs

.

•

Sticker

(

RQLC

0142

-

1

)

.

.

.

1

pc

.

•

EP

record

adaptor

(

SFWE

010

A

)

...

1

pc

.

•

Shell

weight

(

SFPZB

3501

)

.

.

.

1

pc

.

2

Page 3

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

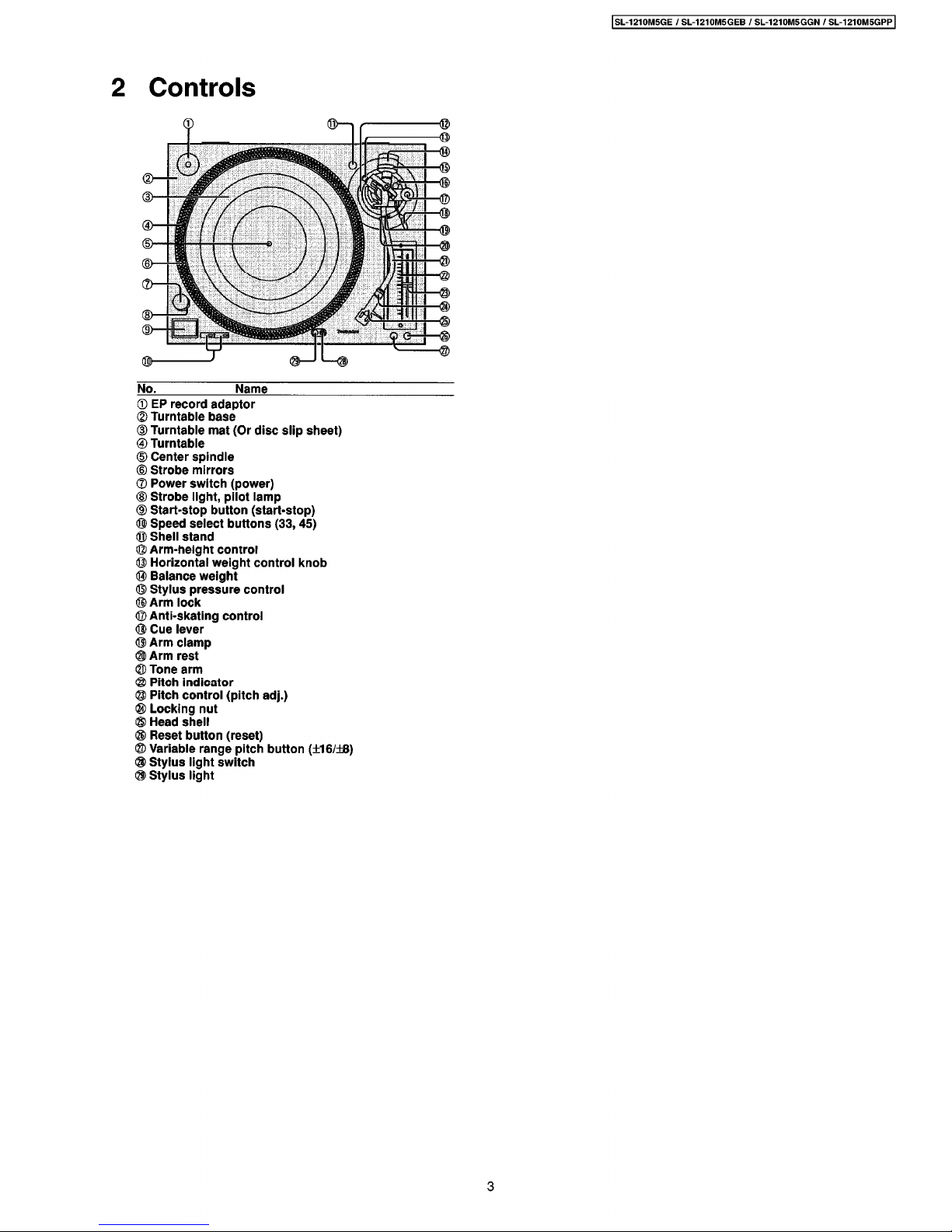

2

Controls

i

©

<S>

2

<

©

d

>

©

>

E

©

<

2

>

d

>

©

d

>

©

<g>

#

No

.

Name

©

EP

record

adaptor

©

Turntable

base

(

D

Turntable

mat

(

Or

disc

slip

sheet

)

®

Turntable

@

Center

spindle

®

Strobe

mirrors

®

Power

switch

(

power

)

®

Strobe

llght

,

pilot

lamp

CD

Start

-

stop

button

(

start

-

stop

)

®

Speed

select

buttons

(

33

,

45

)

®

Shell

stand

©

Arm

-

height

control

©

Horizontal

weight

control

knob

®

Balance

weight

©

Stylus

pressure

control

©

Arm

lock

©

Anti

-

skating

control

®

Cue

lever

®

Arm

clamp

©

Arm

rest

©

Tone

arm

®

Pitch

indicator

©

Pitch

control

(

pitch

adj

.

)

®

Locking

nut

©

Head

Shell

®

Reset

button

(

reset

)

@

Variable

range

pitch

button

(

±

16

/

±

8

)

®

Stylus

light

switch

©

Stylus

light

3

Page 4

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

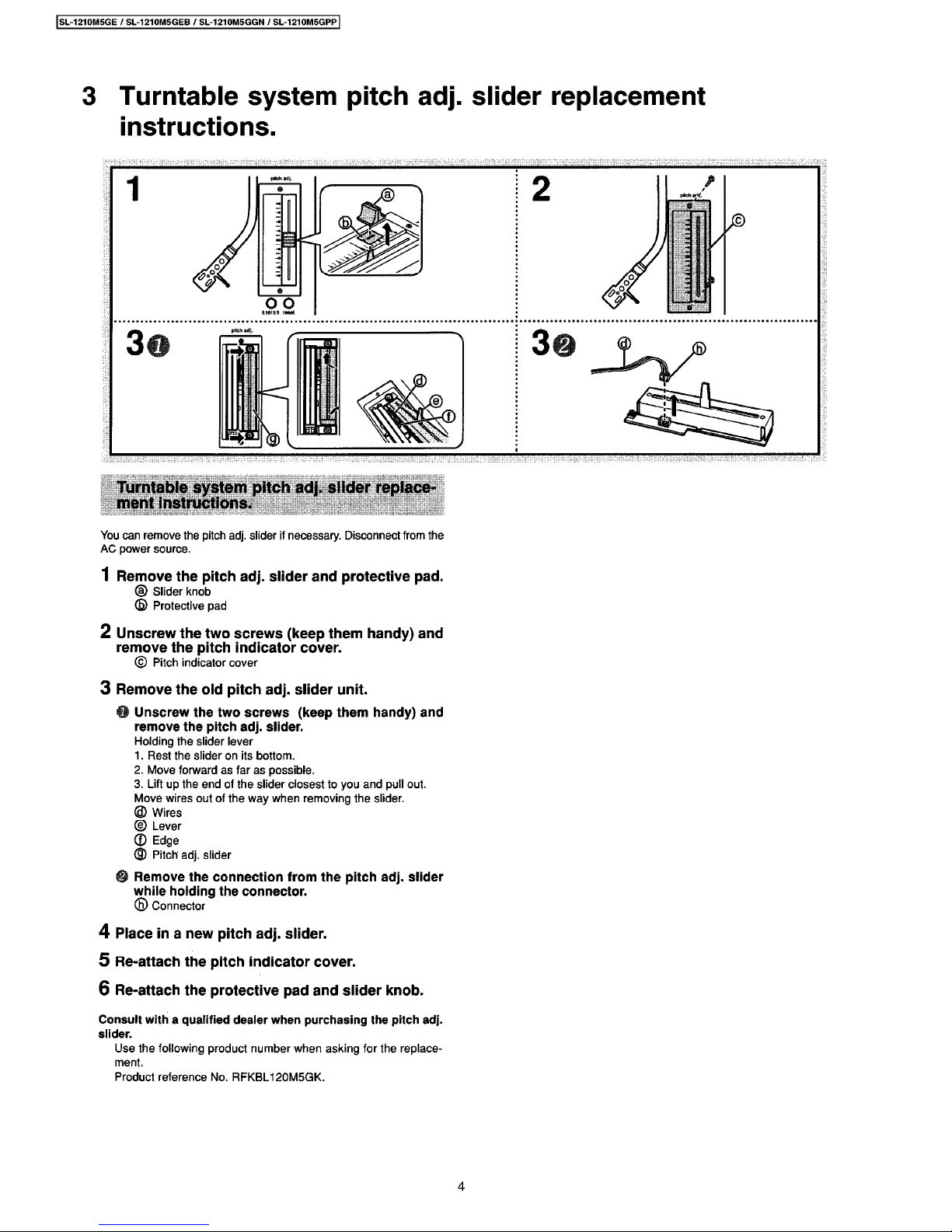

3

Turntable

System

pitch

adj

.

slider

replacement

instructions

.

®

B

.

4

m

5.1

2

i

3

vi

:

:

i

i

1

4

Ì

'

?

!

il

V.V

:

fi

il

?

1

•

1

'

:

ì

.

V

i

il

!

f

I

:

:

%

Hi

I

2

i

'

y

.

t

li

:

K

2

i

&

Si

555

HH

;

Ì

.

-

VV

.

5

,

’

H

-

,

,

-

.

H

,

-V-

|

i

-

HVHHHHH

'

i

'

iiiHrH

Hii

:

Turntable

System

pitch

adj

.

slider

replace

-

ment

instructions

.

You

can

remove

th

è

pitch

adj

.

slider

if

necessary

.

Disconnect

tram

th

è

AC

power

source

.

1

Remove

th

è

pitch

adj

.

slider

and

protective

pad

.

©

Slider

knob

(

B

)

Protective

pad

2

Unscrew

th

è

two

screws

(

keep

them

handy

)

and

remove

th

è

pitch

indicator

cover

.

©

Pitch

indicator

cover

3

Remove

th

è

old

pitch

adj

.

slider

unit

.

Unscrew

th

è

two

screws

(

keep

them

handy

)

and

remove

th

è

pitch

adj

.

slider

.

Holding

th

è

slider

lever

1

.

Rest

th

è

slideronits

bottom

.

2

.

Move

forward

as

far

as

possible

.

3

.

Lift

up

th

è

end

of

th

è

slider

closest

to

you

and

pul

ì

out

.

Move

wires

out

of

th

è

way

when

removing

th

è

slider

.

©

Wires

©

Lever

©

Edge

©

Pitch

adj

.

slider

Remove

thèconnection

from

th

è

pitch

adj

.

slider

while

holding

th

è

connector

.

©

Connector

4

Place

in

a

new

pitch

adj

.

slider

.

5

Re-attach

th

è

pitch

indicator

cover

.

6

Re

-

attach

th

è

protective

pad

and

slider

knob

.

Consult

with

a

qualified

dealer

when

purchasing

th

è

pitch

adj

.

slider

.

Use

th

è

following

product

number

when

asking

for

th

è

replace

-

ment

.

Product

reference

No

.

RFKBL

120

M

5

GK

.

4

Page 5

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

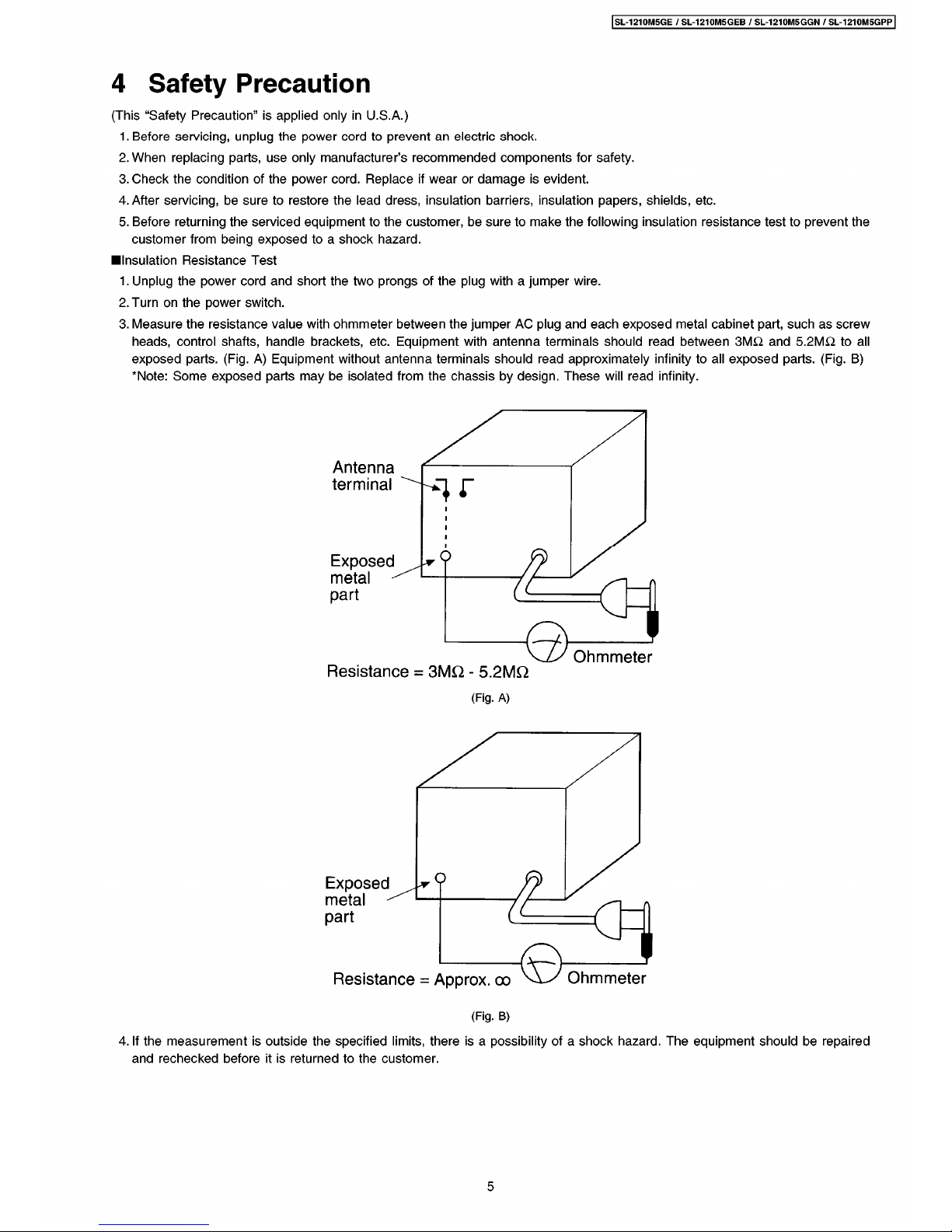

4

Safety

Precaution

(

This

“

Safety

Precaution”is

applied

only

in

U

.S.A.

)

1

.

Before

servicing

,

unplug

th

è

power

cord

to

prevent

an

electric

shock

.

2

.

When

replacing

parts

,

use

only

manufacturer

’

s

recommended

components

for

safety

.

3

.

Check

th

è

condition

of

th

è

power

cord

.

Replace

if

wear

or

damage

is

evident

.

4

.

After

servicing

,

be

sure

to

restore

th

è

lead

dress

,

insulation

barriers

,

insulation

papers

,

shields

,

etc

.

5

.

Before

returning

th

è

serviced

equipment

to

th

è

customer

,

be

sure

to

make

th

è

following

insulation

resistance

test

to

prevent

th

è

customer

from

being

exposed

to

a

shock

hazard

.

Insulation

Resistance

Test

1

.

Unplug

th

è

power

cord

and

short

th

è

two

prongs

of

th

è

plug

with

a

jumper

wire

.

2

.

Turn

on

th

è

power

switch

.

3

.

Measure

th

è

resistance

value

with

ohmmeter

between

th

è

jumper

AC

plug

and

each

exposed

metal

cabinet

part

,

such

as

screw

heads

,

control

shafts

,

handle

brackets

,

etc

.

Equipment

with

antenna

terminals

should

read

between

3

M

£

2

and

5.2

M

&

to

all

exposed

parts

.

(

Fig

.

A

)

Equipment

without

antenna

terminals

should

read

approximately

infinity

to

all

exposed

parts

.

(

Fig

.

B

)

*

Note

:

Some

exposed

parts

may

be

isolated

from

th

è

chassis

by

design

.

These

will

read

infinity

.

Antenna

terminal

/

2

o

Exposed

metal

-

Zt

part

Ohmmeter

Resistance

=

3

MQ

-

5.2

MQ

(

Fig

.

A

)

*

9

Exposed

metal

-

part

Ohmmeter

Resistance

=

Approx

.

oo

(

Fig

.

B

)

4

.

If

th

è

measurement

is

outside

th

è

specified

limits

,

there

is

a

possibility

of

a

shock

hazard.The

equipment

should

be

repaired

and

rechecked

before

it

is

returned

to

th

è

customer

.

5

Page 6

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

5

Caution

for

AC

Mains

Lead

WARNING:DO

NOT

CONNECT

EITHER

WIRETOTHE

EARTH

TERMINAL

WHICH

IS

MARKED

WITH

THE

LETTER

E,BY

THE

EARTH

SYMBOL

OR

COLOURED

GREENORGREEN/YELLOW

.

(

For

United

Kingdom

)

(

“

EB

”

area

code

model

only

)

Foryour

safety

,

please

read

th

è

following

text

carefully

.

THIS

PLUG

IS

NOT

WATERPROOF

—

KEEP

DRY

.

This

appliance

is

supplied

with

a

moulded

three

pin

mains

plug

for

your

safety

and

convenience

.

A

5

-

ampere

fuse

is

fitted

in

this

plug

.

Should

th

è

fuse

needtobe

replaced

please

ensure

that

th

è

replacement

fuse

has

a

rating

of

5

-

ampere

and

that

it

is

approved

by

ASTAorBSI

to

BS

1362

.

Check

for

th

è

ASTA

mark

<

^

>

or

th

è

BSI

mark

^

on

th

è

body

of

th

è

fuse

.

Before

use

Remove

th

è

connector

cover

.

How

to

replace

th

è

fuse

The

location

of

th

è

fuse

differ

according

to

th

è

type

of

AC

mains

plug

(

figures

A

and

B

)

.

Confirm

th

è

AC

mains

plug

fitted

and

follow

th

è

instructions

below

.

Illustrations

may

differ

from

actual

AC

mains

plug

.

If

th

è

plug

containsaremovable

fuse

cover

you

must

ensure

that

it

is

refitted

when

th

è

fuse

is

replaced

.

If

you

lose

th

è

fuse

cover

th

è

plug

must

not

be

used

until

a

replacement

cover

is

obtained

.

A

replacement

fuse

cover

can

be

purchased

from

your

locai

dealer

.

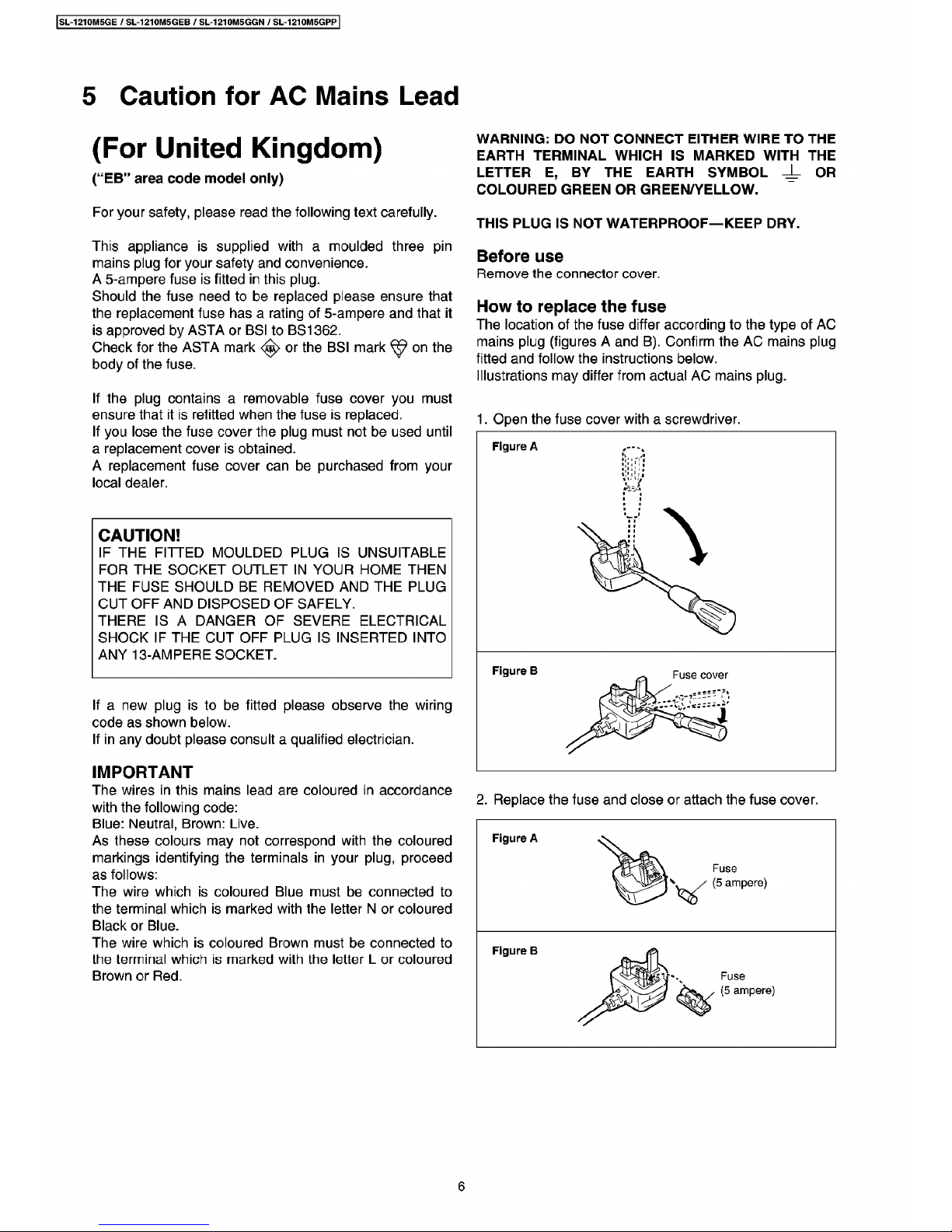

1

.

Open

th

è

fuse

cover

with

a

screwdriver

.

CAUTION

!

IF

THE

FITTED

MOULDED

PLUG

IS

UNSUITABLE

FOR

THE

SOCKET

OUTLET

IN

YOUR

HOME

THEN

THE

FUSE

SHOULDBEREMOVED

AND

THE

PLUG

CUT

OFF

AND

DISPOSED

OF

SAFELY

.

THERE

ISADANGER

OF

SEVERE

ELECTRICAL

SHOCK

IF

THE

CUT

OFF

PLUG

IS

INSERTED

INTO

ANY

13

-

AMPERE

SOCKET

.

If

a

new

plug

istobe

fitted

please

observe

th

è

wiring

code

as

shown

below

.

If

in

any

doubt

please

consult

a

qualified

electrician

.

IMPORTANT

The

wires

in

this

mains

lead

are

coloured

in

accordance

with

th

è

following

code

:

Blue:Neutral

,

Brown:Live

.

As

these

colours

may

not

correspond

with

th

è

coloured

markings

identifying

th

è

terminals

in

your

plug

,

proceed

as

follows

:

The

wire

whichiscoloured

Blue

must

be

connected

to

th

è

terminal

whichismarked

with

th

è

letter

N

or

coloured

Black

or

Blue

.

The

wire

which

is

coloured

Brown

must

be

connected

to

th

è

terminal

whichismarked

with

th

è

letter

L

or

coloured

Brown

or

Red

.

2

.

Replace

th

è

fuse

and

doseorattach

th

è

fuse

cover

.

Figure

A

6

Page 7

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

6

Operation

Checks

and

Component

Replacement

Procedures

•

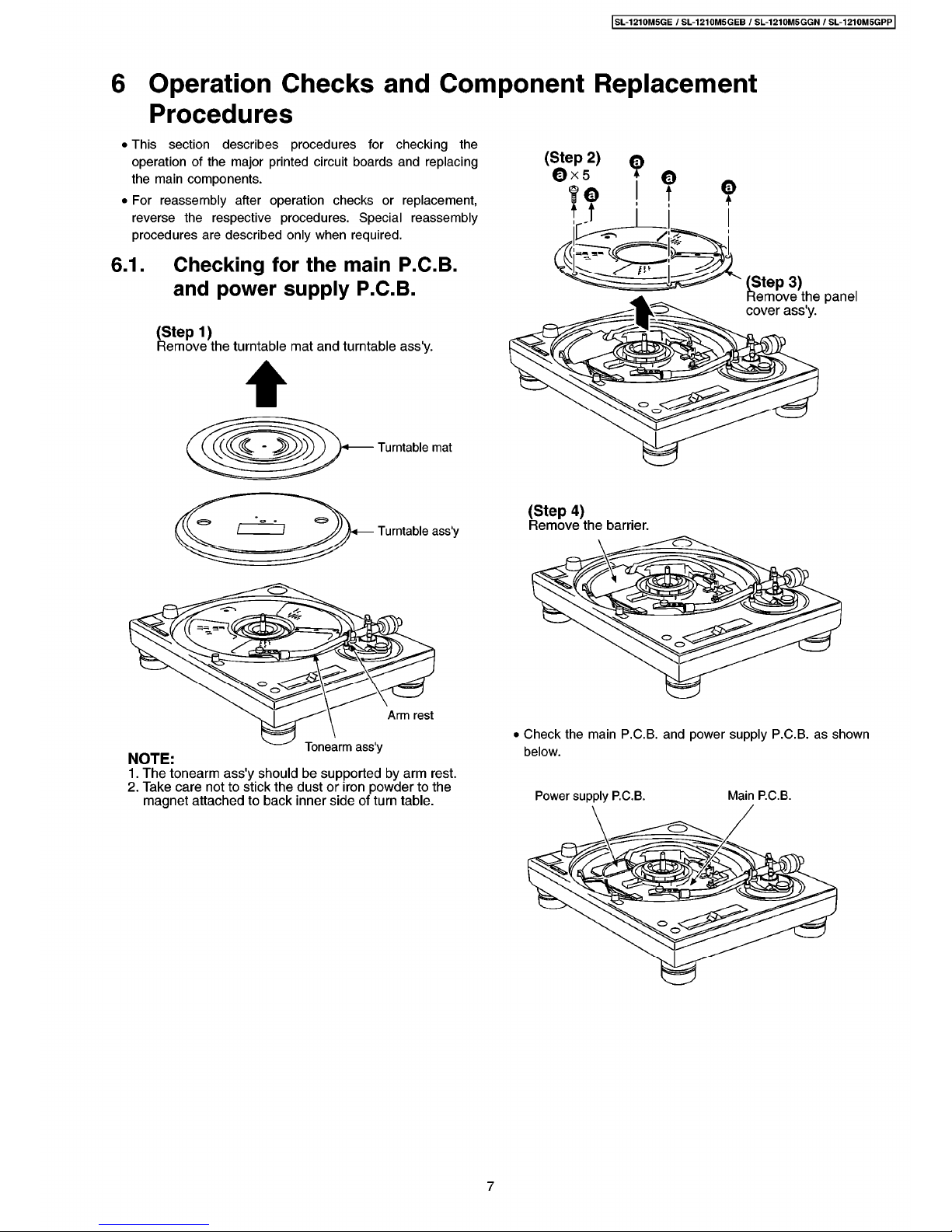

This

section

describes

procedures

for

checking

th

è

operation

of

th

è

major

printed

Circuit

boards

and

replacing

th

è

main

components

.

•

For

reassembly

after

operation

checks

or

replacement

,

reverse

th

è

respective

procedures

.

Special

reassembly

procedures

are

described

only

when

required

.

(

Step

2

)

©

x

5

o

t

©

©

t

©

t

/

il

(

;

=

-

=

-

Checking

for

thèmain

P

.C.B.

and

power

supply

P

.C.B.

6.1

.

fi

'

(

Step

3

)

Remove

th

è

panel

cover

ass

'

y

.

(

Step

1

)

Remove

th

è

turntable

mat

and

turntable

ass

'

y

.

&

o

Turntable

mat

<

(

Step

4

)

Remove

th

è

barrier

.

&

Turntable

ass

'

y

&

%

Arm

rest

•

Check

th

è

main

P

.C.B.

and

power

supply

P

.C.B.

as

shown

below

.

Tonearm

ass

'

y

NOTE

:

1

.

The

tonearm

ass

'

y

should

be

supported

by

arm

rest

.

2

.

Take

care

not

to

stick

th

è

dustoriron

powder

to

th

è

magnet

attachedtoback

inner

side

of

turn

table

.

Power

supply

P

.C.

B

.

Main

P

.

C

.B.

7

Page 8

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

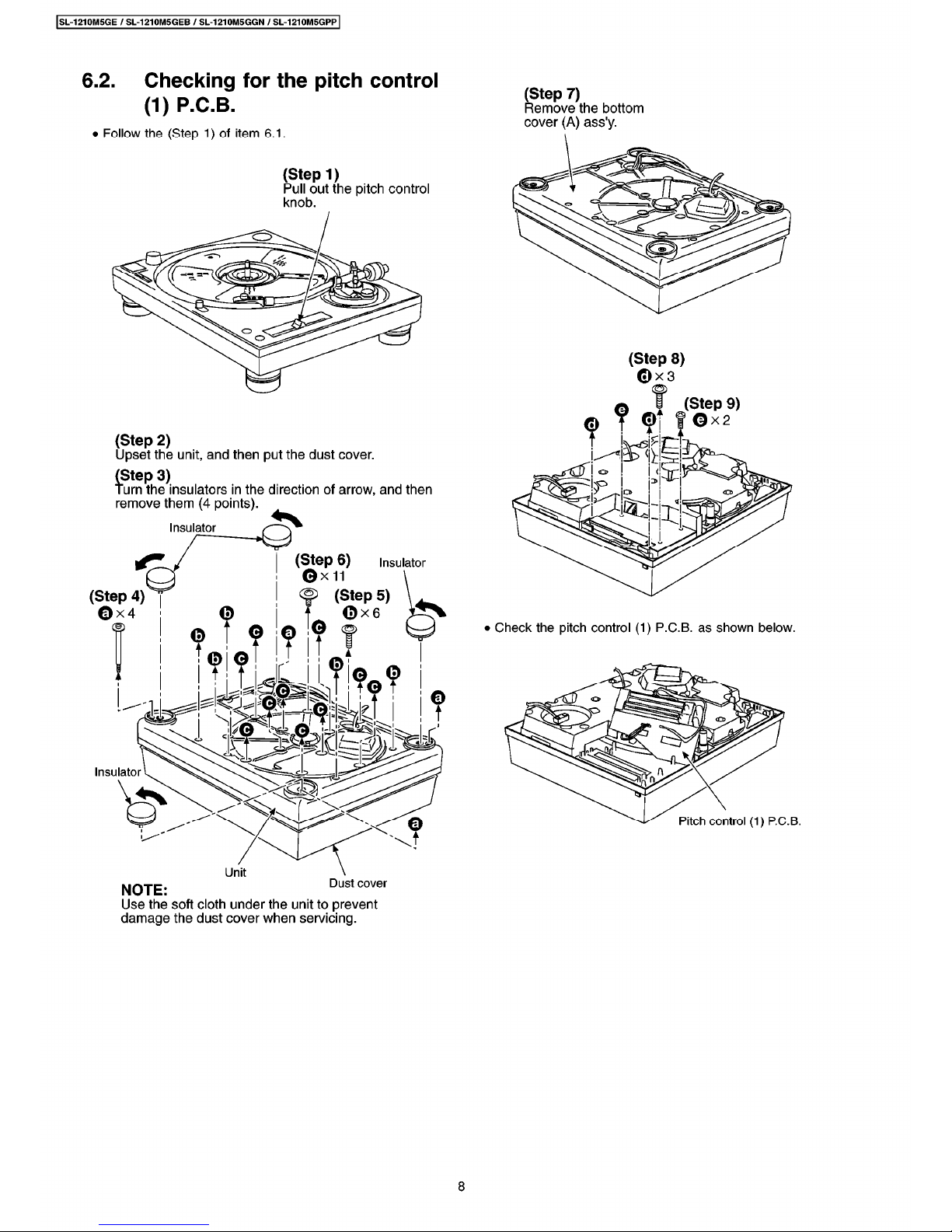

6.2

.

Checking

for

th

è

pitch

control

(1)

P

.C.B.

(

Step

7

)

Remove

th

è

bottom

cover

(A)

ass

'

y

.

•

Follow

th

è

(

Step

1

)

of

item

6.1

.

(

Step

1

)

Pul

ì

out

th

è

pitch

control

knob

.

(

Step

8

)

©

x

3

(

Step

9

)

©

x

2

(

Step

2

)

Upset

th

è

unit,and

then

put

th

è

dust

cover

.

(

Step

3

)

Turn

th

è

insulators

in

th

è

direction

of

arrow

,

and

then

remove

them

(

4

points

)

.

Insulator

(

Step

6

)

©

X

11

Insulator

S

>

(

Step

5

)

(

Step

4

)

©

X

4

•

Check

th

è

pitch

control

(1)

P

.C.

B

.

as

shown

below

.

<

&

<o>

fe

.

4

Insulator

Pitch

control

(

1

)

P

.

C

.

B

.

Dust

cover

NOTE

:

Use

th

è

soft

cloth

under

th

è

unit

to

prevent

damage

th

è

dust

cover

when

servicing

.

8

Page 9

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

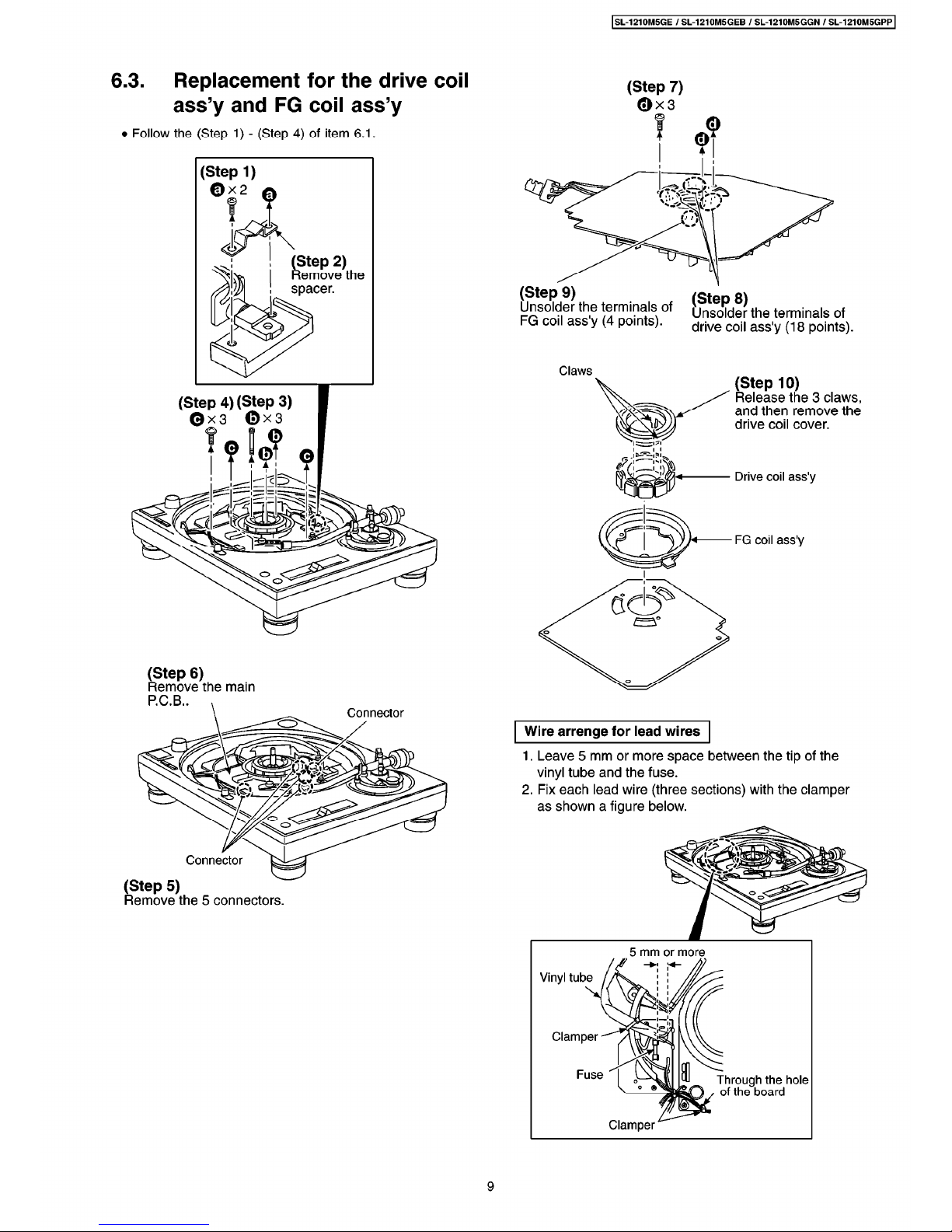

6.3

.

Replacement

for

thèdrive

coil

ass

’

y

and

FG

coil

ass

’

y

•

Follow

th

è

(

Step

1

)-(

Step

4

)

of

item

6.1

.

(

Step

7

)

0

x

3

(

Step

1

)

0

x

2

7

(

Step

2

)

Re

move

th

è

spacer

.

(

Step

9

)

Unsolder

th

è

terminals

of

FG

coil

ass

'

y

(

4

points

)

.

(

Step

8

)

Unsolder

th

è

terminals

of

drive

coil

ass

'

y

(

18

points

)

.

Claws

(

Step

10

)

Release

th

è

3

claws

,

and

then

remove

th

è

drive

coil

cover

.

(

Step

4

)

(

Step

3

)

©

x

3

0

x

3

Drive

coil

ass

'

y

FG

coil

ass

'

y

(

Step

6

)

Remove

th

è

mairi

P

.C.B.

.

Connector

Wire

arrenge

for

lead

wires

1

.

Leave

5

mirri

or

more

space

between

th

è

tip

of

th

è

vinyl

tube

and

th

è

fuse

.

2

.

Fix

each

lead

wire(three

sections

)

with

th

è

damper

as

shown

a

figure

below

.

Connector

(

Step

5

)

Remove

th

è

5

connectors

.

9

Page 10

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

6.4

.

Replacement

for

th

è

tonearm

unit

•

Follow

th

è

(

Step

1

)

of

item

6.1

.

•

Follow

th

è

(

Step

2

)-(

Step

7

)

of

item

6.2

.

(

Step

8

)

©

x

2

(

Step

7

)

0

x

2

(

Step

10

)

Remove

th

è

arm

base

cover

piate

.

(

Step

1

)

©

x

5

?

9

(

Step

2

)

Remove

th

è

bottoni

cover

(B)

.

(

Step

5

)

(

Step

3

)

(

Step

9

)

Release

th

è

2

claws,and

then

remove

th

è

phono

cord

damper

and

phono

cord

spacer

.

(

Step

12

)

(

Step

14

)

Remove

th

è

PU

output

P

.C.B.

.

(

Step

13

)

0

(

Step

4

)

Remove

th

è

lug

terminal

.

Tonearm

unit

NOTE

:

Hold

th

è

tonearm

unit

with

hand

when

removing

th

è

3

screws

(

©

)

.

Cabinet

ass

'

y

Tonearm

ass

'

y

(

Step

6

)

Separate

th

è

dust

cover

and

th

è

cabinet

ass

'

y

,

and

then

remove

th

è

tonearm

ass

'

y

.

Dust

cover

(

Step

11

)

Unsolder

th

è

terminals

(

5

points

)

.

10

Page 11

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

When

passing

th

è

lead

wire

through

\

\

ir

th

è

hole

,

for

easy

operation

,

wrap

th

è

jp

ends

of

5

lead

wires

IW

with

tape

.

(

Step

3

)

Pass

th

è

5

lead

wires

through

th

è

hole

of

arm

basement

.

(

Step

15

)

Release

th

è

arm

rest

.

Arm

rest

(

Step

4

)

Instali

th

è

tonearm

unit

.

(

Step

16

)

0

x

2

P

(

Step

5

)

Support

th

è

tonearm

unit

with

arm

rest

.

Arm

rest

Arm

base

(

Step

6

)

Tighten

th

è

tonearm

unit

screws

.

0

x

2

/

Tonearm

unit

%

(

Step

17

)

Remove

th

è

tonearm

unit

.

Reassembly

procedures

for

tonearm

ass

'

y

(

Stepl

)

(

Step

2

)

Rotate

th

è

arm

base

knob

Rotate

th

è

canceler

knob

in

in

th

è

direction

of

arrow

,

th

è

direction

of

arrow

,

and

and

then

align

th

è

pointer

then

align

th

è

pointer

with

with

th

è

scale

"0"

.

(

Step

7

)

Remove

th

è

tape

of

lead

wire

.

th

è

scale

"0"

.

Pointer

Pointer

Canceler

knob

Arm

base

knob

11

Page 12

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

6.5

.

Replacement

for

th

è

parts

mounted

onspeed

selector

P

.C.B.

and

power

switch

•

Follow

th

è

(

Step

1

)

of

item

6.1

.

•

Follow

th

è

(

Step

2

)

-

(

Step

7

)

of

item

6.2

.

6.6

.

Replacement

for

th

è

LED

and

Stylus

illuminator

switch

•

Follow

th

è

(

Step

1

)

of

item

6.1

.

•

Follow

th

è

(

Step

2

)-(

Step

7

)

of

item

6.2

.

Cautions

1

.

For

lightening

th

è

needle

tip

,

this

unit

uses

a

blue

LED

instead

of

a

conventional

lamp

.

The

blue

LED

is

very

much

sensitivetostatic

electricity

;

therefore

,

be

especially

careful

of

handling

it

.

2

.

This

LED

may

be

destroyed

or

worsened

by

th

è

static

electricity

charged

in

clothes

and

human

bodies

.

When

handling

and

repairing

th

è

LED

,

be

especially

careful

of

such

destruction.Be

sure

to

take

necessary

measures

such

as

wearing

a

wrist

strap

.

(

Step

1

)

©

x

2

T

(

Step

1

)

(

CT

<a>

©

(

Step

2

)

<o>

<

a

>

<

o

>

(

Step

2

)

Remove

th

è

LED

unit

.

0

\

(

Step

4

)

Remove

th

è

lamp

case

.

©

(

Step

4

)

e

a

©

(

Step

3

)

Speed

selector

P

.C.

B

.

1

À

J

&

&

Syilus

illuminator

switch

&

_

T

7

AJV

.

3

3

WLI

O

,

V

<

©

p

5

)

x

2

Power

switch

(

Step

3

)

Remove

th

è

speed

selector

P

.C.B..

12

Page 13

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

(

Step

7

)

Remove

th

è

LED

.

Si

&

LED

P

.C.B.

e

&

)

o

)

Black

o

Red

(

Step

6

)

Unsolder

th

è

terminals

of

lead

wire

(

2

points

)

.

13

Page 14

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

7

Cautions

in

handling

of

th

è

blue

LED

•

For

lightening

th

è

needle

tip

,

this

unit

uses

a

blue

LED

instead

of

a

conventional

lamp

.

The

blue

LED

is

very

much

sensitive

to

static

electricity

;

therefore

,

be

especially

careful

of

handling

it

.

A

Be

careful

of

destruction

by

th

è

static

electricity

•

This

LED

may

be

destroyed

or

worsened

by

th

è

static

electricity

charged

in

clothes

and

human

bodies

.

When

handling

and

repairing

th

è

LED

,

be

especially

careful

of

such

destruction

.

Be

su

re

to

take

necessary

measures

such

as

wearing

a

wrist

strap

.

Grounding

for

electrostatic

breakdown

prevention

1

.

Human

body

grounding

•

Use

th

è

anti-static

wrist

strap

to

discharge

th

è

static

electricity

from

your

body

.

(

Fig

.

12

-

1

)

2

.

Work

table

grounding

•

Put

a

conductive

material(sheet

)

or

steel

sheet

on

th

è

area

where

th

è

traverse

deck

(

optical

pick

-

up

)

is

placed

,

and

ground

th

è

sheet

.

(

Fig

.

12

-

2

)

*

ir

Iron

piate

or

some

metals

to

conduct

electricity

(

Fig

.

12-2

)

Caution

:

The

static

electricity

of

your

clothes

will

not

be

grounded

through

th

è

wrist

strap

.

So

take

care

not

to

let

your

clothes

touch

th

è

traverse

deck

(

optical

pick

-

up

)

.

Wrist

strap

(

Anti

-

static

bracelet

)

1

M

£

2

777777

/

(

Fig

.

12

-

1

)

8

Type

lllustration

of

IC

’

s

,

Transistors

and

Diods

2

SD

637

-

QRS

D

2

SBA

20

SVDPR

3902

S

-

9

LN

21

CAL

RXQ

1004

_

B3AFA

0000034

LMW9A

8

BYB

0

A

1

Anode

Anode

Anode

Cathde

A

Cathde

A

(

f

£

—

Ca

Cathde

A

(

§

)

Ca

Ca

14

Page 15

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

9

Measurements

and

Adjustments

9.1

.

The

state

of

set

and

th

è

use

apparatus

PITCH

CONTROL

±

0

%

ADJUSTMENT

VR

501

É

~

[

•

Make

th

è

following

adjustments

after

replacing

parts

as

IC

’

s

,

Transistore

,

Diodes

,

etc

.

•

Condition

of

th

è

set

.

1

.

Power

switch

:

ON

2

.

Pitch

control

:

Center

position

3

.

Speed

selector

switch

:

33

-

1

/

3

r

/

min

•

Instruments

to

be

used

-

Tester

-

Frequency

counter

Measuring

apparatus

oo

o

©

O

XL

Lever

o

+

c

>

Center

ir

o

©

O O P

PITCH

CONTROL

(

2

)

P

.

C

.

B

.

053

PITCH

CONTROL

(1)

P

.C.B.

9.2

.

Measurements

and

Adjustments

9.2

.1.

Pitch

control

±

0

%

adjustment

(

PITCH

)

1

.

Connect

th

è

frequency

counter

[

(+)

:

TP

1

,

(-)

:

GND

]

and

turn

th

è

power

supply

ON

.

2

.

Set

th

è

pitch

control

knob

(

VR

303

)

to

“

0

”

(

center

position

)

.

(

Indicator

lights

up

.

)

3

.

Adjust

VR

501

so

that

th

è

output

becomes

th

è

maximum

.

(

Fig

.

2

)

9.2

.2.

Brake

adjustment

(

BRAKE

)

I

.

Adjust

VR

201

so

that

th

è

rotation

at

33

-

1

/

3

r

/

min

stops

within

th

è

stop

range

after

pressing

th

è

stop

button

.

(

Fig

.

l

)

(

Fig

.

3

)

9.3

.

Alignment

points

(

Fig

.

2

)

The

direction

of

EP

record

adaptor

.

Turntable

Turntable

sheet

Record

disc

(

30

cm

)

Stop

range

Stop

signal

(

Stylus

tight

position

)

(

Fig

.

3

)

PITCH

CONTROL

±

0

%

ADJUSTMENT

VR

501

Measuring

apparatus

oo

o

Lever

O

-

a

*

r

—

Center

s

©

o

m

O O P

PITCH

CONTROL

(2)

P

.

C

.B.

PITCH

CONTROL

(1)

P

.C.B.

(

Fig

.

1

)

15

Page 16

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

10

Schematic

Diagram

10.1

.

Schematic

Diagram

Notes

S

201

SPEED

SELECTOR

(

33

-

1

/

3

r

/

min

)

switch

.

SPEED

SELECTOR

(

45

r

/

min

)

switch

.

START

/

STOP

switch

in

“

OFF

”

position

.

STYLUS

ILLUMINATOR

switch

in

“

ON

”

position

.

PITCH

RESET

switch

in

“

ON

”

position

.

PITCH

SELECT

(

±

8

%

/

±

16

%

)

switch

in

“

±

16

%

”

position

.

POWER

switch

in

“

ON

”

position

.

VOLTAGE

SELECTOR

switch

in

“

220

-

240

V

”

position

.

[

E,EB

,

GN

]

BRAKE

ADJUSTMENT

VR

.

PITCH

CONTROL

ADJUSTMENT

VR

.

PITCH

CONTROL

±

0

%

ADJUSTMENT

5202

5203

S

401

S

501

:

S

502

:

S

601

:

S

602

:

VR

201

VR

303

VR

501

VR

.

•

The

voltage

value

and

waveforms

are

th

è

reference

voltage

of

this

measured

by

DC

electronic

voltmeter

(

high

impedance

)

and

oscilloscope

on

th

è

basis

of

chassis

.

Accordingly

,

there

may

arise

some

errors

in

th

è

voltage

values

and

waveforms

depending

upon

th

è

internai

impedance

of

th

è

tester

or

th

è

measuring

unit

.

No

mark

:

Voltage

when

at

a

stop

(

)

:

Voltage

during

rotation

•

Signal

line

:

+

B

line

•

Important

safety

notice

:

Components

identified

by

A

mark

have

special

characteristics

important

for

safety

.

When

replacing

any

of

these

components

,

use

only

manufacture

’

s

specified

parts

.

•

This

schematic

diagram

may

be

modified

at

any

time

with

th

è

development

of

new

technology

.

16

Page 17

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

10.2

.

Schematic

Diagram

0

REGULATOR

CIRCUIT

B

POWER

SUPPLY

CIRCUIT

For

[PP]

area

.

4

}

For

[

EB

,

GN

]

areas

.

35.8

V

21

V

r

AS

601

(

POWER

)

Q

1

AC

601„0.047

C

2

SD

126507

[

21.6

V

REGULATOR

I

II

A

r

IA

R

601

3.3

M

I

\

POWER

SUPPLY

CIRCUIT

S

601

4

^

(

POWER

)

,

Q

For

[

E

]

area

.

i

H

OFF

ON

1

A

F

2

I

125

V

1.2

A

4

j

-

<

r

^

o

-

r

)

—

D

1

Q

DRIVE

CONTROL

CIRCUIT

AFI

125V250

mA

ATI

ATI

D

2

SBA

20

A

F

2

A

TP

1

TP

3

Z

ì

i

S

602

(

VOLTAGE

SELECTOR

)

Q

2

o

T1A

i

35.8

V

21.6

V

1

AC

1

11

°

i

+

(

2

)

o

>

2

:

^

6

O

r

Q

2

,

3

T

A

F

1

T

250

mA

AC

601AR601

0.047

1/2

W

4.7

!

4

i

I

A

I

AC

LINE

'

110-120

VS

/

220-240

V

,

50/60

Hz

.

2

SD

637

-

QRS

REGULATOR

OP

I

&

I

I

h

1

AC

120

V

(

60

Hz

)

ò

4

22.1

V

~

CM

§

1

+

22.1

V

J

-

2

?

og

2

Z

8

AC

30

V

UC

30

V

I

I

R

2

4

CM

IO

CM

TP

2

«

I

I

'

1

'

I

I

6.8

K

L

.

i

vw

AC

2

?

t

R

5

SS

5.4

V

R

4

G

470

470

?

i

—

wv

wv

TP

4

2

*

23

l

o

TP

5

<

?

4

4

4

<

21

V

>

2

_

+

•

S

501

•

•

•

OFF

,

5.3

V

Q

°

T

OWT

"

S

501

—

ON.OV

«

8

+

o

%

21

CM

CD

^

J

>

•

ROTATION

II

0

>

y

.

CM

*

*

ce

CO

STOP

<

$

0.8

V

o

2

START

I

5

dI

cc

<

N

5

3

V

2.9

V

R

218

CN

IV

1

K

C

215

R

203

5

V10V

Q

203

2

SC

2458

GR

FG

AMP

0

V

3.8

ws

.

33

rpm

,

20

ms

.

45

rpm

,

15

ms

.

TP

12

O

-

i

F

I

gei

3.8

V

TP

11

.

0.4

V

R

206

TP

18

W

«

CM

>

2

E

WV

n

Oo

R

221

18

18

K

470

CM

r

-

+

R

207

56

K

•

ROTATION

-

Wv

R

208

220

K

|

—

Wv

—

ov

R

204

WV

\

TP

20

2.7

K

O

io

C

108

.

.

25V100

<

2

^

+

o

®

R

107

1

-

WV

9

V

o

C

211

C

110

"

+

0.1

C

204

0.047

POSITION

DET

.

COIL

0.22

II

5

V

C

210

..

0

,

22

•

ROTATION

S

203

-

-

Push

TP

19

II

n

R

108

10

K

TP

21

^

S

*

N

WV

R

209

330

K

(

.

—

wv

—

u

1

V

TP

17

O

—

i

CM

/

1.5

£

C

111

5600

P

O

è

“

>

+

§

CM

CO

T

-

+

oK

\

n

33

rpm

—

20

ms

.

45

rpnr

*

-

15

ms

.

wv

30

V

o

P

3

R

205

120

K

CD

TP

7

+

$

3

E

R

210

18

K

TP

16

L

WV

O

WV

o

3

50

KHz

A

CM

TP

22

TP

23

P

2

O O

2

l

20

W

$

.

ss

OC

”

*

(

2.8

V

)I(

0.3

V

)

7

V

Ì

5.9

V

C

107

C

112

R

104

E

P

1

o

0.3

V

0.5V8.1

V

1.2

V5V

0.2

V

3.2V3.2

V

I

2.8

V

50

V

4.7

47

K

0.1

II

»

7

wv

15

V

fl

8

VHl

9

J

fi

3

VH14HH

15

V

-

<

16

HH

1

A

)

1

•

STOP

,

0

V

o o o

<

»

o

cc

5

o

£

<

D

1.2

V

O

>

o

_

2

CD

CD

50

KHz

(

0

Li

-

LLI

LL LL

(

2.8

V

)

IC

201

AN

6680

SYSTEM

CONTROL

0

V

20.7

V

|

(

Ì

5

V

>

33

rpm

*

-

20

ms

.

45

rpnv

15

ms

.

•

ROTATION

Jl

5.8

V

115.8V115.9

V

(

Ì

6

)

—

HI

15.9

V

121.1

Vi

21V21

V

J

20.7

V

7

>

—

(

m

—

(

Ì

9

W

—

(

20

)—(

2

Ì

)

"

^

0.2

V

:

3

)

:

4

)

co

co

o

IC

101

I

S

!

AN

6675

L

TURNTABLE

^

DRIVE

J

Q

O O

o

2

o o

z

51

<

o

co

CM

8

o

co

o

CL

co

0

-

£

z

z

g

co co

cn

o

o

2

8

3

o

E

O O

CD

CD

CO

> >

LL

5.2

V

•

ROTATION

I

”

41

V

—

(

10

>

-

H

9

8

6

3

[

1

4

1

0

V

R

201

33

rpm

•••

20

ms

.

45

rpm

--

*

15

ms

.

0.2V9.4V10V0

V

3.3V3.4

V

2.1

V

3.4V3.9

V

2.7

V

560

X

-

WV

—

11

V

R

202

0

V

D

10

K

A/W

—

I

TP

15

10

V

.

R

101

10

K

WV

X

*

4

8

§

>

2

Z

3

d

50

KHz

ARMATURE

9.4

V21V

in

^

CC

'

*

l

o

C

213

470

P

4.13

MHZ

COIL

I

Q

201

2

SC

1846

-

QRS

REGULATOR

BRAKE

A

1

3.8

V

TP

8

"

N

ADJ

.

TP

9

mm

A

2

1.2

V

Li

i

o

“

/

II

0

V

A

3

8

m

a

.

•

S

501

—

ON

rw

-

v

•

STOP

*

S

501

—

OFF

0.9

V

cc

®

80

:

8

§

2

Z

+

^

>

:

2

E

+

l

§

2

Z

+

5.6

V

oc

n

m

5.6

V

M

-

8

ov

+

3.8

ws

.

TP

29

33

rpnr

**

10

ms

.

45

rpm

**

*

7.3

ms

.

§

1

*

>

O

T

-

5

dT

oc

VR

303

Center

,

3.8

ws

.

VR

303

-

%

,

4.1

W

s

.

VR

303

+

%

,

3.6

WS

.

c

CM

o

17

V

R

211

4.7

K

R

214

©

?

1

22

K

0.2

V

11

—

WV

wv

O

)

R

213

in

<

£

fi

ó

T

Q

202

0

1

2

SD

637

-

QRS

LED

DRIVE

i

—

O

TP

13

TP

14

1.2

K

¥

WV

5

-

1

Q

5

11

-

O

35

I

a

TP

28

CN

103

CN

101

“

Kp

©®©

©

^

^

OXYXBXMKP

)

M

1

X

2

X

3

,

1

H

OUTPUT

CIRCUIT

B

PWB

CARTRIDGEl

R

510

R

B

,

2.2

K

i

i

D

201,202

SVDPR

3902

S

-

9

i

R

509

.

’

2.2

K

1

sr

Lch

.

+

)

n

S

401

(

STYLUS

ILLUMI

NATO

R

SWITCH

)

CN

106

O

1

CM

I

—

CO

cc

D

203

-

206

LN

21

CAL

(

STROBE

ILLUMINATOR

)

OUTPUT

Sor

I

(

f

ò

ia

I I

I

R

-

J

1

?

*

*

Rch

WV

VR

303

(

PITCH

ADJ

.

)

co

^

I

I

I

i

E

.

P

i

GND

E

D

203

D

204D205D206

R

507

R

508

A

<

2

±

Ss

-

1

”

S

'

X

o

co

3

^

VR

501

1

K

820

STROBE

ILLUMINATOR

CIRCUIT

A

1

•

—

Wv

—

O

-

WV

—

wv

T

\

PITCH

CONTROL

SL

-

1210

M

5

G

(

E,EB

,GN,

PP

)

DRIVE

CONTROL

,

POWER

SUPPLY

,

REGULATOR

,

PITCH

C

0

NTR0L

(1)

,

PITCH

C

0

NTR0L

(2)

,

SPEED

SELECTOR

,

STROBE

ILLUMINATOR

.

STYLUS

ILLUMINATOR

SWITCH

,

OUTPUT

CIRCUIT

GAIN

ADJ

.

B

STYLUS

ILLUMINATOR

IH

SWITCH

CIRCUIT

SPEED

SELECTOR

CIRCUIT

Q

PITCH

CONTROL

(1)

CIRCUIT

Q

PITCH

CONTROL

(2)

CIRCUIT

T T

1

2

3

4

6

8

9

10

11

12

5

7

17

Page 18

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

18

Page 19

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

11

Printed

Circuit

Board

Diagram

Note

:

This

printed

Circuit

board

diagram

may

be

modified

at

any

time

with

th

è

development

of

new

technology

.

H

IBI

STROBE

ILLUMINATOR

P

.C.B.

PI

REGULATOR

P

.C.B.

H

DRIVE

CONTROL

P

.C.B.

0

TP

27

GND

©

I

E

G

©

^

B

(

REP

3552

A

-

S

)

(

REP

3461

B

-

M

)

F

OUTPUT

P

.C.B.

GND

E

OUTPUT

777

D

SFDP

122

-

23

»

!

{

a

|

(

SFDH

122

-

09

E

3

)

l

START

/

I

STOP

<

!

>

WHT

Lch

I

BLU

c

I

<

!

>

GRN

I

R

eh

RED

BLK

CARTRIDGE

B

(

REP

3461

B-M

)

A

SL

-

1210

M

5

G

(

PP

,E,

EB

,

GN

)

DRIVE

CONTROUREGULATOR

/

STROBE

ILLUMINATOR

/

SPEED

SELECTOR

/

OUTPUT

P

.

C

.

B

.

T

T

I

T

T

I

T

I

I

T

I

T

1

1

2

3

4

5

6

7

8

9

10

11

12

13

19

Page 20

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

POWER

SUPPLY

P

.C.B.

For

[

E,EB

,

GN

]

areas

.

B

H

RI

PITCH

CONTROL

(I)

P

.C.B.

POWER

SUPPLY

P

.C.B.

For

[PP]

area

.

B

13

PITCH

CONTROL

(2)

P

.C.

B

.

2677

/

.

S

602

(

VOLTAGE

G

SELECTOR

)

‘

r

j

J

(

BRN

)

CN

106

«

©

«

few

I

I

s

I

I

i

—

i

For

[E]

area

.

i

LP

1

S

601

I

F

(

POWER

)

8

FW

105

For

[

EB

,

GN

]

areas

.

§

Mk

C

6

®

J

É

1

F2T1A

r

E

A

(

SFDP

122

C

09

E

)

FW

106

(

REP

2093

A

-

1

[E]

REP

2346

A

-

1

[

EB

,

GN

]

.

&

D

%

r

.

P

503

m

[

i

il

0501

dH

)

sf

i

STYLUS

ILLUMINATOR

SWITCH

P

.C.B.

:

D

502D501

(

±

8

)

(

±

16

)

c

rara

i

(

REP

3458

BB

-

S

)

S

401

I

C

1

OFF

PITCH

ADJ

.

A

r

I

*

D

504

H

—

v

R

509

C

i

L

±

16

J

R

510

2677

AA

B

@

*

®

(

REP

3458

BA

-

S

)

(

REP

3553

A

-

S

)

A

SL

-

1210

M

5

G

(

PP

,E,

EB

,

GN

)

POWER

SUPPLY

/

STYLUS

ILLUMINATOR

SWITCH

/

PITCH

CONTROL

(1),(

2

)

P

.

C

.

B

.

I

T

I

T

T

I

T

T

I

T

I

T

1

1

2

3

4

5

6

7

8

9

10

11

12

13

20

Page 21

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

12

Block

Diagram

POSITION

DETECTOR

COIL

+

B

1

-

4

-

T

1

<

!

>

S

601

P

3

For

[PP]

area

.

(

POWER

)

3

oc

Q

1

~

3

,

D

3

D

1

I

P

2

\

3

AN

6675

AC

IN

l

—

REGULATOR

—

RECT

.

I

P

1

IC

101

TURNTABLE

DRIVE

VOLT

oc

'

+

SEL

i

-

S

602

18

19

20

I

21

1

23

ose

11

Vcc

BSCSATC

For

[

E,EB

,

GN

]

areas

.

ose

(

50

kHz

)

3

-

DIFFERENCE

FULL

-

WAVE

NPN

i

POWER

TR

.

DRIVE

COIL

ì

DRIVE

COIL

PC

17

AMPLITUED

CREATION

24

A

1

8

T

I

1

13

Ì

P

2

A

2

A

2

T

I

A

3

A

3

P

-

SIGNAL

DETECTOR

+

T

+

L

+

2

l

II

P

3

‘

"

H

POWER

TR

.

DRIVE

COIL

11

3

-

DIFFERENCE

FULL

-

WAVE

PNP

I I

C

1

14

AC

1

^

>

C

2

10

lC

3

POSITION

DETECTOR

{

+

.

-

)

PULSE

GENERATOR

111

I

III

I

PC

EC

ECR

O

0

—

0

22

5

6

AN

6680

IC

201

SYSYTEM

CONTROL

VO

113

O

—

—

Wr

SPEED

CONTROL

1

/

16

BUFFER

3

JLFO

«

PO

14

PHASE

CONTROL

4

Q

—

-

wv

—

>

23

JLFGO

FILTER

AMP

Q

203

FAI

I

16

22

^

FGG

FG

AMP

T

FGI

24

FG

AMP

—

r

ECR

SCH

-

.

17

MITT

FG

I

D

203

-

206

12

JLFNC

Z2Z

STROBE

ILLUMINATOR

Q

202

i

FAO

11

JLSRB

LED

l

/

N

—

I

RESET

\

#

+

B

1

—

DRIVE

r

*

-

=

zi

T

Wv

REGU

-

LATOR

\

REGULATOR

!

—

1

»

fH

,

BRAKE

TIMER

START

/

STOP

SPEED

SELECT

Q

201

J

±

»

18 19

6

7

1

+

B

1

NJM

78M05

FA

+

B

3

20

IC

502

I

Q

501

D

201

(33)

REGU

-

LATOR

+

B

3

-

*

+

B

1

+

B

1

ESSI

RESET

4

r

I

D

202

(45)

1

r

4

Vcc

18

S

203

(

START

/

STOP

)

>

/

RESET

\

!

t

!

ì

TP

27

19

T

>

XIN

C

2

BAED

000009

9

^

'

IC

501

S

202

S

201

(45)

(33)

X

501

P

02

/

SCLK

2

PITCH

CONTROL

.

^

P

^

OXOUT

-

+

B

2

V

*

VR

201

(

BRAKE

ADJ

.

)

P

17

/

P

16

/

P

07

/

P

30

/

(

LED

7

)

—

-o-

(

LED

6

)

AN

8

ANO

O

-

|

+

B

1

\

7

D

204

22

23

30

42

D

401

(

RESET

)

TC

4011

BP

Wf

IC

302

S

502

(

PITCH

SELECT

)

-

L

£

D

301

PITCH

CONTROL

ON/OFF