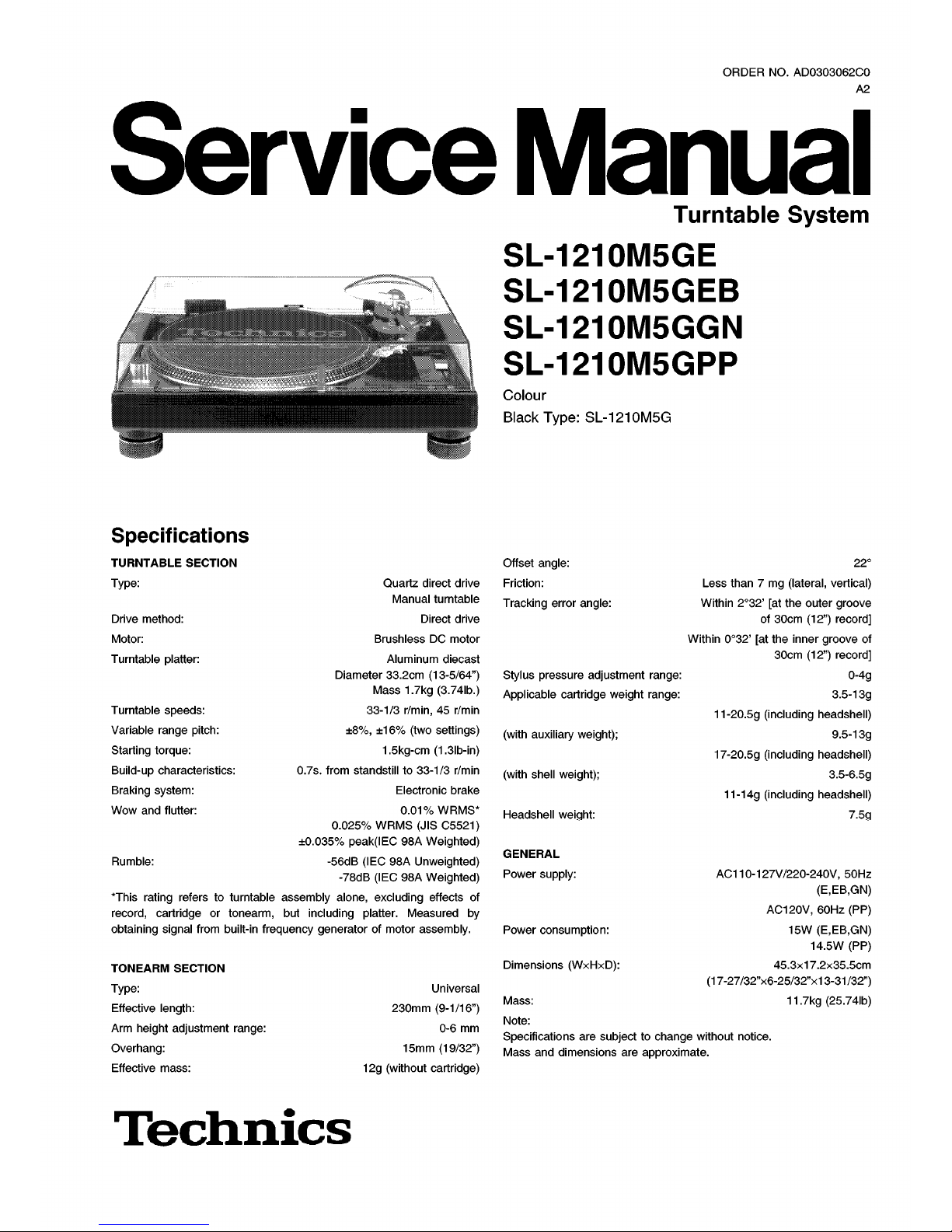

Technics SL-1210M5GE, SL-1210M5GEB, SL-1210M5GGN, SL-1210M5GPP, SL-1210M5G Service Manual

ORDER

NO

.

AD

0303062

C

0

A

2

Service

Man

ual

Turntable

System

SL

-

1210

M

5

GE

SL

-

1210

M

5

GEB

SL

-

1210

M

5

GGN

SL

-

1210

M

5

GPP

Colour

Black

Type

:

SL

-

1210

M

5

G

Specifications

TURNTABLE

SECTION

Type

:

Offset

angle

:

Friction

:

Tracking

errar

angle

:

22

°

Guartz

direct

drive

Manual

turntable

Direct

drive

Brushless

DC

motor

Aluminum

diecast

Diameter

33.2

cm

(

13

-

5

/

64

”

)

Mass

1.7

kg

(

3.74

lb

.

)

33

-

1

/

3

r

/

min

,

45

r

/

min

±

8

%

,

±

16

%

(

two

settings

)

1.5

kg

-

cm

(

1.3

lb

-

in

)

0.7

s

.

tram

standstill

to

33

-

1

/

3

r

/

min

Electronic

brake

0.01

%

WRMS

*

0.025

%

WRMS

(

JIS

C

5521

)

±

0.035

%

peak

(

IEC

98

A

Weighted

)

-

56

dB

(

IEC

98

A

Unweighted

)

-

78

dB

(

IEC

98

A

Weighted

)

*

This

rating

refers

to

turntable

assembly

alone

,

excluding

effects

of

record

,

cartridge

or

tonearm

,

but

including

platter

.

Measured

by

obtaining

signal

tram

built

-

in

frequency

generator

of

motor

assembly

.

Less

than

7

mg

(

lateral

,

vertical

)

Within

2

°

32

’

[

at

th

è

outer

groove

of

30

cm

(

12

”

)

record

]

Within

0

°

32

’

[

at

th

è

inner

groove

of

30

cm

(

12

”

)

record

]

0

-

4

g

3.5-13

g

11

-

20.5

g

(

including

headshell

)

9.5

-

13

g

17

-

20.5

g

(

including

headshell

)

3.5

-

6.5

g

11

-

14

g

(

including

headshell

)

Drive

method

:

Motor

:

Turntable

platter

:

Stylus

pressure

adjustment

range

:

Applicable

cartridge

weight

range

:

Turntable

speeds

:

Variable

range

pitch

:

Starting

torque

:

Build

-

up

characteristics

:

Braking

System

:

Wow

and

flutter

:

(

with

auxiliary

weight

)

;

(

with

shell

weight

)

;

Headshell

weight

:

7.5

g

GENERAL

Power

supply

:

Rumble

:

AC

110

-

127

V

/

220-240

V

,

50

Hz

(

E,EB

,

GN

)

AC

120

V

,

60

Hz(PP

)

15

W(E,EB

,

GN

)

14.5

W(PP

)

45.3

x

17.2

x

35.5

cm

(

17

-

27

/

32

”

x

6

-

25

/

32

”

x

13-31/32

”

)

11.7

kg

(

25.74

lb

)

Power

consumption

:

Dimensions

(

WxHxD

)

:

TONEARM

SECTION

Type

:

Effective

length

:

Arm

height

adjustment

range

:

Overhang

:

Effective

mass

:

Universal

230

mm

(

9

-

1

/

16

”

)

0-6

mm

15

mm

(

19

/

32

”

)

12

g

(

without

cartridge

)

Mass

:

Note

:

Specifications

are

subjecttochange

without

notice

.

Mass

and

dimensions

are

approximate

.

Techmcs

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

A

WARNING

This

Service

information

is

designed

for

experienced

repair

technicians

only

and

is

not

designed

for

use

by

th

è

generai

public

.

It

does

not

contain

warnings

or

cautionstoadvise

non

-

technical

individuals

of

potential

dangersinattempting

to

Service

a

product

.

Products

powered

by

electricity

shouldbeserviced

or

repaired

only

by

experienced

professional

technicians

.

Any

attempt

to

Service

or

repair

th

è

productorproducts

dealt

with

in

this

Service

information

by

anyone

else

could

resultinserious

injury

or

death

.

CONTENTS

Page

Page

1

Accessories

2

Controls

3

Turntable

System

pitch

adj

.

slider

replacement

instructions

.

4

4

Safety

Precaution

5

Caution

for

AC

Mains

Lead

6

Operation

Checks

and

Component

Replacement

Procedures

7

6.1

.

Checking

for

th

è

main

P

.C.B.

and

power

supply

P

.

C

.B.

—

7

6.2

.

Checking

for

th

è

pitch

control

(1)

P

.C.B.

6.3

.

Replacement

for

th

è

drive

coil

ass

’

y

and

FG

coil

ass

’

y

—

•

9

6.4

.

Replacement

for

th

è

tonearm

unit

6.5

.

Replacement

for

th

è

parts

mounted

onspeed

selector

P

.C.

B

.

and

power

switch

6.6

.

Replacement

for

th

è

LED

and

Stylus

illuminator

switch

-

12

7

Cautions

in

handling

of

thèblue

LED

8

Type

lllustration

of

IC

’

s

,

Transistors

and

Diods

9

Measurements

and

Adjustments

9.1

.

The

stateofset

and

th

è

use

apparatus

9.2

.

Measurements

and

Adjustments

9.3

.

Alignment

points

10

Schematic

Diagram

10.1

.

Schematic

Diagram

Notes

10.2

.

Schematic

Diagram

11

Printed

Circuit

Board

Diagram

12

Block

Diagram

13

Wiring

Connection

Diagram

14

Replacement

Parts

List

15

Cabinet

Parts

Location

15.1

.

Cabinet

15.2

.

Tonearm

16

Packaging

2

15

3

15

15

5

15

6

16

16

17

8

19

21

10

22

23

12

27

27

14

28

14

29

1

Accessories

•

Disc

slip

sheet

set

(

RGS

0005

Z

-

1

)

.

.

.

1

pc

.

•

Overhang

gauge

(

SFK

0135

-

01

)

..

.

1

pc

.

Teclmics

SDYmioe

.i.

-

Disc

slip

sheet

-

Transparent

sheet

•

Auxiliary

weight

(

SFPWG

17202

)

..

.

1

pc

.

•

Nuts

(

RHN

26003

)

..

.

2

pcs

.

•

Screws

(

short

) (

SFCZV

8801

-

1

)

..

.

2

pcs

.

•

Screws

(

long

)

(

SFPEV

9801

-

1

)

..

.

2

pcs

.

•

Washers

(

SFPEW

9601

)

...

2

pcs

.

•

Sticker

(

RQLC

0142

-

1

)

.

.

.

1

pc

.

•

EP

record

adaptor

(

SFWE

010

A

)

...

1

pc

.

•

Shell

weight

(

SFPZB

3501

)

.

.

.

1

pc

.

2

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

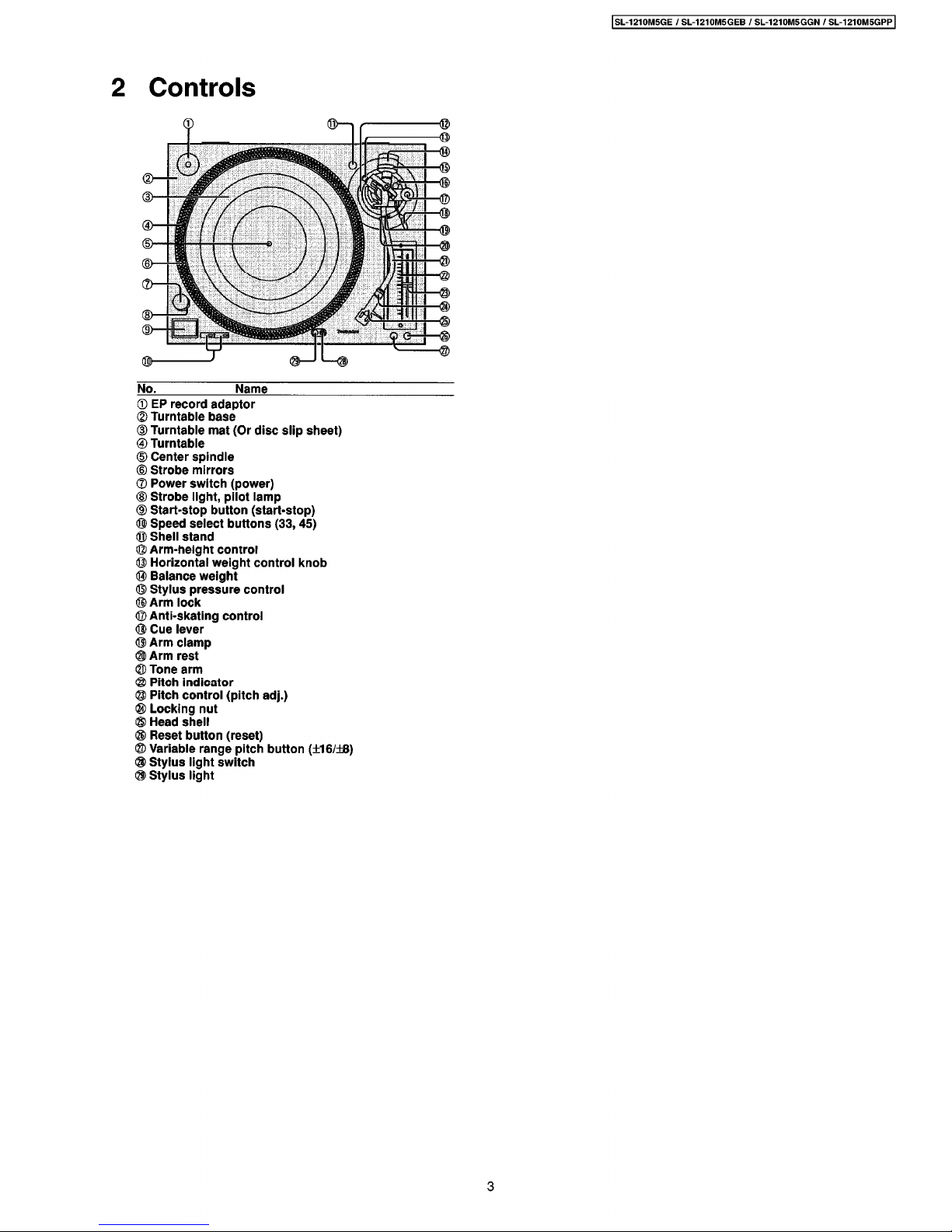

2

Controls

i

©

<S>

2

<

©

d

>

©

>

E

©

<

2

>

d

>

©

d

>

©

<g>

#

No

.

Name

©

EP

record

adaptor

©

Turntable

base

(

D

Turntable

mat

(

Or

disc

slip

sheet

)

®

Turntable

@

Center

spindle

®

Strobe

mirrors

®

Power

switch

(

power

)

®

Strobe

llght

,

pilot

lamp

CD

Start

-

stop

button

(

start

-

stop

)

®

Speed

select

buttons

(

33

,

45

)

®

Shell

stand

©

Arm

-

height

control

©

Horizontal

weight

control

knob

®

Balance

weight

©

Stylus

pressure

control

©

Arm

lock

©

Anti

-

skating

control

®

Cue

lever

®

Arm

clamp

©

Arm

rest

©

Tone

arm

®

Pitch

indicator

©

Pitch

control

(

pitch

adj

.

)

®

Locking

nut

©

Head

Shell

®

Reset

button

(

reset

)

@

Variable

range

pitch

button

(

±

16

/

±

8

)

®

Stylus

light

switch

©

Stylus

light

3

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

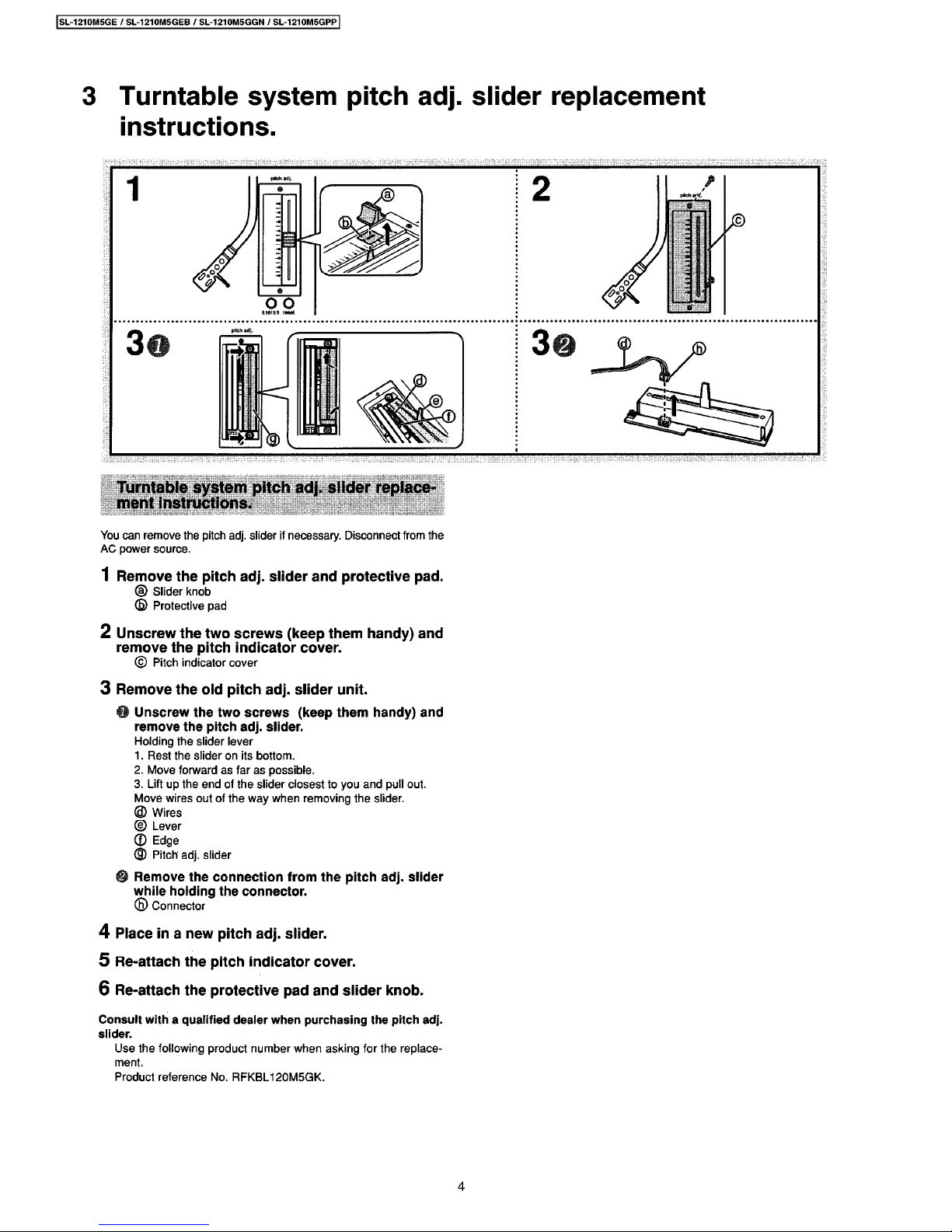

3

Turntable

System

pitch

adj

.

slider

replacement

instructions

.

®

B

.

4

m

5.1

2

i

3

vi

:

:

i

i

1

4

Ì

'

?

!

il

V.V

:

fi

il

?

1

•

1

'

:

ì

.

V

i

il

!

f

I

:

:

%

Hi

I

2

i

'

y

.

t

li

:

K

2

i

&

Si

555

HH

;

Ì

.

-

VV

.

5

,

’

H

-

,

,

-

.

H

,

-V-

|

i

-

HVHHHHH

'

i

'

iiiHrH

Hii

:

Turntable

System

pitch

adj

.

slider

replace

-

ment

instructions

.

You

can

remove

th

è

pitch

adj

.

slider

if

necessary

.

Disconnect

tram

th

è

AC

power

source

.

1

Remove

th

è

pitch

adj

.

slider

and

protective

pad

.

©

Slider

knob

(

B

)

Protective

pad

2

Unscrew

th

è

two

screws

(

keep

them

handy

)

and

remove

th

è

pitch

indicator

cover

.

©

Pitch

indicator

cover

3

Remove

th

è

old

pitch

adj

.

slider

unit

.

Unscrew

th

è

two

screws

(

keep

them

handy

)

and

remove

th

è

pitch

adj

.

slider

.

Holding

th

è

slider

lever

1

.

Rest

th

è

slideronits

bottom

.

2

.

Move

forward

as

far

as

possible

.

3

.

Lift

up

th

è

end

of

th

è

slider

closest

to

you

and

pul

ì

out

.

Move

wires

out

of

th

è

way

when

removing

th

è

slider

.

©

Wires

©

Lever

©

Edge

©

Pitch

adj

.

slider

Remove

thèconnection

from

th

è

pitch

adj

.

slider

while

holding

th

è

connector

.

©

Connector

4

Place

in

a

new

pitch

adj

.

slider

.

5

Re-attach

th

è

pitch

indicator

cover

.

6

Re

-

attach

th

è

protective

pad

and

slider

knob

.

Consult

with

a

qualified

dealer

when

purchasing

th

è

pitch

adj

.

slider

.

Use

th

è

following

product

number

when

asking

for

th

è

replace

-

ment

.

Product

reference

No

.

RFKBL

120

M

5

GK

.

4

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

4

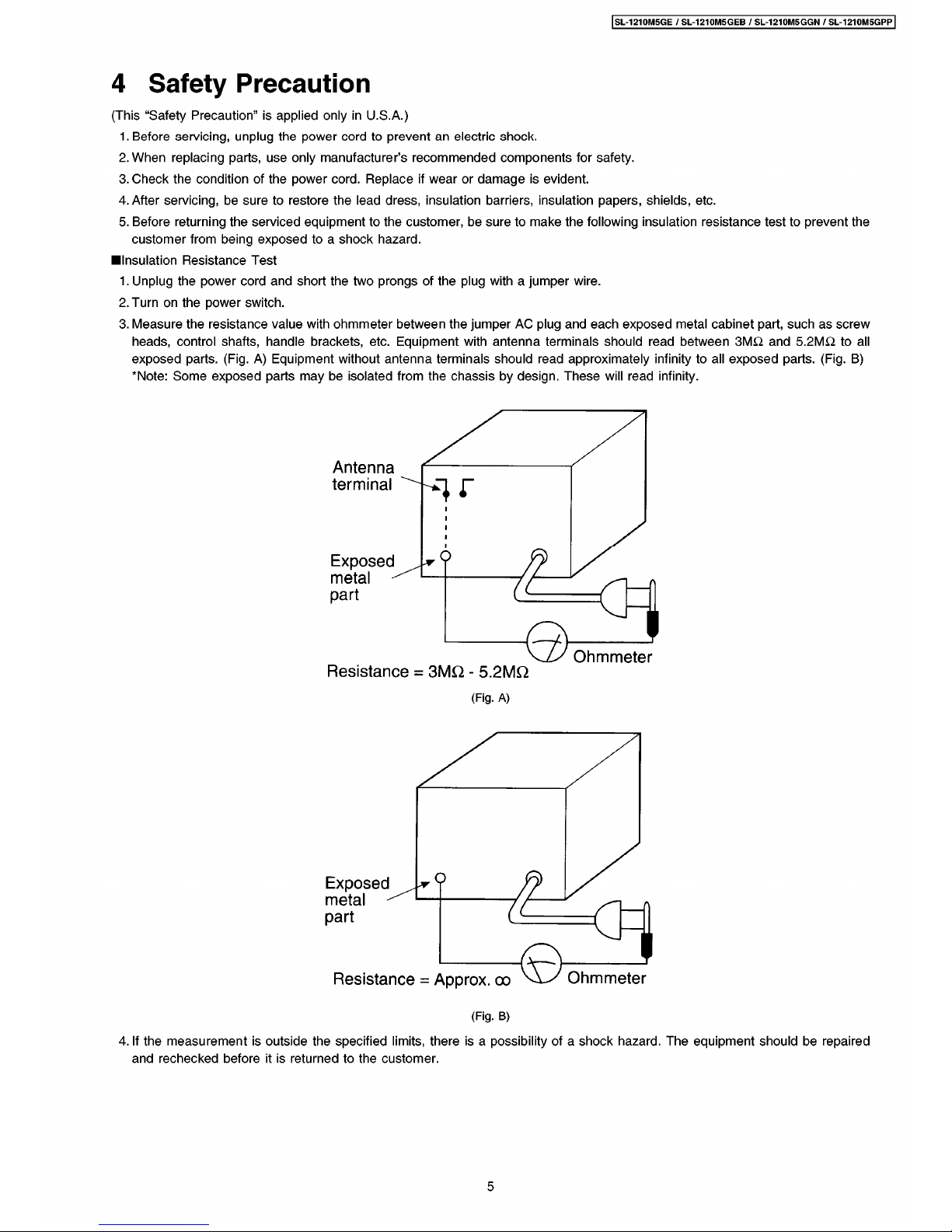

Safety

Precaution

(

This

“

Safety

Precaution”is

applied

only

in

U

.S.A.

)

1

.

Before

servicing

,

unplug

th

è

power

cord

to

prevent

an

electric

shock

.

2

.

When

replacing

parts

,

use

only

manufacturer

’

s

recommended

components

for

safety

.

3

.

Check

th

è

condition

of

th

è

power

cord

.

Replace

if

wear

or

damage

is

evident

.

4

.

After

servicing

,

be

sure

to

restore

th

è

lead

dress

,

insulation

barriers

,

insulation

papers

,

shields

,

etc

.

5

.

Before

returning

th

è

serviced

equipment

to

th

è

customer

,

be

sure

to

make

th

è

following

insulation

resistance

test

to

prevent

th

è

customer

from

being

exposed

to

a

shock

hazard

.

Insulation

Resistance

Test

1

.

Unplug

th

è

power

cord

and

short

th

è

two

prongs

of

th

è

plug

with

a

jumper

wire

.

2

.

Turn

on

th

è

power

switch

.

3

.

Measure

th

è

resistance

value

with

ohmmeter

between

th

è

jumper

AC

plug

and

each

exposed

metal

cabinet

part

,

such

as

screw

heads

,

control

shafts

,

handle

brackets

,

etc

.

Equipment

with

antenna

terminals

should

read

between

3

M

£

2

and

5.2

M

&

to

all

exposed

parts

.

(

Fig

.

A

)

Equipment

without

antenna

terminals

should

read

approximately

infinity

to

all

exposed

parts

.

(

Fig

.

B

)

*

Note

:

Some

exposed

parts

may

be

isolated

from

th

è

chassis

by

design

.

These

will

read

infinity

.

Antenna

terminal

/

2

o

Exposed

metal

-

Zt

part

Ohmmeter

Resistance

=

3

MQ

-

5.2

MQ

(

Fig

.

A

)

*

9

Exposed

metal

-

part

Ohmmeter

Resistance

=

Approx

.

oo

(

Fig

.

B

)

4

.

If

th

è

measurement

is

outside

th

è

specified

limits

,

there

is

a

possibility

of

a

shock

hazard.The

equipment

should

be

repaired

and

rechecked

before

it

is

returned

to

th

è

customer

.

5

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

5

Caution

for

AC

Mains

Lead

WARNING:DO

NOT

CONNECT

EITHER

WIRETOTHE

EARTH

TERMINAL

WHICH

IS

MARKED

WITH

THE

LETTER

E,BY

THE

EARTH

SYMBOL

OR

COLOURED

GREENORGREEN/YELLOW

.

(

For

United

Kingdom

)

(

“

EB

”

area

code

model

only

)

Foryour

safety

,

please

read

th

è

following

text

carefully

.

THIS

PLUG

IS

NOT

WATERPROOF

—

KEEP

DRY

.

This

appliance

is

supplied

with

a

moulded

three

pin

mains

plug

for

your

safety

and

convenience

.

A

5

-

ampere

fuse

is

fitted

in

this

plug

.

Should

th

è

fuse

needtobe

replaced

please

ensure

that

th

è

replacement

fuse

has

a

rating

of

5

-

ampere

and

that

it

is

approved

by

ASTAorBSI

to

BS

1362

.

Check

for

th

è

ASTA

mark

<

^

>

or

th

è

BSI

mark

^

on

th

è

body

of

th

è

fuse

.

Before

use

Remove

th

è

connector

cover

.

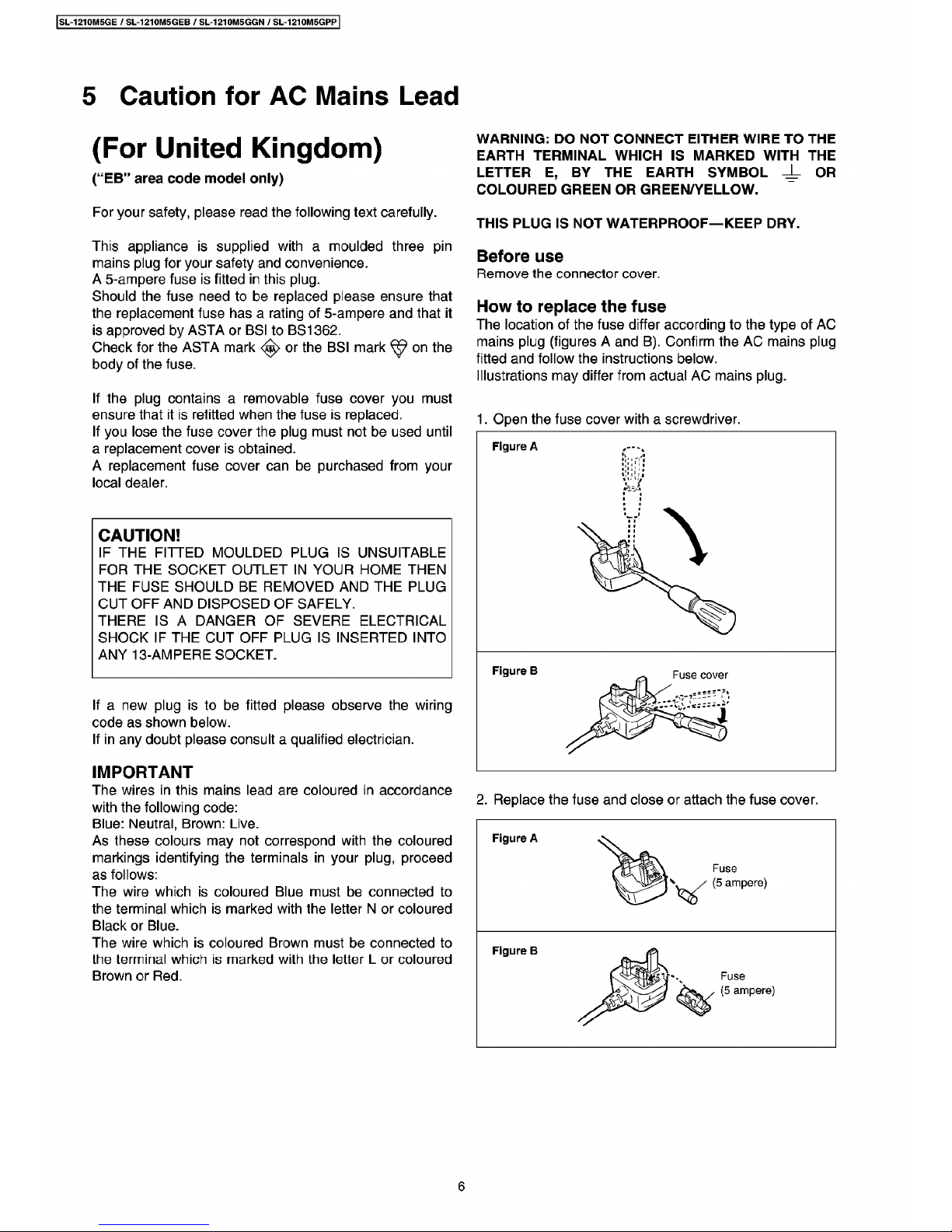

How

to

replace

th

è

fuse

The

location

of

th

è

fuse

differ

according

to

th

è

type

of

AC

mains

plug

(

figures

A

and

B

)

.

Confirm

th

è

AC

mains

plug

fitted

and

follow

th

è

instructions

below

.

Illustrations

may

differ

from

actual

AC

mains

plug

.

If

th

è

plug

containsaremovable

fuse

cover

you

must

ensure

that

it

is

refitted

when

th

è

fuse

is

replaced

.

If

you

lose

th

è

fuse

cover

th

è

plug

must

not

be

used

until

a

replacement

cover

is

obtained

.

A

replacement

fuse

cover

can

be

purchased

from

your

locai

dealer

.

1

.

Open

th

è

fuse

cover

with

a

screwdriver

.

CAUTION

!

IF

THE

FITTED

MOULDED

PLUG

IS

UNSUITABLE

FOR

THE

SOCKET

OUTLET

IN

YOUR

HOME

THEN

THE

FUSE

SHOULDBEREMOVED

AND

THE

PLUG

CUT

OFF

AND

DISPOSED

OF

SAFELY

.

THERE

ISADANGER

OF

SEVERE

ELECTRICAL

SHOCK

IF

THE

CUT

OFF

PLUG

IS

INSERTED

INTO

ANY

13

-

AMPERE

SOCKET

.

If

a

new

plug

istobe

fitted

please

observe

th

è

wiring

code

as

shown

below

.

If

in

any

doubt

please

consult

a

qualified

electrician

.

IMPORTANT

The

wires

in

this

mains

lead

are

coloured

in

accordance

with

th

è

following

code

:

Blue:Neutral

,

Brown:Live

.

As

these

colours

may

not

correspond

with

th

è

coloured

markings

identifying

th

è

terminals

in

your

plug

,

proceed

as

follows

:

The

wire

whichiscoloured

Blue

must

be

connected

to

th

è

terminal

whichismarked

with

th

è

letter

N

or

coloured

Black

or

Blue

.

The

wire

which

is

coloured

Brown

must

be

connected

to

th

è

terminal

whichismarked

with

th

è

letter

L

or

coloured

Brown

or

Red

.

2

.

Replace

th

è

fuse

and

doseorattach

th

è

fuse

cover

.

Figure

A

6

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

6

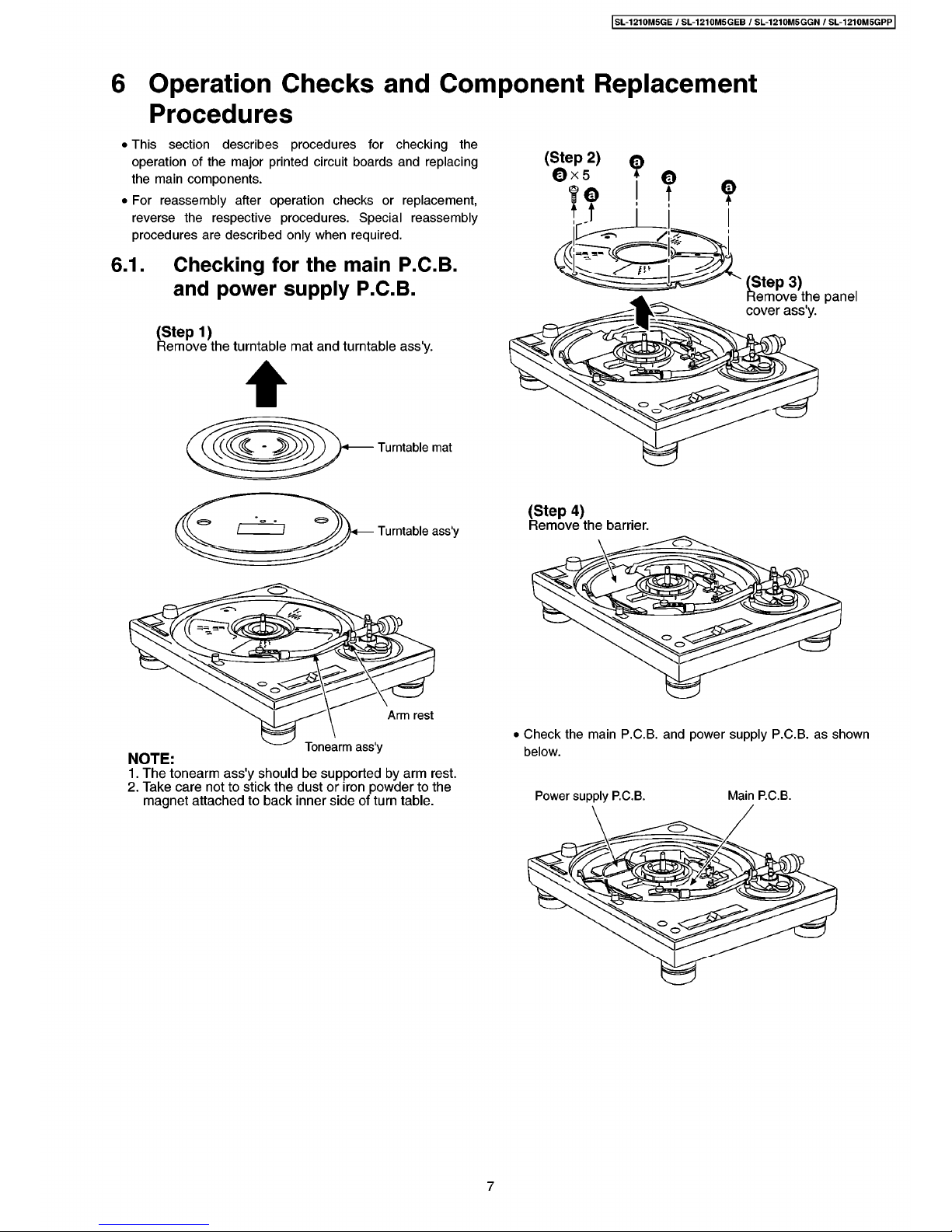

Operation

Checks

and

Component

Replacement

Procedures

•

This

section

describes

procedures

for

checking

th

è

operation

of

th

è

major

printed

Circuit

boards

and

replacing

th

è

main

components

.

•

For

reassembly

after

operation

checks

or

replacement

,

reverse

th

è

respective

procedures

.

Special

reassembly

procedures

are

described

only

when

required

.

(

Step

2

)

©

x

5

o

t

©

©

t

©

t

/

il

(

;

=

-

=

-

Checking

for

thèmain

P

.C.B.

and

power

supply

P

.C.B.

6.1

.

fi

'

(

Step

3

)

Remove

th

è

panel

cover

ass

'

y

.

(

Step

1

)

Remove

th

è

turntable

mat

and

turntable

ass

'

y

.

&

o

Turntable

mat

<

(

Step

4

)

Remove

th

è

barrier

.

&

Turntable

ass

'

y

&

%

Arm

rest

•

Check

th

è

main

P

.C.B.

and

power

supply

P

.C.B.

as

shown

below

.

Tonearm

ass

'

y

NOTE

:

1

.

The

tonearm

ass

'

y

should

be

supported

by

arm

rest

.

2

.

Take

care

not

to

stick

th

è

dustoriron

powder

to

th

è

magnet

attachedtoback

inner

side

of

turn

table

.

Power

supply

P

.C.

B

.

Main

P

.

C

.B.

7

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN/SL

-

1210

M

5

GPP

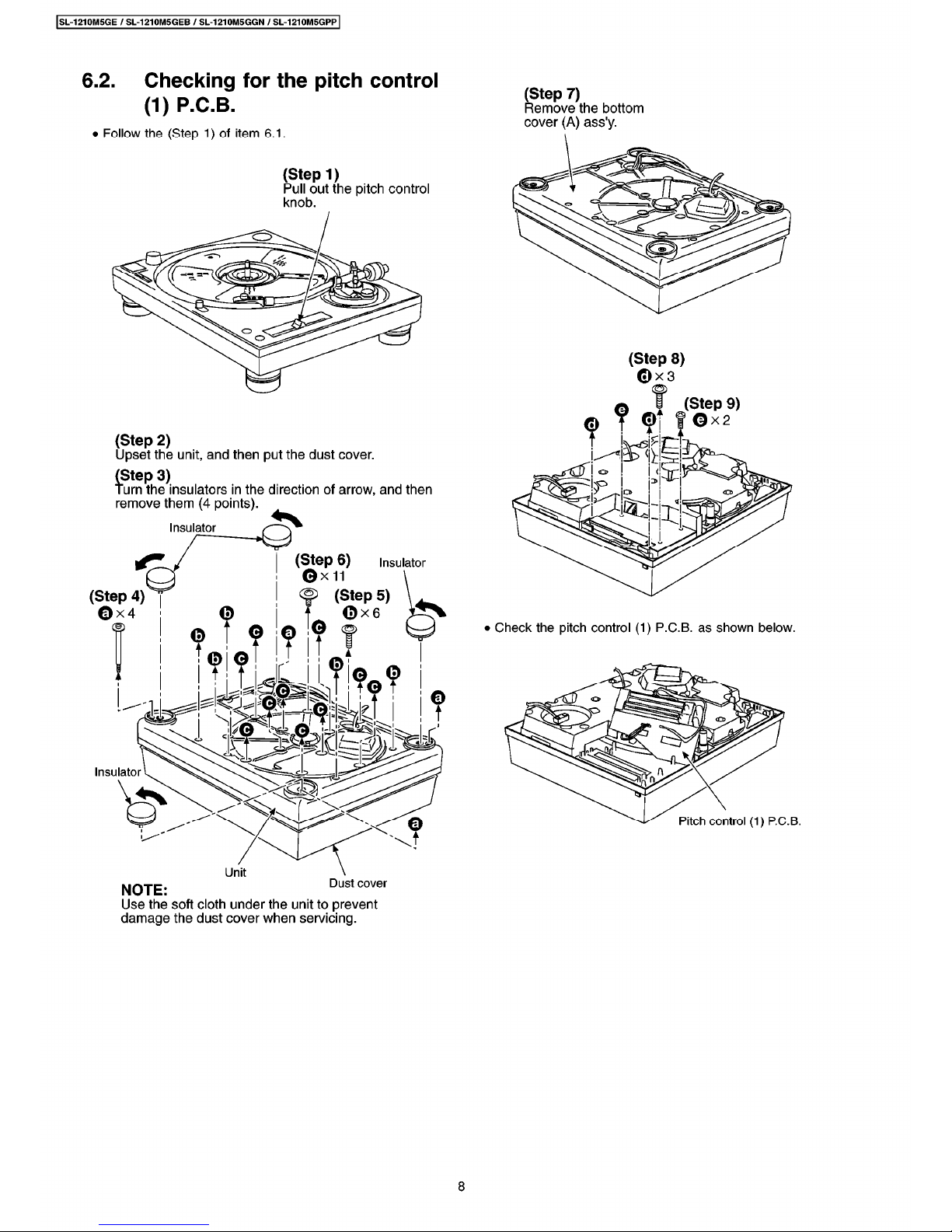

6.2

.

Checking

for

th

è

pitch

control

(1)

P

.C.B.

(

Step

7

)

Remove

th

è

bottom

cover

(A)

ass

'

y

.

•

Follow

th

è

(

Step

1

)

of

item

6.1

.

(

Step

1

)

Pul

ì

out

th

è

pitch

control

knob

.

(

Step

8

)

©

x

3

(

Step

9

)

©

x

2

(

Step

2

)

Upset

th

è

unit,and

then

put

th

è

dust

cover

.

(

Step

3

)

Turn

th

è

insulators

in

th

è

direction

of

arrow

,

and

then

remove

them

(

4

points

)

.

Insulator

(

Step

6

)

©

X

11

Insulator

S

>

(

Step

5

)

(

Step

4

)

©

X

4

•

Check

th

è

pitch

control

(1)

P

.C.

B

.

as

shown

below

.

<

&

<o>

fe

.

4

Insulator

Pitch

control

(

1

)

P

.

C

.

B

.

Dust

cover

NOTE

:

Use

th

è

soft

cloth

under

th

è

unit

to

prevent

damage

th

è

dust

cover

when

servicing

.

8

SL

-

1210

M

5

GE

/

SL

-

1210

M

5

GEB

/

SL

-

1210

M

5

GGN

/

SL

-

1210

M

5

GPP

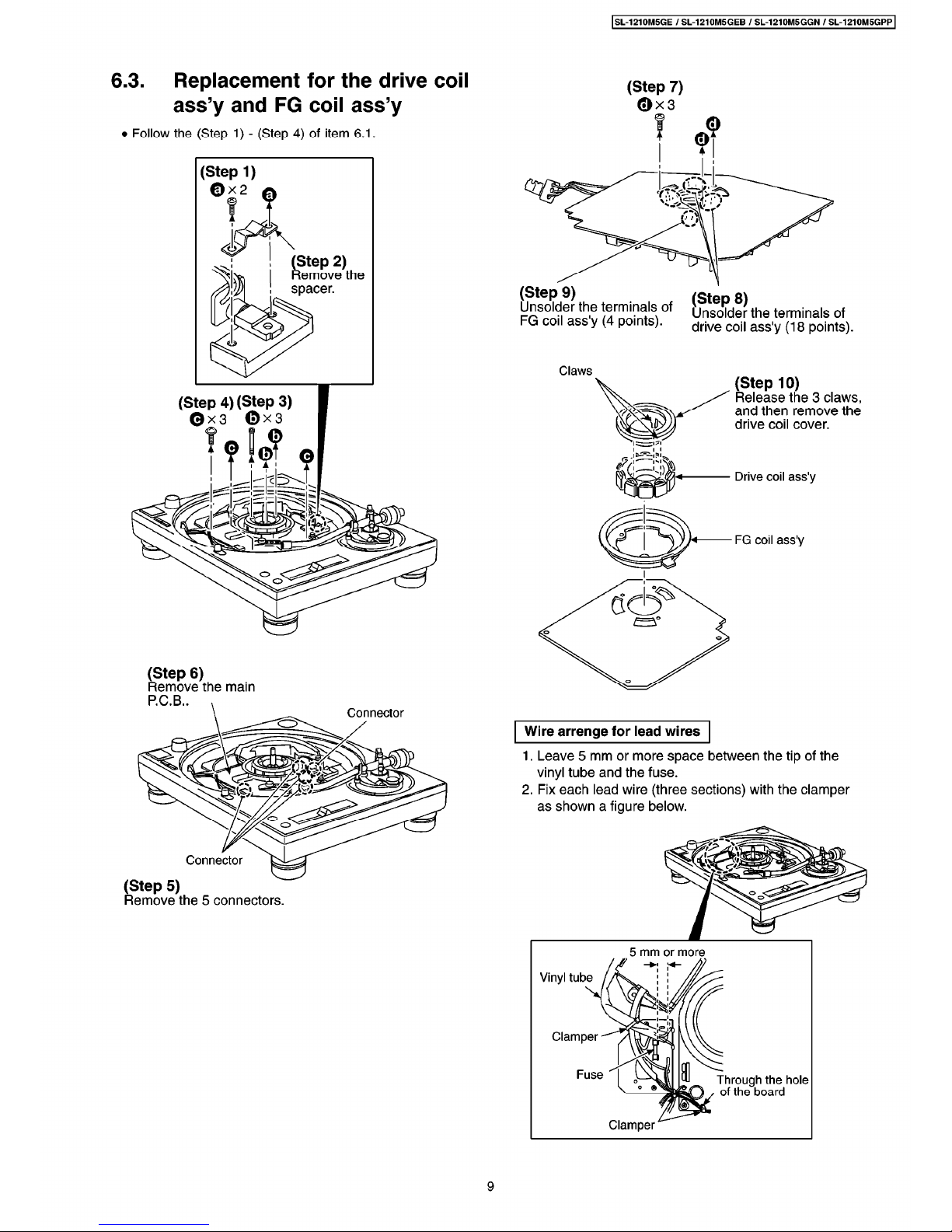

6.3

.

Replacement

for

thèdrive

coil

ass

’

y

and

FG

coil

ass

’

y

•

Follow

th

è

(

Step

1

)-(

Step

4

)

of

item

6.1

.

(

Step

7

)

0

x

3

(

Step

1

)

0

x

2

7

(

Step

2

)

Re

move

th

è

spacer

.

(

Step

9

)

Unsolder

th

è

terminals

of

FG

coil

ass

'

y

(

4

points

)

.

(

Step

8

)

Unsolder

th

è

terminals

of

drive

coil

ass

'

y

(

18

points

)

.

Claws

(

Step

10

)

Release

th

è

3

claws

,

and

then

remove

th

è

drive

coil

cover

.

(

Step

4

)

(

Step

3

)

©

x

3

0

x

3

Drive

coil

ass

'

y

FG

coil

ass

'

y

(

Step

6

)

Remove

th

è

mairi

P

.C.B.

.

Connector

Wire

arrenge

for

lead

wires

1

.

Leave

5

mirri

or

more

space

between

th

è

tip

of

th

è

vinyl

tube

and

th

è

fuse

.

2

.

Fix

each

lead

wire(three

sections

)

with

th

è

damper

as

shown

a

figure

below

.

Connector

(

Step

5

)

Remove

th

è

5

connectors

.

9

Loading...

Loading...