Page 1

ORDER

NO.SD7908-1601

Service

Manual

service

This

andisnot

only

contain

potential

by

electricity

professional

or,,products

in..serious

rest''

SL-12

A

WARNING

designed

literature

warnings

dangers

technicians.C

dealt

"

*The

is

designed

cau:'.ons

or

in

attempting

should

with

injuryordeath

The

model

model

be

in

SL-11

SL-1200MK2

for

use

to

to

serviced

attempt

.iy

service

this

.

200MK2

Turntable

OM

(M),

experienced

for

the

general

by

non-technical

advise

a

service

repaired

or

to

service

literature

(M)isavailableinU.S.A.only

(MC)

repair

public

.

Products

product

only

or

repair

anyone

t

;+

is

availableinCanada

by

System

K2

(MC)

technicians

It

does

.

individuals

powered

experienced

the

product

could

else

not

of

only

.

.

SPECIFICATIONS

General

supply

Power

Power

Dimensions

(WxHxD)

Weight

Turntable

Type

:

Drive

Motor

Turntable

Turntablespeeds

Pitch control

;

:carting

Build-up

characteristics

Braking

Speed

load

Wow

and

*

This

effects

platter.Measuredby

quency

:

consumption

:

:

section

method

:

:

platter

:

:

:

torque

:

:

system

:

change

due

torque

:

flutter

:

rating

refers

of record,

generatorofmotor

Specifications subject to

120

V,AC,50or60Hz

:

12W

45

.3x16.2

(17-27/32"x6-19/64"xl4-11/64")

11

kg (24.3lb)

Quartz

Manual

Direct

BrushlessDCmotor

Aluminum

Diameter33.2cm(13-5/64")

Weight

33-1/3

All

quartz-locked

1.5kg-cm(1.3

0

.7 s.from

Electronic

to

0%

within1.0

0

.01%

0

.025%

±0

.035%

to turntable

cartridge

obtaining

x36

direct

drive

turntable

drive

diecast

2 kg(4.4 lb

rpm

and

Ib-in)

standstillto33-1/3

brake

kg-cm

WRMS*

WRMS

assembly

peak

assembly

or

tonarm,

signal

(JIS

(IEC

.

cm

45

±8%

from

.)

rpm

(0

C5521)

98A

alone,

but

range

Ib-in)

.87

Weighted)

excluding

including

built-in

change

rpm

fre-

without

notice

.

Rumble

:

Tonearm

Type

:

Effective

Arm

height

range

:

Overhang

Effective

Offset angle

Friction

Tracking

Stylus

Applicable

Headshell

:

pressure

adjustment

weight

(with

auxiliary

weight)

(with

shell

Cud

All

copying

Weight

and

section

length

:

adjustment

:

mass

:

:

error angle

range

cartridge

range

:

:

weight):3

weight

:

Matsushita

rights

reserved

and

dimensions

-56

dB(IEC

-78

dB

Universal

230mm

31

.8-37.8mm

(1-21

/32"-3-35/64")

(helicoid

15

mm

12 g

(without

22

°

Less

than7mg

Within2°

:

30

cm

(12") record

Within0°

cm

(12") record

30

:

0-2.5g

g

6-10

13

.5-17

9

.5-13

17-20.5g

.5-6.5g

11-14g(including

7.5g

Electric

Industrial

.

Unauthenzed

distribution

is

a

shown

are

98A

Unweighted)

(IEC

98A

Weighted)

(9-1/16")

(helicoid

part

15/64")

(19/32")

cartridge)

(lateral,

the

32'

(at

32'

the

(at

.5g(including

g

(including

Co.Ltd

.

violation

of

law

approximate

part6mm)

vertical)

outer

groove

inner

groove

headshell)

headshell)

headshell)

.

of

of

Panasonic

DivisionofMatsushita

CorporationofAmerica

One

New

Company

Panasonic

Jersey

Way,

07094

Electric

Secaucus,

Panasonic

320

Waiakamilo

.Hawaii

96817

Hawaii,

Inc

Road,

.

Honolulu,

Matsushita

5770

Ambler

Mississauga,

ElectricofCanada

Drive,

Ontario

LAW

2T3

Ltd

.

Page 2

SL-1200MK2

CONTENTS

DISASSEMBLY

PARTS

IDENTIFICATIONS

ARM

BASE

FEATURES

ADJUSTMENTS

SCHEMATIC

REPLACEMENT

TROUBLE

SHOOTING

PROCEDURE

ASSEMBLING

.

. . ..... . . . . . . . . . . . . ... . . . ... . . . . . . . . ...

. ..... . . . . . . . . . . ... . ... . . . . . . . . . . ...6

DIAGRAM

PARTS

. ... . ..... . . . . . . . . . . . . . . .

. . . ... . . . ... . . . . . . . . . . . . . . .3

PROCEDURE.. . ... . . . . ... . ...4

.

... . . .

LIST

. ....... . . . . . . ... . . . . . . . . . . . . .10

. . . . ...

. . .

(Electrical)

. . . . . . . .

..... . . . . . . . . ...9

. . .

2,3

5

7,8

PRINTED

ADJUSTMENT

REFERENCE

PIN

. . . . . . . . .

BLOCK

DIAGRAM.. . ... . . . . . . . . . . . . ..... . ... . . . . .

EXPLODED

REPLACEMENT

EXPLODED

CIRCUIT

BOARD

(Electrical)

VOLTAGE

...

. ... . . . . . . . . . ... . . . ... . . . . . . . . .

VIEWS.. . . . . . . . . . . . . . . . . . . ..... . . . . . . .

PARTS

VIEWS

. . ... . ... . . . . ... . ..... . . . . . . . . .20

. . . . . . . . ....... . . . . . . . . .

. . . . . . . . . .

AND

WAVEFORM

LIST

(Mechanical)

......... . . . . . . .

AT

. ... . . . . . . . . .19

EACH

11,12

13

IC

13,14

15,16

17,18

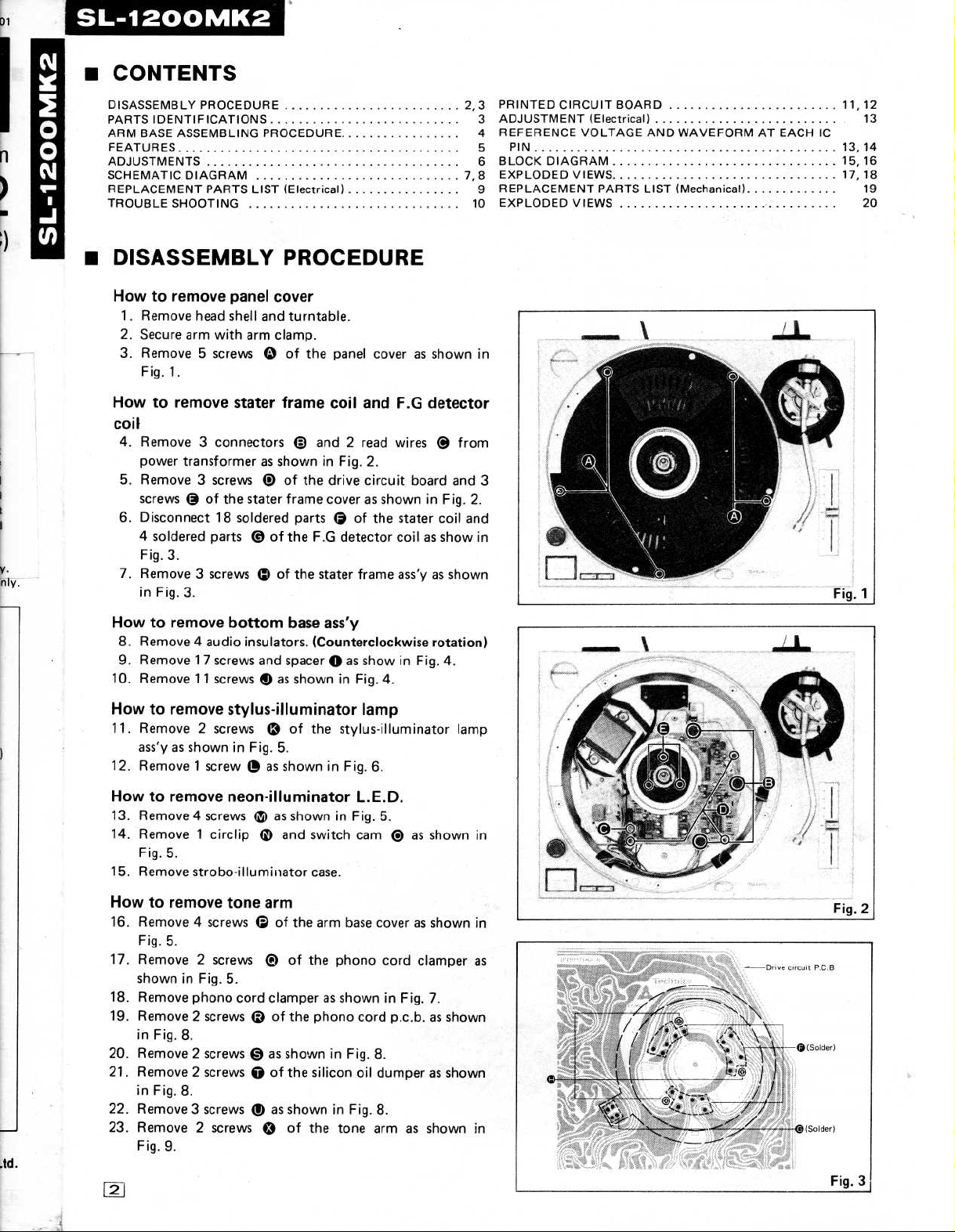

DISASSEMBLY

How

to

remove

1.Remove

2.Secure

3.Remove5screws

Fig

. 1

.

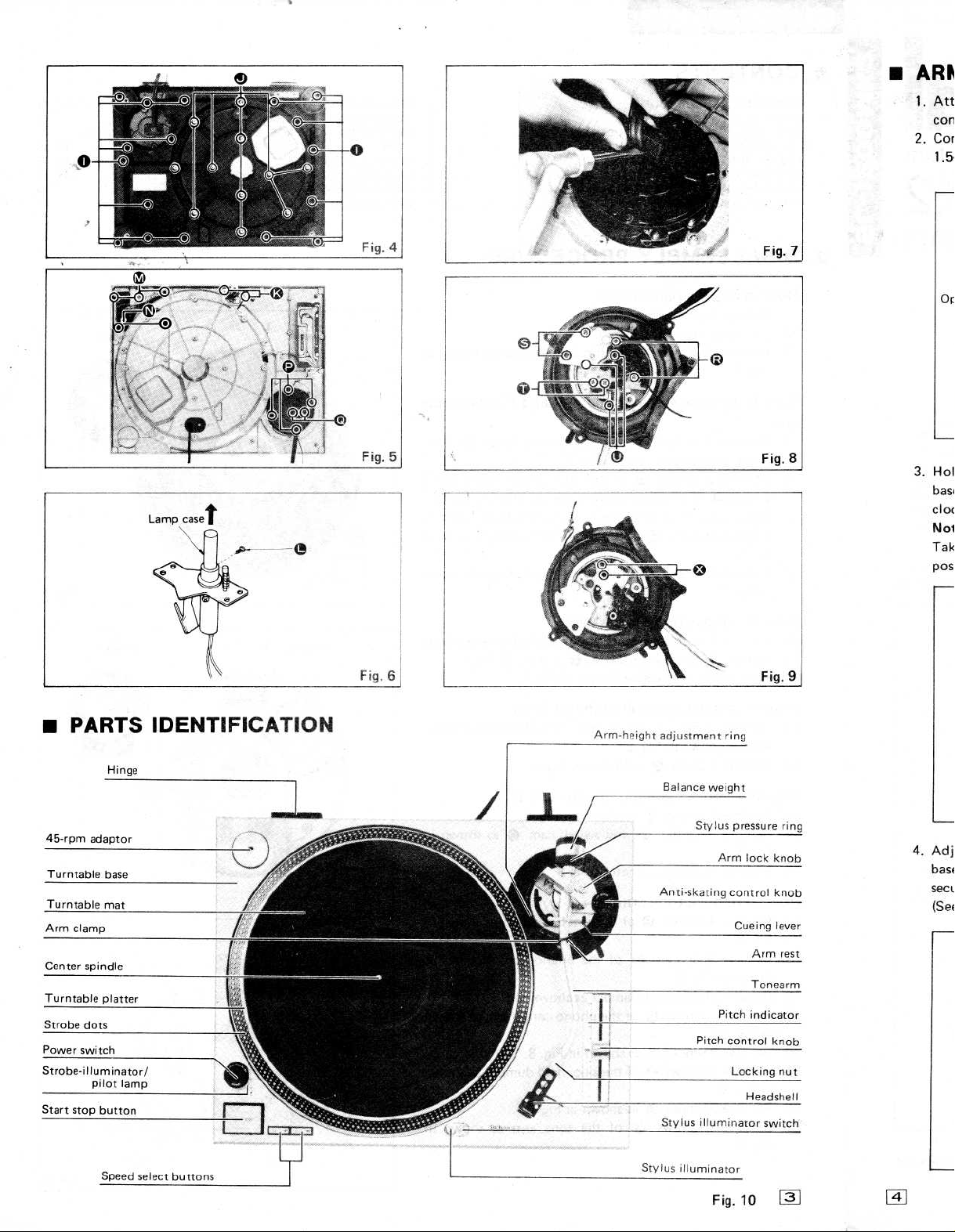

How

to

remove

coil

4.Remove

power

transformerasshown

5.Remove3screws

screws©of

6.Disconnect

4

soldered

Fig.3

.

7.Remove3screwsQof

in

Fig.3

How

to

remove

8.Remove

9.Remove

10.Remove

How

to

remove

11.Remove

ass'yasshowninFig.5

12.Remove1screwOas

panel

head

shell

and

arm

with

arm

O

stater

3

connectorsOand

@

the

stater

18

soldered

parts

OoftheF.G detector

.

bottom

4

audio

insulators.(Counterclockwise

17

screws

and

11

screwsOas

stylus-illuminator

2

screws

PROCEDURE

cover

turntable

clamp

.

of

the

panel coverasshown

frame

Q

coil

in

of

the

drive

frame

coverasshowninFig.2

partsOof

the

stater

base

ass'y

spacerQas

shown

of

the

.

showninFig.6

.

2

read

Fig.2

frame

andF.G

.

circuit

the

detector

wires@from

board

and

stater

coil

coil as

show

ass'yasshown

rotation)

showinFig.4

in

Fig.4

.

.

lamp

stylus-illuminator

.

in

3

.

and

in

lamp

How

to

remove

13.Remove4

14.Remove1circlip

Fig.5

.

15.Remove

How

to

remove

16.Remove4screws

Fig.5

.

17.Remove

showninFig

18.Remove

19.Remove

in

Fig

.

neon-illuminatorL.E.D.

screwsQas

Q

strobo-illuminator

tone

arm

Q

2

screws

phono

2

screwsQof

8

.

©

.

5

.

cord

clamperasshowninFig.7

20.Remove2screws©as

21.Remove2screwsQof

in

Fig.8

.

22.Remove3screwsQas

23

.

Remove

Fig

2

screws

.

9

.

0

showninFig.5

and

switch

case

.

of

the

arm

base

of

the

phono

the

phono

shown

in

the

silicon

showninFig.8

of

the

tone

.

cam

as

shown

QQ

coverasshown

cord

clamper

.

cordp.c.b.asshown

Fig.8

.

oil

dumperasshown

.

arm

as

shown

in

in

as

in

Page 3

Lamp

caset

Fig

.

Fig

9

.

m

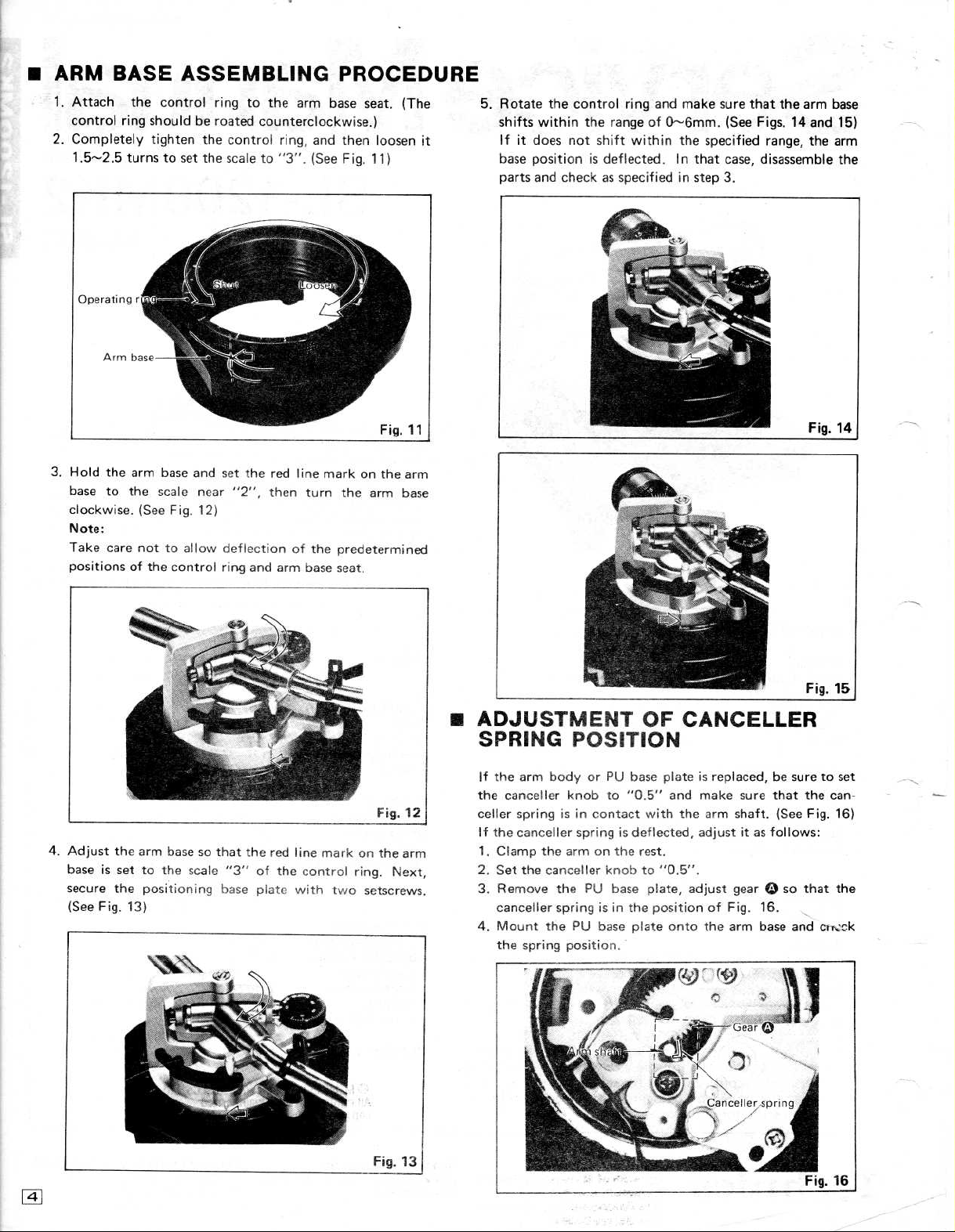

PARTS

Hinge

Power

switch

Strobe-illuminator/

pilot

Speed

lamp

IDENTIFICATION

select

buttons

Arm-height

adjustment

Balance

ring

weight

Fig.10

10

Page 4

.

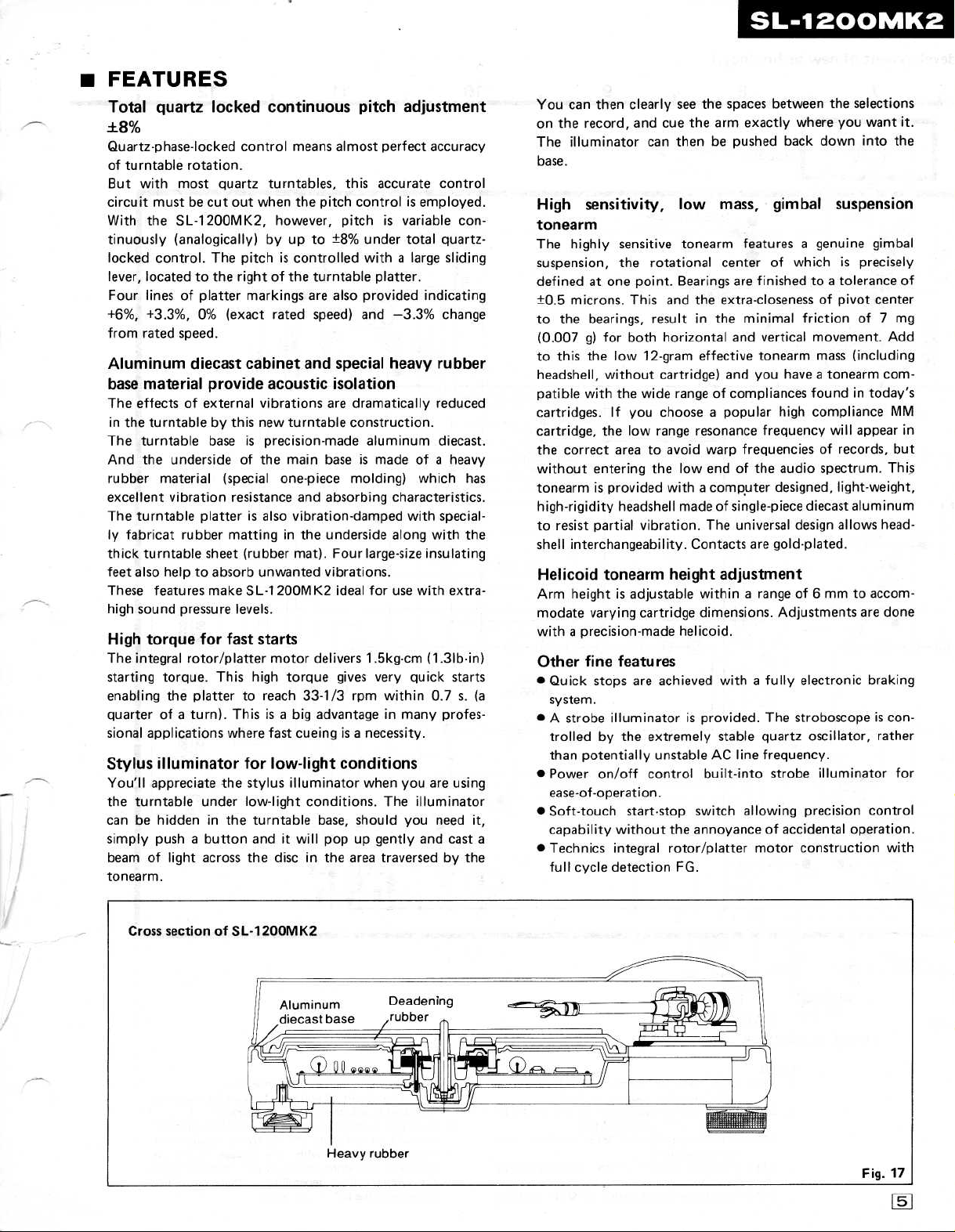

ARM

1.Attach

2.Completely

control

1

.5---2 .5

BASE

the control

ring

shouldberoated

tighten

turns to

ASSEMBLING

ring

to the

counterclockwise

the

control

set

the

scaleto"3".(See Fig.11)

ring,

PROCEDURE

arm

base

and

seat.(The

.)

then

loosen

5.Rotate

shifts

it

base

parts

the control

within

the

rangeof0-6mm.(See Figs.14

If it

not

does

positionisdeflected.In

and

shift

checkasspecifiedinstep 3

ring

within

and

make

the

that

sure

specified

case,

.

that the

range,

disassemble

arm

and

the

base

15)

arm

the

3.Hold

4.Adjust

the

base to the

clockwise

Note

:

Take

care

positions

baseissettothe

secure

(See

of

the

the

Fig.13)

arm

base

scale

.

(See Fig.12)

not

to allow

the

control

arm

base

positioning

and

near

so

scale

set

the

"2", then

deflection

ring

and

that the

"3"

of the

base

plate

red

red

arm

line

turn the

of the

base

line

control

with

markon

arm

predetermined

seat

.

mark

on

ring.Next,

two

setscrews

the

base

Fig.12

the

arm

arm

®

ADJUST

SPRING

If

the

arm

the

canceller

celler

springisin

if

the

canceller

1.Clamp

2.Set

the

.

3.Remove

canceller

4.Mount

the

spring

ENT

POSITION

body

or

PU

knob

to"0.5"

contact

springisdeflected,

the

armonthe

canceller

the

springisin

the

PU

PU

base

position

knobto"0

OF

base

plateisreplaced,besure to

and

with

rest

.

.5"

base

plate,

the

positionofFig.16

plate

onto

.

CANCELLER

make

sure that the can-

the

arm

shaft.(See Fig.16)

adjustitas

.

adjust gearQso that the

the

arm

follows

.

base

and

:

cit~ck

set

4

Page 5

FEATURES

Total

f8%

Quartz-phase-locked

of

But

circuit

With

tinuously

locked

lever,

+6%,+3.3%,

from

Aluminum

base

The

The

And

rubber

excellent

The

ly

thick turntable sheet

feet also

Thesefeatures

high

High

The

starting

enabling

quarterofa

sional

Stylus

You'll

the

canbehiddeninthe

simply

beam

tonearm

quartz locked

turntable

with

mustbecut

the

control

located

Four

linesofplatter

rated

material

effects

in

the turntable

turntable

the

material

turntable

fabricat

help to

sound

torque

integral

torque.This

the

applications

illuminator

appreciate

turntable

pushabutton

of

.

rotation

most

quartz

out

SL-1200MK2,

(analogically)

The

.

to

the

0%

(exact

speed

.

diecast

provide

of external

this

by

baseisprecision-made

undersideofthe

(special

vibration

rubber

pressure

light

resistance

platterisalso

mattinginthe

absorb

make

for

fast

rotor/platter

plattertoreach

turn).Thisisa

where

the

under

across

continuous

control

.

turntables,

when

however,

by

pitch

right

of

markings

rated

cabinet

acoustic

vibrations

new

(rubber

unwanted

SL-11

200MK2

levels

.

starts

motor

high

fast

for

low-light

stylus

low-light

turntable

anditwill

the

discinthe

adjustment

pitch

means

almost

perfect

this

accurate

the

pitch

controlisemployed

pitchisvariable

up

to

±8%

under

total

controlled

is

turntable

the

are

speed)

and

turntable construction

main

one-piece

and

vibration-damped

mat).Four

delivers1.5kg-cm(1.3lb-in)

torque

33-1/3

big

cueingisa

illuminator

conditions.The

provided

also

and

special

isolation

are

dramatically

baseismade

molding)

absorbing

underside along

vibrations

ideal

gives

rpm

advantageinmany

conditions

base,

should

popupgently

area

large

with

a

platter

-3

.3%

heavy

aluminum

characteristics

with

large-size

.

for

use

very

quick

within0.7s.

necessity

when

you

you

traversedbythe

accuracy

control

con-

quartz-

sliding

.

indicating

change

rubber

reduced

.

diecast

ofaheavy

which

with

illuminator

has

special-

with

the

insulating

extra-

starts

profes-

.

are

using

need

it,

and

cast

(a

a

SL-1200MK2

You

can

on the

illuminator

The

base

.

.

.

.

High

tonearm

The

highly

suspension,

definedatone

microns.This

±0

.5

to

the

(0

.007

to

this

headshell,

patible

cartridges.If

cartridge,

the

correct

without

tonearmisprovided withacomputer

high-rigidity

to

resist

shell

interchangeability.Contacts

Helicoid

Arm

heightisadjustable

modate

withaprecision-made

Other

"

Quick

system

"Astrobe

trolledbythe

than

Power

ease-of-operation

Soft-touch

capability

"

Technics

full

cycle

clearly

then

record,

sensitivity,

sensitive

the

bearings,

g)

for

both

the

low 12-gram

without

with

the

you

the

low

area to

entering

headshell

partial

tonearm

varying

fine features

stops

.

illuminatorisprovided.The

potentially

on/off

start-stop

without

integral

detectionFG.

see

the spaces

and

cue the

can

then

low

tonearm

rotational

Bearings

point

.

and

the

resultinthe

horizontal

effective

cartridge)

wide

rangeofcompliances

choose a

range

resonance

avoid

warp

the

low

endofthe

madeofsingle-piece diecast

vibration.The

height

withinarangeof6

cartridge

are

extremely

control

dimensions.Adjustments

helicoid

achieved

unstableACline

built-into

.

switch

the

annoyanceofaccidental

rotor/platter

between

arm

exactly

be pushed back

mass,

featuresagenuine

center

are

extra-closeness of

minimal

and

and

popular

frequencies

universal

adjustment

.

withafully

stable

allowing

where

gimbal

of

whichisprecisely

finishedtoa

vertical

tonearm

you

haveatonearm

high

frequency

audio spectrum

designed,

design allows

are

gold-plated

electronic

stroboscopeiscon-

quartz

frequency

strobe

motor

construction

the

selections

you

wantit.

down

into

suspension

gimbal

tolerance

pivot

frictionof7

movement.Add

mass

(including

in

found

compliance

of

oscillator,

illuminator

precision

today's

will

appear

records,

light-weight,

aluminum

.

mmtoaccom-

are

braking

.

control

operation

the

of

center

mg

com-

MM

in

but

.

This

head-

done

rather

for

with

.

Page 6

)MK2

lections

wantit.

nto

the

~ension

gimbal

recisely

of

-

ance

t

center

f7

mg

nt.Add

icluding

m

com-

today's

ice

MM

in

)pear

As,

but

m.This

weight,

iminum

vs

head-

accomre

done

braking

is

con-

,

rather

for

itor

control

eration

)n

with

SL-1200MK2

ADJUSTMENTS

for

fre-

.

and

the

into

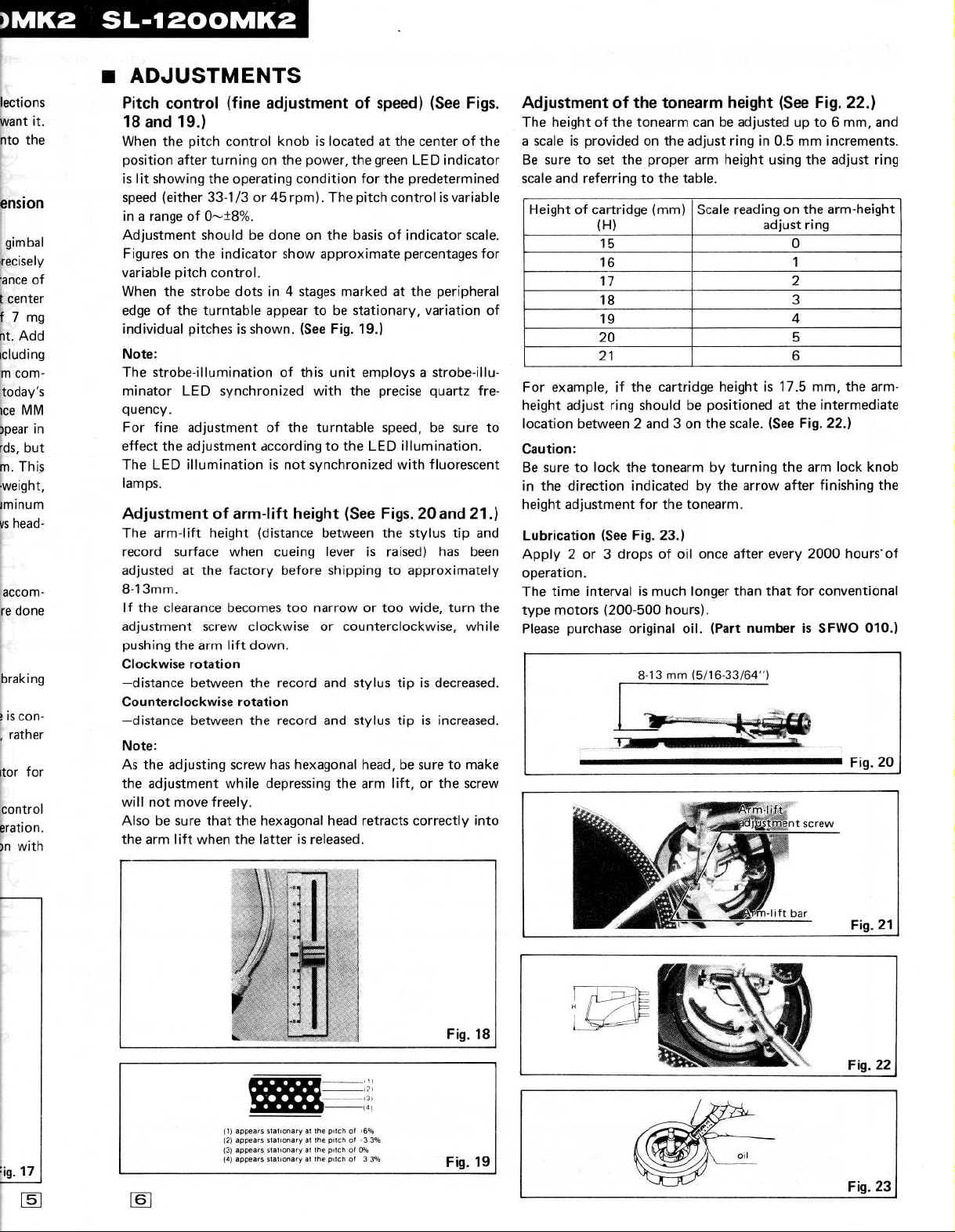

Adjustment

.

The

a

scaleisprovidedonthe adjust

Be

sure to

scale

Heightofcartridge

.

of

For

height

location

Caution

Be

sure to

in

the

height

.)

Lubrication

Apply

operation

The

typemotors

Please

.

.

height of the

and

example,ifthe

time

Pitch

control

18

and

19

When

the

position

is

speed

in a

lit

showing

range of

after

(either

Adjustment

Figuresonthe

variable

When

edge

pitch control

the strobe dotsin4

of the turntable

individual

Note

:

The

strobe-illumination of

minator

quency

.

For

fine

effect

the

The

LED

lamps

.

Adjustment

The

arm-lift

record

surface

adjustedatthe

8-13mm

If

.

the clearance

adjustment screw

pushing

the

Clockwise

-distance

Counterclockwise

-distance

Note

:

As

the adjusting

the

adjustment

will

not

move

.

Alsobesure that the

the

arm

lift

(fine

adjustment

.)

pitch

control

knobislocatedatthe

turningonthe power,

the

operating

33-1/3or45

0-±8%

condition

rpm).The

.

shouldbedone

indicator

show

.

stages

appeartobe

pitchesisshown.(See

LED

synchronized

adjustment

adjustment

illumination

of

height

of

accordingtothe

is

arm-lift

(distance

when

cueing

factory

becomes

the

not synchronized

height

before

too

clockwise

arm

lift

down

.

rotation

between

the

record

rotation

between

screw

while

freely

the

record

has

depressing

.

hexagonal

hexagonal

when

the

latterisreleased

of

speed)

center of the

on

the

approximate

marked

the green

for

pitch

basisofindicator

LED

the

predetermined

controlisvariable

percentages

at the

stationary,

Fig.19

.)

this

unit

employsastrobe-illu-

with

the

precise

turntable

speed, be sure to

LED

illumination

with

(See

Figs.20

between

the

stylus tip

leverisraised)

shippingtoapproximately

narrow

or

too

wide,

or

counterclockwise, while

and

stylus

tipisdecreased

and

stylus

tipisincreased

head,

be sure to

the

arm

lift,orthe

head

retracts

correctly

.

(See

Figs

indicator

scale

peripheral

variation

quartz

fluorescent

and

21

has

been

turn

make

screw

ofthe

tonearm

tonearm

set

the

proper

referringtothe

(mm)

(H)

15

16

17

18

19

20

21

cartridge

adjust

ring

shouldbepositionedatthe

between2and3on

:

lock

the

tonearm

direction

adjustment

indicatedbythe

for the

(See

Fig.23

.)

2 or3dropsofoil

.

intervalismuch

(200-500

purchase

hours)

original

height

(See

Fig.22

canbeadjustedupto6mm,

ringin0.5mm

arm

height using the

table

.

Scale readingonthe

adjust

increments

arm-height

ring

0

1

2

3

4

5

heightis17.5mm,

intermediate

the

by

tonearm

once

longer

scale.(See

turning

arrow

.

after

than

every

that

Fig.22

the

after

for

arm

finishing

2000

conventional

.

oil.(Part

number

is

SFWO

adjust

the

.)

lock

hours'of

.)

arm-

knob

010

and

.

ring

the

.)

:ig.

(t)

appears

stahonaryatthe

(2)

appears

stahonaryatthe

slat,

appears

f3f

(4)

appears

stahonary

17

onaryatthe

at

pitchof,611,

pitchof"3.3%

pitcho;1

the

pitcho33%

1

Fig

19

.

Page 7

3456

Schematic

Diagram

2

(This

schematic

diagram

maybe

modifiedatanytime

SVDSl

with

D1

RBA20

the

development

of

7

Q

C

A

AC

117V

B

(50/60Hz)

POWER

{YtiO--~

r

1

350

MA

~pnai

i F

R601

4

.7

SWITCH

BLU

ORG

120

T

.I

.6

J

Q3

C

R5

4

°}

'

TP4

SVORD5

D2

.1E

C

R2042.

Braking

D

adjustment

R2154.7K

R214

VR201

22K

50KB

IC201

TP21

R205

TP22

AN6680

E

Adjustment

F

pitch control

0%(Pitch)

±

Pitch

Adjustment

(GAIN)

G

H

THE

SHADED

SAFETY

WHEN

COMPONENTS

.

SERVICING

AREA

IN

THE

of

IT IS

ON

ESSENTIAL

SHADED

THIS

SCHEMATIC

AREAS

THAT

OF

IMPORTANT

ONLY

THE

DIAGRAM

MANUFACTURER

SCHEMATIC

SAFETY

INCORPORATES

.

VR303

NOTICE

PITCH

PITCH

SPECIFIED

MA150

LOCKSWITCH

CONTROL

SPECIAL

PARTS

D204

VOLUME

FEATURES

BE

USED

5203

S/S

SPEED

IMPORTANT

FOR

THE

5201

33

45

SELECTOR

CRITICAL

1

5202

FOR

SVDSR105C

SWITCH

D201,

TF

Q202

202

STR(

u

Page 8

,developmentofnew

technology

.)

7

fP3

220

P19

~

8

9

10

OVI

.213

Ilop

i

WITCH

STROBE

D204 D205

ILLUMINATOR

D206

5401

PLl

STYLUS-ILLUMINATOR

NOTO

:

1

.

S201:Speed

2.S202:Speed

selector

"ON"

position.(push condition)

selector

position.(not-push

3.S203:Start/Stop

push

4

.

S301:Pitch

condition)

lock

switchin"ON"

position)

5

.

S401:Stylus-illuminator

switch

(33-1/3

switch (45r.p.m.)in"OFF"

condition)

switchin"OFF"

position.(not-

position.(center

switchin"OFF"

r.p.m.)

position

in

.

S601:Power

6

.

The

7

.

indicated

Indicated

8

.

the

(high

drive

unit

switchin"ON"

circuit

in

side

voltage

measured by

impedance)

the

standard.Therefore, there

the

voltage

values,

pedanceoftheDCcircuit

IC

voltage

schematic

values

are the

DC

with

may

depending on

tester

position

and

wave

diagram

standard

electronic

the

chassis

exist

the

.

.

form

.

circuit

some

internal

are

values

tester

taken

errors

not

for

as

in

im-

Page 9

REPLACEMENT

Notes

:1.Part

numbers

Please

2.©

3.SL-1200MK2(M)

use

indicates

this

that

are

part

only

PARTS

indicatedonmost

number

for

parts

+

[MI,SL-1200MK2

parts

specifiedbymanufacturer

LIST

mechanical

orders

(Electrical)

parts

(MC1

.

be

used

.

(MC)+

for

safety

.

Ref.No

.

INTEGRATED

IC101

IC201

IC301

IC302

TRANSISTORS

Q1

Q2,3,202

Q201

Q203

DIODES

D1

D2,301

D204

D201,

202

D203-206

D401

CRYSTAL

X201

VARIABLE

VR201

VR301

VR302 EVLS6AAOOB54

VR303 EVBJ05Cl9ABE

SWITCHES

S201

5202

S203

5401

S601

LAMP

PL1

TRANSFORMER

Tl

FUSE

F1

RESISTORS

R1

R2

R3

R4

R5

R101

R102

R103

R104

R105

R106

R107

CIRCUITS

RESISTORS

AN6675

AN6680

AN6682

SVITC4011BP

2SD389A-Q

2SD637

2SC1846-R

2SC1328-T

A

SVDSIRBA40

MA7051

MA162A

SVDSR-105C

SVDEBR5505S

SVDGL-9PG2

SVQU306115

EVLS6AA00a54

EVMH2GAOOB53

EVQP5RO4K

EVQP5RO4K

SFDSSS5GLl3C

SFDSD2MSL-4

©

SFDSSS5GL-2

SFDN122-01

©

~SLT60EL)713

©

XBA2FO3NU100

ERD25FJ562

ERD25FJ682

ERD25FJ272

ERD25FJ561

ERD25FJ471

ERD25FJ103

©

ERXIANJ4R7

ERD25FJ472

ERD25TJ473

ER026FJ403

ERD25FJISO

ERXIANJlR5

©

PartNo.

Part

Name&Description

Integrated

Circuit

Integrated

Circuit

Integrated

Circuit

Integrated

Circuit

Transistor

Transistor

Transistor

Transistor

Rectifier

Diode,Zener5

Diode

Light

Light

Light

Crystal,4.19328MHz

Braking

AdjustmentofPitch

5kn

Pitch,Adjustlnent (Gain)

Pitch

Switch,

Switch,

Switch,

Switch,

Switch,

Lamp,

Power

Fuse,

Carbon,

Carbon,

Carbon,

Carbon,

Carbon,

Carbon,

Metal

Carbon,

Carbon,

Carbon,

Carbon,

Metal Film,1.511,

.iV

Emitting

Diode

Emitting

Diode

Emitting

Diode

Adjustment

(B)

Control

Volume

Speed

Selector

Speed

Selector

Start/Stop

Stylus-illuminator

Power

Stylus-illuminator

Transformer

350mA

6

.6k

fl,

6

.8kfl,

2

.7kfl,

560fl, 1/4W,

470fl, 1/4W,

10kfl,

Film,4.7fl,

4

.7kfl,

47kQ,

10kfl,

1511,

(BRAKE),

Control

Oscillator

f0°%(PITCH),

50kfl

(33-1/3r.p.m

(45r.p.m

1/4W,

1/4W,

1/4W,

1/4W,

1W,

1/4W,

1/4W,

1/4W,

1/4W,

1W,

50k(1

.)

.)

t

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

(B)

5%

Ref,No.

8108

8109,

R201

R202

8203

R204

8205

R206

8207

R208

R209

R210

R211

R212

R213

8214

R215

R216

8217

R218

R219

R220

R221

8301

R302

R303

R304

R306

R601

CAPACITORS

Cl

C2

C3

C101,

C103

C104,105

C106,107

C108

C109,

C111

0112

C201

C202,203

C204

C205

C206

C207

C208

C209

C210

C211

C212

C213

C214

C215

C216

C301,302

C303

C304

C305

C306

C601

[MI

C601

[MCI

-

102

110

110

A

©

©

©

A

ECQMlH562KZ

ECEAIJS4R7

ECEAICS330

ECEA50ZI

ECQMlH473KZ

ECEA1AS221

ECCDlH390K

Part

No

ERD25FJ103

ERXIANJ4R7

ERGlANJ561

EAD25FJ103

ERD25FJ470

ERD25FJ272

ERD25TJ124

ERD25TJ"183

ERD25TJ563

ERD25TJ224

ER025TJ154

ERD25TJ183

ERD25FJ103

ERD25FJ121

ERD25FJ122

ERD25TJ223

ERD25FJ472

ERD25TJ154

ERD25TJ223

ERD25FJ102

ERD25FJ332

ERD25FJ221

ERD25FJ471

ER025CKF3301

ERD25FJ471

ERD25FJ822

ERD25FJ152

ERD25TJ223

ERD25FJ4R7

ECEBlHS471

ECEAIVS330

ECEAIES220

ECEAlVS330

ECEAlVS330

ECQMlH104KZ

ECQMlHl04KZ

ECEAlES101

ECQMIH104KZ

ECEA50ZI

ECCDIHt01K

ECEAIES101

ECQMlH224KZ

ECQMlH473KZ

ECEA50Z3R3

ECCDlH47lK

ECEAIES101

ECEA50Z1

ECEAIES470

ECQK1123FZ

ECEA50ZI

ECEA1HS100

ECQMlHl22KZ

ECEA50Z1

ECQFlA473MD

ECQUIA473ME

.

Carbon,

Metal Film,4.7fl,

Metal Oxide,

Carbon,

Carbon,

Carbon, 2

Carbon,

Carbon,

Carbon,

Carbon,

Carbon, 150kfl,

Carbon,

Carbon,

Carbon,

Carbon,

Carbon,

Carbon, 4

Carbon, 150kfl,

Carbon,

Carbon,

Carbon, 3

Carbon,

Carbon,

Metal

Carbon,

Carbon,

Carbon,

Carbon,

Carbon, 4

Electrolytic,

Electrolytic,

Electrolytic,

Electrolytic,

Electrolytic,

Polyester,0.1PF,

Polyester,0.1,uF,

Electrolytic,

Polyester,

Polyester,0.0056pF,

Electrolytic,

Electrolytic,

Electrolytic,

Polyester,0.047liF,

Electrolytic,

Electrolytic,

Ceramic,

Ceramic,

Electrolytic,

Polyester,

Polyester,0.047pF,

Electrolytic,

Ceramic,

Electrolytic,

Electrolytic,

Electrolytic,

Polyester,--0

Electrolytic

ElectrOiytic,

Polyest&;"0.0012pF,

Electrolytic,

Polyester,0.047pF,

Polyester,0.047pF,

Part

Name&Description

10kn, 1/4W,

560fl,

1Okfl,

47fl,

.7kfl,

120kfl,

18kf1,

56kfl,

220k

18kf2,

1OkQ,

120fl,

1

.2kfl,

22kfl,

.7kfl,

22kf1,

lkfl,

.3kf2,

22012,

47012,

Film, 3

.3kfl,

470(2,

8

.2kf2,

1

.5kfl,

22kfl,

.7(2,

470yF,

33juF,

22/AF,

33juF,

33pF,

100UF,

0,1yF,

4,7pF,

33pF,

luF,

220pF,

luF,

100pF,

39pF,

100pF, 16V

0.22pF,

3.3pF,

470pF,

100pF,

1uF,

47uF,

.012pF,

;`'

I#F,

10pF,

1pF,

fl,

1W,

1W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,

1/4W,t1%

1/4W,

1/4W,

1/4W,t5°%

1/4W,

1/4W,

50V

35V

25V

35V

35V

50V,

50V,

25V

50V,

50V,

63V

16V

50V

50V,

1ov

50V

50V,

50V,

50V,

50V,

50V

50V,

25V

50V

25V

125V,t1%

50V

50V

50V,

50V

400V,

400V,

t

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t 5%

t

t 5%

t

t 5%

t 5%

t 5%

t 5%

t

t 5%

t10%

t10%

t10%

t10%

t10%

t10%

t10%

110%

t10%

t10%

±10%

t20%

t20%

5%

5°%

5%

5%

5%

0

TERMINAL

AN6675

r

13

GUIDEOFTRANSISTOR

AN6680

2

J2

1

12

~~

13

12

1

AN6682

123456189

SVITC4011BP

1

:

AND

IC

2SC1846

2SC1328

F

2SD637

B

C

2SD389

Page 10

TROUBLE

(B)

SHOOTING

Power

switch

operate

I

It

doesn't

Start/Stop

Runaway

doesn't

rotate

"push"

operation

switch

Power

circuity

"

TP5-20V

Reference

TP5-20V

"

Control

circuity

"

Check

voltage

formatIC201

Drive

circuity

"

Check

voltage

formatIC101

heck

voltageonQ201

"

Base

voltage-10V

Reference

"

TP5-

20V

Control

circuity

"

Check

voltage

formatIC201

voltage

YES

YES

voltage

YES

check

check

and

check

and

check

and

circuity

wave

wave

circuity

wave

check

check

NO

NO

NO

NO

NO

NO

F1,

S601,

D1,61.1

IC201

X201

Q201

Q1

D2

IC201

T1

-Q3

-Q3

Turntable

abnormally

Speed

defective

(F)Strobe

illuminating

rotates

changeover

not

Drive

circuity

Check

"

formatIC101

FG

circuity

"

Check

Control

"

Check

formatI

Pitch

Check

formatIC301,

is

Speed

"

TP13

"

TP14-0V

Check

"

TP28-18AV

"

TP29-9

check

voltage

and

YES

check

voltageonQ203

circuity

check

voltage

and

C201

control

circuity

voltage

and

select

circuity

-3

.4V

voltageatTP28

.6V

wave

IC302

wave

check

wave

check

and

TP29

NO

NO

NO

NO

NO

NO

Q203,

FG

X201

I

C201

IC301

IC302

IC201

S

201,S202

13201,

Q202

13203-.

coil

13202

.13206

Page 11

Printed

A

B

C

Circuit

2

Board

D202

S20f

+

B

lines

Earth

(Ground)

SPEED

r

r

02

133

SELECTOR

SWITCH

lines

START/STOP

SWITCH

D

E

D204

D203

POWER

TRANSFORMER

F

G

117V

AC

(50/60

Hz)

BLU

H

ORG

BLU

BRN

RED

Page 12

5401

SVITC4011

Q203

2SC1328

BRN

RED

ORG

-

YEL

IC302

NL1

BP

C202

R211

TP23 0203

16VID0

10K

TP

E

1+

R221

"

---Mh-.-"

R216

50'11

BLK

BLK

-

470

73

. .

-8 .2K

.Mr305

r

~

R21J

t

~

P2~4~~

fi,

k

470

R

219: :

150F

FT

'T04 0.0"'

-IF.

R204 2_7K

OOVI

aft-

206

5f

IF

.'2

7P74

.

0 .0012

.

i

H

Q201

.

(6

10

c2c5

R4011.5K

~91

TP27

s

STYLUS-ILLUMINATOR

ORG

BRN

r

L

SWITCH

IC301

RED

ORG

YEL

AN6682

Q1

2S

D389

T

zv

__

"

PSi4T'~

A

k

BLU

S601

POWER

C21

SWITCH

3

.3

Q262

2SD637

C20

8212

BRN

RED

ORG

1601

AN6680

YEL

BLK

BLU

PPL

'20

R

Q2, 3

D637

t

5-of

R5

470

O

BLUB_

LU

C109

gar

1

X201

x-11

(201

p

-if--

R10.11

G

6

nC

R101

C101

405

01632v

C106

01

25V33

DV33

1

0"

ll!t

+3

}1.

~RI:In

rc,

-At~

NOMINEE

2SC

0201

1846

AN

IC101

6675

2S

Page 13

SL-1200MK2

SL-12

ADJUSTMENT

Adjustments

Notes:9

A

B

C

Make

Conditionofthe

1

.

Power

2.Pitch control.. .

3

.

Speed

Instrumentstobe

1.Tester

2.Frequency

Adjustment Connection

Adjustment

of

pitch

control

t0%

(PITCH)

Adjustment

pitch

of

control

gain

Braking

adjustment

(BRAKE)

(Electrical)

(Electrical)

the

following

switch.. .

selector

counter

Frequency

Tester

TP31

TP32

adjustments

set

.

. .

. .

. . .

. .

switch

. . .

used

(2)-.

-

0

and

-

after

. . . . .

.

. . . ..Center

. . ..33-1/3

Points

counter

TP27

GROUND

replacing

ON

Adjustment

parts

position

r.p.m

.

VR301

VR302

VR201

suchasIC's,

Point

1.Pitch

2.Adjust

Adjust

value

Adjust

after

few

transistors,

control

VR301

frequency

VR302

VR201

stop

signal

seconds

diodes,

Adjustment

switch

for

.

for2.7

for

complete

initiated

after stop)

SIGNAL

STOP

etc

.

Method

to center position

262

.08

kHz

10

.05

.

kHz

k92t0.1ofresistance

stop

within

120°-

.

(Turntable

becomes

of

270°

free

(D

O

OO

a

REFERENCE

PIN

IC101

(AN6675)

Start

©

~3

O

Os

©

OO

08

VOLTAGE

Stop

2V

2V

0v

sv

sV

5V

(

'S

oV

5V 5V

6.6V

2V

2V,~,

ov

sV

sv

ov

04""W

(

q

0

-

0

S

0

..©

,

AND

©

©

WAVEFORM

Start

=

15V

15V

ATEACH

Stop

15V

~

15V

209.

,

T

(S

2700

&1

Turntable

0

IC

Start

Same

as at

®

15V

©

,

f

®

right

20V

20V

20V 20Vo.l,

0.2v 0.2V,t

Stop

1

""

20V

20V

ao

10

,uV

.6

.1

Q2

1

15v

'

r

*4

0

©

"1

15V

,

.,_

15V

©

T

ov ov

15V

15V

©

.7V

1

.7V

C

Page 14

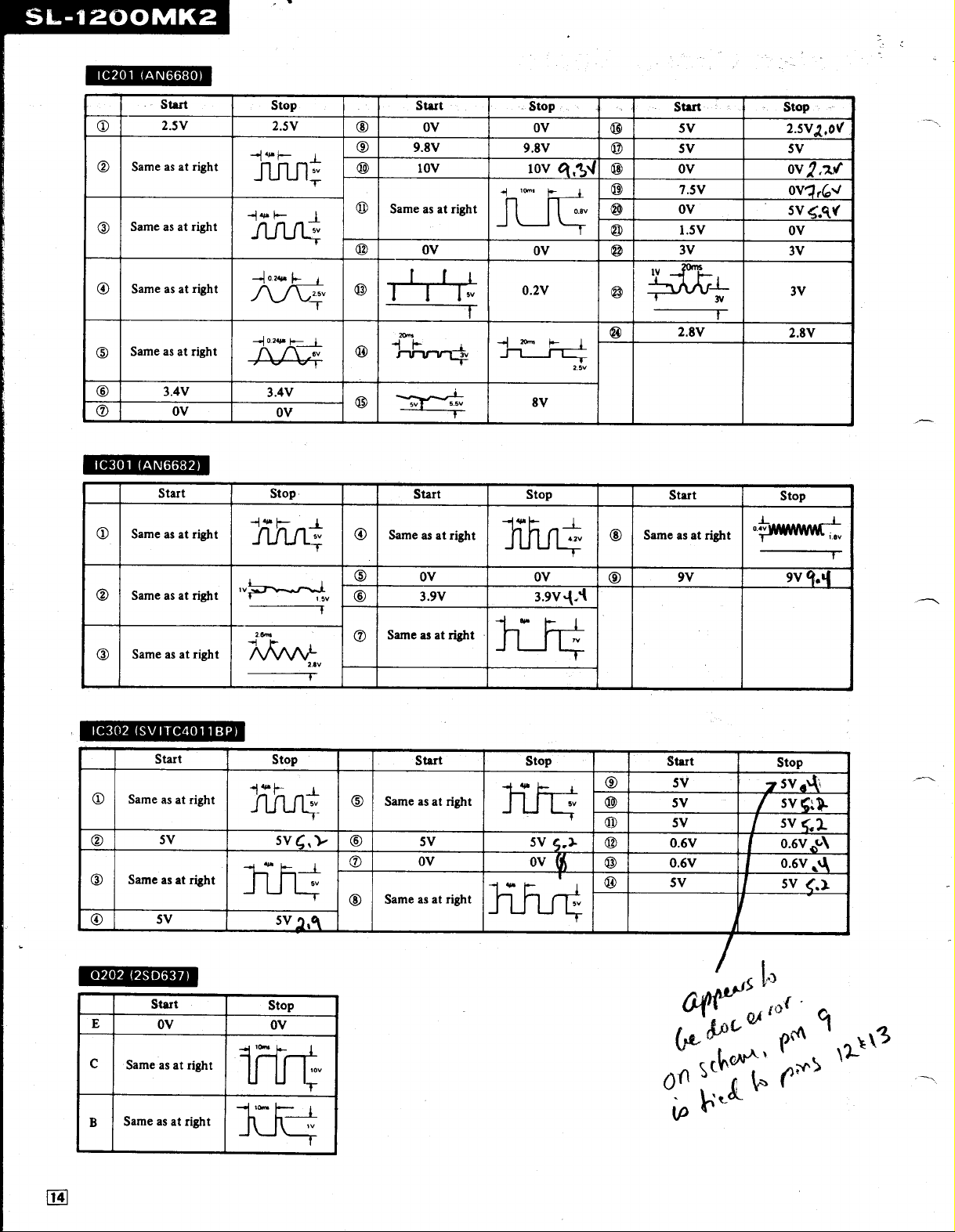

IC201

(AN6680)

Ot

T

T

T5

©

T7

IC301

Tt

T

Start

2

.5V 2

Same

as at

Same

as at

Same

as at

Same

as at

3

.4V

OV

(AN6682)

Start

Same

as at

Same

as at

Same

as at

Stop

.5V

right

right

right

41.

fl

fl

u

u

w

A

6v

v

.xw

x

.sv

7

right

~oxw

-[A-,-!V

3

.4V

i

OV

Stop

right

JULJ

sv

L

T

right'v

right

x

.sv

~-

Start

®

1)

OV

9.8V

tov

Same

as at

right

-

©

®3

Ov Ov

-

20-

,

T

Stop

Ov

9.8V

iov

.2V

0

.

,3J

o

9v

Start

I

LM

Q

5V

5V

Ov

OO

I

t

®

®

®

®

i

~~

IV

7

.5V

OV

1

.5V

3V

2.8V

r

st

o

p

- :

2

.5VZ,OV

5V

OV,?,7. ,V`

Ov

4

Sv

,qY

OV

3V

3V

2

.8V

.4

®

2

.5V

S .SV

©

sv

Start

Same

®

TO

©

as at

right

OV Ov

3.9V

lhf

8v

Stop

3

t

.9V,(A

,.,®

TB

Start

Same

as at

right

9V 9v

Stop

-

-v

-

T

'

w

Same

as at

right

I

I I

1

IC302

T1

Ts

®

0202

E

C

t

B

(SV

ITC4011

Start

Same

as at

right

5V

Same

as at

right

SV

(2SD637)

Start

OV OV

Sameasat

Same

as at

right

right

BP)

T4A

~

Stop

41 ~-

Stop

Start

T5

Same

as at

right

5V

-~

OO

5V

OV

Sv

®

Same

as at

right

,

Stop

y,

5V

OVI~t

Start

Stop

O

,

'~

©

SV

t .

Sv

5V

v

T

Page 15

BLOCK

DIAGRAM

Position

detection

coil

0

U

D201

(33r.p.m.

D202

(45r.p.m.

D201

(33r.p.m.

D202

(45r.p.m.

S203

(Start/Stop

indicator)

indicator)

switch)

switch)

switch)

Page 16

01-2

.3

D1

AC

line

50/60

Hz

Rectifier

IC201

Speed

control

(AN6680)

0

.S .C

0203

0

~

E

~E

0

c

ci

ca

c

CD

cli

IC301

f

C

.R

OSC

1

_

2 3

P

.C

u

vCC

(AN6682)

C

u

9

{

.P

PF

!

16

S

~C

rtUU'a

"tVh

0

U

S301

VR303

1~

S301

~7

PITCH

SWITCH

LOCK

,n

0

M

v

Page 17

SL-1200MK2

SL-12C

EXPLODED

VIEWS

POWER

CIRCUIT

P

.C.B.

Page 18

TONE

ARM

and

ARM

BASE

ASS'Y

Page 19

REPLACEMENT

Notes

:1.Part

Ref.No

CABINET

1

2

-

3

4

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25__

26

27

28

29

30

31

32

33

34

35

36 SFUP025-01

37

38

39

40

41

42

43

44

45 SFUP122-01

46

47

48

49

50

51

52

53

54

55

IM]

65

[MCI

56

57

58

TONE

61

62

63

64

65

66

67

68

70

71

72

73

74

numbers

Please

and

indicates

CHASSIS

and

use

ARM

2.©

3.SL-1200MK2(M)

.

ARM

this part

that

PartNo.

PARTS

SFAD122-01A

SFTG172-01

SFTE172-01Z

SFUM172-05

SFMGQ20401

SFMG520-31A

SFMZ172

SFMZQ20-01A

SFUP122-12

SFAC122-01

SFUM172-04

SFKT122-01

SFKK122-01E

SFKTO15-06

SFQA122-01

SFUM122-01

SF

KTbtS-01E

SFDJ

SFGZ122-01

SFYB5-32

SFQA520-01

SFUM122-03

SFUM015-11

SF

KK172-01

SFXB122-02

SFQA172-01

SFXJ172-01

SFUP122-02E

SFUP122-03

SFDJ122-03E

SFX0172-01

SFQA520-01

SFQA001-02

SFXJ172-05

SFHKO40L

RJASVA

SFUP132-03

SFGC122-01

SFUP122-10

KT122-02

SF

SFKK122-03

SFUZ122-01

'

F

SFDJ122-01E

SFUP122-13

SFAU122-01

SFUP122-05

SFUP122-04

SFUM170-07

SFGC122-02E

SFUP122-06

SFKTO15-02E

SFNN122M01

SFNN122COI

SFX0122-01

SFX0122-02

SFAT122-01A

BASE

SFPCC31001

SFPAM18201

SFPWG17201K

SFPRT18201K

SFPZB17202

SFQA829-03

SFPAB13202

SFPJL18202K

SFPZB12203

SFUM170-06

SFPZB12204

SFPAB18201

SFPZB12201

PARTS

are

indicatedonmost

number

only

parts

+(MI,SL-120wIK2(MC)

-01E

I22,02E

-

"

1

K

K

K

K

LIST

for

parts

specifiedbymanufacturer

Part

Name&

Dust

Cover

Turntable

Mat

Turntable

Cover, Turntable

Cover,

Stater

Stater

rame

Detector

FG

Shaft,

Stater

Plate,

Shield

Cabinet

Ornament,

Knob,

Case,

Knob,

Spring,

Base,

Knob,

Connector,

Spacer,

Ball,

Spring,

Cam,

Spacer,

Cover,

Boss, Drive

Spring,

Pin,

Bracket,

Plate,

Connector,

Pin,

Spring,

Spring,

Pin,

Clamper;AC

Bracket,

AC

Bracket,

Cushion,

Spacer,

Knob,

Ornament,

Shading

Hqlder,

-

Bucket,

Connector,

Supporter,

Base,

Supporter

Supporter

Case,

Audio

Supporter

Knob, Speed

Name

Stylus-illuminator

Power

Strobe-illuminator

Start/Stop

Start/S1op

Operation

Speed

7-PIN

Rubber

Switch

Switch

Switch

LED

Lamp

Drive Boss 0

Lock

Canceler 0

Stylus-illuminator

.Lock

Operation

3-PIN

Guide

Lock

Lock

Lock

Operating

AC

Cord

Power

Power

Power

Pitch

Pitch

Cloth,

LED

Pitch

4-PIN

Bottom

Bottom

(A),

(B),

Hinge

Insulator

(C),

Plate

Name

Plate

Pipe

(A)

Pipe

(B)

Hinge

Ass'y

Head

Shell

Tone

Arm

Balance

Lift

Knob,

Spring,

Knob,

Oil

Plate,

Spacer,

Clamper,

Tone

Ass'y

Weight

Assy

Arm

Lift

Arm

Damper P4

Arm

Base

Phono

Phono

Arm

Fixing

Plate,

Position

(Mechanical)

mechanical

orders

Frame

Coil

Frame

Switch

Selector

(Speed

Cam

Cam

Canceler

Operating

Cord

Cord

Transformer

Transformer

Transformer

Control

Pitch

Control

Hinge

Hinge

Hinge

Selector

Base

Ass'y

Lift

Cord

Fix

parts

+[MC1

Selector)

Pin

Plate

M'tg

Volume

Volume

Ass'y

.

M'tg

Volume

.m)

.

Description

-

Ass'y

Ass'y

Ass'y

Switch 0

Knob

(33-1/3r.p.m

Plate

Volume

Control

Control

Base

(45r.p

Ass'y

Lock

Cover

Cord

Plate

for

be

used

.)

-

-

safety

Ref.No

75

[M]

75

(MC)

76

77

78

79

80

81

SCREWS,

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

ACCESSORIES

A1

[MI

A1

[MCI

A2

A3

A4

A5

A6

A7

A8

PACKINGS

[M]

P1

P1

[MCI

P2

P3

P5

P6

P7

P8

.

.

WASHERS

-

PartNo.

SFDH360MOl

SFDH028-01

-

SFP1720

SFPKDKD1720

SFPKB17201S

SF P

12201

SFPAB

17206

and

CIRCLIPS

XTN3+88FZ

-FXGQ20-02

XTN3+88

XTN26+88

XTN4+10B

XWA48

XUC3FT

XUC2FT

XUC25FT

SFXW910J02

XTN3+408FZ

XSN3+10BVS

XWE3F12FZ

XTN3+25BFZ

SFXW122-01

XWE3E10

SFPEW1100

SFPEW11003

XSN3+BS

SFXG132-01

XTV3+BBFN

XTN3+108

XTN2+108

XSN17+3FY

XSN3+149

SFXW172-04

XUB14FT

SFUZ172-05

XTN3+6B

XSN3+8S

XWA3BFZ

XWA38

XWG3

SFXG829-1

XUCSFT

XTW3+SB

XTV3+88FN

XWE4A10EW

XTN3+258

XYN3+C6FZS

XSN3+128VS

SFPEW17201

XWG26

SFNU122MOl

SFNU122C01'

SFWE010

SFPEN3302

SFPEW9601

SFCZV8801

SFPEV9801

SFK0135-01

SFPZB3501

SFHP122MOl

SFHP122COl

SFHH122-01

SFHH122-02

SFHD122-01

SFHD122-02

SFHD122-03

SFYH60X60

SFYH40X45

Part

Name&Description

Phono

Cord

Phono

Cord

GroundWire

ArmRest

Arm

Base

Ring,

ng,

Arm

Base Operation

Arm

Anti-skate

45

Cartridge

Cartridge

Cartridge

Cartridge

Gauge

Weight

Front

Rear

Top

(A),

Turntable

(B),

Turntable

Book

Book

r.p.m

Base

Force

Control

.

Turntable Unit

Bracket,

Knob,

Screw

Screw

Screw

Screw

Screw

Washer

Circlip

Circlip

Circlip

Washer

Screw

Screw

Washer

Screw

Washer

Washer

Washer

Washer

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Washer

Circlip

O

Ring

Screw

Screw

Washer

Washer

Washer

Screw

Circlip

Screw

Screw

Washer

Screw

Screw

Screw

Washer

Washer

Instruction

Instruction

Adaptor,

Nut,

Washer,

Screw,

Screw,

Overhang

Shell

Carton

Carton

Pad,

Pad,

Pad,

Pad,

Pad,

Polyethylene Cover,

Dust Cover

Polyehtylene Cover, Turntable

and

Page 20

EXPLODED

VIEWS

20

PrintedinJapan

Loading...

Loading...