Page 1

ORDERNO.AD9903091C1

Service Manual

Direct Drive Turntable System Turntable System

SL-1200M3D

Colour

(S)............Silver Type

Areas

(P)............ U.S.A.

(PC).......... Canada.

• Specifications

• General

Power supply:

Power consumption:

Dimensions (WxHxD):

Weight:

• Turntable section

Type:

Drive method:

Motor:

Turntable platter:

Turntable speeds:

Starting torque:

Build-upcharacteristics:

Braking system:

Wow and flutter:

Rumble:

AC 120V,60Hz

14W

453 x 162 x 353 mm

(17-27/32" x 6-12/32" x 13-29/32")

12 kg (26.4 lb.)

Quads direct drive

Manual turntable

Direct drive

Brushlees DC motor

Aluminum diecast

Diameter 332 mm (13-5/64")

Weight 1.7 kg (3.74 lb.)

33-1/3 rpm snd 45 rpm

1.5 kg-cm (1.3 Ib-in)

0.7s.ffrrom standstill to 33-1/3 rpm

Electronic brake

0.01% W.R.M.S."

0.025% W.R.M.S.(JIS C5521 )

±0.035% peak (IEC 98A Weighted)

-56 dB (IEC 98A Unweighted)

-78 dB (IEC 98A Weighted)

• Tonearm section

Type:

Effective lenghth:

Arm height adjustment

range:

Overhang:

Effective mass:

Offset angle:

Friction:

Tracking error angle:

Stylus pressure

adjustment range:

Applicable cartridge

weight range:

(with auxiliary weight);

(with shell weight);

Headshell weight:

Universal

230 mm (9-1/16")

0-6mm

15 mm (19/32")

12 g (without cartridge)

22°

Less than 7 mg (lateral, vertical)

Within 2032' (at the outer groove

of 30 cm <12"> record)

Within 0032' (at the inner groove

of 30 cm <:12">record)

0-4g

11- 20.5 g (including headshell)

9.5- 13g

17 -20.5 g (including headshell)

3.5 - 6.5 g

11- 14g (inaluding headshell)

7.5 g

*This rating refers to turntable assembly atone, excluding effects

of record, cartridge or tonearm, but including platterMeasured by

obtaining signal from built-in frequency generator of motor as

sembly.

/i,. WARNING

This serviGe information is designed for experienced _epair technicians only and is not designed for use by the general public. _tdoes not

contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to serwce or

repair the product or products dealt with in this service information by anyone else cou(d result in serious injury or death.

Technics °

Note:

Specifications are subject to change without notice.

Weight and dimensions are approximate.

© 1999 Matsushita Electric Industrial Co., Ltd.

All rights reserved Unauthorized copying

and distribution is a violation of law,

Page 2

SL-1200M3D J

• Contents Page

• Safety Precaution ..................................................... 2

• Accassorles ............................................................... 2

• Features ..................................................................... 3

• Controls ..................................................................... 3

• Preparation of the cartridge ..................................... 3

• Putting the player together ...................................... 4

• Connections and installation ................................... 5

• Preparatory adjustments ...................................... 6,7

• Playing records ......................................................... 8

• Adjustments while using the unit ............................ 9

• Maintenance ............................................................ 10

• Troubleshooting guide ........................................... 11

•Operation Checks and

Component Replacement Precedures ... 12-16

•Schematic Diagram .......................................... 17-19

•Printed Circuit Boards ...................................... 20-22

• Measurements and Adjustments ........................... 23

•Block Diagram ......................................................... 24

•Wiring Connection Diagram ................................... 25

• Repracement Parts List ..................................... 26,27

•Cabinet Parts Location ...................................... 28,29

• Packaging ................................................................ 30

Page

• Product service ....................................................... 10

• Safety Precaution (This "Safety Precaution" is applied only inU.S.A.)

1.Before servicing,unplug the power cordto prevent anelectric shock.

2. When replacing pads, use only maanufaacturer's recomended components for safety.

3. Check the COnditionof the power cord. Replace if wear or damage isevident.

4. After servicing, be sure to restore the lead dress,insulationbarriers, insulation papers, shields,etc.

5. Before returningthe serviced equipment to the customer,be sure to make the following insulation resistancetest to prevent the customer from

being exposed to a shock hazard.

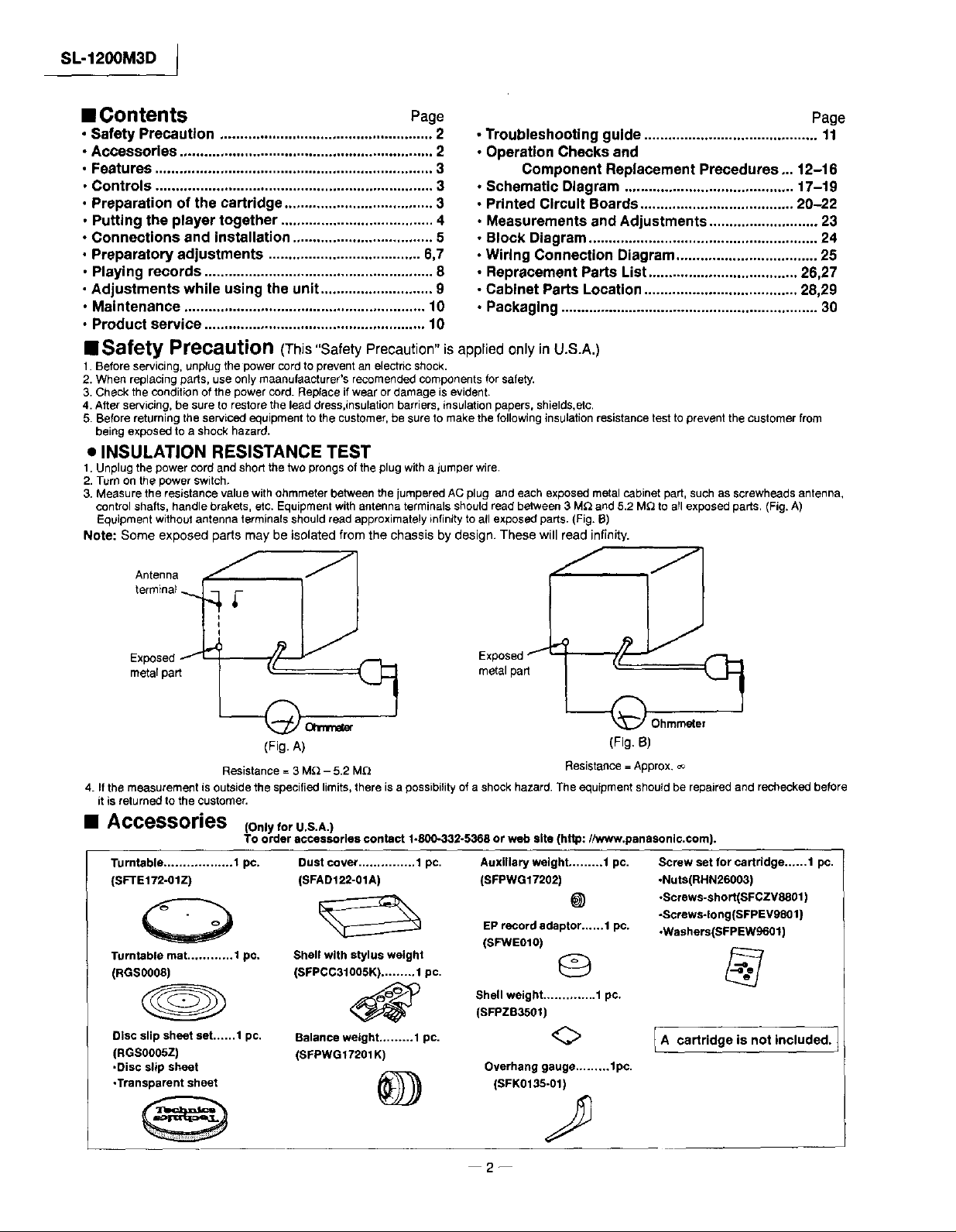

• INSULATION RESISTANCE TEST

1. Unplugthe power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value withohmmeter between the jumpered AC plug and each exposed metal cabinet pad, such as screwheads antenna,

controlshafts, handle brakets, etc. Equipmentwithantenna terminals shouldread between 3 MQ and 5.2 MQ to all exposed pads. (Fig. A)

Equipment withoutantenna terminals should read approximately infinityto all exposed pads. (Fig. B)

Note: Some exposed pads may be isolated from the chassis by design. These will read infinity.

Antenna J

terminal _

Ohmmeter

(Fig. A)

Resistance = 3 MQ - 5.2 M_

4. If the measurement is outside the specified limits, there is a possibilityofa shock hazard. The equipment should be repaired and rechecked before

it isreturned to the customer.

(Fig. B)

Resistance= Approx. o_

Accessories (onlyforU.S.A.)

TOorder accessories contact 1.800-332-5368 or web site (http://www.panasonlc.com).

Turntable .................. 1 pc.

(SFTE172-OIZ)

0

Turntable mat ............ t pc,

(RGS0OOS)

Disc slip sheet set......1 pc.

(RGS0005Z)

•Disc slip sheet

•Transparent sheet

Dust cover ............... 1 pc.

(SFADI22-OIA)

Shell with stylus weight

(SFPCC31005K) ......... 1 pc.

Balance weight ......... 1 pc.

(SFPWG17201 K)

@

Auxiliary weight ......... t pc.

(SFPWG17202)

@

EP record adaptor......1 pc.

(SFWE0t0)

Shell weight .............. 1 pc.

(SFPZB3501)

<>

Overhang gauge ......... 1pc.

(SFK0135-01)

Screw set for cartridge..,...1 pc.

.Nuts(RHN26003)

•Screws-short(SFCZV8801 )

•Screws-long(SFPEVg801 )

-Washers(SFPEW9601)

I A cartridge is not included. 1

2--

Page 3

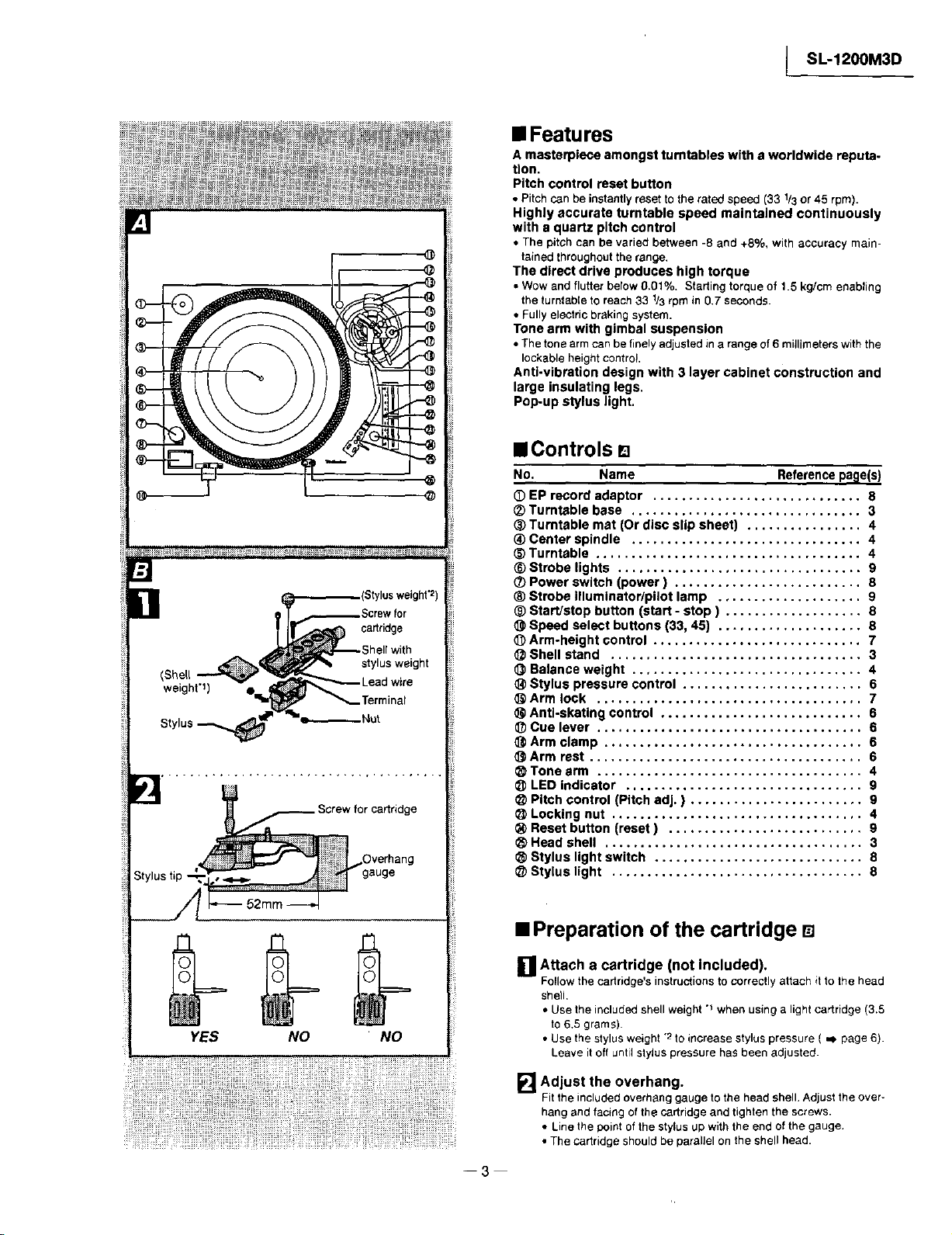

(Shell

weight'l)

Stylus

@

@

--@

/-@

--@

(Stylusweight"2)

cartridge

stylus weight

gauge

I SL-1200M3D

• Featu res

A masterpiece amongst turntables with a worldwide reputa-

tion.

Pitch control reset button

• Pitchcan beinstantlyresettothe rated speed(33 1/3 or 45 rpm).

Highly accurate turntable speed maintained continuously

with a quartz pitch control

• The pitchcanbe variedbetween-8 and+8%, withaccuracymain-

tainedthroughouttherange.

The direct drive produces high torque

• Wowand flutterbelow0.01%. Starting torqueof 1.5 kg/cmenabting

theturntableto reach33 1/3rpm in 0.7seconds.

• Fullyelectricbrakingsystem.

Tone arm with gimbal suspension

• Thetonearmcanbefinelyadjustedina rangeof 6 millimeterswiththe

Iockableheightcontrol

Anti-vibration design with 3 layer cabinet construction and

large insulating legs.

Pop-up stylus light.

• Controls []

No. Name Referenceparle(s)

(DEP record adaptor ............................. 8

_) Turntable base ................................ 3

_) Turntable mat (Or disc slip sheet) ................ 4

_) Center spindle ................................ 4

_) Turntable ..................................... 4

® Strobe lights .................................. 9

(_ Power switch (power) .......................... 8

_) Strobe illuminator/pilot lamp .................... 9

® Start/stop button (start - stop ) ................... 8

Speed select buttons (33, 45) .................... 8

Arm-height control ............................. 7

Shell stand ................................... 3

O Balance weight ................................ 4

@ Stylus pressure control ......................... 6

Arm lock ..................................... 7

Anti-skating control ............................ 6

_) Cue lever ..................................... 6

Arm clamp .................................... 6

(_ Arm rest ...................................... 6

Tone arm ..................................... 4

LED indicator ................................. 9

Pitch control (Pitch adj. ) ........................ 9

Locking nut ................................... 4

Reset button (reset) ........................... 9

Head shell .................................... 3

Stylus light switch ............................. 8

@ Stylus light ................................... 8

YES NO NO

• Preparation of the cartridge D

[] Attach a cartridge (not included).

Follow the cartridge's instructions to correctly attach Stto the head

shell,

• Use the included shell weight "_ when using a light cartridge (3.5

to6.5 grams).

• Usethestylusweight-2toincreasestyluspressure( ,,_page 6).

Leaveit oftuntilstylus pressurehasbeenadjusted.

[] Adjust the overhang.

Fit the included overhang gauge to the head shell.Adjust the over-

hang and facing of the cartridge and tighten the screws.

• Line the point of the stylus up with the end of the gauge,

• The cartridge should be parallel on the shell head.

--3--

Page 4

SL-1200M3D J

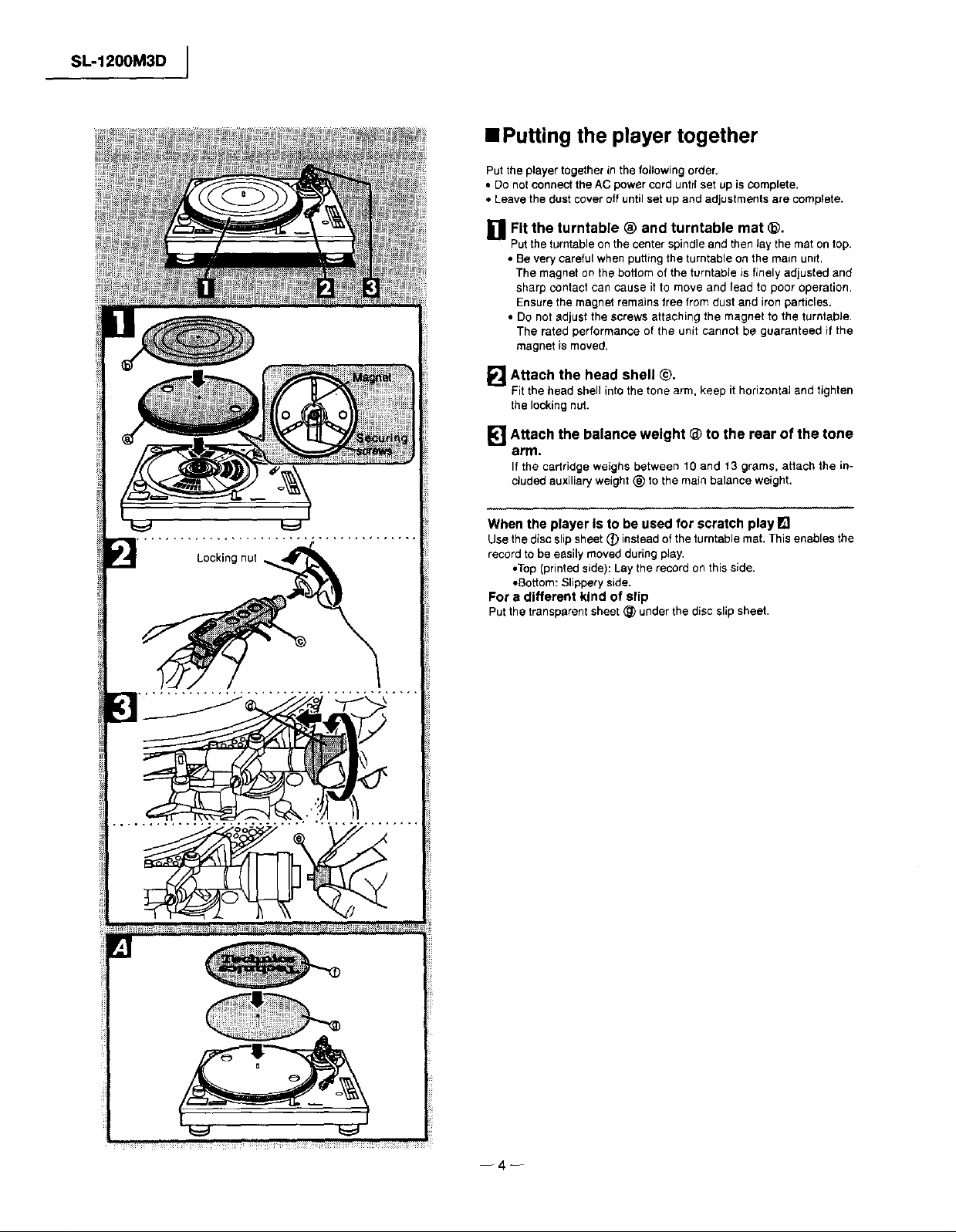

• Putting the player together

Put the player together in the following order.

• Do not connect the AC power cord until set up is complete.

• Leave the dust cover off until set up and adjustments are complete.

ill Fit the turntable ® and turntable mat @.

Putthe turntable on the center spindleand then Jaythe mat on top.

• Be very careful when putting the turntable on the main unit.

The magnet on the bottom of the turntable is finely adjusted and

sharp contact can cause it to move and lead to poor operation.

Ensure the magnet remains free from dust and iron particles.

• Do not adjust the screws attaching the magnet to the turntable.

The rated performance of the unit cannot be guaranteed if the

magnet is moved.

[] Attach the head shell @.

Fittheheadshellintothetonearm,keep it horizontalandtighten

thelockingnut.

[_"] Attach the balance weight @ to the rear of the tone

arm.

If thecartridge weighsbetween 10and 13 grams, attachthe in-

cludedauxiliaryweight_) tothemainbalanceweight.

ill ...... ii i_uH

When the player Is to be used for scratch play IE]

Use the disc slipsheet _) instead of the turntable mat. This enables the

record to be easily moved during play,

•Top (printedside): Lay the record on this side.

•Bottom: Slippery side,

For a different kind of slip

Putthe transparent sheet @ under the disc slip sheet,

--4--

Page 5

I SL-1200M3D

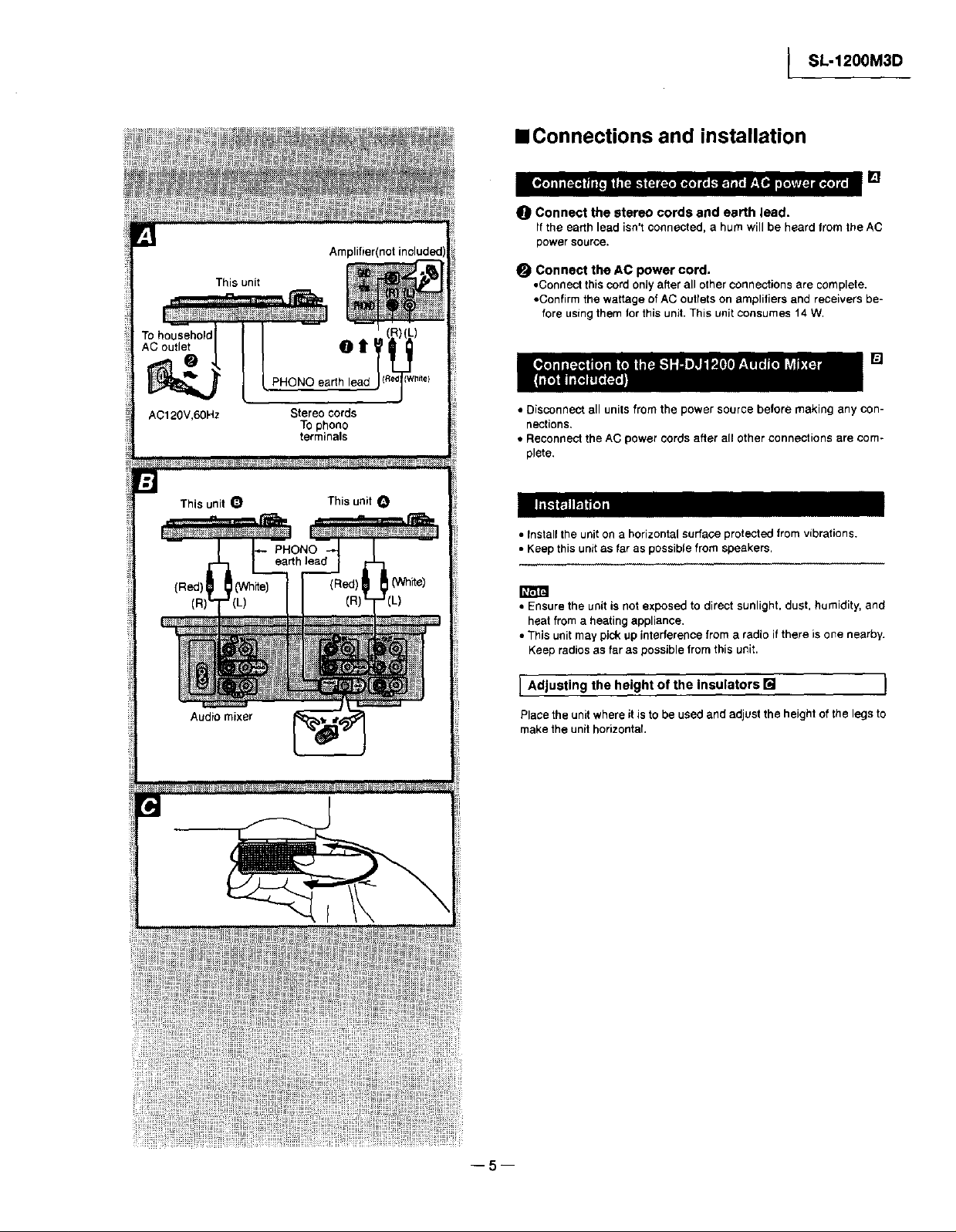

• Connections and installation

0 Connect the stereo cords and earth lead.

If the earth lead isn't connected, a hum will be heard from the AC

power source.

This unit

To household

AC outlet O l

AC120V,60Hz Stereo cords

This unit O This unit O

, N

_" _ (Whffe)_ r _(Red) 6 _ (White)

To phono

terminals

earth lead

'"")(°)-25!...........11 ,.,-°,L,

9

? _N Nk

Audio mixer I

Connect the AC power cord.

• Connect this cord onlyafter all other connections are complete.

• Confirm the wattage of AC outlets on amplifiers and receivers be-

fore using them for this unit. This unit consumes 14 W.

[]

• Disconnect all units from the power source before making any con-

nections.

• Reconnect the AC power cords after all other connections are com-

plete.

[_

• Install the unit on a horizontal surtaoe protected from vibrations.

• Keep this unit as far as possible from speakers.

• Ensure the unit is not exposed to direct sunlight, dust, humidity, and

heat from a heatingappliance.

• This unit may pick up interference from a radio if there is one nearby.

Keep radios as far as possible from this unit.

] Adjusting the height of the insulators [] I

Place the unit where it is to be used and adjust the height of the legs to

make the unit horizontal,

Page 6

SL-1200M3D I

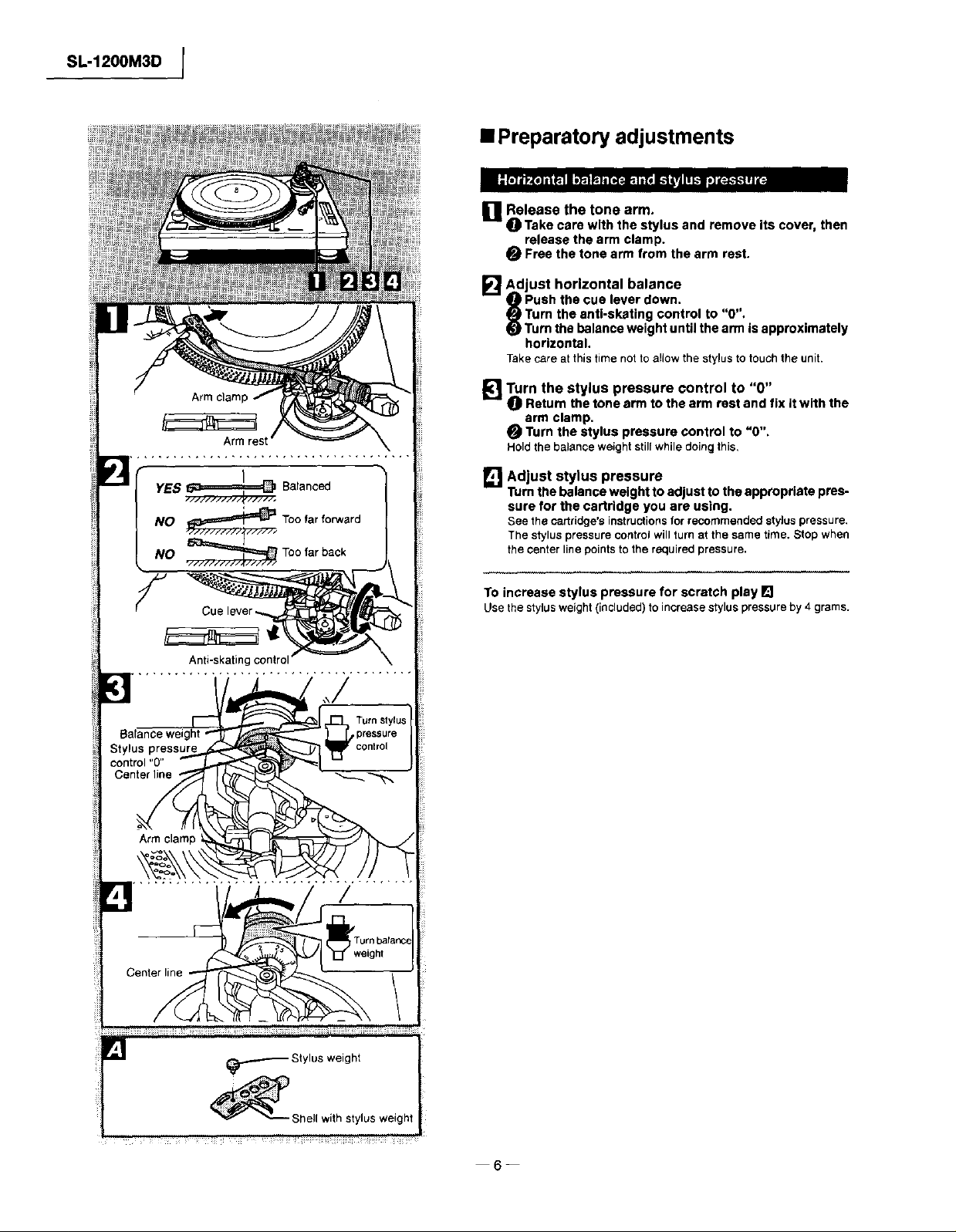

• Preparatory adjustments

i'_Release the tone arm.

O Take care with the stylus and removeits cover, then

release the arm clamp.

O Free the tone arm fromthe armrest.

_'_1Adjust horizontal balance

9 Push the cue lever down.

_P_Turn the anti-skating control to "0",

(fJ)Turn the balance weight until the arm is approximately

horizontal.

Takecareatthistime notto allowthe stylus totouch theunit.

Armclam

Armrest

, . ,

YES 6_======_ Balanced

,,/#///'/,,'///_/#/#/,

NO _ Too far forward

NO _ Toofarback

./#////-////,r/..-//-#/

F

Anti-skatingco

[]Turn the stylus pressure control to "0"

Return the tone arm to the arm rest and fix it with the

arm clamp.

Turn the stylus pressure control to "0",

Holdthebalanceweightstillwhiledoingthis,

[] Adjust stylus pressure

Turnthebalanceweightto adjustto theappropriatepres-

sure for the cartridge you are using.

See the cartridge's instructionsfor recommended stylus pressure.

The stylus pressure contrctwill turn at the same time. Stop when

the center linepoints to the required pressure.

To increase stylus pressure for scratch play []

Usethestylusweight(included)toincreasestyluspressureby4 grams.

Armclamp

/

Page 7

[_ ;._Released_ i_d i

I SL-1200M3D

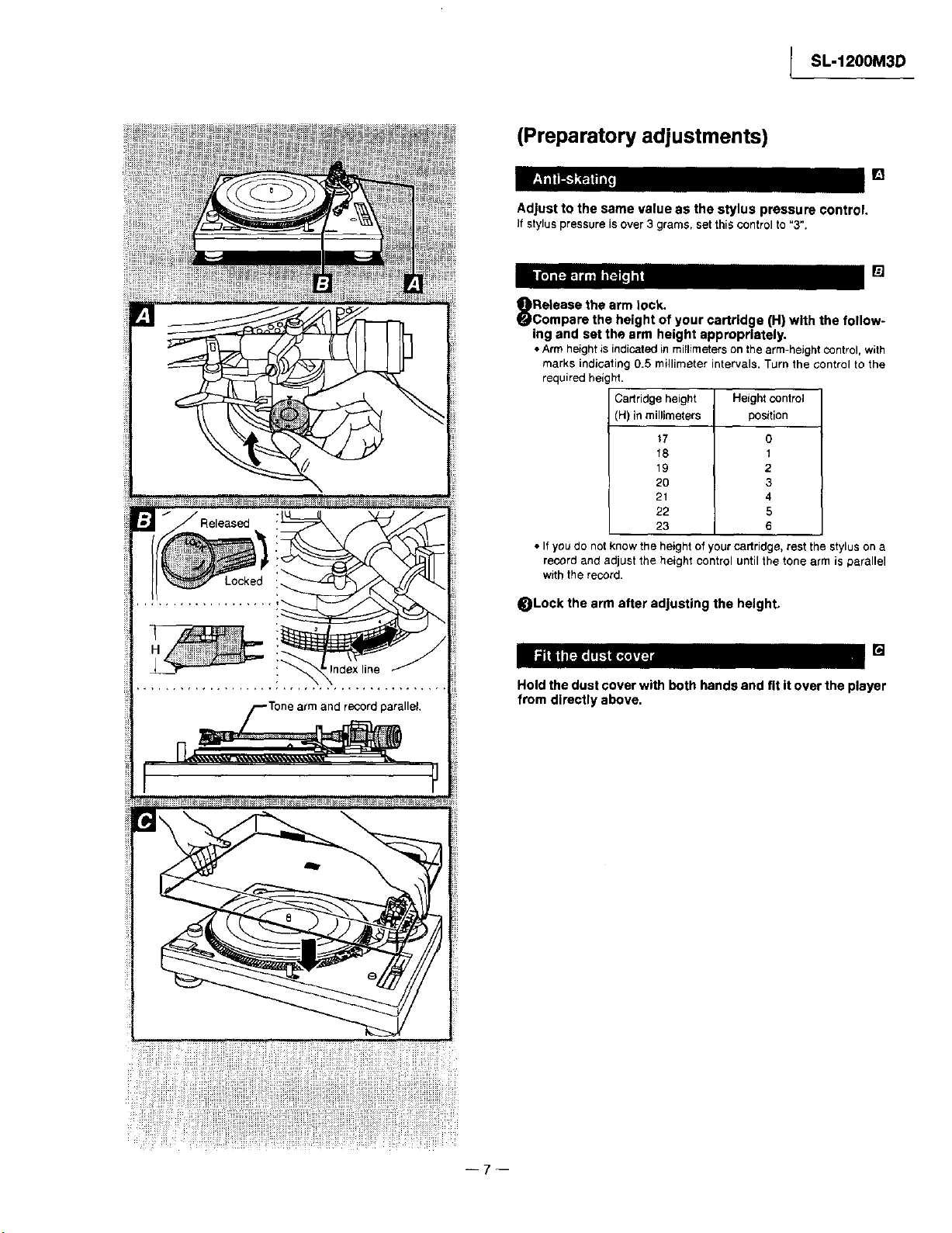

(Preparatory adjustments)

, o J I_

Adjust to the same value as the stylus pressure control.

Ifstyluspressureisover3 grams,setthiscontrolto"3".

• - o - • _']

Release the arm lock.

Compare the height of your cartridge (H) with the follow-

ing and set the arm height appropriately.

• Arm heightis indicatedin millimeters on the arm-height control,with

marks indicating 0.5 millimeter intervals, Turn the control to the

required height.

Cartridge height

(H) in millimeters

t7

18

19

2O

21

22

23

• If you do not know the height of your cartridge, rest the stylus on a

record and adjust the height control until the tone arm is parallel

with the record.

Height control

position

0

1

2

3

4

5

6

_Lock the arm after adjusting the height.

• • • o []

Hold the dust cover with both hands and fit itover the player

from directly above,

--7 1

Page 8

SL-1200M3D J

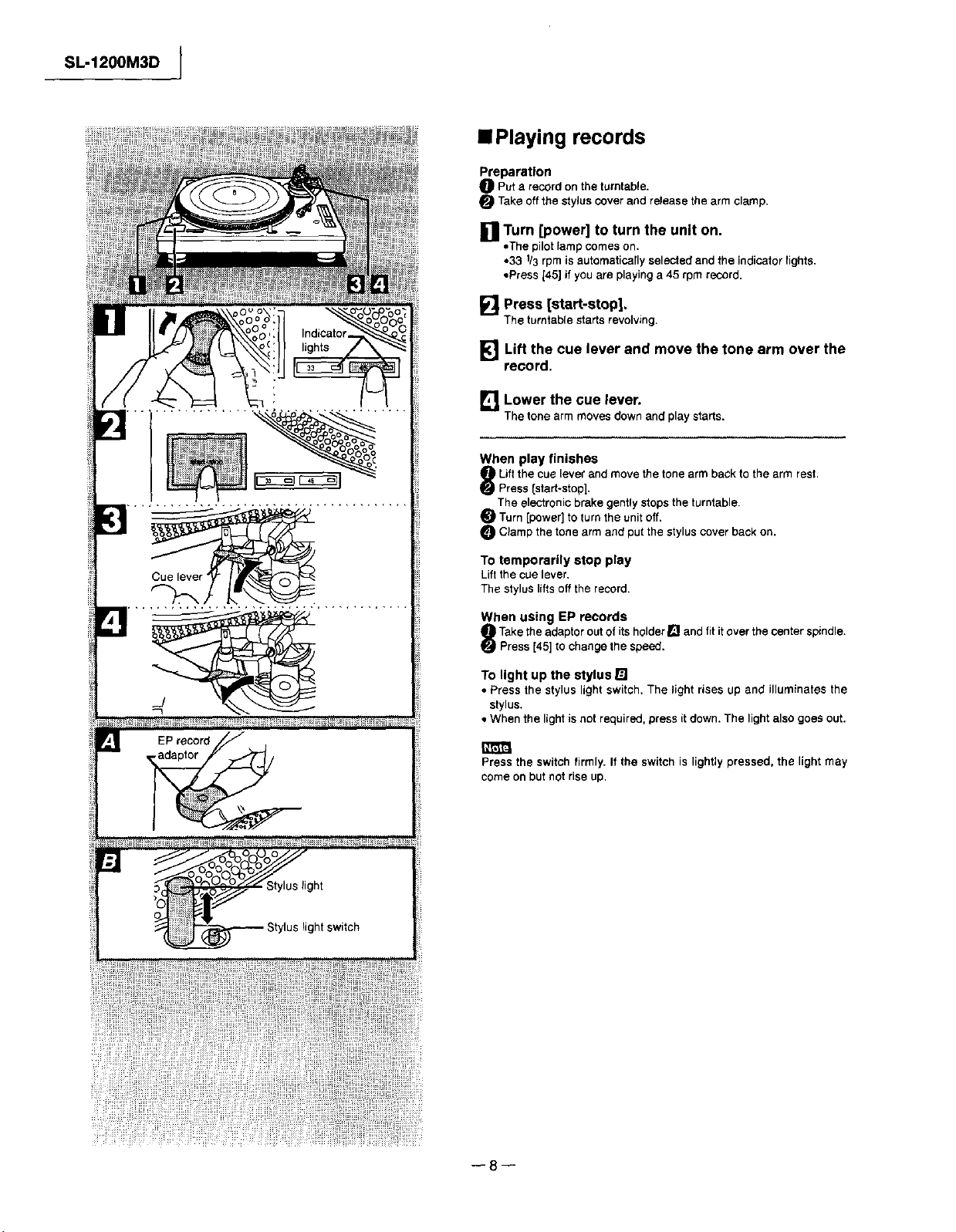

==Playing records

Preparation

Put a record on the turntable.

Take off the stylus cover and release the arm clamp.

[] Turn [power] to turn the unit on.

•The pilot _ampcomes on.

• 33 1/3rpm is automatically selected and the indicator lights.

• Press 145]if you are playing a 45 rpm record.

[] Press [start-stop].

Theturntablestartsrevolving,

_] Lift the cue lever and move the tone arm over the

record.

LK1Lower the cue lever.

Thetonearmmovesdownandplaystarts.

When play finishes

! Liftthe cue lever end move the tone arm back tothe arm rest.

I Press [start-stop].

The electronic brake gently stops the turntable,

Turn [power]to turn the unitoff.

C_ampthe tone arm and put the styluscover back on.

] EP record

adaptor

To temporarily stop play

Lift the cue lever,

The stylus liftsoff the record.

When using EP records

Takethe adaptor out of itsholder[] and fit itover the center spindle.

Press [45] to change the speed.

To light up the stylus []

• Press the stylus light switch, The light rises up and illuminates the

stylus,

• When the light is not required, press it down, The light also goes out.

Press the switch firmly. If the switch is lightly pressed, the light may

come on but not rise up.

o _oo

_ght

os,ohtswtch

--8--

Page 9

[] I ........

_-- LED indicator

-- Reset button

oo o o\ Strobe illuminator

oO° o

SL-1200M3D

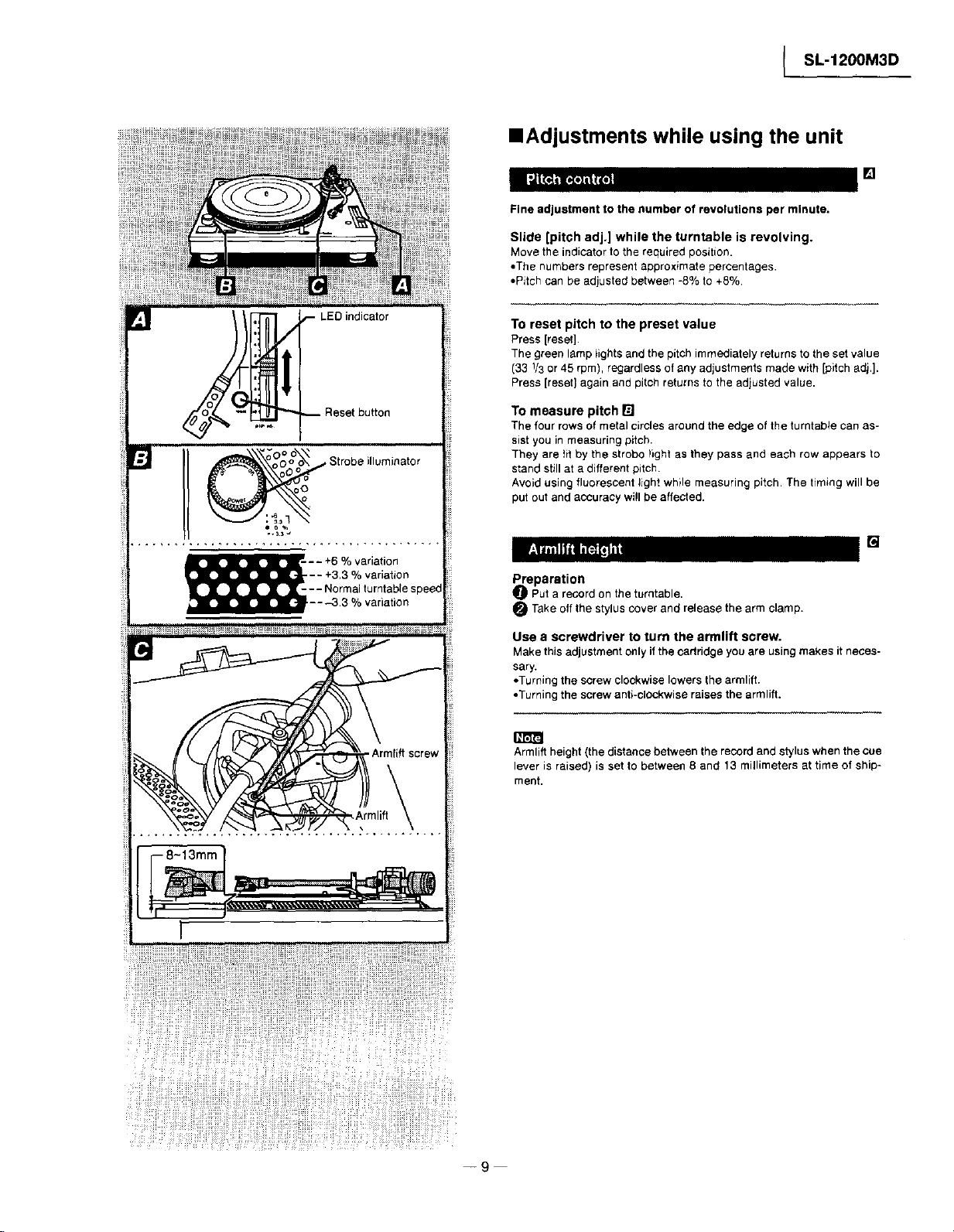

==Adjustments while using the unit

Fine adjustment to the number of revolutions per minute.

Slide [pitch adj.] while the turntable is revolving.

Move the indicator tothe required position.

•The numbers represent approx+mate percentages.

•Pitch can be adjusted between -8% to +8%

To reset pitch to the preset value

Press [reset].

The green lamp _ights and the pitch immediately returns to the set value

(33 1/3or 45 rpm), regardless of any adjustments made with [pitchadj.].

Press [reset] again and pitch returns tothe adjusted value.

To measure pitch

The four rows ofmetal circles around the edge of the turntable can as-

sist you in measuring pitch.

They are fit by the strobo llght as they pass and each row appears to

stand still at a differentpitch.

Avoid usingfluorescent tight while measuring pitch. The timing will be

put out and accuracy wi!l be affected.

-- +3.3 % variation

,__-- - +6 % variation

--- Normal turntablespeed

---3.3 % variation

• . • []

Preparation

_]_ Put a record on the turntable.

O Take off the stylus cover and release the arm clamp.

Use a screwdriver to turn the armlift screw.

Make this adjustmentonly if the cartridge you are using makes itneces-

sary.

• Turning the screw clockwise lowers the armlift.

• Turning the screw anti-ctockwise raises the armliff.

Armlift height (the distance between the record and styluswhen the cue

lever is raised) is set to between 8 and 13 millimeters at time of ship-

ment.

--9

Page 10

SL-1200M3D I

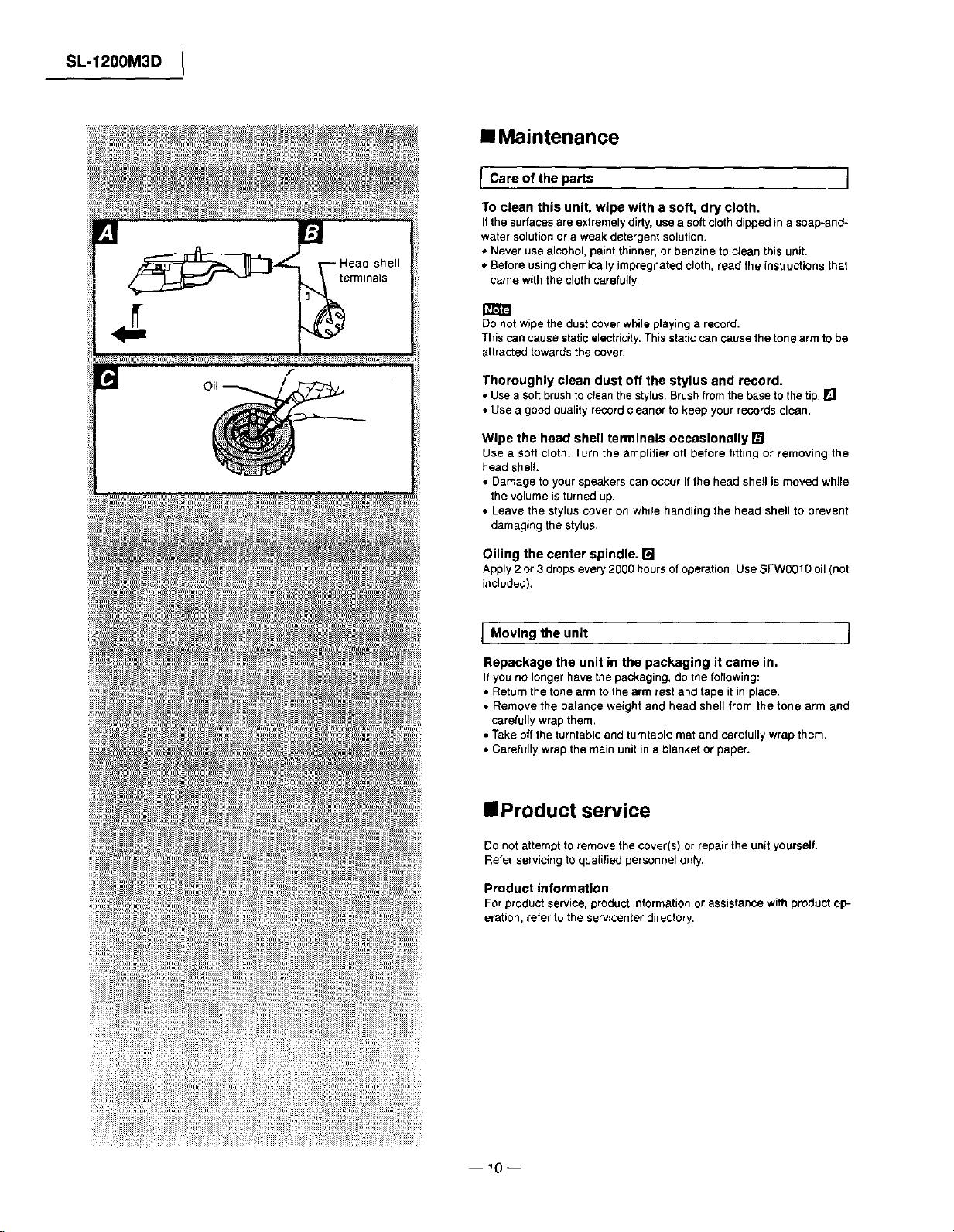

• Maintenance

I Care of the parts I

To clean this unit, wipe with a soft, dry cloth.

If the surfaces are extremely dirty, usea soft clothdipped ina soap-and-

water solution ora weak detergent solution.

• Never use alcohol, paint thinner,or benzine to clean this unit.

• Before using chemically impregnated cloth, read the instructions that

came withthe cloth carefully.

Do not wipe the dust cover while playing a record.

This can cause static electricity. This staticcan cause the tone arm to be

attracted towards the cover.

Thoroughly clean dust off the stylus and record.

• Use a softbrush to clean the stylus.Brushfrom the base to the tip. []

• Use a good quality record cleaner to keep your records clean.

Wipe the head shell terminals occasionally []

Use a soft cloth. Turn the amplifier off before fitting or removing the

head shell.

• Damage to your speakers can occur if the head shell is moved while

the volume is turned up.

• Leave the stylus cover on while handling the head shell to prevent

damaging the stylus.

Oiling the center spindle. []

Apply2 or 3 dropsevery 2000 hoursof operation. Use SFW0O10 oil (not

included).

Moving the unit ]

Repackage the unit in the packaging it came in.

If you no longer have the packaging, do the following:

• Return the tone arm to the arm rest and tape itin place.

• Remove the balance weight and head shell from the tone arm and

carefully wrap them,

• Take off the turntable and turntable mat and carefullywrap them.

• Carefully wrap the main unit in a blanket or paper.

• Product service

Do not attempt to remove the cover(s) or repair the unit yourself.

Refer servicing to quaIified personnel only.

Product information

For productservice, product informationor assistance with product oP-

eration, refer to the servicenter directory,

10--

Page 11

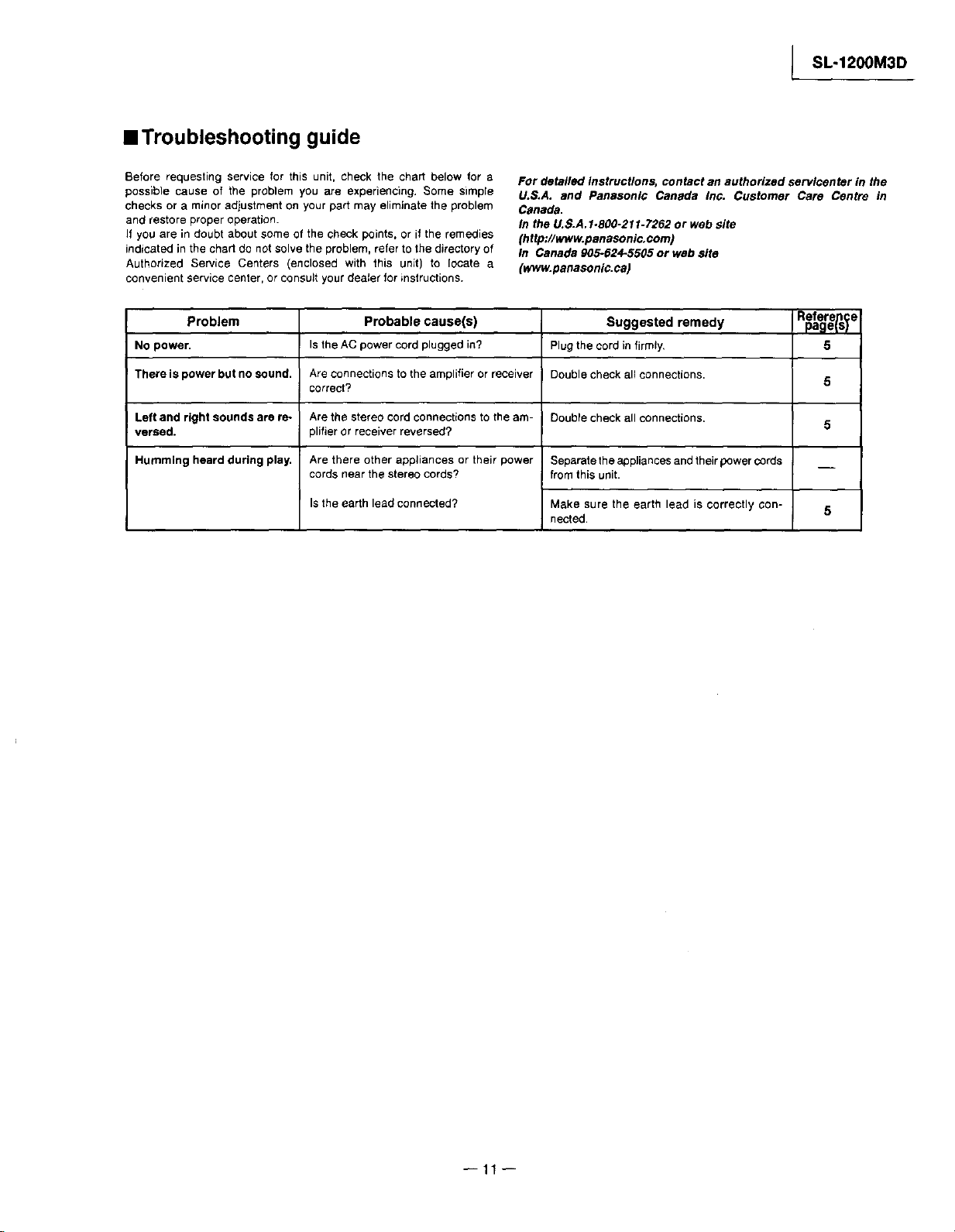

==Troubleshooting guide

l SL-1200M3D

Before requesting service for this unit, check the chart below for a

possible cause of the problem you are experiencing. Some simple

cheeks or a minor adjustment on your part may eliminate the problem

and restore proper operation.

If you are in doubt about some of the check points, or if the remedies

indicated in the chart do not solve the problem, refer to the directory of

Authorized Service Centers (enclosed with this unit) to locate a

convenient service center, or consult your dealer for instructions.

Problem Probable cause(s) Suggested remedy

No power.

There is power but no sound.

Left and right sounds are re-

versed.

Humming heard during play.

Is the AC power cord plugged in?

Are connections to the amplifier or receiver

correct?

Are the stereo cord connections to the am-

plifier or receiver reversed?

Are there other appliances or their power

cords near the stereo cords?

Isthe earth lead connected?

For detailed instructions, contact an authorized servlcenter in the

U.S.A. and Panasoni_ Canada Inc. Customer Care Centre in

Canada.

In the U.S.A. 1.800-211-7262 or web site

(http://www.panasonic, com)

In Canada 905-624-5505 or web site

(www.panasonic, ca)

Reference

page_st

Plug the cord in firmly.

Double check all connections.

Double check all connections.

Separate the appliances andtheir p_wer cords

from this unit.

Make sure the earth lead is correctly con-

nected.

5

5

5

5

11

Page 12

SL-1200M3D I

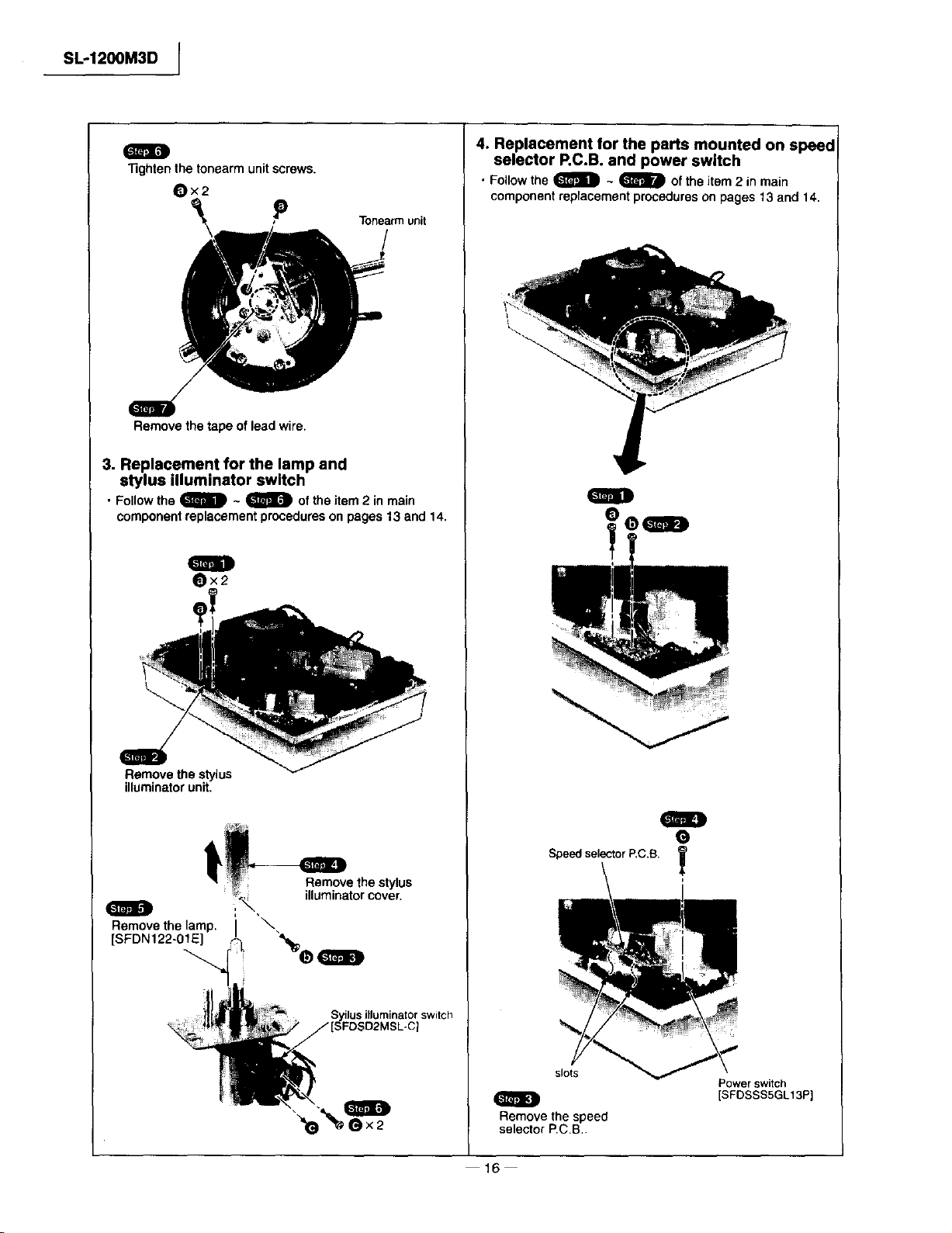

• Operation Checks and Component Replacement Procedures

m l. This section describes procedures for checking the operation of the major printed circuit

boards and replacing the main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures,

Special reassembly procedures are described only when required.

3. Select item from the following index when checks or replacement are required.

• Contents

• Checking Procedures for each P.C.B. Page.

l. Checking for the drivecontrolF_C,B.and power supplyP.C.B_ . .................... 12.

• Main Component Replacement Procedures

1. Replacementfor the drive coil ass'y and FG coilass'y. ......................... 13,

2. Replacementfor the tonearm unit. • ............................... 13-16.

3. Replacementfor the lamp and stylusilluminatorswitch. • ....................... 16.

4. Replacementfor the parts mountedonspeed selector P,C.B. and powerswitch.• ............. 16.

• Checking Procedures for each P.C.B,

1. Checking for the drive control P.C.B. and

Power supply P.C.B.

Remove the turntable mat and turntable ass'y.

t1"

Tonearm ass'y

Remove the panel

• Check the drive control P,C.B. and power

supply P.C.B, as shown below.

Powersupply P.C.B.

Drive control P.C.B

1. The tonearm ass'y should be supported by arm rest.

2, Take care not to stick the dust or iron powder to the

magnet attached to back inner side of turn table.

--12

Page 13

• Main Component Replacement

Procedures

1. Replacement for the drive coil ass'y and

FG coil ass'y

• Follow the _ - _ of the item 1 in checking

procedure for each P.C.B. on page 12.

_i',= i Remove the

/_!),_ ! spacer.

Claws

_ ._Release the _ claws,

_N-_)_/ ana-th;n remove the

I

drive coil cover.

Drive coilass'y

[SFMG520-31A]

FG coil ass'y

[SFMZ172-01 El

I SL-1200M3D

Connector

(CN103)

Conne_or

(CN101)

m

Remove the 3 connectors.

Removal of the connector

• Release the claws,and then

pulloutthe connector.

Remove the drive

controlP.C.B..

Connector

(CN102)

2. Replacement for the tonearm unit

• Follow the _D of the item 1 in checking procedure

for each P,C.B. on page 12,

Upset the unit, and then put the dust cover.

Turn the insulatorsin the directionof arrow,and then

removethem (4 points).

Insulator

Q

Insulator

¢Dx6

Insulator _'

Unsolder the terminals of

FG coil ass'y (4 points).

Unsolder the terminals of

drive coil ass'y (18 points).

13 +

Unit

Dust cover

I_[ol] =

Use the soft cloth under the unit to prevent

damage the dust cover when servicing.

Page 14

SL-1200M3D I

Remove the bottom

cover (A) ass'y.

Tonearrn ass'y Cabinet ass'y

a

°i°

Dust cover Separatethe dust cover and

the cabinetass'y,and then

removethetonearm ass'y.

Remove the bottom

cover (B) ass'y,

Remove the arm

basecoverplate.

Claws Phonocordclamper

Hold the tonearm with hand when

removing the 3 screws (0),

P ono cord spacer

Remove the lug terminal,

Release the 2 claws, and thenremove the phono

cord clamperand phonocordspacer.

14 w

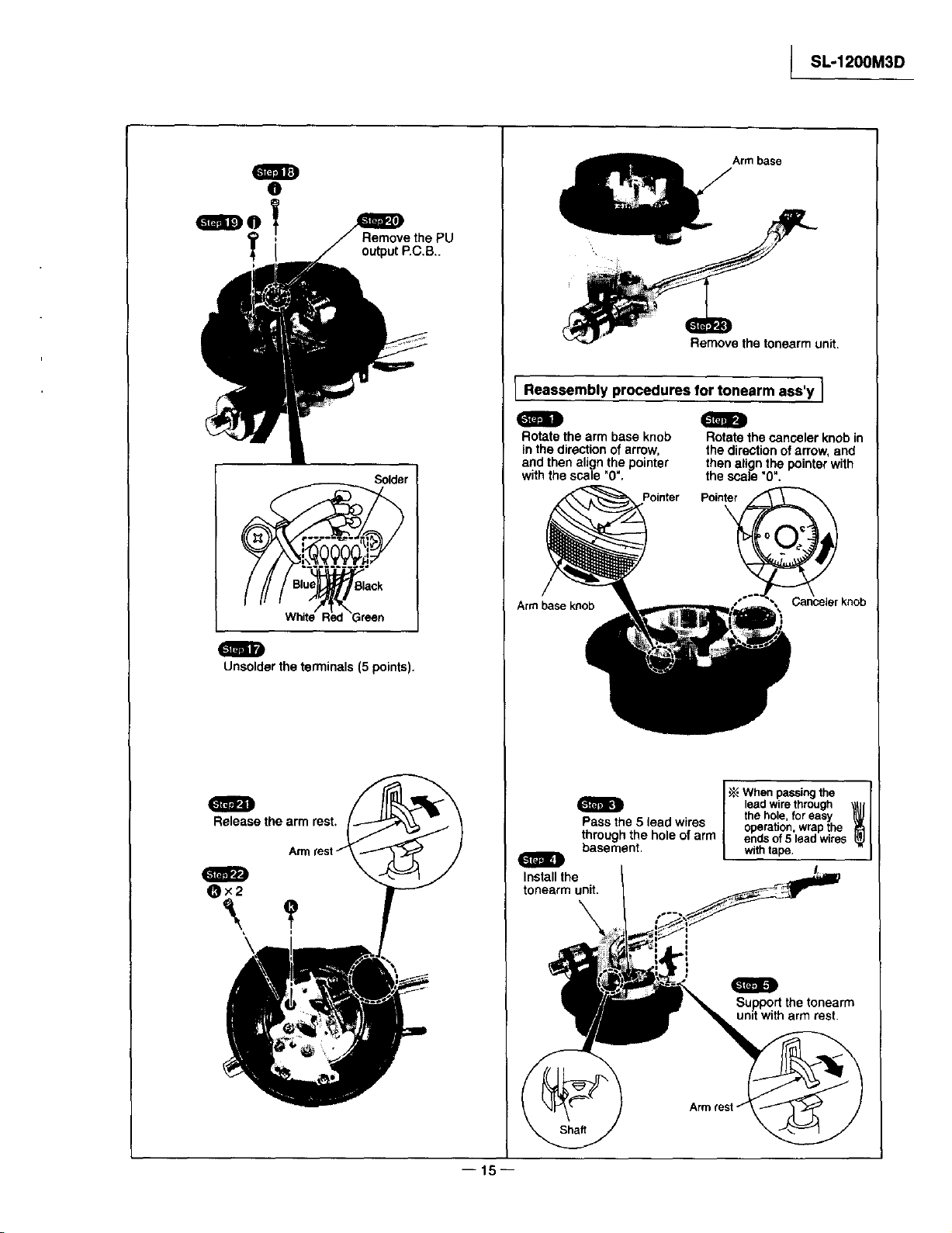

Page 15

O

Remove the PU

outputP.C,B,.

Solder

Arm base

Remove the tonearm unit.

Reassembly procedures for tonearm ass'y I

/

Rotate the arm base knob

in the directionof arrow,

and then align the pointer

withthe scale "0",

Pointer Pointer

Rotatethe canceler knob in

the directionof arrow,and

thenatignthe pointerwith

the scale _0".

SL-1200M3D

White Red Green

Unsoldarthe terminals (5 points).

I

Release the arm rest.

Arm base knob

Pass the 5 lead wires I oneration wran the

through the hole of arm e_ds of 5'lead_virss

basement, with tape.

Install the

tonearm unit.

\

When passingthe ,,,,,

, the hole, for easy

lead wirethrough

Supportthe tonearm

unit witharm rest.

I16h

Page 16

SL-1200M3D [

!

"13ghten the tonearm unit screws.

Ox2

P Tonearmunit

Remove the tape of lead wire.

3. Replacement for the lamp and

stylus illuminator switch

• Follow the _ ~ _ of the item 2 in main

component replacement procedures on pages 13 end 14.

mll

Ox2

4. Replacement for the parts mounted on speed

selector P.C.B. and power switch

• Follow the _D ~ _ Of the item 2 in main

component replacement procedures on pages 13 and 14.

!

Remove the stylus

illuminatorunit.

t

_',._ illuminator cover.

n

Remove the lamp.

[SFDN122-01E] "%h,..

"e

Remove the stylus

Syilus illuminator switch

Speed selector P,C.B.

slots

Remove the speed

selector P.CB,

16

m

Power switch

[SFOSSSSGL13P}

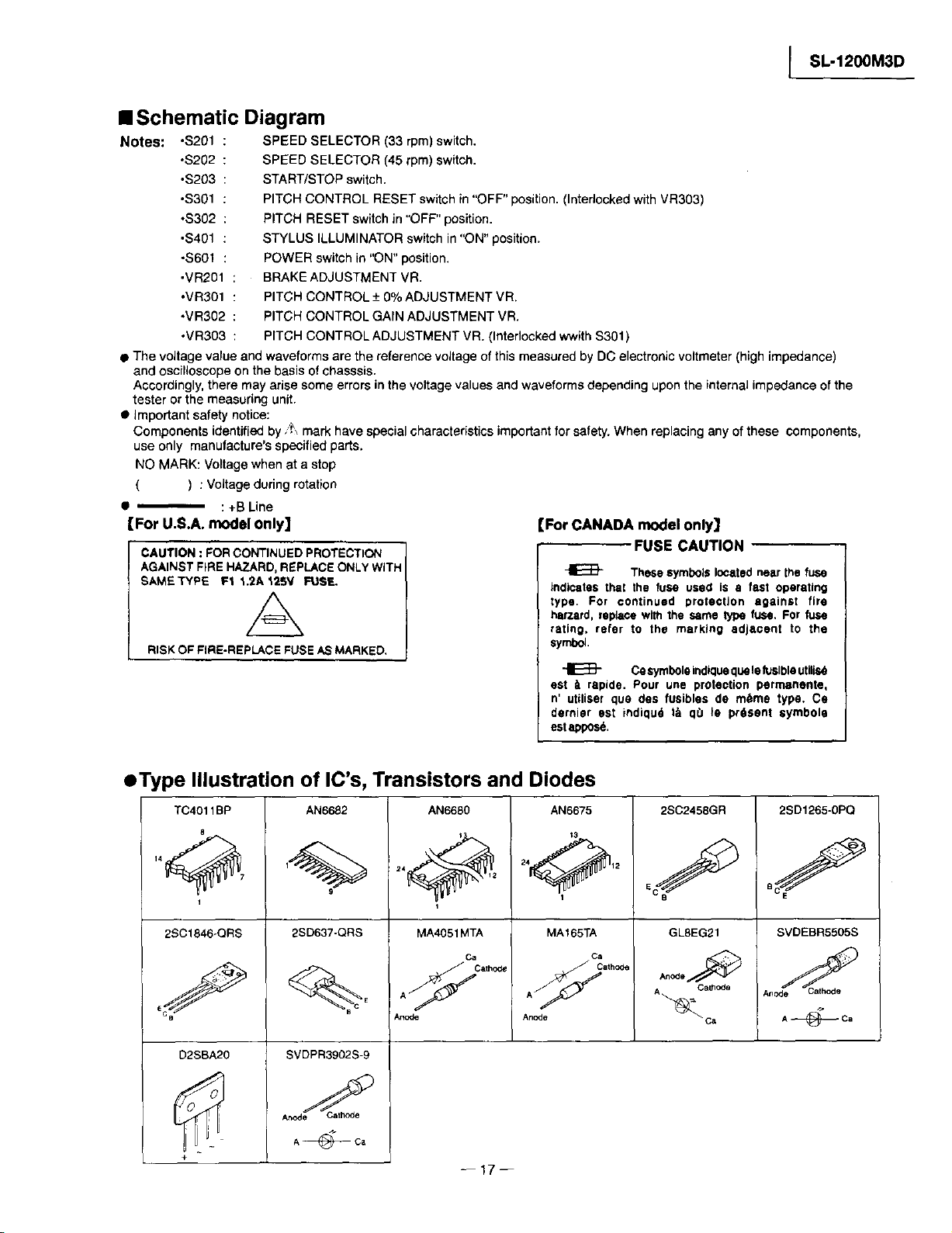

Page 17

I SL-1200M3D

• Schematic Diagram

Notes: ,S201

• The voffage value and waveforms are the reference voltage of this measured by DC electronic voltmeter (high impedance)

and oscilloscope onthe basis of chasssis.

Accordingly, there may arise some errors in the voltage values and waveforms depending upon the internal impedance of the

tester or the measuring unit.

• important safety notice:

Components identified by ,_ mark have special characteristics important for safety. When replacing any of these components,

use only manufacture's specified parts.

NO MARK: Voltage when at a stop

For U.S.A. model only]

CAUTION: FORCONTINUEDPROTECTION

AGAINSTFIREHAZARD,REPLACEONLYWITH

SAM_TYPE FI 1.2A125V FUSE.

RISK OF FIRE-REPLACE FUSE AS MARKED,

: SPEED SELECTOR (33 rpm) switch.

,$202

: SPEED SELECTOR (45 rpm) switch.

.S203

: START/STOP switch.

,S301

: PITCH CONTROL RESET switch in "OFF" position. (Interlocked with VR303)

*$302

: PITCH RESET switch in "OFF" position.

,S401

: STYLUS ILLUMINATOR switch in "ON" position.

,S601

: POWER switch in "ON" position.

.VR201

: BRAKE ADJUSTMENT VR.

•VR301 : PITCH CONTROL + 0% ADJUSTMENT VR.

,VR302 : PITCH CONTROL GAIN ADJUSTMENT VR.

•VR303 : PITCH CONTROL ADJUSTMENT VR. (Interlocked wwith $301)

) : Voltage during rotation

: +BLine

[For CANADA model only]

indicates thai the fuse used is a fast operating

type, For continued protection against fire

harzard, replace with the same _ fuse. For fuse

rating, refer to the marking adjacent to the

symbol.

est _1rapide. Pour une protection parrrmnente,

n' utiliser qua des fusibles do m_me type. Co

dernier est indiqud t_ q0 le pr6sent eymbola

est appos6.

FUSE CAUTION

These symbols located near the fuse

Cesymbole indiquaquale luslble utilisd

• Type Illustration of IC's, Transistors and Diodes

TC4011BP

8

1

2SC1846-QRS

D2SBA20

+

AN6682

9

2SD637-QRS

SVDPR3902S-9

A@Ca

24_ 2

C

AN6680

MA4051 MTA

Ca

A _ cath_

--17--

AN6675

t3

24_ 12

1

MA165TA

A _ath_

Anode

2SC2458GR

GL8EG21

ca

An °de

CalhOde

A_C a

2SD1265-0PQ

SVDEBR5505S

A@Ca

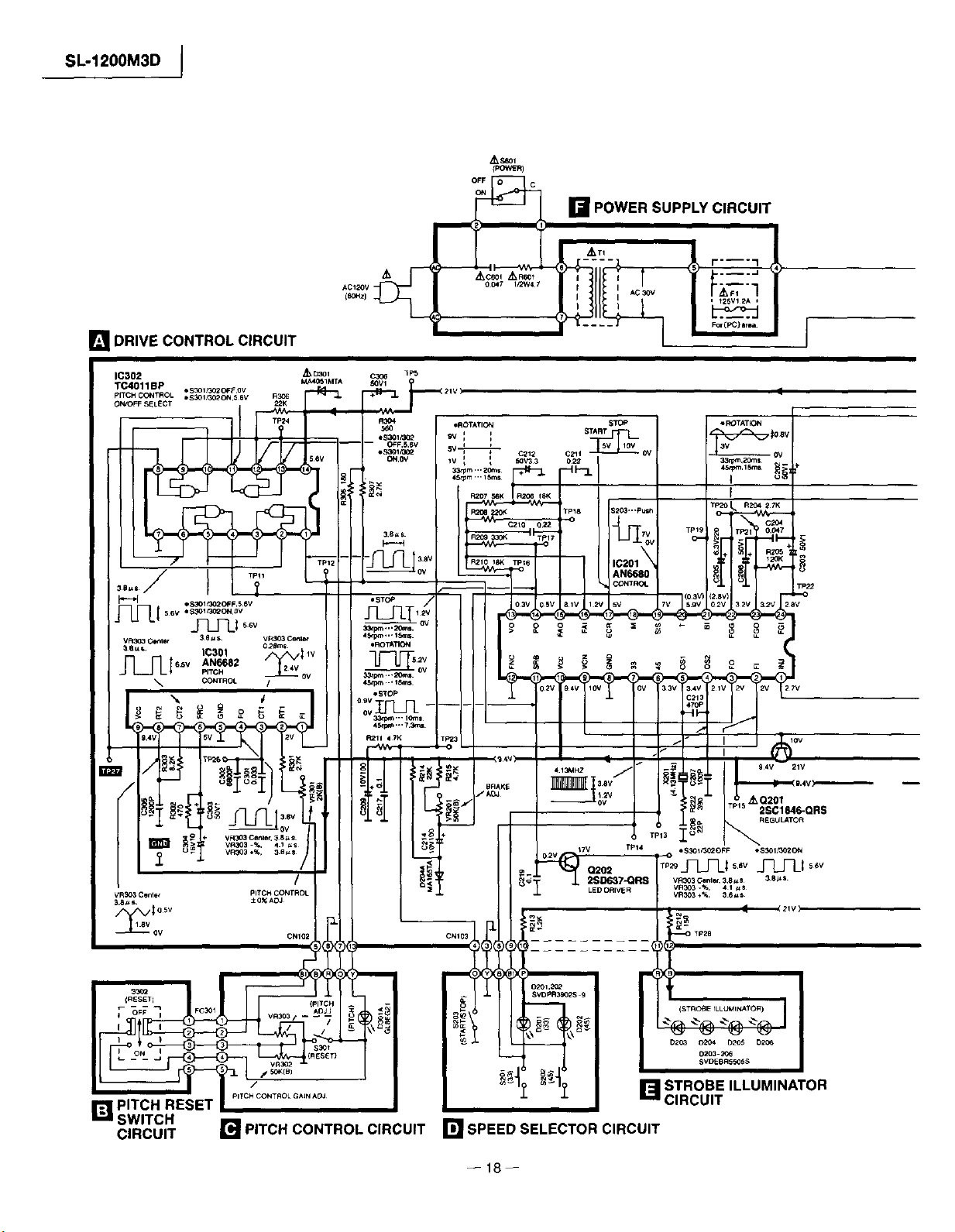

Page 18

SL-1200M3D J

[] DRIVE CONTROL CIRCUIT

IC302

TC4011BP *S_I_O2OFFOv

pITCHCONTROL eS_I/302ON56V

OWO_SELECT

/_, S6Ol

{PO_R)

o_._._ [] POWERSUPPLYCIRCUIT

,

VR303Ce_ PITCH CONTROL

3.8=s ±O_AOJ

(RESETI

PITCHCONTROLGAiNAOJ

[] PITCH RESET

SWITCH

CIRCUIT

[] PITCH CONTROL CIRCUIT

CNI02

/

CNI03

SVDPR3902S 9

[] STROBE ILLUMINATOR

CIRCUIT

[] SPEED SELECTOR CIRCUIT

--18--

Page 19

[] REGULATOR CIRCUIT

I SL-1200M3D

--19--

[] OUTPUT CIRCUIT

C_I_PUT

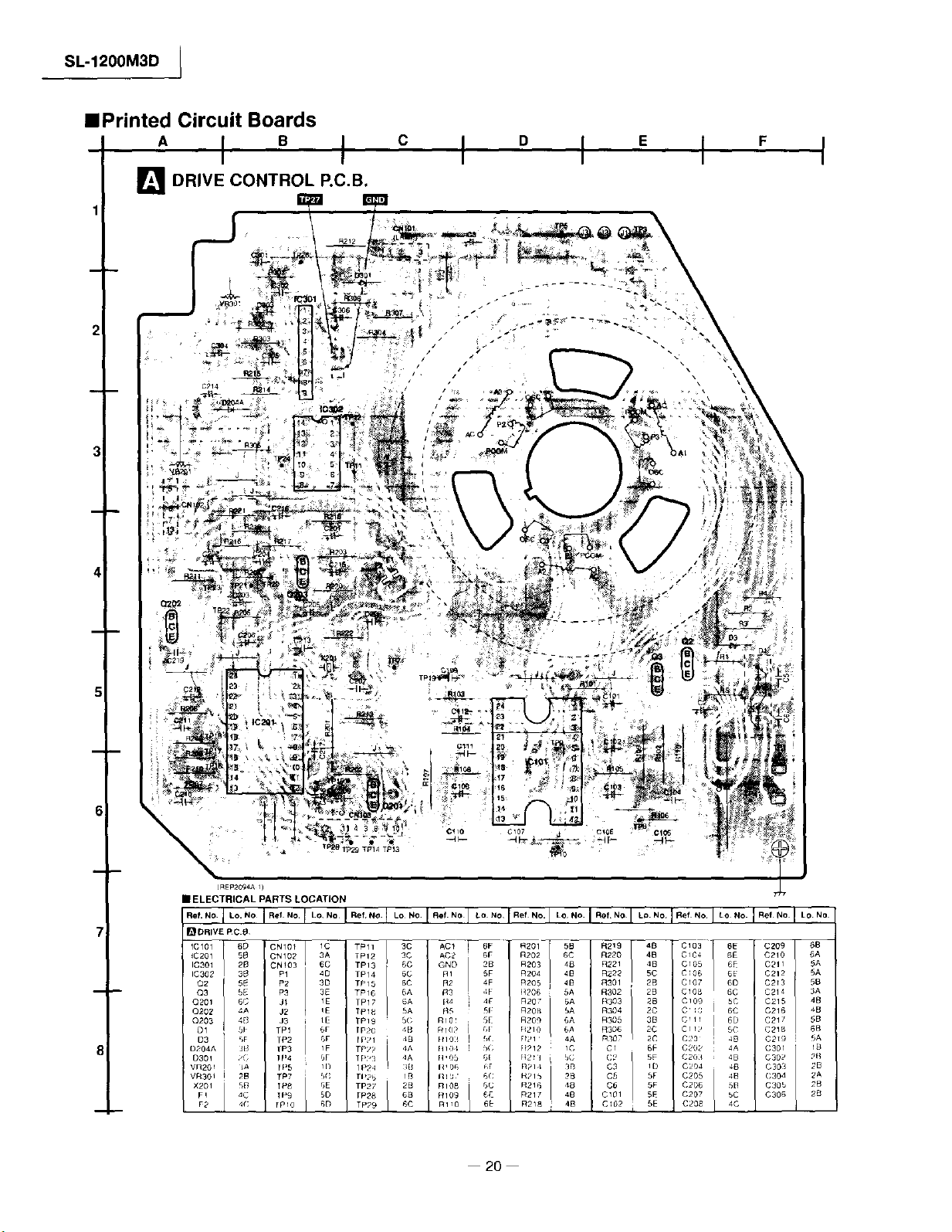

Page 20

SL-1200M3D 1

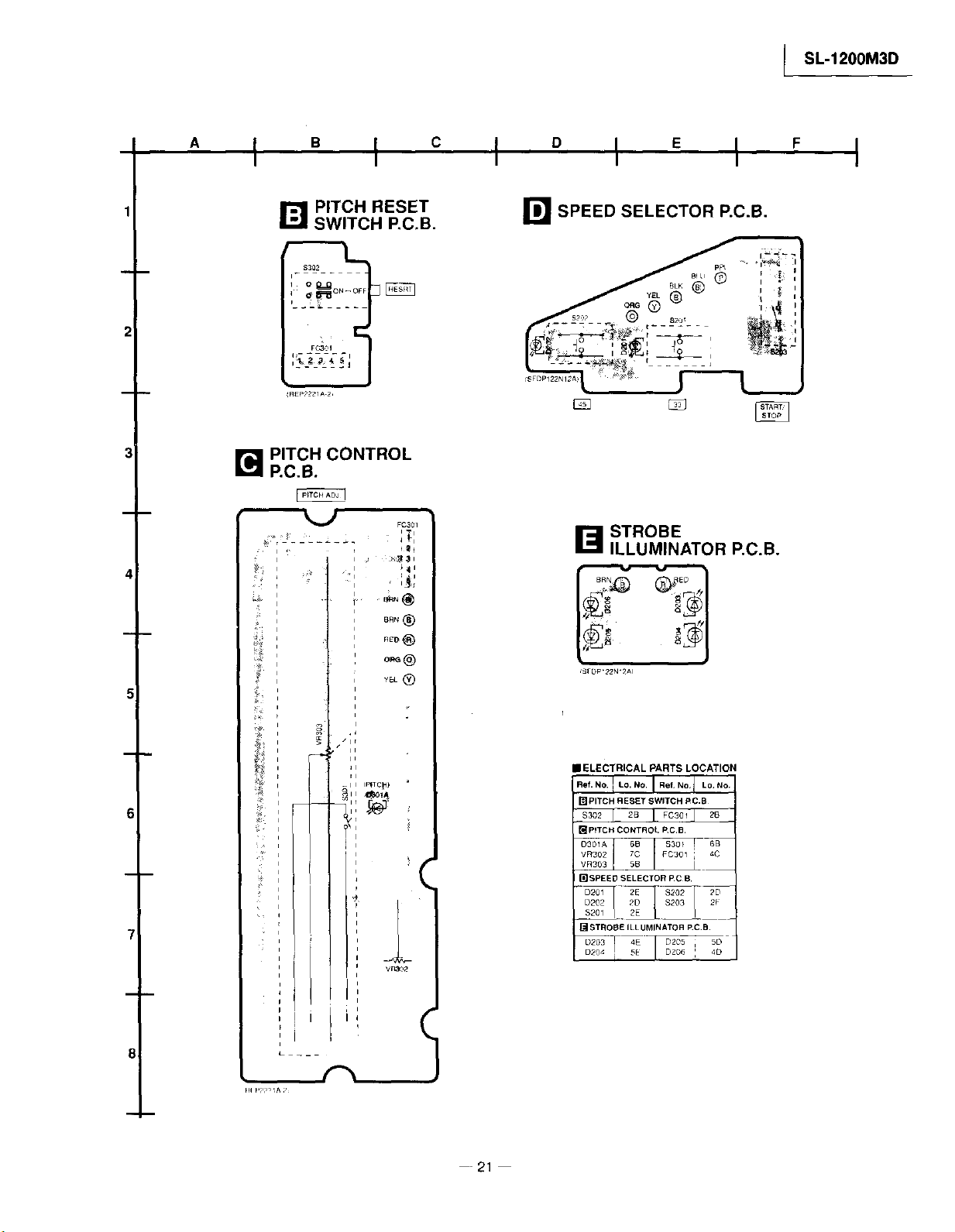

==Printed Circuit Boards

" I ° I

I_ DRIVE CONTROL P.C.B.

2i

C D E

F

_REP20_A I)

• ELECTRICAL PARTS LOCATION

i

20--

Page 21

I SL-1200M3D

" I '_ I c I ° I E I '_ I

I'_1 PITCH RESET []

SWITCH P.C.B.

m

FC301

i

_Ep22_lA 2_

B PITCH CONTROL

P.C.B.

B

FC301

:;7:

m

REIr)

SPEED SELECTOR P.C.B.

_'_ STROBE

ILLUMINATOR P.C.B.

7-

8

Hi Ppp_I^ ;,

- _ I rFfTC_)

I

VR3O_

(.

-- 21--

IELECTRICAL PARTS LOCATION

Ref. NO. I LO, NO. J Ref, NO, I Lo, No

ITI PITCH RESET _WlTCH PC,B

_P_TCH CONTROL _C,B

O301A

VR302 FC301 : 4C

[_SPEED SELECTOR PC B

" [3201 _-_2E $202 _D_

D202 22D I $203

STROBE ILLUMINATOR P.CB

_'_ D205 5D

D204 i 5E | D206 i 4D

Page 22

SL-1200M3D I

' I " I c I ° I E I F I

2I

i

POWER SUPPLY P.C.B.

r-J

r._ REGULATOR

P.C.B.

_REP2094A 1)

3

• ELECTRICAL PARTS LOCATION

I.:.2OwJ::uN:;L!::._Lo.No.

1_ REGULATOR P.C,B,

m OUTPUT P,C.B.

L+ 6D E 6D

_1°°1_'4°°

R- 6D

I_] OUTPUT P.C.B.

8

-- 22 --

Page 23

• Measurements and Adjustments

Notes: • Make the following adjustmentsafter replacing parts suchas IC's,Transistors,Diodes, etc.

• Condition ofthe set.

1.Power switch........................ ON

2 Pitch control......................... Center position

3.Speed selectorswitch............. 33 r.p.m.

• Instrumentsto be used

1Tester

2.Frequency counter

l SL-1200M3D

Adjustment Connection adjusted Procedure

Pitch control ± 0% VR301 2. Set the pitch controt knob to "0",

I (+} ... TP27

adjustment (-) ... Earth point (Fig. 1) (Indicator lights up.)

2 Pitch control gain (+} ... CN102 terminal _) VR302 3. Connect the testerto terminals,(_ and (_) of connector CN102

adjustment (-) ... CN102 terminal _) (Fig. 2) on the pitch control P.C.B. side.

3 Brake adjustment

Frequency counter 1. Connect the frequency counter and turn the power supply ON.

Tester 2, Pull out the connectorCN 102 of drive P.C.B.

Parts

3.Adjust VR301 so that the frequency is 262.08 kHz ± 0.05 kHz.

1. Set the pitch control knob to "0".

4, Adjust VR302 sothat the resistance value of the tester is

2,875 ± 0.25 kQ.

VR201 1.Adjust VR201 so that the rotation at 33 r.p.m, stops within

(Fig. 1) the angle of 30° - 210 ° after depressing the stop position.

• Alignment Points

Please refer to PrintedCircuit Board Diagram for test point locations.

pITCH CONTROl.

-t- 0% ADJUSTMENT

PITCH CONTROL

P.C.B.

DRIVE P,C B

Fig. 1

-- 23

BRAKE

ADJUSTMENT

oa_o

Fig. 2

0

YEL

=5

=6

=7

= 13

PITCHCONTROL

GAIN ADJIJSTMENT

Page 24

SL-1200M3D i

• Block Diagram

POSIT_+I

OETECTOR CO_IL +15_ TI S6O 1

,o+'_'+°,+, ,°,o

12 C2 AC .

AN66a0

CONTROL

_____X201 5 O SCI "_,___

z _T--_-_ Ol c-m_ _L-

4 0_C;2

•',+' °°++t_-#-z_t_.I

Q203 23 FGO II F_LT£R AMp :

o+o+.+o°+°+-- ++_-_+ _ , _ ++

-L + +p ,_-_S_m....... +, + t %6+TM + +

++,+I'__, + "",+° "-'-' : L+'o

_ -- 1o

l Io _P_+ oi++,+,,+oo I I i ! 1.+.1_

I _ i i ,_+i +,+)

I pH_S _ _ +C_L+-RG£ i _¢ vt-n FOI4 i _1 _--

I , ,_,+_, ,_+"' o++..

-- 14 4

v_p++, ,,

+ $202 $201

o+, ,,,+Co.gO_,_g_"

Z. J (+_ES_T)

24--

Page 25

IIIWiring Connection Diagram

Sd01

PL1

AC120V

[] REGULATOR

SUPPLY P.C.B.

laPOWER

P.C.B.

[] PITCH RESET

SWITCHP.C.B.

I

SL-1200M3D

B PITCH

CONTROL P.C.B.

I_l DRIVE CONTROL P.C.B.

Tl(Powe_ transiormer)

]STROBE

ILLUMINATOR RC.B.

CN103

-- 25 --

Page 26

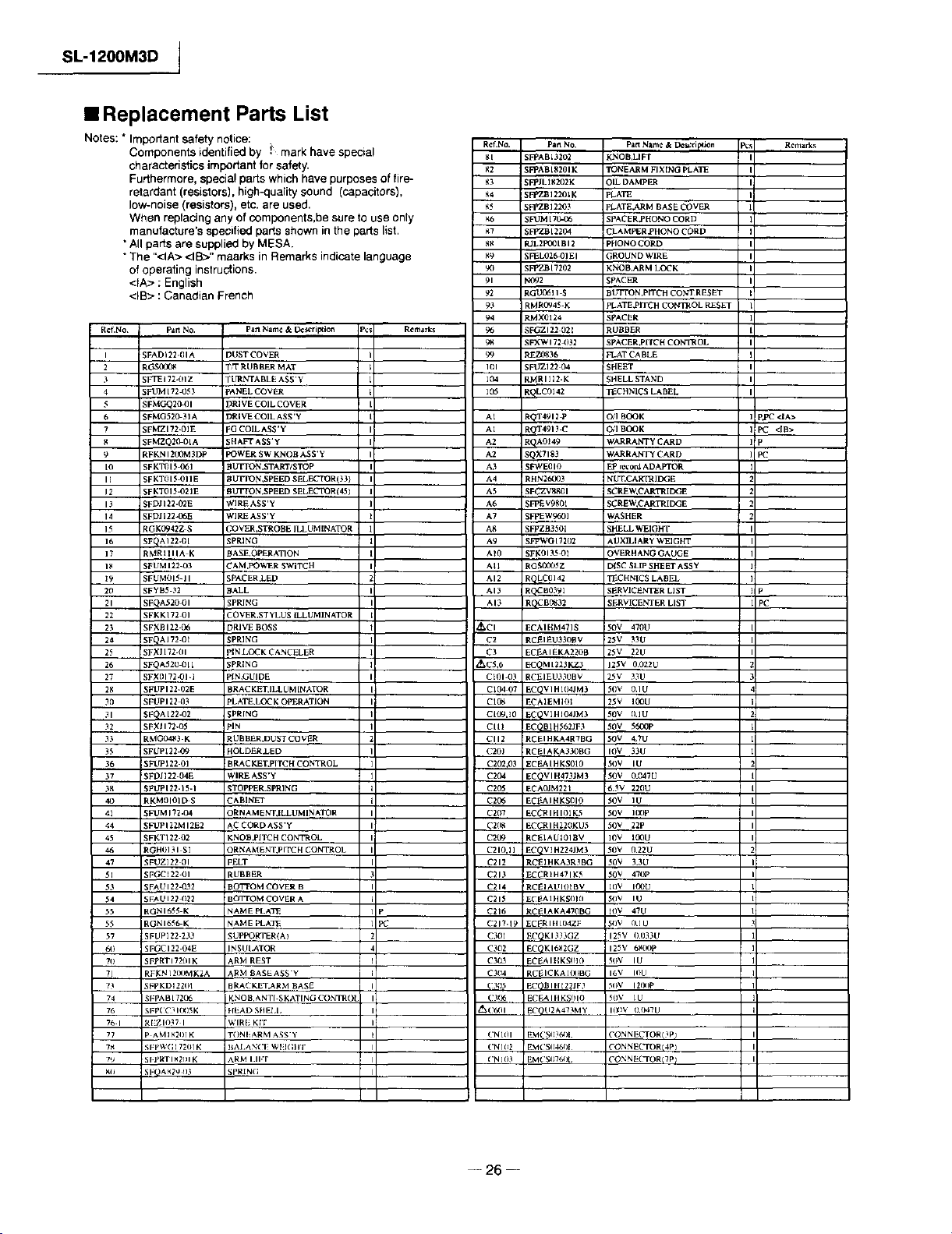

SL-1200M3D I

• Replacement Parts List

Notes: * IHI[J4jI1_[111_¢ll_ty[IUIl_l_,

Components identifiedby _ mark have special

characteristics important for safety.

Furthermore, special parts which have purposes of fire-

retardant (resistors), high-quality sound (capacitors),

low-noise (resistors), etc. are used.

When replacing any of components,be sure to use only

manufacture's specified parts shown in the parts list.

• All parts are supplied by MESA.

• The "<IA> <IB>" maarks in Remarks indicate language

of operating instructions.

<lA> : English

<IB> : Canadian French

Ref.No Pan NO part Name & De_'ri[xiea pcs Remarks

i SFADI22-OlA DUST COVER

2 R OSO(X)_ T;T RUBBER MAT

3 SFTEI72-OIZ TURNTABLE ASS'y

4 SFUM 172 053 'ANEL COVER

5 _FMGQ20-01 DRIVE COIL COVER

6 _FMG520-31A DRIVE COIL ASS'Y

7 _FMZI72-OIE FG COIL ASS'Y

8 _FMZQ2P, 01A _HAFT ASS'y

9 RFKN 12OOM3DP POWER SW KNOB ASS'Y

I0 SFKT015-_I BUTTON.START/STOP

I_ SFKT015-OIIE BUTI_N,SPEED SELF_TTOR (33)

12 $FKTOI5.021E BUITON,S PEED SELECTOR (45)

13 _FDJI22-ff2E WIRE ASS'Y

14 SFDII22_6E WIRE ASS'Y

15 ROKO942Z S COVER,STROBE ILLUMINATOR

16 SFQAI22-OI SPRING

17 RMR 1111A K BASE,OPERAqqON

18 SFUMI22-O3 CAM.POWER SWITCH

19 FUMOIS-I I SPACER J_ED

20 SFYB5 32 BALL

21 SFQA520 OI SPRING

22 SFKKI72 OI COVER.STYLUS ILLUMINATOR

23 SFXBI22-06 DRIVE BOSS

24 SFQAI72-01 SPRING

25 SFXJI72-OI pIN.LOCK CANCELER

26 SFQA520 011 SPRING

27 SFX0172-01-1 p[N_UIDE

28 SFUPI22-02E BRACKET,ILLUMINATOR

30 SFUP1224)3 pLATE,LOCK OPERATION

31 $FQA 122-02 SPRING

32 SFXII?2-O5 pIN

33 RMG0483 K RUBBER,DUST COV£R

35 FUPI22.09 HOLDERJ.ED

36 SFUPI22-OI !BRACKET_PITCHCONTROL

37 $FDJI22-04E WIRE ASS'Y

38 FUPI22-15-1 STOPPER.SPRING

40 RKM0101D S CABINET

41 FUM 172.04 ORNAMENT.ILLUMINATOR

44 FUPI22MI2E2 AC CORD ASS'Y

45 $FKTI22.02 KNOB_°ITCH CONTROL

46 RGHB]31 SI ORNAM ENT,p ITCH CONTROL

47 SFUZI22 OI IFELT

51 SFGC] 22-01 !RUBBER

53 SFAU 122-032 BOTTOM COVER B

54 FAU 122 022 BOT/-OM COVER A

55 RGNI655 K NAMEPLATE.

55 RGNI656 K NAMEPLATE

57 SFUPI22 233 _UPPORTER(A}

6_) SFGCI22-O4E INSULATOR

70 SFPRTI7201K RM REST

7] RFKN/21X)MK2A _RM BASE ASS'Y

73 SFPKDI22(B BRACKET.ARM BASE

74 SFPA B [7205 KNOB,ANTI.SKATING CONTROL

76 SFPCC3 I(X)5K HEAD SHELL

76 I REZIO37 I WIRE KIT

77 p AMIX20]K FONEARM ASS y

7X SFpW(;] 72(}] K BAI AN(TE Wlil(;l I I

7U SFI_R[ IH_CHK RM iJl:r

x¢) SFOAX2V I)3 _pRIN(;

Ref.No. Pan NO partName & De_xrip_ion

81 5FPABI3202 KNOB,UFI"

X2 _FPABI8201 K TONEARM FIXING PLA3_

g3 _FPJLI8202K }ILDAMPER

_4 SFPZBI220_ K pLATE

_5 SFI'ZBI2203 PLATE.ARM BASE COVER

x6 SFUM 170-06 SPACER.PHONO CORD

_7 FPZBI2204 CLAMpER,PHONO CORD

8_ RJL2FO31 BI 2 pHONO CORD

149 SFEL026_I El GROUND WIRE

90 SFPZBI7202 KNOB.ARM LOCK

91 N092 SPACER

92 RGU_SII S BIII'FON.pITCH CONT RESET

93 RMR0945 K pLATE,PITCH CONTROL RESET

94 RMXOI24 SPACER

9_ SFGZI22 {)21 RUBBER

9_ SFXW1724)32 SPACER,PITCH CONTROL

99 REZO_ 36 FLAT CABLE

101 SFIJZI22 04 SHEET

104 RMR I 112-K HELLSTAND

105 RQLC0142 T_CHNICS LABEL

AI RQT4912 -p O/I BOOK

AI RQT4913 C b'l BOOK

A2 RQAO149 WARRANTY CARD

A2 SQX71g3 WARRANTy CARD

A3 $FWE010 EP record ADAPTOR

A4 RHN26CO3 NLrr.c ARTR IDGE

A5 sr-CzvsRol SCREgLCARTRIDGE

A6 FPEV9801 SCRE_LCAKIRIDGE

A7 SFPEW9601 WASHER

A8 SFPZB3501 SHELL WEIGHT

A9 SFFWGI7202 AUXB.IARy WEIGHT

At0 SFKOI35 OI OVERHANG GAUGE

AI 1 RG$0OOSZ DISC SLIP SHEET ASSY

AI2 RQLC0142 TECHNICS LABEL

AI3 RQCB0391 S6RVICENTER LIST

AI3 ROCBC_32 S_RVICENTER LIST

ACI ECAI HM471S 50V 470U

C2 RCEI EU330BV 25v 33U

C3 ECEA I EKA22OB 25V 22U

_C5,6 ECQM 1223KZ3 125V 0.022U

C101 (3 RCI_IEU330BV 25V 33U

C10407 ECQVIHIIMIM3 5(IV 01U

C108 ECAIEMIOI 25V I_)U

CIO9,10 ECQVIHIO4JM3 50V II.IU

CIII ECQBIH562JF3 50V 56OOP

CII2 RCEIHKA4RTBG 50V 4,7U

C2Ol RC_I AKA330BG IOV 33U

C20"2,03 EC_AIHKSOI0 5OV IU

C204 ECQVIH473JM3 5OV 0.047U

C205 ECAOJM221 6.3V 220U

C206 ECI_A I HKS010 50V IU

C207 ECCRIHIOI K5 5OV 10Op

C208 ECCRI H220KU5 50V 22P

C209 RCEIAUI01BV ]0V IODU

C210,11 ECQVIH224JM3 50V 022U

C212 RCEIHKA3R3BG 50V 33U

C213 ECCR! H471K5 50V 47(_

C214 RC_IAUIOI BV 10V IC_U

P

PC

C215 ECEAIHKSOI0 50V IU

C216 RCEIAKA470BG IOV 47U

C217.19 ECFRIH[[MZF 50V O]U

C3(H ECQKI333GZ 125V B (133U

C3(12 ECQK 16_2GZ 125V 68(X)p

C3(13 EC6AIHKS(}]O 5OV IU

C3114 RCI_ICKA](W)BG 16V BIU

C305 ECQBIHt22JF3 50V 12(X)p

(731)5 ECEAI[I KSI)I(} 50V IU

_.C6OI F.CQU2 A 4_3M y I(XIV 0047U

CNI01 EMCSI)36_IL CONNECrOR(3P)

CN](12 EMCS046Oi CON NECI'ORI4PI

I'N]03 EMCS076tlL ('ON NE(_ORITP I

Pc Remark_

p.FC <IA>

PC <IB>

Pc

-- 26 --

Page 27

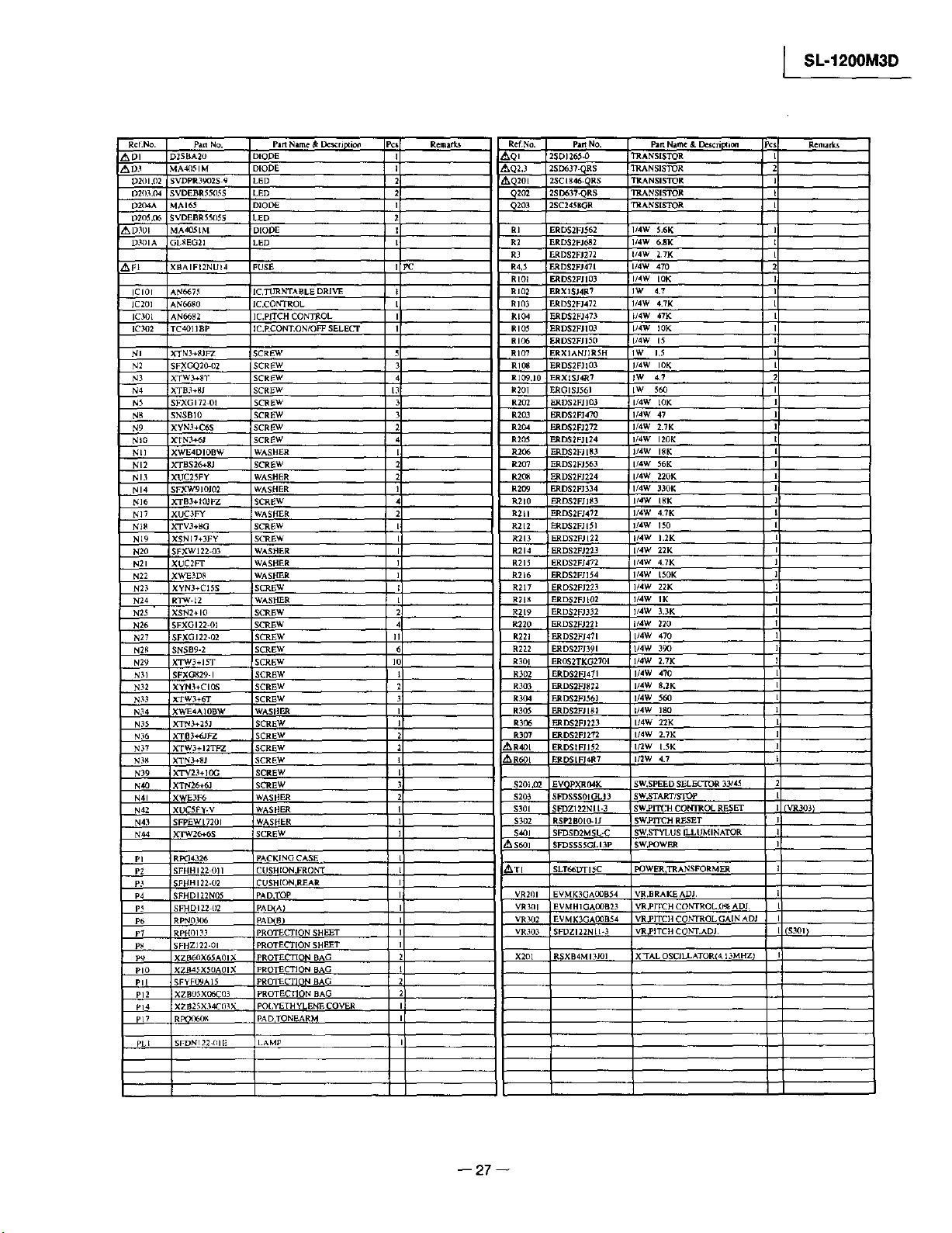

I SL-1200M3D

Ap30t

AFI

Rcl.No.

D201.02

D2IB._

D204A

D205,('_

D3OIA

ICIOI

1C201

]C301

1C302

NI

N2

N3

N4

N5

Ng

N9

NIO

Nil

NI2

NI3

NI4

N]6

N]7

N18

NI9

N20

N21

N22

N23

N24

N25 "

N26

N27

N2g

N29

N3I

N32

N33

N34

N35

N36

N37

N38

N39

N40

N41

N42

N43

Na,4

PI

P2

P3

P5

pC,

P7

p_

pIo

pII

pI2

p]4

pT7

pL t

Part No.

D2SBA20

MA4OSIM

SVDPR3902S 9

SVDEBR5505S

MAI65

SVDEBR5505S

MA4051M

GLSEG2I

XBAIF12NUI4

AN6675

AN6680

AN6682

TC4OIIBP

XTN3+SJFZ

SFXGQ2(_O2

XTW3÷8T

XTB3+SJ

SFXGI72 OI

SNSBI0

XYN3+C6S

XTN3+6J

XWE4DIOBW

XTBS26+8J

XUC25FY

SFXW910Jff/

XTB3+IOIFZ

XUC3FY

XTV3+SG

XSNI7+3FY

SFXWI22 03

XUC2FT

_WE3D8

XYN3+CISS

RTW-12

XSN2÷IO

_FXGI22-01

SFXGI22-02

SNSB9-2

XTW3+I5T

SFXG829-1

XYN3+CI(3_

XTW3+6T

XWE4AIOBW

XTN3÷25J

XTB3+6JFZ

XTW3+I2Tt_

XTN3÷81

KTV23+IOG

KTN26+_d

XWE3F6

XUC5Fy.V

SFFEWI7201

XTW26*6S

R_4326

SFHHI22 Oil

SFHHI22-02

_FHDI22N05

SFHD122 (}2

RPN0306

RPHO133

SFHZ]22-01

XZB6OX65A01 X

XZB45XS(IA01 X

SFYFOgAI5

XZBO5X06C03

XZB25X34C03X

RFQO6_X_

SFDNI22-(IIE

Pan Name&De_ri_io_

DIODE

DIODE

LED

LED

DIODE

LED

ID[ODE

LED

FUSE

!IC,TLrRNTABLE DRIVE

IC.CONTROL

IC.pITCH CONTROL

IC.I_CONT.ON/OFF SELECT

gCREW

_CREW

_CREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SCREW

WASHER

WASHER

SCREW

WASHER

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

PACKING CASE

CUSHIONrFRONT

CUSH [ONrREAR

PADITOP

PAD_AI

PAD_)

pROTECTION SHEET

PROTECTION SHEET

PROTECTION BAG

PROTECTION BAG

pROTECTION BAG

pROTECTION BAG

POLYETHYLENE COVER

PAD_TONEARM

q.AMP

_s Rema_s

PC

ReLNo.

AQ_

AQ2,3

_Q2ol

Q2O',t

Q203

RI

R2

R3

R4,5

RIOt

RI02

RIO3

RIO4

RIO5

RI06

RIO7

RI08

RI09,10

R201

R202

R203

R204

R205

R2_

R207

R20g

R2_

R210

R211

R212

R213

R214

R215

R2)6

R217

R218

R219

R220

R221

R222

R301

R302

R_3

113O1

R_5

*,r_ot

'_,$60]

ATI

R3_

R3_

$20t.¢(2

$203

S30I

S302

$4OI

VR201

VR3{II

VR ?_)2

VR303

X201

par, NO.

2SD1265_

2SD637-QRS

2SC1846-QRS

2SD637.QRS

2SC245_0R

ERDS2FJ562

ERDS2FJ682

ERDS2FI272

ERDS2FJ47t

ERDS2FJIO3

ERXISJ4R7

ERDS2FJ472

ERDS2FJ473

ERDS2FJI03

ERDS2FJISO

ERXIANJIRSH

ERDS2FJI03

ERXISJCR7

ERGISJ561

ERDS2FJI03

ERDS2FJ470

ERDS2FJ272

ERDS2FJ[24

ERDS2FJ[83

ERDS2FJ563

ERDS2FJ224

ERDS2FJ334

ERDS2FJ]83

ERDS2FJ472

ERDS2FJI51

ERDS2FJI22

ERDS2FJ223

ERDS2FJ472

FRDS2FJI54

ERDS2FJ223

ERDS2FJ[02

ERDS2FJ332

ERDS2FJ221

ERDS2FJ471

ERDS2FJ391

ER0_2TKG2701

ERDS2FJ471

ERDS2FJS_2

ERDS2FJ56]

ERDS2FJI_I

ERDS2FJ223

ERDS2FJ272

ERDStFJI52

ERDS[FJ4R7

EVQPXRt_K

SFDSSS01GLI3

SFDZI22NI 1-3

RSP2B0[0-1J

SFDSD2MSL-C

SFDSSSSGLI3P

SLT66DTISC

EVMK3GAOOB54

EVMHIGAOOB23

EVMK3GAOOB54

SFDZI22Nll-3

RSXB4MI3JO]

Pan Name & Description

TRANSISTOR

TRANSISTOR

TRANSISTOR

'IRANSISTOR

TRANSISTOR

I/4W 5.6K

I/4W 6.8K

1/4w 27K

II4W 470

I/4W [OK

IW 4.7

I/4W 4.7K

I/4W 47K

1/4W I0K

I/4W 15

I W 1,5

1/4W 10K

IW 47

IW 560

I/4W 10K

114W 47

I/4W 2.7K

I/4W 120K

I/4W 18K

I/4W 56K

114W 220K

I/4W 330K

l/4W IBK

l/4W 4,7K

I/4W 150

114W 1.2K

[/4W 22K

U4W 4.7K

I/4W [50K

I/'IW 22K

I/4W IK

I/4W 3,3K

t/4W 220

II4W 470

[14W 390

II4W 2,7K

I/4W 470

l/4W 8.2K

I/4W 560

I/4W 180

I/4W 22K

1/4W 2.7K

I_W 1.5K

]/2W 4.7

SW.SPEED S_LF.C/_R 33/45

SW#TARTt S'I'Op

SW.PITCH CONTROL RESET

SW,PlTCH RESET

SW,STYLUS ILLUMINATOR

SW.FOWER

FOWER,'I_ANSFORMER

VR,BRAKE ADJ

VR.PITCH CONTROL.G% ADJ

VR,PITCH CONTROL GAIN AD/

VR.PITC H CONT.ADJ

X_FAL OSCILLATOR(4 13MHZ /

Pcs

Rema_s

(VR303)

:S301)

-- 27 --

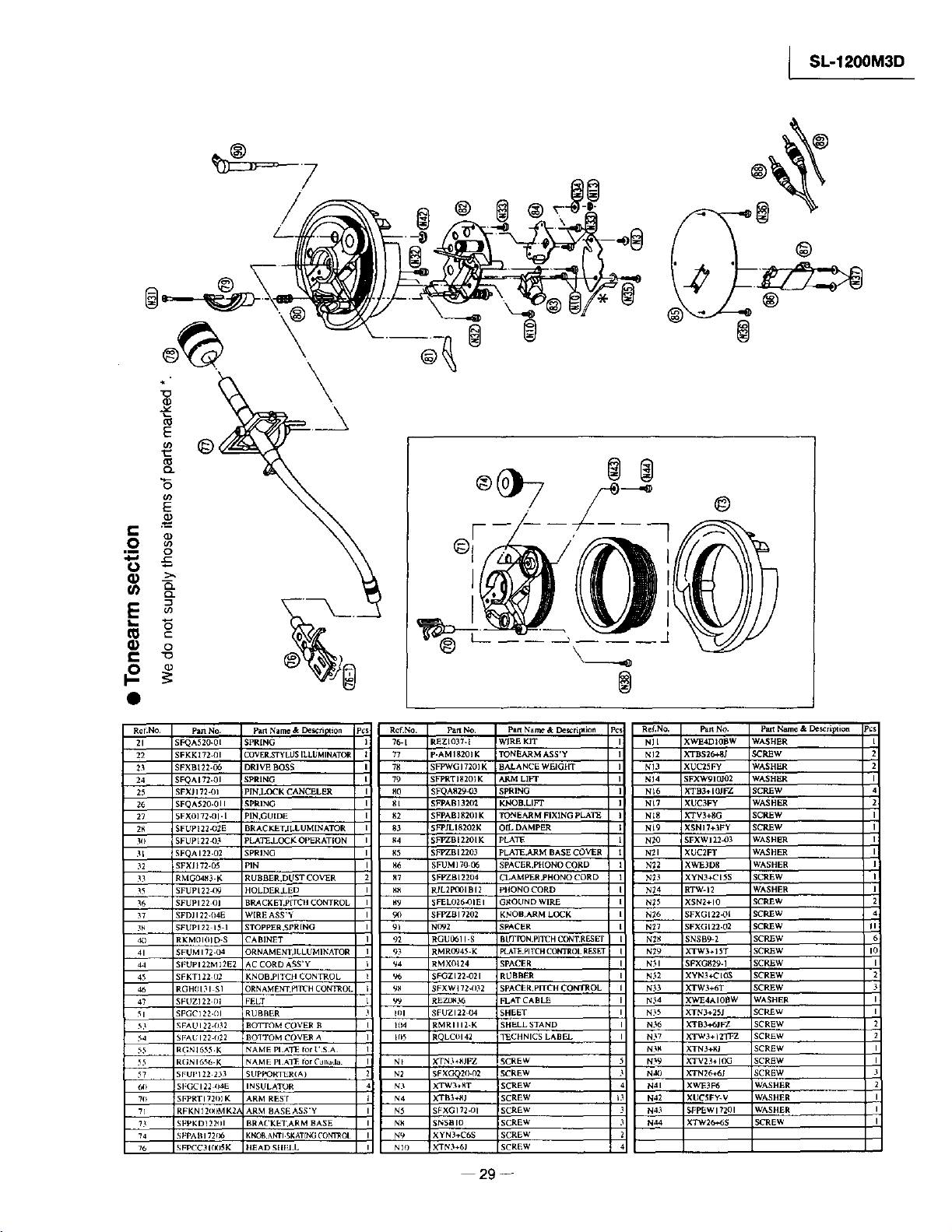

Page 28

SL-1200M3D I

lCabinet Parts Location

0

@

2 RGSOT_)_ T/T RUBBER MAT t 9 RFKN ! 2ODM3DP pOWER SW KNOB A$$'y I 16 SFQAI22 O_ SPRING

3 SFTEI72 OIZ TURNTABi,E ASS+y 1 IO SFKTOI 5-(_SI BU ]'/'ON.START/STOp I l? RMRIIIIA-K BASE,OPER ATION

4 SFUMI72.O53 PANEL COVER i I1 SFKTOISX)IIE BUTTON3PEED SELECTOR(3] j I 18 SFUMI22/)3 CAM,FOWER SWITCH /

I Ret.No pa_l NO. part Name & Dcscrilxion pc_ RcfNo panNo part Name & Descript ion pc_ Rcf.No part No par( Name & Dcscdption pCS

6 SFMG5211 31A I 13 SFDJ 122 O2E WIRE ASS'Y I 20 SFYB5 32

I SFADI22-OIA DRIVE COll. ASS'YDUST COVER I 8 SFMZQ2fl OIA SHAFTASS'Y I 15 RGK(_42Z-$ BALI.COVER'STROB E ILLUMINATOR

5 SFM(;Q20 OI DRIVE COIL COVER I 12 SFKTOI5 O2}E B UTTON.S PEED S ELECTOR(45J I 19 $FUMOIS.II SPACER,LED

-- 28 --

Page 29

©

SL-1200M3D

©

Re_No. Pan No. part Name & Descfi p_ion R_ENo. Part No. PaM Name & Desc ri_ioa Pcs: Ref. NO, PaR NO.

21 SFQA520-01 SPRING 76-[ REZlO3"L_ WIRE KIT NIl XWE4DIOBW

22 SFKKI72-01 COV ER.STy LU$ [LLUMliqATO_ 77 -AMI820]K TONEARM ASS'Y II NI2 XTBS26+SJ

23 SFXBI22-06 DRIVE BOSS 78 SFPWG]7201 K BALANCE WEIGW[" N J3 XUC25Fy

24 SFQAI72.01 SPRING 79 FPRT]820IK _M LIFT NI4 SFXW910JO2

25 SFXJ]72-01 PIN,LOCK CANCELER 80 SFQA829_3 SpRING NI6 XTB3÷[OJI _Z

26 SFQA520.OI I SPRING 81 SFPAB]32(TZ KNOB.LIFT N_7 XUC3FY

27 SFXOI72d)I- [ PIN,GUIDE 82 FPAB]I_201K TONEARM FIXING pLATE N_8 XTV3+SG

28 SFLrPI22_E BRACY.ETJLLUMINATOR 83 FPJLIS/O2K OgL DAMPER N_9 XSN]7+3FY

3O SFUPI22_3 PLATiLLOC K OPERATION _4 FFZB[2201K PLATE N20 SFXW]21_93

31 SFQAI22-02 SPRING _5 SFPZBI2203 PLATE,ARM BASE COVER N21 XUC2FT

32 SFXJ172.05 PIN _6 FUM] 7(_P,6 SPACER,PHONO CORD N22 _WE3D8

35 RMGO4_3.K RUBBER.DUST COVER _7 FPZBI2204 CLAMPER.PHONO CORD N_3 _yN3+CISS

35 SFUPI22 (_9 HOLDER.LED I;8 RIL2P_OI BI 2 PHONO CORD N_4 :('TW. 12

36 SFUPI22 OI BRACK E'I ,pITCH CONTROL 89 FEL026_31E I GROUND WIRE N_5 _SN2+IO

37 SFDJI22.O4E WIRE ASS'Y 90 SFPZBI7202 KNOB.ARM LOCK N_6 _FXG[22_)[

3_ SFUPI22 15.1 STOppER.SpR[NG 91 NO92 SPACER N_7 _FXG [ 22.02

4(i RKM/II()I D.S _AB]NET 92 [GU061 I.S BUTION.PITCH C_'_R ESET N_ gNSBg-2

,11 SFUMI72 O4 _RNAMENT,ILLUMI_ATOR 93 RMRO945.K FLAT_.PITCH CONTROL RE3 E'f N_9 XTW3+IST

44 SEUPI22M 12E_ _C CORD ASSAY _4 RMXO_24 SPACER N_I _EXG829. I

4_ :FKT122 112 gNOB.PITCH CONTROL 96 ;FGZI22-021 RUBBER N_2 ×YN3+CIOS

46 RGH(II31 $1 _R N AM ENT.pITC H CONTROL 9_ IFXWi72.O32 SPACER,pITCH CONTROL N_3 XTW3 +6T

47 SFUZI22 Ill _ELT 99 REZO836 FLAT CABLE N_4 KWE4AIOBW

51 SFGC122.111 ;RUS]BER IIII SFUZI22kO4 SHEET N_5 XTN3+25J

53 SFAUI22-O32 BOTTOM COVER B 1114 _MRIII2-K SHELL STAND N_6 XTB3+6|FZ

54 S[_.UI22 O_2 BOI"!'OM COVER A 11_5 RQLC(II42 TECHNICS LABEL N_7 XTW 3 + 12'YFZ

_ RGN 165_ .K _AME PLATE _or USA N_ XTN3+I_J

55 RGNI6'i6 K _AM E PLATE Ior C_l_ada N_ XTN3+SJF'Z SCREW N_9 XTV23+IOG

_7 SFUP122 233 _Up_offI_R( A ) N2 SFXGQ20-O2 SCREW N,I_) XTN 26+6_

_) SFGCI22 O4E INSULATOR N3 XTW3+_T _CREW N41 XWE3F6

70 SFPRTI72()I K ARMREST N4 X'FB3÷_;J _CREW 13 N42 XUCSF_V

7] RFKNI21_MK_A ARM BASEASS'Y N_ _FXGI?2_)I _CREW N43 SFPEWI?201

73 SFPKD1221_1 BRACKE I_ARM BASE N8 SNSBIO i SCREW N44 XTW26_6S

74 SFPABI721)6 KgOB.ANTI SK A$[NG CONTROl N9 XYN3_'6S SCREW

_6 _;FPf'C3 HKI_K HEAD SHEII. NIl) X'TN3÷6J SCREW

29--

par_Name & De scriF_ioa

€/ASHER

/CREW

_VASHF¢R

.VASHER

_CREW

WASHER

SCREW

SCP,_W

WASHIER

WASHER

WASHER

SCREW

WASHER

SCREW

SCP_W

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

Page 30

SL-1200M3D J

• Packaging

1:'4

(T/T RUBBER MAT)

P9

"P7

<_12

P3

AI, A2, A13

A3

Pa_ NO.

Rl_rr4912 P O/] BOOK

RQT4913 12 _I BOOK

RQA0149 WARRANTY CARD

SQXTI _3 WARRANTy CARD

SFWEOIO EP r_ord ADAPTOR

RHN26_)3 NLrI'£'ARTR]DGE

SFCZV_801 $CREV_CARTrIDGE

SFPEVg'g01 SCRE_CARTR[DGE

SFPEWgN) I WASHER

SFPZB35(II SHEt,L WEIGHT

SFPWGI?202 AUXILIARY WEIGHT

SFKIII35-OI OVERHANG GAUGE

RGS0_SZ DISC SLIP SHEET ASSY

RQLC01 _ I_CHNICS LABEL

R1_'_)391 _ERV[CENTER LIST

_ERV[CENTER LIST

P1

(HEAD SHELL)

Pan No. Pan Name & l_criptton

RPG4326 )ACKING CASE

SFHHI22 (111 _USH[ON,FRONT

5FHHI22-02 _USHION,REAR

SFHD122N05 _AD TOp

SFHDI22 02 _AD(A)

RPN0306 _AD(B)

RPH0133 _ROTECTION SHEET

SFHZI22-OI )ROTECTION SHEET

XZB6OX65A(II_ )ROrECTION BAG

XZB45XSOAOI_ )ROTECTION BAG

SFyFOgA 15 )ROTEC'I'ION BAG

XZBt)SXO6C03 _ROTECTION BAG

XZB25X34C03X _OLYETHyLENE COVER

RFQO6t_ _AD TONEARM

30 w

AIO

A8

A9

Printed in Japan

K990301850YH/AM

Page 31

I SL-1200M3D

Loading...

Loading...