Page 1

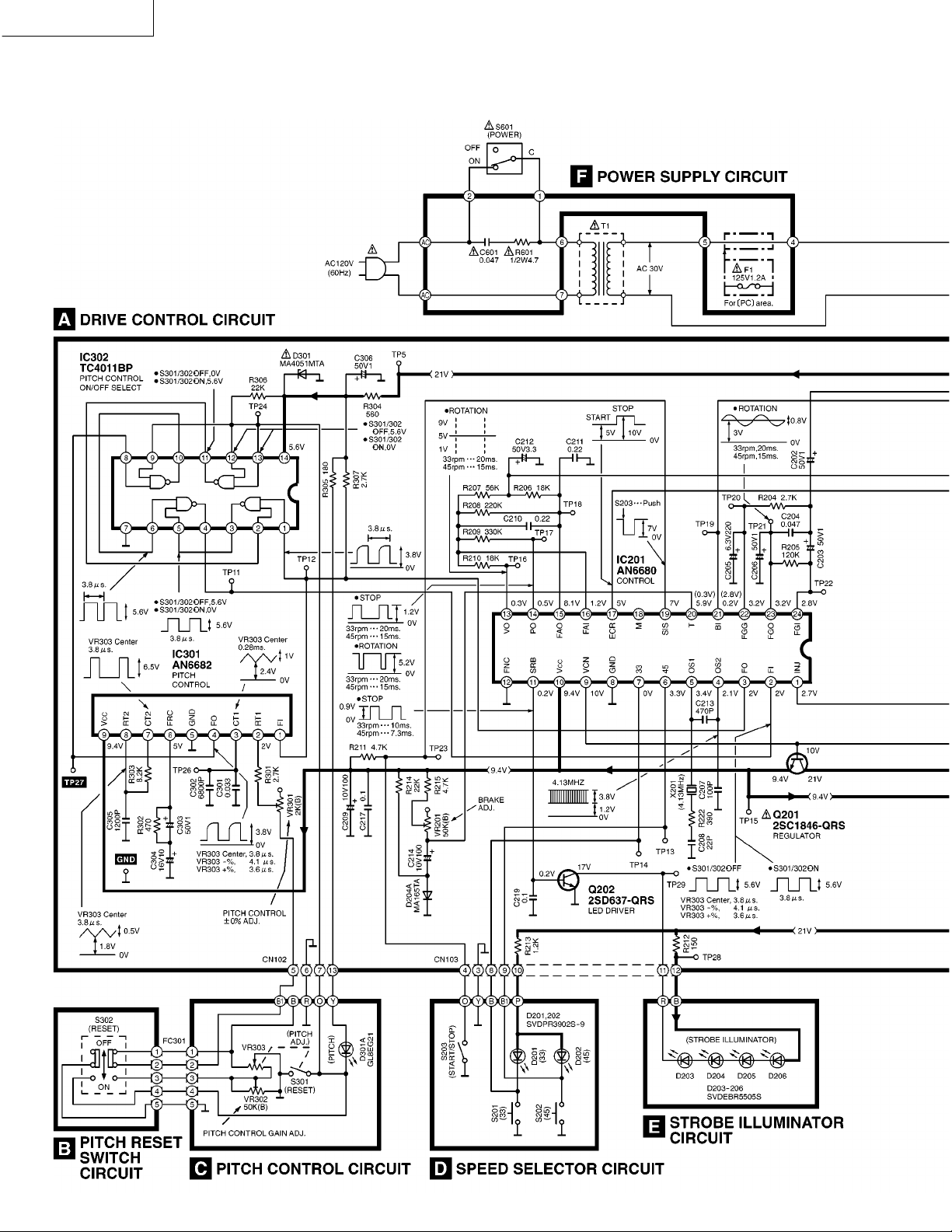

SL-1200M3D

Schematic Diagram

Notes:

The voltage value and waveforms are the reference voltage of this measured by DC electronic voltmeter (high impedance)

and oscilloscope on the basis of chasssis.

Accordingly, there may arise some errors in the voltage values and waveforms depending upon the internal impedance of the

tester or the measuring unit.

Important safety notice:

Components identified by

use only manufacture’s specified parts.

NO MARK: Voltage when at a stop

( ) : Voltage during rotation

•S201 :

•S202 :

•S203 :

•S301 :

•S302 :

•S401 :

•S601 :

•VR201 :

•VR301 :

•VR302 :

•VR303 :

SPEED SELECTOR (33 rpm) switch.

SPEED SELECTOR (45 rpm) switch.

START/STOP switch.

PITCH CONTROL RESET switch in “OFF” position. (Interlocked with VR303)

PITCH RESET switch in “OFF” position.

STYLUS ILLUMINATOR switch in “ON” position.

POWER switch in “ON” position.

BRAKE ADJUSTMENT VR.

PITCH CONTROL ± 0% ADJUSTMENT VR.

PITCH CONTROL GAIN ADJUSTMENT VR.

PITCH CONTROL ADJUSTMENT VR. (Interlocked wwith S301)

!

mark have special characteristics important for safety. When replacing any of these components,

: +B Line

Type Illustration of IC’s, Transistors and Diodes

. 17 .

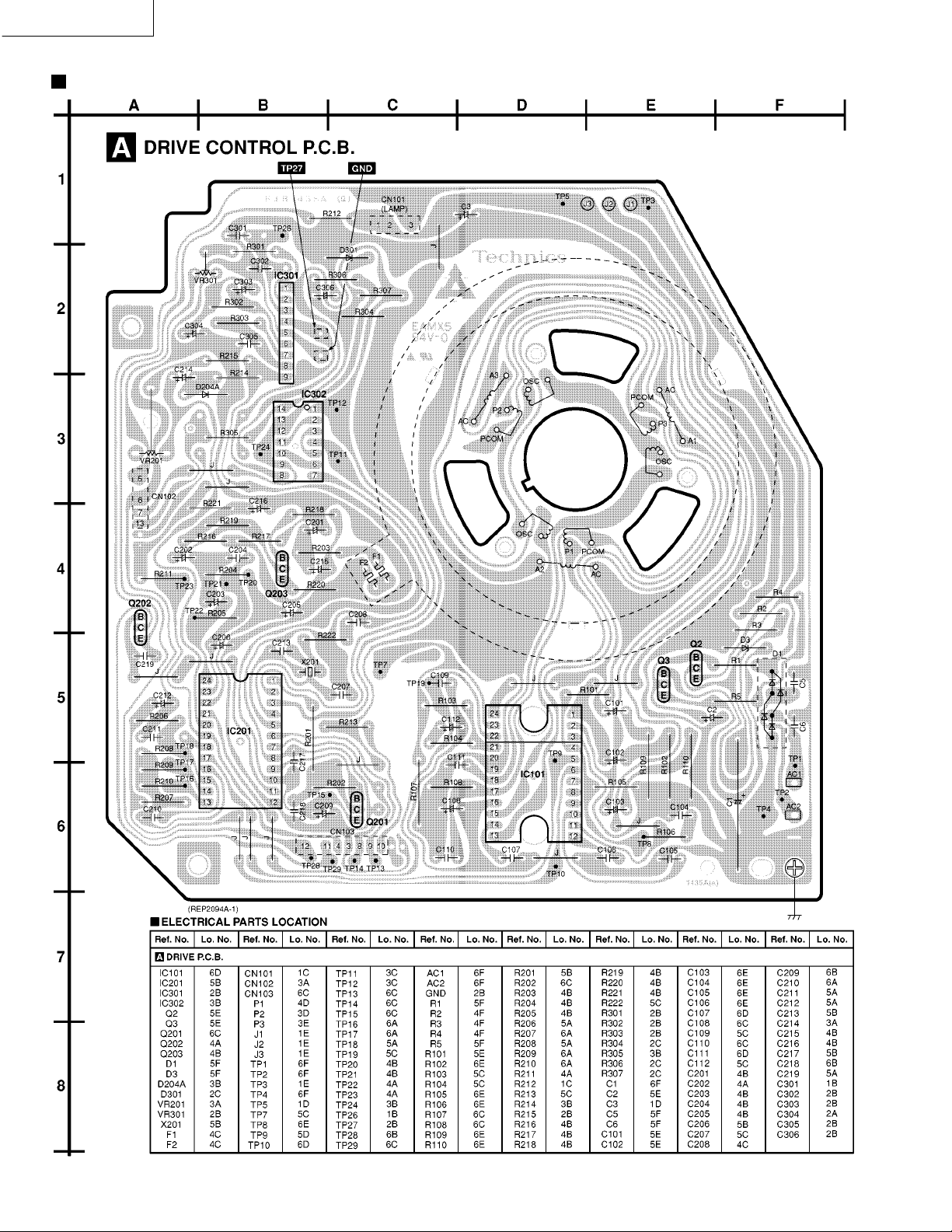

Page 2

SL-1200M3D

. 18 .

Page 3

SL-1200M3D

. 19 .

Page 4

SL-1200M3D

Printed Circuit Boards

. 20 .

Page 5

SL-1200M3D

. 21 .

Page 6

SL-1200M3D

. 22 .

Page 7

Measurements and Adjustments

Notes:

• Make the following adjustments after replacing parts such as IC’s, Transistors, Diodes, etc.

• Condition of the set.

1.Power switch……………………ON

2.Pitch control…………………….Center position

3.Speed selector switch………….33 r.p.m.

• Instruments to be used

1.Tester

2.Frequency counter

SL-1200M3D

Adjustment

2

Pitch control ± 0%

adjustment

Pitch control gain

adjustment

Brake adjustment

1

3

Connection

Frequency counter

(+) … TP27

(–) … Earth point

Tester

(+) … CN102 terminal

(–) … CN102 terminal

Parts

adjusted

VR301

(Fig. 1)

VR302

(Fig. 2)

VR201

(Fig. 1)

Alignment Points

Please refer to Printed Circuit Board Diagram for test point locations.

Procedure

1. Connect the frequency counter and turn the power supply ON.

2. Set the pitch control knob to “0”.

(Indicator lights up.)

3. Adjust VR301 so that the frequency is 262.08 kHz ± 0.05 kHz.

1. Set the pitch control knob to “0”.

2. Pull out the connector CN102 of drive P.C.B.

3. Connect the tester to terminals, and of connector CN102

on the pitch control P.C.B. side.

4. Adjust VR302 so that the resistance value of the tester is

2.875 ± 0.25 kΩ.

1. Adjust VR201 so that the rotation at 33 r.p.m. stops within

the angle of 30° ~ 210° after depressing the stop position.

. 23 .

Page 8

SL-1200M3D

Block Diagram

. 24 .

Page 9

Wiring Connection Diagram

SL-1200M3D

. 25 .

Page 10

SL-1200M3D

Replacement Parts List

Notes: *

Important safety notice:

Components identified by mark have special

!

characteristics important for safety.

Furthermore, special parts which have purposes of fireretardant (resistors), high-quality sound (capacitors),

low-noise (resistors), etc. are used.

When replacing any of components,be sure to use only

manufacture’s specified parts shown in the parts list.

All parts are supplied by MESA.

*

The “<IA> <IB>” maarks in Remarks indicate language

*

of operating instructions.

<IA> : English

<IB> : Canadian French

Ref.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

30

31

32

33

35

36

37

38

40

41

44

45

46

47

51

53

54

55

55

57

60

70

71

73

74

76

76-1

77

78

79

80

Part No.

SFAD122-01A

RGS0008

SFTE172-01Z

SFUM172-053

SFMGQ20-01

SFMG520-31A

SFMZ172-01E

SFMZQ20-01A

RFKN1200M3DP

SFKT015-061

SFKT015-011E

SFKT015-021E

SFDJ122-02E

SFDJ122-06E

RGK0942Z-S

SFQA122-01

RMR1111A-K

SFUM122-03

SFUM015-11

SFYB5-32

SFQA520-01

SFKK172-01

SFXB122-06

SFQA172-01

SFXJ172-01

SFQA520-011

SFX0172-01-1

SFUP122-02E

SFUP122-03

SFQA122-02

SFXJ172-05

RMG0483-K

SFUP122-09

SFUP122-01

SFDJ122-04E

SFUP122-15-1

RKM0101D-S

SFUM172-04

SFUP122M12E2

SFKT122-02

RGH0131-S1

SFUZ122-01

SFGC122-01

SFAU122-032

SFAU122-022

RGN1655-K

RGN1656-K

SFUP122-233

SFGC122-04E

SFPRT17201K

RFKN1200MK2A

SFPKD12201

SFPAB17206

SFPCC31005K

REZ1037-1

P-AM18201K

SFPWG17201K

SFPRT18201K

SFQA829-03

Part Name & Description Pcs Remarks

DUST COVER

T/T RUBBER MAT

TURNTABLE ASS’Y

PANEL COVER

DRIVE COIL COVER

DRIVE COIL ASS’Y

FG COIL ASS’Y

SHAFT ASS’Y

POWER SW KNOB ASS’Y

BUTTON,START/STOP

BUTTON,SPEED SELECTOR(33)

BUTTON,SPEED SELECTOR(45)

WIRE ASS’Y

WIRE ASS’Y

COVER,STROBE ILLUMINATOR

SPRING

BASE,OPERATION

CAM,POWER SWITCH

SPACER,LED

BALL

SPRING

COVER,STYLUS ILLUMINATOR

DRIVE BOSS

SPRING

PIN,LOCK CANCELER

SPRING

PIN,GUIDE

BRACKET,ILLUMINATOR

PLATE,LOCK OPERATION

SPRING

PIN

RUBBER,DUST COVER

HOLDER,LED

BRACKET,PITCH CONTROL

WIRE ASS’Y

STOPPER,SPRING

CABINET

ORNAMENT,ILLUMINATOR

AC CORD ASS’Y

KNOB,PITCH CONTROL

ORNAMENT,PITCH CONTROL

FELT

RUBBER

BOTTOM COVER B

BOTTOM COVER A

NAME PLATE

NAME PLATE

SUPPORTER(A)

INSULATOR

ARM REST

ARM BASE ASS’Y

BRACKET,ARM BASE

KNOB,ANTI-SKATING CONTROL

HEAD SHELL

WIRE KIT

TONEARM ASS’Y

BALANCE WEIGHT

ARM LIFT

SPRING

Ref.No.

81

82

83

84

85

86

87

88

89

90

91

92

93

94

96

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

3

1

1

P

1

PC

1

2

4

1

1

1

1

1

1

1

1

1

1

98

99

101

104

105

A1

A1

A2

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A13

C1

C2

C3

C5,6

C101-03

C104-07

C108

C109,10

C111

C112

C201

C202,03

C204

C205

C206

C207

C208

C209

C210,11

C212

C213

C214

C215

C216

C217-19

C301

C302

C303

C304

C305

C306

C601

CN101

CN102

CN103

Part No.

SFPAB13202

SFPAB18201K

SFPJL18202K

SFPZB12201K

SFPZB12203

SFUM170-06

SFPZB12204

RJL2P001B12

SFEL026-01E1

SFPZB17202

N092

RGU0611-S

RMR0945-K

RMX0124

SFGZ122-021

SFXW172-032

REZ0836

SFUZ122-04

RMR1112-K

RQLC0142

RQT4912-P

RQT4913-C

RQA0149

SQX7183

SFWE010

RHN26003

SFCZV8801

SFPEV9801

SFPEW9601

SFPZB3501

SFPWG17202

SFK0135-01

RGS0005Z

RQLC0142

RQCB0391

RQCB0832

ECA1HM471S

RCE1EU330BV

ECEA1EKA220B

ECQM1223KZ3

RCE1EU330BV

ECQV1H104JM3

ECA1EM101

ECQV1H104JM3

ECQB1H562JF3

RCE1HKA4R7BG

RCE1AKA330BG

ECEA1HKS010

ECQV1H473JM3

ECA0JM221

ECEA1HKS010

ECCR1H101K5

ECCR1H220KU5

RCE1AU101BV

ECQV1H224JM3

RCE1HKA3R3BG

ECCR1H471K5

RCE1AU101BV

ECEA1HKS010

RCE1AKA470BG

ECFR1H104ZF

ECQK1333GZ

ECQK1682GZ

ECEA1HKS010

RCE1CKA100BG

ECQB1H122JF3

ECEA1HKS010

ECQU2A473MY

EMCS0360L

EMCS0460L

EMCS0760L

Part Name & Description

KNOB,LIFT

TONEARM FIXING PLATE

OIL DAMPER

PLATE

PLATE,ARM BASE COVER

SPACER,PHONO CORD

CLAMPER,PHONO CORD

PHONO CORD

GROUND WIRE

KNOB,ARM LOCK

SPACER

BUTTON,PITCH CONT.RESET

PLATE,PITCH CONTROL RESET

SPACER

RUBBER

SPACER,PITCH CONTROL

FLAT CABLE

SHEET

SHELL STAND

TECHNICS LABEL

O/I BOOK

O/I BOOK

WARRANTY CARD

WARRANTY CARD

EP record ADAPTOR

NUT,CARTRIDGE

SCREW,CARTRIDGE

SCREW,CARTRIDGE

WASHER

SHELL WEIGHT

AUXILIARY WEIGHT

OVERHANG GAUGE

DISC SLIP SHEET ASSY

TECHNICS LABEL

SERVICENTER LIST

SERVICENTER LIST

50V 470U

25V 33U

25V 22U

125V 0.022U

25V 33U

50V 0.1U

25V 100U

50V 0.1U

50V 5600P

50V 4.7U

10V 33U

50V 1U

50V 0.047U

6.3V 220U

50V 1U

50V 100P

50V 22P

10V 100U

50V 0.22U

50V 3.3U

50V 470P

10V 100U

50V 1U

10V 47U

50V 0.1U

125V 0.033U

125V 6800P

50V 1U

16V 10U

50V 1200P

50V 1U

100V 0.047U

CONNECTOR(3P)

CONNECTOR(4P)

CONNECTOR(7P)

Pcs

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

3

4

1

2

1

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

P,PC <IA>

PC <IB>

P

PC

P

PC

Remarks

. 26 .

Page 11

SL-1200M3D

Ref.No.

D1

D3

D201,02

D203,04

D204A

D205,06

D301

D301A

F1

IC101

IC201

IC301

IC302

N1

N2

N3

N4

N5

N8

N9

N10

N11

N12

N13

N14

N16

N17

N18

N19

N20

N21

N22

N23

N24

N25

N26

N27

N28

N29

N31

N32

N33

N34

N35

N36

N37

N38

N39

N40

N41

N42

N43

N44

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P14

P17

PL1

Part No. Part Name & Description Pcs Remarks

D2SBA20

MA4051M

SVDPR3902S-9

SVDEBR5505S

MA165

SVDEBR5505S

MA4051M

GL8EG21

XBA1F12NU14

AN6675

AN6680

AN6682

TC4011BP

XTN3+8JFZ

SFXGQ20-02

XTW3+8T

XTB3+8J

SFXG172-01

SNSB10

XYN3+C6S

XTN3+6J

XWE4D10BW

XTBS26+8J

XUC25FY

SFXW910J02

XTB3+10JFZ

XUC3FY

XTV3+8G

XSN17+3FY

SFXW122-03

XUC2FT

XWE3D8

XYN3+C15S

RTW-12

XSN2+10

SFXG122-01

SFXG122-02

SNSB9-2

XTW3+15T

SFXG829-1

XYN3+C10S

XTW3+6T

XWE4A10BW

XTN3+25J

XTB3+6JFZ

XTW3+12TFZ

XTN3+8J

XTV23+10G

XTN26+6J

XWE3F6

XUC5FY-V

SFPEW17201

XTW26+6S

RPG4326

SFHH122-011

SFHH122-02

SFHD122N05

SFHD122-02

RPN0306

RPH0133

SFHZ122-01

XZB60X65A01X

XZB45X50A01X

SFYF09A15

XZB05X06C03

XZB25X34C03X

RPQ0608

SFDN122-01E

DIODE

DIODE

LED

LED

DIODE

LED

DIODE

LED

FUSE

IC,TURNTABLE DRIVE

IC,CONTROL

IC,PITCH CONTROL

IC,P.CONT.ON/OFF SELECT

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SCREW

WASHER

WASHER

SCREW

WASHER

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

PACKING CASE

CUSHION,FRONT

CUSHION,REAR

PAD,TOP

PAD(A)

PAD(B)

PROTECTION SHEET

PROTECTION SHEET

PROTECTION BAG

PROTECTION BAG

PROTECTION BAG

PROTECTION BAG

POLYETHYLENE COVER

PAD,TONEARM

LAMP

1

1

2

2

1

2

1

1

1

1

1

1

1

5

3

4

13

3

3

2

4

1

2

2

1

4

2

1

1

1

1

1

1

1

2

4

11

6

10

1

2

3

1

1

2

2

1

1

3

2

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

1

Ref.No.

Q1

Q2,3

Q201

Q202

Q203

R1

R2

PC

R3

R4,5

R101

R102

R103

R104

R105

R106

R107

R108

R109,10

R201

R202

R203

R204

R205

R206

R207

R208

R209

R210

R211

R212

R213

R214

R215

R216

R217

R218

R219

R220

R221

R222

R301

R302

R303

R304

R305

R306

R307

R401

R601

S201,02

S203

S301

S302

S401

S601

T1

VR201

VR301

VR302

VR303

X201

Part No. Part Name & Description Pcs Remarks

2SD1265-0

2SD637-QRS

2SC1846-QRS

2SD637-QRS

2SC2458GR

ERDS2FJ562

ERDS2FJ682

ERDS2FJ272

ERDS2FJ471

ERDS2FJ103

ERX1SJ4R7

ERDS2FJ472

ERDS2FJ473

ERDS2FJ103

ERDS2FJ150

ERX1ANJ1R5H

ERDS2FJ103

ERX1SJ4R7

ERG1SJ561

ERDS2FJ103

ERDS2FJ470

ERDS2FJ272

ERDS2FJ124

ERDS2FJ183

ERDS2FJ563

ERDS2FJ224

ERDS2FJ334

ERDS2FJ183

ERDS2FJ472

ERDS2FJ151

ERDS2FJ122

ERDS2FJ223

ERDS2FJ472

ERDS2FJ154

ERDS2FJ223

ERDS2FJ102

ERDS2FJ332

ERDS2FJ221

ERDS2FJ471

ERDS2FJ391

ER0S2TKG2701

ERDS2FJ471

ERDS2FJ822

ERDS2FJ561

ERDS2FJ181

ERDS2FJ223

ERDS2FJ272

ERDS1FJ152

ERDS1FJ4R7

EVQPXR04K

SFDSSS01GL13

SFDZ122N11-3

RSP2B010-1J

SFDSD2MSL-C

SFDSSS5GL13P

SLT66DT15C

EVMK3GA00B54

EVMH1GA00B23

EVMK3GA00B54

SFDZ122N11-3

RSXB4M13J01

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

1/4W 5.6K

1/4W 6.8K

1/4W 2.7K

1/4W 470

1/4W 10K

1W 4.7

1/4W 4.7K

1/4W 47K

1/4W 10K

1/4W 15

1W 1.5

1/4W 10K

1W 4.7

1W 560

1/4W 10K

1/4W 47

1/4W 2.7K

1/4W 120K

1/4W 18K

1/4W 56K

1/4W 220K

1/4W 330K

1/4W 18K

1/4W 4.7K

1/4W 150

1/4W 1.2K

1/4W 22K

1/4W 4.7K

1/4W 150K

1/4W 22K

1/4W 1K

1/4W 3.3K

1/4W 220

1/4W 470

1/4W 390

1/4W 2.7K

1/4W 470

1/4W 8.2K

1/4W 560

1/4W 180

1/4W 22K

1/4W 2.7K

1/2W 1.5K

1/2W 4.7

SW,SPEED SELECTOR 33/45

SW,START/STOP

SW,PITCH CONTROL RESET

SW,PITCH RESET

SW,STYLUS ILLUMINATOR

SW,POWER

POWER,TRANSFORMER

VR,BRAKE ADJ.

VR,PITCH CONTROL,0% ADJ.

VR,PITCH CONTROL GAIN ADJ

VR,PITCH CONT.ADJ.

X’TAL OSCILLATOR(4.13MHZ)

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

(VR303)

(S301)

. 27 .

Page 12

SL-1200M3D

Cabinet Parts Location

Ref.No.

1

2

3

4

5

6

Part No. Part Name & Description Pcs

SFAD122-01A

RGS0008

SFTE172-01Z

SFUM172-053

SFMGQ20-01

SFMG520-31A

DUST COVER

T/T RUBBER MAT

TURNTABLE ASS’Y

PANEL COVER

DRIVE COIL COVER

DRIVE COIL ASS’Y

Ref.No.

7

1

8

1

9

1

10

1

11

1

12

1

13

Part No. Part Name & Description Pcs

SFMZ172-01E

SFMZQ20-01A

RFKN1200M3DP

SFKT015-061

SFKT015-011E

SFKT015-021E

SFDJ122-02E

FG COIL ASS’Y

SHAFT ASS’Y

POWER SW KNOB ASS’Y

BUTTON,START/STOP

BUTTON,SPEED SELECTOR(33)

BUTTON,SPEED SELECTOR(45)

WIRE ASS’Y

Ref.No.

1

14

1

15

1

16

1

17

1

18

1

19

1

20

Part No. Part Name & Description Pcs

SFDJ122-06E

RGK0942Z-S

SFQA122-01

RMR1111A-K

SFUM122-03

SFUM015-11

SFYB5-32

WIRE ASS’Y

COVER,STROBE ILLUMINATOR

SPRING

BASE,OPERATION

CAM,POWER SWITCH

SPACER,LED

BALL

1

1

1

1

1

2

1

. 28 .

Page 13

SL-1200M3D

We do not supply those items of parts marked *.

Tonearm section

Ref.No.

21

22

23

24

25

26

27

28

30

31

32

33

35

36

37

38

40

41

44

45

46

47

51

53

54

55

55

57

60

70

71

73

74

76

Part No. Part Name & Description Pcs

SFQA520-01

SFKK172-01

SFXB122-06

SFQA172-01

SFXJ172-01

SFQA520-011

SFX0172-01-1

SFUP122-02E

SFUP122-03

SFQA122-02

SFXJ172-05

RMG0483-K

SFUP122-09

SFUP122-01

SFDJ122-04E

SFUP122-15-1

RKM0101D-S

SFUM172-04

SFUP122M12E2

SFKT122-02

RGH0131-S1

SFUZ122-01

SFGC122-01

SFAU122-032

SFAU122-022

RGN1655-K

RGN1656-K

SFUP122-233

SFGC122-04E

SFPRT17201K

RFKN1200MK2A

SFPKD12201

SFPAB17206

SFPCC31005K

SPRING

COVER,STYLUS ILLUMINATOR

DRIVE BOSS

SPRING

PIN,LOCK CANCELER

SPRING

PIN,GUIDE

BRACKET,ILLUMINATOR

PLATE,LOCK OPERATION

SPRING

PIN

RUBBER,DUST COVER

HOLDER,LED

BRACKET,PITCH CONTROL

WIRE ASS’Y

STOPPER,SPRING

CABINET

ORNAMENT,ILLUMINATOR

AC CORD ASS’Y

KNOB,PITCH CONTROL

ORNAMENT,PITCH CONTROL

FELT

RUBBER

BOTTOM COVER B

BOTTOM COVER A

NAME PLATE for U.S.A.

NAME PLATE for Canada.

SUPPORTER(A)

INSULATOR

ARM REST

ARM BASE ASS’Y

BRACKET,ARM BASE

KNOB,ANTI-SKATING CONTROL

HEAD SHELL

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

2

4

1

1

1

1

1

Ref.No.

76-1

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

96

98

99

101

104

105

N1

N2

N3

N4

N5

N8

N9

N10

Part No. Part Name & Description Pcs

REZ1037-1

P-AM18201K

SFPWG17201K

SFPRT18201K

SFQA829-03

SFPAB13202

SFPAB18201K

SFPJL18202K

SFPZB12201K

SFPZB12203

SFUM170-06

SFPZB12204

RJL2P001B12

SFEL026-01E1

SFPZB17202

N092

RGU0611-S

RMR0945-K

RMX0124

SFGZ122-021

SFXW172-032

REZ0836

SFUZ122-04

RMR1112-K

RQLC0142

XTN3+8JFZ

SFXGQ20-02

XTW3+8T

XTB3+8J

SFXG172-01

SNSB10

XYN3+C6S

XTN3+6J

WIRE KIT

TONEARM ASS’Y

BALANCE WEIGHT

ARM LIFT

SPRING

KNOB,LIFT

TONEARM FIXING PLATE

OIL DAMPER

PLATE

PLATE,ARM BASE COVER

SPACER,PHONO CORD

CLAMPER,PHONO CORD

PHONO CORD

GROUND WIRE

KNOB,ARM LOCK

SPACER

BUTTON,PITCH CONT.RESET

PLATE,PITCH CONTROL RESET

SPACER

RUBBER

SPACER,PITCH CONTROL

FLAT CABLE

SHEET

SHELL STAND

TECHNICS LABEL

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

Ref.No.

1

N11

1

N12

1

N13

1

N14

1

N16

1

N17

1

N18

1

N19

1

N20

1

N21

1

N22

1

N23

1

N24

1

N25

1

N26

1

N27

1

N28

1

N29

1

N31

1

N32

1

N33

1

N34

1

N35

1

N36

1

N37

N38

5

N39

3

N40

4

N41

13

N42

3

N43

3

N44

2

4

Part No. Part Name & Description Pcs

XWE4D10BW

XTBS26+8J

XUC25FY

SFXW910J02

XTB3+10JFZ

XUC3FY

XTV3+8G

XSN17+3FY

SFXW122-03

XUC2FT

XWE3D8

XYN3+C15S

RTW-12

XSN2+10

SFXG122-01

SFXG122-02

SNSB9-2

XTW3+15T

SFXG829-1

XYN3+C10S

XTW3+6T

XWE4A10BW

XTN3+25J

XTB3+6JFZ

XTW3+12TFZ

XTN3+8J

XTV23+10G

XTN26+6J

XWE3F6

XUC5FY-V

SFPEW17201

XTW26+6S

WASHER

SCREW

WASHER

WASHER

SCREW

WASHER

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

WASHER

WASHER

SCREW

1

2

2

1

4

2

1

1

1

1

1

1

1

2

4

11

6

10

1

2

3

1

1

2

2

1

1

3

2

1

1

1

. 29 .

Page 14

SL-1200M3D

Packaging

Ref.No.

A1

A1

A2

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A13

Part No. Part Name & Description Pcs

RQT4912-P

RQT4913-C

RQA0149

SQX7183

SFWE010

RHN26003

SFCZV8801

SFPEV9801

SFPEW9601

SFPZB3501

SFPWG17202

SFK0135-01

RGS0005Z

RQLC0142

RQCB0391

RQCB0832

O/I BOOK

O/I BOOK

WARRANTY CARD

WARRANTY CARD

EP record ADAPTOR

NUT,CARTRIDGE

SCREW,CARTRIDGE

SCREW,CARTRIDGE

WASHER

SHELL WEIGHT

AUXILIARY WEIGHT

OVERHANG GAUGE

DISC SLIP SHEET ASSY

TECHNICS LABEL

SERVICENTER LIST

SERVICENTER LIST

Ref.No.

P1

1

P2

1

P3

1

P4

1

P5

1

P6

2

P7

2

P8

2

P9

2

P10

1

P11

1

P12

1

P14

1

P17

1

1

1

Part No. Part Name & Description Pcs

RPG4326

SFHH122-011

SFHH122-02

SFHD122N05

SFHD122-02

RPN0306

RPH0133

SFHZ122-01

XZB60X65A01X

XZB45X50A01X

SFYF09A15

XZB05X06C03

XZB25X34C03X

RPQ0608

PACKING CASE

CUSHION,FRONT

CUSHION,REAR

PAD,TOP

PAD(A)

PAD(B)

PROTECTION SHEET

PROTECTION SHEET

PROTECTION BAG

PROTECTION BAG

PROTECTION BAG

PROTECTION BAG

POLYETHYLENE COVER

PAD,TONEARM

1

1

1

1

1

1

1

1

2

1

2

2

1

1

Printed in Japan

. 30 .

K990301850YH/AM

Loading...

Loading...