Page 1

Table Of Contents

PV

COVER

1 Safety Precautions

1.1 GENERAL GUIDELINES

1.1.1 LEAKAGE CURRENT COLD CHECK

1.1.2 LEAKAGE CURRENT HOT CHECK (See Figure 1.)

2 Handling the Lead-free Solder

2.1 About lead free solder (PbF)

3 Before Repair and Adjustment

4 Protection Circuitry

5 Connection of the Speaker Cables

6 Disassembly Procedure

6.1 Disassembly of the Speaker Unit

6.2 Main Component Replacement Procedures

6.2.1 Replacement of the Power IC

7 Connection of the Speaker Wiring

8 Block Diagram

9 Schematic Diagram

10 Printed Circuit Board

11 Wiring Connection Diagram

Page 2

12 Illustration of IC ’ s, Transistors and Diodes

13 Parts Location and Replacement Parts List

13.1 Cabinet

13.1.1 Cabinet Parts Location

13.1.2 Cabinet Parts List

13.2 Component Parts List

13.3 Packing Materials & Accessories Parts List

13.4 Packaging

Page 3

Service Manual

TOP NEXT

ORDER NO. MD0305153C2

Active Subwoofer System

● SB-WA330E

SB-WA330EB

Colour

(S)...Silver Type

Specification

Active subwoofer

Type 1 way, 1 speaker, bass-ref.

Speaker unit

Woofer

Input power 200 W (Music)

Output sound pressure level 80 dB/ W (1.0 m)

Frequency range 40 Hz-220 Hz (-16 dB)

Dimensions (W x H x D) 160 x 450 x 424 mm

Mass 11.5 kg

General

Power supply AC 230 V, 50 Hz (E)

Power consumption 210 W

Note :

Specifications are subject to change without notice.

Mass and dimensions are approximate.

17 cm cone type 4Ω

45 Hz-180 Hz (-10 dB)

AC 230-240 V, 50 Hz (EB)

Page 4

System : SC-HT500 (E) Music Center: SA-HT500 (E)

Satellite speakers: SB-HT500 (E)

Active Subwoofer: SB-WA330 (E)

System : SC-HT500 (EG) Music Center: SA-HT500 (EG)

Satellite speakers: SB-HT500 (E)

Active Subwoofer: SB-WA330 (E)

System : SC-HT500 (EB) Music Center: SA-HT500 (EB)

Satellite speakers: SB-HT500 (E)

Active Subwoofer: SB-WA330 (EB)

SB-STP1EG-S consists of SB-WA330E-S x1,

SB-FS900E-S x 4 and SB-PC52E-S x 1

SB-STP1EB-S consists of SB-WA330EB-S x1,

SB-FS900E-S x 4 and SB-PC52E-S x 1

© 2003 PANASONIC AVC Networks Singapore Pte. Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

TOP NEXT

Page 5

1 Safety Precautions

TOP PREVIOUS NEXT

1.1 GENERAL GUIDELINES

1.1.1 LEAKAGE CURRENT COLD CHECK

1.1.2 LEAKAGE CURRENT HOT CHECK (See Figure 1.)

TOP PREVIOUS NEXT

Page 6

1.1 GENERAL GUIDELINES

TOP PREVIOUS NEXT

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation

papers shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

1.1.1 LEAKAGE CURRENT COLD CHECK

1.1.2 LEAKAGE CURRENT HOT CHECK (See Figure 1.)

TOP PREVIOUS NEXT

Page 7

1.1.1 LEAKAGE CURRENT COLD CHECK

TOP PREVIOUS NEXT

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each

exposed metallic cabinet part on the equipment such as screwheads, connectors, control shafts,

etc. When the exposed metallic part has a return path to the chassis,the reading should be

between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Fig. 1

TOP PREVIOUS NEXT

Page 8

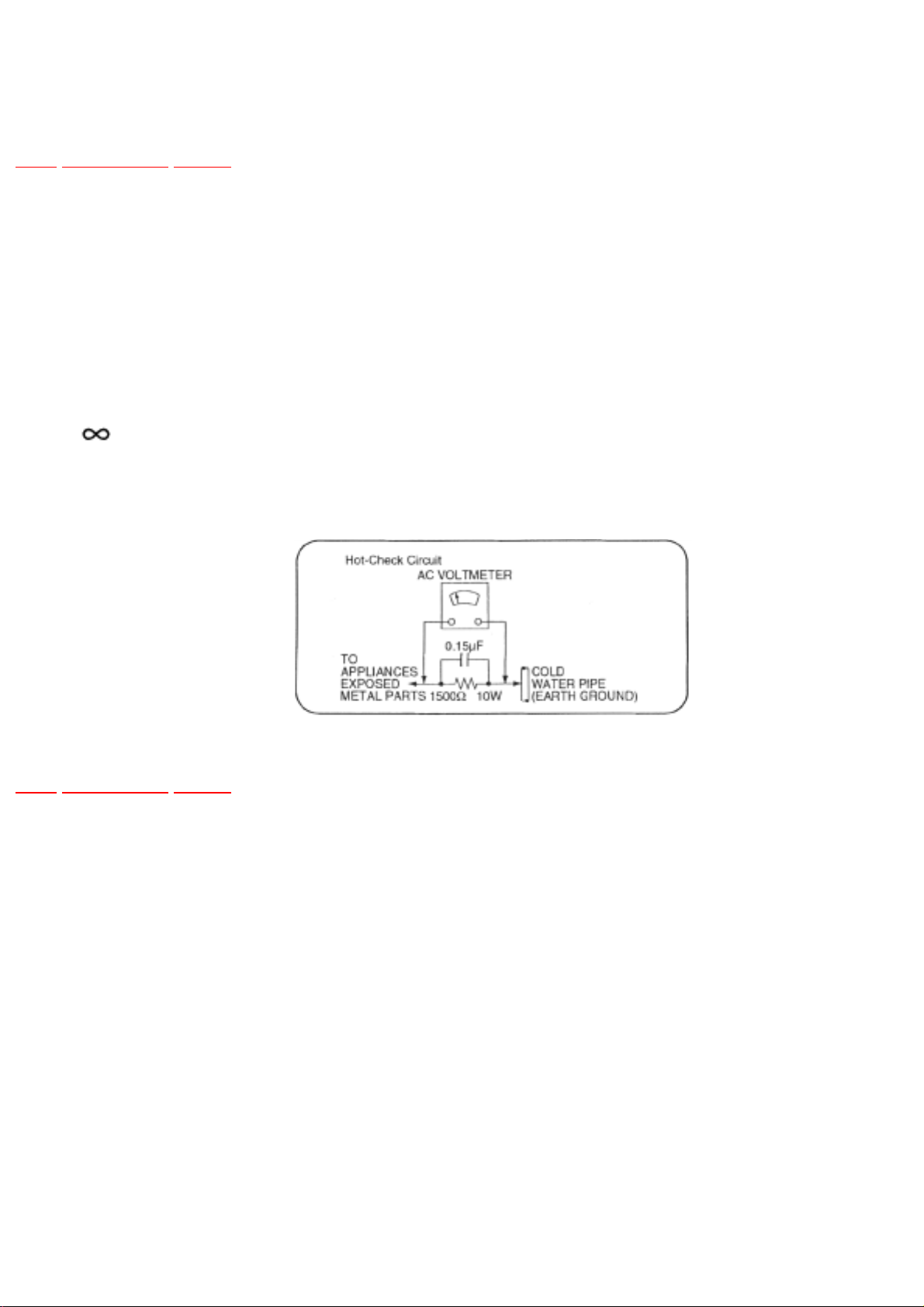

1.1.2 LEAKAGE CURRENT HOT CHECK (See

Figure 1.)

TOP PREVIOUS NEXT

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this

check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each

exposed metallic part on the set and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across

the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester

(Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must

not exceed 1/2 milliamp. In case a measurement is outsideof the limits specified, there is a

possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

TOP PREVIOUS NEXT

Page 9

2 Handling the Lead-free Solder

TOP PREVIOUS NEXT

2.1 About lead free solder (PbF)

TOP PREVIOUS NEXT

Page 10

2.1 About lead free solder (PbF)

TOP PREVIOUS NEXT

Distinction of PbF P.C.B. :

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

● Pb free solder has a higher melting point that standard solder; Typically the melting point is 50

- 70°F (30 - 40°C) higher.

Please use a high temperature soldering iron. In case of the soldering iron with

temperaturecontrol, please set it to 700 ± 20°F (370 ± 10°C).

● Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

● When soldering or unsoldering, please completely remove all of the solder on the pins or

solder area, and be sure to heat the soldering points with the Pb free solder until it melts

enough.

TOP PREVIOUS NEXT

Page 11

3 Before Repair and Adjustment

TOP PREVIOUS NEXT

Disconnect AC power, discharge Power Supply Capacitors C546, C547, C548, C549 through a 10 Ω,

1 W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may

destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 230V, 50Hz in NO SIGNAL mode should be ~400 mA (E).

Current consumption at AC 230~240V, 50Hz in NO SIGNAL mode should be ~400 mA (EB).

TOP PREVIOUS NEXT

Page 12

4 Protection Circuitry

TOP PREVIOUS NEXT

The protection circuitry may have operated if either of the following conditions are noticed:

● No sound is heard when the power is turned on.

● Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative

speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the

amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off

and then on again.

TOP PREVIOUS NEXT

Page 13

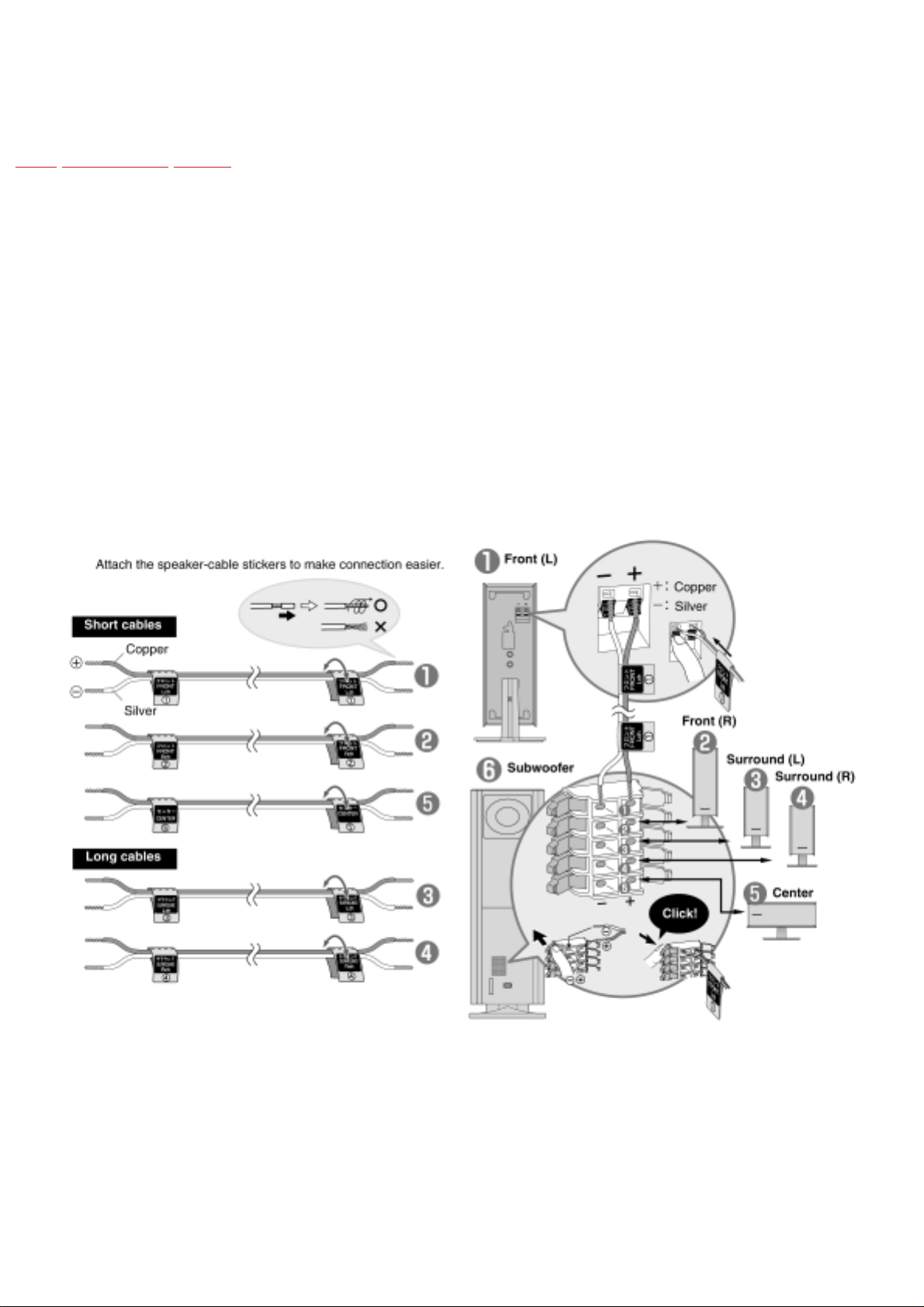

5 Connection of the Speaker Cables

TOP PREVIOUS NEXT

● Be sure to connect speaker cables before connecting the AC power supply cord.

● The load impedance of any speaker used with this unit must be 4Ω.

● Be sure to connect the cable from the right speaker to the right terminal and the cable from the

left speaker to the left terminal.

1. Strip off the outer covering, and twist the center conductor. Make sure the bare ends of the

wires are not unravelled. (If they are, twist them tight again.)

2. Insert the wire to the rear panel of the unit and close the lever.

Notes :

● To prevent damage to circuitry, never short-circuit positive (+) and negative (-) speaker wires.

● Be sure to connect only positive (red) wires to positive (+) terminals and negative (black)

wires to negative (-) terminals.

Page 14

6 Disassembly Procedure

TOP PREVIOUS NEXT

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit

boards and replacing the main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Contents

● Disassembly of the Speaker Unit

● Main Component Replacement Procedures

6.1 Disassembly of the Speaker Unit

6.2 Main Component Replacement Procedures

6.2.1 Replacement of the Power IC

TOP PREVIOUS NEXT

Page 15

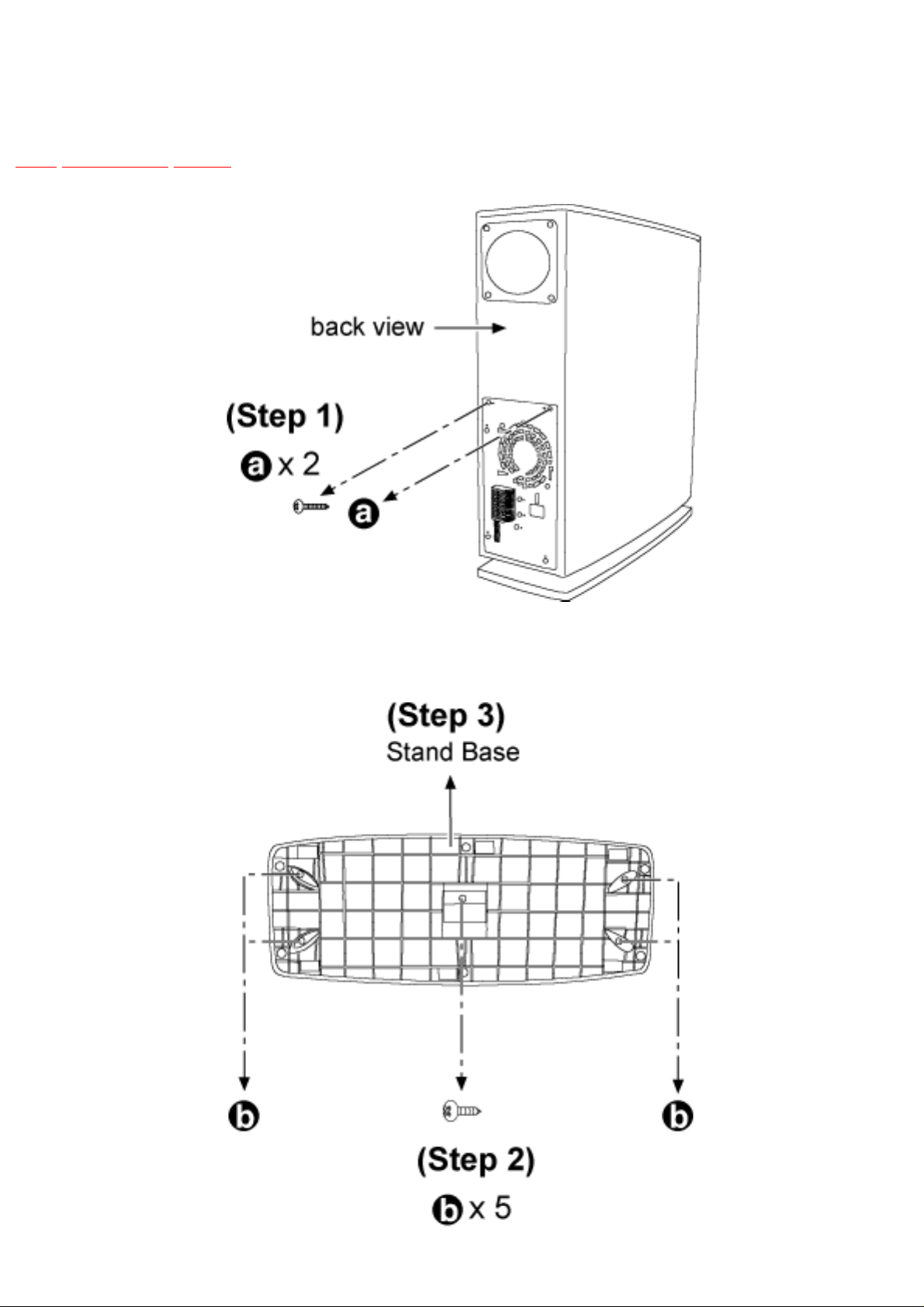

6.1 Disassembly of the Speaker Unit

TOP PREVIOUS NEXT

Step 1: Remove 2 screws from the rear panel.

Page 16

Step 2: Remove all screws.

Step 3: Remove the Stand Base.

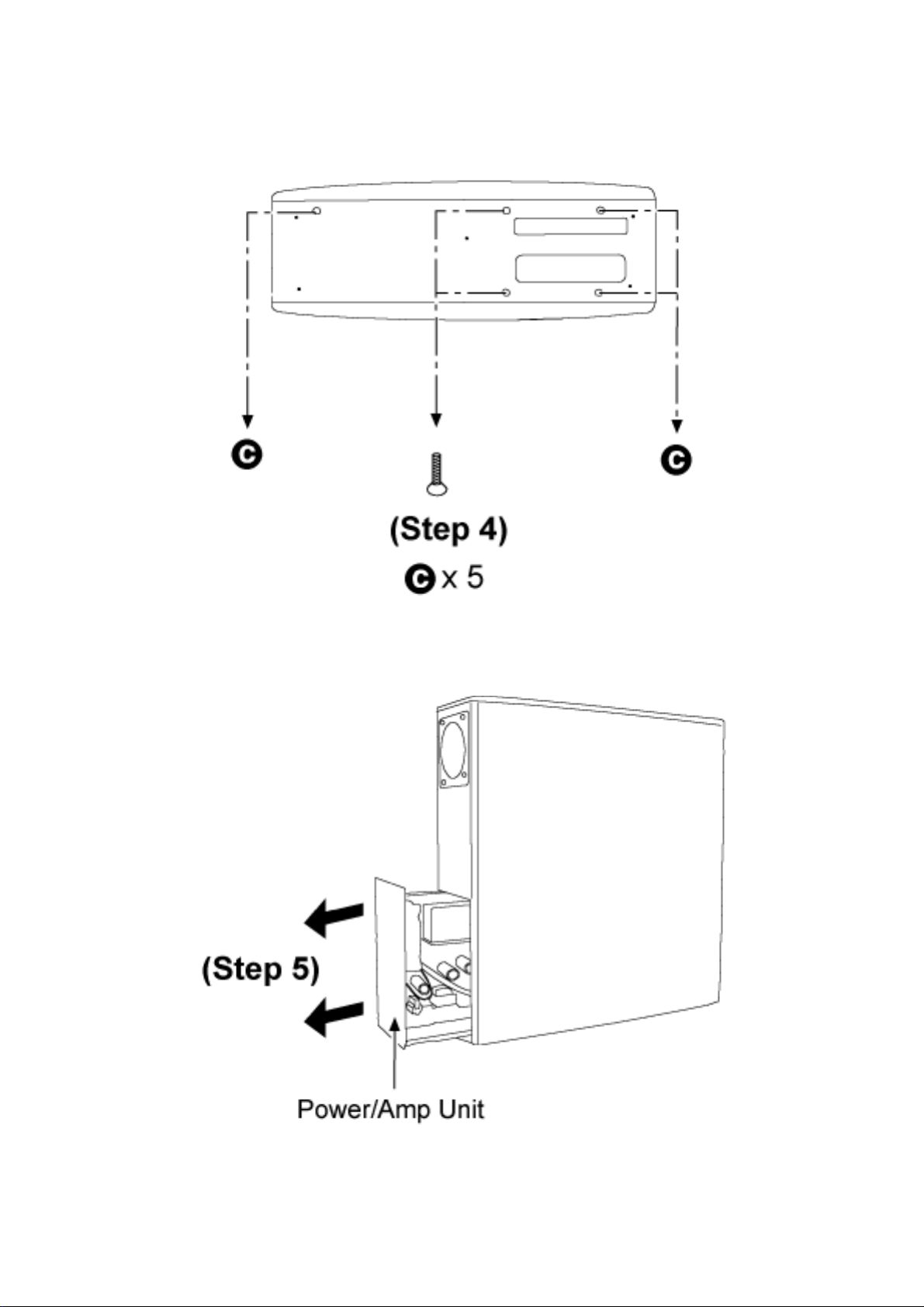

Step 4: Remove 5 screws from the speaker bottom.

Step 5: Pull the Power/Amp Unit as shown.

Page 17

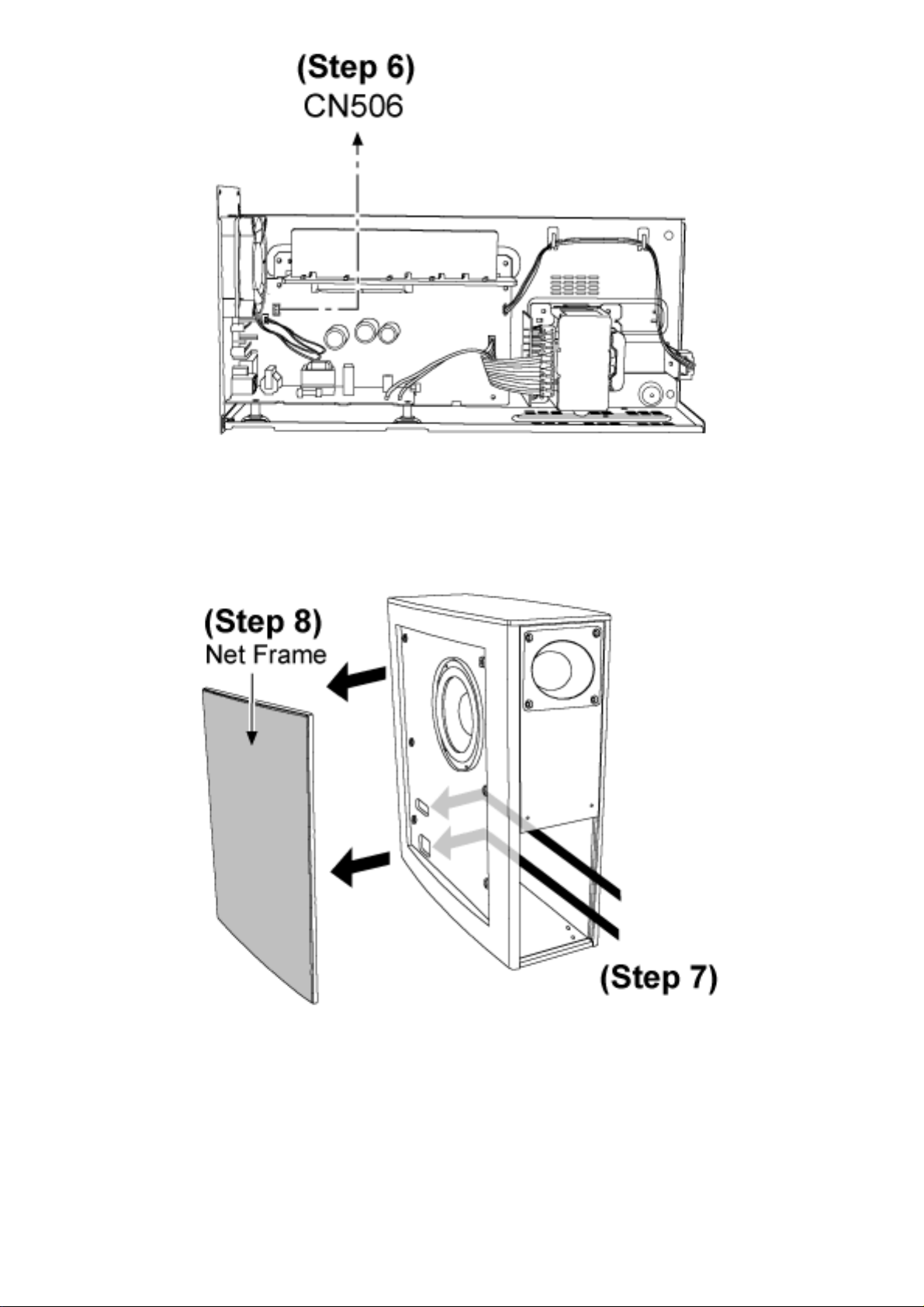

Step 6: Release the connector CN506 and pull out the Power/Amp Unit.

Step 7: Push the Net Frame from two holes inside the unit.

Step 8: Remove the Net Frame.

Page 18

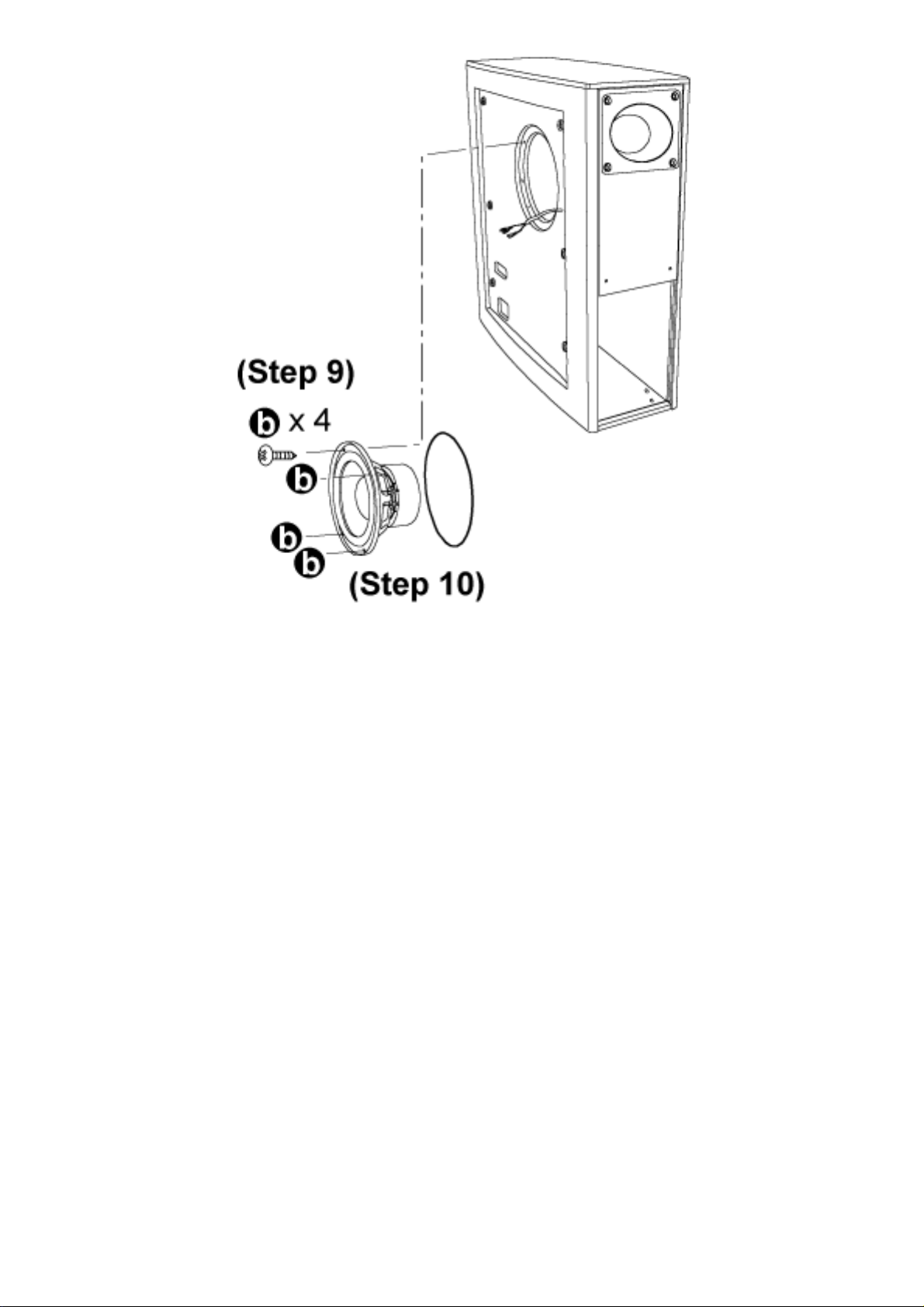

Step 9: Remove all the screws.

Step 10: Remove the Speaker.

Page 19

Step 11 & 12: Remove all the screws.

Page 20

Step 13: Release the connector CN507.

Step 14: Remove the 2 screws.

Step 15 & 16: Remove all the screws.

Page 21

Step 17: Place the Power PCB as shown for checking.

Page 22

Checking for AC Inlet PCB.

TOP PREVIOUS NEXT

Page 23

6.2 Main Component Replacement Procedures

TOP PREVIOUS NEXT

6.2.1 Replacement of the Power IC

TOP PREVIOUS NEXT

Page 24

6.2.1 Replacement of the Power IC

TOP PREVIOUS NEXT

Step 1 & 2: Remove all the screws.

Page 25

Step 3: Desolder the Power IC terminal and replace the component.

TOP PREVIOUS NEXT

Page 26

7 Connection of the Speaker Wiring

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 27

8 Block Diagram

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 28

9 Schematic Diagram

TOP PREVIOUS NEXT

(All schematic diagrams may be modified at any time with the development of the new technology)

Note:

● The voltage value and waveforms are the reference voltage of this unit measured by DC

electronic voltmeter (high impedance) and oscilloscope on the basis of chassis. Accordingly,

there may arise some error in voltage values and waveformsdepending upon the internal

impedance of the tester or the measuring unit.

● Importance safety notice :

Components identified by

; mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality

sound (capacitors), low-noise (resistors), etc. are used. Whenreplacing any of components, be

sure to use only manufacturer´s specified parts shown in the parts list.

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

● Cover the parts boxes made of plastics with aluminium foil.

● Put a conductive mat on the work table.

● Ground the soldering iron.

● Do not touch the pins of IC, LSI or VLSI with fingers directly.

TOP PREVIOUS NEXT

Page 29

10 Printed Circuit Board

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 30

11 Wiring Connection Diagram

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 31

12 Illustration of IC’ s, Transistors and Diodes

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 32

13 Parts Location and Replacement Parts List

TOP PREVIOUS NEXT

Notes:

● Important safety notice:

Components identified by

mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardent (resistors), high-quality

sound (capacitors), low noise (resistors), etc are used.

When replacing any of these components, be sure to use only manufacturer’s specified parts

shown in the parts list.

● The parenthesized indications in the Remarks columns specify the areas or colour. (Refer to

the cover page for area or colour)

Parts without these indications can be used for all areas.

● Capacitor values are in microfarads (μF) unless specified otherwise, P= Pico-farads (pF), F=

Farads.

● Resistance values are in ohms, unless specified otherwise, 1K=1,000 (OHM).

● The marking (RTL) indicates that the Retention Time is limited for this items. After the

discontinuation of this assembly in production, the item will continue to be available for a

specific period of time. The retention period of a availabilityis dependent on the type of

assembly, and in accordance with the laws governing part and product retention. After the end

of this period, the assembly will no longer be available.

● [M] Indicates in the Remarks columns indicates parts supplied by PAVCSG.

● The “(SF)” mark denotes the standard part.

13.1 Cabinet

13.1.1 Cabinet Parts Location

13.1.2 Cabinet Parts List

Page 33

13.2 Component Parts List

13.3 Packing Materials & Accessories Parts List

13.4 Packaging

TOP PREVIOUS NEXT

Page 34

13.1 Cabinet

TOP PREVIOUS NEXT

13.1.1 Cabinet Parts Location

13.1.2 Cabinet Parts List

TOP PREVIOUS NEXT

Page 35

13.1.1 Cabinet Parts Location

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 36

13.1.2 Cabinet Parts List

TOP PREVIOUS NEXT

Ref. No. Part No. Part Name & Description Remarks

CABINET AND CHASSIS

1 RFKHBWAMT1PS SPK CABINET ASS’Y [M]

1-1 RMG0520-K CATCH [M]

1-2 XTB4+12AFN SCREW [M]

2 RGK1601-S STAND ORNAMENT [M]

3 RMQ0705 EVA PACKING [M]

4 RKA0147-K FOOT [M]

5 RYB0298AJ NET FRAME ASS’Y [M]

6 XTB4+14AFN SCREW (WOOFER) [M]

7 RGNX0175A-S NAME PLATE LABEL [M]E

7 RGNX0175B-S NAME PLATE LABEL [M]EB

8 REM0072-3 FAN [M]

9 RGR0332A-JA REAR PANEL [M]

10 RHD30092 SCREW (MAIN PCB) [M]

11 RMR1485-W LED HOLDER [M]

12 XTB3+16AFZ SCREW [M]

13 XTB3+20JFZ SCREW [M]

14 XTBS3+8JFZ1 SCREW [M]

15 XTS4+20JFZ SCREW [M]

16 XTW3+15T SCREW [M]

17 XYC26+CJ6FZ SCREW [M]

18 SHE187-6J PCB SUPPORT [M]

19 RMC0158-S TR-FIXTURE [M]

TOP PREVIOUS NEXT

Page 37

13.2 Component Parts List

TOP PREVIOUS NEXT

Ref. No. Part No. Part Name & Description Remarks

PRINTED CIRCUIT BOARD

REP3435F POWER P.C.B./ AC INLET P.C.B./ TRANSFORMER P.C.B./ LED P.C.B. [M]E (RTL)

REP3435G POWER P.C.B./ AC INLET P.C.B./ TRANSFORMER P.C.B./ LED P.C.B. [M]EB (RTL)

INTEGRATED CIRCUITS

IC501 RSN311W64B-P IC HIC [M]

IC502 C0AABB000055 IC AMP [M]

TRANSISTORS

Q501 KTC3199GRTA TRANSISTOR [M]

Q502 KTC3199GRTA TRANSISTOR [M]

Q503 KTC3199GRTA TRANSISTOR [M]

Q505 KTC3199GRTA TRANSISTOR [M]

Q506 KRA102MTA TRANSISTOR [M]

Q507 KTC3199GRTA TRANSISTOR [M]

Q508 KTA12710YTA TRANSISTOR [M]

Q509 KTC3199GRTA TRANSISTOR [M]

Q510 KTC3199GRTA TRANSISTOR [M]

Q511 KTC2026 TRANSISTOR [M]

Q513 KTC3199GRTA TRANSISTOR [M]

Q514 KTC3199GRTA TRANSISTOR [M]

Q515 KTC3199GRTA TRANSISTOR [M]

Q516 KRC102MTA TRANSISTOR [M]

Q517 KTC2026 TRANSISTOR [M]

Q519 KTC3199GRTA TRANSISTOR [M]

Q520 KRA102MTA TRANSISTOR [M]

DIODES

Page 38

D500 B0AACK000004 DIODE [M]

D501 B0JAPG000019 DIODE [M]

D502 B0JAPG000019 DIODE [M]

D503 MA2C700A0F DIODE [M]

D504 B0AACK000004 DIODE [M]

D505 B0AACK000004 DIODE [M]

D506 B0AACK000004 DIODE [M]

D507 B0AACK000004 DIODE [M]

D508 B0AACK000004 DIODE [M]

D509 B0BA5R100013 DIODE [M]

D510 B0BA9R600002 DIODE [M]

D511 B0HARM000017 DIODE [M]

D512 B0HARM000017 DIODE [M]

D513 B0HARM000017 DIODE [M]

D514 B0HARM000017 DIODE [M]

D515 B0EAKM000085 DIODE [M]

D516 B0EAKM000085 DIODE [M]

D517 B0HARM000017 DIODE [M]

D518 B0HARM000017 DIODE [M]

D519 B0AACK000004 DIODE [M]

D524 SLI325URCT31 DIODE [M]

D525 B0BA6R600008 DIODE [M]

D527 B0EAKM000085 DIODE [M]

D528 B0EAKM000085 DIODE [M]

D529 B0EAKM000085 DIODE [M]

D530 B0EAKM000085 DIODE [M]

D533 B0BA5R100013 DIODE [M]

CONNECTORS

CN501 K1FB125B0095 SYSTEM CONNECTOR [M]

CN502 K1KB07B00020 2P CONNECTOR [M]

CN503 K1KA12A00066 CONNECTOR [M]

CN506 K1KA03A00006 CONNECTOR [M]

CN507 K1KA02A00008 CONNECTOR [M]

Page 39

CP502 K1KA07A00123 2P CONNECTOR [M]

COILS & TRANSFORMERS

L500 RLQZ371 LINE FILTER [M]

L501 G0AR76Y00001 CHOKE COIL [M]

L502 G0AR76Y00001 CHOKE COIL [M]

L503 G0AR76Y00001 CHOKE COIL [M]

L504 G0AR76Y00001 CHOKE COIL [M]

L505 G0AR76Y00001 CHOKE COIL [M]

T501 ETP76VSU62CA POWER TRANSFORMER [M]

T502 G4C2AAJ00005 BACK-UP TRANSFORMER [M]

COMPONENT COMBINATION

Z501 ERZV10V511CS ZENER [M]

RELAY

RLY501 RSY0040M-0 PRIMARY RELAY [M]

SPEAKER

SP1 EAST17PL21A6 SPEAKER

FUSES

F1 K5D202BK0005 250V 2A FUSE [M]

FUSE HOLDERS

FC501 EYF52BC FUSE HOLDER [M]

FC502 EYF52BC FUSE HOLDER [M]

FUSE PROTECTOR

FP1 K5G502AA0002 5A FUSE PROTECTOR [M]

Page 40

HOLDERS

H500 K1YF12000002 12P WIRE HOLDER [M]

H505A RMR0312 3P CABLE HOLDER [M]

H505B RMR0312 3P CABLE HOLDER [M]

WIRES

W1 REE1205 WIRE UNIT [M]

W2 REE1204 WIRE UNIT [M]

W500 REX1146 WIRE UNIT [M]

W505 RWJ1103320XX 3P STRAND WIRE [M]

JACKS

JK500 K2AA2B000004 JK AC INLET [M]

JK501 K4BC06B00027 JK 6P SPEAKER [M]

JK502 K4BC04B00056 JK 4P SPEAKER [M]

EARTH TERMINAL

E500 K4CZ01000027 TERMINALS [M]

E501 K4CZ01000027 TERMINALS [M]

RESISTORS

R401 ERDS2TJ224T 220K 1/4W [M]

R402 ERDS2TJ102T 1K 1/4W [M]

R403 ERDS2TJ104T 100K 1/4W [M]

R501 ERDS2TJ472T 4.7K 1/4W [M]

R502 ERDS2TJ472T 4.7K 1/4W [M]

R503 ERDS2TJ153T 15K 1/4W [M]

R504 ERDS2TJ153T 15K 1/4W [M]

R505 ERDS2TJ153T 15K 1/4W [M]

R506 ERDS2TJ153T 15K 1/4W [M]

R507 ERDS2TJ392T 3.9K 1/4W [M]

R508 ERDS2TJ392T 3.9K 1/4W [M]

Page 41

R509 ERDS2TJ472T 4.7K 1/4W [M]

R510 ERDS2TJ472T 4.7K 1/4W [M]

R511 ERDS2TJ153T 15K 1/4W [M]

R512 ERDS2TJ153T 15K 1/4W [M]

R513 ERDS2TJ563T 56K 1/4W [M]

R514 ERDS2TJ563T 56K 1/4W [M]

R515 ERDS2TJ563T 56K 1/4W [M]

R516 ERDS2TJ563T 56K 1/4W [M]

R517 ERDS2TJ563T 56K 1/4W [M]

R518 ERDS2TJ563T 56K 1/4W [M]

R519 ERDS2TJ824T 820K 1/4W [M]

R520 ERDS2TJ223T 22K 1/4W [M]

R521 ERDS2TJ103T 10K 1/4W [M]

R522 ERDS2TJ273T 27K 1/4W [M]

R523 ERDS2TJ124T 120K 1/4W [M]

R524 ERDS2TJ124T 120K 1/4W [M]

R525 ERDS2TJ154T 150K 1/4W [M]

R526 ERDS2TJ124T 120K 1/4W [M]

R527 ERDS2TJ124T 120K 1/4W [M]

R528 ERDS2TJ154T 150K 1/4W [M]

R529 ERDS2TJ223T 22K 1/4W [M]

R530 ERD25FVJ1R0T 1 1/4W [M]

R531 ERD25FVJ1R0T 1 1/4W [M]

R532 ERDS2TJ472T 4.7K 1/4W [M]

R533 ERDS1FVJ100T 10 1/2W [M]

R534 ERDS1FVJ100T 10 1/2W [M]

R535 ERDS1FVJ100T 10 1/2W [M]

R536 ERDS1FVJ100T 10 1/2W [M]

R537 ERDS1FVJ100T 10 1/2W [M]

R538 ERDS1FVJ100T 10 1/2W [M]

R539 ERDS2TJ101T 100 1/4W [M]

R540 ERDS2TJ101T 100 1/4W [M]

R541 ERDS2TJ101T 100 1/4W [M]

R542 ERDS2TJ101T 100 1/4W [M]

R543 ERDS2TJ101T 100 1/4W [M]

R544 ERDS2TJ101T 100 1/4W [M]

R545 ERDS2TJ224T 220K 1/4W [M]

Page 42

R546 ERDS2TJ102T 1K 1/4W [M]

R547 ERDS2TJ394T 390K 1/4W [M]

R548 ERDS2TJ334T 330K 1/4W [M]

R549 ERDS2TJ473T 47K 1/4W [M]

R550 ERDS2TJ103T 10K 1/4W [M]

R551 ERDS2TJ472T 4.7K 1/4W [M]

R552 ERDS2TJ562T 5.6K 1/4W [M]

R553 ERDS2TJ563T 56K 1/4W [M]

R554 ERDS2TJ824T 820K 1/4W [M]

R555 ERDS2TJ104T 100K 1/4W [M]

R556 ERDS2TJ103T 10K 1/4W [M]

R557 ERDS2TJ563T 56K 1/4W [M]

R558 ERDS1FVJ180T 18 1/2W [M]

R559 ERDS2TJ563T 56K 1/4W [M]

R560 ERDS2TJ103T 10K 1/4W [M]

R561 ERDS2TJ101T 100 1/4W [M]

R565 ERDS1FVJ392T 3.9K 1/2W [M]

R566 ERDS2TJ271T 270 1/4W [M]

R567 ERDS1FVJ152T 1.5K 1/2W [M]

R568 ERDS2TJ151T 150 1/4W [M]

R569 ERDS1FVJ392T 3.9K 1/2W [M]

R570 ERDS2TJ103T 10K 1/4W [M]

R571 ERDS2TJ332T 3.3K 1/4W [M]

R572 ERDS2TJ223T 22K 1/4W [M]

R573 D0XGR10JA005 10 1/10W [M]

R575 ERDS2TJ682T 6.8K 1/4W [M]

R577 ERDS2TJ152T 1.5K 1/4W [M]

R578 ERDS2TJ103T 10K 1/4W [M]

R579 ERDS2TJ332T 3.3K 1/4W [M]

R580 ERDS2TJ220T 22 1/4W [M]

R581 ERDS2TJ100T 10 1/4W [M]

R582 ERDS2TJ100T 10 1/4W [M]

R583 ERDS2TJ100T 10 1/4W [M]

R584 ERDS2TJ100T 10 1/4W [M]

R585 ERDS2TJ100T 10 1/4W [M]

R587 ERDS2TJ272T 2.7K 1/4W [M]

R588 ERDS2TJ151T 150 1/4W [M]

Page 43

R589 ERDS2TJ103T 10K 1/4W [M]

R590 ERDS2TJ102T 1K 1/4W [M]

R591 ERDS2TJ682T 6.8K 1/4W [M]

R592 ERDS2TJ683T 68K 1/4W [M]

R593 ERDS2TJ474T 470K 1/4W [M]

R594 ERDS2TJ103T 10K 1/4W [M]

R595 ERDS2TJ101T 100 1/4W [M]

R596 ERDS2TJ473T 47K 1/4W [M]

R597 ERDS2TJ103T 10K 1/4W [M]

R598 ERDS1FVJ152T 1.5K 1/2W [M]

R599 ERDS2TJ223T 22K 1/4W [M]

CAPACITORS

C500 ECKWRS102MBC 1000P 400V [M]

C501 ECBT1H102KB5 1000P 50V [M]

C502 ECBT1H102KB5 1000P 50V [M]

C503 ECBT1H102KB5 1000P 50V [M]

C504 ECBT1H681KB5 680P 50V [M]

C505 ECBT1H102KB5 1000P 50V [M]

C506 ECBT1H102KB5 1000P 50V [M]

C507 ECBT1H180JC5 18P 50V [M]

C508 ECBT1H180JC5 18P 50V [M]

C509 ECBT1H220JC5 22P 50V [M]

C510 ECBT1H220JC5 22P 50V [M]

C511 ECBT1H220JC5 22P 50V [M]

C512 ECBT1H220JC5 22P 50V [M]

C513 F1D1H473A012 0.047 50V [M]

C514 ECA0JM101B 100 6.3V [M]

C515 ECKR2H103ZF5 0.01 500V [M]

C516 ECKR2H103ZF5 0.01 500V [M]

C517 ECBT1C103NS5 0.01 16V [M]

C518 F1D1H473A012 0.047 50V [M]

C519 F1D1H473A012 0.047 50V [M]

C520 F1D1H473A012 0.047 50V [M]

C521 F1D1H473A012 0.047 50V [M]

C522 F1D1H473A012 0.047 50V [M]

Page 44

C523 F1D1H473A012 0.047 50V [M]

C524 F1D1H1040002 0.1 50V [M]

C525 F1D1H1040002 0.1 50V [M]

C526 F1D1H1040002 0.1 50V [M]

C527 F1D1H1040002 0.1 50V [M]

C528 F1D1H473A012 0.047 50V [M]

C529 F1D1H1040002 0.1 50V [M]

C530 ECBT1H102KB5 1000P 50V [M]

C531 ECBT1H102KB5 1000P 50V [M]

C532 ECBT1H102KB5 1000P 50V [M]

C533 ECBT1H102KB5 1000P 50V [M]

C534 ECA1HM330B 33 50V [M]

C536 ECEA1CKA330B 33 16V [M]

C537 F1D1H1040002 0.1 50V [M]

C538 ECA0JM101B 100 6.3V [M]

C539 ECEA0JKA221B 220 6.3V [M]

C540 ECEA1HKA2R2B 2.2 50V [M]

C541 ECEA1CKA100B 10 16V [M]

C543 ECBT1H102KB5 1000P 50V [M]

C544 ECA1HM101B 100 50V [M]

C545 F1D1H1040002 0.1 50V [M]

C546 ECA1VM332B 3300 35V [M]

C547 ECA1VM472B 4700 35V [M]

C548 ECA1VM472B 4700 35V [M]

C549 ECA1VM332B 3300 35V [M]

C550 ECBT1C103NS5 0.01 16V [M]

C551 ECBT1H103KB5 0.01 50V [M]

C552 F1D1H1040002 0.1 50V [M]

C553 ECQE1104KF3 0.1 100V [M]

C554 ECQE1104KF3 0.1 100V [M]

C555 ECEA1VKA4R7B 4.7 35V [M]

C556 ECBT1H103KB5 0.01 50V [M]

C557 ECEA1CKA220B 22 16V [M]

C558 ECA1CM102B 1000 16V [M]

C559 ECBT1H103KB5 0.01 50V [M]

C560 ECA1HM100B 10 50V [M]

C561 ECEA1HKA2R2B 2.2 50V [M]

Page 45

C562 ECQB1H562JF3 5600P 50V [M]

C563 ECQV1H823JL3 0.082 50V [M]

C564 ECBT1C122KR5 1200P 16V [M]

C565 F1D1H1040002 0.1 50V [M]

C566 F1D1H1040002 0.1 50V [M]

C567 ECA1HM100B 10 50V [M]

C568 ECBT1C103NS5 0.01 16V [M]

C569 F1D1H473A012 0.047 50V [M]

TOP PREVIOUS NEXT

Page 46

13.3 Packing Materials& Accessories Parts List

TOP PREVIOUS NEXT

Ref. No. Part No. Part Name & Description Remarks

PACKING MATERIALS

P1 RPF0357 MIRAMAT (STAND) [M]

P2 RPNX0189 POLYFOAM [M]

P3 RPFX0045 MIRAMAT (S.WOOFER) [M]

TOP PREVIOUS NEXT

Page 47

13.4 Packaging

TOP PREVIOUS

TOP PREVIOUS

Page 48

Page 49

Page 50

C0AABB000055

5

RSN311W64B-P

KTA12710YTA

KTC3199GRTA

KRA102MTA

KRC102MTA

8

KTC2026

E

C

B

B0EAKM000085

B0JAPG000019

Ca

A

Anode

1

Cathode

4

1

..................

26

MA2C700A0F

Ca

Cathode

A

Anode

B0BA6R600008

E

C

B

B0HARM000017

Ca

Cathode

A

Anode

SLI325URCT31

B0BA9R600002

B

C

E

B0AACK000004

B0BA5R100013

A

Anode

Ca

Cathode

Anode

Cathode

ACa

Page 51

CN501

25

24

.

.

.

.

.

.

.

.

.

.

.

.

.

TO MAIN UNIT

2

1

C

JK502

SR

SL

SPEAKERS

FR

FL

JK501

CN507

2

1

1

2

3

CN506

POWER P.C.B.

7. . . . . .1

CP502

FAN

-

+

1

.

.

.

.

.

.

.

12

H500/W500

SPEAKER

WOOFER

SOLDER SIDE

BLU

PbF

12

.

.

.

.

.

.

.

1

CN503

3

2

1

H505B/W505

W1

W2

BRW

LED P.C.B.

PbF

1

2

3

H505A/W505

SOLDER SIDE

AC IN

230~240V

50HZ

T501(POWER TRANSFORMER)

TRANSFORMER

JK500

SOLDER SIDE

PbF

P.C.B.

T502(POWER TRANSFORMER)

CN502

7. . . . . .1

W2

BLU

AC INLET

P.C.B.

SOLDER SIDE

W1

BRW

PbF

Page 52

ABCDEFG

6

D506

1

POWER P.C.B. (REP3435F...E)

(REP3435G...EB)

2

CAUTION

RISK OF ELECTRIC SHOCK

AC VOLTAGE LINE. PLEASE DO NOT

TOUCH THIS P.C.B

3

CN501

25

24

23

22

21

20

19

18

17

16

15

14

13

JK502

12

11

10

9

8

7

6

5

4

3

2

1

4

TO MAIN UNITSPEAKERS

5

C

SR

SL

6

FR

C525

FL

JK501

7

C528

C524

J591

C519

C527

C526

R536

J592

C532

C522

C518

C521

L503

R583

J570

J528

R543

R544

R540

R539

R537

R533

-

+

CN507

C531

R534

C520

J519

C530

R581

L501

R584

L504

J571

R585

L505

R582

L502

J410

+

PbF

J572

1

2

3

R535

J521

E500

J575

CN506

C533

J574

R573

C552

C549

R593

R597

C565

C561

J409

J595

C563

C566

5678

IC502

R403

R591

J573

J593

J594

R592

J581

C550

J596

1234

C564

CP502

7654321

R542

R522

R521

R545

C529

D504

J538

J531

C562

R538

R595

R596

R594

C569

C523

J539

R547

D503

R531

R530

J536

J597

J533

C534

C548

J504

R548

Q505

R541

R549

J577

J537

J550

15

IC501

B

C

E

D501

R572

Q506

B

C

E

J563

J562

J511

J599

J561

Q513

EB

C

EB

C

Q514

R599

J517

J515

J565

R565

J576

10

R571

J579

J532

D508

C568

J598

J580

J514

D507

Q509

J507

J508

R554

R555

C540

R557

B

C

J408

E

C539

D516

D515

C547

R529

C545

R519

C513

C517

D502

15 20

J506

D518

C537

R556

Q510

J552

J564

C505

Q507

B

C

R559

R553

E

R561

B

B

C

C

E

R552

R523

C515

J509

C546

R501

J510

C516

C504

E

Q508

R513

C507

C503

C50

R551

R524

8

9

Page 53

R555

J408

J508

C540

D516

C539

R554

R557

D515

R556

J506

D518

C537

Q510

J552

HG

Q507

B

C

R559

R553

E

R561

D506

R551

R560

C536

D505

R550

D512

J586

B

B

C

C

E

E

J509

Q508

R552

C546

J587

J588

C538

D519

R558

J512

R570

D511

IJKLM

J582

J583

J566

FP1

J505

J513

5A

CN503

12

11

10

9

8

7

6

5

4

3

2

1

J418

R402

D514

R566

J567

J568

J569

J560

C541

EB

C

Q520

D513

C514

J535

R546

J548

B

C

E

Q501

D517

J547

J401

J546

J589

R520

C554

C553

J545

B

C

E

J544

Q502

J402

J403

J404

J405

J406

J564

C545

R519

02

520 26

C517

C505

R523

C515

R501

J510

C516

C504

R513

C507

C503

C506

J584

Q503

EB

R514

R524

C

C508

R516

R526

C502

C501

C510

R532

R525

J518

R515

R510

R509

C509

R527

R517

R575

C511

R528

R518

R512

J417

R502

R504

R508

R507

R506

C543

Q511

B

R568

J541

C

R503

E

J590

R505

C512

R511

R569

D510

J551

J516

J585

R598

R567

C544

C567

C551

D533

D509

C560

H505B/W505

E501

3

2

1

Page 54

SCHEMATIC DIAGRAM-1

POWER CIRCUIT

: -B SIGNAL LINE

: +B SIGNAL LINE

: MAIN SIGNAL LINE

TO

MAIN CIRCUIT

(JK700) OF

SA-HT500E/EB/EG-S,

SA-ST1EB/EG-S

CN501

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

E501

K4CZ01000027

AC1

1

DC_DET

2

AC2

3

SYS6V

4

HP_CNT

5

D.GND

6

FL

7

HELP

8

A.GND

9

A.GND

FR

SL

A.GND

SR

C

A.GND

SW

A.GND

PCONT

MUTE A/CNTR SURR

SYNC

FL1

AC3

FL2

AC4

C551

0.01

R501

4.7K

R502

4.7K

R506

15K

R505

15K

R539 100

R540 100

R543 100

IC501

FLin

FRin

IN GND

SUBin

Cin

-VD

+VD

SRin

SLin

RELAY

-Di SENS

+Di SENS

IH DET

R532

4.7K

R546

1K

Q506

Q505

SWITCHING

C538

R558

18

DISP HMUT

R523

820K

R519

R557

56K

120K

R520

R530 1

R531 1

26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9

R513

56K

C507 18P

R514 56K

C508 18P

C505 1000P

C506 1000P

R516 56K

C501

1000P

R507

3.9K

R503

15K

R504

15K

R541

100

R542

100

MA2C700A0F

C529 0.1

3.9K

R508

D503

R547

390K

R549 47K

C502

1000P

C503

1000P

R509

4.7K

R511

15K

R512

15K

R544

100

B0AACK000004

C534

50V33

R553

56K

R550

10K

C536

16V33

C504 680P

R510 4.7K

C516

0.01

R402

1K

D504

C510 22P

R515 56K

C509 22P

R517 56K

C511 22P

R518 56K

C512 22P

C515

0.01

C517

0.01

KRA102MTA

INTERFACE SWITCH

R545

220K

D503

R548

330K

Q507

KTC3199GRTA

SWITCH

Q507

R561

100

D506

10K

D505

R560

C513

0.047

Q520

KRA102MTA

INTERFACE SWITCH

KTC3199GRTA

6.3V100

R559

56K

SL_O

R526

120K

R525

150K

R527

120K

R528

22K

Q503

6.3V220

SR_O

R524

120K

150K

C539

GND

C514

6.3V100

AC IN

C_O

-VCC LOW

+VCC LOW

8

6 5

7

D502

D501

R529

22K

Q503

KTC3199GRTA

SWITCH

Q502

Q501

Q509

KTC3199GRTA

SWITCH

D505-D506

B0AACK000004

SUB_O

-VCC HI

+VCC HI

432

FR_O

FL_O

1

27K

R522

D508

B0AACK000004

RSN311W64B-P

POWER HIC

D501-D502

B0JAPG000019

R521

10K

Q501-Q502

KTC3199GRTA

SWITCH

IC501

TO FAN

CN507

16V10

D507

C541

R566

270

D507, D519

B0AACK000004

D519

R551

4.7K

R554 820K

C537 0.1

R552

5.6K

Q508

+

1

-

2

Q508

KTA12710YTA

CURRENT AMP

Q510

KTC3199GRTA

SWITCH

Q510

R556

10K

R555

100K

C540

50V2.2

Page 55

L501

R581 10

L502

R582 10

L505

R585 10

L503

R583 10

L504

R584 10

L501-L505

G0AR76Y00001

SCHEMATIC DIAGRAM-2

POWER CIRCUIT

R593

R591

470K

6.8K

C562

5600P

C563

0.082

C561

R575

50V2.2

6.8K

Q513

KTC3199GRTA

DC DETECT SWITCH

KTC3199GRTA

DC DETECT SWITCH

: -B SIGNAL LINE

: +B SIGNAL LINE

C564

1200P

R592

IC502

C522

0.047

C518

0.047

R533

68K

10

C523

0.047

C569

0.047

10

C565

0.1

C0AABB000055

DUAL LOW-NOISE OP AMP

5 6 7 8

Q514

C520

C521

0.047

0.047

R53510R53610R53710R538

R597

1234

10K

R403

100K

R594 10K

0.1

C566

C519

0.047

R596

R534

47K

10

C552

0.1

: MAIN SIGNAL LINE

C568

0.01

C524

0.1

Q514

R599

22K

R571

3.3K

C526

0.1

C525

0.1

C528

0.047

C527

Q513

0.1

R572

22K

R595

100

R573

0.1

JK501

+

FLch

-

+

FRch

-

+

SRLch

-

JK502

+

SRRch

-

+

CENTER

-

3

2

SUB WOOFFER

1

CN506

C560

50V10

Q511

KTC2026

VOLTAGE REGULATOR

C544

50V100

D509

C543

1000P

C567

50V10

D509, D533

B0BA5R100013

R568

150

D533

R569

3.9K

D510

B0BA9R600002

R598

1.5K

R567

1.5K

C545

0.1

R570

10K

D515

C546

35V3300

D517

D515, D516

B0EAKM000085

C547

35V4700

D513

D514

D511-D514,D517-D518

B0HARM000017

C530

1000P

C550

0.01

C548

35V4700

D511

D512

R565

3.9K

C531

1000P

E500

K4CZ01000027

D516

C549

35V3300

C532

1000P

D518

C554

0.1

C553

0.1

FP1

K5G502AA0002

C533

1000P

PCONT

SYS6V

3

3

2

2

1

1

H505B/W505

FP1

1

2

GND

3

SYNC

4

5

HELP

6

7

D524

SLI325URCT31

H505A/W505

1

2

3

4

5

6

7

8

9

10

11

12

CP502

TO

AC INLET

CIRCUIT

(CN502) ON

SCHEMATIC

DIAGRAM-3

R577

1.5K

LED

CIRCUIT

CN503

TO

TRANSFORMER

CIRCUIT

(H500/W500) ON

SCHEMATIC

DIAGRAM-3

Page 56

SCHEMATIC DIAGRAM-3

: -B SIGNAL LINE

: +B SIGNAL LINE

H500/W500

TO

POWER CIRCUIT

(CN503) ON

SCHEMATIC

DIAGRAM-2

D530

D529

D527-D530

B0EAKM000085

C559

0.01

R578

10K

C555

35V4.7

D528

D527

TO

POWER CIRCUIT

(CP502) ON

SCHEMATIC

DIAGRAM-2

CN502

R589

10K

Q516

KRC102MTA

SYNC SWITCH

1

PCONT

2

GND

3

SYNC

4

SYS6V

5

HELP

6

7

R590

1K

R580

22

Q517

KTC2026

VOLTAGE REGULATOR

C557

16V22

R401

220K

R579

3.3K

C556

0.01

R587

2.7K

R588

150

D525

D525

B0BA6R600008

C558

16V1000

TRANSFORMER CIRCUIT

Q519

KTC3199GRTA

DC DET SWITCH

W1

T501

ETP76VSU62CA

1

2

3

4

5

6

7

8

9

10

11

12

FOR E/EG

FOR EB

W2

Q515

Q515

KTC3199GRTA

DC DET SWITCH

D500

B0AACK000004

D500

T502

G4C2AAJ00005

RLY501

RSY0040M-0

4 3

2 1

C500

1000P

AC INLET CIRCUIT

Z501

ERZV10V511CS

F1

250V T2AL

FC502

FC501

L500

RLQZ371

JK500

AC IN

230V-240V

50HZ

Page 57

POWER CONTROL

CIRCUIT

IC501

RSN311W64B-P

-

+

-

+

-

+

-

+

POWER CONTROL/PROTECTION CIRCUIT

POWER HIC

TO MAIN

BLOCK

(JK700) OF

SA-HT500E/EB/EG-S,

SA-ST1EB/EG-S

A

SL(R)

CCH

FL(R)

DC_DET

SUBWO

HP_CNT

AC1(4)

AC2(5)

26

(25)

FLIN(R)

CIN

SUBIN

22 23 18

SLIN(R)

+DI SENS

2015 3 6 1

(19)

B

D508

IC502

C0AABB000055

DUAL

LOW-NOISE

OP AMP

INTERFACE

+VD

B B

Q520

SWITCH

+VCC HI

+VCC LOW

D501

FILTER

FILTER

FILTER

FILTER

Q513,

Q514

FL_O(R)

(2)

DC DET

SWITCH

Q503

SWITCH

C_O

8 512(11) 24

Q501,

Q502

SWITCH

Q507~Q510

FAN

MOTOR

DRIVE

SL_O(R)

M

B

Q511

VOLTAGE

REGULATOR

FILTER

FILTER

FILTER

SUB_O

B

B

IN GND

B

Q506

INTERFACE

SWITCH

Q505

SWITCHING

D513~D515,

D517

D511,D512,

D516,D518

DISP HMUT

IH DET

AC IN

91314 7421

TO FL

DISPLAY

-VCC LOW

D502

-VCC HI

-VD

B B

T501

POWER TRANSFORMER

-DI SENS

16

JK501(JK502)

SURROUND

SPEAKER

JK502

CENTRE

SPEAKER

SUBWOOFER

JK501

FRONT

SPEAKER

RLY501

B

PCONT

SYNC

Q515,Q519

DCDET

SWITCH

B

Q517

VOLTAGE

REGULATOR

B

D527~D530

Q516

SYNC

SWITCH

SIGNAL LINES

: MAIN SIGNAL LINE

( ) Indicates Pin No. of Right Channel Note : Signal Lines are applicable to the Left Channel only.

T502

SUB

TRANSFORMER

Z501

JK500

AC INLET

L500

F1

E500

Page 58

ABCDEFG

1

AC INLET P.C.B. (REP3435F...E)

(REP3435G...EB)

CAUTION

RISK OF ELECTRIC SHOCK

2

3

JK500

AC IN

230V-240V

50HZ

4

J500

J501

J502

J503

AC VOLTAGE LINE. PLEASE DO NOT

TOUCH THIS P.C.B

FC501

F1 250V T2AL

L500

PbF

T502 (POWER TRANSFORMER)

J525

J526

7

J540

CN502

FC502

W2

W1

C558

C555

BRWBLU

C557

Q517

E

R587

C

C556

R588

D525

B

Z501

C500

RLY501

2

1

R590

34

R579

D500

J523

R401

1

J522

J529

Q515

Q516

EB

C

R589

R578

B

C

Q519

E

D527

C559

J527

R580

D529

D530

D528

B

C

E

5

TRANSFORMER P.C.B. (REP3435F...E)

(REP3435G...EB)

6

CAUTION

RISK OF ELECTRIC SHOCK

AC VOLTAGE LINE. PLEASE DO NOT

TOUCH THIS P.C.B

LED P.C.B.(REP3435F...E)

W1W2

BRW

7

1

J520

2

3

4

5

6

7

H500/W500

8

8

9

10

11

12

BLU

R577

D524

PbF

(REP3435G...EB)

3

2

1

H505A

/W505

9

T501 (POWER TRANSFORMER)

PbF

Loading...

Loading...