Page 1

Industrial Fluidised Baths

IFB-51 and IFB-52

Instruction Manual

7002661 / Version 5

Page 2

CONTENTS

2

IMPORTANT SUPPLEMENTARY SAFETY INFORMATION 3

GENERAL DESCRIPTION 4

BEFORE USE 5

SAFETY AND INSTALLATION 6

English 6

Français 8

Deutsch 10

Español 12

Italia 14

WARNING 16

PRINCIPLE OF OPERATION AND SAFETY FEATURES 17

DESCRIPTION OF COMPONENTS AND FRONT PANEL CONTROLS 18

INSTALLATION 19

Set-up 19

OPERATION 20

Start-Up 20

Air adjustment 20

Bath temperature 20

Extraction Air setup 20

Shut-Down 21

PID Temperature Controller 21

THE CLEANING PROCESS 22

FUME IGNITION 23

FUME EXTRACTION AND CLEANING 24

OPERATOR MAINTENANCE 25

Special maintenance procedures when burning off PVC or other halogenated polymers 26

FAULT FINDING 27

SERVICE, REPAIR AND TECHNICAL SUPPORT 28

Warranty 28

TECHNICAL SPECIFICATION 29

REPLACEMENT PARTS 30

ACCESSORIES 30

DECLARATION OF CONFORMITY 31

Page 3

IMPORTANT SUPPLEMENTARY SAFETY INFORMATION

3

Introduction

Techne fluidised baths are safe and effective equipment when installed and operated correctly in

accordance with the user manual. However, if used incorrectly they can pose a safety risk. Techne have

designed all models of fluidised baths to protect operators from hazards but users should pay attention to

the following points.

Symbols Defined

WARNING

Caution

1. Please read the Instruction Manual before installation and use.

2. Some Techne fluidised baths can heat up to 700°C. High temperatures are dangerous and can cause

serious burns to operators and ignite combustible material.

3. Use care and wear protective gloves to protect hands and protective glasses to protect eyes.

4. Do not put hot objects on or near combustible objects.

5. Do not operate the unit close to inflammable liquids or gases.

6. Do not place any liquid directly in the unit.

7. Always ensure a suitable, adequate ventilation system is used when equipment is in use.

8. Always install fireproof metal ducting with sufficient airflow where applicable.

Maintenance

1. When performing maintenance, always disconnect from power supply and cool below 50°C.

2. Techne recommend regular cleaning of fluidised baths. Externally, wipe with a damp soapy cloth. No

abrasive cleaners should be used. Care should be taken to prevent any water entering the unit.

3. Regular internal and external inspection of extraction ducting is recommended to detect any damage

and ensure the internals are clean. Any build-up of particles or debris discovered in the extraction

ducting requires the ducting to be cleaned or replaced.

4. In fluidised baths used for polymer burn-off, please regularly inspect fluidising medium, remove any

foreign debris and replace with clean fluidising medium as required.

5. Never top-up a hot fluidised bath with cold fluidising medium. Always cool below 50°C first.

FIRE

HAZARD

HOT

SURFACE

RISK OF

ELECTRIC

SHOCK

HEAVY OBJECT

2 PERSON LIFT

REQUIRED

EARTH

Please note:

1. Please ensure an adequate risk assessment is performed before use of a fluidised bath.

2. Please ensure the appropriate temperature is used for the application, always stay safely below the

combustion temperature of any material or sample in a fluidised bath.

3. Fluidising airflow must be switched on before heating a fluidised bath and left operational until the

bath cools to below 50°C.

4. Do not overfill fluidising media. When fluidized, the aluminium oxide level should be approximately

100mm (4”) from the top surface of the bath at your maximum operating temperature.

5. In fluidised baths used for polymer burn-off, always remove excess polymer from sample.

6. In applications where materials being treated produce acidic vapours during thermal decomposition, it

is recommended a fume scrubber is utilised to ensure fume emission from the plant conforms to local

regulations.

7. If you have any questions, please contact cptechsupport@coleparmer.com

.

Page 4

GENERAL DESCRIPTION

4

The Techne Indust

residue from extruder tools, moulding machine tools and associated parts.

The fluidised bath employs the principle of fluidisation of a mass of finely divided inert particles by means

of an upward flow of gas. A state of fluidisation is achieved when the individual particles become

microscopically separated from each other by the moving gas. This “fluidised bed” of particles has unusual

properties which differ markedly from either those of the gas or of the solid particles. Instead, the fluidised

bed behaves remarkably like a liquid, exhibiting characteristics which generally attribute to a liquid state.

For example, the fluidised bed can be agitated and bubbled; it always seeks a common level; materials of

less density will float while those with densities greater than the equivalent fluidised bed density will sink;

and, most important, the heat transfer characteristics between the fluidised bed and a solid interface can

have an efficiency approaching that of an agitated liquid.

In addition, the fluidised solid phase has a most unusual physical behaviour, in that its basic characteristics

change only slightly over very large temperature ranges; it has no melting point and no boiling point. The

lowest temperature available is the liquefaction point of the gas used for fluidisation, while the highest

temperature level is the usable temperature of the inert solid. Various metal oxides with allowable

temperatures of over 1700°C are readily available. The metal oxide beds commonly used, (e.g. aluminium

oxide) are non-flammable, non-explosive and non-toxic.

The most commonly used fluidising gas is compressed air. It is important that it should be clean, dry, free

from oil and at a constant pressure. Any other inert gas, such as nitrogen, could be used for special

applications e.g. if a non-oxidising atmosphere is required, provided appropriate precautions are taken.

rial Fluidised Baths IFB-51 and IFB-52 have been specially designed for removing plastic

The unique characteristics of gas-fluidised particles is the relatively high rate of heat transfer which yields

highly isothermal conditions, as well as excellent heat transfer to solid surfaces. This characteristic is due to

the turbulent motion and rapid circulation rate of the solid particles in conjunction with the extremely high

solid-gas interface area. Therefore, even though gas-solid interfaces normally yield low heat transfer

coefficients and the solids normally have low thermal conductivities, the overall heat transfer characteristics

of fluidised particles approach those of a liquid.

The combination of excellent heat transfer characteristics and high heat capacity are ideal for attaining

rapid stabilisation at an isothermal condition.

Techne industrial fluidised baths use alundum - fused brown aluminium oxide - as the fluidising medium.

They have been designed to remove plastic residue from extruder and moulding machine tools, paint build

up from paint fixtures and carry out various heat treatment processes. When used for burning plastic

residues, the IFB’s should be installed with an adequate fume extraction system. An extraction fan and

fume extraction collar can be supplied.

Page 5

BEFORE USE

5

Thank you for purchasing this Techne product. To get the best performance from the equipment, and for

your own safety, please read these instructions carefully before use. If there is any doubt relating to the

proper use of this equipment, the staff at Cole-Parmer Ltd. or your supplier will be happy to assist you.

UNPACKING

When unpacking the unit please ensure that the following have been removed from the packaging:

Part code

FIFB51D or FIFB52D

7002661

Please note that the aluminium oxide fluidising medium must be ordered separately:

Part code Item description

Brown/ALO Alundum - brown aluminium oxide, 25kg.

The IFB-51 requires 40kg of aluminium oxide and the IFB-52, 73kg of aluminium oxide.

The user is advised to keep the original packaging in case the instrument ever needs to be returned for

service or repair. Cole

packed and transported in its original packaging.

If the equipment is not used in the manner described in this manual and with accessories other than those

recommended by the manufacturer, the protection provided may be impaired.

Item description

IFB Industrial fluidised bath

Instruction manual

Eurotherm controller instructions

Warranty card

-Parmer Ltd. accepts no responsibility for damage incurred unless the unit is correctly

Page 6

SAFETY AND INSTALLATION

6

Please read all the information in this Instruction Manual before using the unit.

WARNING

HIGH TEMPERATURES ARE DANGEROUS: they can cause serious burns to operators and ignite

combustible material.

Techne have taken great care in the design of these units to protect operators from hazards, but

operators should pay attention to the following points:

• USE CARE AND WEAR PROTECTIVE GLOVES TO PROTECT HANDS AND SAFETY GLASSES TO

PROTECT EYES.

• DO NOT use combustible substances near hot objects.

• DO NOT operate the instrument in the vicinity of inflammable liquids or gases.

• DO NOT place any liquid directly into the instrument.

• At all times USE COMMON SENSE.

OPERATOR SAFETY

All operators of Techne equipment must have available the relevant literature needed to ensure their

safety. It is important that only suitably trained personnel operate this equipment in accordance with the

instructions contained in this manual and with general safety standards and procedures. If the equipment

is used in a manner not specified by Techne the protection provided by the equipment to the operator

may be impaired.

All Techne units have been designed to conform to international safety requirements and are fitted with

an over-temperature cut-out. On some models, the cut-out is adjustable and should be set to suit the

application. On all other models the cut-out is pre-set to protect the unit.

If a safety problem should be encountered, switch off at the mains power supply.

INSTALLATION

Before connecting the instrument to the mains electricity supply, check the voltage against the

rating plate (located on the back of the unit). Please note that the unit must be earthed to

ensure proper electrical safety.

Connections 220V-240V

Live Brown

Neutral Blue

Earth Green/yellow

Note: The IFB-51 and IFB-52 are classified as “Permanently Connected Equipment” and should be

connected to the electricity supply by a qualified electrician.

A suitable supply for the IFB-51 is rated at 4kW, 220-240V, 50/60Hz~ single phase.

A suitable supply for the IFB-52 is rated at 6kW, 220-240V, 50/60Hz~ single phase.

The equipment is supplied with 2.5m of flexible, triple core, circular cable to the following specification:

4.0mm², to BS 6500 or equivalent and <HAR> or BASEC approved. Connection to the mains electrical

supply should be via a double pole 30mA Residual Current Breaker with Overcurrent protection (RCBO)

isolating circuit breaker switch with a continuous current carrying capacity of 30A at 250V and

overcurrent of 30A.

Do not switch on until the unit is fully installed.

Page 7

ENVIRONMENTAL CONDITIONS

7

This equipment is designed to operate under the following conditions:

• Indoor use

• Use in a well-ventilated area

• Ambient temperature range +5°C to +40°C

• Altitude to 2000 m (6500 ft.)

• Relative humidity 80%

• Mains supply fluctuations not exceeding 10%

• Overvoltage category II IEC60364-4-443

• Pollution degree 2 IEC664

GUARANTEE

The unit is guaranteed against any defect in material or workmanship for the period specified on the

enclosed guarantee card. This period is from the date of purchase, and within this period all defective parts

will be replaced free of charge provided that the defect is not the result of misuse, accident or

negligence. Servicing under this guarantee should be obtained from the supplier.

Notwithstanding the description and specification(s) of the units contained in the operator’s manual,

Techne hereby reserves the right to make such changes as it sees fit to the units or to any component of

the units.

This manual has been prepared solely for the convenience of Techne customers and nothing in this

instruction book shall be taken as a warranty, condition or representation concerning the description,

merchantability, fitness for purpose or otherwise of the units or components.

OPERATOR MAINTENANCE

NOTE: THAT THIS EQUIPMENT SHOULD ONLY BE DISMANTLED BY PROPERLY TRAINED PERSONNEL.

REMOVING THE SIDE, FRONT OR REAR PANELS EXPOSES POTENTIALLY LETHAL MAINS VOLTAGES.

THERE ARE NO OPERATOR MAINTAINABLE PARTS WITHIN THE EQUIPMENT.

In the unlikely event that you experience any problems with your unit which cannot easily be remedied, you

should contact your supplier and return the unit if necessary. Please include any details of the fault observed

and remember to return the unit in its original packing. Techne accept no responsibility for damage to units

which are not properly packed for shipping: if in doubt, contact your supplier.

1.Cleaning

Before cleaning your unit ALWAYS disconnect it from the power

Your unit can be cleaned by wiping with a damp soapy cloth. Care should be exercised to prevent water

from running inside the unit. Do not use abrasive cleaners.

2.Over-temperature cut-out

In the event of no heater power, check the mains plug and lead. Repeated operation of the cut-out

indicates a serious fault: you may need to return the unit to your supplier for repair.

3.Fuses

Your unit is protected by one or two fuses. These should only be changed by suitably qualified personnel.

If the fuses blow persistently, a serious fault is indicated and you may need to return the unit to your

supplier for repair.

supply and allow it to cool below 50°C.

Page 8

SÉCURITÉ ET CONSIGNES D’INSTALLATION

8

Veuillez lire attentivement toutes les instructions de ce document avant d’utiliser l’appareil.

AVERTISSEMENT

DANGER DE TEMPERATURES ELEVEES: les opérateurs peuvent subir de graves brûlures et les matériaux

combustibles risquent de prendre feu.

Techne a apporté un soin tout particulier à la conception de ces appareils de façon à assurer une

protection maximale des opérateurs, mais il est recommandé aux utilisateurs de porter une attention

spéciale aux points suivants :

• UTILISEZ ET PORTEZ DES GANTS DE PROTECTION POUR PROTÉGER VOS MAINS ET DES

LUNETTES DE SÉCURITÉ POUR PROTÉGER VOS YEUX.

• NE PAS poser d’objets chauds sur ou près de matériaux combustibles.

• NE PAS utiliser l’appareil à proximité de liquides ou de gaz inflammables.

• NE PAS verser de liquide directement dans l’appareil.

• FAIRE TOUJOURS PREUVE DE BON SENS.

SÉCURITÉ DE L’OPÉRATEUR

Tous les utilisateurs de produits Techne doivent avoir pris connaissance des manuels et instructions

nécessaires à la garantie de leur sécurité.

Important : cet appareil doit impérativement être manipulé par un personnel qualifié et utilisé selon les

instructions données dans ce document, en accord avec les normes et procédures de sécurité

générales. Dans le cas où cet appareil ne serait pas utilisé selon les consignes précisées par Techne, la

protection pour l’utilisateur ne serait alors plus garantie.

Tous les appareils Techne sont conçus pour répondre aux normes de sécurité internationales et sont

dotés d’un coupe-circuit en cas d’excès de température. Sur certains modèles, ce coupe-circuit est

réglable pour s’adapter à l’application désirée. Sur d’autres modèles, il est pré-réglé en usine pour

assurer la protection de l’appareil.

En cas de problèmes de sécurité, coupez l'alimentation secteur.

INSTALLATION

Avant de raccorder l’appareil à l’alimentation électrique sur secteur, vérifier la tension requise

indiquée sur la plaque d’identification (située au dos de l’appareil). Il est important que

l’appareil soit relié à la terre pour assurer la protection électrique requise.

Connexions 220V-240V

Phase Marron

Neutre Bleu

Terre Vert/jaune

Remarque : les modèles IFB-51 et IFB-52 sont classés en tant qu'« Équipement branché en permanence »

et devraient être raccordés au réseau électrique par un électricien qualifié.

Une alimentation électrique adaptée au modèle IFB-51 correspond à 4 kW, 220-240 V, 50/60 Hz~ monophasé.

Une alimentation électrique adaptée au modèle IFB-52 correspond à 6 kW, 220-240 V, 50/60 Hz~ monophasé.

L'équipement est doté d’un câble circulaire flexible à trois conducteurs, de 2,5 m de long, répondant aux

spécifications suivantes : 4,0 mm², à BS 6500 ou équivalent et approuvé par <HAR> ou BASEC. La connexion au réseau électrique devrait être faite par le biais d'un disjoncteur à courant continu résiduel bipolaire

de 30 mA, doté d’un système de protection de surintensité (RCBO), un disjoncteur isolant avec

une capacité de transport de courant de 30 A à 250 V et surintensité de courant de 30 A.

Ne pas allumer avant que l'unité soit complètement installée.

Page 9

CONDITIONS ENVIRONNEMENTALES

9

Cet appareil est conçu pour fonctionner dans les conditions suivantes:

• Pour un usage intérieur seulement

• Utilisation dans un lieu correctement ventilé

• Température ambiante +5°C à +40°C

• Altitude inférieure à 2000m

• Humidité relative ne dépassant pas 80%

• Fluctuations de l’alimentation n’excédant pas 10% de la valeur nominale

• Catégorie II IEC 60364-4-443 de surtension

• Degré de pollution 2 IEC664

GARANTIE

L’appareil est garanti contre tout défaut ou visde fabrication pour la durée figurant sur la carte de garantie, à

compter de la date d’achat de l’appareil. Au cours de cette période, toutes les pieces défectueuses seront

remplacées gratuitement, dans la mesure où la défaillance n’est pas due à une mauvaise utilisation, un

accident ou une négligence. Toute réparation sous garantie sera effectuée par le fournisseur.

Malgré la description et les spécifications de l’appareil données dans le manuel de l’utilisateur, Techne se

réserve le droit d’effectuer les changements nécessaires à l’appareil ou à tout élément qui entre dans sa

composition.

Ce manuel a été exclusivement rédigé à l’attention des clients de Techne, et aucun élément de ce guide

d’instructions ne peut être utilisé comme garantie, condition ou représentation concernant la description,

commercialisation, adaptation aux conditions d’utilisation ou autre des appareils ou leurs composants.

ENTRETIEN UTILISATEUR

IMPORTANT: CET APPAREIL NE PEUT ETRE DEMONTE QUE PAR DU PERSONNEL QUALIFIE.

LORSQUE LES PANNEAUX AVANT, ARRIERE ET LATERAUX SONT DEMONTES, L’OPERATEUR EST EXPOSE

A DES TENSIONS QUI PEUVENT ETRE MORTELLES.

CET APPAREIL NE CONTIENT AUCUN ELEMENT QUI DEMANDE UN ENTRETIEN DE LA PART DE

L’UTILISATEUR.

Dans le cas peu probable où votre appareil présente un défaut de fonctionnement auquel il est difficile de

remédier, il est alors préférable de contacter votre fournisseur et, le cas échéant, de renvoyer le matériel.

Veuillez inclure une description détaillée du problème constaté et retourner l’appareil dans son emballage

d’origine. Techne ne sera pas tenu responsable des dommages subis par tout appareil don’t l’emballage

est inadéquat pour le transport. Pour plus de sûreté, contactez votre fournisseur.

1.Nettoyage

Avant de nettoyer l’appareil, assurez-vous TOUJOURS que le câble d’alimentation est déconnecté et

laissez la température redescendre en dessous de 50°C.

Utilisez un chiffon imprégné d’eau savonneuse pour nettoyer l’appareil. Veillez à ne pas introduire d’eau

dans l’appareil. N’utilisez pas de produits abrasifs.

2.Coupe-circuit d’excès de température

• En l’absence de puissance de chauffe, vérifiez la prise et le câble d’alimentation puis réglez la commande

du coupe-circuit (si votre appareil est doté de ce mécanisme).

• Si la sécurité se déclenche trop souvent, il s’agit d’un problème plus sérieux. Nous vous conseillons

dansce cas de prendre contact avec votre fournisseur pour réparation.

3.Fusibles

La protection de l’appareil est assurée par un ou deux fusibles dont le remplacement ne peut être effectué

que par un personnel qualifié.

Si les fusibles sautent sans arrêt, il s’agit d’un problème sérieux. Nous vous conseillons dans ce cas de

rendre contact avec votre fournisseur pour réparation.

Page 10

SICHERHEITS - UND INSTALLATIONSINFORMATIONEN

10

Bitte lesen Sie diese Bedienungsanleitung komplett bevor Sie dieses Gerät benutzen.

WARNUNG

HOHE TEMPERATUREN SIND GEFÄHRLICH: sie können dem Bediener ernsthafte Verletzungen zufügen

und brennbare Materialien können sich leicht entzünden.

Techne hat bei der Konstruktion dieses Gerätes sehr darauf geachtet, daß der Bediener vor Gefahren

geschützt ist. Dennoch sollten Sie auf die folgenden Punkte achten:

• TRAGEN SIE SCHUTZHANDSCHUHE ZUM SCHUTZ IHRER HÄNDE UND SETZEN SIE EINE

AUGENSCHUTZBRILLE AUF.

• KEINE brennbaren Stoffe in der Nähe heißer Gegenstände verwenden.

• Das Gerät NICHT in der Nähe entzündlicher Flüssigkeiten oder Gase betreiben.

• Flüssigkeiten NICHT direkt auf das Gerät auftragen.

• Benutzen Sie immer den normalen Menschenverstand.

SICHERHEIT DES ANWENDERS

Alle Benutzer von Techne Geräten müssen Zugang zu der entsprechenden Literatur haben, um ihre

Sicherheit zu gewähren.

Es ist wichtig, daß diese Geräte nur von entsprechend geschultem Personal betrieben werden, das die in

dieser Gebrauchsanweisung enthaltenen Maßnahmen und allgemeine Sicherheitsbestimmungen und

-vorkehrungen beachtet. Wenn das Gerät anders eingesetzt wird als vom Hersteller empfohlen, kann dies

die persönliche Sicherheit des Anwenders beeinträchtigen. Die Geräte von Techne entsprechen den internationalen Sicherheitsbestimmungen und sind mit einem automatischen Übertemperaturabschalter ausgestattet. Bei einigen Modellen ist der Übertemperaturabschalter verstellbar und sollte je nach Anwendung

entsprechend eingestellt werden. Bei allen anderen Modellen ist der Temperaturschutz

voreingestellt um Schäden am Gerät zu vermeiden.

Sollte ein Sicherheitsproblem auftreten, schalten Sie die Hauptstromversorgung aus.

INSTALLATION

Vor dem Anschluss bitte kontrollieren, ob die Stromversorgung den Angaben auf dem Typenschild

auf der Geräterückseite) entspricht. Um die elektrische Sicherheit zu gewährleisten, muss

dieses Gerät geerdet werden.

Anschluss 220V-240V

Phase Braun

Neutral Blau

Erde Grün/Gelb

Hinweis: IFB-51 und IFB-52 sind als „Permanent angeschlossene Geräte“ eingestuft und sollten von einem

qualifizierten Elektriker an den Stromanschluss angeschlossen werden.

Die geeignete Stromversorgung für das Gerät IFB-51 beträgt 4kW, 220-240V, 50/60Hz~, einphasig.

Die geeignete Stromversorgung für das Gerät IFB-52 beträgt 6kW, 220-240V, 50/60Hz~, einphasig.

Das Gerät wird mit einem 2,5 m langen flexiblen, dreiadrigen Rundkabel mit folgenden Spezifikationen

betrieben: 4,0 mm², BS 6500 oder gleichwertig und <HAR>- oder BASEC-zertifiziert. Der Anschluss an das

Stromnetz sollte über einen doppelpoligen 30 mA Fehlerstrom-Schutzschalter mit Überstromauslöser

(RCBO) und einen Trennschalter mit einer kontinuierlichen Strombelastbarkeit von 30 A bei 250 V und

Überstrom von 30 A erfolgen.

Schalten Sie das Gerät erst ein, wenn das Gerät vollständig installiert ist.

Page 11

UMWELTBEDINGUNGEN

11

Dieses Gerät ist für den Betrieb unter folgenden Bedingungen ausgelegt:

• Nur für den Betrieb in Innenräumen

• Betrieb in gut belüfteten Räumen

• Umgebungstemperaturbereich: +5°C bis +40°C

• Höhenlagen bis 2000 m

• Relative Luftfeuchtigkeit maximal 80 %

• Schwankungen in der Stromversorgung maximal 10 %

• Überspannungskategorie II IEC60364-4-443

• Verschmutzungsgrad 2 IEC664

GARANTIE

Die Garantiedauer des Gerätes ist auf der beiliegenden Garantiekarte angegeben und schließt Fehler im

Material oder der Verarbeitung ein. Die Garantiedauer beginnt am Tag des Einkaufs. Sämtliche defekte Teile

werden innerhalb dieses Zeitraumes kostenlos ersetzt unter der Voraussetzung, daß dem Defekt keine

unsachgemäße Handhabung, Fahrlässigkeit oder ein Unfall zugrundeliegt. Der unter diese Garantie fallend

Service wird vom Lieferanten geleistet.

Ungeachtet der in dieser Gebrauchsanweisung enthaltenen Beschreibungen und Spezifikationen, behält sich

Techne hiermit das Recht vor, Änderungen an den Geräten bzw. an einzelnen Geräteteilen durchzuführen.

Diese Gebrauchsanleitung wurde ausschließlich dazu erstellt, um Kunden die Handhabung der Techne-Geräte zu

erleichtern. Nichts in dieser Gebrauchsanleitung darf als Garantie, Bedingung oder Voraussetzung verstanden

werden, sei es die Beschreibung, Marktgängigkeit, Zweckdienlichkeit oder sonstiges bezüglich der Geräte

oder deren Bestandteile.

WARTUNG DURCH DEN BEDIENER

BEACHTEN SIE, DASS DIESES GERÄT NUR VON TECHNISCHEN FACHKRÄFTEN GEÖFFNET UND DEMONTIERT

WERDEN DARF.

DURCH ENTFERNEN DES GERÄUSES ODER GEHÄUSETEILEN SIND BAUTEILE MIT LEBENGEFÄHRLICHEN

SPANNUNGEN FREI ZUGÄNGLICH.

IM INNERN DES GERÄTES BEFINDEN SICH KEINE TEILE, DIE VOM ANWENDER GEWARTET

WERDEN MÜSSEN.

Falls Ihr Gerät nicht ordnungsgemäß arbeitet, wenden Sie sich an Ihren Lieferanten oder senden Sie das Gerät

wenn nötig zurück. Fügen Sie eine genaue Beschreibung des Defektes bei. Verpacken Sie das Gerät möglichst im

Originalkarton. Bitte beachten Sie, daß Techne und thermo-DUX keine Haftung bei Transportschäden aufgrund

unzureichender Verpackung übernehmen. Setzen Sie sich im Zweifelsfall mit Ihrem Lieferanten in

Verbindung.

1.Reinigen

Bevor Sie Ihr Gerät reinigen, sollten Sie

• zuerst den Netzstecker ziehen

• das Gerät unter 50°C abkühlen lassen.

Ein feuchtes Tuch mit Seifenlösung reinigt Ihr Gerät am besten. Achten Sie darauf, daß kein Wasser in das Gerät

gelangt. Verwenden Sie keine Scheuermittel.

2.Übertemperaturabschalter

• Der Übertemperaturschutz ist ein empfindliches mechanisches Teil. Schon eine Erschütterung kann

diesenauslösen.

• Falls die Heizung nicht funktioniert, überprüfen Sie zuerst Netzstecker und Kabel. Setzen Sie dann

denÜbertemperaturabschalter (an der Rückseite des Gerätes) wieder zurück, indem Sie den roten Knopf

einmalbis zum Anschlag drücken.

• Wenn der Übertemperaturabschalter wiederholt auslöst, liegt ein größerer Defekt vor. Das Gerät mußzur

Reparatur an Ihren Lieferanten eingesandt werden.

3.Sicherungen

Die Stromzuleitung ist durch ein oder zwei Sicherungen geschützt. Diese sollten nur durch qualifiziertes Fachpersonal ausgetauscht werden. Wenn die Sicherung wiederholt durchbrennt, liegt ein größerer Defekt vor.

Das Gerät muß zur Reparatur an Ihren Lieferanten eingesandt werden.

Page 12

INFORMACIÓN DE SEGURIDAD E INSTALACIÓN

12

Le rogamos lea cuidadosamente la información contenida en este folleto antes de manipular el aparato.

AVISO

LAS TEMPERATURAS ELEVADAS SON PELIGROSAS: pueden causarle graves quemaduras y provocarfuego

en materiales combustibles.

Techne ha puesto gran cuidado en el diseño de estos aparatos para proteger al usuario de cualquier

peligro; aún así se deberá prestar atención a los siguientes puntos:

• UTILIZAR CON PRECAUCIÓN Y CON GUANTES PROTECTORES PARA PROTEGER LAS MANOS

Y GAFAS DE SEGURIDAD PARA PROTEGER LOS OJOS.

• NO coloque objetos calientes encima o cerca de objetos combustibles;

• NO maneje el aparato cerca de líquidos inflamables o gases;

• NO introduzca ningún líquido directamente en el aparato;

• UTILICE EL SENTIDO COMUN en todo momento.

SEGURIDAD DEL USUARIO

Todos los usuarios de equipos Techne deben disponer de la información necesaria para asegurar su

seguridad.

De acuerdo con las instrucciones contenidas en este manual y con las normas y procedimientos generals de

seguridad, es muy importante que sólo personal debidamente capacitado opere estos aparatos. De no

ser así, la protección que el equipo le proporciona al usuario puede verse reducida.

Todos los equipos Techne han sido diseñados para cumplir con los requisitos internacionales de seguridad

y traen incorporados un sistema de desconexión en caso de sobretemperatura. En algunos modelos el

sistema de desconexión es variable, lo que le permite elegir la temperatura según sus necesidades. En

otros, el sistema de desconexión viene ya ajustado para evitar daños en el equipo.

Si encuentra un problema de seguridad, desconecte el dispositivo de la red eléctrica.

INSTALACIÓN

Antes de conectar el instrumento al suministro eléctrico, compruebe que el voltaj coincida

con el indicado en la placa de régimen (situada en la parte trasera de la unidad). El instrumento

debe disponer de una toma de tierra para garantizar la seguridad eléctrica adecuada.

Conexión 220V-240V

Con corriente Marrón

Neutro Azul

Toma de tierra Verde/amarillo

Nota: El IFB-51 y el IFB-52 tienen la clasificación de “Equipo Permanentemente Conectado” y deben ser

conectados a la red eléctrica por un electricista cualificado.

Un suministro apto para el IFB-51 tiene una calificación de 4 kW, 220-240 V, 50/60 Hz~ monofase.

Un suministro apto para el IFB-52 tiene una calificación de 6 kW, 220-240 V, 50/60 Hz~ monofase.

El equipo cuenta con un cable circular flexible de triple núcleo de 2,5 m con la siguiente especificación:

4,0 mm², conforme a BS 6500 o equivalente y <HAR> o aprobado por el BASEC. La conexión a la red eléctri-

ca debe ser a través de un disyuntor por corriente diferencial con protección de sobrevoltaje (RCBO) doble

polo de 30 mA con una capacidad de conducción de corriente continua de 30 A a 250 V y

sobrevoltaje de 30 A.

No conectar hasta que la unidad esté totalmente instalada.

Page 13

CONDICIONES AMBIENTALES

13

Este equipo se ha diseñado para funcionar en las condiciones siguientes:

• Sólo para uso en interior

• Se debe utilizar en un área bien ventilada

• Rango de temperatura ambiente: de +5°C a +40°C

• Altitud: hasta 2000 m

• Humedad relativa: inferior al 80%

• Fluctuación de la alimentación eléctrica: inferior al 10%

• Categoría de sobretensión II: según IEC 60364-4-443

• Grado de contaminación: 2 IEC664

GARANTÍA

Este aparato está garantizado contra cualquier defecto material o de fabricación durante el period especificado en la tarjeta de garantía adjunta. Este plazo inicia a partir de la fecha de compra, y dentro de este

periodo todas las piezas defectuosas serán reemplazadas gratuitamente siempre que el defecto no sea

resultado de un uso incorrecto, accidente o negligencia. Mientras se encuentre bajo garantía las

revisiones las debe llevar a cabo el proveedor.

A pesar de la descripción y las especificaciones de los aparatos contenidas en el Manual del Usuario,

Techne se reserva por medio de este documento el derecho a efectuar los cambios que estime oportunos

tanto en los aparatos como en cualquier componente de los mismos.

Este manual ha sido preparado exclusivamente para los clientes de Techne y nada de lo especificado en este

folleto de instrucciones se tomará como una garantía, condición o aseveración de la descripción,

comerciabilidad o adecuación para cualquier fin específico de los aparatos o sus componentes.

MANTENIMIENTO

ESTE APARATO DEBE SER DESMONTADO SOLO Y EXCLUSIVAMENTE POR PERSONAL DEBIDAMENTE

CAPACITADO.

EL RETIRAR LOS PANELES LATERALES, FRONTALES O TRASEROS SUPONE DEJAR AL DESCUBIERTO

TENSION DE LA RED PELIGROSA.

EL EQUIPO NO CONSTA DE NINGUNA PIEZA DE CUYO MANTENIMIENTO SE PUEDA ENCARGAR

EL USUARIO.

En el caso improbable de que experimentara algún problema con su aparato que no pudiera resolver con

facilidad, debería ponerse en contacto con su proveedor y devolverlo si fuera necesario. Indique de forma

detallada todos los defectos que haya notado y devuelva el equipo en su embalaje original. Techne no

aceptará responsabilidad alguna por daños causados en equipos que no estuvieran debidamente embalados

para su envío; si tuviera alguna duda, póngase en contacto con su proveedor.

1.Limpieza

Antes de limpiar su aparato, desconéctelo SIEMPRE de la fuente de alimentación y permita que se enfríe

por debajo de los 50°C.

Este aparato se puede limpiar pasándole un paño húmedo enjabonado. Hágalo con cuidado parae evitar

que caiga agua dentro del mismo. No utilice limpiadores abrasivos.

2.Desconexión en caso de sobretemperaturas

El sistema de desconexión en caso de sobretemperaturas es un dispositivo mecánico sensible (una sacudida

mecánica podría desconectarlo).

• Si el calefactor no recibiera alimentación, compruebe el enchufe y el cable de la toma de corriente;

acontinuación vuelva a ajustar el control del dispositivo (si su equipo lo lleva montado).

• Una desconexión repetida indicaría una avería grave; puede que tenga que devolverle el aparato a

suproveedor para su reparación.

3.Fusibles

Su aparato está protegido por uno o dos fusibles. Sólo deben cambiarlos personal debidamente capacitado.

Si los fusibles se fundieran repetidamente, esto indicaría una avería grave y puede que tuviera que devolverle

el aparato a su proveedor para su reparación.

Page 14

INFORMAZIONI SULLA SICUREZZA E L'INSTALLAZIONE

14

Prima di utilizzare l’apparecchio, leggere tutte le informazioni contenute in questo manuale.

ATTENZIONE

Le alte temperature sono pericolose: possono causare ustioni gravi all’utilizzatore e possono causare la

combustione di materiale infiammabile. La Techne ha posto particolare cura nel progettare questo

strumento, al fine di proteggere gli operatori da eventuali pericoli, ma gli utilizzatori devono prestare

attenzione ai seguenti punti::

• USARE CON PRUDENZA E INDOSSARE GUANTI PROTETTIVI PER PROTEGGERE LE MANI E

OCCHIALI DI SICUREZZA PER PROTEGGERE GLI OCCHI.

• NON usare sostanze combustibili vicino ad oggetti caldi

• NON mettere in funzione lo strumento nei pressi di liquidi o gas infiammabili

• NON collocare alcun tipo di liquido direttamente nello strumento.

• In ogni caso Usare Buon Senso.

SICUREZZA PER L’UTILIZZATORE

Il personale che utilizza l’apparecchiatura Techne deve avere a disposizione la documentazione necessaria

al fine di assicurare la loro incolumità.

È importante che solo personale adeguatamente addestrato utilizzi questo apparecchio, in conformità alle

istruzioni contenute in questo manuale e nel rispetto delle normative e procedure generali di sicurezza. Se

l’apparecchio è utilizzato in modo non specificato da Techne, la protezione fornita dall’apparecchiatura

all’utilizzatore potrebbe essere a rischio.

Tutte le unità Techne sono state progettate in conformità ai requisiti internazionali di sicurezza e sono

equipaggiate con un interruttore anti surriscaldamento. Su alcuni modelli, l’interruttore è regolabile e

dovrebbe essere impostato secondo l’utilizzo. In tutti gli altri modelli l’interruttore è preregolato per

proteggere l’unità.

Se si dovesse verificare un problema di sicurezza, spegnere l'alimentazione generale.

INSTALLAZIONE

Prima di collegare lo strumento all'alimentazione elettrica di rete, controllare la tensione

confrontandola con la targhetta riportante i valori nominali (si trova sul retro dell'unità).

Notare che al fine di garantire la corretta sicurezza elettrica, occorre che l'unità sia

messa a terra.

Connessione 220V-240V

Sotto tensione Marrone

Neutro Blu

Terra Verde/giallo

Attenzione: IFB-51 e IFB-52 sono classificati come "Apparecchiature Collegate Permanentemente" e

dovrebbero essere collegati all’impianto elettrico da un elettricista qualificato.

L'alimentazione adeguata per l'IFB-51 è indicata come monofase a 4kW, 220-240V, 50/60Hz~.

L'alimentazione adeguata per l'IFB-52 è indicata come monofase a 6kW, 220-240V, 50/60Hz~.

L'attrezzatura viene fornita con 2,5 m di cavo flessibile, tripolare e a sezione circolare, secondo le seguenti

specifiche: 4,0mm², conforme a BS 6500 o equivalenti e approvato da <HAR> o BASEC. Il collegamento

all'alimentazione generale dovrebbe essere effettuato tramite un interruttore differenziale bipolare da

30mA con sganciatore di sovracorrente isolante (RCBO) con capacità di trasporto di corrente continua di

30A a 250V e sovracorrente di 30A.

Non accendere fino a quando l'unità non sia stata completamente installata.

Page 15

ENVIRONMENTAL CONDITIONS

15

Condizioni di esercizio previste:

• Solo per uso in ambienti chiusi

• Usare in ambienti ben ventilati

• Temperatura ambiente da +5°C a +40°C

• Altitudine fino a 2000 m

• Umidità relativa non superiore all’80%

• Oscillazione dell’alimentazione elettrica non superiore al 10%

• Categoria di sovratensione II IEC60364-4-443

• Grado di inquinamento 2 IEC664

GARANZIA

L’apparecchio è garantito contro ogni difetto del materiale o fabbricazione per il periodo specificato sul

certificato di garanzia accluso. Questo periodo decorre dalla data di acquisto, e durante il quale tutte le parti

difettose verranno sostituite gratuitamente purché il difetto non sia causato da un uso non appropriato, da

cause non imputabili a difetti di fabbricazione o negligenza. L’assistenza durante questo periodo

sarà garantita dal fornitore.

Ferme restando la descrizione e le caratteristiche dell’apparecchio contenute nel Manuale d’uso

dell’utilizzatore, la Techne si riserva in ogni caso il diritto di effettuare le modifiche che riterrà necessarie

all’apparecchio o ai suoi componenti.

Questo Manuale è stato realizzato esclusivamente a vantaggio dei clienti della Techne e in alcun modo potrà

essere utilizzato come garanzia, condizione o rappresentazione concernente la descrizione,

commercializzazione, adeguamento alle condizioni di utilizzo o altro degli apparecchi o delle sue componenti.

MANUTENZIONE

QUESTO APPARECCHIO DOVRÀ ESSERE APERTO ESCLUSIVAMENTE DA PERSONALE ADEGUATAMENTE

ADDESTRATO.

LA RIMOZIONE DEI PANNELLI LATERALI, FRONTALI O POSTERIORI PUÒ ESPORRE POTENZIALMENTE A

VOLTAGGI DI CORRENTE LETALI.

ALL’INTERNO DELL’APPARECCHIO NON CI SONO PARTI MANUTENIBILI DA PARTE DELL’UTILIZZATORE.

Nell’eventualità che si riscontri un problema con l’apparecchio che non può essere facilmente risolto, si

dovrà contattare il proprio fornitore e restituire, se necessario, l’apparecchio. Si prega di specificare nel

dettaglio i difetti riscontrati e di ricordare di restituire l’apparecchio nel suo involucro originale. La Techne

non si fa carico di alcuna responsabilità per danni subiti dall’apparecchio che non sia stato propriamente

imballato per il trasporto; in caso di dubbio, rivolgersi al fornitore.

1.Pulizia

Prima di pulire il vostro apparecchio, disconnettere sempre la presa di alimentazione e lasciare raffreddare

sotto i 50°C. Questo apparecchio può essere pulito passando un panno inumidito con sapone. Si deve

prestare attenzione onde prevenire l’ingresso dell’acqua all’interno dell’apparecchio. Non utilizzare per la

pulizia sostanze abrasive.

2.Disconnessione in caso di surriscaldamento

In caso di non funzionamento dell’apparecchio, controllare la spina elettrica e il relativo cavo collegati alla

rete. Ripetute interruzioni del funzionamento dell’apparecchio indicano un serio malfunzionamento: in

questo caso restituire l’apparecchio al fornitore per la riparazione.

3.Fusibili

L’apparecchio è protetto da uno o due fusibili. Questi dovrebbero essere sostituiti solo da personale qualificato.

Se i fusibili si bruciano frequentemente ciò indica un malfunzionamento serio e in questo caso

si consiglia di contattare il fornitore per le riparazioni.

Page 16

WARNING

16

Poor fluidisa

carefully. For correct fluidisation, pay attention to the following:

INSTALLATION

• Ensure the bath is level and air supply is adequate.

OPERATION

• Adjust air valve for even fluidisation.

• Do not insert objects larger than recommended.

• Ensure objects do not lie in contact with container wall or porous plate. Sample buckets are available.

MAINTENANCE

• Regularly inspect and maintain the air filter to eliminate oil vapour in the air supply.

ALUMINIUM OXIDE

• Before handling the aluminium oxide, consult the MSDS for safe handling. Contact

cptechsupport@coleparmer.com

• Aluminium oxide is non-hazardous but dust may irritate the eyes and the respiratory system and cause

skin irritation.

• Provide appropriate exhaust ventilation at places where dust is formed.

• For storage: protect from moisture. Avoid dust formation. Keep container tightly closed. Store in a

well-ventilated place. Guard against dust accumulation of this material.

• Wear correct PPE whilst handling the aluminium oxide material. Wear safety glasses with side shields,

appropriate chemical resistant gloves and suitable protective clothing.

• Should the fluidised bath be stored for a long period under damp or humid conditions, moisture may

be absorbed by the aluminium oxide which is hydroscopic. To avoid violent fluidisation which occurs

when damp aluminium oxide is heated above 100°C, operate the bath for a period of approximately

8 hours at 90°C prior to operation at elevated temperatures.

• NEVER ADD COLD OR DAMP ALUMINIUM OXIDE TO A HOT BATH AS THIS WILL ALSO CAUSE VIOLENT

FLUIDISATION WHICH CAN BE DANGEROUS. Allow the bath to cool then add the fresh aluminium

oxide. If this fresh aluminium oxide is a large portion of the charge, then dry the whole charge as

above.

tion causes hot spots, heater failure and damage to other parts. Follow this Instruction Manual

if you require a copy.

FUME EXTRACTION

• When used for processing items which may emit toxic or inflammable fumes, it is essential that an

adequate fume extraction system be installed. The extraction system must be correctly sized to ensure

that any toxic fumes are removed from the working environment.

• To eliminate the risk of spontaneous ignition, the concentration of inflammable fumes above the bath

and within the exhaust duct work must be kept below the lower explosive limit. See section

INSTALLATION.

Page 17

PRINCIPLE OF OPERATION AND SAFETY FEATURES

17

The equipment, as described in this Instruction Manual, has been designed for use by properly trained

personnel.

It is important that all relevant information relating to the equipment be distributed to employees who may

handle or encounter it. We would stress the importance of standard, common sense rules and adherence

to normal, safety standards and procedures. (For example, any covers or enclosures should only be removed

by trained personnel.) Please ensure that all those involved in the operation of this equipment are

knowledgeable of the design criteria and that it is used in accordance with the instructions and

recommendations contained in this manual. If there is any doubt whatsoever relating to the proper use of

this equipment, please contact your supplier.

The industrial fluidised baths detailed in this manual are designed specifically for "burning off" residue

from plastic machinery tools. However, the IFB baths are also a good choice for many heat treatment,

reactive chemistry and exothermic reaction type of applications. The systems are effective on the full range

of plastics, including polyethylene, polypropylene, PVC, nylon, polyester, polycarbonates, acrylic,

polystyrene and acetyl. In addition, they are effective with rubber, EPR, epoxy resins and acrylic paints. They

provide a safe, dry and fast means of removing all plastic residue with a minimum amount of effort and

physical contact with the tools. The "burning off" operation is controlled at a uniform temperature so that

distortion is avoided. Furthermore, as the fluidised bath is non-abrasive, physical damage to parts is minimal.

Each of these factors extends tool life.

The fluidised bed is housed in a circular container manufactured from 0.075" (14 gauge) stainless steel.

This container is surrounded by electrical heating elements and housed in a square insulated case. The

temperature of the fluidised bed is set and maintained by digital PID temperature controller, which is

governed by the electrical signal from a type "K" (chrome/alumel) thermocouple placed along the fluidised

bath container inner wall. Current to the heating elements is switched on and off by means of solid state

relay actuated by the temperature controller. The controller has a resolution of 1° and can be switched

between °C and °F.

The IFB-51 and IFB-52 are supplied with an internal contactor that disables power to the heaters if one of

the following conditions occur: thermocouple failure, loss of power to or controller fault and/or exceeding

the factory set high temperature limit of 620°C (1148°F). The controller will flash a message when one of

these conditions has occurred and can be reset for operation once the situation is corrected. See section

OPERATION for more details on the PID temperature controller.

The air supply to the bed must be clean and dry. An air filter and pressure regulator can be supplied as

optional equipment (part number F5915).

Page 18

DESCRIPTION OF COMPONENTS AND FRONT PANEL

18

CONTROLS

Figure 1: Co

Item Description Function

1 Fluidised bath chamber Heated chamber containing the fluidised aluminium oxide.

2 Operating instructions Quick operating guide.

Eurotherm 3216

3

temperature controller

4 Power indicator (green) Lights green when there is mains power to the unit.

5 Heater indicator (amber)

6 Air flow table Indicates approximate air flow according to temperature.

7 Flow meter

8 Air flow valve Controls the amount of air for fluidising the bed.

9 Fuses The unit is fitted with 2 x 25A (IFB-51) or 2 x 30A (IFB-52) fuses

10 Rating plate Details the model number, serial number and power rating.

mponents and controls – IFB-51 shown

Used to set the required bath set point temperature. The

control parameters have been factory pre-set.

Lights amber when the heaters are on. Will flash on and off

when the bath is at set temperature.

A float indicates the fluidisation air pressure set by the control

valve. The flow rate indicated by the float in the tube is on a

scale of 0.5 to 4.0 CFM (cubic feet per minute).

11 Mains power cord Connect to mains power supply.

12 Compressed air inlet The air supply should be connected via suitable flexible hose.

Page 19

INSTALLATION

19

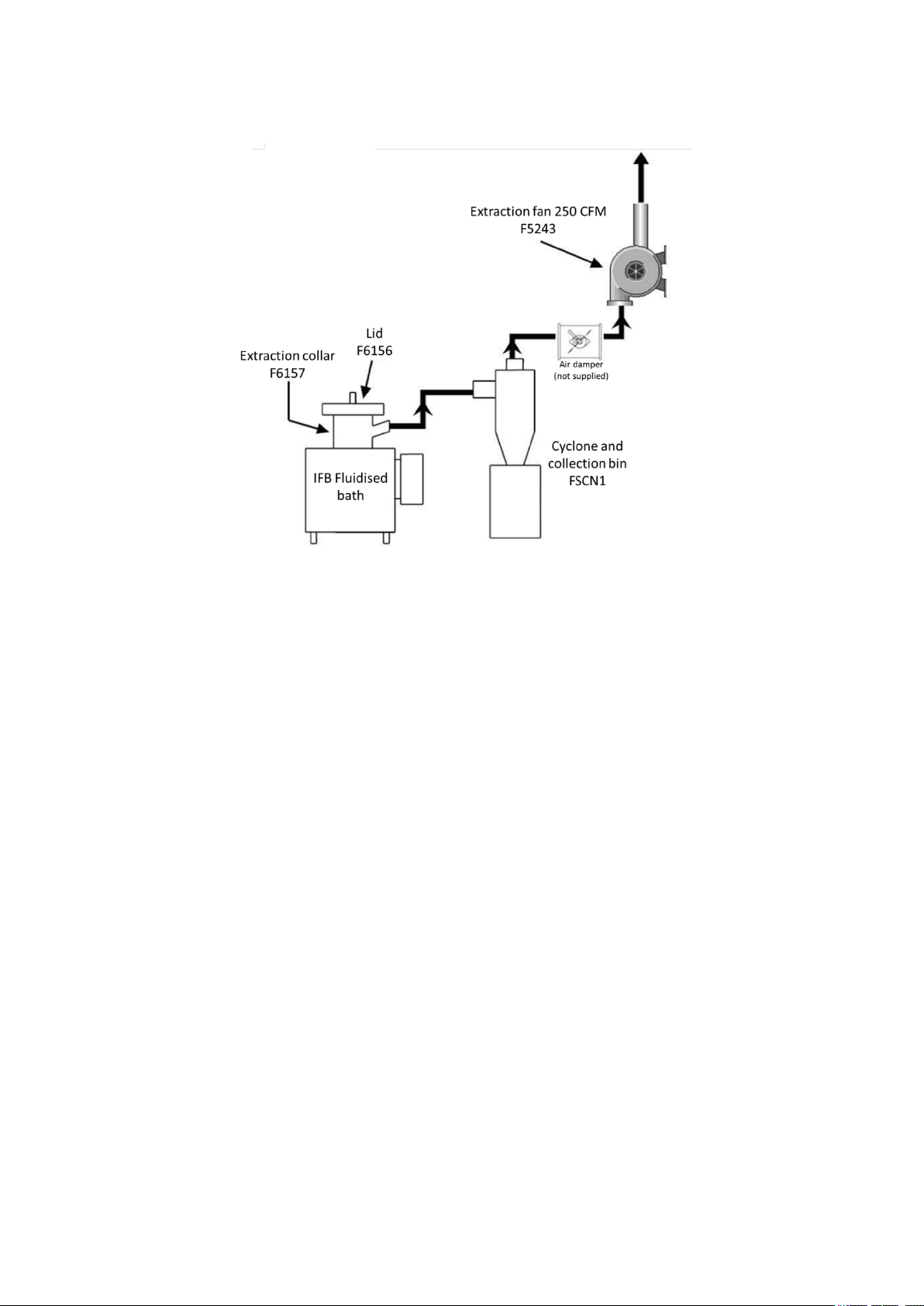

Figure 2: Schematic of IFB fluidised bath set up with cyclone and basic exhaust extraction

system.

SET-UP

The extraction collar, cyclone and extraction fan should be interconnected using appropriate 100mm (4”)

ducting. The

sieved and reused. An air damper should be positioned in the ducting between the cyclone and extraction

fan to control fume extraction and pull fumes away from the bath into the exhaust system. If the damper

is open too much it would create a negative pressure in the bath working area resulting in significant heat

and sand loss. A dilution tee (not shown) may also be included in the ductwork between the fluidised bath

and cyclone to dilute effluent gasses.

POWER

The IFB-51 and IFB-52 require a power supply of 230V, 50/60Hz, single phase. A 208V supply is insufficient

and should be boosted to 230V with a suitable boost transformer.

AIR

The compressed air supply to the bath must be clean, dry and free from oil. The pressure delivered to be

bath should be 30 psi (207 kPa) and capable of delivering 5 cubic feet/minute (CFM) (142 litres/min).

MECHANICAL

The unit should be mounted on a firm level surface. It is important to ensure that the bath is level, otherwise

it will fluidise incorrectly. This will lead to the formation of large temperature gradients across the bath

which results in premature heater failure and possible damage to the porous plate and inner container

assemblies.

1. Mount the fl

2. Connect a 30 psi air supply to the compressed air inlet on the rear of the control panel. The tubing and

any fittings should not be less than 13mm (1/2”) ID at any one point or bath performance may be

reduced.

3. Wire up the bath to a 220 to 240V single phase power supply. See section ELECTRICAL INSTALLATION.

4. Fill the bath with aluminium oxide to within 80 to 100mm (3 or 4 inches) of the top.

purpose of the cyclone is to recover any aluminium oxide pulled out of the bath which can be

uidised bath in the position where it is to be used on a dry, level surface.

Page 20

5. Place the ext

20

6. Install and connect any associated fume treatment equipment with appropriate ducting and connect

to the fluidised bath extraction collar. See figure 2 above and section FUME CLEANING.

raction collar (if used) into the bath.

OPERATION

START-UP

1. Check that the unit has been set up as described in the previous section and that required services are

available.

2. Check that aluminium oxide level is correct and adjust if necessary. Never add new, cold aluminium

oxide (which may contain moisture) to a hot bath. Should the fluidised bath be stored for long periods

of time under damp or humid conditions, moisture may be absorbed by the aluminium oxide which is

hydroscopic. To avoid violent fluidisation which occurs when damp aluminium oxide is heated above

100°C, operate the bath for a period of approximately 8 hours at 90°C prior to operation at elevated

temperatures.

3. Turn on power and air to the unit. Following the instructions displayed on the label on the unit, set the

air flow to 4 CFM when at ambient temperature. When fluidised and bubbling make sure the

aluminium oxide level is still within 80-100mm of the top.

4. Place the extraction collar (if purchased) into the bath and place the lid on.

AIR ADJUSTMENT

5. Important: as the bath heats up you will need to adjust the airflow settings based on the front label

chart or the heat up time will greatly increase. See Table 1 below. The reverse needs to happen when

cooling down.

Indicated bath temperature

Temperature (°C) Temperature (°F)

Ambient to 50 Ambient to 122 4.0

50 to 100 122 to 212 3.5

100 to 200 212 to 392 3.0

200 to 300 392 to 572 2.2

300 to 400 572 to 752 1.9

400 to 500 752 to 932 1.7

500 to 600 932 to 1112 1.4

Table 1: Ai

r flow rate settings at indicated bath temperatures.

Flow rate (CFM)

BATH TEMPERATURE

6. Set the controller to the required operating temperature. Once the controller has reached the set point,

allow 1 hour for the bath to fully stabilize before attempting to use it.

An initial temperature drop or quenching of the bath can occur after inserting a workpiece to be cleaned.

This temperature drop depends on the size of the immersed object, but is generally in the order of 25°C

(77°F). Carbon is burned to carbon dioxide quickly above 400°C (752°F). It may be found desirable to preheat the bath to as high as 550°C (1020°F) to obtain quick results, but caution should be exercised not to

damage tools by overheating.

EXTRACTION AIR SETUP

If you use an exhaust hood for ventilation, please ignore this section.

Page 21

7. Make sure

21

FUME CLEANING).

8. With the exhaust fan on, close the damper so there is no extraction to the bath.

9. Place parts to be cleaned in the basket and lower into the bath. Place the lid on the bath.

10. When smoke and fumes start to come up and around the lid, slowly open the damper just to the point

where they are pulled back into the bath and no longer entering the room, then stop adjusting. This

setting will give good results with minimal heat and sand loss.

11. With your first tool cleaning, start with a smaller number of tools and at a lower temperature. Adjust

the bath set temperature and the number of tools cleaned based on your results and the amount of

time required. It is always a good idea to clean at the lowest possible temperature.

12. After repeated tool cleanings heavier clumps and larger particles should be sieved from the aluminium

oxide.

13. In time, the aluminium oxide may become dense and fluidise poorly at which point it should be

replaced.

the exhaust system is plumbed according to our recommendation (see Figure 2 and section

SHUT-DOWN

14. The bath air supply and power can be turned off after the temperature has cooled to 200°C/400°F.

15. Alternatively, if used daily, reduce the overnight temperature to 300°C for quicker start up.

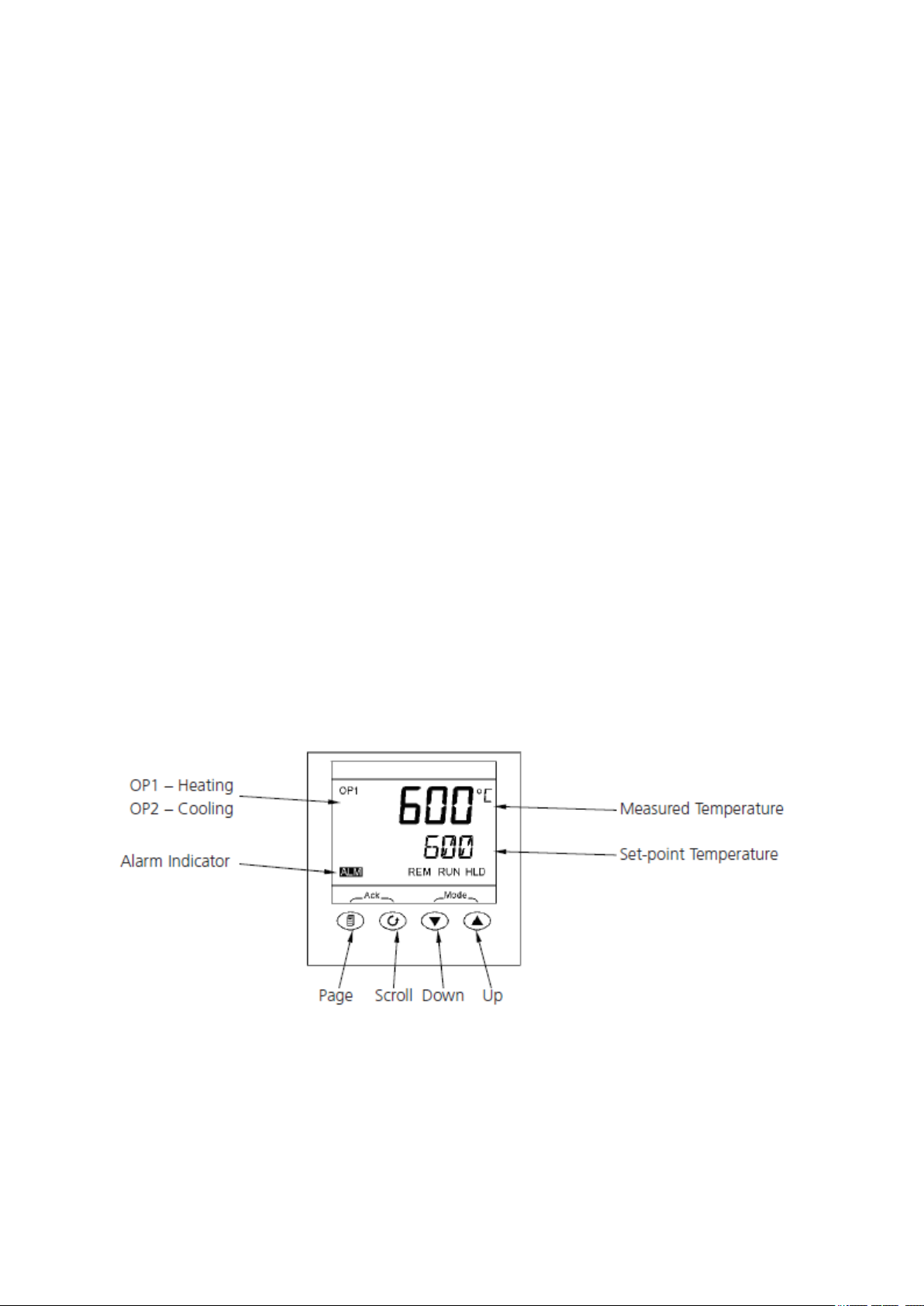

PID TEMPERATURE CONTROLLER

The control parameters in the PID temperature controller have been optimized by the factory during

manufacture to give the best results for most applications. Per the image below use the “scroll” button to

navigate to the menu option UNITS for changing display from °C to °F and vice versa.

Two set points can be entered for future recall, press the “scroll” button to access SP1 and SP2. Set a

different set point in each of these. Then “Scroll” to SP.SEL to select either set point SP1 or SP2. The up/

down buttons are used to set the bath set point temperature. If an alarm indicates an overtemperature

condition or thermocouple failure the two buttons labelled as ACK need to be depressed together after

the alarm condition is corrected. If the alarm cannot be cleared please contact Cole-Parmer for support.

Figure 3

: Eurotherm 3216 temperature controller.

Page 22

THE CLEANING PROCESS

22

The cle

heat then degrades the plastic residue. Objects to be cleaned should be supported in a basket or suitable

holder for ease of handling and lowered into the fluidised bed. To avoid physical damage and local

overheating, it is important to ensure that any items placed in the bed are supported and not allowed to

rest either on the porous plate at the bottom of the bed or against the wall of the inner container.

The bath should be operated generally in the temperature range of 450°C to 500°C, depending on the

polymer to be removed. The process time depends upon the thermal mass of the object, the amount and

type of polymer to be removed. During the first two thirds of the process time the polymer is reduced to a

tar mix, in this phase all the initially combustible products of the polymer are emitted from the fluidised

bath in the form of fumes that must be extracted and treated by suitable fume handling equipment. During

the last third of the process time, the polymer is reduced to carbon which either burns away or remains

loosely bound to the object being cleaned.

Any carbon or incombustible filler that remains on the processed item can be removed by a secondary

cleaning operation, either by brushing or some form of water wash.

It is important to ensure that the items being processed do not exceed the maximum loading capacity (see

section TECHNICAL SPECIFICATION) and that they are loaded into the fluidised bath in such a way that the

fluidisation is not impeded.

THE PROCESS RELIES UPON GOOD FLUIDISATION TO ENSURE GOOD HEAT TRANSFER; OVERLOADING OR

INCORRECT LOADING OF THE BATH WILL RESULT IN EXTENDED CYCLE TIMES GIVING INFERIOR RESULTS.

LOCAL OVERHEATING MAY ALSO OCCUR, GIVING RISE TO PREMATURE HEATER FAILURE AND POSSIBLE

DISTORTION OF THE INNER CONTAINER.

aning process relies on heat being transferred from the fluidised bed to the immersed tools, the

The aluminium oxide fluidising medium does not degrade but will need to be replenished due to loss from

spillage or entrainment in the exhaust (from where it may be recovered by the cyclone trap).

All articles should be completely cleaned and removed from the bed before shut down. Corrosion of

processed parts could be seriously increased if they are left immersed overnight. Furthermore, residual

polymer, instead of being burned off in a fluidised state, could percolate down through a static bed and

settle on the porous plate to cause a blockage and result in poor fluidisation. In the case of PVC, chlorinated

hydrocarbons remain in the fluidised bath after burn off which dictates special maintenance procedures.

See section SPECIAL MAINTENANCE PROCEDURES WHEN BURNING OFF PVC AND OTHER HALOGENATED

POLYMERS.

When parts are removed from the bed they should be allowed to cool in air and, whilst still warm, treated

to prevent rusting.

It should be noted that some plastics and, in particular, paints contain fillers. These fillers are usually

inorganic materials and will not therefore burn when put into a fluidised bath, with the result that the

material falls away from the article being cleaned and is retained in the bath, either on the surface or at

the base of the bath, depending upon the density of the material involved. If this happens it is

recommended that the bath be checked and cleaned at least once a week or more frequently if the bath

is used continuously.

Table 2 details recommended operating temperatures for particular polymers. The temperatures quoted

should be used as an initial guide. The ideal operating temperature will vary depending on the size of the

components being cleaned and the amount of material being removed. In general temperatures below

400°C should be avoided to obviate the danger of the polymer melting and sinking to the bottom of the

bath where it may block the porous plate. With some large objects, it may be desirable to preheat the bath

to well above the operating temperature so that the polymer temperature rapidly moves through the

melting phase to the burning condition.

Page 23

Excessive

23

bath and may result in the formation of condensed fumes within the extraction system.

operating temperatures should be avoided as they increase the fume concentration above the

Material Burn-off temperature (°C)

Nylon 450

Paint 475-575

Polythene 450-500

Polypropylene 425-500

PTFE 500

PVC 450-500

Silicone rubber 550

Ethylene methacrylic 450-480

Polyurethane 440-450

Rubber de-bonding 350 (de-bonding)

Polycarbonate 400-425

Polystyrene 450

Organic matter oil/grease 450-500

High density polythene 450

Polyesters 450

Fluoropolymers 500

Styrene 450

Table 2: Rec

CAUTION

Car

e should be taken when handling hot parts which have been removed from a fluidised bath. We

recommend that protective clothing (safety glasses, etc.) be worn when working with fluidised baths and

that the installation and maintenance procedures outlined in this booklet be followed explicitly.

ommended operating temperatures for various polymers.

FUME IGNITION

Spontaneous ignition may occur above the surface of the fluidised bath or within the exhaust ductwork if

the fume concentration exceeds the lower explosive limit.

The fume concentration is dependent upon the rate of fume production in the fluidised bath and the level

of dilution achieved by entraining air from above the bath or through the dilution tee.

The rate of fume production is dependent upon the type and amount of material being treated and the

temperature of the bath.

To ensure that the concentration of inflammable fumes is below the lower explosive limit, ensure that the

amount of combustible material immersed in the bath at any one time is within the design capacity of the

extraction system.

Ensure that the temperature of the bath is at minimum level to which satisfactory results can be achieved.

Increased working temperatures result in increased fume concentration. By way of example, an extraction

Page 24

3

24

rate of 2m

limit when thermally decomposing 1kg/hr of polythene at 450°C.

To safeguard the fluidised bath from damage, two safety features are included in the control console: an

adjustable over temperature cut-out which guards against controller failure, and an air pressure switch

which inhibits operation if the compressed air supply to the fluidised bath fails. Both devices isolate the

electrical supply to the heater elements and illuminate the cut-out indicator in a fault condition. The over

temperature cut-out is factory pre-set at 630°C. Under no circumstances should this setting be increased,

but lower limits may be set to safeguard particular processes in the fluidised bath.

/min is required to ensure that the fume concentration is below 25% of the lower explosive

FUME EXTRACTION AND CLEANING

When used for processing items which may emit toxic or inflammable fumes, it is essential that an adequate

fume extraction system be installed. A typical schematic diagram of a full fume extraction system is shown

in Figure 4. The system consists of the following components: -

Ductwork to connect the fluidised bath extract duct via the various fume treatment equipment to the input

of the fume extraction fan. The ductwork should include an air dilution tee, positioned as close as possible

to the fluidised bath. The dilution tee enables the fumes within the system to be diluted with air. The

ductwork should also include a damper valve which is normally positioned adjacent to the extraction fan.

This valve allows the extraction velocity to be reduced. In general, the ductwork may be manufactured out

of galvanised mild steel; however, in installations where PVC or other halogenated polymers are being

processed, it is recommended that stainless steel ducting is used. The ductwork should be as short as

possible and contain the minimum number of bends and horizontal runs to reduce the possibility of a

blockage.

A cyclone separator should be mounted directly after the dilution tee. The cyclone removes any fluidised

medium that may be present in the extracted fumes. The fluidised medium is collected in the cyclone

collection bin from where it may be returned to the fluidised bath. In applications where the components

being cleaned are contaminated by polymers which contain inorganic pigments or fillers such as titanium

oxide, of a particle size less than 0.005mm diameter which will not be retained by the cyclone, it is

recommended that a filtration system be fitted after the cyclone.

In applications where the materials being treated produce acidic vapours during thermal decomposition, it

is recommended that a fume scrubber be utilised to ensure that the final fume emission from the plant

conforms with local regulations. A caustic dosing system may also be required to ensure that the scrubbing

liquid is maintained at an acceptable pH level.

An extraction fan is required in all applications to provide the motive force for the exhaust.

In applications where it is not permissible to emit visible smoke from the plant or where local regulations

specify the maximum fume concentrations that may be emitted from an exhaust stack, an afterburner may

be required. The afterburner heats the fumes to a point where thermal incineration eliminates the visible

content of the fumes while reducing the fume concentration.

Finally, an exhaust stack is required to direct the treated fumes away from the working environment. The

exhaust stack will generally be manufactured out of the same materials as the ductwork system. However,

in installations where an afterburner is fitted, the exhaust stack should be manufactured out of insulated

stainless steel.

The exact combination of fume treatment components required depends upon the application and local

conditions.

Page 25

Figure 4: Full extraction system required for burn-off of toxic fumes and PVC. *Items not supplied

25

by Techne.

OPERATOR MAINTENANCE

The aluminium oxide fluidising medium, not being degradable, will only require replacement when losses

occur due to attrition, spillage or contamination with inert pigments, filler or acidic by-products from the

burn-off process. Note that the aluminium oxide pulled out of the bath through the exhaust duct can be

captured for reuse by the cyclone trap.

Should the fluidised bath be stored for long periods of time under damp or humid conditions, moisture

may be absorbed by the aluminium oxide which is hydroscopic. To avoid violent fluidisation which occurs

when damp aluminium oxide is heated above 100°C, operate the bath for a period of approximately 8

hours at 90°C prior to operation at elevated temperatures.

On at least daily intervals, the bed should be cleaned of floating residues by means of a wire mesh hand

scoop. This procedure removes carbon char which impairs fluidization and acts as an absorbent. More

importantly, it can also remove uncharred plastic and so reduce the quantity of fumes produced and the

time of processing.

The optional air-line filter into the bed is self-draining. However, it should be kept in good condition by

inspection at two week intervals and by cleaning the bowl and washing or replacing the filter element as

necessary. With exceptionally dirty or wet air supplies, this frequency may have to be increased. Free water

or water vapour in the air supply acts as a solvent to produce hydrochloric acid in the bed when PVC is

burned off. In addition, oil vapours in the air supply which reach the fluidising plate are carbonized within

the pores of the plate, quickly causing blockage and consequent poor fluidization, local overheating,

premature heater failure and possible distortion of the inner container.

Page 26

All artic

26

processed parts could be seriously increased if they are left immersed overnight. Furthermore, residual

plastic, instead of being burned off in a fluidised state, could percolate down through a static bed and

settle on the porous plate causing blockage and poor fluidization.

When parts are removed from the bed, they should be allowed to cool in the air and, while still warm,

wiped with on oily cloth to prevent rusting. If the bath is left unused for long periods of time, empty the

aluminium oxide and store it in a separate container. Keep the inside of the bath clean and dry.

The fume extraction system (if used) should be regularly maintained. The cyclone trap collection bin should

be emptied at the end of each day’s use; the collected fluidising medium being returned to the fluidised

bath. It is important to ensure that the air tight seal between the cyclone and collector bin is re-made.

les should be completely cleaned and removed from the bed before shut down. Corrosion of

SPECIAL MA

INTENANCE PROCEDURES WHEN BURNING OFF PVC OR

OTHER HALOGENATED POLYMERS

Burning off PVC (polyvinyl chloride) in a fluidised bath offers one of the most severe conditions of operation.

Hydrogen chloride (HCl) liberated on the breakdown of PVC is absorbed by the bed medium creating an

acidic environment within the bed. This happens especially when the bed also absorbs water from the

atmosphere or when the fluidising air is cold. HCl is extremely corrosive, especially when it is aerated and

wet. In addition, in water it produces chloride ions which, even in neutral or alkaline solutions, promote

corrosion and rusting in steel.

Consequently, fluidising beds used for burning off PVC require strict supervision to minimize corrosion of

the bed itself and of parts cleaned in it, especially if these are of un-coated steel. The purpose of most of

the recommended maintenance procedures is aimed at keeping the bed medium clean, free-flowing, free

of gums, acids, agglomerates, partly decomposed plastic, char and larger particles. These cleaning

processes have the additional benefit of ensuring good fluidization and thus good heat transfer throughout

the bed and through immersed parts. This, in turn, reduces burn-off time, uneven heating of parts and

thus distortion, increases heater life by eliminating localized hotspots and makes cleaning easier on a regular

basis.

The following instructions apply generally to halogenated polymers and specifically to PVC. They are aimed

at minimising corrosion of the bath and of immersed metals.

DAILY INTERVALS - at the end of each working day

1. Maintain the working temperature (about 400°C) for half an hour after the last processed batch, to

assist removal of corrosive acids from the bath.

2. If possible, maintain the temperature of the bath at about 100°C overnight and over weekends and

holidays to reduce absorption of water vapour into the batch. Overnight, the residual heat in the bath

will usually ensure this.

3. Scoop out charred plastic residues, clods of media and articles being processed.

WEEKLY INTERVALS - at the end of each working week and before prolonged shut-downs

1. Ensure compliance with daily instructions above.

2. Add about 50g (2oz) of powdered mild alkali to the bath and mix in well by maintaining fluidisation

for 5 minutes. Suitable alkalis are limestone, dolomite, hydrated or slaked lime, sodium bicarbonate,

sodium carbonate, magnesia. The addition of corrosive alkalis such as caustic soda (sodium hydroxide)

and quick lime (calcium oxide) should be avoided.

MONTHLY INTERVALS

1. Empty the bath and inspect it for signs of corrosion, especially pitted surfaces and flaking scale. The

inside should be wiped out with a rag wetted with 5% washing soda (sodium carbonate) solution.

Page 27

2. Screen the

27

scale, agglomerated medium, char, undegraded polymer and lost parts and helps maintain a good

quality of fluidisation.

HALF-YEARLY INTERVALS

1. The bath should be emptied, cleaned, inspected and the medium replaced by a fresh charge.

2. Alternatively, if the facilities are available, the medium may be thoroughly washed in several changes

of clean water, washed through a 70-mesh sieve, drained, dried and returned to the bath where drying

is completed by fluidisation and heating at 150°C, until the medium fluidises in the normal manner.

The washing procedure removes acidic residues and accumulated soluble salts and residues.

Symptoms of neglect should be dealt with immediately. These include: pitting of metallic surfaces,

formation of lumps of agglomerated medium, accumulation of polymer or polymer filler material,

indications of bad or uneven fluidisation, blockage of the fluidising plate and wetness or stickiness of the

medium.

medium through a 50 to 70 mesh sieve before returning it to the cleaned bath. This removes

FAULT FINDING

Any service or repair work should only be carried out by a trained electronic or electro mechanical

technicians. Untrained personnel should not attempt to dismantle this equipment.

If the heater indicator fails to go off, the unit fails to reach its operating temperature or heat up rate

decreases, check:

1. Fluidization – remove aluminium oxide from bath leaving approximately 50mm (2”) in the bottom. If

an area of one quarter or more is not bubbling, then most likely the porous plate is blocked and should

be replaced. Check that the porous plate is not blocked with plastic residue or other material.

2. Heater - Empty medium from the bed and disconnect the main supply. Turn the unit upside down and

check the resistance of the heater. If one or more heater windings are faulty, replace the heater.

Reassemble in the reverse order.

3. Thermocouple – check with an instrument that can measure and simulate thermocouple signals to

verify its operation.

4. Controller and/or SSR – the controller will output a DC signal to the SSR when heat is called for. If the

SSR is receiving a DC control signal but not passing power to the heaters, then it should be replaced.

Alternatively, a problem may exist with the controller. If the fluidization deteriorates, check the air filter

assembly for clogging of the filter element; if necessary, replace the element.

If the fault remains, run your bath at 600°C (1100°F) for a period of one hour to allow any accumulated

residue in the bath to burn off. If the fault persists, empty the medium from the bed, check the stainless

steel porous plate for damage due to clogging by plastic residue, distortion of the plate or corrosion.

Factory PID Parameters (For IFB51 S/N: 451 and higher, IFB52 S/N: 214 and higher)

Parameter IFB-51 IFB-52

Pb 15 12

Ti 450 480

Tg 75 80

1PLS 5.0 5.0

CBHI 20 20

CBLO 20 20

Page 28

SAFETY, REPAIR AND TECHNICAL SUPPORT

28

NOTE THAT THIS EQUIPMENT SHOULD ONLY BE DISMANTLED BY PROPERLY TRAINED PERSONNEL.

REMOVING THE CASE EXPOSES POTENTIALLY LETHAL MAINS VOLTAGE.

THERE ARE NO OPERATOR MAINTAINABLE PARTS WITHIN THE EQUIPMENT.

In the unlikely event that you experience any problems with your fluidised bath which cannot easily be

remedied, it may be necessary for your equipment to be sent back to our service department for

repair. In this case please contact the service department for all the required returns paperwork,

including the decontamination certificate, which must be included when you return the equipment.

Please also ensure you include a clear description of the fault. The decontamination certificate must be

completed to certify that the returned item is not contaminated with any harmful substance. Failure to

complete this will prevent the repair of your equipment.

Please return the unit in its original packing. Techne accept no responsibility for damage to units which are

not properly packed for shipping: if in doubt, contact your supplier. Clearly mark the package for the

attention of the Service Department and post to the following address:

Cole-Parmer Ltd

Beacon Road

Stone

Staffordshire

ST15 0SA

United Kingdom

Only spare parts supplied by the manufacturer or its agent should be used. Fitting of non-approved parts

may affect the performance of the safety features of the equipment. If in doubt, please contact Techne.

If you require further technical or application assistance, please contact Techne at:

E-mail: cptechsupport@coleparmer.com

Phone: +44 (0)1785 810433

WARRANTY

Techne warrants this equipment to be free from defects in material and workmanship, when used under

normal laboratory conditions, for a period of three (3) years. In the event of a justified claim, Techne will

replace any defective component or replace the unit free of charge.

This warranty does NOT apply if:

• Any repair has been made or attempted other than by the manufacturer or its agent.

• Any minor coating chips or scratches occur during normal use (i.e., wear and tear).

• Damage is caused by fire, accident, misuse, neglect, incorrect adjustment or repair, damage

caused by installation, adaptation, modification or fitting of non-approved parts.

Page 29

TECHNICAL SPECIFICATION

Temperature range

50°C to 600°C (122°F to 1112°F)

50°C to 600°C (122°F to 1112°F)

±1.0°C (20cm/8" immersion depth

with lid after 2 hours at set point)

±1.0°C (46cm/18" immersion depth

with lid after 2 hours at set point)

±10.0°C (20cm/8" immersion depth

with lid after 2 hours at set point)