Total Energy Controls

TEC 100/200 Programming

& Installation Manual

As of software v7.2

Contents

2

Installation Instructions

General Notes 3

Mains Wiring 3

Control Wiring 4

Other Wiring Options 5

Fitting and Wiring Temperature Sensors 6

Temperature Display Calibration 8

Commissioning Instructions

Keypad Overview 9

Establishing the System Max Flow Temp 11

Setting the Programs 12

Setting the Calendar 12

Programming the On / Off Times 14

Frequency (How the Time Clock works) 16

Select Days 17

Optimise On Time 18

Setting the Maximum Flow Temperature 20

Setting the Minimum Flow Temperature 21

Setting the Minimum Return Temperature 22

Setting the Mid Temperature 23

Setting the Night Temperature 24

Setting the Frost Temperature 25

Setting the External Cut-Off Temperature 26

The Plant Relay 27

Hot Water Priority 28

Internal / External Optimisation 29

Calibration 30

Rotation 32

Exiting Programming Mode 33

TEC 100/200 with Monitoring Socket

Monitor Installation and Operation 34

Description Page

Introduction 9

Optimise Off Time 19

Installation

General Notes

The installation of all TEC units should be carried out by a qualified electrical

engineer familiar with heating systems and control wiring.

All control circuits of TEC units are ‘volt free’ and may be used to switch

240V AC or low voltage control systems.

Extreme care must be taken to ensure that all wiring is correct before applying

power, as irrepairable damage to the PCB could result due to incorrect

connections.

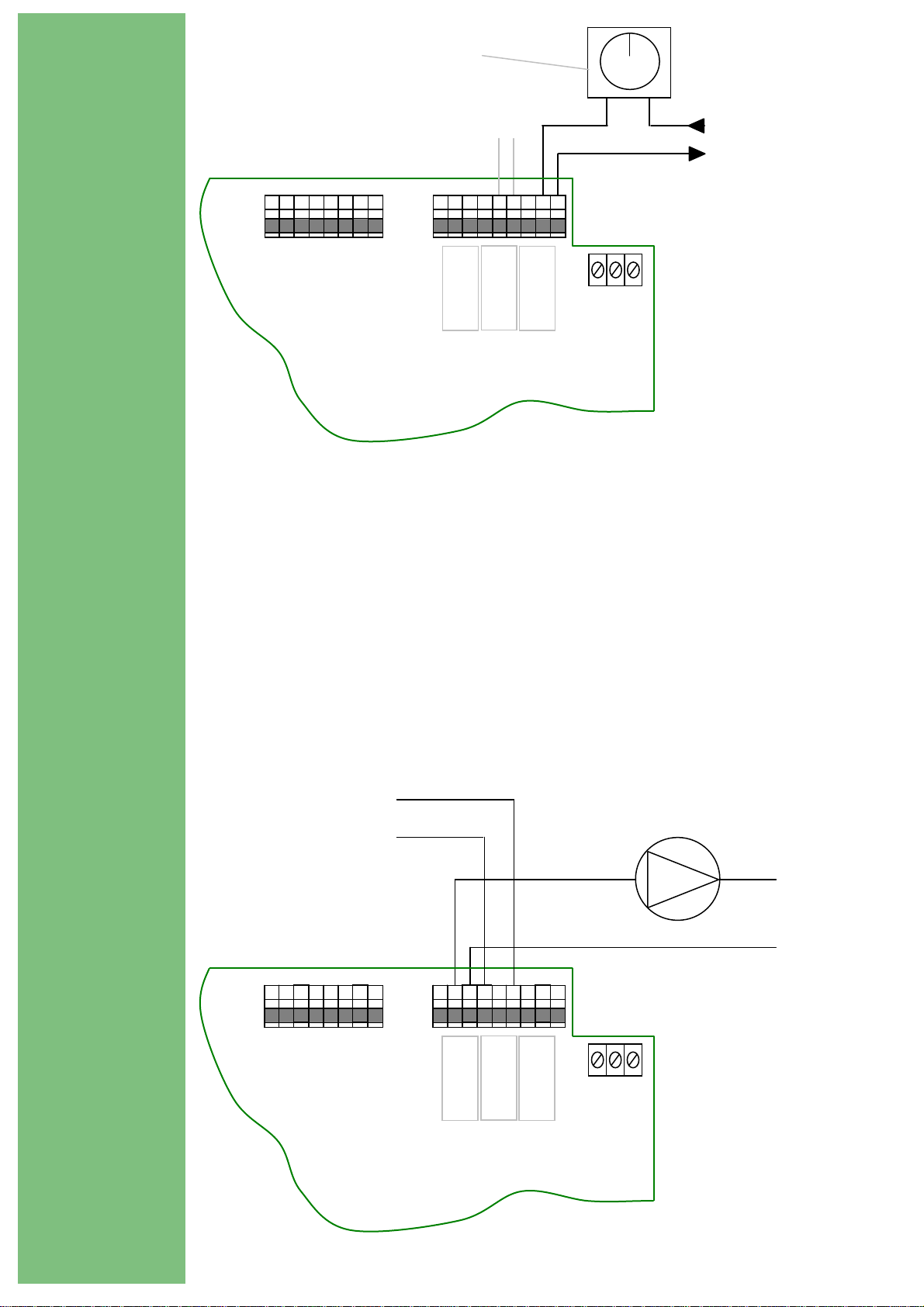

Mains Wiring

Unscrew the four screws of the TEC 100/200 and remove the lid to gain access

to the PCB and wiring connections.

A 240V AC 1Ph 50Hz supply may be taken from the existing time clock

switched or permanent supply, or direct from the boiler mains input connections

(where available), which ever is the most suitable. The 240V connection to the

TEC 100/200 is shown in Fig.1 below.

3

TEC 100/200 PCB

Fig. 1

240 V Supply as described

E L

N

)

4

Control Wiring

NOTE: If a wiring harness is provided in the rear of the enclosure please

follow cables to TEC 100/200 PCB to determine connections as described in

the following sections.

Many boilers are provided with an accessible mains terminal block. Most

have a pair of connections (usually unused) for use with external controls.

These connections will have a link which needs to be removed so that the

TEC 100/200 control wires can be connected as shown in Fig.2.

Remove link

To boiler 2 (TEC 200

To boiler

N L

E

TEC 100/200 PCB

If the boiler is a simple

permanent pilot type, i.e.

Ideal Concord, Potterton,

Kingfisher etc, the

connections may be made

into the mains supply of

the boiler if more

convenient.

Fig. 2

Note: A 5-core heat resistant flex is ideal for connecting the TEC 100/200 to the

boiler. The recommended connection method is via a flexible nylon

conduit to house the cable.

Where a terminal block arrangement as shown in Fig.2 is not available, the

control wiring should be connected directly into the boiler thermostat wiring

as shown in Fig.3.

p

Boiler Thermostat

Boiler 2 (TEC200):

Connections as per

Boiler 1

Live in

Live to Burner

ut

5

N L

E

TEC 100/200 PCB

Fig. 3

Other Wiring Options

The TEC 100/200 has three control relays. On the TEC 100 the left hand relay

is the Plant Relay which may be used to control a circulating pump and the

right hand relay is the boiler control circuit. The centre relay (Tec 100 only)

make and breaks on RTN/HW settings and may be used to control a HW pump,

solenoid etc, see Fig 4. On the TEC 200 the left hand relay is the Plant Relay,

the middle relay is boiler 2 control circuit and the right hand relay is boiler 1

control circuit.

Make on

RTN/HW

temperature

drop.

TEC 100/200 PCB

Pump

Neutral

Live

1 P 2

E

N L

Fig. 4

6

Fitting and Wiring Temperature Sensors

The TEC 100/200 has three temperature sensor inputs, these being Flow,

Return/Hot Water and External. Connections are as shown in Fig.5.

FLOW Sensor

RETURN / HW Sensor

EXTERNAL Sensor

Aux Extn Flow Retn

P 2 1

N E L

TEC 100/200 PCB

Fig. 5

Flow / Return Temperature Sensors (Cable Type)

Using heat resistant cloth tape, tightly strap the sensors to the relevant

flow and return pipes, close to boiler, before any branching connections.

Cover the sensors with heating pipe insulation and strap with ty-wraps or

similar. See Fig.6.

Heat Resistant Cloth Tape

Securing Ty-Wraps

Sensor Head

Pipe Insulation fixed over Sensor

Flow / Return Pipe

Fig. 6

connections

7

Optional Hot Water Tank Sensor connections (replaces Return Temperature

Sensor) are shown in Fig.7.

Optional HW Tank Sensor.

Connect in place of Return

Temperature Sensor.

Mount 1/3 to 1/2 way up

Fix Tank Sensor

with expanding

wire (supplied

with optional

Tank Sensor).

TEC 100/200 Return

Temperature Sensor

Fig. 7

If the hot water tank is a distance from the boiler, wiring to it may be

impractical.

If hot water priority is important then the Return Sensor should be fitted

to the Hot Water Tank Return Pipe. If this is also impractical, then fit

as normal to the main Return Pipe and set the Minimum Return

Temperature to provide an adequate level of hot water supply.

Where the tank option is used, set the Minimum Return Temperature

to the stored water temperature requirement.

External Sensor

The External Sensor should preferably be positioned on a north facing

exterior wall, and connected to the appropriate terminals of the TEC 100/200.

If it is not possible to mount the sensor on a north facing wall, then mount

in a shaded position, under eaves, and away from boiler house vent grilles etc.

Note A special reflective, insulated external sensor is available when fitting

in a position where solar heat is unavoidable.

8

Temperature Display Calibration

When required, the temperatures as displayed on the TEC 100/200 may be

adjusted to cater for heat losses on pipework, losses on external temperature

sensor etc. Program 17 (see page 30) can be used to calibrate the temperature

display by -10ºC/+20ºC.

C

ommissioning - Introduction

9

The TEC 100/200 Digital has 18 main programs, these being:

1. Calendar

2. On/Off Times (Two On/Off Periods per day)

3. Frequency (Once, Twice, 24 Hours)

4. Select Days (Every Day, Weekends, Week Days)

5. Optimise On Time ( 0 to 240 minutes)

6. Optimise Off Time ( 0 to 240 minutes)

7. Maximum Flow Temperature (30ºC to 85ºC)

8. Minimum Flow Temperature (25ºC to 85ºC)

9. Minimum Return Temperature (20ºC to 65ºC)

10. Mid Temperature (0ºC to 85ºC)

11. Night Temperature (0ºC to 85ºC)

12. Frost Temperature (0ºC to 35ºC)

13. External Cut Off Temperature (0ºC to 35ºC)

14. Differential (1ºC to 5ºC)

15. Hot Water Priority (Yes / No)

16. Internal/External Optimisation (Yes / No)

17. Calibration (-10ºC/+20ºC)

18. Rotation (Yes / No)

Certain Differentials and the Compensation Slope are fixed within the software,

i.e. Return Temp 2ºC, External Temp 2ºC, Compensation Slope 1.5.

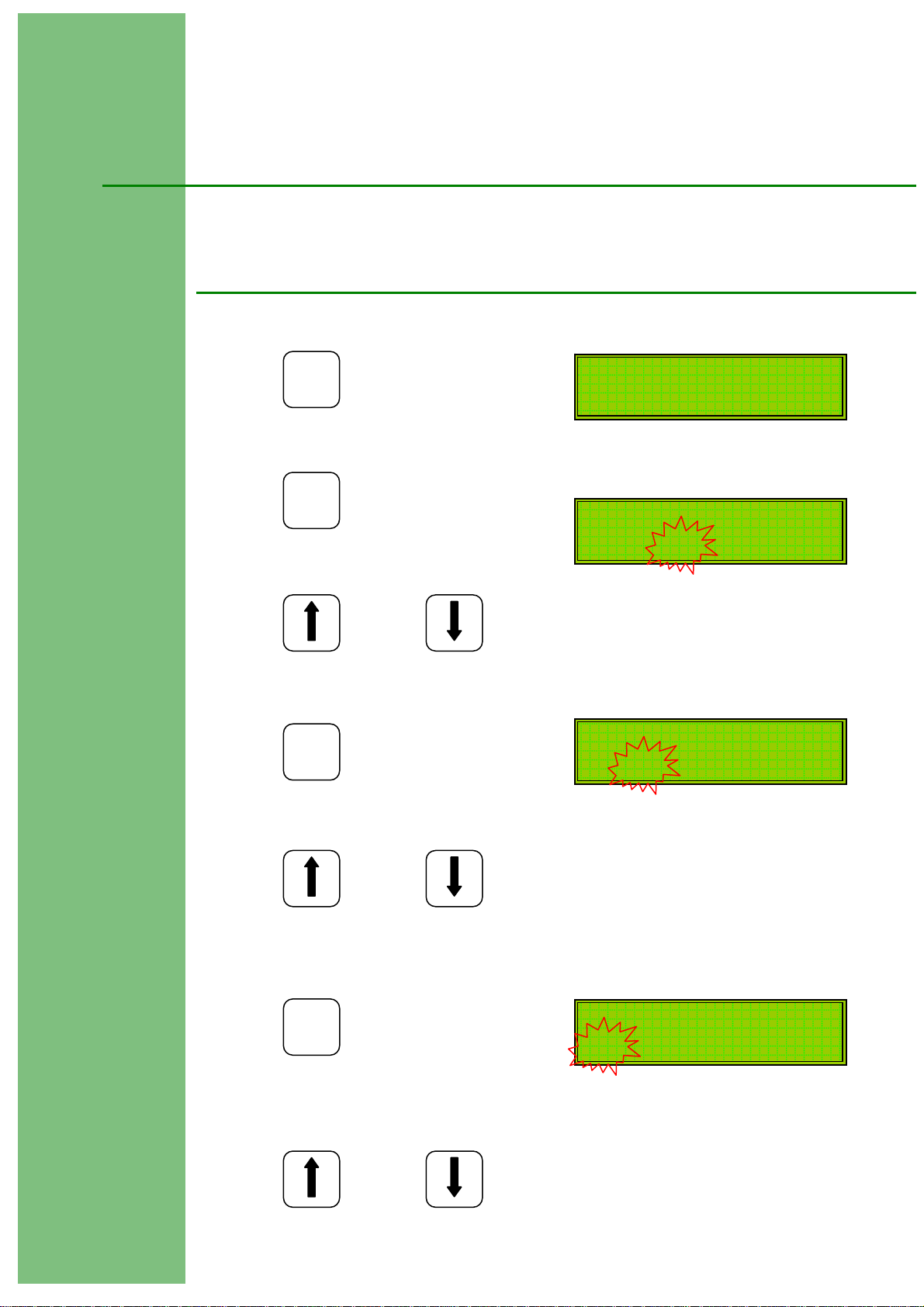

Keypad and Running Mode Overview

Used to enter Programming Mode from normal running mode,

P

and to access Change Mode for the selected program.

PROGRAM

Used to cycle through the program list when in Programming

Mode and to change program settings when in Change Mode.

SELECT

RETURN

Used to cycle through the program list when in Programming

Mode and to change program settings when in Change Mode.

10

Used to confirm a programming change and to exit from the

E

ENTER

The TEC 100/200 will go into Boost mode from a cold

start. It will stay in this mode for 15 minutes, or

until the Return Temp is within10ºC of the Flow

Temp If a Hot Water Sensor is fitted then the

TEC 100/200 will go into Boost mode if the HW Tank

is cold.

Firing mode indicates that the boiler is firing.

Temp Set indicates that the actual Flow Temp is

above the system set temperature**. The boiler will

not be firing at this point.

Economising indicate that the TEC 100/200 has entered

self learning mode and is making economies. The

boiler will not be firing at this point.

Ext ‘flashing’ indicates that the external temp

is above the level set in the Ext Cut-Off program.

Programming Mode.

BOOST

S57 F20 R20 E12

FIRING

S57 F50 R42 E12

TEMPERATURE SET

S57 F59 R53 E12

ECONOMISING

S57 F59 R53 E12

EXT

S57 F36 R34 E16

** The system set temperature as indicated in the display, represents the

heating system aiming temperature based on current climatic conditions,

as determined by the TEC 100/200’s weather compensation circuitry.

11

Establishing the System Maximum Flow Temp

Switch on the power to the TEC 100/200.

1. Set the Bypass Switch to the bypass position.

Allow the heating system to cycle twice at the normal winter setting of the

boiler thermostat (see plant engineer, caretaker, maintenance manger etc to

establish winter thermostat position).

2. The display will show:

3. When the actual Flow Temperature exceeds the Set Temperature, the display

will change:

4. When the boiler has cycled twice with the TEC 100/200 in bypass, observe the

actual flow temperature as shown on the display:

In this example, the winter setting for the heating system (TEC 100/200

maximum flow setting) should be set to 72ºC (73ºC - 1ºC).

The Boiler Thermostat should now be set to a higher setting to ensure correct

operation of the TEC 100/200.

Actual Return / HW Temp

Actual External Temp

Current Mode

Set Temp

Actual Flow Temp

FIRING Tu 10:05

S57 F50 R42 E05

TEMP.SET Tu 10:05

S57 F58 R48 E05

TEMP.SET Tu 10:05

S57 F73 R65 E05

Setting the Programs

P1. Setting the Calendar (Factory Set)

1. Press to change display to:

2. Press again to display:

3. Press or to set the year.

4.

Press to change display to:

5. Press or to set the month.

Press to change display to:

6.

7. Press or to set the date.

P

PROGRAM

P

PROGRAM

RETURN SELECT

E

ENTER

RETURN SELECT

E

ENTER

12

1 CALENDAR

21/11/03 11:29

SET YEAR

21/11/03 11:29

SET MONTH

21/11/03 11:29

SET DATE

21/11/03 11:29

RETURN SELECT

8.

Press to change display to:

9. Press or to set the hour.

8.

Press to change display to:

9. Press or to set the minutes.

10.

Press to change display to:

11. Press or to set the day.

Press to confirm the program change and return to main menu.

12.

Press to advance to next program.

13.

E

ENTER

SELECT RETURN

E

ENTER

SELECT RETURN

E

ENTER

SELECT RETURN

E

ENTER

SELECT

SET HOUR

21/11/03 11:29

SET MINS

21/11/03 11:29

SET DAY Fr

13

P2. Programming the Time Clock (On/Off Times)

1. Press or to select program 2:

2. Press again to display:

There are two (2) programmable On/Off times per day.

The second OFF time must ALWAYS be programmed, and set to a time

after, but in the same 24 hour period as the first ON time.

3. To change On/Off Times select the required day with

4. Press to enter programming mode for the chosen day:

5. Press to set first ON time:

6. Press or to set the hour as required.

7. Press to set first ON time minutes:

SELECT RETURN

P

PROGRAM

P

PROGRAM

P

PROGRAM

SELECT RETURN

2 ON/OFF TIMES

MO 1 07:30-00:00

2 00:00-16:30

SELECT RETURN

MO 1 07:30-00:00

* 2 00:00-16:30

MO 1 07:30-00:00

* 2 00:00-16:30

14

E

ENTER

MO 1 07:30-00:00

* 2 00:00-16:30

8. Press or to set the minutes as required.

9. Press to set first OFF** time:

** If the FIRST OFF time is not required leave at 00:00.

Adjust HOUR and MINUTES in the same way as previously described.

10. Press to set the second ON time and repeat as above.

11. Press to set the second OFF time and repeat as above.

If different On/Off times are required for each day, then repeat the above

instructions for each day’s times.

To repeat a days On/Off times into the next day, select the next day as

described above and press followed by .

12.

Press to confirm program changes and return to main menu.

SELECT RETURN

E

ENTER

E

ENTER

E

ENTER

PROGRAM ENTER

E

ENTER

P

MO 1 07:30-00:00

* 2 00:00-16:30

E

15

16

P3. Frequency (How the Time Clock operates)

1. Press or to select program 3:

2. Press to display:

3. Press or to set as described below:

ONCE The time clock operates from the first ON time to the second

OFF time.

TWICE The time clock operates on both ON and OFF times i.e. two

On/Off periods per day.

24 HOUR The time clock operates 24 hours a day regardless of the

On/Off settings.

4.

Press to confirm program changes and return to main menu.

SELECT RETURN

P

PROGRAM

SELECT RETURN

E

3 FREQUENCY

CURRENT ONCE

UP/DN TO CHANGE

CURRENT ONCE

ENTER

P4. Select Days

1. Press or to select program 4:

2. Press to display:

3. Press or to set as described below:

EVERY DAY The heating will operate everyday as set by the time

clock On/Off times.

WEEK ENDS The heating will operate at week ends only as set by

time clock On/Off time for Sat – Sun. If reduced

heating is required at week ends then set the time clock

for reduced hours during Saturday and Sunday, and then

set program 4 to EVERY DAY.

WEEK DAYS The heating will operate during week days only as set

by the time clock On/Off times Mon – Fri. The heating

will be OFF at weekends.

4.

Press to confirm program changes and return to main menu.

SELECT RETURN

P

PROGRAM

RETURN SELECT

4 SELECT DAYS

CURRENT EVERY DAY

UP/DN TO CHANGE

CURRENT EVERY DAY

E

17

ENTER

18

P5. Optimise On (Pre-Heat)

1. Press or to select program 5:

When programming a Variable Pre-Heat period (Optimum On) the first switch

on time (P2) should be set to the buildings occupation time. If a variable pre-

heat period is not required, then the first switch on time must allow for a

sufficient warm-up period before occupation time.

When selected, the full programmed variable pre-heat period will occur at 0ºC

external temperature. At temperatures above 0ºC the system will calculate the

required pre-heat time.

Note: To assure adequate temperatures are achieved by occupation time

If Optimum On is not required then set to 000 mins.

2. Press to display:

3. Press or to set the required number of minutes.

4.

Press to confirm program changes and return to main menu.

SELECT RETURN

5 OPTIMISE ON

CURRENT 000 MINS

the maximum pre-heat period must satisfy the building’s thermal

characteristics.

UP/DN TO CHANGE

P

PROGRAM

SELECT RETURN

CURRENT 000 MINS

E

ENTER

19

P6. Optimise Off

1. Press or to select program 6:

Optimum Off periods will, when selected, switch off a boiler / heating system

earlier than the programmed off time.

At 15ºC external temperature the full optimum off period will occur and the

boilers will switch off early. At 0ºC external temperature there will be no

optimum off and the boilers will switch off at the normal programmed time. At

external temperatures between 0ºC and 15ºC the system will calculate the

required off time.

If Optimum Off is not required then set to 000 mins.

2. Press to display:

3. Press or to set the required number of minutes.

Press to confirm program changes and return to main menu.

4.

P

PROGRAM

E

RETURN SELECT

6 OPTIMISE OFF

CURRENT 000 MINS

UP/DN TO CHANGE

CURRENT 000 MINS

RETURN SELECT

ENTER

P7. Setting the Maximum Flow Temperature

2. Press to change display to:

3. Press or to change the temperature setting to that

required (i.e. 73ºC).

4. Press to confirm the program changes and return to main menu.

1. Press or to select program 7:

SELECT

P

PROGRAM

SELECT

RETURN

RETURN

7 MAX FLOW TEMP

CURRENT 60

UP/DN TO CHANGE

CURRENT 73

E

ENTER

20

P8. Setting the Minimum Flow Temperature

2. Press to change display to:

3. Press or to change the temperature setting to that

required.

4. Press to confirm the program changes and return to main menu.

1. Press or to select program 8:

SELECT

P

PROGRAM

SELECT

RETURN

RETURN

8 MIN FLOW TEMP

CURRENT 40

UP/DN TO CHANGE

CURRENT 40

E

ENTER

Setting a Minimum Flow Temperature is required to limit the effect of the

Compensation. The flow temperature will not fall below that set in the

Minimum Flow program ( - differential), even if the compensated flow

temperature is below this level.

The Minimum Flow Temperature should be chosen to meet heating criteria.

21

P9. Setting the Minimum Return Temperature

The Minimum Return temperature will depend on the type of heating system:

Heating and Hot Water.

Where convenient, the return temperature sensor should be fitted to the hot

water storage tank (see installation instructions), the hot water return pipework

or the hot water circulating pipework.

The minimum return temperature should be set to provide normal hot water

tank temperature, i.e. 60ºC.

Heating Only.

In this instance, the minimum return temperature should be set to the boiler

manufacturers recommended level, i.e. 55ºC for oil fired systems, 50ºC or lower

for gas fired systems. These figures are examples only. Refer to your boiler

manual for manufacturer recommended settings.

1. Press or to select program 9:

2. Press to change display to:

3. Press or to set the required temperature.

4. Press to confirm program changes and return to main menu.

SELECT

P

PROGRAM

SELECT

E

ENTER

RETURN

RETURN

9 MIN RETN TEMP

CURRENT 50

UP/DN TO CHANGE

CURRENT 55

22

23

P10. Setting the Mid Temperature

The Mid Temperature is used (if required) to set the flow temperature during

st

the period between the 1

Off Time and the 2nd On Time.

If a second On Period is not required, then set Frequency (P3) to Once.

1. Press or to select program 10:

SELECT

RETURN

10 MID TEMP

CURRENT 65

2. Press to change display to:

P

PROGRAM

UP/DN TO CHANGE

CURRENT 65

3. Press or to set the required temperature.

SELECT

RETURN

4. Press to confirm program changes and return to main menu.

E

ENTER

24

P11. Setting the Night Temperature

The Night Temperature can be used in 2 ways:

1. To provide basic frost protection in conjunction with the frost

temperature (P12).

2. To provide night time economies on 24 hour systems by selecting

a lower flow temperature during the programmed off periods.

1. Press or to select program 11:

2. Press to change display to:

3. Press or to set the required temperature.

4. Press to confirm program changes and return to main menu.

SELECT

P

PROGRAM

SELECT

RETURN

RETURN

11 NIGHT TEMP

CURRENT 35

UP/DN TO CHANGE

CURRENT 35

E

ENTER

25

P12. Setting the Frost Temperature

The Frost Temperature can be set to cancel the Night Temperature (P11)

at a programmed external temperature.

E.G. For frost protection only set P12 to say 1ºC.

The night temperature will not be activated until the external temperature falls

to this level.

If the unit is installed in a nursing or residential home it may be possible to set

P12 to 15ºC - 16ºC so that the night temperature will not be activated at

temperatures above this and the heating will switch off.

If night temperature is required whatever the external temperature, set P12 to

maximum, i.e. 35ºC. Discuss this aspect with the building manager / owner to

establish the requirements.

Operation of the Frost Temperature will cancel 24 Hr Hot Water Priority.

1. Press or to select program 12:

2. Press to change display to:

3. Press or to set the required temperature.

4. Press to confirm program changes and return to main menu.

SELECT

P

PROGRAM

SELECT

RETURN

RETURN

12 FROST TEMP

CURRENT 03

UP/DN TO CHANGE

CURRENT 03

E

ENTER

13. Setting the External Cut-Off Temperature

The External Cut-Off Temperature sets the outside temperature above which

the heating system will switch off. This setting is also referred to as the

Summer Cut-Off Temperature. The heating will come back on at 2ºC below the

External Cut-Off Temperature.

1. Press or to select program 13:

2. Press to change display to:

3. Press or to set the required temperature.

4. Press to confirm program changes and return to main menu.

SELECT RETURN

P

PROGRAM

SELECT RETURN

E

ENTER

13 EXT C/O TEMP

CURRENT 35

UP/DN TO CHANGE

CURRENT 35

26

27

14. Differential

The Differential should be set to match existing boiler thermostat cycling

temperature.

1. Press or to select program 14:

2. Press to change display to:

3. Press or to set required differential.

4. Press to confirm program changes and return to main menu.

SELECT RETURN

P

PROGRAM

RETURN SELECT

E

ENTER

14 DIFF

CURRENT 2

UP/DN TO CHANGE

CURRENT 2

28

P15. Hot Water Priority (24 Hour)

1. Press or to select program 15:

2. Press to change display to:

3. Press or to set YES, NO or HW Only.

4. Press to confirm program changes and return to main menu.

When set to NO the TEC 100/200 Hot Water Priority operates during the

programmed ON periods.

When set to YES, 24 hour hot water priority is provided.

When set to HW ONLY the plant relay controlling the heating pump will

switch off when the external cut-off temperature is exceeded. This may only

be set if a separate HW pump is installed, or gravity flow to the hot water

cylinder is used.

Note: The centre relay of the TEC 100 is programmed to operate at the

RTN/HW temperature setting and may be used to control the HW pump etc.

Consideration should be given to the Night Temperature when setting Hot

Water Priority. It should also be noted that operation of the Frost

Temperature can cancel 24 Hour Hot Water Priority.

P

PROGRAM

E

ENTER

RETURN SELECT

RETURN SELECT

15 HW PRIORITY

CURRENT NO

UP/DN TO CHANGE

CURRENT NO

29

P16. Internal / External Optimisation

Program 16 allows the TEC 100/200 to utilise either Internal AND External

Optimisation or just External Optimisation.

Internal Optimisation requires the heating pump to be connected to the

Plant/Pump Relay as described on page 5.

To use both modes of Optimisation set to YES.

To use just External Optimisation set to NO.

1. Press or to select program 16:

2. Press to change display to:

3. Press or to set YES or NO.

4. Press to confirm program changes and return to main menu.

SELECT RETURN

P

PROGRAM

SELECT RETURN

E

16 INT&EXT OPTIM

CURRENT NO

UP/DN TO CHANGE

CURRENT NO

ENTER

30

P17. Calibration

Program 17 allows individual calibration of the Flow, Return and External

temperature sensors. Each sensor reading can be adjusted by -10ºC/+20ºC.

1. Press or to select program 17:

2. Press to change display to:

3. Press or to adjust the displayed temp (-10ºC/+20ºC).

4. Press to confirm program changes and display:

5. Press or to adjust the displayed temp (-10ºC/+20ºC).

6. Press to confirm program changes and display:

SELECT RETURN

P

PROGRAM

SELECT RETURN

E

ENTER

SELECT RETURN

E

17 CALIBRATE

17 CALIBRATE

FLOW 60

17 CALIBRATE

RETN 50

ENTER

17 CALIBRATE

EXTN 16

7. Press or to adjust the displayed temp (-10ºC/+20ºC).

8. Press to confirm program changes and return to main menu.

SELECT RETURN

E

ENTER

31

32

P18. Rotation (TEC 200 only)

Program 18 allows the TEC 200 to rotate the lead boiler every 24 hours.

When set to YES the lead boiler is changed at midnight i.e. boiler 1 leads one

day, and boiler 2 the next, then boiler 1 next etc etc.

When set to NO the boiler connected as boiler one will always be the lead

boiler.

1. Press or to select program 18:

2. Press to change display to:

3. Press or to set YES or NO.

4. Press to confirm program changes and return to main menu.

SELECT RETURN

P

PROGRAM

SELECT RETURN

E

18 ROTATION

CURRENT YES

UP/DN TO CHANGE

CURRENT NO

ENTER

33

Exiting Programming Mode

To exit from the programming mode, first ensure that the display indicates

you are in the main menu.

At this point, press to exit programming mode.

The display will change to:

And then, after a few seconds to:

The display may show slightly different information depending on the

current mode of operation, i.e. boost, firing, economising etc.

Note: When in programming mode the TEC 100/200 will revert to

normal

running mode if the keypad is not operated for a period of 30

seconds (4 minutes if in program change mode).

To access programming mode from normal running mode:

Press and then select required program with .

Make any program changes as described previously.

P

PROGRAM SELECT RETURN

E

ENTER

TEC 100 V3

ACTIVE

FIRING Tu 15:35

S57 F50 R42 E05

TEC 100/200 with Monitor Socket

The TEC 100/200 is available with a pre-wired Monitoring Socket. In such a

case, the control wiring must be as shown in Fig.3 (page 5).

The power supply to the unit must be from a permanent source to enable the

monitoring system to function in the correct manner.

Within the TEC 100/200 you will see an orange fly lead. This should be

connected to the timeswitch output to provide a signal for the demand meters

(lower set).

If for any reason the system will not allow connections into the control

thermostat as shown in Fig.3, then remove the red link wire as shown in Fig.9.

Connect the white fly lead to the now spare connector on the monitor socket

(originally connected to red link), and connect directly to burner supply to

provide a signal for the firing meters (upper set).

The monitoring system has an integral digital timer that has been programmed

to operate the Day On/Day Off changeover at 00:05 – 00:10 hrs. Open the

monitor lid and operate the change button on the digital timer to initiate an

active period (red LED off).

With the boiler firing and the heating timeswitch on, the two active meters

should be operating. The top active meter indicating firing hours, and the

bottom active meter indicating demand hours.

If they are not operating, re-check all connections.

Allow the TEC 100/200 to reach Temp Set mode (boiler cut-off), and note the

firing meter has stopped. Operate the change button on the digital timer to

initiate a bypass period (red LED on). Providing that the boiler thermostat

is on, the boiler will re-fire (TEC 100/200 bypassed), and the bypass meters

will operate. The top bypass meter indicating firing hours, and the bottom

bypass meter indicating demand hours.

When ready to start the monitored test, operate the change button on the

digital timer to enter an active period (red LED off), ensuring that the timer is

itself in the off state. If necessary, reset the hour meters to zero with the reset

button provided in the top right hand corner of the unit. The system will now

34

35

record firing and demand hours in both active and bypass modes. These

modes will alternate on a day to day basis.

To PCB

0.0

ACTIVE

0.0

BYPASS

0.0

ACTIVE

0.0

Remove RED link from

here and connect white fly

lead in it’s place. Connect

the other end of the white

fly lead direct to the burner.

Firing Meters

Demand Meters

BYPASS

Flashing indicator when operating

Fig. 9

Monitor

Loading...

Loading...