Page 1

Page 2

2

:: Introduction

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and maintaining your new RC10TC6.2.

Please take a moment to read through this manual to help familiarize yourself with these steps.

We are continually changing and improving our designs; therefore, actual parts may appear slightly different than in the illustrations. New parts will be noted on

supplementary sheets located in the appropriate parts bags. Check each bag for these sheets before you start to build.

:: KIT Features

Team Associated is proud to release the next step in its developmental line of 1:10th scale 4WD electric touring car kits, the RC10TC6.2-FT, further refining the

already successful TC6 platform.

The touring car racing class has been moving forward at an aggressive rate, and the Engineers behind the doors of Area-51 have been hard at work evolving

the TC6 platform to keep the pace. The RC10TC6.2-FT car kit comes equipped with a host of new features to allow for more precise suspension adjustment and

consistent handling for any track condition.

With over two year’s development on the TC6 chassis, the TC6.2-FT car kit ties together all the experience and Factory Team race tested parts. Focusing on precise

suspension adjustments with features such as the new independent arm mount system with interchangeable toe inserts and pivot ball joints. A new dual

bellcrank steering system has optimal Ackermann and steering rates, and is controlled by a servo on a floating mount for steering to match today’s aggressive

racing conditions. Updated bulkhead and top plate configurations allow for optimized flex through the entire length of chassis to give the best grip on any surface.

The RC10TC6.2-FT packs together the key features necessary to keep you at the top of the racing circuit. All without sacrificing low part count or affordability.

It’s plain to see that the RC10TC6.2-FT kit is… another “Champion by Design” from Team Associated!

:: Key Features

• Updated arm mount system

o Pivot ball on inner hinge pin allows free pin movement at any toe

or kickup angle

o Insert system for precise adjustment of inner pin width and toe

o Independent arm mount design to allow maximum flex through

entire chassis length, resulting in better grip on all track conditions

• Dual bellcrank steering system

o Optimized Ackermann and steering rates

o Horizontal ballstuds for fine Ackermann adjustments

o 8 precision bearings for accurate swing motion

• Floating servo mount

o Servo mounts to chassis center to allow equal chassis flex in both

directions and a tweak free assembly

o Mount ties to steering bellcrank posts for stable servo positioning

o Slotted servo mount design allows fit for almost any standard servo

• Narrow chassis with optimized flex characteristics

o 2.25mm graphite laminate for optimized flex characteristics

o A narrow 88mm wide to minimize chassis dragging at maximum

chassis roll angles

o Chassis ballast mass mounting locations to fine tune mass balance

• Updated spur gear bulkheads

o Mounting pattern has been made independent of arm mount to

allow flex through entire length of chassis improving overall grip

o Narrowed mounting pattern to allow for more chassis flex and

consistent traction

o Symmetric design helps to minimize part count

• Updated motor mount & spur gear mount

o Floating spur gear design allows for more flex from rear of chassis

helping to gain traction in all conditions

o Motor mount attaches to center line of chassis with a floating post

connection to allow free chassis flex in both directions

• Updated vertical ball stud bearing caps

o Optimized position for inner ball stud

o Vertical ballstud orientation allows for fine adjustments of roll

center height

o 3 link position options give precise control of camber gain

• Spur gear lowered by 1.50mm to give more aggressive handling

characteristics

• Top plate lowered by 1.50mm to allow for more chassis flex and increased

traction in any condition

• Rear gear diff for maximum performance and minimal maintenance

o Lightweight design

o Durable composite construction

o Optimized for a wide “tuning window” to maximize useable

adjustability

o Hard anodized aluminum outdrives for low wear and long life

• Front spool with replaceable composite outdrives

o Outdrives allow the use of existing CVA bone blades to minimize

binding at the bearing surface

o Composite outdrives are replaceable at low cost in the event of a

CVA bone blade failure

• Cross-compatibility with all TC6.1 suspension components

• VCS3 Shock with hard anodized threaded shock bodies

o Bottom loading seal system for ease of build

o TiN coated shock shaft

o Piston attaches to shock shaft with screw for tight clamping and no

slop

o Threaded collar with fine pitch thread for ease of accurate ride

height adjustment

• Titanium turnbuckles with turnbuckle eyelets for easy access to ball stud for

adjustment

• 22 precision ball bearings

:: Items Needed

Your new FT TC6.2 comes unassembled and requires the following items for completion. (refer to catalog section for suggestions):

• 1:10th scale electric motor and electronic speed control • 1:10th scale 190mm lexan touring car body and Lexan specific paint for body

• 3.7V-7.4V LiPo, 6.6V LiFe, or 4.8V-7.2V NiMh/NiCd battery

• Battery charger (suited for, and particular to, one of the batteries mentioned) • Strapping tape for battery

• 2 channel surface transmitter, 2 channel receiver, and steering servo • 1:10th scale rubber (or foam) touring car tires, rims and inserts

:: Other Helpful Items

• Silicone Shock Fluid (Refer to catalog for complete listings) • Silicone Diff Fluid (Refer to catalog for complete listings) • Thread Lock (AE Part #1596)

• Body Scissors (AE Part # 1737) • Reamer / Hole Punch • FT Hex Wrenches (AE Part # 1541) • Hobby Knife

• Needle Nose Pliers • Wire Cutters • Soldering Iron • Calipers or a Precision Ruler

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 3

1/14

:: Table of Contents

3

1...................Cover

2...................Introduction

3...................Table of Contents

4-5...............Shock Build (Bag A-AA)

5-8..............Spool and Differential Build

(Bag B-BB)

8-9.............. CVA’s and Turnbuckles Build

(Bag C-CC)

10-11.........Suspension Arms Build

(Bag D-DD)

12-16........Bulkheads, Spur Gear, and

Steering Rack Build (Bag E-EE)

16-20........Steering/Caster Blocks and

Rear HubsBuild (Bag F)

26-28.........Tuning Tips

29................Gear Chart

30-37.........Catalog

38................Notes

39................Setup Sheet “Kit Setup”

40................1:1 Hardware “Fold Out”

41.................Setup Sheet “Blank”

42................Back Cover

21-25.......Bumper, Anti Roll Bar, and

Electronics Build (Bag G-GG)

:: Notes

This symbol indicates a special

note or instruction in the manual.

!

This symbol indicates a Racers Tip.

There is a 1:1 hardware fold out page in the

back of the manual. To check the size of a part,

line up your hardare with the correct drawing

until you find the exact size. Each part in the

foldout has a number assigned to it for ordering

replacement parts.

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 4

4

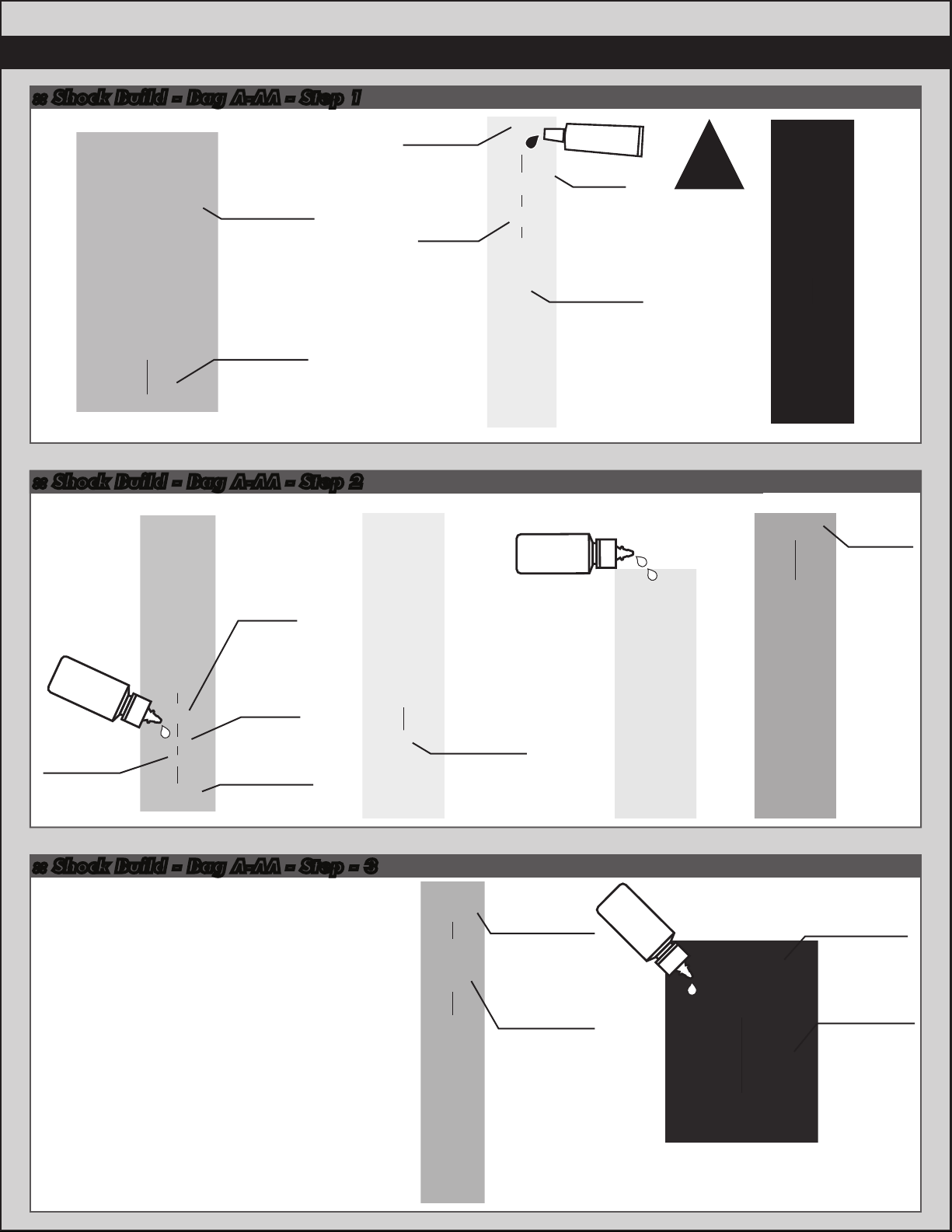

:: Shock Build - Bag A-AA - Step 1

31325

VCS3 shock

body

31327

VCS3 shock

bottom cap

o-ring

:: Shock Build - Bag A-AA - Step 2

31510

M2x4mm

bhcs

31324

VCS3

piston

bushing

#1596

thread lock

6465

Shock

piston

(#2)

31330

VCS3 shock

shaft

Shock oil

#5423

(40wt)

!

Thread lock

not included!

31324

Shock

bladder

31324

VCS3

o-ring

Shock oil

#5423

(40wt)

spacer

5407

Red

o-rings

31324

Hat

bushing

31327

VCS3 shock

bottom cap

:: Shock Build - Bag A-AA - Step - 3

Bladder Installation

With the shaft extended 25%, place bladder on

the top of the shock body, displacing the extra oil.

While maintaining pressure on the bladder against

the shock body, carefully lift one side of the bladder

to allow any extra oil to escape. Place stock cap on

top of bladder, and secure it by threading the

aluminum cap retainer onto the shock body.

31305

Turnbuckle

eyelet

31328

Aluminum

cap retainer

VCS3 shock

VCS3

31329

cap

Shock oil

#5423

(40wt)

31326

VCS3 shock

collar o-ring

31326

VCS3

shock collar

Page 5

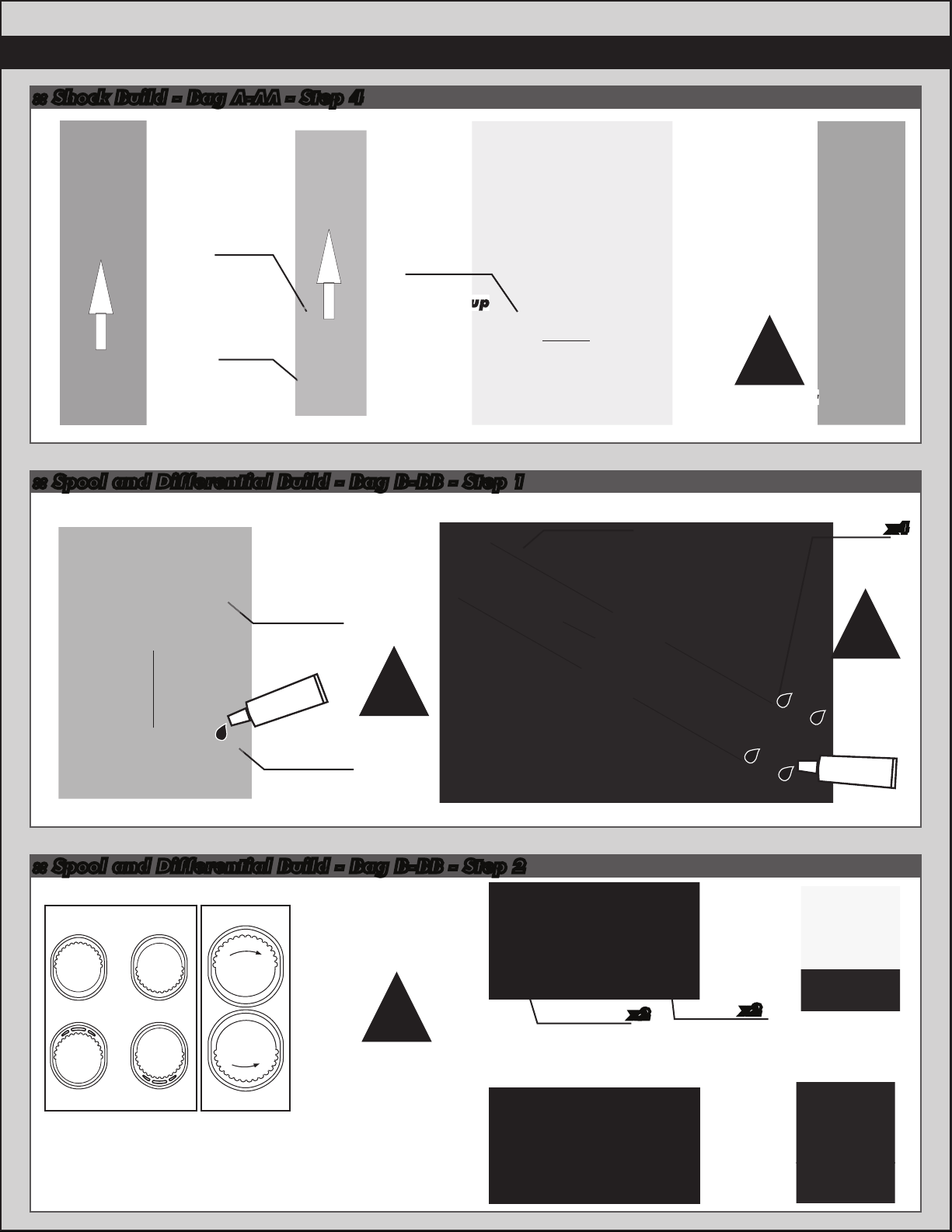

:: Shock Build - Bag A-AA - Step 4

3942

Silver

spring

14.5lb

(front)

3942

Silver

spring

14.5lb

(rear)

6475

Shock

spring cup

:: Spool and Differential Build - Bag B-BB - Step 1

5

!

Build four

shocks

31175

Diff pulley

flange

#1597

ca glue

31175

Diff pulley

(40T)

!

CA glue

not included!

:: Spool and Differential Build - Bag B-BB - Step 2

Belt Tension

Cam Position

Number

Left Side

161

31342

Spool hub

31510

M2x4mm

bhcs

!

Thread lock

not included!

#1596

thread lock

x4

Mid-Low

Low

Note!

Always use the same

cam position on both

sides of the car.

Mid-High

High

17 32

View from left

side of car

!

Use belt tension

position 8 for

standard setup.

Right Side

31615

Cam

holder

(mid-low)

x2

31615

Diff

bearing

cam

x2

Page 6

6

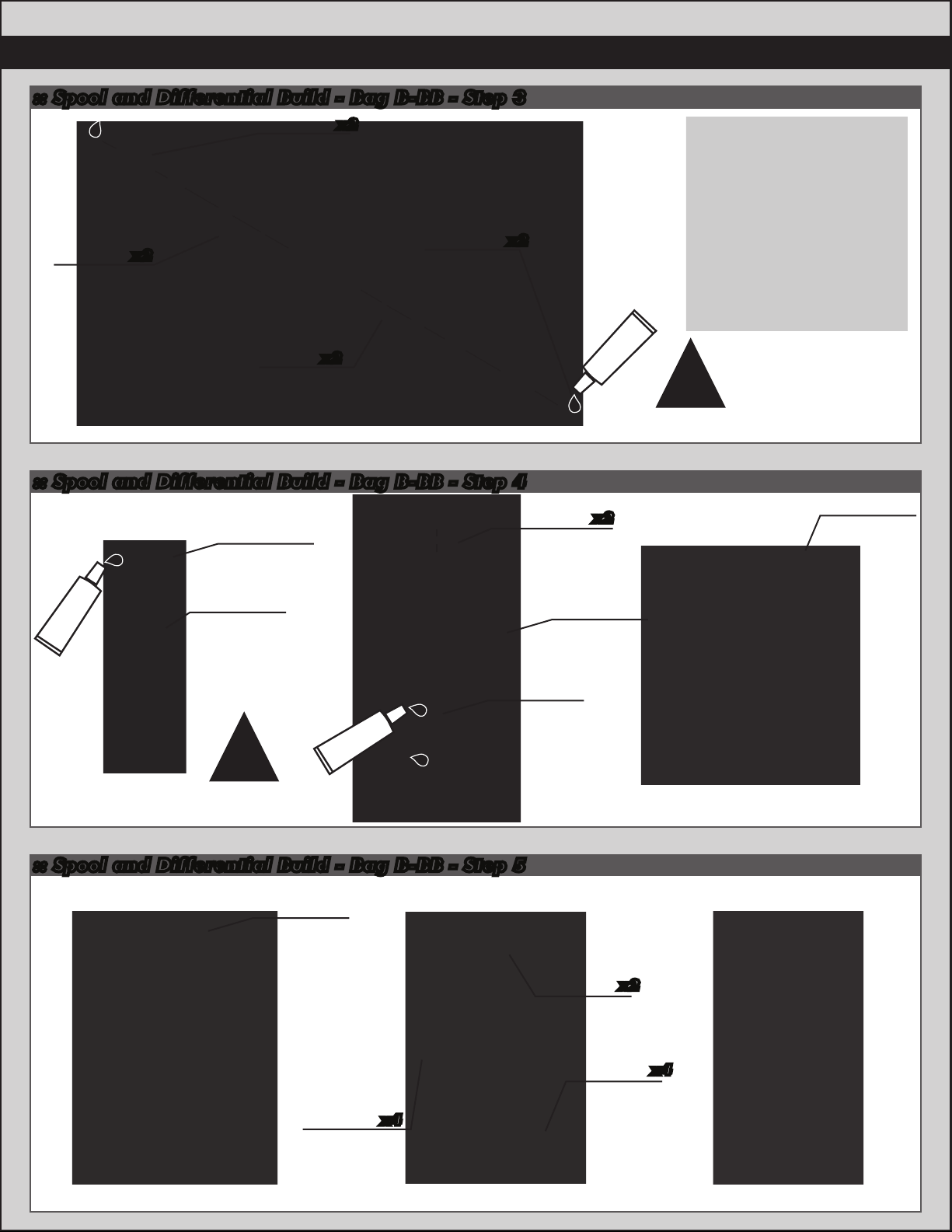

:: Spool and Differential Build - Bag B-BB - Step 3

31341

TC6 spool

outdrive

x2

31401

10x15mm

bearing

x2

31162

Shim

31350

M2.5x10mm

fhcs

x2

x2

:: Spool and Differential Build - Bag B-BB - Step 4

31349

TC6 gear

#6588

black grease

diff seals

31346

TC6 gear

diff outdrive

(1 small, 1 big)

31348

TC6 gear

diff shim

31347

TC6 gear

diff case

#1596

thread lock

x2

!

Thread lock

not included!

31348

TC6 gear

diff pin

31349

TC6 gear

diff seals

!

#6588

black grease

Build two

outdrives

:: Spool and Differential Build - Bag B-BB - Step 5

31345

TC6 gear

diff sun

gear

31348

TC6 gear

diff shim

x4

31348

TC6 gear

diff pin

31345

TC6 gear

diff planet

gear

x2

x4

Page 7

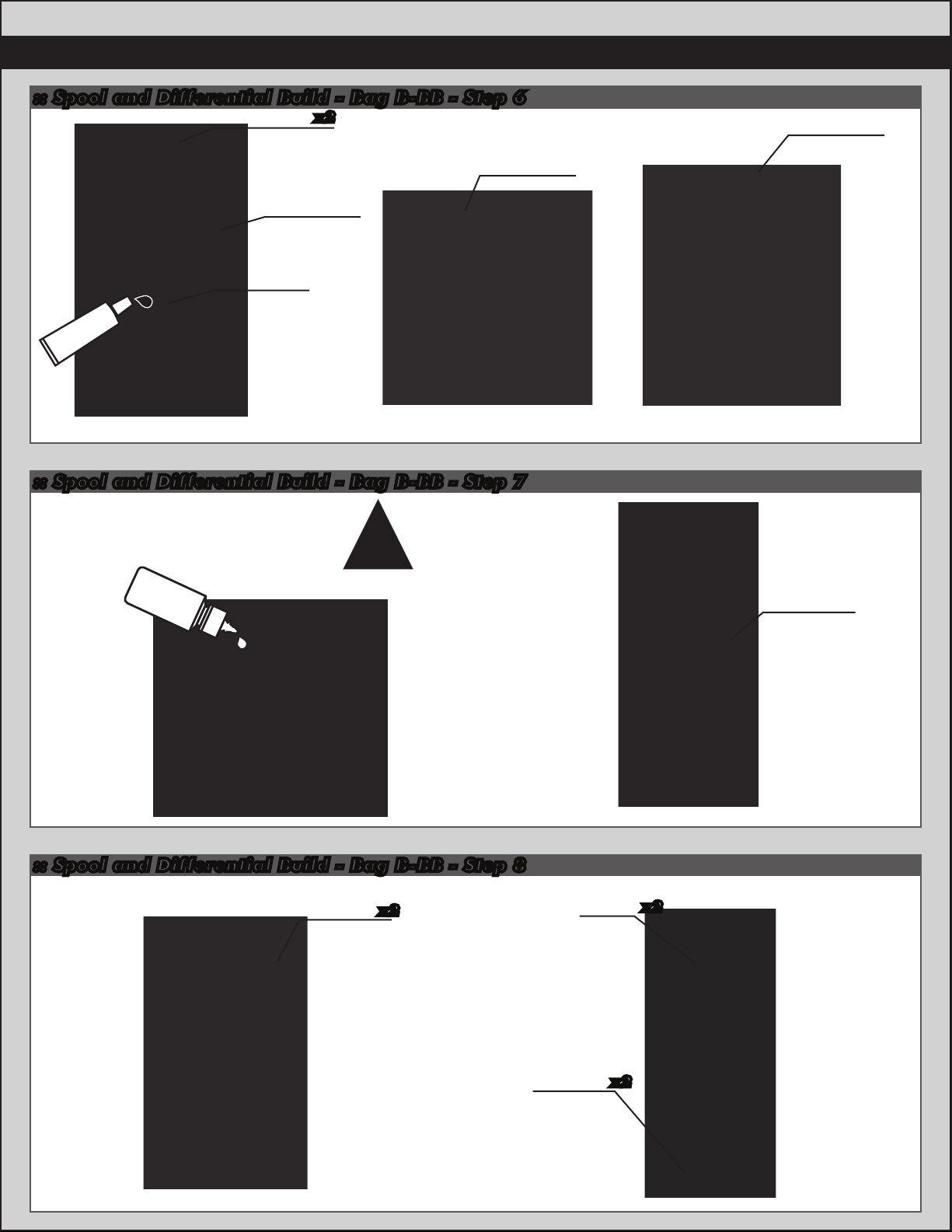

:: Spool and Differential Build - Bag B-BB - Step 6

31348

TC6 gear

diff shim

(1 small, 1 big)

31349

TC6 gear

diff seals

#6588

black grease

x2

31347

TC6 gear

diff pulley

31348

TC6 gear

diff pin

:: Spool and Differential Build - Bag B-BB - Step 7

7

31345

TC6 gear

diff sun

gear

!

Shock oil

#5423

(40wt)

:: Spool and Differential Build - Bag B-BB - Step 8

Fill to top of

cross pins

4675

M2.5x6mm

fhcs

x2

31162

Shim

31347

TC6 gear

diff gasket

x2

10x15mm

bearing

x231401

Page 8

8

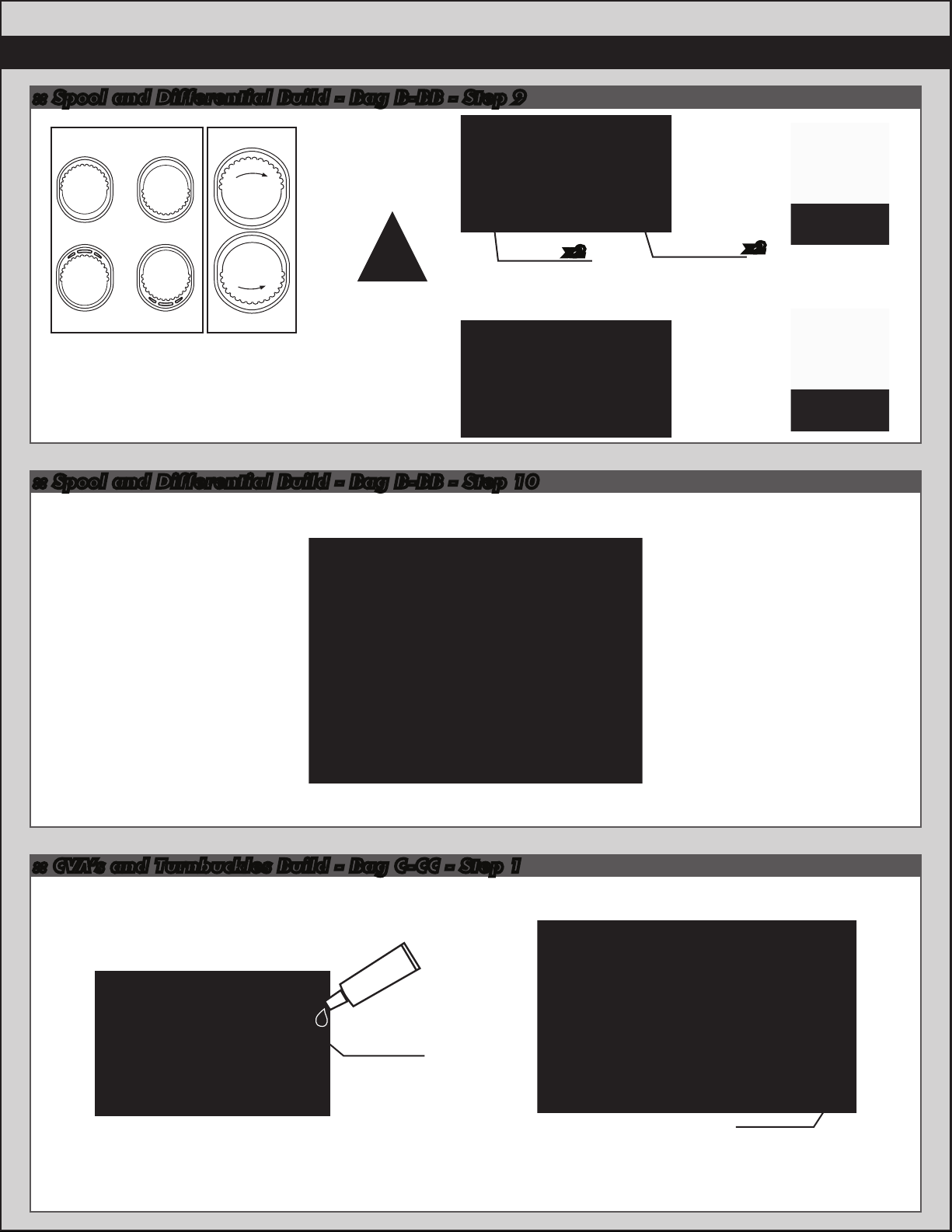

:: Spool and Differential Build - Bag B-BB - Step 9

Belt Tension

Cam Position

Number

Left Side

Mid-Low

161

Mid-High

31615

Low

Note!

Always use the same

cam position on both

sides of the car.

High

17 32

View from left

side of car

!

Use belt tension

position 7 for

standard setup.

Right Side

Diff

bearing

cam

:: Spool and Differential Build - Bag B-BB - Step 10

x2

31615

Cam

holder

(mid-low)

x2

:: CVA’s and Turnbuckles Build - Bag C-CC - Step 1

#6588

black grease

31367

31368

TC6.1 CVA

bones

TC6.1 CVA

coupler

31367

CVA

cross pin

31369

TC6.1 CVA

axle

Page 9

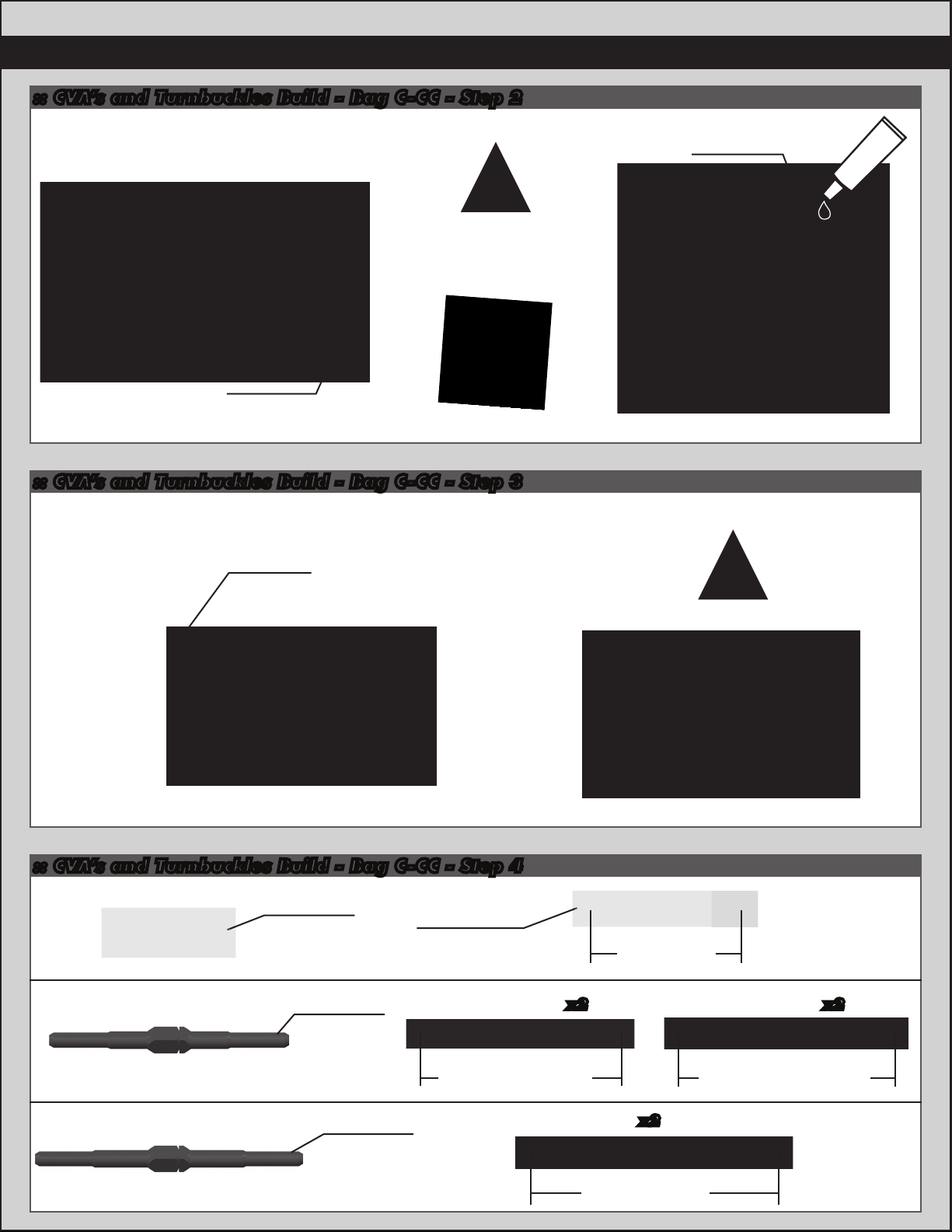

:: CVA’s and Turnbuckles Build - Bag C-CC - Step 2

!

Note!

Align the gap in the

pin retainer to be

opposite of the CVA

pin.

31237

retaining

clip

:: CVA’s and Turnbuckles Build - Bag C-CC - Step 3

31500

M3x2.5mm

setscrew

!

Thread lock

not included!

9

#1596

thread lock

31238

CVA blade

:: CVA’s and Turnbuckles Build - Bag C-CC - Step 4

Servo Turnbuckle

Camber Turnbuckle

1418

0.825”

turnbuckle

1402

1.375”

turnbuckle

31305

Turnbuckle

eyelet

Front Rear

!

Build four

CVA’s

34.65mm

x2 x2

Steering Turnbuckle

1405

1.875”

turnbuckle

46mm

49.50mm

x2

57mm

Page 10

10

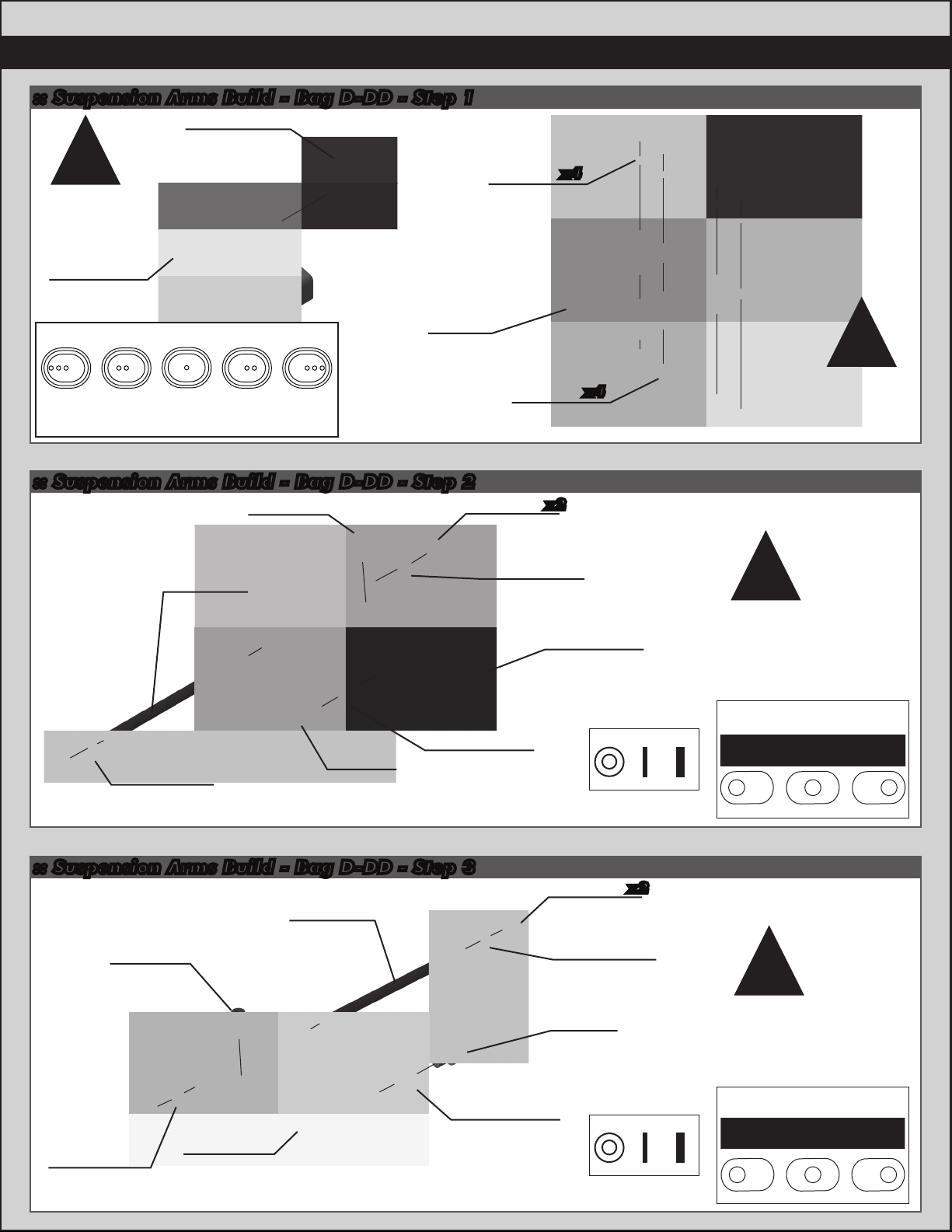

:: Suspension Arms Build - Bag D-DD - Step 1

31620

TC6.2 arm

mount insert

!

Build four

inner arm

mounts

31619

TC6.2 Inner

arm mount

Arm Mount Inserts

-3 DOT

-1 °

:: Suspension Arms Build - Bag D-DD - Step 2

-2 DOT

-1/2 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

1 DOT

0 °

(1 dot)

+2 DOT

+1/2 °

M4x8mm

setscrew

+3 DOT

+1 °

25227

31600

TC6.2

chassis

4617

Front

bulkhead

shim

(0.5mm)

31541

M3x6mm

fhcs

31621

x2

Inner hinge

pin ball

x4

x4

!

Install

front and

rear

31221

Inner

hinge pin

31356

Front

suspension

arm insert

31200

Wheelbase

shim (1mm)

31280

5mm

ballstud

(short)

:: Suspension Arms Build - Bag D-DD - Step 3

31221

Inner

25227

M4x8mm

setscrew

31200

Wheelbase

shim (2mm)

31357

Rear

suspension

arm

hinge pin

31200

Wheelbase

shim (2mm)

(B)

31357

Rear

suspension

arm insert

(B)

31356

Front

suspension

arm

Wheel Base Shims

1mm

31621

x2

Inner hinge

pin ball

31200

Wheelbase

shim (1mm)

31283

5mm

ballstud

(long)

Wheel Base Shims

1mm

2mm

2mm

!

Build left

and right

sides

Suspension Arm Insert

(front)

A

A

B

!

Build left

and right

sides

Suspension Arm Insert

(rear)

A

C

B

C B A

C

B

C

Page 11

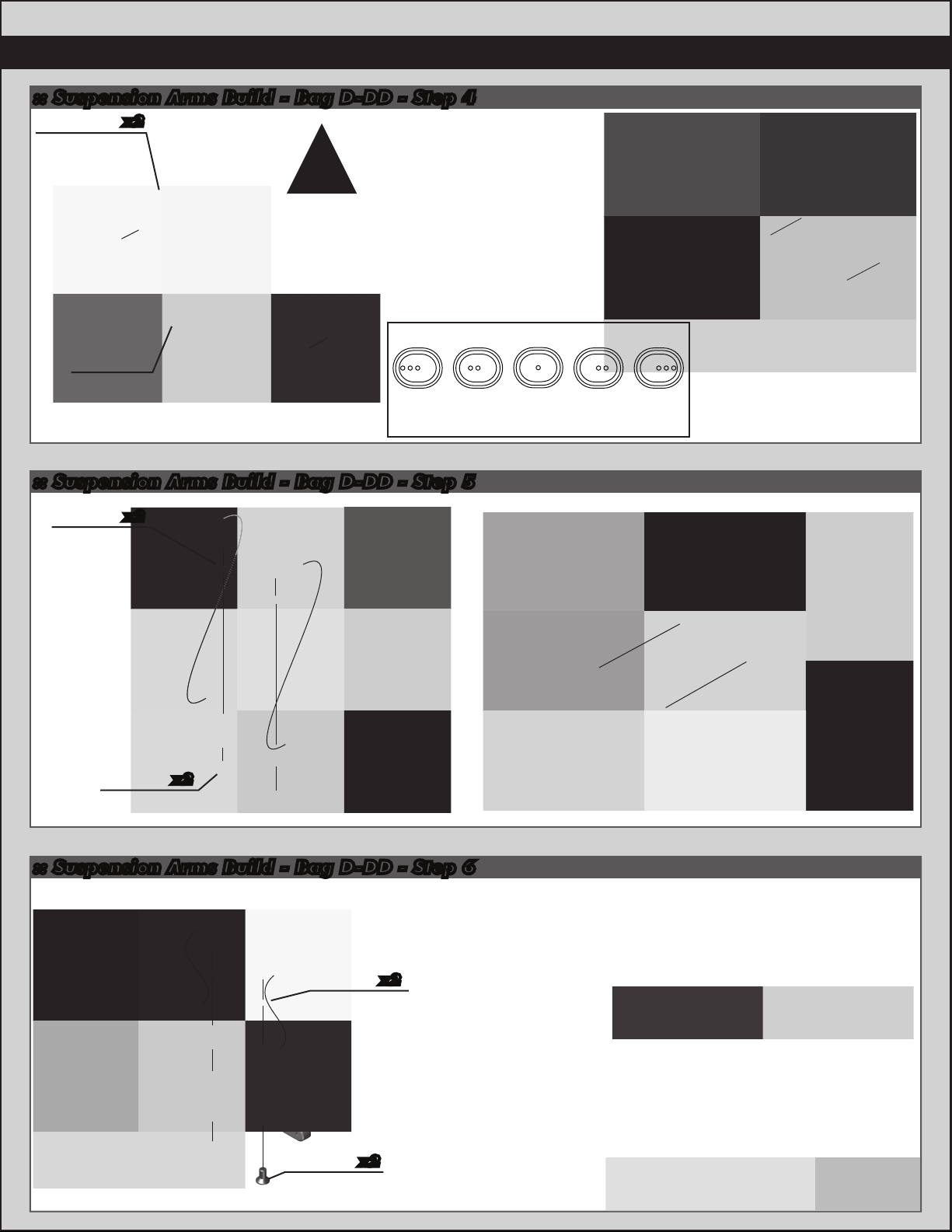

:: Suspension Arms Build - Bag D-DD - Step 4

31620

TC6.2 arm

mount insert

(1 dot)

x2

!

Build two, one for

front, one for rear.

Both with 1 dot inserts

-2 DOT

Negative to the inside of vehicle.

Positive to the outside of vehicle.

31618

TC6.2

Outer Arm

Mount

-3 DOT

-1 °

:: Suspension Arms Build - Bag D-DD - Step 5

Arm Mount Inserts

1 DOT

-1/2 °

0 °

+2 DOT

+1/2 °

11

+3 DOT

+1 °

4617

x2

Front

bulkhead

shim

(0.5mm)

31541

x2

M3x6mm

fhcs

:: Suspension Arms Build - Bag D-DD - Step 6

Droop:

The standard settings of

6mm front and 5mm rear

will work best in most cases.

Droop is measured just

x2

4617

Front

bulkhead

shim

(0.5mm)

31541

M3x6mm

fhcs

x2

underneath the outer hinge

pin as shown in the photos

to the right.

On bumpy or low grip

surfaces, increase the droop

(going to a lower number on

the droop gauge), this will

help increase traction and

consistency.

Droop adjustments of

0.5mm to 1mm can be

very effective on the track!

Front Droop

Setting: 6mm

Rear Droop

Setting: 5mm

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

Page 12

12

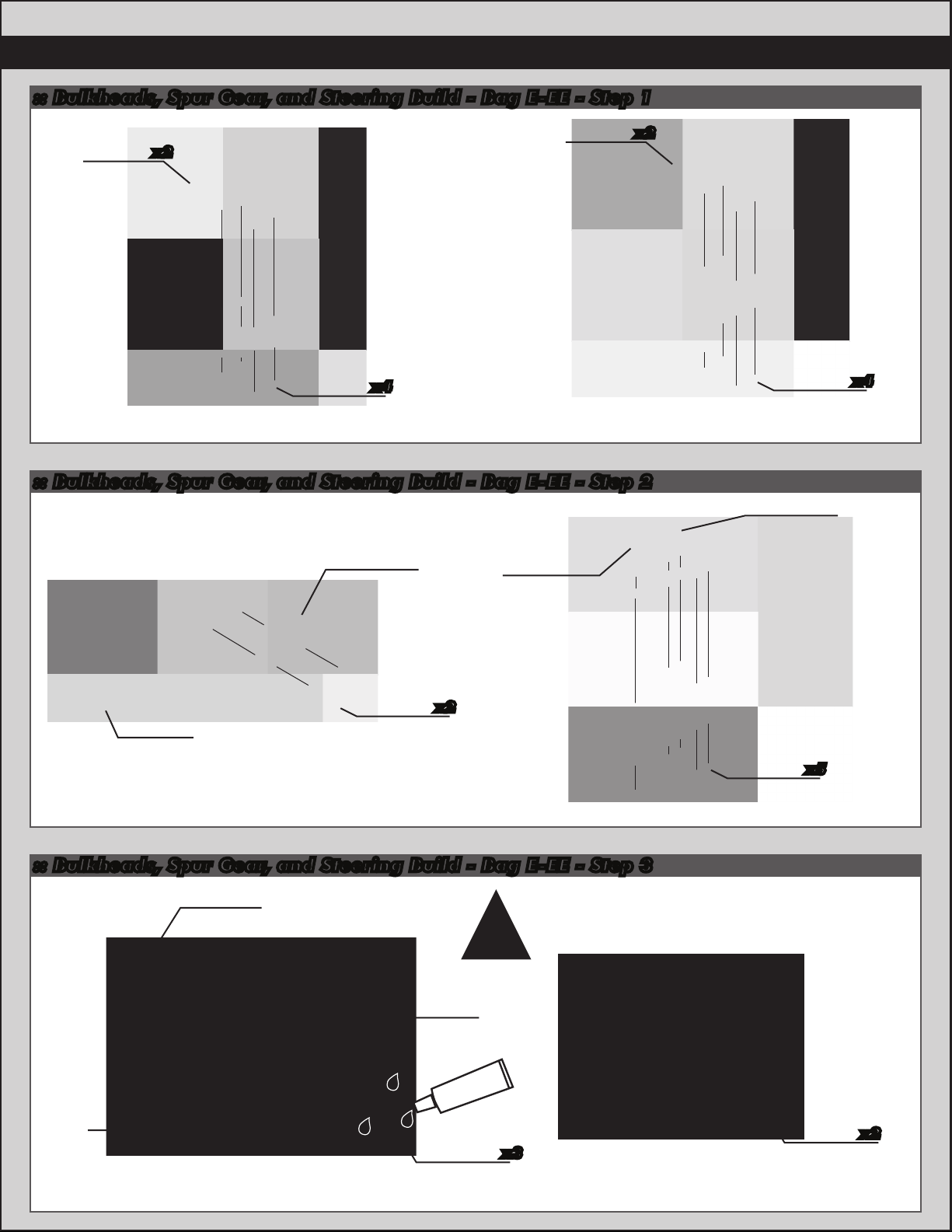

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 1

x2

31612

TC6.2

Bulkhead

x2

31540

M3x5mm

fhcs

31612

TC6.2

Bulkhead

x4

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 2

31616

TC6.2

spur gear

bulkhead

31617

TC6.2 motor

mount

standoff

31540

M3x5mm

fhcs

31616

TC6.2

spur gear

bulkhead

x4

31617

TC6.2

motor

mount

31532

M3x8mm

bhcs

x2

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 3

31314

TC6 spur

31333

TC6

spur gear

(87T / 48P)

gear hub

31319

TC6 spur gear

clamping ring

31530

M3x5mm

!

Thread lock

not included!

#1596

thread lock

x3

bhcs

31540

M3x5mm

fhcs

TC6 spur

x5

31320

pulley

(20T)

x2

Page 13

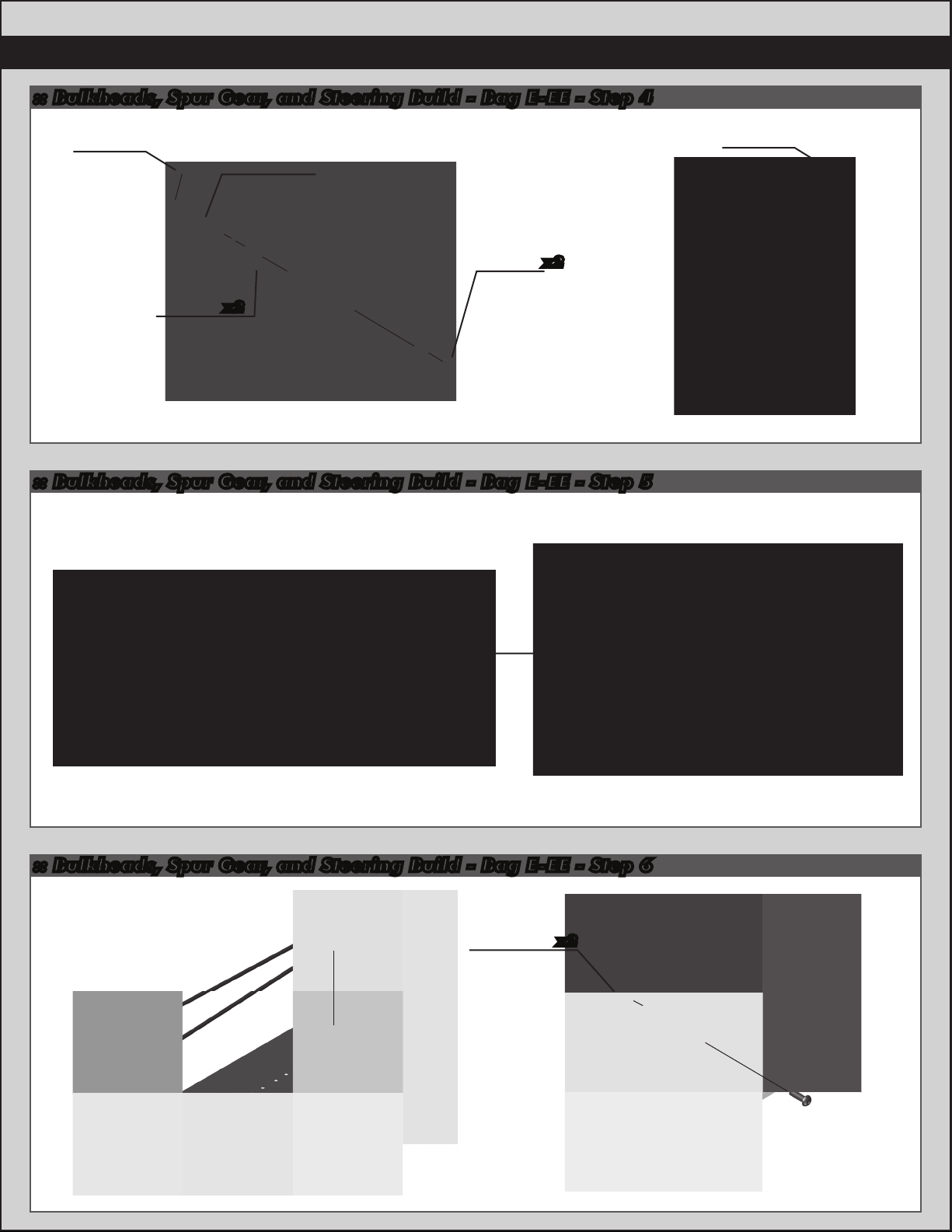

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 4

13

31160

3mm

E-clip

31331

4x8x3

flanged

bearing

31315

TC6 spur

gear shaft

x2

31162

Shim

x2

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 5

Rear Belt

31160

3mm

E-clip

Front Belt

31188

Rear belt

31187

Front belt

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 6

x231521

M2.5x8mm

bhcs

Page 14

14

Slide belt over

gear diff pulley!

!

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 7

!

Slide belt over

spool pulley!

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 8

x2

31531

M3x6mm

bhcs

x4

31286

FT ballstud

washer,

aluminum

(2mm)

x2

31280

Ballstud,

short,

5mm

!

Slide belt over

gear diff pulley!

31613

TC6.2

bearing

cap (A)

31614

TC6.2

bearing

cap (B)

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 9

31286

FT ballstud

washer,

aluminum

(1mm)

31614

TC6.2

bearing

cap (B)

x2

31280

Ballstud,

short,

5mm

31613

TC6.2

bearing

cap (A)

x2

31531

M3x6mm

bhcs

x4

Page 15

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 10

Note!

Place top

plate between

the front belt.

!

!

15

!

Note!

Place top

plate between

the front belt.

31601

TC6.2

top plate

!

Belt hidden for

view clarity!

M3x5mm

bhcs

x931530

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 11

31531

M3x6mm

bhcs

x2

31604

TC6.2 front

shock tower

31250

Shock

bushing

x2

31541

M3x6mm

fhcs

x4

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 12

31531

M3x6mm

bhcs

31250

Shock

bushing

x2

x2

31605

TC6.2 rear

shock tower

31541

M3x6mm

fhcs

x4

Page 16

16

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 13

31374

TiN 3.25mm

31286

FT ballstud

washer,

aluminum

(1mm)

x2

ballstud,

short neck

31610

TC6.2

steering

bellcrank

x2

31611

31283

Ballstud,

long,

5mm

x2

TC6.2

steering

rack

31609

TC6.2

steering

bellcrank

post

x2

:: Bulkheads, Spur Gear, and Steering Build - Bag E-EE - Step 14

31611

TC6.2 steering

rack hat

bushing

25211

M3x10mm

bhcs

x2

x2

31609

TC6.2 steering

bellcrank post

spacer

!

Top Plate and

Belts hidden for

view clarity!

x2

31403

Bearing,

4 x 7mm

31540

M3x5mm

fhcs

x8

x2

:: Steering / Caster Blocks Build - Bag F - Step 1

31360

TC6.1

steering

blocks

!

Note offset

(Left side shown)

31280

5mm

ballstud

(short)

31370

TC6.1

axle crush

tube

25237

5x10mm

bearing

!

Build left

and right

sides

x2

Page 17

:: Steering / Caster Blocks Build - Bag F - Step 2

31162

Axle shim

:: Steering / Caster Blocks Build - Bag F - Step 3

!

Build left

and right

sides

31511

M2x5mm

shcs

17

31112

1/16” x 5/16”

dowel pins

31234

Clamping

wheel hex

31358

TC6.1 caster

blocks

(left and right)

!

31358

!

TC6.1 caster

block

inserts

(4 deg)

Use the supplied

symmetric inserts to

select caster angle. When

viewed from the front, the

number should be located

on the top side of the pin,

as shown in the view to the

right. When viewed from

the rear, the number should

be located on the bottom.

!

x2

:: Steering / Caster Blocks Build - Bag F - Step 4

Use small amount ca glue to

permanently secure the caster

RACERS TIP:

block inserts in the caster

Left

4

blocks.

Right

4

31214

Caster

block

bushing

x2

!

Build left

and right

sides

Page 18

18

:: Steering / Caster Blocks Build - Bag F - Step 5

31284

8mm

ballstud

(long)

!

Build left

and right

sides

:: Steering / Caster Blocks Build - Bag F - Step 6

31532

M3x8mm

bhcs

!

Build left

and right

sides

31510

M2x4mm

bhcs

:: Steering / Caster Blocks Build - Bag F - Step 7

!

Orient the notch

to the left throughout

the car. The notch

indicates which end has

the left hand threads!

31222

Outer

hinge pin

Page 19

:: Steering / Caster Blocks Build - Bag F - Step 8

!

:: Steering / Caster Blocks Build - Bag F - Step 9

19

It is important that the turnbuckle eyelets move freely

once snapped on to the ballstud. If the fit is too tight,

the car handling will be inconsistent. To check, grab

turnbuckle eyelet with fingers and rotate the cup. If

there is resistance, lightly squeeze ball cup with needle

nose pliers as shown and test again. It is important

that the ball cup be snapped onto the ballstud before

squeezing with needle nose pliers. Be sure to check

and adjust the fit for each ball cup that is installed.

31359

TC6.1

rear hub

carrier

31359

TC6.1

rear hub

carrier

inserts

(0 deg)

x2

!

!

!

Use the supplied

symmetric inserts to select

rear hub toe angle.

When viewed from the

back, the number should

be located on the outside

of the hinge pin, as shown

in the view to the right.

When viewed from the

front, the number should

be located on the inside

of the hinge pin.

:: Steering / Caster Blocks Build - Bag F - Step 10

31284

8mm

ballstud

(long)

31286

Aluminum

ballstud

washer

(2mm)

31370

TC6.1

axle crush

tube

25237

5x10mm

bearing

x2

RACERS TIP:

Use small amount of ca

0

glue to permanently secure

the rear hub inserts in the

hubs.

0

RightLeft

31162

Axle shim

Page 20

20

Build left

and right

sides

!

:: Steering / Caster Blocks Build - Bag F - Step 11

31112

1/16” x 5/16”

dowel pins

31234

Clamping

wheel hex

!

Build left

and right

sides

:: Steering / Caster Blocks Build - Bag F - Step 12

31511

M2x5mm

shcs

!

Build left

and right

sides

31510

M2x4mm

bhcs

31222

Outer

hinge pin

!

Orient the notch

to the left throughout

the car. The notch

indicates which end has

the left hand threads!

:: Steering / Caster Blocks Build - Bag F - Step 13

M3x5mm

bhcs

x231530

x231530

M3x5mm

bhcs

Page 21

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 1

21

4673

M2.5x4mm

x3

bhcs

!

Transponder

not included!

31623

TC6.2

bumper

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 2

x2

3897

Pivoting

body mounts

x2

1736

FT body

clips, blue

(short)

31625

TC6.2 front

body posts

x2

31624

TC6.2

foam

bumper

25203

M3x12mm

fhcs

x2

31623

TC6.2

bumper

brace

25201

M3x8mm

fhcs

x3

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 3

31532

M3x8mm

bhcs

x2

3897

Pivoting

body mounts

x2

1736

FT body

clips, blue

(short)

x2

25201

M3x8mm

fhcs

x2

31625

TC6.2 rear

body posts

x2

Page 22

22

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 4

6338

Antenna

tube & cap

31626

Antenna

31626

TC6.2 lipo

brace

31626

TC6.2 lipo

brace

(offset)

31541

M3x6mm

fhcs

x4

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 5

8828

Anti roll

bar cups

mount

31626

Inner lipo

brace

M3x2.5mm

set screw

Top Plate and

Belts hidden for

31540

M3x5mm

fhcs

31500

!

view clarity!

x3

!

31269

Anti roll

bar pivot

mount

31058

Anti roll

bar

ballstud

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 6

Front

31364

1.1mm

roll bar

(yellow)

31628

Anti roll

bar pivot

Build four antiroll bar mounts

Anti Roll Bar

Link Adjust

x2

31500

M3x2.5mm

set screw

x4

ment

14mm

Anti Roll Bar

Color/Size Chart

Green

White

Blue

Yellow

Red

M2x5mm

0.8mm

0.9mm

1.0mm

1.1mm

1.2mm

31511

shcs

x2

!

Install four

anti-roll bar mounts,

two for the front

arms and two for

the rear arms.

31627

TC6.2

anti roll

bar tube

!

Shrink the colored

heat shrink tubing to

the anti roll bar!

Page 23

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 7

x2

Rear

Anti Roll Bar

Color/Size Chart

Green

White

Blue

Yellow

Red

0.8mm

0.9mm

1.0mm

1.1mm

1.2mm

31364

0.9mm

roll bar

(white)

31627

TC6.2

anti roll

bar tube

31365

Anti roll

bar mounts

31511

M2x5mm

shcs

x2

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 8

31628

Anti roll

bar pivot

M3x2.5mm

set screw

x2

31500

x4

!

Shrink the colored

heat shrink tubing to

the anti roll bar!

23

31365

x2

Anti roll

bar mounts

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 9

Steering Servo Chart

Associated

Airtronics

Airtronics

Hitec

Hitec

JR

JR

Futaba

Futaba

Futaba

KO

* Not all servo’s are listed

* Make sure servo linkage clears the servo through full travel in both

directions. Use #7336 servo spacers to adjust servos position as necessary.

XP-1015, XP-1313

94102

94738, 94157, 94158, 94257, 94258, 94357,

94358, 94452, 94453, 94751, 94755

HS-5625MG, HS-5645MG, HS625MG, HS645MG

HS-322HD, HS-325HB, HS-965, HS-985MG,

HS-5965, HS-5985MG, HS-425BB, HS-422

Z4725, Z4750, Z2750, Z8450, Z8550, NES-4750

Z250, Z550

S9204, S9250, S9450, S148

S3003, S9202, S9101

S9404

PS-401, PS-2001, PS-2004, PS -2015, PS-2173,

PS-2174, PS-2123, PS-2143, PS -2144

# 89007

servo arm

F

A

A

H

H

J

J

F

F

F

J

!

31286

Aluminum

ballstud washer

(1mm, 2mm)

31285

10mm

ballstud

(long)

Drill top hole to

2.5mm, then install

ballstud and locknut

31511

M2x5mm

shcs

FT M3 Locknut,

blue aluminum

89007

Servo

horn

x2

31550

89007

Servo

horn ring

Page 24

24

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 10

7336

Servo

spacer

x2

!

Use screw that was included

with your servo.

Servo not included!

31532

M3x8mm

bhcs

x4

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 11

31530

M3x5mm

bhcs

x5

.250x.125x.015

washer

7337

x4

31622

TC6.2

servo

mounts

x2

31608

TC6.2 servo

mount brace

31540

M3x5mm

fhcs

!

Top Plate

hidden for

view clarity!

x2

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 12

!

Receiver not

included!

!

ESC not included!

6727

Servo tape

6727

Servo tape

Page 25

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 13

Gearing will depend on the

motor and track size.

Gear chart on page 29.

Motor, pinion gear, and set

screw are not included!

!

25

31286

Aluminum

ballstud

washer

(1mm)

x2

31532

M3x8mm

bhcs

x2

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 14

!

Use strapping tape to

secure battery into chassis.

Wrap the tape around the

#31626 LiPo brace an back

onto itself.

Battery tape not included!

Battery and strapping

tape not included!

!

:: Bumper, Anti-Roll Bar and Electronics Build - Bag G-GG - Step 15

!

Wheels, tires, and inserts

not included!

91148

M4

locknut

x4

Page 26

26

:: Tuning Tips

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing. Changes to your car

will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your car. Make only ONE adjustment at a time, testing it before making

another change. If the result of your adjustment is a faster lap, mark the change on the included setup sheet (make additional

copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back to the previous setup and try another

change.

When you are satisfied with your car, fill in the setup sheet thoroughly and file it away. Use this as a guide for future track days or

conditions.

Ride Height:

The standard starting point for ride height is 5.0mm (keep in mind that your local track may have minimum ride height

requirements). You can slightly raise the rear relative to the front to give the car more steering. Raise the car slightly for tracks

with large bumps.

Battery Placement:

For most cases, run the battery in the standard forward position. Typically this will be the most stable and easiest to drive. Try

moving the battery back if you encounter a low traction surface by switching LiPo braces front to back.

Wheelbase:

Wheel Base Shims

Lengthening the front will reduce steering, shortening the front will increase steering. Shortening the rear will

1mm

increase rear grip, lengthening the rear will decrease rear traction.

2mm

Rear Toe-In:

The TC6.2 allows rear toe adjustments in two positions: inner hinge pin, and outer hinge pin at the rear hub. In general, decreasing

rear toe-in will decrease rear traction and increase corner speed.

-3 DOT

Rear toe-in can be adjusted by 0.5° increments at the inner hinge pin with

supplied arm mount inserts (see chart to right). Standard toe-in angle for

inner hinge pin when using same insert front and rear is 3°.

-1 °

Standard insert used is 1 dot.

Use rear hub inserts to change toe at the outer hinge pin by 0.5° increments.

Note the number on hub insert should be on outside of hinge pin for proper installation.

Ackermann & Steering Rate:

Ackermann refers to the relative angle difference between the front wheels as they are

turned to steer the car. The outside wheel will turn less than the inside wheel in most

conditions. Settings with more Ackermann will have a bigger difference in wheel angle,

causing the outside wheel to turn less. Likewise, settings with less Ackermann will cause

the outside wheel to turn more.

Increasing the Ackermann will smooth out the steering and is used most often on high

traction surfaces such as carpet. This is a result of the reduced outside wheel angle.

Settings with reduced Ackermann will help to increase corner entry steering, and are

typically used when running a spool in the front.

Arm Mount Inserts

-2 DOT

-1/2 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

1 DOT

0 °

Steering

Block

Position

B

B

B

A

+2 DOT

+1/2 °

Steering

Rack

Shims

2mm

1mm

0mm

2mm

+3 DOT

+1 °

Less Ackermann

STD

The chart to the right lists the different Ackermann options.

A

B

Steering Block

A

A

1mm

0mm

More Ackermann

Page 27

27

:: Tuning Tips

Caster:

Caster describes the angle of the kingpin from vertical while looking from the side of the car. Positive caster means the top of the

kingpin leans rearward. Negative caster means the kingpin is leaning towards the front of the car. Since caster is measured at the

wheel, it is affected by running any inclination in your inner arm mount. Kick-up adds (+) caster, and anti-dive adds (-) caster.

When figuring out your caster at the wheel, add the number of degrees of kick-up or anti-dive and add it to the degree caster blocks

you have on the car.

Typically for most racing surfaces, 4 degrees caster is the normal starting point for the Team. From there, increase caster to reduce

mid to exit steering and make the front end less responsive. Conversely, decreased caster gives a more responsive feel and more exit

steering.

Droop:

The standard settings of 6mm front and 5mm

rear will work best in most cases. Droop is

measured just underneath the outer hinge pin

as shown in the photos to the right.

On bumpy or low grip surfaces, increase the

droop (going to a lower number on the droop

gauge), this will help increase traction and

consistency.

Droop adjustments of 0.5mm to 1mm can be

very effective on the track!

Increase IncreaseDecrease Decrease

Front Droop

Setting: 6mm

4

3

2

1

0

Rear Droop

Setting: 5mm

8

7

6

5

0

4

3

2

1

8

7

6

5

Camber Link Position:

The camber link is used to set static camber at ride height, but it is also an effective setting to adjust roll center height and camber

gain. The TC6.2 has three optimized length positions at the front, and six at the rear, for a wide range of camber gain adjustments.

All camber link mounting positions use vertical ballstuds that can be shimmed for precise roll center height adjustments.

Longer links will produce less camber gain, stiffening that particular end of the car in roll. These are particularly effective on large

tracks with big sweeping corners. Shorter links will give more camber gain, softening that end of the car in roll. This will make the

car more aggressive, and is a good setting for smaller indoor tracks with high grip levels.

The angle of the camber link will make fine adjustments to the roll center height. Typically the camber link will be no more than

parallel to the suspension arm with the inboard side of the link lower than the outboard side. As the inboard side of the camber link

is moved down, the roll center goes up, stiffening that end of the car. Camber link angle is a good adjustment to help fine tune the

balance of the car to the track by setting the front and rear at slightly different angles.

Arm Mount Position:

The TC6.2’s arm mount system allows for maximum adjustability for all track and racing conditions. Independent inner and outer arm mounts

with interchangeable inserts provide multiple pin configurations... flat, or with angle, to give a host of kickup/tow and pin width options.

Use the TC6.2’s included arm mount inserts to adjust pin width and angle. The arm

mount inserts are indicated one, two, and three with the corresponding amount of dots

on their exposed face. Each insert will index the hinge pin by 1/2 degree (or 0.43mm).

Standard pin angle is achieved when using the same insert in both the inner and outer

mounts. Rear hinge pin angle is 3° when using the same insert in both inner and outer

mounts.

The chart to the right shows the pin angle change for the right rear pin when using

a 1 dot insert in the inner arm mount.

Pin width can also be adjusted by changing the inserts in the inner and outer mounts

by an equal amount. The standard pin width for the TC6.2 uses 1 dot inserts at all

corners, and is best suited for rubber tire racing.

The TC6.2’s independent inner and outer arm mount system also allows for roll center

height adjustements as well as options for anti-dive/kick-up and anti-squat/pro-squat

hinge pin angles. Precise adjustments can be made by changing the shim thickness

between the arm mounts and chassis.

The standard roll center height uses o.5mm shims on all mounts. This produces a

relatively low roll center with more chassis roll on the corners... typically good for lower

grip conditions such as rubber tires on asphalt. If the grip level is high, try raising the

roll center by using thicker shims between the mounts and chassis.

Anti-dive/kick-up and anti-squat/pro-squat angles can be adjusted by varying the

amount of shims under the inner and outer mounts. A 0.5mm difference will produce

an angle of about 1/2 degree. The following sections briefly describe front and rear

pin angles and their effect on the track.

-3 DOT

-1 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

4

3

2

1

Arm Mount Inserts

-2 DOT

-1/2 °

1 DOT

0 °

ABC

+2 DOT

+1/2 °

+3 DOT

+1 °

Page 28

28

:: Tuning Tips

Anti-Dive (front):

Anti-dive is a front arm angle where the rear mount is higher than the front mount. Adding anti-dive reduces weight transfer to the

front on deceleration entering corners. It also reduces caster at the wheel.

Kick-Up (front):

Kick-up describes the angle of the front suspension arm, where the front mount is higher than the rear mount. Increasing kick-up will

give more entry steering, as well as increasing caster at the wheel.

Anti-Squat (rear):

Anti-Squat describes a rear arm angle where the front mount is higher than the rear mount. Increasing anti-squat will make the rear

suspension stiffer. It tends to give the car more entry steering and reduce rearward weight transfer on power.

Pro-Squat (rear):

Pro-squat is a rear arm angle where the rear mount is higher than the front mount. Running Pro-Squat will increase rearward

weight transfer on power.

Anti-Roll Bar:

Anti-roll bars are only effective during roll (when the chassis leans from side to side when cornering).

Because of this they isolate a change in the suspensions spring rate in the corners only, and can be a very useful

tuning option.

Anti-roll bars stiffen the spring rate of the suspension during roll movements when cornering. The larger the

roll bar wire, the stiffer the spring rate will be in roll. The chart on the right shows the available anti-roll bar

sizes (as well as their corresponding colors) from the softest on the top, to the stiffest on the bottom.

The standard setup, using yellow front anti-roll bars (1.1mm) and white rear anti-roll bars (0.9mm), is a balanced starting point.

Changing the size of the front or rear anti-roll bars can help to make the chassis more consistent through the corner. Decreasing the

size of the front anti-roll bars will help to increase mid-corner steering, but will tend to be less stable in sweepers. This is a

typical setup for smaller tracks with tighter turns. Increasing the size of the front anti-roll bars will give more stability in the

sweepers, and is better for larger tracks with high speed corners. Increasing the size of the rear ant-roll bars will help add stability

into and through the corner in high traction conditions, but can make the car inconsistent in low traction, or bumpy, surfaces.

Belt Tension:

When altering the differential height, you will need

to adjust the tension of the belt. The following chart

shows suggested starting positions.

TighterLooser Tighter Looser

Left Side

Front

Note! Charts show left side cam positions from the left side of the car. Match right side cam position to left side cam position.

Cam Position

Mid-Low

Low

Left Side

Front

Mid-High

High

Belt Tension

Number

161

17 32

View from left

side of car

Anti Roll Bar

Color/Size Chart

Green

White

Blue

Yellow

Red

Height

High

Mid-High

Front

Height

High

Mid-High

Rear

0.8mm

0.9mm

1.0mm

1.1mm

1.2mm

Pos.

31

28

Mid

Low

Pos.

18

20

Mid

Low

8

5

7

9

Motor Gearing:

The gear charts on the following page show final drive ratio numbers for the TC6.2. Refer to motor manufacturer’s suggested gear

ratio for starting point. You may need to adjust the gearing according to your track size.

The following formula’s can also be helpful in determining final drive ratios and pinion size.

TC6 Internal Ratio = 2.0

# of Teeth on Pinion

Final Drive Ratio

Final Drive Ratio = (# of Teeth Spur) x (Internal Ratio)

# of Teeth on Pinion = (# of Teeth on Spur) x (Internal Ratio)

Page 29

:: Gear Chart 48 Pitch

!

Blank spaces in the gear

charts designates a gear

ratio that will not fit in the

vehicle. Gear fitment will

also depend on the motor

brand.

29

:: Gear Chart 64 Pitch

Page 30

30

:: Shocks

5407

6465

6475

31305

31323

31324

31325

31326

31327

31328

31329

31330

31510

Red O-Rings

Shock Piston, PTFE

Preload Spacers, Collars, Cups

Turnbuckle Eyelet

VCS3 Shock Kit

VCS3 Shock Rebuild

VCS3 Shock Body

VCS3 Shock Collar

VCS3 Shock Bottom Cap

VCS3 Aluminum Cap Retainer

VCS3 Shock Cap

VCS3 Shock Shaft

M2x4mm BHCS

:: Springs

3941

3942

3943

3944

3945

3946

3952

3953

3954

3988

TC Spring, Green, 12.0lbs

TC Spring, Silver, 14.5lbs (Kit)

TC Spring, Blue, 17.0lbs

TC Spring, Gold, 19.5lbs

TC Spring, Red, 22.0lbs

TC Spring, Copper, 25.0lbs

TC Spring, Purple, 30.0lbs

TC Spring, Yellow, 35.0lbs

TC Spring, White, 40.0lbs

TC Spring Set, 1 pr. each

31510

6465

12

14

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

:: CVA’s

8

1

1

1

2

2

2

2

4

2

6

31328

31329

31324

31325

31327

31324

5407

31324

31327

1

31326

31326

31237

31238

31366

31367

31368

31369

31500

CVA Pin Retaining Clip

CVA Bone Blade

TC6.1 CVA Kit

TC6.1 CVA Rebuild Kit

TC6.1 CVA Bone

TC6.1 Stub Axle

M3x2.5mm Set Screw

31238

31368

31366

:: Anti-Roll Bars

8828

31058

31364

31365

31500

31511

31627

31628

Anti-Roll Bar Cups, Set

Anti-Roll Bar Ballstud,blue aluminum

TC6.1 Anti-Roll Bar Wire, Set

TC6.1 Anti-Roll Bar Mounts

M3x2.5mm Set Screw

M2x5mm SHCS

TC6.2 Anti-Roll Bar Tube

TC6.2 Anti-Roll Bar Kit

2

8

1

1

Pr.

Pr.

6

31367

31500

31369

31237

1

2

1

4

6

6

1

1

31324

31330

Front

3942

Rear

3942

6475

31500

31364

31500

31628

31269

31511

31500

31305

31627

:: Shock Fluid :: Turnbuckles

5420

5421

5422

5423

5424

5425

5426

5427

5428

5429

5430

5431

5432

5433

5434

5435

5436

5437

5438

10 Weight Silicone Shock Fluid

20 Weight Silicone Shock Fluid

30 Weight Silicone Shock Fluid

40 Weight Silicone Shock Fluid

22.5 Weight Silicone Shock Fluid

80 Weight Silicone Shock Fluid

27.5 Weight Silicone Shock Fluid

15 Weight Silicone Shock Fluid

25 Weight Silicone Shock Fluid

35 Weight Silicone Shock Fluid

45 Weight Silicone Shock Fluid

55 Weight Silicone Shock Fluid

32.5 Weight Silicone Shock Fluid

37.5 Weight Silicone Shock Fluid

42.5 Weight Silicone Shock Fluid

50 Weight Silicone Shock Fluid

60 Weight Silicone Shock Fluid

70 Weight Silicone Shock Fluid

47.5 Weight Silicone Shock Fluid

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

1402

1405

1418

31305

FT Blue Titanium Turnbuckles 1.375”

FT Blue Titanium Turnbuckle 1.875”

FT Blue Titanium Turnbuckle 0.825”

Turnbuckle Eyelet

31305 31305

31305 31305

31305 31305

31058

31364

1418

1402

1405

8828

31511

31511

31511

31365

31365

31500

31628

Pr.

Pr.

Pr.

14

Page 31

:: Front Spool

31162

31175

31339

31341

31342

31350

31401

31510

31615

Axle Shim Kit

Oneway/Spool Pulley

TC6 Spool Kit

TC6 Spool Outdrives

TC6 Spool Hub

M2.5x10mm FHCS

10 x 15mm Bearing

M2x4mm BHCS

TC6.2 Diff Bearing Cam Set

31

1

1

1

4

1

6

2

6

1

31350

31401

31341

31342

31162

31175

31510

31162

31341

:: Rear Gear Differential

4675

31162

31344

31345

31346

31347

31348

31349

31401

31615

M2.5 X .45 X 6 FHCS

Axle Shim Kit

TC6 Gear Diff

TC6 Gear Diff Rebuild

TC6 Gear Diff Outdrives

TC6 Gear Diff Case,

O-Ring, Pulley

TC6 Gear Diff Pins & Shims

TC6 Gear Diff Seals

10 x 15mm Bearing

TC6.2 Diff Bearing Cam Set

See page 30 for shock fluids for use

with the TC gear differential.

6

1

1

1

2

1

1

1

2

1

31401

31345

31348

31615

31346

31348

31349

31345

31348

31348

31162

31348

31615

31348

31345

31345

31349

31345

31347

31349

31348

31349

31510

31348

31401

31348

4675

31615

31347

31349

31162

31350

31615

31348

31346

4675

31401

:: Spur Gear Assembly

31160

31162

31314

31315

31319

31320

31331

31333

31521

31530

3mm E-Clip

Axle Shim Kit

TC6 Spur Gear Hub

TC6 Spur Gear Shaft

TC6 Spur Clamping Ring

TC6 Spur Pulley (20T)

4x8x3mm Flanged Bearing

TC6 Spur Gear (87T/48P)

M2.5x0.5x8mm BHCS

M3x0.5x5mm BHCS

6

1

1

1

1

2

2

1

6

6

31521

31162

31160

31320

31331

31333

31314

31319

31530

31530

31331

31320

31315

31162

31160

31521

Page 32

32

:: Steering Bellcrank and Servo Mounts

7336

7337

25211

31283

31286

31374

31403

31530

31532

31540

31550

31608

31609

31610

31611

31622

89007

Steering Servo Mount Kit

.250” x.125” x.015” Washer

M3x10mm BHCS

5mm Ballstud, long

Aluminum Ballstud Washers, Set

FT TiN 3.25mm Ballstud, short

4x7mm Bearing

M3x5mm BHCS

M3x8mm BHCS

M3x5mm FHCS

FT M3 Locknut, blue aluminum

TC6.2 Servo Mount Brace

TC6.2 Steering Bellcrank Post Set

TC6.2 Steering Bellcrank

TC6.2 Steering Rack Set

TC6.2 Servo Mount Set

Steering Servo Horn & Ring

:: Front Bumper

1736

3897

4673

25201

25203

31623

31624

31625

FT Body Clips, short

Pivoting Body Mounts, Set

M2.5x4mm BHCS

M3x8mm FHCS

M3x12mm FHCS

TC6.2 Bumper Set

TC6.2 Foam Bumper

TC6.2 Body Post Set

20

20

1

4

20

31611

6

1

31403

2

2

6

6

6

6

31403

1

1

1

25211

1

1

1

6

1

6

1

1

1

31540

31609

31403

31403

31609

31283

25201

31610

31286

31285

31374

31550

89007

31532

31611

31286

1736

31625

31530

31608

7336

7337

31540

31532

3897

31530

31622

7336

7337

3897

1736

:: Front and Rear Shock Towers

1736

3897

31250

31280

31286

31530

31531

31532

31541

31604

31605

31613

31614

31625

FT Body Clips, short

Pivoting Body Mounts, Set

Shock Bushing

5mm Ballstud, short

Aluminum Ballstud Washers, Set

M3x5mm BHCS

M3x6mm BHCS

M3x8mm BHCS

M3x6mm FHCS

TC6.2 Front Shock Tower

TC6.2 Rear Shock Tower

TC6.2 Bearing Cap (A)

TC6.2 Bearing Cap (B)

TC6.2 Body Post Set

6

1

4

6

1

6

6

6

6

1

1

1

1

1

31250

31530

31280

31286

31613

31541

31530

31531

31623

31531

31250

31280

31286

31624

31531

31604

31532

31623

25203

1736

31250

4673

31625

25201

25203

3897

31625

3897

31530

1736

31541

31625

31531

31531

31531

31614

31531

31605

31531

31532

31530

31250

Page 33

:: Front Bulkhead

25227

25237

31112

31162

31200

31214

31221

31222

31234

31280

31284

31356

31358

31360

31370

31510

31511

31532

31540

31612

31621

91148

M4x8mm Setscrew

5x10mm Bearing

1/16” x 5/16” Dowel Pins

Axle Shim Kit

Wheelbase Shim Set

Caster Block Bushing

Inner Hinge Pin Set

Outer Hinge Pin Set

Clamping Wheel Hex

5mm Ballstud, short

8mm Ballstud, long

TC6.1 Front Arms

TC6.1 Caster Blocks

TC6.1 Steering Blocks

TC6.1 Axle Crush Tubes

M2x4mm BHCS

M2x5mm SHCS

M3x8mm BHCS

M3x5mm FHCS

TC6.2 Bulkhead

TC6.2 Inner Hinge Pin Ball Set

M4 Locknut, with flange and

knurl

20

2

8

1

1

Pr.

1

1

4

6

6

Pr.

Pr.

Pr.

4

6

6

6

6

1

1

8

31358

31532

31621

31284

31200

31358

31358

25237

31356

31280

31214

31214

25227

31510

31370

31222

31280

31360

31162

31511

33

31621

31200

31221

31356

31612

31540

31540

25237

31112

31234

91148

:: Rear Bulkhead

25227

25237

31112

31162

31200

31221

31222

31234

31283

31284

31286

31357

31359

31370

31510

31511

31540

31612

31621

91148

M4x8mm Setscrew

5x10mm Bearing

1/16” x 5/16” Dowel Pins

Axle Shim Kit

Wheelbase Shim Set

Inner Hinge Pin Set

Outer Hinge Pin Set

Clamping Wheel Hex

5mm Ballstud, long

8mm Ballstud, long

Aluminum Ballstud Washers, Set

TC6.1 Rear Arms

TC6.1 Rear Hub Carrier

TC6.1 Axle Crush Tubes

M2x4mm BHCS

M2x5mm SHCS

M3x5mm FHCS

TC6.2 Bulkhead

TC6.2 Inner Hinge Pin Ball Set

M4 Locknut, with flange and

knurl

20

2

8

1

1

1

1

4

6

6

1

Pr.

Pr.

4

6

6

6

1

1

8

31612

31540

31540

25227

25237

31359

31200

31359

31621

31284

31286

31357

31359

25237

31112

31283

31370

31222

31511

31510

31162

31234

91148

31621

31221

31357

31200

Page 34

34

:: Motor Mount / Battery Mount

31286

31532

31540

31541

31616

31617

31626

Aluminum Ballstud Washers, Set

M3x8mm BHCS

M3x5mm FHCS

M3x6mm FHCS

TC6.2 Spur Gear Bulkhead

TC6.2 Motor Mount Set

TC6.2 LiPo Brace Set

1

6

6

6

1

1

1

31532

31617

31616

31626

31286

31541

31617

31626

31541

31541

31541

:: Chassis / Top Plate / Belts / Antenna / Arm Mounts

4617

6338

31187

31188

31500

31530

31540

31541

31600

31601

31618

31619

31620

31626

Front Bulkhead Shim Set

Antenna Tube 12”, black

Front Belt

Rear Belt

M3x2.5mm Set Screw

M3x5mm BHCS

M3x5mm FHCS

M3x6mm FHCS

TC6.2 Chassis

TC6.2 Top Plate

TC6.2 Outer Arm Mount

TC6.2 Inner Arm Mount

TC6.2 Arm Mount Insert Set

TC6.2 LiPo Brace /Antenna Mount Set

1

1

1

1

6

6

6

6

1

1

1

1

1

1

31540

31530

31540

31530

31601

31616

31540

31532

31530

31620

4617

31541

31620

4617

31541

4617

31541

31620

31618

31619

4617

31541

31188

31187

31500

6338

31600

31626

31626

31540

Page 35

35

:: Pinions / Spur Gears

8253

8254

8255

8256

8257

8258

8259

8260

8261

8263

8264

8265

8266

8267

8268

8269

8270

8271

8272

16T 48P Pinion Gear

17T 48P Pinion Gear

18T 48P Pinion Gear

19T 48P Pinion Gear

20T 48P Pinion Gear

21T 48P Pinion Gear

22T 48P Pinion Gear

23T 48P Pinion Gear

24T 48P Pinion Gear

26T 48P Pinion Gear

27T 48P Pinion Gear

28T 48P Pinion Gear

29T 48P Pinion Gear

30T 48P Pinion Gear

31T 48P Pinion Gear

32T 48P Pinion Gear

33T 48P Pinion Gear

34T 48P Pinion Gear

35T 48P Pinion Gear

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3921

3922

3923

3924

3994

4462

4615

31332

31333

31334

31335

69T 48P Spur Gear

72T 48P Spur Gear

75T 48P Spur Gear

66T 48P Spur Gear

73T 48P Spur Gear

100T 64P Spur Gear

96T 64P Spur Gear

80T 48P Spur Gear

87T 48P Spur Gear

106T 64P Spur Gear

115T 64P Spur Gear

:: Factory Team and Option Parts

1401

1404

1734

1735

1736

3927

3928

3991

4617

6463

25391

31280

31281

31282

31283

31284

31285

31286

31288

31289

31290

31291

31292

31293

31296

31339

31344

31441

31442

31443

31550

31551

31629

31630

31632

31633

31634

31635

31636

31637

31638

31639

31640

31641

91156

FT Blue Titanium Turnbuckle 1.300”

FT Blue Titanium Turnbuckle 1.775”

FT Blue Body Clip, 4 long, 6 short

FT Blue Body Clip, long

FT Blue Body Clip, short

Radial Heatsink, narrow

Radial Heatsink, wide

TC Aero Dish Wheel 24mm

12R5 Front Bulkhead Shims (0.5, 1.0, 2.0)mm 4 ea

1:10 Blank Shock Pistons

FT 4mm Locknuts, blue

5mm Ballstud, short

8mm Ballstud, short

10mm Ballstud, short

5mm Ballstud, long

8mm Ballstud, long

10mm Ballstud, long

Aluminum Ballstud Washer, Set

Ti Nitride Ballstuds 5mm, short

Ti Nitride Ballstuds 8mm, short

Ti Nitride Ballstuds 10mm, short

Ti Nitride Ballstuds 5mm, long

Ti Nitride Ballstuds 8mm, long

Ti Nitride Ballstuds 10mm, long

TC6 Ballast Weight

TC6 Spool Kit

TC6 Gear Differential Kit

10-Spoke Wheel, black

5-Spoke Wheel, black

5-Spoke Wheel, white

M3 Aluminum Lock Nut, blue

M4 Aluminum Flange Lock Nut, blue

TC6.2 Arm Mount Shims (outer)

TC6.2 Arm Mount Shims (inner)

TC6.2 DCV Kit, builds 2 DCV’s

(requires #91156 Bearings, 5 x 10 x 3)

TC6.2 DCV Rebuild Kit

TC6.2 DCV Stub Axle

TC6.2 DCV Bone

TC6.2 DCV Coupler Tube

TC6.2 Gear Diff Outdrive, Steel

TC6.2 Spool Outdrive, Steel

TC6.2 Belt Tensioner Kit

TC6.2 Fan Mount Set

TC6.2 30mm Cooling Fan

Bearing, 5 x 10 x 3, metal (used with #31632)

2

2

10

4

6

1

1

4

12

8

10

6

6

6

6

6

6

1

2

2

2

2

2

2

1

1

1

2

2

2

6

6

4ea.

2ea.

1

1

1

1

1

1

1

1

1

1

2

:: Lubes & Adhesives

1

1

1

1

1

1

1

1

1

1

1

:: Decals

1105

1596

1597

6588

6591

6636

6727

9787

716

3816

3820

3834

31642

FT Green Slime Shock Lube

FT Locking Adhesive

FT Tire Adhesive, medium

Black Grease - 4cc

S.Diff Lube - 4cc

Silicone Grease - 4cc

Servo Tape

Chassis Protective Sheet

Reedy 2009 Sticker Set

American Bumper Sticker

AE Logo Decal Sheet

AE Blue Embossed Logo Sticker

TC6.2 Decal Sheet

:: XP Electronics

29138

29139

29141

29142

29143

29144

29166

29167

29168

29209

29210

29211

29212

29214

29215

29216

29250

29251

29252

29253

29254

XP SC500 Brushless ESC

XP SC900-BL ESC

XP SC450-BL Brushless ESC

XP ESC Fan Option

XP SC700-BL Brushless ESC

XP SC1200 Brushless ESC

XP DS1313 Digital Servo

XP DS1015 Digital Servo

XP DS1510MG Servo

Gear Set, DS1313

Gear Set, DS1015

Servo Case , DS1313/DS1015

Accessory Pack, DS1313/DS1015

TRS 403-SSi Receiver

XP2G Radio System

XP3G Radio System

XP DS1505 Servo

XP DS1505MG Servo

XP DS1505 Metal Gear Set

XP DS1510 Metal Gear Set

Receiver Antenna

:: Reedy Motors

228

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

954

955

956

957

958

987

Sonic 540 Mach 2 25.5 Comp. Brushless Motor

Sonic 540 Mach 2 21.5 Comp. Brushless Motor

Sonic 540 Mach 2 17.5 Comp. Brushless Motor

Sonic 540 Mach 2 13.5 Comp. Brushless Motor

Sonic 540 Mach 2 10.5 Comp. Brushless Motor

Sonic 540 Mach 2 9.5 Comp. Brushless Motor

Sonic 540 Mach 2 8.5 Comp. Brushless Motor

Sonic 540 Mach 2 8.0 Comp. Brushless Motor

Sonic 540 Mach 2 7.5 Comp. Brushless Motor

Sonic 540 Mach 2 7.0 Comp. Brushless Motor

Sonic 540 Mach 2 6.5 Comp. Brushless Motor

Sonic 540 Mach 2 6.0 Comp. Brushless Motor

Sonic 540 Mach 2 5.5 Comp. Brushless Motor

Sonic 540 Mach 2 5.0 Comp. Brushless Motor

Sonic 540 Mach 2 4.5 Comp. Brushless Motor

Sonic 540 Mach 2 4.0 Comp. Brushless Motor

Sonic 540 Mach 2 3.5 Comp. Brushless Motor

Sonic 540 Stock Rotor 12.3 x 24.2 (7.25)

Sonic 540 Stock Rotor 12.3 x 25.0 (7.25)

Sonic 540 Stock Rotor 12.5 x 25.0 (7.25)

Sonic 540 Modified Rotor 12.2 x 25.0 (5.0)

Sonic 540 Modified Rotor 12.5 x 25.0 (5.0)

Sonic 540 Modified Rotor 13.0 x 25.0 (5.0)

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 36

36

:: Reedy Batteries and Chargers

302

304

305

309

313

602

604

632

637

736

738

739

AA Alkaline 1.5V (4)

LiPo Pro TX/RX Battery 1600mAh 7.4V Flat

LiFe Pro TX/RX Battery 1300mAh 6.6V Flat

LiPo 65C 7000mAh 7.4V

LiPo 65C 7000mAh 7.4V (5mm)

LiPo 65C 4100mAh 7.4V Shorty

526-S AC/DC 2S-6S LiPo/LiFe Charger

LiPo TX Lightweight Battery 1350mAh 11.1V

LiPo TX Battery - M11X 2500mAh 7.4V

Wolfpack LiPo 5000mAh 7.4V 25C

Wolfpack LiPo 3800mAh 7.4V 25C Shorty

Wolfpack LiPo 5500mAh 7.4V 60C

:: Reedy Accessories

233S

247

248

249

250

605

607

654

655

656

657

658

659

669

941S

959

960

961

962

972

973

978

979

980

981

982

992

Sonic 540/540 Mach 2 Stator 13.5

Sonic 540 Mach 2 Sensor w/bearing

Sonic 540 Mach 2 Steel Bearing Set

Sonic 540 Mach 2 Ceramic Bearing Set

Sonic 540 Mach 2 Insulator Set

Motor Cooling Fans (2)

Charge Harness 2S Standard Pack 4mm

4.0mm Bullet Plugs (2M, 2F)

4.0mm Bullet Plugs (2M, 10F)

4.0mm Bullet Plugs (10F)

4.0mm Bullet Plugs (100F)

4.0mm Bullet Plugs (10M)

4.0mm Bullet Plugs (30M)

5mm Bullet Connector

Sonic 540/540 Mach 2 Stator 17.5

Sonic 540/550 Sensor w/Bearing

Sonic 540/550 Insulator Set (2 pcs.)

Sonic 540/550 Timing Cap w/Screws

Sonic 540/540 Mach 2 Case Screws (3 pcs.)

Sonic 540 Steel Bearing Set

Sonic 540 Ceramic Bearing Set

Flat Sensor Wire 70mm

Flat Sensor Wire 110mm

Flat Sensor Wire 150mm

Flat Sensor Wire 200mm

Flat Sensor Wire 270mm

Sonic 540 Rotor Spacers

:: RePlay Cameras

RP001

RP002

RP021

RP022

RP023

RP024

RP029

RP030

RP032

RP033

RP034

RP036

RP038

RP041

RP042

RP043

RP044

RP045

RP046

RP047

RP048

RP049

RP054

Replay XD1080 Complete Camera System

Replay XD720 Complete Camera System

Replay XD1080 Lens Bezel Kit

Replay XD1080 Clear Lens Cover

Replay XD1080 Lens Bezel & Rear Cap O-Ring

Replay XD Lens Bezel

Replay XD1080 HDMI to Mini-HDMI

Replay XD1080 Mini 8-pin USB Charge Data Cable

USB DC Car Charger 1A Stubby

USB DC Car Charger 500mAh

Micro SDHC USB Reader

3M VHB 4991 Mount Adhesive for SnapTray

3M VHB 5962 Mount Adhesive for SnapTray

Replay XD Suction Cup Arm Mini Clamp

Replay XD Suction Cup Short Arm Base

Replay XD Skateboard Mount

Replay XD VHB SnapTray, Convex

Replay XD VHB SnapTray, Flat

Au Plug for Universal DC Wall Charger

Eu Plug for Universal DC Wall Charger

Uk Plug for Universal DC Wall Charger

Universal USB DC Wall Charger 1A

Replay ReView Field Monitor

:: Qualifier Series Vehicles

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

7052

20111

20119

20510

30112

Pro Lite 4x4 RTR, 1/10 Scale (ready-to-run)

Rival Mini Monster Truck 1/18 Scale (ready-to-run)

APEX Mini Touring RTR

RIVAL Electric Monster Truck RTR, 1/8 Scale

(ready-to-run)

APEX Touring V-Type, 1/10 Scale (ready-to-run)

:: 1/18 Kits and RTR’s

20103

20121

RC18B2 - RC18T2 Team Kit

SC18 RTR Brushless (ready-to-run)

:: 1/12, 1/10 Kits and RTR’s

4020

FT 12R5.2 Kit

6001

RC10 Classic Kit

7025

FT RC10T4.2 Kit

7029

SC10 Associated/RC10.com Truck RTR (ready-to-run)

7030

SC10 KMC Wheels Race Truck RTR (ready-to-run)

7038

FT SC10.2 Kit

7039

RC10T4.2 RS RTR 2.4GHz Brushless (ready-to-run)

7046

1

1

1

1

1

1

1

1

1

1

1

1

1

1

30101

1

30109

1

90005

1

90006

1

90008

1

90010

1

1

1

1

SC10 RS RTR, Lucas Oil (ready-to-run)

7049

SC10 RS RTR, Rockstar/Makita (ready-to-run)

7050

SC10 RS RTR, Hart and Huntington (ready-to-run)

7051

SC10 RS RTR, Lucas Slick Mist® Body

7054

SC10 RS RTR, Toyota Racing/TRD

7055

SC10 RS RTR, Monster Energy Toyota

7093

SC10GT RTR (ready-to-run)

8020

FT RC10R5 Kit

8022

FT RC10R5.1 Kit

9040

FT RC10B4.1 Worlds Kit

9041

FT RC10B4.2 Kit

9042

RC10B4.2 RS RTR 2.4GHz Brushless (ready-to-run)

9050

SC10B RS RTR (ready-to-run)

9062

FT B44.2 4WD Buggy Kit

TC4 Club Racer 4WD Touring Car Race Roller

FT TC6.2 WC 4WD Touring Car Kit

SC10 4x4 Lucas Oil RTR (ready-to-run)

SC10 4x4 Pro Comp RTR (ready-to-run)

Limited Edition SC10 4x4 RTR Monster Energy

SC10 4x4 FT Kit

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 37

37

:: 1/8 Kits and RTR’s

20501

20502

20503

20504

80906

80907

80908

80909

80912

80933

80934

MGT 4.60 SE RTR (ready-to-run)

MGT 8.0 Nitro RTR (ready-to-run)

Limited Edition MGT 4.60 Nitro RTR, w/flag body

(ready-to-run)

Limited Edition MGT 8.0 Nitro RTR, w/flag body

(ready-to-run)

RC8.2 Nitro Buggy FT Kit

RC8.2e Electric Buggy FT Kit

RC8.2e Electric Buggy RTR (ready-to-run)

RC8.2RS Nitro Buggy RTR (ready-to-run)

RC8T Championship Edition

SC8.2e Short Course Race Truck, Rockstar/Makita

Electric RTR (ready-to-run)

SC8.2e Short Course Race Truck, Slick Mist Electric

RTR (ready-to-run)

:: Tools

1111

1112

1450

1541

1542

1543

1544

1545

1546

1547

1548

1553

1554

1561

1562

1563

1564

1565

1567

1589

1590

1592

1655

1656

1657

1658

1659

1660

1661

1662

1663

1664

1665

1666

1667

1668

1669

1670

1671

1672

1673

1674

1719

1737

3718

3719

3720

3987

6429

6956

7494

7709

FT Turnbuckle Wrench

FT 4mm Turnbuckle Wrench

FT On Road Ride Height Gauge

FT Hex Driver Set, (7 pcs)

FT .050” Silver Hex Driver

FT 1/16” Black Hex Driver

FT 1.5mm Purple Hex Driver

FT 5/64” Blue Hex Driver

FT 3/32” Gold Hex Driver

FT 2.5mm Green Hex Driver

FT 3mm Red Hex Driver

FT Phillips Silver Screwdriver

FT Silver Spring Hook Tool

FT Nut Driver Set, (6 pcs)

FT 3/16” Black Nut Driver

FT 1/4” Red Nut Driver

FT 5.5mm Red Nut Driver

FT 11/32” Green Nut Driver

FT 8mm Gold Nut Driver

FT 5/64” Blue Ball Hex Driver

FT 3/32” Gold Ball Hex Driver

FT Ball Hex Driver Set, (3 pcs)

FT 8-Piece 1/4” Hex Drive Set

FT 1/4” Hex Drive Handle, without tips

FT 1/4” Hex Drive .050” Tip

FT 1/4” Hex Drive 1/16” Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Tip

FT 1/4” Hex Drive 3/32” Tip

FT 1/4” Hex Drive 1.5mm Tip

FT 1/4” Hex Drive 2.5mm Tip

FT 1/4” Hex Drive 3/16” Nut Driver Tip

FT 1/4” Hex Drive 1/4” Nut Driver Tip

FT 1/4” Hex Drive 11/32” Nut Driver Tip

FT 1/4” Hex Drive 5.5mm Nut Driver Tip

FT 1/4” Hex Drive 7.0mm Nut Driver Tip

FT 1/4” Hex Drive 8.0mm Nut Driver Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Ball End Tip

FT 1/4” Hex Drive 3/32” Ball End Tip

FT 1/4” Hex Drive Standard Screwdriver Tip

FT 1/4” Hex Drive Phillips Screwdriver Tip

FT 1/4” Hex Drive 2.5mm Ball End Tip

FT 1/4” 5 Piece Power Tool Tips Set (5/64-2.0mm,

1.5mm, 2.5mm, 5/64”- 2.0mm ball, 2.5mm ball)

FT Camber + Track Width Tool

FT Body Scissors

12 Inch Nylon Wire Ties

6 Inch Nylon Wire Ties

8 Inch Nylon Wire Ties

Composite Droop Gauge

Shock Building Tool

Molded Tools, Set

V2 Stamped Multi-tool

4 Inch Nylon Wire Ties

:: Apparel

SP31**

1

SP32**

1

SP37**

1

SP38

SP39

1

SP71**

SP77**

1

SP78**

1

SP79**

1

SP84**

1

SP86**

1

SP90**

1

SP91**

SP92**

1

SP93**

SP94**

SP95**

SP96**

SP97**

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

12

12

1

1

1

1

12

SP98

SP99

SP411S

SP411L

SP416

SP417

SP420**

SP421S

SP421L

SP422S

SP422L

SP423S

SP423L

SP424S

SP424L

715

110684

:: Contact Information

Check out the following web sites for all

of our electric kits, current products, new