Page 1

4/12

Page 2

2

:: Introduction

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and

maintaining your new SC10GT RTR. Please take a moment to read through this manual to help familiarize yourself with these

steps.

Now you can have Team Associated’s world class performance with true scale authenticity in a 1:10 scale nitro truck!

Team Associated is proud to bring to you the SC10GT; a 1:10 scale nitro 2WD off road short course race truck.

Based on the ROAR National Winning RC10 GT2, the engineers behind the doors in Area 51 made the SC10GT both, all show

and all go! The result is the SC10GT, an authentic scale experience at a level of performance that has never been seen before in

1:10 scale short course.

The SC10GT comes ready to run with a painted and decaled short course race truck body, KMC™ style wheels, aggressive tread

multi-terrain tires, all that have been designed to look just like the full-size race trucks that run in short course off-road series

around the country. The world of high-performance 1:10 scale Nitro R/C has never before seen this level of scale accuracy!

At first glance it’s easy to see that the SC10GT is another champion by design!

:: RTR Features

Features in the SC10GT RTR:

• V2 Dual disc slipper clutch.

• Modular radio tray that easily removes for cleaning and maintenance, and protects the receiver against fuel spills during

pit stops.

• Radio tray has optional space for a high capacity 150cc fuel tank for longer run times.

• Special tuned pipe and header, which produces a perfect balance of maximum power and efficiency.

• V2 Blue anodized aluminum shock bodies.

• All new sealed battery box keeps the receiver batteries safe.

• Blue anodized aircraft aluminum chassis. Radical new chassis design adds tremendous rigidity for the ultimate in consistency

and handling that no other truck can claim.

• Radical pre-printed body shell that any pro painter would be proud to produce.

• Our proven #2918 AE .18X engine will shock customers with its power and speed, like no other manufacturer’s pull start

engine sold in any RTR. Our Engine Replacement Policy is a win-win deal for customers and hobby shops.

• High traction JConcepts racing rear tires for consistent handling.

• Ball differential with lightweight outdrives

• Shielded bearings throughout the truck.

• Glow igniter, fuel bottle

• Rubber AE logo mud flaps

:: Additional Items Needed: :: Optional Items:

• AA-size batteries for transmitter / receiver pack (x12)

(#302, 303 recommended)

• One D-size battery (for the glow igniter)

• Model car fuel (20% - 30% nitro recommended)

• Glow plugs (#MC59 recommended)

• Slotted screwdriver (#1655, 1656, 1671, 1551)

• Battery charger (peak detection charger recommended)

(#LRP41281, LRP41555)(#604 LiPo/LiFe, #610 NiCd/NiMH)

• Rechargeable receiver battery pack (#612, 630, 638)

• Glow plugs (#MC59)

• Starter Box for non-pull start engines (#1750 recommended)

• Thread Locking compound (#1596 recommended)

• FT Glow Igniter rechargeable (#1738 recommended)

:: Other Helpful Items

• Silicone Shock Fluid (Refer to catalog for complete listings)

• Body Scissors (AE Part # 1737) • Reamer / Hole Punch • FT Turnbuckle Wrench (#1111)

• FT Hex Wrenches (AE Part # 1541, 1655) • Needle Nose Pliers • Multi Tool (AE Part #7494)

• FT Nut Drivers (AE Part #1561, 1663-1668) • Calipers or a Precision Ruler • Green Slime shock lube (AE Part # 1105)

• Soldering Iron (#LRP65800) • Hobby Knife • Wire Cutters

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 3

:: Table of Contents

1....................Cover

3

43.................Setup Sheet “RTR Setup”

2....................Introduction

3....................Table of Contents

BAG A

4-8...............Steering, Front Shock Tower,

and Bumper Build

BAG B

9-13.............Ball Differential, Gearbox, and

Rear Shock Tower Build

Bag C

13-15..........Rear Suspension Build

Bag D

15-19..........Radio Tray Build

Bag E

19-20..........Throttle and Brake Linkage

Build

44.................1:1 Hardware “Fold Out

45.................Setup Sheet “Blank”

46.................Back Cover

Bag F

21-24..........Engine Build

Bag G

25-27..........Shocks Build

27-28.........Tire Build

28.................Body Installation

29-30.........Tuning Tips

31-40.........Catalog

41.................Contact Info

42.................Notes

:: Notes

!

This symbols indicates a

special note or instruction

in the manual.

There is a 1:1 hardware foldout page in the back

of the manual. To check the size of a part, line

up your hardware with the correct drawing until

you find the exact size. Each part in the foldout

has a number assigned to it for ordering

replacement parts.

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 4

4

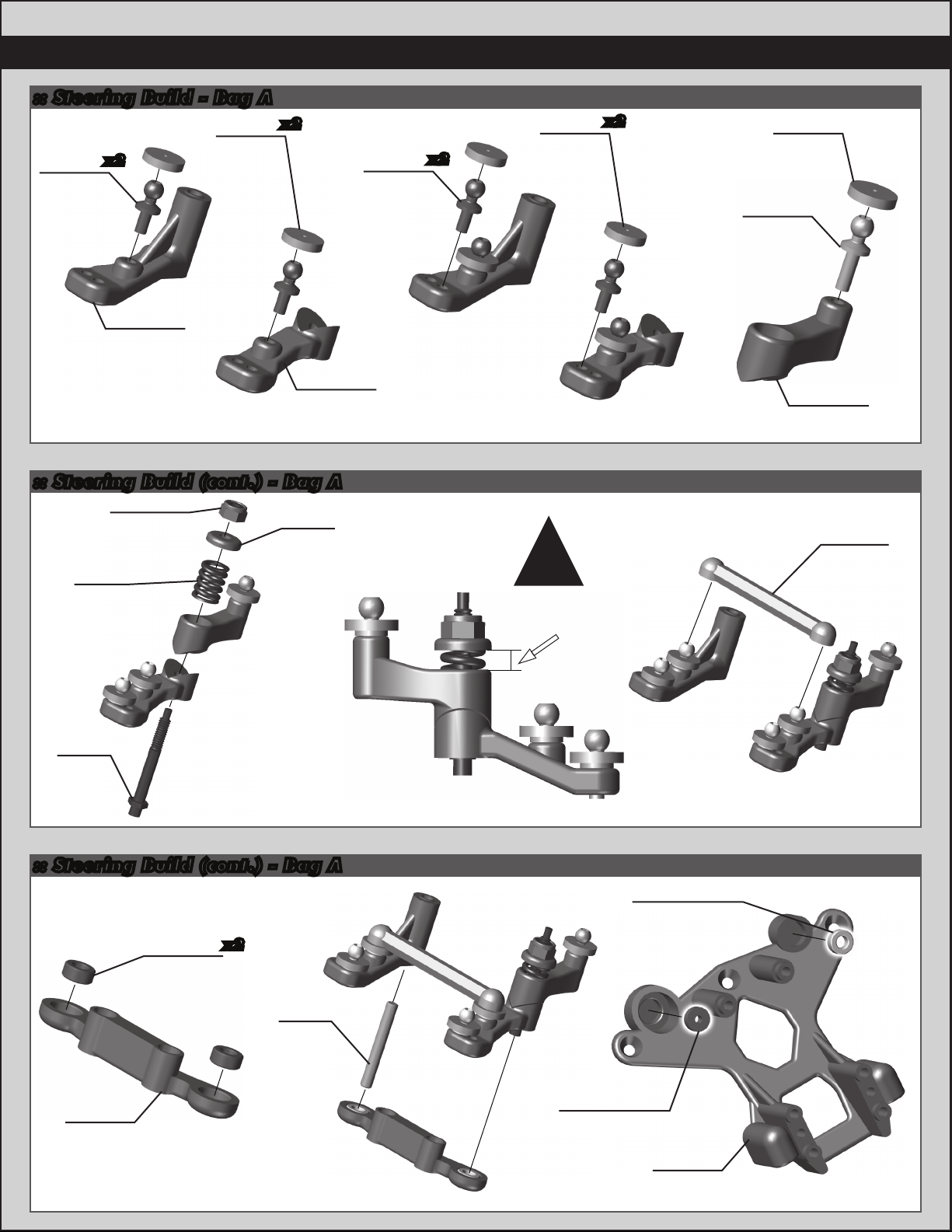

:: Steering Build - Bag A

6272

Foam

6276

Ballstud

.20 silver

(short)

x2

7908

Idler arm

dust

cover

:: Steering Build (cont.) - Bag A

6629

5-40

locknut

7908

Servo

saver

spring

x2

7908

Servo saver

arm, lower

7908

Servo

saver

spring

6276

Ballstud

.20 silver

(short)

x2

6272

Foam

dust

cover

!

Tighten to

2.5mm

(0.1”)

x2

6272

Foam

dust

cover

6277

Ballstud

.30 silver

(long)

7908

Servo saver

arm, upper

7908

Steering

draglink

7908

Servo

saver

post

:: Steering Build (cont.) - Bag A

2234

1/8” x 1/4”

bushing

7908

Lower

bearing

cap

x2

7908

Idler

post

2234

1/8” x 1/4”

bushing

7908

5/64” x 1/4”

bushing

7893

Top

plate

Page 5

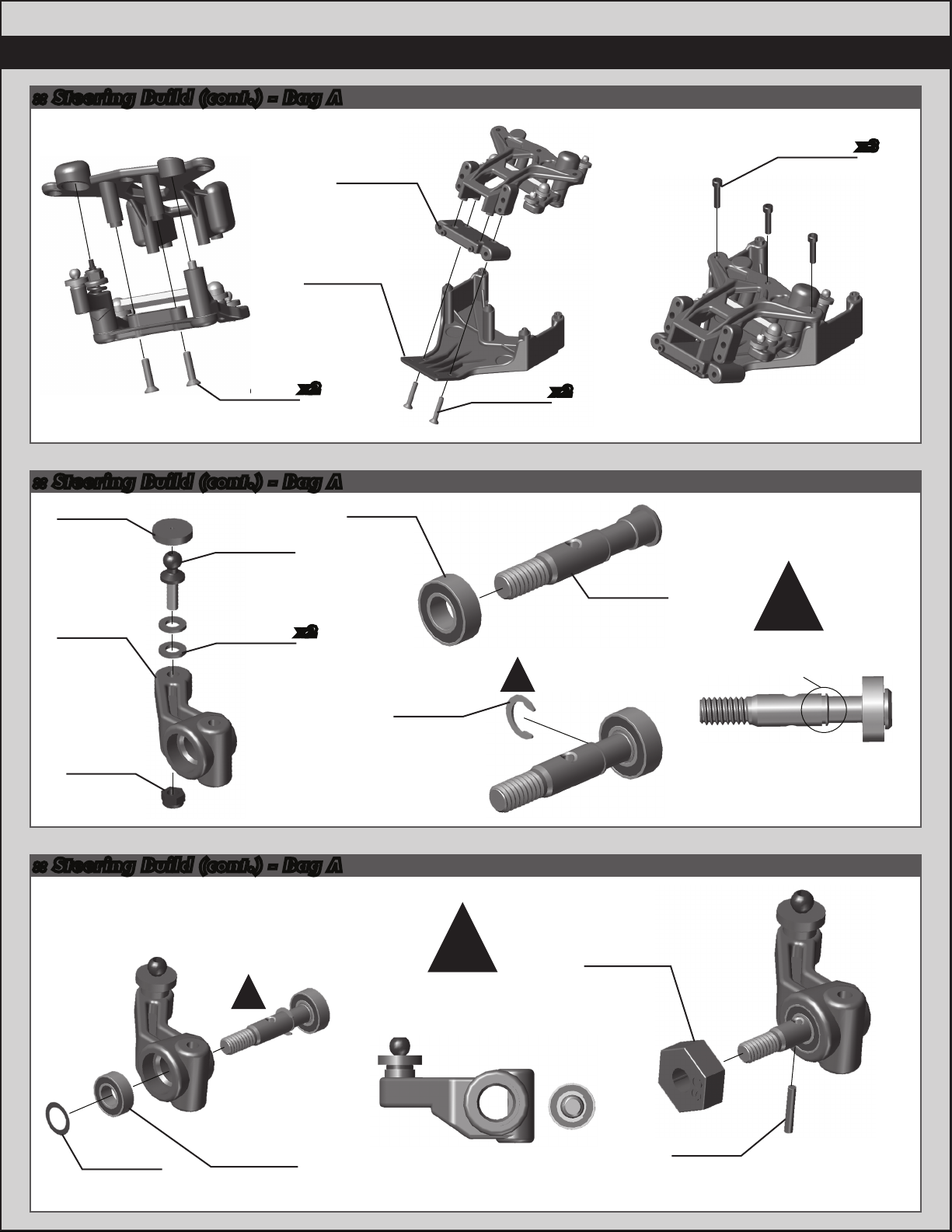

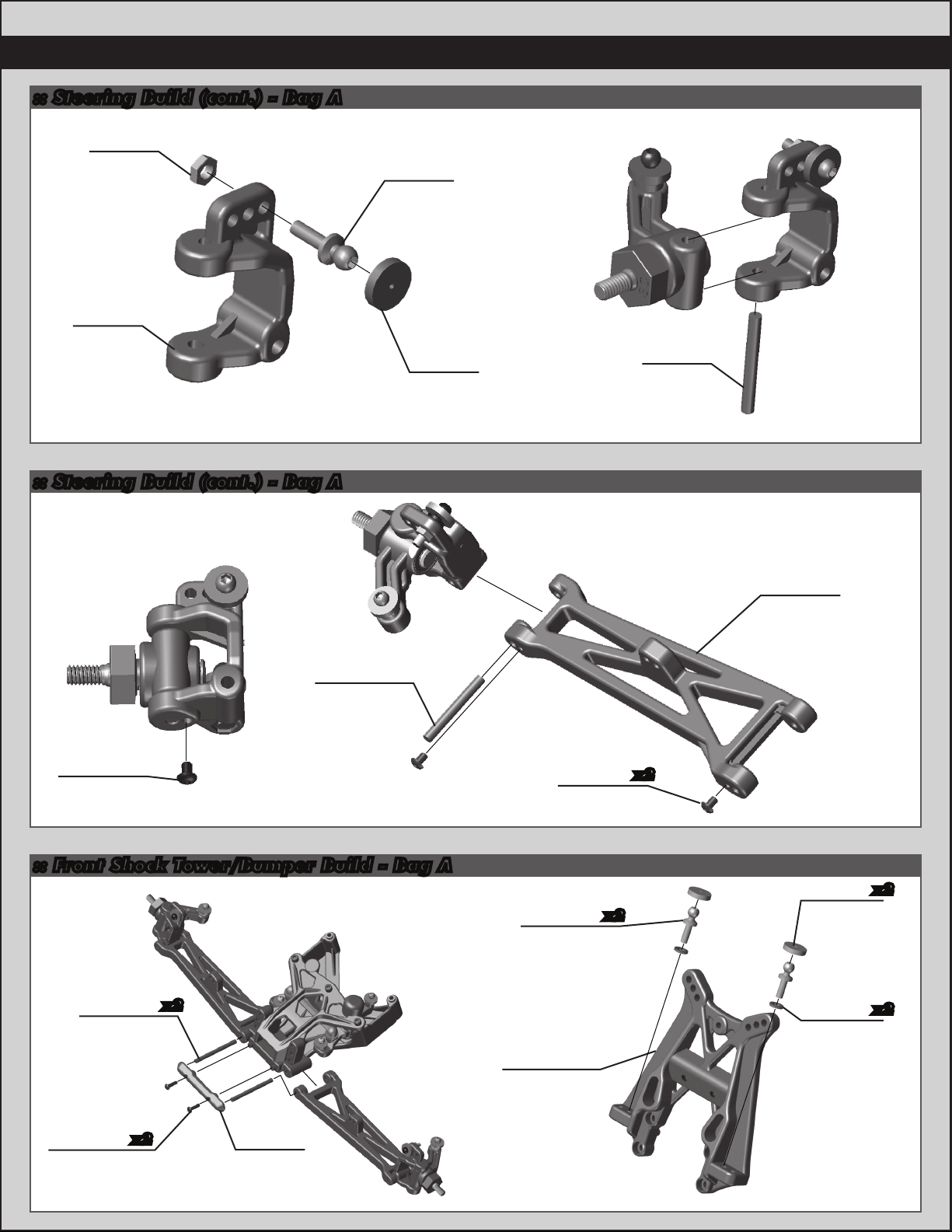

:: Steering Build (cont.) - Bag A

5

7892

Front sub

chassis

kickup

6922

4-40 x 1/2”

x2

fhcs

:: Steering Build (cont.) - Bag A

6272

Foam

dust

cover

9880

Steering

blocks

hex style

1 left &

1 right

4449

4-40 x 3/16

aluminum

locknut

6277

Ballstud

.30 silver

(long)

4187

.030 washer

(nylon)

x2

9563

Front

bulkhead

3977

3/16 x 3/8

bearing

9882

C clip

(3/16”)

6915

4-40 x 5/8”

x2

fhcs

!

9881

Front axle

(hex style)

6925

4-40 x 1/2”

shcs

!

Install the C clip on

the groove shown

below.

Build left and

right sides!

x3

:: Steering Build (cont.) - Bag A

!

7368

3/16” axle

shim

3977

3/16 x 3/8

bearing

!

Align the C clip on

the front axles

with the D shape

inside the steering

blocks.

9883

Wheel hex

adapter

(thin)

universal

7369

1/16”

roll pin

Build left and

right sides!

Page 6

6

:: Steering Build (cont.) - Bag A

7260

4-40

small

plain nut

7922

Caster

block

(30˚)

:: Steering Build (cont.) - Bag A

3983

Ballstud

.30 black

(long)

6272

Foam

dust

cover

7927

Outer

hinge

pin

Build left and

right sides!

7927

Outer

hinge pin

9645

2-56 x 1/8

bhcs

:: Front Shock Tower/Bumper Build - Bag A

9621

Inner

hinge pin

x2

9645

2-56 x 1/8

bhcs

6277

Balstud

.30 silver

(long)

9825

Front shock

tower

x2

x2

7917

Front arm

(left &

right)

Build left and

right sides!

6272

Foam

dust

cover

9630

Ballstud

washer,

aluminum

(.030”)

x2

x2

4334

2-56 x 5/16

bhcs

x2

9564

Front

hinge pin

brace

Page 7

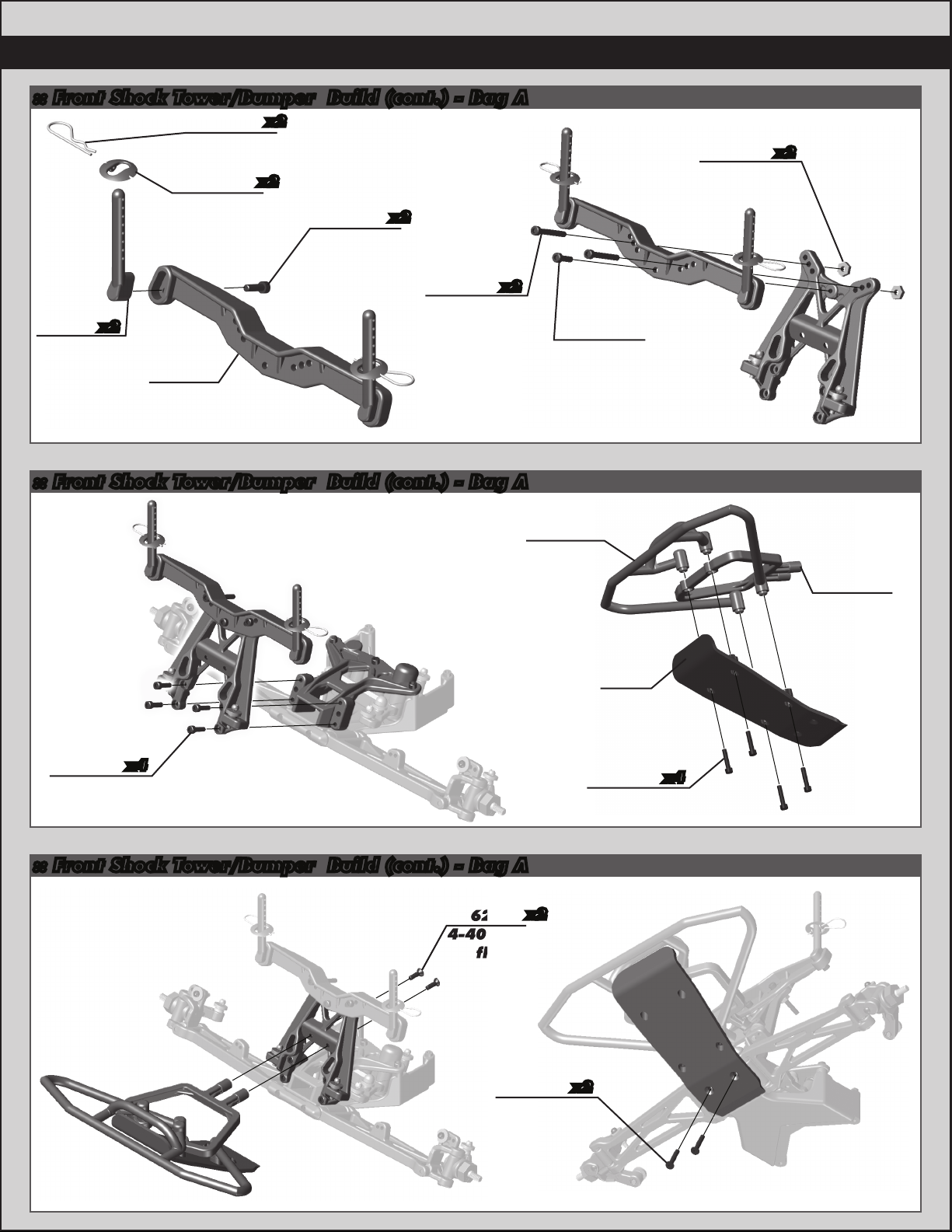

:: Front Shock Tower/Bumper Build (cont.) - Bag A

6292

4-40 x 3/8

fhcs

6332

Body clips

3897

Pivoting

body mount

x2

x2

6924

4-40 x 3/8

shcs

x2

6295

4-40 plain

nut

x2

7

7103

Front

body

post

x2

7738

4-40 x 7/8

shcs

9820

Front

body

mount

x2

:: Front Shock Tower/Bumper Build (cont.) - Bag A

6924

4-40 x 3/8

shcs

9816

Front

bumper

9816

Front

bumper

brace

9816

Skid

plate

6924

4-40 x 3/8

shcs

x4

:: Front Shock Tower/Bumper Build (cont.) - Bag A

6292

4-40 x 3/8

fhcs

4-40 x 5/8

x2

6915

fhcs

6925

4-40 x 1/2

shcs

x2

x4

Page 8

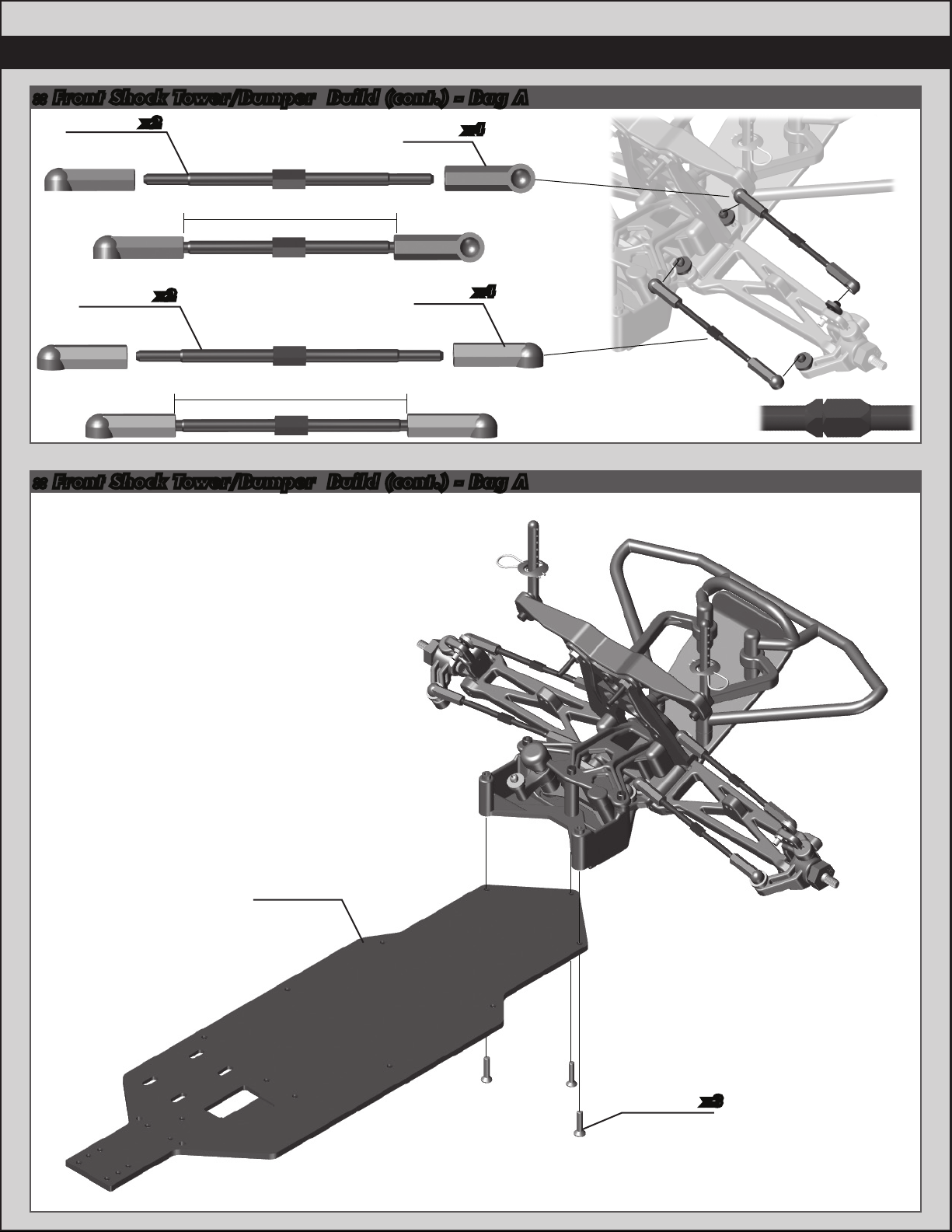

8

:: Front Shock Tower/Bumper Build (cont.) - Bag A

7253

2.62” steel

turnbuckle

x2

Front Camber

Turnbuckle

48.5mm

7230

Ballcup

x4

Build left and

right sides!

7101

2.80” steel

turnbuckle

x2

Steering Camber

Turnbuckle

7230

Ballcup

x4

53mm

:: Front Shock Tower/Bumper Build (cont.) - Bag A

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

7107

SC10GT

chassis

6922

4-40 x 1/2

fhcs

x3

Page 9

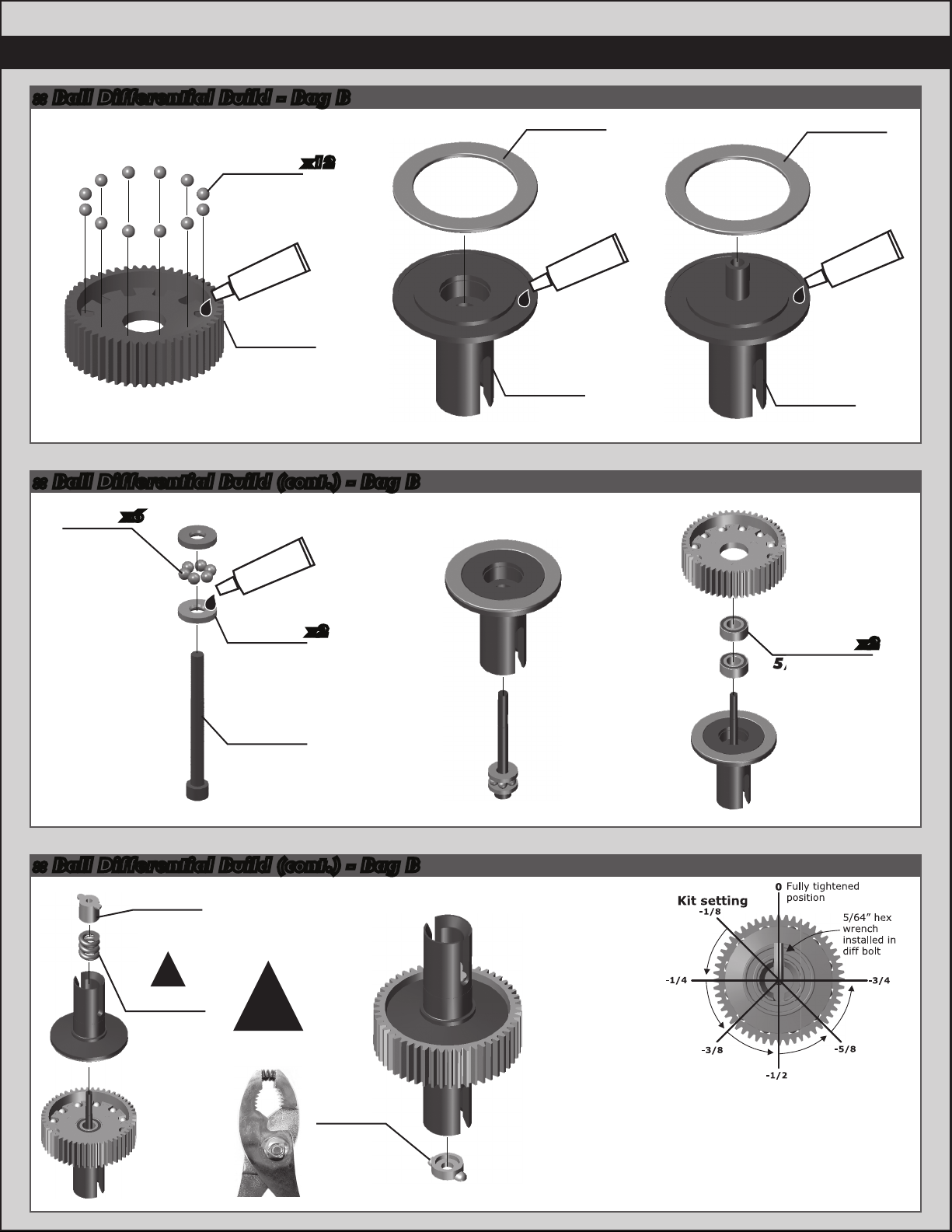

:: Ball Differential Build - Bag B

5/32 x 5/16

6581

3/32”

carbide

diff balls

x12

7666

Diff ring

9

7666

Diff ring

#6591

Diff lube

7664

Diff gear

52T

:: Ball Differential Build (cont.) - Bag B

6574

5/64

diff

thrust

ball

x6

#6588

black grease

6573

Thrust

washer

x2

#6591

Diff lube

7667

Diff outdrive

hub, right

#6591

Diff lube

7668

Diff outdrive

hub, left

6589

x2

5/32 x 5/16

bearing

6575

Diff

thrust

bolt

:: Ball Differential Build (cont.) - Bag B

6575

Locking

T-nut

!

6582

Diff

thrust

spring

!

Pre-compress

spring

6575

Diff bolt

cover

As you tighten the diff bolt, you will notice the T-nut ears moving closer

to the bottom of the outdrive slot. This compresses the spring

behind the T-nut. The spring should be completely compressed at the

same time the T-nut reaches the end of the slot.

CAUTION! Pay close attention to the feeling when the spring is

completely compressed. Do not over tighten the bolt. When you

feel the spring completely compressed, loosen the diff bolt 1/8” of

a turn. You diff should now operate smoothly with resistance as the

outdrives move in opposite directions.

After you have driven the car once, re-check the dif f setting.

Page 10

10

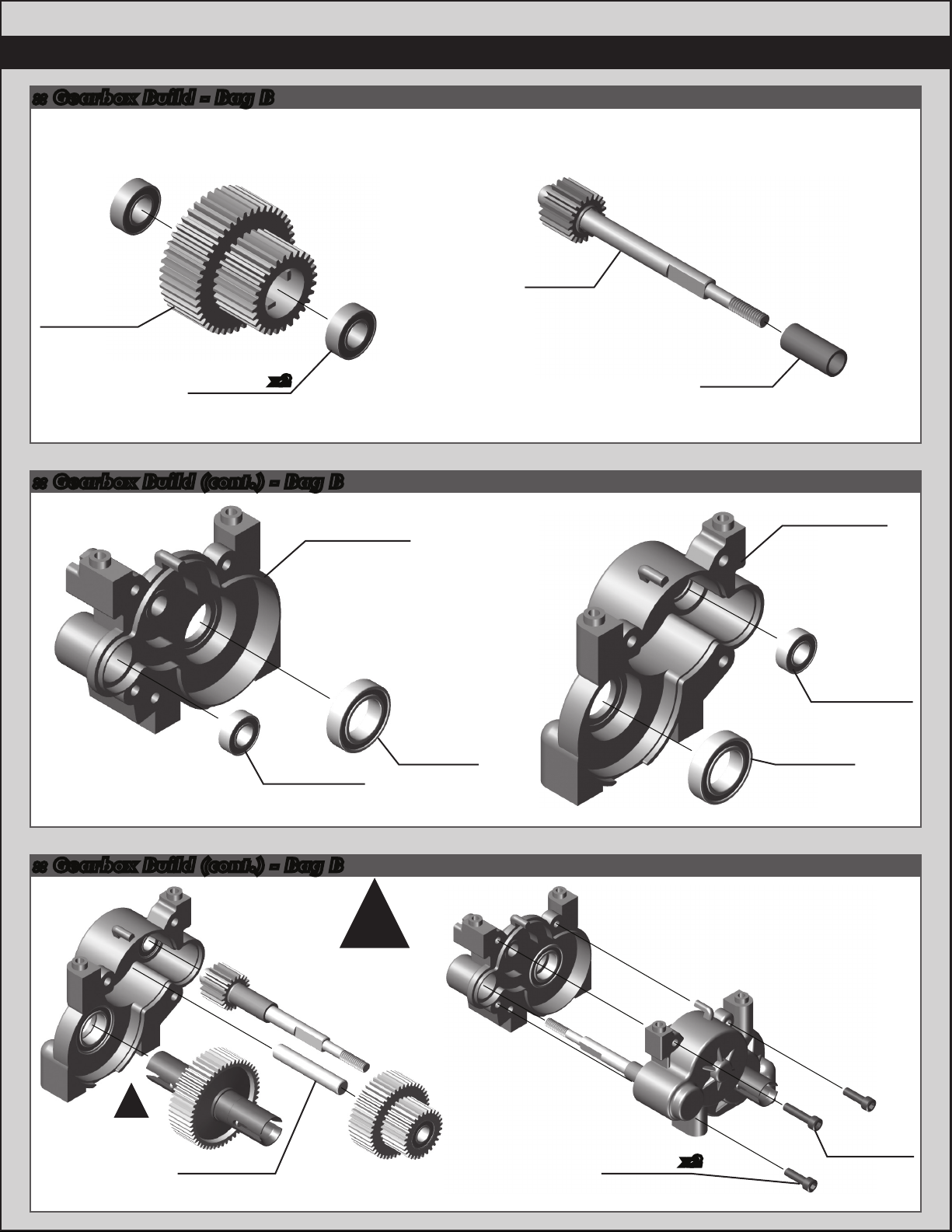

:: Gearbox Build - Bag B

7963

Idler gear

cluster 44-28T

3977

3/16 x 3/8

ball bearing

:: Gearbox Build (cont.) - Bag B

x2

7960

top

shaft

7961

top shaft

spacer

Transmission

(right side)

3977

3/16 x 3/8

ball bearing

:: Gearbox Build (cont.) - Bag B

Diff adjustment

bolt head on

same side as

7945

case

!

Note:

spur gear

3976

3/8 x 5/8

ball

bearing

7945

Transmission

case

(left side)

3977

3/16 x 3/8

ball bearing

3976

3/8 x 5/8

ball

bearing

!

7874

4-40 x 7/16

shcs

7964

Idler gear

shaft

6924

4-40 x 3/8

shcs

x2

Page 11

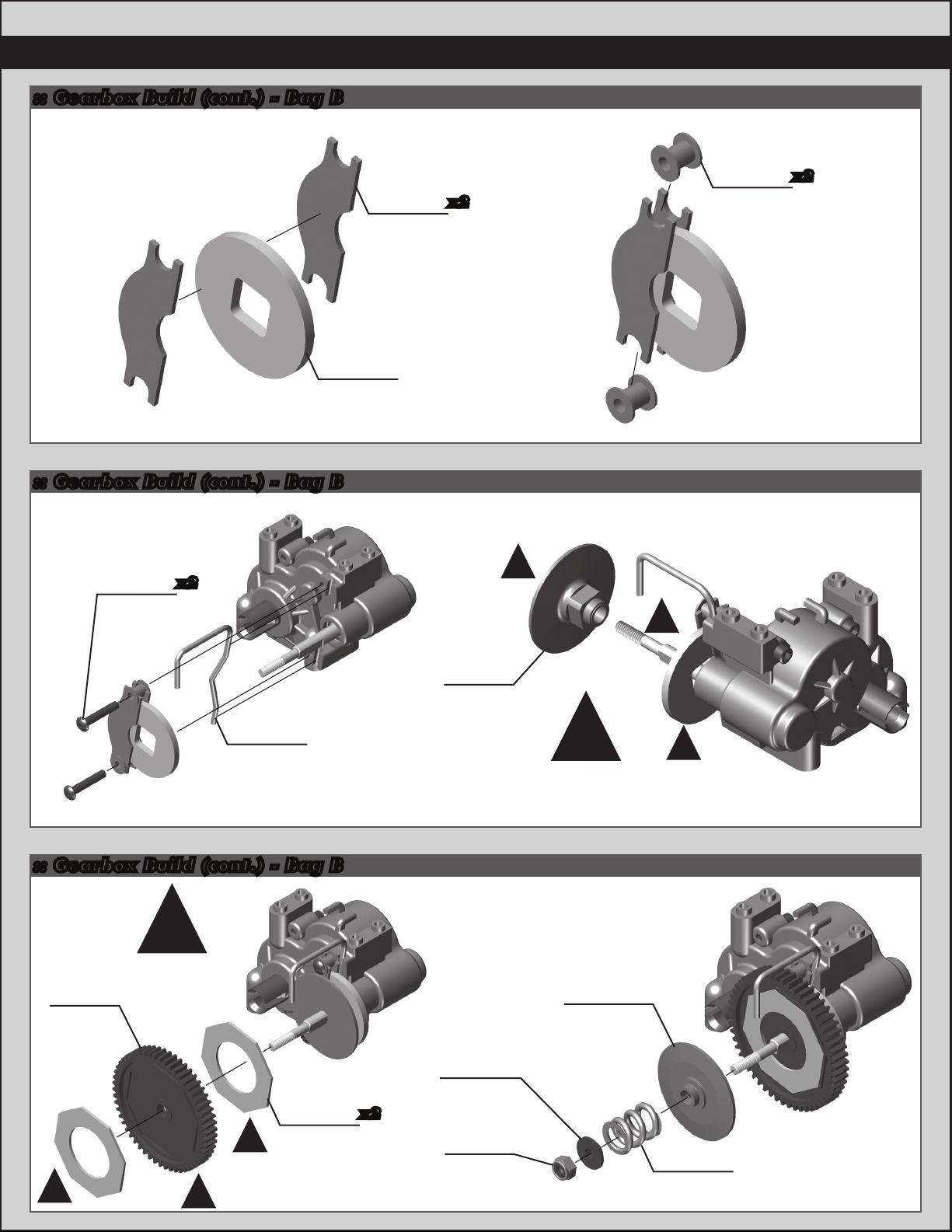

:: Gearbox Build (cont.) - Bag B

11

:: Gearbox Build (cont.) - Bag B

7633

4-40 x 5/8

bhcs

x2

7950

Brake

disc

7949

Brake

pad

x2

7947

Brake

top hat

bushing

x2

!

!

7948

Brake

cam

:: Gearbox Build (cont.) - Bag B

!

Align

pads into

7955

54T

spur

gear

!

spur gear.

!

9603

!

Slipper

pads

x2

7953

Slipper

plate,

inner

7486

V2 slipper

spring

6629

5-40

locknut

!

Align the flat spots

on the inner slipper

plate to the brake

disc and top shaft.

7485

V2 slipper

plate

!

7486

V2 slipper

spring

Page 12

12

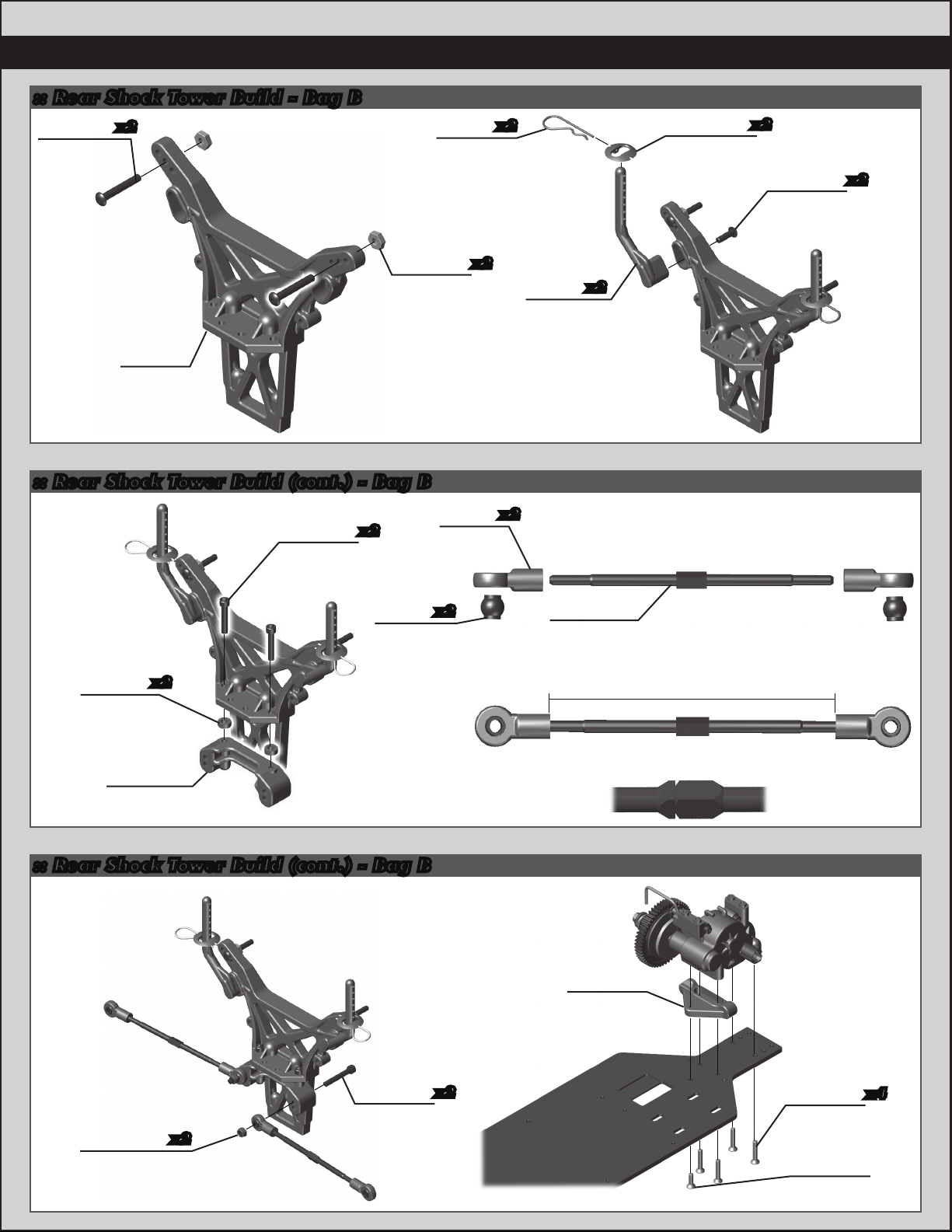

:: Rear Shock Tower Build - Bag B

7413

4-40 x 3/4

bhcs

x2

6332

Body

clips

x2

3897

Pivoting

body mount

x2

6917

4-40 x 3/8

bhcs

x2

7260

Plain nut

7102

Rear shock

tower

(SC10 GT)

:: Rear Shock Tower Build (cont.) - Bag B

x2

7217

Pivot

ball end

9273

1/8 x 1/4

spacer

6926

4-40 x 5/8

shcs

x2

7217

Shock

end

x2

x2

x2

7103

Rear

body

mounts

7937

3.0” steel

turnbuckle

x2

Rear Camber

Turnbuckle

65mm

7941

Camber

link mount

to the left throughout the

car. It indicates which end

has the left hand threads!

:: Rear Shock Tower Build (cont.) - Bag B

6927

4-40 x 3/4

4449

4-40 x 3/16

locknut

x2

shcs

Orient the notch

x2

7928

Rear arm

mount

Build left and

right sides!

6915

4-40 x 5/8

fhcs

6292

4-40 x 3/8

x4

fhcs

Page 13

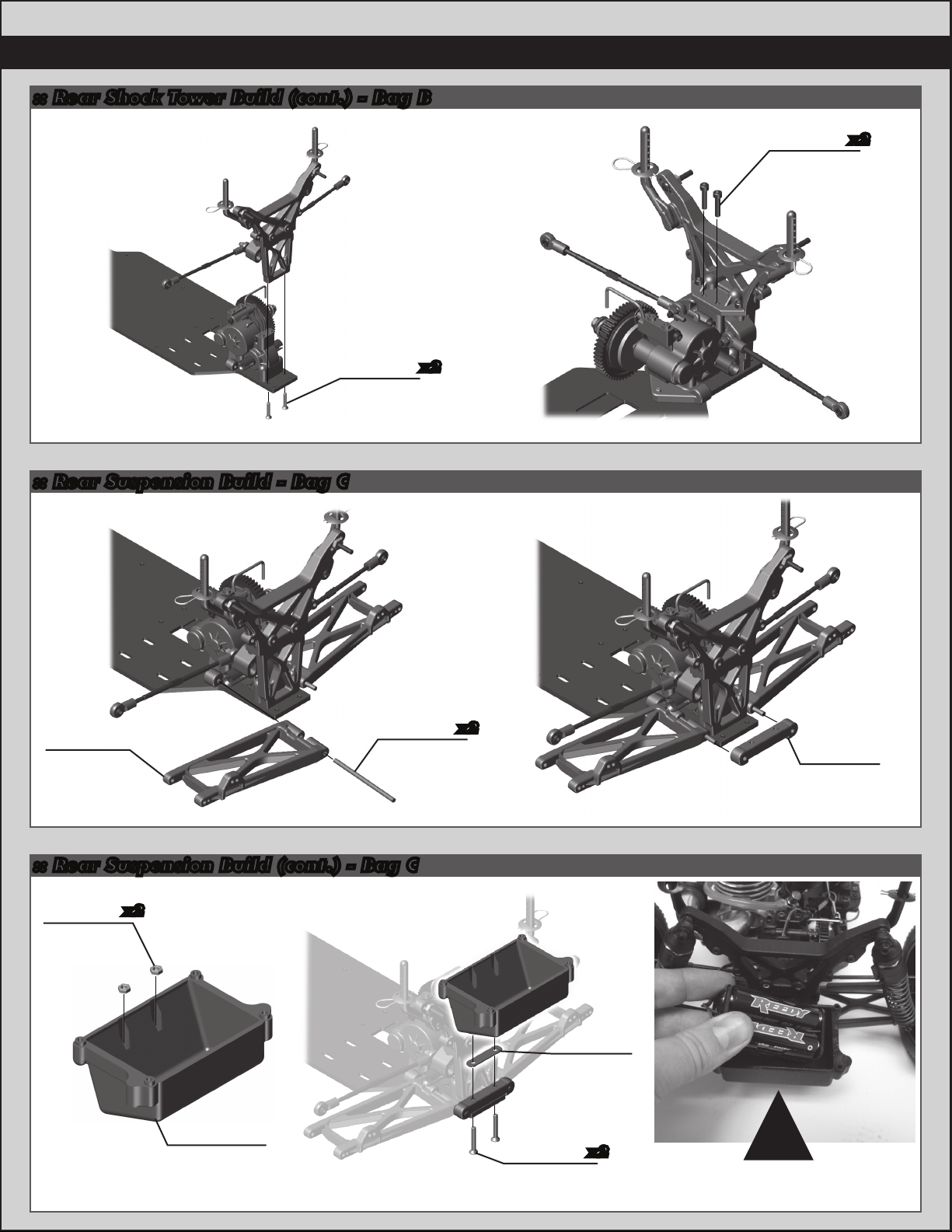

:: Rear Shock Tower Build (cont.) - Bag B

13

:: Rear Suspension Build - Bag C

6915

4-40 x 5/8

fhcs

x2

6925

4-40 x 1/2

shcs

x2

7930

Rear arms

(1 left &

1 right)

9621

Rear inner

hinge pins

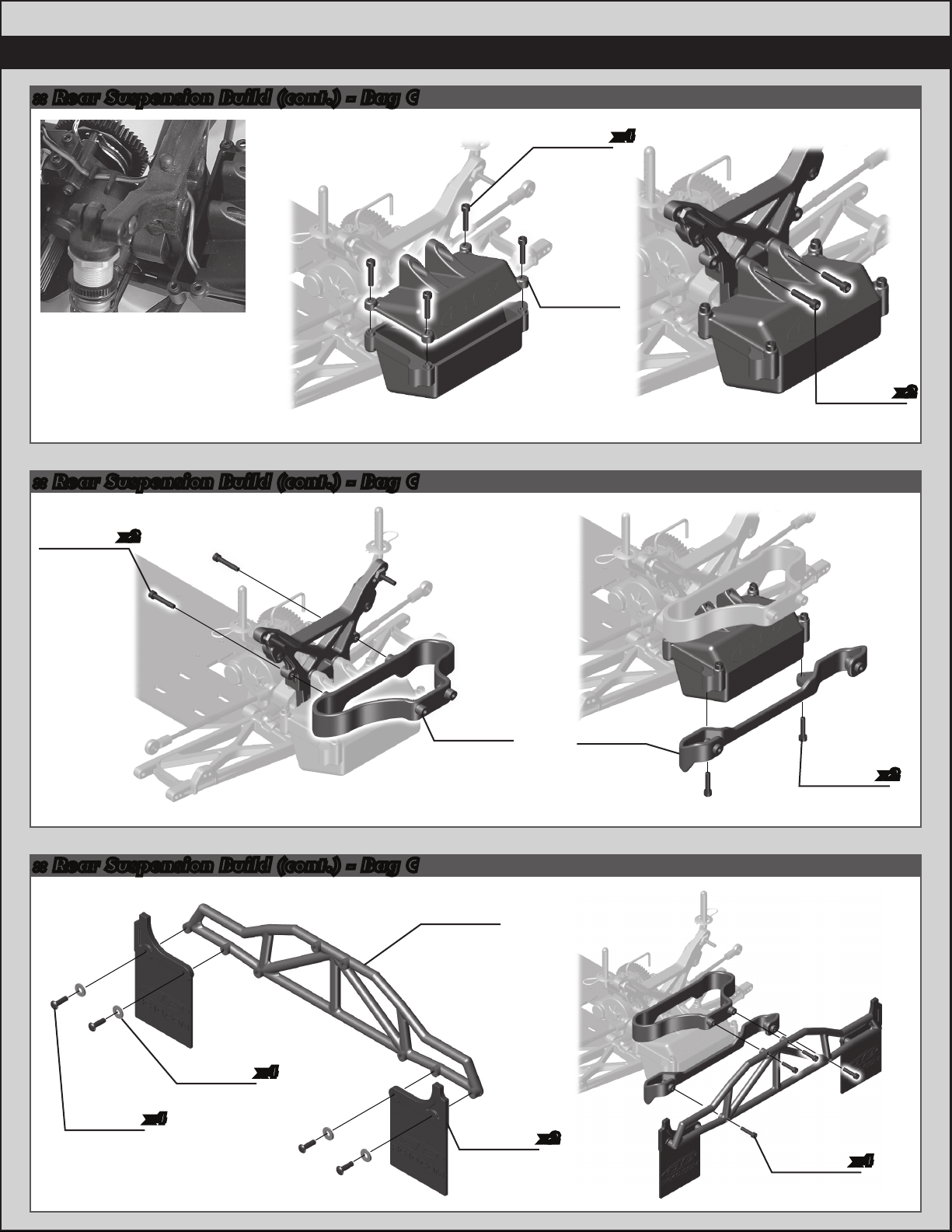

:: Rear Suspension Build (cont.) - Bag C

7260

4-40 small

plain nut

x2

7904

Battery box

bottom

x2

7928

Rear arm

mount

shim

6923

4-40 x 3/4

fhcs

x2

7928

Arm

mount

(3+2)

!

Install receiver

pack.

Page 14

14

:: Rear Suspension Build (cont.) - Bag C

Note: Wire opening in receiver

pack lid and wire hooks in

transmission case.

Racer Tip: Add foam padding

(not inluded) to cushion receiver

pack.

:: Rear Suspension Build (cont.) - Bag C

6926

4-40 x 5/8

shcs

x2

6925

4-40 x 1/2

shcs

7904

Battery

box top

x4

6925

4-40 x 1/2

shcs

x2

:: Rear Suspension Build (cont.) - Bag C

x4

6917

4-40 x 3/8

bhcs

x4

89218

3x8mm

washer

7105

Rear

bumper

mount

(upper)

7104

Rear

bumper

89430

Mud flaps

x2

7105

Rear

bumper

mount

(lower)

6925

4-40 x 1/2

shcs

6925

4-40 x 1/2

shcs

x2

x4

Page 15

:: Rear Suspension Build (cont.) - Bag C

7932

1.5 degree

7462

Dogbone

5407

Red

o-ring

9670

3/16

rear

axle

Build left and

right sides!

rear hubs

(1 left &

1 right)

3977

3/16 x 3/8

bearing

7935

.187x.50x.196

bearing

7933

Crush

tube

:: Rear Suspension Build (cont.) - Bag C

6926

4-40 x 5/8

shcs

5407

Red

o-ring

9645

2-56 x 1/8

bhcs

7369

1/16”

universal

roll pin

15

7927

Outer

hinge pin

9273

1/8 x 1/4

spacer

Build left and

right sides!

x2

7260

3/16

plain

nut

:: Radio Tray Build - Bag D

Steering

servo

9630

.030

washer

3981

Ballstud

.20 black

(short)

Foam dust

6272

cover

7368

3/16

axle

shims

7336

Servo

mounts

x2

9883

Wheel hex

adapters

(thick)

7336

Servo

mount

spacers

x2

6917

4-40 x 3/8

bhcs

x2

9180

Servo

horn

Screw supplied

with servo

7337

.250 x .125 x .015

washer

x2

Page 16

16

7337

.250 x .125 x .015

Washer

:: Radio Tray Build (cont.) - Bag D

7106

Radio

tray

(SC10GT)

:: Radio Tray Build (cont.) - Bag D

6917

4-40 x 3/8

bhcs

x2

Throttle

servo

6924

4-40 x 3/8

shcs

.250 x .125 x .015

x4

Washer

7337

Receiver

x4

7896

Radio

box,

lower

9146

2-56 x 3/16

bhcs

x2

:: Radio Tray Build (cont.) - Bag D

9146

2-56 x 3/16

bhcs

x2

On/Off

switch

plate

!

Route the two servos and the

receiver pack wires into receiver

box. To avoid pinching the wires,

route them around the standoffs

as shown.

6338

Antenna

tube and

cap

7896

Radio

box lid

29115

Switch

harness

tr-404a

Page 17

:: Radio Tray Build (cont.) - Bag D

.250 x .125 x .015

17

21173

Small

body

clip

x2

:: Radio Tray Build (cont.) - Bag D

You have the option of using the larger 1/8

scale fuel tank (#89324 not included) for

longer run times. This will require the use

of red o-rings (#5407) to mount the large

tank (see page 30 for details).

For the stock fuel tank, install the

#7106 radio tray insert as seen below.

6924

4-40 x 3/8

shcs

7337

.250 x .125 x .015

Washer

7108

Muffler

wire

(SC10GT)

!

!

7724

Fuel tank

mount

!

:: Radio Tray Build (cont.) - Bag D

grommet

7899

Fuel tank

x2

Cut two 5.6mm”

pieces of fuel tubing for

fuel tank grommets.

!

6288

4-40 x 1/4

bhcs

x2

7106

Radio

tray

!

insert

6918

4-40 x 1/2

bhcs

x2

Page 18

18

:: Radio Tray Build (cont.) - Bag D

6925

4-40 x 1/2

shcs

x2

:: Radio Tray Build (cont.) - Bag D

6922

4-40 x 1/2

fhcs

x7

Page 19

:: Radio Tray Build (cont.) - Bag D

6925

4-40 x 1/2

shcs

7891

Chassis

brace

x4

:: Throttle and Brake Linkage Build - Bag E

Large

Small

7911

Ball

cup

x2

!

Use

large

hole

Steering

servo link

7911

Servo

link rod

11.5mm

7975

Throttle

pivot

19

4449

4-40 x 3/16

locknut

4187

.030 nylon

washer

!

Note: There are two

hole sizes in this servo

horn. Make sure you

use the correct set

when building.

:: Throttle and Brake Linkage Build (cont.) - Bag E

25225

M3x3

7975

Set

collar

7975

Throttle

spring

Throttle

setscrew

7975

Set

collar

7975

rod

2337

Throttle

servo horn

6918

4-40 x 1/2

bhcs

25225

M3x3

setscrew

7975

2-56

ballcup

Page 20

20

:: Throttle and Brake Linkage Build (cont.) - Bag E

8427

.018

7975

wire

spring

7975

Set

collar

7975

Throttle

pivot

!

Use

small

hole

25225

M3x3

setscrew

Brake

linkage

:: Throttle and Brake Linkage Build (cont.) - Bag E

7975

Brake

adjustment

knob

7562

Throttle

return

spring

:: Throttle and Brake Linkage Build (cont.) - Bag E

Screw

4-40 x 3/8

included

with servo

7562

Throttle

return

spring

mount

7975

Set

collar

6924

shcs

25225

M3x3

setscrew

!

Install throttlr

return spring to

throttle return

spring mount.

Page 21

:: Engine Build - Bag F

7975

2-56

plain

nut

21

Nitro

Engine

#1596

thread lock

7618

Flywheel

shim

:: Engine Build (cont.) - Bag F

7993

Flywheel

2-shoe

p/s

7975

2-56

ballstud

7618

Collet

2313

SG

clutch

nut

:: Engine Build (cont.) - Bag F

7971

0.9mm

Clutch

spring

x2

2310

Clutch

shoe

!

Assembled

example

x2

Page 22

22

:: Engine Build (cont.) - Bag F

2321

Clutch

shim

!

The amount of shims

may vary depending

on engine type.

Min. shims - 2

Max shims - 4

Shim until clutch spins

freely with minimal play.

7968

20T

clutch

bell

2320

5x9x3

flanged

bearing

:: Engine Build (cont.) - Bag F

2320

5x10x4

bearing

4-40 x 1/2

7778

3x30mm

manifold

shcs

Manifold

washer

6925

shcs

7778

x2

x2

x2

2321

3mm

bhcs

2321

4.8mm

clutch

shim

x2

#1596

thread lock

7734

Side

exhaust

manifold

gasket

Build left and

right sides!

:: Engine Build (cont.) - Bag F

7731

Tuned

muffler

7733

Exhaust

coupler

2340

Engine

mounts,

pullstart

x2

3719

6”

Nylon

wire ties

7735

Side exhaust

manifold

x2

Attach nylon wire ties to the

exhaust coupler. Attach nylon

wire tie from the pull start to

the exhaust coupler wire tie.

!

Page 23

:: Engine Build (cont.) - Bag F

!

Oil the foam pre-

filter element using

#7710 Prefilter

Treatment.

:: Engine Build (cont.) - Bag F

23

!

Attach the air filter

to the carburetor

with a nylon wire tie.

7705

Air

filter

3719

6”

Nylon

wire ties

#1596

thread lock

7773

6-32 x 3/8

bhcs

!

NOTE: Make sure to set

gear mesh (see page 24)

before tightening engine

mount screws #7773.

x4

Page 24

24

:: Engine Build (cont.) - Bag F

To correctly set the gear mesh,

follow the steps below:

Loosen engine mount screws

1.

so you can slide your engine and

mount.

Slide engine and mount until the

2.

clutchbell gear comes in contact

with the spur gear. Tighten

engine mount screws. Hold the

spur gear in place and rock the

clutchbell gear. There should be

little “free-play” between the two

gears.

Repeat Step 2 if necessary.

It is important that you have a

little gap between the two gears

without pushing them completely

together.

:: Engine Build (cont.) - Bag F

#1596

thread lock

7732

4mm

setscrew

Attach the included fuel tubing as follows:

· Top of tank lid to exhaust pipe.

· Back of tank lid to carburetor.

!

!

Snap into place.

:: Engine Build (cont.) - Bag F

To properly set your linkage, follow these steps:

Turn on your transmitter,

turn on your vehicle (DO

NOT START THE ENGINE).

Set your throttle trim (or

adjust servo horn) until it

is 90˚ with the servo.

Set throttle linkage, spring side

first, to 15mm. The throttle

should be completely closed on

the carburetor. Next, set the

throttle linklage collar gap to

0.5mm.

Fuel tubing length

= 170mm

Set brake linkage, thumbscrew

3.2.1.

side first. Turn thumbscrew

until brake cam barely touches

the brake pads and brake disc.

Next, set the brake linkage

collar gap to 0.5mm.

Pressure line length

= 78mm

Racer’s Tip:

If you need more linkage

travel, move the linkage to

hole #3 (from #2) on the

servo horn.

Throttle

link

3

2

1

Set max throttle EPA. Hold full throttle on transmitter and check carburetor.

4.

Adjust EPA so that carburetor is completely open at full throttle.

5.

Set max brake EPA. It is easiest to do this while driving the SC10GT. Start at 50% and adjust accordingly.

Lower % = less brake. Higher % = more brake.

15mm

0.5mm 0.5mm

1

2

3

Brake

link

Page 25

:: Shocks Build - Bag G

25

6469

Shock

cap

o-ring

7484

Shock

internal

spacer

Front

Shock

9884

V2 RTR

front shock

body 1.02”

stroke

(blue)

5407

Red

o-ring

7484

Lower shock

seal cap

:: Shocks Build (cont.) - Bag G

6465

Shock

piston

#3

6469

Shock

cap

o-ring

7484

Shock

internal

spacer

Rear

Shock

6299

E-clip

9885

V2 RTR

front shock

body 1.39”

stroke

(blue)

5407

Red

o-ring

7484

Lower shock

seal cap

Remove

spurs

Piston

Piston number here

Use #3 = front shocks

Use #1 = rear shocks

6465

Shock

piston

#1

6459

Shock

shaft

1.02”

stroke

6299

E-clip

Front

Shock

:: Shocks Build (cont.) - Bag G

7217

Eyelet

6466

Downstop

1/32”

x5

7217

Pivot

Front

Shock

ball

6299

E-clip

Rear

Shock

Downstop

Rear

Shock

6458

Shock

shaft

1.32”

stroke

6466

1/32”

x2

6299

E-clip

7217

Eyelet

7217

Pivot

ball

Page 26

26

I

:: Shocks Build (cont.) - Bag G

Shock fluid

30wt #5422

:: Shocks Build (cont.) - Bag G

Shock fluid

30wt #5422

6441

Shock

cap

(molded)

* Shock Bleeding Steps:

1. Pull shock shaf t down.

2. Fill shock body 3/4 full with silicone fluid.

3. Slowly move the shock shaf t up and

down to remove air from under piston.

4. Wait for bubbles to come to surface.

5. Fill shock body to top with silicone fluid.

6. Place several drops of oil in the cap and

on cap threads.

7. Install cap and tighten completely.

8. Slowly compress shaf t all the way to

the top. If there is pressure at the top

of the stroke, there is too much oil or air.

You must bleed it out.

9. Slowly pull shaft down.

10. Unscrew the cap 3/4 turn and tilt the

shock at a slight angle.

11. Slowly compress the shaft to push out

excess oil and air. You should see

bubbles coming out from under the cap.

12. With the shaft compressed, tighten the

cap and re-check for pressure at the top

Step 7Step 5-6Step 3-4Step 1-3

of the stroke. If there is still pressure,

repeat steps 9 thru11.

6475

Spring

collar

8846

7425

Front

spring

Preload

spacers

x1

(gold)

3.70lb

Front

Shock

.12

:: Shocks Build (cont.) - Bag G

6473

Shock

bushings

Front

Shock

x1

.03

4-40 x 1/2

6925

shcs

6475

Spring

collar

6480

Rear

6475

Spring

cup

spring

(green)

1.90lb

Rear

Shock

6472

Shock

mounting

nut

Build left and

right sides!

8846

Preload

spacers

x1 x1 x1

.25 .25

.06

3

O

6475

Spring

cup

2

1

I

Page 27

:: Shocks Build (cont.) - Bag G

91101

KMC Hex

Wheel

(black)

89413

tire insert

JConcepts

!

KMC Hex

Wheel

(black)

89413

tire insert

6473

Shock

bushings

6472

Shock

mounting

nut

3

2

O

27

1

I

Rear

Shock

:: Wheel and Tire Assembly

91101

KMC Hex

Wheel

(black)

6925

4-40 x 1/2

shcs

1/8th molded

tire insert

89413

Build left and

right sides!

KMC Hex

(black)

91101

Wheel

89413

1/8th molded

tire insert

!

Note: Clean the rims and tire bead

where the two will mount to each other

before you glue them together. You

can clean them with either rubbing

alchohol, or r/c electric motor spray.

Place the foam insert inside the tire.

Install the tire on the rim, and push the

tire beads inside the groves on the rim.

Use Tire glue #1597 to glue the tire

to the wheel. Glue one side at a time,

allowing enough time for the glue to dry

before continuing to the other side.

Tip: You can use a rubber band to hold

the tire tight against the wheel while

the glue is drying.

!

Build 2 Front!

!

Tire glue is

not included!

JConcepts subculture

tire, green compound

9809

SC10 Tire

w/foam

insert

JConcepts

#3042

(use on rear)

!

Build 2 Rear!

The rear tires included in this

RTR are made by JConcepts.

JConcepts tires can be

purchased at their website:

http://www.jconcepts.net

Page 28

28

:: Wheel and Tire Assembly (cont.)

:: Body Install

6332

Body clip

x4

6953

8-32

low profile

steel locknut

x2

6952

8-32

steel

locknut

x2

Page 29

29

:: Tuning Tips

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing. Changes

to your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testing

it before making another change. If the result of your adjustment is a faster lap, mark the change on the included setup

sheet (make adddtional copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back to

the previous setup and try another change.

When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this as a guide for future

track days or conditions.

Recommended Gearing:

To calculate your SC10GT Final Drive Ration (a.k.a. gear ratio), use the following formula:

(spur gear # teeth) / (clutch bell # teeth) x 4.09 = Final Drive Ratio

For higher top speeds, use either a larger tooth clutch bell or a smaller tooth spur gear.

For more torque and acceleration use a smaller tooth clutch bell or larger tooth spur gear.

SC10GT gear chart

Spur Gear

54

19

11.62

11. 0 4

20

10.51

21

Clutch Bell

55 56

11. 8 4

11.25

10.71

12.05

11.45

10.91

Slipper Clutch:

The instructions provide a base setting for the slipper clutch, but depending on the surface you are running on, it may be

adjusted for better performance. The intent of the slipper clutch is to absorb shocks to the drivetrain and to improve

power delivery to the wheels. If the car is doing wheelies too easily on a high grip surface, try loosening the slipper.

In cases of excessive wheel spin on a low grip surface, try loosening the slipper for smoother acceleration. The slipper

settings will vary depending on tire grip and driving surface. Adjust the slipper in 1/8 turn increments when tuning.

Clutch Springs:

The clutch spring stiffness determines at what RPM the engine begins to engage the clutch bell. The kit comes with a

0.9mm clutch spring (#7971), this provides the smoothest power delivery. For more aggressive power delivery, try the

1.0mm clutch spring (#2306) and for most aggressive engagement try the 1.1mm clutch spring (#2307).

Caster:

The kit/ RTR comes with 30 degree caster blocks (#7922). For less aggressive steering try the optional 25 degree

caster blocks (#7919).

Front Camber Links and Vertical Adjustment:

Changing the length of the camber link is considered a bigger change than adjusting the ballstud height on the shock

tower. Shortening the camber link (or lowering the ball end) will give the front end less roll and quicken steering

response, especially on corner entry. Lengthening the camber link (or raising the ball end) will give the front more roll and

slower steering response, but can produce more corner exit steering. Longer camber links are typically used on high

grip tracks and shorter links tend to work better on medium grip and loose tracks.

Rear Camber Links and Vertical Adjustment:

Changing the length of the camber link is considered a bigger step than adjusting the ball end height on the shock tower.

The rear camber link length is adjusted on the hub and the inboard height is adjusted on the rear camber link mount.

The rear camber link mount can be shimmed up or down, and you can change the vertical hole location. From the kit

setting, lowering the inner pivot will slide more predictably and give you more entry steering, but not have as much

cornering grip.

Front Toe-In:

Zero degrees toe-in (tires pointing straight forward) is the setting that should be used in almost all track conditions.

Occasionally, adding a little bit of toe-out (tires pointing slightly out) can increase initial turn in response. A slight amount

of toe-in will increase front end stability a little, and results in less aggressive steering but this option is rarely used.

Front Camber:

Camber is the angle of the wheel when looked at from the front. The angle is measured from a line perpendicular to the

ground to the face of the wheel. Camber is used to ensure a wider tire contact patch while cornering. A good starting

point for the front is -1°. Performance will begin to decrease after -3°. Positive camber, where the top of the tire is

leaning out, is not recommended in the front. To set your camber use the included #1719 camber gauge.

Page 30

30

5407

5407

89324

6918

6918

:: Tuning Tips (cont.)

Rear Camber:

A good starting point for the rear camber setting is -1°. In loose track conditions, going to 0° camber can improve

straight-line acceleration.

Rear Hub Spacing:

There are three options for rear hub spacing, FORWARD, MIDDLE, & BACK. The kit setting provides the best possible

rear traction. The FORWARD position will provide more rear traction for low grip tracks. The BACK position will provide

more steering on high grip tracks.

Ride Height:

Ride height is the distance from the ground to the bottom of the chassis. The standard front ride height setting is with

the front arms level (referred to as “arms level”). The standard rear ride height setting is when the outdrive, driveshaft,

and axles all are on the same imaginary horizontal line (referred to as “bones level”). Check the ride height by lifting the

car about 8-12 inches off a table and drop it level. After the suspension “settles” into place, add or remove pre-load clips

on the shock bodies so that the left and right arms appear to be parallel. For precise ride height measurements, use

the Factory Team ride height gauge #1449.

Anti-Squat:

Anti-squat denotes the angle of the rear arms relative to the ground. The kit setting is 2 degrees, and can be adjust to

1 degree by removing the included shim above the rear arm mount and replacing it below the rear arm mount.

Changing to less anti-squat tends to make the truck produce more rear traction and less steering in the corners.

Optional Large Fuel Tank:

The SC10GT has a unique radio tray that allows you to install a

larger fuel tank (# 89324) for longer run times. Simply removing

the radio tray insert, and install the optional fuel tank (not included)

over the molded posts on the radio tray with red O-rings (#5407)

for vibration dampening.

89324

6918

6918

5407

5407

Shock Piston and Fluid:

The SC10 GT shocks are built with our 2 hole, #1 pistons in the front shocks, and #3 pistons in the rear shocks.

All pistons have a number molded on it.

As a rule of thumb, larger hole pistons decrease damping which can help the truck in bumpy and low-grip situations.

On smoother tracks, or for large jumps, you may want use a smaller hole piston which will increase damping and take

away some grip. [#1 large hole, #2 medium hole, #3 small hole]

Typically, your SC10 GT shocks will work best with shock fluid rates between 25 and 35 wt (275 - 425 CST).

Use the thicker fluids in the range when changing to larger hole pistons, and also use the thinner weight fluids when

changing to a smaller hole pistons.

Setup Sheets:

Most often, the best way to get your car handling right is to go to our website www.rc10.com and click on the links to

Setup Sheets, then SC10 GT setups. Our team of professional drivers help develop these setups at National events.

Also, most drivers have a “base” setup that they use as a starting point for every event. Try running some of our base

setups OR look for track conditions and tires that are similar to your local track and mimic that setup.

Remember, each adjustment has a purpose, so copy everything from the setup sheet and then make adjustments

based on the recommendations in here and in our online tuning guide.

Page 31

31

:: Shocks

5407

6299

6441

6458

6459

6465

6466

6469

6473

6475

6925

7217

7484

8846

9884

9885

9884 (F)

9885 (R)

Red O-Rings

1/8” E-Clips

Shock Cap, Molded

Shock Shaft, 1.32“ stroke

Shock Shaft, 1.02” stroke

Shock Pistons, 4 each

Shock Down Stops, Set

Black Shock Cap O-Ring

Shock Bushings

Preload Spacers, Collars & Cups

4 thicknesses, 4 sets each

4-40 x 1/2“ SHCS

Shock Rod Ends / Plastic Pivot Balls

V2 1/10 Shocks Rebuild Kit

Preload Spacers, 4 each

V2 RTR Front Shock Bodies 1.02“

V2 RTR Rear Shock Bodies 1.39”

6441

6469

(RTR)

:: Springs

1580

1582

6478

6480

6481

6482

7425

7426

7427

7428

7429

7430

7434

7435

7436

FT Truck Front Spring Kit. I pair of green,

silver, blue, gold, and red front springs

FT Truck Front Spring Kit. I pair of green,

silver, blue, gold, and red rear springs

Rear Spring Silver 2.10 lb

Rear Spring Green 1.90 lb (Kit)

Rear Spring Black 1.74 lb

Rear Spring Gray 2.33 lb

Front Spring Gold 3.70 lb (Kit)

Front Spring Black 2.765 lb

Front Spring Green 2.99 lb

Front Spring Silver 3.225 lb

Front Spring Blue 3.45 lb

Front Spring Red 3.90 lb

Rear Spring Blue 2.55 lb

Rear Spring Gold 2.75 lb

Rear Spring Red 2.95 lb

:: Shock Fluid

5420

5421

5422

5423

5424

5425

5426

5427

5428

5429

5430

5431

5432

5433

5434

5435

5436

5437

5438

10 Weight Silicone Shock Fluid

20 Weight Silicone Shock Fluid

30 Weight Silicone Shock Fluid

40 Weight Silicone Shock Fluid

22.5 Weight Silicone Shock Fluid

80 Weight Silicone Shock Fluid

27.5 Weight Silicone Shock Fluid

15 Weight Silicone Shock Fluid

25 Weight Silicone Shock Fluid

35 Weight Silicone Shock Fluid

45 Weight Silicone Shock Fluid

55 Weight Silicone Shock Fluid

32.5 Weight Silicone Shock Fluid

37.5 Weight Silicone Shock Fluid

42.5 Weight Silicone Shock Fluid

50 Weight Silicone Shock Fluid

60 Weight Silicone Shock Fluid

70 Weight Silicone Shock Fluid

47.5 Weight Silicone Shock Fluid

5407

7484

5407

7484

8846

6475

8

12

4

1

1

1

1

4

4

1

6

2

1

1

Pr.

Pr.

6459 (F)

6458 (R)

6475

7217

6925

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

6299

6465

6299

6466

1

1

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

:: Ball Differential

6573

6574

6575

6581

6582

6589

7664

7666

7667

7668

7677

7678

6575

Diff Thrust Washer & Bolt

Precision Diff Thrust Balls, 5/64”

Locking T-Nut, Diff Thrust Bolt, & Cover

3/32” Carbide Diff Balls

Diff Thrust Spring

Ball Bearing, 5/32 x 5/16” unflanged

Diff Gear 52T

Diff Drive Rings, 2.60:1

Diff Outdrive Hub, Right, 2.60:1

Diff Outdrive Hub, Left, 2.60:1

Offroad Diff Rebuild Kit

Offroad Diff Kit

6574

7667

6589

6573

7666

7664

7666

6581

6582

:: Lubes & Adhesives / Decals / Misc.

1105

1596

1597

5450

5451

5452

5453

5454

5455

5456

5457

5458

5459

6588

6591

6636

6727

7710

716

717

3816

3820

3834

7109

FT Green Slime Shock Lube

FT Locking Adhesive

FT Tire Adhesive, medium

Silicone Diff Fluid 1000cst

Silicone Diff Fluid 2000cst

Silicone Diff Fluid 3000cst

Silicone Diff Fluid 5000cst

Silicone Diff Fluid 7000cst

Silicone Diff Fluid 10000cst

Silicone Diff Fluid 20000cst

Silicone Diff Fluid 30000cst

Silicone Diff Fluid 60000cst

Silicone Diff Fluid 100000cst

Black Grease - 4cc

S.Diff Lube - 4cc

Silicone Grease - 4cc

Servo Tape

FT Filter Treatment

Reedy 2009 Sticker Set

Reedy Powered Logo Decal

American Bumper Sticker

AE Logo Decal Sheet

AE Blue Embossed Logo Sticker

SC10GT Decal Sheet

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

2

6

1

12

1

2

1

2

1

1

1

1

7668

6575

Page 32

32

:: Steering

2234

3981

6272

6276

6277

6629

6917

6922

7336

7337

7908

9180

Swing Rack Bushing

Ballstud .20” Black, short

Foam Ballend Dust Covers

Ballstud .20” Silver, short

Ballstud .30” Silver, short

5-40 Locknuts

4-40 x 3/8 BHCS

4-40 x 1/2 FHCS

Steering Servo Mount Kit

.250 x .125 x .015 Washer

Servo Saver & Steering Kit

Servo Horns, Set

3981

9180

6272

28

6917

7336

1

6

2234

7908

6

6

6

6

6

1

4

1

1

6276

6272

7908

6629

7908

7908

6272

6277

7908

7908

7908

6272

6276

6276

7908

2234

7908

7908

6917

7336

7337

:: Front Bumper, Front Shock Tower

3897

6272

6277

6292

6295

6332

6472

6473

6915

6924

6925

7103

7738

9630

9816

9820

9825

Pivoting Body Mounts

Foam Ballend Dust Covers

Ballstud .30” Silver, short

4-40 x 3/8 FHCS

4-40 Nuts

Body Clips

Shock Mount Nuts

Shock Bushings

4-40 x 5/8 FHCS

4-40 x 3/8 SHCS

4-40 x 1/2 SHCS

SC10 GT Body Posts, Set

4-40 x 7/8 SHCS

Ballstud Washer

SC10 Front Skid, Bumper

SC10 Body Mounts

Front Shock Tower

4

28

6

6

6ea.

6

4

4

6

6

6

1

6

10

1

1

1

6292

6922

7103

7738

6272

6277

9630

6332

6924

3897

7738

6922

6924

2234

6295

9825

9820

6473

6472

6473

6295

9816

6925

9816

6915

6924

6272

6277

9630

6924

Page 33

:: Front Bulkhead

4334

6915

6922

6925

7892

7893

9563

9564

2-56 x 5/16 BHCS

4-40 x 5/8 FHCS

4-40 x 1/2 FHCS

4-40 x 1/2 SHCS

Front Sub Chassis

Top Plate

Front Bulkhead

Front Chassis Brace

8

6

6

6

1

1

1

1

4334

33

6925

6925

6925

7893

9564

9563

6915

6915

:: Front Suspension

3977

3983

4187

4449

6272

6277

6953

7260

7368

7369

7917

7922

7927

9621

9645

9880

9881

9882

9883

3/16 x 3/8 RS Ball Bearing

Ballstud .30” Black, short

.030” Nylon Washers

4-40 x 3/16 Aluminum Locknut

Foam Ballend Dust Covers

Ballstud .30” Silver, short

8-32 Low Profile Steel Locknut

4-40 Small Plain Nut

3/16” Axle Shim

1/16” Universal Roll Pins

Front Suspension Arm

30D Caster Blocks L&R

Outer Hinge Pins, Set

Front / Rear Inner Hinge Pins

2-56 x 1/8 BHCS

SC10 Steering Blocks, Hex

SC10 Front Axle & C-Clips, Hex

C-Clips, 3/16”

SC10 Wheel Hex Adapters, Set

12

28

12

14

Pr.

Pr.

Pr.

7892

6922

6922

2

6

5

6

6

4

6272

3983

7260

6922

6272

1

1

6

2

6

1

9621

7922

7927

9645

9881

3977

9880

9882

4449

7368

6277

3977

9883

(thin)

4187

7369

6953

7917

9645

7927

Page 34

34

:: Chassis / Radio Tray

6288

6292

6338

6915

6918

6922

6923

6924

6925

7106

7107

7108

7337

7562

7724

7891

7896

7899

7928

9146

21173

4-40 x 1/4 BHCS

4-40 x 3/8 FHCS

Antenna Tube, 12” black

4-40 x 5/8 FHCS

4-40 x 1/2 BHCS

4-40 x 1/2 FHCS

4-40 x 3/4 FHCS

4-40 x 3/8 SHCS

4-40 x 1/2 SHCS

SC10GT Radio Tray

SC10GT Chassis

SC10GT Muffler Wire

.250 x .125 x .015 Washer

Throttle Return Spring

Fuel Line 15”

Chassis Brace

Receiver Box

Fuel Tank

Rear Arm Mounts

2-56 x 3/16 BHCS

Small Body Clips

6

6

1

6

6

6

6

6

6

1

1

1

4

1

1

1

1

1

1

6

12

6338

21173

7896

7896

9146

21173

6924

7562

6924

6924

7337

7106

6924

7337

6925

6925

7891

6288

7928

6292

:: Turnbuckles

7101

7217

7230

7253

7911

7937

Turnbuckle 2.80”

Shock Rod Ends with Plastic Pivot Balls

Ball Cups, Large

Turnbuckle 2.62”

Steering Servo Link

Turnbuckle 3.00”

7106

7928

6915

6288

6923

6918

7724

7899

2

2

12

2

1

2

6925

7108

7107

6922

Front Camber

Turnbuckle

72307230

7253

7911

Steering

servo link

7911

7911

Steering Camber

Turnbuckle

7230

7101

Rear Camber

Turnbuckle

7217 7217

7937

7230

72177217

Page 35

:: Slipper

6629

7485

7486

7953

7955

7956

7957

9603

5-40 Locknuts

FT V2 Slipper Hubs

FT V2 Slipper Spring and Washer

Slipper Hub Inboard

54T Spur Gear - Kit

55T Spur Gear

56T Spur Gear

Slipper Pads

:: Gearbox

3976

3977

6915

6924

7874

7945

7960

7961

7963

7964

7965

3/8 x 5/8 RS Ball Bearing

3/16 x 3/8 RS Ball Bearing

4-40 x 5/8 FHCS

4-40 x 3/8 SHCS

4-40 x 7/16 SHCS

Transmission Case

Top Shaft

Top Shaft Spacer

Idler Gear (44T-28T)

Idler Gear Shaft

Transmission (Complete) Set

35

6

2

1

1

1

1

1

2

7955

9603

9603

7485

7486

6629

2

2

6

6

8

1

1

1

1

1

1

7953

6915

3977

7945

7961

3976

7964

3977

7960

3977

7963

3977

3976

7945

6924

7874

6915

6924

Page 36

36

:: Throttle / Brake Linkage

2337

4187

4449

6918

7562

7975

8427

25225

Throttle Servo Horn, Set

.030” Nylon Washers

4-40 x 3/16 Aluminum Locknut

4-40 x 1/2 BHCS

Throttle Return Spring

Linkage Kit

.018 Springs

3x3mm Setscrew

12

20

1

5

6

1

1

2

25225

7562

8427

7975

7975

7975

:: Brakes

7633

7947

7948

7949

7950

4-40 x 5/8 BHCS

Brake Tophat Bushing

Brake Cam

Brake Pad

Brake Disk

7975

7975

6

2

1

2

1

25225

4187

7633

7633

2337

4449

6918

7975

7949

7947

7975

7947

7950

25225

7975

7975

25225

7975

7948

7949

:: Exhaust

3719

7731

7732

7733

7734

7735

6 Inch Nylon Wire Ties

RPM Muffler

4x4mm Set Screw

Exhaust Tubing Coupler

Manifold Gasket Side Exhaust

Manifold, Side Exhaust

12

1

6

1

3

1

3719

7731

7732

7733

7734

7735

Page 37

:: Engine / Clutch / Air Filter

2310

2313

2320

2321

2340

2918

6925

7618

7705

7773

7778

7967

7968

7969

7970

7971

7975

7976

7978

7993

Clutch Shoes

SG Crank Clutch Nut

Clutch Bearings, Set

Clutch Shim & Screws, Set

Pull Start Engine Mount

AE .18 Engine SG Crank

4-40 x 1/2 SHCS

Flywheel Collet & Shim

Air Filter Kit

6-32 x 3/8 BHCS

3x30mm Manifold SHCS &

Lock Washers

Clutch Bell 21T

Clutch Bell 20T - Kit

Clutch Bell 19T

Clutch Springs, 0.8mm

Clutch Springs, 0.9mm - Kit

Linkage Kit

10mm Clutch Nut Wrench

Flywheel Non -Pull Start 2-shoe

Flywheel Pull Start 2-shoe - Kit

37

2

1

1

1

2

1

6

1

1

6

2

1

1

1

2

2

1

1

1

1

2918

2340

6925

7778

7705

7975

7618

7993

2321

7971

7968

:: Rear Shock Tower

3897

4449

6332

6472

6473

6917

6925

6926

6927

7102

7103

7260

7413

7904

7941

9273

Pivoting Body Mounts

4-40 x 3/16 Locknut

Body Clips

Shock Mount Nuts

Shock Bushings

4-40 x 3/8 BHCS

4-40 x 1/2 SHCS

4-40 x 5/8 SHCS

4-40 x 3/4 SHCS

SC10GT Rear Shock Tower

SC10GT Body Posts, Set

4-40 Small Plain Nut

4-40 x 3/4 BHCS

Battery Box

Rear Camber Link Mount

Dogbone Spacer, with Spring

4

5

6

4

4

6

6

6

6

1

1

12

6

1

1

2

6332

7773

3897

7103

7260

7413

7773

6925

6926

6472

6473

6917

2313

6926

6473

7102

2310

7260

7413

2321

2320

2320

6472

6925

6925

6926

4449

9273

4449

9273

7941

6927

7260

7904

7904

Page 38

38

:: Rear Suspension

3977

5407

6926

6952

7260

7368

7369

7462

7927

7930

7932

7933

7935

9273

9621

9630

9645

9670

9883

:: Rear Bumper

6917

6925

7104

7105

89218

89430

3/16 x 3/8 RS Ball Bearing

Red O-Rings

4-40 x 5/8 SHCS

8-32 Locknut, Steel

4-40 Small Plain Nut

3/16 Axle Shim

1/16” Universal Roll Pins

T4/GT2 Dogbone

Outer Hinge Pins, Set

Rear Suspension Arms, L&R

1.5 Degree Rear Hubs L&R

Crush Tube

.187 x .50 x .196 Bearing

Dogbone Spacer, with Spring

Front & Rear Inner Hinge Pin Set

Ballstud Washer

2-56 x 1/8 BHCS

3/16 Rear Axle

SC10 Wheel Hex Adapters Set

4-40 x 3/8 BHCS

4-40 x 1/2 SHCS

SC10GT Rear Bumper

SC10GT Rear Bumper Mount Set

3x8mm Washer

Mud Flaps

12

14

Pr.

Pr.

10

10

Pr.

2

8

6

6

4

1

1

2

2

2

1

6

2

1

7462

7930

5407

5407

9621

9670

7260

3977

7932

9645

7927

9630

6926

7933

7368

7935

7369

9883

(thick)

6952

9273

6

6

1

1

89430

6925

6925

6925

89218

6925

:: Wheels, Tires, Inserts

9809

89413

91101

91102

91103

91104

91105

91106

SC10 Tires w/Foam Inserts

1/8 Molded Tire Inserts

KMC Hex Wheels, Black (Kit)

KMC Hex Wheels, Silver

KMC Hex Wheels, Chrome

KMC Hex Wheels/Tire Black

KMC Hex Wheels/Tire Silver

KMC Hex Wheels/Tire Chrome

7105

2

2

2

2

2

2

2

2

6917

7105

6925

7104

89218

89430

6917

6925

91101

89413

9809

Page 39

39

:: Factory Team and Option Parts

1408

1417

1419

1420

1654

1710

1734

1735

1736

1766

1777

1779

1780

1781

6416

6417

6937

6943

7416

7476

7477

7480

7481

7484

7485

7486

7495

7889

7989

7990

9665

9795

9796

9797

9798

9799

31286

31550

91170

91175

91176

91177

91178

91179

FT Titanium Turnbuckles, 2.65”

FT Titanium Turnbuckles, 2.8”

FT Titanium Turnbuckles, 3.0”

FT Titanium Turnbuckle Set

FT Solid Axle Pins

FT Aluminum Non Pull Start Engine Mounts, blue

FT Body Clips, 4 Long, 6 Short

FT Long Body Clips, Blue

FT Short Body Clips, Blue

FT Lightweight Outdrive Set

FT Aluminum Shock Pivot Ball with Eyelet

FT Aluminum Servo Mounts, blue

FT Aluminum Shock Bushing Standard, blue

FT Aluminum Shock Bushing Short, blue

FT Shock Shaft Gold 1.32”

FT Shock Shaft Gold 1.02”

4-40 Aluminum Locknuts, blue

FT Blue 8-32 Locknuts

Shock Collar Threaded

FT V2 1.02” Threaded Shocks, Complete Set

FT V2 1.02” Threaded Bodies, Set

FT V2 1.32” Threaded Shocks, Complete Set

FT V2 1.32” Threaded Bodies, Set

FT V2 1:10 Shock Rebuild Kit

FT V2 Slipper Hubs - Kit

FT V2 Slipper Spring and Washer

FT V2 Vented Slipper Hubs (fits front only)

Steering Bearing Set

Aluminum Chassis Brace, blue

Aluminum Front Bulkhead, blue

FT Hinge Pn Brace, blue

Ti Nitride Ballstuds 4-40x.20 - long

Ti Nitride Ballstuds 4-40x.30 - long

Ti Nitride Ballstuds 4-40x.40 - long

Ti Nitride Ballstuds 4-40x.20 - short

Ti Nitride Ballstuds 4-40x.20 - short

Aluminum Ballstud Washers, blue

M3 Aluminum Locknuts, blue

Hi -Torque Slipper Pad

VTS Slipper Conversion

VTS Slipper Housing

VTS Slipper Pads

VTS Slipper Plate

VTS Slipper Hub, Outer

:: AE Manifolds and Mufflers

1771

1772

1773

1774

7730

7731

7737

7743

7973

7974

7977

FT Torque-Tuned Side Exhaust Tuned Pipe, blue

FT Torque-Tuned Side Exhaust Tuned Pipe, natural

FT Torque-Tuned Side Exhaust Tuned Pipe, black

FT RPM-Tuned Side Exhaust Tuned Pipe, blue

Torque Muffler

RPM Muffler

GT Rear Exhaust Manifold

FT Torque-Tuned Side Exhaust Tuned Pipe, purple

Rear Exhaust Manifold, black

FT Smoothy Muffler, black

Rear Exhaust Manifold, blue

:: AE Nitro Engines and Accessories

MC59

2

2

2

1

4

Pr.

10

4

6

1

4

2

4

4

1

1

6

4

Pr.

1

1

1

1

1

Pr.

1

Pr.

1

1

1

1

2

2

2

2

2

2

6

2

1

1

2

1

1

1738

1748

1749

1750

2403

3718

3719

3720

7705

7706

7707

7708

7709

7710

7724

7725

7994

25076

29013

29016

29017

29021

29023

29025

29034

29050

29052

29053

29054

29056

29058

29092

29093

29094

29095

29096

29097

29098

:: Bodies and Decals

9836

9837

9838

9840

9842

9843

9844

9846

9847

9848

9849

9856

9857

9858

9859

9860

9861

9862

1

9863

1

9874

1

1

9875

1

9876

1

9886

1

9887

1

1

1

1

McCoy Glow Plug

FT Glow Starter

Nitro Fuel Bottle, 600cc

Nitro Fuel Bottle, 400cc

FT Starter Box

Air Filter Slide Carb

12 Inch Nylon Wire Ties

6 Inch Nylon Wire Ties

8 Inch Nylon Wire Ties

Air Filter Kit

Paper Filter Element

Foam Prefilter Element

Air Filter Boot

4 Inch Nylon Wire Ties

Pre Filter Treatment

Fuel Line 15”

Fuel Line 3’

D Size Glow Igniter

Fuel Primer Bulb

Carb Retaining Bolt

Ball Bearing 2 Pack

Engine Screw Set

.12/.15 /.18 Pull Start Handle Set

.12/.15 /.18 Pull Start Spring

.12/.15 /.18 Pull Start Wire

Backplate (converts to non pull start)

.12/.15/.18 Pull Start Oneway

.12/.15 /.18 Pull Start Starting Axle

.12/.15 /.18 Pull Start

.12/.15 /.18 Pull Start Backplate

.12/.15 /.18 Pull Start Wheel

.12/.15 /.18 Pull Start Set (no oneway included)

.18 Crankcase

.18 Wrist Pin Assembly

.18 Gasket Set

.18 Crankshaft

.18 Cylinder Head

.18 Connecting Rod

.18 Cylinder & Piston

SC10 Clear Body

SC10 ‘09 Clear Body

SC10 KMC Body, pre-painted & detailed

SC10 Bully Dog Body, pre-painted & detailed

SC10 AE Body, pre-painted & detailed

SC10 KMC Decal Sheet

SC10 Lucas Oil Decal Sheet

SC10 Pro Comp Decal Sheet

SC10 AE Decal Sheet

SC10 Ready Lift Body, pre-painted & detailed

SC10 Ready Lift Decal Sheet

SC10 ‘09 Lucas Oil Body, pre-painted & detailed

SC10 ’09 Lucas Oil Decal Sheet

SC10 ‘09 Pro Comp Body, pre-painted & detailed

SC10 ’09 Pro Comp Decal Sheet

SC10 ‘09 Speed Tech Body, pre-painted & detailed

SC10 ’09 Speed Tech Decal Sheet

SC10 ‘09 Rockstar/Makita Body,

pre-painted & detailed

SC10 ’09 Rockstar/Makita Decal Sheet

SC10 ‘09 Monster Energy Body,

pre-painted & detailed

SC10 ‘09 Monster Energy Decal Sheet

SC10 Contender Body, clear

SC10 09’ Slick Mist Body, pre-painted & detailed

SC10 Slick Mist Decal Sheet

1

1

1

1

1

1

12

12

12

1

1

1

1

12

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 40

40

:: XP Electronics

29107

29125

29126

29127

29150

29156

29166

29167

29209

29210

29211

29212

29221

29222

S1903 Metal Gear Set

S1903MG Servo

S2008MG Servo

S2008MG Gear Set

XP2/XP3 RX/TX Charger, 110V

XP3D FM Radio System 75mHz

XP DS1313 Digital Servo

XP DS1015 Digital Servo

Gear Set, DS1313

Gear Set, DS1015

Servo Case , DS1313/DS1015

Accessory Pack, DS1313/DS1015

XP3SS 2.4GHz Radio System

TRS401SS 2.4GHz 4Ch Receiver

:: Reedy Batteries and Chargers

302

303

604

610

612

630

632

633

634

635

636

637

638

AA Alkaline 1.5V (4)

AA 2700mAh NiMH 1.2V Rechargeable

526-S AC/DC 2S-6S LiPo/LiFe Charger

447-S AC/DC NiMH Peak Charger

1600 Series 6.0V Hump Receiver Pack

Pro RX Battery 1600mAh 7.4V 10C

TX Lightweight Battery 1350mAh 11.1V

TX Battery - 3PK, M11 3000mAh 11.1V

TX Battery - Helios, Z1 2400mAh 11.1V

Starter Box Battery 2200mAh 14.8V 20C

6.0V 5A Voltage Regulator

TX Battery - M11X 2500mAh 7.4V

LiFe 1700mAh RX Battery

:: RePlay Cameras

1

RP001

1

RP002

1

RP021

1

RP022

1

RP023

1

RP029

1

RP030

1

RP032

1

RP033

1

RP034

1

RP036

1

RP037

1

RP038

1

RP041

RP042

RP043

RP044

RP045

1

RP046

1

RP047

1

RP048

1

RP049

1

1

1

1

1

1

1

1

1

Replay XD1080 Complete Camera System

Replay XD720 Complete Camera System

Replay XD1080 Lens Bezel Kit

Replay XD1080 Clear Lens Cover

Replay XD1080 Lens Bezel & Rear Cap O-Ring

Replay XD1080 HDMI to Mini-HDMI

Replay XD1080 Mini 8-pin USB Charge Data Cable

USB DC Car Charger 1A Stubby

USB DC Car Charger 500mAh

Micro SDHC USB Reader

3M VHB 4991 Mount Adhesive for SnapTray

3M VHB 5962 Mount Adhesive for Pro Flat Mount

3M VHB 5962 Mount Adhesive for SnapTray

Replay XD Suction Cup Arm Mini Clamp

Replay XD Suction Cup Short Arm Base

Replay XD Skateboard Mount

Replay XD VHB SnapTray, Convex

Replay XD VHB SnapTray, Flat

Au Plug for Universal DC Wall Charger

Eu Plug for Universal DC Wall Charger

Uk Plug for Universal DC Wall Charger

Universal USB DC Wall Charger 1A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:: Reedy Accessories

716

28050

SP35M

SP35L

SP35XL

SP35XXL

SP35XXXL

SP36M

SP36L

SP36XL

SP36XXL

SP36XXXL

SP37S

SP37M

SP37L

SP37XL

SP37XXL

SP37XXL

SP38

SP39

SP417

SP418

Reedy 09 Decal Set

Reedy Turbo Glow Plug Caddy

Reedy Logo T-Shirt - White M

Reedy Logo T-Shirt - White L

Reedy Logo T-Shirt - White XL

Reedy Logo T-Shirt - White XXL

Reedy Logo T-Shirt - White XXXL

Reedy Logo T-Shirt - Black M

Reedy Logo T-Shirt - Black L

Reedy Logo T-Shirt - Black XL

Reedy Logo T-Shirt - Black XXL

Reedy Logo T-Shirt - Black XXXL

Reedy Retro T-shirt - Black S

Reedy Retro T-shirt - Black M

Reedy Retro T-shirt - Black L

Reedy Retro T-shirt - Black XL

Reedy Retro T-shirt - Black XXL

Reedy Retro T-shirt - Black XXL

Reedy Trucker Hat

Reedy Patch

Factory Team 1/10 Motor Storage Bag

Factory Team 1/10 Car Carrier Bag

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:: LRP Charger, Power Supply, Balancer, Iron

LRP41281

LRP41552

LRP41555

LRP42103

LRP42104

LRP42105

LRP42305

LRP43150

LRP45200

LRP65800

LRP65802

LRP65803

LRP65804

Quadra Pro 2 Charger

Pulsar Competition 3 Charger

Pulsar Touch Charger

LiPo Balance Board XH

LiPo Balance Board FP/TP

LiPo Balance Board PQ

Temp. Sensor for Pulsar Touch

Power Supply Competition

LiPo Parallel Balancer

High Power Solder Station

Soldering Tip 5mm

Soldering Tip 1.2mm

Soldering Handle

1

1

1

1

1

1

1

1

1

1

1

1

1

:: Apparel

SP35**

SP36**

SP62**

SP63**

SP64**

SP65**

SP66**

SP67**

SP69**

SP70**

SP71**

SP411S

SP411L

SP413S

SP413L

SP416

SP417

SP420**

715

110684

Reedy 09’ White T-Shirt (M, L, XL, 2XL, 3XL)

Reedy 09’ Black T-Shirt (M, L, XL, 2XL, 3XL)

AE Vertigo Long Sleeve T-Shirt (S, M, L, XL, 2XL)

AE Vertigo White T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Vertigo Blue T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Vertigo Black T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Stencil Blue T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Stencil Gray Sweatshirt (S, M, L, XL, 2XL, 3XL)

AE 26 Time World Championship T-Shirt, Black

(S, M, L, XL, 2XL, 3XL)

Associated Windbreaker (S, M, L, XL, 2XL, 3XL)

Associated Winter Jacket (S, M, L, XL, 2XL)

AE Hat 11’ Flatbill Black S/M

AE Hat 11’ Flatbill Black L/XL

26 Time World Championship Hat S/M

26 Time World Championship Hat L/XL

1/10 Car Carrier Bag Only

1/10 FT Motor Bag

AE Pit Gloves (M, L, XL)

Reedy 2009 Track Banner

Team Associated Track Banner

** Use part number plus the desired size when ordering!

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Pr.

1

1

Page 41

41

:: 1/18 Kits and RTR’s

20103

20104

20105

20106

20108

20110

20115

20118

20121

20130

RC18B2 - RC18T2 Team Kit

RC18T2 Brushless RTR (ready-to-run)

RC18B RTR (ready-to-run)

RC18B2 2.4ghz RTR (ready-to-run)

RC18B2 Brushless RTR (ready-to-run)

RC18MT RTR (ready-to-run)

RC18R Kamino RTR (ready-to-run)

RC18R Niteline RTR (ready-to-run)

SC18 Brushless RTR (ready-to-run)

RC18LM RTR (ready-to-run)

:: 1/12, 1/10 Kits and RTR’s

2042

4019

7023

7029

7030

7032

7034

7037

7046

7047

7048

7049

7080

7092

7093

8020

8021

9039

9040

9061

30107

30111

90004

90005

90006

90007

90010

Nitro TC3 RTR Plus (ready-to-run)

FT 12R5.1 Kit

RC10T4.1 FT Kit

SC10 Associated/RC10.com Truck RTR (ready-to-run)

SC10 KMC Wheels Race Truck RTR (ready-to-run)

SC10 Ready Lift RTR (ready-to-run)

SC10 FT Kit

RC10T4.1 RTR 2.4GHz Brushless (ready-to-run)

SC10 RS RTR, 2.4ghz Brushless Lucas Oil Body

SC10 RS RTR, 2.4ghz Brushless Monster Energy Body

SC10 RS RTR, 2.4ghz Brushless Pro Comp Body

SC10 RS RTR, 2.4ghz Brushless Rockstar/Makita Body

FT GT2 Nitro Truck Kit

GT2 RS Truck Nitro RTR (ready-to-run)

SC10 GT Nitro RTR (ready-to-run)

FT RC10R5 Kit

FT RC10R5-OVAL Kit

RC10B4.1 RTR 2.4GHz Brushless (ready-to-run)

RC10B4.1 Worlds Kit

FT B44.1 4WD Buggy Kit

FT TC6.1 4WD Touring Car Kit

TC4 4WD Touring Car RTR (ready-to-run)

SC10 4x4 Kit

SC10 4x4 Lucas Oil RTR (ready-to-run)

SC10 4x4 Pro Comp RTR (ready-to-run)

SC10 4x4 Rockstar/Makita RTR (ready-to-run)

SC10 4x4 FT Kit

:: 1/8 Kits and RTR’s

20503

20504

80904

80905

80906

80907

80912

80922

80923

80924

80925

80932

Limited Edition MGT 4.60 Nitro RTR, w/flag body

(ready-to-run)

Limited Edition MGT 8.0 Nitro RTR, w/flag body

(ready-to-run)

FT RC8Be Electric Buggy Kit

RC8RS “Race Spec” Nitro Buggy RTR (ready-to-run)

RC8.2 FT Nitro Buggy Kit

RC8.2e FT Electric Buggy Kit

RC8T Championship Edition

SC8 Short Course Race Truck, KMC Wheels Nitro RTR

(ready-to-run)

SC8 Short Course Race Truck, Bully Dog Nitro RTR

(ready-to-run)

SC8 Short Course Race Truck, AE Team Nitro RTR

(ready-to-run)

SC8 Short Course Race Truck, Pro Comp Nitro RTR

(ready-to-run)

SC8e Short Course Race Truck Rockstar/Makita RTR

(ready-to-run)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:: Tools

1111

1112

1449

1450

1541

1542

1543

1544

1545

1546

1547

1548

1551

1553

1554

1561

1562

1563

1564

1565

1567

1589

1590

1592

1655

1656

1657

1658

1659

1660

1661

1662

1663

1664

1665

1666

1667

1668

1669

1670

1671

1672

1673

1674

1719

1737

3718

3719

3720

3987

6429

6956

7494

7709

7976

91107

electric kits, current products, new releases, setup

FT Turnbuckle Wrench

FT 4mm Turnbuckle Wrench (4x4 only)

Offroad Ride Height Gauge

FT Ride Height Gauge

FT Hex Driver Set, (7 pcs)

FT .050” Silver Hex Driver

FT 1/16” Black Hex Driver

FT 1.5mm Purple Hex Driver

FT 5/64” Blue Hex Driver

FT 3/32” Gold Hex Driver

FT 2.5mm Green Hex Driver

FT 3mm Red Hex Driver

FT Screwdriver Set

FT Phillips Silver Screwdriver

FT Silver Spring Hook Tool

FT Nut Driver Set, (6 pcs)

FT 3/16” Black Nut Driver

FT 1/4” Red Nut Driver

FT 5.5mm Red Nut Driver

FT 11/32” Green Nut Driver

FT 8mm Gold Nut Driver

FT 5/64” Blue Ball Hex Driver

FT 3/32” Gold Ball Hex Driver

FT Ball Hex Driver Set, (3 pcs)

FT 8-Piece 1/4” Hex Drive Set

FT 1/4” Hex Drive Handle, without tips

FT 1/4” Hex Drive .050” Tip

FT 1/4” Hex Drive 1/16” Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Tip

FT 1/4” Hex Drive 3/32” Tip

FT 1/4” Hex Drive 1.5mm Tip

FT 1/4” Hex Drive 2.5mm Tip

FT 1/4” Hex Drive 3/16” Nut Driver Tip

FT 1/4” Hex Drive 1/4” Nut Driver Tip

FT 1/4” Hex Drive 11/32” Nut Driver Tip

FT 1/4” Hex Drive 5.5mm Nut Driver Tip

FT 1/4” Hex Drive 7.0mm Nut Driver Tip

FT 1/4” Hex Drive 8.0mm Nut Driver Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Ball End Tip

FT 1/4” Hex Drive 3/32” Ball End Tip

FT 1/4” Hex Drive Flat Screwdriver Tip

FT 1/4” Hex Drive Phillips Screwdriver Tip

FT 1/4” Hex Drive 2.5mm Ball End Tip

FT 1/4” 5 Piece Power Tool Tips Set (5/64-2.0mm,

1.5mm, 2.5mm, 5/64”- 2.0mm ball, 2.5mm ball)

FT Camber + Track Width Tool

FT Body Scissors

12 Inch Nylon Wire Ties

6 Inch Nylon Wire Ties