Page 1

3/13

Page 2

2

:: Introduction

Thank you for purchasing this Team Associated Qualifier Series product. This manual contains

instructions and tips for maintaining your new RIVAL MT RTR. Please take a moment to read through

it and familiarize yourself with these steps as they will help you to understand each component’s

function and show you some tips for getting the most out of your RIVAL MT RTR. We are continually

changing and improving our designs; therefore, actual parts may appear slightly different than the

illustrations.

As part of the ongoing additions to the already successful Qualifier Series, Team Associated is proud

to release the RIVAL-MT RTR; a 1:8 scale 4WD electric off-road RTR monster truck.

For more information, scan the QR code to the right for videos and tutorials on the

RIVAL MT RTR!

http://www.teamassociated.com/Rival_Monster_Truck/

:: RIVAL MT Platform Features

• Ultra rigid aluminum chassis

• 3 gear gearbox with center differential for superior traction and performance

with 6.06:1 internal ratio

• Includes 2 - 8.4V (7 cell) NiMH batteries with Deans ™ Ultra plugs ®

• XP SC1300-DB ESC with Deans ™ Ultra plug ®

o Works with 2-8.4V NiMH or NiCd or 2-7.4V LiPo batteries.

o Dual battery plugs for independent battery voltage sensing and optimum performance

• 8 oil filled shock absorbers

• Front and rear impact absorbing bumpers

• 4mm steel wire roll bar to protect body under impact

• Electronics tray with water resistant receiver box can hold 6-7 cell NiCd or NiMh batteries as well

as ROAR-approved 2S LiPo batteries, and is easily removed for cleaning or maintenance

• Reedy 1515-SL 2000kV brushless motor

• XP3G 2.4Ghz transmitter and micro receiver

• Alloy steel turnbuckles

:: Additional Items Needed

Your RIVAL MT RTR requires the following items to complete your kit:

• Transmitter batteries (x6 AA’s) (#302, 303 AA batteries recommended)

• NiMH Battery charger (peak detection charger recommended)

(AE #610 NiMh/NiCD)

:: Other Helpful Items

• Silicone Shock Fluid / Differential Fluid (Refer to catalog for complete listings)

• Body Scissors (AE Part # 1737) • FT Threadlock (#1596)

• FT Hex Wrenches (AE Part # 1541, 1655) • Reamer / Hole Punch

• FT Nut Drivers (AE Part #1561, 1663-1668) • Calipers or a Precision Ruler

• FT Turnbuckle Wrench (#25384) • Needle Nose Pliers

• Green Slime shock lube (AE Part # 1105) • Soldering Iron / Wire cutters / Hobby knife

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 3

:: Table of Contents

3

1....................Cover

2....................Introduction

3....................Table of Contents

4....................Blueprint of the RIVAL MT

5-7................Quick Start Guide

8....................Electronics Wiring /

Camber & Toe Settings

9...................Gear Mesh & Ride Height

10.................Spur Gear Access

12-14..........Front / Rear Diff Access

15-...............Shock Maintenance

16.................Motor Manual

17................. ESC Manual

18-27..........Catalog

28................1:1 Hardware “Fold Out”

29................Catalog cont.

30................Trouble Shooting

11..................Center Diff Access

:: Notes

!

This symbols indicates a

special note or instruction

in the manual.

There is a 1:1 hardware foldout page in the back

of the manual. To check the size of a part, line

up your hardare with the correct drawing until

you find the exact size. Each part in the foldout

has a number assigned to it for ordering

replacement parts.

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 4

4

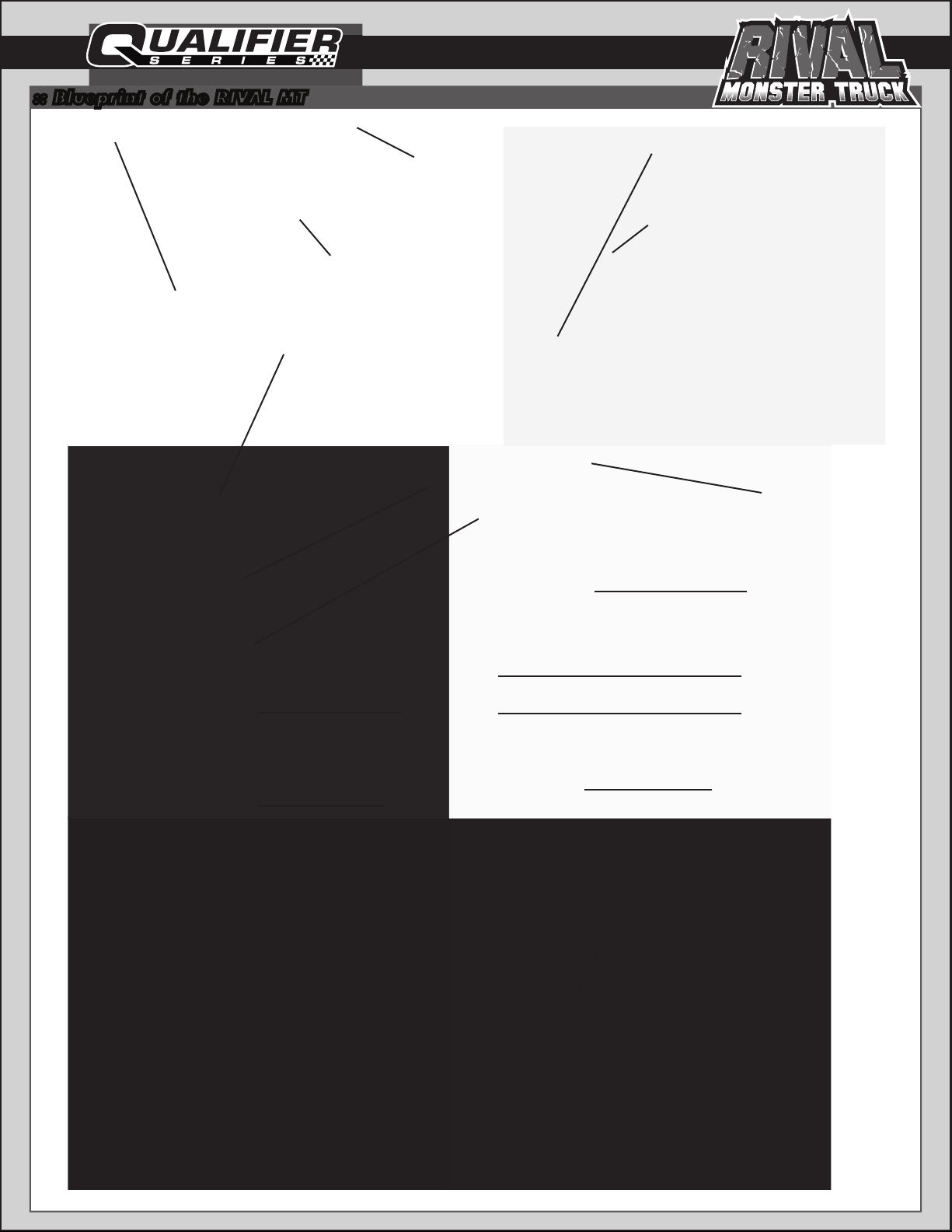

:: Blueprint of the RIVAL MT

Steering

Block

Bumper

Front

Front

Body Mount

Front

Steering Link

Battery

w/ Deans®

Plug

Battery Strap

Front

Arm

Front

Shock

Servo

Receiver

Box

Rear

Hub

Pinion

Motor

Chassis

Rear

Arm

Rear

Shock

Roll Bar

Spur Gear

Electronic Speed

Control

Rear

Body Mount

Rear

Camber Link

Rear

Bumper

Page 5

:: Quick Start Guide

Battery Charging Steps and Safety:

NiMH Wall Charger: (Part #29154 Wall Charger AC 120V 350MaH)

NiMH Quick Charger: (Part #610 Reedy 447-S AC/DC 4-7 Cell Peak Prediction

NiMH/NiCd Charger)

Remove the battery from the vehicle before

charging. Be sure to select the correct

charging mode for the type of battery you

are charging.

NEVER leave the battery unattended while

charging!

5

NiMH: NiMH batteries (nickel-metal hydride)

are high current rechargeable batteries.

If you use a peak detection charger, make sure

it is designed for NiMH batteries!

:: Quick Start Guide - (cont.)

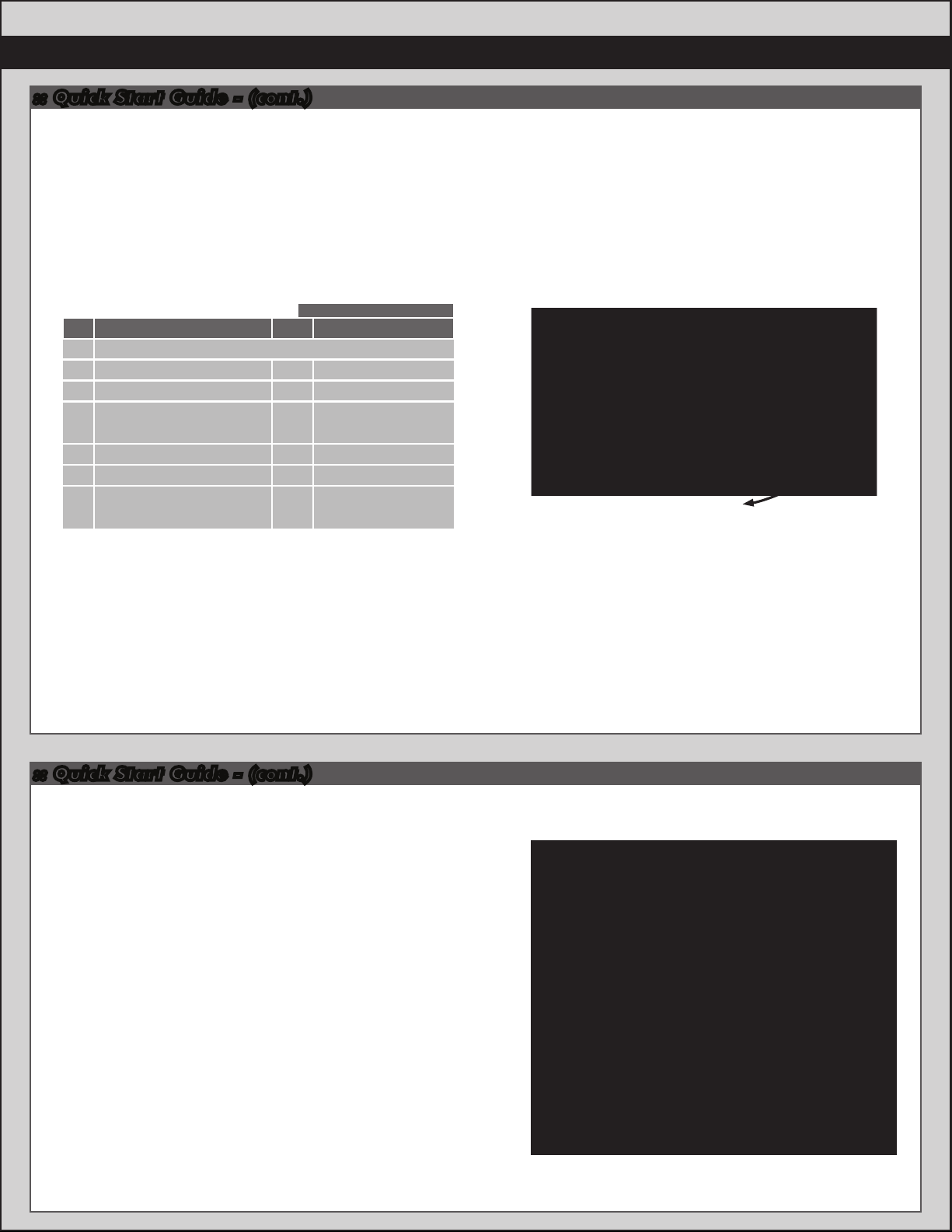

Battery Installation:

1. Install the batteries with the battery wires directed

towards the rear of the vehicle.

2. Insert the battery strap onto the battery post

screws.

3. Secure battery strap with thumb knobs.

Wall Charger Peak Detection

Quick Charger

1

:: Quick Start Guide - (cont.)

2 3

Page 6

6

:: Quick Start Guide - (cont.)

Change the speed control to NiMH or LiPo battery

modes.

Battery Management System - A choice of either LiPo mode or NiMH

mode adjusts the low voltage cutoff point. This is critically important

when using LiPo batteries that should not, for performance and safety

reasons, be discharged below 3.0V per cell. In LiPo mode, the ESC

detects whether you are using 2 or 3 cells and adjusts the cutoff

accordingly.

The ESC can be toggled between LiPo mode and NiMH mode by

following the steps outlined below.

Signal From ESC

Step #

1

Trigger position to maximum brake (hold)

2

3

4

5

6

Procedure

Battery Management System

Power ON Transmitter

Power On ESC

Throttle position to neutral

Power OFF ESC, then transmitter

Power ON transmitter, then ESC

IMPORTANT! When the transmitter and ESC are turned on, the color

of the ESC LED at neutral indicates which mode the ESC is in. When the

LED is green, the ESC is in LiPo mode. When the LED is red, the ESC is

in NiMH mode.

Audio

bi-bi

2 green flash/ green static (LiPo Mode)

or red static (NiMH Mode)

melody

bibi-bibi

3 green flash, 2 red flash,

green static or red static

LED

Throttle set to Neutral when turning on the radio !

Pull for Throttle

Push for

Brake

Neutral

Vehicle Operation - To operate the vehicle, pull back on the throttle

trigger to move forward, push forward on the throttle trigger to

engage brakes. To engage reverse, push forward on the throttle

trigger to maximum brakes. Hold the trigger in this position for at

least 0.5 seconds before returning the throttle trigger to neutral.

Now push the throttle trigger forward to reverse the vehicle.

:: Quick Start Guide - (cont.)

Battery Notes and Tip:

Plug the batteries in as shown. Unplug batteries when not in use!

There are two types of batteries you can use with this vehicle.

NiMH (nickel-metal hydride) and LiPo (lithium polymer).

LiPo: LiPo batteries (lithium polymer) are high current

rechargeable batteries. LiPo batteries offer extended run time

and peak performance over NiMH batteries. They require a

peak detection charger designed specifically for LiPo batteries.

LiPo/LiFe Charger: (Part # 604 - Reedy 526-S AC/DC 2S-6S

Cell LiPo/LiFe Balance Charger)

These batteries require specal care and handling.

LiPo batteries are recommended for advanced users only!

ALWAYS charge a LiPo battery in LiPo mode.

CAUTION! If using a LiPo battery, you need to change the speed

control settings to LiPo mode (see instructions at top of page or

for complete speed control options and programming page 17

for detailed instructions).

Page 7

:: Quick Start Guide - (cont.)

Radio System Tuning and Controls:

7

RULE: Transmitter on First/Vehicle on Second.

When done driving: Vehicle off First/ Transmitter off Last!

1) Slide the battery cover in the direction shown to

remove cover.

2) Install eight (6) alkaline or rechargeable AA size

batteries into the battery holder.

3) Slide the battery cover back into place making

sure it is completely closed and secure.

4) Turn the power ON. If the power indicator LED

fails to light, check the batteries for insufficient

contact or incorrect polarity.

While pressing this part Battery cell (x6)

1 2 3

Battery cover

:: Quick Start Guide - (cont.)

Radio System Tuning and Controls:

DO NOT hold the trigger when turning on the radio.

If using optional battery for transmitter, be sure to plug

it in correctly. Plugging in a battery backwards can

cause damage.

4

On/Off Switch

RightLeft

Refer to Radio owners manual for more in-depth

instructions on radio operation and functions.

:: Quick Start Guide - (cont.)

Adjust steering

trim so front

wheels point

straight.

Push for

Brake

Pull for Throttle

Neutral

Throttle set to Neutral when turning on the radio !

Install body and body clips.

Ready to go!

Page 8

8

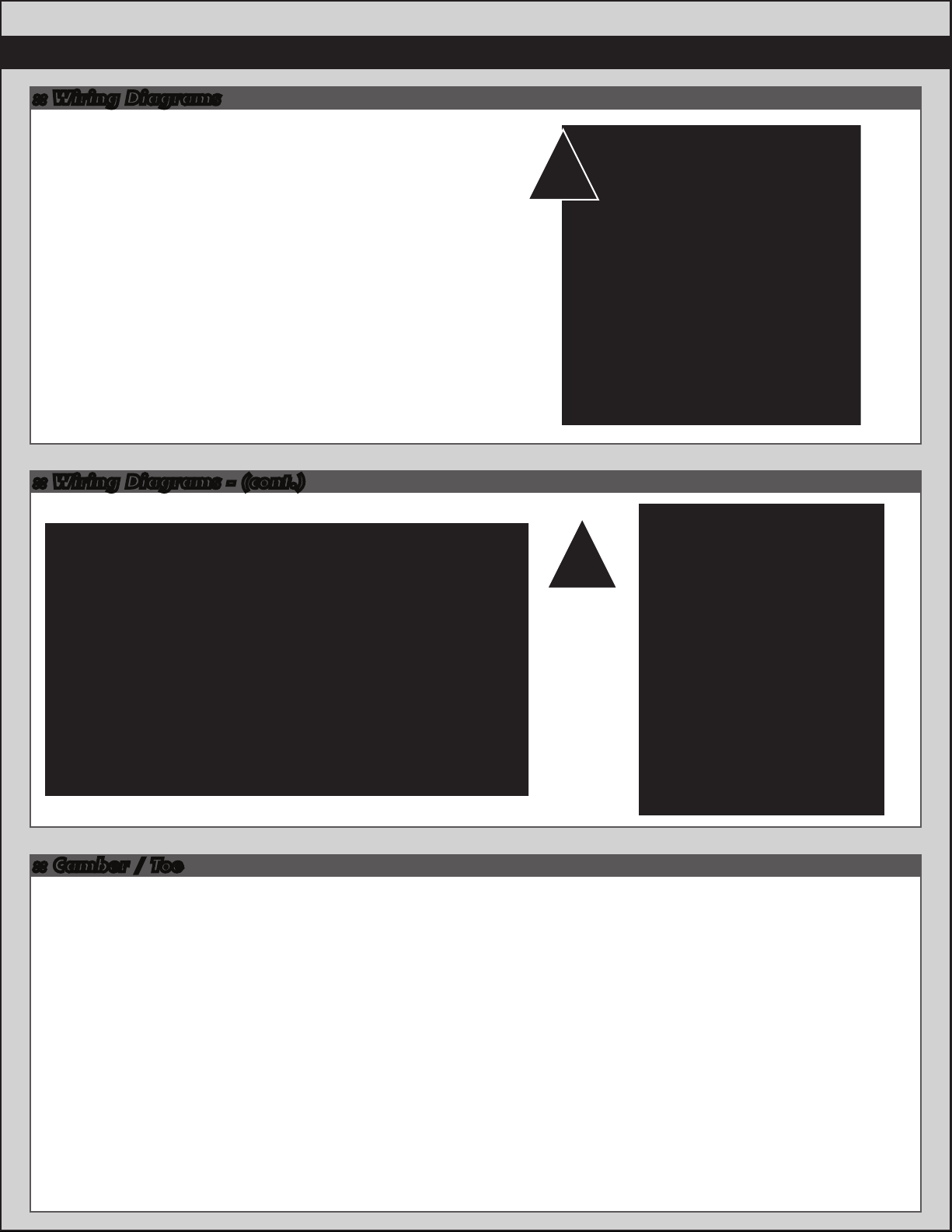

:: Wiring Diagrams

Motor and Receiver Wiring:

1. If motor runs in reverse when you apply throttle,

unplug any two of the motor wires and switch them.

2. Your Receiver has multiple channel ports for plugs.

Channel 1 - you should always plug your steering

servo into this channel port.

Channel 2 - you should always plug your speed

control (ESC) into this channel port.

Channel 3 - Used for optional equipment such as

fans, lights, ect...

Batt - Used for optional receiver battery pack.

Not used in this model.

Negative black wires on steering servo and speed control

plugs should face the outside edge of receiver where

channel markers are located.

:: Wiring Diagrams - (cont.)

1

2

:: Camber / Toe

Front Camber Angle:

A good starting camber setting is –2 degrees (where the top of the tires lean inwards). Positive camber, where the top

of the tire is leaning out, is typically not recommended.

Front Toe-In:

Zero degree toe-in (tires pointing straight forward) is a good starting setting. You can increase steering into corners

by adding 1-2 degrees of toe-out (front of tires point slightly outward). Toe - in is not a typical tuning adjustment used.

Rear Camber:

A good starting camber setting is –2 degrees. Use #1719 camber gauge (not included) to set your camber. Adding a

small amount of positive camber, where the top of the tire is leaning out, will tend to improve straight-line acceleration on

loose tracks.

Page 9

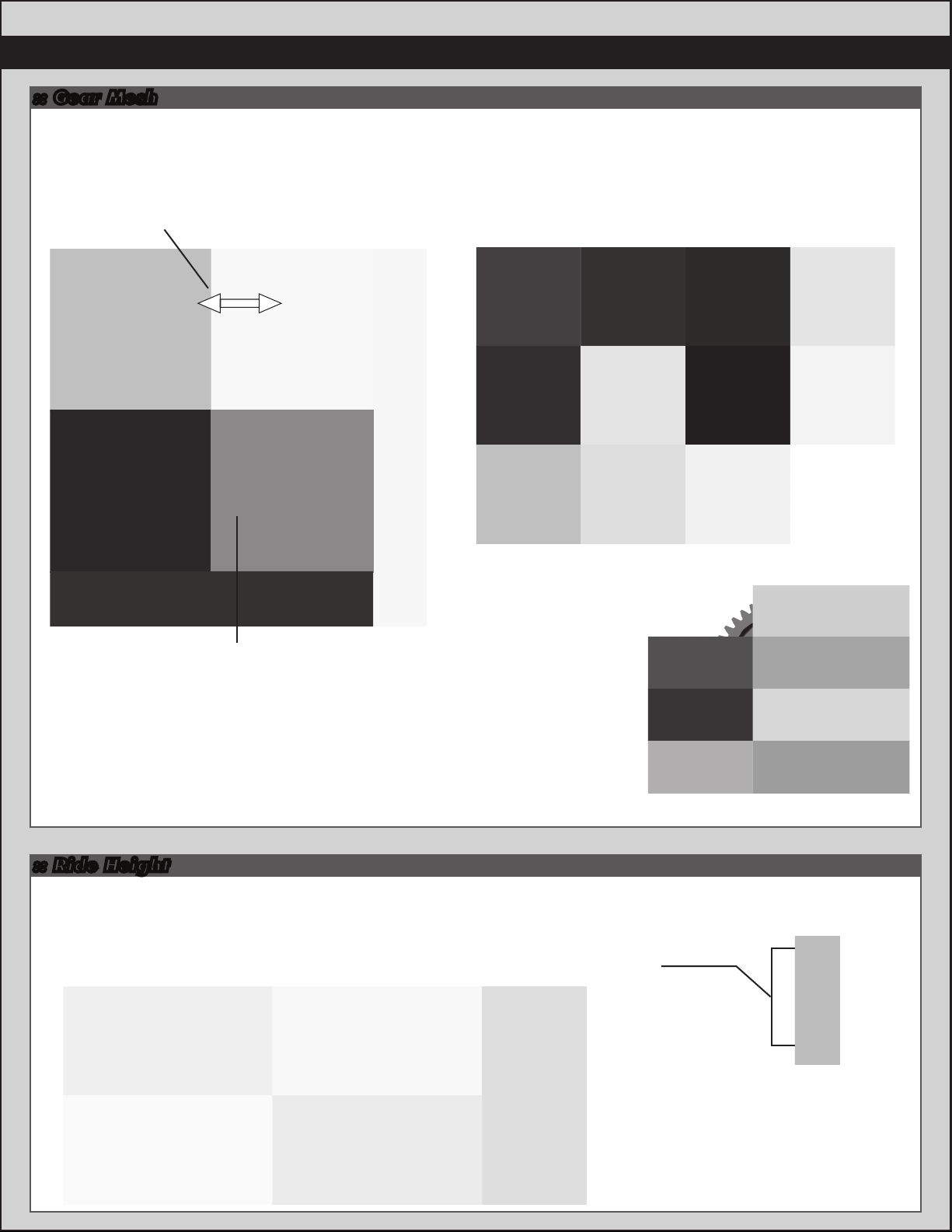

:: Gear Mesh

Gear Mesh:

To correctly set your gear mesh, follow the steps below:

1. Loosen the set screw on the motor’s pinion gear. Slide the pinion on the motor shaft until the gear face of the pinion

is entirely aligned with the gear face of the spur gear (see diagram). Tighten the set screw while ensuring it is aligned

with the flat face on the motor shaft.

Pinion

9

Spur Gear

2. Loosen the motor screws until the motor is able to move freely.

Slidethe motor as far as it can go towards the spur gear, ensuring that

the teeth of the pinion and the spur gear are interlocking. Slide the motor

back (approximately 0.5 mm), and tighten the motor screws.

Proper gear mesh has been achieved when the teeth are meshing closely,

but the gears still have a small amount of clearance between them. If you hold

one gear, you should be able to rock the other gear back and forth a small

amount. If there is no clearance, your gear mesh is too tight and you should

readjust the motor again.

:: Ride Height

Adjusting Ride Height:

The truck’s ride height can be increased by adding pre-load clips to the shocks.

Removing pre-load clips will decrease the ride height. Compress the spring and

insert the pre-load clips between the spring collar and the shock body flange.

Adding or removing ride height clips does not increase or decrease spring rate.

Pinion

7149

Shock

pre-load

clips

Spur Gear

1mm

2mm

4mm

6mm

Page 10

10

:: Spur Gear Access

:: Spur Gear Access - (cont.)

Spur Gear Maintenance:

When accessing your spur gear, check for wear on the

teeth of the gear. If teeth are deformed or sharp at the

peak, the spur gear should be replaced.

Also, check the slipper pads for wear.

Replace if necessary.

Slipper nut should be fully tightened!

Page 11

:: Center Diff Access

:: Center Diff Access - (cont.)

11

:: Center Diff Access - (cont.)

Stock Diff

Fluid Setting:

Center Diff:

Grease

Grease

Center Differential Maintenance:

Once you have removed the Center Diff gear, you can now

clean the existing diff grease from the dif ferential.

Check the diff gasket for wear or damage.

Replace if necessary

Fill the diff to the top of the cross pin with your choice of

diff fluids.

Suggested Diff Fluid Range: 100K to 500K

Thicker Diff Fluids:

Thicker fluids will get less low speed steering and better

acceleration out of turns.

Thinner Diff Fluids:

Thinner fluids will give more low speed traction.

Page 12

12

:: :: Front Diff Access

:: :: Front Diff Access - (cont.)

:: Front Diff Access - (cont.)

Page 13

:: Front Diff Access - (cont.)

!

Diff gear teeth

pointed towards

the right hand side

of the vehicle.

:: Rear Diff Access

13

:: Rear Diff Access - (cont.)

Page 14

14

:: Rear Diff Access - (cont.)

:: Rear Diff Access - (cont.)

!

Diff gear teeth

pointed towards

the left hand side

of the vehicle.

:: Front and Rear Diff Maintenance

Stock Shock

Fluid Setting:

Front:

grease

Rear:

grease

Grease

Differential Maintenance:

Once you have removed the Dif f gear, you can now clean

the existing diff fluid from the differential.

Check the diff gasket for wear or damage.

Replace if necessary

Fill the diff to the top of the cross pin with your choice of

diff fluids.

Front Diff: Suggested Diff Fluid Range: 10K to100K

Thicker oil will get less low speed steering and better

acceleration out of turns.

Rear Diff: Suggested Diff Fluid Range: 10K to100K

Thicker oil will rotate less in the turns and accelerate

straight on power. Thinner oil will give more low speed

traction.

Page 15

:: Shock Maintenance

:: Shock Maintenance - (cont.)

40wt

Shock fluid

Stock Shock

Fluid Setting:

Front: 40wt

Rear: 40wt

15

Bladder Installation

A B C

As you install the shock cap with the bladder, it will force

out any extra fluid. If you install the cap with the shaft

fully extended, you are running FULL REBOUND.This

means the shaft will fully rebound when compressed.

To run less rebound, unthread the cap 1-2 turns and

compress the shaft to the desired position and

re-tighten the cap with the shaf t compressed.

Start with no rebound.

:: Shock Maintenance - (cont.)

Step 5Step 3-4Step 1-2

Shock Maintenance:

If you need to only refill your shocks with oil, follow the steps

above only then move to the shock bleeding steps.

If your shocks leak from the bottom shock cap, follow all

shock maintenance sections.

Replace the inner O-Rings in the bottom cap, then begin

the shock oil filling and bleeding process.

Shock Bleeding Steps:

1. Pull shock shaft down.

2. Fill shock body 3/4 full with silicone

shock fluid.

3. Slowly move the shock shaf t up and

down to remove air from under the

piston.

4. Wait for bubbles to come to surface.

5. Fill shock body to top with silicone

shock fluid.

6. Place a drop of oil in the cap and on

cap threads.

7. Install cap and tighten completely.

8. Unscrew the cap 3/4 turns and tilt

the shock at a slight angle.

9. Slowly compress shaf t all the way to

bleed excess silicone shock fluid and

air. You should see bubbles coming

out from under the cap. (use rag

around shock to catch excess fluid).

10. With the shaft compressed, tighten

the cap and re-check for pressure at

the top of the stroke. If there is still

pressure, repeat steps 3-9.

Check for

pressure

Slow

Some residual

shock fluid may

appear from your

first few runs

around the shock

cap as a result of

bleeding.

Slow

Step 9-10Step 6-8

!

Page 16

16

:: Motor Manual

BRUSHLESS

Introduction

Congratulations on your purchase of the Reedy

1515-SL Brushless Motor. The latest brushless

motor technology along with the design and

engineering experience that is responsible for 28

World Championship titles has been incorporated

into its design.

Due to its sensorless design, the Reedy 1515-SL

Brushless Motor operates powerfully and efficiently

without complicated sensor harnesses. This motor

is perfectly suited for use with ESCs that are

designed to operate sensorless brushless motors.

Features

• Oversized Precision Ball Bearings

• High-Torque 4-Pole Rotor

• Hardened 5mm Steel Shaft

• Triple-Insulated Windings

• Sensorless Operation

• 4.0mm Connectors

Be sure to visit www.reedypower.com for the

latest application and gearing charts and to

view a complete list of spare and option parts.

Please read the following before

installing and using your new motor.

Precautions and Warnings

• Please read the instructions before installing

and operating your motor.

• Avoid over gearing by monitoring motor

temperature. Operating temperatures should

not exceed 80C (175F).

• Be sure to use the proper size motor mounting

screws.

• Do not over-tighten the motor mounting screws.

• Do not use a Schottky diode with this motor

Installation and Maintenance

• Your motor should be installed using 3mm

screws with a length (generally 10mm or less)

that does not allow the screw to extend into the

motor more than 5mm. Otherwise, the screw

can damage the motor’s internal components.

• Do not over-tighten the motor mounting screws.

Doing so may strip the mounting hole threads.

• Connect the three leads exiting the motor to the

three motor leads from your Electronic Speed

1515-SL

MOTOR

Control (ESC). If the motor runs backwards

when giving it forward throttle, reverse any two

motor leads. The motor will now turn in the

desired direction.

• To clean your motor, lightly brush dirt away on

a regular basis paying particularly close attention

to the areas around the ball bearings. DO NOT

spray cleaners or solvents into the motor.

Caution

When switching to a higher voltage battery from a

lower one (to 18.5V from 14.8V, for example), a

change in gear ratio or a lower kV motor might be

necessary. Otherwise, the motor or ESC may

overheat and sustain permanent damage. Please

visit www.reedypower.com for the latest gear ratio

suggestions for your particular motor and vehicle.

Safety Precautions

This product is a sophisticated hobby product and

not a toy. It must be operated with caution and

common sense and requires some basic

mechanical ability. Failure to operate this product

in a safe and responsible manner could result in

injury or damage to the product or property. This

product is not intended to be used by children

without direct adult supervision. It is essential to

read and follow all instructions and warning found

in this manual prior to installation, set up, and use

in order for the product to operate properly and to

avoid damage or injury.

Specifications

Model

Item No.

Cells

RPM/Volt

Diameter

Length

Weight

Shaft Diameter

Max. Efficiency Current

Max. Surge Current

Internal Resistance

1515-SL 2000kV

929

3S-4S LiPo

2000

40mm

74mm

380g/13.4oz

5.0mm

20~50A

100A/15s

Warranty

Your motor is warranted to the original purchaser

for 30 days from the date of purchase against

defects in material and workmanship. Motors that

have been mishandled, abused, used incorrectly,

used for an application other than intended or

damaged by the user are not covered under

warranty.

Associated Electrics Inc. is not liable for any loss or

damage, whether direct or indirect, incidental or

consequential, or from any special situation, arising

from the use, misuse, or abuse of this product.

Page 17

:: ESC Manual

#29146

XP SC1300-DB

17

Brushless ESC

Introduction

Congratulations on your XP Brushless Electronic Speed Control (ESC)

purchase. The latest electronics technology along with the design and

engineering experience that is responsible for multiple World

Championship titles has been incorporated into its design.

Your XP Brushless ESC is water-resistant for maximum durability. Its light

and compact design allows for easy installation in most 1/8 vehicles. Dual

connectors allow plug and play use in vehicles that require two batteries.

Simple calibration and a wide variety of tuning options make this ESC

perfect for both casual enthusiast and racers. When paired with a Reedy

Brushless Motors, you create a potent combination of power and efficiency

that brings performance to a new level. More power and less maintenance

elevate the fun factor by increasing top speeds and reducing down time.

Please read the following before installing and operating

your new ESC.

Features

• Adjustable LiPo Low-Voltage Cutoff

• LiPo Cell Count Auto Detect

• Reversible With Reverse Lockout

• Fully Proportional Brakes

• Adjustable Drag Brakes

• Adjustable Throttle Profile

• Hard Case with Aluminum Heat Sink

• Water Resistant

• Heavy Duty Silicone Wires

• Dual Deans® Ultra Plug® Connector

• 4.0mm Motor Connectors

• Pre-Wired For Optional Cooling Fan

Safety Precautions

This product is a sophisticated hobby product and not a toy. It must be

operated with caution and common sense and requires some basic

mechanical ability. Failure to operate this product in a safe and responsible

manner could result in injury or damage to the product or property.

This product is not intended to be used by children without direct adult

supervision. It is essential to read and follow all instructions and warnings

found in this manual prior to installation, set up, and use, in order for the

product to operate properly and to avoid damage or injury.

Throttle Calibration

Your new ESC must be calibrated before use. Before calibration, be sure to

set your radio’s throttle and brake EPAs to 100% and your throttle trim to

neutral. Then follow the steps outlined below.

Procedure

Step #

Power ON transmitter

1

Throttle position to maximum throttle (hold)

2

Power ON ESC

3

Throttle trigger position to neutral

4

Throttle trigger position to maximum brake

5

Throttle trigger position to neutral

6

Power OFF ESC, then transmitter

7

Once the calibration procedure is complete, turn on your transmitter, then

your ESC, and begin operating your vehicle. Note: If you choose to make

settings adjustments at this time, you can do so immediately after step #6

of the throttle calibration procedure.

Audio

bibibibibibi

bibi-bibi

bibi-bibi

Signal From ESC

LED

red static/6 green flash

red static/4 green flash

red static /4 green flash

red static

Step #

1

Throttle trigger position to maximum to select value

2

Throttle trigger position to maximum to select value

3

Throttle trigger position to maximum to select value

4

5

Procedure

Drag Brakes

0% (default)

2.5%

5%

10%

Throttle position to neutral

Throttle Profile

Very Soft

Soft

Standard (default)

Maximum

Throttle position to neutral

Run Mode

Reverse Off (Forward Only)

2-Stage Reverse (default)

Throttle position to neutral

Power OFF ESC and transmitter

Power ON transmitter and ESC

Signal From ESC

LED

red static/green flashes

red static/4 green flash

red static

red static/green flashes

red static/4 green flash

red static

red static/green flashes

red static/4 green flash

3 green flash, 2 red flash

green static or red static

Specifications

Description

Cells

On Resistance

Brakes

Motor Limit

Reversible

Low Voltage Cutoff

Dimensions

Weight w/Wires

Power Wires

Connector Type

Installation

• Mount your ESC securely using high quality double-sided tape.

• Install your ESC in a position that allows easy access to all connectors.

• Plug the ESC’s receiver wire into the receiver

(refer to radio manufacturer’s manual)

• To prevent radio interference, arrange ESC wiring so that it is not in close

proximity to the receiver antenna wire.

• Connect the three motor leads exiting the ESC to the three leads exiting

your motor. If the motor runs backwards when giving it forward throttle,

reverse any two motor leads. The motor will now run the desired direction.

• Mount the switch to the case using the tab provided.

• Always power ON your transmitter before the ESC, and power OFF the

ESC before the transmitter.

Programmable Settings

Your ESC comes with pre-programmed default settings. You can also

change the setting based on the type of vehicle used as well as personal

performance preferences based on the track you are driving on and your

driving style.

Drag Brake - Drag brake is the amount of braking achieved when the

throttle is returned to neutral. A setting of 0% means the vehicle will free

wheel to a stop while higher settings will stop the car faster. Please note

that regardless of the drag brake setting, you will still be able to use the

brake trigger to manually slow the car.

Throttle Profile – This setting adjusts the power delivery of your

ESC/motor combination. The Very Soft setting can be used on loose or

bumpy track to reduce wheel spin while the Maximum setting works well

when high traction is available. Four settings provide options for any track

condition.

Run Mode - This gives the option of using reverse or eliminating it

completely (for competition). With reverse activated, you will still have fully

proportional braking.

To make settings adjustments, you must first follow the calibration

procedure. After step #6, you will encounter a 5-second delay before

entering the settings adjustment mode. All changes will be made using

your transmitter’s throttle trigger. Note: Once you enter the settings

adjustment mode, the ESC will scroll through all options. If you fail to

choose a setting, the ESC will keep the previously saved setting.

For example, if you want to change the throttle profile from Soft to

Standard, enter the settings mode. You will encounter the Drag Brake

mode first at which time you can let the ESC scroll through the choices

(the previously saved setting will be kept) until you reach the Throttle

Profile choices. You must make the selection by pulling the throttle trigger

to maximum after the ESC scrolls to the desired setting (in this case

Standard) indicated by the appropriate audible tones. Once this setting

(or any setting for that matter) is chosen, you can skip to Step #5 if no

other changes are desired.

Battery Management System

Battery Management System - A choice of either LiPo mode or NiMH mode

adjusts the low voltage cutoff point. This is critically important when using

LiPo batteries that should not, for performance and safety reasons, be

discharged below 3.0V per cell. In LiPo mode, the ESC detects whether you

are using 2 or 3 cells and adjusts the cutoff accordingly.

The ESC can be toggled between LiPo and NiMH by following the steps

outlined below. The default setting is NiMH mode.

Procedure

Step #

Battery Management System

Power ON transmitter

1

Throttle position to maximum brake (hold)

2

Power ON ESC

3

Throttle trigger position to neutral

4

Power OFF ESC, then transmitter

5

Power ON transmitter, the ESC

6

IMPORTANT! When the transmitter and ESC are turned on, the color of the

ESC LED at neutral indicates which mode the ESC is in. When the LED is

green, the ESC is in LiPo mode (3.2V/cell cut off). When the LED is red, the

ESC is in NiMH mode (default).

Vehicle Operation - To operate the vehicle, pull back on the throttle trigger

to move forward and push forward on the throttle trigger to engage brakes.

To engage reverse, push forward on the throttle trigger to maximum brakes.

Hold the trigger in this position for at least .5 seconds before returning the

throttle trigger to neutral. Now push the throttle trigger forward to reverse the

vehicle.

Signal From ESC

Audio

bi-bi

melody

bibi-bibi

LED

2 green flash

green static (LiPo) or

red static (NiMH)

3 green flash, 2 red flash

green static or red static

Page 18

18

:: Shocks :: Drive Shafts

25058

25059

25061

25062

25063

25064

25065

25069

25070

Assembled Shocks, Set of eight

Assembled Shocks, Set of two

Shock Rebuild & Shafts, Set

Blue/Soft Shock Springs, 4.40 lbs

Gold/Medium Shock Springs, 5.10 lbs

Red/Firm Shock Springs, 5.95 lbs

Copper/Extra Firm Shock Springs, 6.90 lbs

Shock Eyelets & Accessories, Set

Shock Mounting Hardware, Set

8

25689

2

25747

1

25748

4

4

4

4

1

1

Center CVA Rebuild Kit

RIVAL-MT Center Drive Shaft, Front

RIVAL-MT Center Drive Shaft, Rear

25689

25689

1

1

1

25689

25689

25059

25061

25059

25061

25061

25061

25061

25059

25059

25059

25061

25059

25061

25061

25069

25069

25062

25069

:: Steering

25125

25126

25127

25180

25215

Bellcrank Plastic Parts Set

Bellcrank Posts (2) & Bushings (4)

Bellcrank Hardware

M3 x 8mm BHPS

M3 Locknut

25689

25747

25748

25689

25689

25689

25126

25689

25689

25689

25748

25689

25180

25747

25689

25748

25689

1

1

1

20

20

:: Shock Fluid

5420

5421

5422

5423

5424

5425

5426

5427

5428

5429

5430

5431

5432

5433

5434

5435

5436

5437

5438

10 Weight Silicone Shock Fluid

20 Weight Silicone Shock Fluid

30 Weight Silicone Shock Fluid

40 Weight Silicone Shock Fluid

22.5 Weight Silicone Shock Fluid

80 Weight Silicone Shock Fluid

27.5 Weight Silicone Shock Fluid

15 Weight Silicone Shock Fluid

25 Weight Silicone Shock Fluid

35 Weight Silicone Shock Fluid

45 Weight Silicone Shock Fluid

55 Weight Silicone Shock Fluid

32.5 Weight Silicone Shock Fluid

37.5 Weight Silicone Shock Fluid

42.5 Weight Silicone Shock Fluid

50 Weight Silicone Shock Fluid

60 Weight Silicone Shock Fluid

70 Weight Silicone Shock Fluid

47.5 Weight Silicone Shock Fluid

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

25215

25125

25127

25127

25127

25125

25127

25215

25127

25127

25126

25215

25125

25127

25126

25127

25215

25180

25126

25126

25125

25126

Page 19

:: Radio Tray and Servo Saver

6338

25162

25166

25167

25181

25207

25215

25225

25232

25613

25751

89208

Antenna Tube with Cap, black

Servo Saver, XT/Futaba - (Used in RTR)

Servo Saver, Hitec

Servo Saver, JR/Airtronics

M3 x 10mm BHPS

M3 x 10mm BHPTS

M3 Locknut

M3 x 3mm Set Screw

Lock Washer

M3 x 6mm BHPS

RIVAL-MT Receiver Tray

M3 x 14mm FHCS

1

1

1

1

20

20

20

20

20

20

1

10

25751

25751

25181

25181

19

25181

25225

6338

25162

25162

25162

25162

25162

25162

25232

25162

:: Battery Tray / Strap and Roll Bar

3848

4689

7732

25181

25185

25215

25613

25620

25749

25757

Foam Battery Spacer

(Use with LiPo Batteries - Not pictured)

M3 x 16mm Set Screw

4mm x 4mm Set Screw

M3 x 10mm BHPS

M3 x 20mm BHPS

M3 Locknut

M3 x 6mm BHPS

M3 x 10mm SHCS

RIVAL-MT Battery Tray

RIVAL-MT Roll Hoop

1

6

6

20

20

20

20

20

1

1

25215

89208

25215

89208

25207

89208

25207

25215

25751

89208

7732

6338

25751

25613

25757

7732

25757

25185

25749

25185

25749

25749

4689

25749

25749

4689

25215

25181

25181

25613

25757

25749

25613

25613

25620

25613

25620

Page 20

20

2

:: Front Bumper

7164

25183

25184

25203

25208

25763

Washer, 3 x 6 x 0.5mm

M3 x 14mm BHPS

M3 x 16mm BHPS

M3 x 12mm FHCS

M3 x 22mm BHPS

RIVAL-MT Front Bumper

10

20

20

20

20

1

25763

25184

7164

25184

7164

:: Rear Bumper

7164

25182

25184

25203

25208

25764

Washer, 3 x 6 x 0.5mm

M3 x 12mm BHPS

M3 x 16mm BHPS

M3 x 12mm FHCS

M3 x 22mm BHPS

RIVAL-MT Rear Bumper

10

20

20

20

20

1

25183

25208

25208

25184

7164

25764

25183

7164

25764

25763

25763

25763

25203

25184

25764

25182

25208

25182

:: Front and Rear Gear Differential

25081

25085

25204

25236

25715

Assembled Differential

Differential Outdrives & Gaskets

M3 x 16mm FHCS

Bearing, 8 x 16 x 5

Differential Shims

1

1

20

2

10

25204

25764

25085

25236

25203

25081

25085

25208

25081

25085

25715

25236

25081

25081

25715

Page 21

:: Transmission Internal Gears

O-Rings

25236

25238

25741

25742

25743

25744

25745

Bearing, 8 x 16 x 5

Bearing, 6 x 12 x 4

RIVAL-MT Gear Set

RIVAL-MT Center Diff Assembly

RIVAL-MT Center Diff Rebuild

RIVAL-MT Center Diff O-Rings

RIVAL-MT Center Diff Outdrives

2

2

1

1

1

2

1ea

25741

25741

25741

25741

25238

25238

25741

25743

25743

25238

25741

25743

21

25742

25238

2574525741

25236

25742

25744

25742

:: Transmission

25180

25181

25199

25212

25223

25238

25613

25620

25739

25740

89218

89512

89513

89514

89515

89516

89517

89593

89594

89595

89596

M3 x 8mm BHPS

M3 x 10mm BHPS

M3 x 8mm FHPS

M3 x 12 FHPS

M4 x 3mm Set Screw

Bearing, 6 x 12 x 4

M3 x 6mm BHPS

M3 x 10mm SHCS

RIVAL-MT Tranny Case

RIVAL-MT Motor Plate

3 X 8mm Washer

12T Pinion

13T Pinion

14T Pinion

15T Pinion - Kit

16T Pinion

17T Pinion

18T Pinion

19T Pinion

20T Pinion

21T Pinion

25236

25745

20

20

20

20

20

2

20

20

1

1

10

1

1

1

1

1

1

1

1

1

1

25744

25238

25743

25743

25742

25744

25212

25223

25743

25740

25743

25743

25180

25743

25212

25739

25739

25212

25613

25739

25739

25613

25739

25181

89515

25620

89218

25180

25199

Page 22

22

:: Front Gearbox

25051

25056

25080

25082

25106

25125

25128

25184

25190

25191

25199

25201

25202

25203

25208

25209

25215

25236

Front / Rear Drive Input Cup w/ Set Screws

Drive Cup Set Screws

Differential Pinion Gear & Shaft

Front/Rear Transmission Case with screws

Front & Rear Transmission Chassis Mounts

Bellcrank Plastic Parts

Front Skid Plate

M3 x 16mm BHPS

M3 x 14mm SHCS

M3 x 18mm SHCS

M3 x 8mm FHPS

M3 x 8mm FHCS

M3 x 10mm FHCS

M3 x 12mm FHCS

M3 x 23mm BHPS

M3 x 32mm BHPS

M3 Locknut

Bearing, 8 x 16 x 5

1

4

1

1

1

1

1

20

20

20

20

20

20

20

20

20

20

2

25190

25208

25209

25191

25106

25082

25208

25208

25080

25082

25236

25184

25082

25051

25056

25215

25190

25191

25106

:: Front Suspension

25107

25109

25110

25112

25113

25116

25184

25215

25225

25238

25654

25698

25768

25769

89218

89405

Upper Suspension Arm

Lower Suspension Arm

Upper & Lower Arm Hinge Pins

Steering Block/Hub Carrier

Pivot Balls

Axle Bearing Spacers

M3 x 16mm BHPS

M3 Locknut

3mm x 3mm Allen Set Screw

Bearing, 6 x 12 x 4

M3 x 18 BHPS

Universal Rebuild Kit

RIVAL-MT CVA

RIVAL-MT Wheel Hexes

3 X 8mm Washer

Nyloc Wheel Nuts, silver

Pr.

20

20

20

20

10

25125

25215

25128

25199

25203

25202

2

2

8

4

4

2

1

2

4

4

25110

25107

25201

25113

25110

25768

25184

25184

25698

25109

25698

25768

25698

25116

25112

25113

89218

25654

25238

25215

25769

25225

25112

25238

25769

89405

Page 23

:: Rear Gearbox

25769

25051

25056

25080

25082

25106

25134

25184

25191

25199

25202

25208

25209

25215

25236

89218

Front / Rear Drive Input Cup w/ Set Screws

Drive Cup Set Screws

Differential Pinion Gear & Shaft

Front/Rear Transmission Case with screws

Front & Rear Transmission Chassis Mounts

Rear Skid Plate

M3 x 16mm BHPS

M3 x 18mm SHCS

M3 x 8mm FHPS

M3 x 10mm FHCS

M3 x 23mm BHPS

M3 x 32mm BHPS

M3 Locknut

Bearing, 8 x 16 x 5

3 X 8mm Washer

1

4

1

1

1

1

20

20

20

20

20

20

20

2

10

25191

25184

25051

25056

25208

25082

25236

25080

25082

25215

25082

23

25191

25106

25215

89218

25184

:: Rear Suspension

25107

25109

25110

25112

25113

25116

25184

25215

25225

25238

25654

25698

25768

25769

89218

89405

Upper Suspension Arm

Lower Suspension Arm

Upper & Lower Arm Hinge Pins

Steering Block/Hub Carrier

Pivot Balls

Axle Bearing Spacers

M3 x 16mm BHPS

M3 Locknut

3mm x 3mm Allen Set Screw

Bearing, 6 x 12 x 4

M3 x 18 BHPS

Universal Rebuild Kit

RIVAL-MT CVA

RIVAL-MT Wheel Hexes

3 X 8mm Washer

Nyloc Wheel Nuts, silver

Pr.

20

20

20

20

10

89218

25106

25208

25209

25184

25134

25199

25202

2

2

8

4

4

25107

2

1

2

4

4

25113

25110

25238

25769

25225

89405

25112

25769

25238

25116

25112

25112

89218

25698

25768

25215

25654

25698

25113

25698

25109

25768

25184

25110

25184

Page 24

24

:: Front Bumper and Chassis

25102

25105

25181

25201

25207

25215

25753

Chassis Guards (L&R) and End Covers (2)

Front & Rear Upper Arm Mounts

M3 x 10mm BHPS

M3 x 8mm FHCS

M3 x 10mm BHPTS

M3 Locknut

RIVAL-MT Chassis

1

2

20

20

20

20

1

25181

25201

25105

25207

25102

25105

25207

25181

25105

25181

25215

25105

25215

25215

25181

25181

25215

25753

25102

25215

25105

25201

25181

25215

25105

25102

25207

25102

25207

25105

25105

25201

25201

25215

25215

Page 25

:: Front and Rear Shock Towers

2208

25070

25135

25136

25137

25188

25189

25205

Large Hood Pins

Shock Mounting Hardware

Front Shock Tower

Rear Shock Tower

Pivoting Body Mounts (2) & Posts (4)

M3 x 20mm BHCS

M3 x 22mm BHCS

Body Post Mounting Screws

6

1

1

1

1

20

20

20

25205

25137

2208

25137

25

2208

:: Turnbuckles

25754

25756

RIVAL-MT Turnbuckle Set

(8 Ball Joints & eyelets, 2 104mm TB, 2 118mm TB)

RIVAL-MT Turnbuckle Eyelets

(8 Ball Joints & eyelets)

25756

25188

25189

25188

25189

25205

25070

Front - 25135

Rear - 25136

25070

25070

:: Lubes & Adhesives / Decals / Misc.

1

1105

1596

1

1597

5450

5451

5452

5453

5454

5455

5456

5457

5458

5459

6588

6591

6636

6727

FT Green Slime Shock Lube

FT Locking Adhesive

FT Tire Adhesive, Medium

Silicone Diff Fluid 1000cst

Silicone Diff Fluid 2000cst

Silicone Diff Fluid 3000cst

Silicone Diff Fluid 5000cst

Silicone Diff Fluid 7000cst

Silicone Diff Fluid 10000cst

Silicone Diff Fluid 20000cst

Silicone Diff Fluid 30000cst

Silicone Diff Fluid 60000cst

Silicone Diff Fluid 100000cst

Black Grease - 4cc

S.Diff Lube - 4cc

Silicone Grease - 4cc

Servo Tape

25205

25137

25070

25070

25070

25205

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

25756

25754

25756

716

3816

3820

3834

Reedy 2009 Sticker Set

American Bumper Sticker

AE Logo Decal Sheet

AE Blue Embossed Logo Sticker

1

1

1

2

1596

Page 26

26

6

:: Slipper, Spur Gear, Pinion, and Drive Shaft

25677

25678

25679

25680

25681

25746

31541

Slipper Hardware

Spur Gear Hub

Slipper Friction Ring

Slipper Pad

Slipper Hub

RIVAL-MT Spur Gear (56T) - Kit

M3 x 0.5 x 6 FHCS

1

1

1

2

1

1

6

:: Wheels / Tires

25766

25767

25770

RIVAL-MT Tire & Insert

RIVAL-MT Beadlock Wheel

RIVAL-MT Wheel/Tire Pre-Mounted

25677

25677

2

2

2

25746

25677

31541

25681

25680

25679

25678

25766

25766

25767

25767

25767

25767

Page 27

27

:: Body / Decals

25758

25759

25765

Rival MT Body - Painted

Rival MT Body - Clear

Rival MT Decal Sheet

:: Factory Team and Option Parts

25062

25063

25064

25065

25139

25140

25381

25382

25383

25390

25391

25392

25395

25396

25397

25398

25403

25404

25725

25726

25727

25728

MGT Blue Spring, Soft [4.40lb]

MGT Gold Spring, Medium [5.10lb]

MGT Red Spring, Firm [5.95lb]

MGT Copper Spring, Extra Firm [6.90lb]

Rear Clip and Flag Mount

Rear AE Flag and Post

FT Blue Steering Turnbuckle, Titanium

FT Blue Rear Turnbuckle, Titanium

FT Monster GT Turnbuckle Set, Titanium

5mm Blue Aluminum Locknut

4mm Blue Aluminum Locknut

3mm Blue Aluminum Locknut

MGT Aluminum Steering Kit

MGT Aluminum Steering Rack and Arm

MGT Aluminum Servo Saver Hub and Spring

MGT Aluminum Steering Hardware Set

MGT Blue Aluminum Shock Bodies

MGT Blue Aluminum Shock Caps w/ Bladders

FT Steering Bushing

FT Shock Bottoms

FT Aluminum Shock Set, Builds 2 Shocks

FT Blue Wheel Hex

:: Reedy Accessories / Motor

1

1

1

4

4

4

4

1

1

1

1

1

10

10

10

1

1

1

1

4

4

4

4

1

4

604

609

610

654

655

656

658

659

716

929

:: Reedy Batteries

302

303

724

725

730

731

732

734

:: Qualifier Series Vehicles

7052

20510

30112

526-S AC/DC 2S-6S LiPo/LiFe Charger

TAM to DEANS® charge adapter

447-S AC/DC NiMH Peak Charger

4.0mm plugs (2M, 2F)

4.0mm plugs (2M, 10F)

4.0mm plugs (10F)

4.0mm plugs (10M)

4.0mm plugs (30M)

Reedy 09 Decal Set

1515-SL Brushless Motor 2000kV

AA Alkaline 1.5V (4)

AA 2700mAh NiMH 1.2V Rechargeable (4)

Wolfpack 3000mAh 8.4V w/DEANS® connector

Wolfpack 3600mAh 8.4V w/DEANS® connector

Wolfpack LiPo 3000mAh 7.4V 25C w/DEANS®

Wolfpack LiPo 3300mAh 7.4V 35C w/DEANS®

Wolfpack LiPo 3400mAh 7.4V 35C w/DEANS®

Wolfpack LiPo 6500mAh 7.4V 25C w/DEANS®

Pro Lite 4x4 RTR, 1/10 Scale (ready-to-run)

RIVAL Electric Monster Truck RTR, 1/8 Scale

(ready-to-run)

APEX Touring V-Type, 1/10 Scale (ready-to-run)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:: XP Electronics

29142

29146

29166

29167

29168

29209

29210

29211

29212

29214

29215

29216

XP ESC Fan Option

XP SC1300-DB Brushless Dual-Battery ESC

XP DS1313 Digital Servo

XP DS1015 Digital Servo

XP DS1510MG Digital Servo

Gear Set, DS1313

Gear Set, DS1015

Servo Case , DS1313/DS1015

Accessory Pack, DS1313/DS1015

TRS403-SSi 2.4GHz 4Ch Receiver

XP2G 2.4GHz Radio System

XP3G 2.4GHz Radio System

:: LRP Chargers, Power Supply, Balancer

LRP41281

LRP41555

LRP42103

LRP42104

LRP42105

LRP42305

LRP42306

LRP43200

LRP45050

LRP45200

LRP65800

LRP65802

LRP65803

LRP65804

LRP81801

Quadra Pro 2 Charger

Pulsar Touch Competition Charger

LiPo Balance Board XH

LiPo Balance Board FP/TP

LiPo Balance Board PQ

Pulsar Touch Temperature Sensor

Pulsar Touch Sensor Wire Splitter

LRP Competition 20A Power Supply

LRP 2in1 LiPo Guard + BEC

LiPo Parallel Balancer

High Power Solder Station

Soldering Tip 5mm

Soldering Tip 1.2mm

Soldering Handle

LRP Speedo Updater Spec 2

:: 1/18 Kits and RTR’s

20103

20121

1

1

:: 1/12, 1/10 Kits and RTR’s

1

1

2042

1

4020

1

7025

1

7029

1

7030

1

7037

1

7038

1

7046

1

7047

7048

7049

7050

7092

7093

1

8020

1

8022

1

9039

1

9040

1

9041

1

9050

1

9062

1

30101

1

30108

1

90004

1

90005

1

90006

1

90007

1

90010

1

RC18B2 - RC18T2 Team Kit

SC18 RTR Brushless (ready-to-run)

Nitro TC3 RTR Plus (ready-to-run)

FT 12R5.2 Kit

RC10T4.2 FT Kit

SC10 Associated/RC10.com Truck RTR (ready-to-run)

SC10 KMC Wheels Race Truck RTR (ready-to-run)

RC10T4.1 RTR 2.4GHz Brushless (ready-to-run)

SC10.2 FT Kit

SC10 RS RTR, Lucas Oil (ready-to-run)

SC10 RS RTR, Monster Energy (ready-to-run)

SC10 RS RTR, Pro Comp (ready-to-run)

SC10 RS RTR, Rockstar/Makita (ready-to-run)

SC10 RS RTR, Hart and Huntington (ready-to-run)

GT2 RS Truck Nitro RTR (ready-to-run)

SC10GT RTR (ready-to-run)

FT RC10R5 Kit

FT RC10R5.1 Kit

RC10B4.1 RTR 2.4GHz Brushless (ready-to-run)

FT RC10B4.1 Worlds Kit

FT RC10B4.2 Kit

SC10B RS RTR (ready-to-run)

FT B44.2 4WD Buggy Kit

TC4 Club Racer 4WD Touring Car Race Roller

FT TC6.1 WC 4WD Touring Car Kit

SC10 4x4 Kit

SC10 4x4 Lucas Oil RTR (ready-to-run)

SC10 4x4 Pro Comp RTR (ready-to-run)

SC10 4x4 Rockstar/Makita RTR (ready-to-run)

SC10 4x4 FT Kit

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 28

:: Hardware - 1:1 Scale View

28

Cap Head (shcs)

3x12mm w/hole (31427)

Shims and Washers

Nylon Washer .030 (4187)

3x6mm Washer (7164)

3x8mm Thin Washer

4mm Hex Drive Washer

6x12mm Washer (7165)

3x10mm (25620)

3x14mm (25190)

3x18mm (25191)

4x12mm (31426)

(89218)

(31428)

4mm Lock Washer

(31429)

Flat Head (fhcs)

2.5x6mm (4675)

2.5x8mm (31448)

2.5x10mm (31350)

3x6mm (31541)

3x8mm (25201)

3x8mm FHPS (25199)

3x10mm (25202)

3x12mm (25203)

3x14mm (89208)

3x16mm (25204)

3x18mm (89209)

3x22mm (89455)

Button Head (bhcs)

2.5x6mm (31520)

3x4mm(91158)

3x6mm (31531)

3x6mm BHPS (25613)

3x8mm (31532)

3x8mm BHPS (25180)

3x10mm (25211)

3x10mm BHPS (25181)

3x10mm BHPTS (25207)

3x12mm (89202)

3x12mm BHPS (25182)

3x14mm (25187)

3x14mm BHPS (25183)

3x16mm (89203)

3x16mm BHPS (25184)

3x18mm (2308)

3x18mm BHPS (25654)

Setscrew

3x3mm (25225)

3x16mm (4689)

4x3mm (25223)

4x4mm (7732)

4x10mm (31449)

Nuts (lock/plain)

M3 Locknut (25215)

M3 Alum. Locknut, Blue (31550)

M4 Locknut w/Flange & Knurl (91148)

FT M4 Locknuts w/Flange,

Blue (31551)

Ball Bearings

6x12x4mm (25238)

8x16x5mm (25236)

3x20mm (25188)

3x20mm BHPS (25185)

3x22mm (25189)

3x22mm BHPS (25208)

3x24mm (89204)

3x26mm (89205)

3x32mm BHPS (25209)

Page 29

29

:: 1/8 Kits and RTR’s

20501

20502

20503

20504

80905

80906

80907

80908

80912

80933

80934

MGT 4.60 SE RTR (ready-to-run)

MGT 8.0 Nitro RTR (ready-to-run)

Limited Edition MGT 4.60 Nitro RTR, w/flag body

(ready-to-run)

Limited Edition MGT 8.0 Nitro RTR, w/flag body

(ready-to-run)

RC8RS “Race Spec” Nitro Buggy RTR (ready-to-run)

RC8.2 Nitro Buggy FT Kit

RC8.2e Electric Buggy FT Kit

RC8.2e Electric Buggy RTR (ready-to-run)

RC8T Championship Edition

SC8.2e Short Course Race Truck, Rockstar/Makita

Electric RTR (ready-to-run)

SC8.2e Short Course Race Truck, Slick Mist Electric

RTR (ready-to-run)

:: Tools

1449

1541

1542

1543

1544

1545

1546

1547

1548

1551

1553

1554

1561

1562

1563

1564

1565

1567

1589

1590

1592

1655

1656

1657

1658

1659

1660

1661

1662

1663

1664

1665

1666

1667

1668

1669

1670

1671

1672

1673

1674

1719

1737

3718

3719

3720

6429

7709

89240

FT Off Road Ride Height Gauge

FT Hex Driver Set, (7 pcs)

FT .050” Silver Hex Driver

FT 1/16” Black Hex Driver

FT 1.5mm Purple Hex Driver

FT 5/64” Blue Hex Driver

FT 3/32” Gold Hex Driver

FT 2.5mm Green Hex Driver

FT 3mm Red Hex Driver

FT Screwdriver Set

FT Phillips Silver Screwdriver

FT Silver Spring Hook Tool

FT Nut Driver Set, (6 pcs)

FT 3/16” Black Nut Driver

FT 1/4” Red Nut Driver

FT 5.5mm Red Nut Driver

FT 11/32” Green Nut Driver

FT 8mm Gold Nut Driver

FT 5/64” Blue Ball Hex Driver

FT 3/32” Gold Ball Hex Driver

FT Ball Hex Driver Set, (3 pcs)

FT 8-Piece 1/4” Hex Drive Set

FT 1/4” Hex Drive Handle, without tips

FT 1/4” Hex Drive .050” Tip

FT 1/4” Hex Drive 1/16” Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Tip

FT 1/4” Hex Drive 3/32” Tip

FT 1/4” Hex Drive 1.5mm Tip

FT 1/4” Hex Drive 2.5mm Tip

FT 1/4” Hex Drive 3/16” Nut Driver Tip

FT 1/4” Hex Drive 1/4” Nut Driver Tip

FT 1/4” Hex Drive 11/32” Nut Driver Tip

FT 1/4” Hex Drive 5.5mm Nut Driver Tip

FT 1/4” Hex Drive 7.0mm Nut Driver Tip

FT 1/4” Hex Drive 8.0mm Nut Driver Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Ball End Tip

FT 1/4” Hex Drive 3/32” Ball End Tip

FT 1/4” Hex Drive Standard Screwdriver Tip

FT 1/4” Hex Drive Phillips Screwdriver Tip

FT 1/4” Hex Drive 2.5mm Ball End Tip

FT 1/4” 5 Piece Power Tool Tips Set (5/64-2.0mm,

1.5mm, 2.5mm, 5/64”- 2.0mm ball, 2.5mm ball)

FT Camber + Track Width Tool

FT Body Scissors

12 Inch Nylon Wire Ties

6 Inch Nylon Wire Ties

8 Inch Nylon Wire Ties

Shock Building Tool

4 Inch Nylon Wire Ties

FT RC8 Turnbuckle Wrench

:: Apparel

SP35**

1

SP36**

1

SP37**

1

SP38

SP39

1

SP66**

SP67**

1

SP68**

1

SP69**

1

1

SP70**

1

SP71**

1

SP73**

SP74**

1

SP75**

SP76**

SP77**

SP78**

SP79**

SP84**

SP85**

SP86**

SP102

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

12

12

1

12

1

SP103

SP411S

SP411L

SP413S

SP413L

SP416

SP417

SP418

SP420**

SP421S

SP421L

SP422S

SP422L

SP423S

SP423L

SP424S

SP424L

715

110684

:: RePlay Cameras

RP001

RP002

RP021

RP022

RP023

RP029

RP030

RP032

RP033

RP034

RP036

RP037

RP038

RP041

RP042

RP043

RP044

RP045

RP046

RP047

RP048

RP049

Reedy 09’ White T-Shirt (L, XL, 2XL)

Reedy 09’ Black T-Shirt (M, L, XL, 2XL, 3XL)

Reedy 2012 T-shirt - Black (S, M, L, XL, 2XL, 3XL)

Reedy Trucker Hat

Reedy Patch

Stencil Blue T-Shirt (S, M, L, XL, 2-6XL)

AE Stencil Gray Sweatshirt (S, M, L, XL, 2XL, 3XL)

AE Stencil Blue T-Shirt (M, L, XL)

AE 26 Time World Championship T-Shirt, Black

(S, M, L, XL, 2XL, 3XL)

Associated Windbreaker (S, M, L, XL, 3XL)

Associated Winter Jacket (S, M, L, XL, 2XL)

AE Long Sleeve T-Shirt (S, M, L, XL, 2XL)

AE White T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Blue T-Shirt (S, M, L, XL, 2-6XL)

AE Black T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE 2012 T-Shirt, Blue (S, M, L, XL, 2XL, 3XL)

AE 2012 T-Shirt, White (S, M, L, XL, 2XL, 3XL)

AE 2012 T-Shirt, Black (S, M, L, XL, 2XL, 3XL)

Reedy 3D T-Shirt, Black (S, M, L, XL, 2XL, 3XL)

Reedy Zip Hoodie, Black (S, M, L, XL, 2XL, 3XL)

Reedy Girl’s 3D T-Shirt, Black (S, M, L, XL)

Outer & Inner Boxes, for #SP-416

Inner Boxes only, for #SP416

AE Hat 11’ Flat Bill Black S/M

AE Hat 11’ Flat Bill Black L/XL

26 Time World Championship Hat S/M

26 Time World Championship Hat L/XL

Associated Car Carrier Bag, Medium

1/10 FT Motor Bag

Factory Team 1/10 Car Carrier Bag

AE Pit Gloves (M, L, XL)

AE 2012 Hat, Black, Flat Bill, S/M

AE 2012 Hat, Black, Flat Bill, L/XL

AE 2012 Hat, Black, Curved Bill, S/M

AE 2012 Hat, Black, Curved Bill, L/XL

AE 2012 Hat, White, Flat Bill, S/M

AE 2012 Hat, White, Flat Bill, L/XL

AE 2012 Hat, White, Curved Bill, S/M

AE 2012 Hat, White, Curved Bill, L/XL

Reedy 2009 Track Banner

Team Associated Track Banner

** Use part number plus the desired size when ordering!

Replay XD1080 Complete Camera System

Replay XD720 Complete Camera System

Replay XD1080 Lens Bezel Kit

Replay XD1080 Clear Lens Cover

Replay XD1080 Lens Bezel & Rear Cap O-Ring

Replay XD1080 HDMI to Mini-HDMI

Replay XD1080 Mini 8-pin USB Charge Data Cable

USB DC Car Charger 1A Stubby

USB DC Car Charger 500mAh

Micro SDHC USB Reader

3M VHB 4991 Mount Adhesive for SnapTray

3M VHB 5962 Mount Adhesive for Pro Flat Mount

3M VHB 5962 Mount Adhesive for SnapTray

Replay XD Suction Cup Arm Mini Clamp

Replay XD Suction Cup Short Arm Base

Replay XD Skateboard Mount

Replay XD VHB SnapTray, Convex

Replay XD VHB SnapTray, Flat

Au Plug for Universal DC Wall Charger

Eu Plug for Universal DC Wall Charger

Uk Plug for Universal DC Wall Charger

Universal USB DC Wall Charger 1A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Pr.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 30

:: Trouble Shooting

Description

Problem

30

Solution

No Power

No Throttle

No Steering

Throttle

Steering

Battery is discharged...........

Battery not plugged in.........

No light on speed control....

Receiver LED remains red.

Motor not plugged in............

Speed control out of ............

adjustment.

Motor failure............................

Servo not plugged in.............

Locked up steering linkage.

Servo failure.............................

Goes backwards when you

pull the trigger, or forward

when pushing brakes /

reverse.

Goes right when turning......

the wheel left (or left when

turned right.)

Charge battery.

Plug in battery.

Reset speed control using

your instruction manual.

Re-bind transmitter to the receiver.

Plug in motor.

Reset speed control using your

instruction manual.

Replace motor.

Plug servo in.

Free up steering linkage.

Replace servo.

Switch any two motor wires.

Check throttle reversing switches

on transmitter. Reset speed

control.

Check steering reversing switches

on transmitter.

Vehicle is

glitching

Reverse

Vehicle dies

or slows

Vehicle has a problem on.....

power.

No reverse or brakes...........

Speed control overheats....

Motor overheats...................

Gear mesh set too tight......

LiPo mode engages...............

Check for loose wires or check for

or dead radio batteries.

Radio interference.

Check that reverse mode has not

been turned off. Refer to speed

control instructions. Reset speed

control, or send in for repair.

Let speed control cool off. Check

gear, gear mesh, or bind in driveline.

Let motor cool and check

recommended gearing for motor

type.

Reset gear mesh (see instruction

manual).

LiPo mode on the ESC has

engaged, recharge your batteries.

(If running NiMH battery, turn off

LiPo mode)

Loading...

Loading...