Page 1

7/12

Page 2

2

:: Introduction

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and

maintaining your new RC12R5.2. Please take a moment to read through this manual to help familiarize yourself with these steps.

As part of the continued development to the already successful RC12R5.1 platform, Team Associated’s Factory Team is proud to

release the RC12R5.2-FT; a 1:12 scale electric 2WD on-road race-car kit.

Behind the doors of Area 51, the Factory Team engineers have further developed the IFMAR World Champion RC12R5 platform,

optimizing the chassis for the demands of today’s ultra competitive 1:12 scale racing class. The result is the RC12R5.2-FT kit, a

perfect combination of affordable styling and race winning development.

The RC12R5.2-FT kit comes ready to assemble, and includes a host of new parts prototyped and developed by Team Associated’s

Factory Team over the last couple racing seasons. The updated chassis shifts focus purely to LiPo racing batteries, centralizing the

mass for a lower polar moment of inertia and smoother handling characteristics. The RC12R5.2 carries an updated rear pod with

a graphite cross brace for added rigidity, and side damper tubes for easy use, maintenance, and adjustment. With a ROAR

National win under its belt already, it’s easy to see that the RC12R5.2-FT is… yet another Factory Team Champion By Design!

:: KIT Features

1. IFMAR World Championship winning Dynamic Strut front end from RC12R5

• Symmetric part layout in front end assembly helps minimize necessary spare parts

• 0°, 5° and 10° active strut mounts combined to one part

• Suspension arm attaches to aluminum front bulkhead to allow for adjustable front arm spacing

2. Updated motor mount and left rear bulkhead

• 3-point upper pod plate with graphite motor mount cross-brace

∙ Cross-brace stiffens rear pod assembly, and helps minimize twisting of upper and lower rear pod plates

∙ Motor mount and left rear bulkhead sections have been thickened to prevent bending

• Rear pod has been balanced for brushless motors

3. Ultra-rigid 2.5mm thick chassis mounts centralized LiPo battery mounting position

• Centralized mass helps stabilize mass transfer in high traction conditions

• Fits any ROAR approved 3.7V Li-Po battery pack

4. Aluminum side spring retainers

• Help center side spring for accurate adjustment

• Thumb wheel shape eliminates use of allen wrench

5. Innovative thru-shaft center shock

• Consistent shock building with no rebound

6. Damper tubes for error free side damping of rear pod

• Ease of build and simplicity of design allow for a more “tweak” free rear pod

7. Pivot-Ball rear pod design

• Increased durability of fixed length rear pod link

• Tuning options isolated allowing adjustment of roll and bump independently

• Hard anodized aluminum pivot balls at each joint

:: Additional Features

Your new 12R5.2 comes unassembled and requires the following items for completion. (refer to catalog section for suggestions):

• R/C two channel surface frequency radio system with steering servo • AA-sized batteries for transmitter

• 1 cell (3.7V) LiPo battery pack • Battery charger (specific for charging LiPo batteries)

• Electronic Speed Control (ESC) • R/C electric motor

• 1:12 scale lexan race body • Lexan specific spray paint

• 1:12 scale foam tires

• 64 pitch pinion gear (size to be determined by type and wind of motor selected)

:: Other Helpful Items

• Thread Lock (AE Part #1596) • Needle Nose Pliers • Soldering Iron • Wire Cutters

• Body Scissors (AE Part # 1737) • Reamer / Hole Punch • FT Hex Wrenches (AE Part # 1541) • Hobby Knife

• Calipers or a Precision Ruler • Silicone Shock Fluid (Refer to catalog for complete listings) • Silicone Diff Fluid (Refer to catalog for complete listings)

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 3

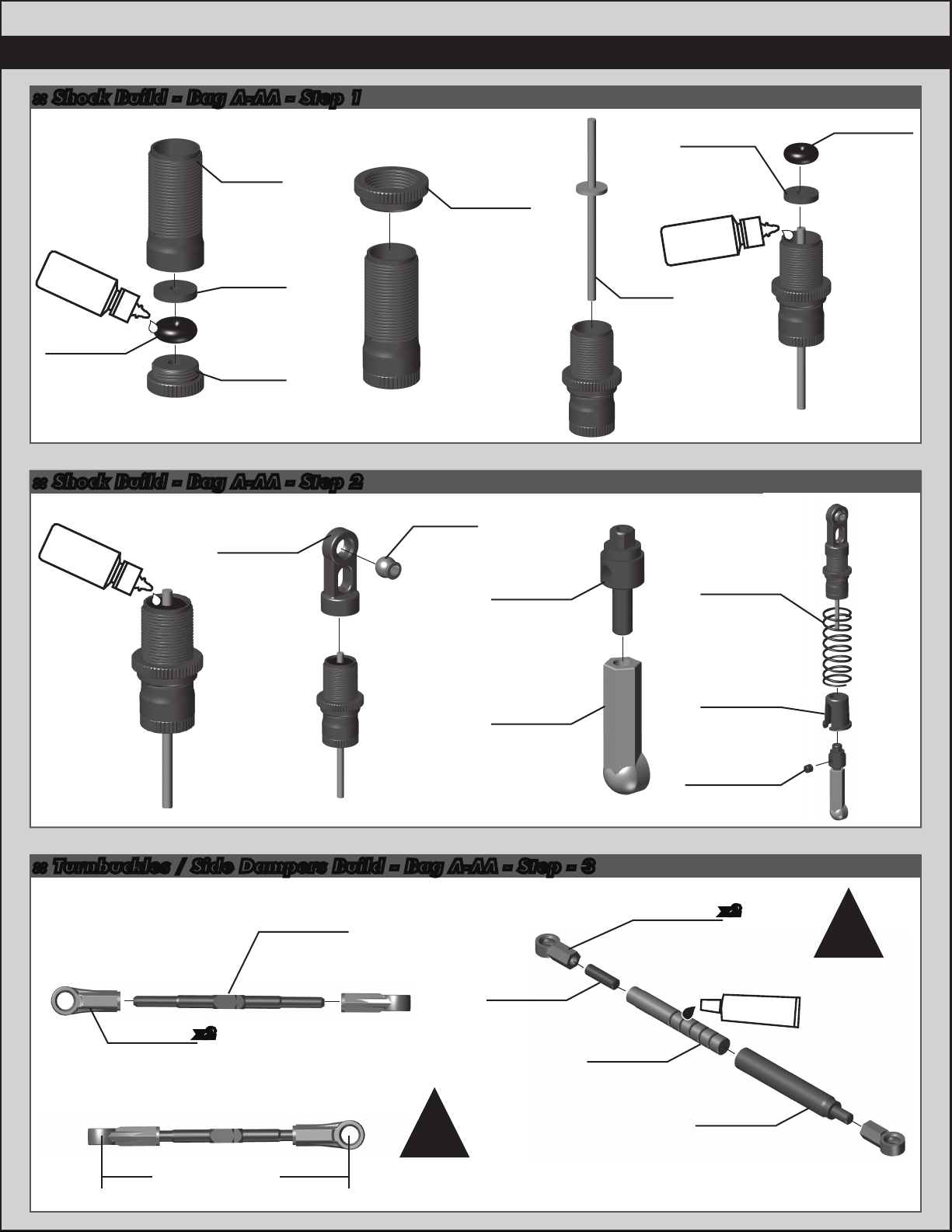

:: Shock Build - Bag A-AA - Step 1

4660

Shock

body

Shock oil

#5422

(30wt)

4663

Micro VCS

o-ring

4662

Shock

o-ring

bearing

4662

Shock

bottom

nut

:: Shock Build - Bag A-AA - Step 2

4661

Threaded

shock

collar

4664

Thru

shaft

4662

Shock

o-ring

bearing

Shock oil

#5422

(30wt)

3

4663

Micro VCS

o-ring

Shock oil

#5422

(30wt)

4662

Shock

thru cap

4637

Pivot

ball

4665

Shock

rod end

7230

Ball cup,

large

:: Turnbuckles / Side Dampers Build - Bag A-AA - Step - 3

Steering Turnbuckle

1403

FT blue Ti

turnbuckle

31305

Turnbuckle

eyelet

(1.65”)

x2

4671

M3x10mm

set screw

tube shaft

Anti roll

bar cup

4709

Damper

8452

Micro VCS

shock spring

(blue, 10lb)

4661

Spring

31500

M3x0.5x2.5

set screw

8828

set

x2

cup

#6636

S. diff grease

!

Build two

dampers

56.40mm

!

Build two

turnbuckles

4708

Damper

tube

Page 4

4

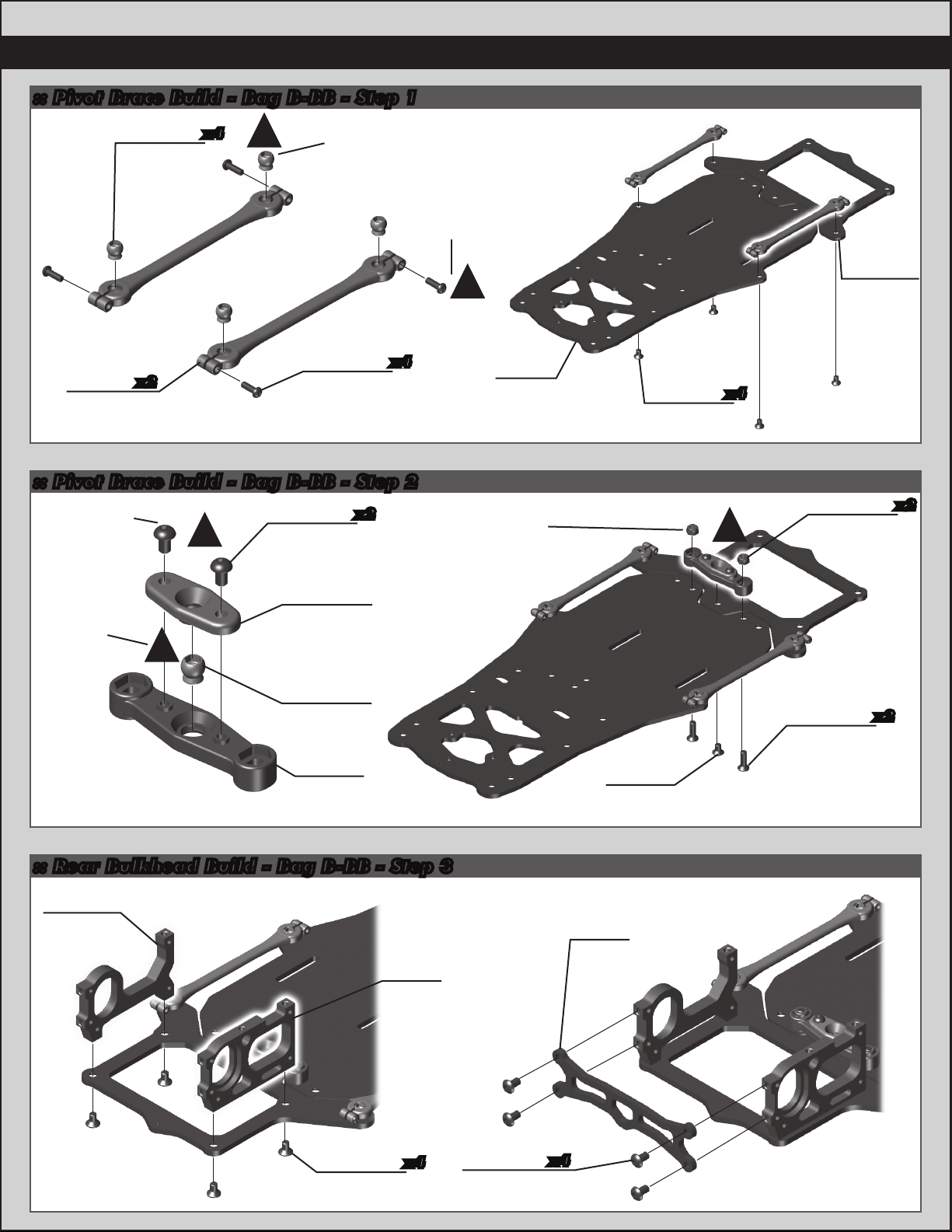

:: Pivot Brace Build - Bag B-BB - Step 1

Note:

Shoulder on pivot ball

should pont downward

Note:

Use screws to adjust for

free pivot ball movement

4672

M2x6mm

bhcs

x4

Pivot ball

4635

Rear

pod link

4637

x2

x4

!

:: Pivot Brace Build - Bag B-BB - Step 2

Note:

Use screws to

adjust for

free pivot ball

movement

Note:

Shoulder on

pivot ball

should pont

downward

4673

!

M2.5x4mm

bhcs

4635

Pivot

brace cap

!

Note:

x2

Leave the locknuts

loose, rock the

chassis and the

lower rear pod

plate side to side.

Slowly tighten

each side so the

plates rotate

freely.

!

4691

Chassis

31540

M3x5mm

fhcs

x4

!

4692

Lower

pod plate

31550

M3x0.5mm

locknut

(blue)

x2

4637

Pivot ball

4635

Pivot

brace

:: Rear Bulkhead Build - Bag B-BB - Step 3

4701

Left rear

bulkhead

4700

Motor

mount

M3x5mm

4702

Motor

mount

brace

31540

fhcs

25202

M3x10mm

fhcs

x2

31540

M3x5mm

fhcs

x4

31530

M3x5mm

bhcs

x4

Page 5

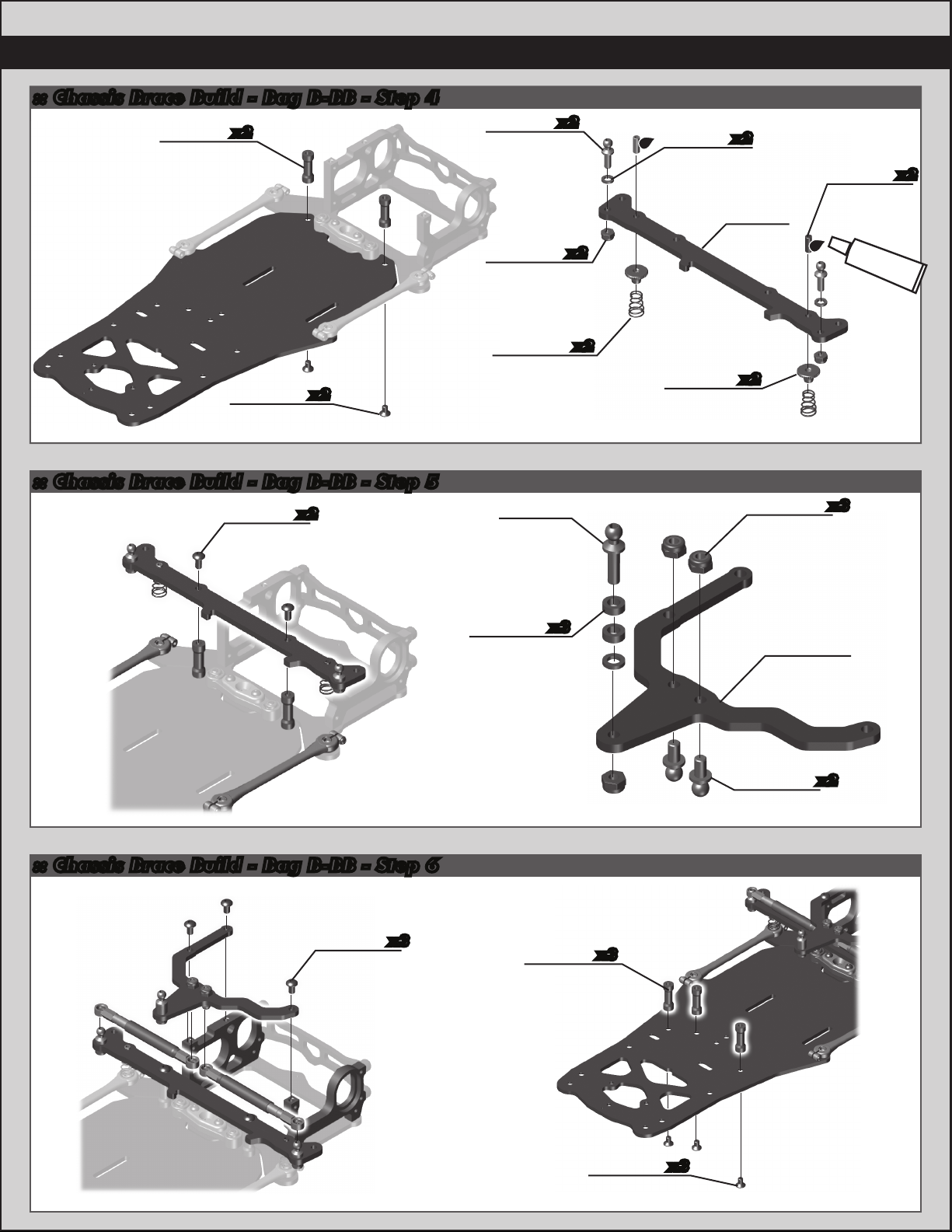

:: Chassis Brace Build - Bag B-BB - Step 4

4699

LiPo

standoff

x2

31284

Ballstud

long,

8mm

31550

M3x0.5mm

Lock nut

(blue)

x2

x2

31286

Ballstud

washer

(1mm)

x2

4704

Chassis

brace

5

4670

M3x8mm

set screw

#1596

thread lock

x2

31540

M3x5mm

fhcs

x2

:: Chassis Brace Build - Bag B-BB - Step 5

31531

M3x6mm

bhcs

x2

4644

Side spring

blue,

5.63 lbs

31285

Ballstud

long,

10mm

31286

Ballstud

washer

(2mm x2,

1mm x1)

x3

x2

4707

Side spring

retainer

x2

M3x0.5mm

Ballstud

short, 5mm

31550

Lock nut

(blue)

4703

Upper pod

plate

31280

x3

x2

:: Chassis Brace Build - Bag B-BB - Step 6

31530

M3x5mm

bhcs

x3

4699

LiPo

standoff

x3

31540

M3x5mm

fhcs

x3

Page 6

6

4621

Upper

arms

Note:

eyelet offset position relative

to the upper suspension arm

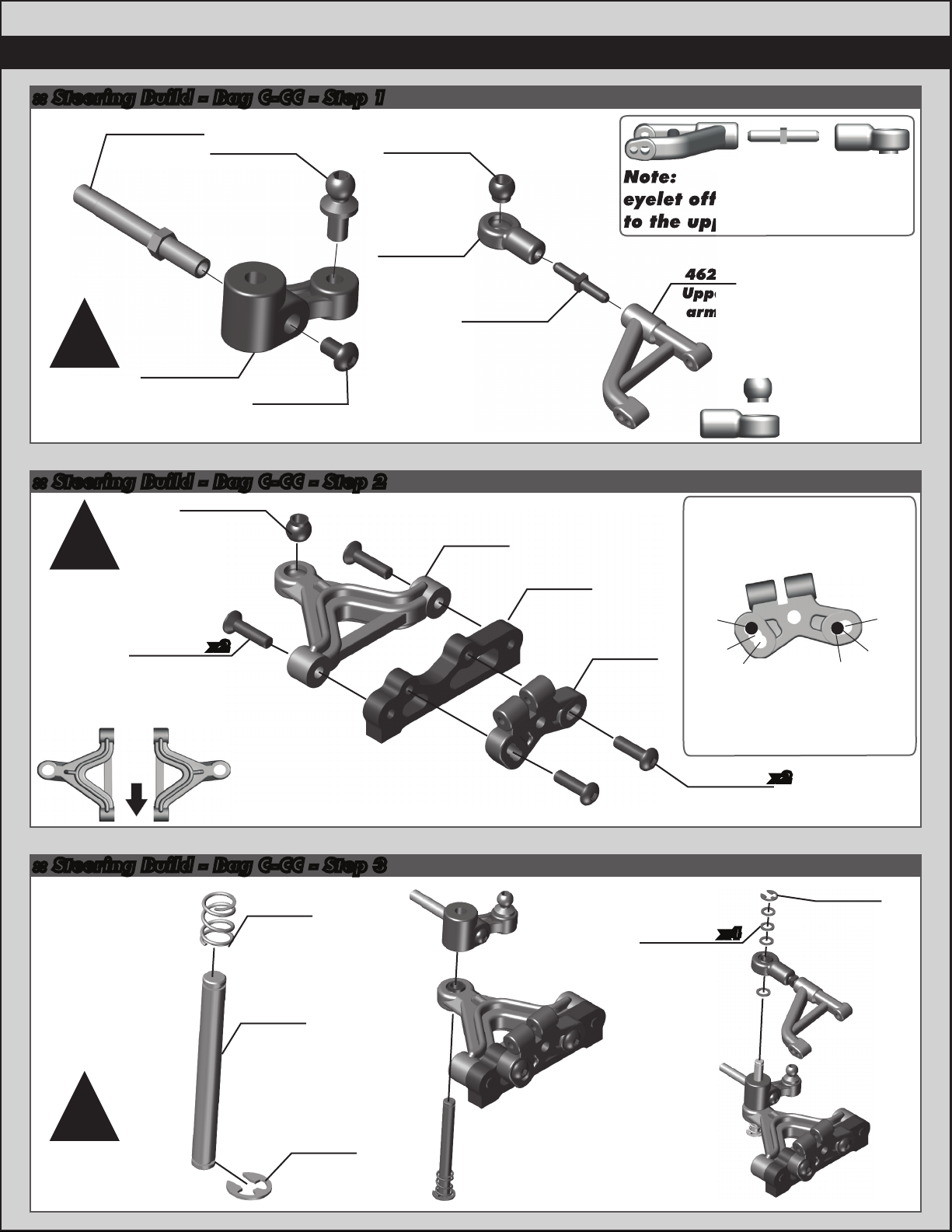

:: Steering Build - Bag C-CC - Step 1

4627

Front axle

!

Build left

and right

sides

4626

Steering

block

(left, right)

31280

Ballstud

short, 5mm

4673

M2.5x4mm

bhcs

:: Steering Build - Bag C-CC - Step 2

8417

Pivot ball

!

Build left

and right

sides

25203

M3x12mm

fhcs

Front

RF LF

of

car

x2

Note:

lower suspension

arm orientation

8417

Pivot ball

4622

Upper arm

eyelet

4706

Lower

arms

1410

FT blue

titanium

turnbuckle

(.630”)

bulkhead

4705

Front

Note:

eyelet offset position relative

to the upper suspension arm

4621

Upper

arms

Note:

eyelet offset

position to

the pivot ball

Upper Suspension

Mount Active

Caster Settings

10°

4626

Upper

arm

mount

0°

Note:

10°

10° is the

standard position

25211

M3x10mm

bhcs

x2

0°

5°5°

:: Steering Build - Bag C-CC - Step 3

4113

Spring

(0.020”)

4403

Grooved

hinge

pin

!

Build left

and right

sides

E-clip

6299

8425

Shim

6299

E-clip

x4

Page 7

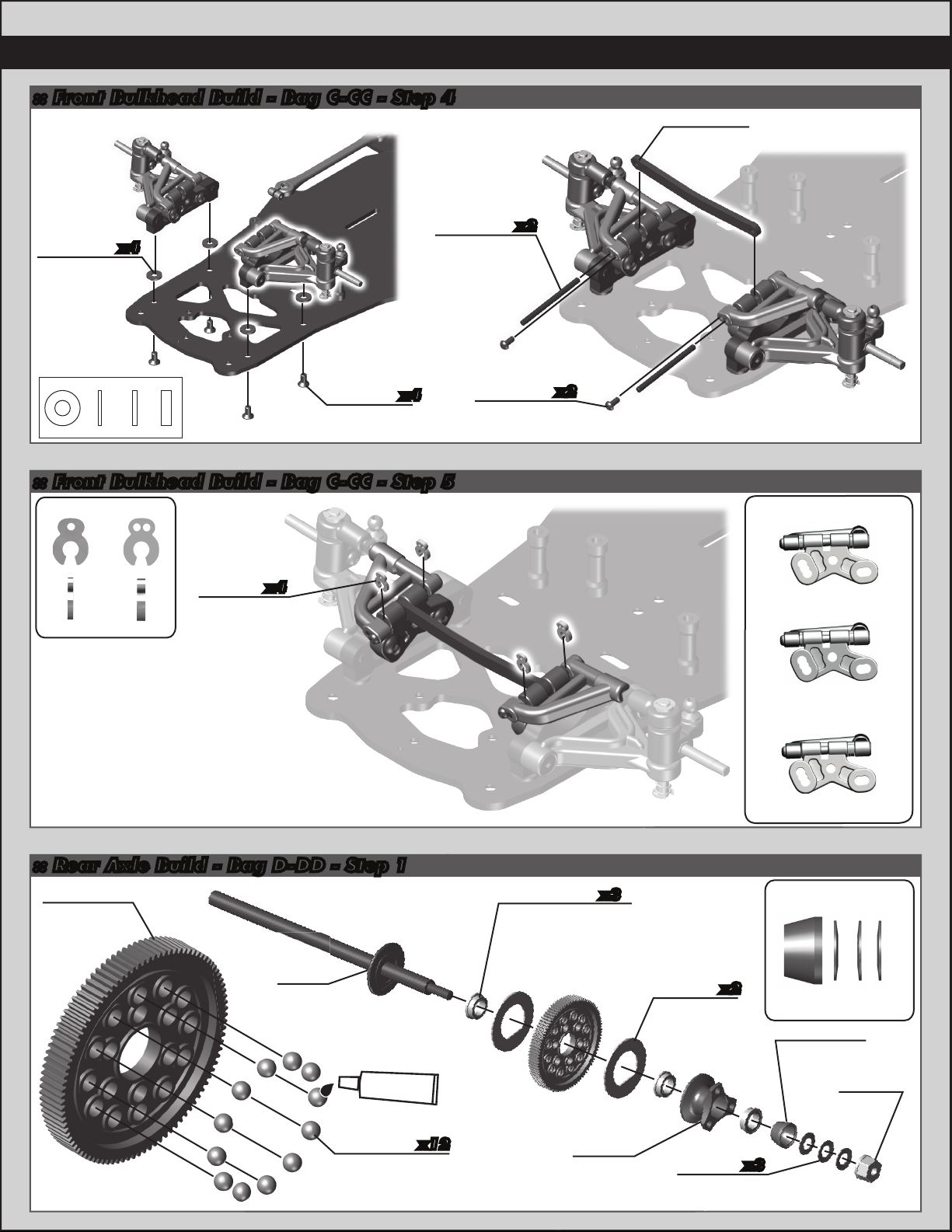

:: Front Bulkhead Build - Bag C-CC - Step 4

7

4698

LiPo hinge

pin brace

4617

Front

x4

hinge pin

bulkhead

shim

(1mm)

Bulkhead Shims

25201

x4

M3x8mm

0.5mm 1mm

2mm

fhcs

:: Front Bulkhead Build - Bag C-CC - Step 5

Caster Spacers

x4

0.8mm 1.2mm

4624

Caster

spacers

4623

Upper

31510

M2x4mm

x2

x2

bhcs

Caster Adjustments

1.80°

:: Rear Axle Build - Bag D-DD - Step 1

4615

Spur gear

96T

4565

Rear

axle

#6636

S. diff grease

6619

.125 carbide

diff balls

x12

897

3/8 x 1/4

flanged

bearing

4608

Right

wheel

hub

x3

8504

Diff

d-ring

4459

Bellville

washer

3.25°

standard

6.15°

Bellville Washers

x2

) ( (

4609

Diff thrust

cone

4185

Plastic

nut

x3

Page 8

8

3/8 x 1/4

flanged

bearing

:: Rear Axle Build - Bag D-DD - Step 2

897

3/8 x 1/4

flanged

bearing

x2

4568

2-56x5/16

shcs

4567

Left

wheel

hub

Rear axle

shims, .005”

4349

Ride height

adjuster #4

x2

:: Servo / Top Plate Build - Bag E-EE - Step 1

Servo not

included

7337

M3x0.5mm

washer

31532

M3x8mm

bhcs

x4

x4

4554

x4

4630

Servo

mount

Note:

this end onto

rear axle first

4624

Servo mount

spacer

Ackerman

Adjustment

Spacers

Note:

use spacers to adjust

ackerman settings

:: Servo / Top Plate Build - Bag E-EE - Step 2

x2

3760

Servo saver

(airtronics)

short, 5mm

31550

M3x0.5mm

locking nut

x2

Screw not

31280

Ballstud

included

31540

M3x5mm

fhcs

x2

Page 9

:: Top Plate Build - Bag E-EE - Step 3

4510

Antenna

tube

4655

31500

M3x2.5mm

set screw

Shock mount

brace

4696

LiPo shock

mount upright

31530

M3x5mm

bhcs

9

x3

31530

M3x5mm

31540

M3x5mm

fhcs

x2

4695

LiPo top

plate

bhcs

:: Center Shock Install - Bag E-EE - Step 4

31530

M3x5mm

x3

bhcs

Page 10

10

:: Turnbuckles - Bag E-EE - Step 5

Orient the notch

throughout the car.

The notch indicates

which end has the left

hand threads!

:: Body Mounts Build - Bag E-EE - Step 6

!

to the left

It is important that the turnbuckle eyelets move freely

once snapped on to the ballstud. If the fit is too tight,

the car handling will be inconsistent. To check, grab

turnbuckle eyelet with fingers and rotate the cup. If

there is resistance, lightly squeeze ball cup with needle

nose pliers as shown and test again. It is important

that the ball cup be snapped onto the ballstud before

squeezing with needle nose pliers. Be sure to check

and adjust the fit for each ball cup that is installed.

4653

Foam

bumper

4535

Body posts

25201

M3x8mm

fhcs

3897

Pivoting

body mount

x2

x2

x2

:: Body Mounts Build / Front Wheel Install - Bag E-EE - Step 7

3897

Pivoting

body mount

x2

1736

Body clip

x2

1736

Body clip

x2

4535

Body posts

31532

M3x8mm

bhcs

x2

x2

8425

Shim

Wheels/

Tires not

included

x3

3655

1/8 x 5/16

flanged

bearing

x2

31550

M3x0.5mm

lock nut

(blue)

Page 11

:: Rear Wheel / Motor Install - Bag E-EE - Step 8

Motor not

included

11

6284

4-40 x 1/4

shcs

Wheels/

Tires not

included

x6

31286

FT ballstud

washer

(1mm)

89229

FT blue

countersunk

washer

25202

M3x10mm

fhcs

Pinion/setscrew

not included

25211

M3x10mm

bhcs

:: Electronics Install - Bag C - Step 3

ESC/Receiver/

Transponder

not included

4675

M2.5x6mm

fhcs

x3

4676

M2.5x0.45mm

lock nut

x3

!

Remove three BHCS (#31530, see page 10) from top

plate standoffs and move top plate to install battery.

Key top plate around battery and replace three BHCS to

secure battery after taping to chassis with battery tape.

Battery not

included

!

Page 12

12

:: Tuning Tips

FRONT

Camber:

Camber is one of the most effective adjustments in tuning the car to the track conditions. In most situations only negative camber

(where the top of the tire is leaning in) is recommended. The typical setting for camber in the front wheels is -1 degree. Adding

more negative camber will give more steering, making the car feel more aggressive. Likewise, adding more positive camber will

make the car more stable and be easier to drive.

Caster:

Caster describes the angle of the kingpin from vertical when looking at the side of the car. Adding angle to the kingpin, or “caster”,

controls the amount of camber gain at the front wheels through steering angle. Negative caster means leaning the top of the

kingpin toward the back of the car, and it adds negative camber on the outside front wheel during steering. Using less negative

caster will give less steering entering the corner, making the car feel smoother and more stable. The standard setting of -3.25

degrees is good for most conditions, and -1.80 degrees is a good setting for extremely high traction conditions.

Active Strut Upper Arm Mount:

The active strut system dynamically controls caster through suspension travel. The active strut upper arm mount adds an angle to the

upper arm hinge pin, pointing the front of the pin down. This angle causes caster to become more positive as the suspension is

compressed. Increasing the angle in the active strut upper arm mount will give more entry steering, but less mid-corner steering.

In most conditions, the standard setting of 10 degrees is optimal. In bumpy, or very high bite conditions, using the 5 degree active

strut position can help to make the car more consistent through the corner.

Kingpin Damping:

Damping is added to the front suspension by applying silicone diff fluid to the outside of the kingpin below the bottom of the pivot

ball in the lower suspension arm. This is a necessary and highly effective adjustment to the front suspension. Typical diff fluid

weights for damping the kingpin spring vary from 5K to 60K. The standard starting point for silicone fluid is 30,000wt. With slower

spec motors, and in high bite conditions, 60,000wt can help to make the car more consistent through the corner.

Kingpin Spring:

The kit standard spring has a wire diameter of 0.020”, and is optimal for most conditions. If the racing surface is bumpy or low

grip, softer, 0.018” springs can help give the car more steering and consistency.

REAR

Rear Suspension Linkage:

It is extremely important that the rear pod linkage can pivot freely and doesn’t have any bind. The best way to check the linkage

is to remove the pod plates from the lower plate, this makes it much easier to feel any binding. We recommend checking the rear

linkage after a hard crash as the center pivot can shift slightly possibly causing rear suspension bind. If the suspension is not free,

loosen the 2 screws that hold the center pivot to the chassis. Place the chassis and rear pod on a flat surface, carefully tighten each

of the screws holding the center pivot. Now check the movement of the rear pod to be sure it’s free.

Side Damping:

Side damping is controlled by the damper tubes, and can be adjusted by changing the silicone “lube” that is applied to the damper

shaft. Increasing the thickness of the lube will increase the side damping, slowing down the speed at which the rear end of the

chassis will transition side-to-side. Increased side damping will help to make the car more stable in high grip conditions.

The standard lube for is 1000cst, increasing to 2000cst or 3000cst will help to make the car more stable when the grip levels are

higher.

Center Spring:

The center spring controls the ride height of the chassis as it is loaded over bumps in the track, and as the car accelerates and

decelerates. This adjustment is mainly relative to the mass of the chassis with all electronics and body included. The kit standard

blue spring is a good starting point for most racing conditions with 3.7V LiPo packs. In bumpier track conditions, a softer center

spring and more droop can help give more grip to the rear end of the car. With heavier 4.8V NiMh packs, a stiffer red spring may be

necessary to help keep the chassis from bottoming out on the track.

Center Damping:

Center damping controls the speed that the chassis will change ride height as it is loaded over bumps, and as the car accelerates and

decelerates. Using between 25wt and 35wt is a good match for the standard gold spring. Thicker oil will help to stiffen the rear of

the car, giving it more mid-corner steering. Likewise, thinner oil can help give the car more rear grip in low bite track conditions.

Page 13

13

4708

4709

4671

:: Shocks

4637

4660

4661

4662

4663

4664

4665

4666

7230

31500

12R5 Pivot Ball

12R5 Shock Body

12R5 Shock Collar & Cup

12R5 Shock Rebuild Kit

Micro VCS O-Ring

12R5 Thru Shaft

12R5 Shock Rod End

12R5 Shock Kit

Ball Cup

Set Screw 3x2.5mm

4637

:: Springs

4113

4114

4116

4117

4118

4119

4475

4476

4641

4642

4643

4644

4645

8449

8451

8452

8453

8454

King Pin Springs (.020) - KIT

King Pin Springs (.018)

King Pin Springs (.024)

King Pin Springs (.022)

King Pin Springs (.014)

King Pin Springs (.016)

Micro VCS Springs Black (4.00 LB)

Micro VCS Springs Green (6.00 LB)

Side Springs Black (3.75 LB)

Side Springs Green (4.38 LB)

Side Springs Silver (5.00 LB)

Side Springs Blue (5.63 LB) - KIT

Side Springs Gold (6.25 LB)

Micro VCS Springs Copper (16 LB)

Micro VCS Springs Silver (8 LB)

Micro VCS Springs Blue (10 LB)

Micro VCS Springs Gold (12 LB) - KIT

Micro VCS Springs Red (14 LB)

4662

4661

4663

4662

4664

4662

8

1

4

1

8

1

1

1

14

6

31550

4660

4662

4663

4662

4661

4665

7230

2

2

4113-4119

2

2

2

2

2

4641-4645

2

2

2

2

2

2

2

2

4475,

2

2

4476,

2

8449,

8451-8454

:: Turnbuckles

1402

1403

1405

1418

31305

FT Blue Titanium Turnbuckles 1.375”

FT Blue Titanium Turnbuckle 1.65” - Kit

FT Blue Titanium Turnbuckle 1.875”

FT Blue Titanium Turnbuckle 0.825”

Turnbuckle Eyelet

31305 1403

:: Damper Tubes

4671

4708

4709

8828

8828

M3x10mm Setscrew

Damper Tube

Damper Tube Shaft

Anti Roll Bar Cup Set

4671

4709

4708

:: Top Plate / Center Shock Mount

4510

4655

4695

4696

4699

31500

31530

31540

Antenna Rod, fiberglass, with end cap

FT Shock Mount Brace

12R5.1 LiPo Top Plate

12R5.1 LiPo Shock Mount Upright

12R5.1 LiPo Standoff

M3 x 2.5mm Set Screw

M3 x 5mm BHCS

M3 x 5mm FHCS

Pr.

Pr.

Pr.

Pr.

14

31305

6

2

2

1

8828

1

1

1

1

5

6

6

6

:: Shock Fluid

5420

5421

5422

5423

5424

5425

5426

5427

5428

5429

5430

5431

5432

5433

5434

5435

5436

5437

5438

10 Weight Silicone Shock Fluid

20 Weight Silicone Shock Fluid

30 Weight Silicone Shock Fluid

40 Weight Silicone Shock Fluid

22.5 Weight Silicone Shock Fluid

80 Weight Silicone Shock Fluid

27.5 Weight Silicone Shock Fluid

15 Weight Silicone Shock Fluid

25 Weight Silicone Shock Fluid

35 Weight Silicone Shock Fluid

45 Weight Silicone Shock Fluid

55 Weight Silicone Shock Fluid

32.5 Weight Silicone Shock Fluid

37.5 Weight Silicone Shock Fluid

42.5 Weight Silicone Shock Fluid

50 Weight Silicone Shock Fluid

60 Weight Silicone Shock Fluid

70 Weight Silicone Shock Fluid

47.5 Weight Silicone Shock Fluid

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

31500

4655

4510

4510

4696

31530

31530

4695

31540

4699

31530

31530

4699

4699

31540

31540

Page 14

14

:: Chassis / Pivots / Links

4635

4637

4672

4673

4675

4676

4691

25202

31540

31550

Pivot Brace/Pod Link Set

FT Pivot Ball

M2 x 6mm BHCS

M2.5 x 4mm BHCS

M2.5 x 6mm FHCS

M2.5 x 0.45mm Locknut

12R5.1 LiPo Chassis

M3 x 10mm FHCS

M3 x 5mm FHCS

FT M3 Locknut,

blue aluminum

1

8

6

6

6

6

1

20

6

6

4676

31550

31540

4635

4673

4637

31550

4635

4635

4672

:: Front Bumper

1736

3897

4535

4653

25201

FT Body Clips, blue

Pivoting Body Mounts

Body Posts

12R5 Foam Bumper

M3 x 8mm FHCS

6

4

2

1

20

4691

4675

1736

3897

4653

25202

4535

4637

4535

4637

31540

4672

31540

3897

1736

:: Servo / Servo Saver

3760

4624

4630

7337

25162

25167

31280

31532

31540

31550

Servo Saver, Airtronics

12R5 Caster / Servo Spacer

12R5 Servo Mount

.250 x .125 x .015 Washer

Servo Saver, XP/Futaba

Servo Saver, Airtronics, JR

5mm Ballstud, Short

M3 x 8mm BHCS

M3 x 5mm FHCS

M3 Aluminum Lock Nut

1

2ea

2

4

1

1

6

6

6

6

31550

25201

31280

3760

31532

7337

25201

4630

4624

31540

7337

Page 15

:: Front Bulkhead

1410

3655

4113

4403

4617

4621

4622

4623

4624

4626

4627

4673

4698

4705

4706

6299

8417

8425

25203

25211

31280

31510

31550

FT Ti Turnbuckle,

.630”, blue

Bearing, .1/8 x 5/16

King Pin Springs (.020)

Kingpin, 1:12 scale

Bulkhead Shims

Upper Arm

Upper Arm Eyelet

Upper Hinge Pin

Caster/Servo Spacer

Upper Arm Mount,

Steering Block

Front Axle

M2.5 x 4mm BHCS

Hinge Pin Brace

Front Bulkhead

Lower Arm

E-Clip, 1/8”

Pivot Ball

Kingpin Shim

M3 x 12mm FHCS

M3 x 10mm BHCS

Ballstud, short, 5mm

M2 x 4mm BHCS

FT M3 Locknut,

blue aluminum

2

2

2

2

4ea.

Pr.

4

2

2ea.

2

2

6

1

1

Pr.

12

4

10

20

20

6

6

6

4698

4624

25211

31510

4626

4617

4623

4705

4621

1410

8425

4673

25203

4626

4706

6299

8425

8417

4622

31280

25203

8417

4113

15

4627

3655

31550

8425

:: Rear Chassis Brace

1736

3897

4535

4644

4670

4699

4704

4707

31284

31286

31531

31532

31540

31550

FT Body Clips, metallic blue. Short

Pivoting Body Mounts, 8 body clips

Front and Rear Body Mounts

Side Spring, Blue, 5.63 lbs

M3 x 8mm Set Screw

12R5.1 LiPo Standoff

12R5.2 Chassis Brace

Side Spring Retainer

Ballstud, long, 8mm

FT Ballstud Washer, aluminum Set

M3 x 6mm BHCS

M3 x 8mm BHCS

M3 x 5mm FHCS

FT M3 Locknut, blue aluminum

6

4

2

2

6

5

1

2

6

1

6

6

6

6

31550

4707

3897

4535

31284

31286

4704

31532

4644

4670

31540

1736

31531

4699

6299

1736

4699

31531

4403

4670

3897

4535

31284

31286

31550

31532

31540

4707

4644

Page 16

16

:: Rear Axle / Differential

897

4185

4459

4462

4554

4565

4567

4568

4608

4609

4615

6284

6619

8504

Bearing, 3/8 x 1/4, flanged

8-32 Nylon Locknut

Belleville Washer

100T, 64 pitch Spur Gear

Rear Axle .005 Shim

FT Rear Axle

FT Wheel Hub, left side,

2-56 x 5/16” SHCS,

FT RC12R5 Hub

RC12R5 Thrust Cone

96T, 64 pitch Spur Gear - Kit

FT 4-40 X 1/4” SHCS,

blue aluminum

FT 1/8” Carbide Diff Balls

D-Drive Ring, for axle

2

6

3

1

6

1

1

6

1

1

1

12

8

2

6284

4554

4185

8504

4459

897

4609

4615

4608

8504

6619

:: Rear Bulkhead

897

4348

4349

4350

4351

4692

4700

4701

4702

4703

25202

25211

31280

31285

31286

31530

31540

31550

89229

Bearing, 3/8 x 1/4, flanged

Axle Height Adjuster, #0

Axle Height Adjuster, #1 - Kit

Axle Height Adjuster, #2

Axle Height Adjuster, #4

Lower Pod Plate

Motor Mount

LR Bulkhead

Motor Mount Brace

Upper Pod Plate

M3 x 10mm FHCS

M3 x 10mm BHCS

Ballstud, short, 5mm

Ballstud, long, 10mm

FT Ballstud Washer, aluminum Set

M3 x 5mm BHCS

M3 x 5mm FHCS

FT M3 Locknut, blue aluminum

FT Blue Countersunk Washer

20

20

10

4565

4554

897

4567

4568

6284

2

2

2

2

2

1

1

1

1

1

31285

31286

31530

31530

31550

31530

4703

6

6

1

6

6

6

89229

25202

25211

31550

897

31280

4349

31530

4702

31530

31286

4692

4700

31540

4701

4349

897

31540

31540

Page 17

17

:: Reedy Motors and ESC’s

940

941

941S

942

943

944

945

946

947

948

949

950

951

952

954

955

956

957

958

987

29225

29226

29227

29228

29229

29230

29234

29235

29236

29237

29238

29239

29240

29241

29242

29243

29244

29245

29246

Reedy Sonic 21.5 Stock (sensored)

Reedy Sonic 17.5 Stock (sensored)

Sonic 540 17.5 Replacement Stator

Reedy Sonic 13.5 Stock (sensored)

Reedy Sonic 10.5 Modified (sensored)

Reedy Sonic 9.5 Modified (sensored)

Reedy Sonic 8.5 Modified (sensored)

Reedy Sonic 7.5 Modified (sensored)

Reedy Sonic 6.5 Modified (sensored)

Reedy Sonic 5.5 Modified (sensored)

Reedy Sonic 5.0 Modified (sensored)

Reedy Sonic 4.5 Modified (sensored)

Reedy Sonic 4.0 Modified (sensored)

Reedy Sonic 3.5 Modified (sensored)

Sonic 540 Stock Rotor 12.3 x 24.2 (7.25)

Sonic 540 Stock Rotor 12.3 x 25.0 (7.25)

Sonic 540 Stock Rotor 12.5 x 25.0 (7.25)

Sonic 540 Modified Rotor 12.2 x 25.0 (5.0)

Sonic 540 Modified Rotor 12.5 x 25.0 (5.0)

Sonic 540 Modified Rotor 12.5 x 25.0 (5.0)

Sonic 540 9.5/LRP SXX Competition V2 ESC Combo

Sonic 540 8.5/LRP SXX Competition V2 ESC Combo

Sonic 540 7.5/LRP SXX Competition V2 ESC Combo

Sonic 540 6.5/LRP SXX Competition V2 ESC Combo

Sonic 540 5.5/LRP SXX Competition V2 ESC Combo

Sonic 540 5.0/LRP SXX Competition V2 ESC Combo

Sonic 540 21.5/LRP SXX Stock Spec V2 ESC Combo

Sonic 540 17.5/LRP SXX Stock Spec V2 ESC Combo

Sonic 540 13.5/LRP SXX Stock Spec V2 ESC Combo

Sonic 540 10.5/LRP SXX Stock Spec V2 ESC Combo

Sonic 540 9.5/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 8.5/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 7.5/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 6.5/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 5.5/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 5.0/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 4.5/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 4.0/LRP SXX TC-Spec V2 ESC Combo

Sonic 540 3.5/LRP SXX TC-Spec V2 ESC Combo

:: Reedy Accessories

605

606

607

651

653

654

655

656

658

659

660

661

663

664

665

667

716

959

960

961

962

972

973

978

979

980

981

982

992

Motor Cooling Fans (2)

Charge Harness 2S Saddle Pack 4mm

Charge Harness 2S Standard Pack 4mm

Battery Bars (8)

Battery Bars (100)

4.0mm plugs (2M, 2F)

4.0mm plugs (2M, 10F)

4.0mm plugs (10F)

4.0mm plugs (10M)

4.0mm plugs (30M)

3.5mm plugs (3M, 3F)

3.5mm plugs (10F)

3.5mm plugs (10M)

3.5mm plugs (30M)

Single Cell Shrink - Clear (12)

Single Cell Shrink - Clear (100)

Reedy 09 Decal Set

Sonic 540/550 Sensor w/Bearing

Sonic 540/550 Insulator Set (2 pcs.)

Sonic 540/550 Timing Cap w/Screws

Sonic 540 Case Screws (3 pcs.)

Sonic 540 Steel Bearing Set

Sonic 540 Ceramic Bearing Set

Flat Sensor Wire 70mm

Flat Sensor Wire 110mm

Flat Sensor Wire 150mm

Flat Sensor Wire 200mm

Flat Sensor Wire 270mm

Sonic 540 Rotor Spacers

:: Reedy Batteries and Chargers

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

302

303

307

600

604

629

632

633

634

637

AA Alkaline 1.5V (4)

AA 2700mAh NiMH 1.2V Rechargeable (4)

LiFe Pro RX Battery 250mAh 6.6V

LiPo 65C 6500mAh 3.7V

Reedy 526-S AC/DC 2S-6S Cell LiPo/LiFe Charger

LiPo 60C 5500mAh 3.7V

TX Lightweight Battery 1350mAh 11.1V

TX Battery - 3PK, M11 3000mAh 11.1V

TX Battery - Helios, Z1 2400mAh 11.1V

TX Battery - M11X 2500mAh 7.4V

:: LRP Speed Controls

LRP80705

LRP80905

LRP80915

LRP80955

SPX Zero

SXX Comp v.2 Speed Control

SXX Stock-Spec v.2

SXX TC-Spec v.2 Speed Control

:: LRP Brushless Motors / Combos

LRP50430

LRP50440

LRP50450

LRP50460

LRP50480

LRP50643

LRP50644

LRP50654

LRP50664

LRP50674

LRP50684

LRP50689

LRP50694

LRP50704

LRP50832

LRP50842

LRP50852

LRP50862

LRP80677

LRP80678

LRP80679

LRP80680

Vector K4 6.5 Turn

Vector K4 8.5 Turn

Vector K4 10.5 Turn

Vector K4 13.5 Turn

Vector K4 17.5 Turn

Vector X-20 10.5 Turn

Vector X-20 9.5 Turn

Vector X-20 8.5 Turn

Vector X-20 7.5 Turn

Vector X-20 6.5 Turn

Vector X-20 5.5 Turn

Vector X-20 5.0 Turn

Vector X-20 4.5 Turn

Vector X-20 4.0 Turn

Vector X-12 Stockspec 10.5 Turn

Vector X-12 Stockspec 13.5 Turn

Vector X-12 Stockspec 17.5 Turn

Vector X-12 Stockspec 21.5 Turn

SXX SS v.2 / 10.5T SS

SXX SS v.2 / 13.5T SS

SXX SS v.2 / 17.5T SS

SXX SS v.2 / 21.5T SS

:: LRP Misc.

LRP50621

LRP50622

LRP50623

LRP50626

LRP50632

LRP50634

LRP50635

LRP50636

LRP50637

LRP50638

LRP50639

LRP80135

LRP82512

LRP82515

LRP82520

LRP82530

LRP82531

LRP819307

LRP819310

LRP819315

LRP819320

X-12 Optional Ceramic Ball Bearings

X-12 Small Parts Set

X-12 PreciSensor Unit

X-12 Alum Rear Cover

X-12 12.0mm Sintered Rotor

X-12 13.0mm Sintered Rotor

X-12 Stock Spec Rotor 12.45mm

Works Team X-12 12.0mm Rotor

Works Team X-12 12.5mm Rotor

Works Team X-12 13.0mm Rotor

X-12 Stock Spec 1S LiPo Rotor

BEC Stabilizing Capacitor

SXX Low Profile Fan

30mm Motor Fan/Clamp, Gunmetal

Radical Cooling Set, Blue

SXX Power Cap 3.7-4.8V

SXX Power Cap 6.0-7.4V

70mm High Flex Sensor Wire

100mm High Flex Sensor Wire

150mm High Flex Sensor Wire

200mm High Flex Sensor Wire

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 18

18

:: LRP Chargers, Soldering Irons

LRP41281

LRP41555

LRP42103

LRP42104

LRP42105

LRP42305

LRP42306

LRP43200

LRP45200

LRP65800

LRP65802

LRP65803

LRP65804

Quadra Pro 2 Charger

Pulsar Touch Competition Charger

LiPo Balance Board XH

LiPo Balance Board FP/TP

LiPo Balance Board PQ

Pulsar Touch Temperature Sensor

Pulsar Touch Sensor Wire Splitter

LRP Competition 20A Power Supply

LiPo Parallel Balancer

High Power Solder Station

Soldering Tip 5mm

Soldering Tip 1.2mm

Soldering Handle

:: XP Electronics

29125

29126

29143

29145

29166

29167

29209

29210

29211

29212

29217

29218

29221

29222

S1903MG Servo

S2008MG Servo

XP SC700-BL Brushless ESC

XP SC1300-BL Brushless ESC

XP DS1313 Digital Servo

XP DS1015 Digital Servo

Gear Set, DS1313

Gear Set, DS1015

Servo Case , DS1313/DS1015

Accessory Pack, DS1313/DS1015

TRS402SSi 2.4GHz 4Ch Receiver

XP2-SSi 2.4GHz Radio System

XP3-SS 2.4GHz Radio System

TRS401SS 2.4GHz 4Ch Receiver

:: Apparel

SP35**

SP36**

SP37**

SP38**

SP39**

SP66**

SP67**

SP69**

SP70**

SP71**

SP73**

SP74**

SP75**

SP76**

SP411S

SP411L

SP413S

SP413L

SP417

SP418

SP420**

715

4710

110684

:: Notes

Reedy 09’ White T-Shirt (M, L, XL, 2XL, 3XL)

Reedy 09’ Black T-Shirt (M, L, XL, 2XL, 3XL)

Reedy 2012 T-shirt - Black (S, M, L, XL, 2XL, 3XL)

Reedy Trucker Hat

Reedy Patch

AE Stencil Blue T-Shirt (S, M, L, XL, 2-6XL)

AE Stencil Gray Sweatshirt (S, M, L, XL, 2XL, 3XL)

AE 26 Time World Championship T-Shirt, Black

(S, M, L, XL, 2XL, 3XL)

Associated Windbreaker (S, M, L, XL, 2XL, 3XL)

Associated Winter Jacket (S, M, L, XL, 2XL)

AE Long Sleeve T-Shirt (S, M, L, XL, 2XL)

AE White T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Blue T-Shirt (S, M, L, XL, 2-6XL)

AE Black T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)

AE Hat 11’ Flatbill Black S/M

AE Hat 11’ Flatbill Black L/XL

26 Time World Championship Hat S/M

26 Time World Championship Hat L/XL

1/10 FT Motor Bag

Factory Team 1/10 Car Carrier Bag

AE Pit Gloves (M, L, XL)

Reedy 2009 Track Banner

12R5.2 Decal Sheet

Team Associated Track Banner

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Pr.

1

1

1

:: Tools

1111

1450

1541

1542

1543

1544

1545

1546

1547

1548

1551

1553

1554

1561

1562

1563

1564

1565

1566

1567

1589

1590

1592

1655

1656

1657

1658

1659

1660

1661

1662

1663

1664

1665

1666

1667

1668

1669

1670

1671

1672

1673

1674

1719

1737

3718

3719

3720

3987

6429

6956

7709

FT Turnbuckle Wrench

FT Ride Height Gauge

FT Hex Driver Set, (7 pcs)

FT .050” Silver Hex Driver

FT 1/16” Black Hex Driver

FT 1.5mm Purple Hex Driver

FT 5/64” Blue Hex Driver

FT 3/32” Gold Hex Driver

FT 2.5mm Green Hex Driver

FT 3mm Red Hex Driver

FT Screwdriver Set

FT Phillips Silver Screwdriver

FT Silver Spring Hook Tool

FT Nut Driver Set, (6 pcs)

FT 3/16” Black Nut Driver

FT 1/4” Red Nut Driver

FT 5.5mm Red Nut Driver

FT 11/32” Green Nut Driver

FT 7.0mm Silver Nut Driver

FT 8mm Gold Nut Driver

FT 5/64” Blue Ball Hex Driver

FT 3/32” Gold Ball Hex Driver

FT Ball Hex Driver Set, (3 pcs)

FT 8-Piece 1/4” Hex Drive Set

FT 1/4” Hex Drive Handle, without tips

FT 1/4” Hex Drive .050” Tip

FT 1/4” Hex Drive 1/16” Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Tip

FT 1/4” Hex Drive 3/32” Tip

FT 1/4” Hex Drive 1.5mm Tip

FT 1/4” Hex Drive 2.5mm Tip

FT 1/4” Hex Drive 3/16” Nut Driver Tip

FT 1/4” Hex Drive 1/4” Nut Driver Tip

FT 1/4” Hex Drive 11/32” Nut Driver Tip

FT 1/4” Hex Drive 5.5mm Nut Driver Tip

FT 1/4” Hex Drive 7.0mm Nut Driver Tip

FT 1/4” Hex Drive 8.0mm Nut Driver Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Ball End Tip

FT 1/4” Hex Drive 3/32” Ball End Tip

FT 1/4” Hex Drive Standard Screwdriver Tip

FT 1/4” Hex Drive Phillips Screwdriver Tip

FT 1/4” Hex Drive 2.5mm Ball End Tip

FT 1/4” 5 Piece Power Tool Tips Set (5/64-2.0mm,

1.5mm, 2.5mm, 5/64”- 2.0mm ball, 2.5mm ball)

FT Camber + Track Width Tool

FT Body Scissors

12 Inch Nylon Wire Ties

6 Inch Nylon Wire Ties

8 Inch Nylon Wire Ties

FT Droop Gauge

Shock Building Tool

Molded Tools, Set

4 Inch Nylon Wire Ties

Associated Electrics, Inc.

26021 Commercentre Drive

Lake Forest, CA 92630-8853 USA

http://www.TeamAssociated.com

http://www.RC10.com

http://twitter/Team Associated

http://bit.ly/AEonFacebook

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

12

12

1

1

1

12

** Use part number plus the desired size when ordering!

call: (949) 544-7500

fax: (949) 544-7501

Check out the following web sites for all of our

electric kits & rtr’s, current products, new

releases, setup help, tips, and racing info!

www.TeamAssociated.com. - www.RC10.com

Page 19

Driver: Date:

Track: Event:

Setup Sheet

Front Suspension

Ride Height: Camber:

3.5mm 3.5mm

Conditions: Rev.1

-1°

Team Setup

Rear Suspension

Ride Height: Droop:

Droop: Toe:

Upper Kingpin Shims Lower Kingpin Shims

3 Shims (0.045”)

Upper Arm

Mount Spacer

None None

FR Shim

1.80°

3.25°

6.15°

Front Tires Rear Tires

Tire:

Diameter:

Additive Amount:

Additive Time:

LF RF LR RR

Body

Body Type:

Notes:

Race and Vehicle Comments

Qualify: Main: Finish: TQ:

Comments:

Thick

Thin

-----

Lower Arm

Spacer

RR Shim

Thin

Thick

Thick, Thin

Tire:

Diameter:

Additive Amount:

Additive Time:

:: For more setups, visit RC10.com and click on “Setup Sheets”

1 Shim (0.015”)

1 Shim (0.015”)

Spring:

Lube:

10°

5°

0°

+1° (out) 4 168mm

Axle Shims

0.020

30,000 cst

Bumpsteer

Ball & Shims

Black +2mm

Ride Height

Spacing

1mm

Front

Shim

Rear

Shim

Ride Height Adjuster: Axle Width:

Center ShockFront Arms

Shock Length

66.5mm

Upper Ball & Shims

Silver +5mm

Spring:

Oil:

Damper Tubes & Side Springs

Outer Ball & Shims

Spring:

Preload:

Rear Pod Links

Motor/Battery

Motor:

Timing: Gearing: /

Rollout:

Battery:

Notes:

Radio

Radio:

Turning Circle:

Steering Expo:

Brake E.P.:

Throttle Expo:

Speed Control

S.C. Type:

S.C. Settings:

S.C. Software:

Notes:

Track Info

Traction: High Medium Low

Surface: Carpet Asphalt

Smooth Bumpy

Other:

Blue

None

Front Link Shims Rear Link Shims

None None

Silver +1mm

25wt

Lube

20,000 cst

Blue

Page 20

:: Hardware - 1:1 Scale View

20

Socket Head (shcs)

Shims and Washers

Kingpin SHim (8425)

Blue Aluminum Shims

Bulkhead Shim (4617)

T-Plate Spacers (4650)

2-56x5/16” (4568)

4-40x1/4” (6284)

.030 Washer (9630)

1mm, 2mm (31286)

Gold Washer (7337)

0.5mm, 1mm, 2mm

Rear Axle Shim

.005” (4554)

Flat Head (fhcs)

Setscrew

Ball Bearings

Rear Axle Bearing (897)

Front Wheel Bearing (3655)

2.5x6mm (4675)

3x5mm (31540)

3x8mm (25201)

3x10mm (25202)

2-56x3/8 (31125)

3x2.5mm (31500)

3x5mm (89219)

3x8mm (4670)

3x16mm (4689)

.250 x .375 x .125

.125 x .313

Button Head (bhcs)

2x4mm (31510)

2x6mm (4672)

2.5x4mm (4673)

3x6mm (31531)

3x8mm (31532)

3x10mm (25211)

Nuts (lock/plain)

M2.5 Locknut (4676)

M3 Locknut (31550)

Pivot Balls

Hard Anodized Pivot Ball (4637)

Plastic Pivot Ball (8417)

Ballstuds

Notes:

Black 5mm short (31280)

(Ti Nitride 5mm short, 31288)

Silver 8mm short (31283)

(Ti Nitride 5mm long, 31291)

Black 8mm short (31281)

(Ti Nitride 8mm short, 31289)

Silver 8mm long (31284)

(Ti Nitride 8mm long, 31292)

Black 10mm short (31285)

(Ti Nitride 10mm short, 31290)

Silver 10mm long (31285)

(Ti Nitride 10mm long, 31293)

Page 21

Driver: Date:

Track: Event:

Setup Sheet

Front Suspension

Ride Height: Camber:

Conditions: Rev.1

Rear Suspension

Ride Height: Droop:

Droop: Toe:

Upper Kingpin Shims Lower Kingpin Shims

Axle Shims

Spring:

Lube:

Upper Arm

Mount Spacer

Lower Arm

Spacer

Bumpsteer

Ball & Shims

Ride Height

Spacing

Ride Height Adjuster: Axle Width:

Center ShockFront Arms

Shock Length

Upper Ball & Shims

Spring:

Oil:

Damper Tubes & Side Springs

Lube

Outer Ball & Shims

Spring:

Preload:

FR Shim

1.80°

3.25°

6.15°

Front Tires Rear Tires

Tire:

Diameter:

Additive Amount:

Additive Time:

LF RF LR RR

Body

Body Type:

Notes:

Race and Vehicle Comments

Qualify: Main: Finish: TQ:

Comments:

Thick

Thin

-----

RR Shim

Thin

Thick

Thick, Thin

Tire:

Diameter:

Additive Amount:

Additive Time:

:: For more setups, visit RC10.com and click on “Setup Sheets”

Front

Shim

10°

5°

0°

Rear

Shim

Rear Pod Links

Front Link Shims Rear Link Shims

Motor/Battery

Motor:

Timing: Gearing: /

Rollout:

Battery:

Notes:

Radio

Radio:

Turning Circle:

Steering Expo:

Brake E.P.:

Throttle Expo:

Speed Control

S.C. Type:

S.C. Settings:

S.C. Software:

Notes:

Track Info

Traction: High Medium Low

Surface: Carpet Asphalt

Smooth Bumpy

Other:

Page 22

current products, new releases, setup help, tips, and racing info!

Check out the following web sites for all of our kits,

www.TeamAssociated.com. - www.RC10.com

call: (949) 544-7500 - fax: (949) 544-7501

http://twitter/Team_Associated

http://bit.ly/AEonFacebook

http://www.TeamAssociated.com

Lake Forest, CA 92630 USA

http://www.RC10.com

26021 Commercentre Dr.

Associated Electrics, Inc.

Loading...

Loading...