Page 1

Page 2

2

:: Introduction

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and

maintaining your new RC10B5 Team Kit. Please take a moment to read through this manual to help familiarize yourself with these

steps.

We are continually changing and improving our designs; therefore, actual parts may appear slightly different than in the

illustrations. New parts will be noted on supplementary sheets located in the appropriate parts bags. Check each bag for these

sheets before you start to build.

:: KIT Features

Features in the RC10B5 Team Kit:

• Narrowed composite tub chassis with centralized mass and optimized motor position for improved handling and balance

• Chassis fits R.O.A.R. approved 2S saddle packs and 2S short packs using optional foam insert

• V2 12mm “Big Bore” threaded aluminum shocks with 3mm shock shafts and updated O-rings for improved smoothness

• VTS (Variable Torque multi-plate Slipper) with 3 drive surfaces and high-resolution spring

• New transmission has stronger gears, precision ball bearings, and a 14 carbide ball differential for increased life and torque

capacity

• Adjustable front suspension mount angle (kick-up) options of 25˚ and 30˚

• New front suspension features heavy duty steering and caster blocks, while the insert system allows for easy caster and trailing

axle adjustments

• One piece front axle/hex adapter and larger front wheel bearing for added durability

• Updated full bearing steering system with horizontal ball studs for finer Ackermann adjustments

• Heavy-duty ball cups and ball studs allow for maximum suspension travel while reducing binding and friction

• Rear hubs feature larger bearings as well as the quick and easy insert system to adjust camber link position and rear toe-in.

• B5 clear body and wing included

:: Additional

Your new B5 Team Kit comes unassembled

and requires the following items for completion

(refer to catalog section for suggestions):

• R/C two channel surface frequency radio system

• AA-size batteries for transmitter (#302 alkaline)

• Electronic Speed Control, ESC (#29140, #29143)

• Steering servo (#29166, #29167) • R/C electric motor

• Pinion gear, size determined by type/wind of motor

• Battery charger (#604 LiPo compatible charger)

• 2 cell LiPo battery pack

(#314 square, #310 Saddle Pack, #602 Shorty)

• Calipers or a precision ruler • Needle nose pliers

• Lexan specific spray paint

• Reamer / hole punch

• Tire glue (#1597)

• Thread locking compound (#1596)

• Tires and Inserts, Fronts and Rears

Tools included:

• Allen wrenches 1.5mm, 2.0mm

• #1113 12mm Shock Tool

• Multi-wrench

:: Other Helpful Items

• Silicone Shock Fluid (Refer to catalog for complete listings)

• Body Scissors (AE Part # 1737) • Reamer / Hole Punch • Wire Cutters / Hobby Knife • Soldering Iron

• 8 Piece Hex Driver Set (AE Part # 1655)• Needle Nose Pliers • Multi Tool (AE Part #7494)

• 7mm Nut Driver • Calipers or a Precision Ruler • Green Slime shock lube (AE Part # 1105)

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 3

12/13

:: Table of Contents

1................... Cover

2................... Introduction

3................... Table of Contents

3

12................ Turnbuckles Build

(Bag H-HH)

13 - 14........ Shocks Build

(Bag I-II)

4................... Front Top Plate and

Steering Build

(Bag A-AA)

5................... Front Arms and Uprights Build

(Bag B)

6 - 7.............. Shock Towers and Rear

Chassis Brace Build

(Bag C)

7 - 8............. Differential Build

(Bag D-DD)

8 - 9............. Gearbox Build

(Bag E)

9 - 10.......... Slipper Build

(Bag F-FF)

11................. Rear Hub and CVA Build

(Bag G)

14 - 16........Electronics Build

(Bag J)

16 - 17.........Wheels, Tires, and Body Build

(Bag K)

18 - 20....... Tuning Tips

21 - 29....... Catalog

30................ Notes / Contact Info

31................ Setup Sheet “Kit Setup”

32................ 1:1 Hardware “Fold Out”

33................ Setup Sheet “Blank”

34................ Back Cover

:: Notes

This symbol indicates a special

note or instruction in the manual.

!

There is a 1:1 hardware foldout page in the back

of the manual. To check the size of a part, line

This symbol indicates a Racers Tip.

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

up your hardare with the correct drawing until

you find the exact size. Each part in the foldout

has a number assigned to it for ordering

replacement parts.

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Page 4

4

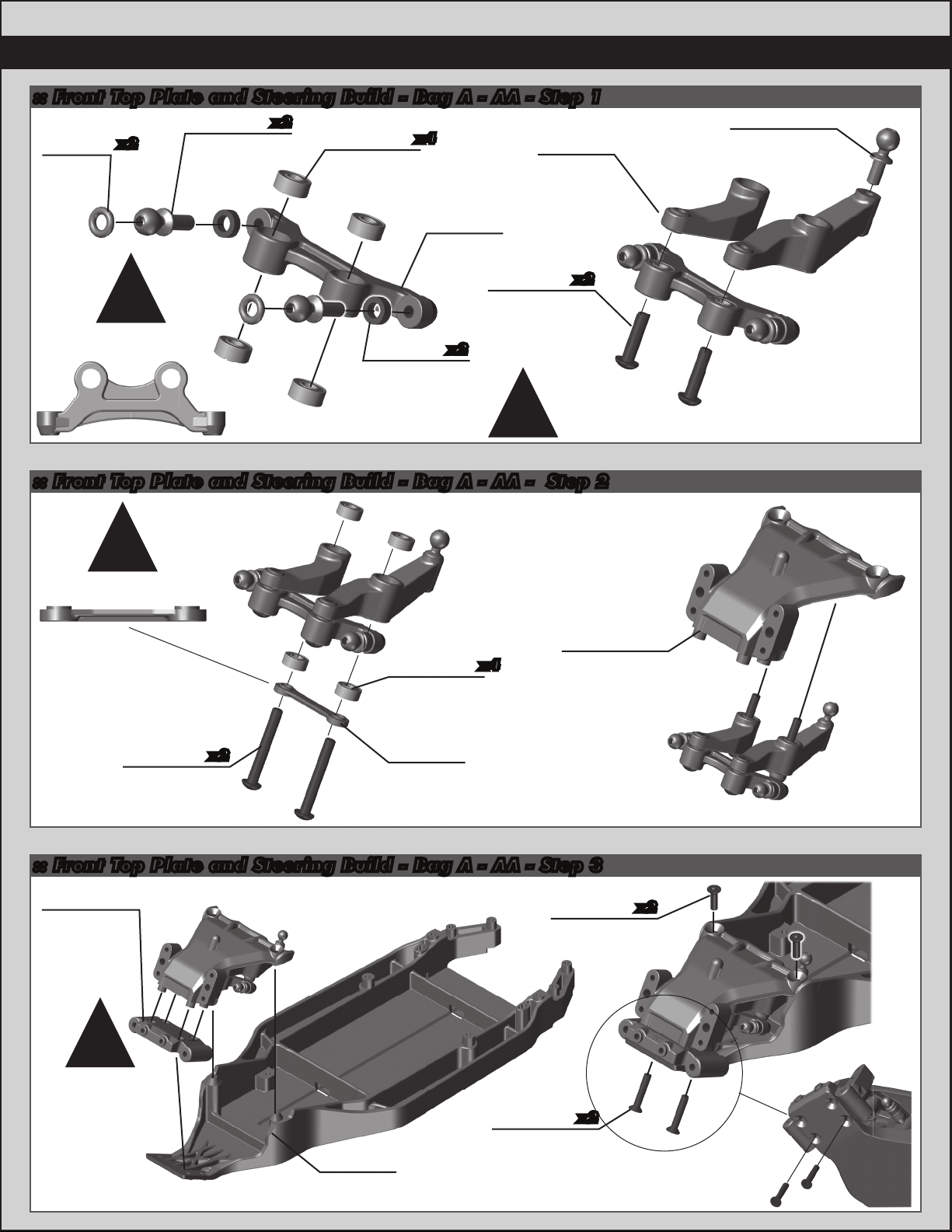

:: Front Top Plate and Steering Build - Bag A - AA - Step 1

91048

5407

Red

O-Ring

x2

Heavy-duty

Ballstud,

8mm

!

Note orientation

of steering rack.

:: Front Top Plate and Steering Build - Bag A - AA - Step 2

x2

91475

3 x 7 x 3

Ball Bearing

FT Ballstud

(2mm, blue)

x4

31286

Washer,

aluminum

91391

Steering

Rack

M3 x 12mm

x2

91391

Steering

Bellcrank

89202

BHCS

!

Brace

x2

Do not overtighten steering bolts. Make sure

there is free movement in the steering rack.

91047

Heavy-duty

Ballstud,

6mm

!

Note orientation

of the brace.

91362

x4

25189

M3 x 22mm

BHCS

x2

91475

3 x 7 x 3

Ball Bearing

91391

Steering

Bellcrank

Brace

:: Front Top Plate and Steering Build - Bag A - AA - Step 3

91364

Bulkhead

(25 °)

B5 Top

Plate

25202

M3 x 10mm

FHCS

x2

!

There are two

bulkheads included

(25 °, 30 °). 25 ° is

the standard one

used.

91360

RC10B5

Chassis

25204

M3 x 16mm

FHCS

x2

Page 5

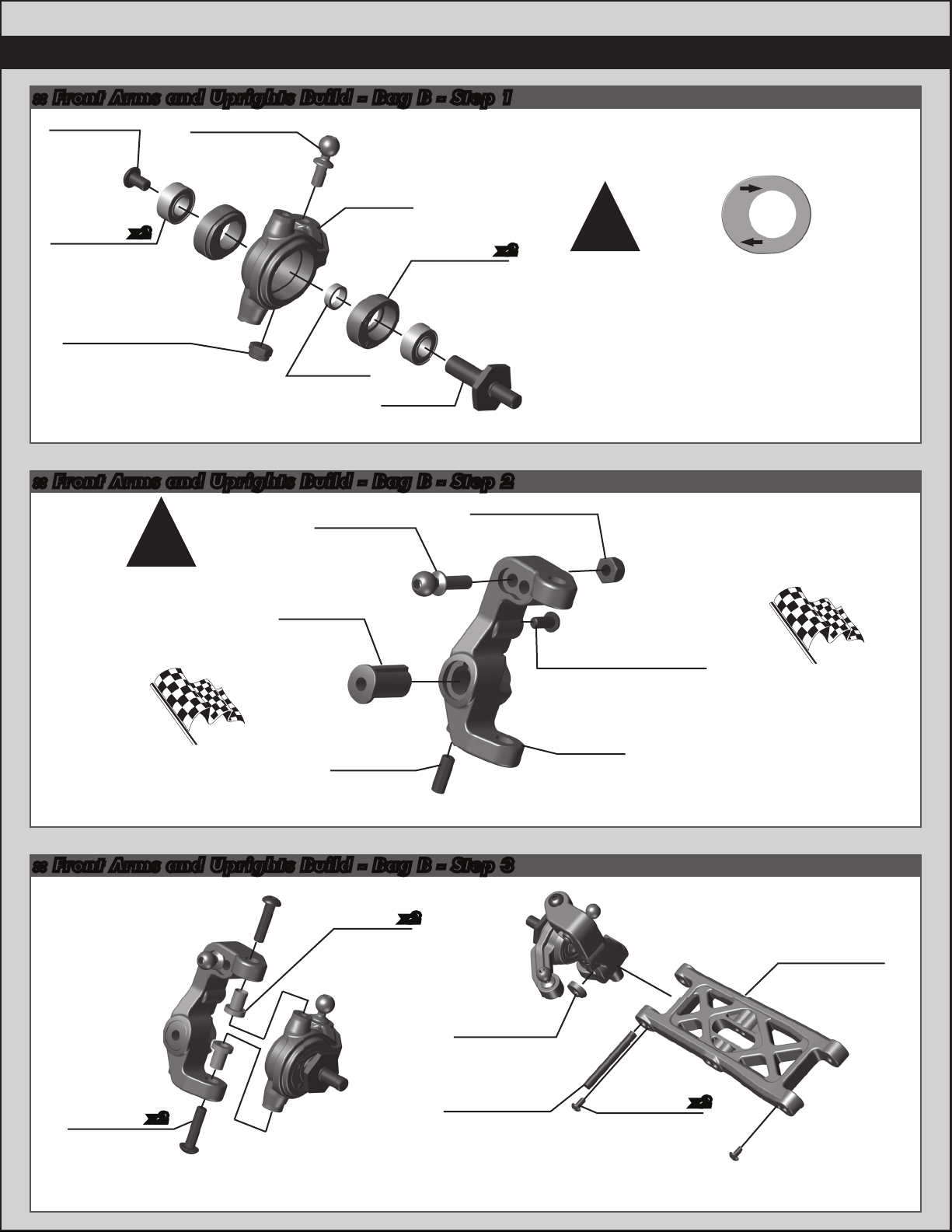

:: Front Arms and Uprights Build - Bag B - Step 1

31530

M3 x 5mm

BHCS

25237

5 x 10 x 4

Bearing

M3 Locknut,

x2

25215

black

Build 2 (1 left, 1 right)

91047

Heavy-duty

Ballstud,

6mm

Front Axle

Crush Tube

91407

91404

Steering

Block

91406

Front

Axles

91404

Steering

Block Insert

(2-4)

x2

:: Front Arms and Uprights Build - Bag B - Step 2

!

There are two

caster block inserts

included (0°, 5 °). 5 ° is the

standard one used.

91049

Heavy-duty

Ballstud,

10mm

91400

Caster

Block Insert

(5°)

M3 Locknut,

!

There are multiple options for the trailing

25215

black

31520

M2.5 x 6mm

BHCS

(not included in kit)

5

Trailing Axle Inserts

2

4

axle inserts. 4 is the stock setup.

Make sure the arrow is pointing forward

for your desired selection.

Also make sure both the right and left

sides are on the same setting.

You can install an

optional #31520

screw to use as a

steering stop setting.

You can install an

optional #4670 set

screw to better hold

the caster block inserts

and hinge pin.

(not included in kit)

4670

M3 x 8mm

Set Screw

:: Front Arms and Uprights Build - Bag B - Step 3

x2

91400

Caster Block

Spacer

91394

Hinge Pin

(front, outer)

89202

M3 x 12mm

BHCS

91402

Caster

Block

Bushing

x2

91400

Caster

Block

Build 2 (1 left, 1 right)

31510

M2 x 4mm

BHCS

91398

Front Arms

x2

Build 2 (1 left, 1 right) Build 2 (1 left, 1 right)

Page 6

6

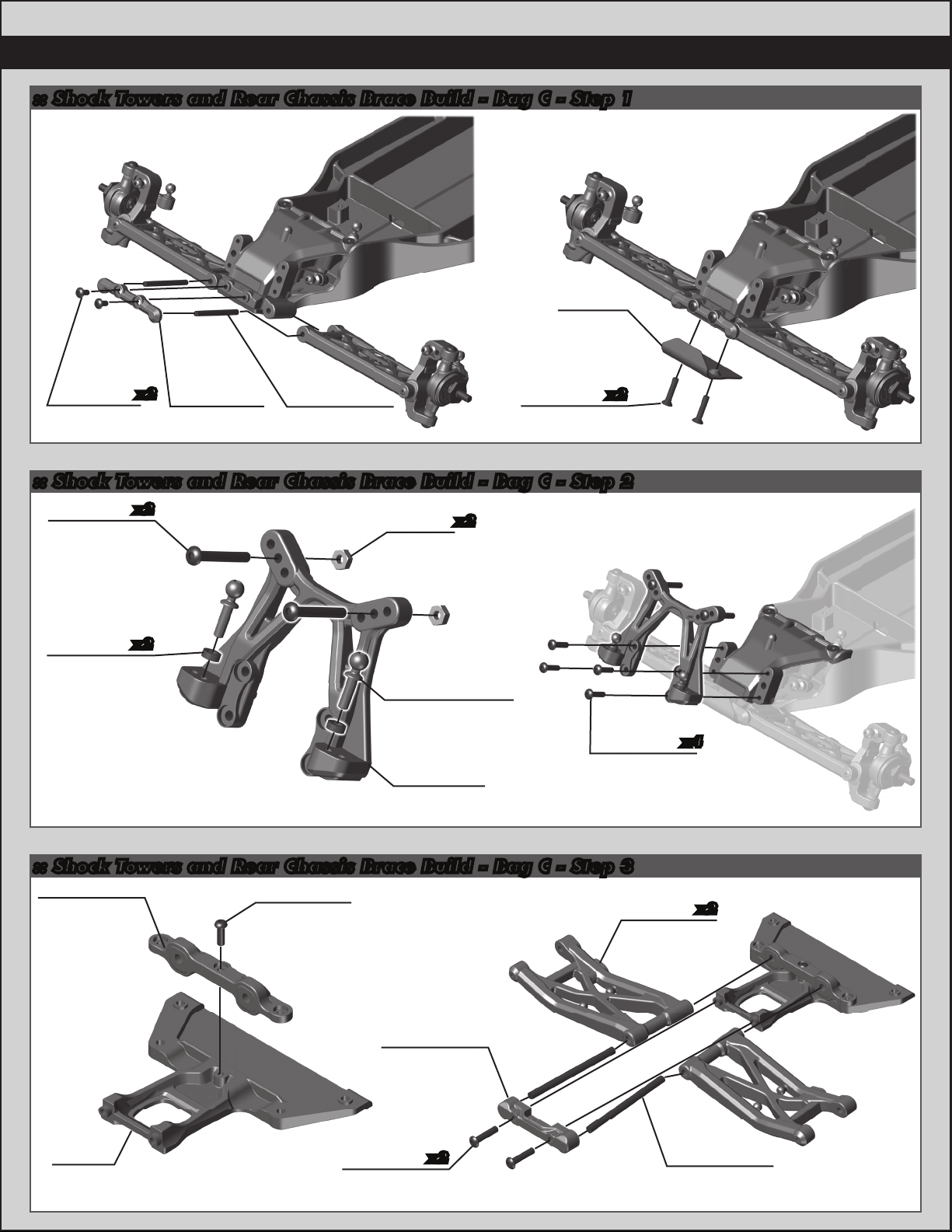

:: Shock Towers and Rear Chassis Brace Build - Bag C - Step 1

91410

Front

Bumper

31521

M2.5 x 8mm

BHCS

x2

91371

Front Hinge

Pin Brace

91394

Hinge Pin

(front, Inner)

25204

M3 x 16mm

FHCS

x2

:: Shock Towers and Rear Chassis Brace Build - Bag C - Step 2

89204

M3 x 24mm

BHCS

31286

FT Ballstud

Washer,

aluminum

(2mm, blue)

x2

x2

91477

M3 Nut

(black)

Heavy-duty

Ballstud, 10mm

Front Shock

x2

91049

91373

Tower

89202

M3 x 12mm

BHCS

x4

:: Shock Towers and Rear Chassis Brace Build - Bag C - Step 3

91382

Arm Mount,

C (3+2)

91379

Chassis

Plate

31521

M2.5 x 8mm

BHCS

M3 x 14mm

91382

Arm Mount,

D

25187

BHCS

x2

91412

Rear

Arms

Hinge Pin

(rear, Inner)

x2

91394

Page 7

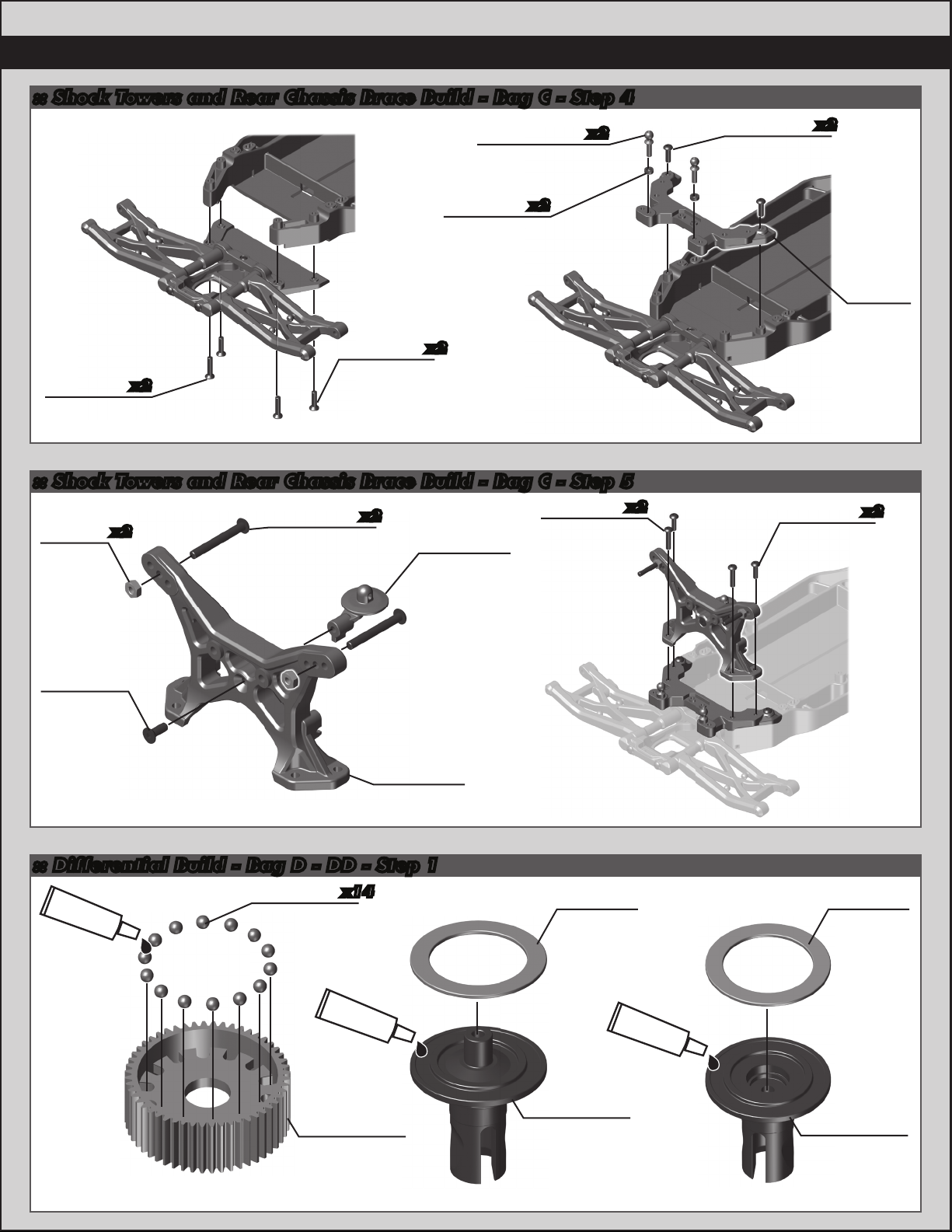

:: Shock Towers and Rear Chassis Brace Build - Bag C - Step 4

91049

Heavy-duty

Ballstud, 10mm

x2

25211

x2

M3 x 10mm

BHCS

7

31286

x2

FT Ballstud

Washer,

aluminum

(2mm, blue)

25203

x2

M3 x 12mm

89208

x2

FHCS

M3 x 14mm

FHCS

:: Shock Towers and Rear Chassis Brace Build - Bag C - Step 5

25187

M3 x 14mm

BHCS

91477

M3 Nut

(black)

x2

89204

x2

M3 x 24mm

BHCS

91433

Rear Body

Mount

x2

91377

Chassis

Brace

25211

x2

M3 x 10mm

BHCS

25201

M3 x 8mm

FHCS

91375

Rear Shock

Tower

:: Differential Build - Bag D - DD - Step 1

#6591

diff lube

6581

3/32 carbide

diff balls

x14

#6591

diff lube

91419

Diff Gear,

52T

7666

Diff Drive

Ring

91420

Ball Diff

Outdrive

#6591

diff lube

7666

Diff Drive

Ring

91420

Ball Diff

Outdrive

Page 8

8

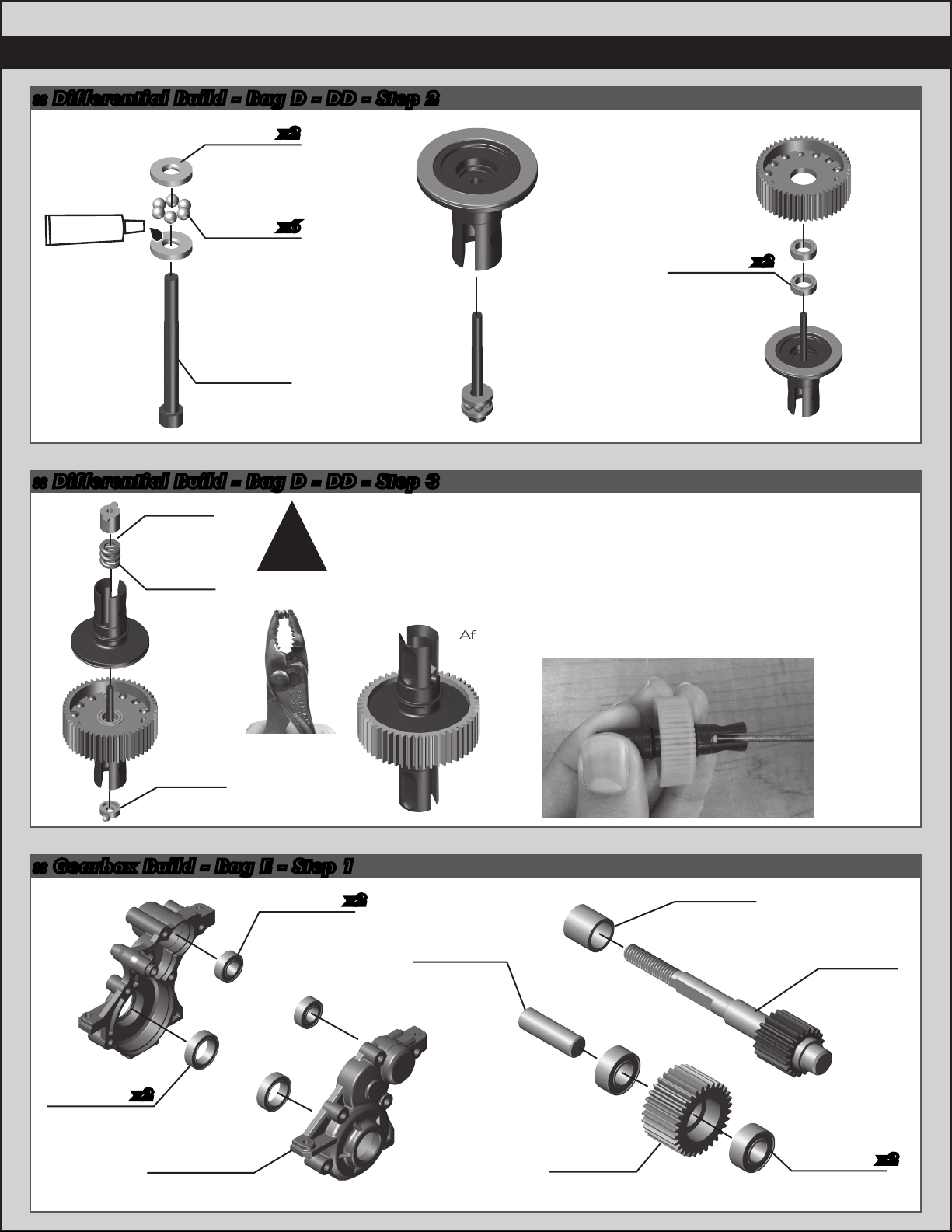

:: Differential Build - Bag D - DD - Step 2

x2

x6

#6588

black grease

6573

Diff thrust

washer

6574

5/64 diff

thrust

balls

6573

Diff thrust

bolt

:: Differential Build - Bag D - DD - Step 3

6575

Locking

t-nut

!

6582

Diff

thrust

spring

Compress

spring first.

31400

5 x 8mm,

Bearing

As you tighten the diff bolt, you will notice the T-nut ears moving

closer to the bottom of the outdrive slot. This compresses the

spring behind the T-nut. The spring should be completely

compressed at the same time the T-nut reaches the end of the

slot. Caution! Pay close attention to the feeling when the spring

is completely compressed. Do not overtighten the bolt. When

you feel the spring completely compressed, loosen the diff bolt

1/8” of a turn. Your diff should now operate smoothly with

resistance as the outdrives move in opposite directions.

After you have driven the car once, re-check the dif f setting.

x2

6575

Diff

cover

:: Gearbox Build - Bag E - Step 1

25238

6 x 12 x 4,

Bearing

25616

10 x 15 x 4,

Bearing

x2

91424

Gearbox

(right & left)

x2

91011

4x4 Idler

Gear Shaft

91429

Idler Gear

91426

Top Shaft

Spacer

91425

Top Shaft

25237

5 x 10 x 4,

Bearing

x2

Page 9

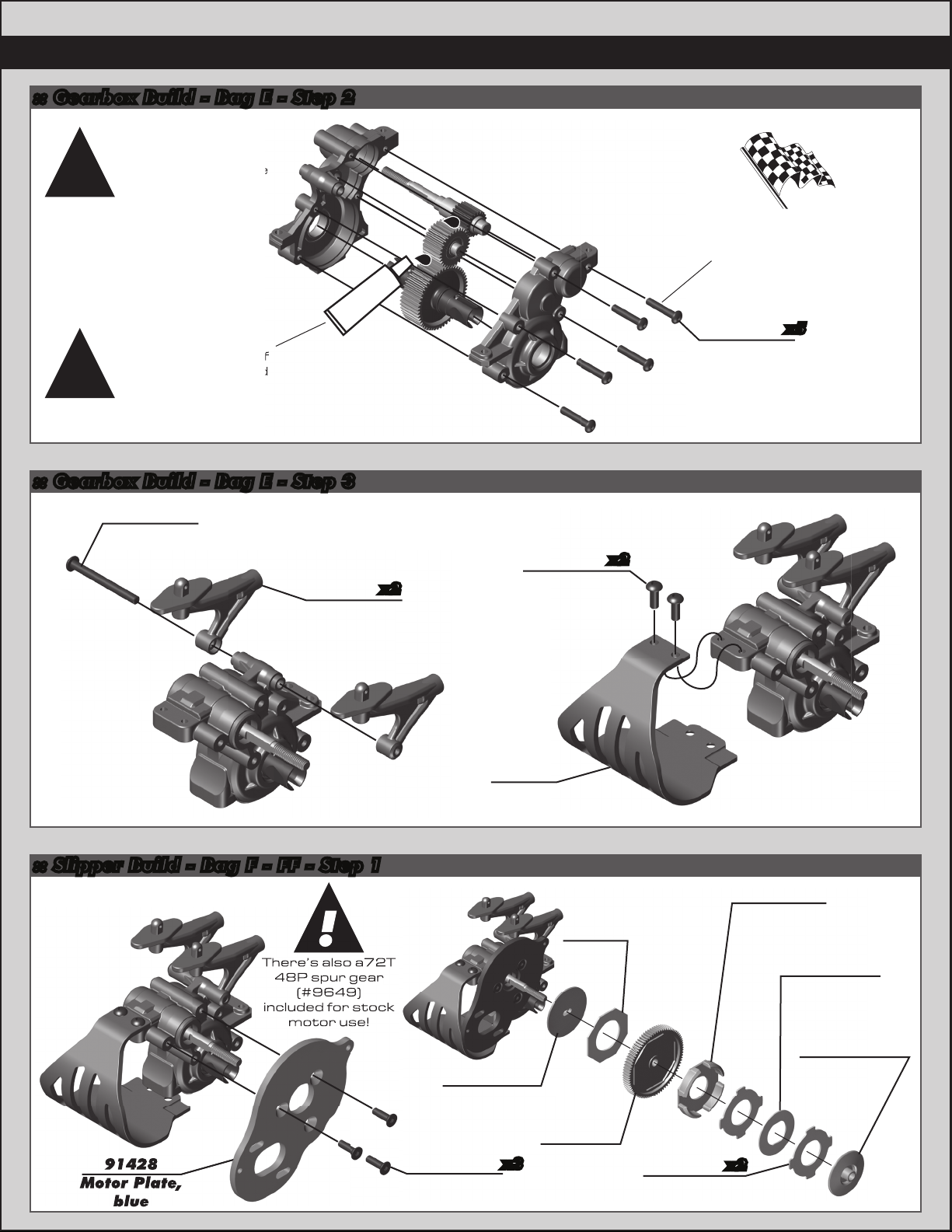

:: Gearbox Build - Bag E - Step 2

91428

Motor Plate,

There’s also a72T

48P spur gear

(#9649)

included for stock

motor use!

!

Install the Diff with

the head of the

Diff Thrust Bolt

(#6573) facing the

!

!

same side as the

spur gear.

Add a drop of Diff

Lube (#6591) to

the teeth of the dif f

gear, idler gear, and

top shaft.

:: Gearbox Build - Bag E - Step 3

#6591

diff lube

You can add black

grease (#6588) to the

screw threads to ease

screw installation.

89203

M3 x 16mm

BHCS

x5

9

91478

M3 x 30mm

BHCS

:: Slipper Build - Bag F - FF - Step 1

There’s also a72T

48P spur gear

(#9649)

included for stock

motor use!

91428

Motor Plate,

blue

91433

Wing

Mounts

!

x2

25202

M3 x 10mm

FHCS

91432

Motor

Guard

7485

FT V2

Slipper Hub

x3

31532

M3 x 8mm

BHCS

9651

81T 48P

Spur Gear

x2

9603

Slipper

Pad

91177

VTS Slipper

Pads

91176

VTS Slipper

Housing

91178

VTS Slipper

Plate

91179

VTS Slipper

Hub, outer

x2

Page 10

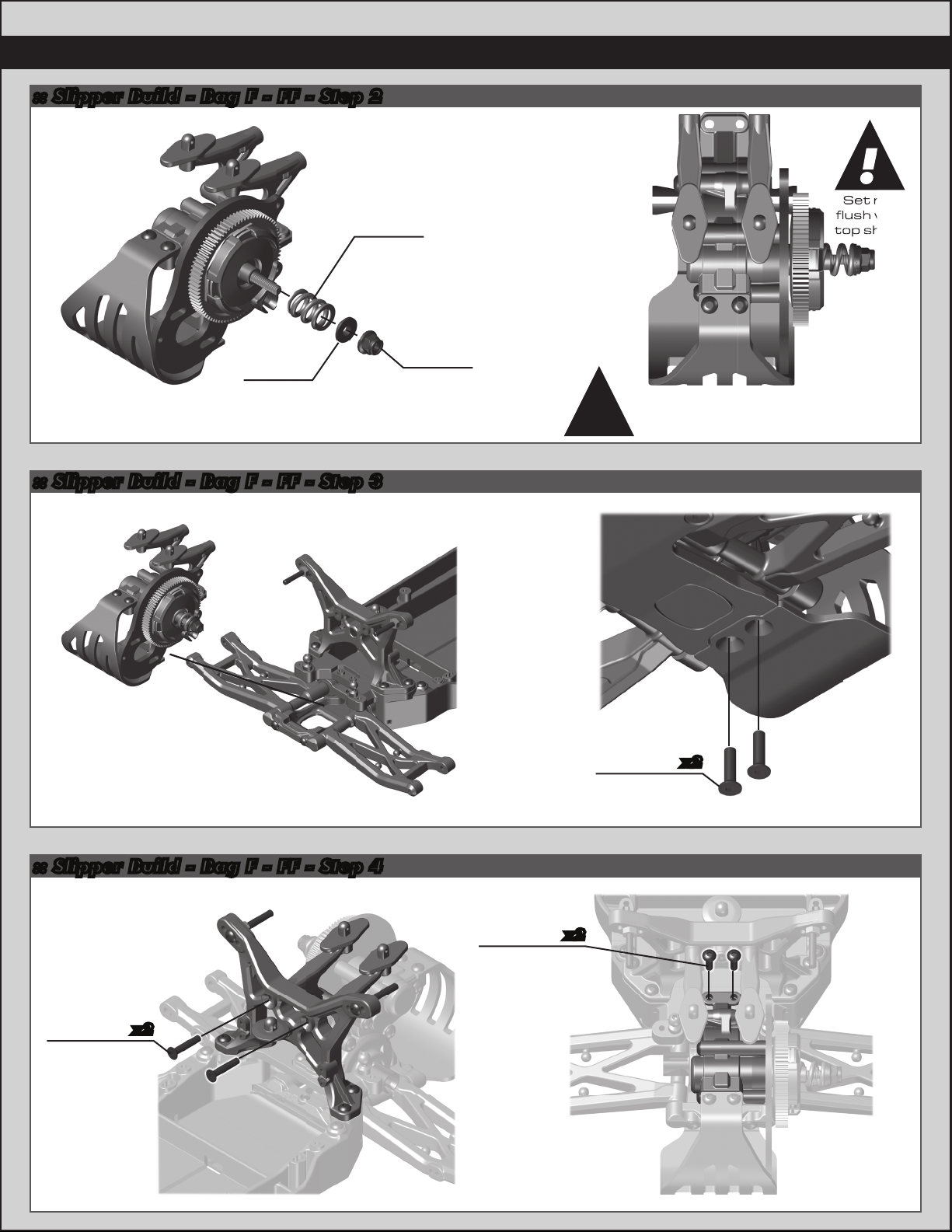

10

Set nut

flush with

top shaft.

!

:: Slipper Build - Bag F - FF - Step 2

Slipper

Spring

9739

!

Set nut

flush with

top shaft.

91423

Slipper

Spring

Adapter

:: Slipper Build - Bag F - FF - Step 3

91148

M4 Locknut,

with flange

and knurl

See page 18 for gear

!

M3 x 12mm

mesh, and slipper clutch

setting instructions!

25203

FHCS

x2

:: Slipper Build - Bag F - FF - Step 4

x2

M3 x 16mm

25204

FHCS

25211

M3 x 10mm

BHCS

x2

Page 11

:: Rear Hub and CVA Build - Bag G - Step 1

11

25616

91047

Heavy-duty

Ballstud, 6mm

91414

Rear Hub

Link Insert

(A)

Build x2 (right and left side)

Rear Hub

10 x 15 x 4

Bearing

91414

91416

Rear Hub

Link Nut

:: Rear Hub and CVA Build - Bag G - Step 2

91438

CVA

Coupler

#6588

black grease

(A)

91414

Rear Hub

Insert

(0°)

91476

6 x 13 x 5

Bearing

!

!

Rear Hub Link Setting:

A

CBBAA

Up

Down

Up

B

Down

There are multiple

optional inserts

for the Rear Hub

Insert (0°, 0.5 °, 1 °).

0° is the standard

insert used.

91436

CVA Wheel

Hex Pin

91439

CVA Bone

91437

CVA Axle

Build x2 (right and left side) Build x2 (right and left side)

91438

CVA

Pin

91441

Wheel

Hex (rear)

:: Rear Hub and CVA Build - Bag G - Step 3

You can install optional

#4670 set screws to

better hold the rear

hub inserts and

hinge pin.

91394

Hinge Pin

(rear, outer)

91414

Rear Hub

Spacer

x2

31510

M2 x 4mm

BHCS

4670

M3 x 8mm

Set Screw

(not included in kit)

x2

Build x2 (right and left side)Build x2 (right and left side)

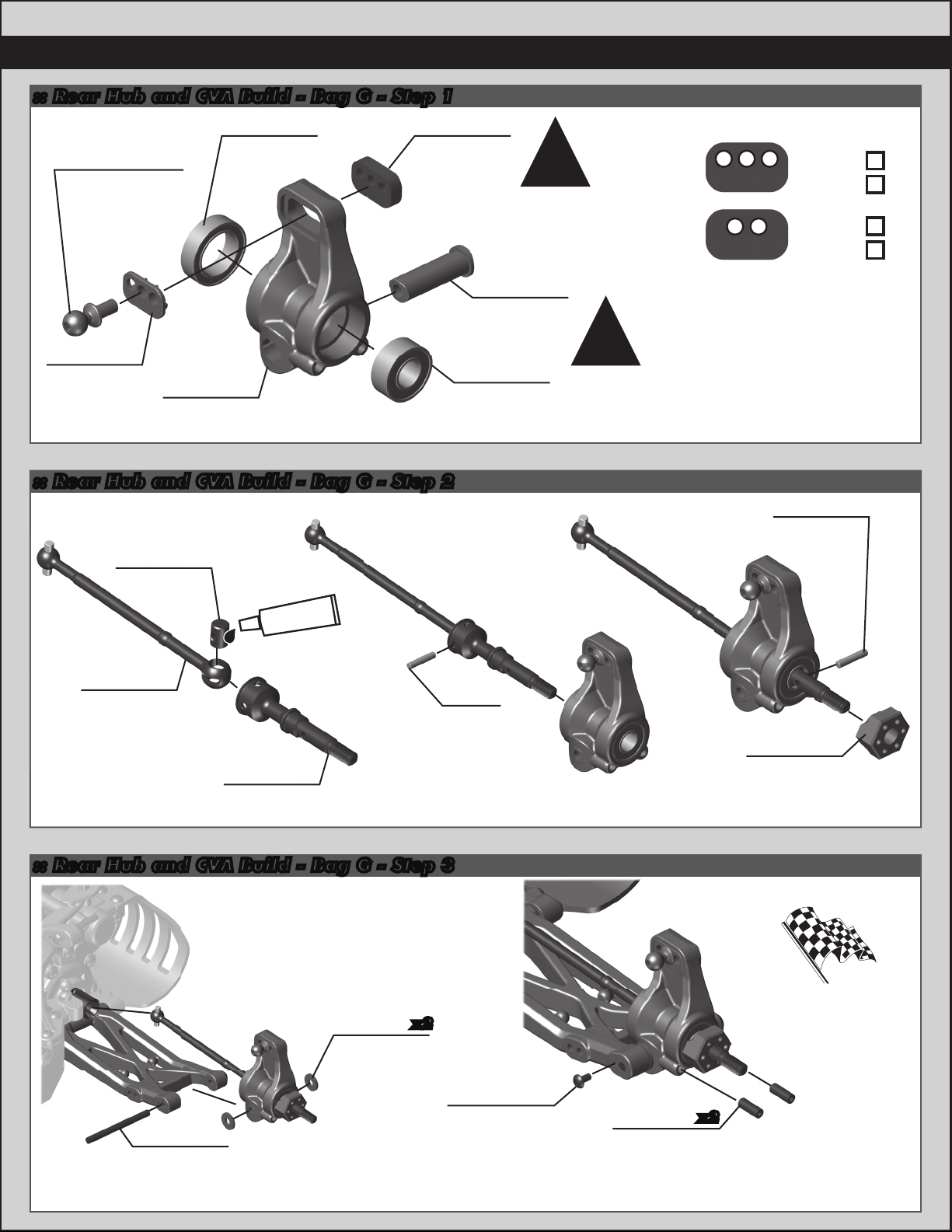

Page 12

12

HD Ball Cup

:: Turnbuckles Build - Bag H - HH - Step 1

!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

:: Turnbuckles Build - Bag H - HH - Step 2

91453

HD Ball Cup

(small)

Racers Tip:

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

installation!

91453

HD Ball Cup

(small)

6263

Turnbuckle,

2.06”

Steering Turnbuckle

27.50mm

!

Install the ballstuds on

curved side of the ballcup!

Build x2 (right and left side)

6263

Turnbuckle,

2.06”

91453

HD Ball Cup

(right)

91453

HD Ball Cup

(small)

!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

:: Turnbuckles Build - Bag H - HH - Step 3

Racers Tip:

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

installation!

91453

HD Ball Cup

(small)

Front Camber Turnbuckle

23.85mm

!

Install the ballstuds on

curved side of the ballcup!

Build x2 (right and left side)

6263

Turnbuckle,

2.06”

Rear Camber Turnbuckle

23.30mm

91453

HD Ball Cup

(small)

!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

Racers Tip:

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

installation!

!

Install the ballstuds on

curved side of the ballcup!

Build x2 (right and left side)

Page 13

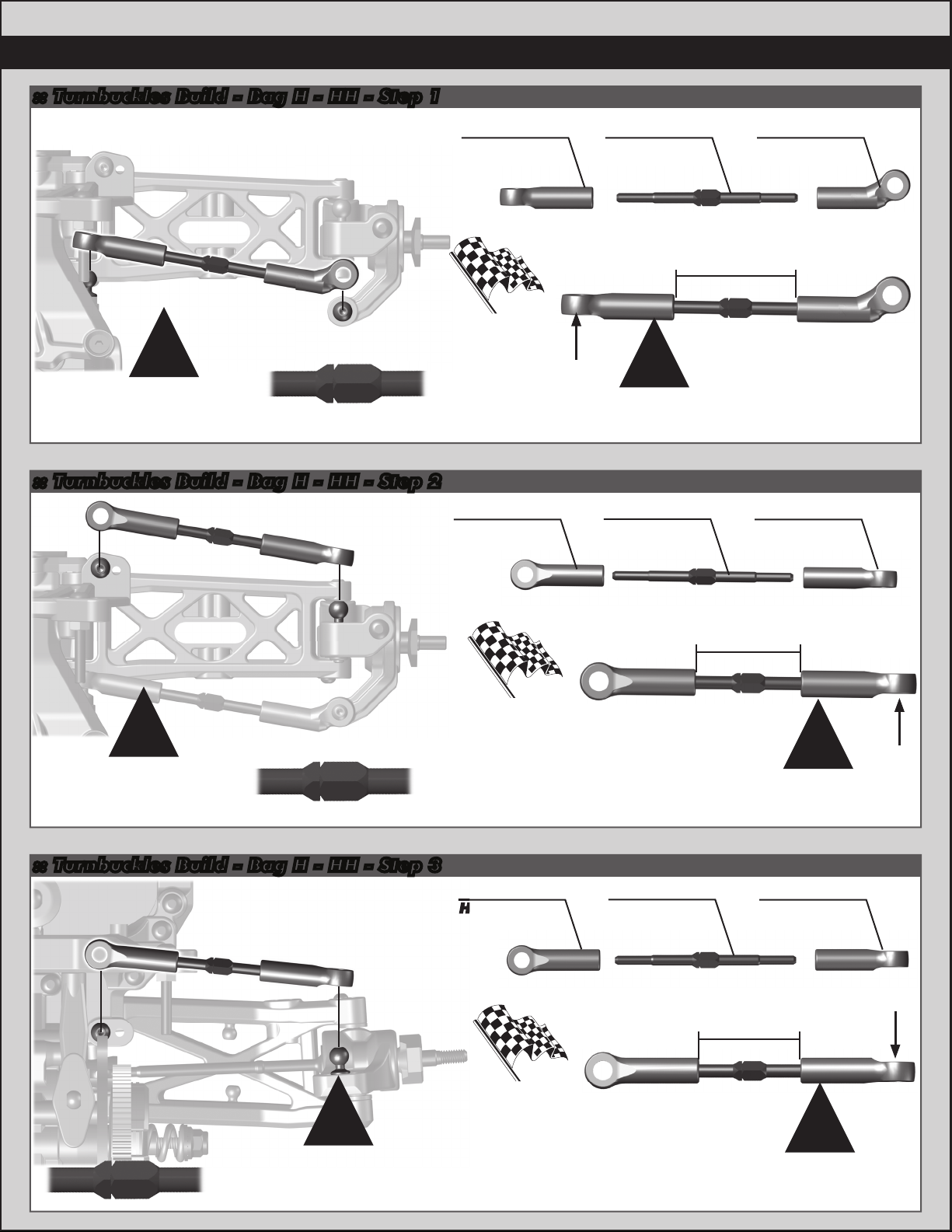

:: Shocks Build - Bag I - II - Step 1

13

91308

12mm

Shock Piston

6299

1/8 E-Clip

(1.6 front)

(1.7 rear)

91488

3 x 21

Shock Shaft

(front)

91489

3 x 27.5

Racers Tip:

Shock Shaft

(rear)

Use a marker over the

numbers on the pistons to

make them easily visible!

:: Shocks Build - Bag I - II - Step 2

91480

12x23mm V2

Shock Bodies

(front)

91482

12x31mm V2

Shock Bodies

(rear)

5407

O-Ring

91491

V2 Shock

Spacer

91491

V2 Shock

Hat Bushing

x2

x2

91491

12mm

Shock Cap

O-Ring

31327

VCS3 Shock

Bottom Cap

O-Ring

#1105

green slime

31327

VCS3 Shock

Bottom Cap

!

Lightly rub shock oil

on the o-ring before

installation!

Racers Tip:

Coating the o-rings

with green slime

(#1105) helps seal

& reduce o-ring

swell! Green slime

not included in kit!

6299

1/8 E-Clip

#1105

green slime

91448

Shock

eyelet

91448

Shock

Pivot Ball

4187

Nylon Spacer,

(.030)

Front:

3 spacers

Rear:

2 spacers

:: Shocks Build - Bag I - II - Step 3

Shock oil

#5422

Step 2-3

Shock oil

#5422

Front Shock: 30 wt

Rear Shock: 30 wt

Shock Bleeding Steps:

1. Before assembly, get each bleed

screw and thread it 1-2 turns into

the shock cap. This will make it easier

when you are bleeding your shocks.

2. Pull shock shaft down.

3. Fill shock body 3/4 full with silicone

shock fluid.

4. Slowly move the shock shaft up and

down to remove air from under the

piston.

5. Wait for bubbles to come to surface.

6. Fill shock body to top with silicone

shock fluid.

7. Place a drop of oil in the cap and on

cap threads.

8. Install cap (without bleed screw) and

tighten completely.

9. Slowly compress shaft all the way to

bleed excess silicone shock fluid out

the hole in the cap (use rag aroundshock to catch excess fluid).

10. Install M2x4mm button head screw

until snug while shaft is fully compressed.

31510

M2 x 4mm

BHCS

Step 9-10Step 8Step 6-7Step 4-5

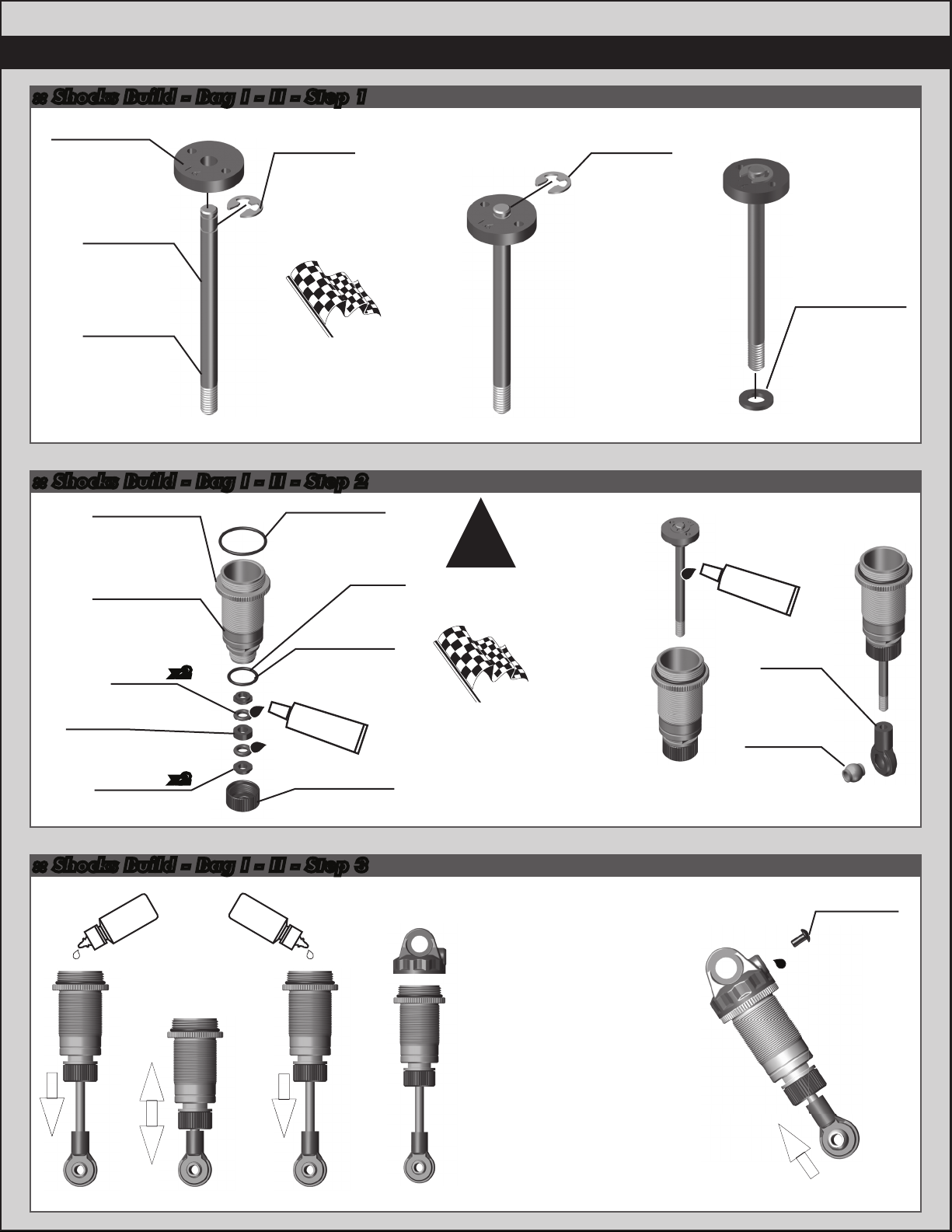

Page 14

14

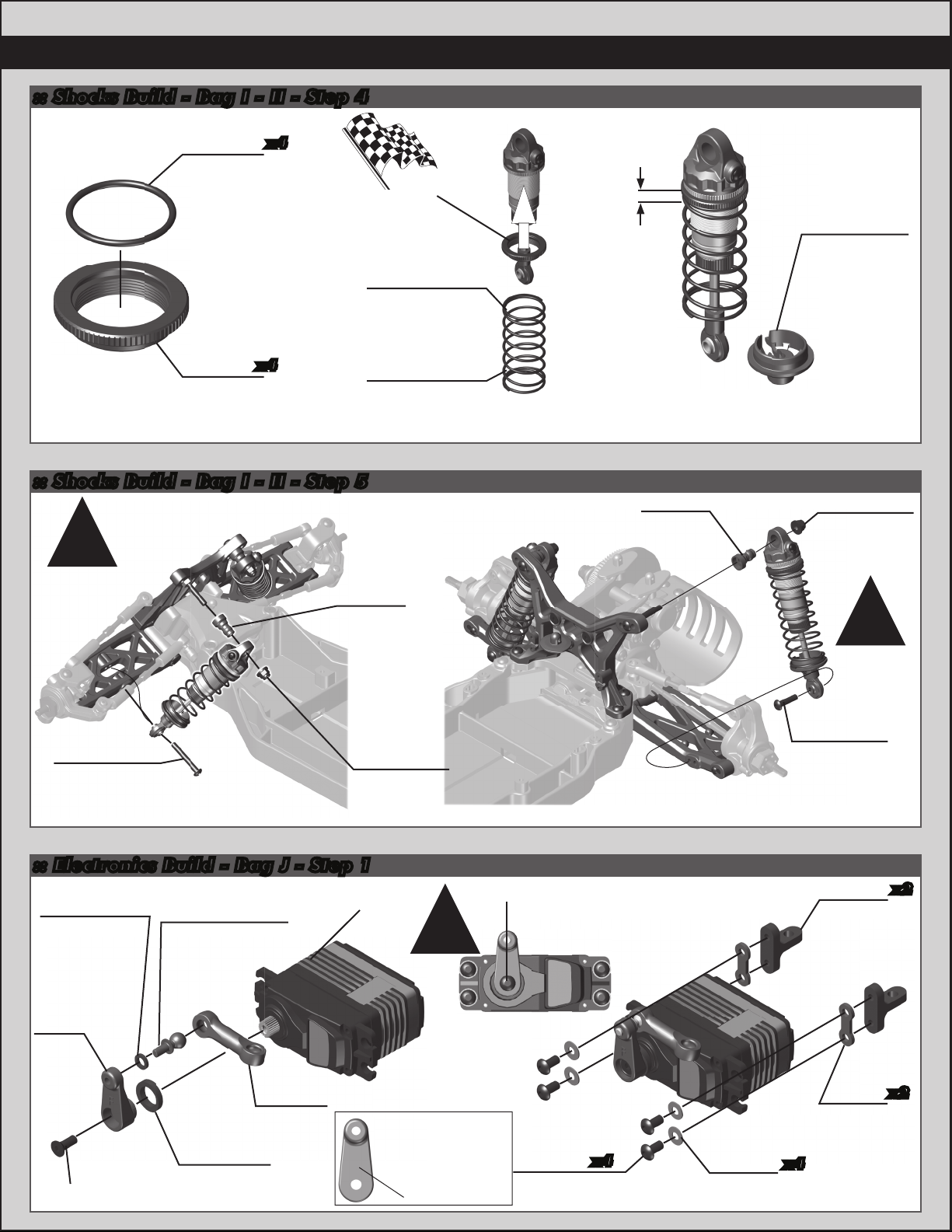

:: Shocks Build - Bag I - II - Step 4

91304

12mm

threaded

collar

o-ring

91304

12mm

threaded

collar

x4

Racers Tip:

Use your finger to rub

shock oil on the o-ring for

smoother adjustment!

x4

:: Shocks Build - Bag I - II - Step 5

!

Use outside

hole in

front arm!

91445

Shock

Bushing

91327

12mm front

spring, Green

(3.15lb)

91337

12mm rear

spring, white

(2.10lb)

Front:

4mm

Rear:

5.5mm

91310

12mm shock

spring cup

(5mm offset)

Build x2 front and x2 rear shocks

91445

Shock

Bushing

25612

M3 Locknut,

with flange

(black)

!

Use inside

hole in

rear arm!

89202

25189

M3 x 22mm

BHCS

Build x2 (right and left side) Build x2 (right and left side)

25612

M3 Locknut,

with flange

(black)

M3 x 12mm

BHCS

:: Electronics Build - Bag J - Step 1

91443

Servo

Mount

91455

Servo

Spacers

31286

FT Ballstud

Washer,

aluminum

(1mm, blue)

9180

Servo

Horn

Servo screw

not included!

91047

Heavy-duty

Ballstud, 6mm

91455

Steering

Link

89009

Servo Horn

Ring

Servo not

included!

!

A - Airtronics

F - Futaba

H - Hitec

J - JR

Printed here

Align the servo

horn 90 degrees

31532

M3 x 8mm

BHCS

x4

7337

Gold

Washer

x4

x2

x2

Page 15

:: Electronics Build - Bag J - Step 2

Receiver not

included!

31532

M3 x 8mm

BHCS

x2

15

Motor not included!

:: Electronics Build - Bag J - Step 3

89218

3 x 8mm

Washer

x2

31532

M3 x 8mm

BHCS

91435

Gear

Cover

(black)

91089

Belt Cover

Cap

x2

Pinion / Setscrew

not included!

:: Electronics Build - Bag J - Step 4

ESC not included!

6727

Servo Tape

!

Receiver not

included!

See page 18 for

gear mesh setting

instructions!

!

Use included

optional

Receiver mount

if ESC clearance

is needed

M3 x 8mm

31532

BHCS

91380

Receiver

Mount

x2

31530

M3 x 5mm

BHCS

x2

Receiver not

included!

6727

Servo Tape

Page 16

16

:: Electronics Build - Bag J - Step 5

!

There are two

options for

mounting your

antenna.

:: Electronics Build - Bag J - Step 6

Battery

not included!

91459

Battery

Spacer

Batteries

not included!

25225

M3 x 3mm

Set Screw

6338

Antenna

Tube & Cap

4689

M3 x 16mm

Set Screw

91459

Battery

Spacer

91458

Battery Strap

Thumb Wheel

91458

Battery Strap

Thumb Wheel

O-Ring

x2

x2

x2

91456

Battery

Strap

91459

Single

Battery

Spacer

:: Wheels / Tires and Body - Bag K - Step 1

9690

Buggy Front

Wheel Hex,

White

Tires / Inserts

not included!

Build x2 Build x2

x2

#1597

ca glue

Carefully apply ca glue

(tire adhesive) to the tire

bead on both sides. Do

one side at a time, allow it

to dry before gluing the

CA glue not included!

!

other side!

9695

Buggy Rear

Wheel Hex,

White

x2

Tires / Inserts

not included!

#1597

ca glue

Page 17

:: Wheels / Tires and Body - Bag K - Step 2

17

91148

M4 Locknut,

with flange

and knurl

91148

M4 Locknut,

with flange

and knurl

Build 2 (1 left, 1 right) Build 2 (1 left, 1 right)

:: Wheels / Tires and Body - Bag K - Step 3

21173

Small

Body Clips

x2

91470

Clear

Body, B5

Instead of using the included body clips

Racers Tip:

(#21173), you can use hook and loop tape

on the inside of the body, and the sides of

the chassis to keep your body in place!

:: Wheels / Tires and Body - Bag K - Step 4

21173

Small

Body Clips

91471

Clear Wing,

91433

Wing Angle

Shim

x2

B5

Painting Tips:

Your B5 Team Kit comes with a clear polycarbonate

body. You will need to prep the body before you can

paint it. Wash the inside thoroughly with warm water

and liquid detergent. Dry the body using a clean, soft,

lint-free cloth. Use the supplied window masks to

cover the windows from the INSIDE of the body

(RC cars get painted from the inside). Using high

quality masking tape, apply tape to the inside of the

body to create a design. Spray (use either rattle can

or airbrush) the paint on the inside of the body

(prefferably dark colors first, lighter colors last).

NOTE: ONLY use paint that is recommended for use

with (polycarbonate) plastics. If you do not, you can

destroy the plastic body!!!!.

After paint has completely dried, cut the body along

the trim lines. Make sure to drill or use a body reamer

to make the holes for the body mounts and antenna!

Page 18

18

:: Tuning Tips

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing.

Changes to your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testing

it before making another change. If the result of your adjustment is a faster lap, mark the change on the included setup

sheet (make adddtional copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back

to the previous setup and try another change.

When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this as a guide for future

track days or conditions. Peridicaly check all moving suspension parts. Suspension components must be kept clean

and move freely without binding to prevent poor and/or inconsistent handling.

Motor Gearing:

Proper motor gearing will result in maximum performance and run time while reducing the chance of overheating and

premature motor failure. The gear ratio chart lists recommended starting gear ratios for the most widely used

motor types. Gear ratios will vary depending upon motor brand, wind, and electronic speed control. Consult your

motor and electronic speed control manufacturers for more information.

Team Associated is not responsible for motor damage due to improper gearing.

B5 Gear Ratio Chart (Internal Gear Ratio 2.60:1)

Motor

Pinion

Spur

Final Drive Ratio

17.5 Reedy Sonic Brushless *

17.5 Reedy Sonic Brushless

13.5 Reedy Sonic Brushless *

13.5 Reedy Sonic Brushless

10.5 Reedy Sonic Brushless

9.5 Reedy Sonic Brushless

8.5 Reedy Sonic Brushless

7.5 Reedy Sonic Brushless

6.5 Reedy Sonic Brushless

3300kV Brushless

3900kV Brushless

4900kV Brushless

6100kV Brushless

* These gearings are for use with advanced timing speed control settings!

23

31

22

30

24

23

22

21

21

21

21

19

18

78

69

81

75

81

81

81

81

81

81

81

81

81

8.82:1

5.79:1

9.57:1

6.50:1

8.78:1

9.15:1

9.57:1

10.03:1

10.03:1

10.03:1

10.03:1

11.08:1

11.70:1

Set The Gear Mesh:

You should be able to rock the spur gear back and forth in the teeth of the pinion gear without making the pinion gear

move. If the spur gear mesh is tight, then loosen the #31532 screws and move the motor away, then try again.

A gear mesh that is too tight or too loose will reduce power and damage the gear teeth.

Slipper Clutch:

The assembly instructions give you a base setting for your clutch. Turn the nut on the shaft so that the end of the top

shaft is even with the outside of the nut. At the track, tighten or loosen the nut in 1/8 turn increments until you hear

a faint slipping sound for 1-2 feet on takeoffs. Another popular way to set the clutch is to hold both rear tires firmly in

place and apply short bursts of throttle. If the clutch is properly set, the front tires should lift slightly up off the surface.

Ride Height:

Ride height is the distance from the ground to the bottom of the chassis.

The standard front ride height setting is with the front arms level

(reffered to as “arms level”) or 24mm (Ride Height Gauge #1449).

Check the ride height by lifting up the entire car about 8-12 inches off the

bench and drop it. After the suspension “settles” into place, measure

ride height (Ride Height Gauge #1449). Raise or lower the shock collars

as necessary so that the left & right arms appear to be level.

The rear ride height setting you should use most often is with the

outdrive, driveshaft, and axles all on the same imaginary horizontal line

(reffered to as “bones level”) or 24mm (Ride Height Gauge#1449).

Check the ride height by lifting up the entire car about 8-12 inches off the

bench and drop it. After the suspension “settles” into place, measure

ride height (Ride Height Gauge #1449). Raise or lower the shock collars

as necessary so that the left & right driveshaf ts appear to be level.

!

*Front arms should

be in a straight line

when ride height is

set at “arms level”

!

*CVA bones should

be in a straight line

when ride height is

set at “CVA bones

level”

Page 19

:: Tuning Tips (cont.)

Wheelbase Adjustment:

You have three options for rear hub spacing, Forward, Middle, & Back.

The kit setting of Middle is the most neutral, and will be used most often.

For improved handling in bumps or rhythm sections, try moving the hubs to the

Back position. This can also make the car handle better in 180° turns.

*Spacers to the rear

will place hubs for-

ward, shortening

the wheelbase

!

Front Camber:

Camber describes the angle at which the tire and wheel rides when

looked at from the front. Negative camber means that the tire leans

inward at the top. A good starting camber setting is -1°. Positive camber,

where the top of the tire is leaning out, is not recommended.

Optional #1719 camber gauge can be used to more accurately set camber.

*Testing camber

with camber gauge

!

Rear Camber:

Camber describes the angle at which the tire and wheel rides when looked at from the back. Negative camber means

that the tire leans inward at the top. A good starting camber setting is -1°. Adding a small amount of positive camber,

where the top of the tire is leaning out, will tend to improve straight-line acceleration on loose tracks.

Optional #1719 camber gauge can be used to more accurately set camber.

Front Camber Links:

Changing the length of the camber link is considered a bigger step than

adjusting the ball end height on the tower. Shortening the camber link

(or lowering the ball end) will give the front end less roll and quicken steering

response. Lengthening the camber link (or raising the ball end) will give the

front more roll and slower steering response. Longer camber links are

typically used on high grip tracks and shorter links tend to work better on

medium-grip loose tracks.

*Raise or lower the

ball end by adding

!

or subtracting

washers here

19

Rear Camber Link:

Changing the length of the camber link is considered a bigger step than adjusting

the ball end height on the rear chassis brace. Shortening the camber link

(or lowering the ball end) will give the rear end less roll and the car will tend to

accelerate or “square up” better. Lengthening the camber link (or raising the ball

end) will give the rear more roll and more cornering grip. Longer camber links are

typically used on high grip tracks, while shorter links tend to work better on

medium grip loose tracks. The kit setting is the best compromise of cornering grip

and acceleration.

!

*Raise or lower

the ball end by

adding or

subtracting

washers here

Kickup:

Kickup is the angle the front suspension arm mounts at where the front of the arm is higher than the rear.

The standard kickup angle for the B5 is 25°, and is most common. If more corner entry steering is desired, try the

included 30° front bulkhead. It is important to adjust the bumpsteer to match the kickup angle adjustment.

Refer to the chart below for some common settings:

Kickup

Angle

25° 1mm 0mm

Less Agressive

Bumpsteer Shims

Standard

Bumpsteer Shims

More Agressive

Bumpsteer Shims

N/A

30° 3mm 2mm 1mm

Caster:

Caster describes the angle of the kingpin as it leans toward the rear of the vehicle. Positive caster means the kingpin

leans rearward at the top. The B5 includes two inserts to adjust caster angle at the caster block, 0° and +5°. The total

caster angle is the sum of the kick-up angle and the caster block angle. Standard total caster angle for the B5 is 30°,

with 25° kick-up and 5° caster block angle. For less entry steering and more exit steering, try 0° caster block angle.

Page 20

20

:: Tuning Tips

Trailing Axle:

Trailing axle is the distance from the king pin to the axle that “trails” behind the pin. The B5 includes inserts to allow

adjustments for trailing axle to three positions: 4mm (standard), 3mm, and 2mm. The standard setup uses 4mm

trailing axle for the most stable handling. For more corner entry steering, try the 3mm trailing axle option.

It is important to adjust the ackermann and wheelbase settings to match the trailing axle adjustment. refer to the

chart below for some common settings:

Trailing Axle

Position

4mm

3mm

2mm

# of Shims

on Rack for

Less Ackermann

3mm

2mm

1mm

# of Shims

on Rack for

Std. Ackermann

2mm

1mm

0mm

# of Shims

on Rack for

More Ackermann

1mm 2mm (forward)

0mm 1mm (middle)

N/A 0mm (back)

Rear Caster Block

Wheelbase Shim

Ackermann:

Ackermann is the angle difference between the front wheels when they are turned to steer the car. For minimal tire

slip, it is standard for the inside wheel to steer to a greater angle than the outside wheel. The B5 allows ackermann

adjustments by changing the washer thickness used behind the steering rack ballstuds. The kit setup uses 2mm washers and is most common for racing conditions. If corner entry steering is too aggressive, try increasing the ackermann

by removing shims from behind the steering rack ballstuds. Increasing the ackermann will increase the angle difference

of the front wheels when steered, resulting in a more stable car on corner entry.

Anti-Roll Bars:

The optional #91468 rear anti-roll bar kit (also called the “swaybar”) allows you to add roll resistance to the rear end

with minimal effect on handling over bumps and jumps. It is an especially helpful tuning item on high-grip tracks

(try the gold bar). The silver and black anti-roll bars are typically used on medium-grip loose tracks.

Page 21

21

:: Shocks

4187

.030 Nylon Washer

5407

Red O-Rings

6299

31327

31510

91304

91308

91310

91448

91449

91480

91482

91488

91489

91491

91496

91498

E-Clip

VCS3 Shock Bottom Cap and O-Ring

M2 x 4mm BHCS

12MM Threaded Collar and O-Ring

12MM Shock Pistons, (1.5, 1.6, 1.7)

12MM Shock Spring Cups (+0mm, +5mm, +9mm)

Shock Pivot Ball and Rod End

12MM V2 Composite Shock Cap

w/O-ring and bleeder screw

12x23MM V2 Shock Bodies

12x31MM V2 Shock Bodies

3x21MM Shock Shaft

3x27.5MM Shock Shaft

12MM V2 Shock Rebuild Kit

12x23B/21S V2 Shock Kit (B5 Front)

12x31B/27.5S V2 Shock Kit (B5 Rear)

91449

91491

31510

6299

91308

91304

12

8

12

2 ea.

6

2

4 ea.

4 ea.

4

4

2

2

1

1

1

2

2

:: Ball Differential

6573

6574

6575

6581

6582

7666

7677

31400

91419

91420

91421

Diff Thrust Washer & Bolt

Precision Diff Thrust Balls, 5/64”

Locking T-Nut, Diff Thrust Bolt, & Cover

3/32” Carbide Diff Balls

Diff Thrust Spring

Diff Drive Rings, 2.60:1

Ball Diff Rebuild Kit

Bearing, 5 x 8mm

Diff Gear, B5

Ball Diff Outdrive, B5

Ball Diff Kit, B5

6575

6582

91420

2

6

1

12

1

2

1

2

1

1 ea.

1

91421

31400

7666

91420

91480

91482

5407

91491

5407

31327

31327

:: Shock Springs

91325

91326

91327

91328

91329

91330

91331

91332

91333

91334

91335

91336

91337

91338

91339

91340

91341

91342

91343

91344

91345

12MM Front SPRING BRN 2.85

12MM Front SPRING BLK 3.00

12MM Front SPRING GRN 3.15 - Kit

12MM Front SPRING WHT 3.30

12MM Front SPRING GRY 3.45

12MM Front SPRING BLU 3.60

12MM Front SPRING YLW 3.75

12MM Front SPRING RED 3.90

12MM Front SPRING ORN 4.05

12MM Front SPRING PRL 4.20

12MM Rear SPRING BLK 1.90

12MM Rear SPRING GRN 2.00

12MM Rear SPRING WHT 2.10 - Kit

12MM Rear SPRING GRY 2.20

12MM Rear SPRING BLU 2.30

12MM Rear SPRING YLW 2.40

12mm Big Bore Front Soft Spring Kit

12mm Big Bore Front Medium Spring Kit

12mm Big Bore Front Hard Spring Kit

12mm Big Bore Rear Soft Spring Kit

12mm Big Bore Rear Medium Spring Kit

6299

91488

91489

4187

91304

91310

91448

91448

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

Pr.

1

1

1

1

1

:: Shock Oil

5420

5421

5422

5423

5424

5425

5426

5427

5428

5429

5430

5431

5432

5433

5434

5435

5436

5437

5438

10 Weight Silicone Shock Oil

20 Weight Silicone Shock Oil

30 Weight Silicone Shock Oil

40 Weight Silicone Shock Oil

22.5 Weight Silicone Shock Oil

80 Weight Silicone Shock Oil

27.5 Weight Silicone Shock Oil

15 Weight Silicone Shock Oil

25 Weight Silicone Shock Oil

35 Weight Silicone Shock Oil

45 Weight Silicone Shock Oil

55 Weight Silicone Shock Oil

32.5 Weight Silicone Shock Oil

37.5 Weight Silicone Shock Oil

42.5 Weight Silicone Shock Oil

50 Weight Silicone Shock Oil

60 Weight Silicone Shock Oil

70 Weight Silicone Shock Oil

47.5 Weight Silicone Shock Oil

31400

7666

6573

6574

6573

6581

6575

91419

6575

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

Page 22

22

:: Transmission

25202

25203

25211

25237

25238

25616

31532

89203

89218

91011

91424

91425

91426

91428

91429

91432

M3 x 10mm FHCS

M3 x 12mm FHCS

M3 x 10mm BHCS

Bearing, 5 x 10 x 4

Bearing, 6 x 12 x 4

Bearing, 10 x 15 x 4

M3 x 8mm BHCS

M3 x 16mm BHC

Washer 3 X 8mm

4x4 Idler Gear Shaft

Gearbox, B5

Top Shaft, B5

Top Shaft Spacer, B5

Motor Plate (Blue), B5

Idler Gear, B5

Motor Guard, B5

20

20

20

10

10

31532

89218

91428

25202

25211

91424

25616

25237

25238

91426

91429

91011

2

31532

2

2

6

89218

25202

1

1

1

1

1

2

1

25203

91425

31532

91432

25238

31532

25203

25237

89203

:: Slipper Clutch

7485

9603

9648

9649

9650

9651

9652

9653

9739

31530

91089

91148

91175

91176

91177

91178

91179

91423

91435

FT V2 Slipper Hubs

Slipper Pad

69T 48P Spur Gear

72T 48P Spur Gear (Kit)

75T 48P Spur Gear

81T 48P Spur Gear (Kit)

78T 48P Spur Gear

84T 48P Spur Gear

Slipper Spring

M3 x 5 BHCS

4X4 Belt Cover Cap

M4 Locknut, w/flange and knurl

FT VTS Slipper Conversion

VTS Slipper Housing

VTS Slipper Pads

VTS Slipper Plate

FT VTS Slipper Hub, outer

Slipper Spring Adapter

Gear Cover (Black), B5

25616

25211

2

2

1

1

1

1

1

1

1

6

2

4

1

1

2

1

1

2

1

7485

9649

9651

9603

91176

91177

91177

9739

91148

91424

91178

91179

91423

31530

89203

89203

89203

91435

31530

91089

:: Pinion Gears

8253

8254

8255

8256

8257

8258

8259

8260

8261

8263

8264

8265

8266

16T 48P Pinion Gear

17T 48P Pinion Gear

18T 48P Pinion Gear

19T 48P Pinion Gear

20T 48P Pinion Gear

21T 48P Pinion Gear

22T 48P Pinion Gear

23T 48P Pinion Gear

24T 48P Pinion Gear

26T 48P Pinion Gear

27T 48P Pinion Gear

28T 48P Pinion Gear

29T 48P Pinion Gear

8267

1

8268

1

8269

1

8270

1

8271

1

8272

1

1

1

1

1

1

1

1

30T 48P Pinion Gear

31T 48P Pinion Gear

32T 48P Pinion Gear

33T 48P Pinion Gear

34T 48P Pinion Gear

35T 48P Pinion Gear

1

1

1

1

1

1

Page 23

:: Optional Gear Differential

4675

91461

91462

91463

91465

M2.5 x 6 FHCS

Gear Diff Kit, B5

Gear Diff Gear/Cover, B5

Gear Diff Rebuild, B5

Gear Diff Outdrives, B5

6

1

1

1

2

91465

91465

91465

91465

4675

91465

4675

23

91462

91463

:: Differential Fluids

5450

5451

5452

5453

5454

5455

5456

5457

5458

5459

Silicone Diff Fluid 1,000CST

Silicone Diff Fluid 2,000CST

Silicone Diff Fluid 3,000CST

Silicone Diff Fluid 5,000CST

Silicone Diff Fluid 7,000CST

Silicone Diff Fluid 10,000CST

Silicone Diff Fluid 20,000CST

Silicone Diff Fluid 30,000CST

Silicone Diff Fluid 60,000CST

Silicone Diff Fluid 100,000CST

1

1

1

1

1

1

1

1

1

1

:: Turnbuckles and Servo Mounts

6263

7337

9180

31286

31532

89007

91047

91443

91453

91455

Turnbuckle, 2.06”

.250 x .125 x .015” Washer

Servo Horns, Molded

FT Ballstud Washer, aluminum

(1mm, 2mm)

M3 x 8 BHCS

Steering Servo Ring, blue

Heavy-duty Ballstud, 6mm

Servo Mount, B5

HD Ball Cup Set (Small), B5

Steering Link, B5

6263

91453

91453

2

4

1

4 ea.

6

1

8

2

1

4

31286

91047

9180

7337

31532

31532

89007

91455

7337

91455

7337

31532

31532

91465

31532

91443

7337

91462

91465

91465

91465

31532

91443

91455

:: Front Bulkhead / Steering

5407

21173

25189

25202

31286

89202

91047

91048

91362

91391

91475

Red O-Ring

Small Body Clips

M3 x 22mm BHCS

M3 x 10mm FHCS

FT Ballstud Washer, aluminum

(1mm, 2mm)

M3 x 12mm BHCS

Heavy-duty Ballstud, 6mm

Heavy-duty Ballstud, 8mm

Top Plate, B5

Steering Set, B5

3x7x3 Ball Bearing

8

12

20

20

4 ea.

10

8

8

1

1

8

21173

5407

25202

31286

91048

91362

5407

25202

91475

31286

91048

91391

89202

91475

91475

91475

91391

91475

25189

91047

91391

91475

91391

Page 24

24

Steering Block, Hex

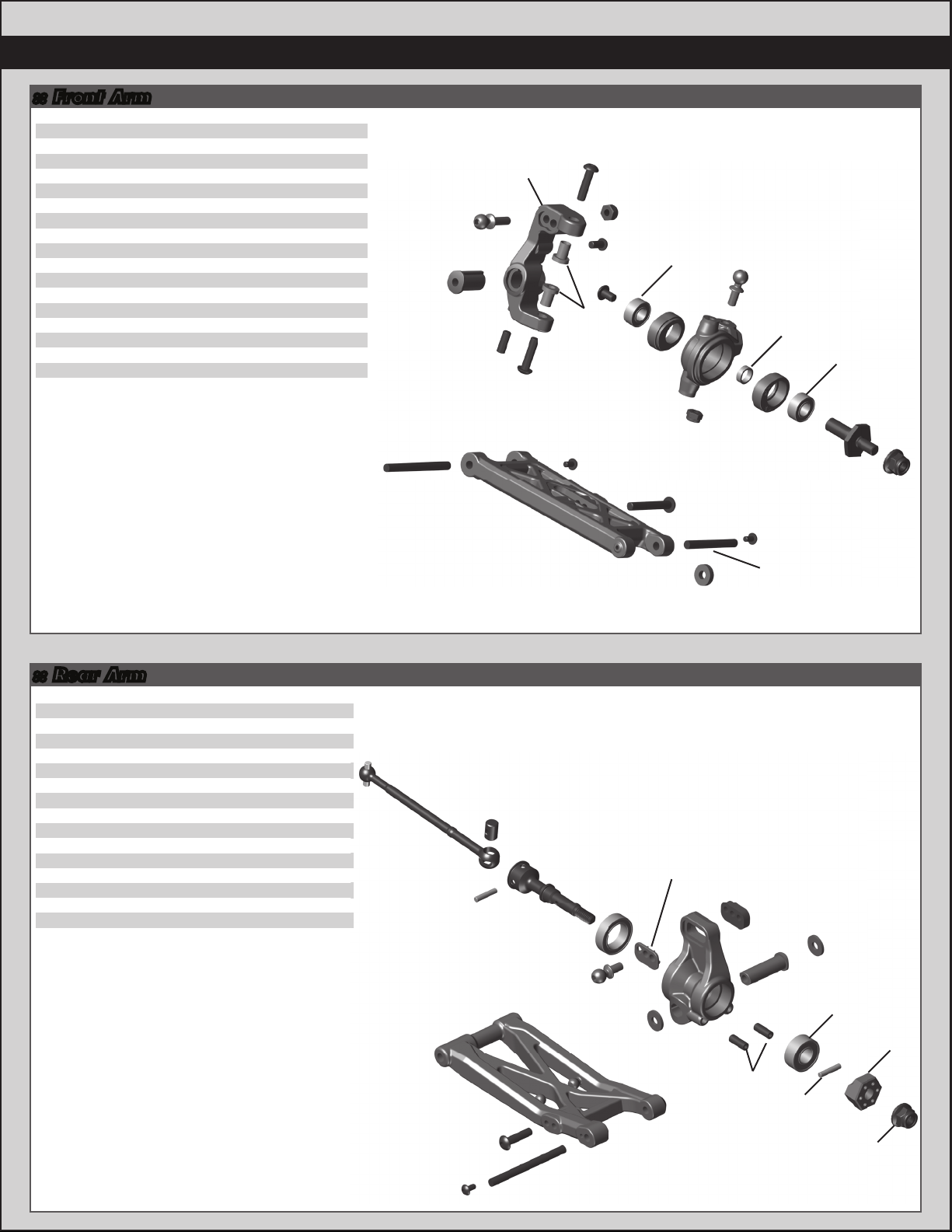

:: Front Arm

4670

25189

25215

25237

31510

31520

31530

89202

91047

91049

91148

91394

91398

91400

91402

91404

91406

91407

M3 x 8mm Set Screw

M3 x 22mm BHCS

M3 Locknut, black

Bearing, 5 x 10 x 4

M2 x 4mm BHCS

M2.5 x 6mm BHC

M3 x 5mm BHCS

M3 x 12mm BHCS

Heavy-duty Ballstud, 6mm

Heavy-duty Ballstud, 10mm

M4 Locknut, with flange and knurl

Hinge Pin Set, B5

Front Arms, B5

Caster Block, B5

Caster Block Bushing, B5

Steering Block, B5

Front Axles, B5

Front Axle Crush Tubes, B5

6

20

20

2

6

6

6

10

8

8

8

1

Pr.

Pr.

4

Pr.

2

2

91049

91400

4670

91400

89202

89202

31530

91402

25215

31520

91404

91404

25237

91047

91407

25237

:: Rear Arm

4670

25616

31510

89202

91047

91148

91394

91412

91414

91416

91436

91437

91438

91439

91441

91476

M3 x 8mm Set Screw

Bearing, 10 x 15 x 4

M2 x 4mm BHCS

M3 x 12mm BHCS

Heavy-duty Ballstud, 6mm

M4 Locknut, with flange and knurl

Hinge Pin Set, B5

Rear Arms, B5

Rear Hubs, B5

Rear Hub Link Nut Set, B5

CVA/Wheel Hex Pin, B5

CVA Axle, B5

CVA Rebuild Kit, B5

CVA Bone, B5

Wheel Hex (Rear), B5

6x13x5 Ball Bearing

6

2

6

10

8

8

1

Pr.

Pr.

1

4

2

1

1

2

2

91394

91439

91438

91398

91438

91437

31510

25616

25215

91414

25189

91400

91404

31510

91394

91416

91414

91406

91148

91414

31510

89202

91047

91394

91414

91412

91414

91476

91441

4670

91436

91148

Page 25

:: Battery Strap

4689

91456

91458

91459

M3 x 16mm Set Screw

Composite Battery Strap, B5

Battery Strap Thumbwheel, B5

Battery Spacers Set, B5

:: Front Shock Tower

25612

31286

89202

89204

91049

91373

91445

91477

M3 Locknut, with flange

FT Ballstud Washer, aluminum

(1mm, 2mm)

M3 x 12mm BHCS

M3 x 24mm BHCS

Heavy-duty Ballstud, 10mm

Front Tower, B5

Shock Bushing (Composite), B5

M3 Nut, Black

6

1

2

1

20

4 ea.

10

10

8

1

4

6

91459

89204

91459

31286

91477

91049

31286

91445

91458

91458

4689

25

91458

91458

4689

91456

91459

91049

25612

:: Rear Shock Tower

21173

25187

25201

25204

25211

25612

89204

91375

91433

91445

91477

91478

Small Body Clips

M3 x 14mm BHCS

M3 x 8mm FHCS

M3 x 16mm FHCS

M3 x 10mm BHCS

M3 Locknut, with flange

M3 x 24mm BHCS

Rear Tower, B5

Wing/Rear Body Mounts, B5

Shock Bushing Composite, B5

M3 Nut, Black

M3 x 30mm BHCS

12

20

20

20

20

20

10

1

1

4

6

6

21173

89204

25204

91433

89202

25211

91477

25204

89202

25187

89204

89204

91445

25612

25211

25201

25187

91375

25612

91445

91477

91373

21173

91433

91477

91433

25612

91445

91433

21173

91478

Page 26

26

:: Chassis

6338

25187

25203

25204

25211

25225

31286

31521

31532

89208

91049

91360

91364

91371

91377

91379

91380

91382

91394

91410

Antenna Tube & Cap (black)

M3 x 14mm BHCS

M3 x 12mm FHCS

M3 x 16mm FHCS

M3 x 10mm BHCS

M3 x 3mm Set Screw

Aluminum Ballstud Washer

(1mm & 2mm)

M2.5 x 8mm BHCS

M3 x 8mm BHCS

M3 x 14mm FHCS

Heavy-duty Ballstud, 10mm

Chassis, B5

Bulkhead (25° & 30°), B5

Hinge Pin Bracem B5

Chassis Brace, B5

Chassis Plate, B5

Receiver Mount, B5

Arm Mount Set, B5

Hinge Pin Set, B5

Front Bumper, B5

91364

1

20

20

20

20

20

4ea

6

6

10

8

1

1

1

1

1

1

1

1

1

6338

6338

25225

25211

31532

91049

31286

31532

91380

91049

31286

25211

91377

25187

91382

91394

31521

:: Wheels

9690

9691

9695

9696

Buggy Front Wheel, hex, white - Kit

Buggy Front Wheel, hex, yellow

Buggy Rear Wheel Hex, white - Kit

Buggy Rear Wheel Hex, yellow

31521

25204

25204

91371

25204

91410

25204

91394

91382

91360

25203

2

2

2

2

9691

89208

25203

9696

91379

89208

Not included

in Kit!

Not included

in Kit!

Page 27

27

:: Factory Team and Option Parts

1406

1409

1734

1735

1736

7485

7486

31286

91175

91176

91177

91178

91179

91363

91372

91374

91376

91378

91381

91382

91383

91385

91387

91389

91392

91395

91399

91401

91403

91405

91408

91409

91413

91415

91442

91446

91447

91450

91457

91468

91492

91493

91495

91516

91526

91527

FT Ti Turnbuckle, 2.00” (blue)

FT Ti Turnbuckle, 1” (sway bar) (blue)

FT Blue Body Clip, 4 long, 6 short

FT Blue Body Clip, long

FT Blue Body Clip, short

FT V2 Slipper Hubs

FT V2 Slipper Spring and Washer

FT Ballstud Washer, aluminum (1mm, 2mm)

FT VTS Slipper Conversion

VTS Slipper Housing

VTS Slipper Pads

VTS Slipper Plate

FT VTS Slipper Hub, outer

Top Plate (HARD), B5

Aluminum Front Pin Brace, B5

Front Tower (HARD), B5

Rear Tower (HARD), B5

Chassis Brace (HARD), B5

ESC Mount Graphite, B5

Arm Mount Set, B5

Aluminum Arm Mount (C), B5

Arm Mount Inserts Set (C), B5

Aluminum Arm Mount (D), B5

Arm Mount Insert (D), B5

Aluminum Steering Set, B5

TiN Hinge Pin Set, B5

Front Arms (HARD), B5

Caster Block (HARD), B5 w/inserts

Caster Block Bushing (Offset - long/short), B5

Steering Block (HARD), B5

Front Axle (Clamp Hex), B5 - Req. #91409

Clamping Hex (Front), B5 - Req. #91408

Rear Arms (HARD), B5

Rear Hubs (HARD), B5 w/inserts

Clamping Hex (Rear), B5

Shock Bushing (Aluminum), B5 - Req. #91447

Shock Bushing Ball, B5 - Req. #91446

12mm V2 Aluminum Shock Cap

(2 screws, 2 bleeder gaskets, and 2 o-rings)

Graphite Battery Strap, B5

Anti-Roll Bar Kit, B5

12mm V2 Bleeder Gasket/Screw

FT Low Friction X-Rings

12mm V2 X-Ring Rebuild Kit

(4 clear x rings, 2 spacers, 4 hat bushings)

RC10B5M Front Tower

RC10B5M Front Arm

RC10B5M Front Arm (HARD)

:: Body and Decals

91470

91471

91472

RC10B5 Clear Body

RC10B5 Clear Wing

RC10B5 Sticker Sheet

Pr.

Pr.

10

4

6

Pr.

1

4ea.

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Pr.

Pr.

2ea.

Pr.

2

2

Pr.

Pr.

2

4

4

2

1

1

1

8

1

1

1

1

1

1

1

:: XP Electronics

29107

29133

29134

29138

29139

29140

29141

29142

29143

29144

29145

29146

29166

29167

29168

29209

29210

29211

29212

29214

29215

29216

29250

29251

29252

29253

29254

XP DS1903/S1903 Metal Gear Set

XP DS1903 Digital Servo

XP DS1903MG Digital Servo

XP SC500-BL Brushless ESC

XP SC900-BL Brushless ESC

XP SC200 Brushed ESC

XP SC450 Brushless ESC

XP ESC Fan Option

XP SC700-BL Brushless ESC

XP SC1200-BL Brushless ESC

XP SC1300-BL Brushless ESC

XP SC1300DB Brushless ESC

XP DS1313 Digital Servo

XP DS1015 Digital Servo

XP DS1510MG Digital Servo

Gear Set, DS1313

Gear Set, DS1015

Servo Case , DS1313/DS1015

Accessory Pack, DS1313/DS1015

TRS403-SSi 2.4GHz 4Ch Receiver

XP2G 2.4GHz Radio System

XP3G 2.4GHz Radio System

XP DS1505 Digital Servo

XP DS1505MG Digital Servo

XP DS1505 Metal Gear Set

XP DS1510 Metal Gear Set

XPSSi Receiver Antenna

:: Reedy Accessories

247

248

249

250

604

606

607

609

610

643

644

645

646

647

648

650

654

655

656

658

659

660

661

663

664

669

716

961

962

974

975

978

979

980

981

982

992

Sonic 540 Mach 2 Sensor w/bearing

Sonic 540 Mach 2 Steel Bearing Set

Sonic 540 Mach 2 Ceramic Bearing Set

Sonic 540 Mach 2 Insulator Set

526-S AC/DC 2S-6S LiPo/LiFe Charger

Charge Harness 2S Saddle Pack 4mm

Charge Harness 2S Standard Pack 4mm

TAM to DEANS® charge adapter

447-S AC/DC NiMH Peak Charger

Low-Profile Bullet Connector, 4mm x 14mm (2)

Low-Profile Bullet Connector, 4mm x 14mm (10)

Low-Profile Bullet Connector, 5mm x 14mm (2)

Low-Profile Bullet Connector, 5mm x 14mm (10)

Pro Silicone Wire, 12AWG Black

Pro Silicone Wire, 14AWG Black

Shrink Tubing (Yellow, Orange, Red, Blue, Black)

4.0mm Bullet Plugs (2M, 2F)

4.0mm Bullet Plugs (2M, 10F)

4.0mm Bullet Plugs (10F)

4.0mm Bullet Plugs (10M)

4.0mm Bullet Plugs (30M)

3.5mm Bullet Plugs (3M, 3F)

3.5mm Bullet Plugs (10F)

3.5mm Bullet Plugs (10M)

3.5mm Bullet Plugs (30M)

5mm Bullet Connector

Reedy 09 Decal Set

Sonic 540/550 Timing Cap with Screws

Sonic 540 Case Screws

540-SL/550-SL Steel Bearing Set

540-SL/550-SL Ceramic Bearing Set

Flat Sensor Wire 70mm

Flat Sensor Wire 110mm

Flat Sensor Wire 150mm

Flat Sensor Wire 200mm

Flat Sensor Wire 270mm

Sonic 540 Rotor Spacers

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3ea.

1

1

1

1

1

1

1

1

1

2

1

1

3

1

1

1

1

1

1

1

1

Page 28

28

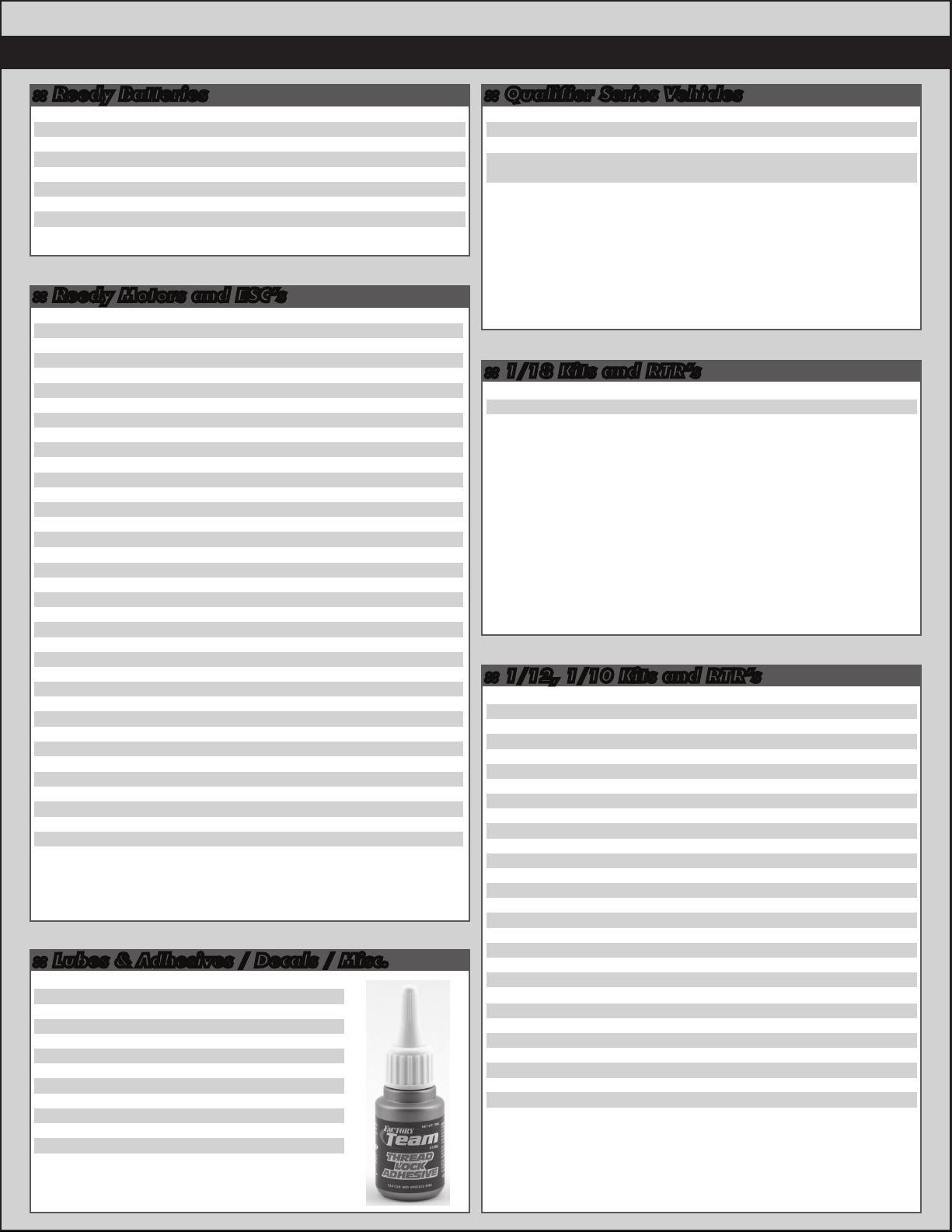

:: Reedy Batteries

302

310

314

602

632

637

737

738

AA Alkaline 1.5V (4)

LiPo 65C 5700mAh 7.4V SP

LiPo 65C 6000mAh 7.4V SQ

LiPo 65C 4100mAh 7.4V Shorty

LiPo TX Lightweight Battery 1350mAh 11.1V

LiPo TX Battery - M11X 2500mAh 7.4V

Wolfpack LiPo 4800mAh 7.4V 25C S.P.

Wolfpack LiPo 3800mAh 7.4V 25C Shorty

:: Reedy Motors and ESC’s

228

231

232

233

233S

234

235

236

237

238

239

240

241

242

243

244

245

246

908

920

921

922

923

941S

954

955

956

957

958

965

966

967

983

984

985

986

987

Sonic 540 Mach 2 25.5 Competition Brushless Motor

Sonic 540 Mach 2 21.5 Competition Brushless Motor

Sonic 540 Mach 2 17.5 Competition Brushless Motor

Sonic 540 Mach 2 13.5 Competition Brushless Motor

Sonic 540/540 Mach 2 Stator 13.5

Sonic 540 Mach 2 10.5 Competition Brushless Motor

Sonic 540 Mach 2 9.5 Competition Brushless Motor

Sonic 540 Mach 2 8.5 Competition Brushless Motor

Sonic 540 Mach 2 8.0 Competition Brushless Motor

Sonic 540 Mach 2 7.5 Competition Brushless Motor

Sonic 540 Mach 2 7.0 Competition Brushless Motor

Sonic 540 Mach 2 6.5 Competition Brushless Motor

Sonic 540 Mach 2 6.0 Competition Brushless Motor

Sonic 540 Mach 2 5.5 Competition Brushless Motor

Sonic 540 Mach 2 5.0 Competition Brushless Motor

Sonic 540 Mach 2 4.5 Competition Brushless Motor

Sonic 540 Mach 2 4.0 Competition Brushless Motor

Sonic 540 Mach 2 3.5 Competition Brushless Motor

Replacement Rotor 540-SL

540-SL Brushless Motor 3300kV

540-SL Brushless Motor 3900kV

540-SL Brushless Motor 4900kV

540-SL Brushless Motor 6100kV

Sonic 540/540 Mach 2 Stator 17.5

Sonic 540 Stock Rotor 12.3 x 24.2 (7.25)

Sonic 540 Stock Rotor 12.3 x 25.0 (7.25)

Sonic 540 Stock Rotor 12.5 x 25.0 (7.25)

Sonic 540 Modified Rotor 12.2 x 25.0 (5.0)

Sonic 540 Modified Rotor 12.5 x 25.0 (5.0)

Reedy 540-SL 3300kV/XP SC700-BL ESC Combo

Reedy 540-SL 3900kV/XP SC700-BL ESC Combo

Reedy 540-SL 4900kV/XP SC700-BL ESC Combo

Reedy 540-SL 3300kV/XP SC1200-BL ESC Combo

Reedy 540-SL 3900kV/XP SC1200-BL ESC Combo

Reedy 540-SL 4900kV/XP SC1200-BL ESC Combo

Reedy 540-SL 6100kV/XP SC1200-BL ESC Combo

Sonic 540 Modified Rotor 13.0 x 25.0 (5.0)

:: Lubes & Adhesives / Decals / Misc.

1105

1596

1597

6588

6591

6636

6727

716

3816

3820

3834

9787

FT Green Slime Shock Lube

FT Locking Adhesive

FT Tire Adhesive, medium

Black Grease - 4cc

S.Diff Lube - 4cc

Silicone Grease - 4cc

Servo Tape

Reedy 2009 Sticker Set

American Bumper Sticker

AE Logo Decal Sheet

AE Blue Embossed Logo Sticker

FT Chassis Protective Sheet

1

1

1

1

1

1

2

1

1

1

2

1

:: Qualifier Series Vehicles

7052

1

20111

1

20119

1

20510

1

1

30112

1

1

1

1

1

1

1

:: 1/18 Kits and RTR’s

1

1

20103

1

20121

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:: 1/12, 1/10 Kits and RTR’s

1

4020

1

7025

1

7028C

1

7030

1

7030C

1

7038

1

7039

1

7046

1

7049

1

7050

1

7051

1

7054

7055

7093

8020

8022

9040

9041

9042

9050

9062

30101

30109

90001

90003

90005

90006

90008

90010

Pro Lite 4x4 RTR, 1/10 Scale (ready-to-run)

Rival Mini Monster Truck 1/18 Scale (ready-to-run)

APEX Mini Touring RTR

RIVAL Electric Monster Truck RTR, 1/8 Scale

(ready-to-run)

APEX Touring V-Type, 1/10 Scale (ready-to-run)

RC18B2 - RC18T2 Team Kit

SC18 RTR Brushless (ready-to-run)

RC12R5.2 Factory Team Kit

RC10T4.2 Factory Team Kit

SC10 Pro Comp RTR (ready-to-run) Combo

SC10 KMC Wheels Race Truck RTR (ready-to-run)

SC10 KMC Wheels RTR (ready-to-run) Combo

SC10.2 Factory Team Kit

RC10T4.2 RS RTR 2.4GHz Brushless (ready-to-run)

SC10 RS RTR, Lucas Oil (ready-to-run)

SC10 RS RTR, Rockstar/Makita (ready-to-run)

SC10 RS RTR, Hart and Huntington (ready-to-run)

SC10 RS RTR, Lucas Slick Mist® Body

SC10 RS RTR, Toyota Racing/TRD

SC10 RS RTR, Monster Energy Toyota

SC10GT RTR (ready-to-run)

RC10R5 Factory Team Kit

RC10R5.1 Factory Team Kit

RC10B4.1 Worlds Kit

RC10B4.2 Factory Team Kit

RC10B4.2 RS RTR 2.4GHz Brushless (ready-to-run)

SC10B RS RTR (ready-to-run)

RC10B44.2 Factory Team 4WD Buggy Kit

TC4 Club Racer 4WD Touring Car Race Roller

RC10TC6.2 Factory Team 4WD Touring Car Kit

RC10B5 Team Kit

RC10B5M Team Kit

SC10 4x4 Lucas Oil RTR (ready-to-run)

SC10 4x4 Pro Comp RTR (ready-to-run)

Limited Edition SC10 4x4 RTR Monster Energy

SC10 4x4 Factory Team Kit

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 29

29

:: 1/8 Kits and RTR’s

20501

20502

20503

20504

80906

80907

80908

80909

80912

80933

80934

MGT 4.60 SE RTR (ready-to-run)

MGT 8.0 Nitro RTR (ready-to-run)

Limited Edition MGT 4.60 Nitro RTR, w/flag body

(ready-to-run)

Limited Edition MGT 8.0 Nitro RTR, w/flag body

(ready-to-run)

RC8.2 Nitro Buggy Factory Team Kit

RC8.2e Electric Buggy Factory Team Kit

RC8.2e Electric Buggy RTR (ready-to-run)

RC8.2RS Nitro Buggy RTR (ready-to-run)

RC8T Championship Edition

SC8.2e Short Course Race Truck, Rockstar/Makita

Electric RTR (ready-to-run)

SC8.2e Short Course Race Truck, Slick Mist Electric

RTR (ready-to-run)

:: Tools

1111

1113

1449

1541

1542

1543

1544

1545

1546

1547

1548

1553

1554

1561

1562

1563

1564

1565

1567

1589

1590

1592

1655

1656

1657

1658

1659

1660

1661

1662

1663

1664

1665

1666

1667

1668

1669

1670

1671

1672

1673

1674

1719

1737

3718

3719

3720

3987

6429

6956

7494

7709

FT Turnbuckle Wrench

12mm Big Bore Shock Tool

FT Off Road Ride Height Gauge

FT Hex Driver Set, (7 pcs)

FT .050” Silver Hex Driver

FT 1/16” Black Hex Driver

FT 1.5mm Purple Hex Driver

FT 5/64” Blue Hex Driver

FT 3/32” Gold Hex Driver

FT 2.5mm Green Hex Driver

FT 3mm Red Hex Driver

FT Phillips Silver Screwdriver

FT Silver Spring Hook Tool

FT Nut Driver Set, (6 pcs)

FT 3/16” Black Nut Driver

FT 1/4” Red Nut Driver

FT 5.5mm Red Nut Driver

FT 11/32” Green Nut Driver

FT 8mm Gold Nut Driver

FT 5/64” Blue Ball Hex Driver

FT 3/32” Gold Ball Hex Driver

FT Ball Hex Driver Set, (3 pcs)

FT 8-Piece 1/4” Hex Drive Set

FT 1/4” Hex Drive Handle, without tips

FT 1/4” Hex Drive .050” Tip

FT 1/4” Hex Drive 1/16” Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Tip

FT 1/4” Hex Drive 3/32” Tip

FT 1/4” Hex Drive 1.5mm Tip

FT 1/4” Hex Drive 2.5mm Tip

FT 1/4” Hex Drive 3/16” Nut Driver Tip

FT 1/4” Hex Drive 1/4” Nut Driver Tip

FT 1/4” Hex Drive 11/32” Nut Driver Tip

FT 1/4” Hex Drive 5.5mm Nut Driver Tip

FT 1/4” Hex Drive 7.0mm Nut Driver Tip

FT 1/4” Hex Drive 8.0mm Nut Driver Tip

FT 1/4” Hex Drive 5/64” - 2.0mm Ball End Tip

FT 1/4” Hex Drive 3/32” Ball End Tip

FT 1/4” Hex Drive Standard Screwdriver Tip

FT 1/4” Hex Drive Phillips Screwdriver Tip

FT 1/4” Hex Drive 2.5mm Ball End Tip

FT 1/4” 5 Piece Power Tool Tips Set (5/64-2.0mm,

1.5mm, 2.5mm, 5/64”- 2.0mm ball, 2.5mm ball)

FT Camber + Track Width Tool

FT Body Scissors

12 Inch Nylon Wire Ties

6 Inch Nylon Wire Ties

8 Inch Nylon Wire Ties

Composite Droop Gauge

Shock Building Tool

Molded Tools, Set

V2 Stamped Multi-tool

4 Inch Nylon Wire Ties

:: RePlay Cameras

1

RP001

1

RP002

1

RP021

RP022

1

RP023

RP024

1

RP029

1

RP030

1

RP032

1

RP033

1

RP034

1

RP036

RP038

1

RP041

RP042

RP043

RP044

RP045

RP046

1

RP047

1

RP048

1

RP049

1

RP054

1

1

1

1

1

1

1

1

:: Apparel

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

SP420**

:: Notes

1

1

1

1

1

1

1

1

1

110684

12

12

12

1

1

1

1

12

SP31**

SP32**

SP37**

SP38

SP39

SP71**

SP77**

SP78**

SP79**

SP84**

SP86**

SP90**

SP91**

SP92**

SP93**

SP94**

SP95**

SP96**

SP97**

SP98**

SP416

SP417

SP421S

SP421L

SP422S

SP422L

SP423S

SP423L

SP424S

SP424L

Replay XD1080 Complete Camera System

Replay XD720 Complete Camera System

Replay XD1080 Lens Bezel Kit

Replay XD1080 Clear Lens Cover

Replay XD1080 Lens Bezel & Rear Cap O-Ring

Replay XD Lens Bezel

Replay XD1080 HDMI to Mini-HDMI

Replay XD1080 Mini 8-pin USB Charge Data Cable

USB DC Car Charger 1A Stubby

USB DC Car Charger 500mAh

Micro SDHC USB Reader

3M VHB 4991 Mount Adhesive for SnapTray

3M VHB 5962 Mount Adhesive for SnapTray

Replay XD Suction Cup Arm Mini Clamp

Replay XD Suction Cup Short Arm Base

Replay XD Skateboard Mount

Replay XD VHB SnapTray, Convex

Replay XD VHB SnapTray, Flat

Au Plug for Universal DC Wall Charger

Eu Plug for Universal DC Wall Charger

Uk Plug for Universal DC Wall Charger

Universal USB DC Wall Charger 1A

Replay ReView Field Monitor

27 Time WC T-Shirt, Black (S, M, L, XL, 2XL, 3XL)

Kids AE 2012 T-Shirt, Blue (S, M, L)

Reedy 2012 T-shirt - Black (S, M, L, XL, 2XL, 3XL)

Reedy Trucker Hat

Reedy Patch

Associated Winter Jacket (M, L, XL)

AE 2012 T-Shirt, Blue (S, M, L, XL, 2XL, 3XL)

AE 2012 T-Shirt, White (S, M, L, XL, 2XL, 3XL)

AE 2012 T-Shirt, Black (S, M, L, XL, 2XL, 3XL)

Reedy 3D T-Shirt, Black (S, M, L, XL, 2XL, 3XL)

Reedy Womens 3D T-Shirt, Black (S, M, L, XL)

AE Retro T-Shirt, Blue (S, M, L, XL, 2-5XL)

AE Retro T-Shirt, Black (S, M, L, XL, 2-5XL)

AE Retro T-Shirt, White (S, M, L, XL, 2-5XL)

2013 Worlds T-Shirt, Blue (S, M, L, XL, 2-5XL)

2013 Worlds T-Shirt, Black (S, M, L, XL, 2-5XL)

2013 Worlds Hoodie, Black (S, M, L, XL, 2-3XL)

AE Retro Womens T-Shirt, Pink (S, M, L, XL)

AE Retro Womens T-Shirt, Black (S, M, L, XL)

AE Womens T-Shirt, Black (S, M, L, XL)

Associated Car Carrier Bag, Medium

1/10 FT Motor Bag

AE Pit Gloves (L, XL)

AE 2012 Hat, Black, Flat Bill, S/M

AE 2012 Hat, Black, Flat Bill, L/XL

AE 2012 Hat, Black, Curved Bill, S/M

AE 2012 Hat, Black, Curved Bill, L/XL

AE 2012 Hat, White, Flat Bill, S/M

AE 2012 Hat, White, Flat Bill, L/XL

AE 2012 Hat, White, Curved Bill, S/M

715

AE 2012 Hat, White, Curved Bill, L/XL

Reedy 2009 Track Banner

Team Associated Track Banner

** Use part number plus the desired size when ordering!

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Pr.

1

1

1

1

1

1

1

1

1

1

Page 30

30

:: Notes

:: Contact Information

Associated Electrics, Inc.

26021 Commercentre Drive

Lake Forest, CA 92630-8853 USA

http://www.TeamAssociated.com

http://www.RC10.com

http://twitter/Team Associated

http://bit.ly/AEonFacebook

call: (949) 544-7500

fax: (949) 544-7501

Check out the following web sites for all

of our electric kits, current products, new

releases, setup help, tips, and racing info!

www.TeamAssociated.com. - www.RC10.com

Page 31

Front Suspension:

Camber: °

Total Toe: °

Ride Height:

Arm Type:

Tower Type:

Caster Block Insert: °

Kick-Up Angle: °

Notes:

Rear Suspension:

Camber: °

Ride Height:

Hub Spacing:

Forward Middle Back

Notes:

-1

0

24mm

Standard

Standard

5

25

-1

24mm

Driver: Date:

Team Kit Stock Setup

Track: Event:Setup Sheet

Axle Height:

Up

Down

Up

Down

Up

Middle

Down

A

B

Ball Stud

Spacing:

Ball Stud

Spacing:

B

A

Bump Steer

Spacing:

0

Steering

Stop

Spacing:

0

Caster Block Spacing:

Anti Roll Bar:

None

Black (1.2mm)

Silver (1.3mm)

Gold (1.4mm)

Trailing Axle

2mm 3mm 4mm

Insert:

02mm

Rear Hub Link Setting:

CBBAA

A

B

Ball Stud

Spacing:

2mm

2mm

3

2mm

2

1

3

2

1

12

Electronics:

Radio: Servo:

EPA: Throttle: % Brake: %

ESC:

ESC Settings:

Motor:

Wind: Timing:

Pinion: Spur:

Battery:

Battery Position:

Track Info:

Size:

Surfaces:

Traction:

Moisture:

Condition:

Temperature:

Notes:

Race Results:

Qualify: Main:

Finish: TQ:

Best Lap Time:

Small

Dirt

Low

Dry

Bumpy

Medium

Carpet

Medium

Damp

Outdoor

Grooved

Ambient: Track:

:: For more setups, visit RC10.com and click on “Setup Sheets”

Large

Astroturf Multi Surface

High

Wet

Dusty

Smooth

Arm Mount:

Inboard Toe: °

Anti-Squat:

Drivetrain:

Differential:

Ball:

Setting:

Gear:

Oil:

Slipper Clutch:

Type:

# of Pads:

Notes:

Extra Large

Very High

Hard PackedIndoor

Loamy

Vehicle Comments:

1/4 Turn Out

3+2

VTS

3

Tires:

Tires (F/R):

Compound (F/R):

Insert (F/R):

Wheel (F/R):

Notes:

Body & Wing:

Body:

Wing:

Wing Angle: 0° 3° 6°

Notes:

Hub Insert:

0° 0.5° 1°

Shocks:

Piston:

Oil:

Spring:

Limiters:

Cup Offset:

Stroke:

Free Length:

Notes:

RC10B5 Body

RC10B5 Wing

Total Vehicle Weight:

Front

1.6

30 wt

Green

3

5mm

AB

/

/

/

/

Rear

1.7

30 wt

White

2

5mm

12

Free

Length

Stroke

Page 32

:: Hardware - 1:1 Scale View

32

Button Head (bhcs)

3x8mm Aluminum (8552)

2x4mm (31510)

2.5x6mm (31520)

2.5x8mm (31521)

3x4mm (91158)

3x5mm (31530)

3x6mm (31531)

3x8mm (31532)

3x10mm (25211)

3x12mm (89202)

3x14mm (25187)

3x16mm (89203)

3x18mm (2308)

3x22mm (25189)

3x24mm (89204)

3x30mm (91478)

Flat Head (fhcs)

3x8mm Aluminum (8553)

Ballstuds

Ti Nitride HD 6mm (91118)

Ti Nitride HD 8mm (91119)

Ti Nitride HD 10mm (91120)

Ti Nitride HD 12mm (91121)

Nuts (lock/plain)

M3 Alum. Locknut, Blue (31550)

3x8mm (25201)

3x10mm (25202)

3x12mm (25203)

3x14mm (89208)

3x16mm (25204)

HD 6mm (91047)

HD 8mm (91048)

HD 10mm (91049)

HD 12mm (91050)

M3 Nut (91477)

Ball Bearings

3x7x3mm (91475)

5x8mm (31400)

5x10x4mm (25237)

6x12x4mm (25238)

6x13x5 (91476)

10x15x4 (25616)

Set Screws

3x3mm (25225)

3x8mm (4670)

Shims and Washers

Servo Mount Washer (7337)

(.250 x .125 x .815)

FT Ballstud Washer, Aluminum

(1mm and 2mm, 4 each) (31286)

Notes:

M3 Locknut w/Flange (25612)

FT 3mm Locknuts, Blue(25392)

M4 Locknut w/Flange (91148)

FT M4 Locknuts w/Flange,

Blue (31551)

3x16mm (4689)

Clips

E-clip 1/8 (6299)

Diff Balls