Page 1

USER MANUAL FOR

GENESYS

TM

10KW/15KW

Programmable DC Power Supplies

Document: 83-530-000 Rev J

TDK-Lambda Americas Inc.

405 Essex Road, Neptune, NJ 07753

High Power Division

Tel: (732) 922-9300

Fax: (732) 922-9334

www.us.TDK-Lambda.com/HP

Page 2

Page 3

Page 4

GenesysTMManual Supplement

For units equipped with the “IEMD” option,

for IEEE-488 with Multi-drop,

also refer to IEMD manual 83030200

For units equipped with the “LAN” option

for Local Area Network with Multi-drop,

also refer to LAN manual 83034100

For units equipped with “MD” option,

Multi-drop, also refer to the respective

IEMD or LAN manuals.

Page 5

Table of Contents

WARRANTY...........................................................................................................................................3

SAFETY INSTRUCTIONS......................................................................................................................4

1. GENERAL INFORMATION.............................................................................................................21

1.1. User Manual Content...........................................................................................................................21

1.2. Introduction..........................................................................................................................................21

1.3. Accessories.........................................................................................................................................22

1.4. Model Number Format.........................................................................................................................23

2. SPECIFICATION.............................................................................................................................24

3. INSTALLATION ..............................................................................................................................30

3.1. General................................................................................................................................................30

3.2. Preparation for Use..............................................................................................................................30

3.3. Initial Inspections.................................................................................................................................30

3.4. Rack Mounting.....................................................................................................................................31

3.5. Location, Mounting and Cooling..........................................................................................................31

3.6. AC Source Requirements....................................................................................................................31

3.7. AC Input Power Connection................................................................................................................31

3.8. Turn-On Checkout Procedure..............................................................................................................32

3.9. Connecting the Load............................................................................................................................35

3.10. Local and Remote Sensing..................................................................................................................39

3.11. Repackaging for Shipment ..................................................................................................................40

4. FRONT AND REAR PANEL CONTROLS AND CONNECTORS..................................................41

4.1. Introduction..........................................................................................................................................41

4.2. Front Panel Controls and Indicators....................................................................................................41

4.3. Rear Panel SW1 Setup Switch............................................................................................................46

4.4. Rear Panel J1 Programming and Monitoring Connector .....................................................................47

5. LOCAL OPERATION......................................................................................................................49

5.1. Introduction..........................................................................................................................................49

5.2. Standard Operation .............................................................................................................................49

5.3. Over Voltage Protection (OVP)............................................................................................................50

5.4. Under Voltage Limit (UVL)...................................................................................................................51

5.5. Foldback Protection.............................................................................................................................51

5.6. Output ON/OFF Control.......................................................................................................................52

5.7. Output SHUT-OFF (SO) Control via Rear Panel J1 Connector...........................................................52

5.8. Enable/Disable Control via Rear Panel J1 Connector.........................................................................53

5.9. CV/CC Signal ......................................................................................................................................53

5.10. PS_OK Signal......................................................................................................................................53

5.11. Safe Start and Auto-Restart Modes.....................................................................................................54

5.12. Front Panel Locking.............................................................................................................................54

5.13. Over Temperature Protection (OTP)....................................................................................................55

5.14. Last Setting Memory............................................................................................................................55

1

83-530-000 Rev J

Page 6

6. SERIES AND PARALLEL SUPPLIES ...........................................................................................56

6.1. Series Operation..................................................................................................................................56

6.2. Parallel Operation................................................................................................................................59

6.3. Daisy-Chain for Shut-Off......................................................................................................................62

6.4. Advanced Parallel Operation...............................................................................................................62

7. REMOTE AND ANALOG PROGRAMMING ..................................................................................65

7.1. Introduction..........................................................................................................................................65

7.2. Local/Remote Analog Indication..........................................................................................................65

7.3. Local/Remote Analog Indication..........................................................................................................65

7.4. Remote Voltage Programming of Output Voltage and Current Limit...................................................66

7.5. Resistive Programming of Output Voltage and Current Limit ..............................................................67

7.6. Remote Monitoring of Output Voltage and Current..............................................................................68

8. RS232 &RS485 REMOTE CONTROL............................................................................................69

8.1. Introduction..........................................................................................................................................69

8.2. Configuration.......................................................................................................................................69

8.3. Rear Panel RS232/485 Connector......................................................................................................70

8.4. Connecting Power Supplies to RS232 Bus..........................................................................................71

8.5. Communication Interface Protocol.......................................................................................................72

8.6. Error Messages ...................................................................................................................................73

8.7. Command Set Description...................................................................................................................74

8.8. Global Output Commands...................................................................................................................77

8.9. Fast Queries........................................................................................................................................79

8.10. Status and Error Commands...............................................................................................................80

8.11. Status, Error, and SRQ Registers........................................................................................................81

8.12. Serial Communication Test Set-Up .....................................................................................................84

9. ISOLATED ANALOG PROGRAMMING OPTION..........................................................................86

9.1. Introduction..........................................................................................................................................86

9.2. Specifications ......................................................................................................................................86

9.3. Isolated Programming & Monitoring Connector...................................................................................87

9.4. Setup and Operating Instructions........................................................................................................88

10.MAINTENANCE ..............................................................................................................................89

10.1. Introduction..........................................................................................................................................89

10.2. Units Under Warranty..........................................................................................................................89

10.3. Periodic Maintenance ..........................................................................................................................89

10.4. Adjustments and Calibration................................................................................................................89

10.5. Parts Replacement and Repairs..........................................................................................................89

10.6. Troubleshooting...................................................................................................................................89

2

83-530-000 Rev J

Page 7

83-000-016 Rev.

F

WARRANTY

This

TDK

-

Lambda

Americas Inc.

product is warranted against defects in materials and workmanship for

a period of five years from date of shipment. During the warranty period,

TDK

-

Lambda

Americas Inc.

will, at it’s option, either repair or replace

products which prove to be defective.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance by

the buyer, buyer supplied products or

interfacing. The warranty shall not apply to defects resulting from

unauthorized modifications, or from operation exceeding the environmental specifications of the

product, or if the QA seal has been removed or altered by anyone other than

TDK

-

Lambda

Ameri

cas

Inc.

authorized personnel.

TDK

-

Lambda

Americas Inc.

does not warrant the buyer’s circuitry or

malfunctions of

TDK

-

Lambda

Americas Inc.

products resulting from the buyer’s circuitry. Furthermore,

TDK

-

Lambda

Americas Inc.

does not warrant any damage occu

rring as a result of the buyer’s circuitry

or the buyer’s

-

supplied products. THIS LIMITED WARRANTY IS IN LIEU OF, AND

TDK

-

LAMBDA

AMERICAS INC

DISCLAIMS AND EXCLUDES, ALL OTHER WARRANTIES, STATUTORY, EXPRESS

OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY

WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, OR OF CONFORMITY TO MODELS OR SAMPLES.

WARRANTY SERVICE

This product must be returned to an authorized

TDK

-

Lambda

Americas Inc.

service facility for repairs or

other warranty service. For p

roducts returned to

TDK

-

Lambda

Americas Inc.

for warranty service, the

buyer shall prepay shipping charges to

TDK

-

Lambda

Americas Inc

. If the unit is covered under the

foregoing warranty then

TDK

-

Lambda

Americas Inc.

shall pay the shipping charges to retu

rn the

product to the buyer. Refer to Section 3.11 for repackaging for shipment.

DISCLAIMER

The information contained in this document is subject to change without notice.

TDK

-

Lambda

Americas

Inc.

shall not be liable for errors contained in this document

or for incidental or consequential damages

in connection with the furnishing, performance or use of this material. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of

TDK

-

Lambda

A

mericas Inc

.

TRADEMARK INFORMATION

Genesys™

power supply is a trademark of

TDK

-

Lambda

Americas Inc.

Microsoft™

and Windows

™

are trademarks of Microsoft Corporation.

THE FCC WANTS YOU TO KNOW

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

Operation of this equipment i

n a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own expense.

FCC WARNING

Modifications not expressly approved by manufacturer could void the user authority to ope

rate the

equipment under FCC Rules.

1

Page 8

ENGLISH

SAFETY INSTRUCTIONS

CAUTION

The following safety precaution must be observed during all phases of operation, service and repair of

this equipment. Failure to comply with the safety precautions or warnings in this document violates

safety standards of design, manufacture and intended use of this equipment and may impair the builtin protections within.

TDK-Lambda Americas Inc. shall not be liable for user’s failure to comply with these requirements.

INSTALLATION CATEGORY

The GenesysTMpower supply series has been evaluated to INSTALLATION CATEGORY II.

Installation category (over voltage category) II: local level, appliances, portable equipment etc. With

smaller transient over voltage than Installation Category (over voltage category) III.

GROUNDING

This product is a Safety Class 1 instrument. To minimize shock hazard, the instrument chassis must

be connected to an electrical ground. The instrument must be connected to the AC power supply

mains through a three conductor power cable, with the ground wire firmly connected to an electrical

ground (safety ground) at the power outlet.

For instruments designed to be hard-wired to the supply mains, the protective earth terminal must be

connected to the safety electrical ground before another connection is made. Any interruption of the

protective ground conductor or disconnection of the protective earth terminal will cause a potential

shock hazard that might cause personal injury.

WARNING

OUTPUT TERMINALS GROUNDING

There is a potential shock hazard at the RS232/RS485/LAN and the IEEE

ports when using power supplies with rated or combined voltage greater

than 400V and the Positive Output of the Power Supply is grounded.

Do Not connect the Positive Output to ground when using the

RS232/RS485/LAN or IEEE.

FUSES

Fuses must be changed by authorized TDK-Lambda Americas Inc. service personnel only. For

continued protection against risk of fire, replace only with the same type and rating of fuse.

INPUT RATINGS

Do not use AC supply, which exceeds the input voltage and frequency rating of this instrument. The

input voltage and frequency rating of the GenesysTMpower supply series has three input ranges

depending on the model type ordered. Ranges are 180-253 Vac/360-440 Vac/432-528 Vac, 50-60Hz.

For safety reasons, the mains supply voltage fluctuations should not exceed above voltage range.

LIVE CIRCUITS

Operating personnel must not remove the instrument cover. No internal adjustment or component

replacement is allowed by non-TDK-Lambda Americas Inc. qualified personnel. Never replace

components with power cable connected. To avoid injuries, always disconnect power, discharge

circuits and remove external voltage source before touching components.

PARTS SUBSTITUTIONS & MODIFICATIONS

Parts substitutions and modifications are allowed by authorized TDK-Lambda Americas Inc. service

personnel only. For repairs or modifications, the instrument must be returned to an authorized TDKLambda Americas Inc. service facility.

4

83-530-000 Rev J

Page 9

SAFETY INSTRUCTIONS

ENVIRONMENTAL CONDITIONS

The GenesysTMpower supply series safety approval applies to the following operating conditions:

*Indoor use *Ambient temperature: 0°C to 50°C

*Maximum relative humidity: 80% (no condensation) *Altitude: up to 3000m

*Pollution degree 2

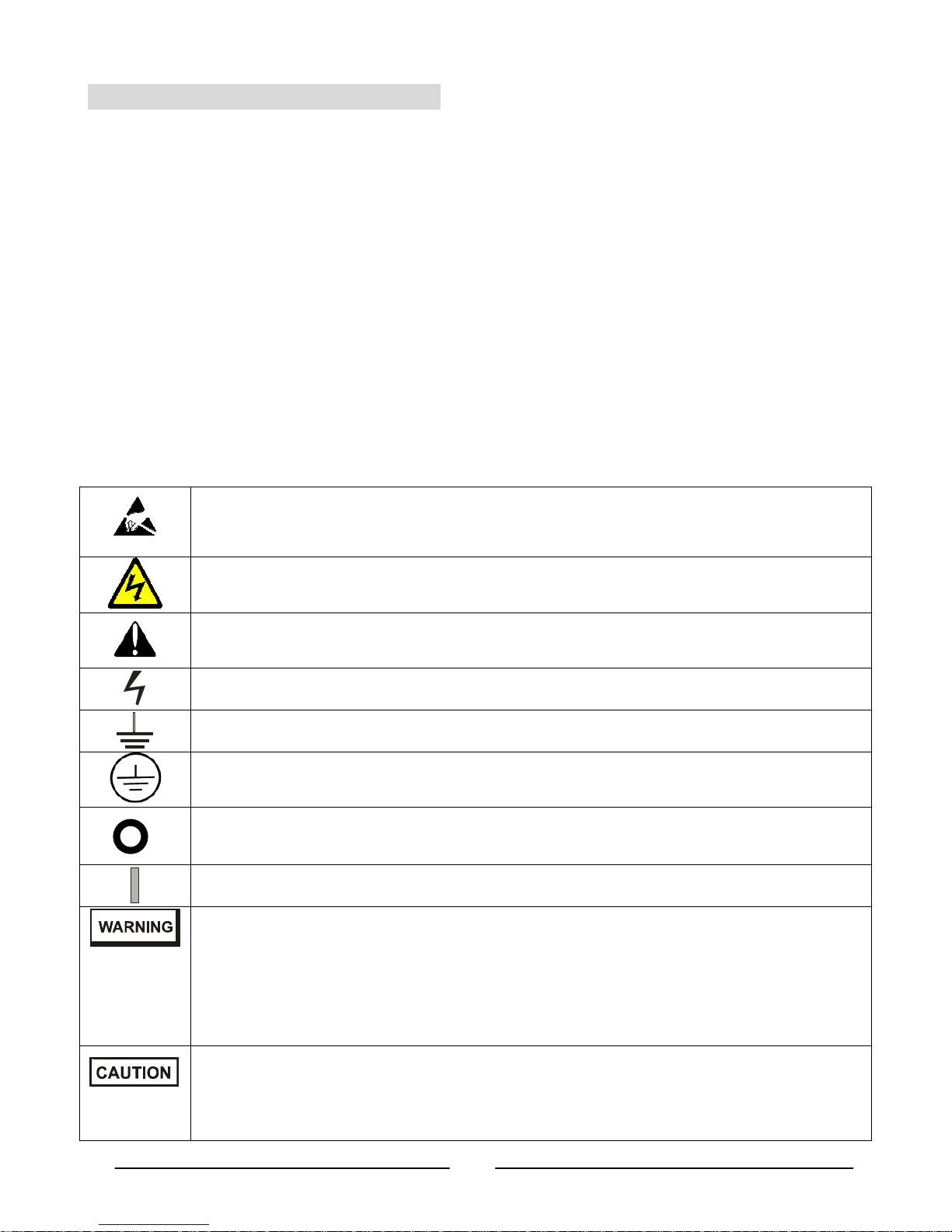

ATTENTION Observe Precautions for handling Electrostatic Sensitive Devices.

CAUTION Risk of Electrical Shock

Instruction manual symbol. The instrument will be marked with this symbol when it is

necessary for the user to refer to the instruction manual.

Indicates hazardous voltage.

Indicates ground terminal.

Protective Ground Conductor Terminal must be connected to Earth Ground.

Off (Supply)

On (Supply)

The WARNING sign denotes a hazard. An attention to a procedure is called.

Not following procedure correctly could result in personal injury.

A WARNING sign should not be skipped and all indicated conditions must be

fully understood and met.

The CAUTION sign denotes a hazard. An attention to a procedure is called. Not

following procedure correctly could result in damage to the equipment. Do not proceed

beyond a CAUTION sign until all indicated conditions are fully understood and met.

5

83-530-000 Rev J

Page 10

FCC COMPLIANCE NOTICE:

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

6

83-530-000 Rev J

Page 11

FRENCH

CONSIGNES DE SECURITE

ATTENTION

Les consignes de sécurité suivantes doivent être observées pendant toutes les phases de l'utilisation,

entretien et réparations de cet équipement. Le non-respect des consignes de sécurité et des

avertissements dans ce document viole les normes sécurité de conception, fabrication et utilisation

prévue de cet équipement et peut compromettre les protections incorporées en lui.

TDK-Lambda Americas Inc. ne sera pas responsable des conséquences si l'utilisateur ne respecte

pas ces consignes.

CATEGORIE D'INSTALLATION

Les alimentations GenesysTMont été classées dans CATEGORIE INSTALLATION II. Catégorie

installation (catégorie surtension) II : utilisation locale, appareils, équipement portable, etc. Avec des

surtensions transitoires plus faibles que celles de la catégorie installation (catégorie surtension) III.

MISE A LA TERRE

Ce produit est un instrument Classe 1 Sécurité. Pour minimiser le risque de choc électrique, son

châssis doit être raccordé à une terre électrique. L'instrument doit être raccordé à l'alimentation

principale AC par un câble à trois conducteurs, le conducteur de terre étant raccordé à une terre

électrique (terre sécurité) sur la prise électrique.

Pour les instruments conçus pour être raccordés à l'alimentation électrique principale, la borne de

terre doit être raccordée à la terre électrique de sécurité avant d'établir une autre connexion. Si le

conducteur de terre est coupé ou si la borne de terre est débranchée, il y a un risque de choc

électrique pouvant provoquer des blessures.

ATTENTION-DANGER

MISE A LA TERRE DES BORNES DE SORTIE

Il y a un danger de choc électrique sur les ports RS232/RS485/LAN et IEEE

lorsqu'on utilise des alimentations électriques ayant à elles seules ou au total une

tension supérieure à 400 V et si la sortie positive de l'alimentation est raccordée à

la terre.

Ne raccordez pas la sortie positive à la terre si vous utilisez les ports

RS232/RS485/LAN ou IEEE.

FUSIBLES

Les fusibles ne doivent être remplacés que par des techniciens d'entretien agréés TDK-Lambda

Americas Inc. Pour assurer une protection continue contre le risque d'incendie, remplacez les fusibles

par des fusibles de même type et de même capacité.

ALIMENTATION PRINCIPALE

N'utilisez pas une alimentation AC dont la tension et la fréquence dépassent les valeurs nominales de

cet instrument. La tension et la fréquence nominales des alimentation GenesysTMcorrespondent à

trois intervalles selon le modèle commandé. Les intervalles sont 180-253 Vac/360-440 Vac/432-528

Vac, 50-60Hz. Pour des raisons de sécurité, la tension d'alimentation principale ne doit pas fluctuer en

dehors des intervalles ci-dessus.

CIRCUITS SOUS TENSION

Le personnel d'exploitation ne doit pas enlever le couvercle de l'instrument. Le réglage ou le

remplacement des composants internes ne peut être effectué que par un personnel qualifié TDKLambda Americas Inc. Ne remplacez jamais les composants lorsque le câble d'alimentation est

connecté. Pour éviter les blessures, débranchez toujours l'alimentation, déchargez les circuits et

retirez la source de tension extérieure avant de toucher les composants.

7

83-530-000 Rev J

Page 12

CONSIGNES DE SECURITE

l'utilisateur doit prendre des mesures pour les supprimer à ses propres frais.

SUBSTITUTIONS ET MODIFICATIONS DE PIECES

Les substitutions et modifications de pièces ne peuvent être effectuées que par les techniciens

d'entretien agréés TDK-Lambda Americas Inc. Pour les réparations ou les modifications, l'instrument

doit être renvoyé à un centre d'entretien agréé TDK-Lambda Americas Inc.

CONDITIONS ENVIRONNEMENTALES

L'approbation sécurité des alimentations GenesysTMs'applique aux conditions opératoires suivantes :

*Utilisation en intérieur *Température ambiante : 0°C à 50°C

*Humidité relative maximum : 80 % (sans condensation) *Altitude : 3000 m maximum

*Pollution degré 2

PRECAUTION. Observez les précautions pour manipuler les composants sensibles à

l'électricité statique.

ATTENTION. Risque de choc électrique

Symbole dans le manuel d'instructions. Ce symbole sera marqué sur l'instrument

lorsque l'utilisateur doit consulter le manuel d'instructions.

Signale une tension dangereuse.

Signale une borne de terre.

La borne du conducteur de terre de protection doit être connectée à la terre électrique.

Coupée (alimentation)

Branchée (alimentation)

Le symbole WARNING signale un danger. Il attire l'attention sur une procédure.

Si la procédure n'est pas suivie correctement, il peut en résulter des blessures.

Le symbole WARNING (Attention-danger) ne doit pas être ignoré et toutes les

conditions indiquées doivent être bien comprises et respectées.

Le symbole CAUTION (Attention) signale un danger. Il attire l'attention sur une

procédure. Si la procédure n'est pas suivie correctement, l'équipement peut être

endommagé. Ne continuez pas après avoir rencontré le symbole CAUTION tant que

vous n'avez pas parfaitement compris et respecté les conditions indiquées.

NOTE CONCERNANT LA CONFORMITE FCC :

Nota : Cet équipement a été testé et s'est avéré conforme aux limites pour un appareil

numérique Classe A selon la part 15 des règles FCC. Ces limites sont conçues pour

assurer une protection raisonnable contre les interférences dangereuses lorsque

l'équipement est utilisé dans un environnement commercial. Cet équipement génère,

utilise et peut rayonner des fréquences radio et, s'il n'est pas installé et utilisé

conformément au manuel d'instructions, il peut provoquer des interférences

dangereuses pour les communications radio. L'utilisation de cet équipement dans une

zone résidentielle provoquera probablement des interférences nocives, et dans ce cas

8

83-530-000 Rev J

Page 13

GERMAN

Sicherheitsvorschriften

VORSICHT

Die folgenden Sicherheitsvorschriften müssen in allen Phasen des Betriebs, der Wartung und der

Reparatur der Anlage eingehalten werden. Eine Missachtung der Sicherheitsvorschriften und

Warnhinweise aus diesem Handbuch führt zur Verletzung der bestehenden Sicherheitsstandards für

Design, Produktion und der zweckbestimmten Verwendung der Anlage und kann die integrierten

Schutzvorrichtungen beschädigen.

TDK-Lambda Americas Inc. ist nicht haftbar für Schäden, die durch Missachtung dieser

Sicherheitsvorschriften entstehen können.

INSTALLATIONSKATEGORIE

Die GenesysTMReihe der Netzgeräte wurde in die INSTALLATIONSKATEGORIE II eingeteilt.

Installationskategorie (Überspannungskategorie) II: die lokale Ebene, Geräte, tragbare Anlagen, etc.

mit kleineren vorübergehenden Überspannungen als die Installationskategorie

(Überspannungskategorie) III.

ERDUNGSKONZEPT

Dieses Produkt ist ein Gerät der Schutzklasse 1. Zur Vermeidung von gefährlichen Energieinhalten

und Spannungen, ist das Gehäuse des Gerätes an eine Schutzerde anzuschließen. Das Gerät muss

über ein Dreileiterstromkabel an die AC-Hauptstromversorgung angeschlossen werden, wobei das

Erdungskabel fest mit einer elektrischen Erdung (Schutzerde PE) am Stromanschluss verbunden sein

muss.

Bei Festverdrahtung der Geräte ist sicherzustellen, dass der PE-Anschluss an die elektrische

Schutzerde angeklemmt wird, bevor das Gerät an die Stromversorgung angeschlossen wird. Jede

Unterbrechung des PE-Leiters oder die Trennung der PE-Verbindung kann einen möglichen

elektrischen Schlag hervorrufen, der Personenschäden zur Folge haben kann.

WARNUNG

ERDUNG DER AUSGANGSANSCHLÜSSE

Es besteht die Gefahr von möglichen Schlägen an der RS232/RS485/LAN und den

IEEE-Anschlüssen, wenn Netzgeräte mit höheren Nenn- oder kombinierten

Spannungen als 400 V verwendet werden und die positive Ausgangsspannung der

Netzgeräte geerdet wurde.

Klemmen Sie die positive Ausgangsspannung nicht an die Schutzerde an, wenn Sie

RS232/RS485/LAN oder IEEE verwenden.

SICHERUNGEN

Sicherungen dürfen nur durch von TDK-Lambda Americas Inc. zugelassenes Personal ausgewechselt

werden. Für anhaltenden Brandschutz dürfen die Sicherungen nur mit baugleichen Sicherungen mit

der gleichen Leistung ersetzt werden.

9

83-530-000 Rev J

Page 14

SICHERHEITSVORSCHRIFTEN

EINGANGSLEISTUNG

Verwenden Sie keine AC-Spannung, die die Eingangsleistung und Frequenzrate dieses Gerätes

übersteigt. Die Eingangsspannung und Frequenzrate der GenesysTMReihe der Netzgeräte verfügt

über drei Eingangsbereiche, je nach bestelltem Bautyp. Die Bereiche sind 180-253 VAC/360-440

VAC/432-528 VAC, 50-60Hz. Aus Sicherheitsgründen sollten die Spannungsschwankungen der

Hauptstromversorgung den oberen Spannungsbereich nicht übersteigen.

SPANNUNGSFÜHRENDE TEILE

Die Geräteabdeckung darf nicht durch Betriebspersonal entfernt werden. Interne Modifikationen sowie

Bauteileaustausch sind nur durch von TDK-Lambda Americas Inc. qualifiziertes Personal erlaubt. Vor

dem Austausch von Komponenten muss immer die Versorgungsspannung getrennt werden. Um

Personenschäden zu vermeiden, muss vor dem Kontakt mit dem Gerät immer die Stromversorgung

unterbrochen, die Stromkreise entladen und externe Spannungsquellen entfernt werden.

ERSATZTEILE & MODIFIKATIONEN

Ersatzteile und Modifikationen dürfen nur durch von TDK-Lambda Americas Inc. zugelassenes

Personal durchgeführt werden. Für Reparaturen oder Modifikationen muss das Gerät an einen

autorisierten TDK-Lambda Americas Inc. Vertriebspartner geschickt werden.

UMGEBUNGSBEDINGUNGEN

Die Sicherheitsbestätigung der GenesysTMNetzteilserie gilt für die folgenden Betriebszustände:

* Gebrauch im Innenbereich *Umgebungstemperatur: 0°C bis

50°C

*Maximale relative Luftfeuchtigkeit: 80% (keine Kondensation) *Höhe: bis zu 3.000 m

* Verschmutzungsgrad 2

ACHTUNG Beachten Sie die Vorsichtsmaßnahmen im Umgang mit elektrostatisch

gefährdeten Bauteilen.

VORSICHT Gefahr von elektrischen Schlägen.

Symbol der Bedienungsanleitung. Dieses Symbol wird am Gerät angezeigt, wenn der

Benutzer die Bedienungsanleitung lesen soll.

Weist auf eine gefährliche Spannung hin.

Weist auf eine Erdungsklemme hin.

PE-Leiterklemme must an Erde angeschlossen werden.

Aus (Versorgung)

Ein (Versorgung)

Das WARNSYMBOL deutet auf eine Gefahr hin. Die Aufmerksamkeit wird auf ein

Verfahren gelenkt.

Eine Missachtung der Einhaltung des Verfahrens kann zu Personenschaden führen.

Eine WARNUNG darf nicht übergangen werden und alle angezeigten Umstände

müssen vollkommen verstanden und eingehalten werden.

10

83-530-000 Rev J

Page 15

SICHERHEITSVORSCHRIFTEN

Das VORSICHTSYMBOL deutet auf eine Gefahr hin. Die Aufmerksamkeit wird auf ein

Verfahren gelenkt. Eine Missachtung der korrekten Einhaltung des Verfahrens kann zu

Materialschaden führen. Ein VORSICHTSYMBOL darf nicht übergangen werden bis

alle angezeigten Umstände vollkommen verstanden und eingehalten werden.

FCC EINHALTUNGSVERMERK:

Hinweis: Das Gerät wurde geprüft und erfüllt die Grenzwerte für ein digitales Gerät der

Klasse A gemäß Teil 15 der FCC-Regeln. Diese Grenzwerte wurden definiert, um

angemessenen Schutz vor gefährlichen Störungen zu bieten, wenn das Gerät im

kommerziellen Umfeld betrieben wird. Dieses Gerät kann Funkfrequenzenergie

erzeugen, verwenden und ausstrahlen und kann, sofern es nicht gemäß dem

Benutzungshandbuch installiert wurde, gefährliche Störungen im Funkverkehr

verursachen. Es ist wahrscheinlich, dass dieses Gerät in Wohngebieten zu schädlichen

Störungen führt, die in solchen Fällen auf Kosten des Benutzers behoben werden

müssen.

11

83-530-000 Rev J

Page 16

ITALIAN

NORME DI SICUREZZA

ATTENZIONE

La seguente precauzione di sicurezza deve essere osservata a tutti gli stadi del funzionamento, della

manutenzione e della riparazione di questa apparecchiatura. L'inosservanza delle precauzioni o delle

avvertenze di sicurezza contenute in questo documento viola gli standard di sicurezza della

progettazione, della produzione e dell'uso previsto di questa apparecchiatura, e può compromettere i

dispositivi di protezione in essa incorporati.

TDK-Lambda Americas Inc. non si assume alcuna responsabilità per il mancato rispetto di questi

requisiti da parte dell'utente.

CATEGORIA DI INSTALLAZIONE

La serie di alimentatori Genesys™ è stata valutata e risulta conforme alla CATEGORIA DI

INSTALLAZIONE II. Categoria di installazione (categoria di sovratensione) II: livello locale,

elettrodomestici, apparecchiature portatili ecc. Con sovratensioni transitorie inferiori alla Categoria di

installazione (categoria di sovratensione) III.

MESSA A TERRA

Questo prodotto è uno strumento di Classe di sicurezza 1. Per minimizzare il pericolo di scosse

elettriche, il telaio dello strumento deve essere collegato a una terra elettrica. Lo strumento deve

essere collegato alla rete di alimentazione a CA mediante un cavo a tre conduttori, con il filo di terra

ben collegato a una terra elettrica (terra di sicurezza) in corrispondenza della presa di corrente.

Per strumenti progettati per il cablaggio alla rete di alimentazione, il terminale protettivo di terra va

collegato alla terra elettrica di sicurezza prima di procedere ad altri collegamenti. Eventuali interruzioni

del conduttore protettivo di terra, o scollegamenti del terminale protettivo di terra, porteranno al rischio

di scossa elettrica e di conseguente potenziale infortunio.

AVVERTENZA

MESSA A TERRA DEI TERMINALI DI USCITA

Vi è rischio di scossa elettrica in corrispondenza delle porte RS232/RS485/LAN e IEEE se

si utilizzano alimentatori con tensione nominale o combinata oltre 400 V e con l'Uscita

positiva dell'alimentatore messa a terra.

Non collegare alla terra l'Uscita positiva quando si usano le porte RS232/RS485/LAN o

IEEE.

FUSIBILI

I fusibili devono essere sostituiti unicamente da addetti autorizzati di TDK-Lambda Americas Inc. Per

una protezione continua dal rischio di incendi, sostituire sono con fusibili di tipo e di potenza nominale

identici.

POTENZE NOMINALI IN INGRESSO

Non usare un'alimentazione a CA che superi la tensione in ingresso e la potenza nominale di

frequenza di questo strumento. La tensione in ingresso e la potenza nominale di frequenza della serie

di alimentatori GenesysTMpresentano tre bande di ingressi, a seconda del tipo di modello ordinato. Le

bande sono: 180 - 253 Vac/360 - 440 Vac/432 - 528 Vac, 50-60 Hz. Per ragioni di sicurezza, eventuali

fluttuazioni nella tensione di rete non devono superare il campo di potenze nominali suddetto.

CIRCUITI SOTTO TENSIONE

Nessun addetto deve mai rimuovere il coperchio dello strumento. Le regolazioni interne e la

sostituzione dei componenti sono consentite unicamente al personale qualificato di TDK-Lambda

Americas Inc. Non sostituire mai un componente con il cavo elettrico ancora collegato. A prevenzione

degli infortuni, staccare sempre la corrente, scaricare i circuiti e scollegare le fonti di tensione esterne

prima di toccare i componenti.

12

83-530-000 Rev J

Page 17

NORME DI SICUREZZA

SOSTITUZIONI E MODIFICHE DEI COMPONENTI

I componenti devono essere sostituiti o modificati unicamente da addetti autorizzati di TDK-Lambda

Americas Inc. Per riparazioni o modifiche, restituire lo strumento al centro assistenza di TDK-Lambda

Americas Inc.

CONDIZIONI AMBIENTALI

L'approvazione della sicurezza della serie di alimentatori Genesys™ è valida in presenza delle

condizioni d'uso seguenti:

*Uso in interni *Temperatura ambiente: 0 ºC - 50 ºC

*Umidità relativa massima: 80% (zero condensa) *Altitudine: fino a 3000 m

*Inquinamento grado 2

ATTENZIONE Osservare le precauzioni su come maneggiare i dispositivi sensibili alle

scariche elettrostatiche.

ATTENZIONE Rischio di scossa elettrica

Simbolo del manuale delle istruzioni. Lo strumento sarà contrassegnato da questo

simbolo ovunque l'utente deve fare riferimento al manuale delle istruzioni.

Indica tensioni pericolose.

Indica il terminale di terra.

Il terminale del conduttore protettivo di terra deve essere collegato alla messa a terra.

Spento (Alimentazione)

Acceso (Alimentazione)

Il simbolo di AVVERTIMENTO denota un periodo. È necessario prestare attenzione alla

procedura.

Il mancato rispetto della procedura può sfociare in un infortunio.

Non ignorare alcun simbolo di AVVERTIMENTO. Tutte le condizioni indicate devono

essere pienamente comprese e rispettate.

Il simbolo di ATTENZIONE denota un pericolo. È necessario prestare attenzione alla

procedura. Il mancato rispetto della procedura può sfociare in danni per

l'apparecchiatura. Non procedere oltre un simbolo di ATTENZIONE senza prima avere

pienamente compreso e rispettato tutte le condizioni indicate.

13

83-530-000 Rev J

Page 18

NORME DI SICUREZZA

AVVISO DI CONFORMITÀ FCC:

NB: Questa apparecchiatura è stata testata ed è risultata conforme ai limiti per i

dispositivi digitali di Classe A, ai sensi della parte 15 dei Regolamenti FCC. Tali limiti

sono formulati per offrire ragionevole protezione dalle interferenze pericolose quando

l'apparecchiatura viene azionata in ambienti commerciali. Questa apparecchiatura

genera, usa e può irradiare energia a radiofrequenza; se non viene installata ed

utilizzata attenendosi al manuale delle istruzioni, può causare interferenze pericolose

per le radiocomunicazioni. È probabile che l'uso di questa apparecchiatura in zone

residenziali provochi interferenze pericolose. In tal caso, l'utente dovrà rettificare a

proprie spese tali interferenze.

14

83-530-000 Rev J

Page 19

PORTUGUESE

INSTRUÇÕES DE SEGURANÇA

CUIDADO

As seguintes precauções de segurança devem ser respeitadas em todas as fases de funcionamento,

assistência e reparação deste equipamento. A não observância dos avisos e precauções de

segurança constantes neste documento viola os padrões de segurança da concepção, fabrico e

utilização pretendida deste equipamento, podendo danificar as protecções integradas no seu interior.

A TDK-Lambda Americas Inc. não poderá ser responsabilizada pelo não cumprimento destes

requisitos por parte do utilizador.

CATEGORIA DA INSTALAÇÃO

A série GenesysTMde fontes de alimentação foi avaliada como sendo uma INSTALAÇÃO DA

CATEGORIA II. Categoria da instalação (categoria de sobretensão) II: nível local, instrumentos,

equipamento portátil, etc. Com uma sobretensão transitória provisória inferior à das instalações da

categoria (categoria de sobretensão) III.

LIGAÇÃO À TERRA

Este produto é um instrumento de Classe de Segurança 1. Para reduzir o risco de choque, o chassis

do instrumento deve ter ligação de terra. O instrumento deve ser ligado à fonte de alimentação de

corrente alternada através de um cabo de alimentação de três condutores, com o fio de terra

firmemente ligado a uma ligação de terra (sistemas de segurança por ligação à terra) na tomada de

alimentação.

Em instrumentos concebidos para serem ligados à fonte de alimentação através de cabos, o terminal

de terra de protecção deve ser ligado ao sistema eléctrico de segurança por ligação à terra antes de

se realizar qualquer outra ligação. Qualquer interrupção do condutor de terra de protecção ou corte

do terminal de terra de protecção poderá originar um risco de choque passível de provocar

ferimentos.

AVISO

LIGAÇÃO À TERRA DE TERMINAIS DE SAÍDA

Há a possibilidade de existir risco de choque nas portas RS232/RS485/LAN e IEEE

quando se utilizam fontes de alimentação com tensão nominal ou combinada

superior a 400 V e a saída positiva da fonte de alimentação está ligada à terra.

Não ligue a saída positiva à terra quando utilizar as portas RS232/RS485/LAN ou

IEEE.

FUSÍVEIS

Os fusíveis apenas devem ser substituídos por pessoal de assistência autorizado da TDK-Lambda

Americas Inc. Para obter uma protecção contínua contra o risco de incêndios, substitua sempre os

fusíveis por outros do mesmo tipo e classificação.

CLASSIFICAÇÃO DAS ENTRADAS

Não utilize fontes de alimentação de corrente alternada que excedam a tensão de entrada e a

classificação de frequência deste instrumento. A tensão de entrada e a classificação de frequência

das fontes de alimentação da série GenesysTMtêm três gamas de entrada, de acordo com o tipo de

modelo encomendado. As gamas são: 180-253 Vac/360-440 Vac/432-528 Vac, 50-60 Hz. Por

motivos de segurança, as flutuações da tensão da fonte de alimentação não devem exceder a gama

da tensão superior.

15

83-530-000 Rev J

Page 20

INSTRUÇÕES DE SEGURANÇA

CIRCUITOS SOB TENSÃO

Os operadores não devem retirar a cobertura do instrumento. A realização de ajustes internos ou

substituições de componentes só é permitida se realizada por pessoal especializado da TDK-Lambda

Americas Inc. Nunca substitua componentes com o cabo de alimentação ligado. Para evitar

ferimentos, desligue sempre a energia, descarregue os circuitos e desligue a fonte de tensão externa

antes de tocar nos componentes.

MODIFICAÇÕES E SUBSTITUIÇÕES DE PEÇAS

As modificações e substituições de peças apenas são permitidas quando realizadas pelo pessoal de

assistência da TDK-Lambda Americas Inc. Para a realização de reparações ou modificações, é

necessário devolver o instrumento a uma unidade de serviço autorizada da TDK-Lambda Americas

Inc.

CONDIÇÕES AMBIENTAIS

A aprovação de segurança das fontes de alimentação da série GenesysTMaplica-se às seguintes

condições de funcionamento:

*Utilização no interior *Temperatura ambiente: De 0 °C a 50 °C

*Humidade relativa máxima: 80% (sem condensação) *Altitude: até 3000 m

*Nível de poluição 2

ATENÇÃO: Respeitar as precauções relativas ao manuseamento de dispositivos

sensíveis a electricidade estática.

CUIDADO: Risco de choque eléctrico

Símbolo do manual de instruções. O instrumento será assinalado com este símbolo

sempre que for necessário que o utilizador consulte o manual de instruções.

Indica tensão perigosa.

Assinala um terminal de ligação à terra.

O terminal do condutor de terra de protecção deve estar ligado à terra.

Desactivado (alimentação)

Activado (alimentação)

O sinal de AVISO assinala um perigo. Solicita-se atenção para um procedimento.

Não seguir correctamente o procedimento pode resultar em ferimentos.

Não se deve ignorar um sinal de AVISO, e todas as condições indicadas devem ser

compreendidas e respeitadas.

O sinal de CUIDADO assinala um perigo. Solicita-se atenção para um procedimento.

Não seguir correctamente o procedimento pode resultar em danos no equipamento.

Quando encontrar um sinal de CUIDADO não avance até que todas as condições

indicadas tenham sido completamente entendidas e respeitadas.

16

83-530-000 Rev J

Page 21

INSTRUÇÕES DE SEGURANÇA

DECLARAÇÃO DE CONFORMIDADE FCC:

Nota: Este equipamento foi testado e considerado estar dentro dos limites necessários

para um dispositivo digital da Classe A, em conformidade com a parte 15 das normas

da FCC. Estes limites estão concebidos de forma a fornecer uma protecção razoável

contra interferências nocivas quando o equipamento é utilizado num ambiente

comercial. Este equipamento gera, utiliza, e pode emitir energia por radiofrequência e,

caso não seja instalado e utilizado de acordo com o manual de instruções, pode

provocar interferências nocivas nas comunicações por rádio. A utilização deste

equipamento numa área residencial poderá provocar interferências nocivas, situação

na qual a correcção da interferência ficará ao encargo do próprio utilizador.

17

83-530-000 Rev J

Page 22

SPANISH

SAFETY INSTRUCTIONSINSTRUCCIONES DE SEGURIDAD

PRECAUCIÓN

La siguiente precaución de seguridad debe ser respetada durante todas las fases de funcionamiento,

mantenimiento y reparación de este equipo. El incumplimiento de las precauciones o advertencias de

seguridad recogidas en este documento infringe las normativas de seguridad de diseño, fabricación y

uso previsto de este equipo y puede afectar a las protecciones incorporadas en el mismo.

TDK-Lambda Americas Inc. no asumirá responsabilidad alguna si el usuario no cumple estos

requisitos.

CATEGORÍA DE INSTALACIÓN

La serie de fuentes de alimentación GenesysTMha sido evaluada conforme a la CATEGORÍA DE

INSTALACIÓN II. Categoría de instalación (categoría de sobretensión) II: equipos de nivel local,

eléctricos, portátiles, etc. Con una sobretensión transitoria menor que la Categoría de Instalación

(categoría de sobretensión) III.

CONEXIÓN A TIERRA

Este producto es un aparato de Seguridad de Clase 1. Para minimizar el riesgo de descargas, el

chasis del aparato se debe conectar a una toma de tierra eléctrica. El aparato se debe conectar a la

toma de energía eléctrica de corriente alterna de la red de distribución a través de un cable de

alimentación de tres conductores, con el conductor de tierra firmemente conectado a una toma de

tierra eléctrica (toma de tierra de seguridad) de la toma de corriente.

En el caso de aquellos aparatos diseñados para quedar cableados a la red de alimentación, el borne

de tierra de protección se debe conectar a la toma de tierra eléctrica de seguridad antes de establecer

cualquier otra conexión. Cualquier interrupción del conductor de tierra de protección o desconexión

del borne de tierra de protección supondrá un riesgo potencial de descarga eléctrica que puede llegar

a causar daños personales.

WARNINGADVERTENCIA

OUTPUT TERMINALS GROUNDINGCONEXIÓN A TIERRA DE LOS BORNES DE

SALIDA

There is a potential shock hazard at the RS232/RS485/LAN and the IEEE ports when using

power supplies with rated or combined voltage greater than 400V and the Positive Output of

the Power Supply is grounded.El uso de fuentes de alimentación con una tensión nominal o

combinada superior a 400V y la Salida Positiva de la Fuente de Alimentación conectada a

tierra, representa un riesgo potencial de descarga en los puertos RS232/RS485/LAN e IEEE.

Do Not connect the Positive Output to ground when using the RS232/RS485/LAN or

IEEE.No conecte la Salida Positiva a tierra si va a utilizar los puertos RS232/RS485/LAN o

IEEE.

FUSIBLES

Los fusibles sólo pueden ser cambiados por el personal de servicio autorizado de TDK-Lambda

Americas Inc. Para una protección permanente contra el peligro de incendios, utilice únicamente

fusibles del mismo tipo y de la misma potencia nominal.

POTENCIAS NOMINALES DE ENTRADA

No utilice fuentes de alimentación de CA cuyos valores nominales superen los de la tensión y

frecuencia de entrada de este aparato. Los valores nominales de la tensión y frecuencia de entrada

de la serie de fuentes de alimentación GenesysTMtienen tres rangos de entrada dependiendo del tipo

de modelo elegido. Los rangos son 180-253 VCA/360-440 VCA/432-528 VCA, 50-60 Hz. Por razones

de seguridad, las fluctuaciones en la tensión de alimentación de la red no deberían superar los rangos

de tensión antedichos.

18

83-530-000 Rev J

Page 23

INSTRUCCIONES DE SEGURIDAD

CIRCUITOS ACTIVOS

El personal operativo no debe retirar la cubierta del aparato. Los ajustes internos o el reemplazo de

componentes sólo pueden ser realizados por el personal cualificado de TDK-Lambda Americas Inc.

Desenchufe siempre el cable de alimentación antes de reemplazar los componentes. Para evitar

lesiones, desenchufe siempre el cable de alimentación, descargue los circuitos y desconecte la fuente

de tensión externa antes de tocar los componentes.

SUSTITUCIÓN Y MODIFICACIÓN DE LAS PIEZAS

Las piezas sólo pueden ser sustituidas o modificadas por el personal de servicio autorizado de TDKLambda Americas Inc. Para cualquier reparación o modificación del aparato, éste debe ser enviado a

un centro de servicio autorizado de TDK-Lambda Americas Inc.

CONDICIONES MEDIOAMBIENTALES

La aprobación de seguridad de la serie de fuentes de alimentación GenesysTMes aplicable a las

siguientes condiciones de funcionamiento:

*Uso en interiores *Temperatura ambiente: 0°C a 50°C

*Humedad relativa máxima: 80% (sin condensación) *Altitud: hasta 3000 m

*Grado de contaminación 2

ATENCIÓN Observe las precauciones de manejo de dispositivos sensibles

electrostáticos

PRECAUCIÓN Riesgo de descargas eléctricas

Símbolo de manual de instrucciones. Este símbolo se pondrá en el aparato siempre

que el usuario tenga que consultar el manual de instrucciones.

Indica una tensión peligrosa.

Indica un borne de tierra.

El borne del conductor de tierra de protección debe estar conectado para poder

establecer una conexión a tierra.

Apagado (fuente de alimentación)

Encendido (fuente de alimentación)

El símbolo de ADVERTENCIA indica un peligro. Llama la atención ante un

procedimiento.

Si el procedimiento no se realiza correctamente, podrían producirse lesiones

personales.

Los símbolos de ADVERTENCIA no se pueden pasar por alto y deben comprenderse y

cumplirse todas las condiciones indicadas.

El símbolo de PRECAUCIÓN indica un peligro. Llama la atención ante un

procedimiento. Si el procedimiento no se realiza correctamente, el equipo podría sufrir

daños. Cuando encuentre un símbolo de PRECAUCIÓN, no siga hasta que no haya

comprendido y esté seguro de que se cumplen las condiciones indicadas.

19

83-530-000 Rev J

Page 24

INSTRUCCIONES DE SEGURIDAD

DECLARACIÓN DE CONFORMIDAD CON LA FCC:

Nota: Este equipo ha sido ensayado y cumple con los límites establecidos para los

dispositivos digitales de Clase A, de conformidad con lo dispuesto en el Apartado 15 de

la normativa de la FCC. Estos límites han sido diseñados para proporcionar una

protección razonable contra interferencias perjudiciales cuando el equipo se utilice en

entornos comerciales. Este equipo genera, usa y puede emitir energía de

radiofrecuencia y, si no se instala y utiliza de acuerdo con el manual de instrucciones,

puede ocasionar interferencias perjudiciales con las comunicaciones por radio. La

utilización de este equipo en un área residencial puede llegar a provocar interferencias

perjudiciales, en cuyo se le pedirá al usuario que las corrija y que se haga cargo del

gasto generado.

20

83-530-000 Rev J

Page 25

1. GENERAL INFORMATION

1.1. User Manual Content

This User’s Manual contains the operating instructions, installation instructions and

specifications of the GenesysTM15KW and 10KW power supply series. The instructions refer

to the standard power supplies, including the built-in RS232/485 serial communication. For

information related to operation with the optional IEEE programming, refer to User’s Manual

for Power Supply IEEE/IEMD Programming Interface. For information related to operation

with the optional LAN programming, refer to the User’s Manual for Power Supply LAN

Programming Interface.

1.2. Introduction

1.2.1. General Description

GenesysTMpower supplies are wide output range, high performance switching power

supplies. The GenesysTMseries is power factor corrected and operates from specified AC

voltage range continuously. Output voltage and current are continuously displayed and

LED indicators show the complete operating status of the power supply. The Front panel

controls allow the user to set the output parameters, the protections levels (Over-Voltage

protection, Under-Voltage limit and Foldback) and preview the settings. The rear panel

includes the necessary connectors to control and monitor the power supply operation by

remote analog signals or by the built-in serial communication (RS232/485). GPIB

programming and Isolated-Analog programming/monitoring are optional

1.2.2. Features and Options

Constant Voltage / Constant Current with automatic crossover.

Embedded Microprocessor Controller.

Built-in RS-232/RS-485 Interface.

Voltage & Current high resolution adjustment by digital encoders.

High accuracy programming/ readback.

Last Setting Memory.

Independent Remote ON/OFF (opto-isolated) and remote Enable/Disable.

Remote sensing to compensate for voltage drop of power leads.

External Analog Programming and Monitoring standard (0-5V or 0-10V, user

selectable).

Zero stacking

No ventilation required at the top and bottom surface of the power supply.

Option IEEE-488 (GPIB) and LAN interface are SCPI compliant.

Optional Isolated Analog programming/monitoring (0-5V or 0-10V, or 4-20mA).

1.2.3. Control via the Serial Communication Port

The following parameters can be programmed via the serial communication port:

a) Output voltage setting.

b) Output current setting.

c) Output voltage measurement.

d) Output On/Off control.

e) Output current measurement.

f) Foldback protection setting

g) Over-voltage protection setting and readback.

h) Under-Voltage limits setting and readback.

i) Power-supply start up mode (last setting or safe mode).

21

83-530-000 Rev J

Page 26

1.2.4. Analog Voltage Programming and Monitoring

GEN to PC (DB25)

Analog inputs and outputs are provided at the rear panel for analog control of the power

supply. The output voltage and the current limit can be programmed by analog voltage or

by resistor, and can be monitored by analog voltage. The power supply output can be

remotely set to On or Off and analog signals monitor the proper operation of the power

supply and the mode of operation (CV/CC).

1.2.5. Parallel Operation

GenesysTMpower supplies of the same output voltage and current rating can be paralleled

in master-slave configuration with automatic current sharing to increase power available.

1.2.6. Output Connections

Output connections are made to rear panel via bus-bars up to 300V. For greater than

300Vo via stud terminals. Either the positive or negative terminal may be grounded or the

output may be floated. Contact factory for assistance with higher float voltage applications.

Local or remote sense may be used. In remote sense, the voltage drop on the load wires

should be minimized. Refer to the specifications for the maximum voltage drop value.

1.2.7. Cooling and Mechanical Construction

The GenesysTMseries is cooled by internal fans. At the installation, care must be taken to

allow free airflow into the power supply via the front panel and out of the power supply via

the rear panel.

CAUTION

Observe all torque guidelines within this manual. Over torqueing may damage

unit or accessories. Such damage is not covered under manufacturer’s warranty.

1.3. Accessories

1.3.1. Included Accessories - The following accessories are delivered with the power supply.

1.3.1.1. Serial Link Cable:

Serial linking cable linking power supplies by RS-485 communication (GEN/RJ45).

Cable description: 0.5m Length, shielded, RJ-45 type plugs, eight (8) contacts

(P/N 15507201)

1.3.1.2. Hardware:

Strain Relief for AC Cord

Output terminal Shield

DB25 Programming Plug kit (AMP 749809-9)

1.3.2. Optional Communication Cables

RS-232 Cables to connect GEN to Serial Port on PC

GEN to PC (DB9) GEN 232/9 P/N 15-507-203

GEN 232/25 P/N 15-507-204

RS-485 Cable to connect GEN to Serial Port on PC

GEN to PC(DB9) GEN/485-9 P/N 15-507-202

1.3.3. AC cables – Not applicable.

22

83-530-000 Rev J

Page 27

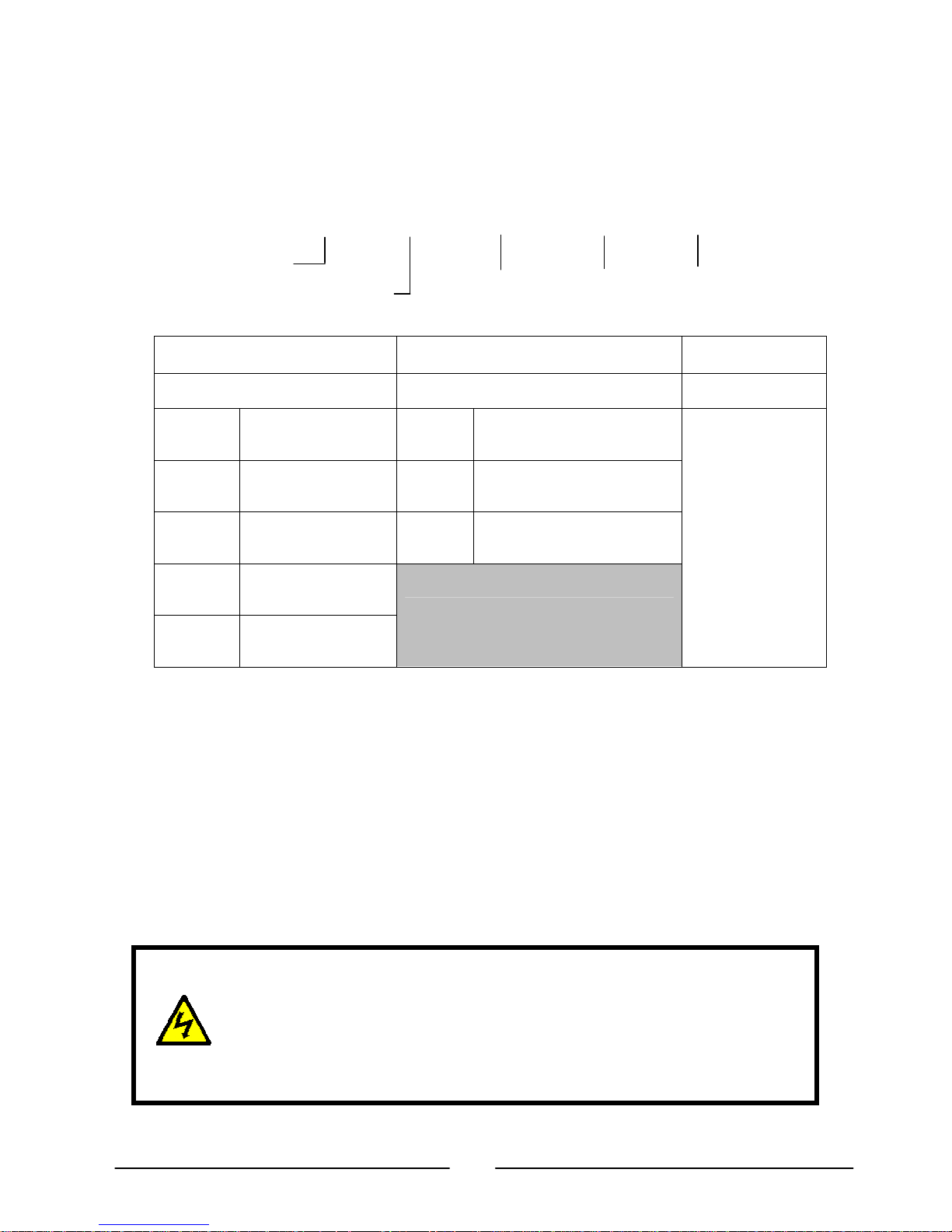

1.4. Model Number Format

The model numbering system for GenesysTMpower supply includes symbols for features and

options. They are separated by dashes.

The following chart explains the model number for the GEN Power Supply Family.

GENXXXX—XXXX—XXXXX—XXXXX—XXXX

DC OUTPUT

VOLTAGE

DC OUTPUT

CURRENT

Option AC Input Volts Factory Specials

Note 5 Note 1,2,3 Note 4

OPTIONS

AC INPUT

VOLTS

FACTORY

SPECIALS

IS510

IS420

IEMD

MD

LAN

ISOL PROG

0-5V, 0-10V

ISOL PROG

4-20mA

IEEE W/

MULTI-DROP

STANDARD W/

MULTI-DROP

LXI CERTIFIED

ETHERNET OPTION

3P208

3P400

3P480

208VAC,3Φ 47 / 63Hz

400VAC,3Φ 47 / 63Hz

480VAC,3Φ 47 / 63Hz

Blank for standard

Note 1: See Specifications for Input Range.

Note 2: CE Mark with IEMD to 400VDC Output, without IEMD to 600VDC

Note 3: All 3are four wire input = 3+ GND (No Neutral).

Note 4: Analog Meters are NOT available.

Note 5: IS510, IS420, IEMD, or LAN may not be installed together.

Factory Installed. Limit one (1) per Power Supply.

EXAMPLES: GEN10-1000-3P208

GEN10-1000-IEMD-3P400

GEN 10-1000-IEMD-3P400-1292

supplies

There is a potential shock hazard at the RS232/485/LAN and the IEEE

ports when using power supplies with rated or combined voltage greater

than 400V and the Positive Output of the Power Supply is grounded.

Do Not connect the Positive Output to ground when using the

WARNING

IEEE 488/ RS232 Option

RS232/485, LAN or IEEE.

23

83-530-000 Rev J

Page 28

2. SPECIFICATION

All specifications are subject to change without notice.

Contact factory for specific model availability.

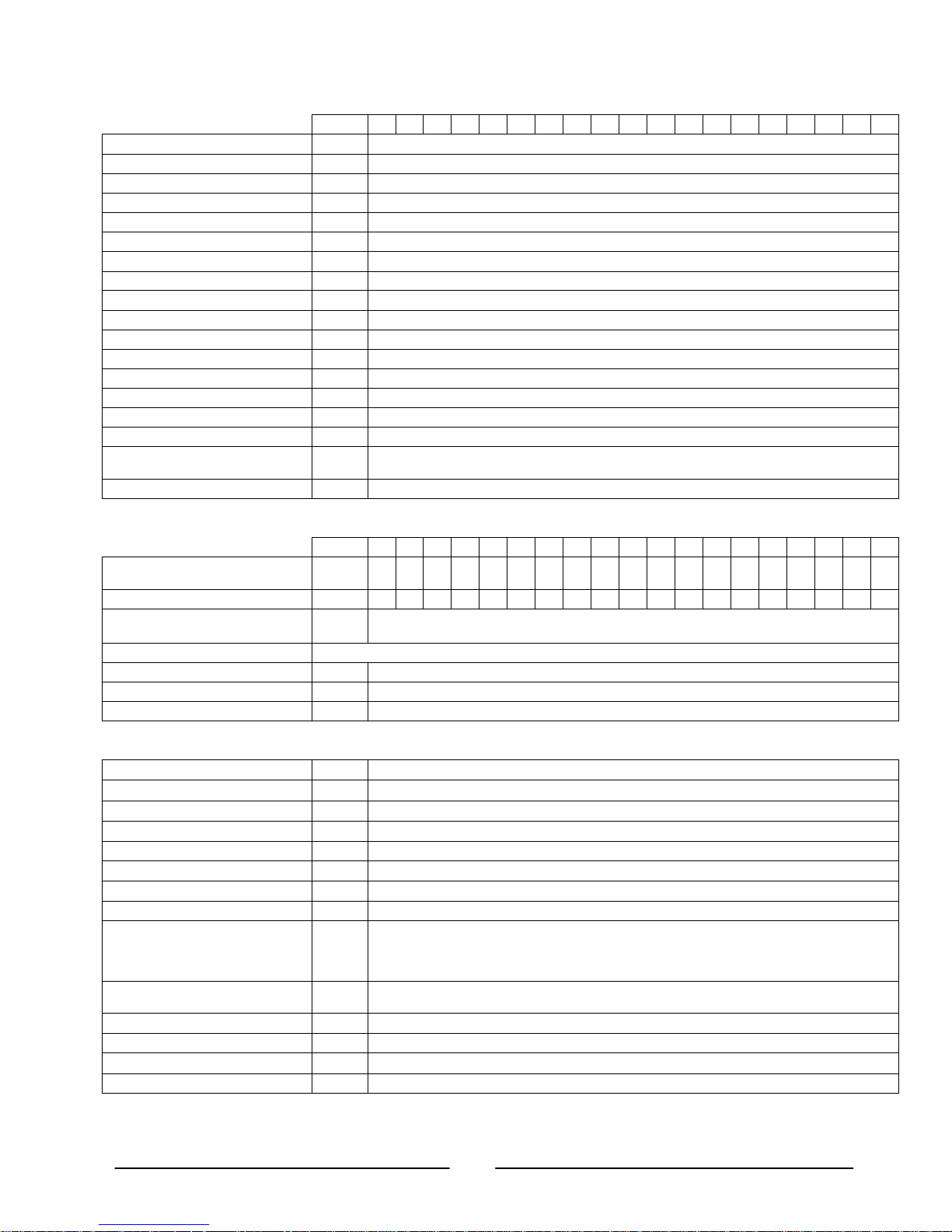

2.1. OUTPUT RATING (Duty Cycle Continuous Duty).

2.1.1. Standard Models – 10kW

1. Rated output Voltage V 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600

2. Rated Output Current A 1000 1000 800 500 400 333 250 200 167 125 100 80 66 50 40 33 25 20 17

3. Rated Output Power kW 7.5 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 9.9 10.0 10.0 9.9 10.0 1.0 10.2

2.1.2. Standard Models – 15kW

1. Rated output Voltage V N/A N/A N/A N/A N/A N/A N/A N/A 60 80 100 125 150 200 250 300 400 500 600

2. Rated Output Current A 250 187.5 150 120 100 75 60 50 37.5 30 25

3. Rated Output Power kW 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0

2.2. INPUT CHARACTERISTICS

V 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600

1. Input voltage/freq. (range) --- 208VAC (180-253), 400 VAC (360-440), 480 VAC (432-528), all 47-63Hz

2. No of phase --- 3 Phase (Wye or Delta) 4 wire total (3 Phase and 1 protective earth ground)

3. Dropout voltage V 175/355/425

4. Input current 180/360/432 VAC A 10kw – 45/23/20 15kw – 64/32/27 All at full rated output power.

5. Power Factor --- 0.88 Passive

6. Efficiency at Low Line, 100% load % 77min for 7.5kw,83 min for 10kw, 88 min for 15kw

7. Inrush current A Not to exceed full rated input current See Para 2.4

8. Leakage current mA 3.5 (EN60950-1)max

9. Input Protection --- 208 Circuit Breaker, 400/480 Line Fuse

10. Fuse --- 400/480 Input Only

11. Input Overvoltage Protection Unit shall not be damaged by line overvoltage with max. durationof 100uSec. Up to 120% of nominal AC

12. Phase Imbalance % = <5% on Three Phase Input

input voltage.

2.3. STATIC CHARACTERISTICS

1. Max. line regulation c.v --- 0.1% of FS from lo min. to lo max 0.01% of FS from lo min. to lo max

2. Max. line regulation c.c --- 0.1% of FS from Vo min. to Vo max 0.05% of FS from lo min. to lo max

3. Max load regulation c.v --- 0.1% of FS from lo min. to lo max 0.02% of FS lo min. tolo max

4. Max load regulation c.c --- 0.1% of FS from Vo min. to Vo max 0.075% of FS from Vo min. to Vomax

5. Temp. drift c.v --- +/-0.05% of Full Scale over 8 hours, after 30 minute warm up, constant Line, Load & Temperature

6. Temp drift c.c --- +/-0.05% of Full Scale over 8 hours, after 30 minute warm up, constant Line, Load & Temperature

7. Stability c.v PPM/C 200 (0.02% Full Scale)/Degree C

8. Stability c.c PPM/C 300 (0.03% Full Scale)/Degree C

9. Output noise p-p (20MHz) c.v mV 60 60 60 60 60 60 60 75 75 100 100 125 135 135 200 200 200 300 350

10. Ripple r.m.s 5Hz1MHzc.v

11. Ripple r.m.s 5Hz1MHzc.c (10kW)

12. Ripple r.m.s 5Hz1MHzc.c(15kW)

*Ripple and Noise at Full Rated Voltage & Load at 25C, Nominal Line. For models not listed use the ripple limit of the next higher voltage model. Per EJ RC9002A.

13. Rem. sense compensation/wire V 1 1 1 1 1 1.5 2 3 3 4 5 5 5 5 5 5 5 5 5

V 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600

mV 20 20 20 20 20 20 20 20 20 25 25 25 25 35 35 60 60 60 60

mA 5100 5100 2600 2600 1700 1700 100 80 67 50 40 32 20 20 16 13 10 8 7

mA - - - - - - - - 100 100 100 50 50 20 20 20 10 10 10

24

83-530-000 Rev J

Page 29

2.4. PROTECTIVE FUNCTIONS

In Advance parallel feature, the current of Master Unit, multiplied by number of units connected in parallel, is

V 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600

1. OCP %

2. OCP Type --- Constant current

3. Knee point protection --- None,No damage at knee point operation

4. Short circuit protection --- Yes

5. Short circuit burn-in --- Yes

6. Foldback protection --- Output shut down, manual reset by front panel OUT button.

7. Foldback response time S Less than 1

8. OVP Type --- Inverter shut-down, manual reset by On/Off recycle or by OUT button.

9. OVP programming accuracy % 5% Full Scale

10. OVP adjustment method --- Adjust by front panel Voltage encoder and comm. port.

11. OVP trip point V 0.05 to (1.02 -1.05) Rated Output Voltage

12. OVP response time mS Less than 10mS for Output to begin to drop.

13. Max. OVP reset time S 7 from Turn On

14. Output under voltage limit --- Preset by front panel or communication port. Prevents from adjusting V

15. Input under voltage protection --- Yes. Power supply shut down below low line.

16. Over temp protection --- Unit shall shut down when internal temperature exceeds safe operatinglevels. (Latched in Safe mode and

17. Phase Loss Protection Yes

0100

Raises the Output good signal in case of output voltage is below limit.

unlatched in auto mode).

below limit.

out

2.5. DYNAMIC CHARACTERISTICS

V 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600

1. Up-prog. Response time, 0Vomax

full-load

2. Down-prog response time full-load mS 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100

3. Transient response time (cv mode)

NOTE: Properties 5.1- 5.6 with Resistive Load.

4. Time for OutputStable S 2 maximum from enable output until output stable.

5. Output fall and rise --- Overshoot limited to 125% Rated Output. Voltage at No-Load, Full-Load, Resistive Load.

6. Start-up delay S Less thank 7 (without IEEE option)

mS 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100

Time for the output voltage to recover within 2% of its rated output voltage for a load change of 50 100% or

mS

100 50% of rated output set-point. Less than 3.

2.6. REMOTE ANALOG CONTROL AND SIGNALS

1. Vout voltage programming ---

2. Iout voltage programming ---

3. Vout resistor programming ---

4. Iout resistor programming ---

5. On/Off control (rear panel) --- By voltage: 0.6V = Disable, 2-15V = enable (default)or dry contact, user selectable logic

6. Output current monitor ---

7. Output voltage monitor ---

8. Power supply OK signal --- Yes. TTL high-OK, 0V (500ohm impedance)-Fail

9. Parallel operation --- Up to Four(4) identical units may be connected in Master/Slave Mode with ‘Single’ wire connection.

10. Series operation --- Possible (with external diodes), up to identical 2 units with total output not to exceed +/-600V from chassis

11. CV/CC signal ---

12. Enable/Disable --- Dry contact. Open: off, Short on. Max. voltage at Enable/Disable Contacts 6V

13. Remote/Local selection ---

14. Remote/Local signal --- Signal operating mode in use.

0 100%, 0 5V or 0 10V, userselectable. Accuracy& Linearity +/-1% of Rate Vo.

0 100%, 0 5V or 0 10V, userselectable. Accuracy& Linearity +/-1% of Rate Io.

0 100%, 0 5/10kohm full scale, user selectable. Accuracy & Linearity +/-1% of Rate Vo.

0 100%, 0 5/10kohm full scale, user selectable. Accuracy & Linearity +/-1% of Rate Io.

0 5V or 0 10V, accuracy 1%, user selectable

0 5V or 0 10V, accuracy 1%, user selectable

made available on digital interface and displayed on front panel of Master unit. Remote analog current

monitor of the Master is scaled to output current of the Master unit (only).

ground.

CV: TTL high (4 5V) source: 10mA, CC: TTL low (0 4V): 10mA

Selects Remote or Local operation by elect. Voltage: 0 0.6V/2 15V, <0.6V = Local 2-15V = Remote.

25

83-530-000 Rev J

Page 30

2.7. FRONT PANEL

1. Control functions

2. Display

3. Indications --- ADDR, OVP/UVL, V/A, FOLD, REM/LOCAL, OUT ON/OFF, LFP/UFP, IEEE, LAN, Hx (Parallel Master) or S

--- Vout/ Iout manual adjust by separate encoders.

--- OVP/UVL manual adjust by Volt. Adjust encoder.

--- Address selection by Voltage adjust encoder. No of addresses: 31

--- Go toLocal

--- Output On/Off

--- AC On/Off

--- Foldback control (CV to CC)

--- RS232/485 and IEEE488.2 selection by IEEE or LAN enable switch and DIP switch

--- Baud rate selection by Current adjust encoder.

--- Re-start modes (auto, safe)

--- Front Panel Lock/Unlock

--- Parallel Master Slave: H1 = One Master, Zero Slave

--- Vout: 4 digits, accuracy: 0.5% of rated Vout+/-1count, Green LED’s, Size:10mm

--- Iout: 4 digits, accuracy: 0.5% of rated Iout+/-1count, Green LED’s, Size:10mm

Voltmeter is user selectable to read either local voltage (at power supply) or remote voltage (at the load).

(Slave).

CC/CV: GREEN LED’s. ALRM (OVP, OTP, FOLD, AC FAIL): RED LED

H2 = One Master, One Slave

H3 = One Master, Two Slaves

H4 = One Master, Three Slaves

S = Slave

2.8. SOFTWARE SPEC.

1. Functions:

1. Voltage/current setting

2. OVP/UVL setting

3. Actual voltage/current setting readback

4. Voltage/current setting readback

5. OVP/UVL setting readback

6. Output On/Off

7. Foldback protection setting

8. Status readback (cc/cv, ovp, otp, foldback, ac fault)

9. Model identification readback

10. Self test.

11. Calibration (not user access.) (DAC-Zero and max points, Display-Zero and max.)

12. Last setting recall (at power off).

13. Re-start mode setting

14. Front Panel Lock/Unlock

1. Drivers to LabView and LabWindows2. Application software:

2. Simple operating program

26

83-530-000 Rev J

Page 31

2.9. DIGITIAL PROGRAMMING AND READBACK

1. Vout programming accuracy --- +/-0.5% of rated output voltage

2. Iout programming accuracy --- +/-0.5% of rated output current for units with Io <187.5 +/-0.7% of rated output current for Io <187.5

3. Vout programming resolution --- 0.02% of full scale (To be confirmed)

4. Iout programming resolution --- 0.04% of full scale (To be confirmed)

5. Vout readback accuracy --- 0.1% + 0.2%of rated output voltage Accuracysame as IEEE Programming Accuracy

6. Iout readback accuracy --- 0.1% + 0.4% of rated output current Accuracysame as IEEE Programming Accuracy

7. Vout readback resolution --- 0.02% of full scale

8. Iout readback resolution --- 0.02% of full scale

OV Response Time mS 20mS maximum between output V exceeding IEEE limit and supply inhibit turning on

Set Over-Voltage Limit, Set Local/RemoteOther Functions

Operating parameters and status available for display via host computer.

2.10. MECHANICAL CONSTRUCTION

V 7.5 10 12.5 20 25 30 40 50 60 80 100 125 150 200 250 300 400 500 600

1. Cooling --- Fan driven, Airflow from Front to Rear. Supplemental vents on side that shall not be blocked. EIA Rack

2. Weight Kg/Lb 43/97

3. Dimensions --- H: 3U, W: 19” Rack, See 02530000 for outline drawing.

4. Types of connectors

5. Front panel material & finish --- RAL7035 Textured finish.

6. Mounting method --- Standard 19” Rack Mount, provision for standard slides. Side/RearSupport is required; do not mount by F/P

7. Mounting positions --- Horizontal

8. Output ground connection --- M5 Stud

9. Color and finish --- Chassis Top/Sides/Bottom Clear zinc plating. Front Panel RAL 7035 painted

10. Output Terminal covers --- Standard for all models with bus-bars. Closedconnection for models with output connector.

mounting, stackable. “Zero Stackable” top and bottom. Slides or suitable rear support required.

--- 1) Input: Threaded Studs and terminal cover. Strain relief option.

2) Output: Iout =>.50A: bus-bars, Iout<37.5a threaded stud terminal.

3) Analog programming:DB25, plastic connector, AMP, 747461-5, Female on Power Supply,Male on

Mating connector 747321. Standard 25 pin D connector.

4) RS232/RS485, STD PhoneJack connector

5) Isolated analog option: refer to Isolated Analog option spec. 08030200

6) IEMD Option, refer to IEMD Option Spec. 08030100.

only.

2.11. ENVIRONMENTAL CONDITIONS

1. Operating temp C

2. Start up temp. C 0

3. Storage temp C -20C to +70C

4. Operating humidity %

5. Storage humidity %

6. Altitude --- Operating:

7. Vibration & Shock (208/400VAC) G ASTM D4169, Standard Practice for performanceTesting of Shipping Containers and Systems,Shipping

8. Audible Noise db 65dBA at Full Load, measured 1m from Front Panel

0 50C, 100% load. No operation > 50C

2080% RH Non-condensing

1090% RH Non-condensing

50oC up to 7500 ft., (2500m) 45oC from 7501 to 10,000ft (2501m – 3000m)

Non Operating 40,000 ft (12,000m)

Unit: Single Package Assurance Level: Level II; Acceptance Criteria: Criterion 1 – No product damage,

Criterion 2 – Package is intact Distribution Cycle: CyAir (intercity) and motor freight (local, single package

up to 100lbs.) (NOTE: for packages over 100 lbs, distribution cycle 12 – Air (intercity) and motor freight

(local), unitized is used)

27

83-530-000 Rev J

Page 32

2.12. EMC

2.12.1. 208 Volts Input Models

CE Mark

1. ESD --- EN61000-4-2 (IEC 801-2) Air-disch. */-8kV, contact disch. +/-4kV

2. Fast transients --- EN61000-4-4 (IEC 1000-4-3)

3. Surge immunity --- EN61000-4-5 (IEC 1000-4-5)

4. Conducted immunity --- EN61000-4-6 (IEC 1000-4-6)

5. Radiated immunity --- EN61000-4-3 (IEC 1000-4-3)

6. Power Frequency Magnetic Field --- EN61000-4-8

7. Conducted emission --- EN55011A, FCC part 15J-A

8. Radiated emission --- EN55011A, FCC part 15J-A

2.12.2. 400 Volts Input Models

CE Mark

1. ESD --- EN61000-4-2 (IEC 801-2) Air-disch. +/-8kV, contact disch. +/-4kV

2. Fast transients --- EN61000-4-4 (IEC 1000-4-3)

3. Surge immunity --- EN61000-4-5 (IEC 1000-4-5)

4. Conducted immunity --- EN61000-4-6 (IEC 1000-4-6)

5. Radiated immunity --- EN61000-4-3 (IEC 1000-4-3)

6. Power Frequency Magnetic Field --- EN61000-4-8

7. Voltage Dips, Short Interruptions and

Voltage Variations Immunity Tests

(400VAC Input Only)

8. Conducted emission --- EN55011A, FCC part 15J-A

9. Radiated emission --- EN55011A, FCC part 15J-A

--- IEC 61000-4-11

2.13. RELIABILITY SPECS

1. Electrolytic capacitors life Yrs. More than3yrs at 40C ambient, 100% load

2. Grade --- G-2, Lambda Group derating criteria & EIAJ RCR-9102A

count Reliability, Generic Failure rates, 25C

4. Warranty Yrs. 5 years

5. Shelf life Yrs. 5 years, electrolytic caps shall be reformed after 2 years

2.14. SAFETY

1. Applicable Standards --- UL/ULC 60950-1, EN60950-1 recognized.All Outputs are Hazardous. (Units with IEMD or ISOL option are

2. Withstand voltage --- Vout=<60V models: Input-Ground: 2818VDC 1 min, Input-Outputs (SELV): 4242VDC 1 min, Output –

3. Insulation resistance --- 100Mohm at 500Vdc

Recognized up to 400 volts output). CE Mark 208 & 400VAC input only (CB Scheme)

Vout≤40V: Output is SELV, IEEE/Isolated analog are SELV.

40<Vout≤400V: Output is hazardous, IEEE/Isolated analog are SELV.

400<Vout≤600V: Output is hazardous, IEEE/Isolated analog are not SELV.

Ground: 1000VDC 1 min. 60<Vout=<300V models: Input-Ground: 2828VDC 1 min, Input-Haz. Output:

3535VDC 1 min, Input-SELV: 2828VDC 1 min. Hazardous Output-SELV: 2121VDC 1 min, Hazardous

Output-Ground: 2121VDC 1 min. 300<Vout=<600V models: Input-Ground: 2828VDC 1 min, Input-Haz.

Output: 3535 1 min, Input-SELV: 2828VDC 1 min. Hazardous Output-SELV: 2688VDC 1 min, Hazardous

Output-Ground: 2688VDC 1 min.

28

83-530-000 Rev J

Page 33

2.15. J1 CONNECTOR

J1-1 ENA_IN Enable/Disable Dry Contact with J1-14

J1-2 IF_COM Isolated Interface Common. Return for SO, PS_OK

J1-3 IF_COM Isolated Interface Common. Return for SO, PS_OK

J1-4 N/C

J1-5 N/C

J1-6 N/C

J1-7 N/C

J1-8 LOC/REM Input for selecting between Local or Remote analog programming.

J1-9 VPGM Input for remote analog voltage/resistance programming of the Output Voltage

J1-10 IPGM Input for remote analog voltage/resistance programming of the Output Current

J1-11 VMON Output Voltage Monitor

J1-12 COM Control Commonfor VMON & IMON

J1-13 CV/CC Output for Constant Voltage / Constant Current mode indication

J1-14 ENA_OUT Enable/Disable Dry Contact with J1-1

J1-15 SO Input for Shut-Off control of the output.

J1-16 PS_OK Output for indication of the power supply status

J1-17 N/C

J1-18 N/C

J1-19 N/C

J1-20 N/C

J1-21 LOC/REM Signal Output for indicating if the unit is in Local or Remote analog programming mode.

J1-22 VPGM_RTN Returnfor VPGM J1-9; connected to Neg Output

J1-23 IPGM_RTN Return for IPGM J1-10; connected to Neg Output

J1-24 IMON Output for Current Monitor

J1-25 P Output for Current Balance in Parallel Operation (One wire – Reference to

Negative Output)

29

83-530-000 Rev J

Page 34

3. INSTALLATION

3.1. General

This Chapter contains instructions for initial inspection, preparation for use and repackaging

for shipment. Connection to PC, setting the communication port and linking Genesys

power supplies are described in Chapter 8.

GenesysTMpower supplies generate magnetic fields, which might affect the operation

of other instruments. If your equipment is susceptible to magnetic fields, do not

3.2. Preparation for Use

In order to be operational the power supply must be connected to an appropriate AC source.

The AC source voltage should be within the power supply specification. Do not apply power

before reading Section 3.6 and 3.7.

Table 3-1 below, describes the basic setup procedure. Follow the instructions in Table 3-1 in