Page 1

TCL

SERVICE MANUAL

48D2700/MT56B-AP

1. Caution…………………………………………………………………………

2. specification……………………………………………………………………

3. Alignment Procedure…………………………………………………………

4.Block diagram…………………………………………………………………

5.Scheme Diagram ……………………………………………………………

6. Troubleshooting………………………………………………………………

([SORGHGUDZLQJ

This m anual i s t he l atest at t he t ime of pr inting, and doe s not

include the modification which may be made after the printing, by

the constant improvement of product

Page 2

RISK OF

ELECTRIC

SHOCK DO

NOT

OPEN.

SCHNEIDER ELECTRONICS GMBH-GERMANY

1. CAUTION

CAUTION:

Use of controls, adjustments or procedures other than those specified herein may result in

hazardous radiation exposure.

CA UTION : TO RE DUCE THE RIS K OF

CA U T IO N

RISK

SHOCK

The lighting flash with arrowhead symbol, with an equilateral triangle is intended to

alert the user to the presence of uninsulated voltage within the product s

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

the person.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

ELECTRI

NOT

OPEN.

ELECTR ICAL SH OCK, DO NOT REMOVE

COVER (OR BACK). NO USER SERVICEABLE

PAR TS INS IDE . RE FER SER VIC ING TO

QUALIFIE D SERVIC E PERS ONNEL.

dangerous

WARNING: TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

2

2

Page 3

SCHNEIDER ELECTRONICS GMBH-GERMANY

IMPORTANT SAFETY INSTRUCTIONS

CAUTION:

Read all of these instructions. Sa ve these instructions for later use . Follo w all Warnings and

Instructions marked on the audio equipment.

1. Read Instructions-All the safety and operating instructionsshouldbe read before the productis operated.

2. Retain Instructions- The safety and operating instructions should be retained for future reference.

3. Heed Warnings- All warnings on the product and in the operating instructions should be adhered to.

4. Follow Instructions- All operating and use instructions should be followed.

FOR YOUR PERSONAL SAFETY

1. When the power cord or plugis damaged or frayed, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

2. Do not overload wall outlets and extension cords as this can result in fire or electric shock.

3. Do not allow anything to rest on or roll over the power cord, and do not place the TV where power cord is subject to

traffic or abuse. This may result in a shock or fire hazard.

4. Do not attempt to service this television set yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

5. Never push objects of any kind into this television set through cabinet slots as they may touch dangerous voltage

points or short out parts that could result in a fire or electric shock. Never spill liquid of any kind on the television set.

6. If the television set has been dropped or the cabinet has been damaged, unplug this television set from the wall outlet

and refer servicing to qualified service personnel.

7. If liquid has been spilled into the television set, unplug this television set from the wall outlet and refer ser vicing to

qualified service personnel.

8. Do not subject your television set to impact of any kind. Be particularly careful not to damage the picture tube surface.

9. Unplug this television set from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

10.1. Do not place this television set on an unstable cart, stand, or table. The television set may fall, causing serious injury

to a child or an adult, and serious damage to the appliance. Use only with a car t or stand recommended by the

manufacturer, or sold with the television set. Wall or shelf mounting should follow the manufacturer s instructions, and

should use a mounting kit approved by the manufacturer.

10.2. An appliance and cart combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

3

3

Page 4

SCHNEIDER ELECTRONICS GMBH-GERMANY

PROTECTION AND LOCATION OF YOUR SET

11. Do not use this television set near water ... for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a

wet basement, or near a swimming pool, etc.

Never expose the set to rain or water. If the set has been exposed to rain or water, unplug the set from the wall

outlet and refer servicing to qualified service personnel.

12. Choose a place where light (artificial or sunlight) does not shine directly on the screen.

13. Avoid dusty places, since piling up of dust inside TV chassis may cause failure of the set when high humidity persists.

14. The set has slots, or openings in the cabinet for ventilation purposes, to provide reliable operation of the receiver, to

protect it from overheating. These openings must not be blocked or covered.

Never cover the slots or openings with cloth or other material.

Never block the bottom ventilation slots of the set by placing it on a bed, sofa, rug, etc.

Never place the set near or over a radiator or heat register.

Never place the set in enclosure, unless proper ventilation is provided.

a built-in

PROTECTION AND LOCATION OF YOUR SET

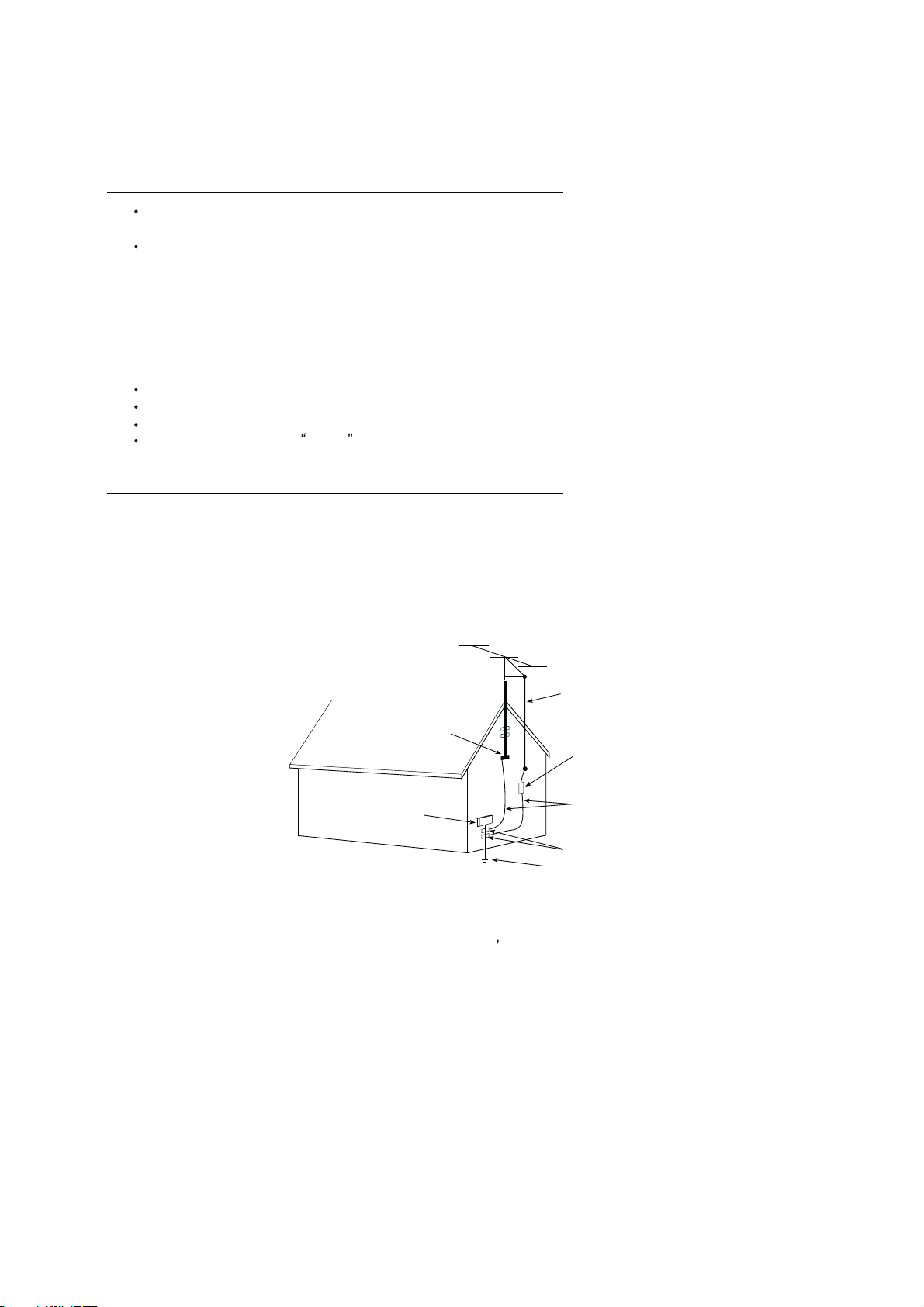

15.1. If an outside antenna is connected to the television set, be sure the antenna system is grounded so as to provide some

protection against voltage surges and built up static charges, Section 810 of the National Electrical Code, NFPA No.

70-1975, provides information with respect to proper grounding of the mast and supportingstructure, grounding of the

lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection

to grounding electrode, and requirements for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER NATIONAL ELECTRICAL CODE INSTRUCTIONS

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE

ANTENNA

LEAD- IN WIRE

GROUND CLAMP

ELECTRIC SERVICE

EQUIPMENT

NEC-NATIONAL ELECTRICAL CODE

ANTENNA DISCHARGE

UNIT (NEC SECTION

810-20)

GROUNDING

CONDUCTORS

(NECSECTION 810-21)

GROUND CLAMPS

POWER SER VICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250. PART H)

15.2. Note to CATV system installer : (Only for the television set with CATV reception)

This reminder is provided to call the CATV system attention to Ar ticle 820-40 of the NEC that provides

installer s

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entr y as practical.

16. An outside antenna system should not be located in the vicinity of overhead power lines or other electric lights or power

circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power lines or circuits as contact with them might be fatal.

17. For added protection for this television set during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect the antenna. This will prevent damage due to lightning

and power-line surges.

4

4

Page 5

SCHNEIDER ELECTRONICS GMBH-GERMANY

OPERATION OF YOUR SET

18.

This television set should be operated only from the type of power source indicated on the marking label.If you are not

sure of the type of power supply at your home, consult your television dealer or local power company. For television

sets designed to operate from battery power, refer to the operating instructions.

19. If the television set does not operate normally by following the operating instructions, unplug this television set from the

wall outlet and refer servicingto qualifiedservice personnel. Adjust only those controls that are covered in the operating

instructions as improper adjustment of other controls may result in damage and will often require extensive work by a

qualified technician to restore the television set to normal operation.

20. When going on a holiday : If your television set is to remain unused for a period of time, for instance, when you go on

a holiday, turn the television set and unplug the television set from the wall outlet.

off

IF THE SET DOES NOT OPERATE PROPERLY

21. If you are unable to restorenormal operation by followingthe detailedprocedurein your operatinginstructions,

do not attempt any further adjustment. Unplug the set and call your dealer or service technician.

22. Whenever the television set is damaged or fails, or a distinct change in performance indicates a need for

service, unplug the set and have it checked by a professional service technician.

23. It is normal for some TV sets to make occasional snapping or popping sounds, particularly when being

turned on or off. If the snapping or popping is continuous or frequent, unplug the set and consult your

dealer or service technician.

FOR SERVICE AND MODIFICATION

24. Do not use attachments not recommendedby the television set manufacturer as they may cause hazards.

25. When replacement parts are required,be sure the service technicianhas used replacementparts specified

by the manufacturer that have the same characteristics as the original part. Unauthorized substitutions

may result in fire, electric shock, or other hazards.

26. Upon completion of any service or repairs to the television set, ask the service technician to perform

routine safety checks to determine that the television is in safe operating condition.

5

5

Page 6

PRODUCT SPECIFICATION RELEASE

AC 100V-240V 50/60H

p()

Screen Mode

16:9\4:3\14:9\Cinerame\Zoom etc

Audio Delay

Yes

!

Model: 48D2700/MT56B/CS1GTA/TT E5

Model: 48D27

Version:1.0 Issued On: 2015-05-12

Basic Information

Product Type

Chassis

CPU Quad Core A7 1GHz Mutilmedia Video/Audio Decoder

GPU Dual Core MALI450MP2 400MHz

OS Android 4.4

Memory/Flash 6Gb DDR3 / 4GB Flash

UI Style CROSS UI

Launcher HomePages Show

OSD Language English/Vietnamese/Thai

TV System

AV System

Channels

Power Supply

Power Consumption(TV On)

Power Consumption(Standby)

Certification

ECO Energy efficiency

Internet Link

LED Indicator Status In The Center of Front,White in Standby

LED 2D Smart DTV

MT56B

APPS、TV、GOLIVE、YouTube

PAL B/G、D/K、I;NTSC-M; DVI Video Format Up to XGA for HDMI-PC

DVB-T/T2 HDMI Video Format up to 1080P

PAL、NTSC

0000-9999

z

110W

≤0.5W

CB

Yes Aspect Ratio 16:9

wireless WiFi Default Panel Active Size (inch) 48

Ethernet Network

Basic Function

Initial Setup

HDMI Auto Switch Auto、Close、Manual Life Time(Typ.) 30,000hrs

Channels Edit For Channel renamed

Input Settings For Input source device choice

Sleep Timer Yes

System Update Yes

T-Link(CEC)

Input Method Smart TV IME

MHL Yes

Teletext Yes

Audio Language/Nicam Yes

PVR/Timeshift Yes (Only for DTV Programme)

Programme Schedule Record/Reminder(Only for DTV Programme)

EPG Yes(Only for DTV Programme)

Subtitle Yes(Only for DTV Programme)

Yes,for user setting in TV first starting Viewing Angle (H/V) 178°/178°

Yes

USB Device Media Format

Music MP3

Picture JPEG/BMP/PNG/GIF

MPEG-(1/2/4)/H.264/H.263/DivX Dolby/AC3

Signal Format Capability

PC Compatibility Up to SXGA

Panel Specification

Backlight Unit

Panel supplier CSOT

Display Resolution 1920*1080

Brightness (cd/m2) 280(typ.)

Contrast Ratio 4000:1

Response Time (G to G) 9ms

Color 16.7 Million(8bit)

Refresh Rate 60Hz

LED

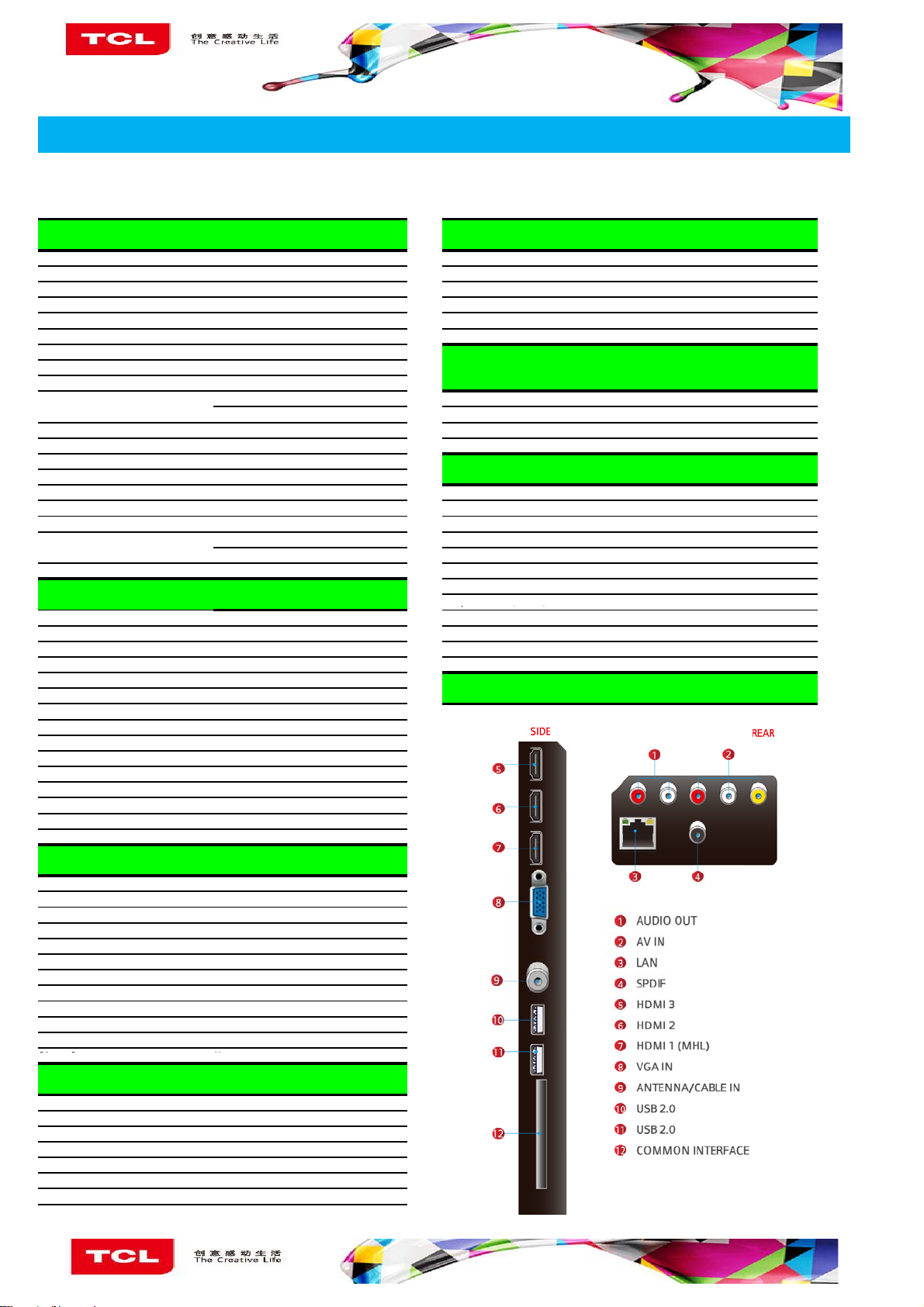

Terminals

Rearview Picture

Picture

Picture Mode Standard\Dynamic\Natural\Movie\Personal

Screen Mode 16:9\4:3\14:9\Cinerame\Zoom etc.

Noise Reduction Low\Middle\High\Auto\Off

Backlight Adjustable Yes (0~100)

Color Temperature Normal/Warm/Cool/Customer

Gamma Adjustable -4 to 4

Dynamic Contrast Yes

Overscan Yes

Picture Freeze Yes

Game Mode Yes

Film Mode Yes

Picture Reset Yes

.

Sound

Speakers Integrated speakers (Bottom side)

Audio Power Output(THD=7%) 2×8W

Auto Volume Control On / Off

Sound Preset Standard\Music\Movie\Clear Voice\Personal

Sound Control

TV Placement

Five band equalizer adjust in Personal mode

Desk top / Wall mount

Yes

Design and specifications are subject to change without notice

Page 7

Pre-Installed Application List

Wirel

p

YouTube

Golive Lots of Global Live TV channels show

Miracast

App Store 3.0 Special App Store available for download

Browser Webpage Browser

TV Tweets a Social App

Deezer Global Online Music Streaming service

Mediacenter Media/Music play for USB Device

Message Box Messages push

Weather forecast Showed in Homepage

E-Sticker as some function demo in Shop mode

E-Manual Some general basic function introduction

nScreen

Zing TV Vietnam local Popular Video App

Zing mp3 Vietnam local Popular Music App

Independent Launcher UI page show Operation Manual English(Default)

Push Popular VOD posters to Homepage Remote Control and batteries RC311(with two batteries)

ess Mirroring connecting,to deliver audio

and video content from smartphone to TV

Connect Mobile phone to TV sets and control

the TV like Remote using Phone;

Push media file in Phone to TV Display and

Enjoy big screen picture quality.

Mechanical ID Picture

Essential Accessories(Default)

Base Stand

AC power cord 1 pcs

Integrated Packaging

Mechanical Key Specification

L1(mm)

W1(mm)

H1(mm)

L2(mm)

W2(mm)

H2(mm)

Net Weight With Stand(Kg)

Net Weight Without Stand(Kg)

Gross Weight With Packaging(Kg)

1090.8

82

632.5

888

222

683

10

9.75

13.5

Diagonal size(cm)

Slim Edge Design---Up(mm)

Slim Edge Design---Bottom(mm)

Slim Edge Design---L&R(mm)

Carton Dimensions LxWxH(mm)

Container Loading---20 feet(pcs)

Container Loading---40 feet(pcs)

Container Loading--40 feet High(pcs)

VESA Mounting Dimensions LxH(mm)

Drafted by: Approved by:

120.9

16.9

19.6

16.9

1282*154*768

192

411

465

200*200

Page 8

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

TCL World-Wide R&D

FPD CENTER

Factory Test & Alignment Specification V1.0

----MT56-AP

PREPARED BY : FENG LIU DATE : 2015-02-13

APPROVED BY: DATE :

1

Page 9

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Content

1. General Description .............................................................................................................................. 3

2. Factory Menu ......................................................................................................................................... 5

2.1 Accessing Way ................................................................................................................................... 5

2.2 Factory Menu ...................................................................................................................................... 6

2.3 White Balance Menu .......................................................................................................................... 7

3. Design Menu .......................................................................................................................................... 7

3.1 Accessing Way ................................................................................................................................... 8

3.2 Design Menu ....................................................................................................................................... 8

3.3 Other Menu ......................................................................................................................................... 9

3.4 Service Menu ...................................................................................................................................... 9

3.5 Param Setting Menu ........................................................................................................................ 10

4. Test & Alignment ................................................................................................................................. 11

4.1 Pre-Conditions and Power Supply Check .................................................................................... 11

4.2 Project ID Modification .................................................................................................................... 11

4.3 Function Test .................................................................................................................................... 12

4.4 LAN/WLAN Test ............................................................................................................................... 13

4.5 SHOP INIT ........................................................................................................................................ 13

Appendix ...................................................................................................................................................... 14

Appendix 1: Warm-up Test .................................................................................................................... 14

Appendix 2: Software Upgrade ............................................................................................................. 15

Appendix 3: Network Connection ......................................................................................................... 17

Appendix 4: White Balance (WB) Adjustment .................................................................................... 18

2

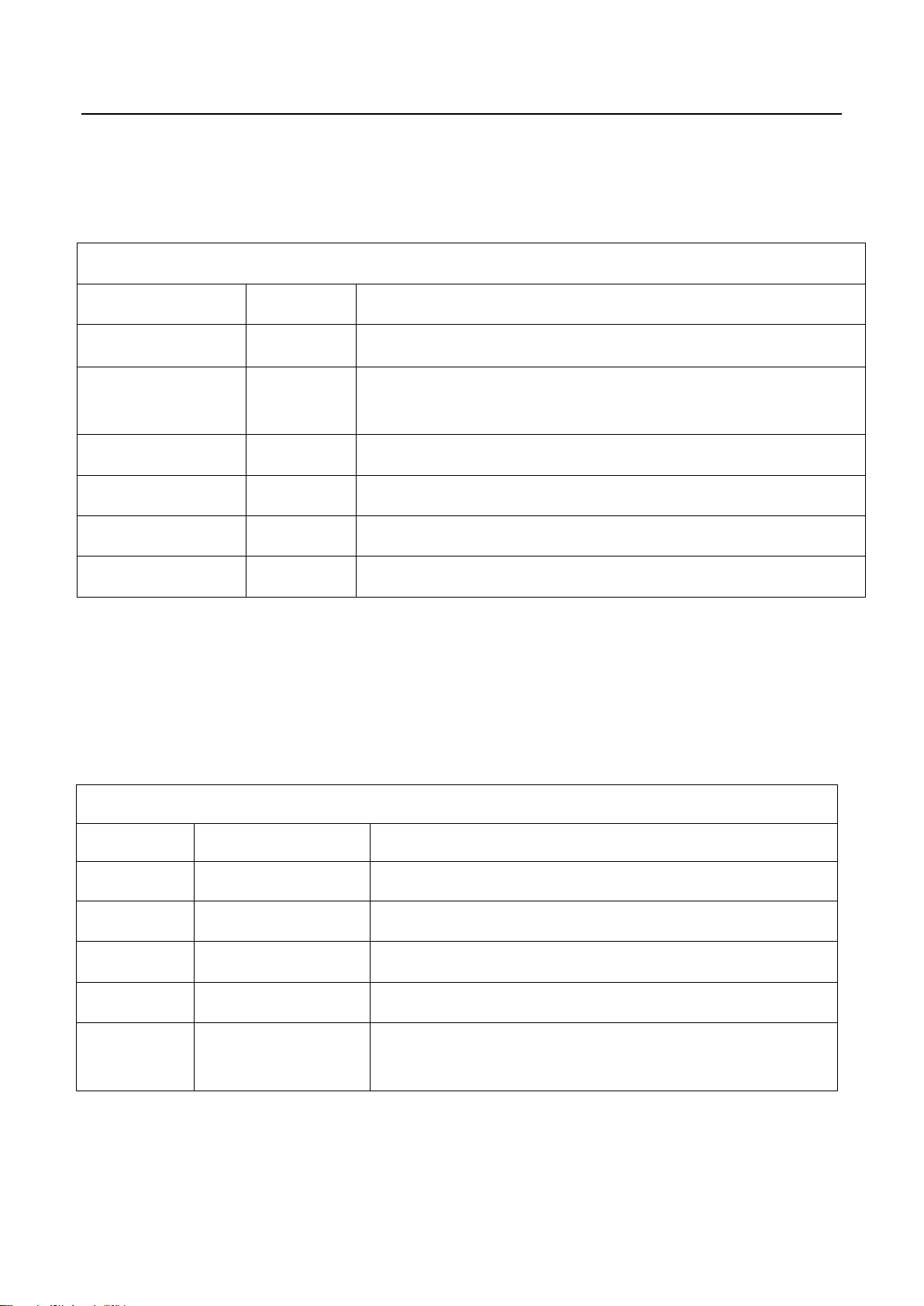

Page 10

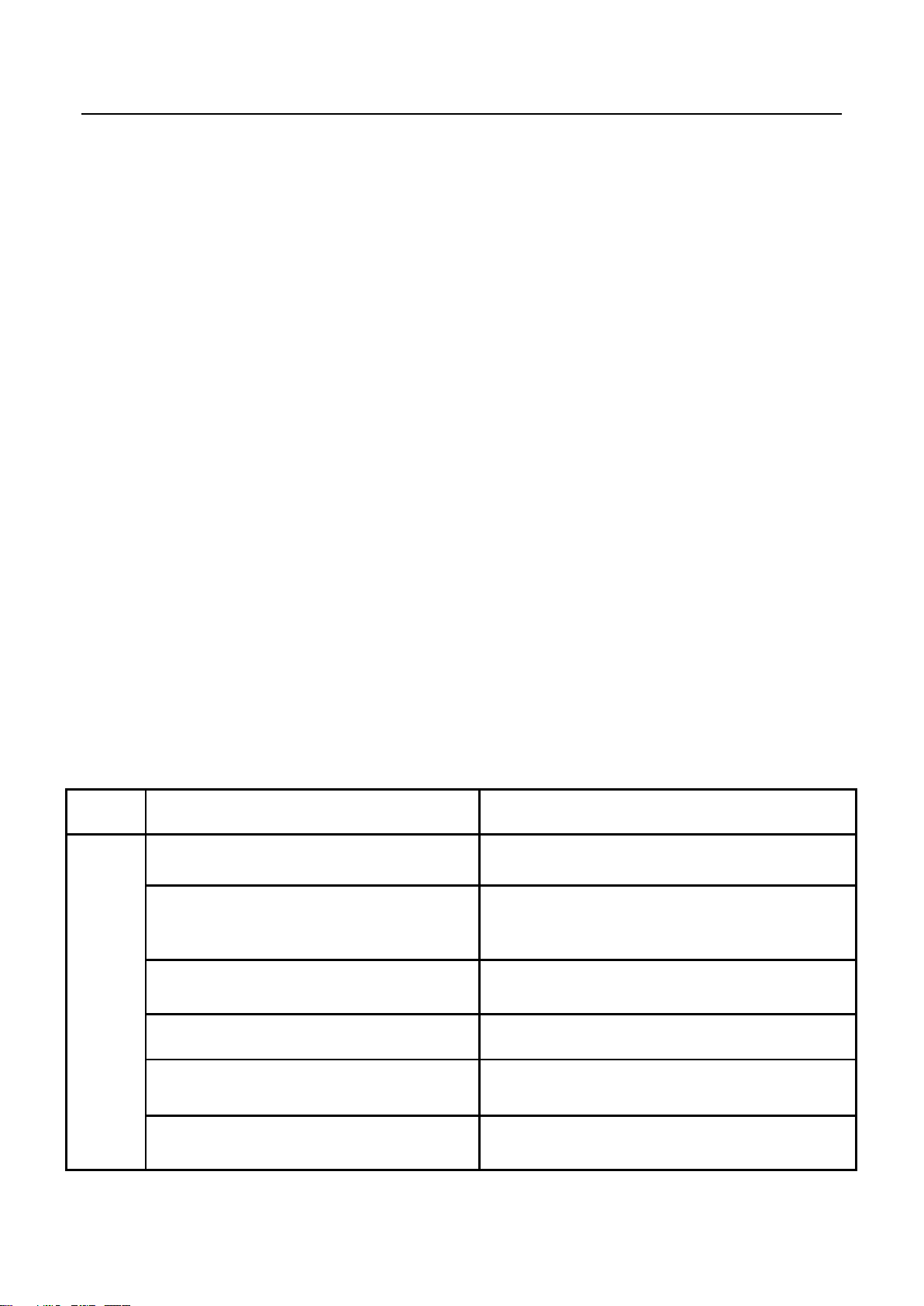

Class

Item

MT56-AP

Input

&

Output

RF Input

(PAL/DVB/DVB-T2)

CABLE&ANTENNA

HDMI

(480i/p, 576i/p, 720p up to 1080i/p, with

HDCP)

HDMI*3

VGA

1

VGA Audio

Shares audio sockets with Audio Input

Component Audio Input

RCA*2 (L+R)

AV Input

RCA*1

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

1. General Description

The information contained in this document is proprietary to TCL SZ FPD lab and shall

not be disclosed by the recipient to the third person without the written permission of

the team leader or GM of R&D.

MT56-AP chassis are designed for Asia & Pacific (AP) market Ready for Smart TV. It

features by its high integration, easy debugging (ADC adjustment free) as well as

convenience in terms of maintenance. Fast software upgrade through USB disk

facilitates both manufacture and after-sale service. Meantime, a variety of functions

involved in Factory Main Menu can not only bring benefits for production, but also

satisfy various demands of customers.

Note: Factory Main Menu (FMM) is divided into Factory menu and Design menu. Factory

Menu covers all indispensable functions during manufacture such as White Balance

Adjustment, SHOP etc., while Design Menu includes Service Menu, Hotel Menu, Param

Setting, Other Setting etc. Some settings like Param Setting and Other Setting is exclusively

used by R&D engineer, anyone else shouldn’t change the settings in the menu. When you

wish to learn the product information like project ID, project name, Hardware, software

version, release date, you can access to Service Menu. In addition, in Hotel Menu, we also

provide a great deal of useful functions for specific applications in hotel.

The main chip is from REALTEK and supports below features matrix:

3

Page 11

Input

&

Output

Audio Out

RCA*2

USB

(Video, audio and picture)

USB2.0*2

MHL

Shares with HDMI 1

PCMCIA

1

SPDIF output

RCA*1

NETWORK

RJ45 Socket

Functions

Internet

WIFI

Others

Serial connector

Multiplexing VGA

IC Details

&

Position

Main program

UF01

(Support online upgrade)

Mboot

UF01

(Support online upgrade)

EEPROM

U702

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Note:

The software boot for U702 can be programed by Flash Tool.exe.

Every set has its unique HDCP key which is purchased from suppliers or HDCP

certification authority. Please check HDCP function in the process of production.

Once in a while, the software of main board may be upgraded. Please pay attention to

use the latest software before production.

4

Page 12

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

2. Factory Menu

Factory Menu is mainly used for factory production and satisfies various demands of customers. It covers

all indispensable functions during manufacture such as Warm up, White Balance, Shop, NVM Reset,

Power on mode, USB Clone etc.

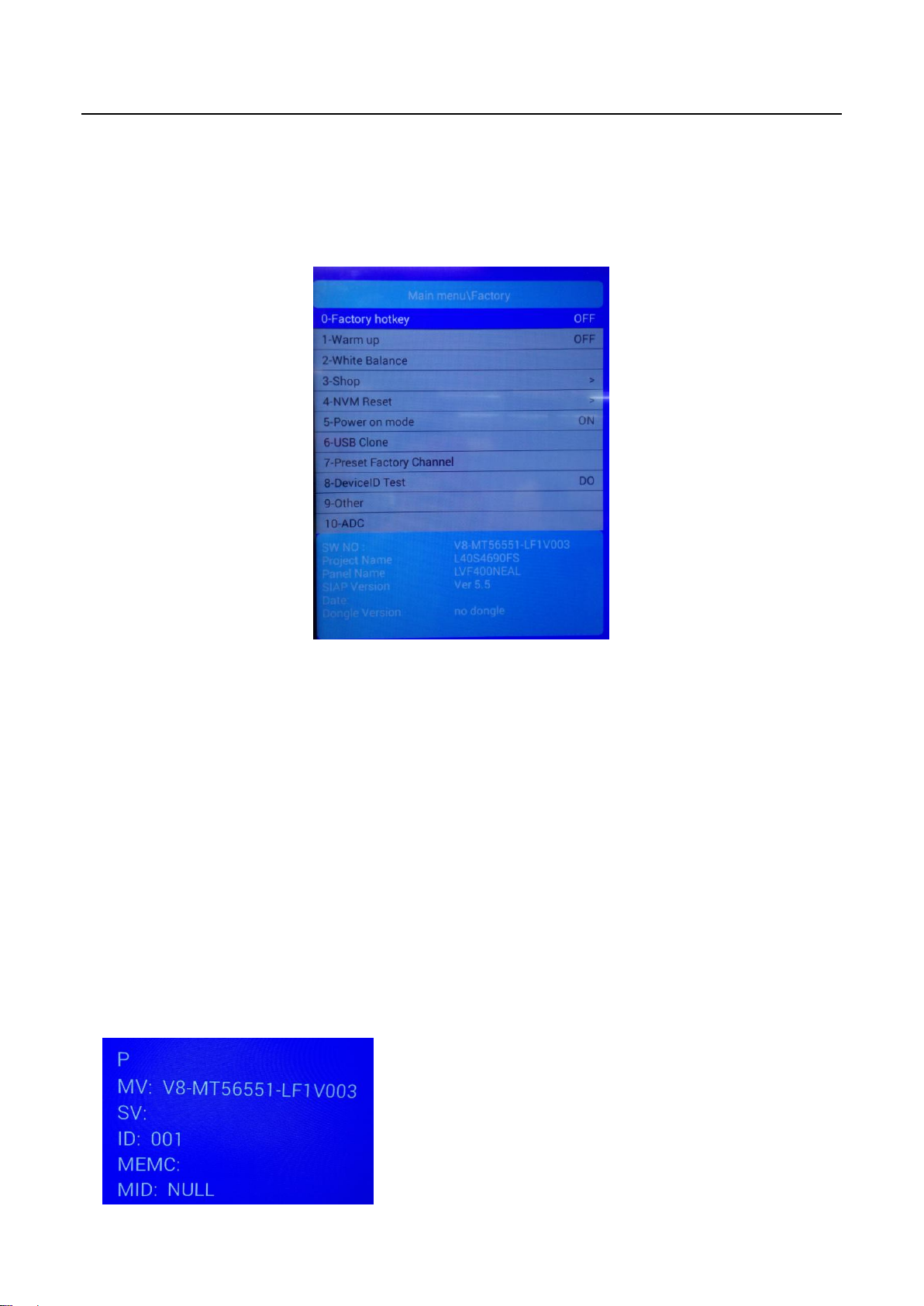

2.1 Accessing Way

a. When the Factory hotkey item of Factory Menu is disabled (OFF), press Menu button of remote

control, then select Settings/Picture, make sure the cursor stop on Contrast item submenu. Finally,

press 9, 7, 3, 5 consecutively.

b. When the Factory hotkey item of Factory Menu is enabled (ON, you can see the flashing Factory

Captions Info on the lower left corner), press Back button of remote control.

Press RCU “OK” key to enter the submenu.

Press RCU “Right” or “Left” key to change the values.

Press RCU “Right” or “Left” key run the function.

Press RCU “Back” or “Menu” key exit the Factory menu.

Factory Captions Info:

While “FactoryKey” is enabled, there is some toggled display information relative to MV, SV, ID, MID, to

facilitate 100% quick screening without accessing to whatever else menu:

P (Production/Factory mode flag)

MV (Mboot SW Version)

SV (Main SW Version)

ID (Project ID)

MEMC

5

Page 13

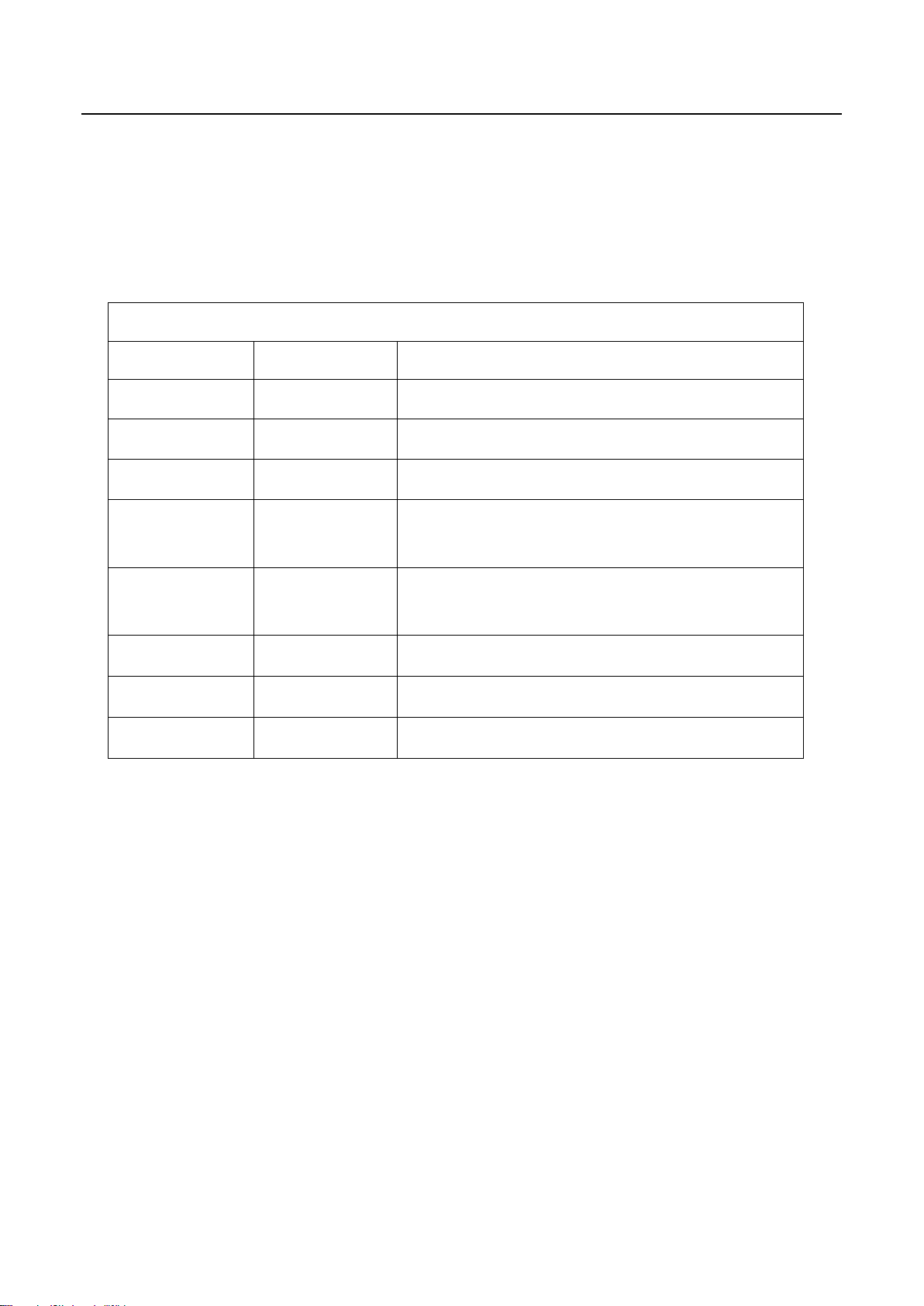

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Factory Menu

Name

Default

Description

Factory hotkey

OFF

Factory Menu shortcut button switch

The item must be disabled (OFF) after production

Warm up

OFF

Aging mode, mainly used for factory aging.

Press “Menu” key on keyboard to exit the burning mode.

See Appendix 1 “Warm-up Test”

White Balance

..

White Balance Adjustment ( see details below)

Shop

>

It is crucial that the function is executed after production aim to clear information

of production process, ensure user cannot access to Factory Menu after

executing the item.

NVM Reset

>

Restore default value except White Balance, ADC data.

Power On Mode

STANDBY

ON: the set will power on after switching on power.

STANDBY: the set will remain standby status after switching on power.

LAST: the set will turn to the status in which it lies when last switching off.

If without requirement from certain customer, by default, the Setting should be

STANDBY

USB Clone

..

Select to choose the things you want to clone.

Preset Factory

Channel

..

Preset the channel table of factory. To preset the channel table of certain factory,

first, choose the corresponding factory name. Then press OK button of remote

control and wait OK is displayed on the screen.

DeviceID test

DO

Test device ID.

Other

Project Information

ADC

..

Analog To Digital Converter

SW NO.

device info

Version information of Main Software

Project Name

device info

Product model

Date

device info

Release date and time of main software

MID

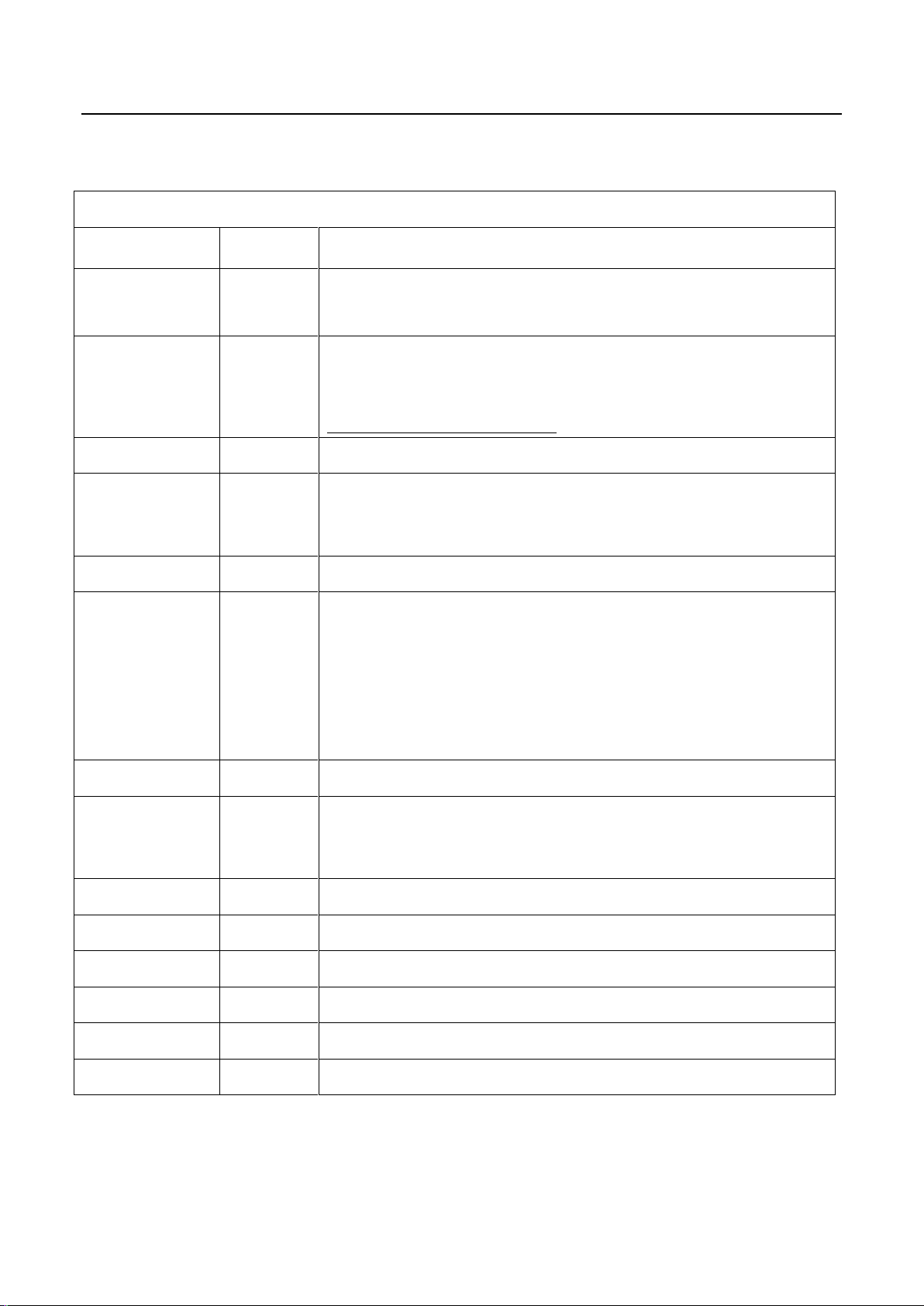

2.2 Factory Menu

6

Page 14

White Balance

Name

Default

Description

Source

ATV

Press RCU left/right key to change the TV source.

Color

normal

Select color temperature you intend to adjust Three groups of color

temperature: normal, Cold, Warm are available.

R gain

0-255

Gain of R channel ( cannot be changed after auto calibration)

G gain

0-255

Gain of G channel ( cannot be changed after auto calibration)

B gain

0-255

Gain of B channel ( cannot be changed after auto calibration)

R offset

128

Disabled, keep the default value

G offset

128

Disabled, keep the default value

B offset

128

Disabled, keep the default value

White Balance

init

>

White Balance Initalization. Before WB adjustment, this item should be

executed.

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

2.3 White Balance Menu

Press the button on remote control to select certain item and OK to adjust White Balance.

3. Design Menu

Design Menu includes Factory Menu, other,

Service Menu, Param Setting, Hotel Menu.

Some settings like Param Setting and Other

Menu is exclusively used by R&D engineer,

anyone else shouldn’t change the settings in the

menu. When you wish to learn the product

information like project ID, project name, chassis

name, software version, release date, you can

access to Service Menu. In addition, in Hotel

Menu, we also provide a great deal of useful

functions for specific applications in hotel.

7

Page 15

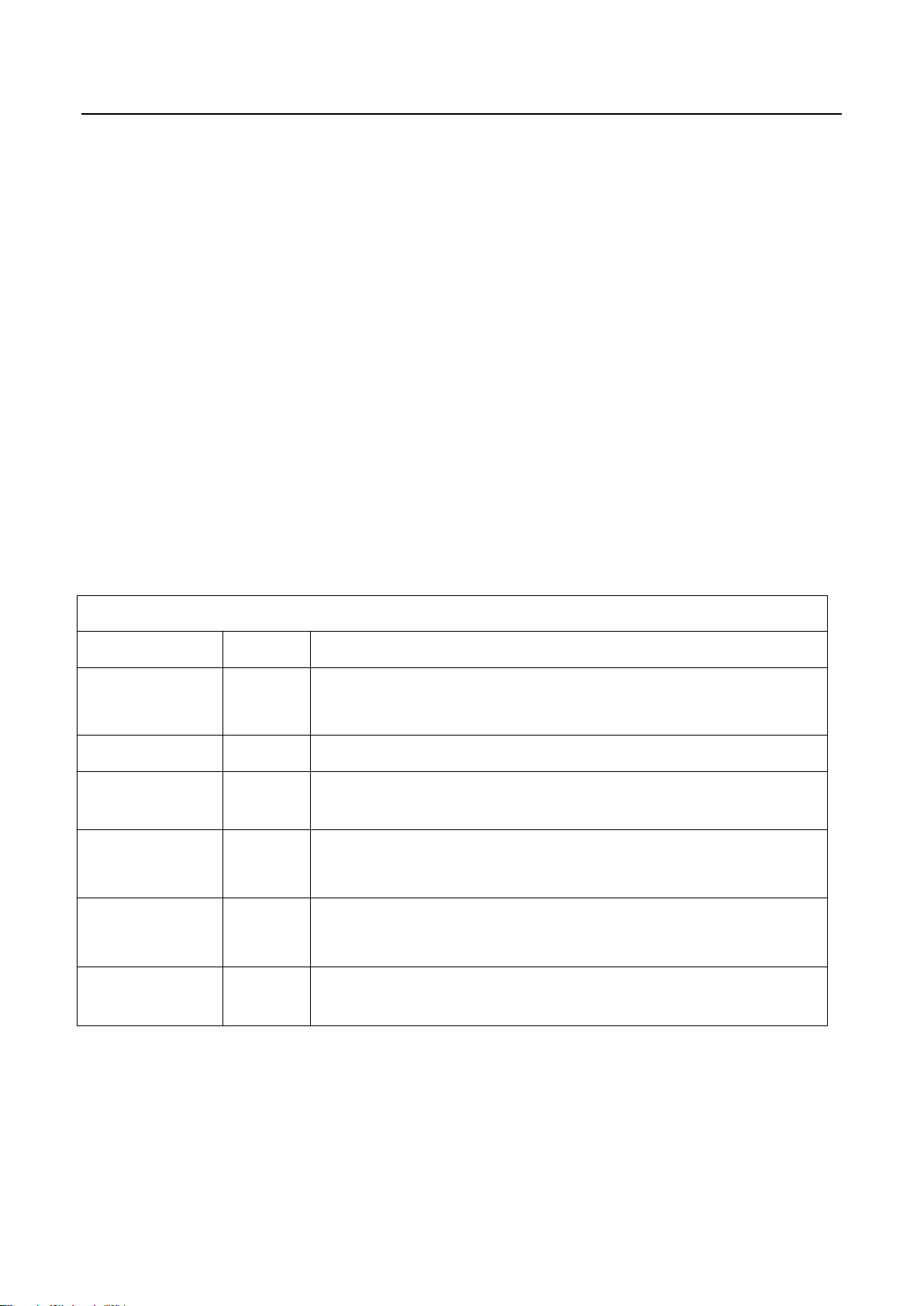

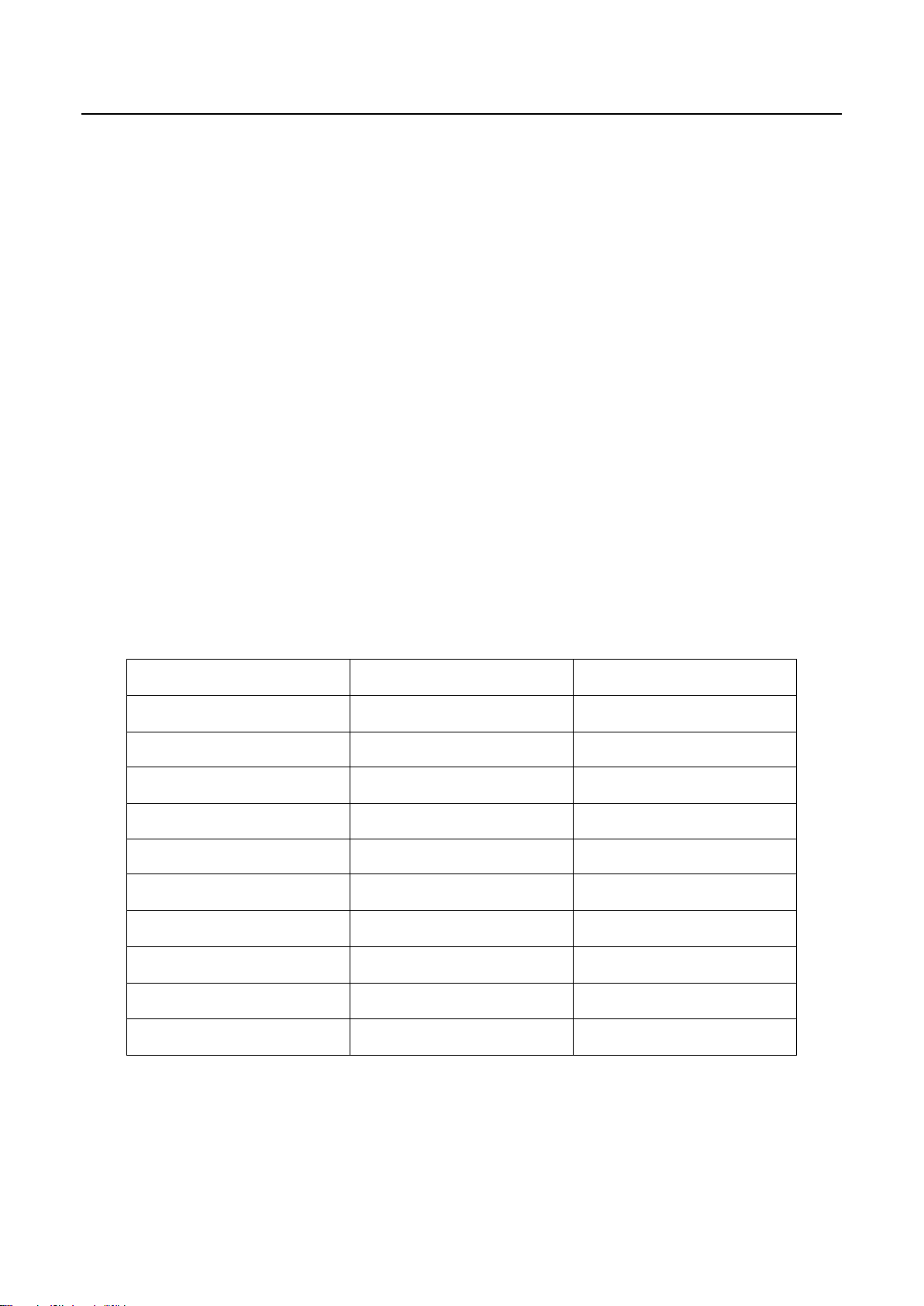

Design Menu

Name

Default

Description

Design Mode

hotkey

OFF

Design Menu shortcut button switch

The item must be disabled (OFF) after production

Factory menu

..

Access to Factory Menu

Other

..

The item includes a number of functions offering convenience for R&D engineer

to solve problems.

Service menu

..

Provide many useful information for after-sale service

Please reference to SERVICE MENU submenu

Param setting

..

Include sound setting,picture setting, SSC, DBC, CI Card, Overscan, WIFI

CHECK and USB FILE. Please reference to PARAM SETTING submenu.

Hotel menu

..

Include special functions which bring benefits to hotel management. The item is

accessible only when Hotel Service On/Off item is enabled (ON).

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

3.1 Accessing Way

a. When the Design mode hotkey item is disabled(OFF), press Menu button of remote

control, then select Settings/ Picture, make sure the cursor stop on Contrast item

submenu, press 1, 9, 5, 0 consecutively.

b. When the Design mode hotkey item of Design Menu is enabled (ON, you can see the

flashing Factory Captions Info on the lower left corner), press Back button of remote

control.

Press RCU OK key to enter the submenu.

Press RCU Right/Left key to change the values.

Press RCU Right/Left key run the function.

Press RCU Back/Menu key exit the Factory menu.

Design Captions Information is the same to Factory Captions Info.

3.2 Design Menu

8

Page 16

Other Menu

Name

Default

Description

TestPattern

>

Switch the TV source into test pattern, and restarting TV is the only way to excit.

UartEnable

OFF

The switch of VGA serial port information.

The item must be disabled (OFF) after production.

DeviceID

..

Show the device id of TV.

MAC

..

Show the MAC address of TV.

HuanID

..

Show the Huan id of TV.

ClientType

..

Show the Client type information.

Service Menu

Name

Default

Description

Project ID

1

Select project parameters, depending on the BOM description.

Hardware

MT5655

mainboard Chassis

Software

V8-MT56551-LF1V003

version number of Main Software

Bootloader

XXX

version number of bootcore

USB Update

..

Update the software by USB disk,

detailed description see Appendix 2 “Software Update”

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

3.3 Other Menu

The Other Menu contains some TV basic information, with which we can check the TV setting before

production.

3.4 Service Menu

Service Menu contains some basic information of the device, such as Project ID, Hardware, Software

version, USB Update etc. This menu is especially useful for after-sale service.

9

Page 17

Param setting Menu

Name

Default

Description

Sound Setting

..

Set sound mode, balance, sound scene, etc.

Picture Curve

..

Exclusively used by R&D

Picture Setting

..

Set picture mode, brightness, contrast, backlight, etc.

SSC Adjust

..

Spread Spectrum clocking.

Exclusively used by R&D.

DBC

..

Dynamic Backlight Control.

Exclusively used by R&D.

CI Card

ON

Common interface Card switch.

WIFI CHEAK

..

Check the WIFI link

USB FILE

..

Access the USB file

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

3.5 Param Setting Menu

Param Setting menu contains Sound Setting, Picture Curve, Picture Setting, SSC, DBC, CI Card,

Overscan, WIFI CHECK and USB FILE. But it is exclusively used by R&D engineer, anyone else shouldn’t

change the settings in the menu.

10

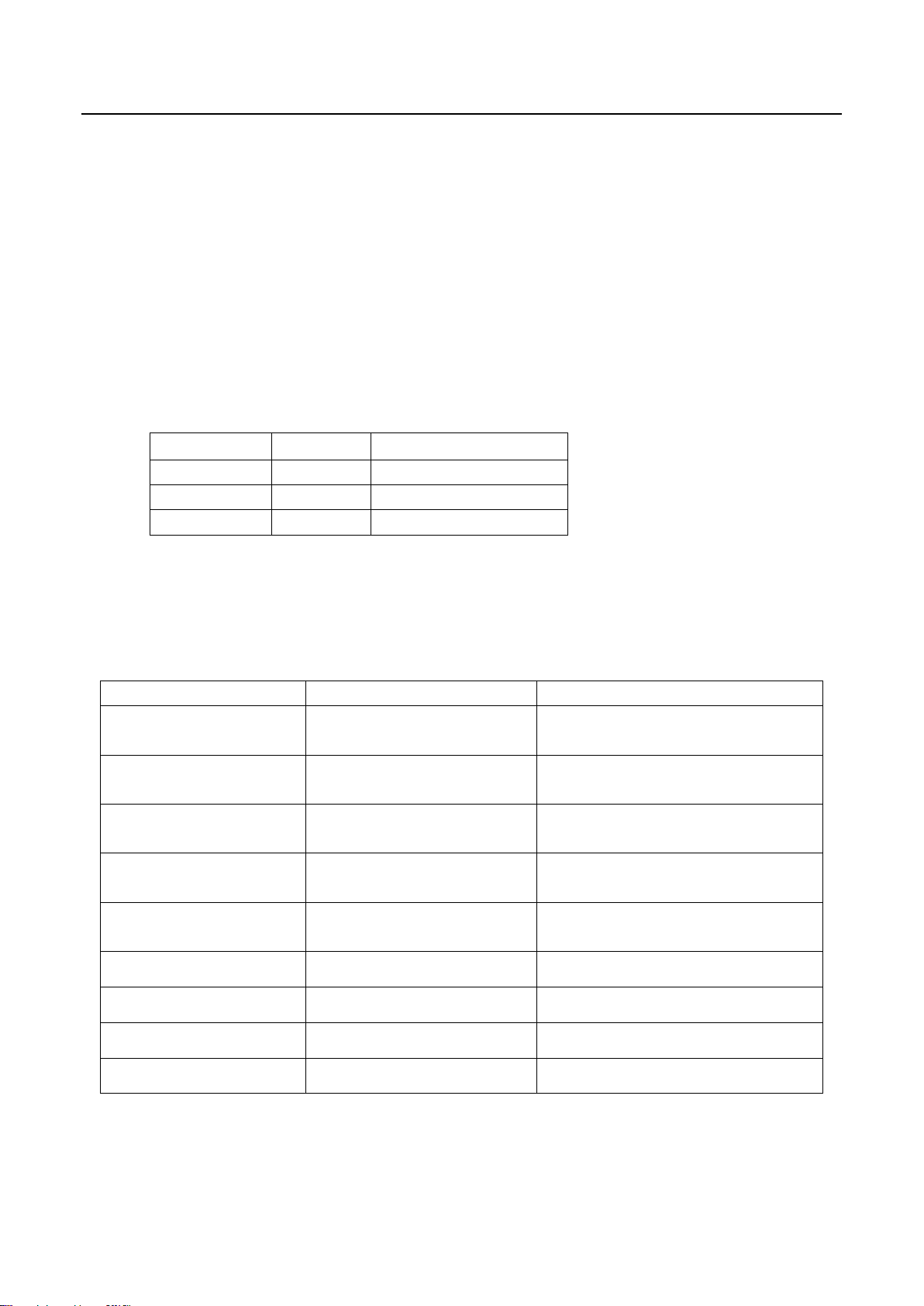

Page 18

Position

Value

Test Point

P103

12V±10%

12V

LDH1

5V±5%

+5V

P103

3.3V ±1%

3V3SB

UD33

3.3V ±1%

3V3

LDJ1

1.5V ±1%

DDR_1V5

LDB0

1.2V±1%

CORE_1V2

UD18

1.8V ±1%

1V8

UT2

3.3V ±1%

TUNER_VCC

U201

3.3V ±1%

3V3_DEMO

L201

1.1V ±1%

NC

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

4. Test & Alignment

According to the requirement of order, we suggest take the below steps to finish the appropriate settings.

Note:

All tests and measurements mentioned hereafter have to be carried out at a normal mains voltage

(100 ~ 240 VAC)

All voltages have to be measured with respect to ground, unless otherwise stated

All final tests have to be done on a complete set including LCD panel in a room with temperature of

25+/-7°C

The Picture Performance assessment such as White Balance (luminance and colour temperature)

has to be performed into subdued lighted room after at least 60min of warm-up in order to avoid any

temperature drift influence (colorimetry vs time).

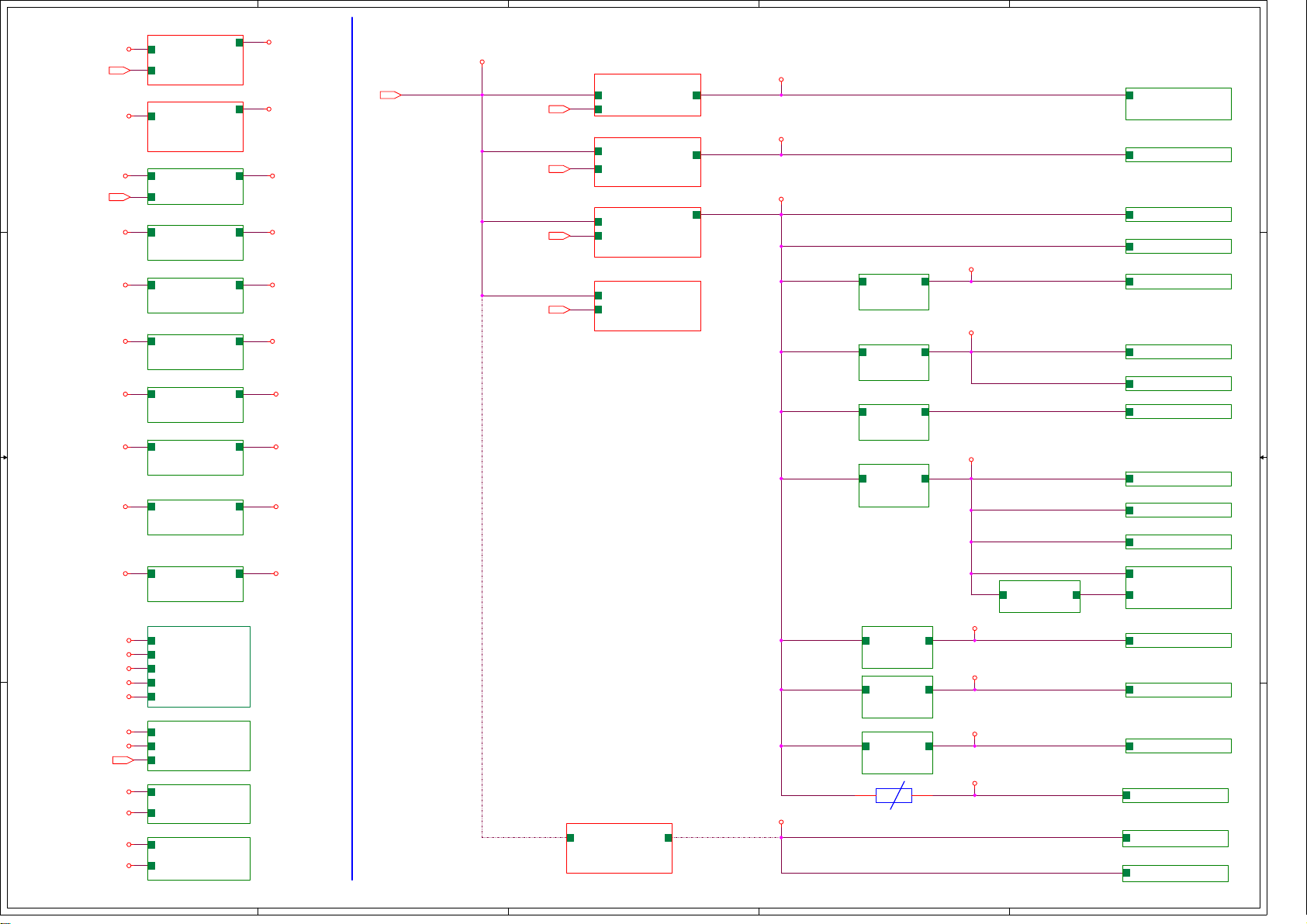

4.1 Pre-Conditions and Power Supply Check

Before power-on, please check the board according to the relevant block diagram and circuit diagram,

make sure that no serious issue or mistake can destroy the board. For example, the output of DC/DC and

LDO should not be shorted to ground.

Supply a suited voltage and power-on, then check the voltage according to the relevant block diagram,

circuit diagram and voltage spec, the error should be less than 5%, for example, the voltage for main chip

(+3V3, +2.5V, VDDC1V15, 1V5_DDR, etc.), the voltage for TUNER (TU_3V3), the voltage for amplifier

(AMP_VCC), etc.

4.2 Project ID Modification

There are different ID stored in the EMMC depending on different Panels settings and Model features, but

there’s only one key branching Project ID able to ensure normal display. And when you power on the TV

set, you should make sure the Project ID is accord with the BOM description. If not, you need to modify

11

Page 19

MODEL

ProjectID

Panel Name

L40S4690FS

001

LVF400NEAL

Source

Test Signal

Test Pattern

RF Input

(PAL/DVB/DVB-T2)

RF cable

Factory signal

AV

(CVBS)

Chroma/Fluke generator

PAL Half Color & Gray bars

VGA

Chroma/QuantumData

generator

1024x768@60Hz

Half Color & Gray bars

HDMI

(Video & Audio)

DVD with HDMI compliancy

Movie 720p@60Hz

LAN

(RJ45)

Ethernet

Any network

Audio OUT

RF signal

Suitable channel

USB

Video/MP3/Image

Home/Media/

SPDIF

DOSS

Audio output

PCMCIA

TV source

Suitbale PCMCIA Card

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

the ID. There are two methods to modify the ID:

Change Project ID in Design Menu

In case of “Design mode hotkey” is enabled, press “Back” button to enter Design Menu. To modify

Project ID, you need to go through “Service menuProject ID”, then press Left or Right key to

select suitable ID (Project name is dynamically refreshed). Finally restart the TV set.

In case of “Design mode hotkey” is unabled, you can enter the Design Menu easily with reference

to 3.1 Design Menu.

Change Project ID with RCU

Press “062598”+”Menu”+”XXX” (XXX represents project ID you’d like to switch to) in the remote

control and wait about half minutes, When the set restart automatically, you have successfully

changed project ID.

Here below is none exhaustive ProjectID table for reference:

4.3 Function Test

Once the Project ID is correct and the TV display normally, plug all external generator devices to relevant

inputs/outputs below according to their respective test patterns format and check picture content and

sound quality accordingly:

12

Page 20

Device ID

User ID

2bbf5dec37068855003ef54b9e27f3be68118899

3546187

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

4.4 LAN/WLAN Test

MAC Address Upgrade

Upgrading MAC address needs to use the tool in factory and through serial command. The specific

method is according to the operation of the factory guidance.

DeviceID (DID) and UserID (UID)

Purpose is to allow Other Network Download (OND) and further specific services over dedicated portal

based on AP. For such, specific DID (32 bytes) and UID (8 bytes) needs to be paired and overwritten into

memory for internal client encryption,as below:

Those DID/UID codes can only be set using UART commands following enclosed SIACP requirements

(rev. v3.9).

LAN Test

A rough LAN test can be done by connecting Ethernet to TV’s RJ45 and check that IP, subnet mask, DNS

addresses, which are visible on “HomeSettingsNetworkEthernet settingsIP settings” (ensure

that “Internet Connection” is Enabled at first). More in-depth test can be performed faster using suitable

UART/IR commands following SIACP requirements. SW will internally manage Network ID (NID) flag

controlling all MAC/DID/UID integrity to facilitate PA screening further.

See Appendix 3 “Network Connection”

4.5 SHOP INIT

At final process stage, it’s necessary to perform Shop init before any packing to leave Factory mode and

restore User default presets according to the requirement of order.

This function is accessible by selecting “Factory MenuShop”, then pressing RCU “Right ”or” Left” key.

Other faster methods are available on above enclosed SIACP requirements (rev. v3.9).

13

Page 21

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Appendix

Appendix 1: Warm-up Test

Following TCL standard and practices, it’s required minimum 15min of Warm-Up that can be considered

as Burn-In. Additional aging for White Balance alignment is no more necessary due to consistent picture

performance with cloning usage. This function is accessible by selecting “Factory menu Warm up”,

pressing RCU “Right” or ”Left” key to set it ON, and then it enter in Warm up mode. Press “Menu” key on

keyboard to exit the burning mode. Other faster methods are available on above enclosed SIACP

requirements (rev. v3.9).

14

Page 22

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

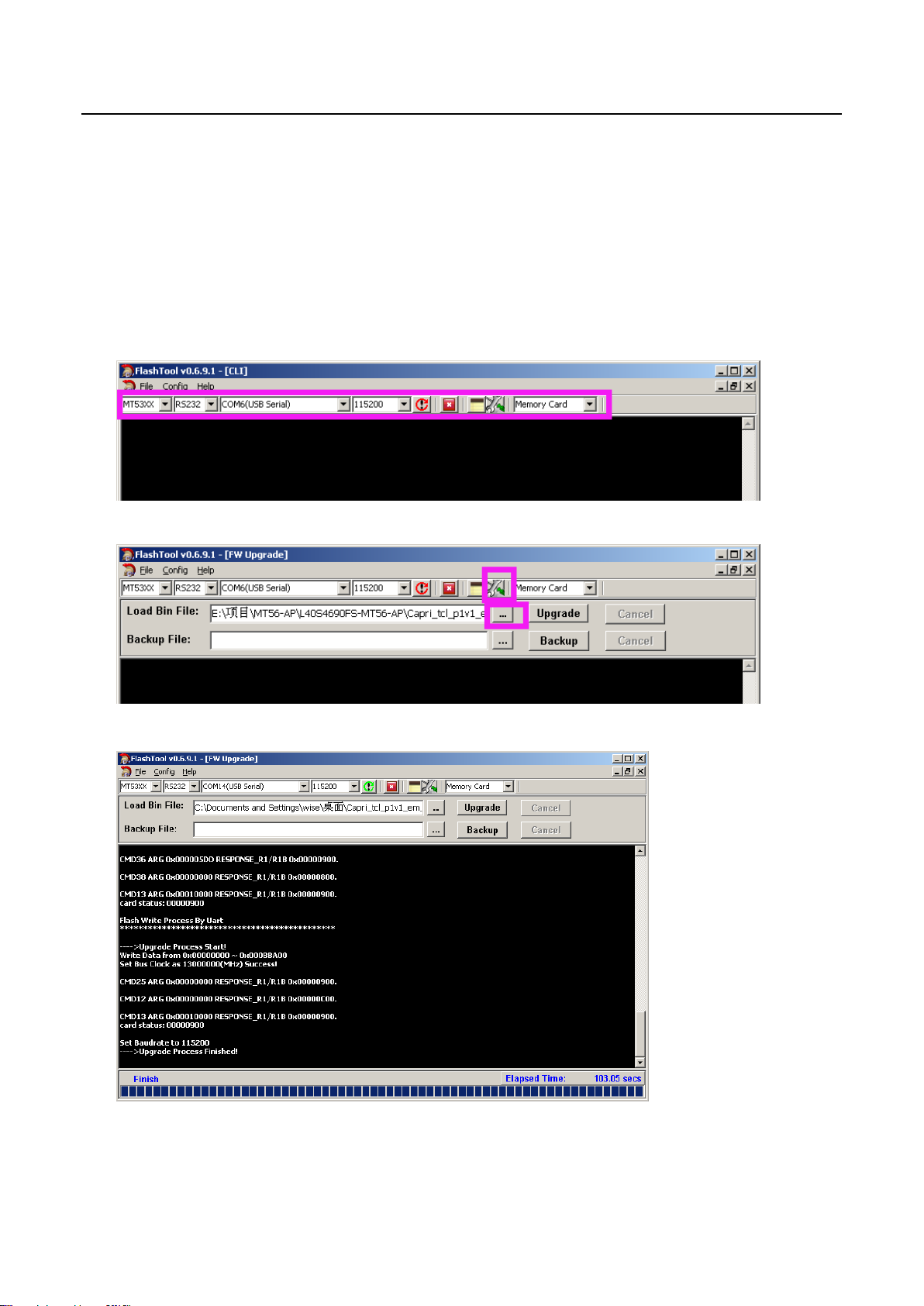

Appendix 2: Software Upgrade

How to upgrade Mboot

Connect the computer and mainboard VGA port by a serial port tool.

Serial connector definition: VGA/P303: Pin4: RXD VGA Pin11:TXD

Open MTK “Mboot” software programming tool “Flash Tool”, and set serial port.

Import the mboot file, as below.

power on the TV, then Click Upgrade key and you will see the below message.

15

Page 23

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

How to upgrade FLASH Software

1. USB Upgrade

Download the update file (generally named V8-MT56551-LF1VXXX.pkg) to the root directory of your

USB device, and make sure there’s no other bin file named analogously. Then insert the USB device

to USB interface of TV set.

Power on the TV set, Press and hold on the menu key of key board at the same time. If the TV is

updating, you’ll see the below screen:

Upgrade process takes about 3~5 minutes.

After updating, the TV set will reset automatically.

2. Online Upgrade

Download the bin zip file “V8-MT56551-LF1VXXX.Zip” to the root directory of your USB device, and

do not change the file name. Then insert the USB device to USB interface of TV set.

Press RCU Menu/Settings/Picture/Contrast/1,9,5,0/Service menu/USB Update /Main

Upgrade/Local Update . If the upgrade file is found, TV will give a message that it verifying. TV

displays a warning message, it means selecting “confirm” to continue or “cancel” to exit. During

updating, do not power off the TV set.

After updating, the TV set will reset automatically.

16

Page 24

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Appendix 3: Network Connection

You can set up your TV so that it can access the Internet through your local area network (LAN) using a

wired or wireless connection.

Connect to a wired network

Attach the TV set to your LAN using cable in three ways:

Connecting the LAN port on the TV to an external modem using a Cat 5 cable.

Connecting the LAN port on the TV to an IP Sharer which is connected to an external modem. Use

Cat 5 cable for the connection.

Depending on how your network is configured, you may be able to attach the TV to your LAN by

connecting the LAN port on your TV directly to a network wall outlet using a network cable. Note that

the wall outlet is attached to a modem or router anywhere in your house.

Select Home→ Settings→ Network → Ethernet Settings→IP Settings, then the TV will obtain IP

address Automatic configuration. In addition, you can set the IP address and password manually.

Connecting to a wireless network

To connect the TV set to your network wirelessly, you need a wireless router or modem and a Wireless

LAN Adapter.

If the TV set is equiped with an internal WiFi module, select Home→ Settings→ Network→ Wireless

Settings, then turn on Wireless Switch, select a wireless network and press OK to connect.

If you want to connect the TV set to a wireless network by a Wireless High Gain USB Adapter (USB

dongle), select Home→ Settings→ Network→ Wireless Settings, then turn on Wireless Switch and

External WiFi, and select a wireless network and press OK to connect.

17

Page 25

Product

type

Color

temperature

state

Color

temperature

chromaticity coordinate

tolerance

(X,Y)

X

Y

LCD

cold

13000K

0.270

0.270

±0.015

normal

10000K

0.280

0.290

warm

7500K

0.300

0.305

source

HDMI

VGA

AV/ATV

CMP

Timing value

69

14

38

79

Pattern value

103

103

103

103

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

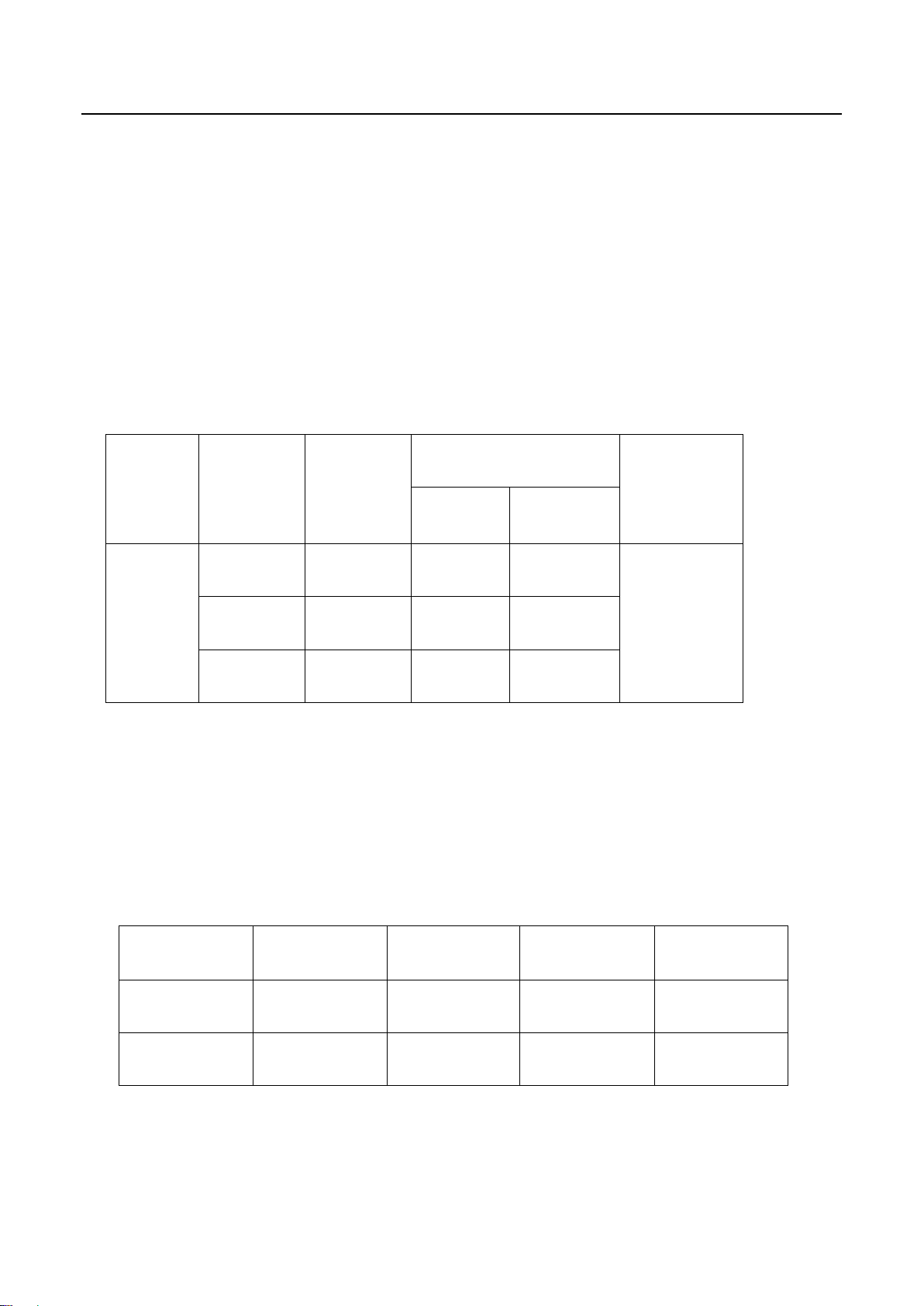

Appendix 4: White Balance (WB) Adjustment

The White Balance generally is customized by PQ engineer, and uploaded to the PDM system, anyone

else shouldn’t change the value in the menu. If it is necessary to adjust, the following content can offer

some reference, but the process of adjusting White Balance is out of the range of this file. Please refer to

the relevant technical file of HuiZhou factory of TCL.

Calibration of Color Temperature

According to TCL standards, the color temperature and white reference coordinates of LCD like the

following table: (This standard is based on CA-310 color temperature meter)

White balance adjustment takes the Normal color temperature of HDMI channel as the reference.

Warm and Cold tone is relative to Normal mode. The adjustable gain range is 0~255.

The Normal color temperature of other channel is relative to the Normal mode of HDMI channel. The

adjustable gain range is also 0~255.

The manual adjustment is according to the regulation above. Additionally, when manually adjust, it

needs to do White Balance init first.

Take signal generator 22293 as an example, the timing value and pattern value of each source show in

the following table:

Note: 1) The input signal is 80% white when the pattern value of 22293 is 103.

2) The adjustment of White Balance should fulfill TCL matching specification.

18

Page 26

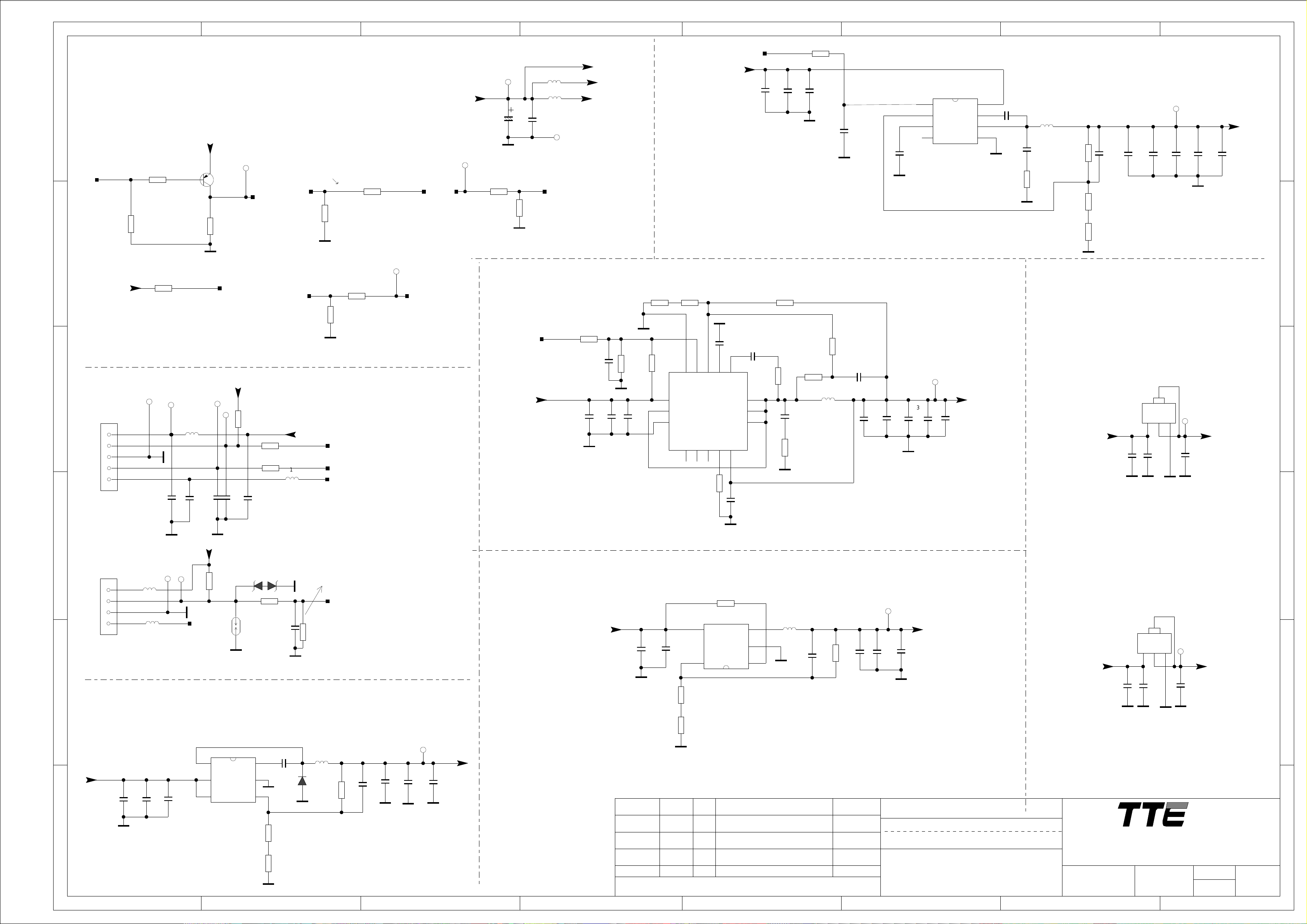

5

4

3

2

1

12V

Power ON

D D

12V

12V

Power ON

5V

5V 3V3_Normal

C C

5V TU_3V3

5V 3V3_DEMO

5V 1V1_DEMO

3V3 1V8

B B

5V MHL_5V

3V33B

CORE_1V2

3V3

3V3

1V8

12V

3V3

Power ON

A A

3V3_DEMO

1V1_DEMO

3V3_Normal

1V8

DC_IN

EN

DC_IN

DC_IN DC_OUT

EN

DC_IN DC_OUT

DC_IN DC_OUT

DC_IN DC_OUT

DC_IN DC_OUT

DC_IN DC_OUT

DC_IN DC_OUT

DC_IN DC_OUT

AVDD33_STB

CORE_1V2

VCC

AVDD33

VCC_EMMC

+12V

+3.3V

EN

VDD33C

CVDD

33V_NORMAL

1.8V

DC_OUT

TPS56528

DC_OUT

TPS560200

MP8765

RT8096A

AS1117-3.3

AS1117-3.3

AS1117-3.3

RT8096A

AS1117-1.8

G524

MT5655

AD82587D

ATBM7811

EMMC

UD4

U101

UDB0

U104

UD33

UT2

U201

U202

UD18

U404

max 5A

max 500mA

max 6A

max 1A

max 1A

U001

U801

UM3

U701

5V

3V3SB

CORE_1V2

DDR_1V5

12V

12V

1510mA

GPIO

350mA

POWER_ON

POWER_ON

POWER_ON

12V_IN 12V_OUT

EN

SWITCH

DC_IN

EN

DC_IN

EN

12V

EN

MP8765

TPS56528

U801

AD82587D

DC_OUT

UDB0

DC_OUT

UD4

Max 6A

Max 5A

备注:

1、该机芯只能适配12V屏,若要搭配5V屏,需更换DC-DC方案;

2、当同时使用MHL+USB+SOC+DDR时,5V电流达到最大,最大3.6A。

65mA

DC_IN DC_OUT

TPS560200 NC/

U101

Max 500mA

1500mA

CORE_1V2

Max 3A

Total 4.4A

3V3SB

PANEL_VCC_12V

5V

190mA

40mA 40mA

DDR_1V5

150mA

DC_IN DC_OUT

Max 1A

RT8096A

USB_5V

5V_IN DC_OUT

750mA1500mA

Max 1.5A

RT9711A

1500mA

5V_IN DC_OUT

Max 1.5A

G524

3V3_Normal

400mA

DC_IN DC_OUT

400mA

AS1117-3.3

DC_IN DC_OUT

AS1117-1.8

TU_3V3

180mA

200mA

DC_IN DC_OUT

AS1117-3.3

DC_IN DC_OUT

3V3_DEMO

AS1117-3.3

TU_1V1

185mA

100mA

DC_IN DC_OUT

RT8096A

PTCPTC

1 2

Max 1A

CI_VCC

max 760mA AV 400mA

175mA

20mA

1500mA

Max 3A

190mA

400mA

750mA

750mA

900mA

100mA

70mA

200mA

180mA

200mA

175mA

20mA

+12V

PANEL

VDD-CPU

SOC

+5V

WIFI

+5V

Blue Tooth

DDR_1V5

+5V

+5V

+5V

+3.3V

+3.3V

AMP AD82587D

+3.3V

33V_NORMAL

1.8V

TU_3V3

TU_3V3

TU_1V1

PCM_VCC

3V3SB

SOC

VCC

KEY/IR/LED

U001

P402

DDR3*2

U601/U602

USB2.0

P403

USB2.0

P406

MHL

P404

SOC

U001

U801

EEPROM

U702

EMMC

U701

TUNER

ATBM7811

UM3

ATBM7811

UM3

PCMCIA

P701

U001

P903

UT1

5

4

3

2

1

Page 27

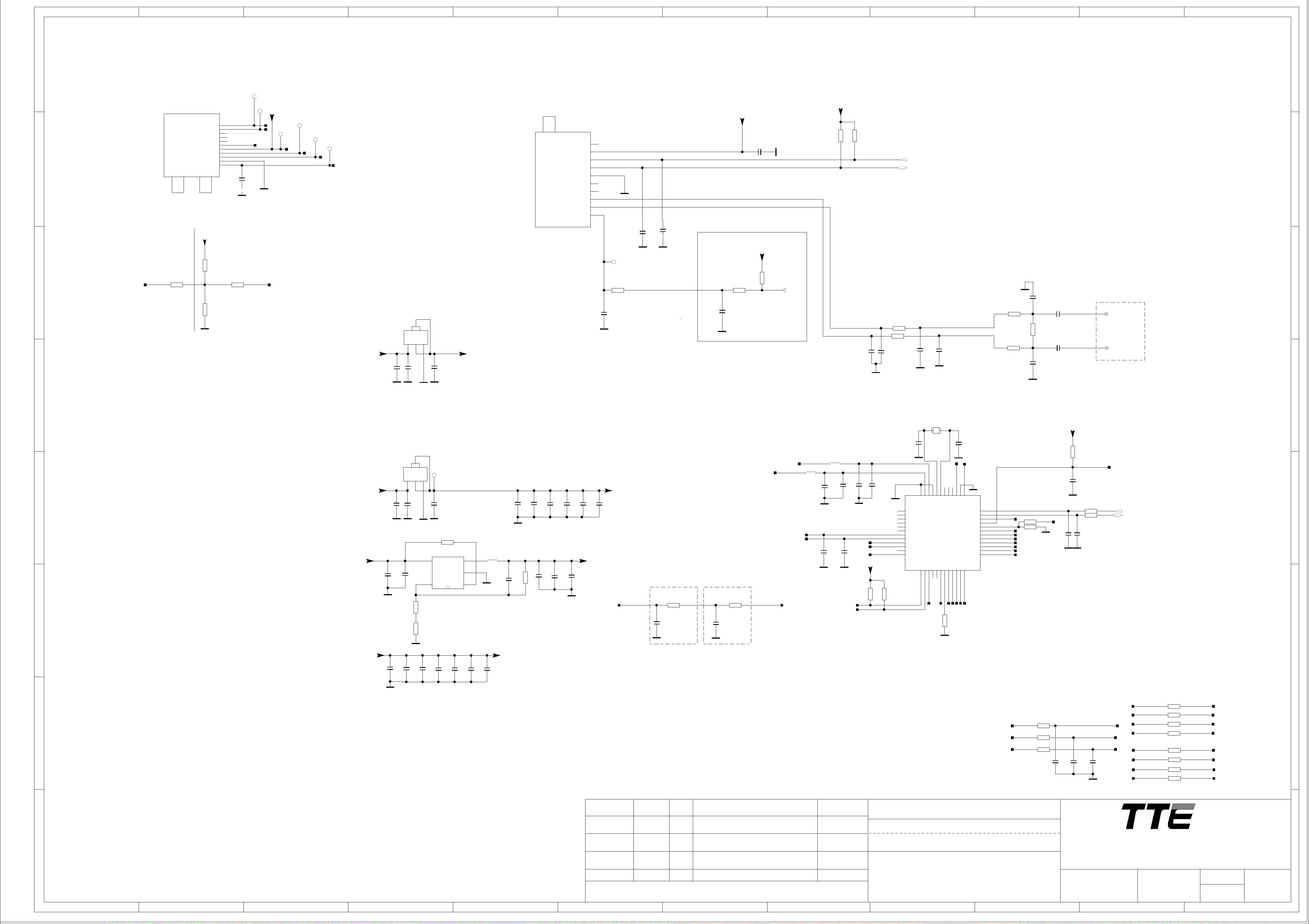

8 7 6 5

4 3 2 1

R001

POWER_ON

1K

C027

0.1U

C029

0.22U

(Vin=4.5V-18V)

C003

10U

R017

4R7

9

16

8

10U

GND

R015

100K

NC/

220P

R018

NC/

10R

GND

Fixed Fsw=500KHZ

Fixed OCP=6.7A

R019

1M

C005C004

0.1U

L005

1UH

GND

R020

510R

C006

0.1U

C030

220P

C032

22UC031

GND

C033

22U

C007

2U2

GND

C034

22U

U001 TPS56528

1

EN

2

VFB

3

VREG5

4

PG

Fsw=650KHz

VIN

VBST

SW

GND

8

7

6

5

GND

12V TO 1V2

CORE_1V2

T

max5A

CORE_1V2

C036

C035

22U

0.1U

0.1UC008

220P

C009

GND

MAIN POWER

12V

12V

L001

T

220R

L002

220R

12V

12V_AMP

12V_M

12V_M

F

C002

R208

220R

GND

C001

16V

470U

DIM_OUT

GND

12V_M

R209

10K

0.01U

(5)

POWER_ON

T

P_GND

C023

/NC

R010

3K3

C026

0.1U

(Vin=5V-22V)

C024

10U

10U

GND

GND

R011

47K

GND

C025

0.1U

R013

8K2

NC/

100K

15

R012

1

2

VIN

SW3

PGND

R014

91K

14

AGND

NC1

3

12

13

EN

U003

MP8765

PG

5

4

R016

NC/

0R

Vref=0.6V

GND

C028

1U

11

FB

VCC

NC2

MODE

6

10

BST

SW2

SW4

SW1

VOUT

7

MTK

3V3SB

L=>POWER_ON

H=>POWER_OFF

R201

10K

IR_GND

R200

10K

R203

T

10K

IR_3V3

IR

C900

0.01U

12_24_DETECT

T

L900

220R

GND

0.1U

C901

B

GND

LED_OUT

C902

220P

POWER_ON_OUT

(5)

E

3V3SB

D

1

2

3

4

5

P900

E

Q200

BT3906

C

POWER_ON

R202

10K

T

CA-0603

POWER_ON

3V3SB

IR

T

R900

10K

C903

470P

T

C904

0.1U

R901

470R

1K

R902

Must controlled by PWM

A_DIMING

(5)

R206

10K

BL_ON_OUT

(5)

3V3SB

IR_IN

LED_OUT

L901

600R

P

5V

GND

(5)

GND

R204

10K

R205

220R

R207

220R

ADIM

BL_ON

T

BL_ON

KEY Connector

(5)

(5)

PDIM

T

PDIM

12V TO 5V

L003

4.7UH

NC/

R002

6R8

NC/

R003

Vref=0.6V

R005

820R

33K

R004

3K6

GND

+5V

T

C010

22P

NC/

C011

10U10U

C013C012

10U

GND

C014

10U

LDO 5V TO 3V3

4

4

VIN

3

C038

0.1U

OUT

2

GND/ADJ

1

GND

3V3

T

C039

10U

GNDGND GND

U005

AS1117-3.3

C037

10U

3V35V

@max5A

C015

0.1U

F

5V

E

D

GND

GND

3V3SB

R903

47K

2 1

F900

GND

D900

PESD5V0S1BLNC/

R904

22K

C905

0.1U

NC/R905

GND

GND

Delete R114 when the I/O(KEY_IN) support 3.3V

*

KEY_IN

Without via on net KEY_IN

The distance between different net via>2mm

150K

(5)

C

GND

KEYKEY_GND

T

T

5V

P901

L902

600R

1

2

3

4

L903

600R

KEY

B

12V TO 3V3SB

SY8291,2015-04-23

GND

D050

SR34

L050

3.3UH

R050

300K

C054

1000P

C055

GND

6

LX

12V_M

(Vin=5V-40V)

GND

2.2U

C051C050

2.2U

C052

0.1U

5

IN

4

EN

AN_SY8291

FSW=800KHz

U002

A

BS

GND

FB

1

2

3

GND

GND

0.1U

0.6V

R051

30K

R052

36K

C053

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

22U

GND

3V3SB

C056

22U

T

GND

C057

0.1U

3V3SB

max:1.2A

5V

5

(Vin=2.5V-6V)

C040

10U

Index-Lab

C041

0.1U

GND

GND

...

...

...

...

DD-MM

DD-MM

DD-MM

DD-MM

DATE

Last saved :

Vref=0.6V

R023

33K

R024

33K

GND

C

DDR 1V5

R021

100K

U004

RT8096A

VIN

4

FB

5

...

...

...

...

LX

3

GND

2

EN

1

...

...

...

...

GND

L006

2.2UH

C042

22P

R022

100K

C043

22U

...

...

...

...

C044

22U

DDR_1V5

T

C045

0.1U

GND

SBU :

TCLNO:

.............

DDR_1V5

@max1A

DESIGNATION

DESCRIPTION Last modifNAME

5-5-2008_15:52

4678

...........

3 2 1

ON:

BY:

LDO 3V3 TO 1V8

4

4

U006

AS1117-1.8

3V3

C046

10U

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

DRAWN

ON:

BY:

OUT

VIN

2

3

C047

0.1U

GND

CHECKED

DD-MM-YY

......

GND/ADJ

1

GNDGND GND

1V8

T

10U

1V8

C048

B

A

PAGE:

OF :

FORMAT DIN A2

Page 28

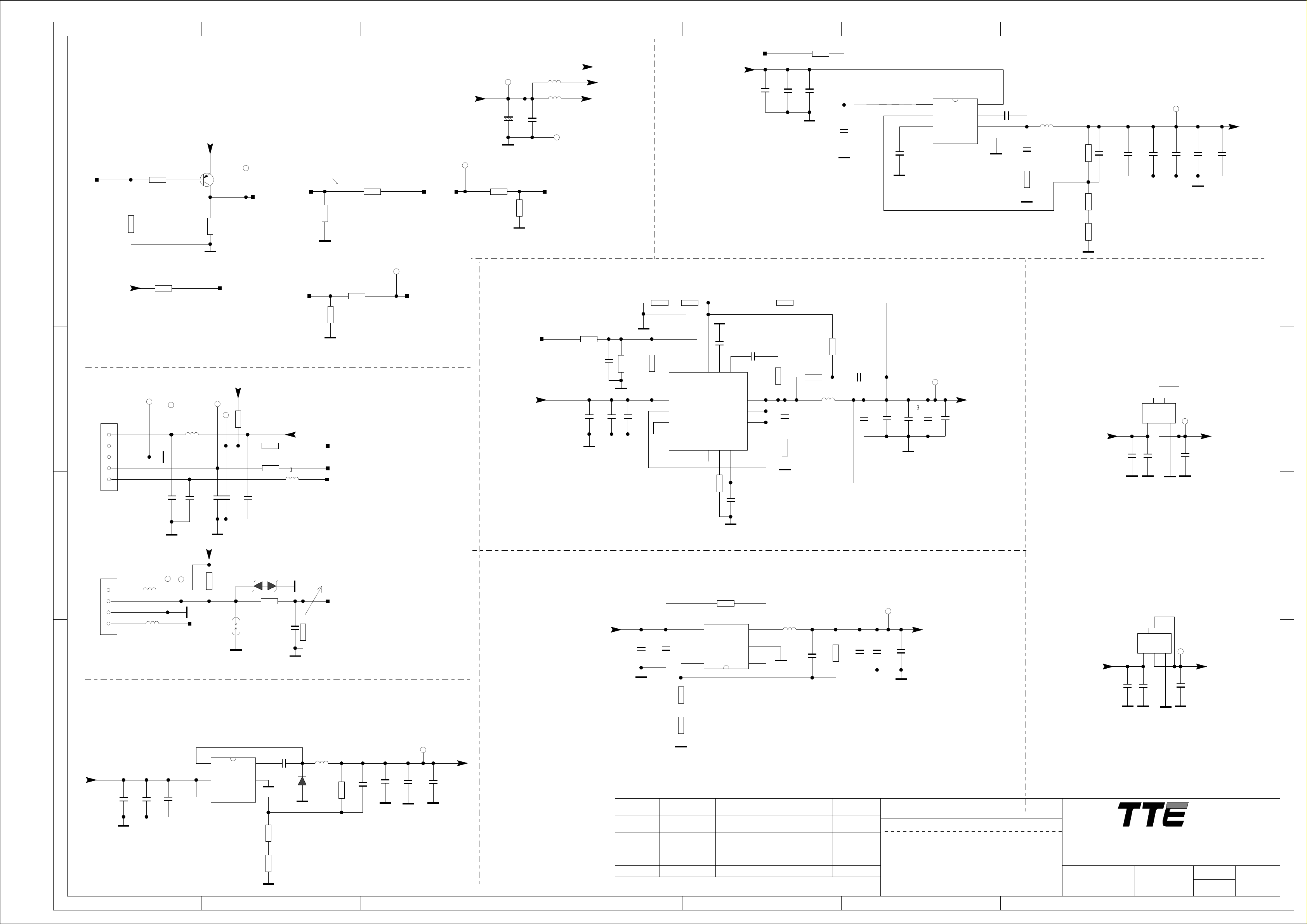

12 11 10 9 8 7 6 5 4 3 2 1

H

H

TUNER_FAT-

T

TUNER_FAT+

T

TU_3V3

TU_3V3

T

TUNER_SDA

T

TUNER_SCL

T

RF_SW

T

TU01

NC1

3V3

SCL

SDA

GND

NC2

NC3

IF_N

IF_P

IF_AGC

1

2

3

4

5

6

7

8

9

10

IF-AN

IF-AP

NC3

NC2

NC1

IF_AGC_D

VCC

SDA

SCL

GND

G

RF_SW

TUNER_FAT-

11

TUNER_FAT+

10

9

8

7

IF_AGC_T2

6

5

TUNER_SDA

4

TUNER_SCL

3

2

RF_SW

1

C939

0.02U

TU02

TU_3V3

10U

C245

TU_3V3

R134

4K7

Close to SOC

Or connect to the nearest 3V3

R135

4K7

TUNER_SCL

TUNER_SDA

(5)

(5)

G

C246

3V3

Close to Tuner

R988

F

RF_SW

R987

33R

R989

GND

Close to SOC

10K

R990

10K

33R

SW_RF

(5)

5V

U101

AS1117-3.3

C105

10U

GND

VIN

GND

3

C106

4

4

OUT

2

GND/ADJ

1

GND

TU_3V3

C107

10U0.1U

GND

T

C248

0.1U

TU_IFAGC

1K

R249

10P

C247

10P

IF_AGC_T2

Close to SOC

1K

R250

C249

0.1U

10K

R251

TU_3V3

IF_AGC

(5)

TUNER_FAT+

TUNER_FAT-

C148

22P

GND

R127

R128

C149

22P

100R

100R

GND

NC/

C150

22P

GND

NC/

C151

22P

Close to MTK SOC

R129

1K

R130

1K

GND

GND

NC/

C154

NC/

C155

R131

680R

22P

22P

C152

C153

0.1U

0.1U

(5)

IFP

SOC OPTION

(5)

IFN

F

E

Read Add:0X81H

Write Add:0X80H

C168

10P

GND

GND

L103

120R

C165

0.01U

C162

NC/

47P

GND

C166

1U

C163

NC/

C167

2U2

GND

47P

3V3_DEMO

3V3_DEMO

1V1

D_IF_AGC

R985

R986

4K7

4K7

GND

37

38

39

40

41

42

43

44

45

46

47

48

GND

SIFIP

SIFIN

SIFQP

SIFQN

RSSI

CLK_IO

TIFP

TIFN

VDD33D

CVDD5

GPO2

GPO3

4

4

VIN

3

C109

OUT

2

GND

R108

100K

GND/ADJ

DEMO_3V3

T

1

GND

VIN

4

FB

5

Vref=0.6V

C110

10U0.1U

U103

RT8096A

R107

100K

LX

GND

EN

3V3_DEMO

C112

C111

2U210U

GND

L101

2.2UH

3

2

1

C119

22P

GND

R110

100K

C120

22U

C121

22U

C113

0.1U

C122

0.1U

0.1U

GND

C115C114

0.1U

1V1

@max1A

C116

0.1U

IF_AGC_T2

Close tuner

R118

1K

Close demod

10K

R119

D_IF_AGC

U102

AS1117-3.3

5V

C108

GND

10U

C118

0.1U

GNDGND

D

5V

(Vin=2.7V-7)

C117

10U

3V3_DEMO

1V1

L104

120R

C164

2U2

TUNER_FAT+

TUNER_FAT-

24M

X100

35

32

34

33

CAVDD

ADDR

30

31

XTALO

XTALI

DISEQC_IN

36

GND1

AVDD33

U100

ATBM7812B

SDAM

SCLM

CVDD1

GPO5

GPO4

VDD33A

123456789

3V3_DEMO

1V1

GND

3V3_DEMO

28

29

261127

GP01

DISEQC_OUT

TEST_MODE

VDD33C

STATUS

TSSYNC

TSVLD

TSCLK

10

TSSYNC

TSCLK

TSVLD

C169

10P

1V1

25

GND

CVDD4

SDAS

SCLS

CVDD3

RESET

CVDD2

VDD33B

TS7

TS6

TS5

TS4

TS3

TS2

TS0

TS1

12

D_TSDATA1

D_TSDATA0

24

23

22

21

20

19

18

17

16

15

14

13

RT18/RT19/RT20 decided by the MTK SOC

3V3_DEMO

R151

47K

1V1

3V3_DEMO

D_TSDATA7

D_TSDATA6

D_TSDATA5

D_TSDATA4

D_TSDATA3

D_TSDATA2

R149

0R

R150

NC/

0R

1V1

GND

C171

10P

GND

GNDGND

C170

1U

T2_RST

R132 100R

R133 100R

C172

10P

(5)

TUNER_SDA

TUNER_SCL

(5)

(5)

E

D

GND

C134

0.1U

C

495mA

1V1

C123

22U

GND

GND

C124

10U

R109

15K

C125

2U2

C126

1V1

C128C127

0.1U0.1U

0.1U

C129

0.1U

GND

C135

0.1U

B

GND

R148

2K7

TSCLK

TSVLD

TSSYNC

R136

22R

R137

22R

R138

22R

C173

10P

C174

10P

/NC/NC

CI_MCLKI

CI_MIVAL

CI_MISTRT

C175

10P

GND

/NC

D_TSDATA7

D_TSDATA6

D_TSDATA5

D_TSDATA4

D_TSDATA3

D_TSDATA2

D_TSDATA1

D_TSDATA0

22RR139

R140 22R

22RR141

R142 22R

22R

R143

R144

22R

R145 22R

22RR146

C

CI_MDI7

CI_MDI6

CI_MDI5

CI_MDI4

CI_MDI3

CI_MDI2

CI_MDI1

CI_MDI0

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

Index-Lab

Last saved :

DD-MM

DD-MM

DD-MM

DD-MM

...

...

...

...

...

...

...

...

...

SBU :

TCLNO:

.............

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

A

Nanshan District, Shenzhen, Guangdong

...

...

NAME Last modifDESCRIPTIONDATE

5-5-2008_16:29

...

DESIGNATION

...........

ON:

BY:

DRAWN

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

123456789101112

FORMAT DIN A1

Page 29

8 7 6 5 4 3 2 1

MINI AV

AV_V

AV_GND

T

AV_V

T

Close to Connector

AV_L

T

AV_R

T

GND

AV_R

AV_L

F903

F902

VGA JACK

CVBS

GND

1

R

2

3

L

4

5

F901

F

P902

E

Close to Connector

AV_V

AV_L

AV_R

AV_V

D901

PESD5V0S1BL

2 1

R909

33K

R910

33K

R907

75R

NC/

150P

C911

C906

NC/

GND

47P

GND

NC/

150P

C912

CLOSE TO U001

R908

100R

C909 1U

1UC910

0.047UC907

1UC908

AV1_L_IN

AV1_R_IN

AV1_V_IN+

AV1_V_IN-

(5)

(5)

(5)

(5)

F

E

GND

D

D

AV AUDIO OUT

T

GND-AVOUT

1

GND

P903

3

R

L

2

4

D902

PESD5V0S1BL

C

PESD5V0S1BL

GND

B

D903

21

AVOUT1_R

AVOUT1_R

T

R911

470R

AR2_ADAC

C

AVOUT1_L

R912

21

T

AVOUT1_L

C913

C914

470P

GND

470R

470P

AL2_ADAC

B

SPDIF

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

SPDIF

T

2

1

T

SPDIF

NC/

F904

12

D904

PESD5V0S1BL

GND

R338

120R

P904

BLACK

SPDIF_GND

45678

R913

220R

C915

220P

Close to IC

C916 0.1U

SPDIF_OUT

A

123

FORMAT DIN A3

Page 30

12 11 10 9 8 7 6 5 4 3 2 1

USB2.0 Port

H

H

D905

D906

D907

D908

NC/

NC/

NC/

NC/

GND

INTERNET

Must be differential 100ohm

2R2

TXVP

TXVN TXN

RXVP

RXVN

R923

R924

13-ESD3V3-6PB

R925 2R2

2R2

R926

2R2

D909

RXP

RXN

TXP

4

7

65

312

• WIFI

USB3D+

USB3D-

C930

3P3

NC/

GND

WIFI_SW

T

C931

0.01U

GND

T T

D910

1

GND

9108

2

3

4

NC/

ESD

13-ESD5V5-O4B0P5

10

9

8

GND

7

65

C925

0.1U

C926

0.1U

C924

0.01U

GND GND

C927

0.01U

U901

1

2

3

4

5

6

7

TS8121CLF

P907

GND

11

12

1

2

3

4

5

6

7

8

9

10

USB3_DM

USB3_DP

WIFI_ON

R933 100R

5V

R931 2R2

R932 2R2

C929

3P3

NC/

16

TX1P

15

TX1N

14

13

12

RX1P

11

10

RX1N

98

R927

75R

R928

75R

GND

C928

1000P

R929

75R

R930

75R

TXC

RXC

TP

TN

RP

TC

RN

RC

T

T

T TT T

GND

TX1P

TX1N

RX1P

TXC

RX1N

RXC

C932

0.1U

WGND

WIFI_PWR

T

GND

GND

T

1

2

3

4

5

6

P908

R934 0R

G

F

U900

RT9711A

5V

C917

10U

GND

USB2_DM

(5)

USB2_DP

(5)

G

3V3SB

R917

4K7

F

5 1

VIN

R914

10K

4

EN/EN# NC

R915 2R2

R916 2R2

R918

4K7

UART_TX

UART_RX

C918

3P3

VOUT

GND

C919

NC/

(5)

(5)

3P3

2

3

GND

C920

470U

NC/

16V

USB1_DM

USB1_DP

USB_5V

C921

10U

GND

R919

R920 2R2

USB_5V

C922

USB1_D-

T

T

USB1_D+

F906

F905

GND

USB_5V

2R2

3P3

NC/

NC/

GND

T

C923

3P3

GND

T

GND

GND

GNDU

P905

1

U2_DM

U2_DP

VCC-1

2

DNEG-1

3

DPOS-1

4

GND-1

5

6

MNT-HOLE1

MNT-HOLE2

When use ESD Device, must delete 3.3pF on USB data line

UART_RX

T

0.1U

C419

U1_DM

USB2_D-

T T

USB2_D+

T

GND

F908F907

UART_TXUSB_5V

T T

UART_RX

UART_TX

U1_DP

R921

NC/470R

R922

NC/470R

GND

9

1

8

2

7

3

6

4

5

10

11

U1_DP

U2_DP

U1_DM

U2_DM

P906

MNT-HOLE1

MNT-HOLE2

2 1

PESD5V0S1BL

2 1

PESD5V0S1BL

2 1

PESD5V0S1BL

2 1

PESD5V0S1BL

HDMI/MHL Prot1

HDMI Port2

E

3

R943

10K

MHL_SENSE

12

H1_HPD

R948

20K

5V

H1_SCL

H1_SDA

H1_SCL

H1_SDA

VBUS

B

C

E

GND

B

Q900

BT3904

GND

VBUS

D911

BAT54C

1 2

R942

4K7

D

H1_SCL_IN

(5)

H1_SDA_IN

(5)

R417

100R

R418

100R

D914

2 1

PESD5V0S1BL

D915

2 1

PESD5V0S1BL

D916

C

PESD5V0S1BL

D917

2 1

PESD5V0S1BL

D918

2 1

PESD5V0S1BL

GND

MHL_SENSE

B

3V3SB

3V3SB

R946

300K

R947

47K

C

E

(5)

(5)

(5)

(5)

(5)

(5)

(5)

Q901

BT3904

H1_RX2+

MHL_SENSE

H1_RX2-

H1_RX1+

H1_RX1MHL+/H1_RX0+

MHL-/H1_RX0-

H1_CLK+

(5)

H1_CLK-

(5)

R949

10K

S

G

D

3

1

100R

4R7

4R7

4R7

4R7

4R7

4R7

VBUS

Q904

PMV65XP

BAT54A

2

R950

820R

R951

33R

4R7

4R7

D919

H1_RX2+_IN

R935

R936

H1_RX2-_IN

R937

R938

R939

MHL+/H1_RX0+_IN

R940

MHL-/H1_RX0-_IN

R941

H1_CLK+_IN

R944

H1_CLK-_IN

R945

MHL_PWR_EN

H1_HPD

H1_RX1+_IN

H1_RX1-_IN

5V

GND

R952

100R

1

2

GND

3

4

D912

1

2

3

4

D913

13-ESD5V5-O4B0P5

C933

0.1U

GND

R953

300K

ESD

13-ESD5V5-O4B0P5

10

9

8

7

65

ESD

VBUS

H1_HPD

C934

10U

4 3

EN/EN# OC

G524

C935

0.047U

GND

10

9

8

7

65

H_CEC

GND

U902

OUTIN

GND

GND

H1_SCL

H1_SDA

15

2

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

0.1U

P909

GND1

RX1+

RX1-

GND3

RXC+

RXC-

NC2

DDCDA

VCC

C937C936

10U

GND

RX2+

RX2-

GND2

RX0+

RX0-

GND4

NC1

DDCCLK

GND5

HPD

VBUS

RX2+

GND1

RX2-

GND2

RX0+

RX0-

GND4

NC1

DDCCLK

GND5

HPD

3V3SB

3V3SB

P910

RX1+

RX1-

GND3

RXC+

RXC-

NC2

DDCDA

VCC

R966

47K

H2_RX2+_IN

H2_RX2-_IN

ESD

R970

100K

10

9

8

7

65

R962

R963

H2_HPD

10

9

8

7

65

100R

100R

GND

H2_SCL_IN

H2_SDA_IN

GND

H2_RX1+_IN

H2_RX1-_IN

H2_RX0+_IN

H2_RX0-_IN

H2_RXC+_IN

H2_RXC-_IN

(5)

(5)

1

2

GND

3

4

ESD

D920

13-ESD5V5-O4B0P5

1

2

3

4

5

6

7

8

9

10

11

12

B

H_CEC

H1_ARC

H2_SCL

H2_SDA

H2_5V

H2_HPD

(5)

C

BT3904

E

GND

R967

47K

HDMI2_HPD

Q902

R968

910R

13

14

15

16

17

18

19

GND

GND

B

1

2

3

4

D921

13-ESD5V5-O4B0P5

R964

47K

47KR965

H2_5V

R969

75R

C

Q903

BT3904

E

GND

4R7

4R7

4R7

4R7

4R7

4R7

4R7

4R7

GND

H2_RX2+

R954

H2_RX2-

R955

H2_RX1+

R956

H2_RX1-

R957

H2_RX0+

R958

H2_RX0-

R959

H2_CLK+

R960

H2_CLK-

R961

D922

2 1

PESD5V0S1BL

D923

PESD5V0S1BL

D924

2 1

PESD5V0S1BL

D925

2 1

PESD5V0S1BL

12

H2_5V

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

H2_SCL

H2_SDA

H2_HPD

H_CEC

27K

R983

3V3SB

D930

R984

100R

HDMI_CEC

27K

R979

82R

R980

GND

5V

47K

R981

1UC938

R982

H1_ARCH1_ARC_OUT

47K

GND

When AC power OFF and HDMI sourc is plugged in, HPD is Low

H1_HPD_CBUS

GND

When Power on or Standby and HDMI source is plugged in, HPD is High

For MTK5507, reading EDID when HPD is High

E

D

C

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

Index-Lab

Last saved :

DD-MM

DD-MM

DD-MM

DD-MM

...

...

...

...

...

...

SBU :

TCLNO:

TCL

ADDRESS1

...

...

...

.............

ADDRESS2

A

ADDRESS3

...

...

NAME Last modifDESCRIPTIONDATE

11-23-2010_14:02

...

DESIGNATION

...........

TELEPHONE

DRAWN

ON:

BY:

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

123456789101112

FORMAT DIN A1

Page 31

12 11 10 9 8 7 6 5 4 3 2 1

H

H

SOC-POWER

CORE_1V2

U201MT5507

Y16

VCCK

W17

VCCK1

Y17

VCCK2

W18

VCCK3

Y18

VCCK4

P19

VCCK5

R19

VCCK6

T19

VCCK7

U19

VCCK8

V19

VCCK9

W19

VCCK10

Y19

VCCK11

P20

VCCK12

R20

VCCK13

T20

VCCK14

U20

VCCK15

V20

VCCK16

W20

VCCK17

G

Y20

U21

V21

W21

VCCK18

VCCK19

VCCK20

VCCK21

VCCK22

VCCK23

VCCK24

VCCK25

VCCK26

VCCK27

VCCK28

VCCK29

VCCK30

VCCK31

VCC3IO_A

VCC3IO_B

F

Y21

W22

Y22

AA22

AB22

Y23

AA23

AB23

AA24

AB24

G21

F22

C200

0.1U

CORE_1V2

C201

NC/

0.1U

GND

C202

4U7

3V3

(3)

(3)

3V3

GND

C216

1U

AV1_R_IN

AV1_L_IN

C217

0.1U

SOC-AUDIO

C22

AIN_R0

C24

AIN_L0

B23

AIN_R1

E23

AIN_L1

D23

AIN_R2

A22

AIN_L2

B22

AIN_R3

C23

AIN_L3

AVDD33_ADAC

E21

AVDD33_AADC

D22

VMID_AADC

K19

AVSS33_CLN

GND

U201MT5507

AR0_ADAC

AL0_ADAC

AR1_ADAC

AL1_ADAC

AR2_ADAC

AL2_ADAC

ASPDIFI

ASPDIFO0

AOBCK

AOLRCK

AOMCLK

AOSDATA1

AOSDATA0

A25

C25

B26

A27

B25

A26

F21

AG27

AH28

AF27

AD26

AG28

AE27

AF28

AR2_ADAC

AL2_ADAC

C219 10U

GND

H1_ARC_O

SPDIF_OUT

I2S_BCLK

I2S_LRCK

I2S_MCLK

I2S_DATA

SOC-VEDIO

HDMI_CEC

(4)

U201MT5507

(2)

(2)

IFP

IFN

CORE_1V2

C220 0.1U

(3)

(3)

3V3

(2)

GND

IF_AGC

0.1UC218

TUNER_SCL

(2)

TUNER_SDA

(2)

(5)

(8)

(8)

(8)

(3)

(3)

(3)

AV1_V_IN-

AV1_V_IN+

(8)

D27

ADCINP_DEMOD

D28

ADCINN_DEMOD

E27

AVDD12_DEMOD

F15

IF_AGC

E14

RF_AGC

E15

OSCL1

D15

OSDA1

H27

CVBS_COM

H28

CVBS3P

J25

CVBS2P

G28

CVBS1P

G26

CVBS0P

G25

SIF_COM

HSYNC

VSYNC

RP

GP

BP

COM

SOG

VGA_SDA

VGA_SCL

COM1

PB1P

PR1P

Y1P

SOY1

COM0

PB0P

PR0P

Y0P

SOY0

VDACX_OUT

AVDD33_VIDEO_STB

AVSS33_XTAL

AVSS33_DEMOD

R27

R28

N26

N28

P28

N27

P27

T28

T27

M25

L28

L27

M26

N25

K26

K25

J26

K27

K28

G27

H23

J20

K20

AVOUT_V

3V3SB

C221 0.1U

GND

75R

GND

AVOUT_V

T

R210

CORE_1V2

CORE_1V2

GND

(4)

(4)

(4)

(4)

(4)

(4)

H1_HPD_CBUS

(4)

HDMI2_HPD

(4)

HDMI3_HPD

(4)

(4)

GND GND

AVDD33_HDMI

H1_SCL_IN

H2_SCL_IN

H3_SCL_IN

H1_SDA_IN

H2_SDA_IN

H3_SDA_IN

MHL_SENSE

C222 0.1U

3V3

5V

0.1UC223

SOC-HDMI

MT5507

C19

HDMI_CEC

C16

HDMI_0_SCL

D19

HDMI_1_SCL

U23

HDMI_2_SCL

D16

HDMI_0_SDA

G19

HDMI_1_SDA

U24

HDMI_2_SDA

E18

HDMI_0_PWR5V

E17

HDMI_0_HPD_CBUS

F19

HDMI_1_HPD

T22

HDMI_2_HPD

E16

MHL_SENSE

A14

AVDD12_HDMI

U26

AVDD12_HDMI1

G20

AVDD33_HDMI

Q201

RTR040N03

HDMI_0_RX_0

HDMI_0_RX_0B

HDMI_0_RX_1

HDMI_0_RX_1B

HDMI_0_RX_2

HDMI_0_RX_2B

HDMI_0_RX_C

HDMI_0_RX_CB

HDMI_1_RX_0

HDMI_1_RX_0B

HDMI_1_RX_1

HDMI_1_RX_1B

HDMI_1_RX_2

HDMI_1_RX_2B

HDMI_1_RX_C

HDMI_1_RX_CB

HDMI_2_RX_0

HDMI_2_RX_0B

HDMI_2_RX_1

HDMI_2_RX_1B

HDMI_2_RX_2

HDMI_2_RX_2B

HDMI_2_RX_C

HDMI_2_RX_CB

U201

A17

B17

A16

B16

A15

B15

C17

D17

A20

B20

A19

B19

C18

D18

C21

B21

W26

W25

V26

V25

V28

V27

Y28

Y27

MHL+/H1_RX0+

MHL-/H1_RX0-

H1_RX1+

H1_RX1-

H1_RX2+

H1_RX2-

H1_CLK+

H1_CLKH2_RX0+

H2_RX0-

H2_RX1+

H2_RX1-

H2_RX2+

H2_RX2-

H2_CLK+

H2_CLK-

H3_RX0+

H3_RX0-

H3_RX1+

H3_RX1-

H3_RX2+

H3_RX2-

H3_CLK+

H3_CLK-

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

When input is 12V reset vol:8.4V

R212

3K9

GND

AVDD33_HDMI

SOC RESET

MTK

Reset at low level

When input is 12V,reset time is 80ms

12V_M

R217

0R

C225

1U

GND

R213

33K

R214

100K

R215

8K2

Q202

E

BT3906

R216

47K

MCU_RESET

T

C226

0.1U

B

C

R218

3K3

NC/

Q203

BT3906

3V3SB

E

C