Taylor Freezer C302 Operation Manual

Slush Freezer

Model C302

Operating Instructions

059661-M

6/22/04 (Original Publication)

(Updated 9/1/10)

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Fax:

E-mail:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E June, 2004 Taylor (Original Publication)

(Updated September, 2010)

All rights reserved.

059661-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents

Section 1 To the Installer 1............................................

Air Cooled Units 1.......................................................

Water Cooled Refrigeration Units (Water Cooled Units Only) 1................

Electrical Connections 1.................................................

Section 2 To the Operator 3...........................................

Compressor Warranty Disclaimer 3.......................................

Section 3 Safety 4....................................................

Section 4 Operator Parts Identification 6...............................

Beater Door Assembly 7.................................................

Accessories 8..........................................................

Section 5 Important: To the Operator 9.................................

Control Switches 9......................................................

Liquid Crystal Displays 10.................................................

Operational Mode Displays 10.............................................

Operator Menu Display 10................................................

Syrup Out Indicator 15....................................................

CO2 Out Indicator 16.....................................................

Water Out Indicator 16....................................................

Audio Alarm Silencer 16..................................................

Product Light 16.........................................................

Sampling Valve 16.......................................................

Daily Procedures 16......................................................

Section 6 Operating Procedures 17.....................................

Assembly 17............................................................

Sanitizing 22............................................................

Priming/Brixing 24........................................................

120 Day Closing Procedure 27............................................

Draining Product From the Freezing Cylinders 27............................

Rinsing 28..............................................................

Cleaning 28.............................................................

Disassembly 29..........................................................

Brush Cleaning 30.......................................................

Table of Contents Model C302

Table of Contents - Page 2

Section 7 Important: Operator Checklist 31..............................

During Cleaning and Sanitizing 31.........................................

Troubleshooting Bacterial Count 31........................................

Regular Maintenance Checks 31...........................................

Winter Storage 32........................................................

Section 8 Troubleshooting Guide 33....................................

Section 9 Parts Replacement Schedule 35...............................

Section 10 Parts List 36.................................................

Wiring Diagrams 48......................................................

Note: Contin u ing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Table of Contents Model C302

Section 1 To the Installer

The C302 is designed for indoor use only.

DO NOT install the freezer in an area where

a water jet could be used. Failure to follow this

instruction may result in serious electrical shock.

Air Cooled Units

Air cooled units require a minimum of 3” (76 mm) of

air space both sides, 3” (76 mm) at the rear, and 12”

(305 mm) on the top of the unit. Minimum air

clearances must be met to assure adequate air flow

for optimum performance.

Water Cooled Refrigeration Units

(Water Cooled Units Only)

On the back of the unit, two additional 3/8” (9.5 mm)

F.P.T. water connections for condenser inlet and

outlet have been provided for easy hook-up. 3/8”

(9.5 mm) inside diameter water lines should be

connected to the machine. Flexible lines are

recommended if local codes permit. Failure to use

adequate size water lines may cause the unit to go

on high head pressure and shut down.

Depending on local water conditions, it may be

advisable to install a water strainer to prevent

foreign substances from clogging the automatic

water valve.

Water Connections

An adequate cold water supply must be provided

with a hand shut-off valve. On the back of the unit, a

3/8” (9.5 m m ) M.F.L. water connection has been

provided for easy hook-up. A flexible line is

recommended, if local codes permit. A minimum of

25 psi water pressure is required to avoid having the

unit cut out the low water pressure switch. A booster

pump must be provided if this pressure is not

available.

Note: Water lines beyond 200 ft. (61 m) require 1/2”

(13 mm) water lines.

INSTALL POTABLE WATER CONNECTION

WITH ADEQUATE BACK-FLOW

PROTECTION TO COMPLY WITH

APPLICABLE NATIONAL, STATE AND

LOCAL CODES.

It is always a good practice to have a filter system to

improve the quality of the water and to avoid

clogging the operating components.

IMPORTANT: The water filter (064422--SER) must

be thoroughly flushed with water before connecting it

to the machine. This removes any loose particles

present from the manufacture of the filter that could

clog the flow control. To flush the filter, connect the

inlet end of the filter to the water supply. Position the

outlet end of the filter over an empty pail. Open the

water supply. Allow water to flow through the filter

until the water exiting the filter is clear. Close the

water supply. Attach the outlet end of the filter to the

machine. Reopen the water supply.

DO NOT INSTALL A HAND SHUT-OFF VALVE ON

THE “OUT” LINE! Water cooled units are counter

flow and the water should flow in this order: First

through the automatic water valve. Second, through

the inlet located at the bottom of the condenser.

Third, through the outlet fitting located at the top of

the condenser toanopentrapdrain.

IMPORTANT: Water pressures are pre-set at the

factory. Do not adjust the water pressure.

Improper water adjustments may cause operation

discrepancies.

Model C302 To the Installer

1

Figure 1

071010

Electrical Connections

Each freezer requires one power supply. Check the

data label on the freezer for fuse, circuit ampacity

and electrical specifications. Refer to the wiring

diagram provided inside of the control box, for

proper power connections.

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. In all

other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

The purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

The NEC is a United States regulatory agency.

International users must follow local electrical codes.

Stationary appliances which are not equipped with a

power cord and a plug or other device to disconnect

the appliance from the power source must have an

all-pole disconnecting device with a contact gap of at

least 3 mm installed in the external installation.

This equipment is provided with a grounding lug

that is to be properly attached to the rear of the frame

by the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021 of

IEC 60417-1) on the removable panel and the frame.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

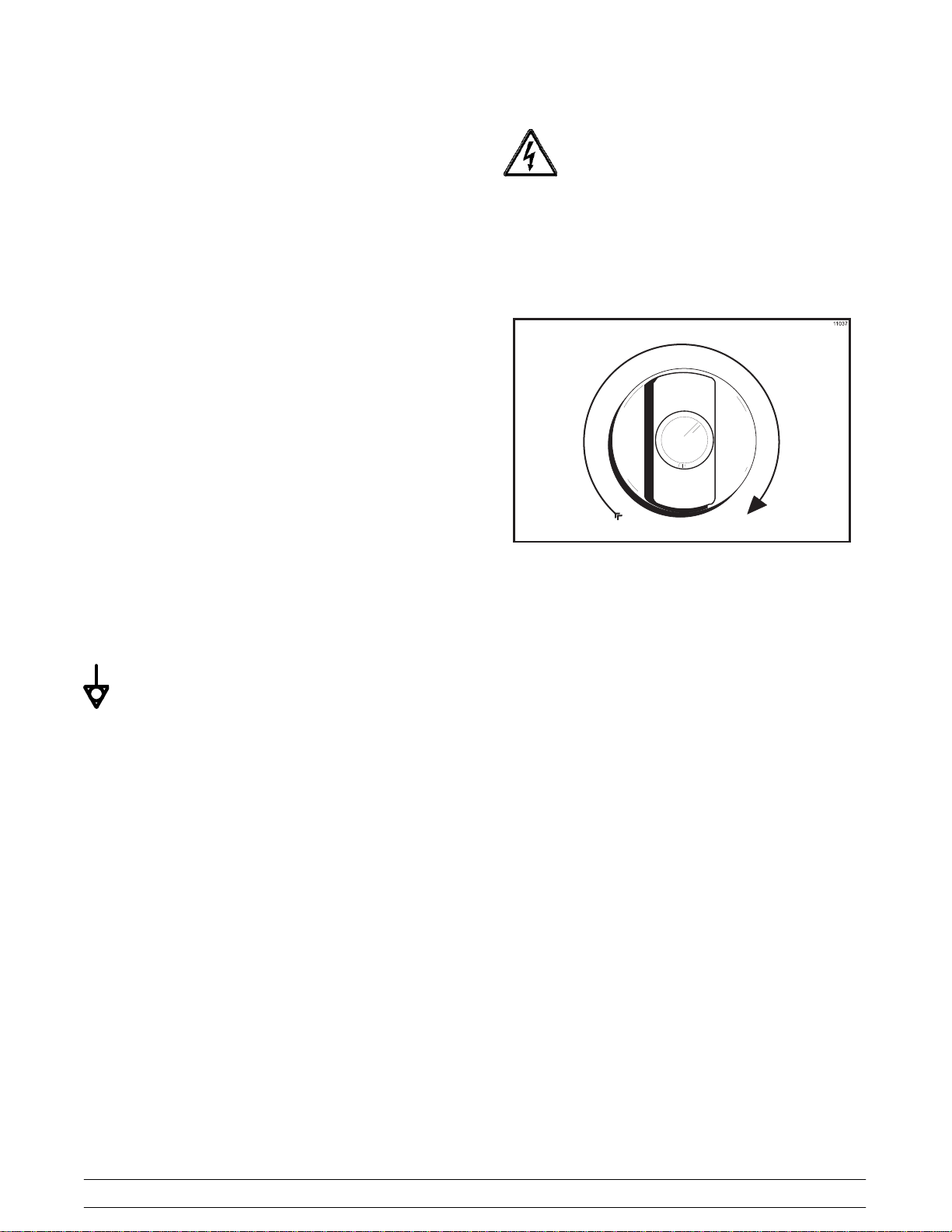

Beater rotation must be clockwise as viewed looking

into the freezing cylinder.

Figure 2

Note: The following procedures should be

performed by a trained service technician.

To correct the rotation on a three-phase unit,

interchange any two incoming power supply lines at

freezer main terminal block only.

To correct rotation on a single-phase unit, change

the leads inside the beater motor. (Follow the

diagram printed on the motor.)

080307

2

Model C302To the Installer

Section 2 To the Operator

The freezer you have purchased has been carefully

engineered and manufactured to give you

dependable operation.

The Model C302, when properly operated and cared

for, will produce a consistent quality product. Like all

mechanical products, this machine will require

cleaning and scheduled maintenance. A minimum

amount of care and attention is necessary if the

operating procedures outlined in this manual are

followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment.

Your freezer will NOT eventually compensate and

correct for any errors during the set-up or filling

operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly

recommended that all personnel responsible for the

equipment's operation study these procedures

together in order to be properly trained and to make

sure that no misunderstandings exist.

In the event you should require technical assistance,

please contact your local authorized Taylor

Distributor for service.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this machine are

warranted for the term indicated on the warranty

card accompanying this machine. However, due to

the Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed, thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop-in

replacements for numerous applications. It should

be noted that, in the event of ordinary service to this

machine's refrigeration system, only the refrigerant

specified on the affixed data label should be

used. The unauthorized use of alternate refrigerants

will void your compressor warranty. It will be the

owner's responsibility to make this fact known to any

technician he employs.

It should also be noted that Taylor does not warrant

the refrigerant used in its equipment. For example, if

the refrigerant is lost during the course of ordinary

service to this machine, Taylor has no obligation to

either supply or provide its replacement either at

billable or unbillable terms. Taylor does have the

obligation to recommend a suitable replacement if

the original refrigerant is banned, obsoleted, or no

longer available during the five year warranty of the

compressor.

Taylor will continue to monitor the industry and test

new alternates as they are being developed. Should

a new alternate prove, through our testing, that it

would be accepted as a drop-in replacement, then

the above disclaimer would become null and void.

To find out the current status of an alternate

refrigerant as it relates to your compressor warranty,

call the local Taylor Distributor or the Taylor Factory.

Be prepared to provide the Model/Serial Number of

the unit in question.

061211

Model C302 To the Operator

3

Section 3 Safety

We at Taylor are concerned about the safety of the

operator when he or she comes in contact with the

freezer and its parts. Taylor has gone to extreme

efforts to design and manufacture built-in safety

features to protect both you and the service

technician. As an example, warning labels have

been attached to the freezer to further point out

safety precautions to the operator.

IMPORTANT - Failure to adhere to the

following safety precautions may result in

severe personal injury or death. Failure to

comply with these warnings may damage the

machine and its components. Component

damage will result in part replacement expense

and service repair expense.

To Operate Safely:

DO NOT operate the freezer without reading this

operator's manual. Failure to follow this instruction

may result in equipment damage, poor freezer

performance, health hazards, or personal injury.

S DO NOT operate the freezer unless it is

properly grounded.

S DO NOT operate the freezer with larger

fuses than specified on the freezer data

label.

S DO NOT attempt any repairs unless the

main power supply to the freezer has been

disconnected.

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

Distributor for service.

S DO NOT allow untrained personnel to

operate this machine.

S DO NOT operate the freezer unless all

service panels and access doors are

restrained with screws.

S DO NOT remove the freezer door or beater

assembly unless the control switches are in

the “OFF” position.

Failure to follow these instructions may result in

severe personal injury from hazardous moving parts.

CAUTION: This unit is pressurized when

in operation. The control switch must be in the OFF

position until the unit is completely assembled. No

part should ever be removed from the machine while

it is in operation. No parts should be removed until

the control switch has been turned to the OFF

position and all pressure has been relieved by

opening the draw valve. Failure to follow this

instruction may result in severe personal injury from

hazardous moving parts or from the impact of

propelled parts.

S DO NOT put objects or fingers in door

spout. Failure to follow this instruction may

result in contaminated product or personal

injury from blade contact.

S USE EXTREME CAUTION when removing

the beater assembly. The scraper blades

are very sharp and may cause injury.

DO NOT use a water jet to clean or rinse

the freezer. Failure to follow these instructions may

result in serious electrical shock.

061211

This freezer must be placed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

4

Model C302Safety

DO NOT obstruct air intake and discharge openings:

Air cooled units require a minimum of 3” (76 mm) of

air space on both sides, 3” (76 mm) at the rear, and

12” (305 mm) on the top of the unit. Minimum air

clearances must be met to assure adequate air flow

for optimum performance.

This freezer is designed to operate indoors, under

normal ambient temperatures of 70°-75°F

(21°-24°C). The freezer has successfully performed

in high ambient temperatures of 104°F (40°C) at

reduced capacities.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

050209

Model C302 Safety

5

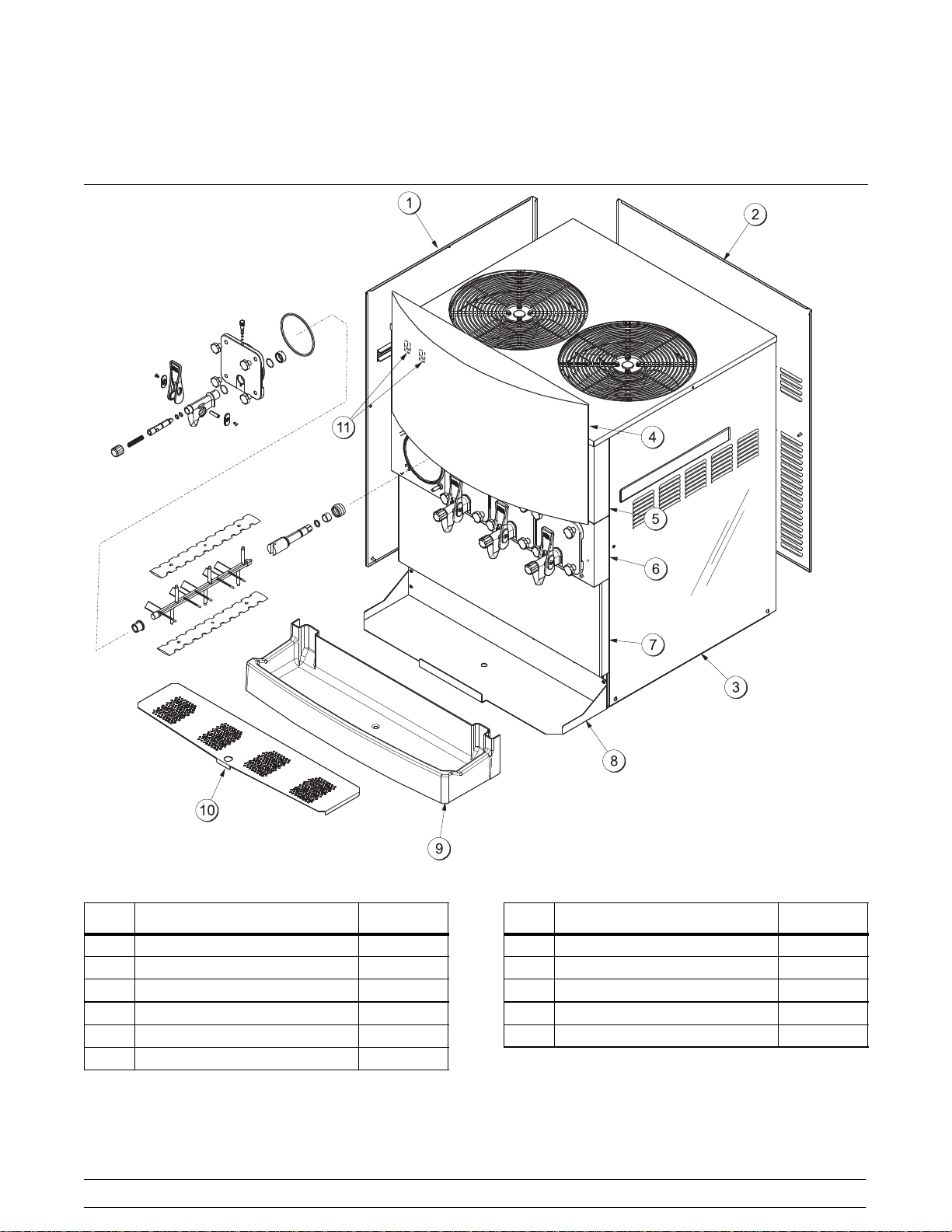

Section 4 Operator Parts Identification

ITEM DESCRIPTION PART NO.

1 PANEL-SIDE*LEFT 059721

2 PANEL-REAR 059657

3 PANEL-SIDE*RIGHT 059722

4 DISPLAY-LIGHTED 059584-27

5 PANEL-FRONT-UPPER 059577

6 PANEL-FRONT-SHELL 059576

Figure 3

6

ITEM DESCRIPTION PART NO.

7 PANEL-FRONT-LOWER 059652

8 SHELF-DRIP TRAY 059653

9 TRAY-DRIP 059654

10 SHIELD-SPLASH 059659

11 SWITCH-ROCKER SPST 059627

Model C302Operator Parts Identification

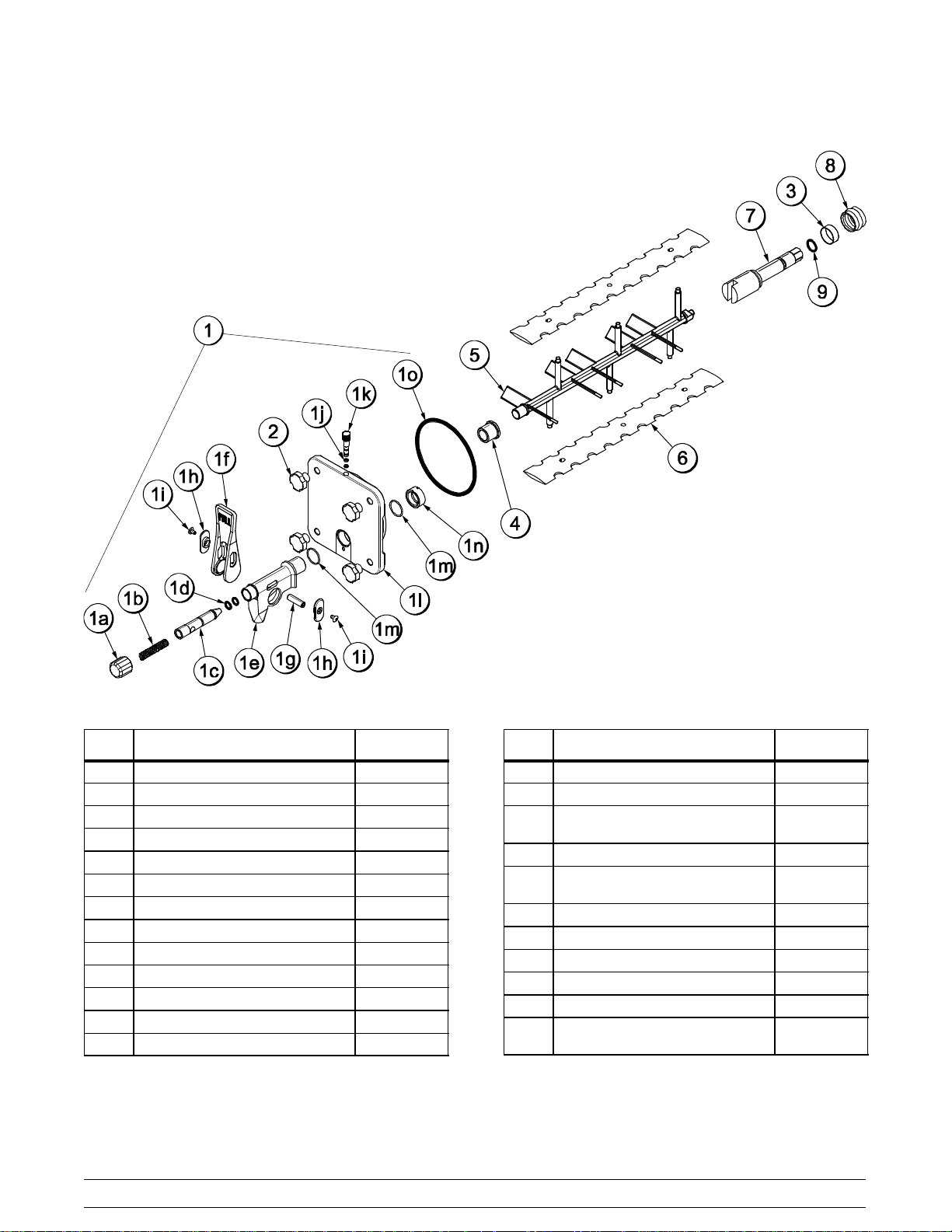

Beater Door Assembly

ITEM DESCRIPTION PART NO.

1 DOOR A.-SLUSH PRESS. X39572-BLA

1a CAP-SPOUT-DOOR-FCB-BLK 046191-BLA

1b SPRING-COMP.480X.072X3.0 039320

1c VALVE-DRAW-DOOR-PRESS. 039324

1d O-RING-9/16 OD X .103W 016369

1e SPOUT-DOOR-FCB-BLACK 046190-BLA

1f HANDLE-DRAW-FCB-BLACK 046192-BLA

1g PIN-PIVOT-SPOUT-DOOR 039321

1h SLIDE-HANDLE-DOOR-BLK 046193-BLA

1i SCREW-10-32X3/8PHL 053869

1j O-RING-9/32 OD X 1/16 WALL 029751

1k PLUG-PRIME-SLUSH-PRESS. 039568

1l DOOR-FREEZER-SLUSH-PRES 039573

Figure 4

ITEM DESCRIPTION PART NO.

1m O-RING-1.129 ODX.989ID 039219

1n NUT-SPOUT-DOOR-PRESS. 039323

1o O-RING-5-1/4ODX.210W

(DOOR)

2 NUT-STUD 043666

3 BUSHING-BEATER

SHAFT/BOOT SEAL

4 BEARING-FRONT-PRESSURE 039349

5 BEATER-PLASTIC-FCB-PRESS. 041182

6 BLADE-SCRAPER-FCB-16INCH 041103

7 SHAFT-BEATER-SLUSH-PRES 039337

8 SEAL-DRIVE SHAFT 032560

9 O-RING-7/8 OD X .139W

(BEATER SHAFT)

017003

042278

025307

100323

Model C302 Operator Parts Identification

7

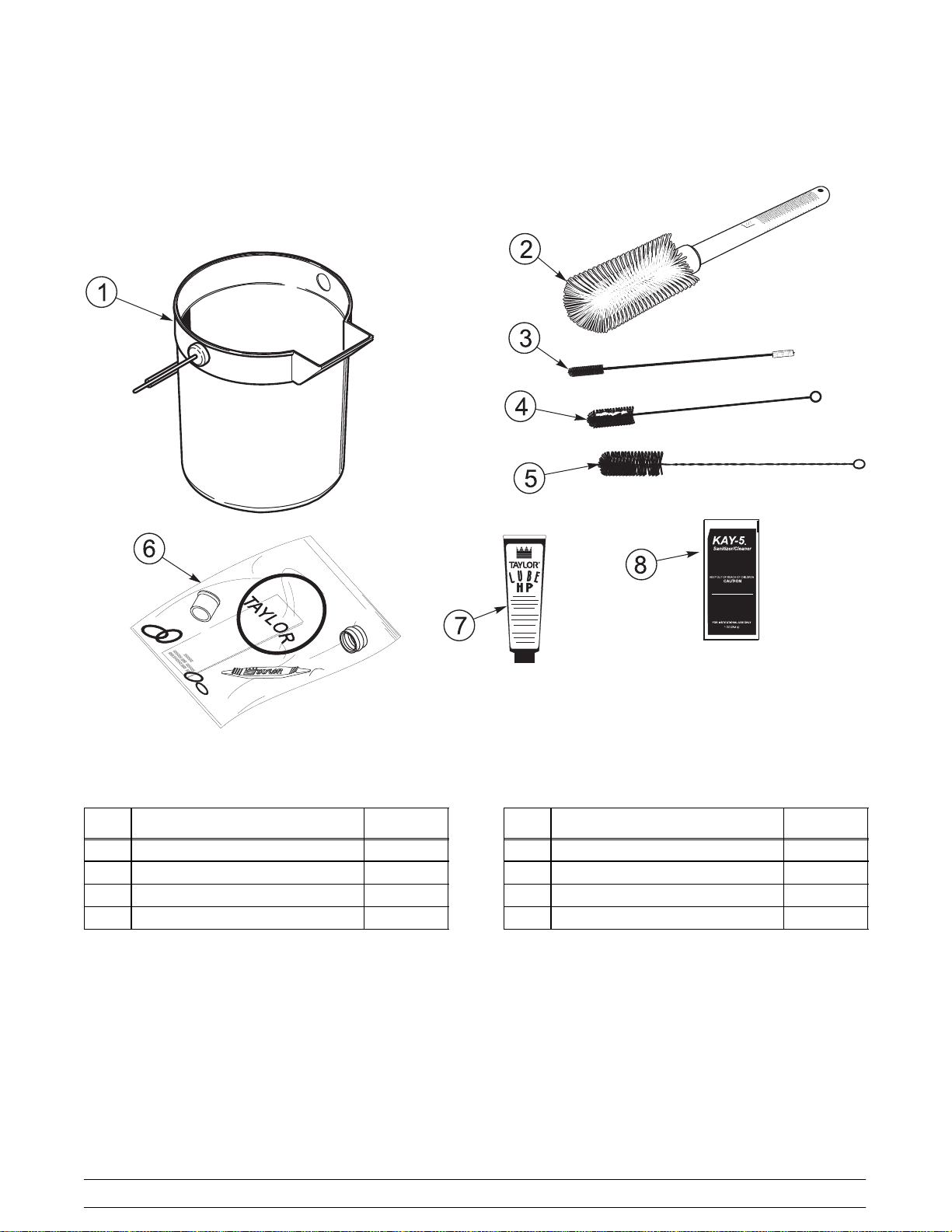

Accessories

ITEM DESCRIPTION PART NO.

1 PAIL-MIX 10 QT 013163

2 BRUSH-MIXPUMP BODY-3”X7” 023316

3 BRUSH-DOUBLE ENDED 013072

4 BRUSH-REAR BRG 1”DX2“L 013071

Figure 5

8

ITEM DESCRIPTION PART NO.

5 BRUSH-DRAW VALVE 1-1/2”OD 014753

6 KIT A.-TUNE UP X59121

7 LUBRICANT-TAYLORHI PERF 048232

8 SANITIZERKAY-5 125 PACKETS 041082

Model C302Operator Parts Identification

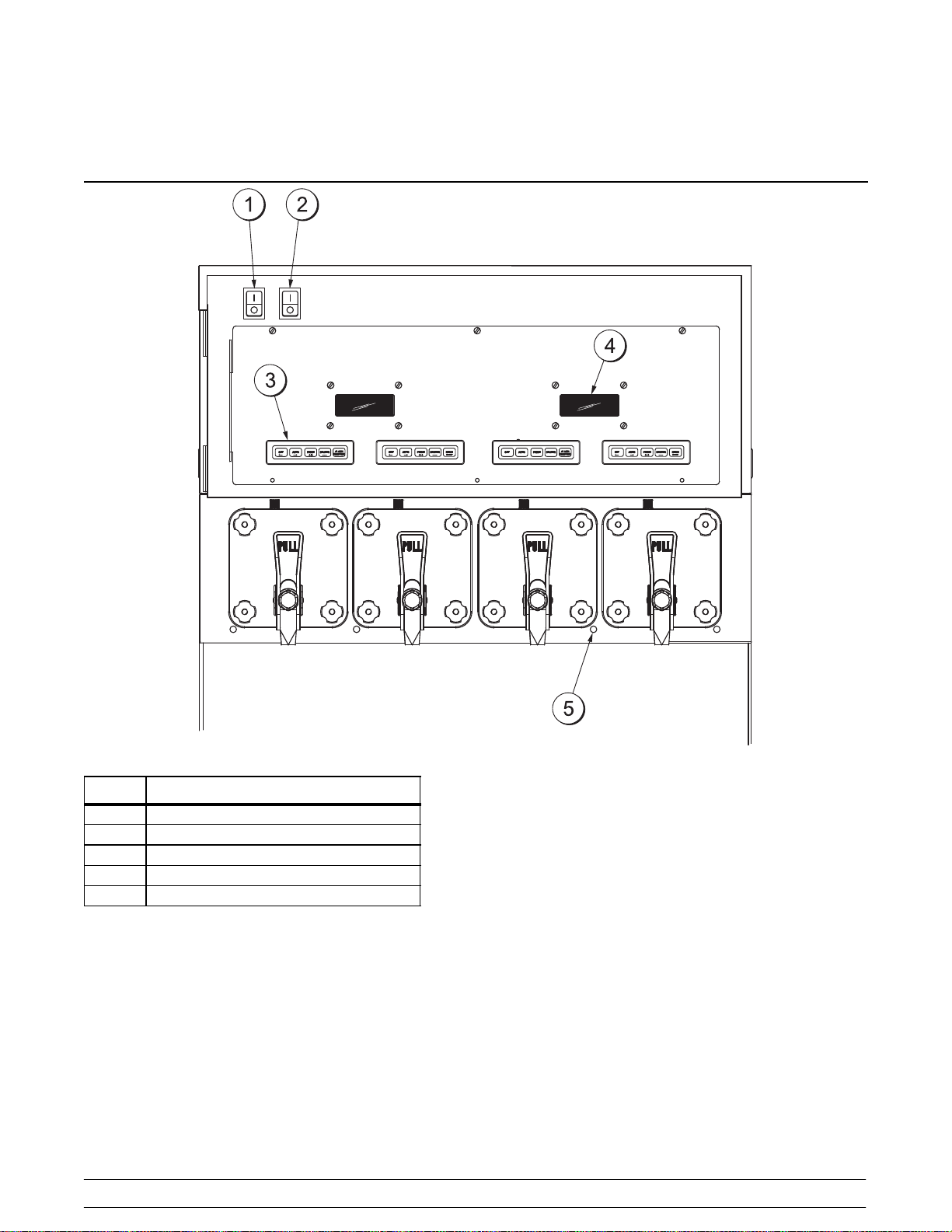

Section 5 Important: To the Operator

Figure 6

ITEM DESCRIPTION

1 CONTROL SWITCH-LEFT SIDE

2 CONTROL SWITCH-RIGHT SIDE

3 KEYPAD

4 LIQUID CRYSTAL DISPLAY

5 PRODUCT LIGHT

Model C302 Important: To the Operator

Control Switches

There are two control switches located at the top left

corner of the upper front panel, behind the

illuminated display. The left switch controls the two

freezing cylinders on the left side of the unit. The

right switch controls the two freezing cylinders on

the right side of the unit. When placed in the ON

position, these control switches allow SLUSHTECH

operation.

9

Liquid Crystal Displays

Pressing the A UTO (- -> ) keys for each freezing

cylinder will display this screen.

There are two Liquid Crystal Displays (LCD's)

located on the upper front panel behind the

illuminated display. The two LCD's display

information for the two freezing cylinders located

directly beneath them. These pairs of freezing

cylinders are each labeled “left” and “right” per LCD.

The LCD's show the current operating mode of the

freezing cylinders. They also indicate whether there

is enough syrup, CO2, and water being supplied to

the freezer. If an error in the machine operation

occurs, a warning tone will sound and the word

“FAULT” will flash on the third line of the display.

Operational Mode Displays

The screens below illustrate the operational mode

information displayed during normal operation. The

two LCD's display information corresponding to the

two freezing cylinders located directly beneath them.

These pairs of freezing cylinders are each labeled

“left” and “right” per LCD.

AUTO MODE AUTO

OK SYRUP OK

CO2-OK WATER-OK

Line 1 indicates the operating mode for each

freezing cylinder.

Line 2 indicates the status of the syrup systems in

each freezing cylinder. As long as syrup is available,

the word “OK” will appear on the LCD. When the

syrup supply is insufficient, the word “OUT” will flash

on the LCD. The same rules apply to the fourth line

which indicates the status of the CO

and the H2O.

2

The third line of this display is a fault indicator. If an

error in machine operation occurs, the word “FAULT

will be displayed on the LCD.

BEATER MODE BEATER

OUT SYRUP OUT

- -FAULT- - - -FAULT- CO2-OUT H2O-OUT

When the unit is plugged into the wall receptacle

and the control switch is in the ON position, this

screen appears.

SAFETY TIMEOUT

ANY KEY ABORT

This display will remain on the LCD for 60 seconds

unless a key is pressed. If any key is pressed (or 60

seconds passes) then the next screen appears.

OFF MODE OFF

OK SYRUP OK

CO2-OK WATER-OK

Note: Syrup, CO2and water are satisfied.

Note: Repeat all information and programming

procedures for each individual control from the left to

the right.

Operator Menu Display

The OPERATOR MENU is used to enter into the

operating screens. To access the OPERATOR

MENU, simply press the MENU (SEL) key. The

cursor will flash under the letter “A”, indicating that

this is screen A. To select a different screen, use the

AUTO (- ->) and OFF (<- -) keys t o move the cursor

to the desired screen selection and press the MENU

(SEL) key.

OPERATOR MENU

B C D E F G H I

A

EXIT MENU

<- - - -> SEL

10

Model C302Important: To the Operator

Operator Menu Timeout

If the display is left in the operator menu or any of

the operator menu selections, except for Current

Conditions, the display will return to the system

mode screen 60 seconds after the last keypress.

The Current Conditions screen will be displayed until

manually changed.

Finding Current Fault Conditions

Screen B is FAULT DESCRIPTION. The fault

description will indicate if there is a fault in one of the

freezing cylinders. When the actual fault is

corrected, the warning tone will stop. Only “BRL

NOT COO LING” requires pr es s ing the OFF (<- -)

key to clear the fault message and the warning tone.

Fault Messages

Beater Overload Beater is out on overload.

2. BEATER OVERLOAD - Beater motor is out on

overload. When this fault occurs, the affected

side of the machine automatically turns off. The

fault clears when the condition is corrected.

FAULT DESCRIPTION

L: BEATER OVERLOAD

R: BEATER OVERLOAD

CLR + + + SEL

3. CHK REFRIG SYS PSI - Compressor is out on

high head pressure. When this fault occurs, the

machine automatically turns off. The fault

clears when the condition is corrected.

Chk Refrig Sys Psi Out on compressor high

pressure cut-out.

Thermistor Short Shorted thermistor probe.

Thermistor Open Open thermistor probe.

H2O Pressure Low Water pressure is low.

CO2 Pressure Low CO2pressure is low.

Syrup Pressure Low Syrup is no longer present.

BRLTemp2High Freezing cylinder

temperature is above 120_F

(49_C).

BRL Not Cooling Freezing cylinder is not

cooling after 5 minutes.

No Fault Found No fault conditions are

apparent.

The following are explanations of the possible faults

and the display screens. Lines 2 and 3 indicate the

faults found in freezing cylinders 1 and 2

respectively.

1. NO FAULT FOUND - No fault conditions are

apparent.

FAULT DESCRIPTION

L: CHK REFRIG SYS PSI

R: CHK REFRIG SYS PSI

CLR + + + SEL

4. THERMISTOR SHORT - One or both of the

barrel (freezing cylinder) thermistor probes are

faulty.

FAULT DESCRIPTION

L: THERMISTOR SHORT

R: NO FAULT FOUND

CLR + + + SEL

5. THERMISTOR OPEN - One or both of the

barrel (freezing cylinder) thermistor probes are

faulty.

FAULT DESCRIPTION

L: NO FAULT FOUND

R: NO FAULT F OUND

CLR + + + SEL

Model C302 Important: To the Operator

11

FAULT DESCRIPTION

L: THERMISTOR OPEN

R: NO FAULT FOUND

CLR + + + SEL

060823

6. SYRUP PRESS LOW - When the syrup out

indicator displays a lack of syrup, the barrel will

enter a HOLD mode. At this time, no

refrigeration or product flow from the flow

control will be allowed. Only the beater will

operate. When the syrup is satisfied the barrel

will refill the product tank and then

automatically return to the AUTO mode. The

fault message and the warning tone will clear.

(See “Syrup Out Indicator ” on page 15.)

FAULT DESCRIPTION

L: NO FAULT FOUND

R: SYRUP PRESS LOW

CLR + + + SEL

7. CO2PRESSURE LOW - When the CO2out

indicator displays a lack of CO

internal timer will start. If the CO

, a 60 second

2

is not

2

replenished at the end of the 60 seconds, both

freezing cylinders will shut down and this fault

message will appear. Replenish the CO

2

and

the fault message and warning tone will clear.

9. BRL NOT COOLING - A freezing cylinder

check has been established for the AUTO

mode of operation. If a freezing cylinder enters

the AUTO mode, the control will check product

temperature. After five minutes, it will again

check product temperature. If product

temperature does not drop in that five minute

time span, the freezing cylinder will shut down

and this message will appear on the fault

screen. For this check to be valid, the product

temperature must be above 40_F(4.4_C).

FAULT DESCRIPTION

L: BARREL NOT COOLING

R: NO FAULT FOUND

CLR + + + SEL

10. BRL TEMP 2 HIGH - A maximum allowable

product temperature has been established to

prevent product from excessive heating. If the

product exceeds 120_F(49_C) temperature for

any reason (in any mode of operation), the

entire unit shuts down.

FAULT DESCRIPTION

L: CO2 PRESSURE LOW

R: CO2 PRESSURE LOW

CLR + + + SEL

8. H2O PRESSURE LOW - When the water out

indicator displays a lack of water, a 60 second

internal timer will start. If the water is not

replenished at the end of the 60 seconds, all

freezing cylinders will shut down and this fault

message will appear. Replenish the water and

the fault message and warning tone will clear.

FAULT DESCRIPTION

L: H2O PRESSURE LOW

R: H2O PRESSURE LOW

CLR + + + SEL

FAULT DESCRIPTION

L: BARREL TEMP 2 HIGH

R: NO FAULT FOUND

CLR + + + SEL

Faults, when corrected, are cleared from the fault

description screen, with the following exception: BRL

NOT COOLING. This fault requires the operator to

press the O FF (<- - ) key (when in the FAULT

DESCRIPTION screen) in order for the fault to

discontinue.

To see if there is more than one fault in either

freezing cylinder, press the P RIME (+ + +) key. To

return to the OPERATOR MENU, press the MENU

(SEL) key once. To return to the Main Screen, use

the AUTO (- ->) key to cycle to MENU ITEM A, t hen

press the MENU (SEL) key.

12

Model C302Important: To the Operator

Screen C is SET CLOCK. Use the AUTO (- ->) and

OFF (<- -) keys to place the curs or under the

element to be set (hours, minutes, month, day, or

year). Use the PRIME (+++) and BEAT ER (- - -)

keys to increment or decrement the value. Press the

MENU (SEL) key to advance to the Daylight Saving

Time screen.

Note: The clock is programmed with military time.

SET CLOCK

:30 2/25/04

14

<- - - -> + + + - - - SEL

Repeat the procedure for the right freezing cylinder

under each LCD.

MANUAL DEFROST

RIGHT SIDE YES

<- - - -> SEL

NO

Note: Only one freezing cylinder per LCD may be

placed in the DEFROST mode at a given time.

Attempting to place more than one freezing cylinder

into DEFROST will result in the following screen:

This screen will appear if an invalid date is entered.

(example: If the date entered exceeds the days of

that month.)

SET CLOCK

:30 02/31/04

14

INVALID DATE

SEL

This screen allows the Daylight Saving Time

options. If the Daylight Saving Time option is

enabled, then the time will be advanced by one hour

at 2:00 a.m. on the first Sunday in April, and will be

retarded by one hour at 2:00 a.m. on the last

Sunday in October.

DAYLIGHT SAVING TIME

ENABLE

<- - - -> SEL

DISABLE

Screen D is MANUAL DEFROST. This screen

allows the operator to manually defrost the left

freezing cylinders under each LCD.

ALREADY IN DEFROST

Press the MENU (SEL) key to return the unit to the

OPERATOR MENU.

Screen E is SYSTEM INFORMATION.Itconsists

of 6 display features.

The first feature indicates the software version.

SYSTEM INFORMATION

C300 CONTROL UVC2

VERSION 1.00

SEL

The second feature indicates the bill of material

number and the serial number.

It also indicates if the unit is equipped with a water

pressure switch.

B.O.M. C30227C000

S/N K0000000

WITH H20 PRESS SW

SEL

Place the cursor under YES, press the MENU (SEL)

key, and the command will be executed.

MANUAL DEFROST

LEFT SIDE YES

<- - - -> SEL

NO

Model C302 Important: To the Operator

The third feature indicates the version number of the

language and text.

SYSTEM INFORMATION

LANGUAGE

VERSION 1.09 ENGLISH 446

SEL

13

Loading...

Loading...