Taylor Freezer 8756P General Manual

Item No.

8756P

Soft Serve Freezer

Twin Twist, Horizon® Mix Delivery System

Features

Offer all the popular soft serve variations from low or nonfat ice creams to custards, yogurt and sorbet. Serve two

separate soft serve flavors, or an equal combination of both

in a twist. The Horizon® Mix Delivery System offers high

capacity in a pressurized system with consistent overrun and

simplified operation.

Freezing Cylinder

Two, 3.4 quart (3.2 liter).

Refrigerated Mix Storage Cabinet

Lower front mix cabinet is independently refrigerated to maintain mix below

41ºF (5ºC). Door is hinged on the right. Two, 9 gallon (34.1 liter) mix tanks.

The Horizon® Mix Delivery Systems deliver the precise amount of air and

mix to the freezing cylinder.

8756P

Indicator Lights

Mix Low light alerts the operator to add mix. When the Mix Out light flashes,

the unit shuts down automatically to prevent damage.

Electronic Controls

Finished product quality is monitored by SoftechTM controls that measure

viscosity.

Standby

During long no-use periods, the Standby feature maintains safe product

temperatures in the freezing cylinder.

Horizon® Mix Delivery System

Easy to clean and offers reliable overrun control. Simple overrun adjustment

from 25 to 70% (depending on mix formulation). Ability to dispense higher

butterfat or fruit products with pulp.

Two Locking Casters

Front casters have a locking feature for operators to lock to maintain

equipment in place. The locking casters can be released to move the

equipment for cleaning.

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

8756P Soft Serve Freezer

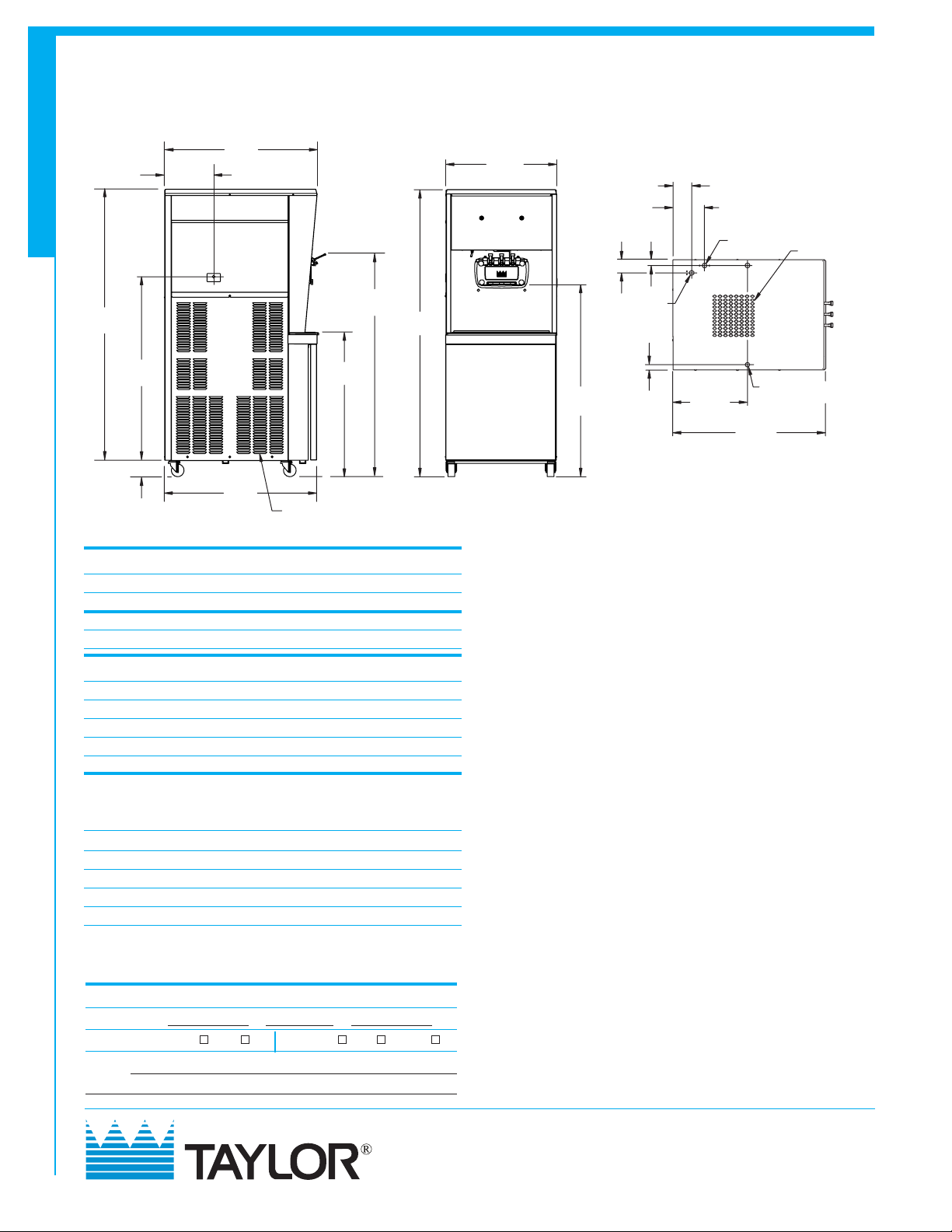

35-7/8

8756P

11-43/64

(296)

(911)

26-7/16

(672)

(76)

3

4-13/32

(112)

13/16

(21)

7-15/32

(190)

*1-1/8 (29) DIA

WATER IN

AIR OUT

53-5/16

34-1/4

(870)

(1354)

68-1/4

(1734)

64

(1626)

43-19/64

(1100)

4-1/4

(108)

36

(914)

AIR IN BOTH SIDES

Weights lbs. kgs.

Net 835 378.8

Crated 868 393.7

cu. ft. cu. m.

Volume 77.9 2.2

Dimensions in. mm.

Width 26-7/16 672

Depth 36 914

Height 68-1/4 1734

Floor Clearance 4-1/4 108

*Mounted on standard casters

Electrical Maximum Minimum Poles (P)

Fuse Size Circuit Ampacity Wires (W)

Left Right Left Right

208-230/60/1 Air 40 35 32 24 2P 3W

208-230/60/1 Water 40 35 29 24 2P 3W

208-230/60/3 Air 30 25 25 18 3P 4W

208-230/60/3 Water 30 25 23 18 3P 4W

380-415/50/3N~ Air 15 9 15 8 4P5W

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

*1-1/32 (26) HEX

WATER OUT

45-3/4

(1162)

13/16

(21)

NOTES:

1. FIGURES IN PARENTHESES INDICATE MILLIMETERS.

2. *FOR WATER COOLED UNITS ONLY.

17-23/32

(450)

1-1/16 (27)DIA

ELECTRIC HOLE

33-23/32

(856)

TOP VIEW - OPERATOR END

Specifications

Electrical

Two dedicated electrical connections are required. See the Electrical chart

for the proper electrical requirements. Manufactured to be permanently

connected. Consult your local Taylor distributor for cord & receptacle

specifications as local codes allow.

Beater Motor

Two, 1.5 HP.

Refrigeration System

Two, 9,500 BTU/hr. R404A

Mix Cabinet, 1,100 BTU/hr. R404A.

(BTUs may vary depending on compressor used.)

Air Cooled

Minimum 3” (76 mm) around all sides and 12” (305 mm) on top. Minimum

air clearances must be met to assure adequate air flow for optimum

performance.

Water Cooled

Water inlet and drain connections under side of base 1/2” FPT.

Options

• Cone Dispenser

• Draw Valve Lock Kit

• Sneeze Guard

• Syrup Rail Kit (side mount)

ALL CONNECTIONS LOCATED UNDERSIDE OF BASE

Bidding Specs

Electrical: Volt Hz ph

Neutral: Yes No Cooling: Air Water NA

Options:

Taylor Company,

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Continuing research results in steady improvements; therefore,

these specifications are subject to change without notice.

052318-ADV 11/11

Loading...

Loading...