Taylor Freezer 390 General Manual

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

390

Item No. _______________________________

390

Serve non-dairy frozen beverages, like smoothies or frozen

lemonade or cocktails, fruit juices, coffees, cappuccino and

tea. Pre-mix directly into a cup or blend flavors for more

variety.

Freezing Cylinder

One, 7 quart (6.6 liter).

Mix Hopper

One, 20 quart (18.9 liter). An adjustable setting in the refrigeration

system maintains mix temperatures in the hopper.

Indicator Lights

The Add Mix Light flashes to alert the operator to add mix. When

the Mix Out Light flashes, the unit shuts down to prevent damage.

Electronic Viscosity Control

Refrigeration is regulated by measuring product viscosity.

Adjustable control allows the operator to serve a wide variety of

frozen beverages at the desired thickness.

Continuous Auto Fill System (Optional)

Mix supply to the hopper can be replenished automatically from a

remote delivery system customized to suit your business by your

local Taylor distributor.

Features

Frozen Uncarbonated Beverage

(FUB) Freezer

Single Flavor

Standard 18

SA4632

390

390Frozen Uncarbonated Beverage (FUB) Freezer

Electrical

One dedicated electrical connection is required. See the Electrical chart for

the proper electrical requirements. Manufactured to be permanently

connected. Consult your local Taylor distributor for cord & receptacle

specifications as local codes allow.

Beater Motor

One, 1/2 HP

Refrigeration System

One, 7,500 BTU/hr. R404A.

(BTUs may vary depending on compressor used.)

Air Cooled

Minimum Clearance: 6” (152 mm) on both sides. Place the rear of the unit

against the wall to prevent recirculation of warm air. Minimum air clearances

must be met to assure adequate air flow for optimum performance.

Water Cooled

Water inlet and drain connections under side of base 3/8” FPT.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

Weights lbs. kgs.

Net 282 127.9

Crated 308 139.7

cu. ft. cu. m.

Volume 16.3 0.46

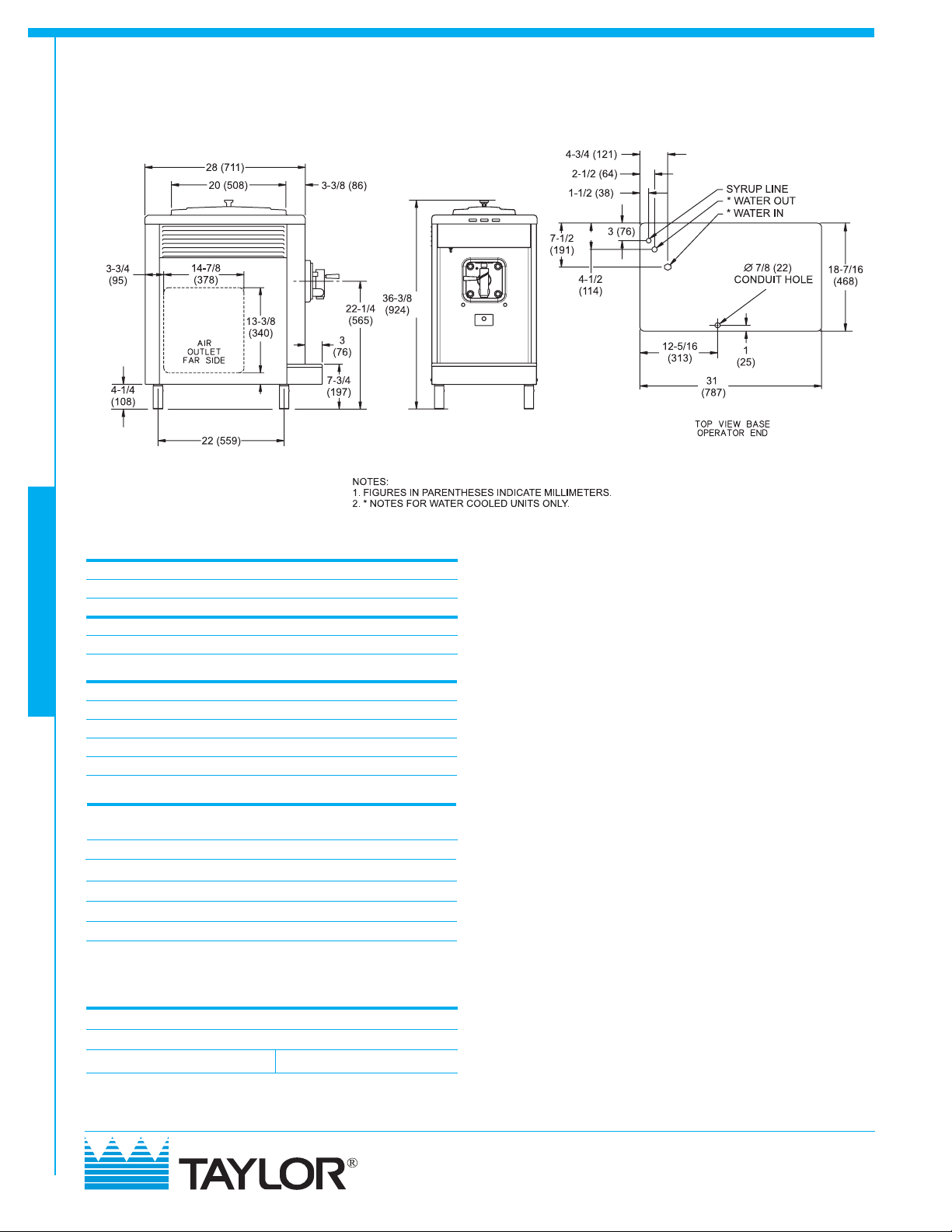

Dimensions in. mm.

Width 18-7/16 468

Depth 31 787

Height 36-3/8 924

Counter Clearance 4-1/4 108

*Mounted on standard legs

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

_________________________________________________________

Customized Mix Delivery System with Continuous Fill

Panel Spinner

Options

Specifications

047244-ADV

6/05

Continuing research results in steady improvements; therefore, these

specifications are subject to change without notice.

Electrical Maximum Minimum Poles (P)

Fuse Size Circuit Ampacity Wires (W)

208-230/60/1 Air 20 15 2P 3W

208-230/60/1 Water 20 14 2P 3W

208-230/60/3 Air 15 11 3P 4W

208-230/60/3 Water 15 10 3P 4W

220-240/50/1 Air 15 12 2P 3W

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Loading...

Loading...