Taylor Freezer 341 General Manual

Item No. _______________________________

341

Frozen Uncarbonated Beverage

(FUB) Freezer

Single Flavor

Features

Vary your m enu by offering smoothies or fr ozen cocktails,

fruit juices, coffees, cappuccino and tea slush beverages, all

served at the desired thickness.

Freezing Cylinder

One, 7 quart (6.6 liter).

Mix Hopper

One, 20 quart (18.9 liter). Optional refrigerated hopper approved

for dairy products.

Indicator Light

Add M ix light alerts the operator to add m ix.

Automatic Consistency Control

A specially designed viscosity control autom atically m aintains

superior pr oduct quality. Adjustable control allow s the operator to

serve a wide variety of frozen beverages at the desir ed thickness.

341

Standard 18

Rockton, Illinois 61072

800- 255-0626

Phone 815-624-8333 Fax 815-624-8000

www. taylor-company.com

e-m ail: info@taylor-com pany.com

SA4632

International Office

Taylor Com pany S.r.l.

Rom a, Italy

Tel: +39- 06-420-12002 Fax: +39-06-420-12034

e-m ail: rom eoff@taylor-company.com

341Frozen Uncarbonated Beverage (FUB) Freezer

Weights lbs. kgs.

Net 393 178.3

Crated 458 207.8

341

Volum e 35.4 0.99

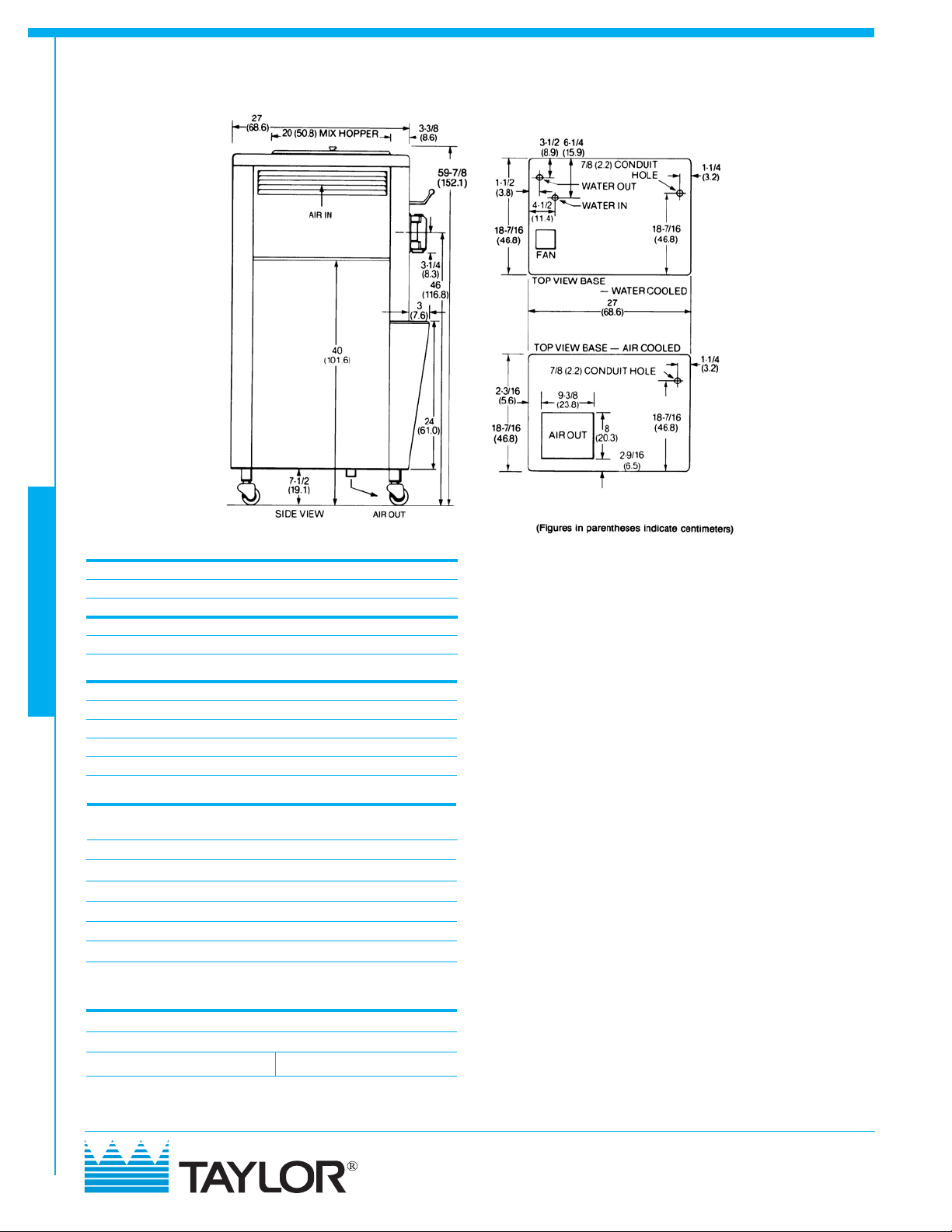

Dimensions in. mm.

Width 18-7/16 468

Depth 30 76 2

Height 59-7/8 1521

Floor Clearance 7-1/2 191

* Mounted o n standar d casters

Electrical M aximum Minimum Poles (P)

Fuse Size Circui t Ampacity Wires (W)

115/60/1 Air 40 29 2P 3W

115/60/1 Water 30 22 2P 3W

208-230/60/1 Air 20 16 2P 3W

208-230/60/3 Air 15 13 3P 4W

220-240/50/1 Air 15 13 2P 3W

380-415/50/3N~ Air 10 9 4P 5W

This unit m ay be m anufactured in other electr ical characterist ic s. Refer to t he

local Taylor Distr ibutor for availability.

(For exact electr ical inf or m ati on , always r efer to the data label of the u ni t.)

Bidding Specs

Electrical: Volt ______________ _____ Hz _________ _ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

________ _______________ _____________ ________________ _____

cu. ft . cu. m.

Specifications

Electrical

One dedicated electri cal connection is r equired. See t he Electr ical char t for

the pr op er electrical requirements. Manufactured to be per m anently

con nected. Consult your local Taylor distributo r fo r cord & receptacle

specificatio ns as local cod es allow.

Beater M otor

One, 1/4 HP

Refrigeration System

One, 7,500 BTU/hr. R404A.

(BTUs m ay var y depending on com pressor used.)

Air Cooled

Minim um 3” (76 m m ) around all si des. I nstall the deflect or p rovided to

prevent recircu lation of warm air. M inim um air clearances must be m et to

assure adequate air flow for optim um perform ance.

Water Cooled

Water inlet and drain connection s under side o f base 3/8” FPT.

Options

Available as Model 341D, w ith Refrigerated Hopper, 1/2 HP Beater

Motor, Beater cycle Timer. M aintains mix below 41ºF (5ºC).

Approved for dairy and non-dairy products.

Rem ote Auto Fill System

Soft Slush

Syr up Jars and Brackets

Continuing research re sults in steady i mprovements; the refore, these

specifi cati ons are subject to change without notice.

Taylor Company,

A Division of Carrier Com m ercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www. taylor-company.com

Printed in U.S.A.

026191-ADV

3/05

Loading...

Loading...