Taylor Freezer 20 General Manual

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

20

Item No. _______________________________

20

Specially designed for the medical profession to make soft

frozen saline or other preferred solution for regional

hypothermia for surgical or emergency procedures, and

transportation of transplant organs. This compact freezer is

self-contained and portable, easy to operate, and offers

continuous production of soft formable ice.

No additional support equipment is required. Stainless steel

basin meets standard hospital specifications. To operate,

pour heat transfer solution, with a freezing point below -35º F

(-37º C), in the outer basin. Add the desired amount of sterile

solution to the inner basin and press the control switch On.

When slush begins to form, simply scrape and stir the

solution. As slush is used, just replace with an equal volume

of sterile solution to continue freezing.

Inner Basin

6 liter volume. Easily removed for sterilization.

One Touch Control

Press the control switch to start refrigeration. A light indicates the

unit is freezing. Press the control switch again to terminate the

refrigeration process.

Scraper

Two scrapers are provided with each unit, to scrape the slush from

the basin wall and remove the slush from the basin. The scrapers

are made of a durable plastic, and may be gas sterilized or

autoclaved.

Easily Movable

Standard casters and hand grips allow the unit to be easily moved

into place. Two casters have locking devices to keep the unit in

place.

Features

Surgical Slush Freezer

Freezing Time

Pre-chilling heat

transfer and saline

solutions reduces

time to freeze.

T

Solution at 40º F

Solution at 65º F

10 20 30 40 50 60

ime i n m inutes

6

5

4

3

2

1

Liters of Frozen Solution

20

20Surgical Slush Freezer

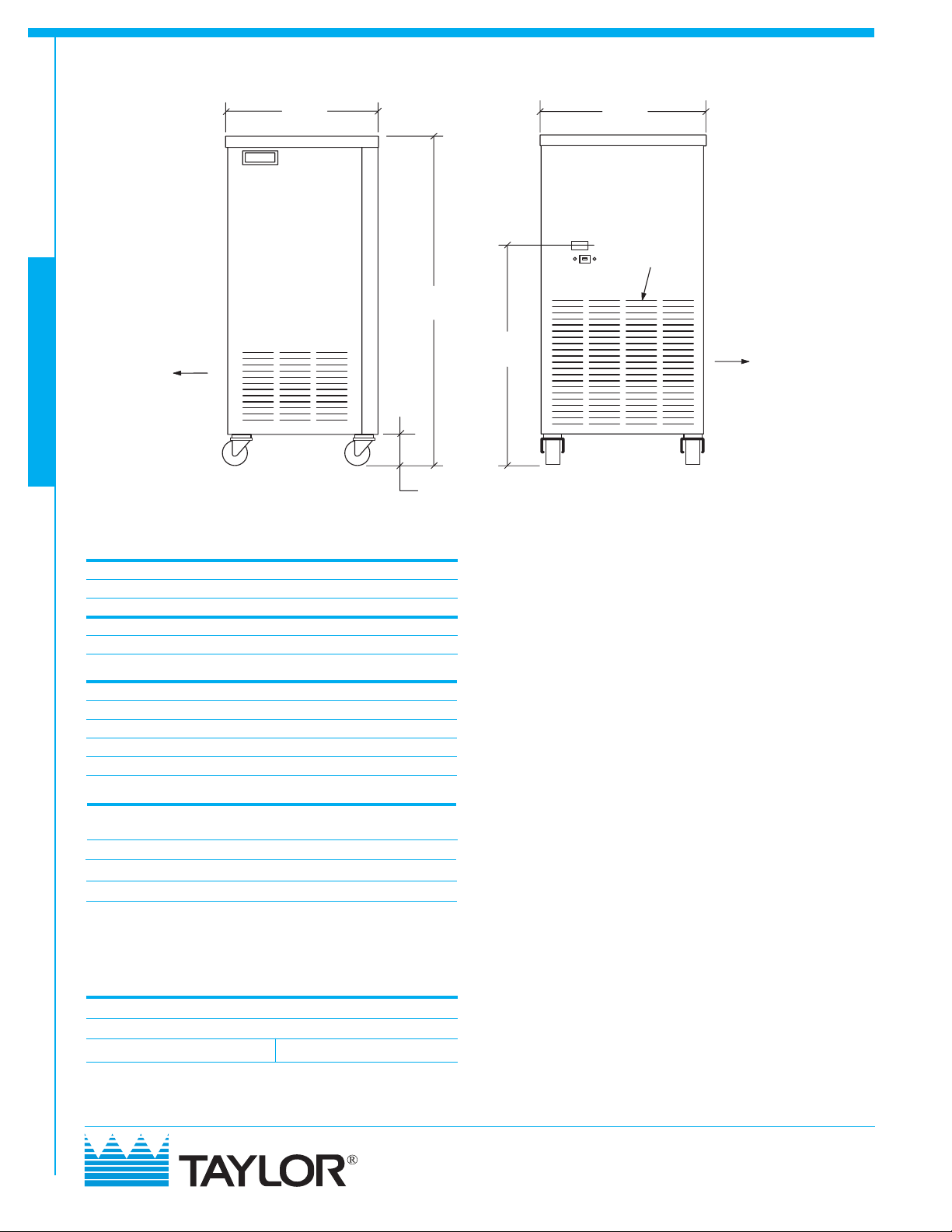

16-1/4

(413)

17-5/8

(448)

AIR IN

(FRONT)

AIR OUT

(RIGHT SIDE)

FIGURES IN PARENTHESES INDICATE MILLIMETERS.

36

(914)

23-3/4

(603)

3-3/4

(95)

AIR OUT

(REAR)

AIR OUT

(LEFT SIDE)

Electrical

One dedicated electrical connection is required. See the Electrical chart for

the proper electrical requirements. Manufactured to be cord connected.

Consult the international Taylor distributor for cord & receptacle specifications

for 50 Hz. equipment.

Refrigeration System

One, approximately 1,200 BTU/hr. R404A.

(BTUs may vary depending on compressor used.)

Air Cooled

Minimum clearance: 3” (76 mm) around all sides. Minimum air clearances

must be met to assure adequate air flow for optimum performance.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

Weights lbs. kgs.

Net 137 62.1

Crated 185 83.9

cu. ft. cu. m.

Volume 11.6 0.33

Dimensions in. mm.

Width 17-5/8 448

Depth 16-1/4 413

Height 36 914

Floor Clearance* 3-3/4 95

*Mounted on standard casters (two locking)

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

_________________________________________________________

Specifications

030899-ADV

8/06

Accessories

Removable Basin

Scraper

Sterile Drape

Electrical Total Supplied

115/60/1 Air 7.0 5-15P

208-230/60/1 Air 2.6 ---220-240/50/1 Air 1.39 ----

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Amps with NEMA Cord

Loading...

Loading...