Page 1

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

794

Item No.

_______________________________

794

Offer all the popular soft serve variations from low or non-fat

ice creams to custards, yogurt and sorbet. Serve two

separate soft serve flavors, or an equal combination of both

in a twist.

Freezing Cylinder

Two, 3.4 quart (3.2 liter).

Mix Hopper

Two, 14 quart (13.2 liter). Separate hopper refrigeration (SHR)

maintains mix below 41ºF (5ºC) during Auto and Standby modes.

Indicator Lights

Mix Low light alerts operator to add mix.

Electronic Controls

Softech tmis our exclusive microprocessor based master control that

regulates refrigeration by measuring product viscosity to maintain

consistent quality.

Standby

During long no-use periods, the standby feature maintains safe

product temperatures in the mix hopper and freezing cylinder.

Optional Drain Assembly

A drain assembly, less funnel, is provided to simplify the cleaning

process. A drain line, connected under the drip tray connects to a

1” FPT coupling in the base pan to drain rinse water directly into the

floor drain.

Features

Soft Serve Freezer

Twin Twist

Page 2

794

794Soft Serve Freezer

Electrical

Two dedicated electrical connections are required. See the Electrical chart for

the proper electrical requirements. Manufactured to be permanently

connected. Consult your local Taylor distributor for cord & receptacle

specifications as local codes allow.

Beater Motor

Two, 1.5 HP.

Refrigeration System

Two, 9,500 BTU/hr. R404A.

Separate Hopper Refrigeration (SHR), One, 400 BTU/hr. R134a.

(BTUs may vary depending on compressor used.)

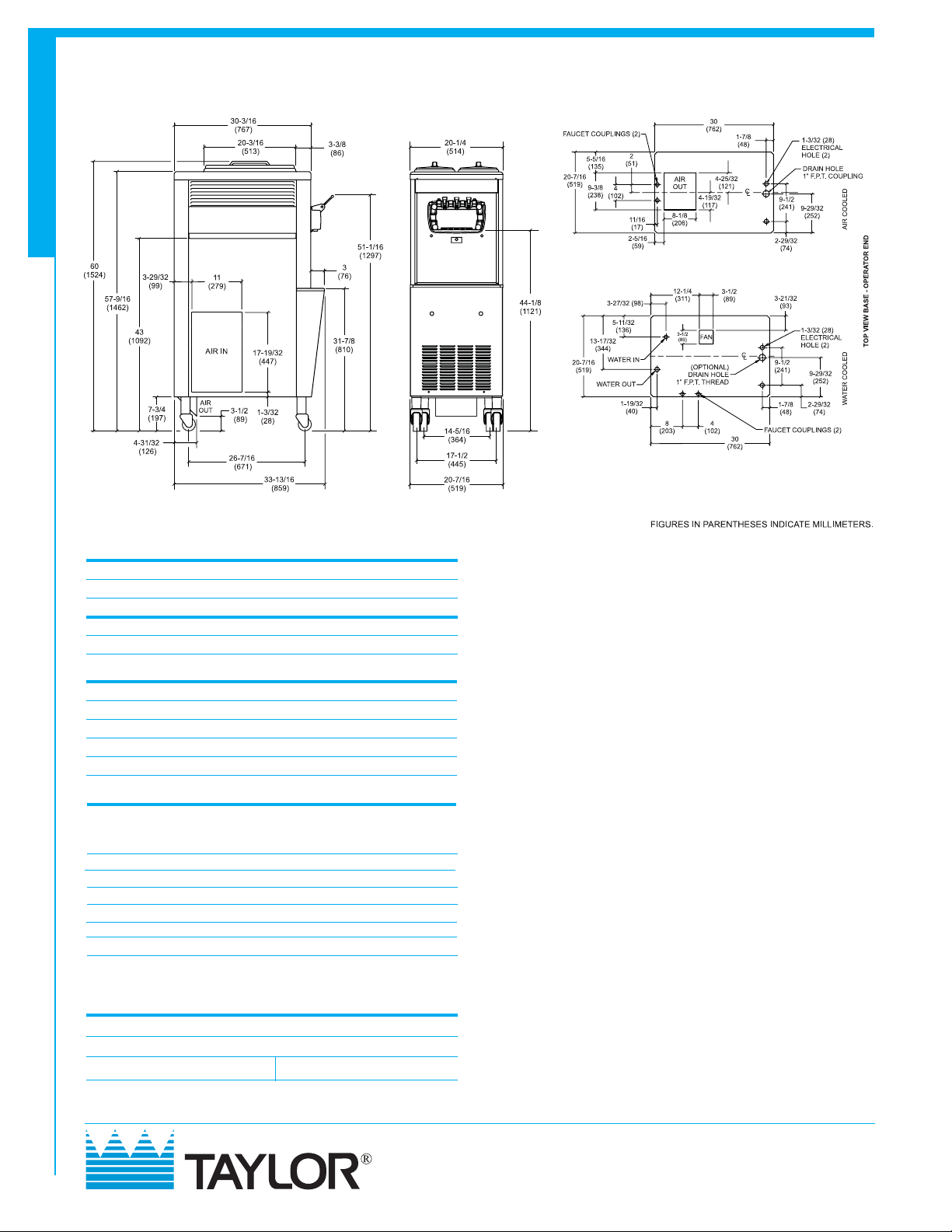

Air Cooled

Minimum 3” (76 mm) around all sides. Install the deflector provided to

prevent recirculation of warm air. Minimum air clearances must be met to

assure adequate air flow for optimum performance.

Water Cooled

Water inlet and drain connections under side of base 1/2” FPT.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

Weights lbs. kgs.

Net 610 276.7

Crated 675 306.2

cu. ft. cu. m.

Volume 48.2 1.346

Dimensions in. mm.

Width 20-7/16 516

Depth 33-13/16 859

Height 60 1524

Floor Clearance 8 203

*Mounted on standard casters

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

_________________________________________________________

Cone Dispenser

Drain with Funnel

Draw Valve Lock Kit

Faucet

Mix Low Chime

Sneeze Guard

Syrup Rail Kit (side mount)

Options

Specifications

044658-ADV

7/10

Continuing research results in steady improvements; therefore, these

specifications are subject to change without notice.

Electrical Maximum Minimum

Fuse Size Circuit Ampacity Poles (P)

Left Right Left Right Wires (W)

208-230/60/1 Air 35 35 27 23 2P 3W

208-230/60/1 Water 35 35 25 23 2P 3W

208-230/60/3 Air 25 20 19 15 3P 4W

208-230/60/3 Water 20 20 17 15 3P 4W

220-240/50/1 Air 30 25 23 19 2P 3W

380-415/50/3N~ Air 12 10 12 8 4P 5W

This unit may be manufactured in other electrical characteristics. Refer to the local

Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Loading...

Loading...