Page 1

Models 750/751/754/774/791/794

Soft Serve Freezers

Original Operating Instructions

028754--M

2/01/02 (Original Publication)

Updated 6/13/12

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E February, 2002 Taylor

All rights reserved.

028754--M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To the Installer 1............................................

Section 2 To the Operator 4...........................................

Compressor Warranty Disclaimer 4.......................................

Section 3 Safety 5....................................................

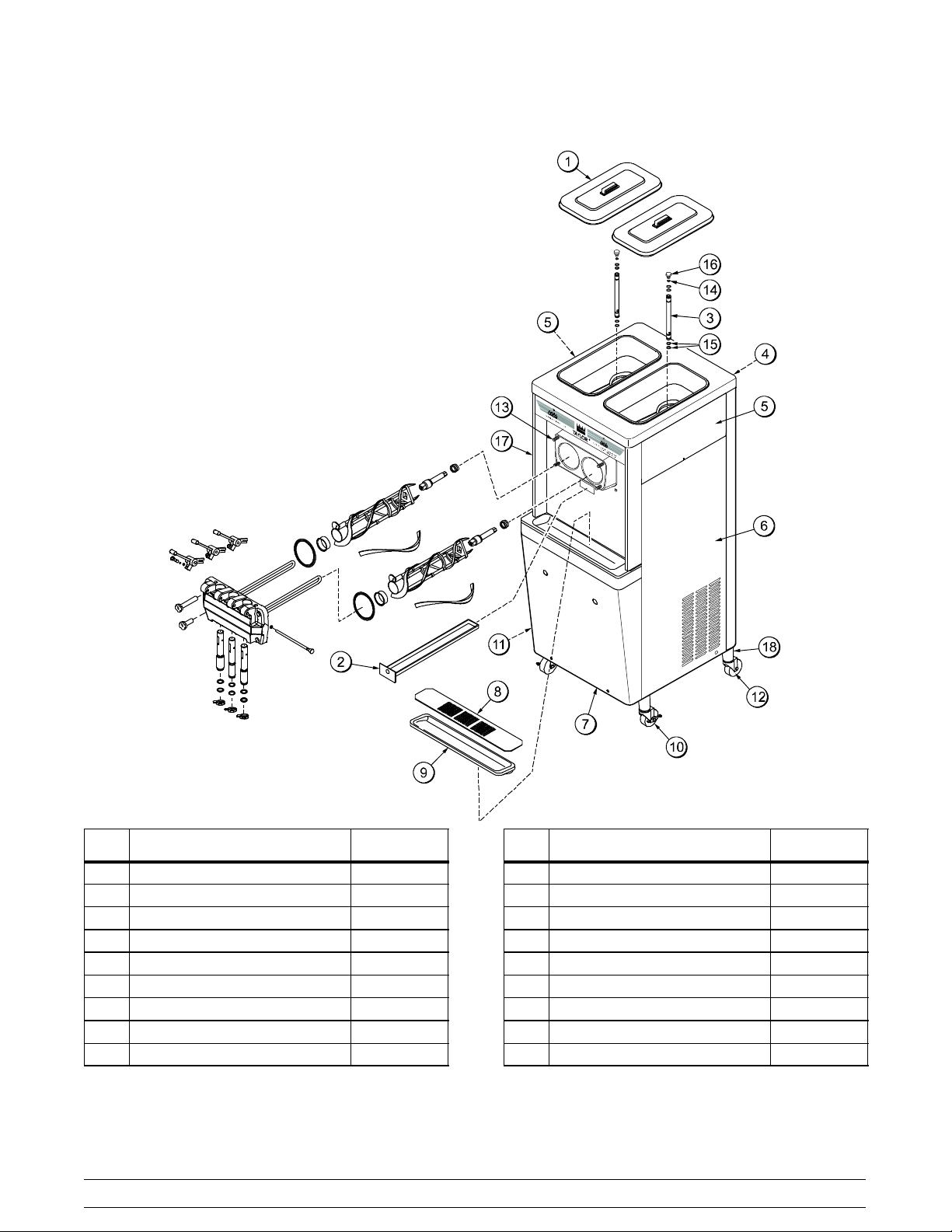

Section 4 Operator Parts Id en t ificatio n 7...............................

Model 750 7............................................................

Model 751 8............................................................

Model 754 9............................................................

Model 774 10............................................................

Model 774 Topping Pump (053794--) 11....................................

Model 791 12............................................................

Model 794 13............................................................

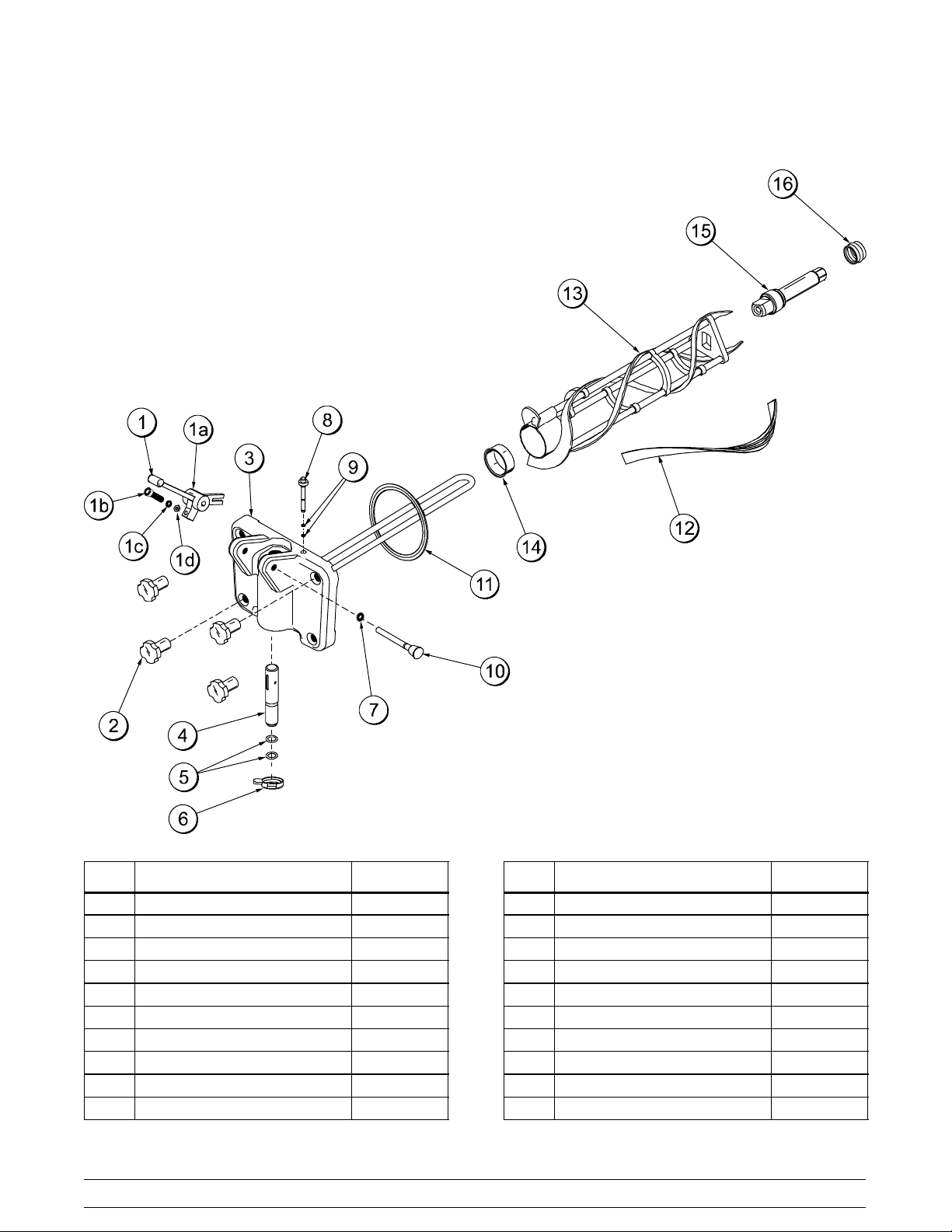

Models 750 & 751 Single Spout Door and Beater Assembly 14................

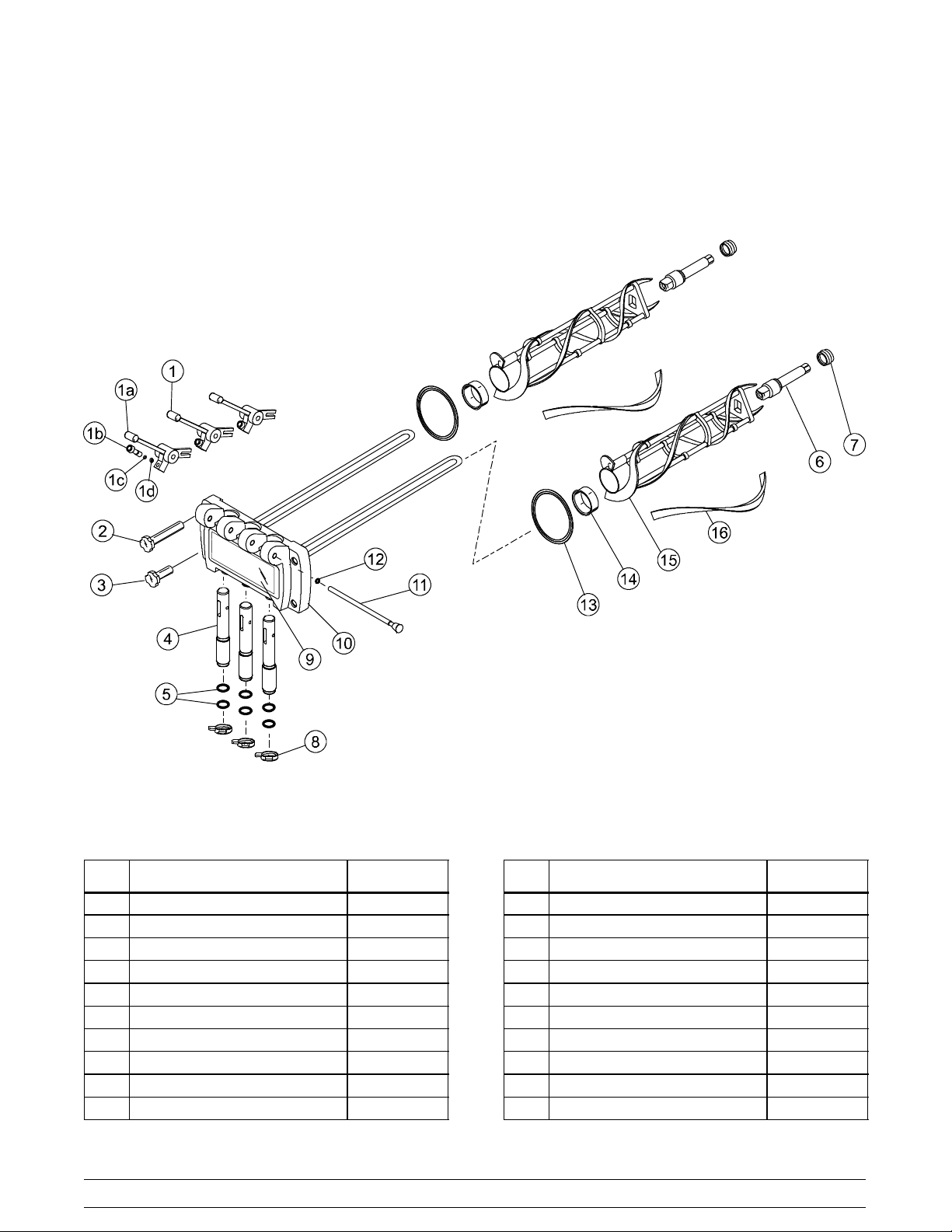

Models 754, 774 & 794 Three Spout Door and Beater Assembly 15............

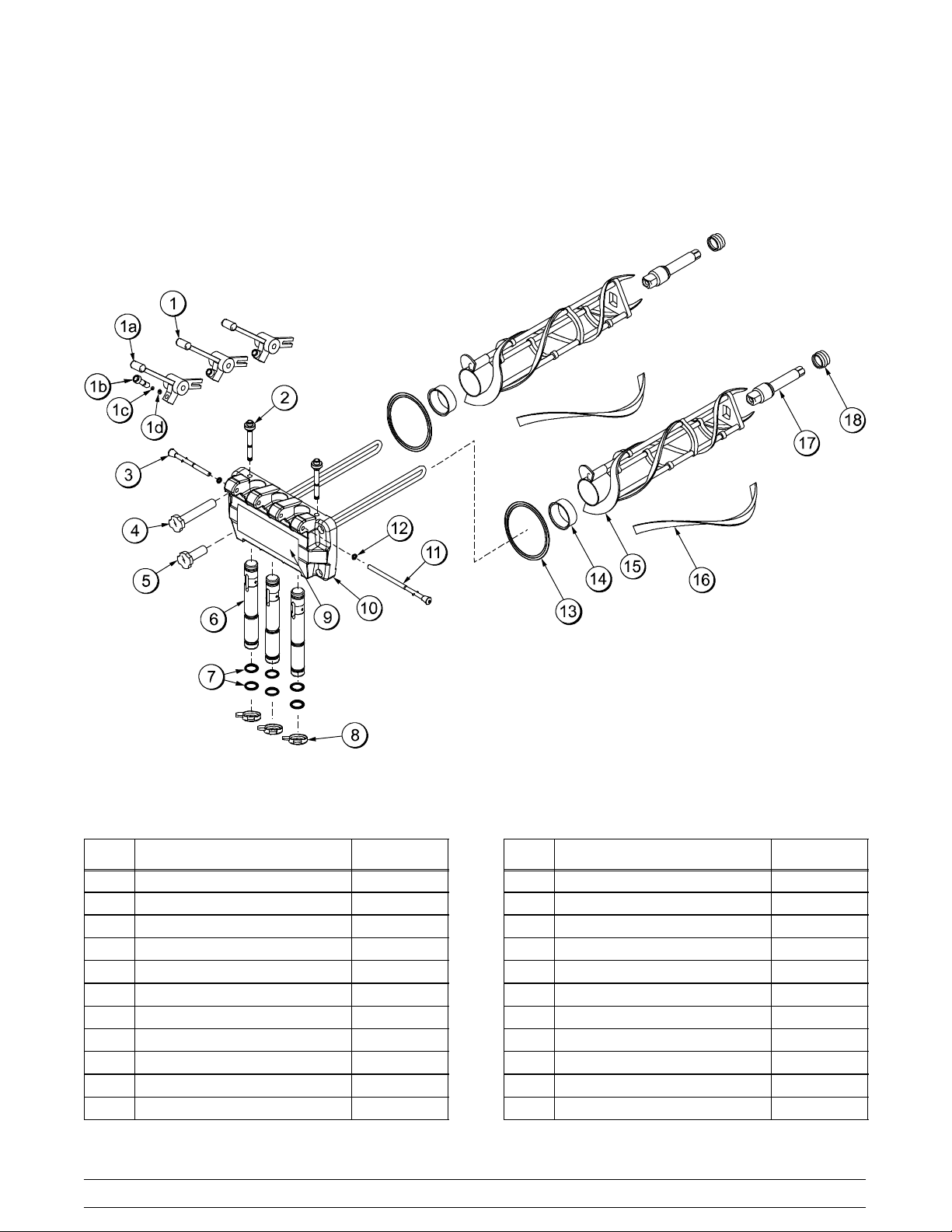

Model 791 Three Spout Door and Beater Assembly 16.......................

Accessories 17..........................................................

Section 5 Important: To the Operator 18.................................

Symbol Definitions 18....................................................

Power Switch 19.........................................................

MIX LOW Indicator Light 19...............................................

MIX REF Key 19.........................................................

STANDBY Key 19........................................................

WASH Key 19...........................................................

AUTO Key 19...........................................................

Reset Button 20.........................................................

Air Tube 20.............................................................

Adjustable Draw Handle 20...............................................

Section 6 Operating Procedures 21.....................................

Prior to Set--Up (Model 774) 21............................................

Assembly 21............................................................

Sanitizing 26............................................................

Priming 28..............................................................

Models 750, 751, 754, 774, 791, 794 Table of Contents

Page 4

Table of Contents -- Page 2

Closing Procedure 29....................................................

Draining Product From T he Freezing Cylinder 29............................

Rinsing 29..............................................................

Cleaning 29.............................................................

Disassembly 30..........................................................

Brush Cleaning 30.......................................................

Section 7 Important: Operator Checklist 31..............................

During Cleaning and Sanitizing 31.........................................

Troubleshooting Bacterial Count 31........................................

Regular Maintenance Checks 31...........................................

Winter Storage 32........................................................

Section 8 Troubleshooting Guide 33....................................

Section 9 Parts Replacement Schedule 36...............................

Section 10 Parts List 37.................................................

Wiring Diagrams 57......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of in structions.

E February, 2002 Taylor (Original Publication)

(Updated June, 2012)

All rights reserved.

028754--M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Table of Contents Models 750, 751, 754, 774, 791, 794

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 5

Section 1 To the Installer

The following are general installation instructions. For

complete installation details, please see the checkout

card.

Installer Safety

In all areas of the world, equipment should be

installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only authorized T aylor service personnel

should perform installation and repairs on the

equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and service.

S Authorized service personnel must remove all

metal jewelry, rings, and watches before

working on electrical equipment.

Site Preparation

Review the area the unit is to be installed in before

uncrating the unit making sure that all possible

hazards the user or equipment may come into have

been addressed.

Air Cooled Units

DO NOT obstruct air intake and discharge openings:

Counter Model: 6” (152 mm) minimum air space on

both sides and 0” on the rear.

Console Models: 3” (76 mm) minimum air space on

all sides.

This will allow for adequate air flow across the

condenser(s). Failure to allow adequate clearance can

reduce the refrigeration capacity of the freezer and

possibly cause permanent damage to the compressor.

For Indoor Use Only: This unit is designed to operate

indoors, under normal ambient temperatures of

70_-75_F(21_-24_C). The freezer has successfully

performed in high ambient temperatures of

104_(40_C) at reduced capacities.

This unit must NOT be installed in an area

where a water jet or hose can be used. NEVER use a

water jet or hose to rinse or clean the unit. Failure to

follow this instruction may result in electrocution.

The main power supply(ies) to the freezer

must be disconnected prior to performing any repairs.

Failure to follow this instruction may result in personal

injury or death from electrical shock or hazardous

moving parts as well as poor performance or damage

to the equipment.

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

This unit has many sharp edges that can

cause severe injuries.

Models 750, 751, 754, 774, 791, 794 To the Installer

to avoid the hazard of tipping. Extreme care should be

taken in moving this equipment for any reason. Two or

more persons are required to safely move this unit.

Failure to comply may result in personal injury or

equipment damage.

Uncrate the unit and inspect it for damage. Report any

damage to your Taylor Distributor.

This piece of equipment is made in the USA and has

USA sizes of hardware. All metric conversions are

approximate and vary in size.

1

This unit must be installed on a level surface

081208

Page 6

Water Connections

(Water Cooled Units Only)

An adequate cold water supply must be provided with

a hand shut--off valve. On the underside rear of the

base pan, two 3/8” I.P.S. (for single--head units) or two

1/2” I.P.S. (for double--head units) water connections

for inlet and outlet have been provided for easy

hook--up. 1/2” inside diameter water lines should be

connected to the machine. (Flexible lines are

recommended, if local codes permit.) Depending on

local water conditions, it may be advisable to install a

water strainer to prevent foreign substances from

clogging the automatic water valve. There will be only

one water “in” and one water “out” connection for both

single--head and double--head units. DO NOT install a

hand shut--off valve on the water “out” line! Water

should always flow in this order: first, through the

automatic water valve; second, through the

condenser; and third, through the outlet fitting to an

opentrapdrain.

A back flow prevention device is required

on the incoming water connection side. Please

refer to the applicable National, State, and local codes

for determining the proper configuration.

Each unit requires one power supply for each data

label on the unit. Check the data label(s) on the freezer

for branch circuit overcurrent protection or fuse, circuit

ampacity, and other electrical specifications. Refer to

the wiring diagram provided inside of the electrical box

for proper power connections.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

DO NOT operate this freezer with larger fuses

than specified on the unit data label. Failure to follow

this instruction may result in electrocution or damage

to the machine.

This unit is provided with an equipotential

grounding lug that is to be properly attached to the rear

of the frame by the authorized installer. The installation

location is marked by the equipotential bonding

symbol (5021 of IEC 60417-1) on both the removable

panel and the equipment’s frame.

Electrical Connections

In the United States, this equipment is intended to be

installed in accordance with the National Electrical

Code (NEC), ANSI/NFPA 70-1987. The purpose of the

NEC code is the practical safeguarding of persons and

property from hazards arising from the use of

electricity. This code contains provisions considered

necessary for safety. In all other areas of the world,

equipment should be installed in accordance with the

existing local codes. Please contact your local

authorities.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

Stationary appliances which are not equipped

with a power cord and a plug or another device to

disconnect the appliance from the power source must

have an all-pole disconnecting device with a contact

gap of at least 3 mm installed in the external

installation.

Appliances that are permanently connected to

fixed wiring and for which leakage currents may

exceed 10 mA, particularly when disconnected or not

used for long periods, or during initial installation, shall

have protective devices such as a GFI, to protect

against the leakage of current, installed by the

authorized personnel to the local codes.

101027

2

Models 750, 751, 754, 774, 791, 794To the Installer

Page 7

Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not lighter than

ordinary polychloroprene or other equivalent synthetic

elastomer-sheathed cord (Code designation 60245

IEC 57) installed with the proper cord anchorage to

relieve conductors from strain, including twisting, at

the terminals and protect the insulation of the

conductors from abrasion.

Refrigerant

In consideration of our environment, Taylor

proudly uses only earth friendly HFC refrigerants. The

HFC refrigerant used in this unit is R404A. This

refrigerant is generally considered non-toxic and

non-flammable, with an Ozone Depleting Potential

(ODP) of zero (0).

However, any gas under pressure is potentially

hazardous and must be handled with caution.

Beater Rotation

Beater rotation must be clockwise as viewed

looking into the freezing cylinder.

Note: The following procedures should be

performed by a trained service technician.

To correct the rotation on a three--phase unit,

interchange any two incoming power supply lines at

freezer main terminal block only.

To correct rotation on a single--phase unit, change the

leads inside the beater motor. (Follow the diagram

printedonthemotor.)

Electrical connections are made directly to the

terminal block provided in the main control box located

under the upper left side panel on the countertop unit,

or behind the service panel on the console units.

NEVER fill any refrigerant cylinder completely with

liquid. Filling the cylinder to approximately 80% will

allow for normal expansion.

Refrigerant liquid sprayed onto the skin may

cause serious damage to tissue. Keep eyes and skin

protected. If refrigerant burns should occur, flush

immediately with cold water. If burns are severe, apply

ice packs and contact a physician immediately.

Taylor reminds technicians to be cautious of

government laws regarding refrigerant recovery,

recycling, and reclaiming systems. If you have any

questions regarding these laws, please contact the

factory Service Department.

WARNING: R404A refrigerant used in

conjunction with polyolester oils is extremely moisture

absorbent. When opening a refrigeration system, the

maximum time the system is open must not exceed 15

minutes. Cap all open tubing to prevent humid air or

water from being absorbed by the oil.

080822

Models 750, 751, 754, 774, 791, 794 To the Installer

3

Page 8

Section 2 To the Operator

The freezer you have purchased has been carefully

engineered and manufactured to give you dependable

operation. The Taylor soft--serve models covered in

this manual consist of the following: 750, 751, 754,

774, 791, and 794.

These units, when properly operated and cared for, will

produce a consistent quality product. Like all

mechanical products, they will require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures

outlined in this manual are followed closely.

This Operator’s Manual should be read before

operating or performing any maintenance on your

equipment.

Your freezer will NOT eventually compensate and

correct for any errors during the set--up or filling

operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly

recommended that all personnel responsible for the

equipment’s operation study these procedures

together in order to be properly trained and to make

sure that no misunderstandings exist.

In the event you should require technical assistance,

please contact your local authorized Taylor Distributor.

Note: Warranty is valid only if the parts are authorized

Taylor parts, purchased from an authorized Taylor

Distributor, and the required service work is provided

by an authorized Taylor service technician. Taylor

reserves the right to deny warranty claims on

equipment or parts if non--approved parts or

refrigerant were installed in the machine, system

modifications were performed beyond factory

recommendations, or it is determined that the failure

was caused by neglect or abuse.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other similar

legislation in effect after August 13, 2005. Therefore,

it must be collected separately after its use is

completed, and cannot be disposed as unsorted

municipal waste.

The user is responsible for returning the product to the

appropriate collection facility, as specified by your local

code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or local

distributor.

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this machine are

warranted for the term indicated on the warranty card

accompanying this machine. However, due to the

Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed, thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop--in

replacements for numerous applications. It should be

noted that, in the event of ordinary service to this

machine’s refrigeration system, only the refrigerant

specified on the affixed datalabel should be used.

The unauthorized use of alternate refrigerants will void

your compressor warranty. It will be the owner’s

responsibility to make this fact known to any technician

he employs.

It should also be noted that Taylor does not warrant the

refrigerant used in its equipment. For example, if the

refrigerant is lost during the course of ordinary service

to this machine, Taylor has no obligation to either

supply or provide its replacement either at billable or

unbillable terms. Taylor does have the obligation to

recommend a suitable replacement if the original

refrigerant is banned, obsoleted, or no longer available

during the five year warranty of the compressor.

The Taylor Company will continue to monitor the

industry and test new alternates as they are being

developed. Should a new alternate prove, through our

testing, that it would be accepted as a drop-- in

replacement, then the above disclaimer would

become null and void. To find out the current status of

an alternate refrigerant as it relates to your

compressor warranty, call the local Taylor Distributor

or the Taylor Factory. Be prepared to provide the

Model/Serial Number of the unit in question.

080822

4

Models 750, 751, 754, 774, 791, 794To the Operator

Page 9

Section 3 Safety

We, at Taylor Company, are concerned about the

safety of the operator when he or she comes in contact

with the freezer and its parts. Taylor has gone to

extreme efforts to design and manufacture built--in

safety features to protect both you and the service

technician. As an example, warning labels have been

attached to the freezer to further point out safety

precautions to the operator.

IMPORTANT -- Failure to adhere to the

following safety precautions may result in severe

personal injury or death. Failure to comply with

these warnings may damage the machine and its

components. Component damage will result in

part replacement expense and service repair

expense.

DO NOT operate the freezer without reading

this Operator Manual. Failure to follow this instruction

may result in equipment damage, poor freezer

performance, health hazards, or personal injury.

Per IEC 60335--1 and its part 2 standards,

“This appliance is to be used only by trained personnel.

It is not intended for use by children or people with

reduced physical, sensory, or mental capabilities, or

lack of experience and knowledge, unless given

supervision or instruction concerning the use of the

appliance by a person responsible for their safety.”

This unit is provided with an equipotential

grounding lug that is to be properly attached to the rear

of the frame by the authorized installer. The installation

location is marked by the equipotential bonding

symbol (5021 of IEC 60417-1) on both the removable

panel and the equipment’s frame.

S DO NOT operate the freezer unless it is

properly grounded.

S DO NOT operate the freezer with larger fuses

than specified on the freezer data label.

S All repairs must be performed by an

authorized Taylor service technician. The

main power supplies to the machine must be

disconnected prior to performing any repairs.

S Cord Connected Units: Only Taylor authorized

service technicians may install a plug on this

unit.

S Stationary appliances which are not equipped

with a power cord and a plug or another device

to disconnect the appliance from the power

source must have an all-pole disconnecting

device with a contact gap of at least 3 mm

installed in the external installation.

S Appliances that are permanently connected to

fixed wiring and for which leakage currents

may exceed 10 mA, particularly when

disconnected or not used for long periods, or

during initial installation, shall have protective

devices such as a GFI, to protect against the

leakage of current, installed by the authorized

personnel to the local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord

(Code designation 60245 IEC 57) installed

with the proper cord anchorage to relieve

conductors from strain, including twisting, at

the terminals and protect the insulation of the

conductors from abrasion.

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

Distributor for service.

DO NOT use a water jet to clean or rinse the

freezer. Failure to follow these instructions may result

in serious electrical shock.

101208

Models 750, 751, 754, 774, 791, 794 Safety

5

Page 10

S DO NOT allow untrained personnel to operate

this machine.

S DO NOT put objects or fingers in door spout.

S DO NOT operate the freezer unless all service

panels and access doors are restrained with

screws.

S DO NOT remove any internal operating parts

(example: freezer door , beater, scraper

blades, etc.) unless all control switches are in

the OFF position.

Failure to follow these instructions may result in

contaminated product or severe personal injury to

fingers or hands from hazardous moving parts.

This unit has many sharp edges that can

cause severe injuries.

S DO NOT put objects or fingers in the door

spout. This may contaminate the product and

cause severe personal injury from blade

contact.

S USE EXTREME CAUTION when removing

the beater asssembly. The scraper blades are

very sharp.

Failure to follow these instructions may result in

electrocution or damage to the machine. Contact your

local authorized Taylor Distributor for service.

Cleaning and sanitizing schedules are

governed by your state or local regulatory agencies

and must be followed accordingly. Please refer to the

cleaning section of this manual for the proper

procedure to clean this unit.

DO NOT obstruct air intake and discharge openings:

Counter Model: 6” (152 mm) minimum air space on

both sides and 0” on the rear.

Console Models: 3” (76 mm) minimum air space on

all sides.

Failure to follow this instruction may cause poor

freezer performance and damage to the machine.

These freezers are designed to operate indoors, under

normal ambient temperatures of 70_-- 7 5 _F

(21_-- 2 4 _C). The freezers have successfully

performed in high ambient temperatures of 104_F

(40_C) at reduced capacities.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of 1.0

meter from the surface of the machine and at a height

of 1.6 meters from the floor.

This freezer must be placed on a level

surface. Failure to comply may result in personal injury

or equipment damage.

6

Models 750, 751, 754, 774, 791, 794Safety

Page 11

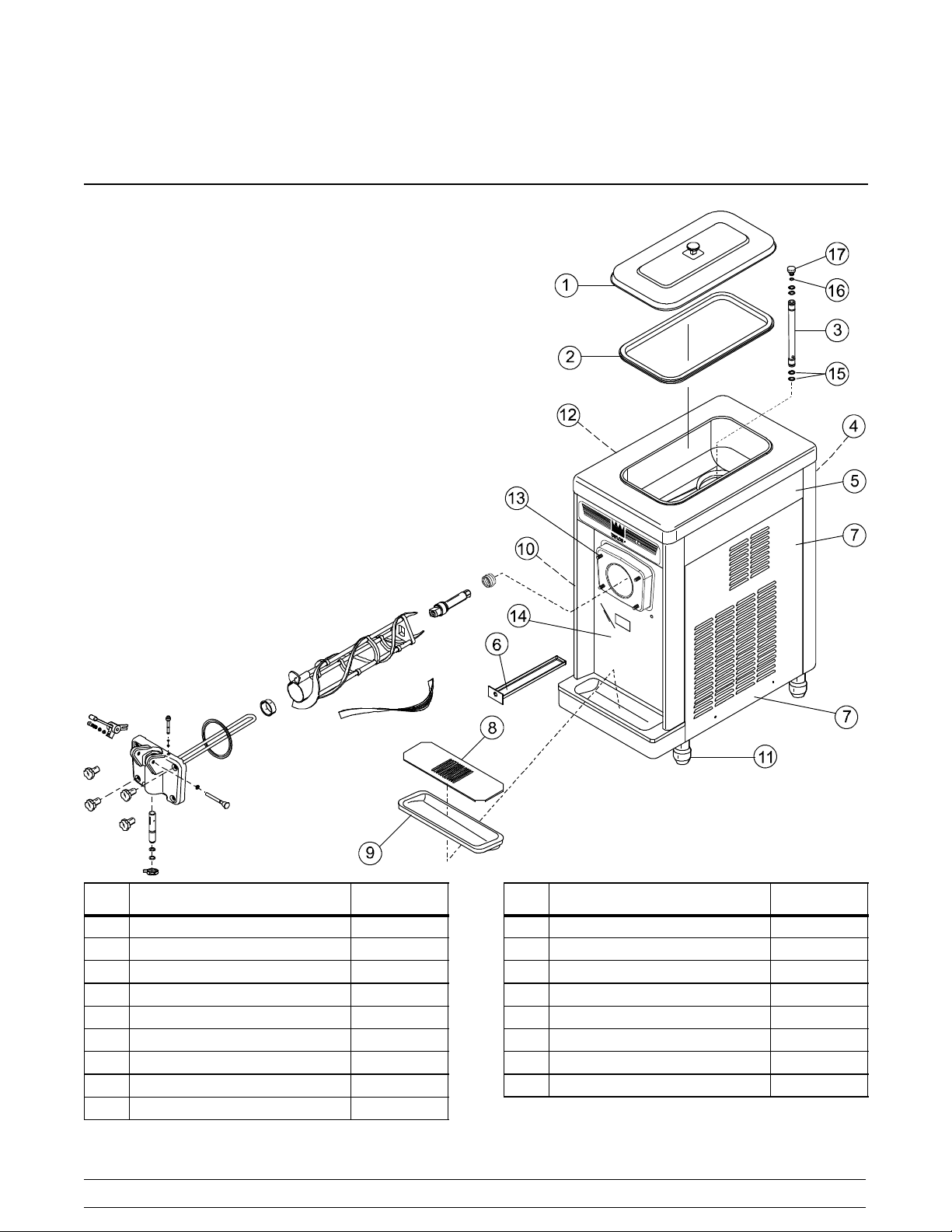

Section 4 Operator Parts I dentification

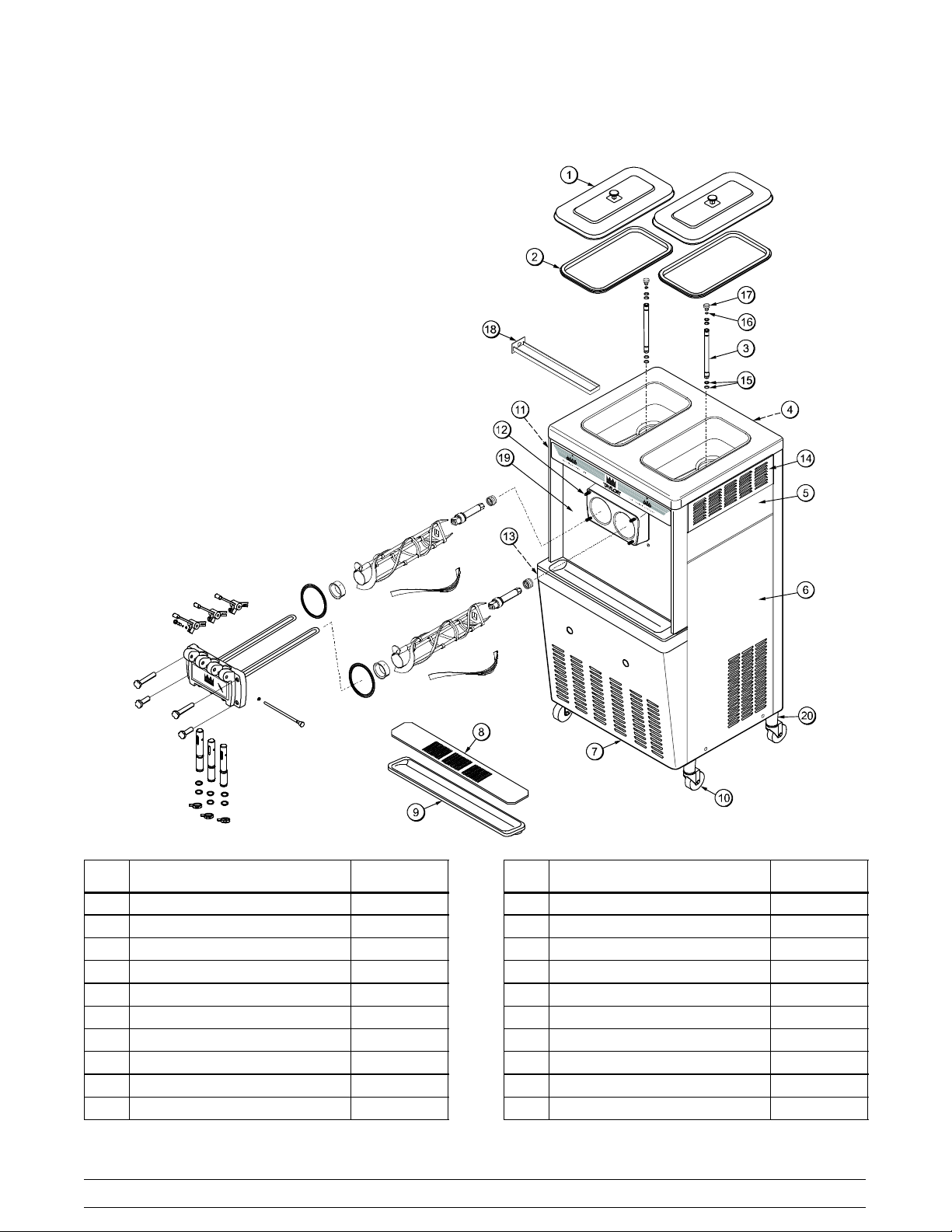

Model 750

Item Description Part No.

1 Cover A.--Hopper X38458--SER

2 Gasket--Hopper Cover 038375

3 Tube A.--Feed X29429--2

4 Panel--Rear 020891

5 Panel--Upper Side Right 042317

6 Pan--Drip 050766

7 Panel--Right Side 050742

8 Shield--Splash 022763

9 Tray--Drip 013690

Item Description Part No.

10 Panel--Side Left 050741

11 Leg--4” SS w/O--Ring 013458

12 Louver--Side 051192

13 Stud--Nose Cone 022822

14 Panel A.--Front X50754

15 O--Ring--.643 OD x .077 W 018572

16 O--Ring--3/8 OD x .070 W 016137

17 Orifice 022465--100

101217

Models 750, 751, 754, 774, 791, 794 Operator Parts Identification

7

Page 12

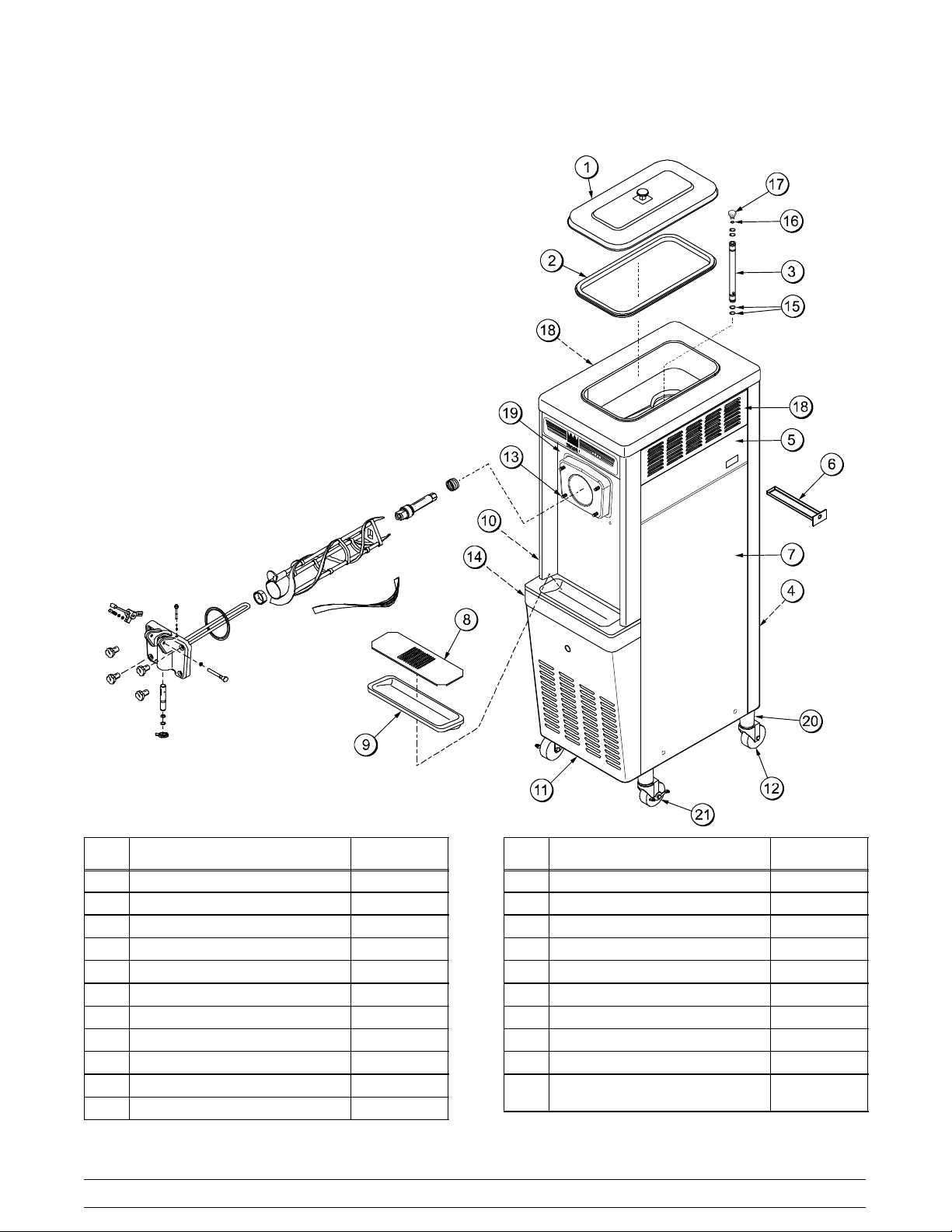

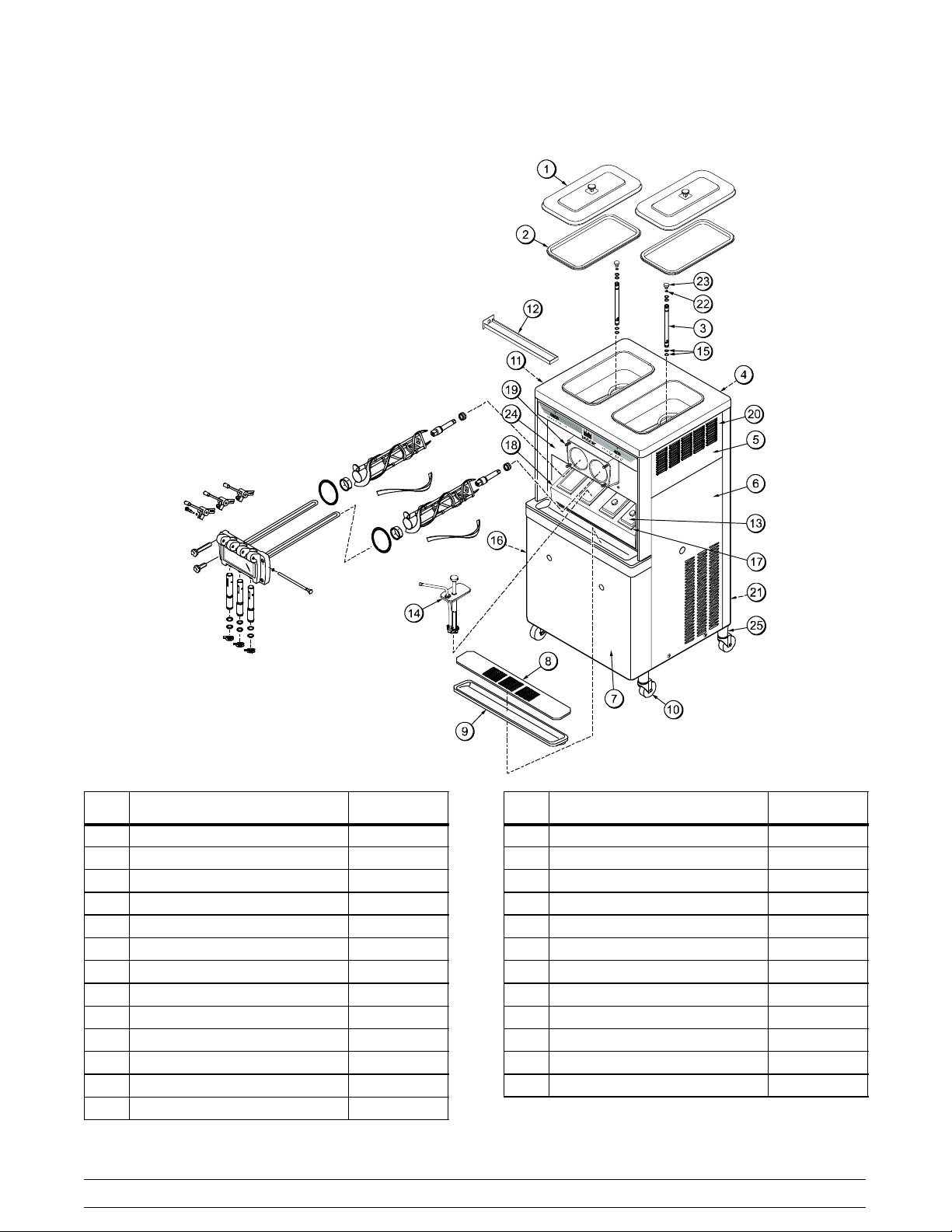

Model 751

Item Description Part No.

1 Cover A.--Hopper X38458--SER

2 Gasket--Hopper Cover 038375

3 Tube A.--Feed X29429--2

4 Panel--Rear 013637

5 Panel--Upper Side Right 028823

6 Pan--Drip 11--5/8 Long 027503

7 Panel A.-- Lower Side Right X24424--SER

8 Shield--Splash 022763

9 Tray-- Drip 14-- 7/8 x 5--1/8 013690

10 Panel--Upper Side 024426

11 Panel-- Service 047170

111101

Item Description Part No.

12 Caster-- Swivel 018794

13 Stud--Nose Cone 022822

14 Panel A.--Side --Lower X39075--SER

15 O--Ring--.643 OD x .077 W 018572

16 O--Ring--3/8 OD x .070 W 016137

17 Orifice 022465--100

18 Louver--Side-- Top 051191

19 Panel A.--Front X33237

20 Adaptor A.--Caster X18915

21 Caster-- 4” Swivel 5/8” Stem

w/Brake

8

Models 750, 751, 754, 774, 791, 794Operator Parts Identification

034081

Page 13

Model 754

Item Description Part No.

1 Cover A.--Hopper X38458--SER

2 Gasket--Hopper Cover 038474

3 Tube A.--Feed X29429--2

4 Panel--Rear 053782

5 Panel--Upper Side Right 028823

6 Panel A.-- Side Lower Right X46448--SER

7 Panel--Service 046584

8 Shield--Splash 022766

9 Tray--Drip 014533

10 Caster-- Swivel 018794

Models 750, 751, 754, 774, 791, 794 Operator Parts Identification

Item Description Part No.

11 Panel-- Upper Side Left 028822

12 Stud--Nose Cone 022822

13 Panel A.--Side Lower Left X46447--SER

14 Louver--Side-- Top 051191

15 O--Ring--.643 OD x .077 W 018572

16 O--Ring--3/8 OD x .070 W 016137

17 Orifice 022465--100

18 Pan--Drip 17 --1/4” Long 027504

19 Panel A.--Front X32956

20 Adaptor A.--Caster X18915

9

Page 14

Model 774

Item Description Part No.

1 Cover A.--Hopper X38458-- SER

2 Gasket--Hopper Cover 038474

3 Tube A.--Feed X29429 --2

4 Panel--Upper Rear X42574

5 Panel--Upper Side Right 028823

6 Panel A.-- Side Lower--Right X46448--SER

7 Panel--Service 047077

8 Shield--Splash 022766

9 Tray--Drip 014533

10 Caster-- Swivel 018794

11 Panel-- Upper Side Left 028822

12 Pan--Drip 17 --1/4” Long 027504

13 Lid with Ladle 1 oz. 036575

Item Description Part No.

14 Pump A.--Syrup-- Tan 053794--TAN

15 O--Ring--.643 OD x .077 W 018572

16 Panel A.--Side Lower--Left X46447--SER

17 Jar-- Syrup--Plastic 036573

18 Jar--Syrup--Stainless-- Shallow 036574

19 Stud--Nose Cone 022822

20 Louver--Side-- Top 051191

21 Panel--Lower Rear 053837

22 O--Ring--3/8 OD x .070 W 016137

23 Orifice 022465--100

24 Panel A.--Front X42539

25 Adaptor A.--Caster X18915

10

Models 750, 751, 754, 774, 791, 794Operator Parts Identification

Page 15

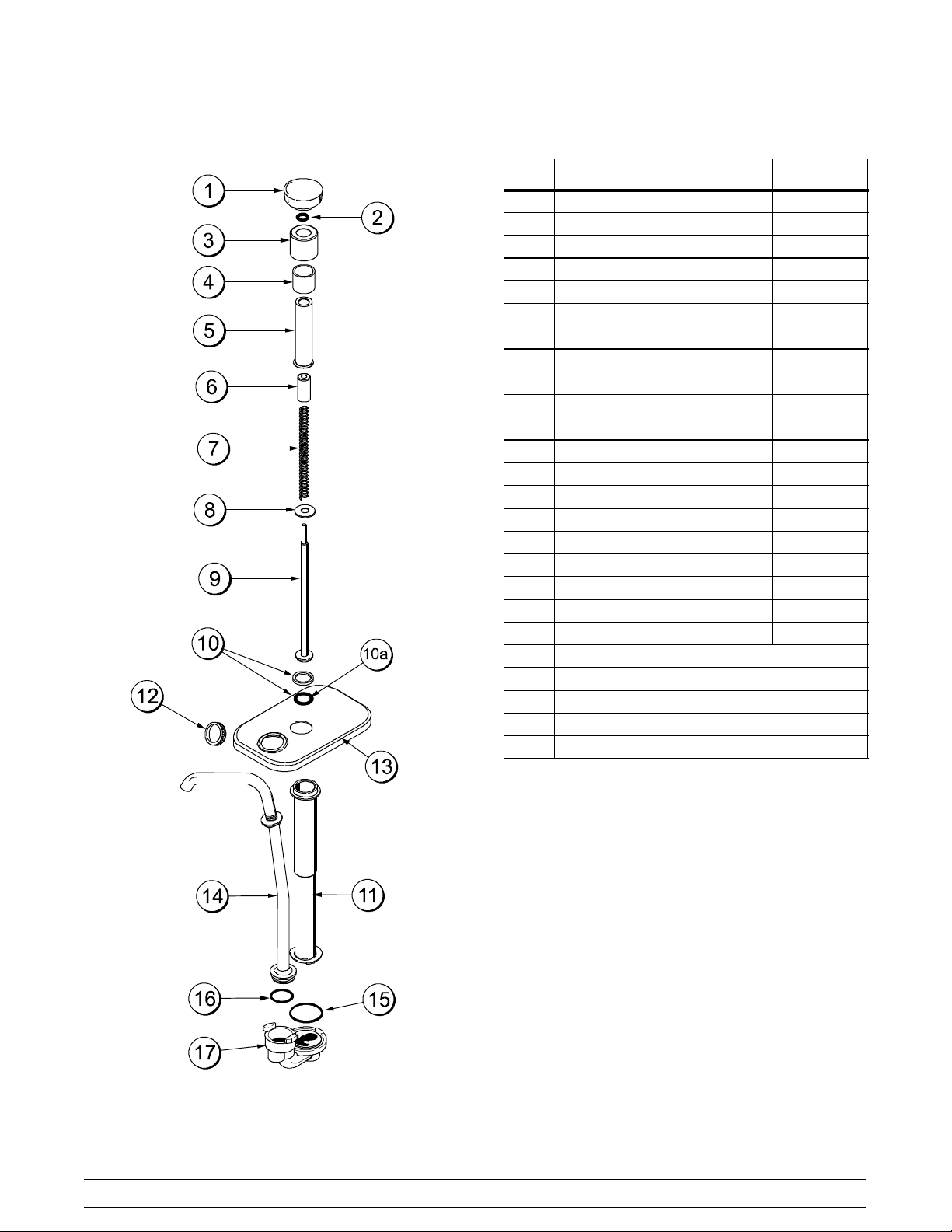

Model 774 Topping Pump (053794--)

ITEM DESCRIPTION PART NO.

1 Knob-Plunger-Tan 032762-TAN

1 Knob-Plunger-Brown 032762-BRN

1 Knob-Plunger-Red 032762-RED

2 O-Ring-9/16 OD x .103 W 016369

3 Nut-Plunger 036577

4 Collar-Gaging 1/2 Ounce 035514

5 Tube-Plunger 032757

6 Insert-Plunger 032758

7 Spring-Plunger 032761

8 Washer-Nylon 032760

9 Plunger 036578

10 Seal Assembly X33057

10a O-Ring-13/16OD x .103 W 019330

11 Body-Syrup Pump 047934

12 Nut-Spout 036821

13 Lid-Pump 036822

14 Tube-Discharge 050912

15 O-Ring-1-5/16 OD x .103 W 048149

16 O-Ring-1OD x .103 W 048148

17 Kit-Valve-Captured Ball Shallow 048166-001

Includes:

1 - Body A.-Pump Valve

1 - O-Ring-1-5/16 OD x .103W (048149)

1 - Brush-cleaning (054068)

1 - Instruction Sheet-Installation/Cleaning

Models 750, 751, 754, 774, 791, 794 Operator Parts Identification

11

Page 16

Model 791

ITEM DESCRIPTION PART NO.

1 PANEL A.--FRONT X41820--SP3

2 STUD-- NOSE CONE 068410

3 PA N EL- -SIDE 069038

4 KIT A.--COVER --HOPPER X68150

5 TUBE A.--FEED--SS--5/32 X29429--2

6 PANEL--REAR 041855

120613

ITEM DESCRIPTION PART NO.

7 CASTER-- 4” SWV 5/8 STEM 018794

8 CASTER-- 4” SWV 5/8 STEM

W/BRAKE

9 TRAY--DRIP 16--7/8L X 5-- 1/8 020157

10 SHIELD--SPLASH 022765

11 PAN--DRIP 19-- 1/2 LONG 035034

12

Models 750, 751, 754, 774, 791, 794Operator Parts Identification

034081

Page 17

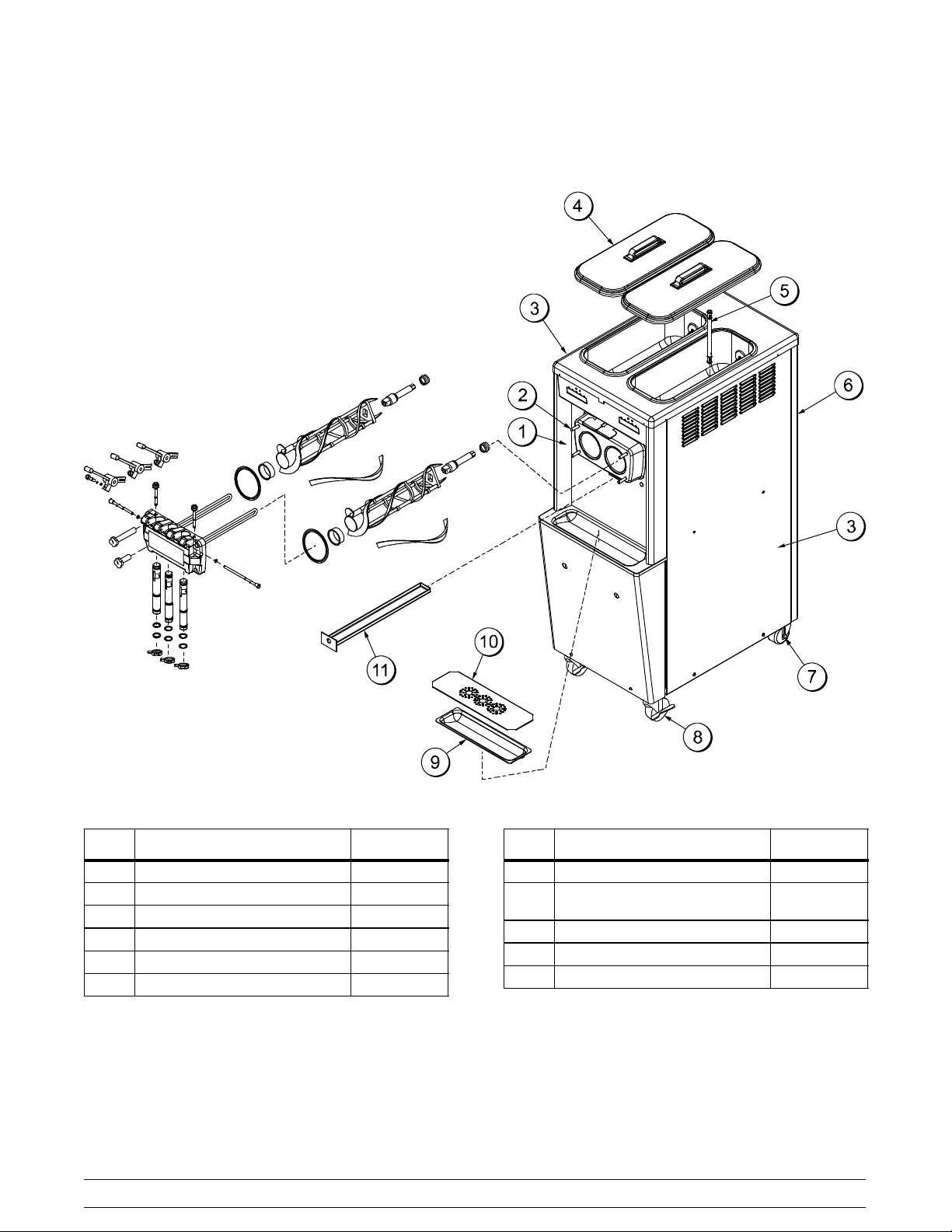

Model 794

Item Description Part No.

1 Cover--Hopper 14 Qt. Grey 041682--GRY

2 Pan--Drip 19--1/2 Long 035034

3 Tube A.--Feed X29429--2

4 Panel--Rear 041855

5 Panel--Side--Upper (Left & Right) 058672

6 Panel A.-- Side Lower Right X46448--SER

7 Panel--Service 064000

8 Shield--Splash 022765

9 Tray--Drip 020157

Item Description Part No.

10 Caster-- 4” Swv 5/8 Stem w/Brake 034081

11 Panel A.--Side Lower Left X46447--SER

12 Caster-- Swivel 018794

13 Stud--Nose Cone 068410

14 O--Ring--3/8 OD x .070 W 016137

15 O--Ring--.643 OD x .077 W 018572

16 Orifice 024465--100

17 Panel A.--Front X41820--SP3

18 Adaptor A.--Caster X18915

111101

Models 750, 751, 754, 774, 791, 794 Operator Parts Identification

13

Page 18

Models 750 & 751 Single Spout Door and Beater Assembly

ITEM DESCRIPTION PART NO.

1 HANDLE A.- DRAW X55096

1a DRAW HANDLE 028804

1b SCREW-ADJUST 055092

1c O-RING 1/4OD X .070W 015872

1d NUT-JAM 029639-BLK

2 NUT-STUD FLAT LONG 021508

3 DOOR A.- 1-SPOUT X51531-10

4 VALVE A.- DRAW X18303

5 O-RING 7/8OD X .070W 014402

6 CAP-DESIGN 014218

ITEM DESCRIPTION PART NO.

7 O-RING 5/16OD X .070W 016272

8 PLUG-PRIME 028805

9 O-RING-PRIME PLUG 016137

10 PIN A.- PIVOT X22820

11 GASKET-DOOR HT 4” 048926

12 BLADE- SCRAPER 035174

13 BEATER A.- HELICORE X31761

14 BEARING-FRONT 050216

15 SHAFT-BEATER 032564

16 SEAL-DRIVE SHAFT 032560

14

Models 750, 751, 754, 774, 791, 794Operator Parts Identification

Page 19

Models 754, 774 & 794 Three Spout Door and Beater Assembly

Item Description Part No.

1 Handle A.--Draw X55096

1a Draw Handle 028804

1b Screw-- Adjustment 055092

1c O--Ring 1/4 OD x .070 W 015872

1d Nut-- Jam 029639--BLK

2 Nut-- Stud Long 034382

3 Nut-- Stud Short 034383

4 Val ve A .- -Dr aw X18303

5 O--Ring 7/8 OD x .070 W 014402

6 Shaft--Beater 032564

Models 750, 751, 754, 774, 791, 794 Operator Parts Identification

Item Description Part No.

7 Seal-- Drive Shaft 032560

8 Cap--Design 014218

9 Decal-- Door 021521

10 Door A.--3 Spout X51532--12

11 Rod A.--Pivot X20683

12 O--Ring5/16ODx.070W 016272

13 Gasket--Door HT 4” 048926

14 Bearing--Front 050216

15 Beater A.--Helicore X31761

16 Blade-- Scraper 035174

15

Page 20

Model 791 Three Spout Door and Beater Assembly

ITEM DESCRIPTION PART NO.

1 HANDLE A.--DRAW X55096

1a DRAW HANDLE 028804

1b SCREW--ADJUST 055092

1c O --RING 1/4OD X .070W 015872

1d NUT-- JAM 029639--BLK

2 PLUG-- PRIME 028805

3 ROD A.-- P IVOT X22388

4 NUT-- STUD LONG 034382

5 NUT-- STUD SHORT 034383

6 VALVE A.-- DRAW X69539

7 O--RING 7/8OD X .070W 014402

120124

ITEM DESCRIPTION PART NO.

8 CAP-- DESIGN 014218

9 DECAL-- DOOR 021521

10 DOOR A.-- 3--SPOUT X49461--4

11 ROD A.-- PIVOT X22387

12 O --RING 5/16OD X .070W 016272

13 GASKET--DOOR HT 4” 048926

14 BEARING--FRONT 050216

15 BEATER A.-- HELICORE X31761

16 BLADE-- SCRAPER 035174

17 SHAFT--BEATER 032564

18 SEAL--DRIVE SHAFT 032560

16

Models 750, 751, 754, 774, 791, 794Operator Parts Identification

Page 21

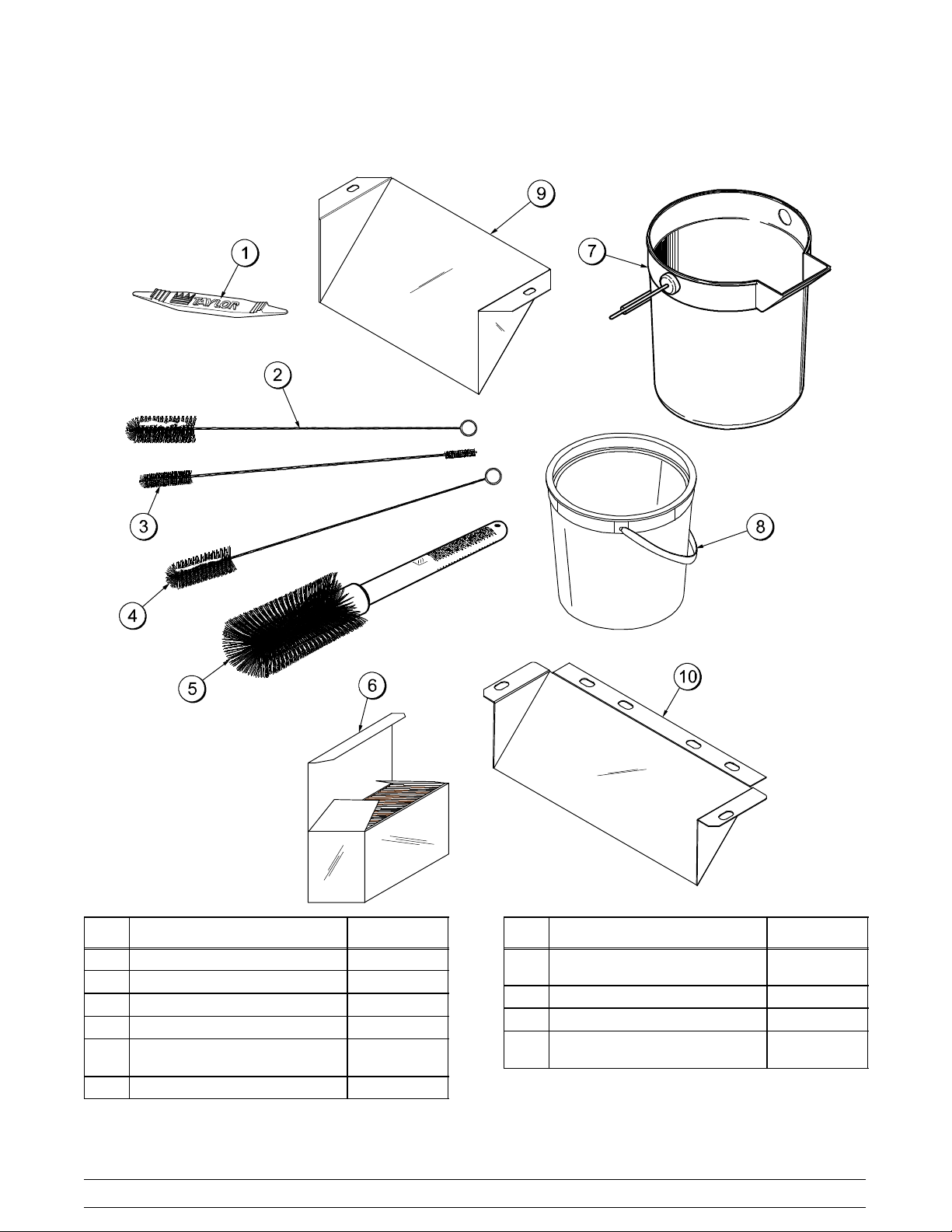

Accessories

Item Description Part No.

1 Tool--O--Ring Removal 048260-- WHT

2 Brush --Rear Bearing 1” D x 2”L 013071

3 Brush --Double Ended 013072

4 Brush --Draw Valve 1” x 2” x 17” 013073

5 Brush --Mix Pump Body 3” x 7”

White

*6 Sanitizer-- Stera Sheen Green See note

023316

Item Description Part No.

7 Pail--Mix 10 Qt.

(751, 754, 774, 791, 794)

8 Pail--Mix 6 Qt. (750) 023348

9 Deflector--Blower Exhaust (794) 047912

10 Deflector--Blower Exhaust

(751, 754, 774)

**Note: A sample container of sanitizer is sent with the

unit. For reorders, order Stera Sheen part no. 055492

(100 2 oz. packs) or Kay-- 5 part no. 041082 (200 packs).

013163

046586

101217

Models 750, 751, 754, 774, 791, 794 Operator Parts Identification

17

Page 22

Section 5 Important: To the Operator

750/751

754/774/791/794

ITEM DESCRIPTION

1 MIX LOW INDICATOR LIGHT

2 MIX REFRIGERATION KEY

3 STANDBY KEY

4 WASH KEY

5 AUTO KEY

6 POWER ON/OFF (TOGGLE)

7 RESET BUTTON

Symbol Definitions

To better communicate in the International arena, the

words on many of our operator switches and keys have

been replaced with symbols to indicate their functions.

Your T aylor equipment is designed with these

International symbols.

18

Models 750, 751, 754, 774, 791, 794Important: To the Operator

Page 23

The following chart identifies the symbol definitions.

=OFF

=ON

=MIX

= STANDBY

= WASH

STANDBY Key

The Separate Hopper Refrigeration System (SHR)

and the Cylinder Temperature Retention System

(CTR) are standard features on these machines. The

SHR incorporates the use of a separate small

refrigeration system to maintain the mix in the hopper

below 40_(4.4_C) to assure bacteria control. The CTR

works with the SHR to maintain a good quality product.

During long “No Sale” periods, it is necessary to warm

the product in the freezing cylinder to approximately

35_Fto40_F(1.7_Cto4.4_C) to prevent overbeating

and product breakdown.

=AUTO

Power Switch

When placed in the ON position, the power switch

allows SOFTECH control panel operation.

MIX LOW Indicator Light

Located on the front of the machine is a mix level

indicating light. When the light is flashing, it indicates

that the mix hopper has a low supply of mix and should

be refilled as soon as possible. Always maintain at

least 3” (7.6 cm) of mix in the hopper. If you neglect to

add mix, a freeze--up may occur. This will cause

eventual damage to the beater, blades, drive shaft,

and freezer door.

To activate the SHR and CTR, press the STANDBY

key. Remove the air orifice and place the air tube (end

without the hole) into the mix inlet hole.

When the STANDBY key is pressed, the light comes

on, indicating the CTR (Cylinder Temperature

Retention System) has been activated. In the

STANDBY mode, the WASH and AUTO functions are

automatically cancelled. The MIX REF function is

automatically locked in to maintain the mix in the

hopper.

To resume normal operation, press the AUTO key.

When the unit cycles off, the product in the freezing

cylinder will be at serving viscosity. At this time, place

the air tube (end with the hole) into the mix inlet hole

and install the air orifice.

WASH Key

When the WASH key is pressed, the light comes on.

This indicates beater motor operation. The STANDBY

or AUTO modes must be cancelled first to activate the

WASH mode.

AUTO Key

MIX REF Key

When the MIX REF key is pressed, the light comes on

indicating the mix hopper refrigeration system is

operating. For the Models 754, 774, 791, and 794 the

MIX REF is controlled by the left side of the freezer as

viewed from the operator end. The MIX REF function

cannot be cancelled unless the AUTO or STANDBY

modes are cancelled first.

Models 750, 751, 754, 774, 791, 794 Important: To the Operator

When the AUTO key is pressed, the light comes on.

This indicates that the main refrigeration system has

been activated. In the AUTO mode, the WASH or

STANDBY functions are automatically cancelled. The

MIX REF function is automatically locked in to

maintain the mix in the mix hopper.

Note: An indicating light and an audible tone will

sound whenever a mode of operation has been

pressed. To cancel any function, press the key again.

The light and mode of operation will shut off.

19

Page 24

Reset Button

On counter models, the reset button is located on the

side of the unit. On console models, the reset button

is located in the service panel. The reset protects the

beater motor from an overload condition. If an overload

occurs, the reset mechanism will trip. To properly reset

the freezer, press the AUTO key to cancel the cycle.

Turn the power switch to the OFF position. Press the

reset button firmly.

Do not use metal objects to press the reset

button. Failure to follow this instruction may

result in electrocution.

Turn the power switch to the ON position. Press the

WASH key and observe the freezer’s performance.

Open the side access panel. Make sure the beater

motor is turning the drive shaft in a clockwise direction

(from the operator end) without binding.

If the beater motor is turning properly, press the WASH

key to cancel the cycle. Press the AUTO key to resume

normal operation. If the freezer shuts down again,

contact a service technician. (For Models 754, 774,

791, and 794 press the AUTO key on both sides of the

unit to resume normal operation.)

Air Tube

draw handle is raised, new mix and air from the

hopper will flow down into the freezing cylinder.

This will keep the freezing cylinder properly

loaded and will maintain overrun.

2. During long “No Sale” periods, remove the air

orifice. Lubricate the o--rings on the air tube

(the end without the hole), and place it into

the mix inlet hole. This will prevent any mix

from entering the freezing cylinder.

The air orifice is used to meter a certain amount

of air into the freezing cylinder . The air orifice

maintains overrun and allows enough mix to enter

the freezing cylinder after a draw.

Adjustable Draw Handle

These units feature an adjustable draw handle to

provide the best portion control. The draw handle

should be adjusted to provide a flow rate of 5 to 7--1/2

oz. (148 to 222 ml) of product per 10 seconds. To

INCREASE the flow rate, turn the screw

COUNTERCLOCKWISE. Turn the screw

CLOCKWISE to DECREASE the flow rate. During

“Sanitizing” and “Rinsing”, the flow rate can be

increased by removing the pivot pin and placing the

restrictive bar on the TOP. When drawing product,

always place the restrictive bar on the bottom.

The air tube serves two purposes. One end of the tube

has a hole and the other end does not.

Figure 1

1. After priming the machine, lubricate the o--rings

on the air tube (the end with the hole) and

place it into the mix inlet hole. Every time the

091030

IMPORTANT! When dispensing product, pull only

one draw handle at a time.

Figure 2

Note: Once the draw rate is set, tighten the lock nut

with a wrench.

20

Models 750, 751, 754, 774, 791, 794Important: To the Operator

Page 25

Section 6 Operating Procedures

The Model 751 has been selected to illustrate the

step--by--step operating procedures for all models

contained in this manual. These models, for all

practical purposes of operation, are the same.

Each unit stores mix in a hopper. The mix then flows

by gravity through an air tube down into the freezing

cylinder. They all have 3.4 quart (3.2 liter) capacity

freezing cylinders. The Models 750, 751, 754, and 774

have 20 quart (18.9 liter) mix hoppers. The Models 791

and 794 have 14 quart (13.2 liter) mix hoppers.

Duplicate the following procedures, where they apply,

for the second freezing cylinder on Models 754, 774,

791, and 794.

We begin our instructions at the point where we enter

the store in the morning and find the parts

disassembled and laid out to air dry from the previous

night’s cleaning.

These opening procedures will show you how to

assemble these parts into the freezer, sanitize them,

and prime the freezer with fresh mix in preparation to

serve your first portion.

If you are disassembling the machine for the first time

or need information to get to this starting point in our

instructions, turn to page 30, “Disassembly”, and start

there.

Prior to Set--Up (Model 774)

Step 3

Prepare a pail of an approved 100 PPM sanitizing solution (examples: 2--1/2 gal. [9.5 liters] of Kay--5R or

2 gal. [7.6 liters] of Stera--SheenR). USE WARM WATER AND FOLLOW THE MANUFACTURER’S SPECIFICATIONS. Sanitize the topping pumps by placing

the entire pump assembly in the pail of sanitizing solution. Pump the solution through the assembly to thoroughly sanitize the pump.

Step 4

Remove the two topping pumps. Fill each stainless

syrup jar with topping. Replace the topping pumps in

the syrup jars.

Assembly

Note: When lubricating parts, use an approved food

grade lubricant (example: Taylor Lube).

MAKE SURE POWER SWITCH IS IN THE

“OFF” POSITION! Failure to follow this instruction

may result in severe personal injury from hazardous

moving parts.

Step 1

Lubricate the groove and shaft portion that comes in

contact with the bearing on the beater drive shaft. Slide

the seal over the shaft and groove until it snaps into

place. DO NOT lubricate the hex end of the drive shaft.

Fill the inside portion of the seal with 1/4” more

lubricant and lubricate the flat side of the seal that fits

onto the rear shell bearing.

Step 1

Remove the two stainless syrup jars with topping

pumps from the syrup rail. Check the water level in the

heated syrup topping well. Make sure the water is filled

to the indicating mark on the bottom of the well. The

heated rail should have 32 oz. (946.2 ml) of water.

Step 2

Place the heater switch in the ON position.

Note: This heating process will take approximately

2--1/2 hours to reach temperature. The water level in

the topping wells must be checked at least once daily.

Models 750, 751, 754, 774, 791, 794 Operating Procedures

21

Figure 3

080602

Page 26

Insert the drive shaft into the freezing cylinder, hex end

first, and into the rear shell bearing until the seal fits

securely over the rear shell bearing. Engage the hex

end firmly into the drive coupling. Be sure the drive

shaft fits into the drive coupling without binding.

Figure 4

Step 2

Take one of the scraper blades and slip it under the

hook at the front of the beater. Wrap the blade around

the beater following the helix and pushing the blade

down onto the helix as you wrap. At the back end of the

beater, slip the blade under the hook. Repeat this

step for the second scraper blade.

Figure 6

Slide the beater the remainder of the way into the

freezing cylinder and over the end of the drive shaft.

The beater should fit snugly, but not so tightly that the

beater cannot be turned slightly to engage the drive

shaft. If the beater slides in too easily with little or no

resistance, there will not be enough force against the

beater to hold the blades in place. If this is the case,

contact your authorized T aylor service technician.

Repeat steps 1 and 2 for the other side of the freezer

on Models 754, 774, 791, and 794.

Step 3

Place the large rubber gasket(s) into the groove(s) on

the back side of the freezer door.

Slide the white plastic front bearing(s) over the baffle

rod(s) onto the bearing hub(s) making certain that the

flanged end of the bearing is resting against the freezer

door.

Figure 5

Holding the beater securely, slide the beater one third

of the way into the freezing cylinder. Looking into the

freezing cylinder, align the hole at the rear of the beater

with the flats on the end of the drive shaft.

Note: Do not lubricate the gasket(s) or the front

bearing(s).

Figure 7

22

Models 750, 751, 754, 774, 791, 794Operating Procedures

Page 27

Note: There are two gaskets and two front bearings

for the Models 754, 774, 791, and 794 door, one for

each freezing cylinder .

Insert the prime plug(s) into the hole(s) in the top of the

freezer door, and push down.

Figure 10

Figure 8

Slide the two o--rings into the grooves on the prime

plug(s). Apply an even coat of Taylor Lube to the

o--rings and shaft(s).

Figure 9

Note: There are two prime plugs for the Models 754,

774, 791, and 794 door, one for each freezing cylinder.

Step 4

Insert the baffle rod(s) through the opening in the

beater(s) and seat the door flush with the freezing

cylinder. With the door seated on the freezer studs,

install the handscrews. Tighten equally in a crisscross

pattern to insure the door is snug.

Figure 11

Note: On the Models 754, 774, 791, and 794, the

short handscrews go on the bottom and the long

handscrews go on the top.

Models 750, 751, 754, 774, 791, 794 Operating Procedures

23

Page 28

Step 5

Install the draw valve(s). Slide the two o--rings into the

grooves on the draw valve(s), and lubricate.

Step 6

Install the adjustable draw handle(s). Slide the o--ring

into the groove on the pivot pin, and lubricate.

Figure 14

Figure 12

Note: Models 754, 774, 791, and 794 have three draw

valves.

Lubricate the inside of the freezer door spout(s), top

and bottom, and insert the draw valve(s) from the

bottom until the slot in the draw valve(s) comes into

view.

Figure 13

Slide the fork over the bar in the slot of the draw valve.

Secure with pivot pin.

Figure 15

Note: Models 754, 774, 791, and 794 have three draw

handles. Slide the fork of the draw handle in the slot of

the draw valve, starting from the right. Slide the pivot

pin through each draw handle as you insert them into

the draw valves.

Note: These units feature adjustable draw handles to

provide the best portion control. The draw handles can

be adjusted for different flow rates. See page 20 for

more information on adjusting these handles.

101109

24

Models 750, 751, 754, 774, 791, 794Operating Procedures

Page 29

Step 7

Snap the design cap(s) over the end of the door

spout(s).

Figure 16

Step 8

Install the front drip tray and the splash shield under

the door spout(s).

Models 791 & 794: Slide the rear drip pan into the hole

in the front panel.

Step 10

Slide two o--rings on one end of the air tube. Slide two

o--rings on the other end of the air tube.

Figure 17

Step 9

Slide the rear drip pan(s) into the hole in the side panel.

Figure 19

Slide the small o--ring into the groove of the air orifice.

Do not lubricate the o--ring.

Figure 20

Note: Make sure the hole in the air orifice is clean and

is not clogged. If the hole in the air orifice should

become clogged, use soap and hot water to clear the

Figure 18

Models 750, 751, 754, 774, 791, 794 Operating Procedures

hole. Do not enlarge the hole in the air orifice.

25

Page 30

Install the air orifice into the hole in the top of the air

tube (in the end without the small hole on the side).

Figure 21

Step 11

Lay the air tube (with the air orifice installed) and the

hopper gasket in the bottom of the mix hopper for

sanitizing.

Figure 22

Step 3

While the solution is flowing into the freezing cylinder,

brush clean the mix hopper. When cleaning the

hopper, take particular care in brushing the mix level

sensing probe on the rear wall of the hopper, the mix

inlet hole, the air tube, and the hopper gasket.

Note: The Models 754 and 774 have one hopper

gasket for each mix hopper. The Models 791 and 794

do not require a hopper gasket.

Repeat steps 10 and 11 for the other side of the

freezer on Models 754, 774, 791, and 794.

Sanitizing

Step 1

Prepare an approved 100 PPM sanitizing solution

(examples: 2--1/2 gal. [9.5 liters] of Kay--5R or 2

gal. [7.6 liters] of Stera--SheenR). USE WARM WATER AND FOLLOW THE MANUFACTURER’S

SPECIFICATIONS.

Step 2

Pour the sanitizing solution into the hopper and allow

it to flow into the freezing cylinder.

Figure 23

Figure 24

080602

26

Models 750, 751, 754, 774, 791, 794Operating Procedures

Page 31

Figure 25

Step 4

Place the power switch in the ON position.

Step 6

Place an empty pail beneath the door spout and raise

the prime plug.

Figure 28

Step 7

When a steady stream of sanitizing solution is flowing

from the prime plug opening in the bottom of the

freezer door, lower the draw handle. Draw off all the

sanitizing solution.

Figure 26

Step 5

Press the WASH key. This will cause the sanitizing

solution in the freezing cylinder to agitate. Allow it to

agitate for five minutes.

Figure 27

Figure 29

Note: On the Models 754, 774, 791, and 794,

momentarily pull the center draw handle down to

sanitize the center door spout.

Step 8

Once the sanitizer stops flowing from the door spout,

raise the draw handle and press the WASH key,

cancelling the beater motor operation.

Note: You have just sanitized the freezer. Be sure

your hands are sanitized before continuing these

instructions.

Models 750, 751, 754, 774, 791, 794 Operating Procedures

27

Page 32

Step 9

Assemble the hopper gasket around the top edge of

the mix hopper. Stand the air tube in the corner of the

hopper.

Step 2

Once a steady stream of mix starts to flow from the

prime plug opening in the bottom of the freezer door,

push down the prime plug.

Figure 30

Repeat steps 1 through 9 for the other side of the

freezer on Models 754, 774, 791, and 794.

Priming

Step 1

With a pail beneath the door spout, lower the draw

handle. Be sure the prime plug is still in the UP

position. Pour two gallons (7.6 liters) of fresh mix into

the mix hopper and allow it to flow into the freezing

cylinder. This will force out any remaining sanitizing

solution. When full strength mix is flowing from the

door spout, raise the draw handle.

Note: Use only fresh mix when priming the freezing

cylinder.

Figure 32

Step 3

Lubricate the o--rings on the air tube on the end with

the small hole on the side.

Step 4

Install the air tube (the end with the hole) with the air

orifice installed into the mix inlet hole in the mix hopper.

Step 5

Press the AUTO key. The AUTO light will come on

indicating the main refrigeration system is operating.

When the unit cycles off, the product will be at serving

viscosity.

Note: On Models 751, 754, 774, 791, and 794 the

MIX REF light will come on, indicating the mix

refrigeration system is operating to maintain the mix in

the mix hopper.

Figure 31

Figure 33

Step 6

Fill the hopper with mix. As the mix level comes in

contact with the mix level sensing probe on the rear

wall of the hopper, the MIX LOW light will shut off.

28

Models 750, 751, 754, 774, 791, 794Operating Procedures

Page 33

Step 7

Place the mix hopper cover in position over the mix

hopper.

Rinsing

Repeat steps 1 through 7 for the other side of the

freezer on Models 754, 774, 791, and 794.

Closing Procedure

To disassemble your unit, the following items will be

needed:

S Two cleaning pails

S Sanitized stainless steel rerun can with lid

S Necessary brushes (provided with freezer)

S Cleaner

S Single service towels

Draining Product From The

Freezing Cylinder

Step 1

Press the AUTO key, cancelling compressor and

beater motor operation.

Step 1

Pour two gallons (7.6 liters) of cool clean water into the

mix hopper. With the brushes provided, scrub the mix

hopper, mix inlet hole and mix level sensing probe.

Step 2

With a pail beneath the door spout, raise the prime plug

and press the WASH key.

Step 3

When a steady stream of rinse water is flowing from

the prime plug opening in the bottom of the freezer

door, lower the draw handle. Drain all the rinse water

from the freezing cylinder, raise the draw handle and

press the WASH key cancelling the WASH mode.

Repeat steps 1 through 3 for the other side of the

freezer on Models 754, 774, 791, and 794.

Cleaning

Press the MIX REF key, cancelling the mix hopper

refrigeration system.

Step 2

Remove the hopper cover, hopper gasket and air tube.

Take these parts to the sink for cleaning.

Step 3

If local health codes permit the use of rerun,place

a sanitized, NSF approved stainless steel rerun

container beneath the door spout. Press the WASH

key and lower the draw handle. Drain the remaining

product from the freezing cylinder and mix hopper .

When the flow of product stops, press the WASH key

and raise the draw handle. Place the sanitized lid on

the rerun container and place it in the walk--in cooler.

Note: If local health codes DO NOT permit the use

of rerun, the product must be discarded. Drain the

product into a mix pail and properly discard it.

Repeat steps 1 through 3 for the other side of the

freezer on Models 754, 774, 791, and 794.

ALWAYS FOLLOW LOCAL HEALTH CODES.

Step 1

Prepare an approved 100 PPM cleaning solution

(examples: 2--1/2 gal. [9.5 liters] of Kay--5R or 2

gal. [7.6 liters] of Stera--SheenR). USE WARM WATER AND FOLLOW THE MANUFACTURER’S

SPECIFICATIONS.

Step 2

Push down the prime plug. Pour the cleaning solution

into the mix hopper.

Step 3

While the solution is flowing into the freezing cylinder,

brush clean the mix hopper, mix level sensing probe,

and the mix inlet hole.

Step 4

Press the WASH key. This will cause the cleaning

solution in the freezing cylinder to agitate.

Step 5

Place an empty pail beneath the door spout and raise

the prime plug.

080324

Models 750, 751, 754, 774, 791, 794 Operating Procedures

29

Page 34

Step 6

When a steady stream of cleaning solution is flowing

from the prime plug opening in the bottom of the

freezer door, lower the draw handle. Draw off all of the

solution.

Step 7

Once the cleaner stops flowing from the door spout,

raise the draw handle and press the WASH key

cancelling the WASH mode.

Repeat steps 1 through 7 for the other side of the

freezer on Models 754, 774, 791, and 794.

Disassembly

MAKE SURE POWER SWITCH IS IN THE

“OFF” POSITION! Failure to follow this instruction

may result in severe personal injury from hazardous

moving parts.

Step 1

Remove the handscrews, freezer door(s), beater(s),

scraper blades, and drive shaft(s) from the freezing

cylinder(s). Take these parts to the sink for cleaning.

S adjustable draw handle(s)

S design cap(s)

S draw valve(s)

S prime plug(s)

S all o--rings

Note: To remove o--rings, use a single service towel

to grasp the o--ring. Apply pressure in an upward

direction until the o--ring pops out of its groove. With

the other hand, push the top of the o--ring forward and

it will roll out of the groove and can be easily removed.

If there is more than one o--ring to be removed, always

remove the rear o--ring first. This will allow the o--ring

to slide over the forward rings without falling into the

open grooves.

Step 4

Remove the o--rings from the air tube(s) and air

orifice(s).

Step 5

Return to the freezer with a small amount of cleaning

solution. Brush clean the rear shell bearing(s) at the

back of the freezing cylinder(s) with the black bristle

brush.

Step 2

Remove the front drip tray and the splash shield.

Brush Cleaning

Step 1

Prepare a sink with an approved cleaning solution (examples: Kay--5r or Stera--Sheenr). USE WARM WATER AND FOLLOW THE MANUFACTURER’S SPECIFICATIONS. If another approved cleaner is used,

dilute it according to the label instructions. (IMPORT-

ANT: Follow the label directions. Too STRONG of a

solution can cause parts damage, while too MILD of a

solution will not provide adequate cleaning.) Make

sure all brushes provided with the freezer are available

for brush cleaning.

Step 2

Remove the seal(s) from the drive shaft(s).

Step 3

From the freezer door(s) remove:

S gasket(s)

S front bearing(s)

S pivot pin(s)

Figure 34

Step 6

Remove the rear drip pan(s) and take to the sink for

cleaning.

Note: If the drip pan is filled with an excessive amount

of mix, refer to the Troubleshooting Guide.

Step 7

Thoroughly brush clean all disassembled parts in the

cleaning solution making sure all lubricant and mix film

is removed. Take particular care to brush clean the

draw valve core(s) in the freezer door. Place all the

cleaned parts on a clean, dry surface to air dry

overnight.

Step 8

Wipe clean all exterior surfaces of the freezer.

080324

30

Models 750, 751, 754, 774, 791, 794Operating Procedures

Page 35

Section 7 Important: Operator Checklist

During Cleaning and Sanitizing

Cleaning and sanitizing schedules are governed

by federal, state, or local regulatory agencies,

and must be followed accordingly. If the unit

has a “Standby mode”, it must not be used in

lieu of proper cleaning and sanitizing

procedures and frequencies set forth by the

ruling health authority. The following check

points should be stressed during the cleaning

and sanitizing operations.

CLEANING AND SANITIZING MUST BE

PERFORMED DAILY.

ALWAYS FOLLOW LOCAL HEALTH CODES.

j 5. IF LOCAL HEALTH CODES PERMIT THE

USE OF RERUN, make sure the mix rerun is

stored in a sanitized, covered stainless steel

container and used the following day. DO NOT

prime the machine with rerun. When using

rerun, skim off the foam and discard. Mix the

rerun with fresh mix in a ratio of 50/50 during the

days operation.

j 6. On a designated day of the week, run the mix as

low as feasible and discard it after closing. This

will break the rerun cycle and reduce the

possibility of high bacteria and coliform counts.

j 7. Properly prepare the cleaning and sanitizing

solutions. Read and follow label directions

carefully. Too strong of a solution may damage

the parts and too weak of a solution will not do

an adequate job of cleaning or sanitizing.

j 8. The temperature of the mix in the mix hopper

and walk--in cooler should be below 40_F.

(4.4_C.).

T roubleshooting Bacterial Count

j 1. Thoroughly clean and sanitize machine

regularly, including complete disassembly and

brush cleaning.

j 2. Use all brushes supplied for thorough cleaning.

The brushes are specially designed to reach all

mix passageways.

j 3. Use the white bristle brush to clean the mix inlet

hole which extends from the mix hopper down

to the rear of the freezing cylinder.

j 4. Use the black bristle brush to thoroughly clean

the rear shell bearing located at the rear of the

freezing cylinder. Be sure to have a generous

amount of cleaning solution on the brush.

Regular Maintenance Checks

j 1. Replace scraper blades that are nicked or

damaged. Before installing the beater

assembly, be certain that scraper blades are

properly attached to the helix.

j 2. Check the rear shell bearing for signs of wear

(excessive mix leakage in rear drip pan) and be

certain it is properly cleaned.

j 3. Using a screwdriver and cloth towel, keep the

rear shell bearing and the 3/4 hex drive coupling

clean and free of lubricant and mix deposits.

j 4. Dispose of o--rings and seals if they are worn,

torn, or fit too loosely, and replace with new

ones.

j 5. Follow all lubricating procedures as outlined in

“Assembly”.

061122

Models 750, 751, 754, 774, 791, 794 Important: Operator Checklist

31

Page 36

j 6. If your machine is air cooled, check the

condensers for accumulation of dirt and lint.

Dirty condensers will reduce the efficiency and

capacity of the machine. Condensers should be

cleaned monthly with a soft brush. Never use

screwdrivers or other metal probes to clean

between the fins.

Note: For machines equipped with an air filter,

it will be necessary to vacuum clean the filters

on a monthly schedule.

Caution: Always disconnect

electrical power prior to cleaning the

condenser. Failure to follow this instruction

may result in electrocution.

j 7. If your machine is equipped with an auxiliary

refrigeration system, check the auxiliary

condenser for accumulation of dirt and lint. Dirty

condensers will reduce the refrigeration

capacity of the mix hopper. Condensers must

be cleaned monthly with a soft brush. Never use

screwdrivers or other metal probes to clean

between the fins. Failure to follow this

instruction may result in electrocution.

Winter Storage

If the place of business is to be closed during the winter

months, it is important to protect the freezer by

following certain precautions, particularly if the

building is subject to freezing conditions.

Disconnect the freezer from the main power source to

prevent possible electrical damage.

On water cooled freezers, disconnect the water

supply. Relieve pressure on the spring in the water

valve. Use air pressure on the outlet side to blow out

any water remaining in the condenser. This is

extremely important. Failure to follow this procedure

may cause severe and costly damage to the

refrigeration system.

Your local Taylor Distributor can perform this winter

storage service for you.

Wrap detachable parts of the freezer such as beater,

blades, drive shaft, and freezer door, and place them

in a protected dry place. Rubber trim parts and gaskets

can be protected by wrapping them with

moisture--proof paper. All parts should be thoroughly

cleaned of dried mix or lubrication which attract mice

and other vermin.

Caution: Always disconnect

electrical power prior to cleaning the

condenser. Failure to follow this instruction

may result in electrocution.

j 8. If your machine is water cooled, check the water

lines for kinks or leaks. Kinks can occur when

the machine is moved back and forth for

cleaning or maintenance purposes.

Deteriorated or cracked water lines should be

replaced only by an authorized Taylor

distributor.

080324

32

Models 750, 751, 754, 774, 791, 794Important: Operator Checklist

Page 37

Section 8 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PA GE

REF.

1. No product is being

dispensed with draw valve

a. Freeze--up in mix inlet

hole.

open and the machine in

the AUTO mode.

b. Beater motor out on reset. b. Reset the freezer.

c. The beater is rotating

counterclockwise from the

operator end.

d. The circuit breaker is off

or the fuse is blown.

e. There is inadequate mix in

the mix hopper.

f. The air orifice is not

installed.

2. The product is too stiff. a. The viscosity needs

adjustment.

b. The air orifice is not

installed.

3. The product is too soft. a. V iscosity needs

adjustment.

a. Call service technician to

adjust the mix hopper

temperature.

c. Contact service technician

to correct rotation to

clockwise from operator

end.

d. Turn the breaker on, or

replace the fuse.

e. Fill the mix hopper with

mix.

f. Install air orifice in air

tube.

a. Contact service

technician.

b. Install air orifice in air

tube.

a. Contact service

technician.

-- -- --

20

-- -- --

-- -- --

28

28

-- -- --

28

-- -- --

b. Not enough air space

around unit. (Air cooled

b. Allow for adequate air flow

across the condenser.

6

units)

c. Worn scraper blades. c. Replace regularly.

d. Dirty condenser (A/C) d. Clean monthly .

e. Mix is out of date. e. Use only fresh mix.

f. Loss of water. (W/C) f. Locate cause of water

36

32

-- -- --

32

loss and correct.

4. The mix in the mix hopper

is too cold.

a. The temperature is out of

adjustment.

a. Call service technician to

adjust the mix hopper

-- -- --

temperature.

Models 750, 751, 754, 774, 791, 794 Troubleshooting Guide

33

Page 38

PROBLEM PROBABLE CAUSE REMEDY PA GE

REF.

5. The mix in the mix hopper

is too warm.

6. The drive shaft is stuck in

the drive coupling.

7. The freezing cylinder walls

are scored.

8. Excessive mix leakage

into the rear drip pan.

a. The temperature is out of

adjustment.

b. Missing or defective mix

hopper gasket.

c. The mix hopper cover is

not in position.

d. The MIX REF light is not

lit.

a. Rounded corners of drive

shaft, coupling, or both.

b. Mix and lubricant collected

in the drive coupling.

a. The beater assembly is

bent.

b. The front bearing is

missing or worn on the

freezer door.

a. Missing or worn drive

shaft seal on drive shaft.

a. Call service technician to

adjust the mix hopper

temperature.

b. Replace/install the gasket

around the mix hopper.

c. Place the cover in

position.

d. Press the MIX REF key.

a. Call service technician to

correct cause, and to

replace the necessary

components. Do not

lubricate the hex end of

the drive shaft.

b. Brush clean the rear shell

bearing area regularly.

a. Call service technician to

repair or replace the

beater and to correct the

cause of insufficient mix

in the freezing cylinder.

b. Install or replace the front

bearing.

a. Install or replace regularly.

-- -- --

28

29

19

-- -- --

30

-- -- --

22

21 / 36

9. Excessive mix leakage

from door spout.

10. No freezer operation after

pressing the AUTO key.

b. The rear shell bearing is

worn.

a. Missing or worn draw

b. Call service technician to

replace rear shell bearing.

a. Install or replace regularly.

valve o--rings.

b. Inadequate lubrication of

b. Lubricate properly.

draw valve o--rings.

c. Wrong type of lubricant is

being used (example:

c. Use the proper lubricant

(example: Taylor Lube).

petroleum base lubricant).

a. Unit is unplugged. a. Plug into wall receptacle.

b. The circuit breaker is off

or the fuse is blown.

c. The beater motor is out on

b. Turn the breaker on, or

replace the fuse.

c. Reset the freezer.

reset.

34

Models 750, 751, 754, 774, 791, 794Troubleshooting Guide

-- -- --

24 / 36

24

21

-- -- --

-- -- --

20

Page 39

PROBLEM PROBABLE CAUSE REMEDY PA GE

REF.

1 1. Product is not feeding into

the freezing cylinder.

a. Inadequate level of mix in

the mix hopper.

b. The mix inlet hole is

frozen up.

c. The air tube is installed

incorrectly.

d. The air orifice is not

installed.

a. Fill the mix hopper with

mix.

b. The mix hopper

temperature needs

adjustment. Call service

technician.

c. Install the air tube in the

mix inlet hole, using the

end with the small hole in

the side.

d. Install the air orifice in the

air tube.

28

-- -- --

28

28

Models 750, 751, 754, 774, 791, 794 Troubleshooting Guide

35

Page 40

Section 9 Parts Replacement Schedule

PART DESCRIPTION EVERY

3MONTHS

Drive Shaft Seal X

Scraper Blade X

Freezer Door Gasket X

Front Bearing X

Draw Valve O--Ring X

Pivot Pin O--Ring X

Prime Plug O--Ring X

Air Tube O--Ring X

Air Orifice O--Ring X

White Bristle Brush, 3” x 7” Inspect & Replace

White Bristle Brush, 1” x 2” Inspect & Replace

Black Bristle Brush, 1” x 2” Inspect & Replace

EVERY

6MONTHS

if Necessary

if Necessary

if Necessary

ANNUALLY

Minimum

Minimum

Minimum

Double--Ended Brush Inspect & Replace

if Necessary

Refer to Parts List on page 37 when ordering the above parts.

36

Models 750, 751, 754, 774, 791, 794Parts Replacement Schedule

Minimum

Page 41

Section 10 Parts List

UPDATE

REMARKS P ARTS

WARR.

CLASS

794

QTY.

774

QTY.

754

QTY.

144

751-J9036440/UP-3PH

144

J9053627/UP-1PH

751-PRIOR TO J9036440-3PH,

J9053627-1PH

Models 750, 751, 754, 774, 794

(HP62 Refrigerant: 750 -- J6110454, 751 -- J6080596, 754 -- J6080465, 774 -- J6092382, and 794 -- J4094101/up)

751

750

PART

DESCRIPTION

QTY.

QTY.

NUMBER

ADAPTOR A.-CASTER X18915 4 4 4 4 103

BEARING-FRONT 050216 1 1 2 2 2 000

BEARING-REAR SHELL 031324 1 1 2 2 2 000

+GUIDE-DRIP SEAL 028992 1 1 2 2 2 000

+NUT-BRASS BEARING 028991 1 1 2 2 2 000

+WASHER-BEARING LOCK 012864 1 1 2 2 2 000

BEATER ASSEMBLY X31761 1 1 2 2 2 103

+BLADE-SCRAPER 035174 2 2 4 4 4 000

BELT-AX40 023875 2 000

BELT-AX35 022848 2 4 000

BELT-AX34 025729 4 000

BELT-AX31 041575 4 000

BLOCK-TERMINAL-2 P 039422 1 1 2 2 2 103 SINGLE PHASE

SCREW-TERMINALBLOCK 039420 2 2 4 4 4 000

BLOCK-TERMINAL-3 P 039423 1 1 2 2 2 103 THREE PHASE

BLOWER ASSEMBLY X53725-27 1 103

MOTOR-BLOWER 053481-27 1 103

BLOWER ASSEMBLY X53478-27 1 1 1 1 103

BOOT-CAPACITOR 031314 1 1 1 1 000

CAPACITOR-RUN 033047 1 1 1 1 103

CLIP-SCREEN BLOWER 053730 4 4 4 4 103

HOUSING-BLOWER 053727 1 1 1 1 103

MOTOR-BLOWER 053480-27 1 1 1 1 103

SCREEN-BLOWER 053729 1 1 1 1 103

WHEEL-BLOWER 053726 1 1 1 1 103

BOARD-LOGIC X36641SER1 1 1 2 2 2 212

BOARD-POWER X32326-SER 1 1 2 2 2 212

FUSE-SLO BLO 051272 1 1 2 2 2 103

BRUSH-BLACK (1” X 2”) 013071 1 1 1 1 1 000

BRUSH-DOUBLE END 013072 1 1 1 1 1 000

+ Available Separately

Models 750, 751, 754, 774, 791, 794 Parts List

37

Page 42

UPDATE

REMARKSWARR.

CLASS

794

QTY.

774

QTY.

754

QTY.

141

142

774-J9041932/UP

144

751-J9053627/UP-1PH

141

142

144

754-PRIOR TO J9036611

774-PRIOR TO J9041932,751-PRIOR TO J9036440,

J9053627

751

750

PART

DESCRIPTION PARTS

QTY.

QTY.

NUMBER

LINE A.-ACCESS COMPRESSOR X42513 1 130 COPELAND 136

CAPACITOR-RUN 012906 1 103 230-60-1

CAPACITOR-START 033044-1 1 103 230-60-1

RELAY-START COMPRESSOR 051957-27 1 103 230-60-1

CAPACITOR-RUN 023606 1 103 230-60-1

CAPACITOR-START 031790 1 103 230-60-1

BRUSH-WHITE (1” X 2”) 013073 1 1 1 1 1 000

BRUSH-WHITE (3” X 7”) 023316 1 1 1 1 1 000

CABLE-RIBBON 032445 1 1 2 2 103

CABLE-RIBBON 042599 2 103

CAP-DESIGN 014218 1 1 3 3 3 000

CAPACITOR-RUN 051785 1 103 FAN MOTOR - 051744-27 136

CAPACITOR-RUN 019624 1 103 FAN MOTOR - 041401-27 136

CASTER-4” SWV 5/8 STEM 018794 2 4 4 2 103

CASTER-4” SWV 5/8 STEM W/BRAKE 034081 2 2 103

COMPRESSOR - COPELAND 051958- 1 512 J8108583/UP 136

COMPRESSOR - BRISTOL 048727- 1 512 PRIOR TO J8108583 112/136

RELAY-START 048765 1 103 230-60-1

COMPRESSOR- COPELAND 052397-33 1 512 751-J9036440/UP-3PH 144

COMPRESSOR- COPELAND 052397- 1 2 1 512 754-J9036611/UP

CAPACITOR-RUN 029439 1 2 1 103 230-60-1

CAPACITOR-START 031304 1 2 1 103 230-60-1

RELAY-START 052401-27 1 2 1 103 230-60-1

COMPRESSOR - BRISTOL 048259- 1 2 2 512

CAPACITOR-RUN 012906 1 2 2 103 230-60-1

CAPACITOR-START 031790 1 2 2 103 230-60-1

RELAY-START 038145 1 2 2 103 230-60-1

CAPACITOR-RUN 048132 2 103

CAPACITOR-START 036048 2 103

COMPRESSOR - TECUMSEH 047519- 2 512

+ Available Separately

111101

Parts List

38

Models 750, 751, 754, 774, 791, 794

Page 43

UPDATE

REMARKSWARR.

CLASS

794

QTY.

774

QTY.

754

QTY.

132

SEE LABEL)

751

750

PART

DESCRIPTION PARTS

QTY.

QTY.

NUMBER

RELAY-START 036047 2 103

COMPRESSOR-AUXILIARY 047701-27 1 1 1 1 1 512

CAPACITOR-START 047703 1 1 1 1 1 103

RELAY-START 047702-27 1 1 1 1 1 103