Page 1

»

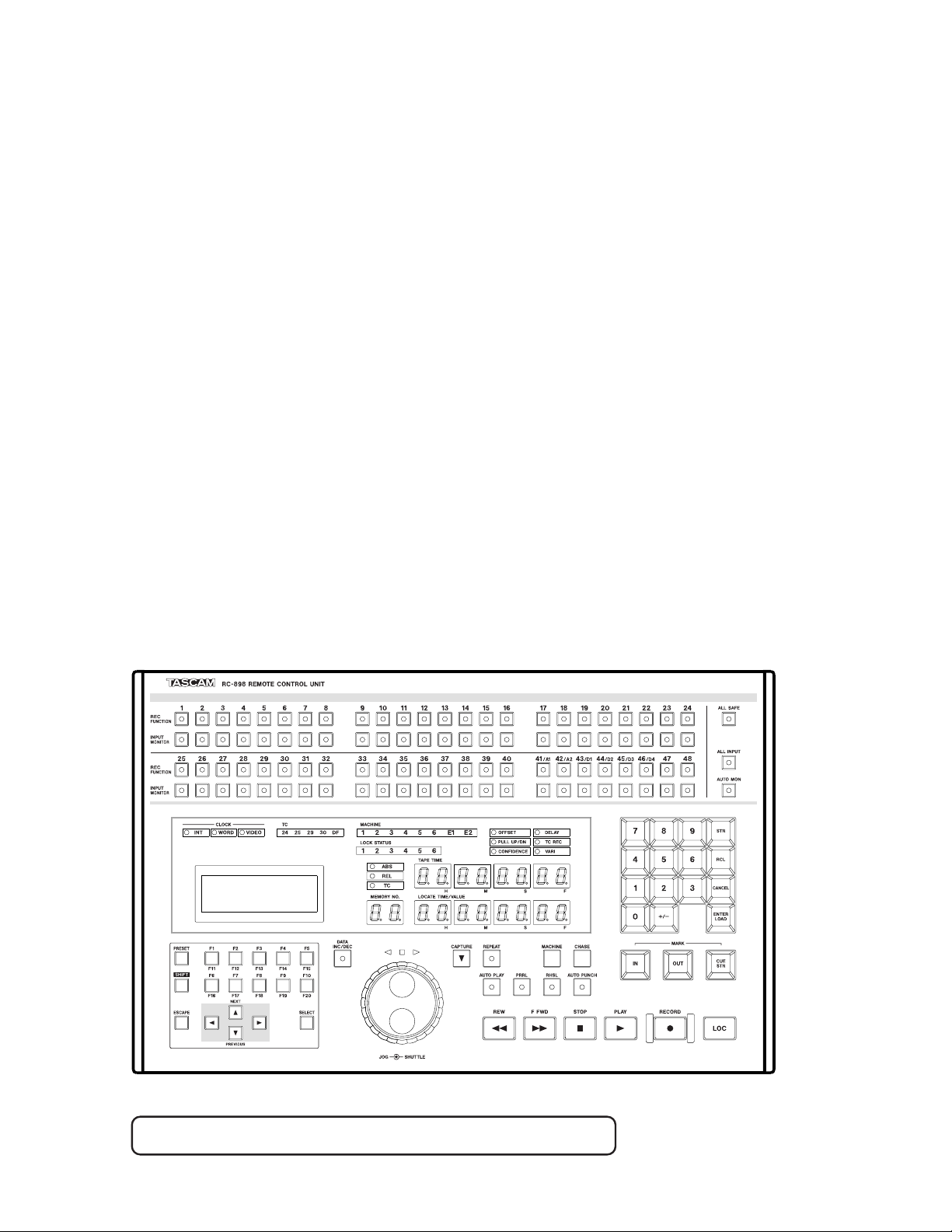

RC-898

Remote Control Unit

D00376100A

O WNER’ S MANUAL

Page 2

TO THE USER

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may

cause harmful interference to radio

communications.

Operation of this equipment in a residental area is

likely to cause harmful interference in which case

the user will be required to correct the interference

at his own expense.

CAUTION

Changes or modifications to this equipment not

expressly approved by TEAC CORPORATION for

compliance could void the user's authority to

operate this equipment.

For the consumers in Europe

WARNING

This is a Class A product. In a domestic environment, this

product may cause radio interference in which case the

user may be required to take adequate measures.

Pour les utilisateurs en Europe

AVERTISSEMENT

Il s'agit d'un produit de Classe A. Dans un environnement

domestique, cet appareil peut provoquer des interférences

radio, dans ce cas l'utilisateur peut être amené à prendre

des mesures appropriées.

Für Kunden in Europa

Warnung

Dies is eine Einrichtung, welche die Funk-Entstörung nach

Klasse A besitzt. Diese Einrichtung kann im Wohnbereich

Funkstörungen versursachen ; in diesem Fall kann vom

Betrieber verlang werden, angemessene Maßnahmen

durchzuführen und dafür aufzukommen.

For U.S.A

i – 1.00

Page 3

Table of Contents

1 –Introduction

1.1 Key features

1.2 Unpacking

1.3 About this manual

1.4 Precautions and recommendations

1.4.1 Environmental conditions.. .. ......... .. ... ......... . 1-2

1.4.2 Battery backup......... .. ......... .. ... ......... .. .. .... 1-2

1.4.3 Digital au dio cables....... ... .................. .. .. .... 1-2

1.4.4 Referenc e clock in a digital stud io ........ .. ...... 1-3

1.5 Accessories

.............................................. 1-1

................................................. 1-1

.................................... 1-1

........ 1-2

............................................... 1-3

2 –RC-898 features

2.1 Front panel

[1] REC FUNCTION keys ........ ................... ........... 2-2

[2] INPUT MONITOR keys..................................... 2-2

[3] ALL SAFE key ............................................... 2-2

[4] ALL INPUT key and indicator ........... ................ 2-2

[5] AUTO MON key and indicator........................... 2-2

[6] CLOCK indicators (INT, WORD and VIDEO) ........ 2-2

[7] TC indicators (24, 25, 29, 30, DF)....................... 2-2

[8] MACHINE number indicators (1 through 6, E1, E2)2-3

[9] LOCK STATUS indicators................................ 2-3

[10] OFFSET, PULL UP/DN, CONFIDENCE, DELAY,

TC REC, VARI indicators................. ......... ......... 2-3

[11] LCD display screen ...................................... 2-3

[12] Time Mode indicators.................................... 2-3

[13] TAPE TIME display ....................................... 2-3

[14] MEMORY NO. display........... .................. ....... 2-3

[15] LOCATE TIME/VALUE display ........................ 2-3

[16] Numeric keypad........................................... 2-3

[17] ST R ke y........ .. ... .. ..... .. .. ... .... .. ... .. .. ..... .. .. ... .. 2-3

[18] RCL key........................ ......... .......... ......... .. 2-3

[19] CANCEL key................................ ................ 2-3

[20] ENTER/LOAD key.... .......... .................. ......... 2-4

[21] PRESET key................................................ 2-4

[22] F1 through F10 function keys.................. ....... 2-4

[23] SHIFT key ................................................... 2-4

[24] ESCAPE key................................................ 2-4

[25] Cursor keys................................................. 2-4

[26] SELECT key ................................................ 2-4

[27] DATA INC/DEC key and indicator.................... 2-4

[28] JOG dial and SHUTTLE wheel......... ......... ....... 2-4

[29] CAPTURE key....................................... ....... 2-4

[30] REPEAT key and indicator ............................. 2-4

[31] MACHINE key ................................ ......... ..... 2-4

[32] CHASE key.................................... .............. 2-4

[33] AUTO PLAY key and indicator........................ 2-5

[34] PRRL key and indicator...... .................. ......... 2-5

[35] RHSL key and indicator...... .................. ......... 2-5

[36] AUTO PUNCH key and indicator...................... 2-5

[37] MARK IN key ...................... .................. ....... 2-5

[38] MARK OUT key... ......... ......... ......... ......... ..... 2-5

[39] C U E STR key.......... ... .. .. ... .... .. ... .. .. ... .... .. ... .. 2- 5

[40] Transport controls................................... ..... 2-5

[41] L OC ke y. ... .. .. .. ..... .. ... .. ..... .. .. .. ... .... ... .. .. ..... .. 2- 5

2.2 Rear Panel

[42] EXT 1 – parallel and GPI port.......................... 2-5

[43] EXT 2 - serial port......................................... 2-5

[44] REMOTE OUT connector . ......... ................... .. 2- 5

[45] DIP switches (1 & 2)...................................... 2-6

[46] C o n t ra st ......... ... .... ... .. .. ..... .. .. ... .. ..... .. .. .. ..... 2- 6

................................................ 2-2

................................................. 2-5

3 –Connections

3.1 Connection to DTRS units

3.1.1 Machine IDs... ... .................. .. ... ......... .. ...... 3-1

3.2 Connections (parallel units)

3.2.1 Connections (GPI event units)..... .. .. ......... ... . 3-2

3.2.2 Parallel control/GPI pinout....... ... .. ......... .. .... 3- 2

....................... 3-1

.................... 3-2

3.3 Connections (RS-422 units)

3.4 A note on system clocks

3.5 Memory and batteries

.....................3-2

.......................... 3-2

...............................3-3

4 –Menu and basic operations

4.1 Navigation

4.1.1 Invalid operations ...................................... 4-1

4.2 Data entry

4.2.1 Resett in g values to zero.............................. 4-2

4.2.2 Fast setting of values.................................. 4-2

4.2.3 Setting values using the VALUE display......... 4-2

4.2.4 “Fin e-tuning” values................................... 4-3

4.3 Selecting the unit controlled by the

menus

4.4 Commonly-used menus

4.4.1 Assi gning menus to function keys ................ 4-4

4.4.2 Recalling menus using the function keys ....... 4-4

4.5 Storing and recalling user setups

4.5.1 Saving the current setup ............................. 4-4

4.5.2 Recalling a user setup or restoring factory

settings

.................................................. 4-1

.................................................. 4-2

............................................................ 4-3

........................... 4-3

...........4-4

......................................................... 4-5

5 –Basic DTRS operations

5.1 Transport controls

5.1.1 Selecting the unit to which operations refer.... 5-1

5.1.2 Formatting tapes........................................ 5-1

5.1.3 Arming tracks............................................ 5-2

5.1.4 ALL SAFE ................................................. 5-2

5.1.5 Transport controls...................................... 5-2

5.1.6 Shuttle mode............................................. 5-2

5.2 Monitoring

5.2.1 ALL INPUT ................................................ 5-3

5.2.2 INPUT MONITOR keys................................. 5-3

5.2.3 Shuttle monitoring...................................... 5-3

5.2.4 Shuttle muting ........................................... 5-3

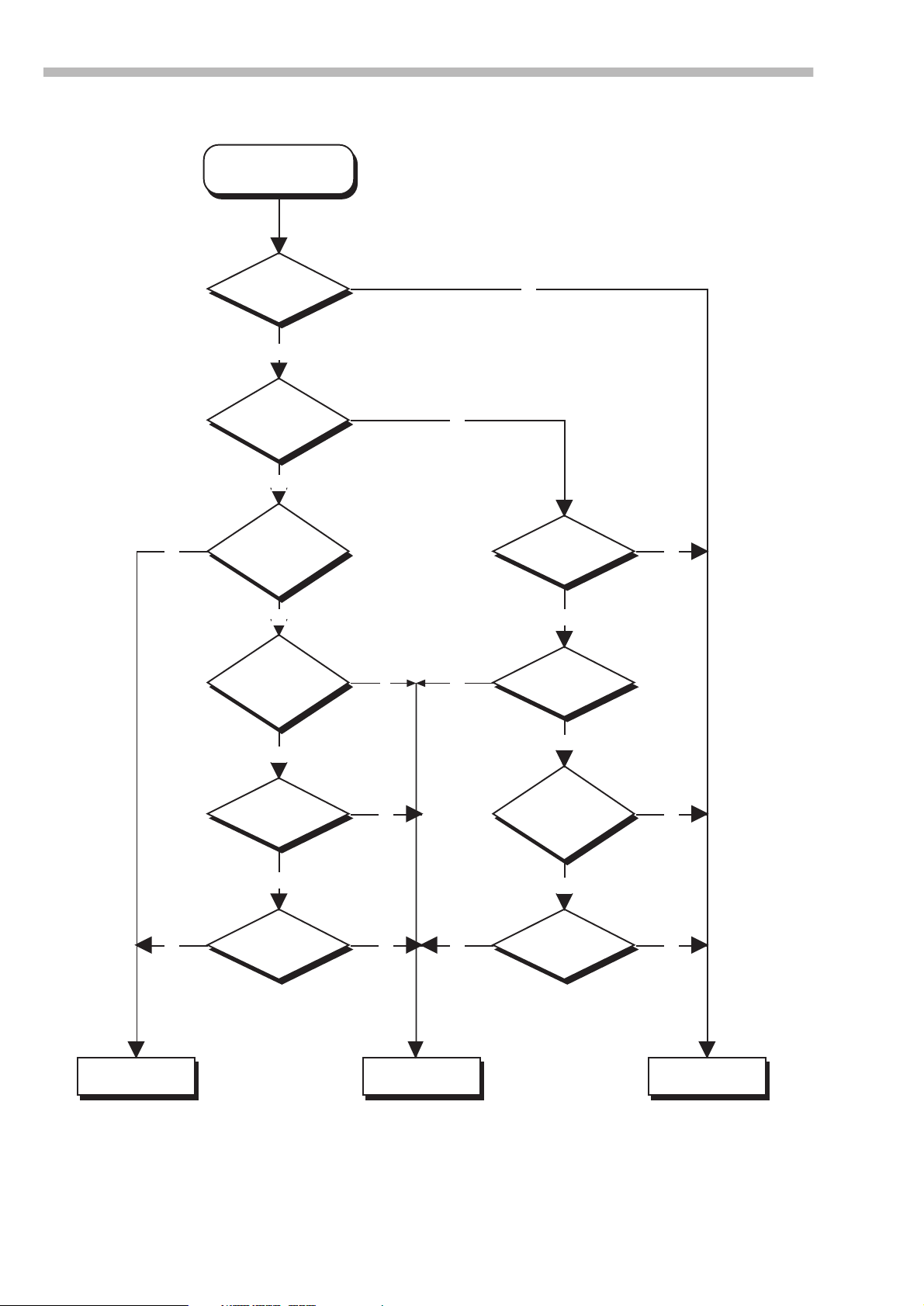

5.2.5 Monitoring flowchart................................... 5-4

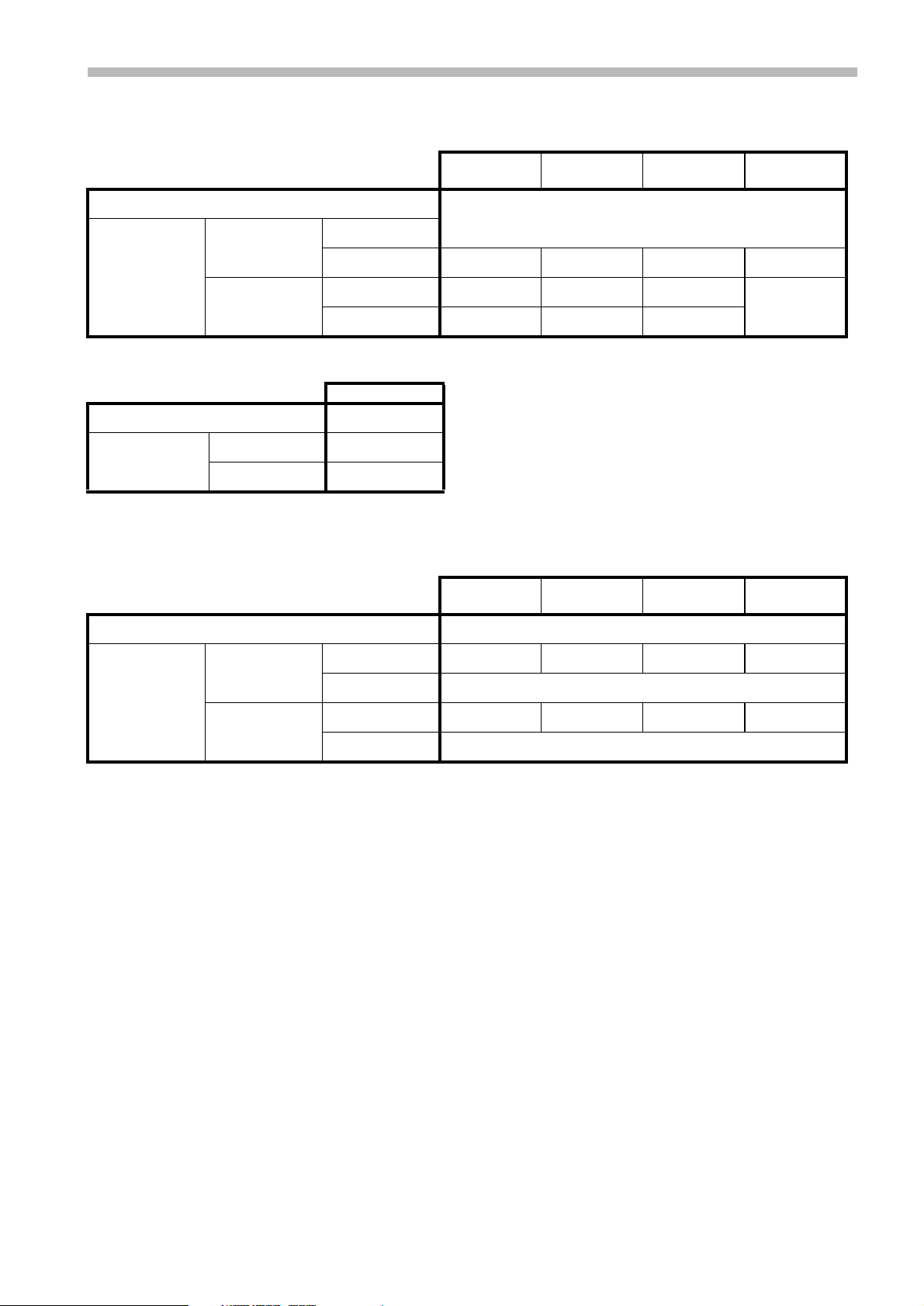

5.2.6 Monitoring tables ....................................... 5-5

.................................................5-2

.................................... 5-1

6 –Location functions

6.1 Reference modes

6.2 Setting the precisi on

6.3 Setting a relative time reference

6.3.1 “Return-to-zero” ........................................ 6-2

6.4 ABS setting

6.4.1 A note on ABS frame rate ............................ 6-2

6.4.2 Selecting Time Mode .................................. 6-2

6.5 Location operations

6.5.1 Setting the location pre-roll value.................. 6-3

6.5.2 Auto play .................................................. 6-3

6.5.3 “Instant” location ....................................... 6-3

6.5.4 Manual entry of a location point.................... 6-4

6.5.5 Edit in g a loc at ion ....................................... 6-4

6.5.6 Stor ing the location in a memory .................. 6-4

6.5.7 Recalling a location memory........................ 6-4

6.5.8 Repeated entry of location points.................. 6-5

6.5.9 Edit in g a loc at ion memo ry ........................... 6-5

6.6 Repeating a section

6.7 Punch operations

6.7.1 Setting punch points .................................. 6-6

6.7.2 Checking punch points ............................... 6-6

6.7.3 Editing punch points .................................. 6-6

6.7.4 Undo function............................................ 6-6

6.7.5 Setting pre-roll and post-roll times ................ 6-7

6.7.6 Crossfade times......................................... 6-7

6.7.7 Rehearsing the punch recording................... 6-7

6.7.8 Performing the punch recording ................... 6-7

......................................6-1

................................6-1

..............6-1

................................................6-2

.................................. 6-3

.................................. 6-5

......................................6-6

TOC-i

Page 4

Table of Contents

7 –Making settings on the DTRS units

7.1 Track operations

7.1.1 Track delay.............. .. .. ......... ... .. ......... .. ... . 7-1

7.1.2 Track copying ..... .. ................... .. .. ......... ... . 7-1

7.1.3 Rec Mute function......... .. ... ......... .. ... ......... . 7-2

7.2 Unit-related functions

7.2.1 Chasing to ABS sync..... ................... .. ........ 7-2

7.2.2 Key Mode......... .. ......... .. ... ......... .. ............. 7-2

7.2.3 Chasing with an offset ... .. ................... .. ...... 7-3

7.2.4 Auto Offset functi on............... ... .. ......... .. ... . 7-3

7.2.5 Checking the offset... ......... .. .. .......... .. .. ...... 7-4

7.2.6 Clock selection.... .. ... ......... .. .................. ... . 7-4

7.2.7 Output timing...... .. ................... .. .. ......... ... . 7-4

7.2.8 Varispeed (pi t ch control)....... ......... ... .......... 7-5

7.2.9 Input selection................ ... .................. .. ... . 7-5

7.2.10 Word length................ .. ... ......... .. ... ......... . 7-5

7.2.11 Dither........................ .. ... ......... .. ............. 7-5

7.2.12 Confidence mode........ ......... ... ................. 7-6

7.2.13 Referen ce levels........ .. ......... ... .. ......... .. ... . 7-6

7.2.14 Meter modes...................... .. ................... . 7-6

7.2.15 Sine osci llator...... ... ......... .. .. .......... .. .. ...... 7-6

....................................... 7-1

............................... 7-2

8 –Timecode functions

8.1 Primary timecode functions

8.1.1 Selecting the timecode source ...... .. ... ......... . 8-1

8.1.2 Synthesizing timecode from ABS times ......... 8-1

8.1.3 Selecting a timecode type............. ......... .. ... . 8-2

8.1.4 Setting the gener ator start time ................ ... . 8-2

8.1.5 Starting and stopping the generator.... .. ........ 8-3

8.1.6 Checking the generator progress.............. ... . 8-3

8.1.7 Recording the timecode on a DTRS

timeco de trac k .... ................... .. .................. ... . 8-3

8.1.8 Chasing to external timecode....................... 8-4

8.1.9 Chasing with a timecode offset............... .. ... . 8-4

8.1.10 Auto Timecode Offset function ...... ... ......... . 8-5

8.1.11 Independe n t clock settings ....... .. ............... 8-5

8.2 Advanced timecode functions

8.2.1 Timecode output source ............ .. .. ......... ... . 8-5

8.2.2 Synchronization of timecode.... .......... .. .. ...... 8-6

8.2.3 Pull up and pull down .................... ... .. ........ 8-6

8.2.4 Error bypass......... ... .................. .. ............. 8-6

8.2.5 Rechase mode................ ... .. ......... ... .......... 8-6

8.2.6 Fast LTC........... .. .. ......... ... .. ......... ... .. ........ 8-7

8.2.7 MIDI Timecode output................ .. ............... 8-7

8.2.8 Park positio n.............. .. ......... ... .. ......... .. ... . 8-7

8.2.9 Individual recording status while chasing

timecode

8.2.10 Video resolve....... ... .. ......... .. ... ......... .. .. .... 8-8

........ .. ......... ... .. ......... .. ... ......... .. .. .... 8-8

.................... 8-1

................. 8-5

9.4.8 Cue-up tally............................................... 9-6

9.4.9 MM C I D..................................................... 9-6

10 –Menu and parameter reference

10.1 Menu groups

10.1 Menu group 0 ........................................... 10-1

10.1 Menu group 1 .......................................... 10-2

10.1 Menu group 2 ........................................... 10-2

10.1 Menu group 3 ........................................... 10-3

10.1 Menu group 4 ........................................... 10-3

10.1 Menu group 5 ........................................... 10-4

10.1 Menu group 6 ........................................... 10-4

10.1 Menu group 7 ........................................... 10-5

10.1 Menu group 8 ........................................... 10-5

10.1 Menu group 9 ........................................... 10-6

10.1 Menu group A........................................... 10-6

10.1 Menu group E........................................... 10-6

10.1 Menu group F........................................... 10-7

10.2 Alphabetical list of menu items

10.3 Specifications

10.4 Dimensions

......................................... 10-1

...........10-8

.......................................10-9

...........................................10-9

9 –External control and settings

9.1 Controlling the parallel por t device

9.2 Controlling GPI devices

9.2.1 Setting up GPI devices... .. .......... .. .. ......... ... . 9-1

9.2.2 Setting the trigger points....... ......... ... .. ........ 9-1

........................... 9-1

9.3 Controlling the serial port (9-pin)

9.3.1 Selecting the serial port device........ ... ......... . 9-2

9.3.2 Location pre-roll on the serial unit ................ 9-2

9.3.3 Serial unit timing source ............ .. .. ......... ... . 9-3

9.3.4 Split mode on the serial unit ........... ......... ... . 9-3

9.3.5 Controlling recording operations on the serial

unit ........ .. ................... .. .. ......... ... ................. 9-3

9.4 Other DTRS control functions

9.4.1 Choosing a control protocol .................. .. ... . 9-4

9.4.2 Track mapping f unctions....... .. .......... .. .. ...... 9-4

9.4.3 Timecode track mapping.. .......... .. .. ......... ... . 9-5

9.4.4 Remote track arming.............. ... .. ......... .. ... . 9-5

9.4.5 Device emulation ... ... ......... .. .. .......... .. .. ...... 9-5

9.4.6 Recording delay............................... .. .. ...... 9-5

9.4.7 Fast wind speed........................ .. ............... 9-6

TOC-ii

........ 9-1

........... 9-2

................. 9-4

Page 5

Section 1.1 - Key features

1 – Introduction

The RC-898 is a fully-featured remote control

unit, which allows you to control up to six DTRS

units (DA-98, DA-88 or DA-38 units) with a single cable, as well as units implementing the Sony

P2 protocol, or using parallel control. As an alternative to parallel control, up to five GPI eventcontrolled units can be connected.

In addition to providing almost all functions available from the front panels of the DTRS units, the

RC-898 in some cases actually extends the capabilities of the basic DTRS system.

1.1 Key features

• DTRS units controlled b y the RC-898 are

locked to sample accuracy, providing you with

a “virtual” digital multitrack recorder, with up

to 48 tracks.

• Up to 99 location memori es may be entered (o r

captured) and edited to frame accuracy, for

marking important points in a recording

project.

• Timecode values are entered and edited using a

positive- feel numeri c ke ypad.

• The DTRS units’ transport functions, including

the shuttle control, are duplicated on the RC-

898. These transport controls may also be used

to control the RS-422 or parallel external

machine.

• The RC-898 also features a jog dial, allowing

frame-by-frame manual location.

• The jog dial can a lso be used as a data entr y

control for the entry of location point and other

values.

• Auto-punch operations are fully supported. The

RC-898 provides one-ke y operation for

rehearsal and recording with automated punch

points.

• System settings, for the DTR S units an d for the

RC-898 itself, are made using a conv enient

menu system, and displayed on a clear backlit

20-character x 4-line display.

• The most frequently-accessed setting menus

can be assigned to function keys, so that they

may be easily recalled.

• Lighted indicators give an instant indication of

the status of the most import ant functions.

• All timecode formats are supported, as well as

pull-up/pull-dow n, making the RC-898 the

ideal choice for po st-production work in both

the movie and vide o fields.

• Up to ten diffe rent setups can be stored and

recalled, allowing instant re-conf iguration, not

only of the RC-898, but also of all DTRS units

connected to it.

1.2 Unpa cking

The box contains the following.

• RC-898 Remote Control Unit (x 1)

• Accessories:

• Remote/sync connection cable (x 1)

• Remote/sync terminator (x 1)

• This manual (x 1)

• Warranty card ( x 1)

1.3 About this manual

This manual is written in sections according to the

function that you will be performing.

• Section 1 - “Introduction”: This section.

• Section 2 - “RC-898 f eatures”: The front and

rear panel features of the RC-898.

• Section 3 - “Connections”: How to hook up the

RC-898 with other equipment.

• Section 4 - “Menu and basic operations”: How

to use the men u sys tem , and th e bas ic p ri nci ples of operating the RC-898.

• Section 5 - “Basic DTRS operations”: The

main everyday transport and other operations

that you will perform when using the RC-898

with DTRS u nit s.

• Section 6 - “Location functions”: Using the

location functions of the RC-898.

• Section 7 - “Making settings o n the DTRS

units”: more advanced DTRS settings, that you

will probably not need to make every day.

• Section 8 - “Timecode function s”: Functions

related to timecode and DTRS units.

• Section 9 - “External control and settings”:

Other control functions, and control of units

other than DTRS (P2, GPI, etc.).

• Section 10 - “ Menu and parameter reference”:

A guide to the menu items, together with

parameters and default values.

Please check both the Table of Contents and the

Index when you are searching for a particular

function or operation. There is also a guide to the

different menu screens available on the RC-898

(10, “Menu and parameter reference”).

When descri bing a control, display or connector,

the name of the control is emphasized, as: “Press

the

STR

key [17]”, or “the

CONFIDENCE

indi-

1-1

Page 6

Section 1.4 - Precautions and recommendations

cator [10] will light”. The number in brackets following the name of the control is the number of

the control as shown on the front panel illustration, as well as that used in the appropriate sections describing the front and rear panels.

A special font is used for showing the messages

that appear on the LCD display screen [11], for

example:

When describing a value as shown on the

TIME

TIME/VALUE

used:

9Pin Locate Preroll.

MEMORY NO

[13],

[14], or

LOCATE

[15] displays, the following font is

00:23:45:12

or on.

TAPE

Some functions of the RC-898 apply to all DTRS

recorders, some only to DA-98 u nits, s ome to DA38 units and some to DA-88 units with the SY-88

synchronizer board fitted. Wherever appropriate,

this manual will use combinations of the following symbols t o show what operations may be performed with the different units in the DTRS range:

• Relativ e humidity should be between 30% a nd

80% non-condensing

• Avoid spraying polish, insecti cides, etc. near

the RC-898.

WARNING

If you need to clean the unit, use a soft cloth, moistened if

necessary with a little detergent and water. Do not use abrasive cleaners or solvents such as alcohol or thinner.

• Avoid subjecti ng the RC-898 to jolts, sudden

shocks, etc.

WARNING

If you have to return the unit for service or repair, use the

original packing materials if possible. If the unit is to be

transported to a recording location, etc., use a suitable trans port case with sufficient shock protection.

TASCAM does not accept responsibility for damage resulting from neglect or accident.

Unit Symbol in text

All units No symbol

DA-88 with SY-88

DA-38

DA-98

88

38

98

This manual may also make references to the

manuals of the DTRS units and the SY-88. In the

case of the DA-98 and DA-38, these references

will be made in terms of section numbers (e.g.

“4.2” and “4-5” respectively). In the case of the

DA-88 and SY-88, page numbers will be provided

(e.g. “p16” and “p5-7” respectively).

1.4 Precautions and recommendations

As with every precision piece of electronic equipment, common-sense precautions apply with the

RC-898.

However, you should note the following points in

particular with regard to the operation of the unit:

1.4.2 Battery backup

The RC-898 requ i res no power su pp l y of i ts own,

drawing its power from the DTRS units to which

it is connected.

Location memories and configuration settings are

stored using a battery backup system. The battery

should provide power for sev eral years of use.

When the battery eventually degrades to the point

where it cannot provide enough power to retain

settings, the message

Memory Error will

be shown on the display screen (this can be

removed by pressing the

ESCAPE

key).

When this message appears, all memories (location memories and configuration settings) are

cleared and reset to the default settings.

If you see this message, contact your TASCAM

dealer for details of battery replacement. Do not

attempt to replace the battery by yourself.

1.4.3 Digital audio cables

When making connections between TASCAM

digital audio units, always use genuine TASCAM

cables. This applies particularly to any T-DIF dig-

1.4.1 Environmental conditions

The RC-898 can be operated in most environments, but we suggest that you keep the environmental conditions within the following limits:

• Ambient temperature between 5° and 35° C

(41° and 95° F).

1-2

Page 7

ital audio connections between DTRS recorders,

DTRS recorders and digital mixing consoles, etc.

WARNING

Only use TASCAM-supplied and TASCAM-approved

cables when making such connections. Though the cables

and connectors may resemble computer cables, they serve

different purposes, and meet a dif f erent set of s pecifications .

The use of cables other than T ASCAM cables will at best

cause the equipment to work erratically, and at worst cause

damage to the equipment.

If the use of cables other than TASCAM cables causes or

results in damage, the warranty is voided.

1.4.4 Reference clock in a digital studio

It is likely that the RC-898 will be operated in an

environment where there is more than one digital

audio source available.

If this is the case, you must make sure that all digital audio sources in the setup are driven by the

same reference clock signal (“word clock” or

“Word sy nc”).

Section 1.5 - Accessories

If different clock sources are used throughout a

setup, it is actually possible to damage speakers,

etc. because of mismatches.

1.5 Accessories

Despite the powerful range of functions which

may be controlled from the RC-898, the unit is

relatively compact. It may be found convenient to

mount the RC-898 on a roll-around stand, available as CS-898.

Should you need extension meters from the tape

decks, this can be achieved usi ng MU-8824 meter

units and appropriate mounting hardware (MK-

8924).

1-3

Page 8

Section 1.5 - Accessories

1-4

Page 9

2 – RC-898 features

2 - RC-898 features

2-1

Page 10

Section 2.1 - Front panel

This section gives a brief ov erview of the front

and rear pane l co ntrols and their functions.

2.1 Front panel

[1] REC FUNCTION keys

These keys with integral indicators allow you to

set and view the track arming status of up to six

DTRS units attached to the RC-898, or f i v e DTRS

units and another recorder.

Trac ks 1 through 8 apply to the first unit, 9

through 16 to the second, and so on.

The last eight are used to control tracks 41

through 48 (the sixth DT RS unit) or may be used

for the two analog and four digital tracks of a P2

recorder, as marked (A1, A2, and D1 through

D4

). These keys are only available for this purpose when recording is enabled for the P2 unit

(see 9.3.5, “Controlling recording operations on

the serial unit”). When used to control the P2 unit

in this way, the last two

are unused.

[2] INPUT MONITOR keys

These keys with integral indicators allow you to

set and view the input monitoring status of the

tracks of any D A-98 units attached to the RC-898.

See section 7.1 of the DA-98 manual for details of

the operation of these keys, which function in the

same way a s t he keys on t he RC-898.

When the RC-898 is used to control DA-88 and

DA-38 units, the keys cannot be used, but the indicators still reflect the current monitoring status, on

a track-by-track basis, of the connected units.

[3] ALL SAFE key

This key (with integral indicator) is equivalent to

turning off all the

When all tracks are safed in this way, the

SAFE

indicator lights. When the

mode is tur ned of f (the indicator goes ou t), the

previous track arming status will be restored.

[4] ALL INPUT key and indicator

This key (with integral indicator) performs the

function of the

DTRS units. The indicator lights when the function is active.

ALL INPUT

REC FUNCTI ON

REC FUNCTI ON

ALL SAFE

key on the connected

keys [1].

keys

ALL

ual tracks when

Start recording or re-set the

ALL INPUT

is turned off again.

REC FUNCTION

keys to restore this.

[5] AUTO MON key and indicator

This key performs the same function as the AUT O

MON key on a DA-98. However , the DA-88 and

DA-38 are not equipped with a key with this label,

so the function is slightly different when controlling one of these units.

Pressing this key is the equivalent of pressing the

INSERT

both the

key on a c onn e cted DA-38, and p res s ing

AUTO INPUT

and

INSERT

keys on a

DA-88. It is used in punch modes to switch automatically between tape and source when punching

in and out automatically. The indicator lights

when this function is active.

Note that the status of the

keys on a DA-98 will be overridden by the

MON

key. Howe ver, when

INPUT MONITOR

AUTO

AUTO MON

is turned

off again, the original status of these keys will be

restored.

Changing the

tracks while

tionship between the

INPUT MONITOR

AUTO MON

when

recording or re-set the

REC FUNCTION

AUTO MON

is on will lose the rela-

REC FUNCTION

status for individual tracks

is turned off again. Start

REC FUNCTI ON

status of DA-98

and

keys t o

restore this.

[6] CLOCK indicators (INT, WORD and

VIDEO)

These indicators correspond to the indicators with

the same names on the currently-selected DTRS

unit.

To use the RC-898 to change the clock source on a

DTRS unit , see 7.2.6, “Clock selection”.

[7] TC indicators (24, 25, 29, 30, DF)

These indicators correspond to the system timecode type of the currently-selected DTRS unit.

Here, the

tion for “29.97” . The DF indicator will light if the

timecode is in drop-frame format.The supported

timecode types are therefore:

29

on the RC-898 panel is an abbrevia-

INPUT MONITOR

The

keys on a DA-98 also

affect the switching between source and tape.

Changing the

tracks while the

lose the relationship between the

TION

and

2-2

REC FUNCTI ON

ALL INPUT

INPUT MONITOR

status of any

function is on will

REC FUNC-

status for individ-

24

25

29

29 DF

30

30 DF

24fps (cine)

25fps (PAL/SECAM)

29.97 (NTSC color non-drop)

29.97 (NTSC drop-frame)

30fps (NTSC mono)

30fps drop-frame (NTSC color)

Page 11

Section 2.1 - Front panel

NOTE

30 fps drop-frame is only supported by DA-98 units.

To change the timecode type used by the system,

see 8.1.3, “Selecting a timecode type” .

[8] MACHINE number indicators (1

through 6, E1, E2)

This indicator shows the machine currently

selected for control with the transport keys. , using

MACHINE

the

key [31]. 1 through 6 refer to

DTRS units. E1 and E2 refer to VTRs, etc. which

may be connected to the RC-898. E1 is connected

to the parallel port, and E2 to the 9-pin RS-422

port

[9] LOCK STATUS indicators

These indicators show the current lock status of

the DTRS units as they chase to external synchronization sources. For units 2 through 6, the external synchronization master will typically be the

first DTRS unit (1) in the chain.

There are four modes displayed by these

indicators:

On

Fast flashing

Slow flshing

Off

The slave unit is chasing the master and is

locked to it.

The slave unit is in chase mode, is in fast forward or rewind mode, and is not locked to the

sync master.

The slave unit is in chase mode, stopped, and

is not locked to the sync master.

The unit is not in chase mode.

[10] OFFSET, PULL UP/DN,

CONFIDENCE, DELAY, TC REC,

VARI indicators

These indicators are used to show the status of the

appropriate mode on the currently-selected unit.

The status is changed using the menus on the display screen.

In addition, changing the values from the front

panel of a DTRS unit connected to the RC-898

will change the status of this indicator, if the unit’s

number corresponds to the current

MACHINE

number [8].

[11] LCD display screen

This 20-character x 4-line backlit display screen is

used to show and set the different parameters

available with the RC-898.

[12] Time Mode indicators

Only one of these indicators will be lit at any one

time. They indicate the timecode reference (time-

code; TC, or absolute time;

ABS

) in use by the

currently-selected DTRS unit and shown on the

TAPE TIME

REL

The

indicat or [13].

indicator, when lit, shows that the current time, relative to a user-defined reference

point, as explained in 6.3, “Setting a relative time

reference”, is currently being displayed.

[13] TAPE TIME display

This display shows the current tape time on the

currently-selected unit. The time reference is

shown by the indicators a t [12].

[14] MEMORY NO. display

This 2-digit counter shows the location memory

which is currently in use (for storage, recall or

location).

[15] LOCATE TIME/VALUE display

This display shows the time of the location memory currently referenced by the

MEMORY NO.

indicator [14] or entered using the numeric keypad

[16].

It is also used to show time values which are set as

control parameters in various menu screens.

[16] Numeric keypad

The ten number keys are used for direct entry of

values for location memories, etc., to select location memories for store, recall, etc., or for the

entry of time values into LCD display menu

parameters. The

+/–

key is used to change a posi-

tive to a negative value, or vice versa.

+/–

The

key is also used with relative times, as

explained in the relative time setting section in see

6.3, “Setting a relative time reference”.

[17] STR key

This key is used to start the process for storing a

timecode value to a location memory . See 6.5.6,

“Storing the location in a memory” for details.

[18] RCL key

This key is used to start the process for recalling a

timecode value from a location memory. See

6.5.7, “Recalling a location memory” for full

details.

[19] CANCEL key

This key is used to cancel the selection of a location memory with the number keys, before storing

a time to it or recalling a time. It may also be used

to cancel the setting of a numerical value if it has

been wrongly entered.

2-3

Page 12

Section 2.1 - Front panel

[20] ENTER/LOAD key

This key is used to confirm the entry of numerical

values of location times or memories or when

used with the

shown in the

[15] to the parameters being set in the display

screen.

SHIFT

LOCATE TIME/VALUE

key [23], transfers the data

display

[21] PRESET key

This key is used to assign sp ecif ic softw are menus

to the function keys [22]. See 4, “Menu and basic

operations” for details of menu operations.

[22] F1 through F10 function keys

These keys are used with frequently-used menus,

so that one keypress will bring up these menus.

The keys may be “shifted” [23] to provide a second bank of 10 less frequently-used menu keys.

[23] SHIFT key

This key is used to provi de a second ba nk of ten

function keys for quick access to frequently-used

menus.

It is also used with the UP and

to use them as

the selection of machines in the display screen

menus.

It is also used in conjunction with the

LOAD

parameters being set in the display screen.

key [20] to transfer entered values to the

NEXT

and

DOWN

PREVIOUS

keys [25]

keys for

ENTER/

[24] ESCAP E key

This key is used to move “up” through the menu

tree to the preceding menu screen.

[25] Cursor keys

The cursor keys are represented in this manual by

the words:

• up key

• down key

•left key

• right key

These keys are used to navigate through the menu

system and the parameters available.

UP

DO W N

LEFT

RIGHT

[26] SELECT key

This key is used as an “enter” key, to select an

item or to confirm the entry of a value.

[27] DATA INC/DEC key and indicator

This key, with its integral indicator, is used to

change the function of the

controlling the transport (indicator is unlit) and

incrementing or decrementing the values being

edited in the

[15] (indicator is lit).

LOCATE TIME/VALUE

JOG

dial [28] between

display

[28] JOG dial and SHUTTLE wheel

These controls work with DTRS units and with

units connected to the

They are used to simulate the “rock and roll” of an

open-reel tape deck, allowing precise positioning

of the controlled units. The indicators above the

controls show the current direction of the

medium’s movement.

When the

the

least significant f ield of the value shown in the

LOCATE TIME/VALUE

DAT A INC/DEC

JOG

dial acts as a data editing control for the

EXT 2

control port [43].

indicator [27] is lit,

display [15 ] .

[29] CAPTURE key

When this is pressed, the current time is displayed

LOCATE TIME/VALUE

on the

where it may be edited and stored as a location

memory, or used f or “one-shot” loc ation pu rposes.

display [15]

[30] REPEAT key and indicator

This key serves the same function as the REPEAT

key on the DTRS units, repeating playback

between the memory locations assigned for repeat

(see 6.6, “Repeating a section”).

The integral indicator will light steadily when

repeat mode is selected and the current time is

between these two locations, and flash when

repeat mode is selected, and the current time is

outside these locations.

[31] MACHINE key

Pressing this key repeatedly will cycle the

machine number indicators [8]. The indicator

which is lit shows which machine will be controlled by the transport controls of the RC-898.

The UP and

SHIFT

which the menu operation will be performed

(when shif t ed, t hey are known as the

PREVIOUS

screen. For details of menu operations, see 4,

“Menu and basic operations”.

2-4

DOWN

key [23] to choose the connected unit on

keys, repsectively). within each

keys are also used with the

NEXT

and

[32] CHASE key

Pressing this

number toggles the chase mode of the appropriate

unit.

See 7.2.1, “Chasing to ABS sync” and 8.1.8,

“Chasing to external timecode” for further details.

CHASE

key together with the unit

Page 13

Section 2.2 - Rear Panel

It is also possible to select “Machine 0” (only with

CHASE

this

(first slave) DTRS unit, and toggle the chase status

of this unit, with all other slave units in the chain

then changing to reflect the chase status of this

first slave unit.

key). This will control the second

[33] AUTO PLAY key and indicator

This key with its integral indicator works with

DTRS units. It allows the units to start playing

back automatically when a location point is

reached.

[34] PRRL key and indicator

This key with its integral indicator works with

DTRS units. It is used to locate the tape to the

punch-in position, minus the pre-roll time set for

punch operations (see 6.7.5, “Setting pre-roll and

post-roll times”).

For instance, if the punch pre-roll value is set to 5

seconds, and the punch-in point is “00:55:12:12”,

the unit will finish locating at 00:55:07:12.

of this key will store the current position to a location memory, and automatically increment the

location memory number, ready for the next store

operation. The memories can later be “fine-tuned”

using the jog dial [28] in the appropriate mode.

[40] Transport controls

These transport controls duplicate those available

on DTRS units. They may also be used to control

units connected to the E1 (parallel) and E2 (9-pin

serial) ports when the appropriate machine is

select ed ([8] and [31]).

[41] LOC key

This key provides one-touch operation to allow

location to the memory position shown on the

LOCATE TIME/VALUE

tion pre-roll time has been set (see 6.5.1, “Setting

the location pre-roll value”) the pre-roll offset will

be subtracted from the location value, and the

location will be to that new calculated value.

display [15]. If a loca-

[35] RHSL key and indicator

This key allo ws you to rehearse auto-punch operations on the units connected to the RC-898. For

full details, see 6.7, “ Punch operations”.

[36] AUTO PUNCH key and indicator

This key allows you to perform auto-punch operations on the units connected to the RC-898. For

full details, see 6.7, “ Punch operations”.

NOTE

The two keys above do not work in the same way as the

rehearsal and auto punch keys on DTRS units. Even if you

are an experienced user of DTRS equipment, we recommend that you read 6.7, “Punch operations” to get a full

understanding of punch operations when using the RC-898

to control recording operations.

[37] MARK IN key

This key allows you to set and check the punch-in

point for automatic punch operations. For full

details of how to use this key, see 6.7.1, “Setting

punch points”.

[38] MARK OUT key

This key allows you to set and check the punchout point for automatic punch operations. For full

details of how to use this key, see 6.7.1, “Setting

punch points”.

[39] CUE STR key

This key is used to capture a series of location

points (a cue list) “on the fly”. Successive presses

2.2 R ear Panel

[42] EXT 1 – parallel and GPI port

This port provides parallel control and tally signals or GPI control for event control, which may

be triggered from a small “cue list” in the RC-898 .

The pinout for this 15-pin ’D’-sub connector is

given in 3.2, “Connections (parallel units)”. You

will need to make your own cabl e, referr ing to the

the table above, and to the equivalent table in the

manual of the other equipment if you wish to control an external unit through parallel control, or if

you wish to send GPI events from the RC-898.

[43] EXT 2 - serial port

This 9-pin ‘D’-sub connector is used for the control of devices implementing the Sony P2 protocol. A cable designed for P2 connections may be

used with this port.

[44] REMOTE OUT connector

This connector is used for the control of the DTRS

units. It should be connected to the REMOTE I N/

SYNC IN of the first DTRS unit in the chain.

Only use a TASCAM cable, as supplied with the

RC-898, to make this connection. If your DTRS

units are at a greater distance than the cable provided (e.g. your machine room is som e distance

from your control roo m), consult your TASCAM

dealer for details of the availability of longer

DTRS control cables.

2-5

Page 14

Section 2.2 - Rear Panel

[45] DIP switches (1 & 2)

The two DIP switches are both on when in the

down position. As shipped from the factory,

switch 1 is off (up) and switch 2 is on (dow), and

you probably will not need to change them.

However, when a passive device is connected to

EXT 1

the

from the device to the tally supply pin, this switch

TALLY POWER

1 (

(down) position, allo wing the RC-898 to use its

own power for this purpose.

connector and power is not provided

) should be set to the on

Switch 2,

isolation of the ground of the RC-848/DTRS system from the ground of devices attached to the

EXT 1

the on (down) positio n, but y ou may need to turn it

off (up) if your system suffers from hum problems. However, a full discussio n of ground loo ps

and their associated problems is outside the scope

of this manual, and we recommend that you consult one of the many reference works on this subject if necessary.

GND LIFT

EXT 2

and

(ground lift) controls the

ports. Usually this switch is in

[46] Contrast

This control alters the contrast on the backlit LCD

display screen [11]. Use it to set the screen so that

it is easil y vi sible from your preferred viewing

angle.

2-6

Page 15

Section 3.1 - Connection to DTRS units

3 – Connections

This section describes not only the connection of

the RC-898 to other equipment, but also provides

some information on setting up a digital audio

system using the RC-898.

WARNING

All connections to the RC-898 should be made with the

power to all units turned off. If this is not done, the operation of the units may become unstable, and damage may

possibly occur.

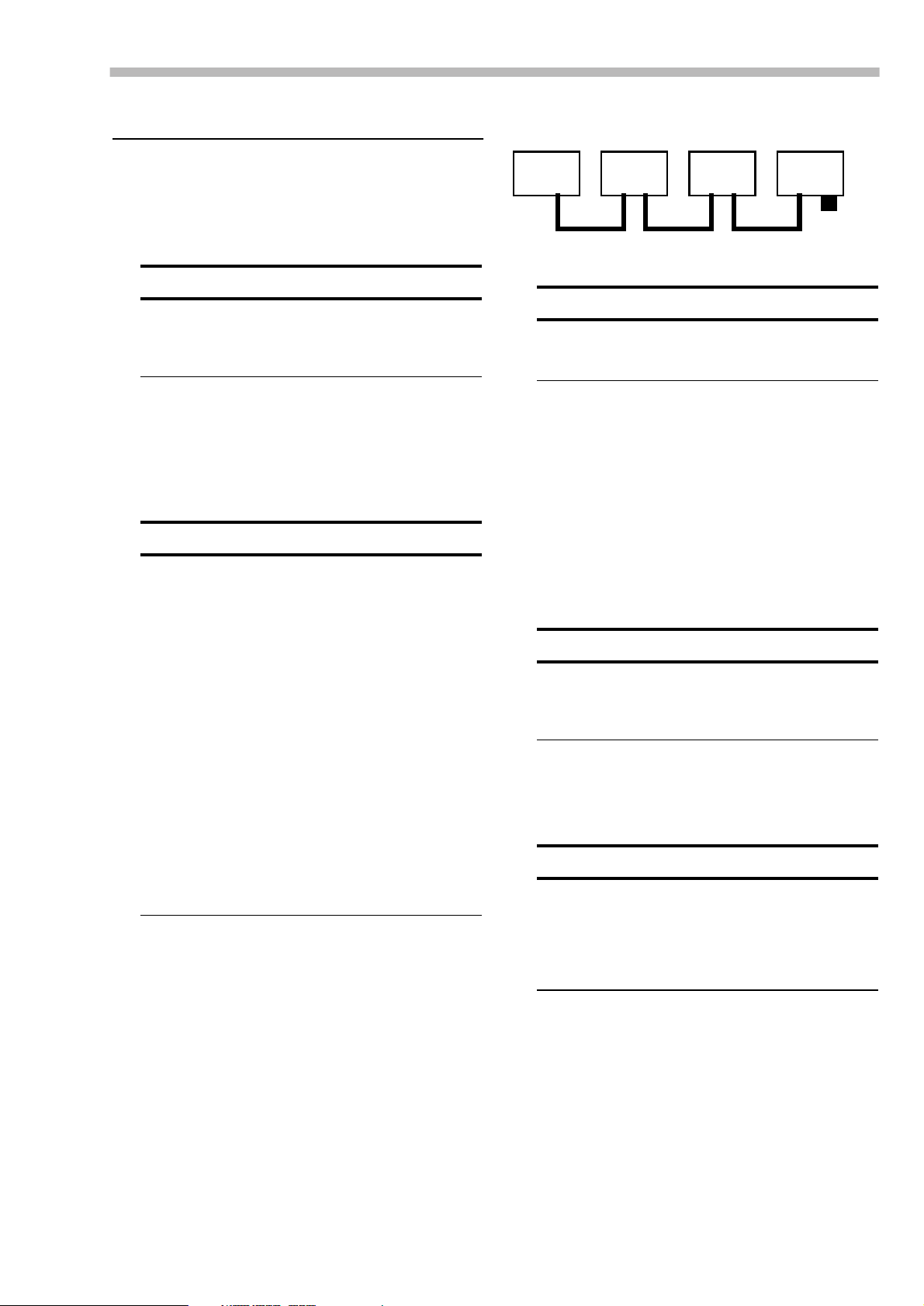

3.1 Conne ction to DTRS units

The RC-898 and DTRS units form a “daisychain”, with the RC-898 being at the head, and the

“tail” unit being terminated with the terminator

supplied with the RC-898.

NOTE

When you connect a number of DTRS units which are of

different types, including DA-98s, the DA-98 units should

be at the head of the chain immediately following the RC-

898. Any DA-38 and DA-88 units s hould then be connected

following the DA-98s. If there is more than one DA-98 in

the chain, they should be connected together, before the DA38s and DA-88s. The order of the DA-38 and DA-88 units is

not important.

If a DTRS unit other than a DA-98 is used as a master unit,

the automatic Output TC Source function and Timecode

Offset functions of the DA-98 may not work correctly (see

the DA-98 Owner’ s Manual, 10.5 and 13.2). In additoin,

remote control operation may not work correctly.

If the DTRS units are DA-88s and DA-38s only, they may

be connected in any order.

However, if you are operating a mixed set of DA-38s, and

DA-88s fitted with the SY-88 synchronizer board, we suggest that the SY-88-equipped DA-88 should follow the RC898, allowing it to serve as a timecode slave, and a DTRS

chase master for the DA-38s.

Use the suppled cable to connect the RC-898 to

the REMOTE IN/SYNC IN of the first DTRS

unit, and a PW-88S cable to connect the SYNC

OUT of the first unit to the REMOTE IN/SYNC

IN of the next unit, and so on, until the terminator

is connected to the SYNC OUT of the last unit in

the chain.

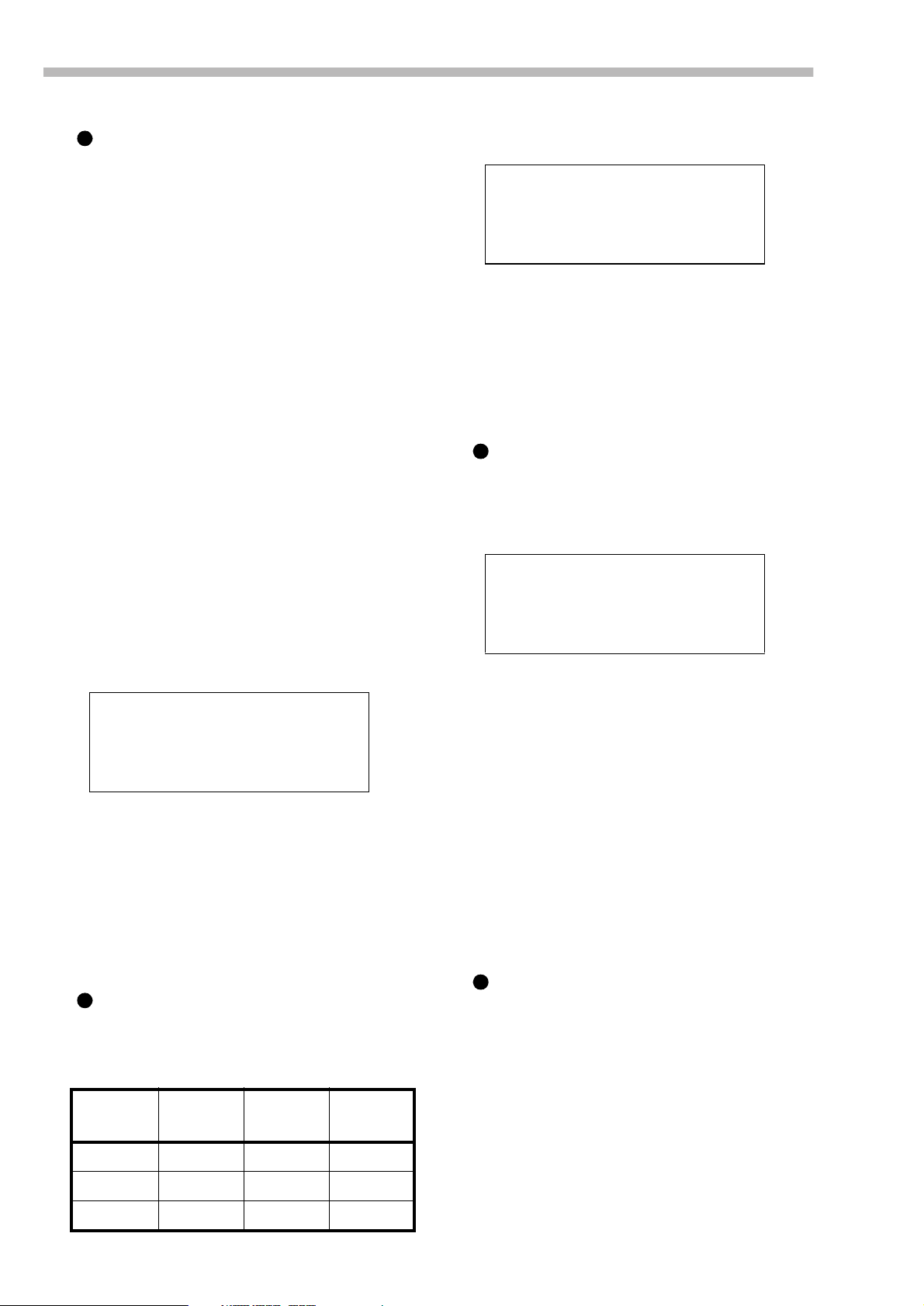

RC-898 DA-38DA-98 DA-88

OUT OUT OUT

Cable su p pl i ed

with RC-898

WARNING

Turn of f po wer to all units when making connections. If you

do not do this, there is a possibility that the RC-898 will

malfunction or even be damaged.

The RC-898’s

MONITOR

IN IN IN

PW-88S PW-88S

REC FUNCTI ON

and

Terminator

INPUT

keys 1 through 8 now control the first

unit, K eys 9 through 16 control the next unit in

the chain, and so on (regardless of the actual

Machine IDs of the units).

Tighten the screws holding the cable connector to

the RC-898 and to the DTRS unit. This will prevent accidental disconnection of the RC-898 in the

middle of a session.

WARNING

Use only TASCAM cables to connect the RC-898 to the first

DTRS unit, and to connect the DTRS units to each other. If

the use of cables other than TASCAM cables causes or

results in damage to the units, the warranty is voided.

No power connection is needed for the RC-898.

All power for the operation of the RC-898 is supplied by the first DTRS unit.

NOTE

The TASCAM TM-D8000 digital mixing console also

allows the control of DTRS units. However, it is not possible to use a TM-D8000 and RC-898 for control of DTRS

units in the same setup. Naturally, however, a TM-D8000

console can be used to mix the audio to and from DTRS

units controlled by an RC-898 unit.

3.1.1 Machine IDs

Set the machine IDs of the DTRS units so that the

IDs run in a sequence from the unit at the “head”

of the chain, closest to the RC-898 (lowest possible ID) to the “tail” unit (highest ID). There

should be no gaps in this sequence.

A DA-88 uses a rotary switch to set the ID and

uses 0 as the lowest ID, and a DA-38 or DA-98

uses software to make this setting, and uses 1 as

3-1

Page 16

Section 3.2 - Connections (parallel units)

the lowest ID. Refer to the units’ manuals for full

details of setting the ID.

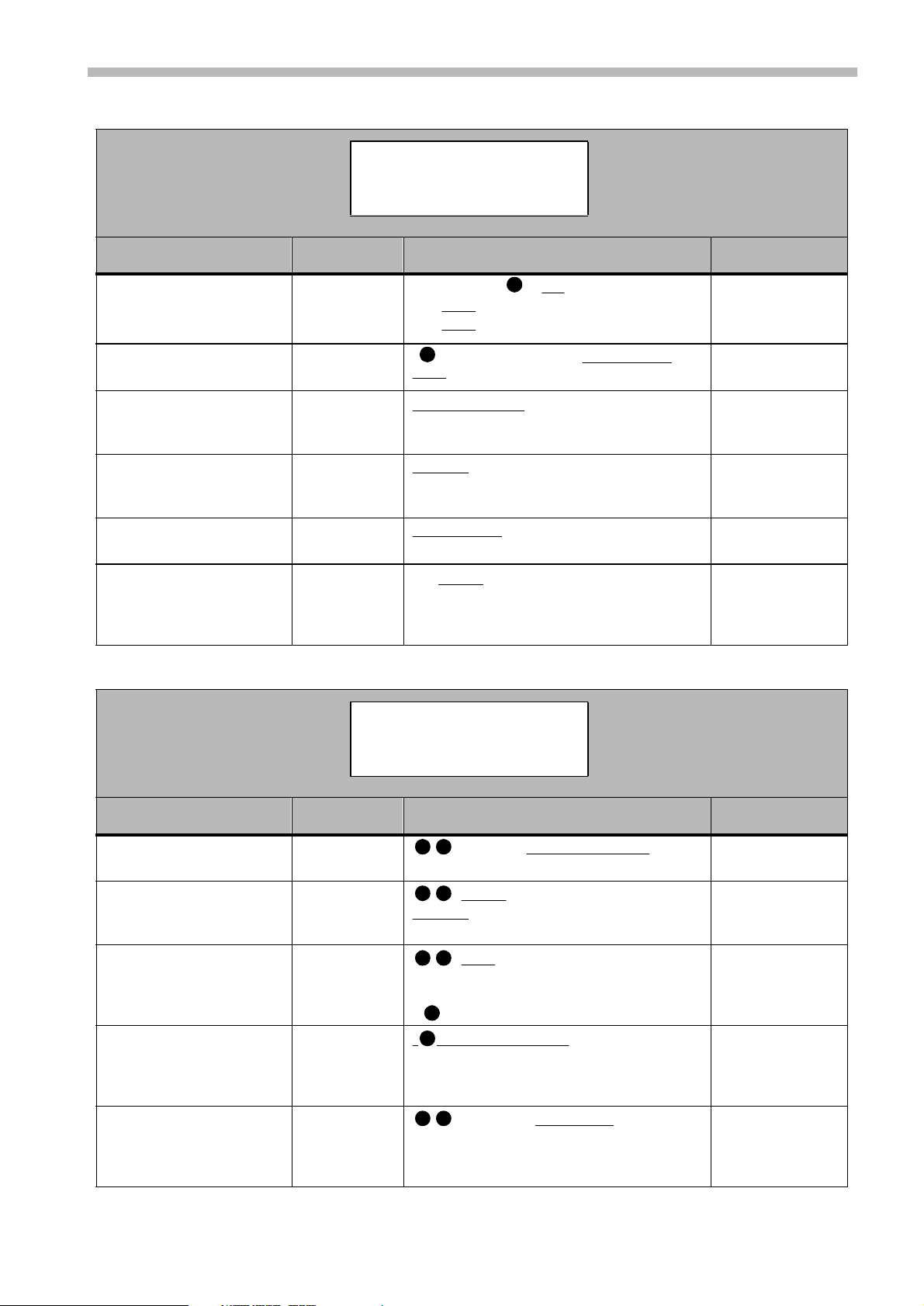

How the ID is

Unit

DA-98 1 1 Menu system (see

DA-88 0 1 Rotary switch on

DA-38 1 1 Tape counter menu

NOTE

When you set the machine IDs, you can set the ID of any

machine first, but we recommend doing this in a standard

sequence, working from the head of the chain to the tail.

set (see the

unit’s manual

for details)

ON

9.2)

OFF

rear panel (see p23–

24)

ON

system (see 7-2)

3.2 Conne ctions (parallel units)

The RC-898 allows transport control of a unit connected to the

this connection, check the specifications of the

other unit to ensure that the control pins available

match those provided by the RC-898, as sho wn

below in 3.2.2, “Parallel control/GPI pinout”.

NOTE

The RC-898 provides only transport control for a unit connected to the parallel port. Functions such as track arming,

etc. are not possible when using the

If a passive unit that does not supply power to the

tally supply pin (8) is being used, switch 1

T A LLY POWER

(

on (down) to allow the RC-898 to provide this

power.

3.2.1 Connections (GPI event units)

EXT 1

The

purpose of controlling up to five GPI event-controlled devices.

The way in which these devices may be triggered

from the RC-898 is explained in 9.2, “Controlling

GPI devices”.

EXT 1

parallel port. Before making

EXT 1

parallel port.

) of the RC-898 [45] must be set

parallel port may also be used for the

3.2.2 Parallel control/GPI pinout

The following table gives the pin assignments for

the parallel/GPI connector (

EXT 1

). GPI connec-

tions are shown in square brackets:

1

STOP/[Event 1]

2

PLAY/[Event 2]

3

FF/[Event 3]

4

REW/[Event 4]

5

REC/[Event 5]

6

N/C

7

Common

8

Tally supply

9

PLAY tally

10

FF tally

11

REW tally

12

STOP ta lly

13

REC tally

14

REC COMMAND tally

15

GND

3.3 Connections (RS-422 units)

The RC-898 allows control of a unit implementing

the Sony P2 protocol. This connection is made

through the

EXT 2

serial p o rt [43], u s ing a seria l

cable designed for this purpose. The pinout for

this connector is as follows:

1

Shield

2

RX+

3

TX–

4

GND

5

—

6

GND

7

RX–

8

TX+

9

Shield

Make the connection using a cable designed for

RS-422 connection (check the pinout of your P2

device before making the connection). This

machine may now be controlled by the RC-898

when the

E2 MACHINE

indicator [8] is lit.

3.4 A note on sy stem clocks

When working with many digital audio units, all

these un i ts must be fed from the same cl ock

source (either word or video). If this is not done,

there is a risk that speakers, etc. may be damaged.

Note that this clock master is entirely different

from the timecode master in a studio setup. It is

perfectly possible for a clock slave to be a timecode master and vice versa.

3-2

Page 17

3.5 Memory and batteries

As you have noticed, the RC-8 98 requires no

power supply of its own, drawing its power fr om

the DTRS units to which it is connected.

Location memories and configuration settings are

stored using a battery backup system. The battery

should provide power for several years of use.

When the battery eventually degrades to the point

where it cannot provide enough power to retain

settings, the message

be shown on the diaply screen (this can be

removed by pressin g t he

When this message appears, all memories (location memories and configuration settings) are

cleared and reset to the default settings.

If you see this message, c ontact your TASCAM

dealer for details of battery replacement. Do not

attempt to replace the battery by yourself.

Memory Error will

ESCAPE

key).

Section 3.5 - Memory and batteries

3-3

Page 18

Section 3.5 - Memory and batteries

3-4

Page 19

Section 4.1 - Navigation

4 – Menu and basic operat ions

The RC-898 sets parameters on the connnected

units using a menu system, with the parameters

and their values displayed on the LCD display

screen and selected and entered using cursor and

data entry keys.

4.1 Navigation

The menus are arranged hierarchically , from a top

(master ) menu, through to individual parameters.

The master “top” menu appears like this:

Select Menu Group

>01234567

89A EF

Dly/Tr.C/Vari /Loct

The cursor is represented here by the

Use the

LEFT

and

RIGHT

keys to move the cursor along a row, and the UP and

move it between rows.

> symbol.

DOWN

keys to

enter. F or the purposed of this example, we will

examine the

Vari Speed

Vari Spd

Machine 1

Fix + 0.0%

menu.

In this menu, there are two editable fields, as you

will see if you move the cursor with the

RIGHT

cursor keys. The cursor changes so that

LEFT

and

the field which is currently to be edited is highlighted by an underline cursor.

The first editable field is the

may be changed between the values of

Vari. The second field is the numerical field

Fix field, which

Fix and

which sets the amount of the varispeed as a percentage of normal speed. The values of both f ields

are set with the UP and

DOWN

cursor keys.

As soon as a value is changed, it is set. There is no

need to press any key to confirm the entry.

As the cursor moves over the menu group numbers, the bottom line of the screen will change to

show an abbreviated summary of the contents of

the menu group. In the example above, the contents of the

0 menu group are: track delay, track

copy settings, varispeed and the location pre-roll

setting.

When the cursor is over the menu group which

you wish to enter, press the

SELECT

key to enter

the menu group (menu group 0 is shown here):

>Delay Trk Copy

Vari Spd Loc Pre

1 0000 sample

Again, the bottom line of the display shows an

abbreviated version of some or all of the settings

made in the menu to which the cursor points.

When in a menu group, use the cursor keys to

move between options, and press

SELECT

when

the cursor is to the left of the menu you wish to

To return to a level above the current level, press

ESCAPE

the

ESCAPE

NOTE

Note that the

being controlled) cannot be set in this way (this is explained

in 4.3, “Selecting the unit controlled by the menus”).

key. You can continue pressing the

key until the top menu is reached.

Machine

value (i.e. which machine is

4.1.1 Invalid operations

Some operations are only possible on certain

models of DTRS recorder. For instance, timecode

functions are only available on the DA-98 and

DA- 88 units equipped with the SY-88 board, and

dithering is only possible with DA-38 and DA-98

units. If you attempt to perform an operation on a

unit where this operation is impossible, the message

Not available! will be shown on

the display screen to let you know that you cannot

perform this operation on the connected DTRS

unit.

Another ki nd of i n v al id ope rati on is whe n a DT RS

unit can perform a certain operation, but the

selected operation cannot be performed under the

current set of conditions (e.g. TDIF word length

cannot be set while analog inputs are selected). In

these cases, the word

shown on the displ ay.

Inoperable will be

4-1

Page 20

Section 4.2 - Data entry

4.2 Data entry

Typically, the UP and

the values in the display screen menus. However,

there are one or two additional features regarding

data entry which are explained here.

4.2.1 Resetting values to zero

In the case of large numerical values, it is sometimes tedious to keep pressing the cursor keys

until the value returns to zero.

Accordingly , to reset a v alue to zero:

1) Press and hold down either the UP or

key.

2) While holding down this key, press the other

DOWN

(i.e.

if you are holding the UP key, and

vice versa).

4.2.2 Fast setting of values

In addition to being able to reset large values to

zero, it also sometimes necessary to input large

values. This can be done easily in the following

way:

DOWN

keys are used to set

DOWN

2) With the cursor as shown (next to the Machine

Offset menu item), press

Machine Offset

Machine 1

+00:00:00:00 ABS

SELECT

again:

3) Use the numeric k eypad to enter the offset time

(use the

+/–

key to change between positive and

negative offset).

The value s enter ed using the key pad will app ear in

LOCA TE TIME/VALUE

the

up” from the right. For instance, if the time to be

entered is 01:23:07:10, the following keys should

be pressed:

Key Display shows

1

00:00:00:01

2

00:00:00:12

3

00:00:01:23

0

00:00:12:30

7

00:01:23:07

1

00:12:30:71

0

01:23:07:10

display [15] , and “f ill

1) Press and hold down the UP or

DOWN

key (as

appropriate).

2) While holding down this key, press and hold

down the

SELECT

key. As long as this key is

held down, the values will change quicker than

if this UP or

DOWN

key on its own is held

down.

4.2.3 Setting values using the VALUE display

As well as using the LCD display, the

TIME/VALUE

LED display [15] and numeric

keypad [16] may be used for entry of time values

into certain parameters which are set through the

menu system.

The machine offs et value from menu group 3,

which is e xpr esse d in ho urs, m inu tes, sec onds and

frames, is a useful example of this operation.

1) In the top level menu, mo ve the cursor to menu

group 3 and press

SELECT

:

LOCATE

The displa y wi ll f l ash while the number s ar e being

entered, to show that the value has not yet been

confirmed.

Negative va lues are sho w n on the

VALUE

digit of the display.

NOTE

If you enter the wrong number by mistake, you can press the

CANCEL

the previous value.

4) Press and hold down the

then press the

If the value is a valid one (i.e. you do not attempt

to enter 71 frames in a second, etc.), it will be

transferred from the LED display, which will stop

flashing, to the LCD display screen:

Machine Offset

display by a per iod aft er the las t “f ra mes”

key of the numeric keypad to reset the number to

SHIFT

ENTER/LOAD

Machine 1

LOCATE TIME/

key [23 ] and

key [20].

>McnOffset Ctrl Prt

TimeMode Trk Arm

+00:00:00:00 ABS

4-2

+01:23:07:10 ABS

Invalid values will be rounded down to the nearest

valid value (e.g. a value of 78 seconds will be

rounded down to 59 seconds).

Page 21

Section 4.3 - Selecting the unit controlled by the menus

4.2.4 “Fine-tuning” values

JOG/SHUTTLE

The

controls [28] may also be

used to “fine-tune” the values entered and displayed on the LED

1) Press the

DATA INC/DEC

VALUE

display.

key [27] so that the

indicator lights.

2) Use the jog dial to change the value shown on

VALUE

the

display in the same way as you

would use them to locate a tape (i.e. the jog dia l

increments (clockwise) or decrements (counterclockwise) the numbers.

NOTE

The jog dial can only be used for data entry and editing of

values which may be entered through the

not for values which may be entered only on the LCD display screen.

VALUE

display,

4.3 Selecting the unit controlled by the menus

As explained above, the Machine parameter

which appears in many menus cannot be changed

directly using the UP or

The DTRS units connected to the RC-898 are

numbered in order, starting at 1. The machine with

the lowest logical number (see 3.1.1, “Machine

IDs”), i.e. the one connected directly to the RC898, is Machine 1, the next in the chain is

Machine 2, and so on.

Howev er, as you can see from the front panel of

the RC-898, the UP and

another meaning when used in combination with

SHIFT

the

NEXT

key [23], and they change to being

PREVIOUS

and

select the next unit in the chain, or the previous

one, respectively.

NOTE

This selection has no effect on the transport or location section of the RC-898 and

MACHINE

[31] is independent of any settings made on the LCD display screen to select the unit whose parameters are to be set.

indicator [8] selected with the

DO W N

DOWN

keys .

keys have

keys, allowing you to

vice versa

. The unit shown on the

MACHINE

key

the unit co ntrolled by the menu’s other

parameters, as in the example menu below.:

TC Frame Mode

Machine 1

30DF

1) Press and hold down the

2) While holding down the

UP

DO W N (NEXT

or

increment or decrement the

SHIFT

SHIFT

PREVIOUS

or

key

key, press the

) key to

Machine

number.

The machine number can be set from 1 through

6

.

Other menus will present the 6 units on one screen

(where there is only an on/off parameter). In these

cases, use the

LEFT

machine, and the UP and

and

RIGHT

DOWN

keys to s elect the

keys to enable

or disable the function:

Shuttle Mute

on » »»»

off » »

Machine123456

4.4 C om m only-used m enus

The F1 through

used to recall the ten functions (menu screens)

that you use most often.

When the

keys can be used as an additional ten function

F11

keys;

NOTE

The menu-to-key assignments made on the RC-898 are

entirely independent of any menu-to-key assignments made

on the RC-898.

F10

SHIFT

through

function keys [22] may be

key [23] is held down, these

F20

.

If the display screen shows a menu with a

Machine parameter, and you want to change

4-3

Page 22

Section 4.5 - Storing and recalling user setups

If you have not assigned a menu to a function key,

the defa ult (factory) menu-to-key assignments

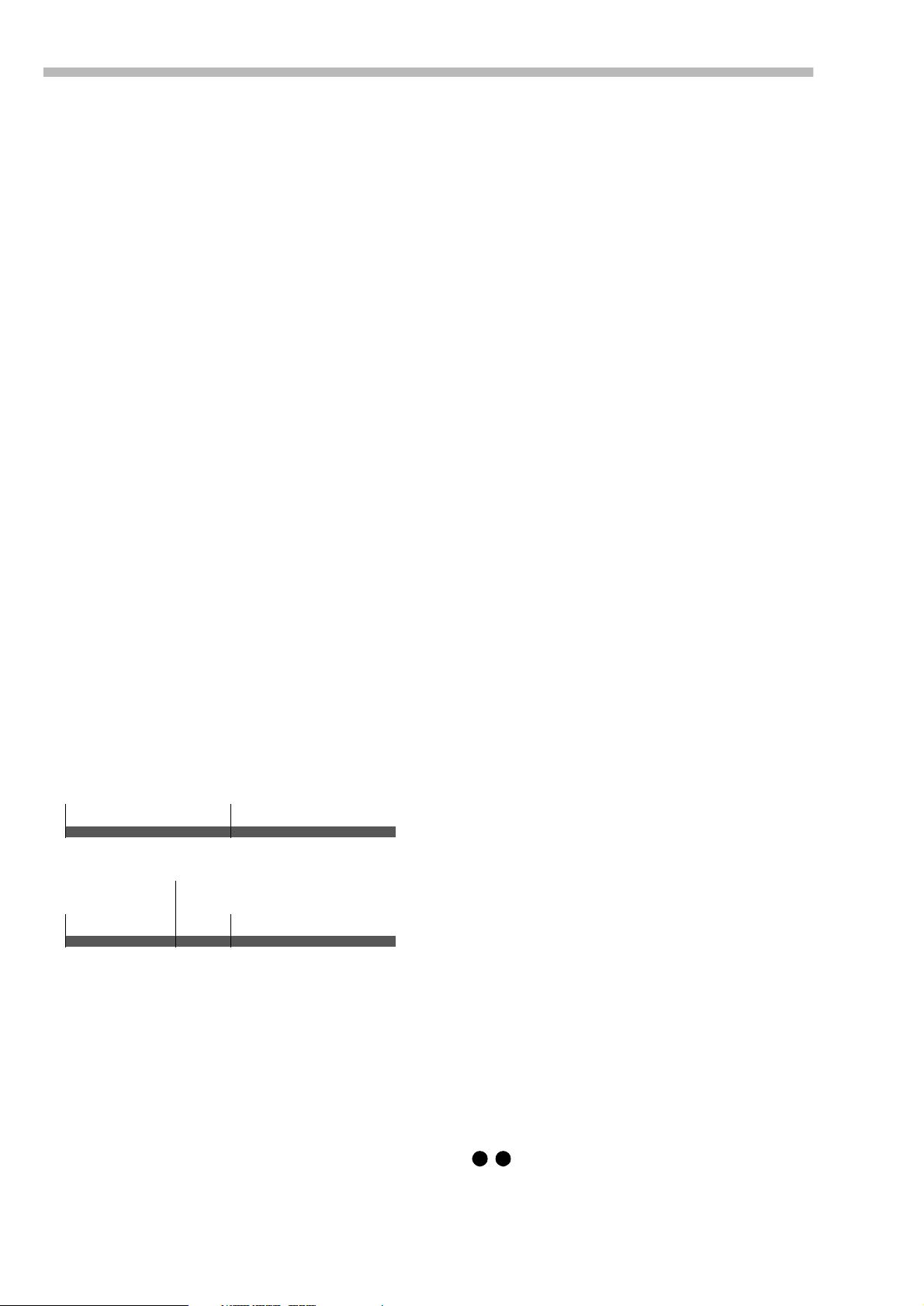

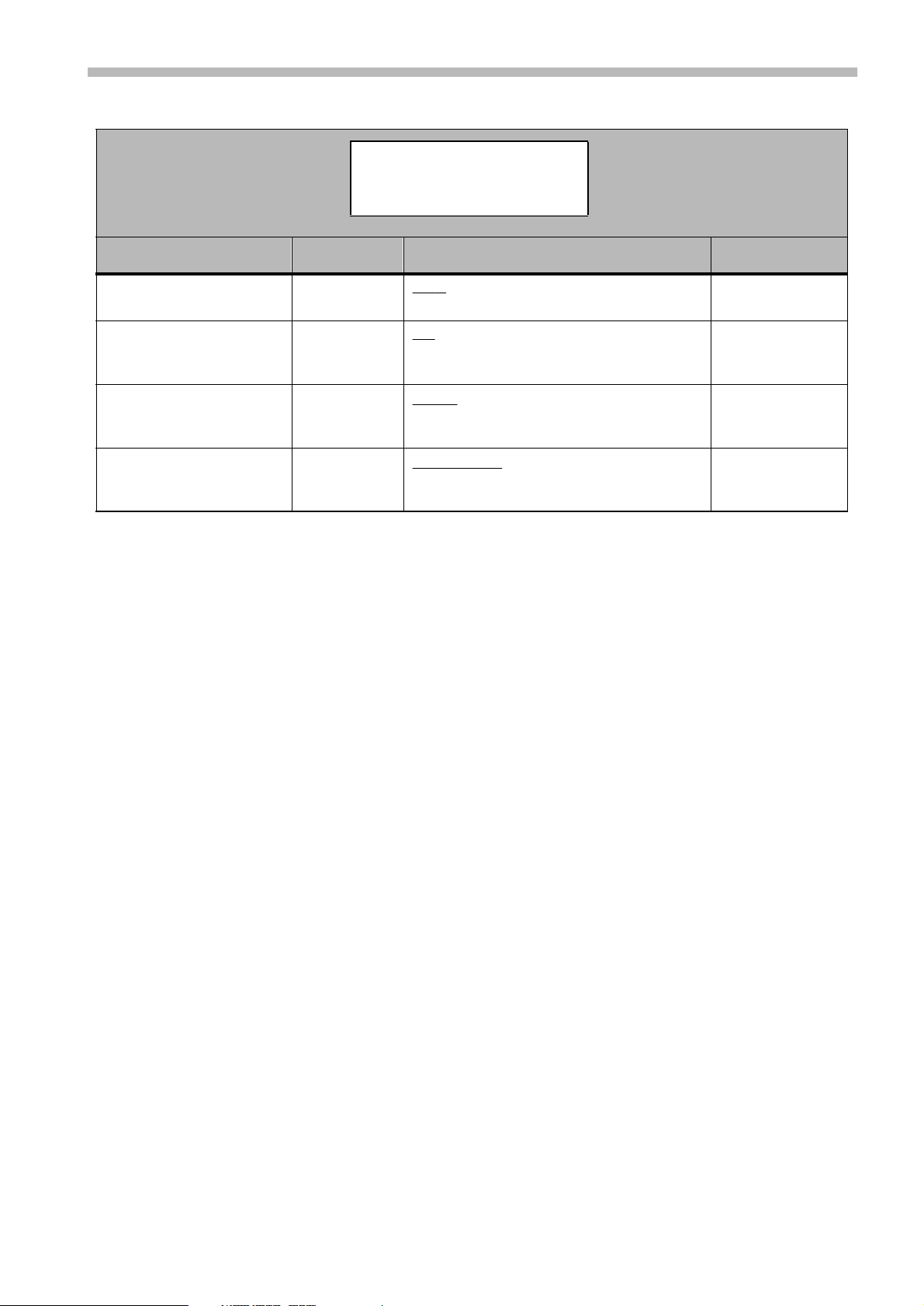

will be used as follows:

Key Menu

F1

Track Delay Time

F2

Track Copy

F3

Vari Speed

F4

Locate Preroll

F5

Machine Offset

F6

Time Mode

F7

Timecode Offset

F8

TC Frame Mode

F9

Generate Start Time

F10

Generate Mode

F11

Crossfade Tome

F12

Confidence Mode

F13

Output TC Source

F14

Repeat Start/End

F15

Analog In/Out

F16

Ext TC

F17

Abs Diff

F18

Tape TC

F19

Rel Diff

F20

Gen TC

Menu

group

0

0

0

0

3

3

4

5

8

8

1

9

5

3

2

E

E

E

E

E

4.4.1 Assigning menus to function keys

To assign a menu to a function key:

1) Use cursor keys and the

see the menu you want to assign to a function

key.

SELECT

key until you

4.4.2 Recalling menus u sing the functio n keys

1) Simply press the function key where you have

previously assigned the menu you want to

recall.

If you have not assigned a menu to the function

key that you press, the display will remain

unchanged.

2) If yo u used the

menu to

the

F11

SHIFT

SHIFT

throu gh

key [23] to assign th e

F20

, press and hold down

key befor e pr essing the function key

to recall the “shifted” menu.

4.5 Storing and re ca lling user setups

The RC-898 allows you to store and recall almost

all parameters set using the menu system, so the

same remote control unit can be used with a variety of different equipment setups with the minimum of reconfiguration.

This is a great time-saver, as not only are the RC898’s parameters stored and recalled, but the settings for the DTRS units connected to the RC-898

are also stored and recalled. In this way, up to six

DTRS units can be reconfigured to preset configuration patterns with the press of one key.

4.5.1 Saving the current setup

2) Press the

Shuttle Monitor

PRESET

Function Preset

Push Function Key

The “Shuttle Monitor” screen is an example only.

The current menu title will be displayed on the

bottom line of the display.

key [21]:

3) Press the function key to which you wish to

assign the m enu.

To use the second “bank” of function keys, press

and hold do wn t he

the function key.

SHIFT

key [23] bef ore pressi ng

1) From the top menu, move the cursor to menu

group F, and press

Key Mode FrameDisp

DispTime >Setup

Setup

2) Move the cursor to

and press

Setup

SELECT

Load 0123456789F

As you can see, there are 10 user se tups, n umbered

0

from

rally, you can reload the factory settings, but you

cannot o ver write them wit h yo ur o wn set tings ; you

must choose one of the 10 user areas.

through 9, and a factory setup (F). Natu-

SELECT

Setup (as shown above),

:

:

4-4

Page 23

Section 4.5 - Storing and recalling user setups

3) Highlight the Load f ield, and change it so that

it reads

4) Use the

Save, using the

LEFT

and

RIGHT

UP

key.

keys to highlight the

user memory into which you wish to store the

current settings, and press the UP key.

Setup

Are you sure?

0

Save 123456789F

5) Press

SELECT

the following:

RIGHT

keys to cancel.

The display will briefly show Execut-

ing..., and the current settings wil l be saved

into the user setup.

to confi rm the save, or any of

ESCAPE, DOWN, LEFT

or

4.5.2 Recalling a user setup or restoring factory settings

Any of the ten user setups, as well as the factory

defaults, can be recalled, using the screen above.

4) Press

the following:

RIGHT

The selected user setup will replace the current

settings.

If you try to load from a setup into which data has

not been sa v ed, the display wi ll br ie fl y show

Data, and the load opera tion wil l not take pla ce.

SELECT

to confirm the load,or any of

ESCAPE, DOWN, LEFT

keys to cancel

or

No

1) From the top screen, select menu gro up F, and

select the

Setup

Setup menu:

Load 0123456789F

2) Make sure that the left parameter shows

Load by moving the cursor under it, and the

DOWN

Save.

key to change its valu e to

Load from

3) Move the cursor under the user area (or

factory setting, represented by

F), and press

the UP key to recall the setup.

Setup

Are you sure?

0

Load 123456789F

4-5

Page 24

Section 4.5 - Storing and recalling user setups

4-6

Page 25

Section 5.1 - Transport controls

5 – Basic DTRS operations

This section covers the basic operations of controlling the DTRS units connected to the RC-898.

For details of how to make parameter settings, etc.

and timecode operations, see 4, “Menu and basic

operations”, 7, “Making settings on the DTRS

units” and 10, “Menu and parameter reference”.

5.1 Transport controls

The transport controls on the RC-898 replicate

those on the DTRS units.

The logic of the transport controls is such that any

mode can be entered from any other mode. There

is no need to go through

5.1.1 Selecting the unit to which

operations refer

Generally speaking, the unit controlled by the

transport keys will be the first unit in the chain

(the other units in the chain are assumed to be

using the ABS chase protocol through DTRS

synchroniz ation.

STOP

.

1) Insert a new tapeor tapes into the DTRS unit

or units. Make sure that it is rewound to the

beginning of the tape.

NOTE

Do not use a tape which has previously been used for

recording video.

2) From menu group 9, move the cursor to

Format, and press

Format

Machine 1

off 44.1 k

3) In this menu, as well a s using the

+ UP) and

PREVIOUS (SHIFT

SELECT

:

NEXT (SHIFT

DOWN

+

) keys

to select an individual unit, all DTRS units

connected to the RC-898 can be selected to

format tapes together.

4) Move t he cursor to the sampling frequency

field, and use the UP and

between

44.1 and 48 (kHz).

DO WN

keys to choose

However, transport operations, etc. can also be

performed on individually-selected machines

other than the first one:

1) Press the

MACHINE

The word

LOCATE TIME/VALUE

MACHINE

key [31 ].

will start to flash in the

display [15].

2) Use the numeric keypad to enter the

number(one digit only) of the machine that you

want to control .

This number will be s hown in the

VALUE

MAC HINE

If you enter a machine number of 0, this is equivalent to setting all DTRS units except the first into

slave mode, to follow the first unit.

Machin e 7 is equivalen t to a unit attached to the

parallel port [42], and machine 8 is equivalent to a

unit attached to the serial port [43].

display [15], and the appropriate

number indicator[8] will light.

LOCATE TIME/

NOTE

If a digital signal is received at the

of the DTRS unit, and digital input has been selected (see

7.2.9, “Input selection”), the sampling frequency is decided

by the frequency of the incoming signal and cannot be

changed.

DIGITAL IN

connector

5) Move the cursor to the “control” field and use

the UP key to ch an ge the settin g from

ready

6) Press the UP key again to change

on.

FORMAT

The

unit will light.

The three values for this parameter prevent accidental formatting of a tape.

7) Press and hold the

PLAY

key.

The tap e w ill start to be formatted.

indicator on each selected DTRS

RECORD

key and press the

off to

ready to

5.1.2 Formatting tapes

The Hi8 tapes used in DTRS units must be formatted. This can be done either from the DTRS

units themselves, or from the RC-898.

It is possible to record audio and format a tape at

the same time. This is done by arming the tracks

before step 5 above. However, if you do this, you

should not interrupt the formatting proces s half way through a tape. Once you start formatting a

5-1

Page 26

Section 5.2 - Monitoring

tape from the beginning, you should wait until the

end of the tape before rewinding and ejecting it.

NOTES

The display shows a negative ABS time for a few seconds at

the beginning of the tape. While a negative time is shown,

no audio can be recorded on the tape.

We suggest that you leave a blank header of at least 30 seconds at the beginning of the tape. This can be marked as a

virtual “zero point” if you like (see 6.3, “Setting a relative

time reference”).

5.1.3 Arming tracks

The tracks of the DTRS units are armed using the

REC FUNCTION

These keys and indicators only work for tracks of

units that are actually connected.

NOTE

Before recording, you should make sure that eit her di gital or

analog inputs, as required, have been selected (see 7.2.9,

“Input selection”) and the appropriate clock settings have

been made (see 7.2.6, “Clock selection”).

keys with their indicators.

5.1.5 Transport controls

The RC-898 shares a common interface with all

DTRS units with regard to transport functions

(including entering end exiting record mode).

Consult the relevant portions of the DTRS unit

manual if you are unsure of the way in which

transport operations are carried out.

One exception to this is the

LOC

key [41] which

does not appear on the front panel of DTRS units.

It is used to locate the tape to the value shown on

LOCATE TIME/V AL UE

the

display [15]. For full

details of how this key is used and the location

facilities av ailable fr om the RC-898, see 6, “Location functions”.

5.1.6 Shuttle mode

The RC-898 incorporates a jog dial and shuttle

wheel to allow precise positioning of the tape in

the DTRS units.

When the

lit, moving either of these controls will control the

selected unit(s) appropriately.

DAT A INC/DEC

indicator [27] is not

Armed tracks, i.e. those which are ready for

recording, are shown by their indicators flashing.

Tracks which are actually recording are shown by

their indicators being steadily lit.

When a DA-88 or DA-38 track is recording, the

INPUT MONITOR

indicator will light, showing

that the monitoring for the tracks is from the input

source, rather than being off-tape. The

MONITOR

keys are not o perational with a DA-88

INPUT