Tapco SD5-1, S1001N-1 Operating Instructions Manual

OPERATIONS MANUAL

Operating Instructions for the Dräco

Metal-Shear SD5-1 and S1001N-1

To avoid any disturbance, please read the following instructions:

FOR YOUR SAFETY:

Valid 10/2002

1 2 3 54

1 Safe operation of this machine is only possible when the

operating instructions and the safety precautions are

read completely and the instructions contained therein

are strictly observed.

2 The machine must not be used or operated in a damp or a

wet environment.

3 Always inspect the cable and plug before using machine.

Damage must only repaired by a qualified professional. The

plug should only be placed into the main socket when the

machine is in the off position.

4+5 Always wear protective goggles, protective gloves and

heavy-duty shoes when working.

For further notes on safety please refer to the red safety leaflet

enclosed in the tool box.

l Do not carry the machine by the cable.

l Always remove the plug from the power supply socket

before carrying out any work on the machine, during work

interruptions or when not using the machine.

l Always place the cable to the rear, away from the machine.

l Apply the machine to the sheet metal only, when switched on.

l Always provide for secure footing when working.

l Firmly clamp the work piece if it does not remain stationary

from its own weight.

l The knife should not rub on the jaws as there is a possible

danger of breaking the cutting tool.

l Do not exceed the maximum allowable material thickness,

especially when cutting over double folded joints or welded

seams.

F

DRÄCO metal shears SD5-1 S1001N-1

max. cutting capacity

steel 400 N/mm² mm/ga. 1.0 / 19 1.3 / 18

stainless steel 600 N/mm² mm/ga. 0.7 / 21 1.0 / 19

stainless steel 800 N/mm² mm/ga. 0.4 / 24 0.7 / 21

aluminium 250 N/mm² mm/ga. 1.5 / 16 2.0 / 14

tightest radius mm/ga. 50 100

working speed ± m/min 5-9 5-9

strokes min

-1

3900 3900

motor capacity Watt 300 300

weight kg 1.6 1.6

all units are ready to use

SD5-1 S1001N-1

spare parts spare parts

knife 01011 knife 01001

set of jaws BG13574/1 set of jaws BG10600

knife-pin set BG12555

optional accessories

metal-box 18000

adjustable guide S/01 up to 100mm 10059

adjustable guide S/01 up to 250mm 10060

adjustable guide S/01 up to 500mm 10061

support roller BG10076

BG=Set other voltages available

2

WWW.TAPCO-EUROPE-TOOLS.COM

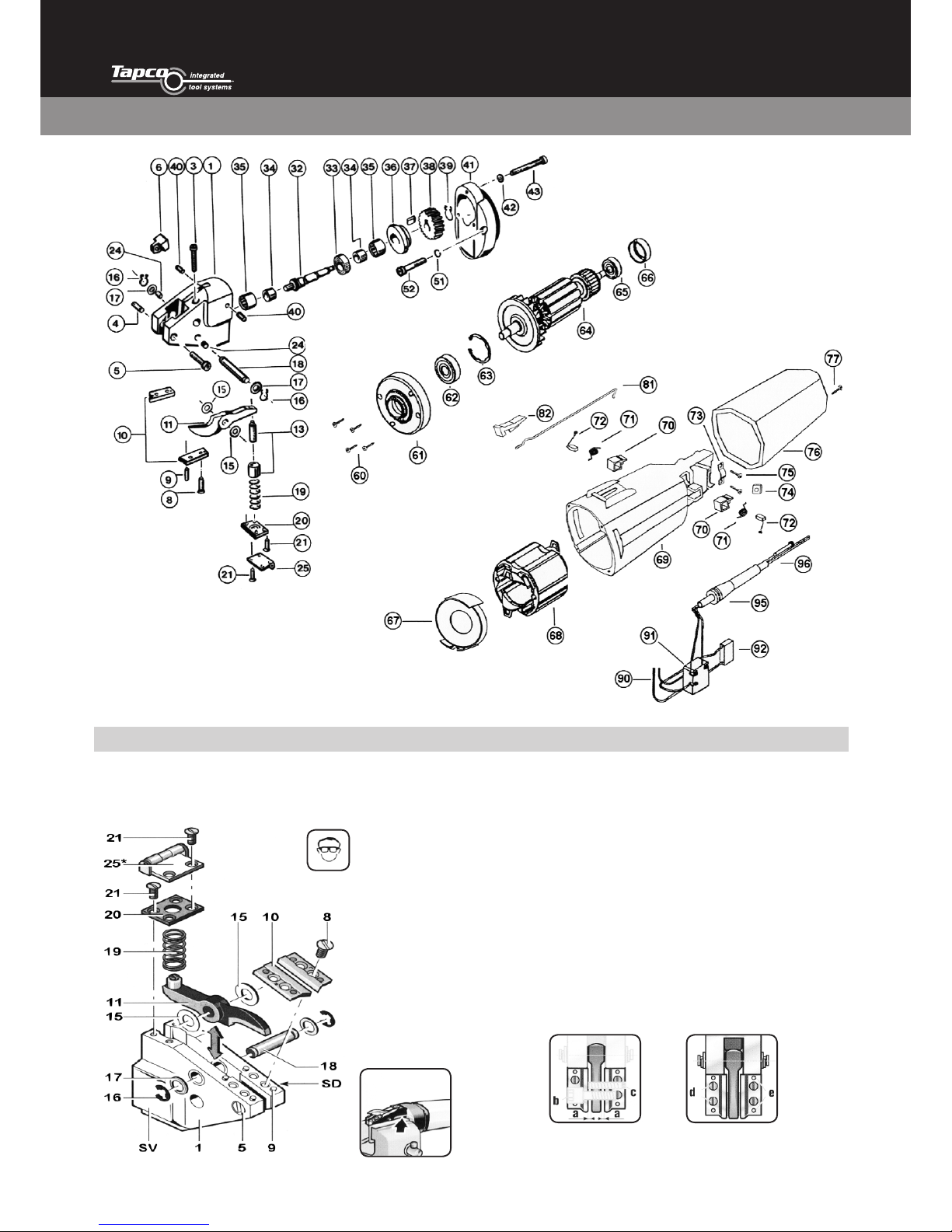

SPARE PARTS FOR SD5-1 AND S1001N-1

SERVICE TIPS

Before working on machine disconnect from power supply by

removing plug from socket.

Wear protective glasses!

1. One drop of oil between knife (11) and head-casting (1) keeps

the spacing shims (15) in place.

2. Dismantle Spring cover (20) and take spring out (19).

3. Take circlip (16) and washer (17) off.

4. Push knife pin (18) out of casting.

5. Take knife out of housing

6. Attention, do not exchange the spacing shims (15).

7. Place the knife inside the housing feed shims in on one side

and push knife pin (18) into housing up to the middle of the

knife.

8. Feed the shims on the other side of the knife.

9. Push knife pin in completely, and secure washer (17) and

circlip (16) again.

10. Assemble spring (19) and spring cover (20).

11. Between the knife (11) and the jaws (10) should be some

distance, approximately 0.1 mm on each side. Knife (11) must

be placed tight in the head casting.

12. Adjustment for the play between the jaws. (a): 0.1 to 0.15 mm.

* optional

13. If knife has contact with the jaws on both sides, adjust with

screws in the head casting. If a burr is on the material, adjust

the space between the knife and the jaws.

Loading...

Loading...