Page 1

®

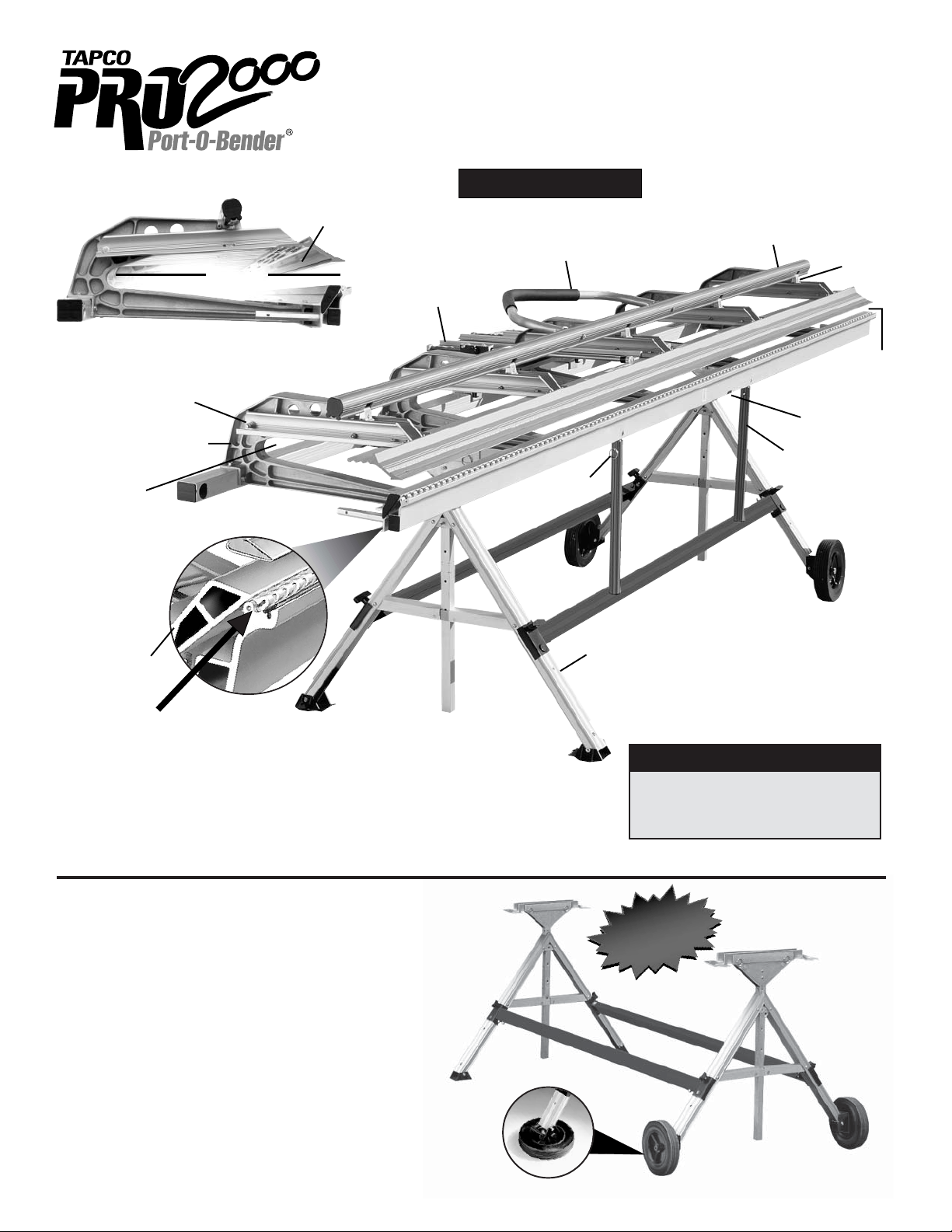

PRO 2000

OPERATIONS MANUAL

Pro-Filer 2000

®

®

Port-O-Bender

®

Pro-Stand

➤

19"

Tapco Exclusive!

Maximum Throat Depth

for Expanded Capabilities

➤

Pro Cut-Off

Tapco PRO 2000 shown

with optional accessories:

Tapco Side-Winder, Pro-Stand,

Pro Cut-Off and Pro-Filer 2000

to maximize your capabilities!

Featuring

• Accessories

• Setup and operating instructions

• How to form the most popular

shapes

• Hints and shortcuts to greater

profits with your Tapco

Port-O-Bender

• Tune-up instructions

• Complete parts list

®

Side-Winder

PRO 2000

®

© 2001 Tapco International Corporation

Page 2

®

Inside Working Pockets

The largest in the industry!

➤

Exclusive, 19" throat depth, largest in the

industry for making larger, more complex

Super strong

redesigned die castings.

Exclusive 19"

throat depth

allows you to store

material inside of

bender reducing

handling and flipping

and speeding up

bending.

shapes faster and easier.

Pivot Arms

computer

19"

TAPCO PRO 2000®Port-O-Bender

Maximum Throat Depth • Expanded Capabilities

PRO 2000

enabling you to do your jobs faster, better and more efficiently.

➤

is specifically engineered for optimum use with all Tapco accessories

(See accessories p. 3 & 4 )

PRO 2000 Features

Locking Handle

Part of a strong, positive

clamping system.

Hemming Handle

TAPCO Pro-Filer

(optional accessory

see pg. 3)

Hinge Clip

(see page 6)

Bending/Lifting

Handle

Faspin

Pivot

Links

Opening

®

Jaw

3

/4"

1

Base Hinge

Patented “Moving Pivot” hinge,

the most advanced hinge design

in the world, increases leverage

and lifting power and eliminates

scratching or marring of materials.

o

(180

hemming capability)

Pro 2000 Port-O-Benders are made under one or more of the following U.S. Patents:

4,493,200, 4,445,356, 4,372,142, 4,766,757, 3,817,075, 4,557,132, 4,240,279, 4,671,094, 3,482,427, 4,494,397, 3,559,444,

5,343,728, 5,353,620, 5,505,069. Other U.S. and Foreign Patents Pending.

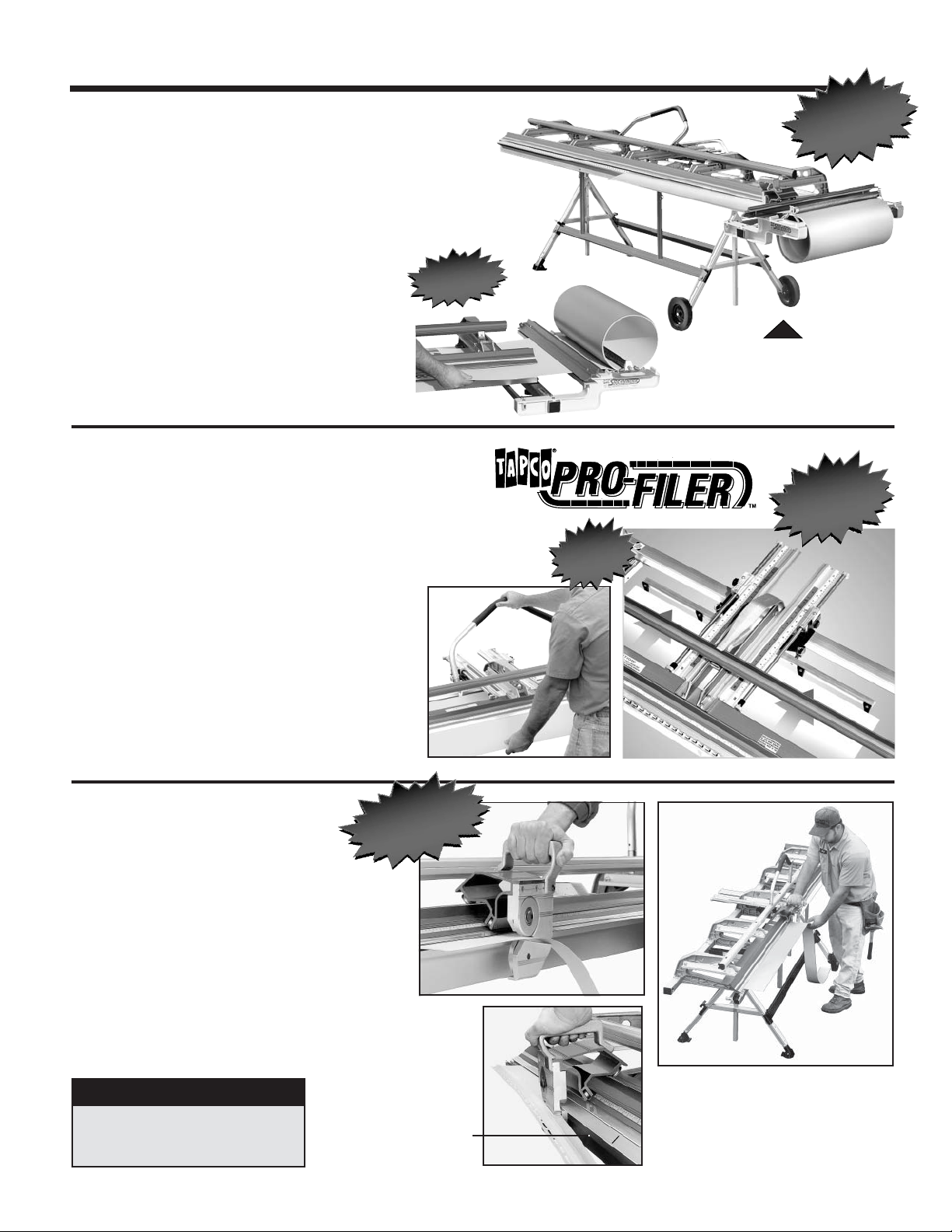

TAPCO PRO-STAND

3,161,223, 4,321,817, 4,651,553, 4,489,583,

™

Deluxe Heavy Duty Transportable Support

for your PRO 2000, PRO-III Port-O-Bender

and E-Z Angle Siding Table

Pro-Stand Features

• Durable lightweight anodized aluminum construction.

• Fast and easy height adjustments from 28" to 37".

• Heavy duty wheels handle the roughest of job site

terrains then convert to support pads.

• Detaches quickly from your Port-O-Bender.

• Fits all 8' 6" through 12' 6" Pro Series

Port-O-Benders and

Siding T able

.

E-Z Angle

Heavy Duty wheels

convert to foot pads

for solid support on

all terrains

2

TAPCO

Pro-Stand

(optional

accessory

see below)

PRO 2000 Bending Capacities

• Up to .030 soft aluminum

• Up to 28 ga. galvanized steel

• Up to 16 oz. copper sheet & coil

PRO 2000 HD Capacities

SOLID

SUPPORT AND

PORTABILITY

TOO!

(see pg. 8)

(See page 9

for Installation

Instructions)

U.S. & Foreign Pats. Pend.

Page 3

PRO 2000®

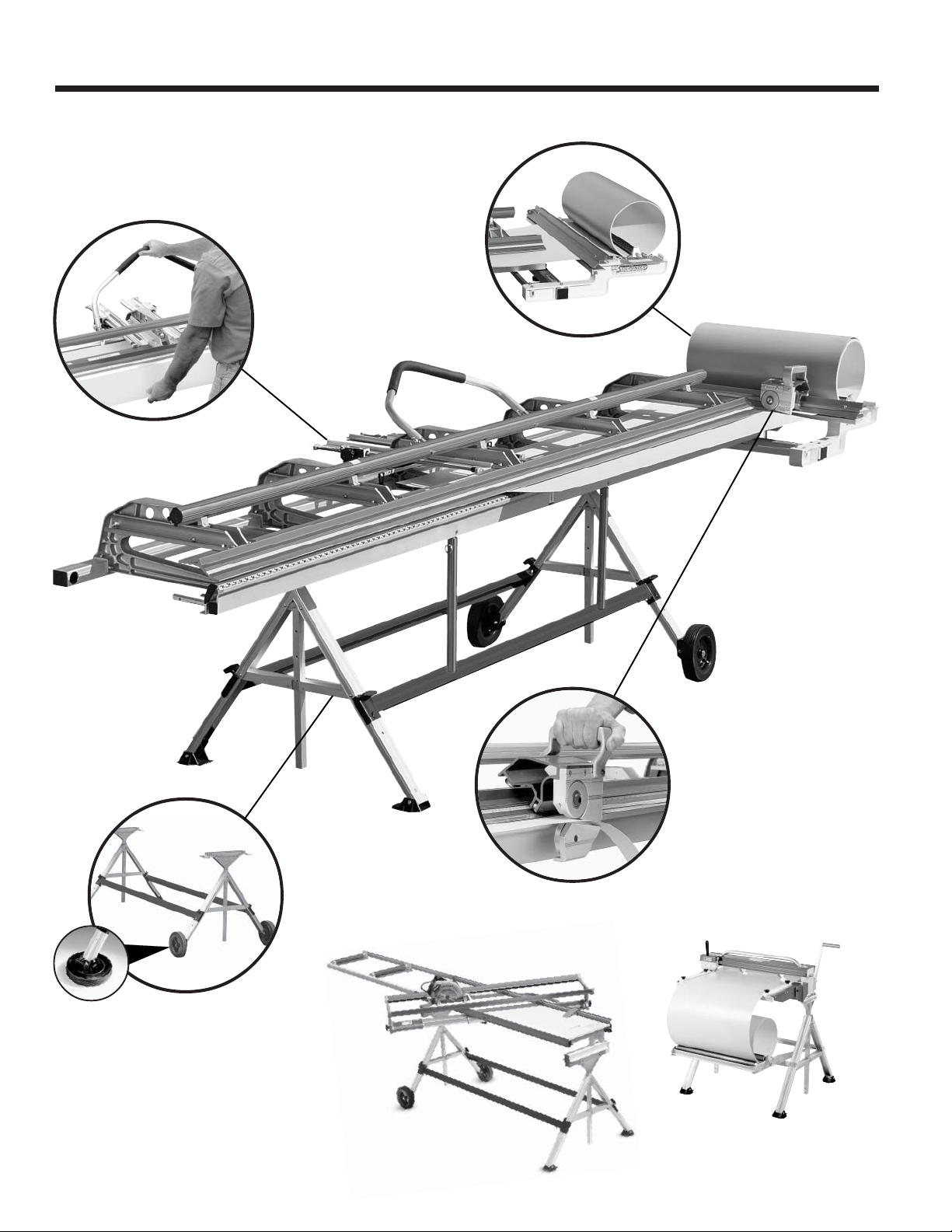

SIDE-WINDER

PORT-O-BENDER® ACCESSORIES

™

Coil Holder

Works in tandem with your Port-O-Bender

and CUT-OFF to form a complete “trim shop”

SIDE-WINDER Features

• Attaches in seconds to the end of your

Port-O-Bender,

• Allows you to feed coil directly into the jaws of

your

Port-O-Bender.

give you factory quality cross cuts. Speeds up

production, decreases waste.

• Helps eliminate damage from handling coil stock,

especially on windy days.

• Holds up to 24"x50' coil*. Weighs only 25 lbs.

When used with Pro-Stand.

*

• New improved versatility! Work both sides of your

coil. Coil can be drawn out finished side up or

down. See photos at right.

standard or heavy duty models.

Uses your

TAPCO PRO-FILER

PRO Series

PRO CUT-OFF

®

to

Speeds U

ending!

B

2000

Automatic Squaring and Measuring Gauge

PRO-FILER 2000 Features

• The

PRO-FILER

measure material fed into your Port-O-Bender,

need to mark and snip on your coil.

•

Automates your production. Saves up to 50% of your

layout time—the largest block of time that slows you

down the most!

• Easy to use as a template and profile maker.

•

PRO-FILER Strips

shapes. Simply form strips to your desired profile

then insert them into the

your bending.

• Turns rookies into pros in hours instead of years.

Makes pros more efficient.

is the first tool ever to automatically square and

store key information for bending

PRO-FILER

and they guide

eliminating the

Keeps

our

here y

.

ou

e coil at y

th

side–w

need it!

p

Saves up

to 50%

your tim

of

Note: When using the

the

PRO CUT-OFF

to cut off material. Both optional

accessories shown with

PRO 2000 Port-O-Bender

See Pro Cut-Off below.

e

SIDE-WINDER

must be used

ore

NO m

guesswork in

laying out

shapes

st

o

PRO CUT-OFF

Quickly, safely and easily

™

revo

sin

he m

T

lutio

ce th

ben

n

e p

ar

der

makes factory quality cut offs

right right on your Port-O-Bender

PRO CUT-OFF Features

• Lightweight aluminum construction built to last.

• Hardened and captured tool steel cutting

knives for safety and durability.

• Pays for itself by reducing scrap and eliminating knifing damage to costly bending hinges.

• Eliminates use of dangerous utility knives and shears.

•

Saves time and labor in scoring and breaking off material.

Also for use with Tapco

PRO CUT-OFF Capacities

• Up to .030 aluminum. All vinyl.

• Up to 28 ga. galvanized steel

• Up to 16 oz. copper

SIDE-WINDER.

Note: Shear point

remains constant

at 11/2" from your

Bending Edge.

y too

table

or

l

Using the

PRO CUT-OFF

The proper technique is to effortlessly

➛

➛

push your

material with a smooth, constant motion

from right to left. Do not stop in the mid-

➛

➛

11/2"

dle

Make

Pro Cut-Off

or cut with a back and forth motion.

sure hinge clip is engaged.

through the

U.S. & Foreign Pats Pend.

3

Page 4

TAPCO ACCESSORIES

A Necessity for Today’s Professional Sider

®

PRO-FILER 2000

— Reduces layout time

and need to snip mark

your coil for measuring.

—Simply feed coil in to your

Bender, the

you measure and square

in one operation.

Pro-Filer

(See page 3)

helps

SIDE-WINDER

— Saves time by allowing you

to roll out coil directly into the

jaws of your Port-O-Bender.

— Decreases coil damage due to

excessive handling especially

on windy days.

™

(See page 3)

PRO-STAND

— Solid support and mobility on

the job site.

— Adjustable, folds up and

detaches in seconds.

™

(See page 2)

OTHER MAJOR ITEMS

Ask your distributor for more information

E-Z ANGLE

Siding Table

®

Slitting & Rib Forming System

PRO CUT-OFF

— Quickly, safely & easily makes

factory quality cut offs right on

your Port-O-Bender.

— Saves time and labor in scoring

and cutting off material.

—Also for use with

PORT-O-SLITTER

™

(See page 3)

Side-Winder.

™

4

Page 5

THE “PRO 2000 COMPLETE” SAVES TIME, INCREASES PROFITS

The “PRO 2000 Complete” system includes: Port-O-Bender, Pro Cut-Off, Side-Winder,

Pro-Filer 2000 and Pr o-Stand. On an average day, they can save you hour s on the job site!

Pro-Stand

time savings:

Pro-Stand

and transports your

1

all accessories around the job site.

Saving you time and effort.

Pro Cut-Off

time savings:

Pro Cut-Off

a factory edge in seconds. No need

4

to score and break off material. Saves

time, effort and reduces scrap.

provides solid support

PRO 2000

safely cuts the coil with

with

Side-Winder

time savings:

Side-Winder Coil Holder

coil directly into the jaws of your

2

5

No need for extra handling of

2000.

coil stock or separate layout table.

Pays off big on windy days.

Pro-Filer 2000

material fed into your

Saves time measuring and snipping

(See step 6).

coil.

automatically squares

PRO 2000.

dispenses

PRO

Pro Cut-Off

on the

3

Also the

duty cutting your coil to width. (See

step 4).

Tapco Pro-Filer

time savings:

In making bend after bend,

eliminates the need to mea-

2000

6

sure, mark and snip each piece of

coil, and ensures accuracy.

cuts your coil to length

Side-Winder

Pro Cut-Off

in seconds.

does double

Pro-Filer

PRO 2000 Hinge

time savings:

PRO 2000’s

pivot” hinge makes bending easier

7

(requires 35% less lifting) and

won’t scuff material, preventing

touch up work.

patented “moving

PRO 2000 Working Pockets, Throat

Depth time savings:

PRO 2000’s

ets and throat depth let you form

8

more complex shapes faster,

easier and better.

large working pock-

5

The

“PRO 2000 Complete” System

•

PRO 2000 Port-O-Bender

•

Pro-Stand

•

Side-Winder

•

Pro Cut-Off

•

Pro-Filer 2000

Saves you 1–2 hours on the

job site in an average day!

In Todays Busy

Economy You Have

to be “COMPLETE”

to Compete.

Page 6

SETTING UP YOUR PRO 2000

Hemming Handle Installation

Hemming

Handle

®

PORT-O-BENDER

®

Handle

Plug

Locking Handle

The PRO-III Hemming Handle Assembly includes: (1) Hemming Han-

dle, (2) Handle Plugs, (2) Faspins, (2)

Hex Bolts.

Faspin

Hex Bolt

Insert Hex Bolt through Locking Handle

of your Port-O-Bender and into base

of Hemming Handle as indicated using the 3/8" Hex Bolts provided. HAND

TIGHTEN ONL Y . Repeat for other side.

Lifting/Bending Handle Installation

Moving

Hinge

Lock Nut

T-Handle

Hex Key

1

/

-20

4

1

/

-20 x 11/2"

4

Screw

Handle

Plug

Faspin

Attach the Hemming Handle over the

Handle Plugs and secure them with

Faspins. Now tighten the 3/8

Bolts with a 9/16

" wrench. Handle can

" Hex

be detached from now on by simply removing the Faspins.

Lifting/

Bending

Handle

Remove the combination Lifting/Bending Handles from each end of the PortO-Bender by removing the Faspins as

shown.

Insert Handle Assembly into hole in

bottom of Moving Hinge. Align hole in

hinge with Handle Plug and insert

screw using T-Handle Hex Key as

shown. Secure with 1/4-20 Lock Nut.

Hinge Clip Installation

The Hinge Clip keeps the Moving Hinge in position for

ease of aligning material. It can also prevent rippling of

the coil during cut off operations.

To install Hinge Clip, locate predrilled hole on bottom

center of Moving Hinge. Align holes in Clip and Hinge

as shown and insert Phillips head screw provided.

Note:

You must use hinge clip when using Pro Cut-Off.

Secure

1

with

/

Lock Nut

-20

4

Repeat for other handle(s). To remove

handles, simply release Faspins. Always use more than one handle when

bending.

6

Page 7

ADJUSTING YOUR PRO 2000® PORT-O-BENDER

Pivot Link Adjustment Instructions

IMPORTANT: Your Port-O-Bender® incorporates an advanced new Micro-Adjust system that enables you to adjust the

gripping tension on material faster and easier than ever. The Pivot Links have been pre-set at the factory for average

holding capacity and ease of operation. However, it’s important that you readjust your Port-O-Bender® to your

stock thickness. Your Port-O-Bender

conditions. It is important that you follow these steps when you adjust your Port-O-Bender

tension and maximum performance.

®

may also need periodic adjustment due to extreme weather and/or working

®

to ensure proper gripping

®

First check the uniformity of the clamping pressure along the entire length

of your Port-O-Bender

®

by using the following method.

TO TEST —

Cut narrow strips of the stock which you will be using and lock one piece

under each frame casting as indicated in figure 1. Then move material from

left to right and try to pull material straight out. If material can be pulled out or

if the material does not move at all then the pivot links need to be adjusted. If

material can be moved from left to right but cannot be pulled out directly then

the pivot links are properly adjusted.

NOTE: All adjustments are

position. All adjustments are

Port-O-Bender® in the “locked” position.

Figure 1

Figure 2

TO ADJUST —

Insert the adjusting wrench provided into the Pivot Link Stud through

the access hole in the upper link. (See Figure 2.) Turn 1/4 turn

either

or

Repeat test step above to check tension.

COUNTER-CLOCKWISE

CLOCKWISE

to DECREASE locking tension.

to INCREASE locking tension

PRO 2000

Port-O-Bender

Pivot Link

Assembly

made

with the Port-O-Bender® in the “open”

tested

with strips of material placed in the

Decrease

Increase

Upper

Adjustment

Link

Pivot Link

Stud

Lower

Adjustment

Link

TO ADJUST (Optional method)—

As an alternate method you may use a 5/8" open-end wrench

directly on the Pivot Link Stud by turning 1/4 turn either

COUNTER-CLOCKWISE

CLOCKWISE

to DECREASE locking tension. (See Figure 3.)

to INCREASE locking tension or

Repeat test step above to check tension.

Figure 3

7

Page 8

USING THE PRO 2000

Basic Hemming and Folding

®

PORT-O-BENDER

®

Insert the material you wish to hem

1

into your Port-O-Bender.

Remove the material from the

4

Port-O-Bender.

Close and lock Bender on the

2

material.

Hemming

Pocket

Moving

Hinge

Position the bent edge of the ma-

5

terial in the Hemming Pocket on

top of the Anvil.

HEMMING POCKET

Material

Care and Maintenance of your Port-O-Bender

Your Tapco Port-O-Bender® is virtually maintenance free and will provide you

with years of reliable and trouble-free performance, however, there are a few

basic necessities required to keep your Port-O-Bender® like new.

1. Clean the clamping surfaces each day before using. Use only clean shop

towels that are free of dirt, oil and metal chips.

Bend as far as you can go.

3

Lift the Bending Handles and

6

compress the bend for a completed

hem.

®

PRO 2000 Bending Capacities

• Up to .030 soft aluminum

• Up to 28 ga. galvanized steel

• Up to 16 oz. copper sheet & coil

Capacities

2. Do not use your bender around your saw table as the cuttings may get in

between clamping surfaces and cause excessive wear or material scratching. Brush away any cuttings or filings that accumulate.

Transport your Port-O-Bender® in the unlocked position. You may transport

3.

it in the locked position if you clamp a piece of cardboard or vinyl siding

between the clamping surfaces.

4. If your material is getting scratched, examine the Stainless Bending Edge,

Base Hinge and Moving Hinge for roughness or burrs. Remove burrs with

emery cloth or replace excessively worn parts. Optional Pro Cut-Off will

help eliminate excessive wear to costly bending edge.

Use a lightweight spray oil along the moving pivot hinge after every

5.

40 hours of use.

8

PRO 2000 HD Bending Capacities

• Up to .040 soft aluminum

• Up to 26 ga.* galvanized steel

• Up to 18 oz. copper sheet & coil

MAX II commercial model Port-O-Benders are

*

available to bend up to 20 ga. galvanized steel.

Page 9

PRO-STAND INSTALLATION INSTRUCTIONS

DETAIL

Brake

Bracket

8

5

B

PRO 2000

PRO-III

Only

FRONT OF

BENDER

2 X 4

Bracket

1

DETAIL

A

“T” Knob

Pin

Cross Brace

Detail

Steps (indicated in diagram)

1. Remove all parts from box. Attach 2 x 4 Bracket to Vertical

Support using 1/4-20 x 1 1/2" Hex Bolt and 1/4-20 2Way Lock Nut.

2. Slide Vertical Support into End Assemblies, setting to

desired height, and secure with Faspin (part #10678).

3. Attach Wheel Assembly to End Assembly using 1/4-20 x

2 1/2" Hex Cap Bolt and 1/4-20 Two Way Lock Nut.

4. Fold wheels to pad position (as indicated in diagram)

and stand End Assemblies apart.

5. Attach both Cross Braces by seating pins into center

holes in legs and tightening the “T” Knobs into the top

threaded holes (see Detail A above).

6.Assemble Brake Brackets (see Detail B above) securing

with hex nuts. Repeat for other Bracket.

7.From bottom of Bender, align holes in Brake Brackets

with holes in Front and Back Rails of Bender. Insert

washer head screws and tighten Brake Brackets in place.

(*Pre '99 Benders will need to be drilled)

8

.

Turn Bender right side up and fit Brake Brackets into 2x4

brackets. Align holes in Brackets and insert Faspins. After

the Brake Brackets are installed on the Port-O-Bender,

entire unit can be quickly detached from Pro-Stand by

removing Faspins.

4

6

(INVERTED VIEW

OF BRAKE

BRACKETS)

7

3

2

BOTT OM VIEW

Faspins

9

Page 10

10539

10531

10550

10540

assembly

10521

10381

assembly

PIVOT LINK

EXPLODED

VIEW

10887

*10448

10536

10355

*10498

*10505

*10490

*12079

*10347

*10510

*10415

10539

10518

10524

10515

10351

assembly

(ships with 10349)

Common Parts

Part No. Part Name

10094 1/4-20 Hex Flange Nut

10347 Pivot Arm - Left

10348 Pivot Arm - Right

10349 Coupling Nut

10351 Lifting Handle Assembly

10355 Pivot Arm Cap

10503 1/4-20 x 2 1/2" Sock Cap Sc

10508 Locking Handle Pin

10515 10-24 x 1/2" Pan HD Sc

10518

10519

10520 1/4-20 Nylok Hex Nut

10521 Upper Link

10524 Lifting Handle Plug

10530 Rubber Pivot Pin Keeper

10531 Hemming Handle Plug

10532 3/8-16 x 3" Hex Cap Bolt

10534 3/8" Flat Washer

10535 3/8-16 Nylok Hex Nut

10536 3/8-16 x 2 1/4" Hex Bolt

10537

10538 3/8" Lock Washer

10539 1/4 x 1 1/4" Faspin

10540 Hemming Handle Assembly

10544 Lifting Handle Cap

10545 Moving Hinge Cap

1/4-20 x 1 1/2" Sock FL HD Sc

1/4-20 x 3/4" Hex Wash HD Sc

1/4-20 x 3/4" Sock Flat HD Sc

10549

10520

10542

10515

10094

10520

10535

10537

10508

10537

10347

10349

*10425

10547

10545

10519

Part No. Part Name

10547 Base Hinge Cap - Right

10548 Base Hinge Cap - Left

10549 Locking Handle Cap - Right

10550 Locking Handle Cap- Left

10551 Back Rail Cap

10552 Key Wrench Clip

10887 T-Handle Hex Key

11056 Pivot Assembly

12061 C Casting

Model Specific Parts

6'8"

10329

10331

10415

10425

10428

10448

10450

10490

10498

10507

10510

12079

12080

8'6"

10333

10335

10417

10430

10433

10452

10454

10491

10499

10506

10511

12081

12082

(* 6'8" part numbers shown in diagram)

10'6"

10337

10339

10419

10435

10438

10456

10458

10492

10500

10505

10512

12083

12084

10

10538

10530

12'6"

10341

10343

10421

10440

10443

10460

10462

10493

10501

10504

10513

12085

12086

10503

10534

*10329

12061

10551

NOTE: Multiple parts of the same

number may not all be called out.

14'6"

10345

—

10423

10445

—

10464

—

10494

10502

—

10514

12087

—

Part Description

Back Rail

HD Back Rail

Moving Hinge

Base Hinge

HD Base Hinge

Locking Handle

HD Locking Handle

Stainless Edge

Hinge Pin

Tape Measure

Vinyl Strip

Locking Anvil

HD Locking Anvil

10348

10532

10519

Page 11

TRADITIONAL BENDING TECHNIQUES

Helpful Hints for Trim Work

1. Measure the total length of the trim area to be covered and

divide by the length of your Bender to determine the number

and length of trim pieces needed.

2. Determine the dimensions of each section of the desired trim

shape by measuring the profile to be covered. As an aid, make

a pattern out of a 1" strip of coil to get your exact profile.

3. Transfer the dimensions in Hint #2 to each end of a piece of

trim coil by making a

These marks now become the bending points and makes

the bending marks visible from either side. On longer lengths

fold the coil over as shown and snip both ends at once. This

saves time and ensures accuracy. The Tapco Pro-Filer was

designed to make this time consuming part of your job easier

and more accurate. See page 3.

4. Lock the pre-marked coil blank into the bender with the cut

marks located directly under the outer edge of the Stainless

Bending Edge. Lock Bender. To cut off the coil with a razor

knife, score the metal against the Stainless Bending Edge.

bend the metal up and push back down by hand until the

Now

exposed

section breaks off. It may require 2 or 3 repetitions.

1

/4" slit in the metal with a pair of shears.

When braking material, bending to just 45° will avoid round-

ing the edge. The Pro Cut-Off was designed to safely and

easily cut your material in seconds. See page 3.

5. For bending, follow the suggested sequence of bends on

page 12. For bending techniques see “Bending the Roof Drip

Edge” below.

6. Don’t fit your trim parts too tight. This will complicate the

joints where parts overlap. A one inch (1") lap joint is enough

to allow for expansion and contraction.

Trim should be lapped

so that laps are facing away from traffic areas.

7. Try to nail the trim parts on an area that will make the nails

less conspicuous. Fasten at laps. When face nailing, use

just enough nails to secure trim; DO NOT DRIVE NAILS

TOO TIGHT!!

8.

Remember,

when designing shapes you are hanging a cover

over the wood parts, not laminating a skin-tight surface. This

is called “Floating Your Trim”. Allow for irregularities in the

wood because your formed trim shapes are straighter than

the wood trim moldings or boards you are covering.

9. With practice, you’ll learn to overbend or underbend certain

sections to achieve a pressure fit of your trim parts which

will, in turn, require fewer nails and give your job a more

wood-like appearance.

10. Hemming (making a 180° bend on the edge of a sheet) will

give your shape a “Factory Edge Look” and will stiffen the

entire trim piece to help eliminate “oil canning”. See page 8.

Bending the Roof Drip Edge

(Use these basic instructions for all examples)

1. This shape is basic to all the other shapes contained in this

manual. Practice this shape before you proceed with the other

trim pieces illustrated on pages 12.

2. To begin, cut off a piece of coil 4

foot long (As shown at right).

3. Mark your coil with a pencil at 2", 2

Then snip these marks in about

both sides of the coil).

4. Put your coil into the Bender with the Finished Side Up. Bend

1

is the 2

3

/4" mark, lock the Bender on the mark; then,

bend 90°.

5. Remove the coil from the Bender. Bend will be at the 2"

mark on the coil, now put the coil into the Bender with the

Finished Side Down. Lock the Bender on this 2" mark. Note

that Bend shows the symbol

be 180°. Bend this as far as it will go (about 165°). Then proceed to hem it in the Bender as shown on Page 8 in “Basic

Hemming and Folding”.

6. Now to Bend put your coil back into the Bender Finished

Side Up and lock on the 4

45° as shown to complete the shape.

2

3

3

/4 inches wide by about 1

3

/4" and 41/4" on both ends.

1

/4" (so they will be visible on

2

which means the bend is to

*

1

/4" mark. Bend this approximately

(continued on next page)

Roof Drip Edge

Finish

*

1

3

Finish

Side

Up

1. Numbers show the sequence of the bends; thus,

would be the first bend, the second bend, etc.

2."Finish Side Up" indicates that the finished or

exposed side of the trim is to be put into the Bender

FACING UP.

3. "Finish Side Down" indicates that the finished or

exposed side of the trim is to be put into the Bender

FACING DOWN.

The bend is to be 180°.

*

2

Side

Down

2"

3

11/2"

1

/2"

/4"

2"

3

2

/4"

1

/4"

4

Material: Aluminum coil 43/4 inches

wide x the desired length. (For

practice, use only about a 1 foot

length of coil)

Finish

Side

Up

1 2

12"

Mark with pencil

Then snip in from

edge 1/4"

2"

3

2

/4"

1

/4"

4

3

4

/4"

11

Page 12

EXAMPLES OF B ASIC SHAPES

NOTE: UP and DOWN refers to the clad, painted or FINISH SIDE of the material as it is placed into the Bender.

1. All Purpose Sill Trim

Down

2

1

Up

2

Down

Down

1

Down

7

4

Up

Down

5

6

3

Up

Up

2. Fascia Trim

Down

7. Counter Flashing

2

Down

1

Down

3

3. One Piece Soffit Mitre 8. Bric k Frieze

Down

3

Up

2

5

Up

4. Rake Trim with “J” Channel

Down

1

4

Up

9. “F” Channel/Inside Corner

Up

2

Down

Down

Down

Up

Down

Up

4

1

6

5

Down

3

Down

3

2

Down

4

5

1

Up

1

Up

5. Soffit or Frieze Trim

®

TAPCO PRODUCTS COMPANY

Plymouth, MI USA Phone: (734) 451-8272 • Fax: (734) 451-0702 • Web site: www.tapcoint.com

Down

2

Down

1

5

Down

3

Down

5

3

Up

Up

5

Up

Up

5

4

3

Down

2

Down

1

Down

Down

6

4

Up

10. Window or Door Casing

with “J” Channel

2

Down

4

Up

A DIVISION OF TAPCO INTERNATIONAL

1

Up

2

Down

3

Up

Down

4

5

Down

10815 B

T1015-LS 3/01

5

Loading...

Loading...