Tapco Port-O-Slitter General Instructions, Set Up, Accessories And Manual To Using

Tapco Products Company

“The World Leader

in Specialty Tools

for the Professional”

®

®

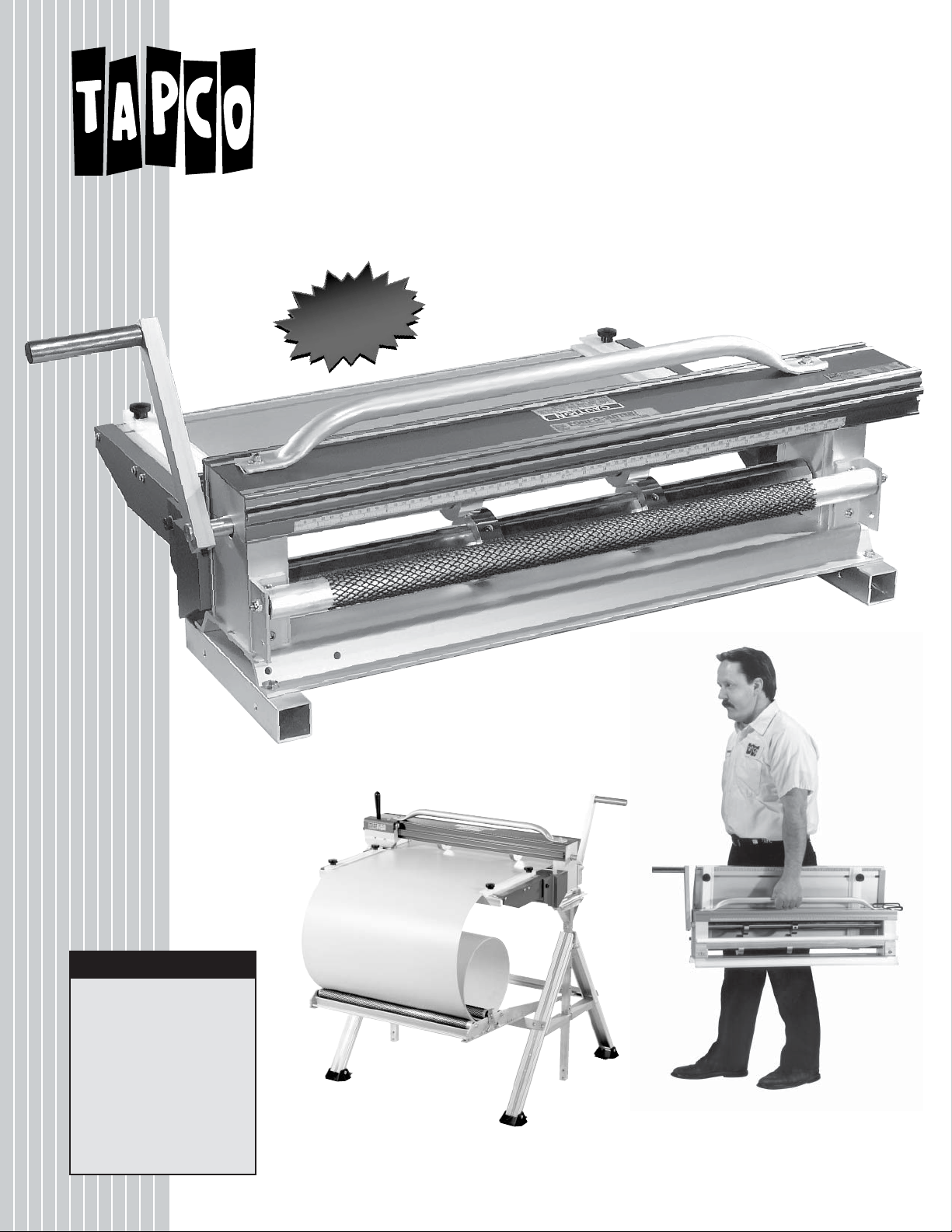

Port-O-Slitter

OPERATIONS MANUAL

General instructions, set up, accessories and guide to using your

portable precision slitting, rib forming and perforating system.

Saves

hours on large

siding jobs!

Contents

General Instructions...2

Knife Set Up ................2

Accessory Set Up .......3

Parts List .....................4

Motor Set Up ...............5

Slitter Stand Set Up ....6

Optional Slitter

Cut-Off .....................7

Optional Knives .......... 8

Page

24" model

optional

Port-O-Slitter

Port-O-Slitter Stand,

Cut-Off and PRO-Coiler.

(see page 6)

with

U.S. & Foreign Pats. Pend.

Tapco

“The Siders Helper” use it in

the shop or on the job site.

Port-O-Slitter

is

PORT-O-SLITTER® SETUP AND OPERATION

KNIFE

SHAFT

SET SCREW

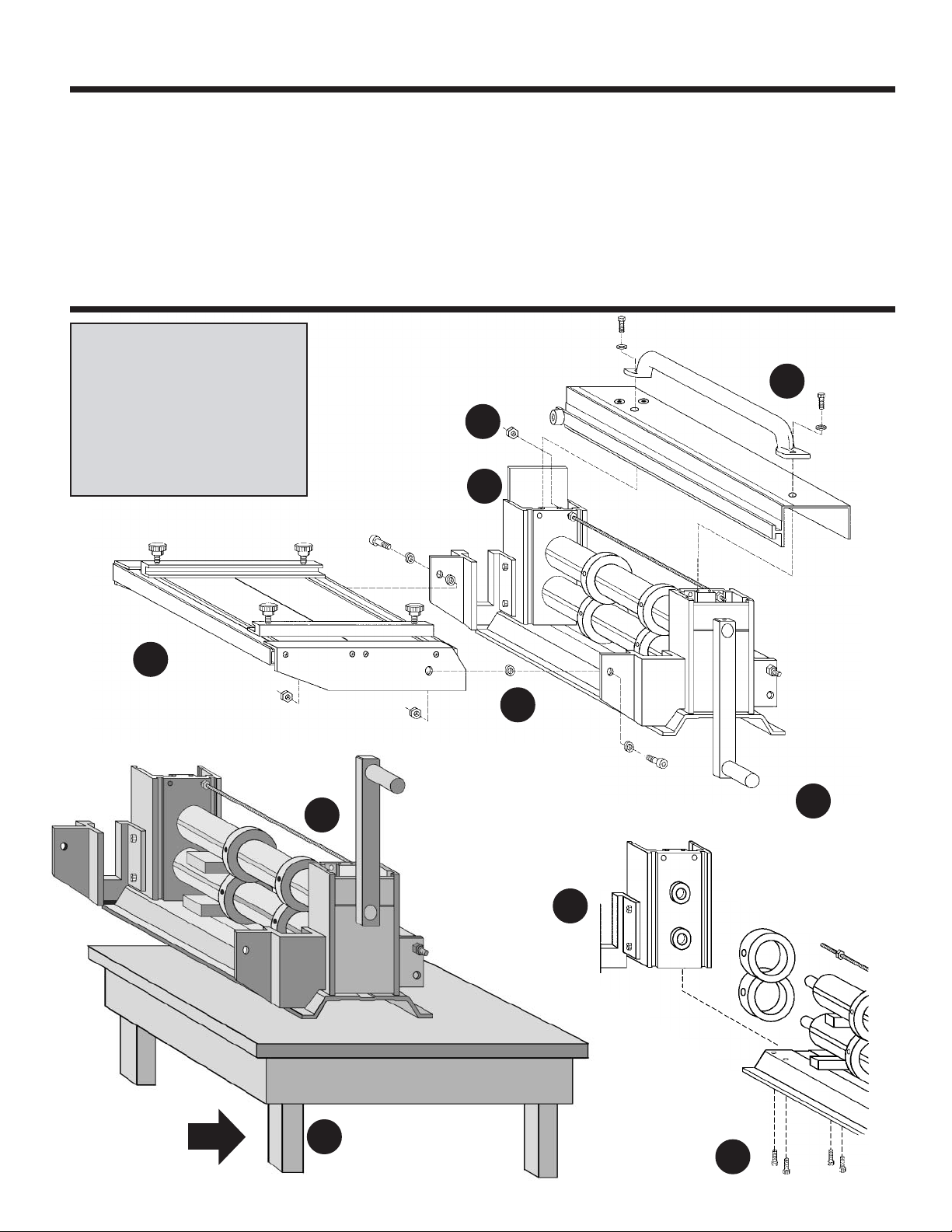

1. ASSEMBLY OF YOUR PORT-O-SLITTER

Remove the contents of the PARTS BAG, which should include 2 “T” WRENCHES and the CRANK HANDLE

ASSEMBLY. Install the HANDLE and tighten the SET SCREW against the “flat” on the SHAFT. Make sure that the

HANDLE turns freely without interference.

2. PORT-O-SLITTER OPERATION—SLITTING

A. Loosen the SET SCREWS on the LOWER SLITTING KNIFE and slide the KNIFE

into the cutting position by aligning the cutting edge of the KNIFE with the desired

measurement on the TAPE MEASURE. Tighten the SET SCREW. IMPORTANT:

Tighten all SET SCREWS against the FLATS of the SHAFTS only. Carefully

slide the upper SLITTING KNIFE against the lower KNIFE and tighten that SET

SCREW securely using the “T” WRENCH provided. To avoid damaging the SLITTING KNIVES, do not “BANG” the KNIVES together when adjusting them. To make

more than one simultaneous cut repeat this procedure with the other KNIVES. If only one cut is being made, move

the remaining KNIVES at least three inches apart to avoid cutting or marking your material.

B. Next, adjust the right and left COIL GUIDE BARS. In most cases, set the right COIL GUIDE BAR at zero on the tape

measure, place the right edge of the material into the slot, then draw the left COIL GUIDE BAR to the left edge of the

material and tighten the knurled knobs. Periodically check COIL GUIDE BARS for squareness.

C. Now push the material into the SLITTER while turning the CRANK HANDLE counterclockwise.

NEVER PLACE HANDS OR CLOTHING NEAR KNIVES WHILE IN OPERATION.

D. For maximum performance during the slitting operation, keep the material flat over the front RECEIVER ROLLER

as the material exits.

E. When slitting harder and thicker materials, or if twisting of the material occurs, separate the KNIVES a few thou-

sandths of an inch to provide a better cut.

F. When slitting close to one edge of wide material, it may be helpful to lightly hold the material down on the COIL

TABLE surface in order to keep it from bowing upwards.

3. PORT-O-SLITTER OPERATION—RIB FORMING

A. To form “RIBS” for stiffening and decoration, set the KNIVES approximately 1/8" apart. Experiment to achieve

different effects. Refer to section 4 below for more information.

4. KNIFE CONFIGURATION AND SET-UP

• Standard KNIFE configurations which can be used are shown below.

QUICK GUIDE

1. CRANK HANDLE ASSEMBLY

2. CRANK HANDLE

3. CRANK HANDLE SET SCREW

4. RIGHT COIL GUIDE BAR

5. LEFT COIL GUIDE BAR

6. KNURLED KNOB

7. COIL TABLE

8. RECEIVER ROLLER

9. KNIFE

10. SHAFT

11. “T” HEX WRENCH (1 OF 2)

STANDARD KNIFE CONFIGURATIONS

KNIFE CONFIGURATION FROM FACTORY

CONFIGURATION FOR 1 SLIT

TWO SLITS SIMULTANEOUSLY

ONE SINGLE “RIB” FORM

TWO SINGLE “RIBS”

FORMED SIMULTANEOUSLY

ONE DOUBLE “RIB” FORMED DOWN

ONE DOUBLE “RIB” FORMED UP

2

ONE SLIT & ONE SINGLE “RIB”

FORMED SIMULTANEOUSLY

MAINTAINING AND LUBRICATING YOUR PORT-O-SLITTER

• Keep a light film of protective oil on the SHAFTS, DRIVE GEARS, SET SCREWS, and when not in service, the KNIVES.

Always inspect KNIVES for dirt and other foreign matter before using. Never clean knives while slitter is in operation.

•To clean knives, spread knives then run a soft cloth over the knife surfaces.

• The SLITTING KNIVES can be re-sharpened on a Surface or Blanchard Grinder. Grind ONLY the sides to regain a new

sharp edge. Do not grind the outside radius of the KNIVES.

• Periodically check the squareness of the stationary COIL GUIDE BAR with a framing square against the SHAFTS or

SLITTING KNIVES. Re-square when necessary.

• CAUTION: Always observe safe work practices when cleaning, maintaining and operating this equipment. To avoid injury,

keep your fingers, hands, clothing and other objects away from the SLITTING KNIVES when this machine is in operation.

ACCESSORY INSTALLATION:

PERFORATING ROLLS

INSTALL MALE ROLL ON TOP SHAFT,

FEMALE ON BOTTOM.

GROOVED KNIFE SET

INSTALL MALE ROLL ON TOP SHAFT,

PLACE SCRAPER IN GROOVE ON FEMALE

ROLL. SLIDE BOTH ON BOTTOM SHAFT.

NYLON PINCH ROLLERS

INSTALL DIRECTLY OVER EACH OTHER.

(SEE PAGE 8 FOR FURTHER DETAILS)

10

To reassemble, reverse the following

steps remembering to realign the tie

bar and receiver roller to the bearing

support as you slide it back in place.

Place wooden

shims under each

shaft for support.

6

Remove the

hex nut from

the tie bar.

Slide the end

cap out of the

bearing support.

Remove the coil table shoulder bolts,

nylon washers and nylox hex nuts. Set

coil table aside. The nylon washers

are of varying thicknesses, reinstall in

the same sequence as removal.

Gently tap bearing support free from

the shafts. At this point the front

receiver roller will dislodge. Set it to

the side. Make sure to reposition it

during reassembly.

Perforating Rolls, Grooved Knife Set, Nylon Pinch Rollers

Remove the handle cap screws

and washers, set handle and

cover aside.

2

4

3

5

9

After applying a light coating of oil to

all parts and surfaces, slide knives,

or perforating roll set onto shafts far

enough to be able to reattach

bearing support. Align set screws to

shaft flat. As a general rule, always

8

install perforating set to the end of

shafts.

START

Place slitter on a stable bench top

with end extended over edge just

1

enough to expose the 4 cap screws

underneath the bearing housing.

Remove all 4 cap screws from

underneath bearing support.

7

3

Loading...

Loading...