Tapco MX Series, MX 10, MX 12, MX Stand, MX 8 Operating Instructions Manual

...

™

MX Series

Operating Instructions

MX 8™ • MX 10™ • MX 12™ • MX Stand™ • MAX Cut-Off

™

Snap StandMX Series

™

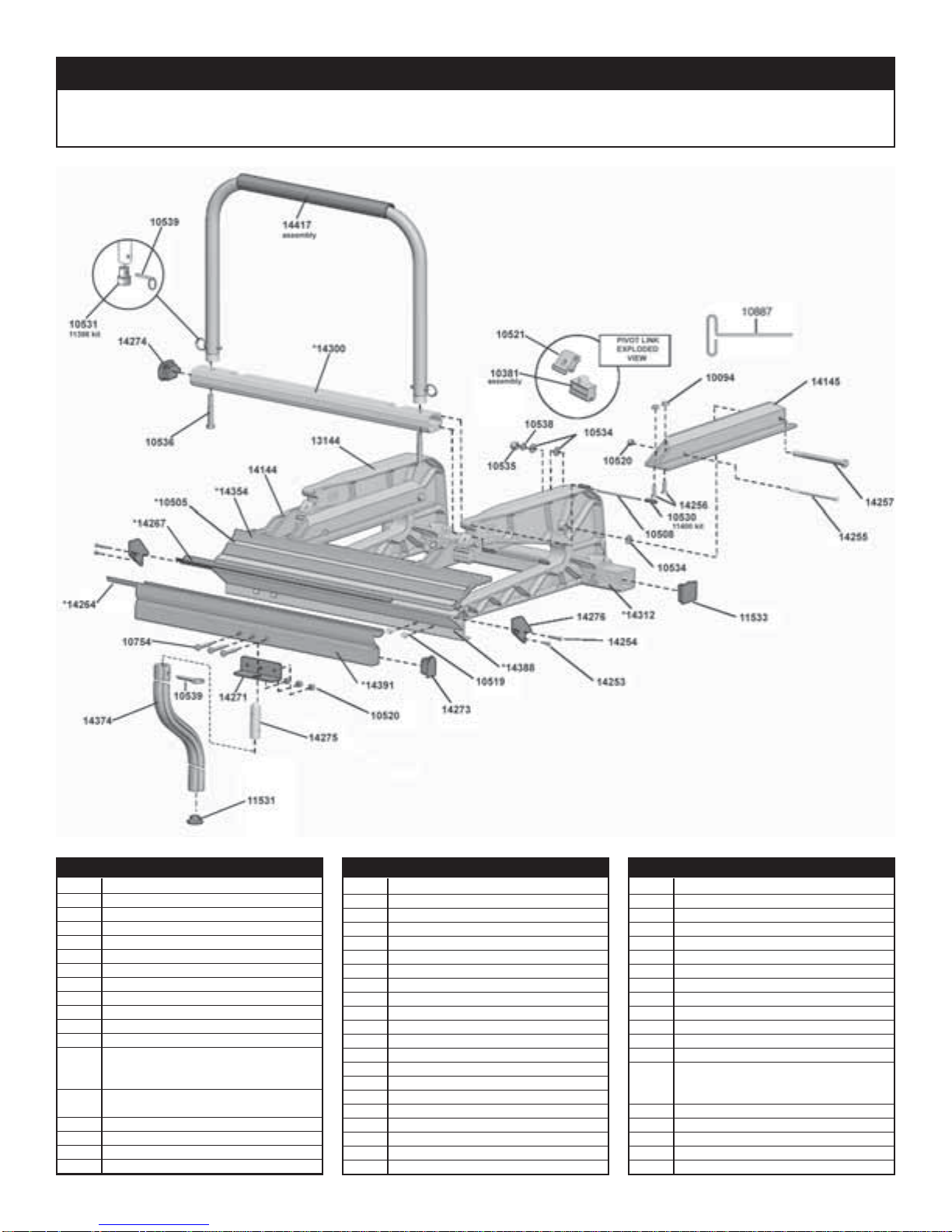

MX Series™ Brake Parts List

Item# Description Item# Description Item# Description

10491 8'6" Stainless Edge

10492 10'6" Stainless Edge

10493 12'6" Stainless Edge

10504 12'6" Tape Measure

10505 10'6" Tape Measure

10506 8'6" Tape Measure

10519 ¼ -20 x ¾ " Hex Wash HD Sc

10534 3/8" Flat Washer

10535 3/8-16 Nylock Hex Nut

10887 T-Handle Hex Key

11396 Pivot Link Assembly Kit (6)

11397 ¼ " x 1 ¼ " Faspin Kit (4)

11398 Locking Handle Plug Kit

Locking Handle Plug

3/8-16 x 2 ¼ " Bolt

11400 Locking bar Pin Kit

10 pins, 20 keepers

11531 Lifting Handle Cap

11533 Back Rail Cap

13144 C Castings

14144 Pivot Arm - Left

14145 Pivot Arm - Right

14253 8-32 x 5/16" Phil Pan HD Sc

14254 8-32 x 1" Phil Pan HD Sc

14256 ¼ -20 x 1" FL HD Sc

14257 3/8-16 x 5" Hex Cap Bolt

14263 8'6" Rubber Strip

14264 10'6" Rubber Strip

14265 12'6" Rubber Strip

14266 8'6" Wear Strip

14267 10'6" Wear Strip

14268 12'6" Wear Strip

14271 Lifting Handle Support Bracket (2)

14273 Moving Hinge Cap

14274 Locking bar Cap

14276 Fixed Hinge Endcap

14299 8'6" Locking bar

14300 10'6" Locking bar

14301 12'6" Locking bar

14311 8'6" Back Rail

14312 10'6" Back Rail

14313 12'6" Back Rail

2

14353 8'6" Locking Anvil

14354 10'6" Locking Anvil

14355 12'6" Locking Anvil

14374 Lifting Handle Assembly

14387 8'6" Fixed Hinge

14388 10'6" Fixed Hinge

14389 12'6" Fixed Hinge

14390 8'6" Moving Hinge

14391 10'6" Moving Hinge

14392 12'6" Moving Hinge

14414 Locking handle Assembly

14456 MX Series™ Brake Parts Bag 8'

14457 MX Series™ Brake Parts Bag 10'/12'

14480 Bolt and Nut Kit

¼ -20 x 4 ½ "" Bolt (5)

¼ -20 x Nylok Nut (5)

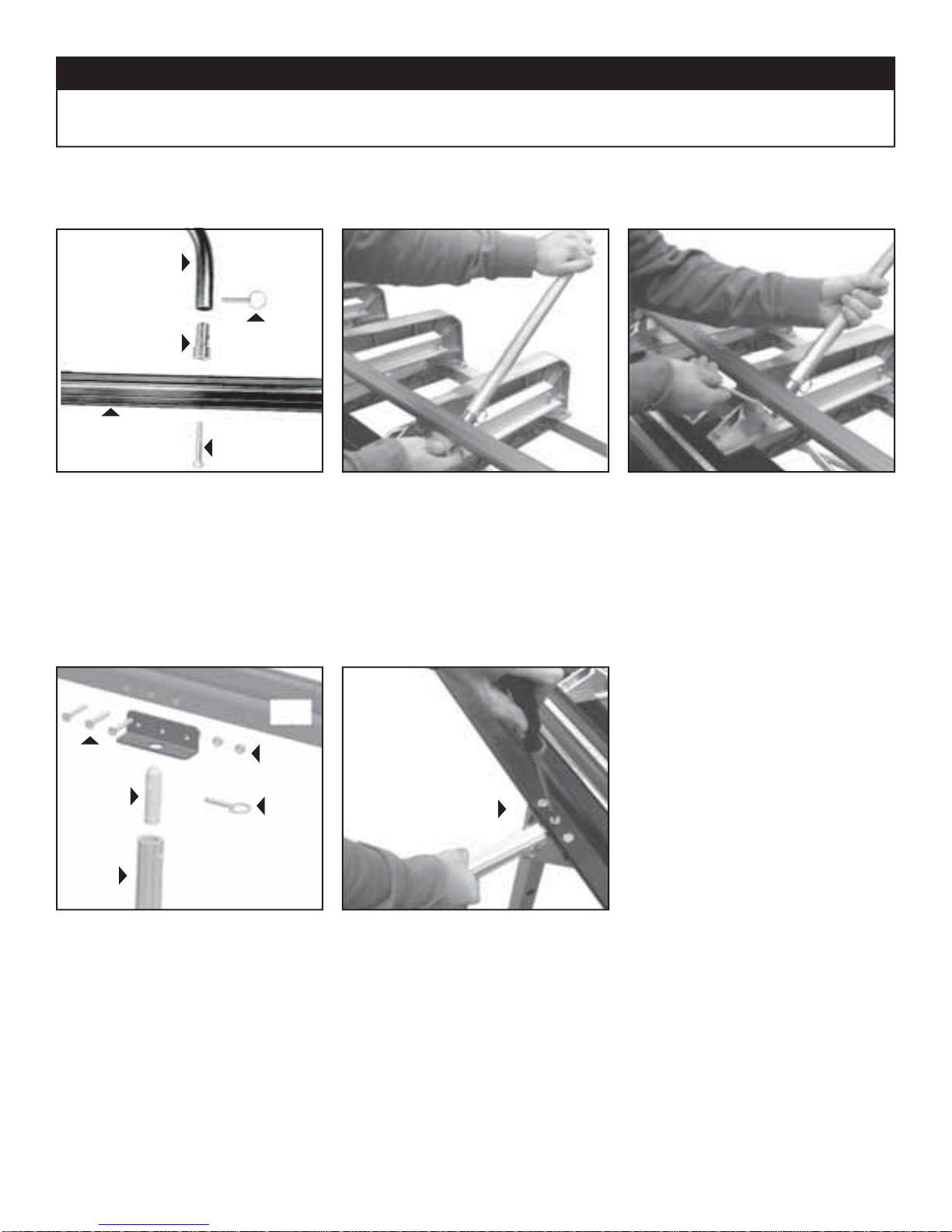

Locking bar Installation

Locking

Handle

Snap StandMX Series

™

Setting up the MX Series™ Brake

Handle

Plug

Locking Bar

MX Locking Bar Assembly includes:

Faspin

Hex Bolt

1. Insert Hex Bolt through Locking bar

(2) Locking bars,

(4) Handle Plugs, (4) Faspins, (4) Hex Bolts

Lifting/Bending Handle Installation

Moving

Hinge

1/4-20 x 1 1/2"

Screw

1/4-20

Lock Nut

of your MX Series™ Brake and into the

base of Locking bar(s) as indicated using the 3/8" Hex Bolts provided. HAND

TIGHTEN ONLY. Repeat for other side.

2. Attach the Locking bar over the Handle

Plugs and secure them with Faspins.

Now tighten the 3/8" Hex Bolts with a

9/16" wrench. Handle can be detached

from now on by simply removing the

Faspins.

Handle

Lifting/

Bending

Handle

Plug

Exploded view of

Handle Assembly

Faspin

1. First insert one end of the Handle Plug

into Lifting / Bending Handle and install

Faspin through holes.

Secure with

1/4-20 Lock Nut

2. Next, insert Handle Assembly into hole

in bottom of Moving Hinge. Align hole

in hinge with Handle Plug and insert

screw using Phillips Screw Driver as

shown. Secure with 1/4-20 Lock Nut

Repeat for other handles. To remove

handles, simply remove Faspins. Always use more than one handle when

bending.

3

Snap StandMX Series

™

Pivot Link Adjustment Instructions

IMPORTANT: The Pivot Links on your MX Industrial Brake have been pre-set at the factory for average holding capacity and ease of

operation. However, it's important that you readjust your MX Industrial Brake to your stock thickness. Your MX Series™ Brake may

also need periodic adjustment due to extreme weather and/or working conditions. It is important that you follow these steps when you

adjust your MX Series™ Brake to ensure proper gripping tension and maximum performance.

First check the uniformity of the clamping pressure along the entire length of your MX Series™ Brake by using the following method.

Decrease

Increase

TO TEST

Cut some narrow strips of aluminum or use

strips from stock you will be using and lock

one under each shoe casting as indicated

above. Then lightly pull the material to

determine the tightness and uniformity

of each Pivot Link. If the material can be

moved when the MX handle is locked or if

it requires excessive pressure to lock the

handle down on the material then the Pivot

Arms may need adjustment.

NOTE: All adjustments are made with the

MX Series™ Brake in the “open" position.

All adjustments are tested with strips of

material placed in the MX Series™ Brake in

the “locked" position.

TO ADJUST

Insert the 3/16" hex wrench into the Pivot

Link Stud through the access hole in the

upper link. Turn 1/4 turn either COUNTERCLOCKWISE to INCREASE locking tension

or CLOCKWISE to DECREASE locking

tension.

Repeat test step above to check tension.

Pivot Link Assembly

Upper

Adjustment

Link

Pivot Link

Stud

Lower

Adjustment

Link

TO ADJUST (Optional method)-

As an alternate method you may use a 5/8"

open-end wrench directly on the Pivot Link

Stud by turning 1/4 turn either COUNTERCLOCKWISE to INCREASE locking tension

or CLOCKWISE to DECREASE locking

tension.

Repeat test step above to check tension.

4

Loading...

Loading...