Page 1

™

MX Series

Operating Instructions

MX 8™ • MX 10™ • MX 12™ • MX Stand™ • MAX Cut-Off

™

Page 2

Snap StandMX Series

™

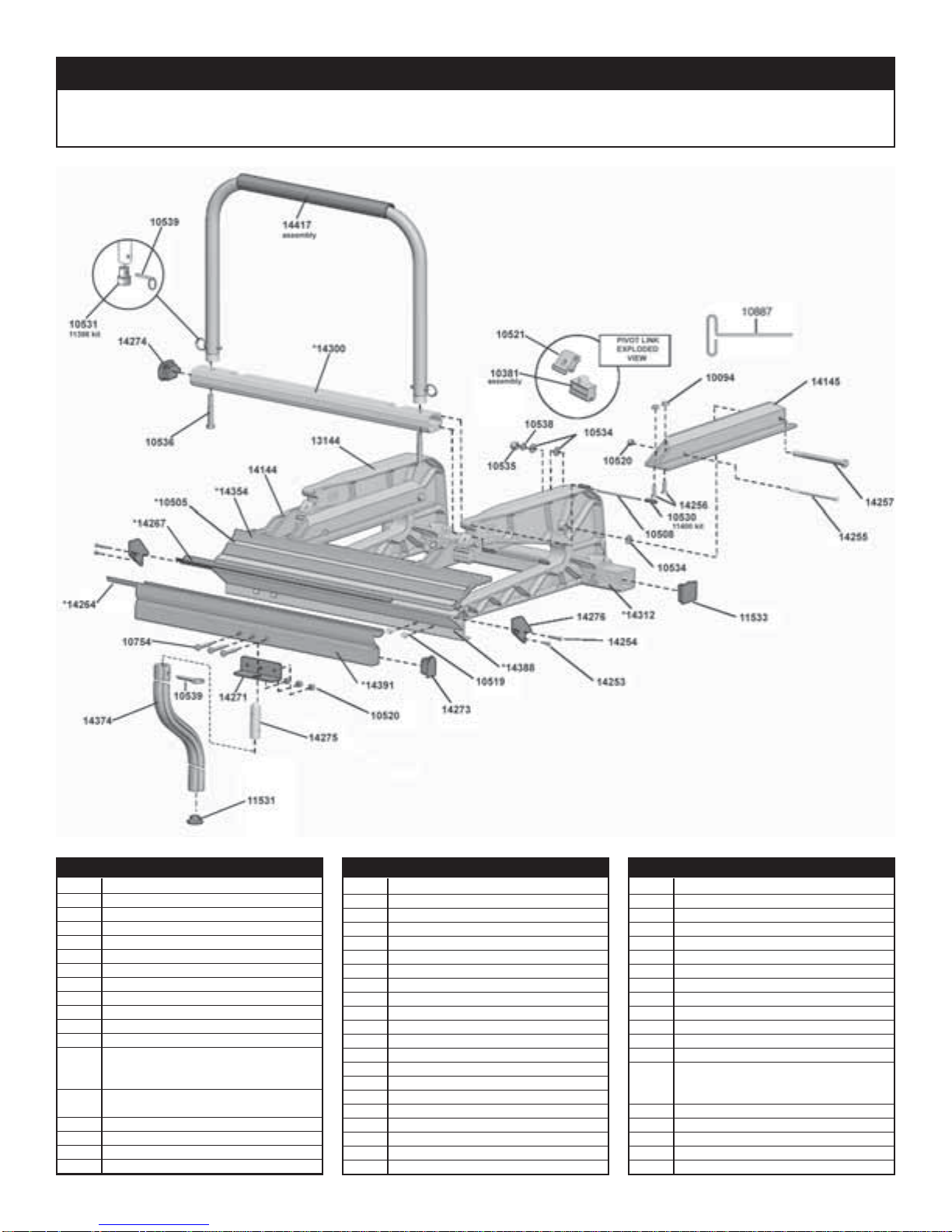

MX Series™ Brake Parts List

Item# Description Item# Description Item# Description

10491 8'6" Stainless Edge

10492 10'6" Stainless Edge

10493 12'6" Stainless Edge

10504 12'6" Tape Measure

10505 10'6" Tape Measure

10506 8'6" Tape Measure

10519 ¼ -20 x ¾ " Hex Wash HD Sc

10534 3/8" Flat Washer

10535 3/8-16 Nylock Hex Nut

10887 T-Handle Hex Key

11396 Pivot Link Assembly Kit (6)

11397 ¼ " x 1 ¼ " Faspin Kit (4)

11398 Locking Handle Plug Kit

Locking Handle Plug

3/8-16 x 2 ¼ " Bolt

11400 Locking bar Pin Kit

10 pins, 20 keepers

11531 Lifting Handle Cap

11533 Back Rail Cap

13144 C Castings

14144 Pivot Arm - Left

14145 Pivot Arm - Right

14253 8-32 x 5/16" Phil Pan HD Sc

14254 8-32 x 1" Phil Pan HD Sc

14256 ¼ -20 x 1" FL HD Sc

14257 3/8-16 x 5" Hex Cap Bolt

14263 8'6" Rubber Strip

14264 10'6" Rubber Strip

14265 12'6" Rubber Strip

14266 8'6" Wear Strip

14267 10'6" Wear Strip

14268 12'6" Wear Strip

14271 Lifting Handle Support Bracket (2)

14273 Moving Hinge Cap

14274 Locking bar Cap

14276 Fixed Hinge Endcap

14299 8'6" Locking bar

14300 10'6" Locking bar

14301 12'6" Locking bar

14311 8'6" Back Rail

14312 10'6" Back Rail

14313 12'6" Back Rail

2

14353 8'6" Locking Anvil

14354 10'6" Locking Anvil

14355 12'6" Locking Anvil

14374 Lifting Handle Assembly

14387 8'6" Fixed Hinge

14388 10'6" Fixed Hinge

14389 12'6" Fixed Hinge

14390 8'6" Moving Hinge

14391 10'6" Moving Hinge

14392 12'6" Moving Hinge

14414 Locking handle Assembly

14456 MX Series™ Brake Parts Bag 8'

14457 MX Series™ Brake Parts Bag 10'/12'

14480 Bolt and Nut Kit

¼ -20 x 4 ½ "" Bolt (5)

¼ -20 x Nylok Nut (5)

Page 3

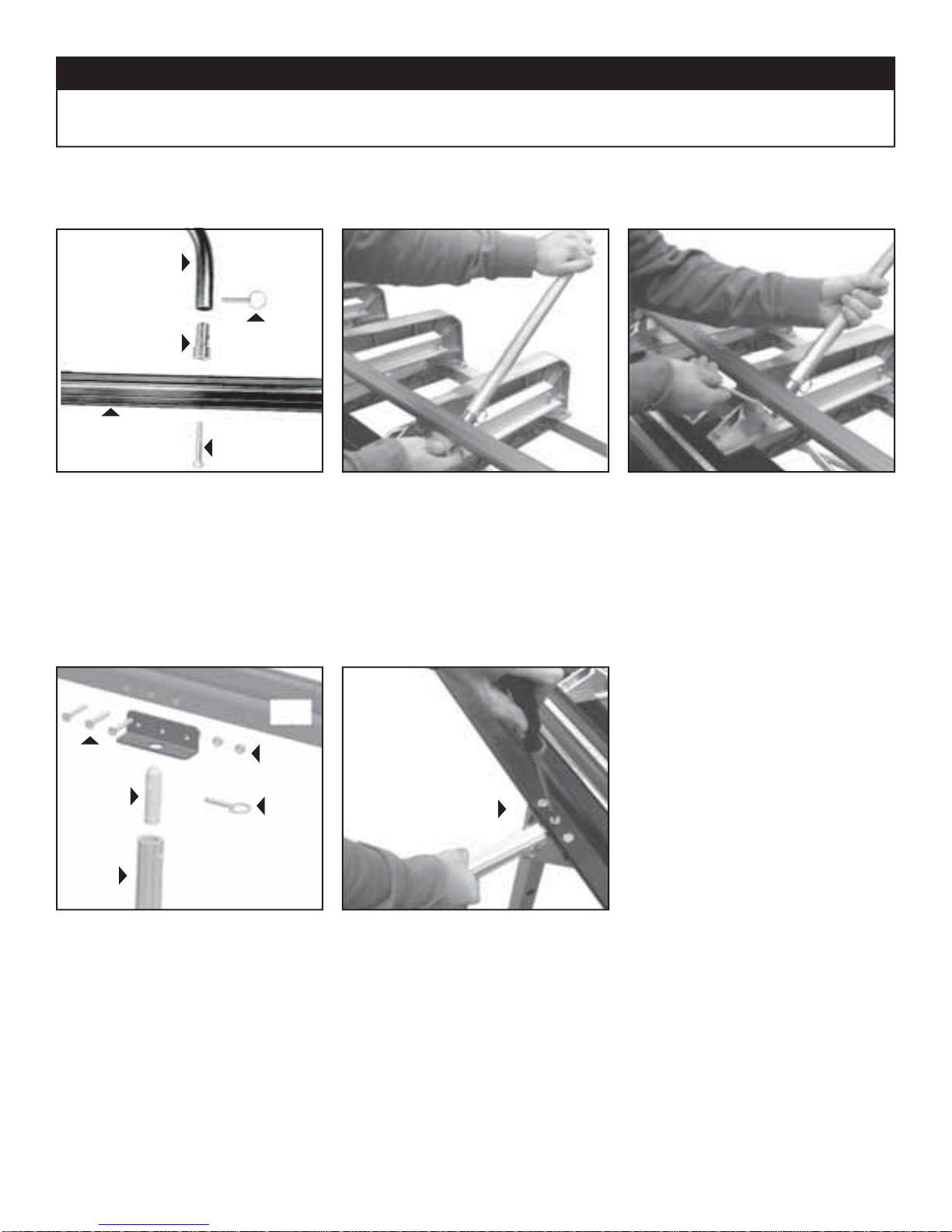

Locking bar Installation

Locking

Handle

Snap StandMX Series

™

Setting up the MX Series™ Brake

Handle

Plug

Locking Bar

MX Locking Bar Assembly includes:

Faspin

Hex Bolt

1. Insert Hex Bolt through Locking bar

(2) Locking bars,

(4) Handle Plugs, (4) Faspins, (4) Hex Bolts

Lifting/Bending Handle Installation

Moving

Hinge

1/4-20 x 1 1/2"

Screw

1/4-20

Lock Nut

of your MX Series™ Brake and into the

base of Locking bar(s) as indicated using the 3/8" Hex Bolts provided. HAND

TIGHTEN ONLY. Repeat for other side.

2. Attach the Locking bar over the Handle

Plugs and secure them with Faspins.

Now tighten the 3/8" Hex Bolts with a

9/16" wrench. Handle can be detached

from now on by simply removing the

Faspins.

Handle

Lifting/

Bending

Handle

Plug

Exploded view of

Handle Assembly

Faspin

1. First insert one end of the Handle Plug

into Lifting / Bending Handle and install

Faspin through holes.

Secure with

1/4-20 Lock Nut

2. Next, insert Handle Assembly into hole

in bottom of Moving Hinge. Align hole

in hinge with Handle Plug and insert

screw using Phillips Screw Driver as

shown. Secure with 1/4-20 Lock Nut

Repeat for other handles. To remove

handles, simply remove Faspins. Always use more than one handle when

bending.

3

Page 4

Snap StandMX Series

™

Pivot Link Adjustment Instructions

IMPORTANT: The Pivot Links on your MX Industrial Brake have been pre-set at the factory for average holding capacity and ease of

operation. However, it's important that you readjust your MX Industrial Brake to your stock thickness. Your MX Series™ Brake may

also need periodic adjustment due to extreme weather and/or working conditions. It is important that you follow these steps when you

adjust your MX Series™ Brake to ensure proper gripping tension and maximum performance.

First check the uniformity of the clamping pressure along the entire length of your MX Series™ Brake by using the following method.

Decrease

Increase

TO TEST

Cut some narrow strips of aluminum or use

strips from stock you will be using and lock

one under each shoe casting as indicated

above. Then lightly pull the material to

determine the tightness and uniformity

of each Pivot Link. If the material can be

moved when the MX handle is locked or if

it requires excessive pressure to lock the

handle down on the material then the Pivot

Arms may need adjustment.

NOTE: All adjustments are made with the

MX Series™ Brake in the “open" position.

All adjustments are tested with strips of

material placed in the MX Series™ Brake in

the “locked" position.

TO ADJUST

Insert the 3/16" hex wrench into the Pivot

Link Stud through the access hole in the

upper link. Turn 1/4 turn either COUNTERCLOCKWISE to INCREASE locking tension

or CLOCKWISE to DECREASE locking

tension.

Repeat test step above to check tension.

Pivot Link Assembly

Upper

Adjustment

Link

Pivot Link

Stud

Lower

Adjustment

Link

TO ADJUST (Optional method)-

As an alternate method you may use a 5/8"

open-end wrench directly on the Pivot Link

Stud by turning 1/4 turn either COUNTERCLOCKWISE to INCREASE locking tension

or CLOCKWISE to DECREASE locking

tension.

Repeat test step above to check tension.

4

Page 5

Snap StandMX Series

™

MX Stand™ Parts List

14394

14318

(large stand) *

10539

14316

(large stand) *

10795

14319

14285

14284

14321

11533

14320

14279

Item# Description

10539 ¼ ” x 1 ¼ ” Faspin

10795 3/8-16 x 2 ½ T-Knob

11533 Back Rail Endcap

14279 Stand Counter Balance Bracket

14284 Right Stand Leg Assembly

14285 Back Rail Clamp

14316 Rear Cross Tube (large stand)

14318 Front Support Tube (large stand)

14319 Back Rail Clamp Wedge

14320 Stand Counter Balance Plank

14321 Toggle Pin

14394 Left Stand Leg Assembly

14402 Front Support Tube (small stand)

14403 Rear Cross Tube (small stand)

5

Page 6

Hardware Requirements: (2) 7/16" & (2) 9/16" Open end wrench.

STEP 1

Attach Stand Counter Balance Brackets to

Plank with Carriage Bolts and Nylock Nuts

using a 7/16" Socket or Open end Wrench.

Counter Balance is required for operation.

Snap StandMX Series

™

MX Stand™ Set-up

Stand Counter

Balance Bracket

1/4-20 x 3/4" Carriage Bolt &

1/4-20 Nylock Nut

Stand Counter

Balance Plank

STEP 2

Slide Stand Counter Balance Assembly up

to the Stand Legs. Insert the 3/8-16 x 2 3/4"

Hex Bolts through the Stand Counter Balance Bracket and Leg as shown in Figure

2. Use a 9/16" wrench to tighten down 3/816 Nylock Nut.

STEP 3

Insert Front Support Tube through both

Right and Left Legs as shown in Figure 3.

Next slide the 1/4-20 x 2 1/2" bolt through

the Stand Leg and Support tube. Use the

7/16" wrench to secure the Support Tube

in place with 1/4-20 Nylock Nuts.

Left Stand

Leg Assembly

Stand Counter

Balance Assembly

Right Stand

Leg Assembly

3/8-16 x 2 3/4" Hex Hd Bolt

3/8" Flat Washer

3/8" Lock Washer

3/8" Nylock Nut

6

Page 7

STEP 4

Rotate the Toggle Pin 90 degrees and

slide the Rear Cross Tube onto the

Pin. To secure the Tube in place allow

the arm on the Toggle Pin to drop

down. Repeat steps in all locations.

Snap StandMX Series

™

MX Stand™ Set-up

Rotate arm on Toggle Pin

to insert Rear Support Tube.

Toggle Pin in

Locked position.

Toggle Pin (locked)

Rear Cross

Tube Assembly

Toggle Pin (unlocked)

7

Page 8

Snap StandMX Series

™

Installing a MX Series™ Brake on MX Stand

STEP 5

Align the hole in the Fixed Hinge with the Slot on the Stand Top

Bracket. See 5a.

Insert Faspin through the Stand Top Bracket and into the Fixed

Hinge to secure Brake in place. See 5b.

The Brake must be secured with Faspins on the Left & Right

Stand Leg Assemblies.

Using 2 people, set Brake on Stand with the hinges above the

Front Support Tube.

™

5a

5b

STEP 6

Place Back Rail Clamp on the Back Rail. Slide Knob through

the Wedge and turn clockwise into the Threaded Insert.

See 6.

Back Rail Clamp Assembly must be attached on Left and

Right Stand Leg Assemblies.

6

Removing a MX Series™ Brake from MX Stand

- Removing the brake from the MX Stand is essentially the opposite of attaching it to the stand.

- Remove the Back Rail Clamp Assembly from the Stand.

- Lift the Moving Hinge and remove the Faspins and place in the Stand Leg Faspin storage hole.

3/8-16 Knob

Stand Back Rail

Clamp Wedge

Stand Back

Rail Clamp

™

8

Page 9

10021

Snap StandMX Series

™

Adjustable MAX Cut-Off Parts

10008

10013

10225

12396

10020

11409

10015

10227

ASSEMBLY

10021

12264

12293

12263

10227

ASSEMBLY

Item# Description

10008 Handle

10013 1/4-20 X 1-1/4” Button Hd Screw

10020 1/4-20 X 5/8” Hex Button HD Screw

10021 1/4-20 X 1” Hex Button Hd Screw

10225 Bridge

10227 MAX Knife Assembly**

10349 Coupling Nut (hook, not shown)

10519 1/4-20 X 3/4” Hex Wash Hd Screw

(not shown)

11393 Track Bearing Kit (not shown)

(2) Track Bearing 10012

11404 Material Stop Kit (not shown)

(2) Material Stop 10740

(2) 1/4-20 Knurled Knob 10776

(2) Cut-Off Tape Measure 10023

Item# Description

11409 Cut-Off Guide Bearing Kit

(2) Guide Bearing 10016

(2) 5/16” Roll Pin 10015

12263 Adjusting Nut

12264 Adjustable MAX Cut-Off Body

12293 1/4-20 X 1 1/2 Socket Head Cap Screws

12396 Flange Track Bearing Kit*

(2) Wide Flange Track Bearing 12334

(2) 1/4-20 X 5/8” Hex Button Hd Screw 12364

* This kit replaces the Track Bearing Kit 11393. Both are

still available for purchase.

** Please contact Customer Service if these parts need to

be replaced.

9

6

Page 10

Snap StandMX Series

™

Setup for Adjustable MAX Cut-Off

LIST OF PARTS:

(1) Adjustable MAX Cut-Off

(2) MX Material Stop Kit #14485

IMPORTANT! Read this safety information before using product.

Tools Needed for Initial Set Up:

hammer, punch or nail set,

9/16" wrench, Phillips screw driver .

1. Always keep hands and fi ngers clear of the knives during all phases of use.

2. If using both hands to push tool through material, ensure hands are not in the path of

the exiting material as it leaves the rear area of the tool.

3. Remove cut-off from anvil prior to bending material. Failure to do so can cause the

tool to fall from brake resulting in tool damage or personal injury to user.

4. Never use tool to cut material not fi rmly clamped in brake.

1. Slide measuring tapes into Pivot Arm

slots from rear of Pivot Arm till they

stop. Tape measures take into account

1 1/2" difference between the bending

edge and the shear point of Cut-Off for

accurate cuts.

2. Slide material stop onto Pivot Arms

from rear as shown.

Note: Recommended locations are on

the second castings in from each end

of your brake.

3. Secure the tape measures in place

by “punching" down the edge of the

pivot arm onto the tape measure. Use a

standard nail set or punch.

10

Page 11

Items Needed

-Clean Cloth

-WD-40® or equivalent

-Phillips Head Screw Driver

Wear Strip and Rubber Strip

• Use a Phillips head screw driver to

loosen the screw enough to allow the

Endcap to be removed by sliding it off of

the screw (see Figure 1 & Figure 2).

• With the Endcap removed, slide the

Moving Hinge half way down the length

of the Fixed Hinge exposing the Wear

Strip and Rubber Strip on the Fixed and

Moving Hinges (see Figure 3).

• Use a clean cloth to wipe the portions of

the Wear Strip and Rubber Strip that are

exposed (see Figures 4-7).

• At this time WD-40® or equivalent

should be used on cleaned Moving

Hinge surfaces to reduce wear and friction. (see Figure 6)

• Return the Moving Hinge to the working position and repeat steps 1 thru 4,

sliding the fi xed hinge in the opposite

direction.

• Slide Moving Hinge back into working

position.

• Reattach Endcaps

Clamping Surfaces

• Clean Clamping Surface each day before using. Use only clean shop towels

that are free of dirt, oil and metal chips.

• Do not use your MX Series™ Brake

around saw tables as the cuttings may

get in between clamping surfaces or

hinges and cause excessive wear or

material scratching.

• If material is getting scratched,

examine the Stainless Bending Edge,

Fixed Hinge, or Moving Hinge for roughness or burrs. Remove burrs with emery

cloth or replace excessively worn parts.

Snap StandMX Series

™

Care and Maintenance

1

2

4

5

6

Wear Strip

Rubber Strip

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Lubricate this

surface only.

x

Moving Hinge

Transportation

• The MX Series™ Brake should be

transported in the unlocked position

unless a piece of cardboard or vinyl

siding is clamped between the clamping

surfaces.

3

Fixed Hinge

7

11

Page 12

MX Series™

™

Examples of BASIC Shapes

NOTE: UP and DOWN refers to the clad, painted or FINISH SIDE of the material as it is placed into the Bender.

1. Gravel Stop

6. Outside Corner

2. Coping Cover 7. Counter Flashing

3. One Piece Soffi t Mitre 8. Brick Frieze

5. Hip/Ridge Cap

© Boral Building Products Inc.

9. “F” Channel/Inside Corner4. Reglet Flashing

10. “D” Style Gutter

Tapco Integrated Tools

www.tapcotools.com • (800) 521-7567

Item # 14489

T5373 4/06

Loading...

Loading...