Page 1

Quick Start Guide

CMS 3.0 SERIES

In-Ceiling loudspeakers

CMS 503DC PI

CMS 603DC PI

CMS 803DC PI

Page 2

3 Unpacking

Every Tannoy product is carefully inspected before

shipment. After unpacking, please inspect your

product to ensure no damage has occurred in

transit. In the unlikely event of damage, please

notify your dealer and retain all shipping materials

as your dealer may require return shipment.

All CMS loudspeakers are shipped in pairs and

provided with the following accessories as

standard: C-ring, tile-bridge kit, cut-out template

and paint mask. A plaster (mud) ring is available

as an optional accessory.

4 Installation in Suspended Ceilings

An optional pre-install backcan is available for all

pre-install (PI) models. The backcan is designed for

pre-installation in newly constructed, non-suspended

ceilings.

NOTE: The CMS 603DC and the CMS 803DC

models have the transformer pre-attached to the

inside of the backcan; the CMS 503DC models have

the transformer pre-attached to the loudspeaker

assembly.

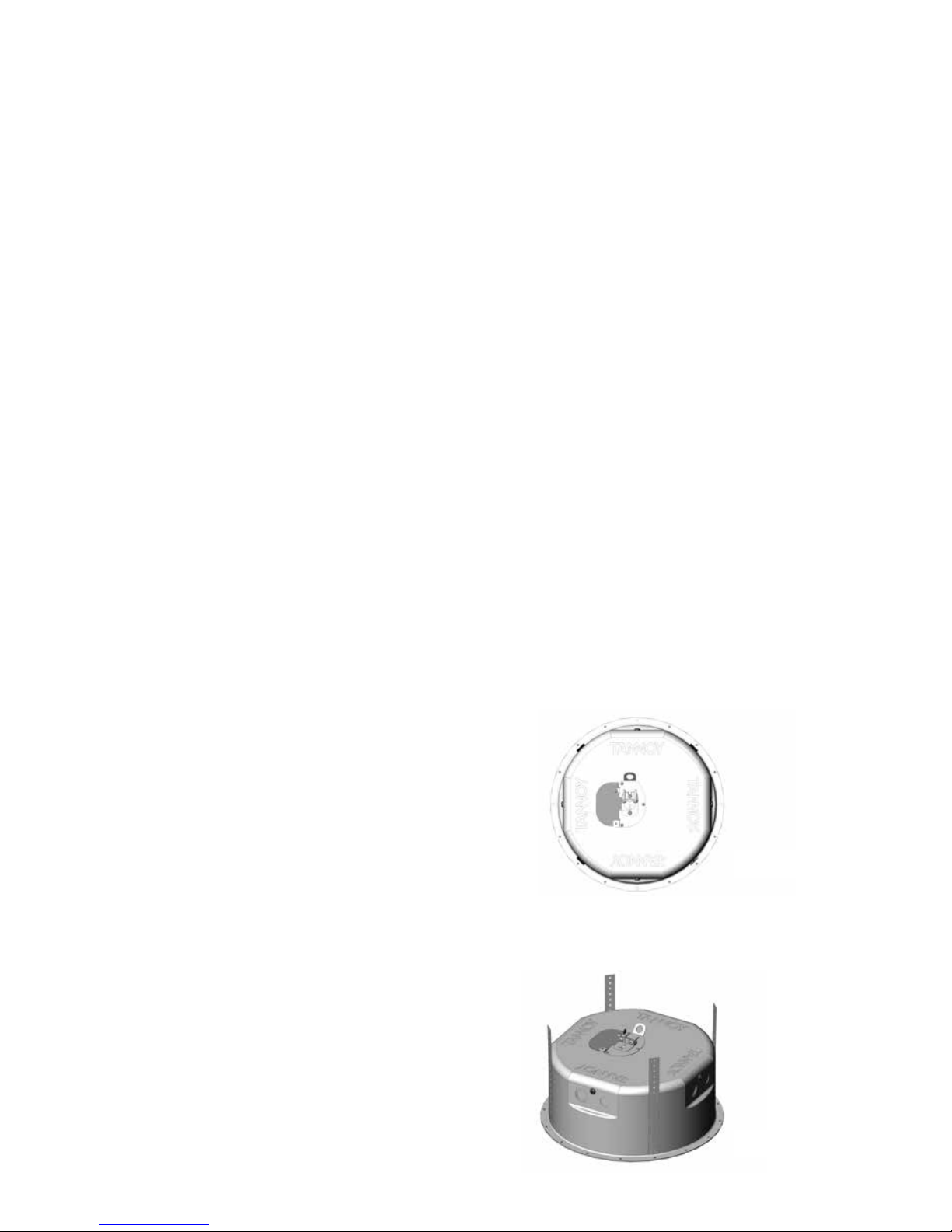

1. Attach the backcan to a secure xing point.

This can be done one of three ways:

METHOD 1: Fix to a secure point using suitable

xings attached to the four xing holes on the PI

backcan. (Fig.1)

.

METHOD 2: Fix to a secure point using suitable

xings and the exible straps attached to the PI

backcan. (Fig. 2)

1 Introduction

This Quick Start Guide (QSG) provides the basic

information required to install and connect the

pre-install (PI) versions of Tannoy CMS Series

in-ceiling loudspeakers.

For additional information, including product

technology, photo identication of product features,

dimensional drawings, and complete technical

specications, please refer to the full CMS Series

Operation Manual.

For installation of CMS Series blind-mount

versions, please refer to either the CMS BM Quick

Start Guide or the full CMS Operation Manual.

2 Safety Notices

Some regional construction codes require the use

of a secondary method of securing loudspeakers

in ceiling to provide security of a back-up support.

A secondary support line should be attached

from the safety loop on the rear of the product to

a source point on the ceiling. For PI models, the

secondary support line should be attached from

the back of the driver chassis to a source point on

the ceiling. Please consult the relevant construction

codes in your region.

When using a power driver to install the product, it

is essential to use the correct torque level settings

to avoid over tightening and damage to the ceiling

material or clamps. Recommended torque setting:

1.5 Nm Tannoy will not be held responsible for any

damages caused by the improper installation of

these loudspeakers.

Electrical Safety Notice: to comply with the

standard UL1480, metal-clad exible conduit (BX)

is required for connection to the terminal block for

proper earth grounding.

SAFETY NOTE: In order to comply with the

relevant re safety regulations (i.e. BS 5839:1998),

it is required that in the event of re, that failure of

the circuit to which the loudspeaker is connected

does not occur before evacuation of the building is

complete. Suitable measures include:

• Use of terminal blocks (for connection to

primary) with a melting point of not less than

650°C, for example constructed from ceramic

materials;

• Use of terminal blocks of a lower melting

point but protected with thermal insulation;

• Use of terminal blocks such that, on melting, an

open-circuit or a short-circuit does not occur.

Fig.1

Fig.2

Page 3

METHOD 3:

a. Attach the PI backcan to the option pre-mount

plaster ring using the xing points provided with the

pre-mount ring. (Fig 3).

b. Secure the wings of the pre-mount ring to a secure

xing point using suitable xings.

2. Attach conduit to the backcan using one of

two methods:

METHOD 1: Use the clamp at the back of the

pre-install backcan. The product will accept a squeeze

connector with a thread size of up to 22 mm. To

remove the cable clamp, simply unscrew the threaded

washer (under the wiring cover) which holds the cable

clamp in place and replace it with a conduit squeeze

connector. (Fig.4)

METHOD 2: Use any of the three knock-out points at

the sides of the backcan (19 mm, 22 mm or 28 mm

diameter). (Fig 5)

3. If conduit not used, run approved speaker cable to

the installed can. Terminate in the top-mounted cable

clamp or with an approved cable connector in one of

the three knock-out points at the sides of the backcan.

4. Cut a hole in the proper ceiling location using the

supplied cut-out template (self-adhesive backing) and

a pad saw. Place the pre-install backcan over the hole.

5. Proceed to Section 5 following on wiring and setting

up. Return to Step 6 below.

6. Slide the speaker assembly through the hole. Turn

the screws (denoted “Screw Fix”) clockwise on the

front of the speaker to extend the mounting wings.

Tighten the screws until a rm grip is achieved.

(NOTE: Screws have a PoziDriv head; use of a PoziDriv

driver is recommended). If using a power driver, Tannoy

recommends a torque setting of 1.5 Nm. (Fig.6)

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

Page 4

5 Wiring and Setting Up

1. Open the wiring cover (if applicable) and locate

the Euro-type connector plug and socket at the

back of the speaker. (Fig.1)

2. For connection to an amplier, use Pins 1 and 2

3. Close the wiring cover and tighten both screws

on the cable clamp (if applicable).

4. Use the rotary switch on the front of the

unit to select low impedance (LoZ) mode

or high impedance (70 V or 100 V) for

distributed applications.

The speaker is supplied in low impedance

mode. Never connect the speaker to a

70 / 100 volt amplier while it is set for

low impedance.

CMS 403DCe and CMS 503DC models (all

variants) use a 30 W transformer. In distributed

line applications, the transformer can be tapped

at 30 W, 15 W and 7.5 W, with an additional

3.75 W tap for 70 V line systems.

CMS 603DC and CMS 803DC models (all

variants) use a 60 W transformer. In distributed

Line applications, the transformer can be tapped

at 60 W, 30 W and 15 W with an additional 7.5 W

tap for 70 V line systems.

8 CMS Series PI Dimensions

Please refer to the full CMS Series Operation

Manual for dimensional drawings.

CMS 503DC PI

Hole cut-out: 190 mm

Diameter1: 205.9 mm (8.11”)

Height2: 133.3 mm (5.25”)

CMS 503 PI BACKCAN

Diameter: 288.0 mm (11.34”)

Height: 153.5 mm (6.04”)

CMS 603DC PI

Hole cut-out: 253 mm

Diameter1:274 mm (10.79”)

Height2: 100 mm (3.94”)

CMS 603 PI BACKCAN

Diameter: 351 mm (13.82”)

Height: 168.5 mm (6.63”)

CMS 803DC PI

Hole cut-out: 295 mm

Diameter1:319 mm (12.56”)

Height2: 125.6 mm (4.94”)

CMS 803 PI BACKCAN

Diameter: 397 mm (15.63”)

Height: 168.5 mm (6.63”)

1

Maximum, including bezel ring

2

Maximum to top of connector, from lower

ceiling surface

Fig.1

• Pin 1 is positive

• Pin 2 is negative

For connection to

additional speakers

in a distributed line,

Pins 3 and 4 are in

parallel where:

• Pin 3 is negative

• Pin 4 is positive

Fig.1

Fig.2

tannoypro.com

Tannoy operates a policy of continuous research and development. The introduction of new materials or

manufacturing methods will always equal or exceed the published specications. All specications are

subject to change without notice. Copyright (c) 2014 Tannoy Limited. All rights reserved.

6481 0665 / 0414

Loading...

Loading...