Page 1

CMS 3.0 Series

In-Ceiling Loudspeakers

Operation Manual

Page 2

CMS 3.0 Series Operation Manual rev 3.0.0

2

Page 3

Table of Contents

Table of Contents

1. Introduction 4

2. Unpacking 4

3. Safety Notices 4

4. Product Feature Identication 5

4.1. Blind Mount ............................................................................................................................................5

4.2. Pre-install ...............................................................................................................................................5

4.3. Pre-install backcan .................................................................................................................................6

5. Accessories 7

6. Installation 8

6.1. Installation Guide for Suspended Ceilings ...............................................................................................8

6.2. Installation Guide for Sheetrock Ceilings .................................................................................................9

6.3. Installation Guide for Optional Plaster Ring ........................................................................................... 10

6.4. Installation Guide for Optional Pre-Installation Backcan (PI Models Only) .............................................. 11

7. Wiring and Setting Up 14

8. CMS Series Model Dimensions 15

9. Technical Specications 25

10. Painting 33

11. Warranty 34

12. Declaration of conformity 35

CMS 3.0 Series Operation Manual rev 3.0.0

3

Page 4

1. Introduction

1. Introduction

Thank you for purchasing this Tannoy Ceiling Monitor System product. Designed for both speech and music

program material, the Tannoy CMS range provides exceptional sonic quality and long-term reliability in all ceilingmount applications. The CMS 3.0 DC series features new 16 ohm Dual Concentric™ drivers for improved

performance and prolonged service life.

2. Unpacking

Every Tannoy product is carefully inspected before shipment. After unpacking, please inspect your product to

ensure no damage has occurred in transit. In the unlikely event of damage, please notify your dealer and retain

all shipping materials as your dealer may require return shipment.

All CMS loudspeakers are shipped in pairs and provided with the following accessories as standard: C-ring,

tile-bridge kit, cut-out template and paint mask. A plaster (mud) ring is available as an optional accessory.

3. Safety Notices

Some regional construction codes require the use of a secondary method of securing loudspeakers in the

ceiling to provide security of a back-up support. A secondary support line should be attached from the safety

loop on the rear of the product to a source point on the ceiling. For PI models, the secondary support line

should be attached from the back of the driver chassis to a source point on the ceiling. Please consult the

relevant construction codes in your region.

When using a power driver to install the product, it is essential to use the correct torque level settings to avoid

over-tightening and damage to the ceiling material or clamps. Recommended torque setting: 1.5 Nm

Tannoy will not be held responsible for any damages caused by the improper installation of these loudspeakers.

The CMS 603 ICT LS is UL-1480, category UUMW, for use with non-DC supervised systems.

Electrical Safety Notice: To comply with the standard UL-1480, metal-clad exible conduit (BX) is required for

connection to the terminal block for proper earth grounding.

In order to comply with UL regulations, the PI backcan must always be used with the CMS PI models.

SAFETY NOTE:

In order to comply with the relevant re safety regulations (ie. BS 5839:1998), it is required that in the event of

re, that failure of the circuit to which the loudspeaker is connected does not occur before evacuation of the

building is complete. Suitable measures include:

a) use of terminal blocks (for connection to primary) with a melting point of not less than 650°C, for example

constructed from ceramic materials;

b) use of terminal blocks of a lower melting point but protected with thermal insulation;

c) use of terminal blocks such that, on melting, an open-circuit or a short-circuit does not occur.

CMS 3.0 Series Operation Manual rev 3.0.0

4

Page 5

4. Product Feature Identification

4. Product Feature Identification

IMPORTANT NOTE: Drawings for each loudspeaker below are generic and apply to the loudspeaker types

specied. Some variations will be apparent in some models, but differences are not critical for installation

purposes except as noted.

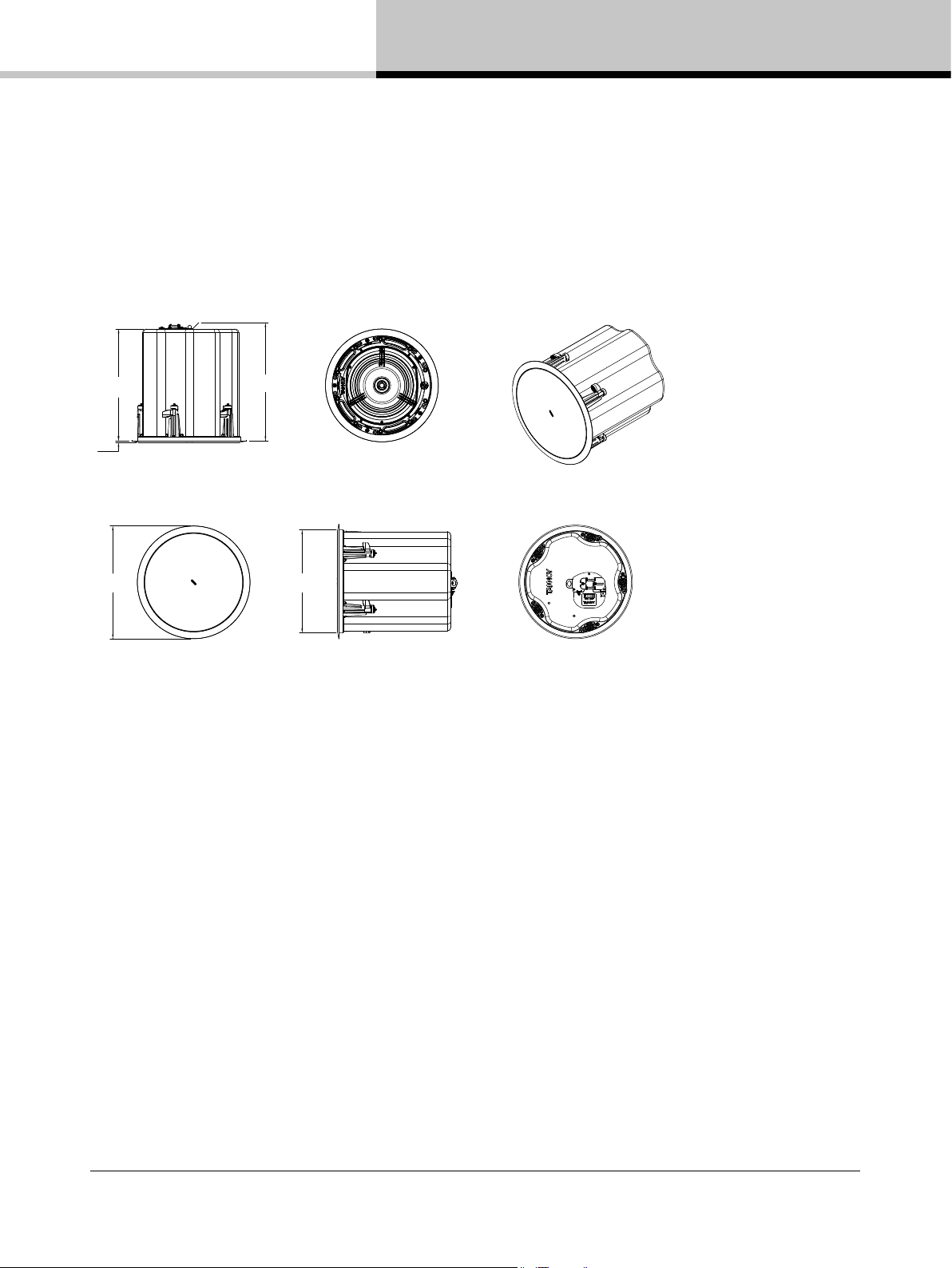

4.1. Blind Mount

The blind-mount models are supplied with a pre-tted backcan. Above applies to all models with a “BM” sufx

as well any others that do NOT have a “PI” sufx.

4.2. Pre-install

A pre-install (PI) unit is shown without the optional pre-install backcan.

CMS 3.0 Series Operation Manual rev 3.0.0

5

Page 6

4. Product Feature Identification

4.3. Pre-install backcan

Optional pre-install (PI) backcan for PI models.

NOTE: The CMS 603DC/ICT and CMS 803DC models have the transformer pre-attached to the inside of the

backcan. The CMS 503DC/ICT has the transformer pre-attached to the loudspeaker assembly.

CMS 3.0 Series Operation Manual rev 3.0.0

6

Page 7

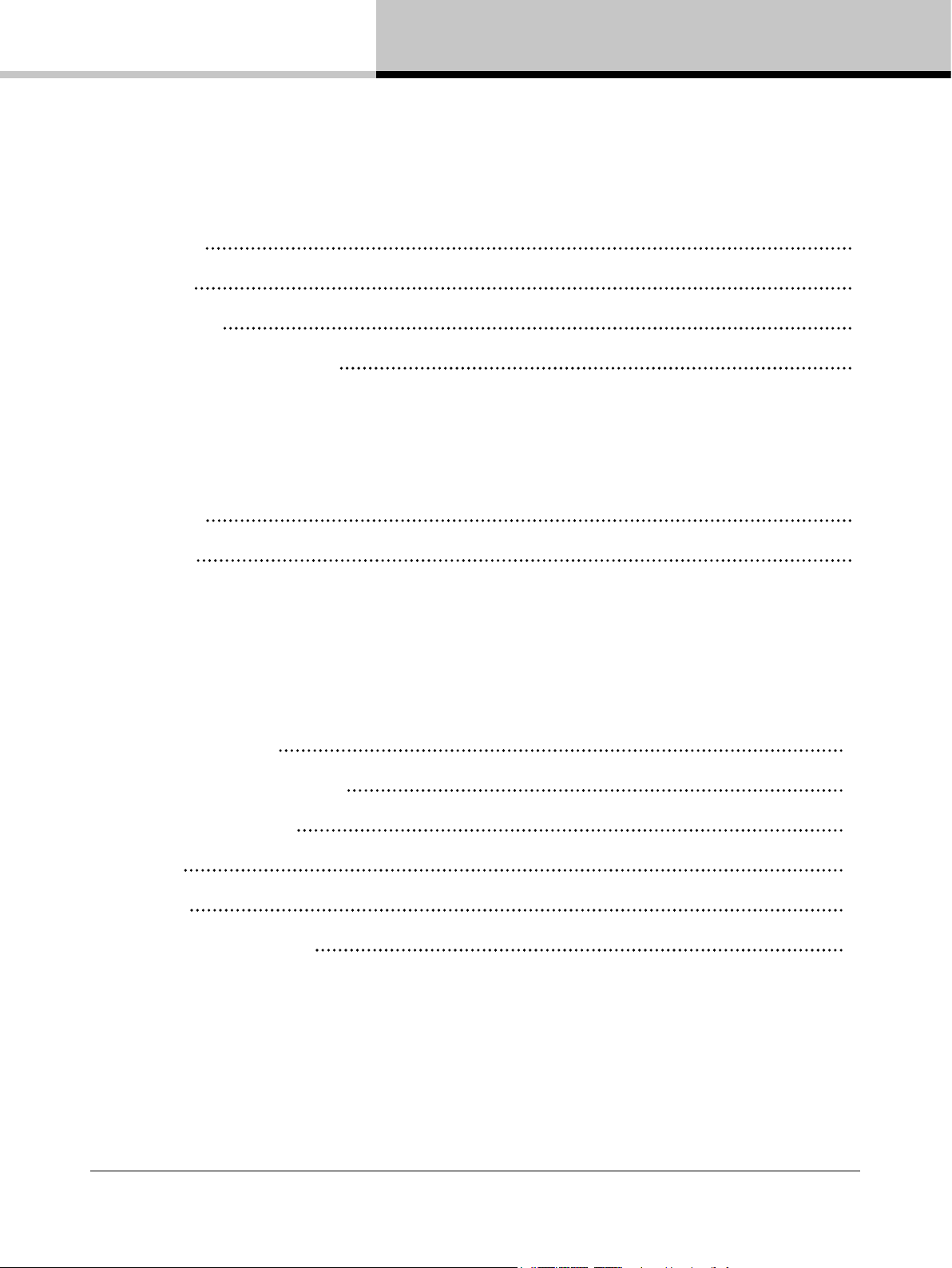

5. Accessories

5. Accessories

Standard Accessories

C-Ring

Grille

Tile-bridge kit

Note: A tile-bridge kit

must always be used

when installing into

suspended ceiling tiles

Cut-out template

Paint Mask

Optional Accessories

Plaster (mud)

ring

60 W Transformer

Note: For use with CMS

803 PI in distributed lines

without backcans.

CMS 3.0 Series Operation Manual rev 3.0.0

7

Page 8

6. Installation

6. Installation

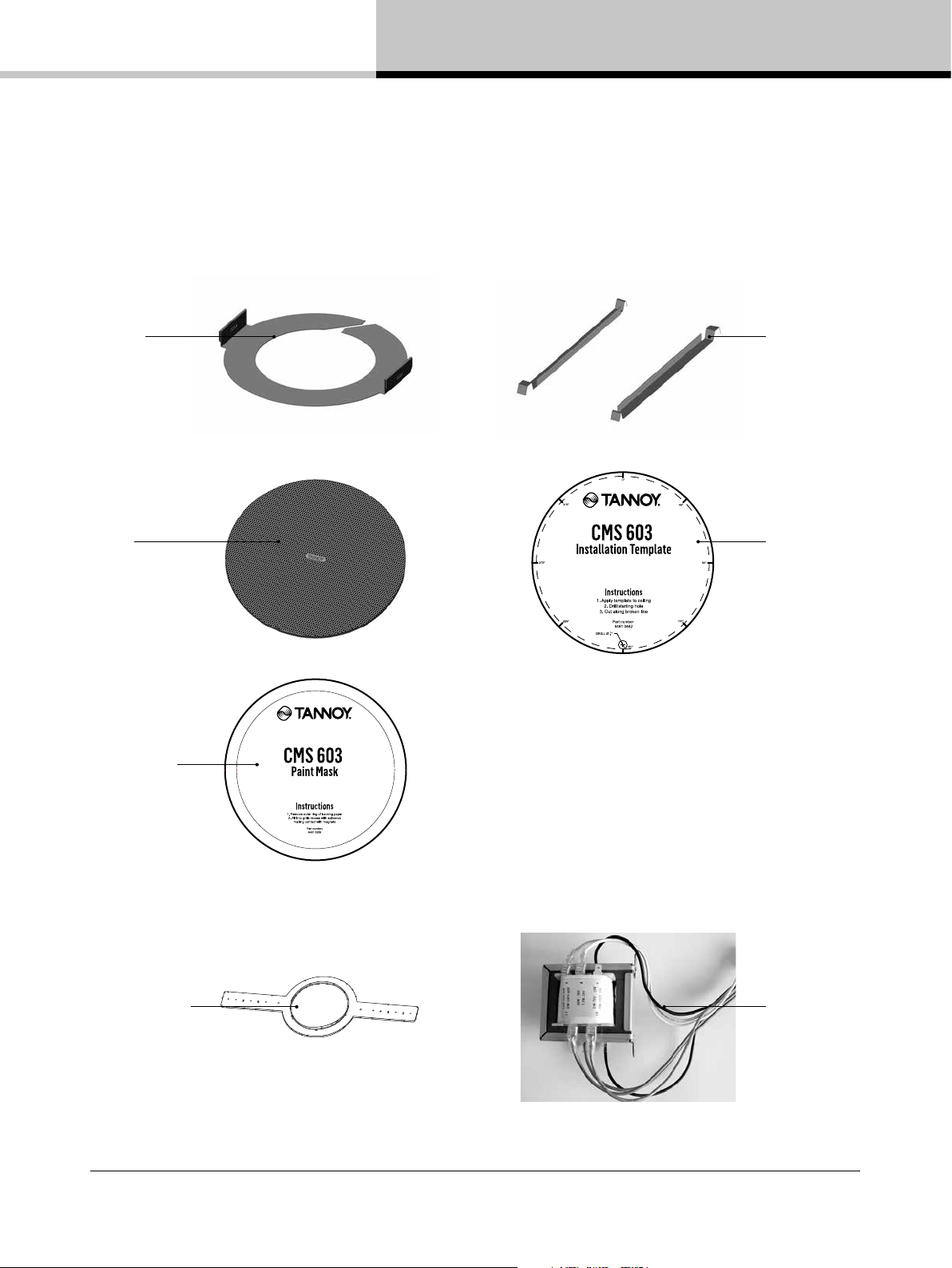

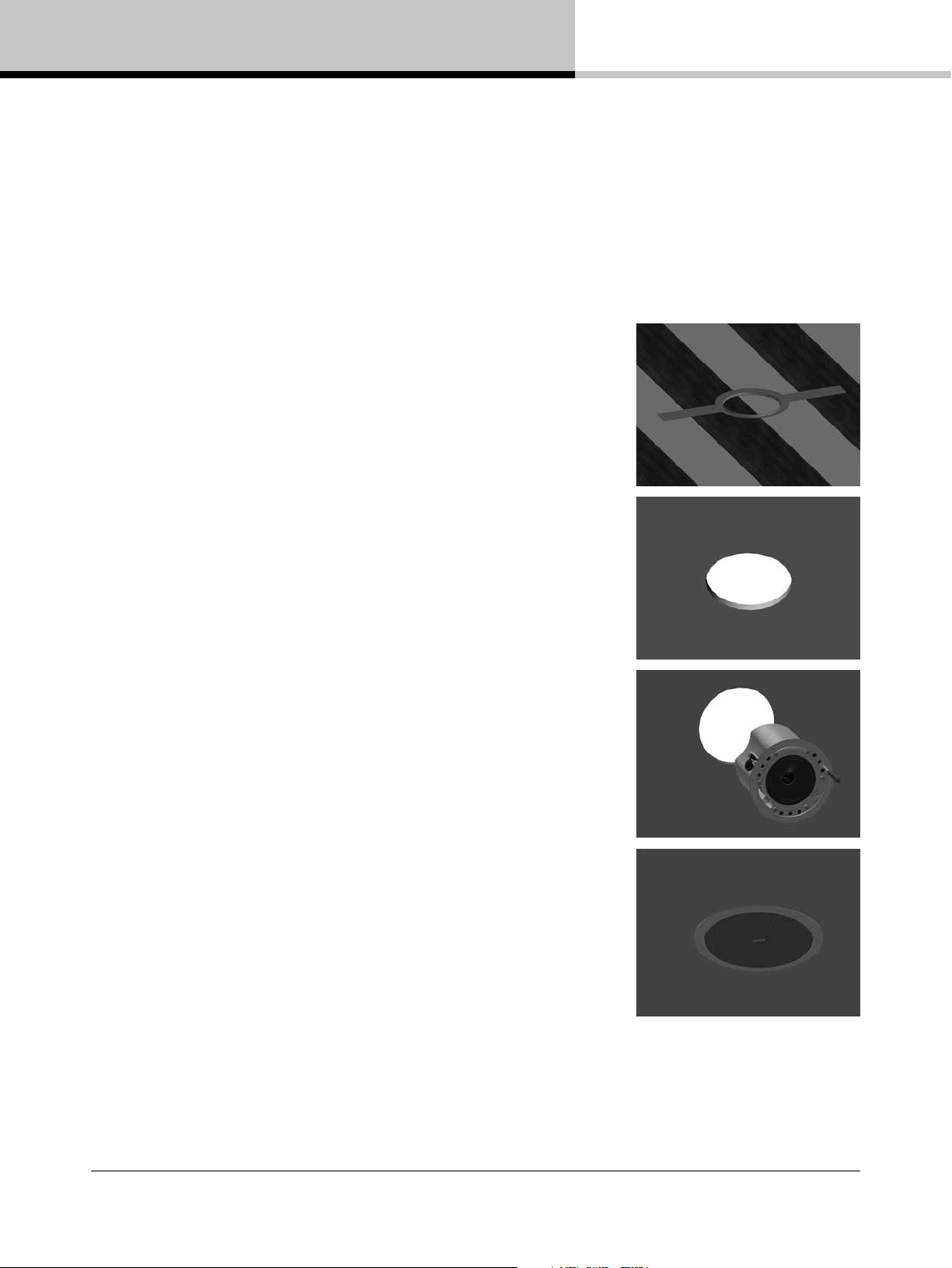

6.1. Installation Guide for Suspended Ceilings

1. Remove the ceiling tile from its frame and place it on a at

surface. Position the cutout template (self adhesive backed) on

the tile. (Fig.1)

2. Cut out the hole in the ceiling tile using a pad saw following

the broken line indicated on the template (Fig.2)

3. Place the C-Ring and tile-bridge on top of the ceiling panel,

aligning the C-Ring over the hole, and screw the C-Ring to the

tile bridge using the xings provided. (Fig.3)

Fig.1

4. Go to section 7 for instructions on wiring and set-up instructions.

5. Slide the speaker assembly through the hole. Turn the screws

(denoted “Screw Fix”) clockwise on the front of the speaker

to extend the mounting wings. Tighten the screws until a rm

grip is achieved. (NOTE: Screws have a PoziDriv head; use of a

PoziDriv driver is recommended). If using a power driver, Tannoy

recommends a torque setting of 1.5 Nm. (Fig.4)

DO NOT OVERTIGHTEN!

6. Attach the nylon safety to the hooks on the front bafe

before attaching the grille by presenting it to the speakers and

allowing the magnets to pull it into position (Fig.5). (With the

CMS 403DCe/ICTe, the grille is already tted to the product.)

NOTE ON INSTALLATION OF CMS 403DCe/ICTe:

Before tightening the screws in step 5, swivel the speaker in the

desired direction. When the screws are tightened, the speaker will

lock into position. Replace the front trim to conceal the mounting

screws.

Fig.2

Fig.3

Fig.4

CMS 3.0 Series Operation Manual rev 3.0.0

8

Fig.5

Page 9

6.2. Installation Guide for Sheetrock Ceilings

1. Position the cutout template (self adhesive backed) on the

ceiling. (Fig.1)

2. Cut out the hole in the ceiling using a pad saw following the

broken line indicated on the template then slide the C-Ring into

the ceiling, aligning it over the cut-out hole. (Fig.2)

3. Go to section 7 for wiring and set-up instructions then return

to point 4 below.

4. Slide the speaker assembly through the hole. Turn the screws

(denoted “Screw Fix”) clockwise on the front of the speaker

to extend the mounting wings. Tighten the screws until a rm

grip is achieved. (NOTE: Screws have a PoziDriv head; use of a

PoziDriv driver is recommended). If using a power driver, Tannoy

recommends a torque setting of 1.5 Nm. (Fig.3)

6. Installation

Fig.1

Fig.2

DO NOT OVERTIGHTEN!

5. Attach the nylon safety to the hooks on the front bafe

before attaching the grille by presenting it to the speakers and

allowing the magnets to pull it into position (Fig.4). (With the

CMS 403DCe/ICTe, the grille is already tted to the product.)

NOTE ON INSTALLATION OF CMS 403DCe/ICTe:

Before tightening the screws in step 4, swivel the speaker in the

desired direction. When the screws are tightened, the speaker will

lock into position. Replace the front trim to conceal the mounting

screws.

Fig.3

Fig.4

CMS 3.0 Series Operation Manual rev 3.0.0

9

Page 10

6. Installation

6. Installation

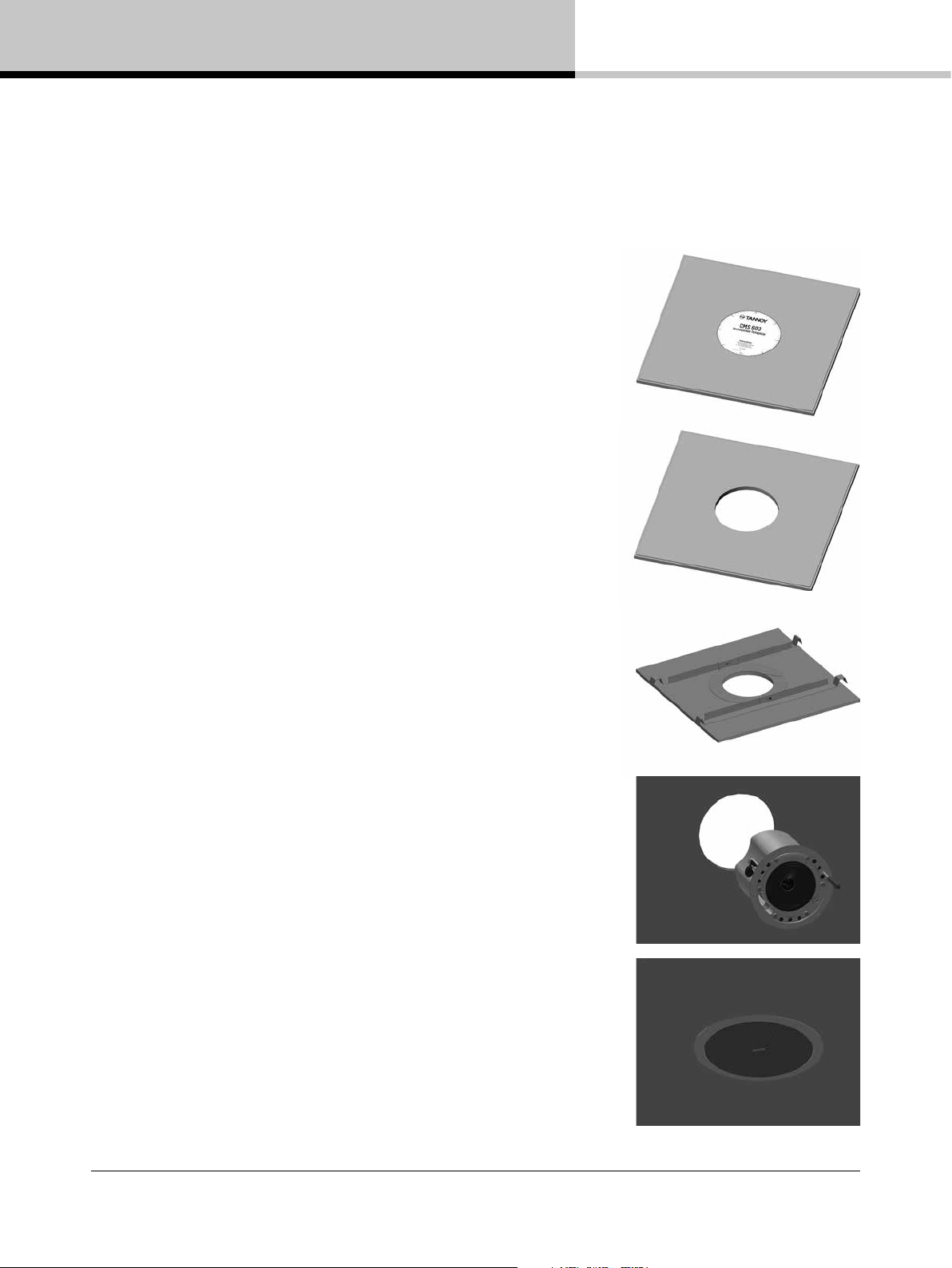

6.3. Installation Guide for Optional Plaster Ring

An optional plaster (mud) ring bracket is available from Tannoy. This bracket is designed to be pre-installed

into newly constructed, non-suspended ceilings.

1. Nail or screw the plaster ring to the joists. (Fig.1)

2. Lay the speaker wiring to where the speaker will be tted and

complete the plastering work on the ceiling. (Fig.2)

3. Go to section 7 for instructions on wiring then return to point 4

below.

4. Slide the speaker assembly through the hole. Turn the screws

(denoted “Screw Fix”) clockwise on the front of the speaker

to extend the mounting wings. Tighten the screws until a rm

grip is achieved. (Note: Screws have a PoziDriv head; use of a

PoziDriv driver is recommended). If using a power driver, Tannoy

recommends a torque setting of 1.5 Nm. (Fig.3)

DO NOT OVERTIGHTEN!

5. Attach the nylon safety to the hooks on the front bafe

before attaching the grille by presenting it to the speakers and

allowing the magnets to pull it into position (Fig.4). (With the

CMS 403DCe/ICTe, the grille is already tted to the product.)

Fig.1

Fig.2

Fig.3

NOTE ON INSTALLATION OF CMS 403DCe/ICTe:

Before tightening the screws in step 4, swivel the speaker in the

desired direction. When the screws are tightened, the speaker

will lock into position.Replace the front trim to conceal the

mounting screws.

CMS 3.0 Series Operation Manual rev 3.0.0

10

Fig.4

Page 11

6. Installation

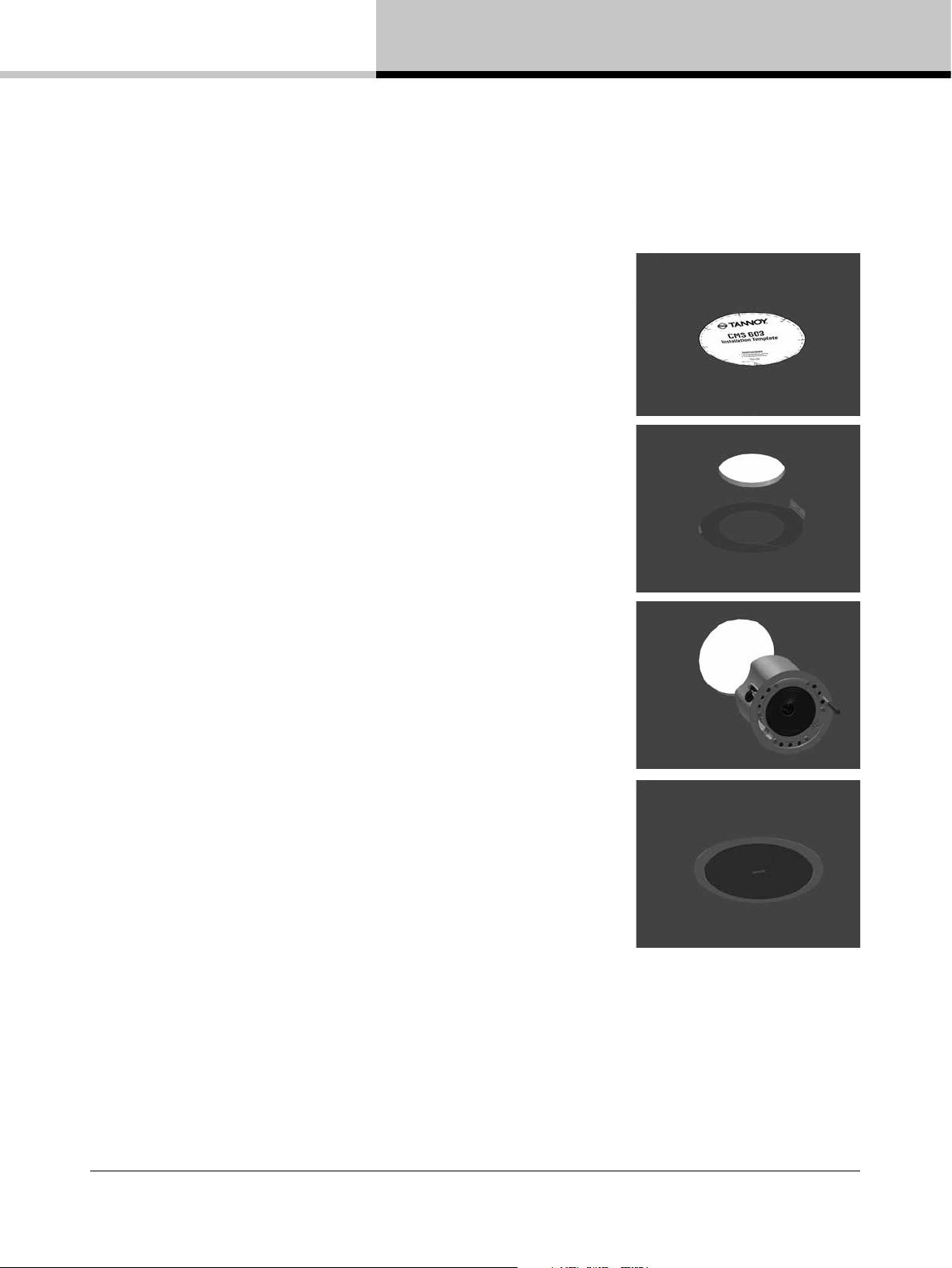

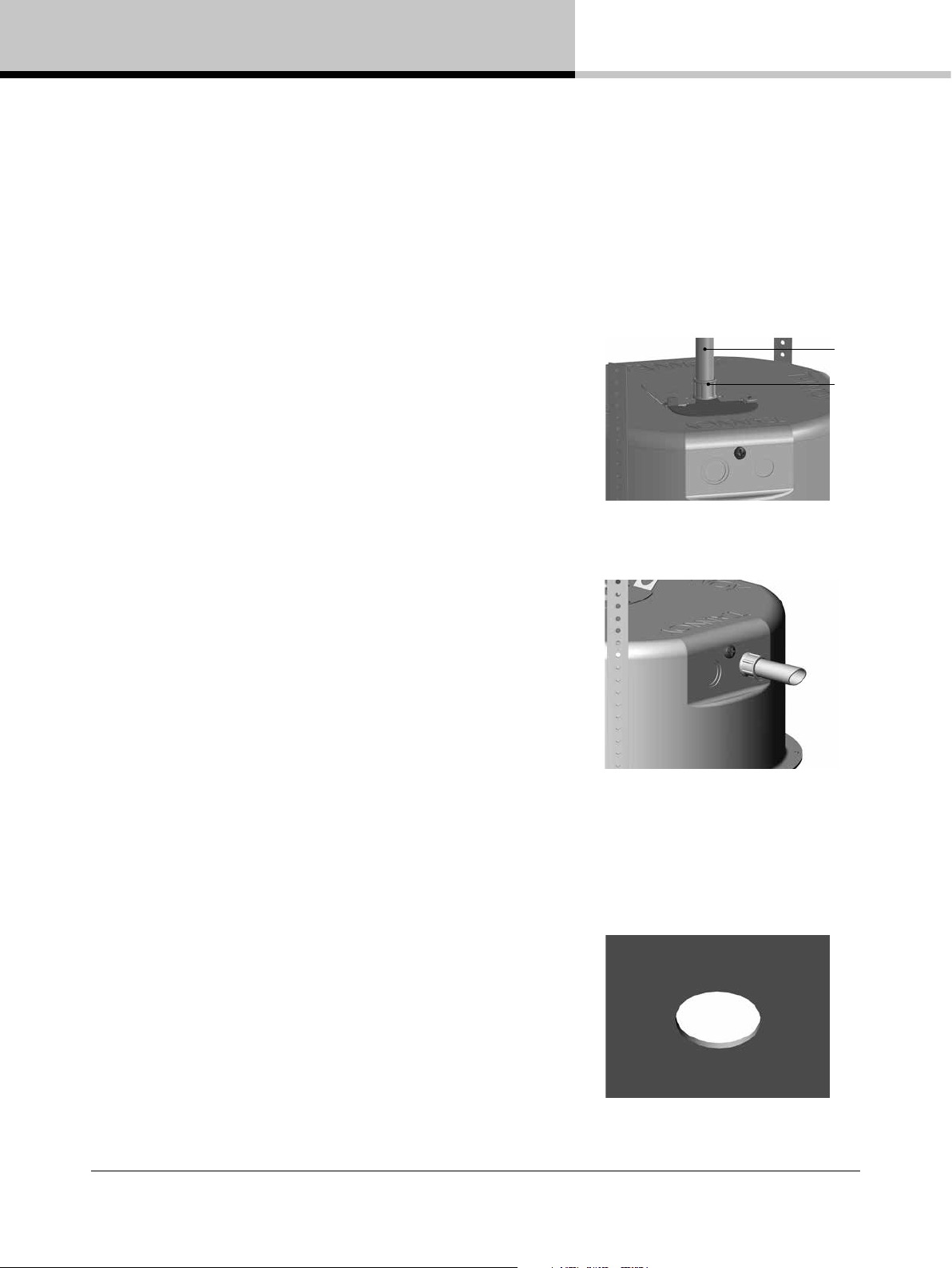

6.4. Installation Guide for Optional Pre-Installation Backcan (PI Models Only)

An optional pre-install backcan is available for all pre-install (PI) models. The backcan is designed for

pre-installation in newly constructed, non-suspended ceilings.

NOTE: The CMS 603DC/ICT and CMS 803DC models have the transformer pre-attached to the inside of the

backcan; the CMS 503DC/ICT models have the transformer pre-attached to the loudspeaker assembly.

1. Attach the backcan to a safe and secure xing point.

This can be done in a number of ways:

METHOD 1: Fix the backcan to a secure xing point by using

suitable xings with the 4 xing holes provided on the PI backcan.

(Fig.1)

Fig.1

METHOD 2: Secure the backcan to a safe and secure xing point

using suitable xings with the exible straps that are attached to

the PI backcan. (Fig.2)

METHOD 3:

a. Attach the PI backcan to the optional pre-mount ring (plaster

ring) using the xings provided with the pre-mount ring. (Fig.3)

b. Next, secure the wings of the pre-mount ring to a safe and

secure xing point by using suitable xings. (Fig.4)

Fig.2

Fig.3

Please turn over

CMS 3.0 Series Operation Manual rev 3.0.0

Fig.4

11

Page 12

6. Installation

6. Installation

6.4. Installation Guide for Optional Pre-Installation Backcan (PI Models Only)

2. Attach the conduit to the installed backcan.

This can be done in two ways:

METHOD 1: You can use the clamp at the back of the pre-install

backcan. The product will accept a squeeze connector with a

thread size of up to 22 mm: To remove the cable clamp, simply

unscrew the threaded washer (under the wiring cover) which

holds the cable clamp in place and replace it with a conduit

squeeze connector. (Fig.5)

METHOD 2: You can use any of the three knock-out points at

the sides of the PI backcan (19 mm, 22 mm or 28 mm diameter).

(Fig.6)

Conduit

Conduit

Squeeze

Connector

Fig.5

Fig.5

Fig.6

3. If conduit is not chosen as the wiring method, run an

approved speaker cable to the installed can. Terminate in the top

mounted cable clamp or with an approved cable connector in

one of the three knock-out points at the sides of the PI backcan.

4. Cut hole in the proper location in the ceiling using a pad saw.

Place the pre-install backcan over the hole. (Fig.7)

CMS 3.0 Series Operation Manual rev 3.0.0

12

Fig.7

Page 13

6.4. Installation Guide for Optional Pre-Installation Backcan (PI Models Only)

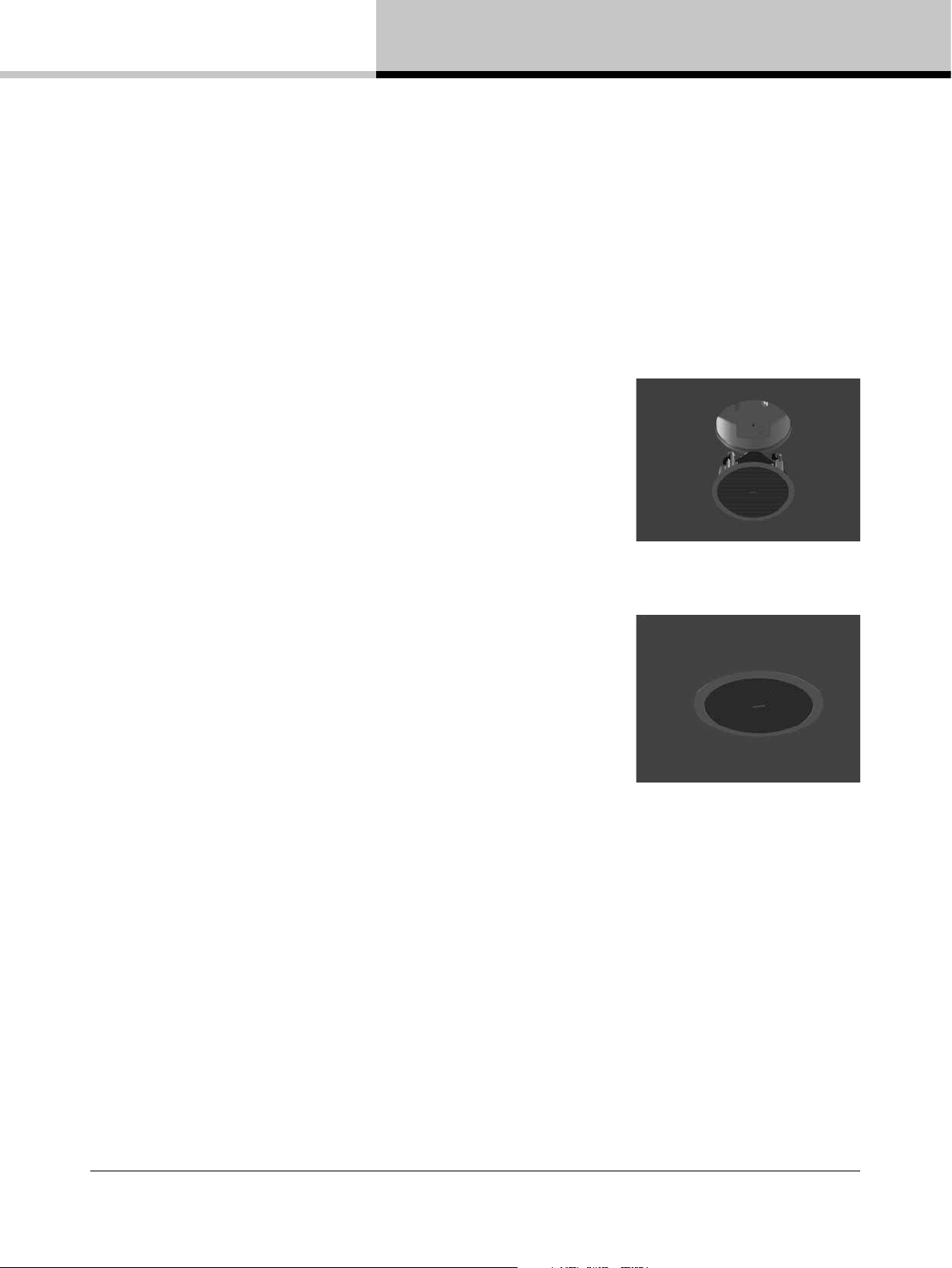

5. Go to section 7 for instructions on wiring and setting up then

return to point 6 below.

6. Slide the speaker assembly through the hole. Turn the screws

(denoted “Screw Fix”) clockwise on the front of the speaker

to extend the mounting wings. Tighten the screws until a rm

grip is achieved. (NOTE: Screws have a PoziDriv head; use of a

PoziDriv driver is recommended). If using a power driver, Tannoy

recommends a torque setting of 1.5 Nm. (Fig.8)

6. Installation

Fig.8

DO NOT OVERTIGHTEN!

7. Attach the nylon safety to the hooks on the front bafe before

attaching the grille by presenting it to the speakers and allowing

the magnets to pull it into position. (Fig.9)

Fig.9

CMS 3.0 Series Operation Manual rev 3.0.0

13

Page 14

7. Wiring and Setting Up

7. Wiring and Setting Up

1. Open the wiring cover (if applicable) and locate the Euro-type

connector plug and socket at the back of the speaker. (Fig.1)

2. For connection to an amplier, use Pins 1 and 2 (Fig.2):

• Pin 1 is positive

• Pin 2 is negative

For connection to additional speakers in a distributed line,

Pins 3 and 4 are in parallel where:

• Pin 3 is negative

• Pin 4 is positive

3. Close the wiring cover and tighten both screws on the cable clamp

(if applicable).

Fig.1

4. Use the rotary switch on the front of the unit to select low

impedance (LoZ) mode or high impedance (70 V or 100 V) for

distributed applications.

THE SPEAKER IS SUPPLIED IN LOW IMPEDANCE MODE. NEVER

CONNECT THE SPEAKER TO A 70/100 VOLT AMPLIFIER WHILE IT

IS SET FOR LOW IMPEDANCE.

CMS 403DCe/ICTe and CMS 503DC/ICT models (all variants) use a

30 W transformer. In distributed line applications, the transformer can

be tapped at 30 W, 15 W and 7.5 W, with an additional 3.75 W tap

for 70 V line systems. (Fig.3)

CMS 603DC/ICT and CMS 803DC models (all variants) use a 60 W

transformer. In distributed line applications, the transformer can be

tapped at 60 W, 30 W and 15 W, with an additional 7.5 W tap for

70 V line systems. (Fig.4)

Fig.2

Fig.3

Fig.4

CMS 3.0 Series Operation Manual rev 3.0.0

14

Page 15

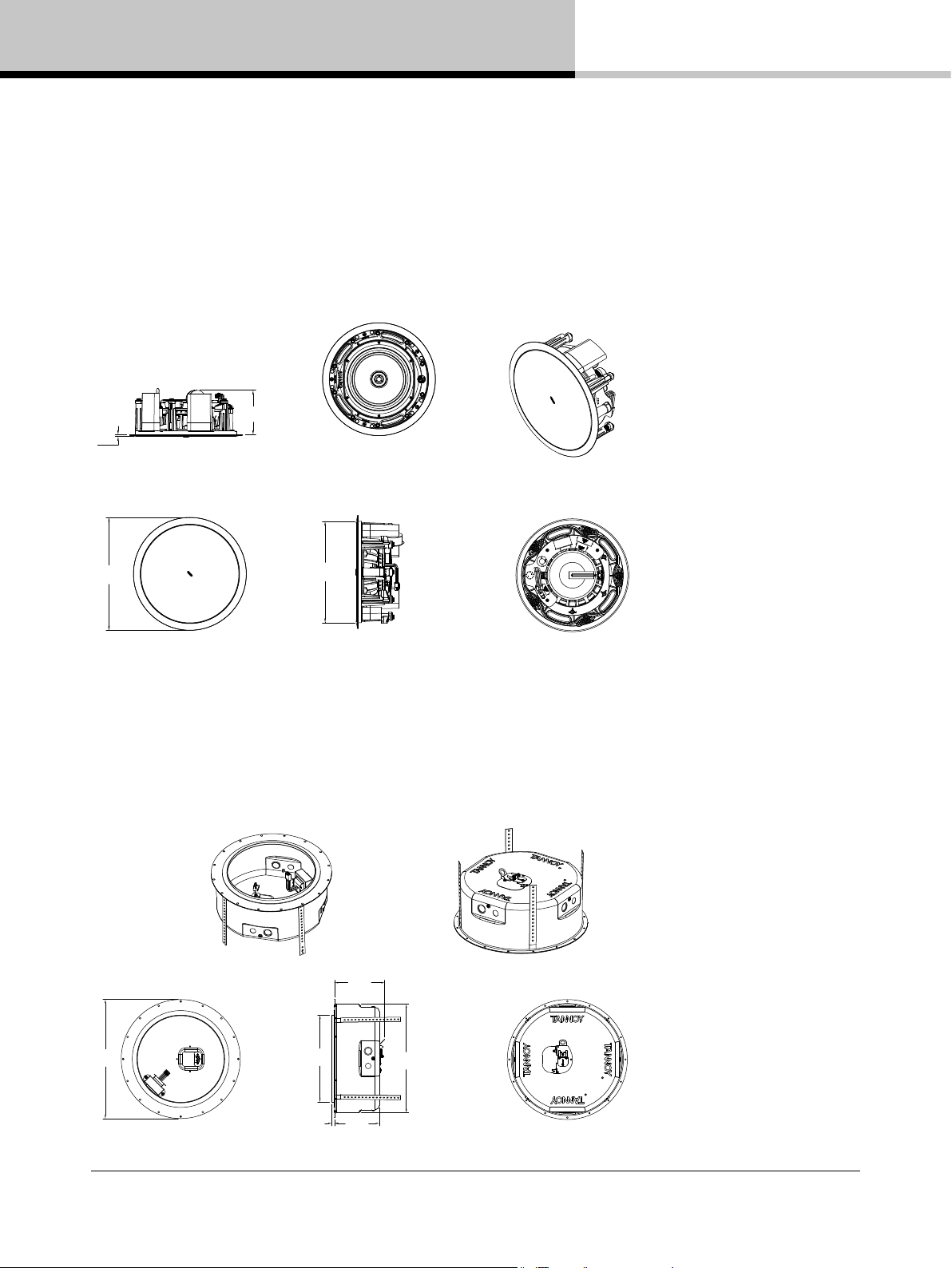

8. CMS Series Model Dimensions

CMS 403DCe

Hole Cut-out Size: 187 mm

147.6

[5.81"]

34.2

[1.35"]

8. CMS Series Model Dimensions

Ø205.0

[8.07"]

CMS 403ICTe

Hole Cut-out Size: 187 mm

147.6

[5.81"]

34.2

[1.35"]

Ø181.1

[7.13"]

Ø205.0

Ø181.1

[7.13"]

CMS 3.0 Series Operation Manual rev 3.0.0

15

Page 16

8. CMS Series Model Dimensions

8. CMS Series Model Dimensions

CMS 503DC BM

Hole Cut-out Size: 190 mm

188.0

[7.40"]

4.5

[0.18"]

205.9

[8.11"]

CMS 503ICT BM

Hole Cut-out Size: 190 mm

205.3

[8.08"]

181.3

[7.14"]

188.5

[7.42"]

4.2

[0.17"]

205.9

[8.11"]

CMS 3.0 Series Operation Manual rev 3.0.0

16

205.8

[8.10"]

181.3

[7.14"]

Page 17

8. CMS Series Model Dimensions

CMS 503DC LP

Hole Cut-out Size: 253 mm

98.6

[3.88"]

4.2

[0.17"]

8. CMS Series Model Dimensions

274.0

[10.79"]

CMS 503ICT LP

Hole Cut-out Size: 253 mm

98.6

[3.88"]

4.2

[0.17"]

244.3

[9.62"]

274.0

[10.79"]

244.3

[9.62"]

CMS 3.0 Series Operation Manual rev 3.0.0

17

Page 18

8. CMS Series Model Dimensions

8. CMS Series Model Dimensions

CMS 503DC PI

Hole Cut-out Size: 190 mm

133.3

[5.25"]

4.2

[0.17"]

205.9

[8.11"]

CMS 503ICT PI

Hole Cut-out Size: 190 mm

131.7

[5.19"]

4.2

[0.17"]

205.9

[8.11"]

CMS 3.0 Series Operation Manual rev 3.0.0

18

181.3

[7.14"]

Page 19

8. CMS Series Model Dimensions

CMS 503DC PI BACKCAN

Hole Cut-out Size: 190 mm

153.5

[6.04"]

8. CMS Series Model Dimensions

Ø288.0

[11.34"]

CMS 503ICT PI BACKCAN

Hole Cut-out Size: 190 mm

Ø186.4

[7.34"]

8.8

[0.35"]

136.2

[5.36"]

153.5

[6.04"]

Ø256.0

[10.08"]

Ø288.0

[11.34"]

Ø186.4

[7.34"]

8.8

[0.35"]

136.2

[5.36"]

Ø256.0

[10.08"]

CMS 3.0 Series Operation Manual rev 3.0.0

19

Page 20

8. CMS Series Model Dimensions

8. CMS Series Model Dimensions

CMS 603DC BM

Hole Cut-out Size: 253 mm

273.3

[10.76"]

4.2

[0.17"]

255.8

[10.07"]

274.0

[10.79"]

CMS 603ICT BM

Hole Cut-out Size: 253 mm

244.3

[9.62"]

256.5

[10.10"]

4.1

[0.16"]

274.0

[10.79"]

CMS 3.0 Series Operation Manual rev 3.0.0

20

273.8

[10.78"]

244.3

[9.62"]

Page 21

8. CMS Series Model Dimensions

CMS 603DC PI

Hole Cut-out Size: 253 mm

100.0

[3.94"]

4.1

[0.16"]

8. CMS Series Model Dimensions

274.0

[10.79"]

CMS 603ICT PI

Hole Cut-out Size: 253 mm

100.0

[3.94"]

4.1

[0.16"]

244.3

[9.62"]

273.5

[10.77"]

244.3

[9.62"]

CMS 3.0 Series Operation Manual rev 3.0.0

21

Page 22

8. CMS Series Model Dimensions

8. CMS Series Model Dimensions

CMS 603DC PI BACKCAN

Hole Cut-out Size: 253 mm

168.5

[6.63"]

Ø351.0

[13.82"]

CMS 603ICT PI BACKCAN

Hole Cut-out Size: 253 mm

Ø249.4

[9.82"]

8.8

[0.35"]

151.2

[5.95"]

168.5

[6.63"]

Ø319.0

[12.56"]

Ø351.0

[13.82"]

CMS 3.0 Series Operation Manual rev 3.0.0

22

Ø249.4

[9.82"]

8.8

[0.35"]

151.2

[5.95"]

Ø319.0

[12.56"]

Page 23

8. CMS Series Model Dimensions

CMS 603ICT LS

Hole Cut-out Size: 253 mm

8. CMS Series Model Dimensions

273.8

[10.78"]

4.1

[0.16"]

256.5

[10.10"]

274.0

[10.79"]

CMS 803DC BM

Hole Cut-out Size: 295 mm

244.3

[9.62"]

5.2

[0.20"]

319.0

[12.56"]

310.5

[12.22"]

327.7

[12.90"]

286.4

[11.27"]

CMS 3.0 Series Operation Manual rev 3.0.0

23

Page 24

8. CMS Series Model Dimensions

8. CMS Series Model Dimensions

CMS 803DC PI

Hole Cut-out Size: 295 mm

125.6

[4.94"]

5.2

[0.20"]

319.0

[12.56"]

CMS 803DC PI BACKCAN

Hole Cut-out Size: 295 mm

286.4

[11.27"]

168.5

[6.63"]

Ø397.0

[15.63"]

CMS 3.0 Series Operation Manual rev 3.0.0

24

[0.35"]

Ø291.4

[11.47"]

8.8

151.2

[5.95"]

Ø365.0

[14.37"]

Page 25

8. CMS Series Model Dimensions

CMS 803DCQ

Hole Cut-out Size: 295 mm

8. CMS Series Model Dimensions

5.2

[0.20"]

[12.56"]

[12.22"]

319.0

310.5

327.7

[12.90"]

286.4

[11.27"]

CMS 3.0 Series Operation Manual rev 3.0.0

25

Page 26

9. Technical Specifications

9. Technical Specifications

CMS 403DCe Model

Performance

Frequency response (-3 dB)

BM Backcan

Frequency range (-10 dB)

BM Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 60 W

Programme 120 W

Peak 240 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 106 dB

Peak 112 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Dual Concentric point source driver

Low Frequency

High Frequency

Physical

Enclosure

Backcan Reex loaded UL 94V-0 rated ABS

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Backcan

Blind Mount (BM) Complete with xed backcan

Connectors

Compliance

Dimensions

Bezel diameter

Front of ceiling to rear of pod

Hole cutout diameter

Net Weight (ea)

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(2)

110 Hz - 50 kHz

80 Hz - 54 kHz

88 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

120 W @ 16 ohms

16 ohms

30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) / 3.75 W (1320 Ω) /

OFF & low impedance operation

30 W (330 Ω) / 15 W (660 Ω) / 7.5 W (1320 Ω) /

OFF & low impedance operation

1 x 100 mm (4.0”) Dual Concentric driver, using Omnimagnet technology

35 mm (1.38”) voice coil, treated multi ber paper pulp cone

20 mm (0.79”) PEI dome

Safety ring located at rear of enclosure for load bearing safety bond

Min / Max clamping range: 0.0 mm (0.0”) /

20.0 mm (0.79”)

Recommended clamp torque: 1.5 Nm

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

205.0 mm (8.07”)

147.6 mm (5.81”)

187 mm (7.36”)

2.75 kg (6.06 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring

2

Orde ring In forma tion

Part N umber Colou r

8001 7410

CMS 40 3DCe Whit e /

Paintable

8001 4180

CMS 40 3e Zinc Pl ated

Plas ter (Mud) Ring Stee l

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 403DCe can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

26

Page 27

9. Technical Specifications

CMS 403ICTe Model

9. Technical Specifications

Performance

Frequency response (-3 dB)

Frequency range (-10 dB)

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Coverage Angle (1 kHz to 6 kHz)

Directivity Factor (Q)

Directivity Index (DI)

Power Handling

Average 50 W

Programme 100 W

Peak 200 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 105 dB

Peak 111 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Crossover

Transducers

Low Frequency

High Frequency

Physical

Enclosure

Backcan Reex loaded UL 94V-0 rated ABS

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Connectors

Compliance

Dimensions

Bezel diameter

Front of ceiling to rear of pod

Hole cutout diameter

Net Weight (ea)

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(2)

110 Hz - 22 kHz

80 Hz - 24 kHz

88 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

120 degrees

5.26 averaged 1 kHz to 6 kHz

6.30 averaged 1 kHz to 6 kHz

100 W @ 16 ohms

16 ohms

30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) / 3.75 W (1320 Ω) /

OFF & low impedance operation

30 W (330 Ω) / 15 W (660 Ω) / 7.5 W (1320 Ω) /

OFF & low impedance operation

7 kHz inductively coupled

100 mm (4.00”) mineral loaded polypropylene

19 mm (0.75”) ICT aluminium dome

Safety ring located at rear of enclosure for load bearing safety bond

Min / Max clamping range: 0.0 mm (0.0”) /

20.0 mm (0.79”)

Recommended clamp torque: 1.5 Nm

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

205.0 mm (8.07”)

147.6 mm (5.81”)

187 mm (7.36”)

2.86 kg (6.31 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring

2

Orde ring In forma tion

Part N umber Colou r

8001 7760

CMS 40 3ICTe Whit e /

Paintable

8001 4180

CMS 40 3e Zinc Pl ated

Plas ter (Mud) Ring Stee l

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 403ICTe can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

27

Page 28

9. Technical Specifications

9. Technical Specifications

CMS 503DC Models

Performance

Frequency response (-3 dB)

BM Backcan

Frequency range (-10 dB)

BM Backcan

Frequency range (-10 dB)

PI Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 60 W

Programme 120 W

Peak 240 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 107 dB

Peak 113 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Dual Concentric point source driver

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Backcan Options

Blind Mount (BM) Complete with xed backcan

Pre Install (PI) Separate backcan for pre-installation

Cable Entry Options

Conduit Knockouts on PI Backcan

Connectors

Compliance

Dimensions

Bezel diameter

BM Model: Front of ceiling to rear of backcan

BM Model: Front of ceiling to top of safety loop

PI Model: Front of ceiling surface to rear of

speaker unit

PI Model: Front of accessory backcan bezel to

top of safety loop

Hole cutout diameter (all models)

Net Weight (ea)

CMS 503DC BM

CMS 503DC PI

PI Backcan

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(1)

(2)

85 Hz - 50 kHz

74 Hz - 54 kHz

70 Hz - 54 kHz

89 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

120 W @ 16 ohms

16 ohms

30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) / 3.75 W (1320 Ω) /

OFF & low impedance operation

30 W (330 Ω) / 15 W (660 Ω) / 7.5 W (1320 Ω) /

OFF & low impedance operation

1 x 130 mm (5.0”) Dual Concentric driver, using Omnimagnet technology

35 mm (1.38”) voice coil, treated multi ber paper pulp cone

20 mm (0.79”) PEI dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

3 Sets of horizontal positions 19 / 22 / 28 mm (0.75” / 0.87” / 1.10”)

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

205.9 mm (8.11”)

188.0 mm (7.40”)

205.3 mm (8.08”)

133.3 mm (5.25”)

153.5 mm (6.04”)

190 mm (7.48”)

4.1 kg (9.04 lbs)

3.1 kg (6.83 lbs)

2.6 kg (5.73 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7420

CMS 50 3DC BM Whit e /

Paintable

8001 7430

CMS 50 3DC PI Whit e /

Paintable

8001 4180

CMS 50 3 Zinc Pl ated

Plas ter (Mud) Ring Stee l

8001 7550

CMS 50 3 PI Backcan Zinc Pl ated

Steel

8001 7880

CMS 50 3 Arco G rille Whit e /

Paintable

UL-1480,

UL-2043

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 503DC can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

28

Page 29

9. Technical Specifications

CMS 503DC LP Model

9. Technical Specifications

Performance

Frequency response (-3 dB)

Frequency range (-10 dB)

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 60 W

Programme 120 W

Peak 240 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 107 dB

Peak 113 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Dual Concentric point source driver

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Cable Entry Options

Connectors

Compliance

Dimensions

Bezel diameter

Front of ceiling to rear of backcan

Hole cutout diameter

Net Weight (ea)

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(2)

88 Hz - 22 kHz

77 Hz - 24 kHz

89 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

120 W @ 16 ohms

16 ohms

30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) / 3.75 W (1320 Ω) /

OFF & low impedance operation

30 W (330 Ω) / 15 W (660 Ω) / 7.5 W (1320 Ω) /

OFF & low impedance operation

1 x 130 mm (5.0”) Dual Concentric driver, using Omnimagnet technology

35 mm (1.38”) voice coil, treated multi ber paper pulp cone

20 mm (0.79”) PEI dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

274.0 mm (10.79”)

98.6 mm (3.88”)

253.0 mm (9.96”)

3.3 kg (7.27 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7930

CMS 50 3DC LP Whit e /

Paintable

8001 7890

CMS 60 3 Arco G rille Whit e /

Paintable

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 503DC LP can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

UL-1480,

UL-2043

CMS 3.0 Series Operation Manual rev 3.0.0

29

Page 30

9. Technical Specifications

9. Technical Specifications

CMS 503ICT Models

Performance

Frequency response (-3 dB)

BM Backcan

Frequency range (-10 dB)

BM Backcan

Frequency range (-10 dB)

PI Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Coverage Angle (1 kHz to 6 kHz)

Directivity Factor (Q)

Directivity Index (DI)

Power Handling

Average 50 W

Programme 100 W

Peak 200 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 106 dB

Peak 112 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Crossover

Transducers

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Backcan Options

Blind Mount (BM) Complete with xed backcan

Pre Install (PI) Separate backcan for pre-installation

Cable Entry Options

Conduit Knockouts on PI Backcan

Connectors

Compliance

Dimensions

Bezel diameter

BM Model: Front of ceiling to rear of backcan

BM Model: Front of ceiling to top of safety loop

PI Model: Front of ceiling surface to rear of

speaker unit

PI Model: Front of accessory backcan bezel to

top of safety loop

Hole cutout diameter (all models)

Net Weight (ea)

CMS 503ICT BM

CMS 503ICT PI

PI Backcan

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(1)

(2)

85 Hz - 22 kHz

74 Hz - 24 kHz

71 Hz - 24 kHz

89 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

105 degrees

5.6 averaged 1 kHz to 6 kHz

7.0 averaged 1 kHz to 6 kHz

100 W @ 16 ohms

16 ohms

30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) / 3.75 W (1320 Ω) /

OFF & low impedance operation

30 W (330 Ω) / 15 W (660 Ω) / 7.5 W (1320 Ω) /

OFF & low impedance operation

7 kHz inductively coupled

130 mm (5.00”) mineral loaded polypropylene

ICT aluminium dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

3 Sets of horizontal positions 19 / 22 / 28 mm (0.75” / 0.87” / 1.10”)

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

205.9 mm (8.11”)

188.5 mm (7.42”)

205.8 mm (8.10”)

131.7 mm (5.19”)

153.5 mm (6.04”)

190 mm (7.48”)

3.85 kg (8.49 lbs)

2.85 kg (6.28 lbs)

2.6 kg (5.73 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7500

CMS 50 3ICT BM Whit e /

Paintable

800 1 7510

CMS 50 3ICT PI Whit e /

Paintable

8001 4180

CMS 50 3 Zinc Pl ated

Plas ter (Mud) Ring Stee l

8001 7550

CMS 50 3 PI Backcan Zinc Pl ated

Steel

8001 7880

CMS 50 3 Arco G rille Whit e /

Paintable

UL-1480,

UL-2043

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 503ICT can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

30

Page 31

9. Technical Specifications

CMS 503ICT LP Model

9. Technical Specifications

Performance

Frequency response (-3 dB)

Frequency range (-10 dB)

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 50 W

Programme 100 W

Peak 200 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 106 dB

Peak 112 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Cable Entry Options

Connectors

Compliance

Dimensions

Bezel diameter

Front of ceiling to rear of backcan

Hole cutout diameter

Net Weight (ea)

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(2)

88 Hz - 50 kHz

77 Hz - 54 kHz

89 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

100 W @ 16 ohms

16 ohms

30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) / 3.75 W (1320 Ω) /

OFF & low impedance operation

30 W (330 Ω) / 15 W (660 Ω) / 7.5 W (1320 Ω) /

OFF & low impedance operation

1 x 130 mm (5.0”) mineral loaded polypropylene

ICT

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

274.0 mm (10.79”)

98.6 mm (3.88”)

253.0 mm (9.96”)

3.1 kg (6.83 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7940

CMS 50 3ICT LP Whit e /

Paintable

8001 7890

CMS 60 3 Arco G rille Whit e /

Paintable

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 503ICT LP can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

UL-1480,

UL-2043

CMS 3.0 Series Operation Manual rev 3.0.0

31

Page 32

9. Technical Specifications

9. Technical Specifications

CMS 603DC Models

Performance

Frequency response (-3 dB)

BM Backcan

Frequency range (-10 dB)

BM Backcan

Frequency range (-10 dB)

PI Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 80 W

Programme 160 W

Peak 320 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 110 dB

Peak 116 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Dual Concentric point source driver

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Backcan Options

Blind Mount (BM) Complete with xed backcan

Pre Install (PI) Separate backcan for pre-installation

Cable Entry Options

Conduit Knockouts on PI Backcan

Connectors

Compliance

Dimensions

Bezel diameter

BM Model: Front of ceiling to rear of backcan

BM Model: Front of ceiling to top of safety loop

PI Model: Front of ceiling surface to rear of

speaker unit

PI Model: Front of accessory backcan bezel to

top of safety loop

Hole cutout diameter (all models)

Net Weight (ea)

CMS 603DC BM

CMS 603DC PI

PI Backcan

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(1)

(2)

75 Hz - 30 kHz

50 Hz - 30 kHz

46 Hz - 30 kHz

91 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

160 W @ 16 ohms

16 ohms

60 W (83 Ω) / 30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) /

OFF & low impedance operation

60 W (165 Ω) / 30 W (330 Ω) / 15 W (660 Ω) /

OFF & low impedance operation

1 x 165 mm (6.5”) Dual Concentric driver, using Omnimagnet technology

44 mm (1.75”) voice coil, treated multi ber paper pulp cone

25 mm (1.00”) PEI dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

3 Sets of horizontal positions 19 / 22 / 28 mm (0.75” / 0.87” / 1.10”)

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

274.0 mm (10.79”)

255.8 mm (10.07”)

273.3 mm (10.76”)

100.7 mm (3.96”)

168.5 mm (6.60”)

253 mm (9.96”)

6.6 kg (14.56 lbs)

3.65 kg (8.05 lbs)

3.68 kg (8.11 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7440

CMS 60 3DC BM Whit e /

Paintable

8001 7450

CMS 60 3DC PI Whit e /

Paintable

8001 4181

CMS 60 3 Zinc Pl ated

Plas ter (Mud) Ring Stee l

8001 7560

CMS 60 3 PI Backc an Zinc Pl ated

Steel

8001 7890

CMS 60 3 Arco G rille Whit e /

Paintable

UL-1480,

UL-2043

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 603DC can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

32

Page 33

9. Technical Specifications

CMS 603ICT Models

9. Technical Specifications

Performance

Frequency response (-3 dB)

BM Backcan

Frequency range (-10 dB)

BM Backcan

Frequency range (-10 dB)

PI Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Coverage Angle (1 kHz to 6 kHz)

Directivity Factor (Q)

Directivity Index (DI)

Power Handling

Average 60 W

Programme 120 W

Peak 240 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 109 dB

Peak 115 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Crossover

Transducers

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Backcan Options

Blind Mount (BM) Complete with xed backcan

Pre Install (PI) Separate backcan for pre-installation

Cable Entry Options

Conduit Knockouts on PI Backcan

Connectors

Compliance

Dimensions

Bezel diameter

BM Model: Front of ceiling to rear of backcan

BM Model: Front of ceiling to top of safety loop

PI Model: Front of ceiling surface to rear of

speaker unit

PI Model: Front of accessory backcan bezel to

top of safety loop

Hole cutout diameter (all models)

Net Weight (ea)

CMS 603ICT BM

CMS 603ICT PI

PI Backcan

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(1)

(2)

78 Hz - 22 kHz

51 Hz - 24 kHz

46 Hz - 24 kHz

91 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

92 degrees

7.1 averaged 1 kHz to 6 kHz

7.9 averaged 1 kHz to 6 kHz

120 W @ 16 ohms

16 ohms

60 W (83 Ω) / 30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) /

OFF & low impedance operation

60 W (165 Ω) / 30 W (330 Ω) / 15 W (660 Ω) /

OFF & low impedance operation

7 kHz inductively coupled

165 mm (6.50”) mineral loaded polypropylene

ICT aluminium dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

3 Sets of horizontal positions 19 / 22 / 28 mm (0.75” / 0.87” / 1.10”)

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

274.0 mm (10.79”)

256.5 mm (10.10”)

273.8 mm (10.78”)

100.0 mm (3.94”)

168.5 mm (6.60”)

253 mm (9.96”)

TBA

TBA

3.68 kg (8.11 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7520

CMS 60 3ICT BM Whit e /

Paintable

8001 7530

CMS 60 3ICT PI Whit e /

Paintable

8001 4181

CMS 60 3 Zinc Pl ated

Plas ter (Mud) Ring Stee l

8001 7560

CMS 60 3 PI Backc an Zinc Pl ated

Steel

8001 7890

CMS 60 3 Arco G rille Whit e /

Paintable

UL-1480,

UL-2043

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 603ICT can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

33

Page 34

9. Technical Specifications

9. Technical Specifications

CMS 803DC Models

Performance

Frequency response (-3 dB)

BM Backcan

Frequency range (-10 dB)

BM Backcan

Frequency range (-10 dB)

PI Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 90 W

Programme 180 W

Peak 360 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 112 dB

Peak 118 dB

With THP60 - Average 110 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Dual Concentric point source driver

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Backcan Options

Blind Mount (BM) Complete with xed backcan

Pre Install (PI) Separate backcan for pre-installation

Cable Entry Options

Conduit Knockouts on PI Backcan

Connectors

Compliance

Dimensions

Bezel diameter

BM Model: Front of ceiling to rear of backcan

BM Model: Front of ceiling to top of safety loop

PI Model: Front of ceiling surface to rear of

speaker unit

PI Model: Front of accessory backcan bezel to

top of safety loop

Hole cutout diameter (all models)

Net Weight (ea)

CMS 803DC BM

CMS 803DC PI

PI Backcan

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(1)

(2)

47 Hz - 30 kHz

40 Hz - 35 kHz

41 Hz - 35 kHz

92 dB (1 W = 4 V for 16 Ohms)

90 degrees conical

180 W @ 16 ohms

16 ohms

60 W (83 Ω) / 30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) /

OFF & low impedance operation

60 W (165 Ω) / 30 W (330 Ω) / 15 W (660 Ω) /

OFF & low impedance operation

1 x 200 mm (8.0”) Dual Concentric driver, using Omnimagnet technology

44 mm (1.75”) voice coil, treated multi ber paper pulp cone

25 mm (1.00”) PEI dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

3 Sets of horizontal positions 19 / 22 / 28 mm (0.75” / 0.87” / 1.10”)

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

319.0 mm (12.56”)

310.5 mm (12.22”)

327.7 mm (12.90”)

125.6 mm (4.94”)

168.5 mm (6.63”)

295 mm (11.61”)

8.5 kg (18.74 lbs)

4.9 kg (10.80 lbs)

4.0 kg (8.81 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 7470

CMS 80 3DC BM Whit e /

Paintable

8001 7480

CMS 80 3DC PI Whit e /

Paintable

8001 4650

CMS 80 3 Zinc Pl ated

Plas ter (Mud) Ring Stee l

8001 7570

CMS 80 3 PI Backc an Zinc Pl ated

Steel

8001 7900

CMS 80 3 Arco G rille Whit e /

Paintable

UL-1480,

UL-2043

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 803DC can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

CMS 3.0 Series Operation Manual rev 3.0.0

34

Page 35

9. Technical Specifications

CMS 803DCQ Model

9. Technical Specifications

Performance

Frequency response (-3 dB)

Frequency range (-10 dB)

BM Backcan

Frequency range (-10 dB)

PI Backcan

System sensitivity (1 W @ 1 m)

Nominal Coverage Angle

Power Handling

Average 90 W

Programme 180 W

Peak 360 W

Recommended Amplier Power

Nominal Impedance (Lo, Z)

Rated maximum SPL

Average 113 dB

Peak 119 dB

With THP60 - Average 111 dB

Transformer Taps (via front rotary switch)

70 V

100 V

Transducers

Dual Concentric point source driver

Low Frequency

High Frequency

Physical

Enclosure

Backcan Zinc plated steel

Bafe Reex loaded UL 94V-0 rated ABS

Grille Steel, with weather resistant coating

Safety Features

Clamping Design

Cable Entry Options

Connectors

Compliance

Dimensions

Bezel diameter

Front of ceiling to rear of backcan

Front of ceiling to top of safety loop

Hole cutout diameter (all models)

Net Weight (ea)

Included Accessories

Optional Accessories

Packed Quantity

(3)

(1)

(1)

(1)

(2)

47 Hz - 30 kHz

40 Hz - 35 kHz

41 Hz - 35 kHz

93 dB (1 W = 4 V for 16 Ohms)

60 degrees conical

180 W @ 16 ohms

16 ohms

60 W (83 Ω) / 30 W (165 Ω) / 15 W (330 Ω) / 7.5 W (660 Ω) /

OFF & low impedance operation

60 W (165 Ω) / 30 W (330 Ω) / 15 W (660 Ω) /

OFF & low impedance operation

1 x 200 mm (8.0”) Dual Concentric driver, using Omnimagnet technology

44 mm (1.75”) voice coil, treated multi ber paper pulp cone

25 mm (1.00”) PEI dome

Safety ring located at rear of enclosure for load bearing safety bond

Security toggle clamp

Min / Max clamping range 9.5 mm (0.37”) /

60 mm (2.36”)

Recommended clamp torque: 1.5 Nm

Cable clamp & squeeze connector for conduit up to 22 mm

Removable locking connector with screw terminals with

“loop through” facility

UL-1480, UL-2043, CE

319.0 mm (12.56”)

310.5 mm (12.22”)

327.7 mm (12.90”)

295 mm (11.61”)

8.5 kg (18.74 lbs)

C-Ring, tile-bridge kit, paint mask, cut-out template, grille

Plaster (mud) ring, Arco grille

2

Orde ring In forma tion

Part N umber Colou r

8001 74 90

CMS 80 3DCQ White /

Paintable

8001 4650

CMS 80 3 Zinc Pl ated

Plas ter (Mud) Ring Stee l

8001 7900

CMS 80 3 Arco G rille Whit e /

Paintable

UL-1480,

Notes:

1. Average ove r stated bandwidt h. Measured in

an IEC baf e in an Anechoic C hamber

2. Unweight ed pink noise inpu t, measured at

1 metre on a xis

3. Long term p ower handling cap acity as dened

in EIA - 426B test

A full ran ge of measuremen ts, performan ce data,

CLF and Ea se™ Data for CM S 803DCQ can be

downloa ded from www.tann oypro.com.

Tannoy operat es a policy of contin uous research

and devel opment. The intro duction of new mater ials

or manuf acturing method s may introduce var iations

in actual p erformance; h owever, actual perfo rmance

always wil l equal or exceed th e published

speci cations, which Tanno y reserves the ri ght to

alter wit hout prior notic e. Please verif y the latest

specications when dealing with critical applications.

Copyrig ht (c) 2014 Tannoy Limited. A ll rights reser ved.

UL-2043

CMS 3.0 Series Operation Manual rev 3.0.0

35

Page 36

10. Painting

10. Painting

If desired, the grille and bafe panel may be painted to match the surrounding décor.

Painting the bafe:

• Carefully mask off the driver assembly using the paint mask provided to ensure that the paint does not come

into contact with the cone and roll surround.

• Apply several thin coats of paint – this will provide a better nish than one overly thick coat.

Painting the grille:

• Carefully remove the acoustically transparent grille cloth from the reverse side of the grille.

• Paint the grille and then replace the grille cloth - several thin coats of paint will provide a better nish than one

overly thick coat.

• Re-bond the grille cloth to the grille over the entire area using a light spray-adhesive to avoid audible resonances.

CMS 3.0 Series Operation Manual rev 3.0.0

36

Page 37

11. Warranty

11. Warranty

No maintenance of the CMS Series loudspeaker is necessary.

As part of the MUSIC Group, Tannoy is committed to providing the highest quality products, service and user

experience for our customers. One element of this commitment is our after sales support which now

incorporates our extended Limited Warranty. In the event of any concern that is not addressed by this extended

Limited Warranty we would ask you to contact us at care@music-group.com

For full warranty details including the extended Limited Warranty, please visit

http://www.music-group.com/warranty.aspx and register your purchase online at www.music-group.com

or www.tannoy.com

CMS 3.0 Series Operation Manual rev 3.0.0

37

Page 38

12. Declaration of conformity

12. Declaration of conformity

(in accordance with ISO/IEC 1750-1)

Document No: CE-CMS3-1

We: Music Group Innovation SC Ltd

Rosehall Industrial Estate, Coatbridge, ML5 4TF, United Kingdom

In accordance with the following Directive(s):

2004/108/RC Electromagnetic Compatibility (EMC)

2011/65/EU Restriction of the use of certain hazardous substances (RoHS)

Hereby declare that:

Type of equipment In-Ceiling Loudspeakers

Models CMS 403DCe, CMS 403ICTe, CMS 503DC BM, CMS 503ICT BM,

CMS 503DC PI, CMS 503ICT PI, CMS 503DC PI BACKCAN,

CMS 503ICT PI BACKCAN, CMS 603DC BM, CMS 603ICT BM,

CMS 603DC PI, CMS 603ICT PI, CMS 603DC PI BACKCAN,

CMS 603ICT PI BACKCAN, CMS 603ICT LS, CMS 803DC BM,

CMS 803DC PI, CMS 803DC PI BACKCAN, CMS 803DCQ

Is/are in conformity with the requirements of the following documents:

Ref. No Title Edition

BS EN 55103-1 Electromagnetic compatibility. Product family standard for audio,

video, audio-visual and entertainment lighting control apparatus 2009

for professional use. Emissions

BS EN 55103-2 Electromagnetic compatibility. Product family standard for audio,

video, audio-visual and entertainment lighting control apparatus 2009

for professional use. Immunity

Name: Philippe Robineau

Position: Director of Engineering

Done at: Coatbridge

Date: 23/11/2015

Director of Engineering

Tannoy

23 November 2015

CMS 3.0 Series Operation Manual rev 3.0.0

38

Page 39

Notes

Notes

CMS 3.0 Series Operation Manual rev 3.0.0

39

Page 40

tannoypro.com

Tannoy operates a policy of continuous research and development. The introduction of new materials or manufacturing

methods will always equal or exceed the published specications. All specications are subject to change without notice.

Copyright (c) 2015 Music Group Innovation SC Ltd. All rights reserved.

6481 0632/231115

Loading...

Loading...