Page 1

TANDBERG SLR

Tandberg SLR7, SLR50,

SLR60, SLR75, SLR100, SLR140

SCSI INTERFACE

FUNCTIONAL SPECIFICATION

TANDBERG DATA ASA

P.O. Box 134 Kjelsås

N-0411 OSLO, NORWAY

Phone + 47 22 18 90 90

Telefax + 47 22 18 95 50

© Tandberg Data ASA

Part No. 43 07 43 – 13

October 2003

Page 2

Related publications available from Tandberg Data ASA:

Part No. Title

43 04 44 - 11 Tandberg SLR7, SLR50, SLR60, SLR75, SLR100,

SLR140 Reference Manual

This publication may describe designs for which patents are granted or pending. By publishing this information, Tandberg Data ASA conveys no license

under any patent or any other rights.

Every effort has been made to avoid errors in text and diagrams. However,

Tandberg Data ASA assumes no responsibility for any errors, which may appear in this publication.

It is the policy of Tandberg Data ASA to improve products as new techniques

and components become available. Tandberg Data ASA therefore reserves

the right to change specifications at any time.

We would appreciate any comments on this publication.

Page 3

i Tandberg SLR Product Line SCSI Functional Specifications

Table Of Contents

1. Introduction .....................................................................1

1.1. General .............................................................................................. 1

1.2. Overview............................................................................................ 2

1.3. Glossary............................................................................................. 3

1.4. Additional Reference Documentation................................................ 5

2. About Tape Streamers ....................................................1

2.1. Physical Elements ............................................................................. 1

2.2. Data Storage Characteristics............................................................. 1

2.3. Partitions Within a Volume ................................................................ 3

2.3.1. Partitioning a Volume................................................................. 4

2.3.2. Selecting a Partition ................................................................... 6

2.3.3. Using Initiator Defined Partitions ............................................... 8

2.3.4. Quick File Access .................................................................... 11

2.4. Logical Elements Within a Partition................................................. 14

2.5. Overwrite ......................................................................................... 15

2.6. Using Fixed and Variable Length Blocks......................................... 17

2.6.1. Variable and Fixed Length Blocks ........................................... 17

2.6.2. Writing...................................................................................... 17

2.6.3. Reading.................................................................................... 18

2.6.4. Illegal Length Conditions when Reading ................................. 18

2.7. Data Buffering.................................................................................. 19

2.7.1. Introduction .............................................................................. 19

2.7.2. Data Formatting ....................................................................... 21

2.7.3. Buffered Mode ......................................................................... 23

2.7.4. Read-Ahead............................................................................. 25

2.7.5. Underrun/Overrun .................................................................... 25

2.7.6. Buffer Thresholds..................................................................... 26

2.7.7. Disconnect/Re-connect............................................................ 27

2.7.8. Data Re-transfer ...................................................................... 28

2.7.9. Buffer Parity Errors .................................................................. 28

2.8. Data Compression........................................................................... 29

2.8.1. Background.............................................................................. 29

2.8.2. Controlling Data Compression................................................. 30

2.9. Optimizing Streaming Operation ..................................................... 33

2.9.1. Forced Streaming .................................................................... 33

2.9.2. AVC (Automatic Velocity Control)............................................ 33

2.9.3. Using both Forced Streaming and AVC................................... 34

2.9.4. Recommended Settings .......................................................... 35

2.10. Recorded Objects............................................................................ 35

2.11. TapeAlert ......................................................................................... 36

3. Logical Characteristics...................................................1

3.1. SCSI-bus Phases .............................................................................. 1

3.1.1. Bus Management Phases.......................................................... 1

3.1.2. Information Transfer Phases ..................................................... 2

3.2. SCSI-bus Phase Sequences ............................................................. 3

3.2.1. Legal Phase Sequences............................................................ 4

3.3. SCSI Pointers .................................................................................... 9

3.4. Unit Attention ................................................................................... 11

3.5. SCSI-bus Conditions ....................................................................... 12

3.5.1. Attention (ATN) ........................................................................ 12

3.5.2. Reset........................................................................................ 13

Page 4

Tandberg Data Table of Contents

ii Tandberg SLR Product Line SCSI Functional Specifications

4. Commands.......................................................................1

4.1. The Command Descriptor Block........................................................ 1

4.2. Command Control Byte ..................................................................... 2

4.3. Reserved Fields................................................................................. 3

4.4. Command Set Summary ................................................................... 4

4.5. Command Sequencing...................................................................... 6

4.5.1. Normal Modes............................................................................ 6

4.6. Multiple Connections ......................................................................... 9

4.6.1. Background................................................................................ 9

4.6.2. Commands Received Serially, LUN Is 0.................................. 10

4.6.3. Commands Received Serially, LUN Not 0............................... 11

4.6.4. Concurrent Command, Same Initiator, LUN Is 0 ..................... 11

4.6.5. Concurrent Command, Any Initiator, LUN Not 0 ..................... 11

4.6.6. Concurrent Command, Different Initiator, LUN Is 0................. 11

5. Status Bytes.....................................................................1

6. Message System .............................................................1

6.1. Message In ........................................................................................ 2

6.2. Message Out ..................................................................................... 3

6.3. Extended Message............................................................................ 5

6.3.1. Wide Data Transfer Request ..................................................... 6

6.3.2. Synchronous Data Transfer Request Message......................... 8

6.4. Message Reject Message Handling................................................ 11

6.4.1. Message-In Phase ................................................................... 11

6.4.2. Message-Out Phase ................................................................ 11

6.5. Abort Message Handling ................................................................. 12

6.6. Unexpected Bus Free...................................................................... 14

7. General Exception Handling...........................................1

7.1. Error Codes ....................................................................................... 1

7.2. Error Conditions for All Commands................................................... 5

7.3. Deferred Errors.................................................................................. 6

7.4. Error Conditions for Media Access Commands ................................ 7

7.5. Power On Selftest (POST) Error Handling ........................................ 8

7.5.1. Commands Executed After POST Error .................................... 8

7.5.2. Commands Terminated After POST Error................................. 9

7.6. Bus Parity Error Handling .................................................................. 9

7.6.1. Errors Detected by the Drive ................................................... 10

7.6.2. Errors Detected by the Initiator ................................................ 11

7.7. Buffer Parity Error Handling............................................................. 11

7.8. Error Priority..................................................................................... 12

7.9. Suggested Error Recovery Action ................................................... 13

8. Erase ................................................................................1

8.1. Command Description....................................................................... 1

8.2. Command Descriptor Block............................................................... 1

8.3. Exception Handling............................................................................ 2

8.4. Phase Sequencing ............................................................................ 2

9. Inquiry ..............................................................................1

9.1. Command Description....................................................................... 1

9.2. Command Descriptor Block............................................................... 1

9.3. Parameter Lists ................................................................................. 3

9.3.1. Standard Inquiry Data................................................................ 3

Page 5

Tandberg Data Table of Contents

iii Tandberg SLR Product Line SCSI Functional Specifications

9.3.2. Vital Product Data ...................................................................... 6

9.4. Exception Handling.......................................................................... 16

9.5. Phase Sequencing .......................................................................... 16

10. Load/Unload.....................................................................1

10.1. Command Description ....................................................................... 1

10.2. Command Descriptor Block............................................................... 2

10.3. Exception Handling............................................................................ 3

10.4. Phase Sequencing ............................................................................ 3

11. Locate...............................................................................1

11.1. Command Description ....................................................................... 1

11.2. Command Descriptor Block............................................................... 2

11.3. Exception Handling............................................................................ 3

11.4. Phase Sequencing ............................................................................ 3

12. Log Select ........................................................................1

12.1. Command Description ....................................................................... 1

12.2. Command Descriptor Block............................................................... 1

12.3. Parameter List ................................................................................... 3

12.3.1. General Parameter Description ................................................. 3

12.3.2. Log Page Headers ..................................................................... 3

12.3.3. Log Parameter Headers ............................................................ 3

12.3.4. Modifiable Parameter Values..................................................... 6

12.3.5. The TapeAlert Information Page................................................ 6

12.4. Exception Handling............................................................................ 7

12.5. Phase Sequencing ............................................................................ 7

13. Log Sense ........................................................................1

13.1. Command Description ....................................................................... 1

13.2. Command Descriptor Block............................................................... 1

13.3. Parameter List ................................................................................... 3

13.3.1. Supported Log Pages ................................................................ 3

13.3.2. Buffer Overrun/Underrun Counters Page .................................. 4

13.3.3. Write Error Counter Page .......................................................... 7

13.3.4. Read Error Counter Page ........................................................ 14

13.3.5. TapeAlert Page ........................................................................ 22

13.3.6. Data Block Counters Page ...................................................... 25

13.3.7. Remaining Capacity Page ....................................................... 29

13.3.8. Tape Mark Counters Page....................................................... 36

13.3.9. Head Cleaning Page................................................................ 39

13.3.10. Drive Page ............................................................................... 43

13.3.11. Servo Page ............................................................................. 46

13.3.12. Track Number Page................................................................. 53

13.3.13. Cartridge Usage Page ............................................................. 54

13.3.14. Compression Ratio Page ......................................................... 62

13.4. Exception Handling.......................................................................... 70

13.5. Phase Sequencing .......................................................................... 70

14. Mode Select .....................................................................1

14.1. Command Description ....................................................................... 1

14.2. Command Descriptor Block............................................................... 1

14.3. Parameter List ................................................................................... 2

14.3.1. Header List................................................................................. 3

14.3.2. Block Descriptor List .................................................................. 6

14.3.3. Read-Write Error Recovery Page ............................................ 11

Page 6

Tandberg Data Table of Contents

iv Tandberg SLR Product Line SCSI Functional Specifications

14.3.4. Disconnect/Reconnect Page ................................................... 13

14.3.5. Control Mode Page .................................................................. 16

14.3.6. Data Compression Page.......................................................... 18

14.3.7. Device Configuration Page ...................................................... 20

14.3.8. Medium Partition Page (1) ....................................................... 23

14.3.9. Informational Exceptions Control Page ................................... 27

14.3.10. Miscellaneous Parameters Page ............................................. 29

14.3.11. User Page 0 ............................................................................. 35

14.3.12. User Page 1 ............................................................................. 36

14.3.13. Cartridge Manufacturer Page .................................................. 37

14.4. Exception Handling.......................................................................... 38

14.5. Phase Sequencing .......................................................................... 38

15. Mode Sense .....................................................................1

15.1. Command Description ....................................................................... 1

15.2. Command Descriptor Block............................................................... 2

15.3. Parameter List ................................................................................... 3

15.3.1. Header List................................................................................. 3

15.3.2. Block Descriptor List .................................................................. 5

15.3.3. Read-Write Error Recovery Page Descriptor ............................ 6

15.3.4. Disconnect/Reconnect Page Descriptor .................................... 6

15.3.5. Control Mode Page .................................................................... 7

15.3.6. Data Compression Page Descriptor .......................................... 7

15.3.7. Device Configuration Parameters Page Descriptor................... 8

15.3.8. Medium Partition Parameters Page Descriptor ......................... 8

15.3.9. TapeAlert Configuration Page ................................................... 9

15.3.10. Miscellaneous Parameters Page Descriptor ........................... 10

15.3.11. User Page 0 Page Descriptor .................................................. 10

15.3.12. User Page 1 Page Descriptor .................................................. 11

15.3.13. Cartridge Manufacturer Page .................................................. 12

15.4. Exception Handling.......................................................................... 13

15.5. Phase Sequencing .......................................................................... 13

16. Prevent/Allow Medium Removal ....................................1

16.1. Command Description ....................................................................... 1

16.2. Command Descriptor Block............................................................... 1

16.3. Exception Handling............................................................................ 2

16.4. Phase Sequencing ............................................................................ 2

17. Read .................................................................................1

17.1. Command Description ....................................................................... 1

17.2. Command Descriptor Block............................................................... 2

17.3. Exception Handling............................................................................ 3

17.3.1. General ...................................................................................... 3

17.3.2. No Data...................................................................................... 3

17.3.3. Tapemark Detected ................................................................... 3

17.3.4. Illegal Length.............................................................................. 4

17.3.5. End of Data ................................................................................ 6

17.3.6. End of Partition .......................................................................... 7

17.3.7. Non-Recoverable Read Error .................................................... 7

17.3.8. Illegal Termination...................................................................... 8

17.3.9. Read After Write ........................................................................ 8

17.4. Phase Sequencing ............................................................................ 9

18. Read Block Limits ...........................................................1

18.1. Command Description ....................................................................... 1

Page 7

Tandberg Data Table of Contents

v Tandberg SLR Product Line SCSI Functional Specifications

18.2. Command Descriptor Block............................................................... 1

18.3. Parameter List ................................................................................... 1

18.4. Exception Handling............................................................................ 2

18.5. Phase Sequencing ............................................................................ 2

19. Read Buffer ......................................................................1

19.1. Command Description ....................................................................... 1

19.2. Command Descriptor Block............................................................... 1

19.3. Read Data Mode (2) .......................................................................... 3

19.3.1. Data Buffer (Buffer ID = 0) ......................................................... 3

19.3.2. Static RAM (Buffer ID = 1) ......................................................... 3

19.3.3. Media Statistics (Buffer ID = 2) .................................................. 3

19.3.4. Microcode Store (Buffer ID = 3)................................................. 3

19.3.5. EEPROM (Buffer ID = 4)............................................................ 3

19.3.6. External RAM Adapter (Buffer ID = 5) ....................................... 3

19.3.7. NVP DATA (Buffer ID = 6) ......................................................... 4

19.3.8. Tape Buffer Control Data (Buffer ID = 7) ................................... 4

19.3.9. Volume Directory (Buffer ID = 8)................................................ 4

19.3.10. Dbase Variables (Buffer ID = 9)................................................ 4

19.3.11. Header File Dates (Buffer ID = 10 )................................................. 4

19.3.12. Trace Buffer Control Blocks (Buffer ID = 11) .................................. 4

19.3.13. Complete Trace Buffer (Buffer ID = 12) .......................................... 4

19.4. Read Descriptor Mode (3) ................................................................. 5

19.5. Exception Handling............................................................................ 6

19.6. Phase Sequencing ............................................................................ 7

20. Read Position ..................................................................1

20.1. Command Description ....................................................................... 1

20.2. Command Descriptor Block............................................................... 2

20.3. Data Format....................................................................................... 3

20.4. Exception Handling............................................................................ 4

20.5. Phase Sequencing ............................................................................ 5

21. Receive Diagnostic Results............................................1

21.1. Command Description ....................................................................... 1

21.2. Command Descriptor Block............................................................... 1

21.3. Results From the SEND DIAGNOSTICS Command......................... 3

21.3.1. The Header Page....................................................................... 3

21.3.2. The Diagnostic Pages................................................................ 4

21.3.3. Supported Page Codes ............................................................. 5

21.4. Results From the Stand Alone Diagnostics Test............................... 6

21.4.1. The Stand Alone Diagnostic Result Page.................................. 6

21.5. Exception Handling............................................................................ 7

21.6. Phase Sequencing ............................................................................ 7

22. Release.............................................................................1

22.1. Command Description ....................................................................... 1

22.2. Command Descriptor Block............................................................... 1

22.3. Exception Handling............................................................................ 2

22.4. Phase Sequencing ............................................................................ 2

23. Request Sense.................................................................1

23.1. Command Description ....................................................................... 1

23.2. Command Descriptor Block............................................................... 1

23.3. Parameter List ................................................................................... 2

23.4. Sense Keys........................................................................................ 5

Page 8

Tandberg Data Table of Contents

vi Tandberg SLR Product Line SCSI Functional Specifications

23.5. Additional Sense Code and Qualifier ................................................ 6

23.6. Exception Handling............................................................................ 8

23.7. Phase Sequencing ............................................................................ 8

24. Reserve ............................................................................1

24.1. Command Description ....................................................................... 1

24.2. Command Descriptor Block............................................................... 2

24.3. Exception Handling............................................................................ 2

24.4. Phase Sequencing ............................................................................ 2

25. Rewind..............................................................................1

25.1. Command Description ....................................................................... 1

25.2. Command Descriptor Block............................................................... 1

25.3. Exception Handling............................................................................ 1

25.4. Phase Sequencing ............................................................................ 2

26. Send Diagnostics ............................................................1

26.1. Command Description ....................................................................... 1

26.2. Command Descriptor Block............................................................... 1

26.3. Predefined Selftest Sequence 1........................................................ 3

26.4. Predefined Selftest Sequence 2........................................................ 4

26.5. Exception Handling............................................................................ 5

26.6. Phase Sequencing ............................................................................ 5

27. Space................................................................................1

27.1. Command Description ....................................................................... 1

27.2. Command Descriptor Block............................................................... 2

27.3. Using Fast Space .............................................................................. 3

27.4. Exception Handling............................................................................ 3

27.4.1. General ...................................................................................... 3

27.4.2. No Data...................................................................................... 4

27.4.3. Filemark Detected...................................................................... 4

27.4.4. Setmark Detected ...................................................................... 4

27.4.5. End of Data ............................................................................... 5

27.4.6. Beginning of Partition................................................................ 5

27.4.7. End of Partition ......................................................................... 5

27.4.8. Non-Recoverable Read Error During Space Forward ............... 6

27.4.9. Error Condition or Bad Block During Space Reverse................ 6

28.4.10. Space Forward After Write ........................................................ 7

27.5. Phase Sequencing ............................................................................ 7

28. Test Unit Ready ...............................................................1

28.1. Command Description ....................................................................... 1

28.2. Command Descriptor Block............................................................... 1

28.3. Exception Handling............................................................................ 1

28.4. Phase Sequencing ............................................................................ 2

29. Verify (not for SLR7 and SLR140) ..................................1

29.1. Command Description ....................................................................... 1

29.2. Command Descriptor Block............................................................... 2

29.3. Exception Handling............................................................................ 3

29.4. Phase Sequencing ............................................................................ 3

30. Write .................................................................................1

Page 9

Tandberg Data Table of Contents

vii Tandberg SLR Product Line SCSI Functional Specifications

30.1. Command Description ....................................................................... 1

30.2. Command Descriptor Block............................................................... 2

30.3. Data Compression............................................................................. 2

30.4. Write from BOP.................................................................................. 2

30.5. Write from EOD, Append................................................................... 3

30.6. Writing Over Existing Data, Overwrite............................................... 3

30.7. Terminating Write Operations............................................................ 3

30.8. Exception Handling............................................................................ 4

30.8.1. General ...................................................................................... 4

30.8.2. Unsupported Block Length ........................................................ 4

30.8.3. Illegal Media Type...................................................................... 5

30.8.4 Illegal Overwrite ......................................................................... 6

30.8.5. Illegal Append Tape Format ...................................................... 6

30.8.6. Logical Early Warning................................................................ 6

30.8.7. End of Partition .......................................................................... 7

30.8.8. Non-Recoverable Write Error .................................................... 7

30.8.9. Append Error.............................................................................. 8

30.9. Phase Sequencing ............................................................................ 8

31. Write Buffer......................................................................1

31.1. Command Description ....................................................................... 1

31.2. Command Descriptor Block............................................................... 1

31.3. Write Combined Header and Data Mode (0)..................................... 2

31.4. Write Data Mode (2) .......................................................................... 3

31.5. Download Microcode Mode (4).......................................................... 3

31.6. Download Microcode and Save Mode (5) ......................................... 3

31.7. Download Microcode with Offsets and Save Mode (7) ..................... 4

31.8. Microcode Verification and Save ....................................................... 4

31.9. Microcode Data Format ..................................................................... 5

31.10. Exception Handling............................................................................ 6

31.11. Phase Sequencing ............................................................................ 7

32. Write Filemarks................................................................1

32.1. Command Description ....................................................................... 1

32.2. Command Descriptor Block............................................................... 1

32.3. Terminating Write Operations............................................................ 2

32.4. Write Filemarks from BOM ................................................................ 2

32.5. Exception Handling............................................................................ 2

32.5.1. General ...................................................................................... 2

32.5.2. Illegal Media Type...................................................................... 3

32.5.3. Illegal Append Tape Format ...................................................... 3

32.5.4. Logical Early Warning................................................................ 3

32.5.5. End of Partition .......................................................................... 4

32.5.6. Non-Recoverable Write Error .................................................... 4

32.5.7. Append Error.............................................................................. 5

32.6. Phase Sequencing ............................................................................ 5

Page 10

Tandberg Data Table of Contents

viii Tandberg SLR Product Line SCSI Functional Specifications

Table Of Figures

Figure 2-1: Serpentine Recording ................................................................. 2

Figure 2-2: Logical Track Areas .................................................................... 2

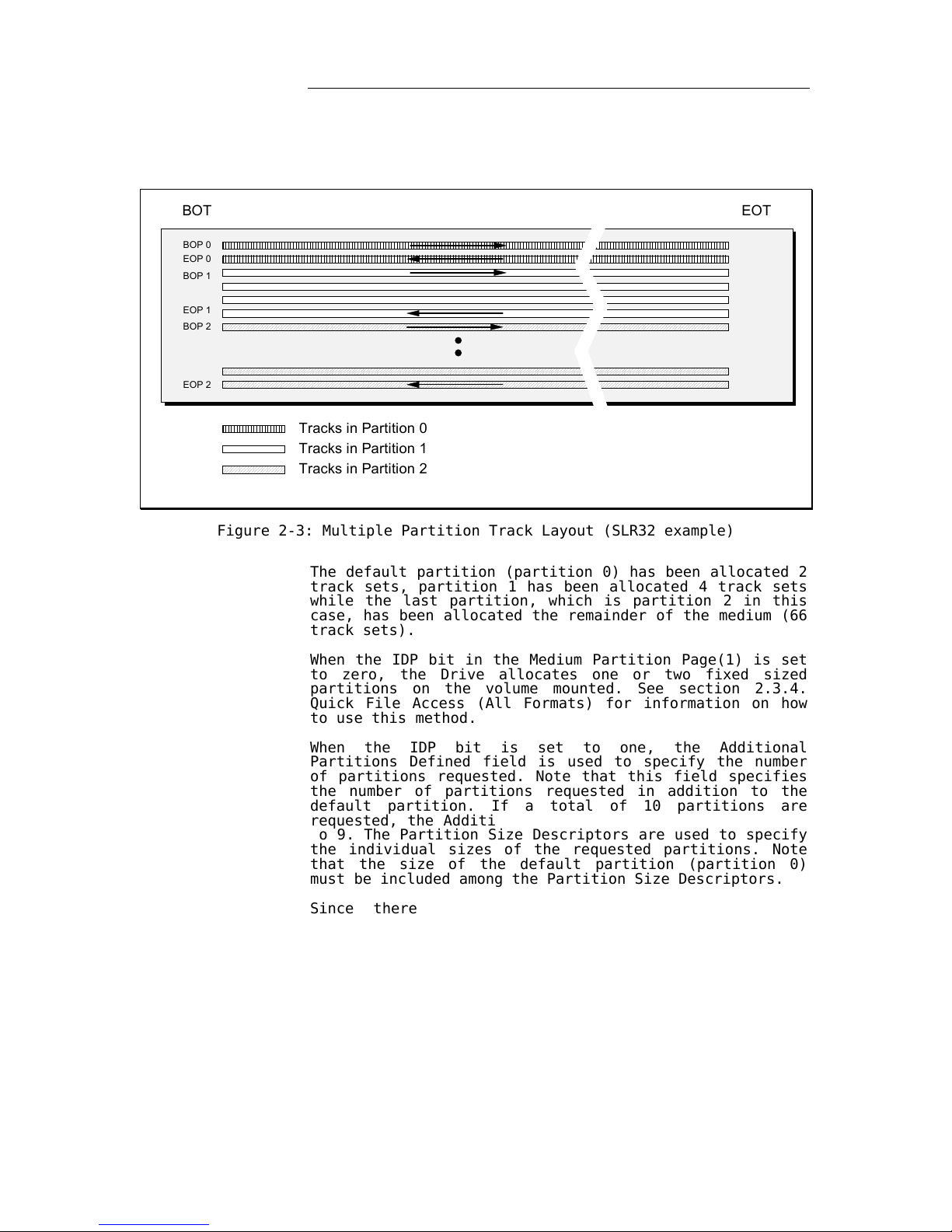

Figure 2-3: Multiple Partition Track Layout (SLR32 example) ....................... 9

Figure 2-4: Overwrite After the 1st Logical Data Block ............................... 16

Figure 2-5: Overwrite of Last Filemark ........................................................ 16

Figure 2-6: The SLR50 Buffer System (Write Mode) .................................. 20

Figure 2-7: The SLR140, SLR100, SLR75, SLR60 and SLR7 Buffer System

(Write Mode) ......................................................................................... 21

Figure 2-8: Host Buffer Data flow During Write Operations ........................ 26

Figure 2-9: Host Buffer Data flow During Read Operations........................ 26

Figure 2-10: Packing Data in Compression Block Groups.......................... 29

Figure 3-1: Phase Sequencing...................................................................... 3

Figure 3-2: SCSI Pointers ........................................................................... 10

Figure 4-1: Connections, Some Examples.................................................. 10

Page 11

Tandberg Data Table of Contents

ix Tandberg SLR Product Line SCSI Functional Specifications

Table Of Tables

Table 1-1: Capacity and medium types.......................................................... 1

Table 2-1: The Medium Partition Page(1) ..................................................... 4

Table 2-2: Minimum Partition Size ................................................................ 8

Table 2-3: Partitions Within A QFA Volume ................................................ 11

Table 2-4: Directory Track set Allocation .................................................... 11

Table 2-5: Data Compression Page Descriptor ........................................... 30

Table 2-6: Forced Streaming and AVC On Different Medium Types (to be

continued…).......................................................................................... 34

Table 3-1: SCSI-bus Phases......................................................................... 1

Table 4-1: Typical Six-byte Command Descriptor Block............................... 1

Table 4-2: Typical Ten-byte Command Descriptor Block .............................. 1

Table 4-3: The Command Control Byte ......................................................... 2

Table 4-4: SCSI Command Set...................................................................... 4

Table 4-5: Normal Mode Actions (to be continued...)..................................... 7

Table 4-6: Connections, LUN and Initiator ID Combinations ...................... 10

Table 5-1: The Status Set ............................................................................. 1

Table 6-1: The Message-In Set..................................................................... 2

Table 6-2: The Message-Out Set .................................................................. 3

Table 6-3: The IDENTIFY Message .............................................................. 4

Table 6-4: Extended Message Format.......................................................... 5

Table 6-5: Supported Extended Message Codes ......................................... 5

Table 6-6: Wide Data Transfer Request ....................................................... 8

Table 6-7: Synchronous Data Transfer Request........................................... 8

Table 6-8: Response to MESSAGE REJECT ............................................. 11

Table 6-9: ABORT TASK SET Message Handling ...................................... 13

Table 7-1: Error Codes (to be continued…) .................................................. 2

Table 7-2: Error Priority ............................................................................... 12

Table 8-1: ERASE Command Descriptor Block ............................................ 1

Table 9-1: INQUIRY Command Descriptor Block ......................................... 1

Table 9-2: INQUIRY Parameter List (to be continued...)............................... 3

Table 9-3: Summary of Supported VPD Pages ............................................ 6

Table 9-4: Unit Serial Number Page ............................................................. 7

Table 9-5: Implemented Operating Definitions Page .................................... 8

Table 9-6: ASCII Implemented Operating Definition Page ........................... 9

Table 9-7: Hardware Revision Levels Page ................................................ 10

Table 9-8: PROM Microcode Revision Level .............................................. 11

Table 9-9: Drive Manufacturing Date Page................................................. 13

Table 9-10: PROM Microcode Creation Date Page .................................... 14

Table 9-11: Drive Adjustment Date Page.................................................... 15

Table 10-1: LOAD/UNLOAD Command Descriptor Block ............................ 2

Table 10-2: LOAD/UNLOAD Operations....................................................... 2

Table 11-1: LOCATE Command Descriptor Block........................................ 2

Table 12-1: LOG SELECT Command Descriptor Block................................ 1

Table 12-2: Parameter Control Byte............................................................... 3

Table 13-1: LOG SENSE Command Descriptor Block ................................. 1

Table 13-2: Supported Log Pages Page....................................................... 3

Table 13-3: Buffer Overrun/Underrun Counters Page .................................. 4

Table 13-4: Underrun Log Parameters ......................................................... 4

Table 13-5: Overrun Log Parameters............................................................. 6

Table 13-6: Write Error Counter Page ........................................................... 7

Table 13-7: Rewrite Counter Log Parameters ............................................... 7

Table 13-8: Total Write Errors Log Parameters ............................................. 9

Table 13-9: Total Write Errors Corrected Log Parameters .......................... 10

Table 13-10: Total Times Errors Processed Log Parameters...................... 11

Table 13-11: Total Bytes Written Parameters .............................................. 12

Table 13-12: Total Uncorrected Write Errors Log Parameters .................... 13

Page 12

Tandberg Data Table of Contents

x Tandberg SLR Product Line SCSI Functional Specifications

Table 13-13: Read Error Counter Page ....................................................... 14

Table 13-14: Reread Counter Log Parameters........................................... 15

Table 13-15: Total Read Error Parameters................................................. 16

Table 13-16: Total Read Error Corrected Log Parameters......................... 17

Table 13-17: ECC Correction Counter Log Parameters ............................. 18

Table 13-18: Total Bytes Read Counter Log Parameters........................... 19

Table 13-19: Total Uncorrected Read Errors Log Parameters .................... 20

Table 13-20: ECC Error Counter Log Parameters ...................................... 21

Table 13-21: TapeAlert Page ....................................................................... 22

Table 13-22: TapeAlert Information Log Parameters................................... 22

Table 13-23: Supported TapeAlert Flags (to be continued…) ..................... 23

Table 13-24: Data Block Counters Page..................................................... 25

Table 13-25: Logical Block Counter Log Parameters ................................. 26

Table 13-26: Write Media Blocks Counter Parameters............................... 27

Table 13-27: Read Media Block Counter Log Parameters ......................... 28

Table 13-28: Remaining Capacity Page ...................................................... 29

Table 13-29: Remaining Capacity Log Parameter code 01 ......................... 30

Table 13-30: Remaining Capacity Log Parameter code 02 ......................... 32

Table 13-31: Maximum Capacity Log Parameter code 03........................... 34

Table 13-32: Maximum Capacity Log Parameter code 04........................... 35

Table 13-33: Tape Mark Counters Page...................................................... 36

Table 13-34: Filemark Counter Log Parameters......................................... 36

Table 13-35: Setmark Counter Log Parameters ......................................... 38

Table 13-36: Head Cleaning Page ............................................................... 39

Table 13-37: Clean Head Log Parameters ................................................. 39

Table 13-38: Head Cleaning Time Log Parameters.................................... 40

Table 13-39: Cleaning Count Log Parameters............................................ 42

Table 13-40: Drive Page ............................................................................. 43

Table 13-41: Total Power On Time Parameters ......................................... 44

Table 13-42: Cartridge Load Counter Parameters...................................... 45

Table 13-43: Servo Page ............................................................................ 46

Table 13-44: Servo Lock Retry Log Parameters........................................ 47

Table 13-45: Servo Track Seek Log Parameters....................................... 48

Table 13-46: Write Servo Lock Lost Counter Log Parameters .................. 49

Table 13-47: Write Servo Dropout Log Parameters.................................... 50

Table 13-48: Read Servo Lock Lost Counter Log Parameters .................. 51

Table 13-49: Read Servo Dropout Log Parameters.................................... 52

Table 13-50: Track Number Page ............................................................... 53

Table 13-51: Cartridge Usage Page............................................................ 54

Table 13-52: Cartridge Serial Number Parameters..................................... 55

Table 13-53: Cartridge Load Counter Parameters...................................... 56

Table 13-54: Cartridge BOT Pass Counter Log Parameters ....................... 58

Table 13-55: Cartridge EOT Pass Counter Log Parameters ....................... 59

Table 13-56: Cartridge Write Pass Counter Log Parameters ...................... 60

Table 13-57: Cartridge Motion Time Log Parameters.................................. 61

Table 13-58: Compression Ratio Page ....................................................... 62

Table 13-59 Write Compression Ratio Log Parameter ................................ 63

Table 13-60: Read Decompression Log Parameter..................................... 64

Table 13-61: Write Compression Interval 1 Log Parameter......................... 65

Table 13-62: Write Compression Interval 2 Log Parameter......................... 66

Table 13-63: Write Compression Interval 3 Log Parameter......................... 67

Table 13-64: Write Compression Interval 4 Log Parameter......................... 68

Table 13-65: Write Compression Interval 5 Log Parameter......................... 69

Table 14-1: MODE SELECT Command Descriptor Block ............................ 1

Table 14-2: MODE SELECT Header List...................................................... 3

Table 14-3: Available Tape Speeds for SLR140............................................ 3

Table 14-4: Available Tape Speeds for SLR100............................................ 4

Table 14-5: Available Tape Speeds for SLR75.............................................. 4

Table 14-6: Available Tape Speeds for SLR60.............................................. 4

Page 13

Tandberg Data Table of Contents

xi Tandberg SLR Product Line SCSI Functional Specifications

Table 14-7: Available Tape Speeds for SLR50............................................. 5

Table 14-8: Available Tape Speeds for SLR7................................................ 5

Table 14-9: MODE SELECT Block Descriptor List ....................................... 6

Table 14-10: Density codes, formats and suitable medium .......................... 6

Table 14-11: Type of Media Related to Tape Format ................................... 8

Table 14-12: Fixed Block Lengths................................................................. 9

Table 14-13: Legal Block Lengths (bytes)................................................... 10

Table 14-14: Read-Write Error Recovery Page Descriptor......................... 11

Table 14-15: Disconnect/Reconnect Page Descriptor ................................ 13

Table 14-16: Control Mode Page Descriptor............................................... 16

Table 14-17: Data Compression Page Descriptor ...................................... 18

Table 14-18: Device Configuration Page Descriptor................................... 20

Table 14-19: Medium Partitions Page......................................................... 23

Table 14-20: Maximum Additional Partitions................................................ 24

Table 14-21: Using the FDP, SDP and IDP bits.......................................... 25

Table 14-22: Informational Exceptions Control Page.................................. 27

Table 14-23: Miscellaneous Page Descriptor ............................................. 29

Table 14-24: BSYI Usage............................................................................. 31

Table 14-25: BSYA Usage ........................................................................... 31

Table 14-26: User Page 0 Page Descriptor ................................................ 35

Table 14-27: User Page 1 Page Descriptor ................................................ 36

Table 14-28: Cartridge Manufacturer Data Parameters.............................. 37

Table 15-1: MODE SENSE Command Descriptor Block .............................. 2

Table 15-2: MODE SENSE Header List........................................................ 3

Table 15-3: MODE SENSE Block Descriptor List ......................................... 5

Table 16-1: PREVENT/ALLOW MEDIUM REMOVAL Cdb ........................... 1

Table 17-1: READ Command Descriptor Block ............................................ 2

Table 17-2: Illegal Length Summary .............................................................. 6

Table 18-1: READ BLOCK LIMITS Command Descriptor Block .................. 1

Table 18-2: READ BLOCK LIMITS Data....................................................... 1

Table 19-1: READ BUFFER Command Descriptor Block............................. 1

Table 19-2: Read Buffer Modes ..................................................................... 2

Table 19-3: Read Buffer ID’s.......................................................................... 2

Table 19-4: READ BUFFER Descriptor List.................................................. 5

Table 19-5: Buffer Capacity............................................................................ 6

Table 20-1: READ POSITION Command Descriptor Block.......................... 2

Table 20-2: READ POSITION Data .............................................................. 3

Table 21-1: RECEIVE DIAGNOSTIC RESULTS Command Block................ 1

Table 21-2: The Header Page........................................................................ 3

Table 21-3: The Diagnostic Pages ................................................................. 4

Table 21-4: Supported Page Codes.............................................................. 5

Table 21-5: The Stand Alone Diagnostic Page ............................................. 6

Table 22-1: RELEASE Command Descriptor Block..................................... 1

Table 23-1: REQUEST SENSE Command Descriptor Block ....................... 1

Table 23-2: REQUEST SENSE Parameter List ............................................ 2

Table 23-3: Sense Key Specific Information, Invalid Fields ........................... 3

Table 23-4: Sense Keys ................................................................................. 5

Table 23-5: Additional Sense Code and Qualifier (to be continued…) ......... 6

Table 24-1: RESERVE Command Descriptor Block..................................... 2

Table 25-1: REWIND Command Descriptor Block........................................ 1

Table 26-1: SEND DIAGNOSTIC Command Descriptor Block..................... 1

Table 26-2: SEND DIAGNOSTICS Functions............................................... 2

Table 27-1: SPACE Command Descriptor Block .......................................... 2

Table 28-1: TEST UNIT READY Command Descriptor Block ...................... 1

Table 28-2: TEST UNIT READY Response................................................... 1

Table 29-1: VERIFY Command Descriptor Block ........................................ 2

Table 30-1: WRITE Command Descriptor Block........................................... 2

Table 30-2: Legal Media/Drive Combinations ............................................... 5

Table 31-1: WRITE BUFFER Command Descriptor Block ........................... 1

Page 14

Tandberg Data Table of Contents

xii Tandberg SLR Product Line SCSI Functional Specifications

Table 31-2: Supported Modes....................................................................... 2

Table 31-3: Microcode Data Format.............................................................. 5

Table 32-1: WRITE FILEMARKS Command Descriptor Block ..................... 1

Page 15

1-1 Tandberg SLR Product Line SCSI Functional Specifications

1.

Introduction

1.1. General

This manual covers the SCSI Specifications for the

Tandberg SLR Product Line Tape Drives. Currently there

are six available models:

Tandberg SLR140

Tandberg SLR100

Tandberg SLR75

Tandberg SLR60

Tandberg SLR50

Tandberg SLR7

This manual replaces Part no. 430743–12, titled,

“ Tandberg SLR7, SLR50, SLR60, SLR75, SLR100. SCSI

Interface Functional Specification.”

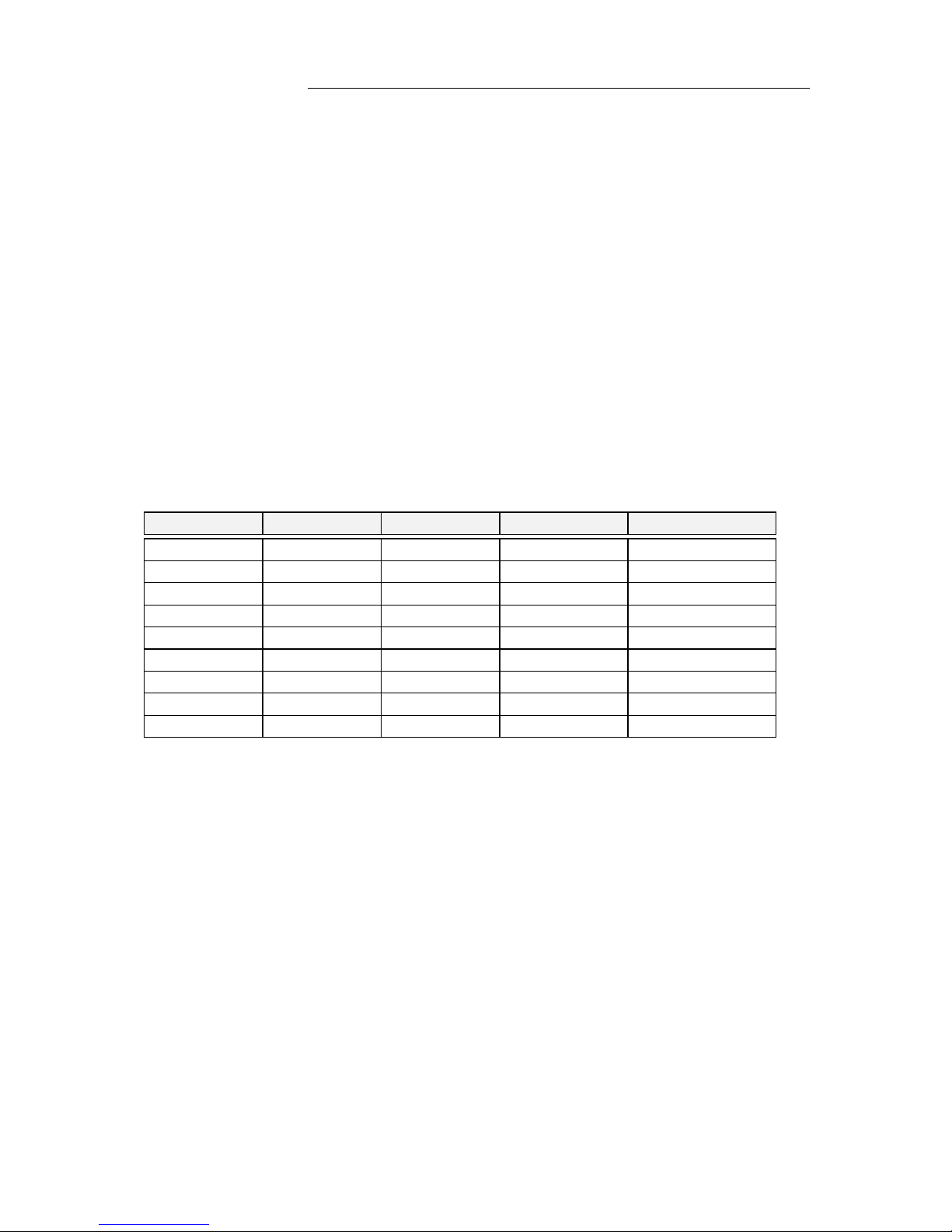

The main differences between the five models are

capacity, data transfer rate and the medium types

supported. The following table shows the different

capacities and read/write compatibility for the various

drive models.

Medium Type1Capacity

2

SLR7 SLR50 SLR60 SLR75 SLR100 SLR140

SLRtape140 70/140 Gbyte N/A N/A N/A N/A N/A Read/Write

SLRtape100 50/100 Gbyte N/A N/A N/A N/A Read/Write Read/Write

SLRtape75 38/75 Gbyte N/A N/A Read/Write Read/Write Read/Write Read/Write

SLRtape60 30/60 Gbyte N/A N/A Read/Write Read/Write Read/Write Read/Write

SLRtape50 25/50 Gbyte N/A Read/Write Read/Write Read/Write Read/Write Read/Write

SLRtape40 20/40 Gbyte N/A N/A Read/Write Read/Write Read/Write Read/Write

SLRtape7 20/40 Gbyte Read/Write N/A Read Read Read Read

SLR32 16/32 Gbyte N/A Read/Write Read Read Read N/A

SLRtape24 12/24 Gbyte N/A Read/Write Read Read Read N/A

SLR5 4/8 Gbyte Read Read Read Read N/A N/A

DC9250 2.5/5 Gbyte N/A Read Read

3

Read N/A N/A

Table 1-1: Capacity and medium types

If a certain functional specification is valid for a

particular drive, two methods are used to separate the

different specifications throughout this manual:

1)

The specific functional specification is marked out

with horizontal lines, or

2)

Footnotes are used to indicate for which drive the

specification applies.

The specifications described in this publication are

subject to change without notice.

1

All drives supports different variants of these medium types. See

table 30-3 for details.

2

The highest number is with 2:1 data compression.

The actual capacity on brand new or old and worn tapes may be lower.

3

On SLR60 tape drives with MAN. DATE 2802 (July 2002) or higher.

Page 16

Tandberg Data Introduction

1-2 Tandberg SLR Product Line SCSI Functional Specifications

1.2. Overview

Chapter 2

Describes tape streamers in general and the Tandberg SLR

Product Line Tape Drives in particular. The chapter also

describes volume partitioning, the overwrite function,

the usage of fixed and variable length data blocks, the

data buffer system and data compression.

Chapter 3

Gives a description of the SCSI logical characteristics

as implemented by the Tandberg SLR Product Line Tape

Drives.

Chapter 4

Specifies the SCSI Command Descriptor Blocks (CDB) in

general.

Chapter 5

Lists the Status Bytes implemented by the Tandberg SLR

Product Line Tape Drives.

Chapter 6

Describes the SCSI Message system as implemented by the

Tandberg SLR Product Line Tape Drives.

Chapter 7

Specifies the Tandberg SLR Product Line Tape Drives

exception handling in general.

Chapters 8 - 32

Detailed specifications of the SCSI commands.

Page 17

Tandberg Data Introduction

1-3 Tandberg SLR Product Line SCSI Functional Specifications

1.3. Glossary

BOM Beginning Of Medium. The extreme position along the medium

in the direction from the supply-reel, which can be

accessed by the use of a REWIND command.

BOP

Beginning Of Partition. The position at the beginning of the

permissible recording region of a partition. If only one

partition is defined, this position is equivalent to BOM

(see above).

BOT

Beginning Of Tape. Physical marker on the tape marking the

start of the useful area of the tape (located at BOM,

see above).

CDB Command Descriptor Block. The structure used to communicate

commands from an Initiator to a Target.

Compression Block

Group

A group of compressed data recorded as one variable

length block. The Compression Block Group either

contains a number of host-defined logical fixed length

blocks, or a complete or partial host-defined variable

length logical block. The Compression Block Group also

contains a Compression Header as its initial sequence of

data.

Compression

Header

A sequence of uncompressed data at the beginning of each

Compression Block Group. The Compression Header contains

specific information related to this Compression Block

Group.

Disconnect

The action that occurs when a SCSI device releases

control of the SCSI-bus, allowing it to go to the BUS

FREE phase.

EOD End Of Data. A tape format specific end-of-data indication

on the current partition. The recording medium may be

positioned at EOD by reading until the Drive signals an

EOD exception or by issuing a SPACE command with a Space

Code of 3 (Space to End-Of-Data).

EOM

End Of Medium. The extreme position along the medium in

the direction from the take-up-reel, which can be

accessed by the device. This position may be accessed by

the use of a LOAD/UNLOAD command with the EOT-bit set to

one.

EOP End Of Partition. The position at the end of the permissible

recording area of a partition. If only one partition is

defined, this position is equivalent to EOM (see above).

EOT

End Of Tape. Physical marker on the tape marking the end

of the useful area of the tape (located at EOM, see

above).

EW

Early Warning. Physical tape-mark near - but logically

before - EOP (independent of physical direction).

Field

A group of one or more contiguous bits. Fields

containing only one bit are usually referred to as the

XX bit instead of the XX field.

Initiator

SCSI-bus Device issuing SCSI commands to a SCSI Target.

LED

Light Emitting Diode. An indicator on the front of the

Drive.

LEW Logical Early Warning. Simulated EW marker on the last track

on each partition. LEW is moved some distance in front

of the actual EW.

LSB

Least Significant Bit.

LUN

Logical Unit Number.

MLR

Multi Channel Linear Recording.

MSB

Most Significant Bit.

Page 18

Tandberg Data Introduction

1-4 Tandberg SLR Product Line SCSI Functional Specifications

Overlength

The incorrect length condition that exists after

executing a read group command, when the length of the

actual block read exceeds the requested transfer length

in the command descriptor block (CDB).

Page

Several commands use regular parameter structures that

are referred to as pages. These pages are identified

with a value known as a page code.

Parameter

A structure containing one or more fields.

Partition

The entire region of recording and reading paths in a

volume or in a portion of a volume.

Reconnect

The act of re-establishing the physical Initiator/Target

connection. A Target reconnects to an Initiator by

issuing RESELECTION and MESSAGE IN phases after winning

arbitration.

Reserved

The term used for bits, fields and code values that are

set aside for future standardization.

SCSI

Small Computer Systems Interface. Industry standard computer

peripheral interface. Used to connect several devices

via a common data and control bus.

SCSI address

The representation of the unique address (0-7) assigned

to a SCSI device. This address would normally be

assigned and set in the SCSI device during system

initialization.

SCSI ID

The bit-significant representation of the SCSI address

referring to one of the SCSI-bus data lines.

Signal assertion

The act of driving a signal to the true state.

Signal de-assertion

The act of driving a signal to the false state.

SLR

Scaleable Linear Recording.

Status

One byte of information sent from a Target to an

Initiator upon completion of each command.

Third-party

When used in reference to RESERVE or RELEASE commands,

third-party means a reservation made on behalf of

another device.

Target

SCSI-bus Device receiving/executing SCSI commands.

TLA Three Letter Acronym.

Track Set

A logical collection of N physical tracks which are

written or read simultaneously. A track set can be

viewed as a logical track that holds N times as much

data as a physical track and can transfer data N times

as fast as a physical track. A track set may consist of

only a single track, i.e. N = 1.

Underlength

The incorrect length condition that exists after

executing a read group command when the requested

transfer length in the command descriptor block (CDB)

exceeds the length of the actual block read.

Volume

A recording medium together with its physical carrier.

Page 19

Tandberg Data Introduction

1-5 Tandberg SLR Product Line SCSI Functional Specifications

1.4. Additional Reference Documentation

[1] Tandberg Data ASA, “ Tandberg SLR Product Line

Reference Manual” , Revision 6, Publ. No. 90316, December 1999.

[2] American National Standards Institute, “ SCSI-2,

Enhanced Small Computer System Interface” , ANSI

Standard X3.131-1994.

[3] American National Standards Institute, “ SCSI-3,

Primary Commands” , ANSI Working Draft

X3T10/995D, Revision 11a, 28 March 1997.

[4] American National Standards Institute, “ SCSI-3

Stream Device Command Set” , ANSI Working Draft

X3T10/997D, Revision 22, 1-Jan-2000.

[5] American National Standards Institute, “ SCSI-3

Interlocked Protocol” , ANSI Working Draft

X3T10/856D, Revision 10, 31 Mar 1996.

[6] American National Standards Institute, “ SCSI-3

Parallel Interface” , ANSI Working Draft

X3T10/855D, Revision 15a.

American National Standards Institute, “ SCSI-3

Parallel Interface 2” , ANSI Working Draft

X3T10/855D, Revision 20b.

[7] QIC, “ Development Standard For 1/4-inch

Cartridge Tape Drive SCSI-2 Interface” , QIC121, Revision P, 14-Dec-1995.

[8] QIC, “ Adaptive Lossless Data Compression” ,

QIC-154, Revision A, 10-Mar-1994.

[9] QIC, “ Serial Recorded Magnetic Tape Cartridge

For Information Interchange” , QIC-2GB-DC,

Revision B, 10-Mar-1994.

[10] QIC, “ Serial Recorded Magnetic Tape Cartridge

For Information Interchange” , QIC-4GB-DC,

Revision B, 20-Apr-1997.

[11] Tandberg Data ASA, “ Serial Recorded Magnetic

Tape Cartridge For Information Interchange” ,

SLR6 Tape Format, Revision A, 1998.

[12] QIC, “ Serial Recorded Magnetic Tape Cartridge

For Information Interchange” , QIC-5010-DC,

Revision E, 15-Dec-1994.

[13] Tandberg Data ASA, “ Serial Recorded Magnetic

Tape Cartridge For Information Interchange” ,

MLR3 Tape Format, Revision A, 30-Aug-1995.

[14] Tandberg Data ASA, “ Advanced Linear Recording

Format 1” , ALRF-1, Revision B, 22-Apr-1998.

[15] QIC, “ Serial Recorded Magnetic Tape Cartridge

For Information Interchange” , QIC-CRF1,

Revision J, 15 Jun 1995.

[16] Tandberg Data ASA, “ Advanced Linear Recording

Format 2” , ALRF-2, Revision 1. 24-Apr-2000.

[17] Tandberg Data ASA, “ Advanced Linear Recording

Format 6” , ALRF-6, Revision 2.00-Oct-2002

[18] American National Standards Institute, “ SCSI-3

Fast-20” , ANSI Working Draft X3T10/1071D,

Revision 6.

Page 20

Tandberg Data Introduction

1-6 Tandberg SLR Product Line SCSI Functional Specifications

This Page Intentionally Left Blank

Page 21

2-1 Tandberg SLR Product Line SCSI Functional Specifications

2.

About Tape Streamers

2.1. Physical Elements

Tape streamer devices optimize their use in storing or

retrieving user data in a sequential manner. Since

access is sequential, position changes typically take

long time, when compared to direct-access devices like

disks.

The recording medium used with the Drive consists of a

flexible substrate coated with a magnetic material. The

recording medium is wound onto two reels.

Both the supply reel and the take-up reel are

encapsulated into a cartridge. Several standards exist,

covering the construction of cartridges for interchange.

A complete unit composed of the recording medium and its

physical carrier (the cartridge) is called a volume. In

tape streamers like the Tandberg SLR Product Line Tape

Drives, the volumes are removable.

When a volume is inserted it has the attribute of being

loaded or unloaded. Loaded is the state when the

streamer device is capable of executing commands that

cause the medium to be moved (so-called media access

commands). A volume is unloaded when the media access

commands can not be executed (that is when these

commands report CHECK CONDITION status and a NOT READY

sense key).

Not Write-Protected

Write-Protected

The write-protected state determines

whether an Initiator may or may not

write information on a volume. This

attribute is controlled by the user of

the volume through the SAFE-switch on

the cartridges.

The recording medium has two physical

attributes called Beginning-Of-Tap

e

(BOT) and End-Of-Tape (EOT). BOT is at

the end of the medium that is attached

to the take-up reel. EOT is at the end

of the medium that is attached to the

supply reel.

2.2. Data Storage Characteristics

Serpentine

Recording Method

The position on the medium where a pattern of recorded

signal may be written by one write component is called a

track or track set which may consist of either one, two

or four tracks, depending on the tape format used. On a

new volume, recording of a track set begins after

mounting the volume and then by moving the tape from BOT

toward EOT. When EOT is approached, the direction of

recording is reversed and the Drive starts recording a

track set from EOT towards BOT. This process repeats the

number of times necessary to record all track sets. The

total number of track sets depends on the tape format

used. This method of recording is called serpentine.

Page 22

Tandberg Data About Tape Streamers

2-2 Tandberg SLR Product Line SCSI Functional Specifications

BO T EO T

BO P

EO P

Figure 2-1: Serpentine Recording

A track set is read in the same sequence as when

writing.

When reading data using a DC9250, SLR5 or SLRtape7

medium, the drive is aided by reference tracks to

position the read/write head accurately.

For the DC9250 and SLR5 media the drive

1

, writing these

tapes from BOT, has to provide the tape with the

required reference bursts during write. The writing and

reading of reference bursts are done automatically by

the drive and are completely transparent to the user.

The reference bursts are pre-recorded on SLRtape7 media.

The reading of reference bursts are done automatically

by the drive and are completely transparent to the user.

On the other hand, SLRtape140, SLRtape100, SLRtape75,

SLRtape60, SLRtape50, SLRtape40, SLR32 and SLRtape24

media have pre-recorded servo tracks, and the reading

and writing of reference bursts are therefore not

required. The servo tracks are used to position the

read/write head both during the read and write

operations. The reader should be aware of this

distinction when meeting the term “ reference bursts”

later in this manual. See [9] – [17] for further

information on reference bursts and servo tracks.

From the Initiators point of view the recording medium

may be looked upon as having a single large continuous

logical track starting with an area called Beginning-Of-

Media (BOM) and ending with an area called End-Of-Media

(EOM). BOM is always on the same side of the volume as

BOT. EOM may be located at the BOT or at the EOT

depending on whether the total number of track sets is

odd or even.

The logical track is split into several areas separated

by markers. At least four parts may be identified:

Beginning-Of-Media End- Of-MediaEarly-Warning AreaRecording Area

BO T L P LEW EW EO T

Figure 2-2: Logical Track Areas

1

Drives covered by this manual can only read DC9250 and SLR5 media.

Page 23

Tandberg Data About Tape Streamers

2-3 Tandberg SLR Product Line SCSI Functional Specifications

Beginning-Of-Media

This area holds no user data. It is used to record a

special reference burst as defined in [9], [10]. This

area starts with the BOT (Beginning Of Tape) tape marker

and ends at the LP (Load Point) tape marker.

Recording Area

This area holds the user data. This area starts with the

LP (Load Point) tape marker and ends at the LEW (Logical

Early Warning) marker.

Early-Warning Area

When writing, the Initiator needs an indication that it

is approaching the end of the Recording-Area. This

position called Logical Early Warning (LEW) is reported

to the Initiator at a position early enough for the

Drive to write out any buffered data to the medium while

still leaving enough room for additional recorded data

or tapemarks. The actual amount of data is user

configurable, see the LEW Position field in Section

14.3.9. This area ends at the EW (Early Warning) tape

marker.

End-Of-Media

This is the short area between the EW (Early Warning)

and the EOT (End-Of-Tape) tape markers. It is usually

possible to complete the writing of a single last frame

between EW and EOT. When this has been done or when EOT

is found, all further write operations are discontinued

even if the there are more data to be written in the

data buffer.

2.3. Partitions Within a Volume

A volume may be split into several mini-volumes called

partitions. Each partition has its own set of beginning

and ending points. Each partition within a volume has

defined its own Beginning-Of-Partition (BOP), RecordingArea, Early-Warning-Area and End-Of-Partition (EOP).

In the first partition (partition zero) on a volume with

n partitions, BOP is identical to BOM. In the last

partition on a volume (partition n-1), EOP is identical

to EOM.

All volumes have a minimum of one partition called

partition zero, or the default partition.

When a volume is mounted (that is inserted into the

Drive and then loaded), the volume is logically

positioned to the beginning of the default partition

(partition zero). This is also true when a LOAD command

(with the Load bit set to one) is executed. When a

REWIND or ERASE command is received in any partition,

the Drive positions to the beginning of the current

partition.

Page 24

Tandberg Data About Tape Streamers

2-4 Tandberg SLR Product Line SCSI Functional Specifications

2.3.1. Partitioning a Volume

Setting up a Medium Partition page and then executing a

MODE SELECT command transferring this page to the Drive

can partition a volume. The table below shows the parts

of the Medium Partition Page(1) that relate to this

procedure. Fields of no interest are marked with

“ XX...XX” .

BYTE BIT 7 6 5 4 3 2 1 0

00

PS

XX Page Code = 11h

01 Parameter Length = 4Eh

02

Maximum Additional Partitions

03

Additional Partitions Defined

04

FDP SDP IDP PSUM

XX XX XX

05 XXXX

06 XXXX

Partition Units

07 XXXX

08

Partition Size Descriptor 0

09

| . . .

|

78

Partition Size Descriptor 35

79

Table 2-1: The Medium Partition Page(1)

Note that the Tandberg SLR Product Line Tape Drives use

the long form of the Medium Partition Page(1). This

means that the Partition Size Descriptor fields are

always present (both in MODE SELECT and MODE SENSE

parameter data).

Note also that the Medium Partition Page(1) is not

savable (the MODE SENSE command returns a Medium

Partition Page(1) where the PS bit is set to zero).

Partitioning a volume is only allowed when the volume is

positioned at BOM (the beginning of partition 0). Note

also that a partition operation may lead to a loss of

all existing data (the Drive runs an erase pass in each

of the existing partitions if the new partitioning is

different from the existing partitioning found on the

medium).

The Tandberg SLR Product Line Tape Drives allow the

Initiator to specify partitioning using two different

methods. The first is the most general. The Initiator

can specify both the number of partitions and their

individual sizes. Using the second method the Initiator

may only specify whether one or two partitions are

requested. When a single partition is requested it will

cover the whole medium. When two partitions are requested the Drive will allocate them fixed sizes (there

will be one large and one small partition).

The Initiator Defined Partitions (IDP) bit is used to

select between the two methods. When the IDP bit is one,

the first method is used (the number and size of

partitions may be specified).

Page 25

Tandberg Data About Tape Streamers

2-5 Tandberg SLR Product Line SCSI Functional Specifications

When the IDP bit is zero, the second method is used. In

this case the FDP bit is used to select one or two fixed

size partitions. This method of using partitions is

often called “ Quick File Access” (QFA).

Regardless of which method is used, executing a MODE

SELECT command where the Medium Partition Page(1) is

included in the parameter list, some form of

partitioning will take place. This means that such a

MODE SELECT command is only accepted at the beginning of

partition 0 (BOP0).

The Partition Size Unit of Measure (PSUM) field defines

the unit of the Partition Size Descriptors. A value of

2 specifies the unit to be MBytes and a value of 3

specifies the unit to be GBytes. MODE SELECT will

ignore this field when the IDP bit is not set. MODE

SENSE will return 2 (MBytes) in this field when the