Page 1

TANDBERG Super DLT

TM

Design & Intergration

Guide

Revision 1 June 2002 - 432588-01

Page 2

SDLT 220 and SDLT 320 Design & Integration Guide

Copyright

Copyright © 2002 by Tandberg Data. All rights reserved.

Document Origination: Oslo, Norway.

Trademarks

Quantum, the Quantum logo, DLTtape, the DLTtape logo, Super DLTtape and the Super DLTtape

logo are trademarks of Quantum Corporation registered in the U.S.A. and other countries. Laser

Guided Magnetic Rec ording (LGMR) and Pivoting Optical Servo (POS) ar e trademarks of

Quantum Corporation.

Other company and product names used in this document are trademar ks, regi ster ed trademar ks, or

service marks of their respective owners.

Legal Disclaimers

The information contained in this document is the exclusive property of Tandberg Data.

Tandberg Data retains its copyright on the information contained herei n in all cases and situations

of usage, including derivative works. The possessor agrees to safeguard this information and to

maintain it in confidenceand not re-publish it in wholeor in part without Tandberg Data’sprior

written consent.

Tandberg Data reserves the right to make changes and improvements to its products, without incurring

any obligation to incorporate such changes or improvements in units previously sold or shipped.

Contact Informat ion

You can request Tandberg Data publications from your Tandberg Data Sales Representativeor

order them directly from Tandberg Data. Telephone numbers and street addresses change frequently;

for the latest, up-to-date contact Tandberg Data, visit:

www.tandberg.com

Telephone numbers, street addresses, time zones, and other pertinent facts are listed in the

Service and Support section of the web site.

Page 3

SDL T 220 and SDLT 320 Design & Integration Guide

Revision History

All revisions made to this document are listed below in chronological order.

Document

Release Date Summary of Chan ges

A April 29, 2002 Initial release.

Page 4

SDLT 220 and SDLT 320 Design & Integration Guide

Page 5

Ta bl e of Contents

CHAPTER 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Purpose and Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Structure of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

For More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Reader Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Tandberg Diagnostics Tools . . . . . . . . .... . . . . . .... . . . . . .... . . . 1-5

CHAPTER 2 General Drive Specifications . . . . . . . . . . . . . . . . 2-1

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SDLT Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SDLT 220/320 Library Tape Drive Interface . . . . . . . . . . . . . . . . . . 2-3

SDLT 220/320 Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Dimensions and Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Positive Engagement Tape Leader Buckling Mechanism . . . . . . . . . 2-9

MTBF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Load and Unload Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Data Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Key Differences Between the SDLT 220 and 320. . . . . . . . . . . . . . 2-11

SDLT 220/320 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Backward-Read Compatibility Transfer Rates . . . . . . . . . . . . . . . . 2-13

Maximum Data Transfer Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Storage Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Page 6

Table of Contents

Recording Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Temperature and Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Air Flow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Storage and Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Altitude. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Particulate Contamination Limits . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Shock and Vibration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Occasional Cleaning of Tape Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Load Time for Cleaning Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Error Reporting (for Cleaning). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

How the Tape Drive Returns Cleaning Status . . . . . . . . . . . . . . 2-24

How TapeAlert Returns Cleaning Status . . . . . . . . . . . . . . . . . . 2-25

Library/Loader Cleaning Error Reporting . . . . . . . . . . . . . . . . . 2-25

SCSI Cleaning Error Reporting . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Front Panel Cleaning Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

CHAPTER 3 Electrical Specifications . . . . . . . . . . . . . . . . . . . . 3-1

Current and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power Supply Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Voltage Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

DC V oltage Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Power Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Supply Transient Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

CHAPTER 4 Thermal Specifications . . . . . . . . . . . . . . . . . . . . . 4-1

Over Temperature Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Air Flow Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Thermal Measurement Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

SDLT 220/320 Thermal Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Temperature Comparison — SDLT 220 versus SDL T 320 . . . . . . . . 4-8

Embedded Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Library Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

CHAPTER 5 Regulatory Requirements. . . . . . . . . . . . . . . . . . . 5-1

Safety Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Safety Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Page 7

Table of Cont ents

Electromagnetic Field Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Electromagnetic Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Electromagnetic Interference Susceptibility . . . . . . . . . . . . . . . . . . . 5-3

Conducted Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Radiated Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Susceptibility and ESD Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Acoustic Noise Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

CHAPTER 6 SCSI and Controller Interface Specification . . . . . 6-1

SCSI Interface Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Setting the SCSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Hardware (Connectors). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

SCSI Stub Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

SCSI Cable Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Power On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

SCSI Command Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

SCSI and Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Loader/Library Controller Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Configuring the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

TERMPWR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Wide SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

CHAPTER 7 Updating the Firmware. . . . . . . . . . . . . . . . . . . . . 7-1

Updating the Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Update the Firmware Using the SCSI Bus. . . . . . . . . . . . . . . . . . . . . 7-1

Making a FUP/CUP Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Using a CUP/FUP Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Code Up d a t e U si n g the L ibrary Tape Drive In t er f a ce. . . . . . . . . . . . . . . 7-4

Firmware (Code) Update Troubleshooting . . . . . . . . . . . . . . . . . . . . 7-5

CHAPTER 8 Insertion and Extraction Guidelines . . . . . . . . . . . 8-1

Applicable Library Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Unloading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Loading a Tape Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Load Forces, Placement, and Timing. . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Page 8

Table of Contents

Insertion Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Cartridge Insertion Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Insertion Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Hold Tim e fo r L o ad in g (D w el l Ti me) . . . . . . . . . . . . . . . . . . . . . 8-4

Debounce Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Initialization Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Unloading a Tape Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Unload Forces, Placement, and Timing . . . . . . . . . . . . . . . . . . . . . . . 8-6

Eject Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Cartridge Extraction Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Extraction Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Page 9

List of T ables

CHAPTER 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-1. Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

CHAPTER 2 General Drive Specifications . . . . . . . . . . . . . . . . 2-1

Table 2-1. SDLT 220/ 320 P hysical Dimensions and Shipping Weight. . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-2. Proper and Acceptable Tape Drive Orientations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 2-3. Load and Unload Cycles (Maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Table 2-4. Data Transfer Error Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Table 2-5. A Comparison of SDLT 220 and SDLT 320 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 2-6. SDLT 220/320 P erformance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Table 2-7. Backward Read Compatibility ( BRC) Transfer Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Table 2-8. Maximum Data Transfer Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Table 2-9. Super DLTtape I Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Table 2-10. DLTtape Media Operating and Storage Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Table 2-11. Temperature and Humidity Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Table 2-12. Drive Storage and Shipment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Table 2-13. Particulate Contamination Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Table 2-14. Non-Operating Shock Specifications (Unpackaged) . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Table 2-15. Non-Operating Shock Specifications (Packaged, Drop) . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Table 2-16. Non-Operating Vibration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Table 2-17. Operating Shock and Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

CHAPTER 3 Electrical Specifications . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-1. Current and Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-2. DC Voltage Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

CHAPTER 4 Thermal Specifications. . . . . . . . . . . . . . . . . . . . . 4-1

Page 10

List of Tables

Ta ble 4-1. SDLT 220/320 Steady State Temperatures: Embed ded Bezel . . . . . . . . . . . . . . . . . . . . . . .4-7

Ta ble 4-2. SDLT 220/320 Steady State Temperatures: Library Bezel. . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Ta ble 4-3. SDLT 320 vers us S D LT 220 with Embedded Bezel, Compression On (2:1). . . . . . . . . . . .4-9

Ta ble 4-4. SDLT 320 vers us S D LT 220 with Library Bezel, Compression On (2:1) . . . . . . . . . . . . .4-10

CHAPTER 5 Regulatory Requirements. . . . . . . . . . . . . . . . . . . 5-1

Table 5-1. EMI Regulations and Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Table 5-2. Conducted Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Table 5-3. Radiated Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Table 5-4. Radiated, Magnetic Radiated, and Conducted Susceptibility. . . . . . . . . . . . . . . . . . . . . . . .5-5

Table 5-5. Electrostatic Discharge (ESD) Failure Level Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Table 5-6. Acoustic Noise Emissions, Nominal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

CHAPTER 6 SCSI and Controller Interface Specification . . . . . 6-1

Table 6-1. SCSI ID Address Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Table 6-2. SCSI Interface Stub Lengths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Table 6-3. Indicator Pattern During POST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Table 6-4. SCSI Command Timeout Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Table 6-5. 8-Pin Loader Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Ta ble 6-6. MSE and SE Mode SCSI Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Table 6-7. MSE LVD Mode SCSI Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Ta ble 6-8. HVD Mode SCSI Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Table 6-9. 4-Pin Power Connector Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

CHAPTER 7 Updating the Firmware . . . . . . . . . . . . . . . . . . . . . 7-1

CHAPTER 8 Insertion and Extraction Guidelines . . . . . . . . . . . 8-1

Page 11

List of Figures

CHAPTER 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CHAPTER 2 General Drive Specifications . . . . . . . . . . . . . . . . 2-1

Figure 2-1. SDLT 220/320 Drive System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2. SDLT 220/320 Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Figure 2-3. Combination Side and Bottom View of SDLT Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-4. Rear View of SDLT 220/320 Tape Drive (Dimensions) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-5. Rear View of SDLT 220/320 Tape Drive (Connectors). . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-6. Front Views of SDL T 220/320 Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-7. Front Panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

CHAPTER 3 Electrical Specifications . . . . . . . . . . . . . . . . . . . . 3-1

CHAPTER 4 Thermal Specifications. . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-1. Library Bezel—Where to Measure Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2. ICM Board Thermal Measurement Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3. HIM Board Thermal Measurement Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-4. Tape Path Thermal Measurement Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

CHAPTER 5 Regulatory Requirements. . . . . . . . . . . . . . . . . . . 5-1

CHAPTER 6 SCSI and Controller Interface Specification. . . . . 6-1

Figure 6-1. Connectors on the Ba ck Pane l. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Figure 6-2. Back Panel Connector Locations (Drawn to Scale). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Page 12

List of Figures

Figure 6-3. Loader Connector

(Internal Version Shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Figure 6-4. TERMPWR Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

CHAPTER 7 Updating the Firmware. . . . . . . . . . . . . . . . . . . . . 7-1

CHAPTER 8 Insertion and Extraction Guidelines . . . . . . . . . . . 8-1

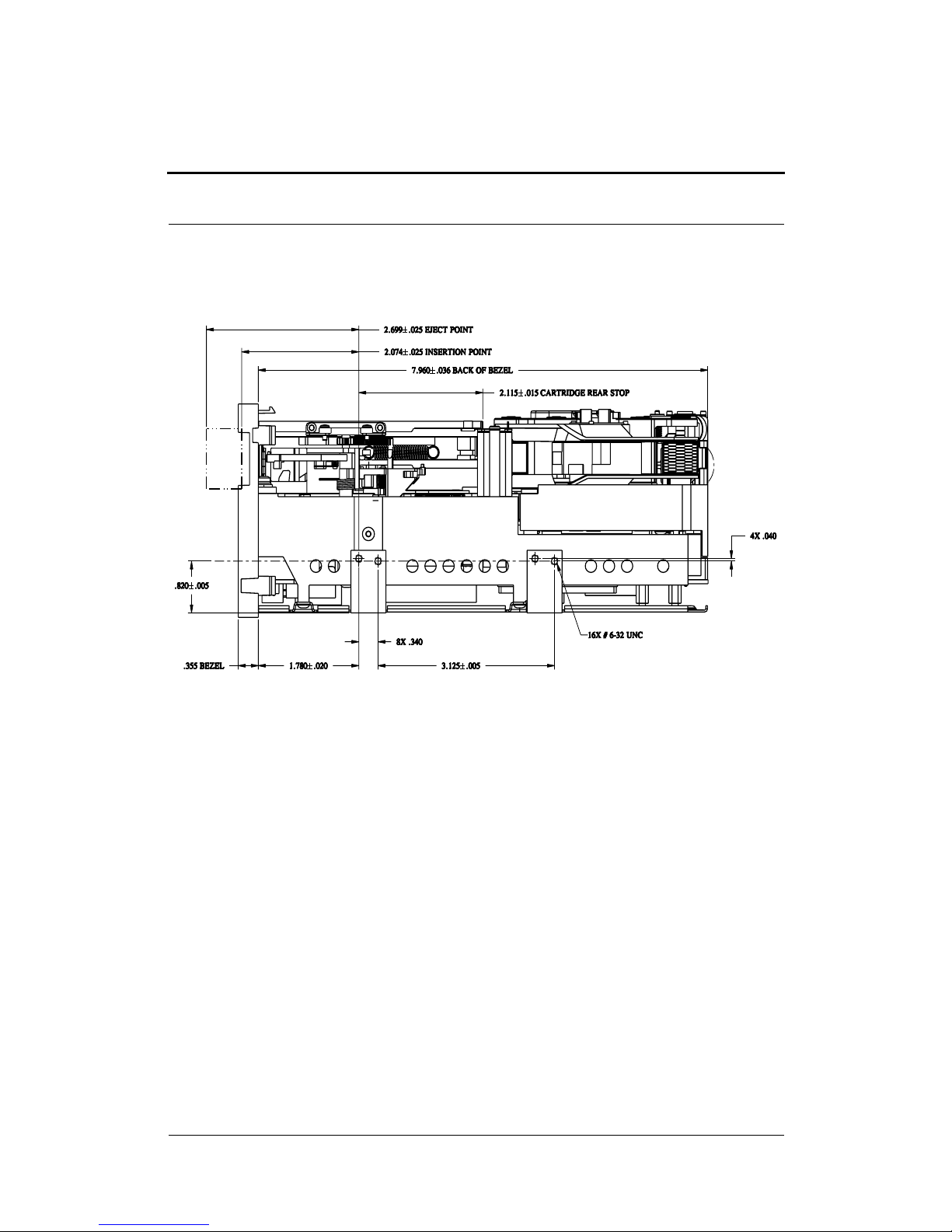

Figure 8-1. Tolerances for Cartridge Insertion and Extraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Page 13

CHAPTER 1 Introduction

1.1 Purpose and Scope

The purpose of this design and integration guide is to provide detailed information

that may be helpful to refer to as you integrate the SDLT 220 and SDLT 320

cartridge tape systems into larger systems. The SDLT 220 and SDLT 320 cartridge

tape systems, subsequently referred to in this document as SDLT 220/320, have

many characteristics in common, enabling both sets of information to be presented

in a single document.

This guide is intended mainly for customers who will be integrating the SDL T

drive into their products. Technical knowledge on the part of the user is assumed.

NOTE: Except where clearly noted, the information in this

document applies to both models of the tape drive.

Page 14

CHAPTER 1: Int roduction

1.2 Referenced Documents

• Super DLTtape™ Interactive Library Interface Specification

• Super DLT Product Manual (432589 rev. 01 or later)

• Super DLT SCSI Interface Guide (432614 rev. 01 or later)

1.3 Related Documents

• DLT Script Tool User Guide

Page 15

CHAPTER 1: I n troduction

1.4 Structure of this Manual

• Chapter 1, Introduction, is the chapter you are currently reading.

• Chapter 2, General Drive Specifications, provides a basic product

description of the SDLT 220/320 tape drive, and the drive specifications such

as dimensions and tolerances, functional, physical vibration and shock, and

environmental requirements.

• Chapter 3, Electrical Specifications, includes the power supply

requirements.

• Chapter 4, Thermal Specifications, includes the temperatur e measur em ent

locations and the thermal profile for the drive.

• Chapter 5, Regulatory Requirements, in cludes safety (UL, CSA, EN/IEC,

“GS Mark”) standards, EMI (EEC Direct i ve, VCCI Class B, BSMI Class A,

FCC MDOC, AS/NZS, IECS), and acoustic noise emissions.

• Chapter 6, SCSI and Controller Interface Specification, is a chapter

providing information that “goes beyond” information in the basic SCSI

specification. This chapter also provides information about the optional

connection to a loader or library system.

• Chapter 7, Updating the Firmware, describes the two processes for

updating the firmware inside the drives.

• Chapter 8, Insertion and Extraction Guidelines, includes the cartridge

insertion and ejection guidelines.

Page 16

CHAPTER 1: I nt roduction

1.5 Conventions

This manual uses the following conventions to designate specific elements:

1.6 For More Information

The web site http://www.superdlttape.com includes much valuable information

about SDLT systems; or to locate very specific product-related information, visit

http://www.tandberg.com

Table 1-1. Typographical Conventions

Element Convention Example

Commands

Uppercase (unless casesensitive)

FORMAT UNIT

Messages Uppercase

INVALID PRODUCT

NUMBER

Hexadecima l N otation

Number followed by

lowercase h

25h

Binary Notation

Number followed by

lowercase b

101b

Decimal Notation Number without su ffix 512

Acronyms Uppercase POST

Abbreviations

Lowercase, except w h ere

standard usage requ ires

uppercase

Mb (megabits)

MB (meg a by t es )

Page 17

CHAPTER 1: I n troduction

1.7 Reader Comments

Tandberg Data is committed to providing the best products and service. We

We encourage your comments, suggestions, and corrections for this manual.

Please send all comments to:

Tandberg Data ASA

P.O. Box 134 Kjelsås

N-0411 Oslo

Norway

1.8 Tandberg Diagnostics Tools

Tandberg frequently provides new and updated tools to use with its tape drives. For

For example:

All tools are available on Tandberg’s web site, http://www.tandberg.com. Follow

the path Service and Support -> DLTtape Drivers and Software and look at the list

to see what is available.

SDLT Update Allows you to update a drive’s firmware

(using the SCSI bus), or to create a code

update (CUP/FUP) tape for an SDLT drive.

GS Link Allows you to quickly diagnose the integrity

of the drive using an infrared (wireless)

communication connector located on the front

panel of the tape drive.

QS Link A cross-platform tool that allows you to

perform functions such as updating firmware,

editing mode pages, viewing log pages,

viewing and editing EEPROM parameters.

Page 18

CHAPTER 1: I nt roduction

Page 19

2.1 Product Description

Figure 2-1. SDLT 220/320 Drive System

Internal drive External drive

The Tandberg Super DLTtape™ System is a highly scalable platform designed

for multiple product generations. It is a follow-on to the DLTtape product family,

which is the industry standard for mid-range UNIX and NT system backup and

archive applications. The SDLT tape system consists of the drive and the tape

cartridge; the system is available in either a built-in (internal) model or a tabletop

model.

CHAPTER 2 General Drive

Specifications

Page 20

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.2 SDLT Product Features

SDLT tape drives offer the following product features:

• A streaming tape drive that uses half-inch wide Digital Linear Tape (DLT)

media.

• Standard 5.25-inch full-height form factor to simplify integration into system

and tape library solutions.

• The SDLT architecture builds on the DLT legacy by offering backward

compatibility: data backed up today using the DLT 8000, DLT 7000, DLT

4000, and DLT 1/VS80 (Benchmark) systems will be retrievable in the f uture

using SDLT-based systems with DLT IV type media .

• Global Storage Link (GS Link) — An infrared (wireless) interface that

provides a wireless remote testing base allowing customers and integrators to

access system diagnostic information from the front of the tape system.

• When needed, the SDLT 320 can be operated in a mode that is completely

compatible with that of the SDLT 220.

• Handle-free load and unload feature to increase ease of use.

• One of three possible SCSI implementations ; these three imple menta tions are

listed in “SCSI Interface Type” on page 6-1.

Page 21

CHAPTER 2: Ge n eral Drive Spe ci fications

2.2.1 SDLT 220/320 Lib ra ry Tape Drive Inter f ace

The library tape drive interface (for SDLT drives) is an RS-422 serial port set to

9600 baud, 8 bits per character, no parity, and 2 stop bits. All data sent to or from

the library tape drive interface consists of bit-wise encoded hex values.

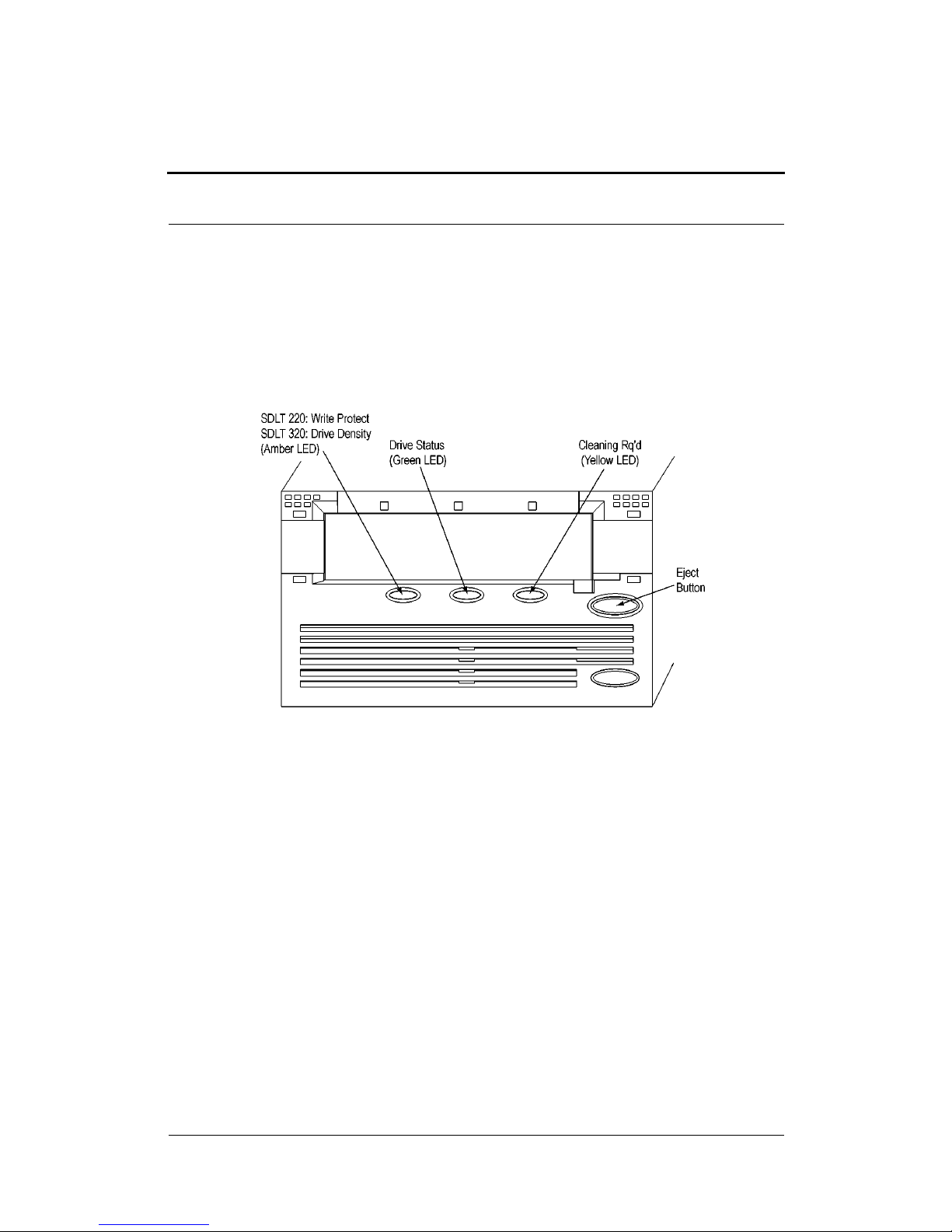

2.2.2 SDLT 220/320 Front Panel LEDs

Figure 2-2 shows the color, position, and meaning (interpretation) of the three

front panel LEDs.

Figure 2-2. SDLT 220/320 Front Panel LEDs

Page 22

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.3 Dimensions and Tolerances

The following figures show the physical specifications of the SDL T 220/3220 tape

drive.

Figure 2-3. Combination Side and Bottom V iew of SDLT Tape Drive

NOTE: Tape cartridge insertion and ejection distances are shown

in Figure 8-1, “Tole ranc e s for Cartridge Insertion and

Extraction,” on page 8-6.

Page 23

CHAPTER 2: Ge n eral Drive Spe ci fications

Figure 2-4. Rear V iew of SDLT 220/320 Tape Drive (Dimensions )

Figure 2-5. Rear View of SDLT 220/320 Tape Drive (Connectors)

Page 24

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

Figure 2-6. Front Views of SDLT 220/320 Tape Drive

Page 25

CHAPTER 2: Ge n eral Drive Spe ci fications

2.4 Physical Dimensions

Table 2-1 provides physical dimensions for the SDLT tape system. Table 2-2

shows acceptable operating orientations for the SDLT tape system.

Tabl e 2-1. SDLT 220/320 Physical Dimensions and Shipping Weight

Description Internal Version Tabletop Version

Height

82.55 mm (3.25 in) without fr ont bezel;

86.36 mm (3.40 in) with front bezel.

160.02 mm (6.30 in)

Width

146.05 mm (5.75 in) behind front bezel;

148.34 mm (5.84 in) with front bez el.

175.26 mm (6.9 in)

Depth

203.20 mm (8.00 in) m easured f rom back of fro nt

bezel; 212.09 mm (8.35 in) including front bezel.

325.12 mm (12.8 in)

W eight* 2.38 kg (5 lbs. 4 oz) 6.27 kg (13 lbs. 13 oz)

Shipping

Weight*

3.77 kg (8 lbs. 5 oz) 9.90 kg (21 lbs. 13 oz)

* Weights de pend on configuration. The packaging may change depending on the shi pping weight.

Note: Mounting hole pattern for the bottom and sides of the system is indu stry standard.

Page 26

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

Tabl e 2-2. Proper and Acceptable Tape Drive Orientations

Orientation Looks Like This

Typical (Top Side Up)

Left Side Down

Right Side Down

Page 27

CHAPTER 2: Ge n eral Drive Spe ci fications

2.5 Reliability

Tandberg Data and its employees and suppliers are committed to providing quality

products. The SDLT tape drive system is a very reliable electromechanical device.

2.5.1 Positive Engagement Tape Leader Buckling

Mechanism

This buckling mechanism is responsible for engaging the tape leaders upon

cartridge load and disengaging them upon cartridge unload. The SDLT tape

buckling mechanism has been designed to work with the new leaders of the SDLT

tape drive design as well as the leaders of the previous DLT drive design, allowing

backward-read compatibility of DLTtape IV cartridges in the SDLT tape system.

Component level tests of buckle arm components have shown at least 250,000

cycles on an SDLT drive without failure, breakage, or binding; this includes the

take-up leader, the supply leader, and the media itself.

2.5.2 MTBF

Mean time between failures (MTBF) for the overall tape system is projected to be

250,000 hours. Head life is a minimum of 30,000 tape motion hours and an

average of 50,000 tape motion hours. Media durability is 1,000,000 passes.

NOTE: Tandberg Data does not warrant that predicted

MTBF is representative of any particula r unit ins ta lled for

customer use. Actual figures vary from unit to unit.

Page 28

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.5. 3 Load and Unl o ad Cycles

Load and unload cycles are rated at 15,000 for the cartridge itself. Table 2-3 shows

the number of load and unload cycles and tape insertions an SDLT drive can

perform before it needs to be replaced.

2.5.4 Data Integrity

SDLT data transfer errors are extremely rare ; data integrity for the overall tape

system is shown in Table 2-4.

Tabl e 2-3. Load and Unlo ad Cycl es (M axi mu m )

SDLT 220 SDLT 320

Load/unload cycles 100,000 100,000

Tape insertions* 100,000 100,000

* An insertion is wh en a tape is insert ed into the receiver, loaded to BOT, and unloaded.

Tabl e 2-4. Data Transfer Error Rates

Error Type Frequency

Error Rates Recoverable READ

<1 error in 10

6

bytes read

Detected, Unrecoverable READ

<1 error in 10

17

bits read

Undetected READ

<1 error in 10

27

bits read

Rewrite errors

<5 per 10

6

bytes written

Page 29

CHAPTER 2: Ge n eral Drive Spe ci fications

2.6 Functional Specifications

2.6.1 Key Differences Between the SDL T 220 and 320

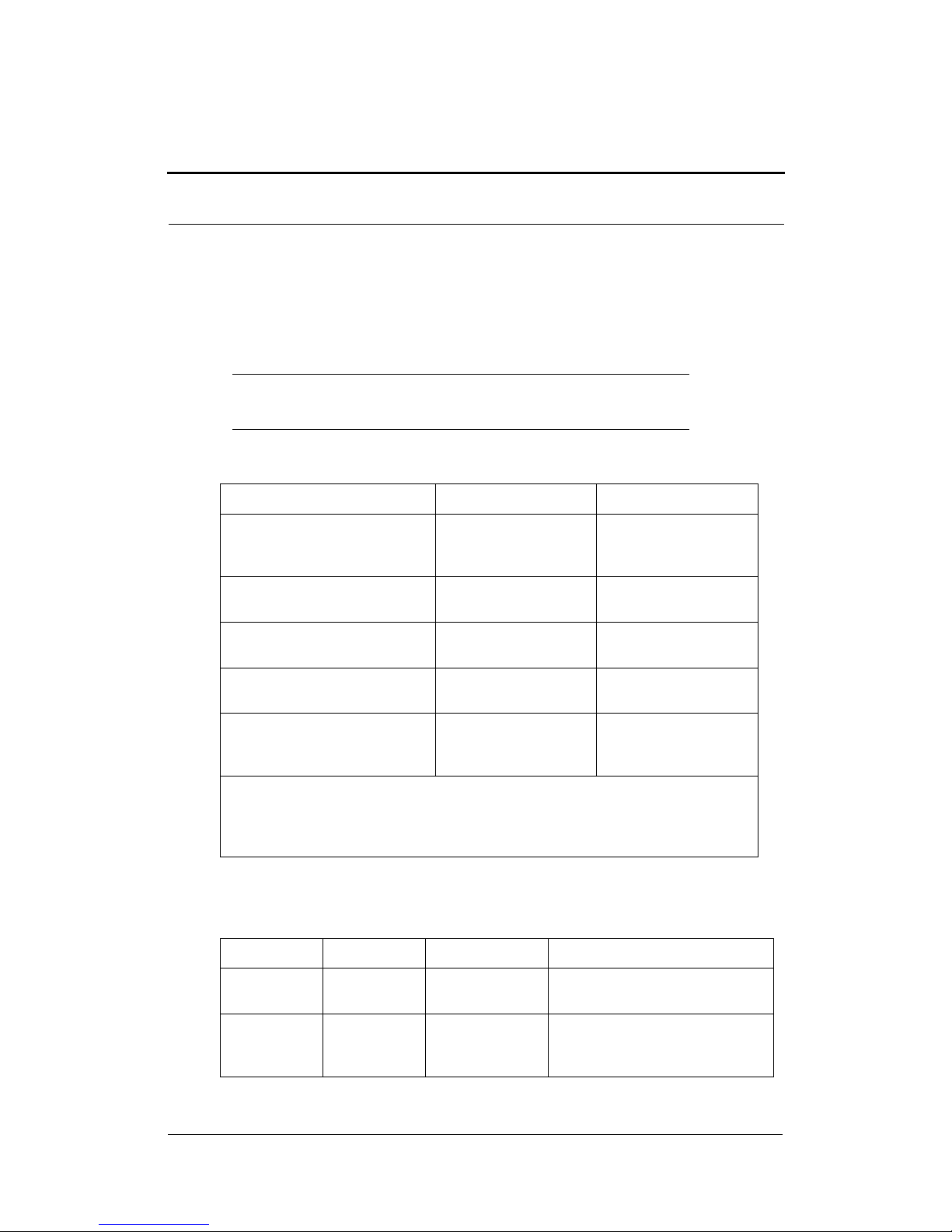

Table 2-5 compar es important features in the SDLT 220 and SDLT 320 products.

Tabl e 2-5. A Comparison of SDLT 220 and SDL T 320 Features

Parameter SDLT 220 SDLT 320

Capacity

Compressed

‡

Uncompressed

220 GB

110 GB

320 GB

160 GB

Data Transfer Rate

Compressed

‡

Uncompressed

22 MB/ s

11 MB/s

32 MB/s

16 MB/s

Media Compatibility SDLT Tape I

DLT Tape IV (Read Only)

DLT 1 by Benchmark:

TRS13 Model (Read Only)

SDLT Tape I

DLT Tape IV (Read Only)

DLT 1 by Benchmark

(Read Only)

‡ The compression rates shown assume an industry standard 2:1 compression ratio. Actual co mpression ratios

achieved depend on the redundancy of data files being recorded.

Reliability

MTBF

Media Durability

Warranty

250,000 Power On Hrs

1,000,000 passes*

3 years

250,000 Power On Hrs

1,000,000 passes*

3 years

* A media pas s is defined as movement of the tape head over the surface of the media (in either dir ection).

Miscellaneous Product Features

Tape Speed 116 ip s 122 ips

Linear Density 133 Kbpi 193 Kbpi

Cache Siz e 32 MB 64 MB

Interfa c es Availab le

Ultra 2 SCSI, LVD

Ultra 2 SCSI, HVD

Ultra 2 SCSI, LVD

Ultra 2 SCSI, HVD

Page 30

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.6.2 SDLT 220/320 Performan ce D ata

Table 2-6 provides performance data for the SDLT tape system. Note: For a

comparison of SDLT 220/320 storage capacities, refer to Section 2.6.1, “Key

Differences Between the SDL T 220 and 320” on page 2-11.

Tabl e 2-6. SDLT 220/320 Performance Data

Feature SDLT 220 SDLT 320

Drive Read / Write

Transf er R a te*

11 MB/second, native 16 MB/second, native

Tracks

56 logical trac ks;

448 physical track s

Same

Track Density 1058 tracks per inch (tpi) Same

Linear Bit Density 133 Kbits per inch (bpi) 193 Kbits per inch (bpi)

Read / Write Tape Speed 116 inches per second (ips) 122 inches per second (ips)

Rewind Tape Speed 160 ips Same

Linear Search Tape Speed 160 ips Same

A verage Rewind Time 69 seconds Same

Maximum Rewind Time 140 seconds Same

Average Access Time

(from BOT)

70 seconds Same

Maximum Access Time

(from BOT)

142 seconds Same

Load to BOT

12 seconds (typical)

40 seconds (unformatted tape)

Same

Unload from BOT 12 seconds Same

Nominal Tape Tension

Stationary = 3.0 ± 0.5 oz

Operating Speed = 3.5 ± 0.5 oz

Same

* Depending on data type and SCSI bus limitations /system configuration.

Note: Data is typical; times may be longer if error recovery time is needed.

Page 31

CHAPTER 2: Ge n eral Drive Spe ci fications

2.6.3 Backward- Read Compa tibi lit y Transf er R at es

Both the SDLT 220 and SDLT 320 drives feature an optional backward-read

compatibility (BRC) mode. W hen in BR C mod e, the drive s are capa ble of rea ding

DLTtape IV tapes with DLT4000, DLT7000, DLT8000, and DLT 1 formats. The

BRC transfer rates for the SDLT drive are listed in Table 2-7.

Tabl e 2-7. Backward Read Compatibility (BRC) Transfer Rates

Format Cartridge Type Native Capacity

(GB)

Native Read

Tr ansfer Rate

(MB/second)

SDLT 320 SDLT I 160 16.0

SDLT 220 SDLT I 110 11.0

DLT 8000 DLT IV 40 4.0

DLT 7000 DLT IV 35 3.5

DLT 4000 DLT IV 20 1.5

DLT 1 (Benchmark) DLT IV 40 3.0

Notes:

• Transfer rates quoted are nominal, measured reading uncompressed data.

• Non-SDLT drives will eject a cartridge written in SDLT 320 format.

• The SDLT 320 can read and write the SDLT 220 format at the native SDLT 220 transfer rate of

11.0 MB/sec.

Page 32

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.6.4 Maximum Data Transfer Rat e

The maximum sustained (and burst) data transfer rates for SDLT drives are shown

in Table 2-8.

NOTE: Cable lengths and cable type can limit attainable transfer

rate; for details, refer to “SCSI Cable Length” on page 6-5.

2.6.5 Storage Capacity

For a comparison of SDL T 220/320 storage capacities, refer to “Key Differences

Between the SDLT 220 and 320” on page 2-11.

Tabl e 2-8. Maximum Data Tr ansfer Rates

SDLT 220

Sustained

SDL T 220

Burst

Max*

SDLT 320

Sustained

SDL T 320

Burst

Max*

Configu

ration

Native

Compressed‡ Native

Compressed‡

HVD

(Ultra 1

SCSI)

Narrow 11 MB/sec 20 MB/sec 20 MB/sec 16 MB/s ec 20 MB/sec 20 MB/sec

Wide 11 MB/sec 22 MB/sec 40 MB/sec 16 MB/sec 32 MB/s ec 40 MB/sec

LVD

(Ultra 2

SCSI)

Narrow 11 MB/sec 22 MB/sec 40 MB/sec 16 MB/s ec 32 MB/sec 40 MB/sec

Wide 11 MB/sec 22 MB/sec 80 MB/sec 16 MB/sec 32 MB/s ec 80 MB/sec

* Burst speeds are limi ted by the SCSI bus itself, not the design of SDLT 220/320 or SDLTtape.

‡ The compression rates shown assume an industry standard 2:1 compression ratio. Actual co mpression ratios

achieved depend on the redundancy of data files being recorded.

Page 33

CHAPTER 2: Ge n eral Drive Spe ci fications

2.6.6 Recording Media Specifications

The following tables provide specifications for Super DLTtape I media. Basic

media specifications for the Super DLTtape I are shown in Table 2-9. Operating,

storage, and shipping environment limits for the DLTtape IV cartridges are shown

in Table 2-10.

Tabl e 2-9. Super DLTtape I Media Specifications

Description Specifications

Width 0.5 in.

Magnetic Coating 300 nm metal particle

Length 1800 feet (1765 feet usable)

Coercivity 1800 Oe

Cartridge Dimensions 4.1 in x 4.1 in x 1.0 in

Shelf Life 30 years min. @ 20°C & 40% RH (non-condensing)

Usage 1,000,000 passes (typical office/computer environment)

Cartridge Housing Color Green

Page 34

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.7 Environmental Requirements

The SDLT tape drive operates in environments that include general offices and

workspaces with systems capable of maintaining standard comfort levels.

The following sections provide the operating, non-operating, storage and shipping

environmental specifications for the SDLT tape systems (both the internal and the

shoebox configurations). For long-term trouble-free operation, it is strongly

recommended that DLTtape systems be used in a clean, smoke-free environment.

Tabl e 2-10. DLTtape Media Operating and Sto rage Limi ts

Operating

Conditions

Temperature 10° to 40°C (50° to 104°F)

Relative Humidity 20% to 80% (non-condensing)

Storage

Conditions

With Data: Without Data:

Temperature 18° to 28°C (64° to 82°F) 16° to 32°C (66° to 89°F)

Relative Humidity 40% to 60% (non-condensing) 20% to 80% (non-condensi ng)

Shipping C onditions

Temperature -17°C to 49°C (0°F to 120°F)

Relative Humidity 20 to 80% (non-condensing)

Maximum Wet Bulb

Temperature

26°C (79°F)

Maximum Dew Point 2°C (36°F)

Page 35

CHAPTER 2: Ge n eral Drive Spe ci fications

2.7.1 Temperature and Hu midity

The ambient operating environment for the tape drive may not exceed the limits

shown in Table 2-11. (The specifications shown in the table are valid for both the

internal and tabletop tape drives.)

2.7.2 Air Flow Requirements

Adequate air flow must be provided for the internal unit to dissipate the heat

resulting from drive operation (see CHAPTER 4, “Thermal Specifications” for

more details about temperatures inside the drive, and illustrations showing where

air flow and various temperatures are measured). The air flow must be sufficient to

keep the tape path temperature below 52°C.

NOTE: It is important to realize that the amount of air flow

provided for the tape drive determines the maximum

ambient temperature in which the drive can operate.

Tabl e 2-11. Temperature and Humidity Specification

Specification Operating Limits

Non-Operating Limits

(Power On ; No Tape

Loaded)

Wet Bulb Temperature 25°C (77°F) 25°C (77°F)

Dry Bulb Temperature

Range

10°C to 40°C (50°F to 104°F) 10°C to 4 0 °C (50°F to 104°F)

Temperature Gradient 11°C (20°F) / hour (across range) 15°C (27°F) / hour (across range)

Relative Humidity 20% to 80% (non-condensing) 10% to 90% (non-condensing)

Humidity Gradient 10% / hour 10% / hour

Page 36

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.7.3 Storage and Shipment

The ambient storage and shipment environment for the tape drive may not exceed

the limits shown in Table 2-12. (The specifications shown in the table are valid for

both the internal and tabletop tape drives.)

2.7.4 Altitude

Both the internal and tabletop tape drives operate in normal pressures from –500 to

10,000 feet when operated within the ambient operating environments specified in

“T emperature and Humidity” on page 2-17.

The drive will operate to 30,000 feet for temperatures within 15

± 5 °C.

Tabl e 2-12. Drive Storage and Shipment Specifications

Description Storage (Unpacked or

Packed)

Shipping

Wet Bulb Temperature 46°C (114°F) 46°C (114°F)

Dry Bulb Temperature -40°C to 66°C (-40°F to 150°F) -40°C to 66°C (-40°F to 150°F)

Temperature Gradient 20°C (36°F) / hour (across range) 20°C (36°F) / hour (across range)

Relative Humidity 10 to 95% (non-condensing) 10 to 95% (non-condensing)

Humidity Gradient 10% / hour 10% / hour

* Note that these specifications apply to the tape driv e only. Media specifications are listed in “Recording

Media Specifications” on page 2-15.

Page 37

CHAPTER 2: Ge n eral Drive Spe ci fications

2.7.5 Particulate Contamination Limits

The ambient operating environment for the tape drive may not exceed the

particulate counts shown in Table 2-13.

Tabl e 2-13. Particulate Contamination Limits

Particle Size

(microns)

Number of Part ic les ≥

Particle Size pe r

Cubic Meter

Num b er of Particles ≥

Particle Size per

Cubic Foot

0.1

8.8 x 10

7

2.5 x 10

6

0.5

3.5 x 10

7

1.0 x 10

6

5.0

2.5 x 10

5

7.0 x 10

3

Page 38

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.8 Shock and Vibration Specifications

The following tables provide non-operating and operating shock and vibration

specifications for the SDLT system.

Tabl e 2-14. Non-Operating Shock Specifications ( Unpackaged)

Shock (Un packaged)

Pulse Shape

Square wave ½ sine pulse

Peak Acceleration 40 G 140 G

Duration 10 ms (180 inches/second) 2 ms

Applicat ion X,Y,Z axes, tw ice in each axis (once in each direction)

Tabl e 2-15. Non-Operating Shock Specifications ( Packaged, Drop)

Shock (Pack a ge d,

Drop)

Height

of Drop

Number

of Drops

Package Weight

Drop

42 inches

36 inches

16 drops total

16 drops total

0 lbs. < package weight

≤ 20 lbs.

20 lbs. < package weight

≤ 50 lbs.

Page 39

CHAPTER 2: Ge n eral Drive Spe ci fications

Tabl e 2-16. Non-Operating Vibration Specifications

Vibration (Unpackaged)

Type

Sine Sweep

Frequency Range 5 - 500 - 5 Hz Upward and downward sweep

Acceleration Level

0.02" DA

1.0 G

Between 5 and 31 Hz (crossover)

Between 31 and 500 Hz (crossover)

Application X,Y,Z axes Sweep rate = ½ octave /minute

Type Random

Frequency Range 10 - 500 Hz

Acceleration Level 2.0 G

PSD Envelope

0.008 G

2

/Hz

Application X,Y,Z axes Sweep rate = 60 minutes / axis

Vibration (Packaged)

Type

Random

Frequency Range

Truck Prof ile* (0.5 Grms)

Air Profile* (1.0 Grms)

Application

X,Y,Z axes (30 minutes, each profile and each axis, for a total of 3

hours)

Type

Sine, Sweep, and Dwell

Frequency Range 5 - 150 - 5 Hz ; 0.5 octave /minute, 0.5 G

Application

X,Y,Z axes; dwell at lowest resonant frequency in axis for 30

minutes.

Additional 30 minutes for each additional resonance; up to 4

resonances total.

* Air and truck profiles ar e sp ec ified in ASTM D4728, Standard Test Method for Random

Vibration Testing of Shipping Containers.

Page 40

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

Tabl e 2-17. Operating Shock and Vibration Specifications

Shock

Pulse Shape

½ sine pulse

Peak Acceleration 10 G

Duration 10 ms

Application X,Y,Z axes, twice in each axis (on ce in each direc tion)

Vibration

Type

Sine Sweep

Frequency Range 5 - 500 - 5 Hz Upward and downward sweep

Acceleration Level

0.25 G

0.010" DA

Between 22 and 500 Hz

Between 5 and 22 Hz (crossover)

Application X,Y,Z axes Sweep rate = 1.0 octave per minute

Page 41

CHAPTER 2: Ge n eral Drive Spe ci fications

2.9 Occasional Cleaning of Tape Head

SDLT uses a built-in tape cleaning algorithm in conjunction with a cleaning tape.

The SDLT cleaning tape is housed in a plastic case, and is light gray in color.

Cleaning cartridges expire after 20 cleaning cycles.

A yellow LED (light) located on the front bezel of the tape drive indicates when

cleaning is needed; the location of this LED (and other front bezel LEDs) is shown

in Figure 2-7 on page 2-26.

NOTE: The tape cleaning algorithm is not used for the BRC

(backward read compatible) head; this head style does not

need cleaning.

2.9.1 Load Time for Cleaning Cartridge

Load (cycle) times for SDLT cleaning cartridges are as follows; these times are

accurate ± 20 seconds:

Shortest load time (1st pass of cleaning cartridge): 2 min. 55 sec.

Longest load time (20th pass of cleaning cartridge): 10 min. 20 sec.

“Expired” load time (expired cleaning tape): 4 min. 30 sec.

On the last pass, the cleaning process stops, the tape is rewound, but the cartridge

is not ejected. If the tape is loade d again after the 20th pas s, it winds a ll the wa y to

the end of the cartridge and back again without performing the cleaning sequence;

the tape does not eject.

C

AUTION: Never use a DLT cleaning tape in an SDLT drive; DLT

cleaning tapes are incompatible with the SDLT heads.

Page 42

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.9.2 Error Reporting (for Cleaning)

NOTE: Use the SDLT Cleaning Tape if cleaning is indicated

through your backup software or when the yellow alert

light is ON. Do not clean the drive unless the drive

specifically indicates cleaning i s necess ar y.

How the Tape Drive Returns Cleaning Status

The General Status Packet, accessible through the RS422 serial interface, contains

three unique bits that communicate cleaning information for the drive. Refe r to the

Super DLTtape Interactive Library Interface Specification for details. They are:

• Cleaning Requested

When this bit is set, it tells the library to cycle a cleaning cartridge through the

tape drive at the next possible opportunity . The Cleaning Requested bit always

sets in conjunction with the Cleaning Required bit (described next).

• Cleaning Required

When this bit is set, it tells the library that it is necessary to cycle a cleaning

cartridge through the tape drive before attempting any further tape operation.

• Cleaning Tape Expired

When this bit is set, it indicates that the current c lean ing tape has exce eded it s

use count. This bit is valid only in the following context:

Af ter attempting a cleaning application.

Until the next cleaning tape is inserted.

Until the power is cycled.

Page 43

CHAPTER 2: Ge n eral Drive Spe ci fications

How TapeAlert Returns Cleaning Status

An EEPROM parameter named EnaCleanTA enables TapeAlert reporting of

Cleaning Status. The General Status Packet contains one flag that conveys

cleaning information for the drive; it is:

• Clean Now

The Clean Now flag will be set on:

SDLT HWE(Hard Write Error)/HRE(Hard Read Error) that are not servo

related.

This flag will not be set unless 100 hours of tape motion has occurred

since the last cleaning.

Corrective action for this flag is a successful cleaning or a power cycle.

Library/Loader Cleaning Error Reporting

The EEPROM parameter EnaCleanTA is used to enable the library/loader

T a peAlert reporting of cleaning status. The EEPROM parameter EnaCleanLib is

used otherwise.

SCSI Cleaning Error Reporting

For HWE(Hard Write Error)/HRE(Hard Read Error) that are not related to servo

problems, the Cleaning Re quested ASC/ASCQ (00/17) is reported using the same

criteria as setting the TapeAlert Clean Now flag. The Sense Key is Medium Error

(03h). The Cleaning Requested ASC/ASCQ replaces the 0C/00 for HWE or the

11/0 0 fo r H R E.

The Cleaning Requested ASC/ASCQ is only reported if the EEPROM parameter

EnaCleanSense is set to 1.

Page 44

CHAPTER 2: G en era l Dr iv e S pe ci fic a t io ns

2.9.3 Front Panel Cleaning Light

The Cleaning Required (yellow) LED on the front panel indicates to the operator

that cleaning is needed. This feature is enabled by the EEPROM parameter

EnaCleanLight. The location of the Cleaning Required LED (and other front

panel LEDs) is shown in Figure 2-7.

Figure 2-7. Front Panel LEDs

If EnaCleanLight is enabled, the yellow LED illuminates steadily for these

conditions:

• When a HWE(Hard Write Error)/HRE(Hard Read Error) is encountered, and

more than 100 hours have passed since the last cleaning.

Once illuminated, the yellow LED stays lit until one of the following occurs:

1) drive is cleaned successfully, or 2) the drive is reset due to a firmware failure or

firmware update, or 3) power is cycled off and on.

Page 45

CHAPTER 3 Electrical Specifications

3.1 Current and Power Requirements

T able 3-1 on page 3-2 lists the current and power requirements for both versions of

the tape system (internal and tabletop). The tabletop version requires AC power.

The highest current (and power) is drawn during the native write modes and

backward-read compatibility (BRC) read modes, so they are outline d in Table 3-1.

Standby is measured with the tape loaded and tensioned or untensioned, and Idle is

measured with power on with no tape loaded. (The power dr awn in these two

modes is similar enough that they are listed together.) Power-up current sur ges are

less than those encountered during motor accelerations, and so are not listed

separately.

NOTE: In Table 3-1, the current and DC power values are relevant

to the internal drive, while the AC power values are

relevant to the tabletop drive.

Page 46

CHAPTER 3: Electrical Specificati ons

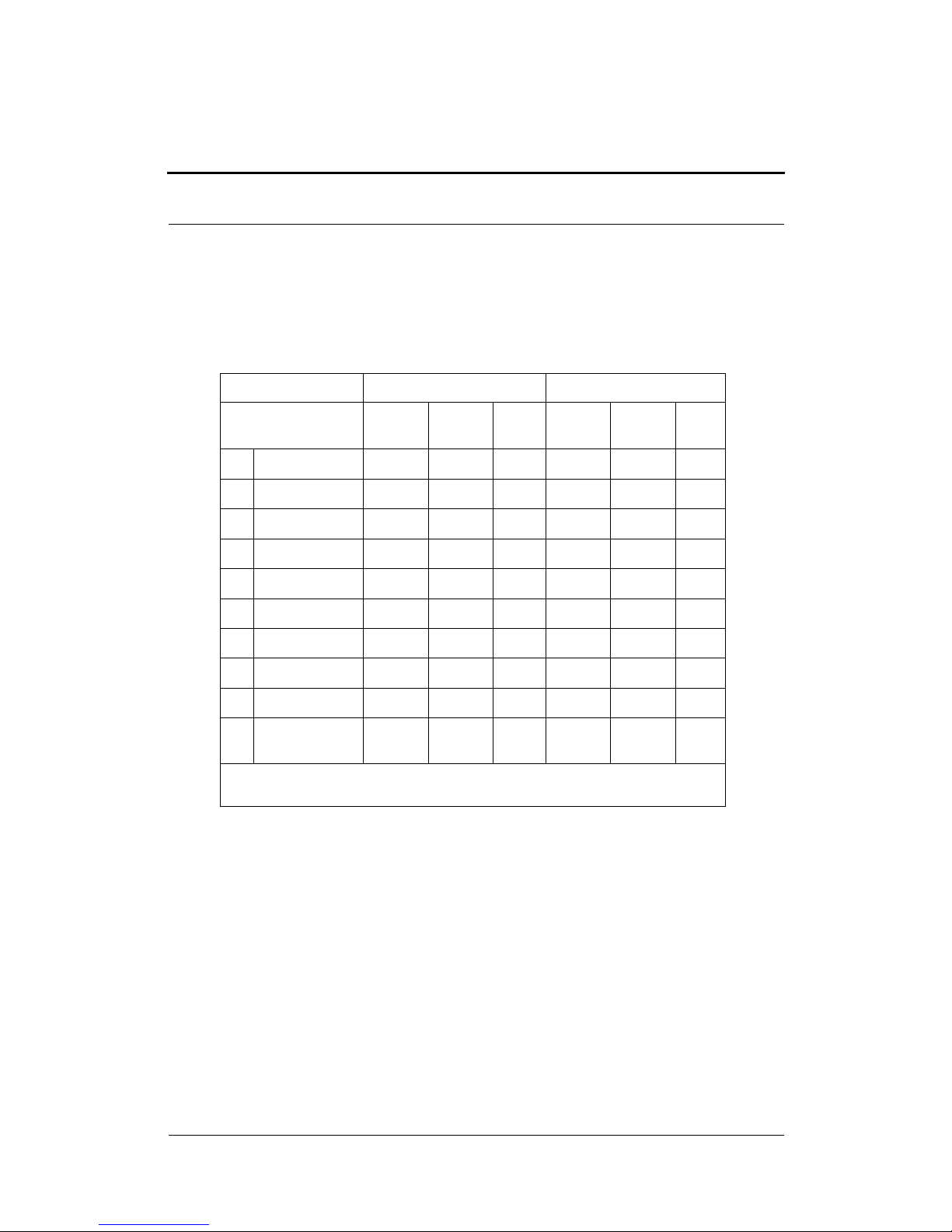

Tabl e 3-1. Current and Power Specifications

Mode

5 V Current (A)

MaxPk

1

MaxRms

2

Typ

3

12 V Current (A)

MaxPk

1

MaxRms

2

Typ

3

DC Power (W)

Max

4

Typ

5

AC Power (W)

Max

6

Typ

7

Standby / Idle 3.2 3.0 2.9 0.6 0.5 0.4 20 19 34 29

Media Load i n g

/ Unloading

3.8 3.1 2.9 4.8 1.0 0.7 25 24 38 33

220/320 Write–

Motor Start

8

6.1 3.1 3.0 4.8 1.0 0.7 25 24 33 30

220/320 Write–

Streaming

6.3 4.3 3.8 2.1 0.7 0.7 28 27 42 38

Max for SDLT

Modes

9

4.3 1.0 28 42

BRC Read–

Motor Start

8

3.9 3.0 2.8 2.3 0.7 0.6 23 22 38 32

BRC Read–

Streaming

5.2 3.3 3.1 1.8 0.7 0.6 24 22 41 33

Max for BRC

Modes

9

3.3 0.7 24 41

1. The Max-Peak value represents short current spikes drawn for dura tions of < 50us. On the 12V supply, the peaks

correspond to the pulse w idth modulated sw itching of the motors. These val ues are calculated from the average of

Peak-ripple-current + 2 sigma, measured at +5% DC vol tage.

2. The Max-Rms value is the av erage of the maximum RMS current drawn during this operating mode. These v alues

are calculated from the ave rage of RMS current + 3 sigm a, measured at nominal DC voltage.

3. The typical current is calculated from the average of all RMS current drawn during this operating m ode, measured

at nominal D C voltage.

4. The Max DC power is calculated from the typical DC power + 3 sigma, measured at nominal DC voltage. This

value takes into account that the peak currents on the 5V and 12V do not occur at the same time.

5. The Ty pical DC power is calculated from the averag e RMS DC power drawn during this operating mode,

measured at nominal DC voltage. This value also takes into account tha t the peak currents on the 5V and 12V do

not occur at the same time.

6. The Max AC power is ca lculated from the typical AC power in tabletop drives + 3 sigm a.

7. The Typical AC power is calculated from the average of AC power drawn in tabletop drives.

8. The motor st art modes draw the most current from the 12V supply , so they are shown separately. These events last

< 1 second and occur at a duty cycle of less than 25%.

9. The Max values for each mode are based on the Max-rms values, since the peak values ar e of very short duration.

Page 47

CHAPTER 3: Electrical Specifications

3.2 Power Supply Tolerances

One of the functions of the power supply is to transform the AC power to DC, and

to step the voltage down from 115/220 Vac to 5 Vdc and 12 Vdc.

3.2.1 Voltage Tolerances

Voltage tolerances are:

• 5 Vdc ± 5%

• 12 Vdc ± 5%

3.2.2 DC Voltage Monitoring

The tape drive will monitor the two input voltages and take protective measures

when the voltages fall or rise beyond the below specified ranges:

3.2.3 Power Cycle Time

T est results show that an SDLT drive is able to power up and perform reliably with

up to 11 seconds of delay time between the 5V and the 12V source. The drive is

also able to power up and perform successfully with rise times of up to 11 seconds

on either the 5V and the 12V supply (while the other is stable).

Tabl e 3-2. DC Voltage Monitoring

Supply Voltage Low Voltage Trip Point

5 Volt 4.75 Volts

12 Volt 11 .4 Vo lts

Page 48

CHAPTER 3: Electrical Specificati ons

3.2.4 Supply Transient Voltage

Allowable power supply transient voltage is:

• 5 Volt rail – 60 mV (peak to peak)

• 12 Volt rail – 1.6 V (peak to peak).

Page 49

CHAPTER 4 Thermal Specifications

4.1 Over Temperature Condition

This chapter presents the results of extensive experimentation and measurements

of drive temperatures, and the resultant impact on SDL T 220/320 drive

performance.

An Overtemp condition is defined to be when the calculated Tape Path Temp =

52 degrees C. At that point, the tape is rewound, unloaded, and ejected if not in a

library. If the drive is in a library, the tape does not eject.

The front temperature sensor is the point used to calculate drive temperature (even

though it is not the hottest point inside the drive). The calculated Tape Path Temp

for the SDLT 220/320 drive is derived using the following formulas:

• Embedded bezel Tape Path Temp = Front Sensor Temp + 3 degrees C

• Library bezel Tape Path Temp = Front Sensor Temp + 6 degrees C

If not in a library, and if the drive temperature exceeds the operating threshold, any

current tape operation is aborted, the tape is rewound, unloaded, and ejected from

the drive. SCSI status then indicates that the drive is in the over temperature

condition.

C

AUTION: Although the Overtemp condition occurs when the Tape

Path Temp = 52 degrees C, Quantum recommends the

operating environment of the drive be maintained such

that the temperature of the tape path not exceed 50

degrees C; this provides a 2 degrees C margin of safety.

Page 50

CHAPTER 4: Th er m al Spec ifications

If a SCSI command is aborted as a result of the over-temperature condition,

the drive returns status of: Hardware Error, W arning — Specified Temperature

Exceeded (04h, 0Bh, 01h).

4.2 Air Flow Measurements

Air flow is measured in the location shown in Figure 4-1. At the specified location,

the air flow needs to be at least 125 LFM (linear feet per minute).

Figure 4-1. Library Bezel—W he re to Me as u re Ai r Flow

Measure Air

Flow Inside

the Gray Area

Page 51

CHAPTER 4: Thermal Specifications

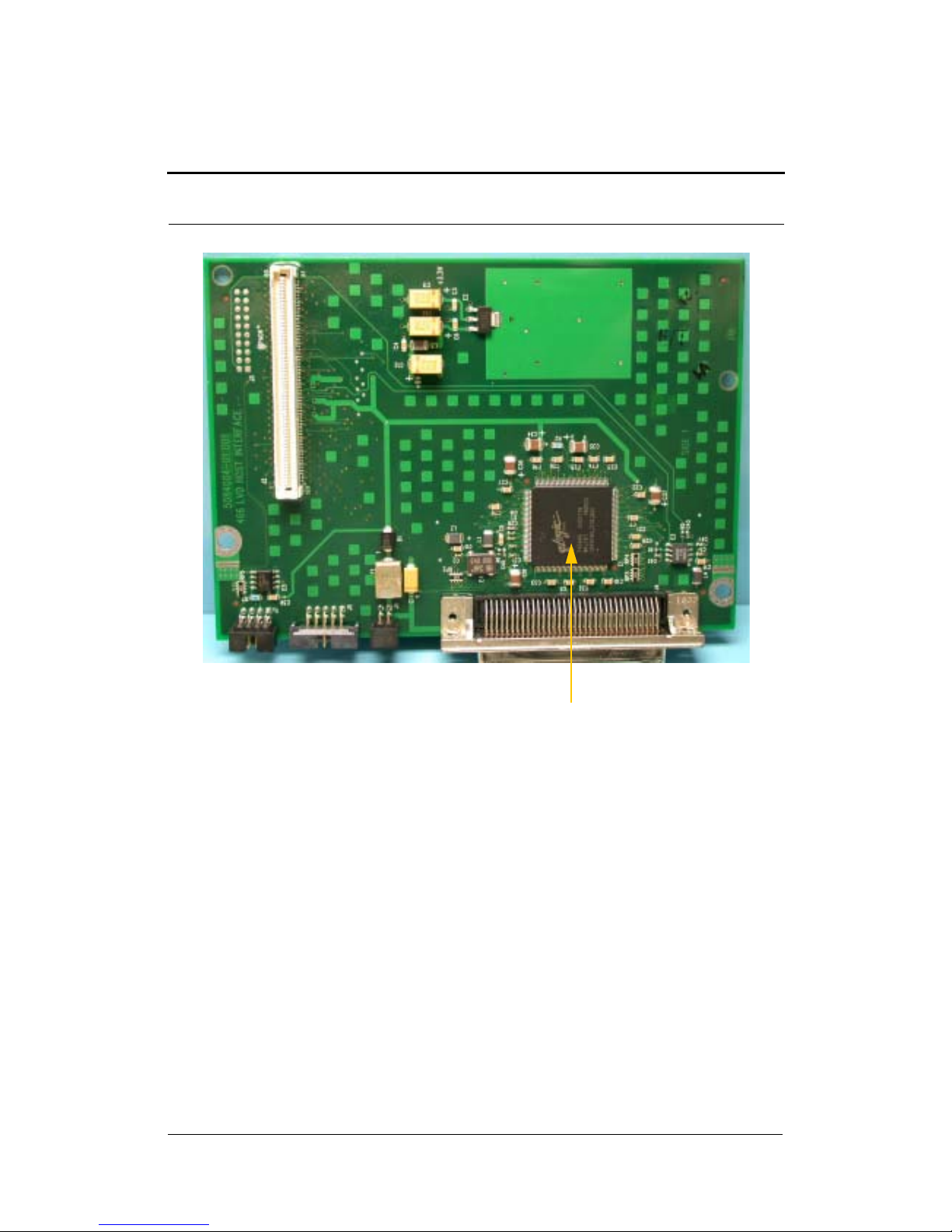

4.3 Thermal Measurement Locations

The Electronics Interface Module (EIM) comprises two boards: the Integrated

Controller Module (ICM) board, and the Host Interface Module (HIM) board.

T emperatures are measured on the ICM board in the locations shown in Figure 4-2,

on the HIM board on the Qlogic chip shown in Figure 4-3, and on the drive’s front

bezel in the locations shown in Figure 4-4.

NOTE: While the most critical temperatures are usually found

along the tape path, data for other key areas inside the

drive, such as the processor and other important circuits

and chips that are known to produce heat, are included as

well.

Page 52

CHAPTER 4: Th er m al Spec ifications

Figure 4-2. ICM Board Thermal Measurement Locations

HiFN XEZ Coldfire

Hydra

(back)

Mac Front

Thermal

Sensor

Rear

Thermal

Sensor

3.3 – 5.0V

Voltage

Regulator

Page 53

CHAPTER 4: Thermal Specifications

Figur e 4-3. HIM Board Therm al Mea s u rem ent Loca tio n

Qlogic

Page 54

CHAPTER 4: Th er m al Spec ifications

Figure 4-4. Tape Path Thermal Measurement Locations

4.4 SDLT 220/320 Thermal Profile

This section lists the temperature of key module components and media at the

extremes of the SDLT 220/320 operating specification as well as at room

temperature. Both styles of bezel were tested: 1) Embedded, and 2) Library.

NOTE: The information in this thermal profile section is not

intended to serve as a temperature specification, nor is it

intended to replace the temperature specifications of

individual chips or chipsets. This information is provided

by Tandberg Data solely as a guideline, and is r epresentative

of temperatures that you can expect to observe during typical

tape drive operation.

Hd Bd

Thermal

Sensor

Media

Temp

Sensor

Page 55

CHAPTER 4: Thermal Specifications

T o evaluate different modes of operation, data was recorded either with data

compression enabled or disabled. Thermocouples were affixed to key board

components as shown in Figure 4-2. In addition, a thermocouple was placed within

the tape path enclosure to monitor the approximate temperature of the media, as

shown in Figure 4-4.

The results of the testing are listed in Table 4-1 and Table 4-2 below.

Tabl e 4-1. SDLT 220/320 Steady State Temperatures: Embedded Bezel

Component

10 degrees C

Ambient

25 degrees C

Ambient

40 degrees C

Ambient

Case

Maximum *

Continuous

Operating

Temperature

(degrees C)

Compression

2:1

Compression

2:1

Compression

2:1

On Off On Off On Off

Temperature

(degrees C)

Temperature

(degrees C)

Temperature

(degrees C)

1

HiFN 42.4 39.9 57.4 55.0 72.5 69.6 96

2

Hydra 1 45.8 46.5 61.3 62.0 77.4 76.9 113

3

Hydra 2 42.3 42.9 57.6 58.5 73.6 73.2 113

4

Coldfire 23.3 23.4 38.5 38.5 53.6 53.5 83

5 3.3-5.0 V Reg 34.2 33.4 49.4 48.8 64.7 63.8 119

6 Front Sensor 17.0 17.0 32.0 32.0 47.0 47.0 52

7

Rear Sensor 35.2 34.3 50.2 49.9 65.8 64.7 125

8

Headboard 33.2 33.9 47.7 48.4 62.8 62.7 125

9

Qlogic 29.7 29.3 45.3 45.0 60.9 60.1 80

10

Media Sensor

(Heads)

19.3 19.6 34.6 34.7 50.3 50.2 n/a

* The number in the Case Maximum Continuous Ope rating Tem perature column are absolute limits that

should not be ex cee ded . In ot her wor ds, exp ect phy sical co mpone nt d amage or failu re if you e xce ed t hese

operating te m perature limits by no t providing adequate air flow through the drive.

Page 56

CHAPTER 4: Th er m al Spec ifications

4.4.1 Temperature Comparison — SDLT 220 versus

SDLT 320

The SDLT 220 and 320 models have many characteristics in common, including

similar temperature profi le s. In Table 4-3 and Table 4-4, the differences in

operating temperature between the two models are shown highlighted in the ∆

column.

Tabl e 4-2. SDLT 220/320 Steady State Temperatures: Library Bezel

Component

10 degrees C

Ambient

25 degrees C

Ambient

40 degrees C

Ambient

Case

Maximum *

Continuous

Operating

Temperature

(degrees C)

Compression

2:1

Compression

2:1

Compression

2:1

On Off On Off On Off

Temperature

(degrees C)

Temperature

(degrees C)

Temperature

(degrees C)

1

HiFN 37.3 34.7 52.1 49.7 66.5 64.6 96

2

Hydra 1 38.6 39.2 54.1 54.4 68.5 69.5 113

3

Hydra 2 35.8 36.4 51.2 51.5 65.8 66.6 113

4

Coldfire 20.8 20.6 35.8 35.8 50.8 50.9 83

5 3.3-5.0 V Reg 29.1 28.3 44.1 43.5 59.0 58.7 119

6

Front Sensor 14.0 14.0 29.0 29.0 44.0 44.0 52

7

Rear Sensor 29.1 29.0 44.0 43.9 59.0 58.9 125

8

Headboard 31.7 32.5 46.4 46.9 60.2 61.2 125

9

Qlogic 25.0 24.6 40.3 39.9 55.4 55.2 80

10

Media Sensor

(Heads)

19.2 19.3 34.5 34.5 49.3 49.6 n/a

* The number in the Case Maximum Continuous Ope rating Tem perature column are absolute limits that

should not be ex cee ded . In ot her wor ds, exp ect phy sical co mpone nt d amage or failu re if you e xce ed t hese

operating te m perature limits by no t providing adequate air flow through the drive.

Page 57

CHAPTER 4: Thermal Specifications

Embedded Bezel

This section lists empir ical temperature da ta from m easurements ta ken while using

the embedded bezel.

Results show certain components running hotter in 320 mode than 220 mode. The

HiFN (compression chip) runs slightly hotter, and the Hydra chips (read channels)

also run hotter. Both of these trends are to be expected as the data transfer rate is

increased from 11 MB/s (220) to 16 MB/s (320). However, mos t other components

show very little difference between the two modes.

Tabl e 4-3. SDLT 320 versus SDL T 220 with Embedded Bezel, Compression On (2:1)

25 degrees C Ambient 40 degrees C Ambient

Sensor

SDLT

320*

SDLT

220‡

∆ SDLT

320*

SDLT

220

‡

∆

1

HiFN 57.4 54.4 3.0 72.5 67.7 4.8

2 Hydra 1 61.3 57.9 4.4 77.4 72.4 5.0

3

Hydra 2 57.6 54.8 2.8 73.6 69.3 4.3

4 Coldfire 38.5 38.3 0.2 53.6 53.3 0.3

5

3.3-5.0 V Reg 49.4 47.9 1.5 64.7 62.4 2.3

6 Front Sensor 32.0 32.0 0.0 47.0 47.0 0.0

7

Rear Sensor 50.2 48.6 1.6 65.8 62.8 3.0

8 Headboard 47.7 48.3 -0.6 62.8 61.8 1.0

9

Qlogic 45.3 44.2 1.1 60.9 59.2 1.7

10

Media Sensor

(Heads)

34.6 34.7 -0.1 50.3 49.5 0.8

* These temperatures measured on SDLT 320 drives.

‡ These temperatures measured on SDLT 320 drives running in 220 read/write mode.

Page 58

CHAPTER 4: Th er m al Spec ifications

Library B ezel

This section lists empir ical temperature da ta from m easurements ta ken while using

the library bezel.

Again, the results show similar components running hotter in 320 mode than 220

mode. The HiFN (compression chip) is slightly hotter and the Hydra chips (read

channels) also run hotter. Overall, the drive running in 220 mode parallels the

drive’ s performance when running in 320 mode f or both th e embedded and library

bezels. For both bezel types, there is little to no difference in the tape path

temperatures.

Tabl e 4-4. SDLT 320 versus SDL T 220 with Library Bezel, Compression On (2:1)

25 degrees C Ambient 40 degrees C Ambient

Sensor

SDLT

320*

SDLT

220‡

∆ SDLT

320*

SDLT

220

‡

∆

1

HiFN 52.1 48.6 3.5 66.5 63.8 2. 7

2 Hydra 1 54.1 50.6 3.5 68.5 66.1 2.4

3

Hydra 2 51.2 48.4 2.8 65.8 63.7 2.1

4 Coldfire 35.8 35.7 0.1 50.8 50.8 0.0

5

3.3-5.0 V Reg 44.1 42.6 1.5 59.0 57.8 1.2

6 Front Sensor 29.0 29.0 0.0 44.0 44.0 0.0

7

Rear Sensor 44.0 42.5 1.5 59.0 57.9 1.1

8 Headboard 46.4 46.3 0.1 60.2 60.8 -0.6

9

Qlogic 40.3 39.5 0.8 55.4 54.8 0.6

10

Media Sensor

(Heads)

34.5 34.5 0.0 49.3 49.4 -0.1

* These temperatures measured on SDLT 320 drives.

‡ These temperatures measured on SDLT 320 drives running in 220 read/write mode.

Page 59

CHAPTER 5 Regulatory Requirements

Regulatory requirements that apply to the SDLT tape system include:

• Safety

• Electromagnetic emissions

• Acoustic.

5.1 Safety Regulations

This section lists the safety regulations that the SDLT tape system meets or

exceeds, such as UL, CSA, EN/IEC, and “GS” Mark.

5.1.1 Safety Certifications

The SDLT tape system meets or exceeds requirements for safety in the United

States (UL 1950), Canada (CSA C22.2 #950) and Europe (EN60950/IEC 950),

and is certified to bear the GS mark.

Page 60

CHAPTER 5: Regulatory Requirements

5.1.2 Safety Requirements

Safety requirements include:

• UL1950: Information Technology Including Electrical Business Equipment

• CSA C22.2 #220: Information Technology Including Electrical Business

Equipment

• EN60950/IEC 950: Information Technology Including Electrical Business

Equipment.

Page 61

CHAPTER 5: Regulatory Requirements

5.2 Electromagnetic Field Specifications

Tandberg Data SDLT tape drives are electrical devices; as such, this equipment

generates, uses, and may emit radio frequency energy. The drives may emit energy

in other frequencies, as well, as discussed in the following subsections.

5.2. 1 Electromagnetic E m i ssions

The internal version of the tape system complies with FCC Class A in a standard

enclosure; the tabletop version complies with the FCC Class B limits.

5.2.2 Electromagnetic Interference Susceptibility

The following table lists the Electromagnetic Interference (EMI) certifications.

Tabl e 5-1. EMI Regulations and Certifications

Type Regulation/Certification

EEC Directive 89/336 CE

BS6527 (UK)

EN55022 (EU)

EN55024 (EU)

CFR 47, 1995 FCC Rules Part 15B Class B (MDOC)

IECS-003 Canada

V-3/97.04 VCCI Class B (Japan)

CNS 13438 BSMI Class A (Taiwan)

AS/NZS 3548 Australia / New Zealand (C-Tick Mark)

Page 62

CHAPTER 5: Regulatory Requirements

5.2.3 Conducted Emissions

Limits for Class B equipment are in the frequency range from 0.15 to 30 MHz.

5.2.4 Radiated Emissions

Limits of radiate d interference field strength, in the frequenc y range from 30 MHz

to 1000 MHz at a test distance of 10 meters, are listed in Table 5-3.

Tabl e 5-2. Conducted Emissions

Frequency Ra nge Lim its dB

Quasi-peak Average

0.15 to 0.50 MHz 66 to 56* 56 to 46

0.50 to 5 MHz 56 46

5 to 30 MHz 60 50

* The limit decreases linearly with the logarithm of the frequency.

Tabl e 5-3. Radiated Emissions

Frequency Ra nge Qu as i- peak limits dB (µV/ m )

Class A Class B

30 to 230 MHz 40 30

230 to 1000 MHz 46 37

Above 1000 MHz 54 Not applicable

Page 63

CHAPTER 5: Regulatory Requirements

5.2.5 Susceptibility and ESD Limits

The following tables list radiated, magnetic radiated, and conducted susceptibility

and ESD failure level limits for the tape system.

NOTE: Proper ESD protection must be observed when handling

Tandberg Data tape drive products.

Tabl e 5-4. Radiated, Magnetic Radiated, and Conducte d Susceptibility

Type Specifications Comments

Radiated Immunity:

High Frequency, Electric Fields

3 V/m (rms),

80% modulated, 1 kHz,

26 – 1000 MHz

No errors*

No screen distortion

Magnetic Radiated:

Low Frequency, Magnetic Fields

3 A/m @ 230V/50 Hz

No errors*

No screen distortion

EFT: Fast Transi ent (Burst s) for

Power and Data Cables

2 kV No errors*

PLT: High Energy Transient

Voltage for Power Cables

1.2 kV (Differential)

2.5 kV (Common mode)

No errors*

Low-level Condu cted‡

Interference for AC and DC

Cables

3 V/m (rms),

80% modulated, 1 kHz,

0.15 – 80 MHz

No errors*

No screen distortion

* The SDLT t ape system shall maintain normal operation both in Read/Write a nd in Standby

conditions. No errors attributable to the test shall be encountered.

‡ Conducted: The transient voltage is the actual peak voltage above the normal AC voltage from the

power sour ce. The maximum energy in a single pulse fr om the transient generator must be limited

to 2.5 W.

Tabl e 5-5. Electrostatic Discharge (ESD) Failure Level Limits

Failure Type Equipment Speci fica t ions Com m en ts

Hardware Office 1 to 12 kV

No operator intervention (soft

recoverable allowe d)

Hardware Office Up to 15 kV

No component damage; operator

intervention allowed (soft/hard

errors allowed)

Page 64

CHAPTER 5: Regulatory Requirements

5.3 Acoustic Noise Emissions

The following table provides the tape system’ s acoustic noise emission levels, both

as noise power and sound pressure.

Tabl e 5-6. Acoustic Noise Emissions, Nominal

Acoustics – Preliminary declared values per ISO 9296 and ISO 7779/EN27779

Mode Noise Power Emission Level

(LNPEc) Internal Version

T abletop Version

Idle Not applicable 5.4 Bel

Streaming 5.9 Bel 5.9 Bel

Mode Sound Pressure Level (LPAc)

Internal Version

T abletop Version

Idle Not applicable 42 dB

Streaming 47 dB 53 dB

Page 65

CHAPTER 6 SCSI and Controlle r

Interface Specification

6.1 SCSI Interface Type

The SDLT drive is available in either of two possible SCSI interface versions;

these versions provide three possible SCSI interface types:

• Multimode Single-Ended (MSE) card provides one of two interfaces

Low Voltage Differential (LVD) running at 80 MB/second, or

Single Ended (SE) running at 40 MB/second.

• High Voltage Differential (HVD) card running at 40 MB/second.

Page 66

CHAPTER 6: SCSI and Controller Inte rface Specif icati on

6.2 Setting the SCSI ID

Each device on the SCSI bus must have a unique SCSI ID address assigned to it.

For specific recommendations for assigning SCSI IDs, refer to the syst em or S CSI

controller documentation.

Internal drives can be configured for SCSI ID addresses that range from 0 to 15 in

one of two ways:

• Jumper the 10-pin SCSI ID block located on the back of the drive (Figure 6-1

on page 6-4), OR

• In a library setting, you can set the IDs through firmware. (The firmware

default = SCSI ID 5 and assumes no jumpers are installed on the jumper

block.)

NOTE: The default setting for the tape drive is 5; the host adapter

setting is typically SCSI ID 7. If you choose to omit all

jumpers from the SCSI ID block, the tape drive will use

the default setting of 5.

This section discusses setting the SCSI ID on the internal drive via the jumper

block. Table 6-1 lists the SCSI ID address and jumper settings.

Page 67

CHAPTER 6: SCSI and Controller Inte rface Specif icati on

Tabl e 6-1. SCSI ID Address Selections

SCSI ID Jumper A cross P ins :

9-10* 7-8 5-6 3-4 1-2

0 10000

1 10001

2 10010

3 10011

4 10100

5 (default)00000

6 10110

7 10111

8 11000

9 11001

10 11010

11 11011

12 11100

13 11101

14 11110

15 11111

0 = No Jumper insta lled, 1 = Jumper installed

* Jumpering Pins 9-10 fo rces the drive to ignore the firmware value

and read the value jumpered on th e block.

Page 68

CHAPTER 6: SCSI and Controller Inte rface Specif icati on

6.3 Hardware (Connectors)

The SCSI interface is made available via the back panel of the drive, as shown in

Figure 6-1 and Figure 6-2 below.

Figure 6-1. Connectors on the Back Panel

Figure 6-2. Back Panel Connector Locat ions (Drawn to Scale)

Controller Diag Port (8 pin)

(Diagnostic use on ly)

Configuration Jumper

(Omit jumper on Pins 1-2

to enable wide SCSI)

SCSI ID Jumper Block

(No jumpers on this block =

default SCSI ID of 5)

TERMPWR Block

(Install jumper on Pins 1-2

to enable TERMPWR)

SCSI Port

(68 pi n)

zDenotes Pin 1 orientation

Pin 1

Power Connector

(4 pin)

Loader Connector

RS-422 (8 pin)

* Figure not drawn to scale

Page 69

CHAPTER 6: SCSI and Controller Inte rface Specif icati on

6.4 SCSI Stub Lengths

The SCSI interface resides on the Host Interface Module (HIM). Quantum

provides two versions, namely:

• LVD (50-84004-01)

• HVD (50-84008-01)

The longest recorded stub lengths on the latest version of each style of PCB are

listed in Table 6-2.

6.5 SCSI Cable Length

This section lists the recommended SCSI cable lengths for optimum drive

performance; cable lengths are:

• 25 meters for Differential Ended Transmission Mode (LVD )

• 6 meters for Single-Ended Transmission Mode (HVD)

For optimum drive performance, limit the cables to a length of 6 meters (in all

cases).

Tabl e 6-2. SCSI Interface Stub Lengths

Board Stub Length Signal Name From To

LVD 1.543 inches SCSI_SEL_H E1-70 J4-27

HVD 1.853 inches SCSI_DBP0_L E7-38 J 4-49

Page 70

CHAPTER 6: SCSI and Controller Inte rface Specif icati on

6.6 Power On Self Test

When power is applied to the tape system, the system performs a Power On Self

Test (POST). POST completes in approximately ten seconds. While POST is

running, the tape system responds BUSY to SCSI commands. The tape system

also responds to various SCSI messages during POST.

During this time, if a host tries to negotiate Synchronous or Wide transfers, the

tape system will negotiate to Asynchronous or Narrow. It may take longer than the

duration of POST for the drive to become ready.

6.7 SCSI Command Timeout

Table 6-4 shows the length of time a SCSI command “waits” for a response be f ore

it times out.

Tabl e 6-3. Indicator Pattern During POST

Stage What Can Be Observed

1 The LEDs light in a progressing pattern from left to right.

2