Page 1

1

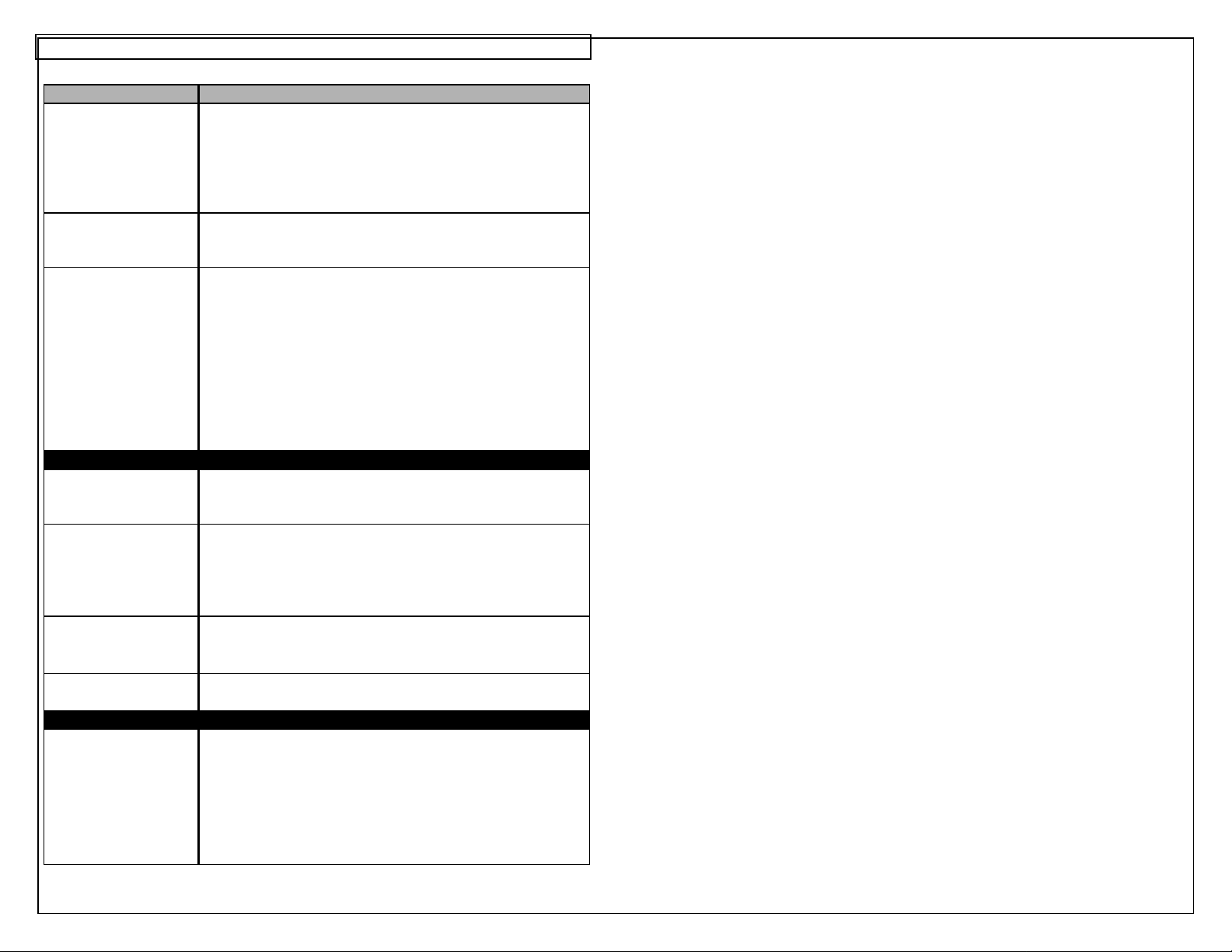

Section 1: Getting Started.............................................................3

Introduction and Safe Operation..................................................4-5

General Description........................................................................6-8

Battery Information.......................................................................9-11

Quick Start with the VIPER™ LS6...................................................12

Ribbon Loading & Selection ......................................................13-14

Label Loading....................................................................................15

Keyboard......................................................................................16-20

Section 2: Working with the VIPER™ LS6................................21

Using the VIPER™ LS6...............................................................22-24

Creating Labels

Creating Text ..................................................................25-27

Creating Serializations ...................................................28-31

Creating Symbols............................................................32-33

Creating Lines .................................................................34-35

Creating Boxes......................................................................36

Creating Data Lists.........................................................37-38

Creating Bar Codes........................................................39-40

Creating Date/Time Stamps..........................................41-42

Using the Pages Function...................................................43

Setting up the VIPER™ LS6.......................................................44-47

Using File Manager ..........................................................................48

Interfacing with a Computer............................................................49

ViperLink™..................................................................................50-52

Using Remote Printer Utility..........................................53-54

Printer Cleaning Instructions...........................................................55

Printer Troubleshooting..............................................................56-59

Warranty Information …..................................................................60

General Specifications .....................................................................61

Replacement Parts and Accessories.............................................62

Page 2

2

Page 3

3

SECTION 1

GETTING STARTED

Page 4

INTRODUCTION & SAFE OPERATION

4

The VIPER LS6 Thermal Transfer Portable Printer is the complete printing

solution for Electricians, Assemblers, Installers, Maintenance & Repair,

Construction, and Network Communications Personnel. This versatile on -site,

on-demand printer provides users with the ability to save, retrieve, and edit

custom or serialized labels for wire and cable marking, component labeling,

network labeling, safety identification, and general facilities identification.

This manual will guide you step by step through the set -up, operation, and

troubleshooting of the VIPER™ LS6 Printer. If you have problems not covered

herein, contact your local Panduit Sales Representative, call Panduit

Technical Support at 866-871-4571, or call Panduit Customer Service at 800777-3300. More information is available on the Internet at www.panduit.com.

SAFE OPERATION PRACTICES

The following general safety practices supplement the specific warnings and

cautions depicted elsewhere in this manual. They are recommended

precautions that must be understood and applied during the operation and

maintenance of this printer.

Do Not Operate In An Explosive Environment

Do not operate the printer in the presence of flammable gases or fumes.

Operation of this printer in such an environment constitutes a definite safety

hazard.

Do Not Operate In Wet Or Damp Areas

Do not operate this printer in wet or damp areas. Operation of the printer in

such an environment constitutes a definite safety hazard.

Do Not Substitute Parts Or Modify Equipment

Because of the danger of introducing additional hazards, do not install

substitute parts or perform an unauthorized modification to the printer or its

accessories. The proper components for service and repair may be obtained

from Panduit Corp.

Page 5

INTRODUCTION & SAFE OPERATION

5

WARNING:

When the printer has been in use for an extended period of time, the

printer motor may become hot. DO NOT touch the printer motor with

bare hands.

Information to USA Users

NOTE: This printer has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of FCC rules. These limits are

designed to provide reasonable protection against harmful interference when

the printer is operated in a commercial environment. This printer generates,

uses, and can radiate radio frequency energy and, if not used in accordance

with this instruction manual, may cause harmful interference to radio

communications. Operation of this printer in a residential area is likely to

cause interference in which case the user will be required to correct the

interference at his own expense.

Information to Canadian Users

This digital apparatus does not exceed Class A limits for radio noise

emissions for digital apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques de la class A

prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

It is possible that infrequent electrical phenomena (static discharge, power

line fluctuations) may cause printer function to be temporarily interrupted. In

this case, the printer will usually reset itself. In extreme cases, the user should

remove then re-apply power (battery pack and/or AC Adapter).

Printer Power Supply

The VIPER LS6 is supplied with a NiMH (Nickel-Metal Hydride) battery. This

battery is re-chargeable. The life expectancy of the NiMH battery is

approximately 500 charge/discharge cycles. After the NiMH has surpassed its

useful life, it must be disposed of properly. DO NOT PLACE THE SPENT

NiMH BATTERY IN AN UNAPPROVED TRASH RECEPTACLE. All NiMH

batteries should be disposed of according to local rules and regulations. It is

strongly recommended that the NiMH battery be recycled.

Page 6

GENERAL DESCRIPTION

6

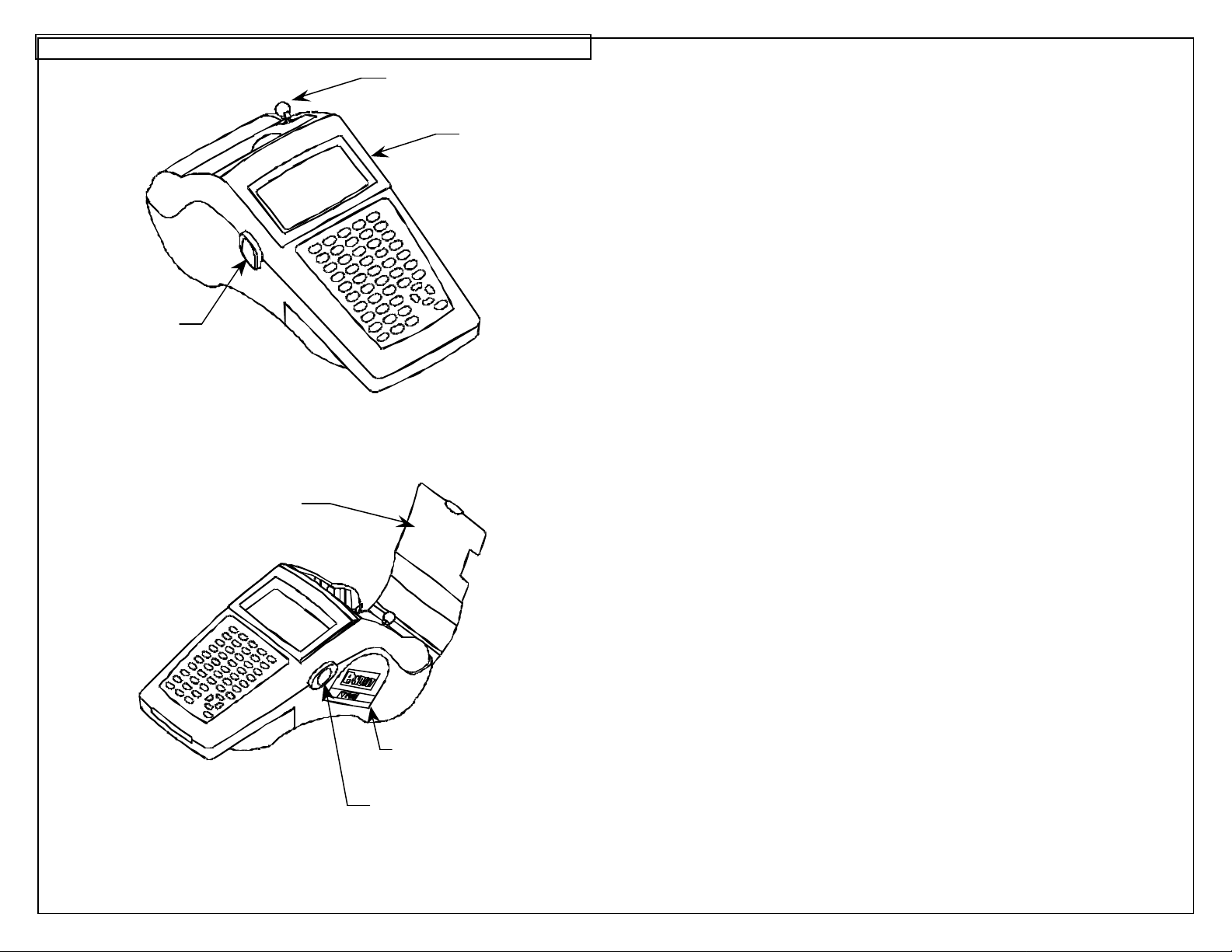

RS232 Serial

Port

Ribbon

Door

Label Door

Cutter Knob

LCD Display

AC Adapter Plug

Page 7

GENERAL DESCRIPTION

7

The VIPER LS6 printer kit contains each of the following items:

1. VIPER LS6 thermal transfer portable printer

2. TPDEMO direct thermal labeling tape sample

3. LS6-RWBLK, black wax ribbon cartridge

4. LS6-ACS, 120 VAC adapter and battery charger

5. LS6-BP, NiMH rechargeable battery pack

6. LS6-CLN, package of 5 cleaning cards

7. LS6-MAN-A, operator’s manual in English*

8. Hardside carrying case

9. Product registration and warranty card

*Operator’s manuals are also available in other languages.

Optional accessories and replacement parts are listed on page 62 of this

operator’s manual.

Page 8

GENERAL DESCRIPTION

8

Print Technology

The VIPER LS6 prints labels using thermal transfer printing technology. The

print head melts ink contained on a thin web of ribbon material allowing the

ink to transfer to the label material. The print head operates at a resolution of

203 dots per inch (dpi).

Smart Label Roll – See page 15

The VIPER LS6 label supplies are wound on a label cartridge that is plugged

into a socket in the printer. The label cartridge is read by the printer operating

system. The operating system AUTOMATICALLY selects the appropriate

printer settings. Also, the operating system will keep track of the number of

labels used from each roll and report the remaining labels to the user unless

labels are manually removed.

Ribbon Cartridge – See page 13

The ribbon material, which contains the thermal transfer ink, is housed in a

plastic housing to keep it clean, and to allow for easy installation and

replacement. Ribbons are available in wax, hybrid, and resin materials.

Battery Pack – See page 9

A 12 volt battery powers the VIPER LS6. The battery is a rechargeable NiMH

(Nickel-Metal Hydride) type which offers longer life than an equivalently sized

Ni-Cad (Nickel-Cadmium) battery. Also, NiMH batteries are more

environmentally friendly than Ni-Cad batteries, resulting in less stringent

recycling requirements.

AC Adapter / Battery Charger – See page 9

An AC Adapter is included for powering the VIPER LS6. The AC adapter is

compatible with international power systems (100 – 240 VAC). The VIPER

LS6 includes an internal overnight battery charging circuit. The AC Adapter is

used to power the charging circuit. This circuit is intended to charge a

completely discharged battery pack in less than 15 hours.

Label Cutter

A manually operated label cutter is included. The VIPER LS6 will

automatically place the printed label in the proper position for cutting.

Carrying Case

A custom carrying case to protect and transport the printer and accessories is

included.

PC-KIT – See page 47

An upgrade kit consisting of a serial cable for connection to a personal

computer (PC) and a CD of ViperLink software. The PC-KIT is used to

communicate between a PC and the VIPER LS6 printer.

Page 9

BATTERY INFORMATION

9

A 12 volt NiMH (Nickel-Metal Hydride) battery comes with the VIPER LS6

printer. The battery is PARTIALLY CHARGED. Panduit recommends

charging the battery for 15 HOURS PRIOR TO USE. Charging of the

VIPER LS6 battery should be accomplished ONLY with Panduit Model LS6

AC Adapter/Battery Chargers (Part No. LS6-ACS, which is supplied with the

printer). The user MUST manually activate the battery charger with the LS6

powered on to start the charging process (see Charging the Battery below).

NOTE: The Battery (LS6-BP) should only be removed during its own

replacement or during the replacement of the Lithium Battery. Charging

of the NiMH battery pack will only occur while the battery (LS6-BP) is

installed INSIDE of the VIPER LS6 printer.

NOTE: The battery may lose capacity after extended periods of non-use,

and may require several charge/use cycles to recover to its full capacity.

Charging the Battery

1. Connect the AC Adapter to the printer at the AC Adapter Plug.

2. Plug the AC Adapter into an ordinary wall outlet.

3. Turn the Printer On.

4. Wait for the printer to cycle through its start up screens.

5. From the Home Screen press the key to enter the setup menu.

6. Next, use the arrow keys to scroll down to Utilities. Select Battery next

to Utilities and press the key.

7. The current charge level of the battery will appear on the screen briefly.

8. The printer will then prompt to Start charger now? 1-Yes 2-No

9. Press 1 first and then press any other key to begin charging or Press 2 to

exit the battery charging prompt screen and return to the setup menu.

10. Press to end charging. A fully charged battery will completely darken

the status bar vertically.

Page 10

BATTERY INFORMATION

10

Battery

Door

Battery

Compartment

Adjustable

NOTE:

• Completely charge the battery pack before use. The operating system

reports the battery charge status.

• Completely drain the battery pack before charging. The operating system

will warn the user on power up and power down of low battery conditions.

• Consult your local guidelines for instructions on proper disposal of spent

battery packs.

Battery Removal

1. Remove battery door by using a coin to depress the tab.

2. Remove battery by unplugging and lifting it out of the battery

compartment.

3. Re-install the battery by reversing steps 1 and 2 ensuring that the battery

is firmly plugged into the plug connection on the printer.

Battery

Strap

Page 11

BATTERY INFORMATION

11

Lithium Battery

The VIPERTM LS6 uses a Lithium coin-cell battery to preserve the printer

settings and stored files when the main battery pack is removed and the AC

Adapter is not plugged in.

Do not leave the main battery pack out for extended

periods of time, as this will drain the Lithium cell.

Do not remove the Lithium cell as this may result in

a loss of all stored settings and files.

If the printer does not preserve the printer settings and files when both the

battery pack and the AC Adapter are disconnected, then the Lithium cell

should be replaced using the procedure below.

Replacing the Lithium Battery

1. Plug-in the AC Adapter to preserve the stored settings and files during the

battery replacement.

2. Remove the main battery pack to gain access to the lithium cell.

3. Peel away the lithium cell warning label to expose the lithium cell in a

plastic holder. Save the warning label.

4. With your finger, firmly push on the circular plastic tab holding the cell in

place to slightly eject the lithium cell from the holder.

5. Noting the polarity markings on the cell, remove the cell and replace it

with a Panasonic CR2032 or equivalent. The cell should snap in place

when properly installed. This common cell can be found at most office

and computer supply stores.

6. Replace Warning Label over Lithium Battery.

7. Replace the main battery pack.

Page 12

QUICK START WITH THE Viper™ LS6

12

1. Plug in the AC adapter.

2. Install a ribbon cartridge. (See section entitled “RIBBON LOADING &

NOTE: A ribbon is not required for TPDEMO, the thermal paper roll

supplied with the printer.

3. Install a label cartridge. (See section entitled “LABEL LOADING” on page

15.)

4. Turn ON the printer by pressing . If the low battery message

appears, select 2 to disregard and continue. (For detailed battery

charging instructions, see page 9.) The home screen will appear:

5. You may immediately begin typing text at the home screen or otherwise

press the key to enter the Tools menu. (See detail instructions for

creating tools beginning on page 23.)

6. From the home screen, press the key to print your label.

Page 13

RIBBON LOADING & SELECTION

13

Ribbon

Ribbon

Ribbon

Lock Knob

Cartridge

Door

The VIPER™ LS6 uses a cartridge based ribbon (wax, resin, or hybrid) to form

legends on labels. The ribbon is loaded into the printer by the following steps:

1. Open the ribbon door on the side of printer.

2. Rotate the ribbon lock knob into the open (unlocked) position

[Counter clockwise].

3. Remove slack from the ribbon by winding the left roller of the ribbon

cartridge.

4. Insert the ribbon cartridge into the printer, the web of the ribbon

should slide freely between the rubber roller and the print head.

5. Rotate the ribbon lock knob into the closed (locked) position –

[Clockwise].

6. Close the ribbon door on the side of printer.

7. Install a label cartridge. (See LABEL LOADING on page 15.)

8. Press the key to advance the ribbon forward.

Page 14

RIBBON LOADING & SELECTION

14

Use the chart below to determine the ri bbon cartridge part number that is

recommended for your application.

Vinyl, Self -Laminating X X

Heat Shrink X X

Vinyl Cloth X X

Vinyl Tape, White X

Vinyl Tape, Colored X X

Polyester, White X

Polyester, Clear X X

Polyolefin X X

Non-Adhesive

Polyester

Thermal Paper No ribbon required

VIPER™ LS6 label media and ribbon compatibility chart

Label Material

Recommended Ribbon

Black Wax

LS6-RWBLK

Black Hybrid

LS6-RHBLK

X X

Black Resin

LS6-RRBLK

White Resin

LS6-RRWHT

Page 15

15

Label Roll

Socket

Width Guide

Adjust)

Cutter Knob

Label Feed

Path

LABEL LOADING

Label Door

Label Roll

Mandrel

(Push Down to

(Pull Forward for

Cutting)

Each roll of labels or tape used in the VIPER LS6 is uniquely identified by the

mandrel holding the labels. This allows the operating system to automatically

set the printer for optimum usage of each label. Also, the operating system

keeps track of the remaining labels on each roll. Use steps 1-5 below to load

each label roll.

1. Ensure that the printer is turned OFF. If the printer is on, press the

and keys to turn the printer off. Insert the Label Roll into the socket

as shown above until it is firmly seated.

2. Ensure that the ribbon knob is in the locked position.

3. Insert the end of the label roll into the label guide path (see yellow

arrows). This requires positioning the label width guide to the proper

width. IF THE WIDTH GUIDE IS NOT LOCKED INTO A WIDTH

NOTCH, LABEL RECOGNI TION FAILURE MAY OCC UR.

4. Labels should be inserted into the label path until resistance is met –

approximately ½”.

5. Turn the printer ON. Press the key to position the label for printing.

6. You are now ready to begin printing!

Page 16

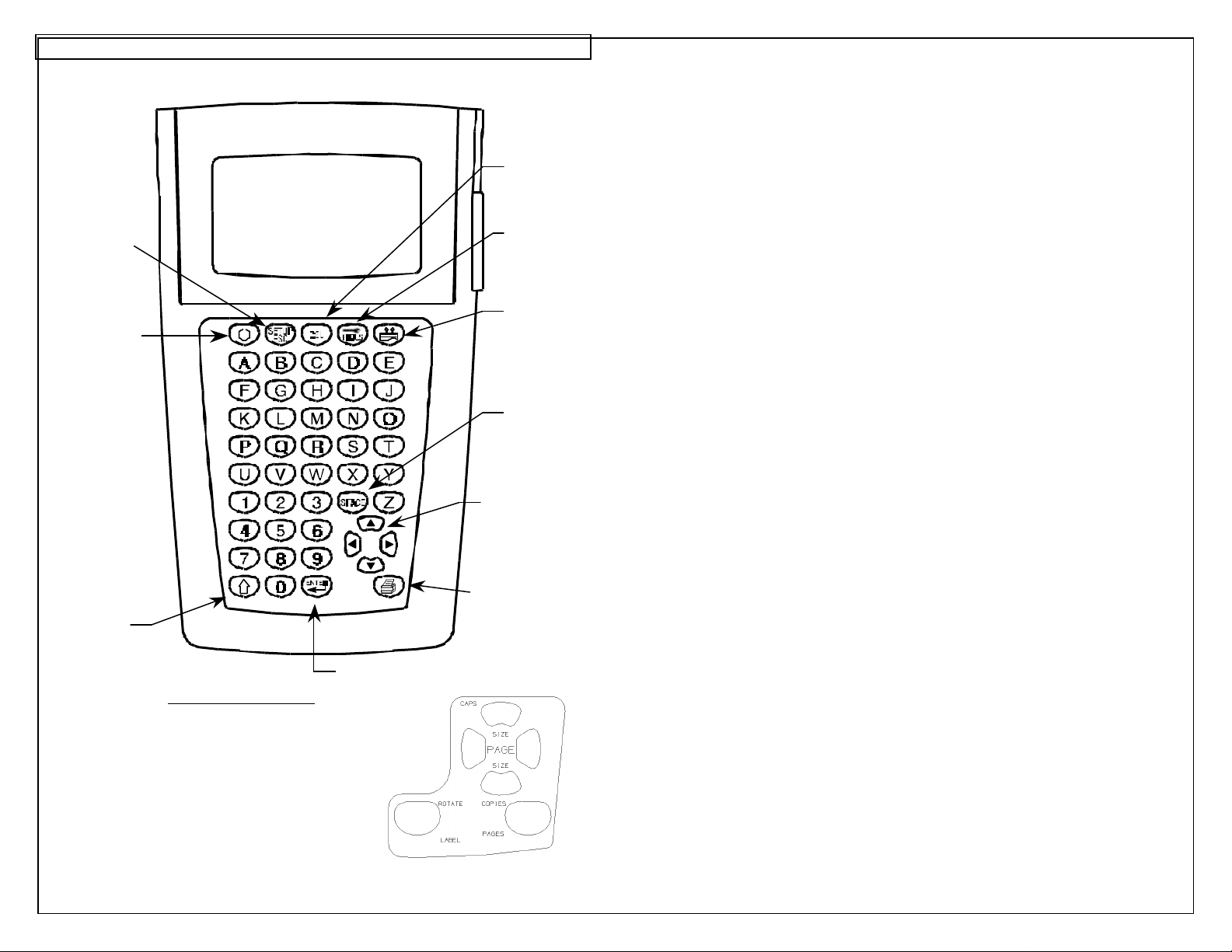

KEYBOARD

16

Shift

Power

Directional

Space

Label

Tools

Delete

More Function Keys

Setup /

Key

Escape Key

On /

Off

Key

Key

or

Ribbon

Feed

Key

Key

Arrows

Print Key

Enter Key

Caps lock

Text size

Change page

Rotate label

Read label mandrel

Print multiple copies

Print selection of pages

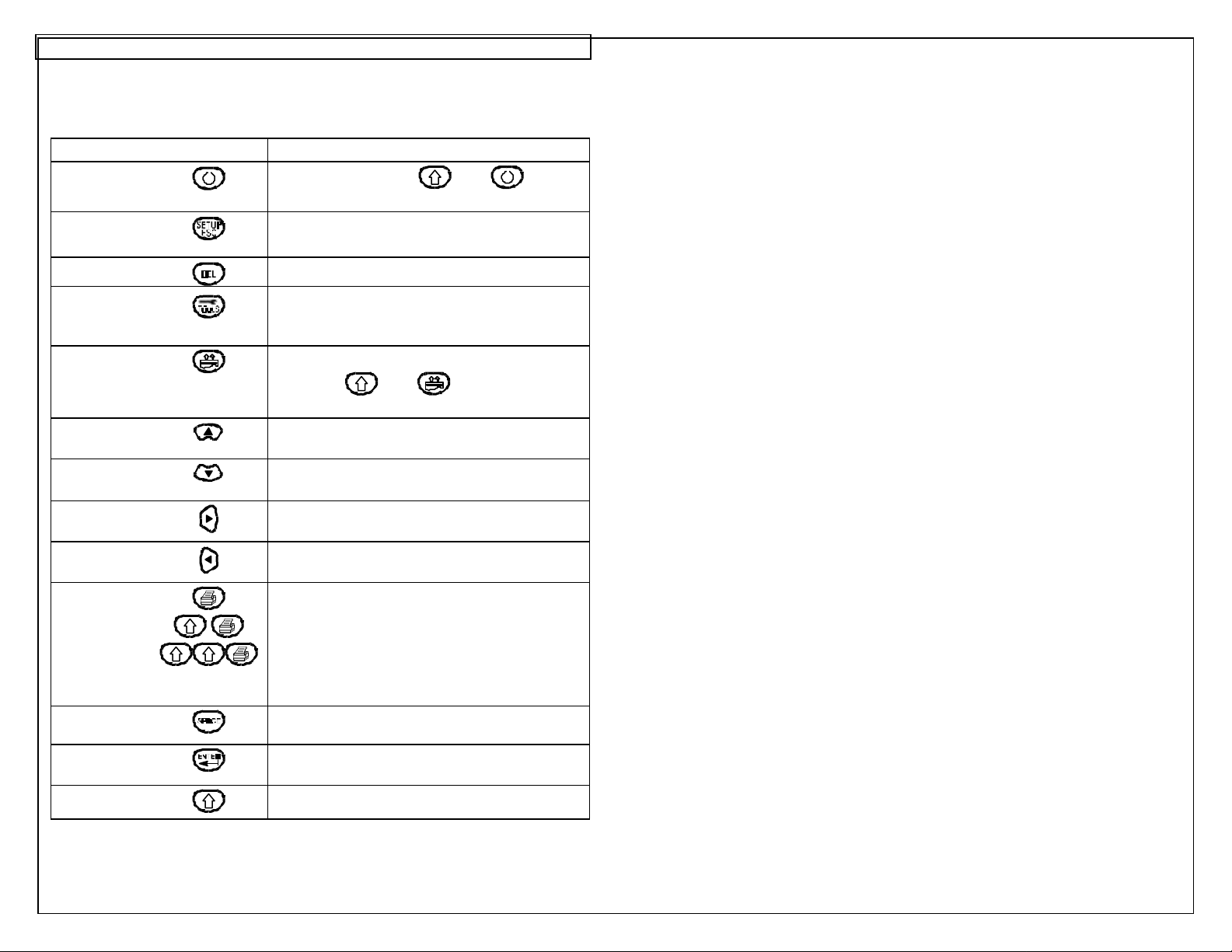

Page 17

17

POWER

SETUP/

ESCAPE

DELETE

TOOLS

FEED

UP

ARROW

DOWN

ARROW

RIGHT

ARROW

LEFT

ARROW

PRINTING

SPACE

KEYBOARD

Basic Keyboard Functions

KEY / SYMBOL COMMON FUNCTIONS

Turn the printer ON, then turns

the printer OFF.

Activate the Setup Menu from the home

screen or back out of internal menus.

Delete characters or tools.

Used for creating serializations, symbols,

data lists, boxes, lines, bar codes, and

date/time stamps.

Advance labels and ribbon.

Pressing then reverse feeds

labels and ribbon.

Move cursor up one line.

Move cursor down one line.

Move cursor one space to the right.

Move cursor one space to the left.

Print label.

Print multiple copies of the entir e label.

Print a selection of pages from the label.

A print job can be terminated by pressing

any key.

Insert a blank character.

ENTER

SHIFT

Complete a selection or move the cursor to

the next line.

Access alternate functions or characters.

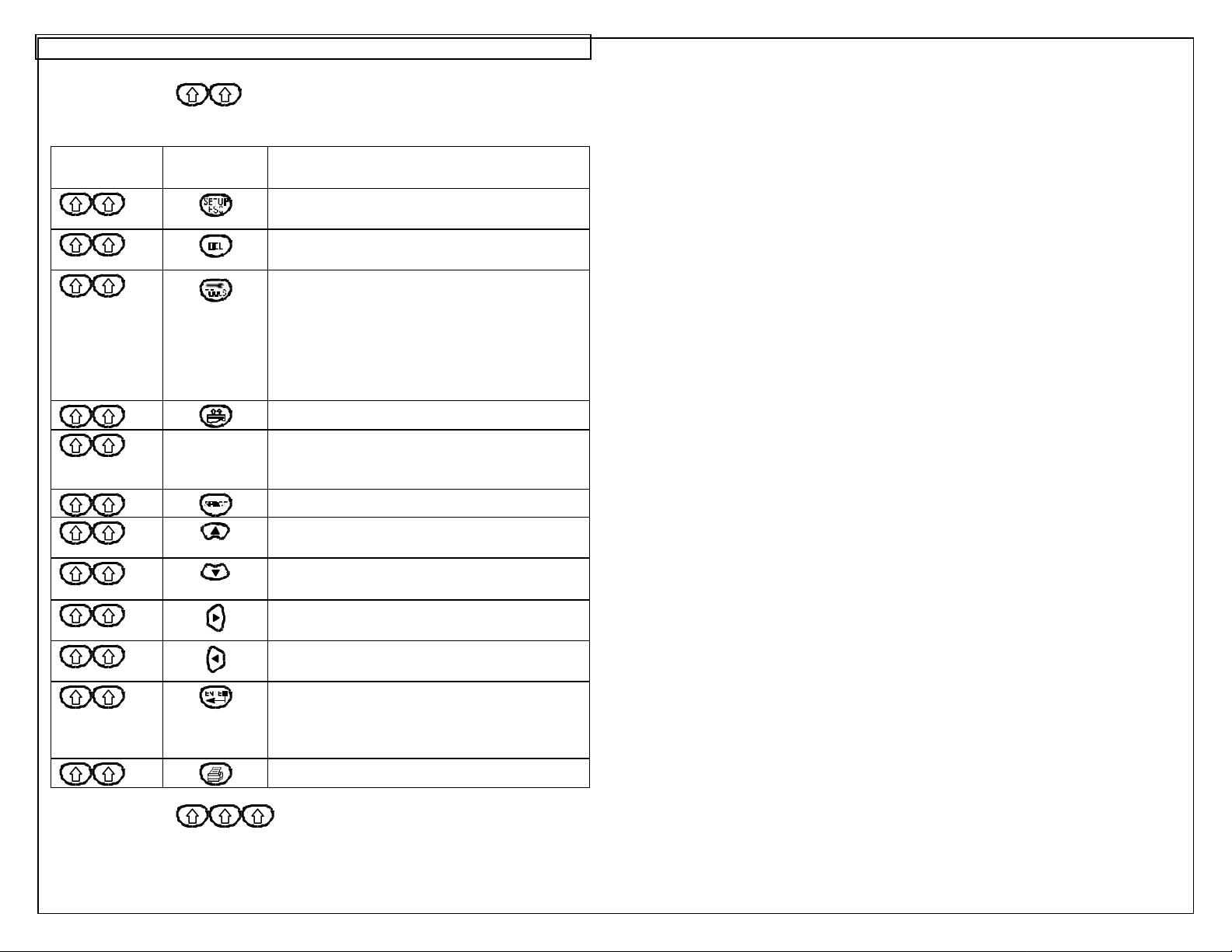

Page 18

KEYBOARD

18

Using the Shift Key

Press the shift key once to access the functions listed in the table below.

PRESS

SHIFT FIRST

THEN

PRESS

Any

Alphabetic

or Numeric

Key

RESULT

Turn the printer OFF.

Delete all items on a label and return

formats to default values.

Delete all items on the current page only.

Does not delete current formats.

Left, center, or right justify the label items.

Reverse feed the label media.

Enter secondary function from keypad

overlay onto text screen.

Enter the = symbol onto text screen

Increase the text size.

Decrease the text size.

Move forward one page in the current label.

Move backward one page in the current

label.

Rotate the label 90 degrees in the clockwise

or counterclockwise directions.

Print multiple copies of the entire label(s).

Page 19

KEYBOARD

19

Press the shift key twice to access the functions listed in the table

below.

PRESS

SHIFT FIRST

Press the shift key three times in a row to exit the shift mode.

THEN

PRESS

Any

Alphabetic

Key

RESULT

Display the version of firmware currently

installed on the printer.

Delete all items on the entire label. Does

not delete current formats.

Activate or deactivate fit checking. Fit

checking automatically checks the size of

the label items to determine if they will fit on

the label. Fit checking occurs after each

new item is entered onto the home screen.

If fit checking if deactivated, the printer will

only perform fit checking before printing.

Reverse feeds the label media.

Enter lower case character if caps lock is

on. Enter upper case character if caps lock

is off.

Activate or deactivate caps lock.

Move cursor to home position on the home

screen.

Move cursor to end position on the home

screen.

Move cursor to far right position of current

line on the home screen.

Move cursor to far left position of current

line on the home screen.

Automatically read the label mandrel in

order to restore default formats for a new

label roll or to enter an exact label length for

continuous tape.

Print a selection of pages from the label.

Page 20

KEYBOARD

20

Using the Delete Function

The four methods available for deleting labels are listed in the table below.

PRESS

FIRST

THEN

PRESS

Delete individual characters or items on a

label.

Delete all items on the current page only.

Does not delete current formats.

Delete all items on the entire label. Does

not delete current formats.

Delete all items on the entire label and

return formats to default values.

RESULT

Page 21

21

SECTION 2

WORKING WITH THE

VIPER™ LS6

Page 22

USING THE VIPER ™ LS6

22

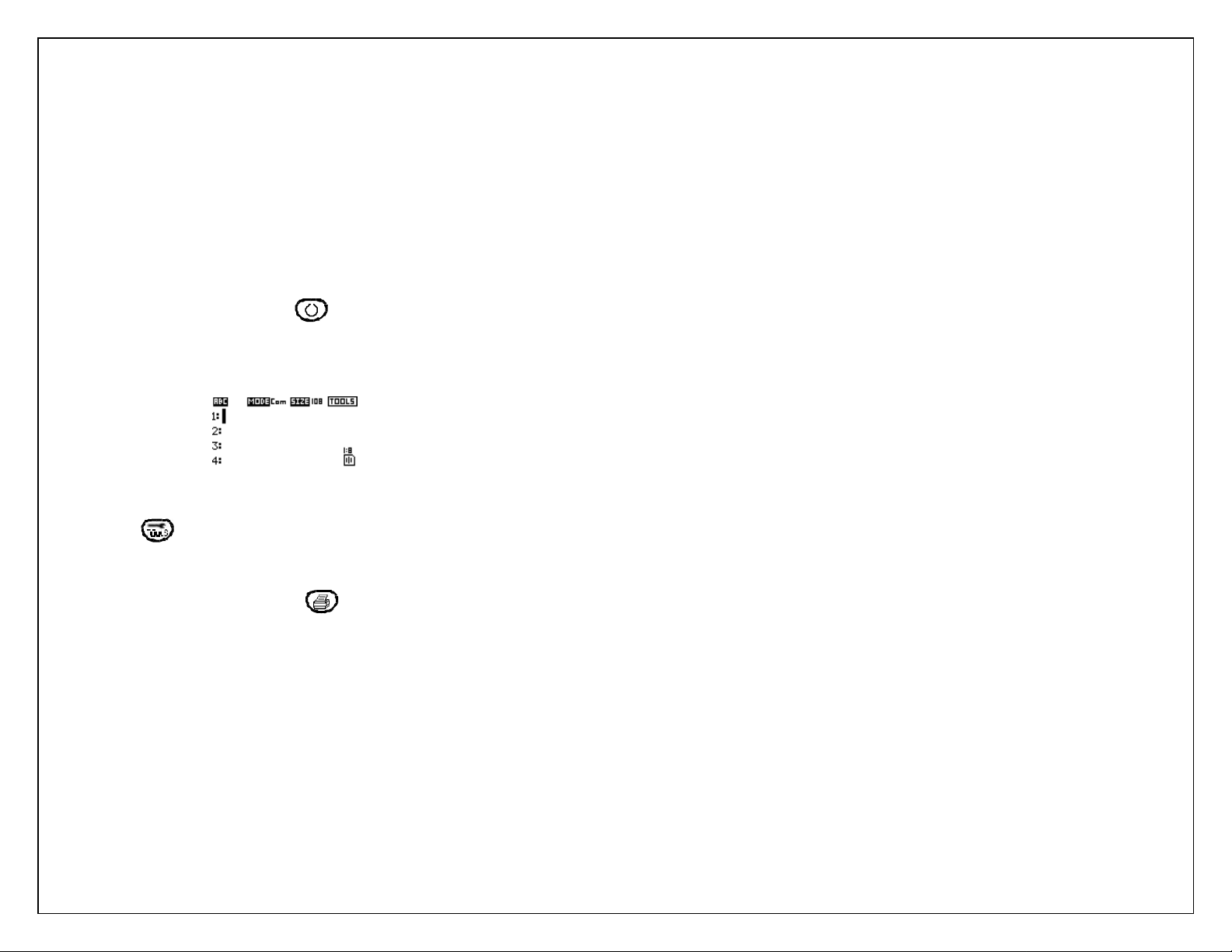

Home Screen

The home screen is where the user enters and edits text or places label items

known as tools. The home screen is also where the user prints labels. The

home screen appears as:

Home Screen Indicators

INDICATOR ICON DESCRIPTION

Caps Lock

Shift

Text Size

Tool

Text Line

Page

Rotation

Rotation

Vertical or

Horizontal Line

Box

or

Indicates if caps lock is on or off.

Indicates if shift or alternate mode is

selected.

Indicates the text size for the current line.

Prompts the user to press and enter

the tools men u.

Indicates the current line.

Indicates the current page. There are 8

total pages.

Indicates 0 degrees rotation.

Indicates 90 degrees clockwise rotation.

Indicates whether the line tool is on or off.

Indicates whether the box tool is on or off.

Fit Checking

Justification

Justification

Justification

Indicates whether fit checking is on or off.

Indicates left justification.

Indicates center justification.

Indicates right justification.

Page 23

USING THE VIPER ™ LS6

23

Tool Menu

The tool menu includes serializations, symbols, data lists, boxes, lines, bar

codes, and date/time stamps. These items are placed on the home screen.

The tool menu is accessed by pressing the key.

Tool Icons

The following icons represent the available tools:

- Serialization

- Symbol

- Line

- Box

- Data List

- Barcode

- Date/Time Stamp

Page 24

USING THE VIPER ™ LS6

24

POWER Key

To turn ON the VIPER™ LS6, press and hold the key until activity is seen

on the display. To turn OFF the VIPER™ LS6, press and release the key,

then press and hold the key until the powering down message appears.

This method of power control reduces the chance of accidentally turning off

the printer. The VIPER™ LS6 will automatically turn off after 10 minutes of idle

time in order to conserve battery life.

SETUP Key

From the home screen, press and release the key to activate the setup

menu. The key also functions as an ESCAPE key to end a function and

return to the previous screen.

DEL Key

The key is used to delete characters or label items. For a detailed

description of the delete function, see page 20.

TOOL Key

The key is used to activate the tool selection menu.

FEED Key

The key is used to manually advance or reverse the label and ribbon.

PRINT Key

The key is used to print labels. A PRINT JOB CAN BE TERMINATED

BY PRESSING ANY KEY.

SHIFT Key

The key is used to select characters from the keypad or access

secondary functions. For a detailed description of the shift key, see pages

18-19.

ARROW Key

The keys are used to move the cursor, change text size, and

move between pages.

Page 25

CREATING TEXT

25

The Text Tool

After turning on the VIPER™ LS6, the home screen will appear. The home

screen is also the text editor.

To create text on the home screen, simply begin pressing the alphabetic or

numeric keys on the keypad. Text will be entered at the position of the

cursor. The cursor is indicated by a dark line or dark box highlighting a

character. To insert blank spaces, press the key. Press to move

down to the next line. Use the directional arrow keys to move the cursor up,

down, right, or left. The maximum number of text characters allowed to be

placed on each line is 32. Typically, continuous tape must be used to fit up to

32 characters on a line. The maximum number of lines available for each

label page is 8.

Inserting or Deleting Text

To remove characters from the screen, press the key. Each press of

the key will delete one character at a time immediately to the left of the

cursor. To insert characters into a string of text, move the cursor to the

position immediately to the right of where the text will be inserted and then

begin entering text.

Text Size

The VIPER™ LS6 has 13 different font sizes available for creating text. The

font sizes range from 6 pt. to 192 pt. Text size can be increased by pressing

the key and then the key. Text size can be decreased by pressing

the key and then the key. The current text size is displayed on the

top of the home screen next to the text size icon.

Page 26

CREATING TEXT

26

Initially, the text size will be set to the default value according to the label

loaded in the printer. The text size can be increased or decreased for each

individual line of the label. There is a maximum of 8 lines available for

creating text.

Text Rotation

Label legends may be rotated from 0 degrees to 90 degrees in the clockwise

direction. The page shaped icon in the lower right hand corner of the display

indicates the current rotation. To change the rotation, press the key and

then press the key. Repeat this procedure to return the rotation back to

the previous setting.

Text Justification

Label legends may be left justified, center justified, or rig ht justified. The page

shaped icon in the lower right hand corner of the display indicates the current

justification setting. To change the justification, press the key and then

press the key. Repeat this procedure until the desired justification is

selected.

Text Options

There are two text options available for each line of text. The options are

called style and orientation. The style can be set to either normal or

underlined. The orientation can be set to 0 degrees, 90 degrees, 180

degrees, or 270 degrees. The orientation setting refers to the rotational

position of the individual text characters, not the rotational position of the

legend as a whole. To rotate the entire legend simultaneously, refer to text

rotation described above.

To access text options, move the cursor over any character within a text string

and then press the key. Use the up or down directional arrows to select

‘Style’ or ‘Orient’. Next, use the right or left directional arrows to change the

settings. Last, press the key to accept the changes and to return to the

home screen. Each individual line on a label may have different text options

selected.

Page 27

CREATING TEXT

27

A

Vertical Text

Vertical text can be created by following these steps:

1. At the home screen, press and then press to rotate the entire

label 90 degrees in the clockwise direction. (Note: when using continuous

tape, the label will automatically be rotated 90 degrees in the clockwise

directions by default.)

2. Enter text

3. Move the cursor over any character within the text string and then press

the key. Use the up or down directional arrows to select ‘Orient’.

Next, use the left directional arrows to change the setting to 270. Last,

press the key to accept the change and to return to the home

screen.

4. The result will appear similar to this example:

B

C

Page 28

CREATING SERIALIZATIONS

28

The Serialization Tool

The serialization tool is used to automatically number labels in a sequence.

The sequence can be either numeric (1 to 999) or alphabetic (A to Z). A

serialization is defined by a start value, an end value, and a step value.

To correctly define a serialization, the end value must be larger than the start

value and the start and end values must be both numeric or both alphabetic.

(Numbers and letters cannot be used together when defining a particular

serialization.)

The step value can be any number between 1 and 99.

Serializations can be combined with other label items, such as text, boxes,

lines, etc. For example, to create a prefix or a suffix to a serialization, enter

text immediately before or after the serialization.

Serializations can be printed as text or as bar codes on a label.

Creating a Serialization

The serialization tool should be accessed from the home screen. To access

the serialization tool:

1. Press the key to enter the tools menu.

2. Press the down directional arrow key to highlight the serialization tool.

3. Press the key to select the serialization tool.

4. Use the up or down directional arrow keys to select the serialization

parameters: Start, End, or Increment.

5. Use the right or left directional arrow keys to set the values for Start,

End, or Increment.

NOTE: Pressing the right directional arrow key will highlight the

current value of the selected parameter. For a new

serialization the start and end values will display an asterisk *.

When the value is highlighted, enter a number (1 to 999) or a

letter (A to Z) and then press the key.

The cursor will automatically move to the next parameter.

6. Repeat step 5 for each parameter.

Page 29

CREATING SERIALIZATIONS

29

7. Press the key to accept the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without accepting changes.

8. On the home screen, the serialization tool icon will appear at the

position of the cursor.

More Serialization Parameters

The serialization tool includes more parameters on a second screen following

the first screen. The second screen includes Text Options, Copies, and

Group. To access the second screen press the down directional arrow twice

after Increment.

1. The Text Options parameter allows greater customization of the

serialization text. There are two text options available in Text Options:

style and orientation. The style can be set to either normal or

underlined. The orientation can be set to 0 degrees, 90 degrees, 180

degrees, or 270 degrees. The orientation setting refers to the rotational

position of the individual serialization characters.

To access text options, press the up or down directional arrow keys to

select the style or orientation.

Press the right directional arrow key to change the value of the text

options.

Press the key to accept the changes and to return to the previous

screen.

2. The Copies parameter determines the number of copies to print for the

serialization. The Copies paramet er can be set to any number from 1 to

99.

To change the Copies parameter, press the up or down directional

arrow keys to highlight Copies.

Press the right directional arrow key to highlight the current value of the

Copies parameter. The Copies parameter will default to a value of 1.

Enter the number of copies to print.

Page 30

CREATING SERIALIZATIONS

30

Press the key to accept the changes and to return to the previous

screen.

3. The Group parameter determines whether or not the copies of the

serialization items will be grouped together. The Group parameter only

works when more than one copy of a serialization is defined. The Group

parameter defaults to Yes.

If Yes is selected, then consecutive copies of the serialization items will

not be placed together. The result will resemble the following legend:

A01 A02 A03 A01 A02 A03

If No is selected, the consecutive copies of the serialization items will be

placed together. The result will resemble the following legend:

A01 A01 A02 A02 A03 A03

To change the Group parameter, press the up or down directional arrow

keys to highlight Group.

Press the right directional arrow key to select Yes or No.

Press the key to accept the changes and to return to the home

screen.

Advanced Serialization Options

The serialization tool includes several advanced options for customizing

labels. The advanced serialization options are Print As and Place On.

1. The Print As option determines whether the serialization will print as text

or as a bar code on the labels. The default setting will print as text. The

bar code settings can be changed in the setup menu. Printing a

serialization as a bar code is useful for asset tracking and component

manufacturing.

Page 31

CREATING SERIALIZATIONS

31

2. The Place On option determines whether the serialization will print on

consecutive labels or on consecutive pages of the same label. The

default setting for will print on labels. Printing a serialization on pages is

useful for creating serialized patch panel labels using die cut network

systems label media.

Editing a Serialization

To edit a serialization on the home screen, move the cursor over the

serialization and then press the key. Follow the steps listed above for

creating a serialization.

Page 32

CREATING SYMBOLS

32

The Symbol Tool

The Symbol Tool is used for creating safety or facility identification labels.

Common applications for these types of labels include pipe marking and

safety hazard signs. Most often these types of labels will require continuous

tape label media. Symbols may also be used on die cut label media, such as

self-laminating labels or heat shrink markers. However, for die cut label

media the symbol size will be restricted by the physical size of the labels.

Creating a Symbol

The symbol tool should be accessed from the home screen. To access the

symbol tool:

1. Press the key to enter the tools menu.

2. Press the down directional arrow key to highlight the symbol tool.

3. Press the key to select the symbol tool.

4. Use the right or left directional arrow keys to search the symbol library.

(see the next page for available symbols

5. Use the up or down directional arro w keys to increase or decrease the

size of the symbol.

6. Press the key to accept the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without accepting changes.

7. On the home screen, the symbol tool icon will appear at the position

of the cursor.

Editing a Symbol

To edit a symbol on the home screen, move the cursor over the symbol and

then press the key.

1. Use the right or left directional arrow keys to search the symbol library.

(see the next page for available symbols

2. Use the up or down directional arrow keys to increase or decrease the

size of the symbol.

3. Press the key to accept the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without accepting changes.

Page 33

CREATING SYMBOLS

33

NOTE: The symbol size will automatically default to match the text size on the

current line. Changing the text size will automatically change the symbol size

accordingly. There are 5 sizes available for each symbol. The sizes range

from 1 (smallest) to 5 (largest).

Currently available symbols and their assigned library numbers are listed

below. Additional symbols may be added to the VIPER™ LS6 firmware in the

future.

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

37 38 39 40 41

Page 34

CREATING LINES

34

A01

The Line Tool

The line tool allows custom placement of vertical and horizontal lines on a

label. The line tool is especially useful for creating patch panel, faceplate, or

terminal block labels. There are seven unique line settings available: Center

Horizontal, Center Vertical, Top, Bottom, Left, Right, and @ Pages. Each

of these settings may be turned on or off independently.

NOTE: The top, bottom, left, and right sides of the label will rotate

with the legend when a label is rotated between 0 and 90

degrees.

1. The Center Horizontal setting places a line through the center of the

label in the horizontal direction.

2. The Center Vertical setting places a line through the center of the label

in the vertical direction.

3. The Top setting places a line at the top of the label.

4. The Bottom setting places a line at the bottom of the label.

5. The Left setting places a line at the far left side of the label.

A02

A01 A02

A01

A01

A01

Page 35

CREATING LINES

35

6. The Right setting places a line at the far right side of the label.

7. The @ Pages setting places lines between each page of a label that has

multiple pages defined. The @ Pages setting is used for patch panel,

outlet, and terminal block labeling.

Creating a Line Tool

The line tool should be accessed from the home screen. To access the line

tool:

1. Press the key to enter the tools menu.

2. Press the right directional arrow key and then press the down directional

arrow key to highlight the line tool.

A01

A01 A02 A03 A04 A05 A06

3. Press the key to select the line tool.

4. Use the up or down directional arrow keys to select the desired line

position.

5. Use the right or left directional arrow keys to turn on or turn off the line

tool at the selected position.

6. Press the key to accept the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without accepting changes.

7. On the home screen, the line tool icon will appear on the right side of

the display when the line tool is activated.

Page 36

CREATING BOXES

36

The Box Tool

The box tool is useful for customizing a label. There are three unique box

settings available: Frame, Reverse, and Box Off.

The Frame setting places a box outline around the perimeter of the entire

label area.

The Reverse setting places a dark background with light text characters on a

label.

The Box Off setting deactivates the box tool.

Creating a Box Tool

The box tool should be accessed from the home screen. To access the box

tool:

1. Press the key to enter the tools menu.

2. Use the right directional arrow key to highlight the box tool.

3. Press the key to select the box tool.

4. Use the right or left directional arrow keys to select the box tool setting.

5. Press the key to accept the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without accepting changes.

6. On the home screen, the box tool icon will appear on the right side of

the display when the box tool is activated.

NOTE: If the box tool is activated, it will appear on all printed pages of a label.

WARNING

WARNING

Page 37

CREATING DATA LISTS

37

The Data Tool

The data tool is used to create printable data lists in the VIPER™ LS6. The

data tool is very useful for customizing labels because it allows up to one

hundred unique labels to be created from a list of data. With the data tool,

users can input, store, or transfer custom lists of data.

Creating a Data Tool

The data tool should be accessed from the home screen. To access the data

tool:

1. Press the key to enter the tools menu.

2. Press the down directional arrow key to highlight the data tool.

3. Press the key to select the data tool.

4. Use the up or down directional arrow keys to highlight the data tool

options, File, Data, Text Options, or Place On (see the description of

the data tool options below).

5. Use the right directional arrow keys to select each data tool option.

6. After making all changes to the data tool options, press the key to

accept all of the changes and to return to the home screen. Otherwise,

press the key to return to the home screen without accepting

changes.

7. On the home screen, the data tool icon will appear at the position of

the cursor.

Data Tool Options

The data tool menu lists four different options: File, Data, Text, and Place

On.

1. Selecting File enters the File Manager. Label files and data lists are

stored in the File Manager. File Manager can also be accessed from the

main setup menu. For detailed information about File Manager see the

section entitled Using File Manager on page 48.

In File Manager, use the up or down directional arrow keys to highlight

the file name or required action.

Use the right or left directional arrow keys to select a file name from the

list. There are twenty file storage locations in the VIPER™ LS6.

Page 38

CREATING DATA LISTS

38

Files may be saved, loaded, or deleted in File Manager.

Note: Selecting Delete All will erase all stored label files and data lists.

2. Selecting Data View/Edit enters the data list editing screen. This screen

looks very similar to the home screen because the data list editing

screen is a text editor. Use the data list editing screen to create or edit

text. Use the directional arrow keys to navigate within the text editor.

A data list may include up to one hundred individual labels. The current

label being edited is denoted by the number at the top of the data list

editing screen. Each list begins at label number one. To increase or

decrease the label number, press the shift key once and then press

either or . To exit the data list editing screen, press the key.

The VIPER™ LS6 will ask to Save the List? Press 1 to save or 2 to

bypass this screen. To save the list, enter a file name and press ,

then press . The screen will return to the data tool menu.

3. Selecting Text Options enters an editing screen for text style and

orientation. These two settings may be changed to provide greater label

customization. For more information about Text Options refer to the

section entitled “CREATING TEXT” on page 25.

4. Selecting Place On determines whether the data list will print on

consecutive labels or on consecutive pages of the same label. The

default setting for Place On will print on labels. Printing a data list on

pages is useful for creating patch panel labels or terminal block labels.

Use the right or left directional arrow keys to change the Place On option.

Editing a Data Tool

To edit a data tool on the home screen, move the cursor over the data tool

and then press the key. Follow the steps list above for creating a data

tool.

Transferring a Data List

A data list created using the data tool may be transferred to or from a

personal computer in the .DAT format by using the LS6-PCKIT. The LS6-

PCKIT includes ViperLink software and a serial cable for connecting the

VIPER™ LS6 to a computer. For more information about ViperLink refer to

the sections entitled “INTERFACING WITH A COMPUTER” and

Page 39

CREATING BAR CODES

39

The Bar Code Tool

The bar code tool can be used for bin labeling, component identification, or

asset management and can be used in combination with other tools. The bar

code tool can be printed with or without a checksum digit or human readable

text. The bar code symbology available in the VIPER™ LS6 is CODE 39.

Creating a Bar Code

The bar code tool should be accessed from the home screen. To access the

bar code tool:

1. Press the key to enter the tools menu.

2. Press the right directional arrow key and then press the down directional

arrow key to highlight the bar code tool.

3. Press the key to select the bar code tool.

4. Press the right directional arrow key to input text. Type the text in the

text window. The bar code must include at least one digit of text.

5. Press the key to accept the text.

6. Use the up or down directional arrow keys to highlight the other bar code

settings.

7. Use the right or left directional arrow keys to change the bar code

settings.

8. Press the key to accept all of the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without accepting changes.

9. On the home screen, the bar code tool icon will appear at the

position of the cursor.

Editing a Bar Code

To edit a bar code on the home screen, move the cursor over the bar code

and then press the key.

1. Press the right directional arrow key to input text. Type the text in the

text window. The bar code must include at least one digit of text.

2. Press the key to accept the text.

3. Use the up or down directional arrow keys to highli ght the other bar code

settings.

Page 40

CREATING BAR CODES

40

4. Use the right or left directional arrow keys to change the bar code

settings.

5. Press the key to accept all of the changes and to return to the home

screen. Otherwise, press the key to return to the home screen

without ac cepting changes.

Bar Code Settings

The default bar code settings can be changed in the setup menu. To change

the default settings, access the printer settings in the setup menu.

Readable: Indicates whether the bar code text is human readable or not. If

activated (bar code text is human readable) the setting will display Yes.

Checksum: Indicates whether the checksum digit is activated or not. If

activated (checksum digit is turned on) the setting will display Yes.

Bar Size: Indicates the width of the bar code. Available sizes are 0.010

inches, 0.015 inches, and 0.020 inches. The default width is 0.010 inches.

Serialized Bar Codes

The VIPER ™ LS6 is able to serialize bar codes. In order to do so, a

serialization must first be defined. Please see the section entitled

“CREATING SERIALIZATIONS” on page 28 for more information about

serialized bar codes.

Page 41

CREATING DATE/TIME STAMPS

41

The Date/Time Tool

The Date/Time Tool allows the user to print a date and/or a time stamp on a

label. The date and time printed on the label are defined by the internal clock

of the VIPER™ LS6. Please see section entitled “SETTING UP THE VIPER™

LS6” on page 44 for more information about setting the internal time and date.

Creating a Date/Time Tool

The date/time tool should be accessed from the home screen. To access the

date/time tool:

1. Press the key to enter the tools menu.

2. Press the up directional arrow key to highlight the date/time tool.

3. Press the key to select the date/time tool.

4. Use the up or down directional arrows to select date/time or text options.

5. Use the right or left directional arrow keys to select time or date

specifically or to modify the text options.

NOTE: The text options available within a date/time tool are the

same as those available for text editing on the home screen.

For more information about text options refer to the section

entitled “CREATING TEXT” on page 25.

6. Press the key to accept the changes and return the home screen.

Otherwise, press the key to return to the home screen without

accepting changes.

NOTE: If editing the text options, press the key twice to accept

the changes and return the home screen. Otherwise, press

the key twice to return to the home screen without

accepting changes.

7. On the home screen, the date/time tool icon will appear at the

position of the cursor.

Page 42

CREATING DATE/TIME STAMPS

42

Editing a Date/Time Tool

To edit a date/time tool on the home screen, move the cursor over the

date/time tool and then press the key.

1. Use the up or down directional arrows to select date/time or text options.

2. Use the right or left directional arrow keys to select time or date

specifically or to modify the text options.

3. Press the key to accept the changes and return the home screen.

Otherwise, press the key to return to the home screen without

accepting changes.

Page 43

USING THE PAGES FUNCTION

43

The Pages Function

The VIPER™ LS6 provides 8 separate pages for each label. Label items,

including text and tools may be placed on each of the 8 pages. The pages

function is particularly useful for creating non -standard serializations that do

not follow a common increment. The pages function is also useful for creating

text on patch panel labels.

Using the Pages Function

The page number icon in the lower right hand corner of the display indicates

the current page. For example, 1:8 indicates that page 1 of 8 is currently

displayed. To move forward one page, press the key and then press the

right directional arrow key. Likewise, to move backward one page, press the

key and then press the left directional arrow key.

Page 44

SETTING UP THE VIPER™ LS6

44

The Setup Menu

The setup menu is used to modify the default printer settings. The setup

menu should be accessed from the home screen. To access the setup menu

press the key. The setup menu will appear:

The available categories in the setup menu are Files, Mode, Utilities, and

Printer. Use the up or down directional arrow keys to highlight these options.

Use the right directional arrow keys to select the settings for each option.

After making all changes to the setup menu, press the key to accept all

of the changes and to return to the home screen.

1. The Files category accesses saved label files. Use the up or down

directional arrows to highlight Files, then use the right directional arrow

to enter File Manager. For more information about File Manager refer

to the section entitled “USING FILE MANAGER” on page 48.

2. The Mode category includes all of the predefined label formats available

in the VIPER™ LS6. These formats are Component, Wiremarker,

Terminal, Tape, Strip, and Network. See Editing Label Mode on page

45.

3. The Utilities category includes the VIPER™ LS6 utility functions. These

functions are Battery, ViperLink mode, and Remote Printer mode. See

Using Printer Utilities on page 45.

4. The Printer category includes VIPER™ LS6 printer settings. The settings

include Time, Date, Contrast, Heat, Label Feed, Languages, Units,

and Bar Code. See Adjusting Printer Settings on page 46.

Page 45

SETTING UP THE VIPER™ LS6

45

Editing Label Mode

To edit the label mode, press to enter the setup menu and:

1. Use the up or down directional arrows to highlight Mode.

2. Use the right or left directional arrow keys to change the mode.

3. Press the key to select the desired mode. A check mark icon will

appear next to the selected mode.

4. Press the key to accept the changes and return to the home screen.

MODE DESCRIPTION APPLICATIONS

Component Vertically centers legend Electrical components

Wiremarker Repeats legend until label is filled Wire and cable marking

Terminal Places legends at terminal

locations

Tape Rotates legends 90° Safety/facility ID, pipe

Strip Repeats legend until label is filled

and copies legend on two sides of

middle perforation

Network Places legends at port locations Data communications

Using Printer Utilities

To use printer utilities, press to enter the setup menu and:

1. Use the up or down directional arrows to highlight Utilities.

2. Use the right or left directional arrow keys to change the utilities setting.

3. Press the key to select the desired utility. A new screen will appear

indicating either Battery, ViperLink, or Remote Printer.

The Battery utility is used to charge the battery. See section entitled

“BATTERY INFORMATION” on pages 9-11.

The ViperLink utility is used to interface with ViperLink ™ software. See

sections entitled “INTERFACING WITH A COMPUTER” and

“VIPERLINK” on pages 49-52.

Terminal blocks

marking

Wire and cable ma rking

components

Page 46

SETTING UP THE VIPER™ LS6

46

The Remote Printer utility is used to print directly from Panduit software

applications such as PAN-MARK® or EASY-MARK™. See section entitled

“USING REMOTE P RINTER UTILITY” on pages 53-54.

Adjusting Printer Settings

To adjust the printer settings, press to enter the setup menu and:

1. Use the up or down directional arrows to highlight Printer.

2. Use the right or left directional arrow keys to change the Printer setting.

1. The Time setting adjusts the internal clock. Press the key to

select Time. Use the right or left directional arrow keys to move the

cursor to the desired position. Use the numeric keys to change the

time. Press A for AM or P for PM. Press the key to accept all

of the changes and return to the setup menu.

2. The Date setting adjusts the internal date. Press the key to

select Date. Use the right or left directional arrow keys to move the

cursor to the desired position. Use the numeric keys to change the

date. Press the key to accept all of the changes and return to

the setup menu.

3. The Contrast setting adjusts the contrast of the printer display.

Press the key to select Contrast. Use the up or down

directional arrow keys to adj ust the contrast from 0 (light) to 9 (dark).

Press the key to accept the change and return to the setup

menu.

4. The Heat setting adjusts the temperature of the print head inside of

the printer. Press the key to select Heat. Use the up or down

directional arrow keys to adjust the heat from 0 (lower temperature)

to 9 (higher temperature). Press the key to accept the change

and return to the setup menu.

Page 47

SETTING UP THE VIPER™ LS6

47

NOTE: The heat setting is automatically adjusted to the

appropriate number for the installed label roll when the

printer is turned on.

5. The Label Feed setting adjusts the amount of media that is fed past

the cutter mechanism after printing. Cut Label feeds just enough

media to allow cutting. Peel Label feeds extra media to allow

convenient removal of die cut labels from the liner. Press the

key to select Label Feed. Use the right or left directional arrow keys

to select Cut Label or Peel Label. Press the key to accept the

change and return to the setup menu.

6. The Languages setting adjusts the operating system language.

Press the key to select Languages. A check mark icon is

displayed next to the currently selected language. Use the right or

left directional arrow keys to select or

Deutsch. Press the key to accept the change and return to the

setup menu. The display will immediately change to the language

selected.

7. The Units setting adjusts the internal unit of measurement within the

printer from English units (inches) to Metric units (millimeters). The

unit of measurement is important when entering a fixed length for

continuous tape. Press the key to select Units. A check mark

icon is displayed next to the currently selected unit of measurement.

Use the right or left directional arrow keys to select Inches or

Millimeters. Press the key to select the desired units and return

to the setup menu.

8. The Bar Code setting adjusts the default values for the bar code

tool. This setting is used to change the default values for human

readable, checksum, and bar size.

Page 48

USING FILE MANAGER

48

The VIPER™ LS6 has the ability to store and recall label files and data lists.

Label files and data lists are stored and recalled within File Manager. Label

files are designated with a .LS6 ending. Data lists are designated with a

.DAT ending.

To access File Manager, enter the setup menu and:

1. Use the up or down directional arrows to highlight File.

2. Press the right directional arrow key to enter File Manager.

3. Use the up or down directional arrow keys to highlight Filename .

4. Use the right or left directional arrow keys to select the desired file.

There are 20 file storage locations in the VIPER™ LS6.

NOTE: When saving a new file, press the key to begin entering

a file name. Use the alphabetic or numeric keys to enter a

file name. After entering a file name, press the key

again to Save .

NOTE: When renaming a previously saved file, press the key to

begin entering the new file name. Use the alphabetic or

numeric keys to enter the new file name. After entering the

name, press the key again to Save . The printer will

then prompt to Overwrite File? 1-Yes 2-No. Press 1 to

accept the new file name or press 2 to keep the previous file

name.

5. Use the up or down directional arrow keys to highlight Action.

6. Use the right or left directional arrow keys to select Save , Load, Delete,

or Delete All.

WARNING: Selecting Delete All will erase all stored label and data

files.

7. Press the key to complete the selected action.

8. Press the key to return to the setup menu.

9. Press the key again to return to the home screen.

NOTE: When recalling a previously stored label file, the part number

of the stored label file must match the part number of the

label roll installed in the printer. If the part numbers do not

match, an error message will display on the screen.

Page 49

INTERFACING WITH A COMPUTER

49

The VIPER™ LS6 can be connected to a personal computer (PC) using the

VIPER™ LS6 Upgrade Kit (Part No. LS6-PCKIT). The kit contains a CD with

ViperLink software and a serial cable for connecting the VIPER™ LS6 to your

personal computer (PC). ViperLink™ must be used with the serial cable to

communicate with the VIPER™ LS6 printer. If the personal computer has a

USB port, but does not have a serial port, it is recommended that the user

purchase a USB to serial adapter.

ViperLink™ software allows the user to:

• Upgrade the printer operating system.

• Transfer files (.DAT or .LS6) from the VIPER™ LS6 to the PC.

• Transfer files (.DAT, .LS6, or .CSV) from the PC to the VIPER™ LS6.

• Create, edit, and store a data list (.DAT file).

• Convert a .DAT file to a .CSV file

• Convert a .CSV file to a .DAT file

• Retrieve printer status information.

• Print directly to the VIPER™ LS6 using a simple label editor.

When printing directly from ViperLink to the VIPER™ LS6, the

VIPER™ LS6 must be in the remote printer utility.

The serial cable also allows the user to:

• Print directly to the VIPER™ LS6 using PAN-MARK® or EASY-MARK™

software from Panduit Corp. PAN-MARK® or EASY-MARK™ files cannot

be stored in the LS6.

For more information about using the Viper™ LS6 with PAN-MARK® or

EASY-MARK™ see the section entitled “USING REMOTE PRINTER

UTILITY” on pages 53 -54.

NOTE: ViperLink software does not allow a user to download .bmp

or .jpg images to the VIPER™ LS6 printer.

Page 50

VIPERLINK

50

Installing ViperLink

Use the ViperLink CD to install ViperLink software onto a personal

computer. The ViperLink CD is only available with the purchase of LS6-

PCKIT.

Insert the CD into a personal computer. The installation program will begin

automatically. Follow the instructions in the installation wizard in order to

complete the installation process.

Using ViperLink

To use ViperLink software with the Viper™ LS6 printer:

1. Connect the serial cable (included with the LS6-PCKIT) to a personal

computer at the 9 pin serial port.

2. Connect the serial cable to the Viper™ LS6 at the RS232 port.

3. Turn ON the Viper ™ LS6.

4. Press the key to access the setup menu.

5. Use the up or down directional arrow keys to highlight Utilities.

6. Use the right or left directional arrow keys to select ViperLink.

7. Press the key to begin using the ViperLink utility. The LS6 is now

ready to communicate to a personal computer.

8. Open ViperLink software on a personal computer.

To upload or download label files or data lists, select:

Transfer -> File Transfer

Choose COM 1 or COM 2

Choose to Upload or Download a file.

Page 51

VIPERLINK

51

If uploading, choose a file from the VIPER™ memory and Save As.

If downloading, first Browse for the file and select the file type, click

Open, and click OK.

To upgrade the LS6 operating system, select:

Transfer -> Upgrade Flash Memory

Browse to locate the operating system file

Click Open

Choose COM 1 or COM 2

Click Upgrade

NOTE: Upgrades for the VIPER™ LS6 internal operating system are

available for downloading from the Panduit Corp. web site at

www.panduit.com.

NOTE: The VIPER™ LS6 screen will go blank and flicker during the

upgrading process.

NOTE: Downloading an unauthorized binary (.BIN) file into the LS6

will result in non-functionality of the printer.

DO NOT INTERRUPT THE FILE TRANFERRING PROCESS!

To convert a .CSV or .DAT file, select:

Transfer -> CSV/DAT conversion

Click CSV to DAT or DAT to CSV

Browse to locate the appropriate file

Click Open, Enter the file name, Click Save

NOTE: Use Microsoft® Excel to create a spreadsheet of up to 4

columns by 100 rows. Save this data as a .CSV file.

Transfer this file to the VIPER™ LS6 by using ViperLink and

selecting download. The .CSV file will be converted into a

.DAT file automatically. The columns from the spreadsheet

will convert into lines 1 through 4 within a data list item. The

rows from the spreadsheet will convert into consecutive items

within a data list.

Page 52

VIPERLINK

52

To request information from the VIPER™ LS6, select:

Request -> LS6 Info

Choose COM 1 or COM 2

Choose Version, Status, or History

Information from the VIPER™ LS6 will be retrieved and displayed in

ViperLink

To access the help topics, select:

Help -> Help Topics

To create a data list,

Enter a database name, Enter text on lines 1-4 of item 1

Use the up directional arrow button to advance to the next item

Use the down directional arrow button to return to the previous item

(The maximum number of items is 100) Click File -> Save

After creating a data list, follow the above instructions for

downloading a data list to the VIPER™ LS6

NOTE: The above operations are also available on the tool bar.

9. Press the key on the VIPER™ LS6 printer to exit the ViperLink

utility and return to the setup menu.

Page 53

USING REMOTE PRINTER UTILITY

53

In order to operate the remote printing feature on the VIPER™ LS6

printer, the personal computer connected to the VIPER™ LS6 must be set

up in the following manner:

1. Either PAN-MARK® or EASY-MARK™ software applications must be installed

on the personal computer. These applications are available exclusively

from Panduit Corp.

2. The LS6 print driver must be installed on the personal computer. The

LS6 print driver is included with PAN-MARK® or EASY-MARK™ software.

3. The communications port (COM PORT) must be set up correctly. For

example, to set up COM1 follow this procedure:

1. Click the start button at the bottom left corner of your computer screen.

2. Select Settings.

3. Select Printers.

4. Right click on PTR3.

5. Select Properties.

6. Select the Details tab.

7. Select Port Settings (make sure COM1 is selected above).

8. Use these settings:

Bits per second: 57600

Data bits: 8

Parity: None

Stop Bits: 1

Flow Control: Xon/Xoff

9. Click OK.

10. Click OK.

NOTE: Example above is for the Windows® 98 operating system.

Other Windows® operating systems may require

modifications to this procedure.

NOTE: Deactivate the communication of other peripheral devices to

the local serial port before using ViperLink.

To access the Remote Printer Utility with the Viper™ LS6 follow this

simple procedure:

1. With the printer ON and at the home screen, press .

2. Use the up or down arrow keys to scroll down to Utilities.

3. At Utilities, use the right or left arrow keys to scroll to Remote Printer.

4. Press Enter. The Remote Printer Screen will appear.

Page 54

USING REMOTE PRINTER UTILITY

54

5. The LS6 is now ready to print directly from PAN-MARK® or EASY-MARK

™

software.

6. If the label roll installed in the VIPER™ LS6 is changed while in the

Remote Printer utility, press the key to automatically adjust the

printer to the default settings for the new label roll.

7. To exit Remote Printer Mode, press .

With the VIPER™ LS6 in Remote Printer utility, open PAN-MARK® or EASY-

™

MARK

and begin creating labels. Make sure to select the appropriate LS6

label format within the software.

EASY-M ARK™ PAN-MARK®

In order to print from PAN-MARK® or EASY-M ARK™:

1. Attach the serial cable to the personal computer and the Viper™ LS6.

2. Click File on the computer screen.

3. Click Print.

4. Choose Panduit PTR3.

5. Ensure that ‘Portrait’ is selected in the PTR3 properties window.

6. Click OK until the print window disappears.

7. The following message may appear:

8. Click Yes.

9. A printing message will appear and the Viper™ LS6 will begin to print.

NOTE: Windows® XP printer properties may default to a larger page

size than allowed by the Viper ™ LS6 and may require

adjustment.

Page 55

PRINTER CLEANING INSTRUCTIONS

55

Cleaning the Print Head and Drive Roller

The print head should be cleaned regularly, and more often in harsh

environments. The drive roller should be cleaned whenever foreign matter,

such as dust or adhesive, is present.

1. Turn OFF power to printer.

2. Open the ribbon lock knob.

3. Remove any label media from print path.

4. Remove the ribbo n.

5. Power the printer on .

6. Position ribbon lock knob in locked position.

7. Extend width guide to greatest width.

8. Insert cleaning card (Part No.LS6-CLN) until resistance is met.

9. Press to feed cleaning card completely through printer.

10. Flip cleaning card over and repeat steps 8 & 9 as necessary.

11. If there are large deposits on the drive rollers, soak cotton swab in

Isopropyl Alcohol (Rubbing Alcohol) and remove deposits from rubber

roller with sweeping motion.

Caution: LS6-CLN (cleaning card) contains

alcohol, keep away from flames.

Page 56

PRINTER TROUBLESHOOTING

56

This section helps identify printer conditions and problems that can often be

solved by the user. If you are unable to correct the problem contact Panduit

Technical Support at 866-871-4571 or Panduit Customer Service at 800-777-

3300.

SYMPTOM ACTION

POWER

Printer does not

power up properly,

and LCD does not

come on.

PRINTING

Not pri nting.

Tools Too Big!

• To turn printer ON, depress the power button.

• Make sure the battery pack is fully charged.

Charge a drained battery pack for a minimum of

15 hours with LS6-ACS.

• Plug in AC Adapter. Ensure power cord is firmly

seated into adapter.

• Make sure battery pack plug is connected to

printer plug in battery compartment

• Battery pack is spent or damaged. Try a new

charged battery pack. (LS6-BP).

• Make sure printer:

1. Is turned ON

2. Has ribbon cartridge properly loaded

3. Ribbon cartridge locked in place

4. Label mandrel seated properly

5. Labels positioned in width guide correctly

• Remove ribbon cartridge and clean print

mechanism with provided cleaning card.

• The items on the home screen are too large for

the printable area. Adjust the text size on the

home screen, adjust the symbol size, rotate the

label, or use a larger label.

Page 57

PRINTER TROUBLESHOOTING

57

SYMPTOM ACTION

Media is not

advancing properly

in the printer.

Printed image is

full, but grayish or

“translucent”.

• Ribbon knob not locked. Rotate ribbon knob into

locked position.

• Ensure that labels are properly positioned in label

path and that width guides are in contact with both

sides of the label. Ensure that adjustable width

guide is locked in place in the correct notch.

• End of label roll reached. Detach end of label roll

from core.

• Label jam in printer. Label is caught in print

mechanism. To clear jam:

1. Turn printer power OFF.

2. Open label door.

3. Detach any printed labels with cutter.

4. Open ribbon lock knob.

5. Remove unprinted labels from the printer.

6. Carefully remove any labels caught in the

printer.

• Print head heat setting is too high. Reduce heat

setting. See procedure on page 46.

• Ribbon and media are incompatible. Test

alternative ribbon or media. See compatibility

chart on page 14.

Voids in printed

image: areas where

there is no print.

• Dust on label. Remove dust with compressed air

or place static tinsel across label unwind.

• Ribbon and media are incompatible. Tes t

alternative ribbon or media. See compatibility

chart on page 14.

• Print head elements or “dots” are dirty or

obstructed. Clean print head with pre-saturated

cleaning card (LS6-CLN) or soft -stemmed swab

and isopropyl alcohol. See cleaning instructions

on page 55.

• Ribbon may be wrinkled.

1. Unlock and remove ribbon cartridge from

printer.

2. Tighten ribbon in ribbon cartridge by turning

knobs.

3. Insert ribbon cartridge into printer.

• Print head elements or “dots” are burned out.

Replace print head.

Page 58

PRINTER TROUBLESHOOTING

58

SYMPTOM ACTION

Repetitive voids in

image.

Not printing any

image (or barely

any image).

Printer stalls or will

not print.

RIBBON

Ribbon is not

advancing properly.

Ribbon wrinkling.

Printer doesn’t stop

when out of ribbon.

Ribbon breaking.

LABELS

Labels not

registering

• Print head elements or “dots” are dirty or

obstructed. Clean print head with pre-saturated

cleaning card (LS6-CLN), or soft -stemmed swab

and isopropyl alcohol. See cleaning instructions

on page 55.

• Ribbon and media are incompatible. Test

alternative ribbon or media. See compatibility

chart on page 14.

• Ribbon or media is not loaded properly. Reload

ribbon and media, making sure both pass under

respective sensors.

• Ensure that labels are properly positioned in label

path and that width guides are in contact with both

sides of the label and locked in place in the

correct notch.

• Ribbon or media sensors are dirty or obstructed.

Clean sensors with soft -stemmed swabs and

isopropyl alcohol or compressed air.

• Ribbon is not loaded correctly. Load ribbon

properly at side of printer and ensure knob is in

lock position.

• Ribbon not loaded correctly. Remove ribbon, reinsert and lock.

• Ribbon not wound tightly prior to installation.

Remove ribbon, wind take-up until slack

disappears, re-insert ribbon and lock in position.

• Ribbon sensor is dirty or obstructed. Clean

sensor with soft -stemmed swab and isopropyl

alcohol or compressed air.

• Ribbon cartridge empty. Replace ribbon

cartridge.

• Make sure that label mandrel is firmly seated in

socket.

• Width guide is loose. Make sure the width guide

is properly located and fixed in place.

• Printer not reset for new label format. Turn printer

OFF, then ON again. Printer will re -calibrate for

new label.

Page 59

PRINTER TROUBLESHOOTING

59

SYMPTOM ACTION

Die-cut labels

continue to feed

without stopping.

BAR CODES

Poor edge

definition (bar

codes and

alphanumerics).

Bar codes

smearing (bar code

edges “bleeding” or

“feathering”.

Bars in bar codes

are too wide or too

narrow resulting in

a poor scan grade.

Insufficient print

contrast: Bars are

not dark enough,

spaces are not light

enough.

OTHER

Printer Locked Up

• Label sensor is dirty or obstructed. Clean sensor

with soft -stemmed swab and isopropyl alcohol or

compressed air.

• Width guide is loose. Make sure the width guide

is properly located and fixed in place.

• Ribbon and media are incompatible. Test

alternative ribbon or media. See compatibility

chart on page 14.

• Print head heat setting is too high. Reduce heat

setting until bar edges are clean. See proced ure

on page 46.

• Print head heat setting it too high/too low. Adjust

to optimize average bar growth (visually or with

verifier). See procedure on page 46.

• Overburn (too much ribbon transfer). Reduce

print head heat setting. See procedure on page

46.

• Print head heat setting is too low. Increase print

head heat setting. See procedure on page 46.

With printer OFF, Press and hold [R] and to

RESET the printer.