TAMKO TAM-RAIL User Manual

STRAIGHT RAIL

INSTALLATION INSTRUCTIONS

6, 8 or 10 Straight Rail Kit available in 36 or 42 rail heights

1

IMPORTANT PRODUCT SAFE TY AND

PRE-INSTALLATION INFORMATION

The following installation instructions are provided to guide you

through the installation process of the TAM‑RAIL® Straight Rail Kit.

TAMKO® Building Products, Inc. shall not be held liable for improper or

unsafe installations. Failure to follow these instructions may lead to an

unsafe product and will adversely effect coverage under the Limited

Warranty. TAMKO recommends that all designs be reviewed by

a licensed architect, engineer or local building official before

installation to ensure that they are safe and in compliance with local

building code requirements.

TOOLS REQUIRED FOR INSTALLATION

Tape measure, miter saw or hack saw, drill, #2 square drive bit, level,

safety glasses, and hearing protection. For larger construction projects, a

miter saw and drill are strongly recommended for quicker installation.

INSTALLATION STEPS

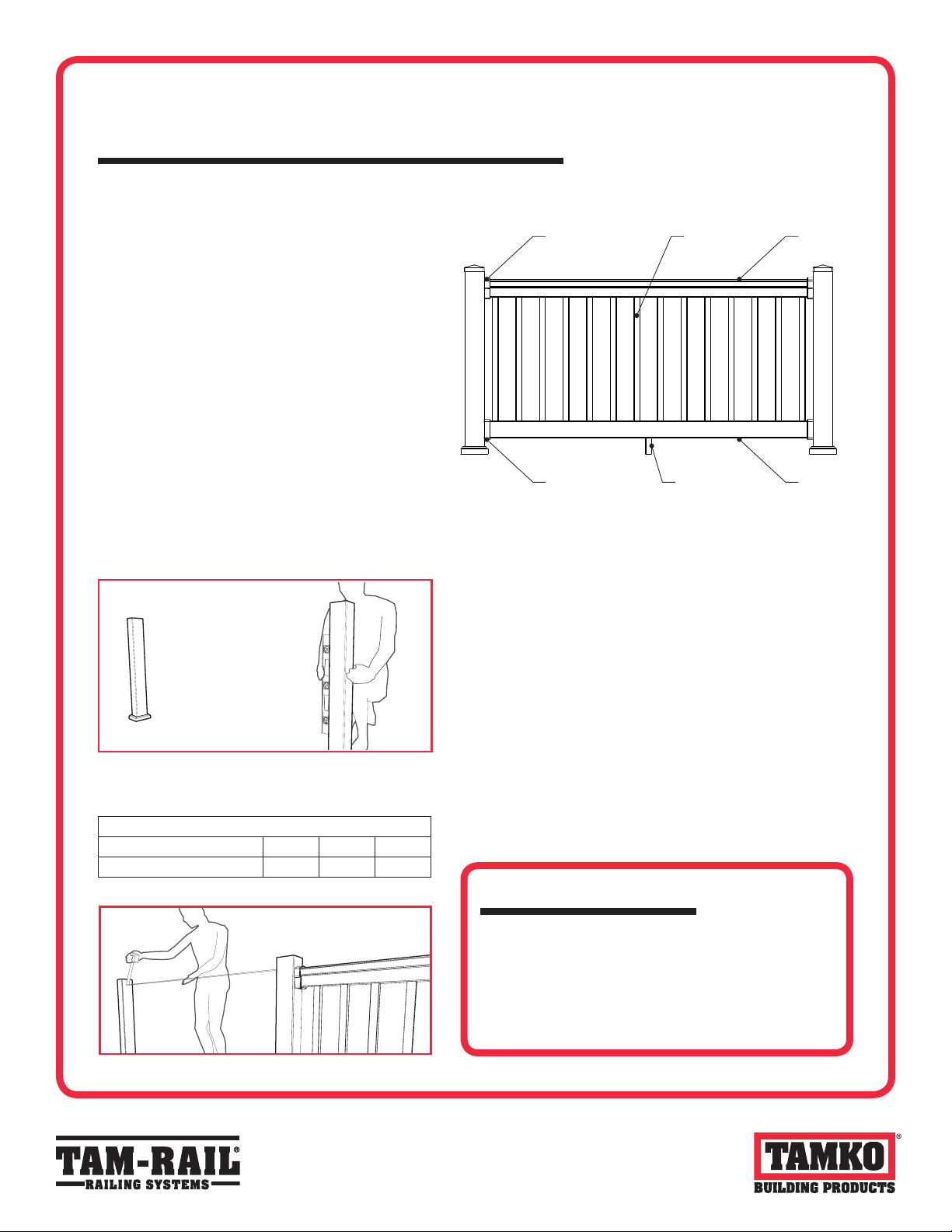

1. Install and prepare posts or other mounting surfaces for TAM‑R AIL

Railing installation. Ensure mounting surfaces are level and plumb.

(Fig. 1) TAMKO recommends using TAM‑R AIL Post Mount Systems

or wood posts covered with our matching TAM‑R AIL Post Sleeve.

FIG. 1

2. Measure the length between posts and confirm the

TAM‑R AIL Railing Kit required. (Fig. 2)

TAM‑RAIL STRAIGHT RAIL KIT RAIL LENGTHS

Nominal Rail Length 6' 8' 10'

Actual Rail Length 70‑1/4" 93‑7/8" 120"

TOP RAIL BRACKET COVER

BOTTOM RAIL BRACKET COVER CRUSH BLOCK BOTTOM RAIL

6 STRAIGHT RAIL

KIT COMPONENTS:

6' TAM‑R AIL Top Rail

6' TAM‑R AIL Bottom Rail

Square or

Colonial Balusters (14)

Top Rail Metal Brackets (2)

Bottom Rail Metal Brackets (2)

Top R ail

Bracket C overs (2)

Bottom Rail

Bracket C overs (2)

1" Stainless Screws (13)

2" Stainless Screws (13)

Crush Block (1)

Bracket Placement

Template (on box)

SUBSTITUTION FOR THESE COMPONENTS IS NOT ALLOWED

AS SUBSTITU TING COMPONENTS COULD CAUSE A SAFETY HAZ ARD.

8 STRAIGHT RAIL

KIT COMPONENTS:

8' TAM‑R AIL Top Rail

8' TAM‑R AIL Bottom Rail

Square or

Colonial Balusters (19)

Top Rail Metal Brackets (2)

Bottom Rail Metal Brackets (2)

Top R ail

Bracket C overs (2)

Bottom Rail

Bracket C overs (2)

1" Stainless Screws (13)

2" Stainless Screws (13)

Crush Block (1)

Bracket Placement

Template (on box)

TABLE OF CONTENTS

SQUARE BALUSTER

10 STRAIGHT RAIL

KIT COMPONENTS:

10' TAM‑R AIL Top Rail

10' TAM‑R AIL Bottom Rail

Square or

Colonial Balusters (24)

Top Rail Metal Brackets (2)

Bottom Rail Metal Brackets (2)

Top R ail

Bracket C overs (2)

Bottom Rail

Bracket C overs (2)

1" Stainless Screws (13)

2" Stainless Screws (13)

Crush Block (2)

Bracket Placement

Template (on box)

TOP RAIL

FIG. 2

Straight Rail .................. 1

Stair Rail ...................... 3

Wood/Composite

Post Mount ................... 5

Concrete Post Mount .... 6

45º Fixed Angle Bracket

Adapter ........................ 8

22.5º Fixed Angle

Bracket Adapter ..........10

Rise/Run Chart ...........12

For assistance, information regarding, or to receive a copy of

TAMKO’s Limited Warranty, contact us at 1‑800‑641‑4691 or

visit us online at tamko.com.

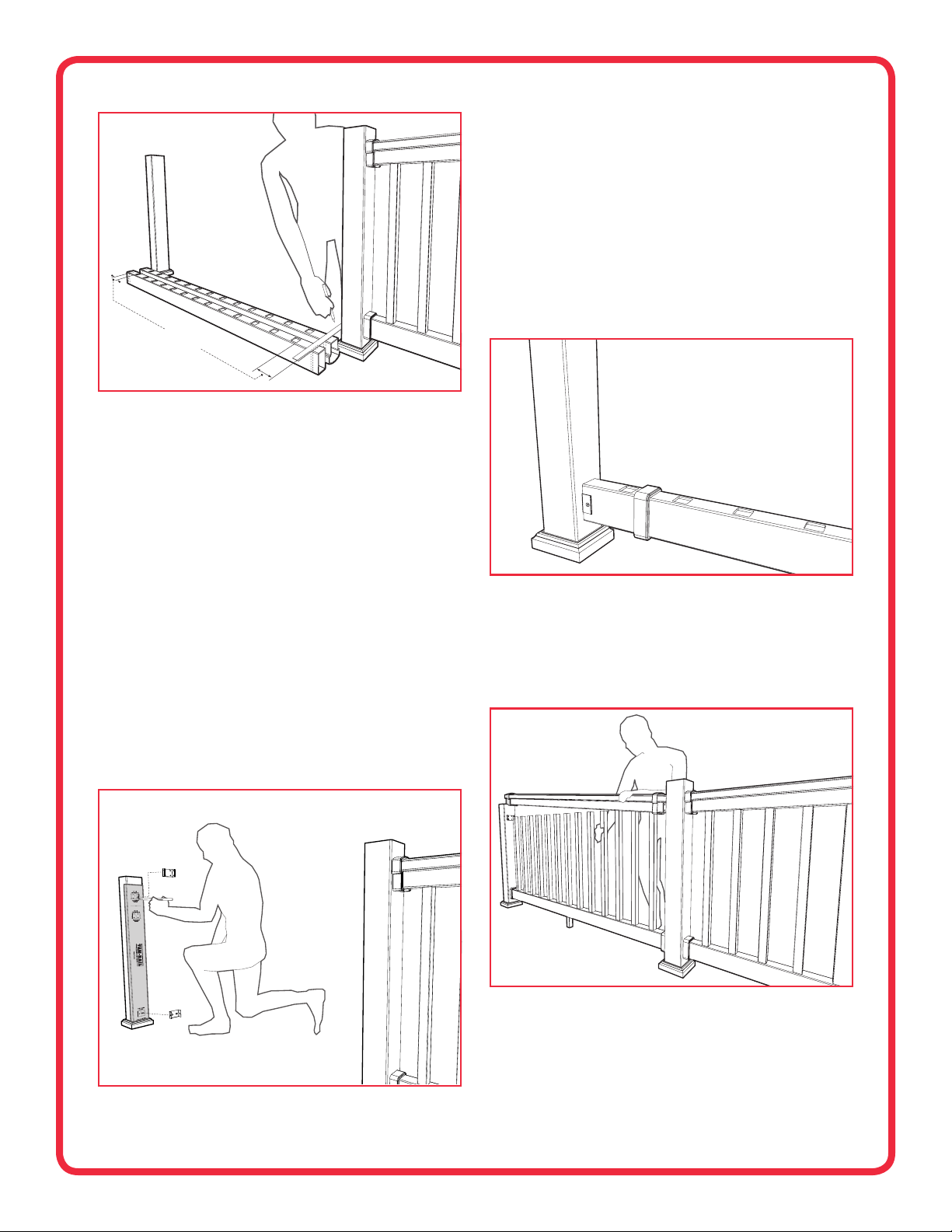

CONTINUED

2

the six screws provided, af fixing four on top and two on the bottom.

(Fig. 4) Use the 2" screws for mounting to a wood post, or the 1" screws

included in TAM‑RA IL Post Mount kit when mounting to the TAM‑RAIL

Post Mount System.

NOTE: The template is designed for a 2" clearance from deck surface to

bottom rail.

7. Slide bottom bracket covers over the bottom rail and position the rail

between the bottom rail metal brackets. (Fig. 5) Level the rail and secure

in place on both sides of the metal brackets using two of the 1" screws

provided. Snap the bracket covers over the metal brackets.

NOTE: When installing the bracket covers over the metal brackets, it may

be necessary to use a flat‑tipped screwdriver or putty knife to assist the

cover over the metal bracket.

MINIMUM

1-7/8"

FIG. 3

3. Lay the bot tom rail beside the posts with the pre‑routed baluster holes

facing upward and evenly spaced. Mark the rail with an additional 1/8"

removed from each end to compensate for the metal brackets. (Fig. 3)

IM POR TA N T: A minimum of 1‑7/8" rail length is required from the end of

rail to first baluster on both ends of the rail. Check end spacing and shift

the position of the rail before cutting if required. Ensure that the gap

between posts and balusters will not exceed 4".

When positioned and marked properly cut the bot tom rail.

4. Lay the top rail beside the bottom rail with baluster holes aligned. Mark

FIG. 5

and cut the top rail to match the bottom rail length and end spacing.

(Fig. 3)

5. Trim the crush block(s) to appropriate length and insert into the pre‑cut

hole(s) on the underside of the bottom rail.

NOTE: Typical crush block length is 5‑1/4" to allow for a 2" clearance

between the deck surface and bot tom rail. Be sure to check with your

local building code officials for any bottom rail clearance or rail

height requirements. Improper rail clearance or rail height could cause

8. Insert balusters into the pre‑routed bottom rail holes. Check with your

local code officials for any rail height requirements.

NOTE: Due to the aluminum inser t in the 10' rail, the top rail of 10'

sections will rest 3/8" higher than the 6' or 8' sections. The bottom of

the top rail metal bracket will install flush with the bottom of the top rail.

This will not af fect the integrity of the railing system.

a safety hazard. The formula for crush block length is: deck sur face to

bottom rail clearance + 3‑1/4".

6. Use the bracket placement template to position the top and bottom

metal brackets (marked “T” and “B”) and secure brackets in place using

FIG. 4

FIG. 6

9. Slide top bracket covers over both ends of the top rail. Align top rail over

the balusters and insert balusters one at a time until the top rail is fully

installed. (Fig. 6)

10. Secure top rail in place by installing two 1" screws on both sides of the

metal brackets. Snap bracket covers over the metal brackets.

NOTE: When installing the bracket covers over the metal brackets, it may

be necessary to use a flat‑tipped screwdriver or putty knife to assist the

cover over the metal bracket.

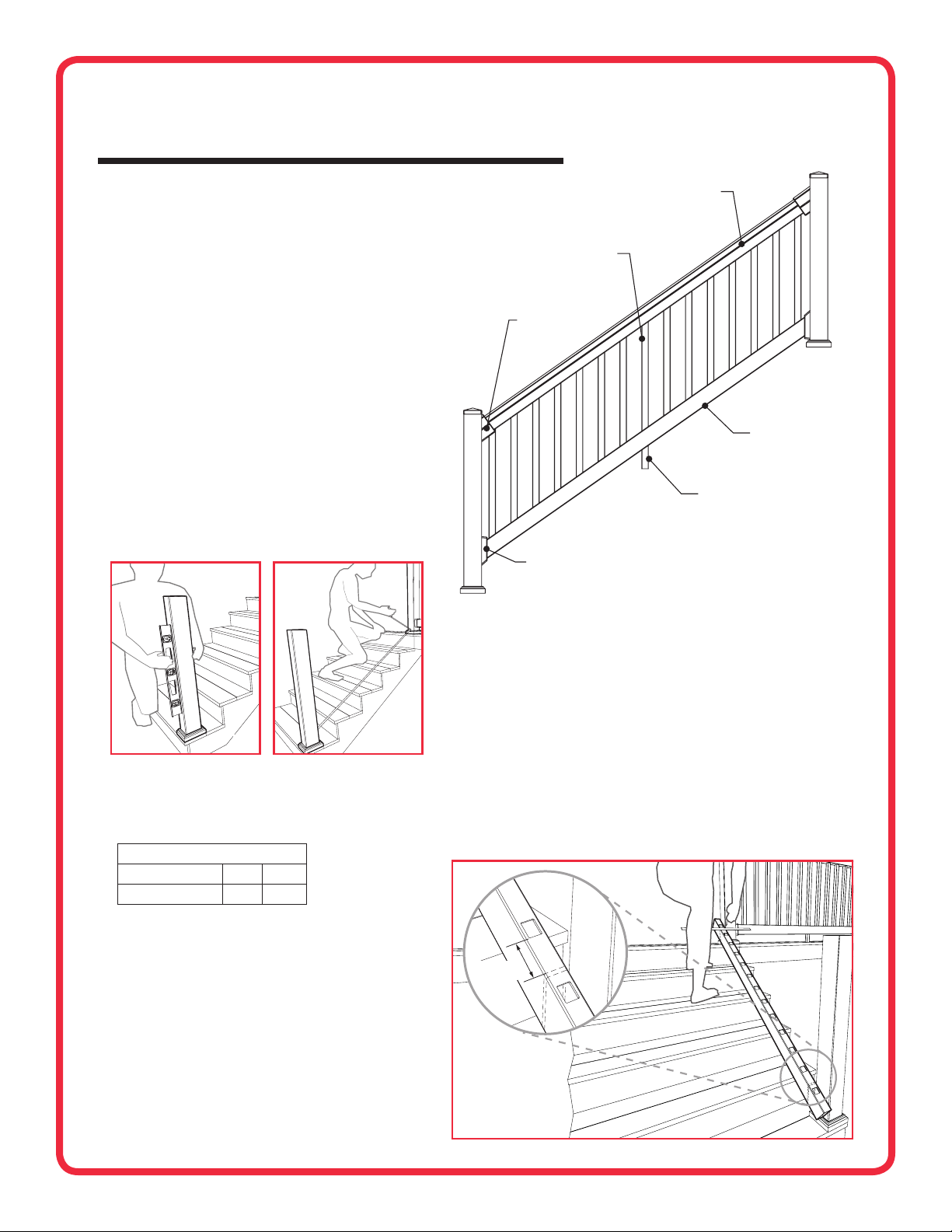

STAIR RAIL

INSTALLATION INSTRUCTIONS

3

6 or 8 Stair Rail Kit available in 36 or 42 rail heights

IMPORTANT PRODUCT SAFE TY AND

PRE-INSTALLATION INFORMATION

The following installation instructions are provided to guide you through

the installation process of the TAM‑RAIL® Stair Rail Kit. TAMKO® Building

Products, Inc. shall not be held liable for improper or unsafe installations.

Failure to follow these instructions may lead to an unsafe product and

will adversely effect coverage under the Limited Warranty. TAMKO

recommends that all designs be reviewed by a licensed architect,

engineer or local building of ficial before installation to ensure that they

are safe and in compliance with local building code requirements.

TOOLS REQUIRED FOR INSTALLATION

Tape measure, miter saw or hack saw, drill, #2 square drive bit, level, safet y

glasses, and hearing protection. For larger construction projects, a miter

saw and drill are strongly recommended for quicker installation.

INSTALLATION STEPS

1. Install and prepare posts for TAM‑R AIL Railing installation. Ensure

mounting surfaces are level and plumb. (Fig. 1) TAMKO recommends

using TAM‑RAIL post mount systems or wood posts covered with our

matching TAM‑RA IL post sleeve.

FIG. 1

FIG. 2

2. Measure the length between posts and confirm the TAM‑R AIL

Railing Kit required. (Fig. 2)

Refer to the TAM‑R AIL Stair Slope Chart on page 12 for the

degree of angle required.

TAM‑RAIL STAIR RAIL KIT RAIL LENGTHS

Nominal Rail Length 6' 8'

Actual Rail Length 78" 102"

3. Lay the bottom rail beside the posts with baluster holes facing

upward. The rail should extend past each of the mounting surfaces.

For 8' Rail Kits, verify that the crush block location on the underside

of the bottom rail will be positioned securely onto the stair tread.

4. Mark the required rail length with an additional 1/8" removed from

each end to compensate for the metal brackets. (Fig. 3)

IM POR TA N T: For even end spacing a minimum of 2‑3/8" rail length

is required from the end of rail to first baluster hole on both ends of

the rail. If even end spacing is not required, a minimum of 2‑3/8"

rail length on the lower end and 2" rail length on the upper end of

the rail is allowable. Check end spacing and verify minimum length

requirements prior to cut ting. Ensure that the end space gaps

between posts and balusters will not exceed 4".

When positioned and marked cut the bottom rail to the proper angle.

SQUARE BALUSTER

TOP RAIL

BRACKET

COVER

BOTTOM RAIL

BRACKET COVER

6 STAIR RAIL KIT COMPONENTS:

6' TAM‑R AIL Top Rail

6' TAM‑R AIL Bottom Rail

Square or C olonial Balusters (11)

Top Rail Metal Brackets (2)

Bottom Rail Metal Brackets (2)

Top Rail Bracket Covers (2)

Bottom Rail Bracket Covers (2)

1" Stainless Screws (13)

2" Stainless Screws (13)

SUBSTITUTION FOR THESE COMPONENTS IS NOT ALLOWED

AS SUBSTITU TING COMPONENTS COULD CAUSE A SAFETY HAZ ARD.

FIG. 3

MINIMUM

2-3/8"

TOP RAIL

BOTTOM RAIL

CRUSH BLOCK

8 STAIR RAIL KIT COMPONENTS:

8' TAM‑R AIL Top Rail

8' TAM‑R AIL Bottom Rail

Square or C olonial Balusters (15)

Top Rail Metal Brackets (2)

Bottom Rail Metal Brackets (2)

Top Rail Bracket Covers (2)

Bottom Rail Bracket Covers (2)

1" Stainless Screws (13)

2" Stainless Screws (13)

Crush Block (1)

CONTINUED

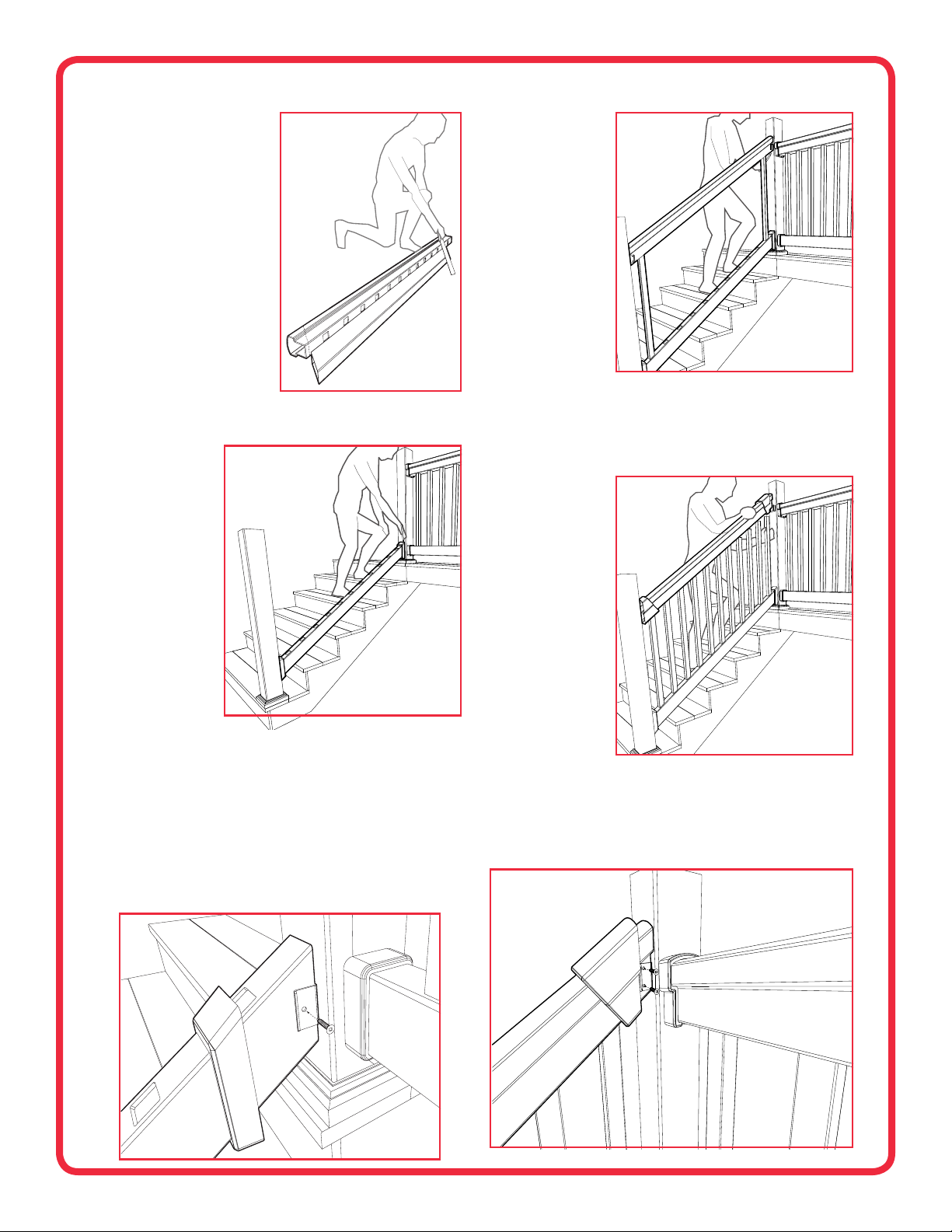

4

5. Lay the top rail beside the bottom

rail with baluster holes facing and

aligned. (Fig. 4) Using a straight

edge mark the continuation of

the bottom rail angle onto the

top rail. Ensure that the end

spacing from end of rail to first

baluster on each end of the top

rail matches the bottom rail end

spacing below. Cut the top rail.

6. Slide the bracket covers over

both ends of the bottom rail and

position the bottom rail between

posts at the desired height and

angle. Mark the location on the

posts. ( Fig. 5)

SkIp STEp 7 If yOU ar E

INSTallINg a 6' STaIr SECTION

FIG. 4

7. Trim the crush block to accommodate the desired bottom rail clearance

and insert into the pre‑cut hole on the underside of the bottom rail.

Be sure to

check with your

local building

code officials

for any bot tom

rail clearance

or rail height

requirements.

Improper clearance

or rail height could

cause a safety

hazard.

8. Position the bottom

rail metal brackets

(marked “B”) so that

they are centered

on both the post

and bottom rail and

FIG. 5

install using two of

the screws provided.

Use the 2" screws for mounting to a wood post, or the 1" screws

included in TAM‑RA IL Post Mount kit when mounting to the TAM‑RAIL

Post Mount System.

9. Position the rail between the bottom rail metal brackets. (Fig. 6) Level the

rail at the desired angle and secure in place on both sides of the metal

brackets using two of the 1" screws provided. Snap the bracket covers

over the metal brackets.

NOTE: When installing the bracket covers over the metal brackets, it may

be necessary to use a flat‑tipped screwdriver or putty knife to assist the

cover over the metal bracket.

10. Determine the

location of the top

rail metal brackets

(marked “T”). Insert

balusters in the first

and last holes of the

bottom rail. (Fig. 7)

Align top rail over the

balusters and install.

Ensure the top rail is

fully nested and level

with the bottom rail.

Position the top rail

metal brackets on

the rail and mark the

bracket locations on

each post.

11. Remove the top rail.

Position the top rail metal brackets on the posts and install using four of

the screws provided. Use the 2" screws for mounting to a wood post, or

the 1" screws included in TAM‑RAIL Post Mount kit when mounting to

the TAM‑RAIL Post Mount System.

12. Insert balusters into the pre‑routed bottom rail holes.

13. Slide bracket covers

over both ends of the

top rail. Align top rail

over the balusters

and insert balusters

one at a time until

the top rail is fully

installed.

(Fig. 8)

14. Secure top rail in

place by installing

two 1" screws on

both sides of the

metal brackets.

(Fig. 9) Snap bracket

covers over the

metal brackets.

NOTE: When

installing the bracket

covers over the metal brackets, it may be necessary to use a flat‑tipped

screwdriver or putty knife to assist the cover over the metal bracket.

FIG. 9

FIG. 7

FIG. 8

FIG. 6

Loading...

Loading...