TAMKO SA User Manual

ALTERNATE

APPLICATION

The instructions below are alternatives

to steps #4 - 7.

TAMKO

SELF-ADHERED

ROOFING SYSTEM

TAMKO® SA BASE

Self-Adhering SBS

Modifi ed Base Sheet

DESCRIPTION

TAMKO SA BASE is a fl exible, fi berglass reinforced, self-adhering

rubberized asphalt sheet membrane with a polymer fi lm on the surface and

a removable treated release fi lm on the adhesive side.

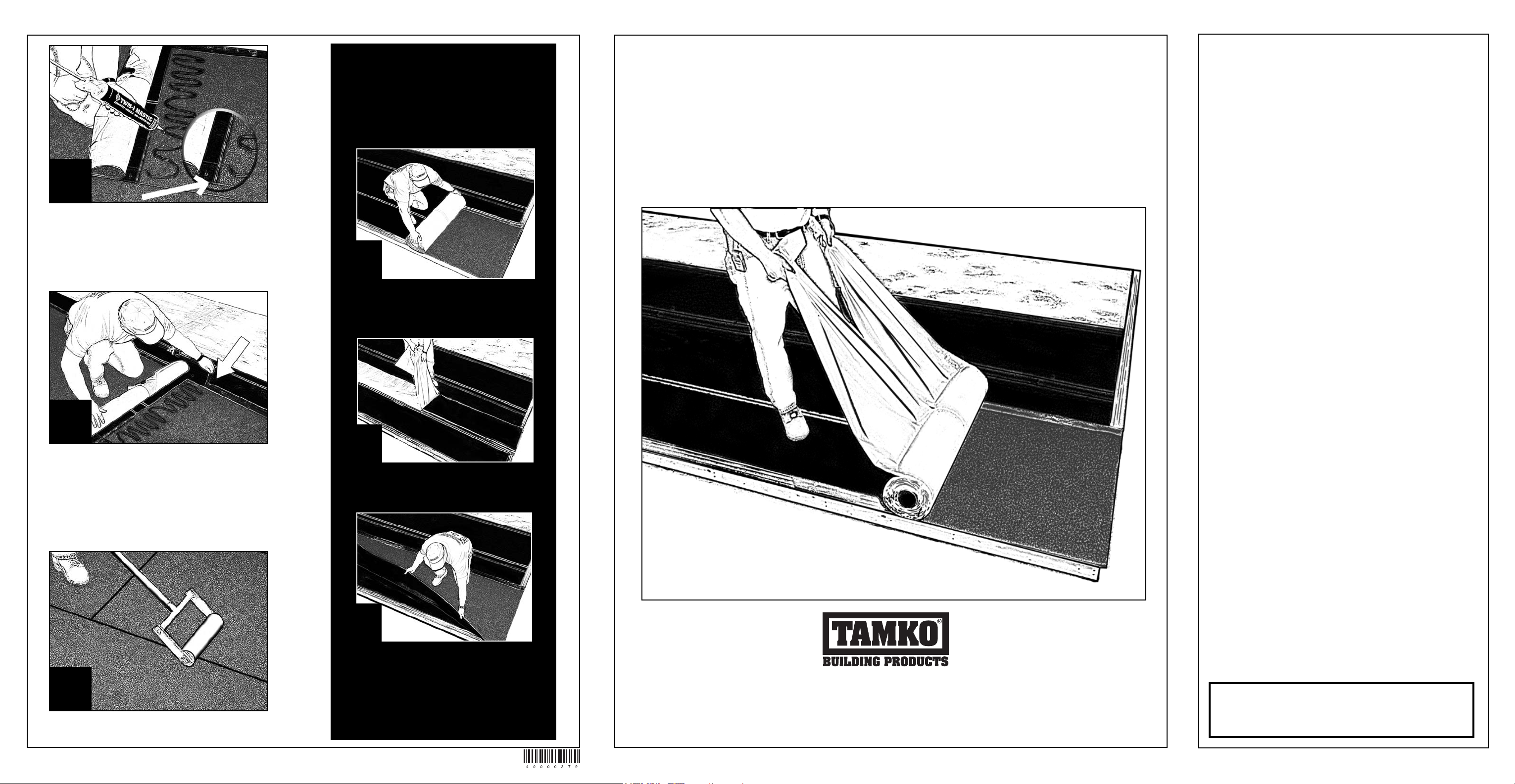

8

6” end laps should be handled as follows:

Apply the next roll by using a 4-6” bead of

TWM-1 Mastic, as pictured above. Apply an

additional bead of adhesive at the T-joint for

added protection against moisture infi ltration. Roll

end lap to ensure a solid contact. Make sure to

remove zip strip from bottom sheet.

9

After removing the release liner be sure to remove

zip strips from bottom sheet and from selvedge

edge on previous course as you apply the end

lap. Roll end lap to ensure a solid contact. As

you continue up the roof, apply additional courses

being sure to overlap all side laps by 3” and all

end laps by 6”. To avoid lining up end laps on

subsequent courses, TAMKO recommends a

minimum stagger of 18”.

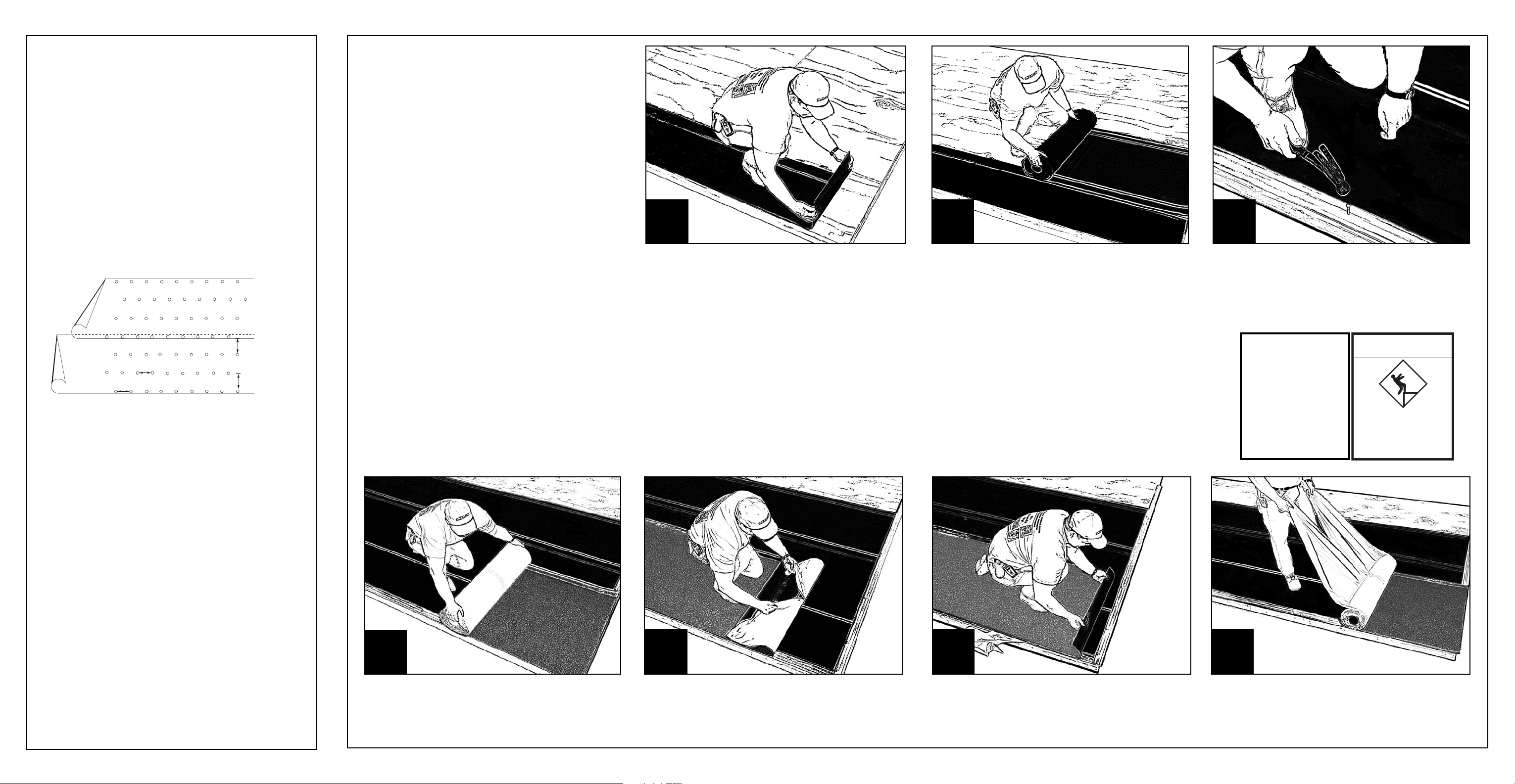

Alternate

Step

4

Roll out TAMKO SA Cap Sheet. Position

it with the selvedge on the high side of

the slope. Aligning it on the lower edge

of the roof.

Alternate

Step

5

The split release allows for application

of only one half of the membrane at a

time.

Alternate

Step

APPLICATION INSTRUCTIONS

USES

TAMKO SA BASE is used in TAMKO SA roofi ng systems along with the

SA CAP sheet. SA BASE can be easily applied by removing the split

release fi lm from the adhesive side and pressing the base sheet’s self

adhesive back surface into place. Alternatively, TAMKO SA BASE can be

mechanically fastened.

PRODUCT DATA

Reinforcement: Fiberglass Mat

Asphalt Modifi er: SBS

Roll Weight: 70 lbs (31.8kg)

Roll Size: 65’-10” x 39-3/8” (20.1m x 1m)

Product Thickness: 61 mils

Coverage: 2 square

1

TAMKO® SA CAP

Self-Adhering SBS

Modifi ed Cap Sheet

DESCRIPTION

TAMKO SA CAP is a lightweight, highly fl exible dual coated SBS modifi ed

cap sheet constructed with a non-woven polyester mat, self-adhering

adhesive, a split removable release fi lm on the adhesive side, and is

surfaced with ceramic granules for protection from ultraviolet degradation.

USES

Roofi ng membrane and fl ashing membrane in low sloped residential

applications and fl ashing details. This cap sheet is easily applied by

removing the split release fi lm from the adhesive side and pressing the

membrane’s self-adhesive back surface into place.

PRODUCT DATA

Reinforcement: Polyester Mat

Asphalt Modifi er: SBS

Roll Weight: 88 lbs (39.9kg)

Roll Size: 33’-6-1/4” x 39-3/8” (10.2m x 1m)

Product Thickness: 142 mils

Coverage: 1 square

1

10

Walk the membrane and roll the edges with a

roller to promote proper adhesion.

JP53813

6

Apply the top half of the sheet fi rst by

removing the release fi lm. Then apply

the bottom half of the roll. In subsequent

rolls when applying the bottom half

simultaneously remove the zip strip and

the bottom half of the release fi lm. Be

sure to overlap sidelaps by 3”.

Rev. 10/12/07

220 West 4th Street,

Joplin, Missouri 64802

1-800-641-4691

tamko.com

1

All values stated as nominal

CAUTION: The National Institute for Occupational Safety

and Health (NIOSH) has concluded that fumes of heated

asphalt are a potential occupational carcinogen. Do not

burn these products.

SPECIAL APPLICATION REQUIREMENTS FOR

AREAS/ZONES REQUIRING WIND UPLIFT RATINGS

Check and follow local building codes for applicable Product Testing and

deck assembly requirements.

This section includes Special Application Requirements for Areas/

Zones requiring wind uplift ratings.

IMPORTANT

The following assembly was used to test for compliance with UL 1897

to obtain a 45 psf wind uplift resistance rating:

Mechanically Fastened Base Sheet and Fully Adhered Cap Sheet

System.

• Wood supports (Joists or Rafters): nominal 2” x 10” deep wood

framing members, No. 2 grade Spruce-Pine-Fir, 24” OC spacing.

• Deck: Minimum 15/32” B- C APA Rated plywood sheathing

• Fasteners used to attach the plywood deck to the joists:

2” long, No. 8 course thread screws, spaced 6” OC at the

plywood edges and 12” OC in the fi eld of the plywood.

• TAMKO SA Base Sheet with 2” side seam mechanically

fastened with 1-1/4” long cap nails with 1” diameter metal

cap: 8” OC in seams and two rows 8” OC in fi eld, staggered.

12 "

8"

8"

TAMKO SA Base Sheet Nailing Pattern

• TAMKO SA Cap Sheet is fully-adhered to SA Base Sheet using self-

adhesive back.

• Be sure to sweep the Base Sheet prior to installation of the

Cap Sheet to help remove dust or dirt and help promote full

adherence.

• Walk the Cap Sheet and roll the edges with a roller to help

promote proper adhesion.

IMPORTANT

The following assembly was used to test for compliance with UL 1897

to obtain a 105 psf wind uplift resistance rating:

Primed Deck and Fully Adhered Base Sheet and Cap Sheet System.

• Wood supports (Joists or Rafters): nominal 2” x 10” deep wood

framing members, No. 2 grade Spruce-Pine-Fir, 24” OC spacing.

• Deck: Minimum 15/32” B-C APA Rated plywood sheathing

• Fasteners used to attach the plywood deck to the joists: 2” long,

No. 8 course thread screws, spaced 6” OC at the plywood edges

and 12” OC in the fi eld of the plywood.

• Deck Preparation: Deck should be primed with TAM-PRO

813 Quick Dry Primer at a rate of 3/4 gallon per square. Follow

primer application instructions on the product label. Drying time

ranges from 30 minutes to 4 hours depending on variations in

atmospheric conditions.

• TAMKO SA Base Sheet with 2” side seam is fully-adhered directly

to primed deck using self-adhesive back of base sheet.

• TAMKO SA Cap Sheet is fully-adhered to SA Base Sheet using

self-adhesive back of cap sheet

• Be sure to sweep the Base Sheet prior to installation of the Cap

Sheet to help remove dust or dirt and help promote full

adherence.

• Walk the Cap Sheet and roll the edges with a roller to help

promote proper adhesion.

12 "

How to Apply TAMKO’s

Self-Adhered Roofi ng System

General Application Instructions

DECK REQUIREMENTS

The deck must be built with a nominal 1/2”

exterior wood decking.

• All wood products must be properly conditioned

to be at moisture equilibrium. Failure to use proper

conditioned deck materials may result in deck

movement, which will distort the overlying roofi ng

materials.

• Distortion of roofi ng materials as the result of

deck movement is not a manufacturing defect of

the roofi ng product.

• Roof must have a positive slope with no ponding

water.

• Inclines over 3/4”:12 will require the SA membrane to be nailed at 6” intervals across the top of the

sheet using standard roofi ng nails and a minimum 1” tin plate or 1” capped nails (plastic or metal)

of adequate length to penetrate 1/2” into the roof deck.

• Proper ventilation is required. (Refer to FHA minimum property standards for ventilation)

• Remove all existing roofi ng materials, dust, dirt, loose nails, and other debris from the deck prior to

installation.

• For best application, prime exterior wood decking with ASTM D 41 primer. Primer should be allowed to

dry to the touch per the primer manufacturerʼs instructions, before applying the base sheet.

• Caution: Apply materials only in fair dry weather when the interface temperature (air, roof deck, membrane) is a minimum of 45ºF and rising.

• TAMKO SA Base and SA Cap should be stored in temperatures above 45° F. If TAMKO SA Base and SA Cap have been stored in temperatures below

45° F, the materials must be restored to a temperature above 45° F prior to installation.

4

Roll out TAMKO SA Cap Sheet. Position it with the

selvedge on the high side of the slope. Aligning it on the

lower edge of the roof.

• Both the TAMKO SA Base Sheet and the TAMKO SA

Cap Sheet must be installed in the same day.

1 2 3

Cut in half one ply of the 39-3/8” wide TAMKO SA Base

Sheet to 19-11/16” width. Starting at the low point of the

roof, remove the release fi lm and install this half sheet at a

right angle to the slope.

Then install a full 39-3/8” wide sheet side lapped 2” and end

lapped 4”. Remove release liner to adhere SA Base. Be

careful to offset the end laps a minimum of 18”. If TAMKO

SA Base nailing is required by local codes, see Alternate

Nailing Application for SA Base.

Alternate Nail Application for SA Base (See Special

Application Requirements and TAMKO SA Base Sheet

Nailing Pattern.) Apply subsequent base sheet courses

with 2” side laps and 4” end laps. Nail sheets along the lap

at intervals of no more than 8”, and stagger-nail down the

center of the sheet on 8” centers using standard roofi ng

nails and a minimum 1” tin plate or a 1” capped nail (metal).

5 6 7

Pull the release fi lm from the center to each edge on a 45˚

angle to expose the adhesive 1 to 2 feet.

Press adhesive side into base sheet and roll with a small

hand roller to assure solid contact.

Install metal drip edge at the rakes and eaves.

• All metal must be cleaned, to ensure excess surface

contaminates are removed, or all metal must be

lightly primed with an ASTM D 41 primer.

• Install metal drip edge at the rakes and eaves and nail

on 4” centers.

THESE ARE THE APPLICATION

INSTRUCTIONS FOR THE SA

BASE AND CAP ROOFING

SYSTEM. TAMKO BUILDING

PRODUCTS, INC. SHALL

NOT BE RESPONSIBLE FOR

LEAKS OR OTHER ROOFING

PROBLEMS RESULTING FROM

FAILURE TO FOLLOW THESE

INSTRUCTIONS. For questions

about or their application contact

TAMKO’s Technical Services

Department at 800-641-4691.

Roll up remaining SA Cap until the edge of the release

fi lm is exposed. Begin pulling the release fi lm up and off

the roll. Once the entire sheet is in place, roll or walk the

membrane to ensure solid contact with the base sheet.

WARNING:

APPROPRIATE FALL

PROTECTION METHODS

SHOULD BE USED WHENEVER

WORKING ON ROOFS.

PRODUCT MAY BE SLIPPERY

WHEN WET.

Information included in these application instructions was current at the time of printing. To obtain a copy of the most current version of these application instructions, visit us online at www.tamko.com or call us at 1-800-641-4691.

Loading...

Loading...