MODEL TK-300U SERIES

TWO THREAD DOUBLE CHAINSTITCH HEAVY

DUTY MACHINE

INSTRUCTION MANUAL &

PARTS BOOK

I.

•

ErA<•H@

~ -

'

r

TA KING INDUSTRIAL CO., LTD

CONTENTS

INSTALLATION .............................................................................................................3

LUBRICATION.................................................................................................................4

OPERAOR INFORMATION .........................................................................................4-7

ADJUSTMENTS................................................................................................................7-14

INDEX

INSTALLATION .............................................................................................................3

LUBRICATION ...............................................................................................................4

ARM SHAFT ....................................................................................................................4

BED SHAFT .....................................................................................................................4

OTHER POINTS .............................................................................................................4

SPEED ...............................................................................................................................5

NEEDLES .........................................................................................................................5

SETTING ..........................................................................................................................5

THREADING ...................................................................................................................6

UPPER ..............................................................................................................................6

LOWER ............................................................................................................................6

PRESSER FOOT. PRESSURE .......................................................................................7

TENSION ..........................................................................................................................7

PRESSER BAR. HEIGHT ..............................................................................................8

STITCH LENGTH ..........................................................................................................8

FEED BAR. HEIGHT .....................................................................................................9

FEED DOG. CENTRALIZING ......................................................................................9

HEIGHT ...........................................................................................................................9

LENGTHWISE SETTING .............................................................................................9

SIDEWISE SETTING .....................................................................................................9

TIMING ..........................................................................................................................10

LOOP DEFLECTOR .....................................................................................................10

NEEDLE BAR. POSITION ..........................................................................................10

LOOPER. POSITIONING ............................................................................................11

LENGTHWISE SEETING ...........................................................................................11

SIDEWISE SETTING ...................................................................................................11

NEEDLE BAR. HEIGHT .............................................................................................11

TIMING ..........................................................................................................................12

NEEDLE GUARD .........................................................................................................12

SPREADER. POSITIONING.........................................................................................13

LENGTHWISE SETTING ...........................................................................................13

SIDEWISE AND HEIGHT SETTING .........................................................................13

T AKE-UP. ADJUSTMENT ...........................................................................................14

LOOPER THREAD .......................................................................................................14

NEEDLE THREAD .......................................................................................................14

RELEASER ....................................................................................................................14

1

INTRUCTIONS FOR USING

ANTI-REVERSING MECHAINISM

ON MACHINES OF CLASSE 300U

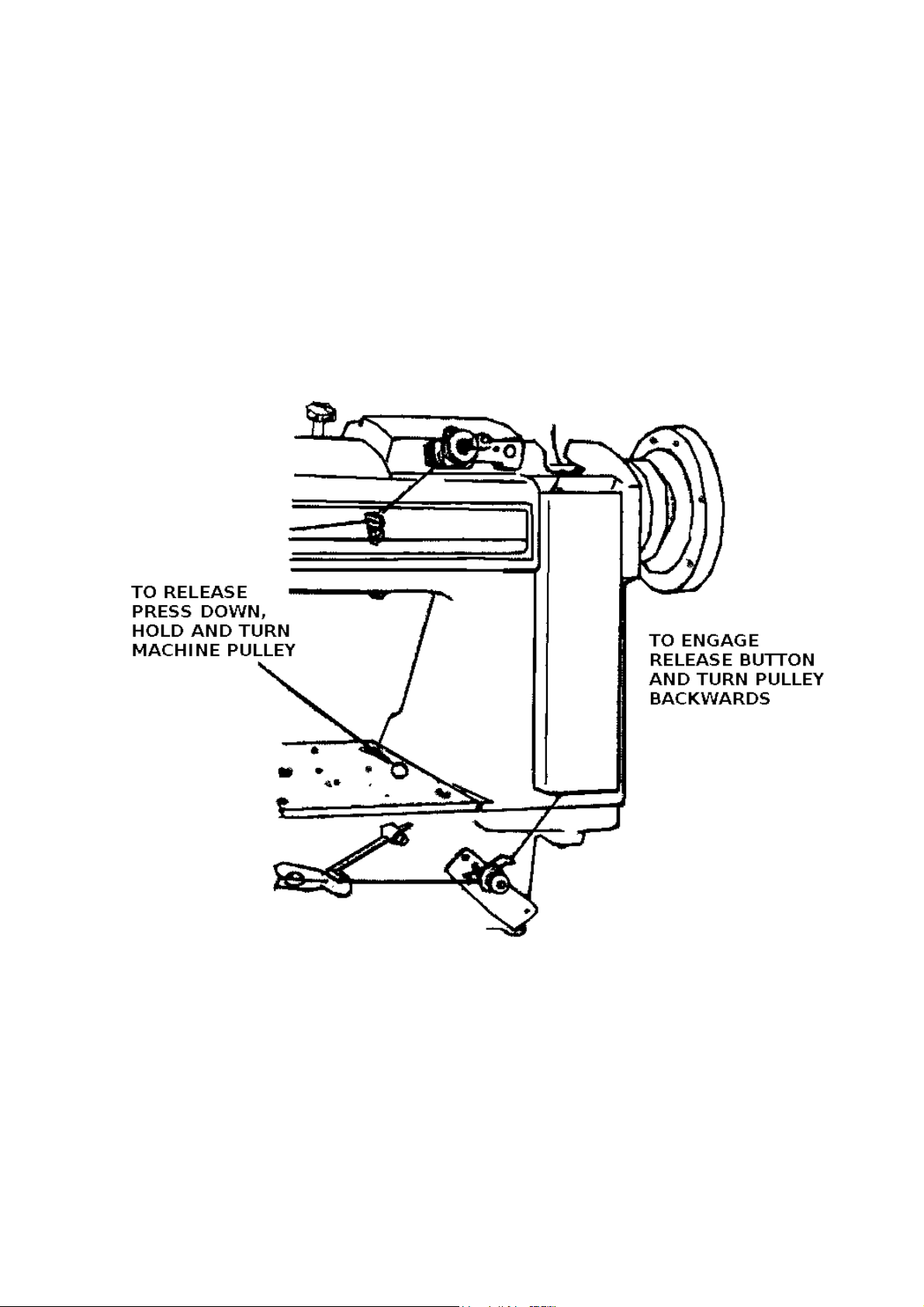

Machine 300U1C, are equipped with an ANTI-REVERSING device.

To release the device, depress button located on right side of bed plate, hold

down and turn machine pulley either forward or backward.

To engage the device, release button and turn machine pulley toward rear of

machine until device “snaps” into place.

TO

RELEASE

PRESS

HOLD

MACHINE

DOWN,

AND

PULLEY

TURN

TO

ENGAGE

RELEASE BUTTON

AND

TURN

BACKWARDS

PULLEY

•

• •

EQUALIZING THE FEEDING MOVEMENT OF THE NEEDLE FEED AND DROP FEED ON

MACHINES OF CLASSE 300U

<l.

The needle feed and drop feed should not only be timed to move

simultaneously, but should also move the same distance during feeding. If the drop

feed moves a greater or less distance than the needle feed, depress the stitch length

button and turn the machine pulley, as required, to cause the drop feed movement to

equal the needle feed movement. The stitch length of both feeds can then be reset

simultaneously, as described on page 8.

2

HANGERS

OIL

PAN

FOOT

LEVER

LIFTER

OIL

PAN

Fig.

3

Fig.2

(

INSTALLATION

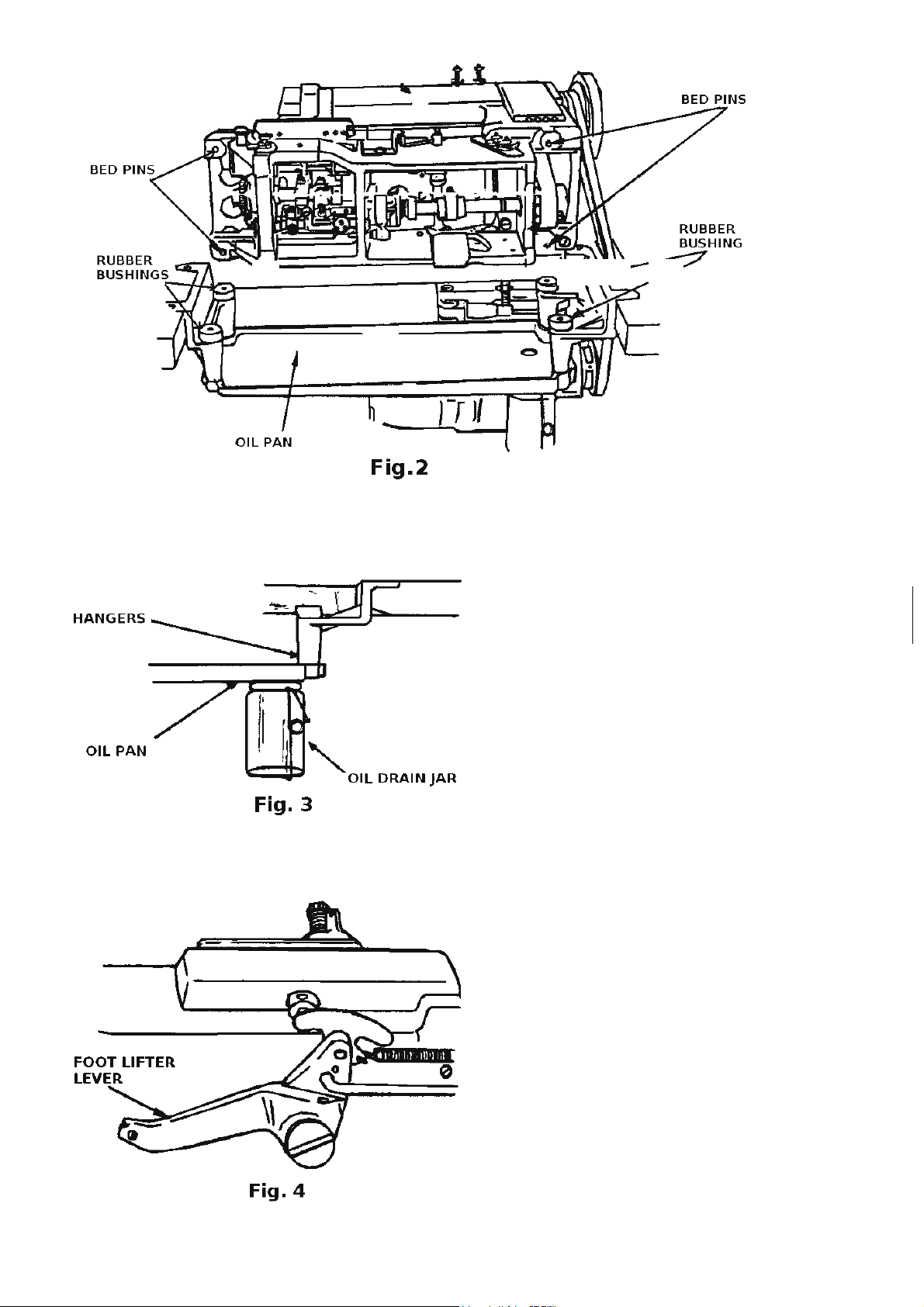

Assemble oil pan to hangers.

Insert assembled oil pan into

machine cut-out of table pacing four

rubber bushings in hanger holes as

shown in Fig. 2. Attach oil drain jar

to oil pan as shown in Fig. 3.

Place machine on oil pa

assembly with the four bed pins

passing through the four rubber

bushings shown in Fig. 2.

Connect foot lifter treadle to

foot lifter lever, Fig.4, at back of

machine by chain furnished for this

0

purpose.

Fig.

4

3

LUBRICATION

Machines of class 300U have a

semi-automatic lubricating system

comprising a hollow arm shaft and a

hollow bed shaft which act as oil

reservoirs. The oil is distributed to all of

the principal bearings by centrifugal force

through small jets in the shafts when the

machine is in operation. Provision is also

made of hand lubricating other movable

parts which are not lubricated from the

reservoirs.

Do not use additives in sewing

machine oil as they may cause a reduction

in the normal flow of oil that can result in

damage to the machine.

BEFORE STARTING machine, the

machine must be oiled as instructed.

Failure to do this will result in damage to

the machine.

Pressure Oil Can, furnished with the

machine, is to be used to oil all points

requiring lubrication.

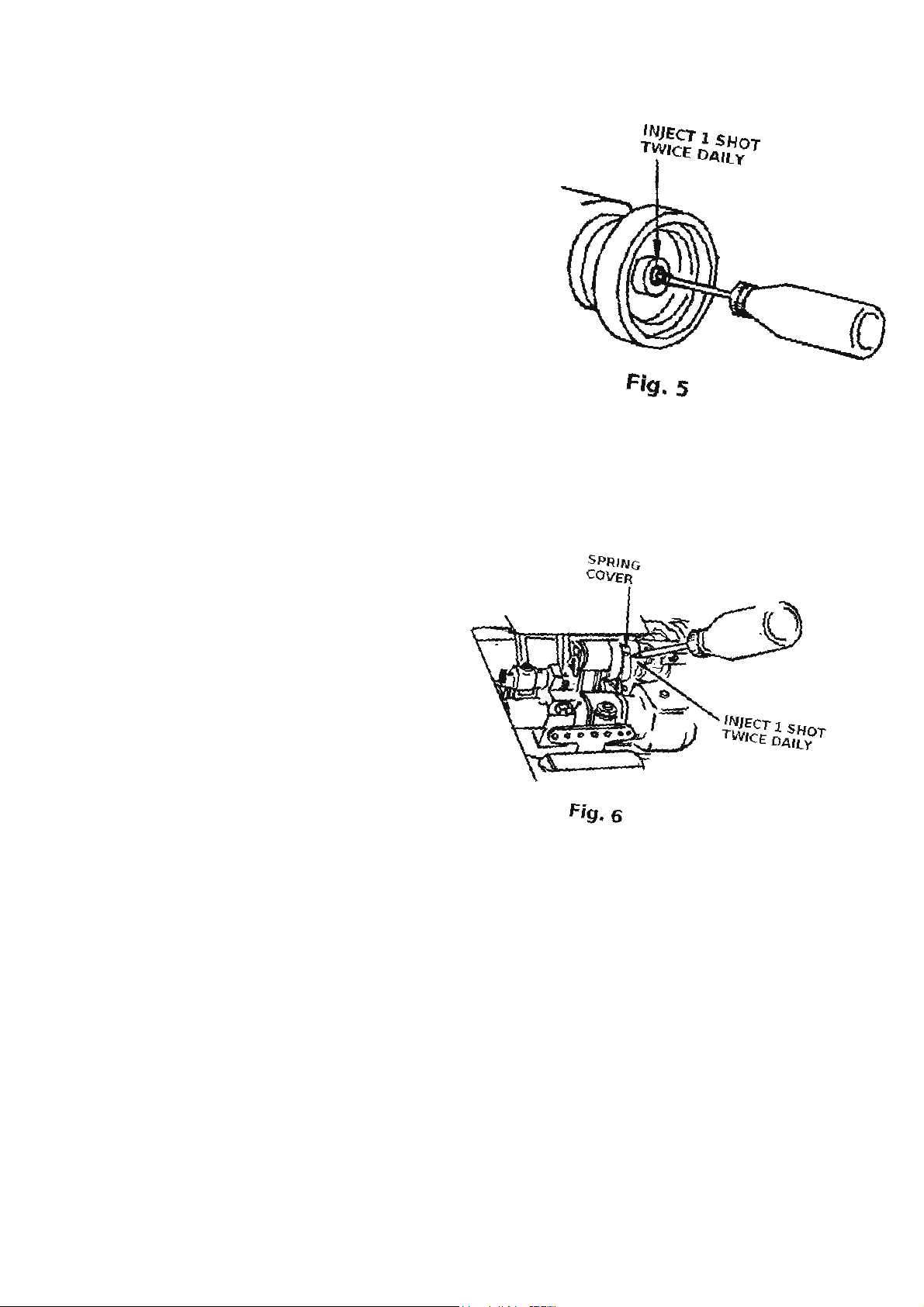

TO OIL ARM SHAFT

To fill arm shaft reservoir, insert

spout of pressure oil can in hole, Fig.5,

and inject 1 shot of oil into shaft twice

daily.

TO OIL BED SHAFT

To fill bed shaft reservoir, push

spring cover, Fig. 6 , to the lef t, insert spout

of pressure oil can into hole and inject 1

shoe of oil into shaft twice daily. Close oil

hole spring cover.

NOTE: Bed shaft may also be oiled

from right hand end of machine.

OTHER OILING POINGS

Apply oil to all work plate and arm

oil holes, needle bar bearings and

connections, needle bar rock frame

bearings, looper rocker sleeve and

presser lifting mechanism.

CAUTION: For machines in

continuous use, all oiling points

must be oiled daily, Occasionally oil

tension release mechanism and looper

pull-out rack.

CO

Fig

S

PRIN

. 6

INJECT l SHOT

TWICE

Fig. 5

G

VER

DAIL

Y

4

For heavier weight material, needle

Catalog 4112 (62x59) may also be used. In

this cause, the needle bar must be adjust

as instructed on page 10.

The size of the needle to be used is

determined by the size of the thread which

LOOSEN

SCREW

MOVE

HIGHEST

SCARF

TOWARD

MOVE

TO

HIGNEST

TO

POINT--~~--

OF

NEEDLE

LEFT

POINT

LOOSEN

SCREWS

must pass freely through the eye of the

needle.

Orders for needles should specify

quantity required, size number and catalog

number.

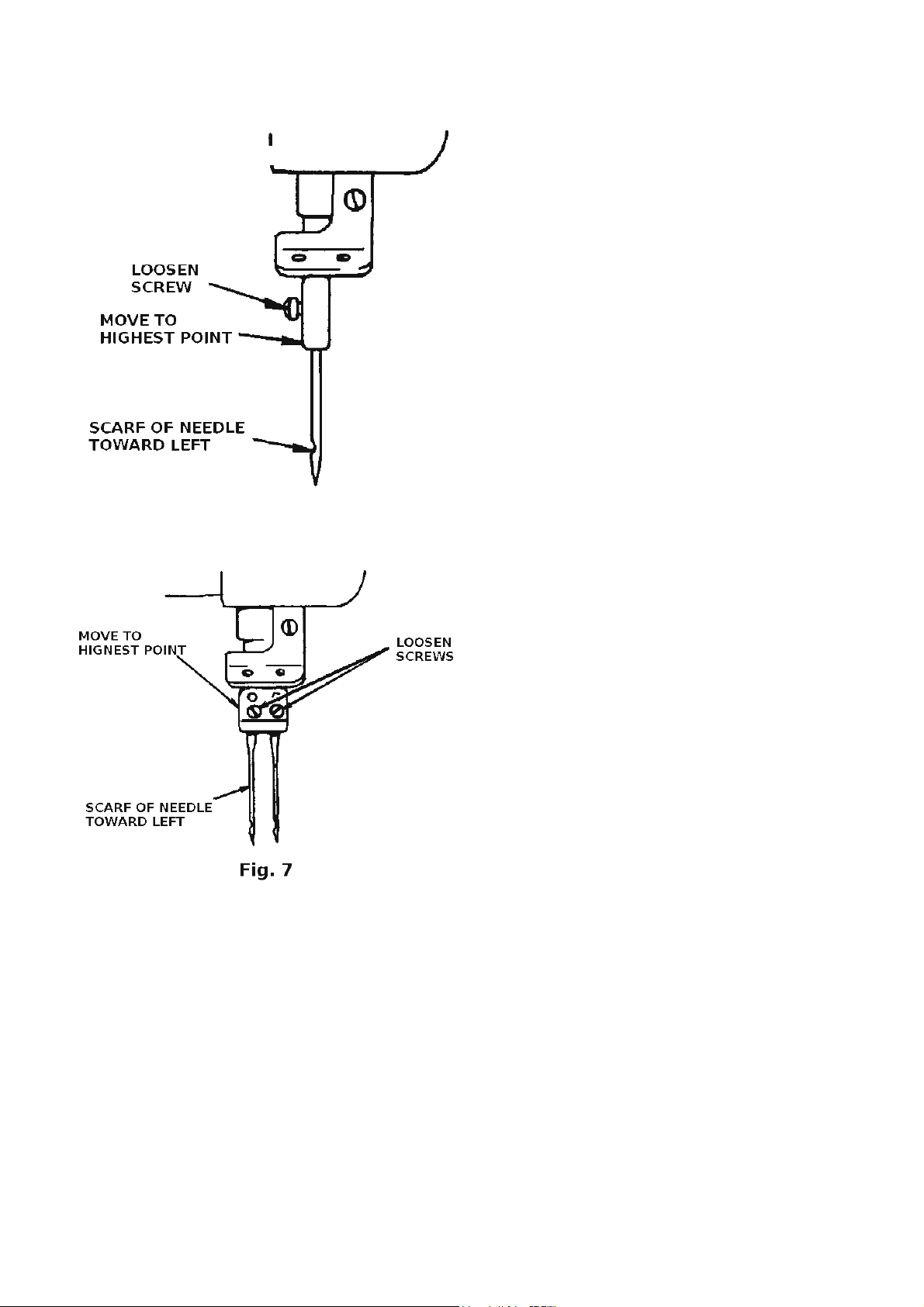

To Set The Needle

Turn machine pulley over toward the

operator until the needle bar is at its

highest point, as shown in Fig. 7.

Loosen needle set screw on single

needle machines or needle clamping

screws on multiple needle machines, as

shown in Fig. 7.

SCARF

TOWARD

OF

LEFT

NEEDLE

Fig.

7

Insert needle into needle bar or

clamp as far as it will go making certain

that the scarf of each needle faces toward

the left, as shown in Fig. 7.

THREAD

Either left twist or right twist thread

may be used in the needles and loopers.

Rough or uneven thread, or thread

which passes through the needle eye with

difficulty will interfere with successful

operation of the machine.

5

THREADING THE MACHINE

Upper Threading

Turn machine pulley over toward operator until needle bar is at its highest point.

Pass thread from unwinder through threading points indicated in Fig. 8. See

insert, Fig.8 for correct threading of needle.

Draw approximately two inches of thread through needle eye with which to start

sewing.

Single and multiple needle machines are all threaded as shown in Fig. 8. Make

certain that each thread passes through thread tension device.

Machines of Class 300U having Alternating Pressers are equipped with a thread

lubricator on front of the arm. The needle thread must pass though the lubricator.

Fig.

8

LOOPER

RACK R

THROW

OD

·OU

T

Lower Threading

Open front table section, remove bed

slide and turn machine pulley over toward

operator until needle bar is at its highest

point.

Move loopers out of sewing position

by pulling looper throw-out gear locking

plunger rod and looper throw-out rack rod,

Fig. 8, out as far as possible. This will place

loopers in position for easier threading and

prevent accidental operation of machine

until loopers are returned to sewing

position.

Threading The Loopers

Pass thread form unwinder through

threading points as indicated. Draw

approximately two inches of thread

through looper eye with which to start

sewing.

6

NEEDLE

THREADS

TENSION

Tension on thread should be light as

possible while still sufficient to set the

stitch correctly in material.

Fig.

MOREA

TENSION.-:.--

Fig.

9

10

LESS

TENSION

LOOPER

THREADS

7

~

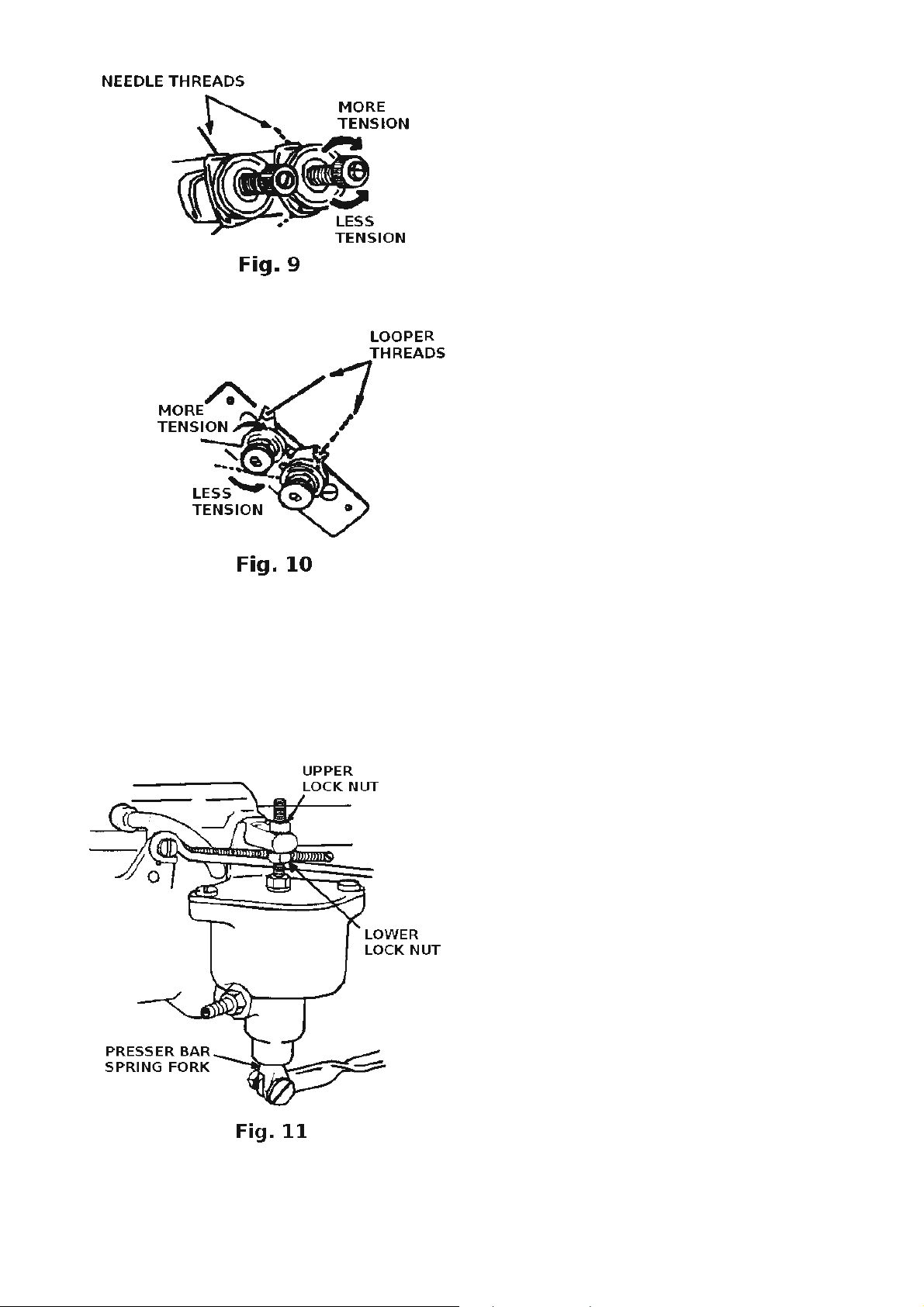

Needle Thread Tension

To regulate needle thread tension,

turn thumb screw, indicated in Fig. 9, as

may be required.

IMPORTANT: Regulate needle

thread tension only when presser foot is

down.

Looper Thread Tension

To regulate looper thread tension,

turn thumb screws, as indicated in Fig. 10,

as may be required.

PRESSER BAR

SPRING

FORK

Fig.

11

LOWER

LOCK

NUT

Altemating Presser with

Penumatic Pressure Control:

Adjust height of Pressure Cylinder

with presser feet resting on throat plate.

There should be a clearance of 6.4mm

between the Presser Bar Spring Fork and

the bottom of the cylinder. To raise

cylinder, loosen lower lock nut and tighten

upper lock nut, see Fig. 11. To lower

cylinder , lossen upper lock nut and tighten

lower lock nut. When correct adjustment is

attained,k tighten both lock nuts.

Resulate air pressure. The correct air

pressure is set for average feeding when

the Presser bar spring For rises to

approximately 1.9mm from the bottom of

the cylinder.

7

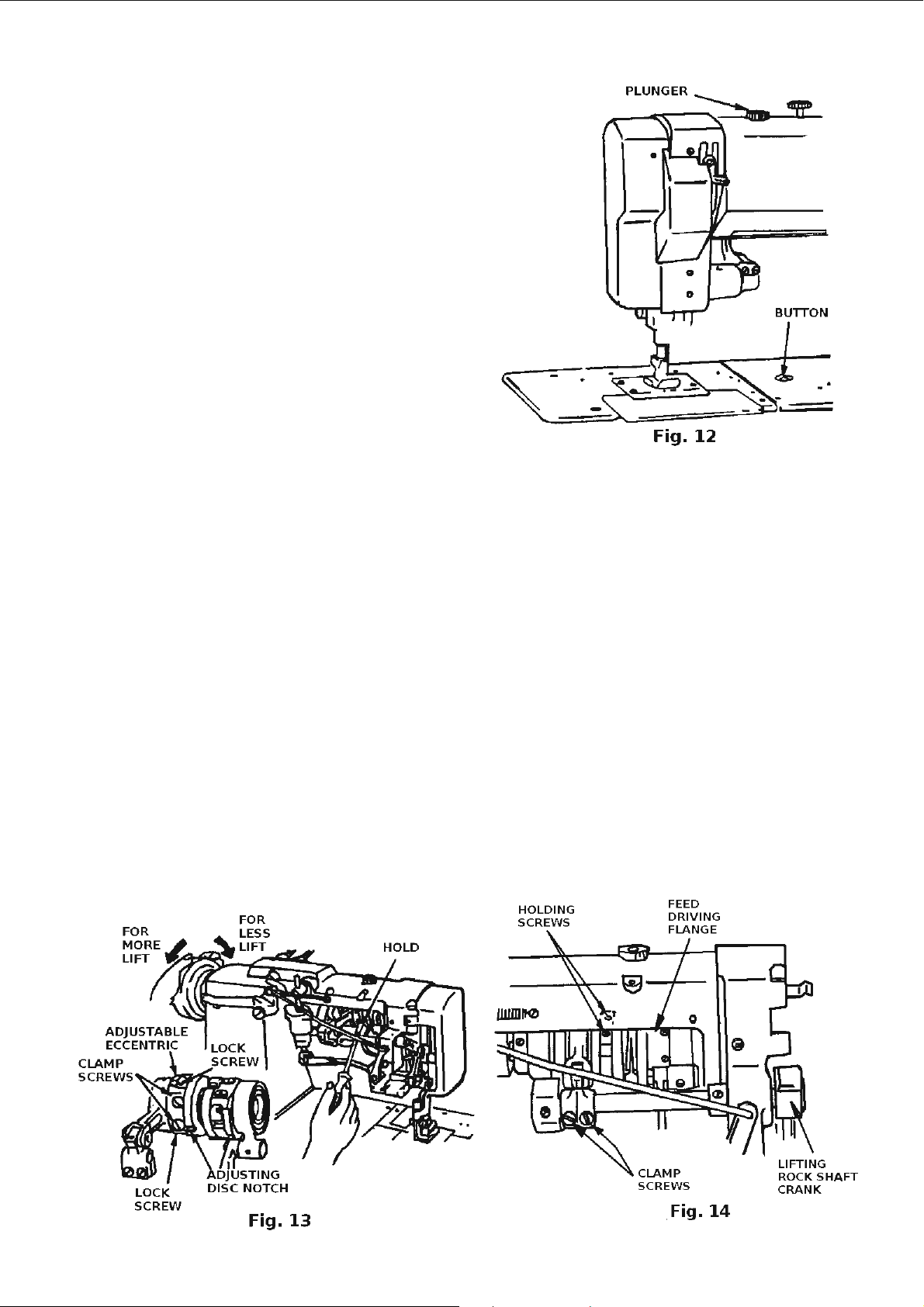

STITCH LENGTH

To adjust the stitch length, depress

plunger, Fig. 12, located on top of arm.

Continue to hold plunger down and turn

machine pulley toward operator until

plunger enters notch in arm shaft

eccentric. Then turn plunger to lock in

position. Depress button, Fig 12, located

on machine bed. Hold down, and turn

machine pulley toward operator to

increase length of stitch, or away from

operator to decrease length of stitch, letter

“A’ on machine pulley indicates the

longest stitch. When desired length,

indicated by letter, is opposite arrow on

front of machine, release button and turn

plunger to right or left until it springs

outward.

Machines with Alternating Pressers

The lift of the vibrating and lifting

pressers is controlled by an adjustable

eccentric. To adjust, remove arm cover at

rear of machine. Turn machine pulley over

toward operator until feeding presser is

down. Loosen the two lock screws, Fig. 13,

and the two clamp screws. Insert screw

driver into notch of adjusting disc, and

turn machine pulley as indicated in Fig. 13.

Then tighten the two clamp screws and

the two lock screws.

When it is desirable to have either

one of the pressers lift higher than the

other, turn machine pulley over toward

operator until the lifting presser is at its

highest position. Loosen the two clamp

screws, Fig.14, and turn lifting rock shaft

crank up or down until desired lift of each

presser is attained. Then tighten the two

clamp screws

FOR

L

OCK

SC

REW

Fig.

13

Fig.

12

CAUTION: Limit lift of

pressers to minimum required for the

work, as this permits higher speeds.

The vibrating presser should be

timed so that under normal sewing

conditions, the presser foot will seat

on the material at approximately the

same time the needle enters material.

This timing can be advanced or

retarded slightly depending on the

type of operation being performed,

such as sewing over seams. T o adjust,

loosen two holding screws, Fig. 14,

not more than one half turn. Then turn

the adjustable eccentric, Fig. 13, until

the vibrating presser seats at the

correct time. Securely tighten the two

holding screws after adjustment is

made.

HOLDING

SCREWS

C

LAMP

SCREWS

,

Fig.14

8

Loading...

Loading...