Takeuchi TB285, TB290 Operator Manual

Safety alert Symbol

Warning

Warning

This symbol represents the safety alert. The message that follows the symbol contains important information about safety.

Read and understand the message to avoid personal injury or death.

It is the owner or employer’s responsibility to fully instruct each operator in the proper and safe operation of all equipment. All persons using this machine should thoroughly familiarize themselves with the contents of this manual.

All operators must be instructed on the proper functions of the excavator before running the machine.

Learn and practice correct use of the machine controls in a safe, clear area before operating this machine on a job site.

Improper operation, inspection and maintenance of this machine can cause injury or death.

Read and understand this manual before performing any operation, inspection or maintenance on this machine.

Always store this manual near at hand preferably on the machine itself. If it should be lost or damaged, immediately order a new one from your Takeuchi dealer.

When transferring ownership of this machine, be sure to hand this manual to the next owner.

Takeuchi supplies machines complying with the local regulations and standards of the country of export. If your machine has been purchased in another country or from a person or company of another country, it may not have the safety devices or safety standards required for use in your country. Should you have any question about whether your machine complies with the regulations and standards of your country, contact a Takeuchi dealer.

Signal wordS

Safety messages appearing in this manual and on machine decals are identified by the words “DENGER”, “WARNING” and “CAUTION”. These signal words mean the following:

Danger

Danger

DANGER indicates a hazard with a high level of risk which, if not avoided, will result in death or serious injury.

Warning

Warning

WARNING indicates a hazard with a medium level of risk which, if not avoided, could result in death or serious injury.

Caution

Caution

CAUTION indicates a hazard with a low level of risk which, if not avoided, could result in minor moderate injury.

IMPORTANT: The word IMPORTANT is used to alert operators and maintenance personnel about situations which could result in damage to the machine and its components.

It is impossible to foresee every possible circumstance that might involve a potential hazard. The warnings in this manual or on the machine can not cover all possible contingencies. You must exercise all due care and follow normal safety procedures when operating the machine so as to ensure that no damage occurs to the machine, its operators or other persons.

0-1

introduction

foreword

This manual describes operation, inspection and maintenance of the machine, as well as safety instructions to be heeded during these operations.

If you have any questions about the machine, please contact a Takeuchi sales or service outlet.

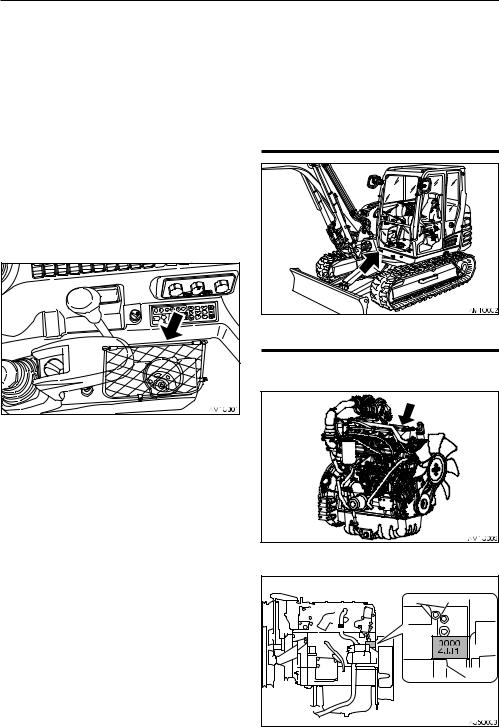

Serial numberS

IMPORTANT: Do not remove the machine name plate with the serial number. Check the serial numbers of the machine and engine and write them down in the spaces below.

Machine number:

manual Storage compartment

A compartment for storing this manual is provided at the position shown on the diagram below.

1.After using the manual, place it in the plastic pouch and store it back in the manual storage compartment.

Engine number:

<TB285>

<TB290> |

0-2

machine deScription

front, rear, left and right

This manual refers the front, rear, left and right of the machine as seen when sitting in the operator’s seat with the dozer blade visible to the front.

deSignated operationS

Use this machine primarily for the following operations:

•Excavation

•Digging ditches

•Digging side ditches

•Leveling

•Loading

featureS

•Hydromounted cab minimizes vibration

•Automatic travel shift-down system

•Self-adjusting shoe tension system

•Short pitch rubber crawler

•Low engine noise and exhaust emissions

•Electronic control of auxiliary hydraulic circuit

•Automatic and manual operation for engine deceleration

•Engine emergency stop system

break-in period

When the machine is new, operate the machine for the first 100 hours (as indicated on the hour meter) by following the instructions below.

Using a new machine without a break-in period will lead to quicker deterioration of machine performance and may shorten the machine’s service life.

•Sufficiently warm up the engine and hydraulic oil.

•Avoid heavy loads and rapid operations.

Operate with a load of about 80% the maximum load.

•Do not abruptly start up, accelerate, change directions, or stop unless necessary.

0-3

noteS on reading thiS manual

Please note that the descriptions and diagrams included in this manual may not be applicable to your machine.

The numbers used in the illustration are with circles around them. The same numbers appear between the parentheses in the text. (Example:

(1))

(1))

Symbols used in this manual

The symbols used in this manual have the following meanings.

, X ....... Prohibition

, X ....... Prohibition

............. Lock

............. Lock

............. Unlock

............. Unlock

0-4

contentS

introduction ..................................... |

0-2 |

machine description........................ |

0-3 |

Safety .............................................. |

1-1 |

General precautions ................................ |

1-2 |

Precautions when preparing .................... |

1-8 |

Precautions when starting ..................... |

1-10 |

Precautions when operating .................. |

1-12 |

Precautions when stopping ................... |

1-21 |

Precautions when transporting .............. |

1-22 |

Precautions on maintenance ................. |

1-24 |

Safety signs (decals) .............................. |

1-33 |

controls ........................................... |

2-1 |

Names of components ............................ |

2-2 |

Covers..................................................... |

2-4 |

Starter key........................................... |

2-4 |

Side cover ........................................... |

2-4 |

Fuel lid................................................. |

2-5 |

Fuel filler port ....................................... |

2-5 |

Engine hood ........................................ |

2-6 |

Fuse box cover.................................... |

2-6 |

Cab ......................................................... |

2-7 |

Cab door ............................................. |

2-7 |

Emergency exit.................................... |

2-7 |

Front window....................................... |

2-8 |

Lower front window............................. |

2-9 |

Side window........................................ |

2-9 |

Emergency hammer (optional) ............. |

2-9 |

Seat and seat belt ................................. |

2-10 |

Seat .................................................. |

2-10 |

Seat belt............................................ |

2-11 |

Air Suspension Seat .......................... |

2-12 |

Instrument cluster.................................. |

2-16 |

Warning lamps................................... |

2-16 |

Indicators........................................... |

2-17 |

Meters ............................................... |

2-17 |

Multi-data display .............................. |

2-18 |

Switches ............................................... |

2-24 |

Starter switch .................................... |

2-24 |

Engine shutdown switch.................... |

2-24 |

Throttle controller............................... |

2-24 |

Horn button....................................... |

2-25 |

Deceleration button ........................... |

2-25 |

Travel speed button ........................... |

2-25 |

Auxiliary 1st switch ............................ |

2-26 |

Auxiliary 2nd/4th switch..................... |

2-26 |

Swing/Second boom select button.... |

2-27 |

Third auxiliary hydraulic button........... |

2-27 |

Auxiliary 2/4 select button.................. |

2-27 |

Wiper switch...................................... |

2-28 |

Washer switch ................................... |

2-28 |

Automatic deceleration switch ........... |

2-28 |

ECO mode switch ............................. |

2-29 |

Highland mode switch....................... |

2-29 |

Auxiliary 1st flow select switch ........... |

2-29 |

Detent mode switch (Auxiliary 1st) ..... |

2-29 |

Light switch....................................... |

2-30 |

Overload warning switch.................... |

2-30 |

Beacon lamp switch .......................... |

2-30 |

Levers and Pedals................................. |

2-31 |

Safety lock lever ................................ |

2-31 |

Operating levers ................................ |

2-31 |

Blade lever......................................... |

2-32 |

Travel levers/pedals ........................... |

2-33 |

Boom swing pedal............................. |

2-33 |

Accessories........................................... |

2-34 |

Air conditioner ................................... |

2-34 |

Cup holder ........................................ |

2-39 |

Cigarette lighter ................................. |

2-40 |

Ashtray .............................................. |

2-40 |

Interior light........................................ |

2-41 |

Mirrors............................................... |

2-41 |

External power sockets .................... |

2-41 |

Radio (for cab) ................................... |

2-42 |

Auxiliary hydraulic lines ...................... |

2-46 |

Operating the machine with an |

|

accumulator ...................................... |

2-51 |

Load safety device............................. |

2-52 |

Overload warning device ................... |

2-53 |

Fuel Supply Pump ............................. |

2-54 |

operation ......................................... |

3-1 |

Before starting operation ......................... |

3-2 |

Getting on or off the machine............... |

3-2 |

Walk-around inspection ....................... |

3-2 |

Daily inspection.................................... |

3-2 |

Starting and stopping the engine ............. |

3-3 |

Before starting the engine.................... |

3-3 |

Starting the Engine .............................. |

3-4 |

Warming up the engine........................ |

3-5 |

Stopping the engine ............................ |

3-5 |

Operating the machine ............................ |

3-6 |

Lever pattern (ISO pattern)................... |

3-6 |

Lever pattern (JCB pattern).................. |

3-7 |

Warming up the machine (hydraulic oil) 3-8 |

|

Inspection after warm-up..................... |

3-9 |

Operating the travel levers ................. |

3-10 |

0-5

Stopping travel .................................. |

3-13 |

Operating the working equipment...... |

3-14 |

Operating procedures............................ |

3-16 |

Prohibited operations......................... |

3-16 |

Cautions on operating ........................... |

3-19 |

Cautions on traveling ......................... |

3-19 |

Cautions on traveling on slopes ........ |

3-20 |

Getting out of mud ............................ |

3-22 |

Operations possible with this |

|

machine............................................. |

3-22 |

Parking the machine.............................. |

3-24 |

Parking .............................................. |

3-24 |

Inspection and checks after stopping |

|

the engine.......................................... |

3-24 |

Handling in cold climates....................... |

3-25 |

Preparing for cold climates ................ |

3-25 |

Cautions after operations................... |

3-25 |

After the cold climate......................... |

3-25 |

Handling rubber crawlers....................... |

3-26 |

Prohibitions........................................ |

3-26 |

Cautions............................................ |

3-27 |

Preventing the rubber crawlers from |

|

coming off ......................................... |

3-27 |

transport ......................................... |

4-1 |

Loading and unloading............................ |

4-2 |

Hoisting the machine............................... |

4-4 |

Securing the machine.............................. |

4-6 |

maintenance.................................... |

5-1 |

General.................................................... |

5-2 |

Maintenance overview ......................... |

5-2 |

Cautions on maintenance .................... |

5-2 |

Service data ............................................ |

5-4 |

Fuel and lubricant table........................ |

5-4 |

Regularly replace the hydraulic oil ........ |

5-6 |

List of consumables............................. |

5-7 |

List of tools.......................................... |

5-8 |

List of tightening torques ..................... |

5-9 |

Safety-critical parts................................ |

5-10 |

Maintenance list..................................... |

5-12 |

Walk-around inspection ......................... |

5-14 |

Inspecting by opening the engine |

|

hood and covers................................ |

5-14 |

Inspecting by walking around the |

|

machine............................................. |

5-15 |

Inspecting while sitting in the |

|

operator’s seat................................... |

5-15 |

Daily inspection (every 10 hours)............ |

5-16 |

Inspecting and replenishing the |

5-16 |

coolant .............................................. |

|

Inspecting and replenishing the |

|

engine oil ........................................... |

5-17 |

Inspecting the water separator and |

|

the fuel filters ..................................... |

5-18 |

Inspecting the fuel level...................... |

5-19 |

Inspecting the hydraulic oil tank level |

|

and replenishing ................................ |

5-20 |

Lubricating the working equipment.... |

5-21 |

After the initial 50 hours |

|

(only for new machines) ......................... |

5-22 |

Replacing the engine oil and the oil |

|

filter ................................................... |

5-22 |

Inspecting and adjusting the fan belt.. |

5-24 |

Inspecting and adjusting the |

|

compressor belt (AC) ......................... |

5-26 |

Every 50 hours ...................................... |

5-28 |

Inspecting the crawler belt tension..... |

5-28 |

Lubricating the slew bearing.............. |

5-30 |

Draining the water from the fuel tank.. 5-31 |

|

Inspecting the battery fluid level and |

|

replenishing ....................................... |

5-32 |

After the initial 250 hours |

|

(only for new machines) ......................... |

5-34 |

Replacing the hydraulic oil return filter 5-34 |

|

Replacing the pilot line filter................ |

5-35 |

Replacing the travel motor gear oil..... |

5-36 |

Every 250 hours .................................... |

5-37 |

Replacing the engine oil and the oil |

|

filter ................................................... |

5-37 |

Inspecting and adjusting the fan belt.. |

5-37 |

Inspecting and adjusting the |

|

compressor belt (AC) ........................ |

5-37 |

Cleaning the air cleaner ..................... |

5-38 |

Cleaning the radiator fins and oil |

|

cooler fins.......................................... |

5-39 |

Cleaning the air filters (air conditioner) 5-40 |

|

Cleaning the condenser (AC) ............. |

5-41 |

Inspecting the refrigerant (gas) level |

|

(AC) ................................................... |

5-42 |

Every 500 hours .................................... |

5-44 |

Replacing the fuel filter....................... |

5-44 |

Replacing the water separator filter |

|

<TB285>........................................... |

5-46 |

Replacing the feed pump filter |

|

<TB290>........................................... |

5-47 |

Every 1000 hours .................................. |

5-48 |

Replacing the hydraulic oil return filter 5-48 |

|

Replacing the pilot line filter................ |

5-48 |

0-6

Replacing the travel motor gear oil..... |

5-48 |

Cleaning the engine cooling system... |

5-48 |

Replacing the air cleaner element ...... |

5-50 |

Replacing the air breather filter .......... |

5-51 |

Inspecting and adjusting the engine |

|

valve clearance .................................. |

5-51 |

Retightening the engine cylinder head |

|

bolt <TB285> .................................... |

5-51 |

Inspecting the engine compression |

|

pressure <TB290>............................. |

5-51 |

Inspecting and cleaning the engine |

|

starter and the alternator <TB290>.... |

5-51 |

Every 1500 hours .................................. |

5-52 |

Inspecting and cleaning the engine |

|

fuel injectors <TB285>....................... |

5-52 |

Inspecting the crankcase breather |

|

system <TB285>............................... |

5-52 |

Every 2000 hours .................................. |

5-53 |

Lapping the engine valve seats |

|

<TB285>........................................... |

5-53 |

Every 4000 hours .................................. |

5-54 |

Replacing the hydraulic oil and |

|

cleaning the suction strainer .............. |

5-54 |

When required....................................... |

5-58 |

Replacing the bucket teeth and the |

|

side cutters........................................ |

5-58 |

Replacing the bucket......................... |

5-60 |

Adjusting the gap between the |

|

bucket and arm (If equipped) ............. |

5-62 |

Inspecting and replenishing the |

|

windshield washer fluid...................... |

5-63 |

Draining the water from the water |

|

separator........................................... |

5-63 |

Lubricating the levers and pedals....... |

5-64 |

Inspecting the rubber crawlers........... |

5-65 |

Replacing the rubber crawlers ........... |

5-66 |

Maintenance during extended storage |

|

period.................................................... |

5-68 |

troubleshooting ............................... |

6-1 |

Symptoms that are not malfunctions ....... |

6-2 |

If the engine overheats............................. |

6-3 |

If the battery goes dead........................... |

6-4 |

If a fuse blows ......................................... |

6-6 |

Inspecting and replacing the fuse......... |

6-6 |

Inspecting the fusible link ..................... |

6-7 |

Restarting after adding fuel ...................... |

6-8 |

Bleeding air from the fuel system ......... |

6-8 |

If a warning lamp flashes ....................... |

6-10 |

Vehicle error code list............................. |

6-12 |

Engine error code list............................. |

6-14 |

Other symptoms.................................... |

6-18 |

Lowering the boom to the ground ......... |

6-20 |

Towing................................................... |

6-21 |

Specifications.................................. |

7-1 |

Basic Specifications................................. |

7-2 |

Machine dimensions................................ |

7-4 |

Operating ranges..................................... |

7-8 |

Lifting Capacities................................... |

7-13 |

options ............................................ |

8-1 |

General precautions ................................ |

8-2 |

Safety precautions............................... |

8-2 |

Cautions when installing attachments .. |

8-2 |

Cautions when operating attachments. 8-3 |

|

Attachment combination table ................. |

8-4 |

Selecting a lever pattern .......................... |

8-5 |

Switching the lever pattern .................. |

8-5 |

Hydraulic breaker .................................... |

8-6 |

Cautions on operating ......................... |

8-6 |

Replacing the hydraulic oil regularly ..... |

8-7 |

Travel alarm ............................................. |

8-8 |

Optional equipment mass ....................... |

8-9 |

Biodegradable oil................................... |

8-10 |

Replacing the hydraulic oil with |

|

biodegradable oil ............................... |

8-10 |

Cab options........................................... |

8-11 |

Angle dozer blade.................................. |

8-12 |

Operating lever switch kit 1.................... |

8-13 |

Horn button....................................... |

8-13 |

Deceleration button ........................... |

8-13 |

Travel speed button ........................... |

8-13 |

Auxiliary 1st switch ............................ |

8-14 |

Auxiliary 2nd/4th switch..................... |

8-14 |

Auxiliary 2/4 select button.................. |

8-15 |

Swing/Second boom select button.... |

8-15 |

0-7

0-8

Safety

1-1

SAFETY

general precautionS

general precautionS

It is your responsibility to observe all pertinent laws and regulations and to follow the manufacture’s instructions on machine operation, inspection and maintenance.

Virtually all accidents occur as the result of a failure to observe basic safety rules and precautions.

Most accidents can be prevented by identifying the potentially hazardous situations beforehand.

Read and understand all safety messages which describe how to prevent accidents. Do not operate the machine until you are sure that you have gained a proper understanding of its operation, inspection and maintenance.

Observe all safety rules

•Operation, inspection and maintenance of this machine must be performed only by a trained and qualified person.

•All rules, regulations, precautions and safety procedures must be understood and followed when performing operation, inspection and maintenance of this machine.

•Do not perform any operation, inspection and maintenance of this machine when under the adverse influence of alcohol, drugs, medication, fatigue, or insufficient sleep.

When a problem is found on the machine

If any problem (noise, vibration, smell, disorder of instrument, smoke, oil leak, wrong indication of alarm or unusual indication in the instrument cluster, etc.) is detected during the operation or inspection and maintenance of the machine, immediately inform your sales or service dealer and take proper actions. Do not operate the machine until the trouble is cleared.

Operating temperature range

To maintain the performance of machine and to prevent it from early wear, observe the following operating conditions.

•Do not operate the machine if the ambient temperature is higher than +45°C (+113°F) or lower than –15°C (+5°F).

·If operated at an ambient temperature of higher than +45°C (+113°F), the engine may overheat and cause the engine oil to degrade.

·If operated at an ambient temperature of lower than –15°C (+5°F), the parts made of rubber such as gaskets may get hardened to cause an early wear or damage to the machine.

·If the machine is to be used outside the ambient temperature range described above, consult your sales or a service dealer.

1-2

SAFETY

general precautionS

Wear appropriate clothing and protective equipment

•Do not wear loose clothing or any accessory that can catch on controls or in moving parts.

•Do not wear oily or fuel stained clothing that can easily catch fire.

•Wear a hard hat, safety shoes, safety glasses, filter mask, heavy gloves, ear protection and other protective equipment as required by job conditions. Wear required appropriate equipment such as safety glasses and filter mask when using grinders, hammers or compressed air, as metal fragments or other objects can fly and cause serious injury.

•Use hearing protection when operating the machine. Loud prolonged noise can cause hearing impairments, even the total loss of hearing.

Install a fire extinguisher and first aid kit

Be prepared for fire and accidents

•Install an extinguisher and a first aid kit, and learn how to use them.

•Lean how to fight a fire and how to deal with accidents.

•Know how to contact emergency assistance and make a list of emergency contacts.

Never remove safety equipment

•Make sure all protective guards, covers and doors are in place and secured. Repair or replace damaged parts before operating the machine.

•Know how to use the safety lock lever, seat belt and other safety equipment and use them properly.

•Never remove any safety equipment except for servicing. Keep all safety equipment in good operating condition.

1-3

SAFETY

general precautionS

Use a signal person and a flag person

Learn how to use the hand signals required for particular jobs and make sure who has the responsibility for signaling.

•All personnel must fully understand all the signals.

•The operator must respond to signals only from the appointed signal person, but must obey a stop signal at any time from anyone.

•The signal person must stand in a clearly visible location when giving signals.

Cautions when standing up from or leaving the operator’s seat

•Before standing up from the operator’s seat to open/close the window or remove/ install the lower window, lower the working equipment to the ground, raise the safety lock levers to engage the lock and stop the engine. If any controls should be accidentally touched when the safety lock levers is lowered (unlocked), the machine will suddenly move and cause serious injury or death.

•Be careful not to touch the operating levers when raising or lowering the safety lock levers.

•Before leaving the operator’s seat, lower the working equipment to the ground, raise the safety lock levers to engage the lock and stop the engine. Also, be sure to remove the key, lock the door and covers, take it with you and store it in a specified place.

1-4

SAFETY

general precautionS

Avoid fire and explosion hazards

Keep flames away from fuel, oil, grease and antifreeze. Fuel is particularly flammable and dangerous.

•When handling these combustible materials, keep lit cigarettes, matches, lighters and other flames or sources of flames away.

•Do not smoke or permit open flames while handling fuel or working on the fuel system.

•Do not leave the location while refilling with fuel or oil.

•Never remove the fuel cap or add fuel when the engine is running or still hot. Also, do not spill the fuel on the hot surface of the machine or the component of the electric system.

•Clean up spilled fuel or oil immediately.

•Check for fuel, oil leak. Stop all leaks and clean the machine before operating.

•When operating with grinder or welding, move inflammables to a safe place.

•Do not cut or weld on pipes or tubes that contain flammable fluids. Clean thoroughly with nonflammable solvent before cutting or welding.

•Remove all trash or debris from the machine. Make sure that oily rags or other flammable material are not stored on the machine.

•Handle all solvents and dry chemicals

(foam type fire extinguisher) according to procedures identified on manufacturer’s containers. Work in a well-ventilated area.

•Never use fuel for cleaning purposes.

Always use a nonflammable solvent.

•When handling the fuel, washing oil or paint, open the door and windows to ventilate thoroughly.

•Store all flammable fluids and materials in a safe and well-ventilated place.

•The short circuit of the electric system may cause the fire. Check for any loosened connections or damage to the wires every day. Retighten the loosened connector and wire clamp. Fix or change the damaged wire.

•Fire from the pipes:

Make sure that the clamps, guards and cushions of the hoses and tubes are securely fixed. If not, hoses or tubes may be damaged due to vibration or contact with other parts during operation. This can cause the high-pressure oil to spurt out, resulting in the fire or injury.

1-5

SAFETY

general precautionS

Exhaust fumes from the engine is poisonous

•Do not operate the engine in an enclosed area without adequate ventilation.

•If natural ventilation is not possible, install ventilators, fans, exhaust extension pipes or other venting devices.

Handling asbestos dust

Inhaling asbestos dust can cause lung cancer. When handling the materials which may contain asbestos, take the following precautions:

•Never use compressed air for cleaning.

•Avoid brushing or grinding parts containing asbestos.

•For clean up, use a vacuum equipped with a high efficiency particulate air filter (HEPA).

•Wear the stipulated respirator if there is no other way to control the dust. When working indoors, install a ventilation system with a macromolecular filter.

•Do not allow unauthorized personnel in the work area while working.

•Follow the rules and environmental standard applicable to the work area.

Be careful not to get crushed or cut

Never put your hands, feet or other parts of your body between the upperstructure and the undercarriage or tracks, between the machine body and working equipment, or between a cylinder and moving part. The sizes of these gaps change when the machine moves, and a person can suffer severe injury or death.

1-6

SAFETY

general precautionS

Using optional products

•Consult with Takeuchi before installing optional attachments. Depending on the type of attachments or the combination of them, the attachment may come into contact with the operator’s compartment or the other parts of the machine. Make sure that the optional attachment installed is not contacted with other parts before use.

•Do not use attachments that have not been approved by Takeuchi. Doing so may compromise safety or adversely affect the machine’s operation or service life.

•Takeuchi will not be held responsible for any injuries, accidents or damage to its products caused by the use by a nonapproved attachment.

Never modify the machine

Unauthorized modifications to this machine can cause injury or death. Never make unauthorized modifications to any part of this machine.

1-7

SAFETY

precautionS when preparing

precautionS when preparing

Know the work area

Before starting operation, know the working area condition to ensure a safety operation.

•Inspect the topography and ground condition of the working area, or the structure of the building when working indoors, and take the safety precautions as necessary.

•Be sure to avoid all hazards and obstructions such as ditches, underground lines, trees, cliffs, overhead electrical wires, or places where there is a danger of falling rocks or slides.

•Check with the administrator for the locations of buried gas pipes, water pipes and power cables. If necessary, determine what specific precautions must be taken to insure safety by consulting with the administrator.

•When working on roads, be sure to consider the safety of pedestrians and vehicles.

·Use a flag person and/or a signal.

·Fence off the working area and keep off unauthorized persons.

•When working in water or crossing shallow streams or creeks, check the depth of the water, the solidity of the ground and the water flow speed beforehand.

Refer to “Cautions on operating” for further instructions.

Check the strength of the bridge

When traveling over a bridge or a structure, check the permissible load. If the strength is insufficient, reinforce the bridge or the structure.

Always keep the machine clean

•Clean windows, mirrors and lights to ensure good visibility.

Adjust the mirror to the best position for the operator to see the rear view (blind spot) from the operator’s seat.

•Wipe off any oil, grease, mud, snow or ice, to prevent accidents due to slipping.

•Remove all loose objects and unnecessary devices from the machine.

•Remove any dirt, oil or grease from the engine area to prevent fires.

•Clean around the operator’s seat and remove any unnecessary object from the machine.

1-8

SAFETY

precautionS when preparing

Perform inspection and maintenance every day

Failure to identify or repair the irregularities or damage on machine can lead to accidents.

•Before operating, perform the specified inspection and make prompt repairs where necessary.

•If a failure occurs and the operation becomes impossible or the engine fails, immediately stop the machine by following the shutdown procedure, and keep machine securely parked until the malfunction is corrected.

Cautions in the operator’s compartment

•Remove mud and grease from shoe soles before entering the operator’s compartment. Pedaling the machine with the shoes with mud and grease will cause a slip accident.

•Do not leave the parts or tools around the operator’s seat.

•Do not leave any plastic bottles in the operator’s compartment or attach any suction cups on the window glass. The plastic bottle or suction cup act as a lens and can cause fire.

•Do not use the mobile phone during traveling or working.

•Do not bring combustibles or explosives into the operator’s compartment.

•After smoking, be sure to tightly close the lid of the ashtray to put out the match or cigarette.

•Do not leave the cigarette lighter in the operator’s compartment. When the room temperature rises, the lighter may explore.

Emergency exit

Front window (excluding machines with a front guard)

If you should become trapped inside the cab, open the front window to get out.

Emergency hammer (optional)

An emergency hammer is installed to be used to escape from the cab in an emergency. When escaping, break the windows with the hammer.

1-9

SAFETY

precautionS when Starting

precautionS when Starting

Support your weight in a three point secure stance when getting on/off the machine

•Do not jump on or down from the machine.

Never attempt to get on or off the moving machine.

•When getting on or off the cab, first fully open the door to the locked position and check that it does not move (for machines with cab).

•Climb up/down the steps facing the machine and holding the handrail to support your weight in a three point secure stance (hand and feet).

•Never use the safety lock lever or control levers as hand holds.

•Check if there is a “DO NOT OPERATE” alert sign or similar sign is on the cab door, controls or starter switch. If there is one, do not start the engine or touch any levers.

•Sound the horn to warn people around the machine.

Sit in the operator’s seat and start the engine

• Adjust the seat to securely latch it.

Before starting the machine, ask any unauthorized personnel to leave the area

Do not start the engine until you are sure it is safe to start the machine by checking the following items.

•Walk around the machine and warn the person who is servicing the machine or is walking near the machine. Do not start the machine until you are certain that no one is around the machine.

•Fasten the seat belt.

•Check if the parking brake is on and all control levers and pedals are in the neutral position.

•Check if the safety lock lever is in the lock position.

•Make sure that no one is near the machine.

•Start and operate the machine only from the operator’s seat.

•Never attempt to start the engine by shorting across the starter terminals.

1-10

SAFETY

precautionS when Starting

Starting with jumper cables

Use jumper cables only in the recommended manner. Improper use of jumper cables can result in battery explosion or unexpected machine motion.

Refer to “If the battery goes dead” for further instructions.

After starting the engine

After starting the engine, perform the operations and checks described below in a safe place with no persons or obstacles in the area. If any malfunction is found, follow the shutdown procedure and report the malfunction.

•Warm up the engine and hydraulic oil.

•Check if all gauges and warning devices are properly working.

•Check for any noises.

•Test the engine speed control.

•Operate each control to ensure they are properly working.

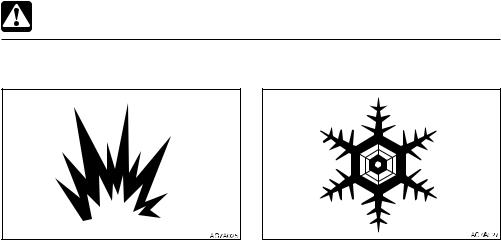

In cold climates

•Be careful of slippery conditions on freezing ground, steps and hand holds.

•In severe cold climates, do not touch any metal parts of the machine with bare hands. The skin will freeze to the metal, resulting in severe injury.

•Do not use ether or starting fluid on this engine. The starting fluids can cause explosion and serious injury or death.

•Warm up the engine and hydraulic oil. If the levers are operated without warming, the machine will not react or move promptly or properly, resulting in accident.

1-11

SAFETY

precautionS when operating

precautionS when operating

Ensure good visibility

•When working in dark places, turn on the machine’s working lights and headlights and additional lighting equipment installed, as necessary.

•When visibility is poor due to bad weather

(fog, snow, rain or a cloud of dust), stop operating the machine and wait until visibility improves.

Do not permit riders on the machine

Do not allow anyone to ride on any part of the machine at any time while traveling or operating.

Check if the work area is safe and secure before operation

•Confirm the performance limits of the machine.

•Use a signal person at road shoulders, narrow places or where your vision is obstructed.

•Never allow anyone to enter the machine’s slewing radius and path.

•Signal your intention to move by sounding the horn.

•There is a blind spot in the rear of the machine. Before traveling in reverse, check that the area is safe and clear.

1-12

SAFETY

precautionS when operating

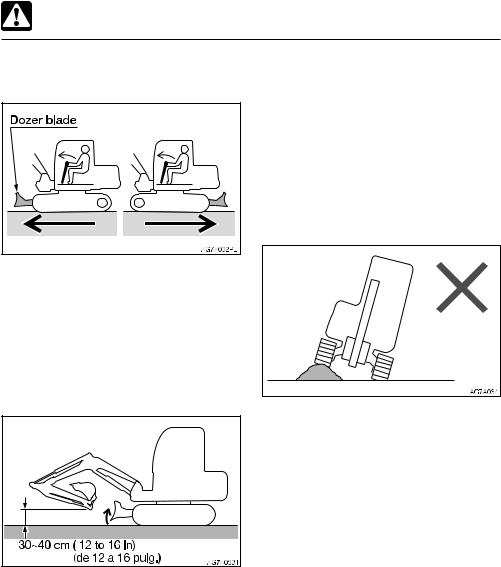

Check the position of the undercarriage (tracks) before traveling

Before operating the travel levers/pedals, make sure that the dozer blade is to the front of the operator’s seat. Remember that when the dozer blade is to the rear of the operator’s seat, the travel levers/pedals must be operated in the reverse direction from when it is to the front.

Travel safely

•Travel with the dozer blade raised, the hoe attachment folded as shown on the figure above, and the bucket raised 30 to 40 cm (12 to 16 in.) above the ground.

•Do not slew while traveling. If you must operate the hoe attachment while traveling, operate at speeds slow enough so you have complete control at all times.

•When a load greater than a set value is applied during traveling in 2nd (high) speed, the speed will automatically slow down to 1st (low) speed. When the load becomes lighter, the speed will increase and return to 2nd (high) speed. Remember

that the travel speed changes depending on the load condition (for machines with the automatic travel shift-down system).

•When traveling on the uneven road or sharp slope, turn off the deceleration switch and the auto-deceleration switch. If the machine is operated on such roads with these switches turned on, the engine speed may increase, causing the machine to travel unexpectedly rapidly (for machines with the deceleration and auto-deceleration switches).

•Avoid crossing over obstacles whenever possible. If you must do so, keep the hoe attachment close to the ground level and travel slowly. Never cross obstacles which will tilt the machine to an angle of 10° or greater.

•On uneven ground, maintain the low speed and avoid starting, stopping or changing directions abruptly. Otherwise, the working equipment may come in contact with the ground, causing the machine to lose its balance and get damaged or to damage the structures in the surrounding area.

1-13

SAFETY

precautionS when operating

Cautions on traveling on slopes

When traveling on slopes or grades, be careful that the machine does not tip (roll) over or slide.

•Never travel on slopes that are too steep for the machine to maintain its stability (maximum gradeability: 35°, lateral tipping angle: 15°). Note that in reality, the machine’s stability becomes lower than the above values depending on the working condition.

•When climbing a hill, keep the operator’s seat facing the hillside. When descending a hill, keep the operator’s seat facing the downhill direction. In either case, travel must be done while paying attention to the ground in front of the machine.

•When traveling on slopes, lower the bucket to a height of 20 to 30 cm (8 to 12 in.) above the ground. When climbing a steep slope, extend the hoe attachment to the front. In emergencies, lower the bucket to the ground and stop the machine.

•When traveling on slopes or grades, drive slowly in 1st (low) speed. When descending a slope, slow down the engine speed.

•Do not descend slopes in reverse.

•Do not change directions on slopes or traverse slopes. First return to a flat surface, and then take an alternative path.

•The machine may slip sideways even on a slight slope if the ground is covered with grass or dead leaves, or when traveling on a wet metal plate or frozen surfaces. Make sure the machine is never positioned sideways on slopes.

•If the machine is stalled on the slope, return each operating lever to the neutral position before restarting the engine.

1-14

SAFETY

precautionS when operating

Operate the machine on snow or ice with extra care

•When traveling on snow or on frozen surfaces, drive at a low speed and avoid starting, stopping or changing directions abruptly.

•In the snowy area, the road shoulder and objects placed beside the road are buried in the snow and cannot be seen. There is a hazard of the machine tipping over or hitting covered objects, so always carry out operations carefully.

•If the machine enters deep snow, there is a hazard that it may tip over or become buried in the snow.

Be careful not to drive beyond the road shoulder or to get trapped in a snow drift.

•With frozen ground surfaces, the ground becomes soft when the temperature rises, and this may cause the machine to tip over, resulting in an operator trapped inside the machine.

•When parking the machine on an unstable ground, lower the dozer blade.

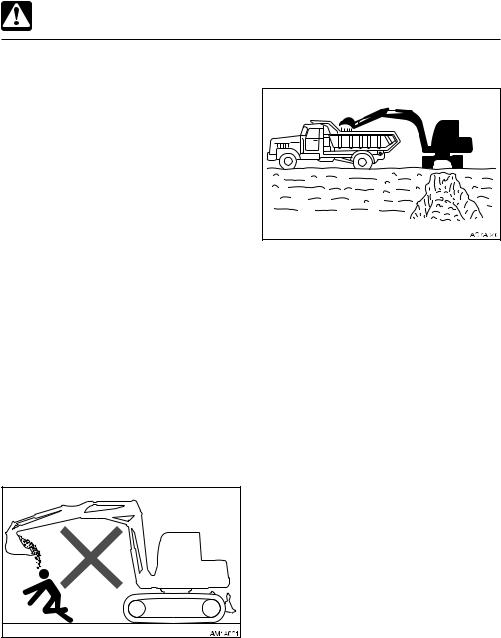

Do not move the bucket over the heads of people

Ensure driver’s safety when loading

Do not load a truck unless the truck driver is in a safe place.

•Never swing or position the bucket over a person or the cab room.

•Load the truck from the rear.

Moving the bucket over the heads of people entails the danger of the load spilling or the sudden dropping of the bucket.

1-15

SAFETY

precautionS when operating

Keep a safe distance from the overhead high-voltage cables

Never bring any part of the machine or loaded material to near to the high voltage cables unless all safety precautions required by the local and national authorities have been installed. If a person comes near to the machine that is discharging sparks or located near to or in contact with the power source, there is a hazard of electric shock and death.

•Always maintain a safe distance between the machine and the high-voltage electric cable.

•Check with the local power company about safe operating procedure before starting operations.

•Consider all cables to be high-voltage cables and treat all cables as energized even though it is known or believed that the power is shut off and the cables are visibly grounded.

•Use a signal person to give warning if the machine approaches too close to the highvoltage electric cables.

•Caution all personnel in the work area not to come close to the machine or the loaded material.

•Pay also careful attention to the highvoltage electric cables buried underground.

1-16

SAFETY

precautionS when operating

Watch out for hazardous working conditions

•Never undercut a high bank. Doing so is dangerous as it may cause ground collapse.

•Do not operate in places where there is a danger of falling rocks.

•Maintain a safe distance between the machine and the edge of the digging site. Do not dig the ground under the front of the machine.

•When working close to the cliffs or road shoulders, to make it easier to escape if there is any problem, set the crawlers at right angles to the cliff or road shoulder and the dozer blade to the front when carrying out operations.

•Do not enter areas where there is soft ground. Doing so could cause the machine to tilt under its own weight, resulting in a machine tipping over or sinking into the ground.

•Do not come close to unstable grounds

(cliffs, road shoulders, deep ditches). If the ground should collapse under the weight or vibration of the machine, there is a hazard that the machine may fall or tip over.

·Remember that the soil after heavy rain or blasting is weak.

·The ground of top of the embankment and of the circumferences of the excavated ditches are also weak.

1-17

SAFETY

precautionS when operating

•Do not perform demolition work under the machine. There is a hazard that the machine may fall down, because the ground becomes unstable.

•When working on or from the top of buildings or other structures, check the strength and the structure before starting operations. If a building or structure collapses, serious injury or damage will result.

•When doing demolition work, do not perform demolition above your head. There is a hazard of broken parts falling or of the building collapsing and causing serious injury or damage.

•Do not use the impact force of the hoe attachment for breaking work. There is a hazard of serious injury being caused by flying pieces of broken materials and by the damaged hoe attachment.

Be careful with flying objects

This machine is not equipped with protective equipment to protect the operator from flying objects. Do not use this machine in places where there are risks of the operator being hit by flying objects.

1-18 |

SAFETY

precautionS when operating

Operating on slopes is dangerous

When operating on slopes or grades, slewing or operation of working equipment may cause the machine to lose stability and tip over. Avoid operating on slopes whenever possible.

• Level off the work area.

•Avoid slewing to the downhill direction with the bucket full of loaded material. This will reduce the stability of the machine and may result in tipping over.

Never slew (swing) sideways with a heavy load

The machine can tip over more easily in the lateral direction than in the longitudinal direction.

•Do not slew (swing) sideways with a heavy load at the tip of the hoe attachment. In particular, do not slew (swing) sideways on slopes.

•The tip of the attachment is heavier for machines equipped with breakers, crushers or long arms than for machines equipped with the standard bucket. For such machines with heavier tips, do not perform excavation with the digging arm (boom) facing the downhill direction or operate toward sideways.

Be careful with the overhead objects

When operating under bridges, in tunnels, near electric cables or indoors, be careful not to let the boom or arm hit overhead objects.

1-19

SAFETY

precautionS when operating

Excavators are not designed for lifting loads

This machine is specifically designed for excavation work. Therefore, it has no safety equipment for crane operation. Extreme caution should be paid if the excavator is used for lifting.

•Never lift loads in excess of capacity.

Overload will cause the machine to roll and can result in serious injury or death.

•All rated lift capacities are determined by using a machine placed on a stable and flat ground. For a safe lifting work, the user is expected to make due allowance for the particular job conditions. They include, soft or uneven ground, non-level condition, side loads, dynamic or jerked loads, hazardous conditions, and experience of personnel. The operator and other personnel should fully acquaint themselves with the operator’s manual before operating this machine, and rules for safe operation of equipment shall be adhered to at all times.

•The bucket linkage or lifting device may fail if chains or lifting device are incorrectly attached, resulting in serious injury or death.

•Do not attempt to pull stumps out of the ground when using the machine as a crane. The loads imposed on the machine under this use are completely unknown.

•Do not allow anyone to stand on or under the lifted loads or come close to the work area.

Cautions when towing

When towing, serious injury or death could result, if performed incorrectly or the wire rope being used is inappropriate or not properly inspected.

•It becomes dangerous if the wire rope breaks or becomes disengaged. Use a wire rope appropriate for the required tractive force.

•Do not use a wire rope that is kinked, twisted or otherwise damaged.

•Do not apply heavy loads abruptly to the wire rope.

•Wear safety gloves when handling the wire rope.

•Make sure there is an operator on the machine being towed as well as on the machine that is towing.

•Never tow on slopes.

•Do not let anyone come near to the wire rope while towing.

1-20

Loading...

Loading...