Page 1

TB15 3

FR

Hydraulic Excavator

Serial No.

¡

TB153FR: 15820004~

¡

TB180FR: 17830004~

Book No. AL5E001

OPERA TOR’S MANUAL

TB18 0

FR

W ARNING

Read and understand these instructions.

Failure to do so can cause injury or death.

Page 2

SAFETY ALERT SYMBOL

This symbol means Attention! Be Alert! Your Safety Is Involved.

The message that follows the symbol contains important information

about safety .

Read and understand the message to avoid personal injury or death.

■ It is the owner or employer’s responsibility to fully instruct each operator in the

proper and safe operation of all equipment. All persons using this machine should

thoroughly familiarize themselves with the following sections.

■ All operators must be instructed on the proper functions of the excavator before

running the machine.

■ Learn and practice correct use of the machine controls in a safe, clear area before

operating this machine on a job site.

CAUTION

Improper operation, inspection and maintenance of this

machine can cause injury or death.

Read and understand this manual before performing any

operation, inspection or maintenance on this machine.

■ Always store this manual near at hand preferably on the machine itself. If it should be lost

or damaged, immediately order a new one from your Takeuchi dealer.

When transferring ownership of this machine, be sure to provide this manual to the next

owner.

■ Takeuchi supplies machines complying to the local regulations and standards of the country

of export. If your machine has been purchased in another country or from a person or

company of another country , it may not have the safety devices or safety standards required

for use in your country . Should you have any question about whether your machine complies

with the regulations and standards of your country, contact a Takeuchi dealer.

■ Please note that the contents and diagrams included in this manual may not match your

machine exactly.

Page 3

It is your responsibility to observe all pertinent laws and regulations and to follow

the manufacturer’s instructions on machine operation, inspection and maintenance.

Virtually all accidents occur as the result of a failure to observe basic safety rules and

precautions. An accident can often be avoided by recognizing potentially hazardous

situations beforehand. Read and understand all of the safety messages which explain

how to prevent these accidents from occurring. Do not operate the machine until you are

sure that you have gained a proper understanding of its operation, inspection and

maintenance.

■ SlGNAL WORDS

Safety messages appearing in this manual and on machine decals are identified by the

words “DANGER”, “WARNING” and “CAUTION”. These signal words mean the following:

DANGER WARNING CAUTION

The word “DANGER”

indicates an imminently

hazardous situation

which, if not avoided,

can result in serious

injury or death.

IMPORT ANT: The word “IMPORTANT” is used to alert against operators and

maintenance personnel about situations which can result in possible damage to the

machine and its components.

The word “WARNING”

indicates a potentially

hazardous situation

which, if not avoided,

could result in serious

injury or death.

The word “CAUTlON”

indicates a potentially

hazardous situation

which, if not avoided,

may result in minor or

moderate injury.

It is impossible to foresee every possible circumstance that might involve a potential hazard.

The warnings in this manual or on the machine can not cover all possible contingencies. Y ou

must exercise all due care and follow normal safety procedures when operating the machine

so as to ensure that no damage occurs to the machine, its operators or other persons.

■ EXPLANA TION OF GRAPHICAL SYMBOLS

Following is an explanation of symbols used in this manual.

, X......... prohibition

/ ....... Lock

/ ...... Unlock

1

Page 4

INTRODUCTION

Foreword

This manual describes operation, inspection

and maintenance of the machine, as well as

safety instructions to be heeded during these

operations.

If you have any questions about the machine,

please contact a Takeuchi sales or service

outlet.

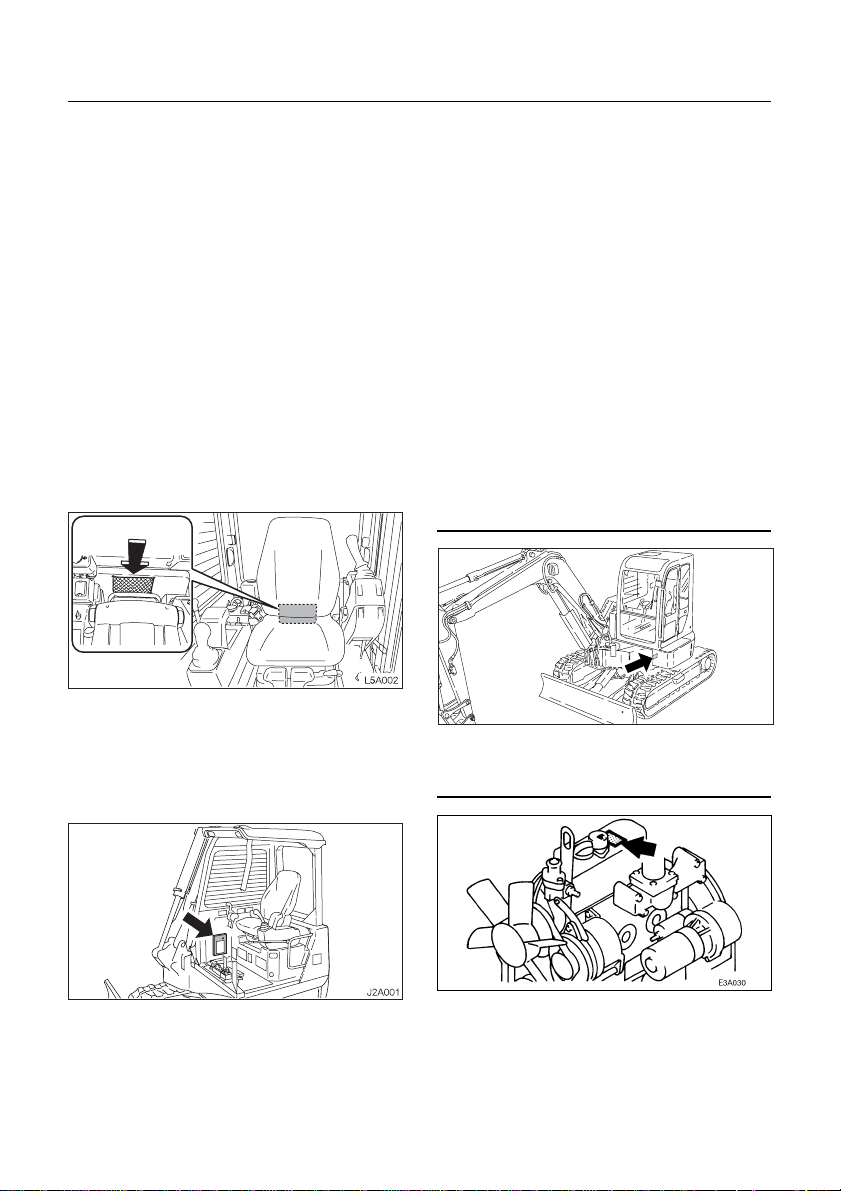

■ Manual storage compartment

A compartment for storing this manual is

provided at the position shown on the

diagram below.

1. After using the manual, place it in the

plastic pouch and store it back in the

manual storage compartment.

< TB153FR : Canopy >

■ Serial numbers

Check the serial numbers of the machine and

the engine and write them in the spaces

provided below.

Machine number :

L4A0011

Engine number :

1. Insert the starter key and turn it

counterclockwise to unlock the manual

storage compartment.

2

Page 5

MACHINE DESCRIPTlON

■ Front, rear, Ieft and right

This manual refers the front, rear, left and

right of the machine as seen when sitting in

the operator’s seat with the dozer blade

visible to the front.

■ Designated operations

Use this machine primarily for the following

operations:

¡ Excavating

¡ Digging ditches

¡ Digging side ditches

¡ Leveling

¡ Loading

■ Features

¡ A unique adjustable offset boom system

¡ Short tail swing radius

¡ Short pitch rubber crawler

¡ Low engine noise and exhaust emissions

¡ Pilot operated joystick controls

¡ One toutch engine deceleration button

¡ Slew cushioning system for easy bucket positioning

¡ Engine emergency stop / idle system

¡ Tilt-up operators platform for easy access to major compartment

FRONT

REAR

RIGHTLEFT

D5A003

■ Break-in period

When the machine is new, heed the instructions below when operating the machine for the

first 100 hours (as indicated on the hour meter).

Using a new machine roughly without breaking it in will lead to quicker deterioration of machine

performance and may shorten the machine’s service life.

¡ Warm up the engine and hydraulic oil sufficiently .

¡ Avoid heavy loads and rapid operations. Operate with a load of about 80% the maximum

load.

¡ Do not start up, accelerate, change directions, or stop abruptly unless necessary.

3

Page 6

4

Page 7

CONTENTS

Introduction .................................... 2

Machine Description ...................... 3

Safety.............................................. 7

Controls .........................................35

Operation.......................................67

Transport .....................................101

Maintenance ................................107

Troubleshooting ..........................161

Specifications..............................175

Options ........................................193

Index ............................................229

5

Page 8

6

Page 9

SAFETY

General Precautions ....................................8

Preparing Precautions...............................12

Starting Precautions ..................................14

Operating Precautions...............................16

Stopping Precautions ................................23

Transporting Precautions ..........................24

Maintenance Precautions ..........................25

Safety Signs (Decals).................................32

7

Page 10

SAFETY

General Precautions

Observe all safety rules

¡ Operation, inspection and maintenance of

this machine must be performed only by

a trained and qualified person.

¡ All rules, regulations, precautions and

safety procedures must be understood

and followed when performing operation,

inspection and maintenance of this

machine.

¡ Do not perform any operation, inspection

and maintenance of this machine when

under the adverse influence of alcohol,

drugs, medication, fatigue, or insufficient

sleep.

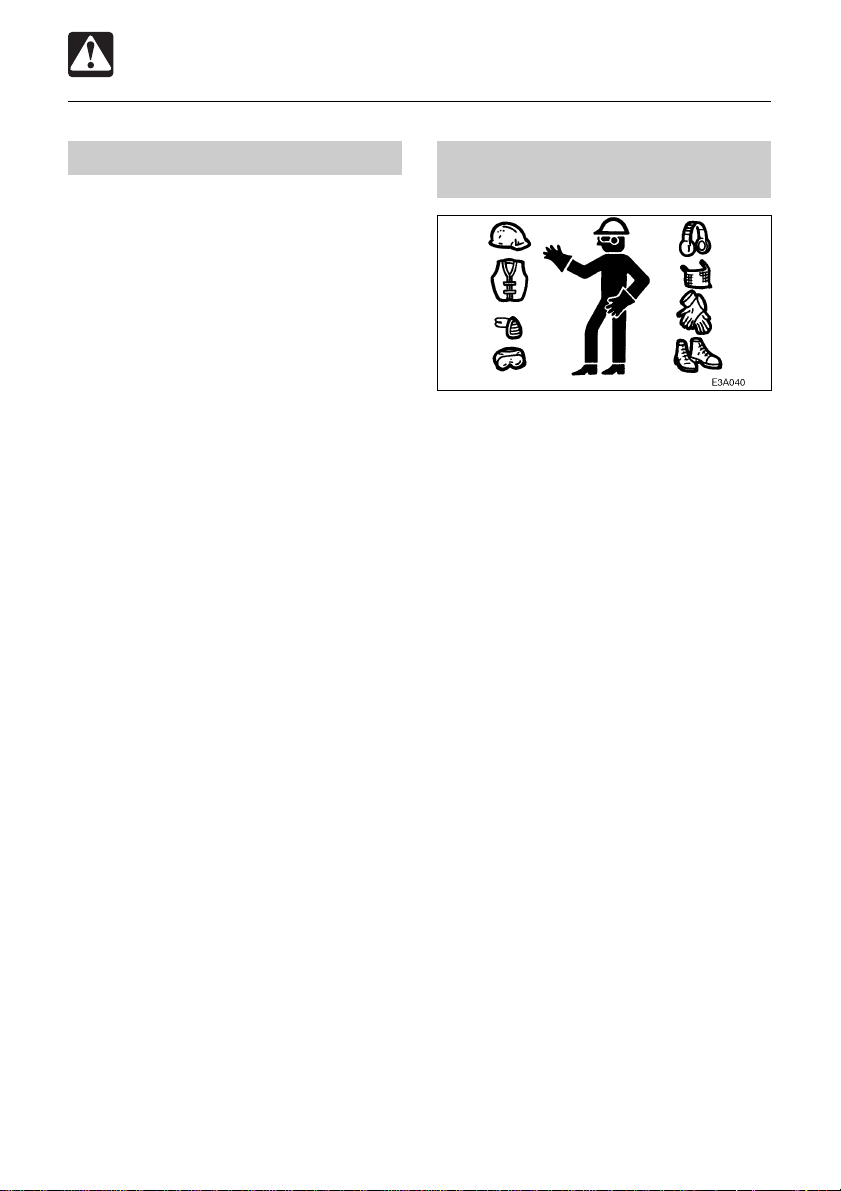

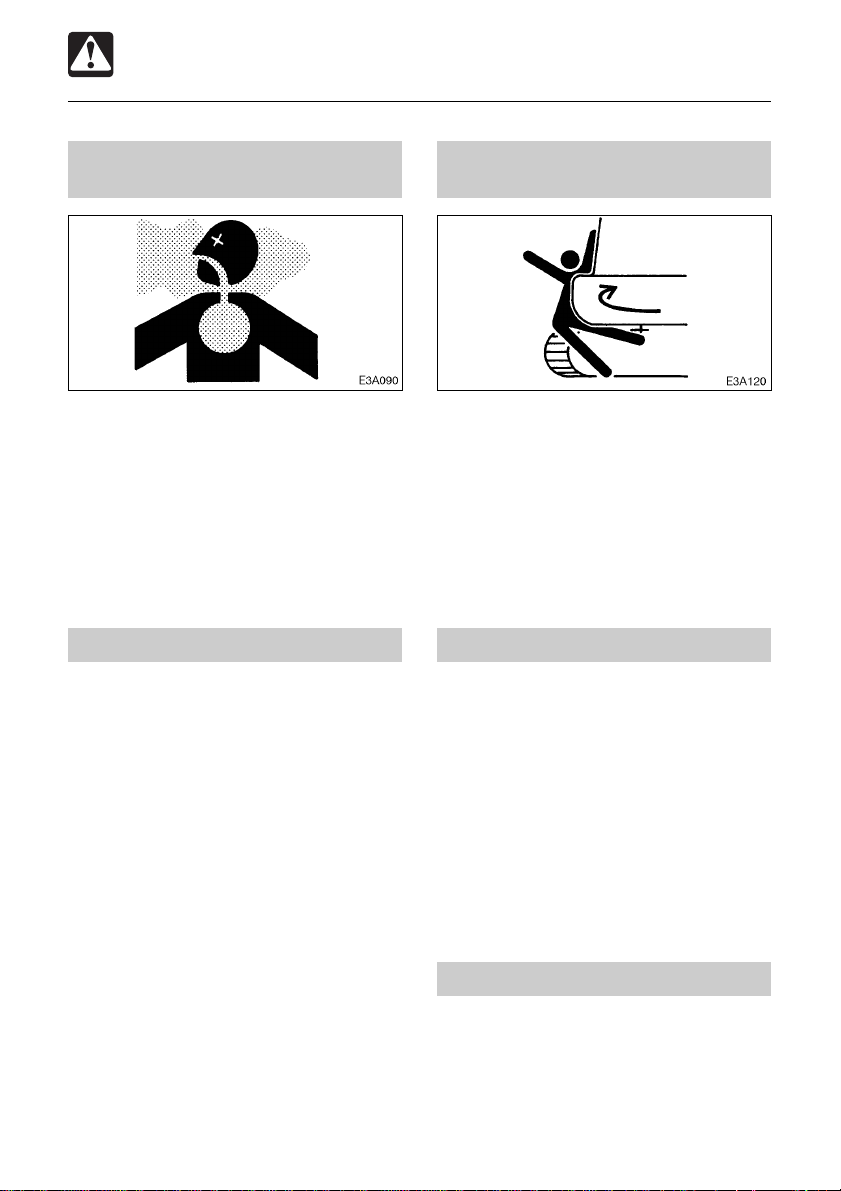

Wear appropriate clothing and personal protective equipment

¡ Do not wear loose clothing or any

accessory that can catch on controls or in

moving parts.

¡ Do not wear oily or fuel stained clothing

that can catch fire.

¡ Wear a hard hat, safety shoes, safety

glasses, filter mask, heavy gloves, ear

protection and other protective equipment

as required by job conditions. Wear

required appropriate equipment such as

safety glasses and filter mask when using

grinders, hammers or compressed air, as

metal fragments or other objects can fly

and cause serious injury.

¡ Use hearing protection when operating the

machine. Loud prolonged noise can cause

hearing impairments, even the total loss

of hearing.

8

Page 11

SAFETY

General Precautions

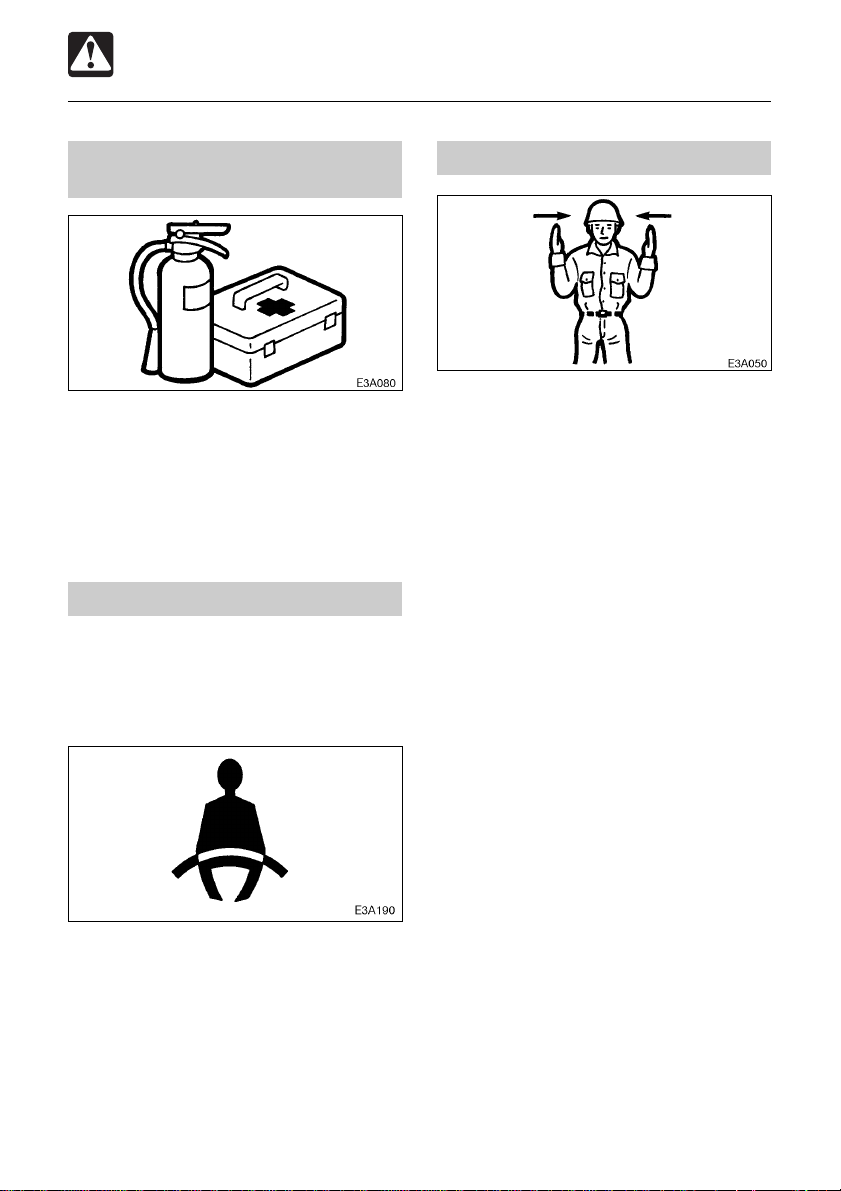

Provide a fire extinguisher and first aid kit

¡ Know where a fire extinguisher and first

aid kit are located and understand how to

use them.

¡ Know how to contact emergency

assistance and first aid help.

Never remove safety equipment

¡ Make sure all protective guards, canopies,

doors, etc., are in place and secure. Repair

or replace damaged components before

operating the machine.

Use a signal person and flagman

Know and use the hand signals required for

particular jobs and make sure who has the

responsibility for signaling.

¡ All personnel must fully understand all the

signals.

¡ The operator shall respond to signals only

from the appointed signal person, but shall

obey a stop signal at any time from

anyone.

¡ The signal person must stand in a clearly

visible location when giving signals.

¡ Know how to use the safety lock lever , seat

belt and other safety equipment and use

them properly .

¡ Never remove any safety equipment

except for service. Keep all safety

equipment in good operating condition.

9

Page 12

SAFETY

General Precautions

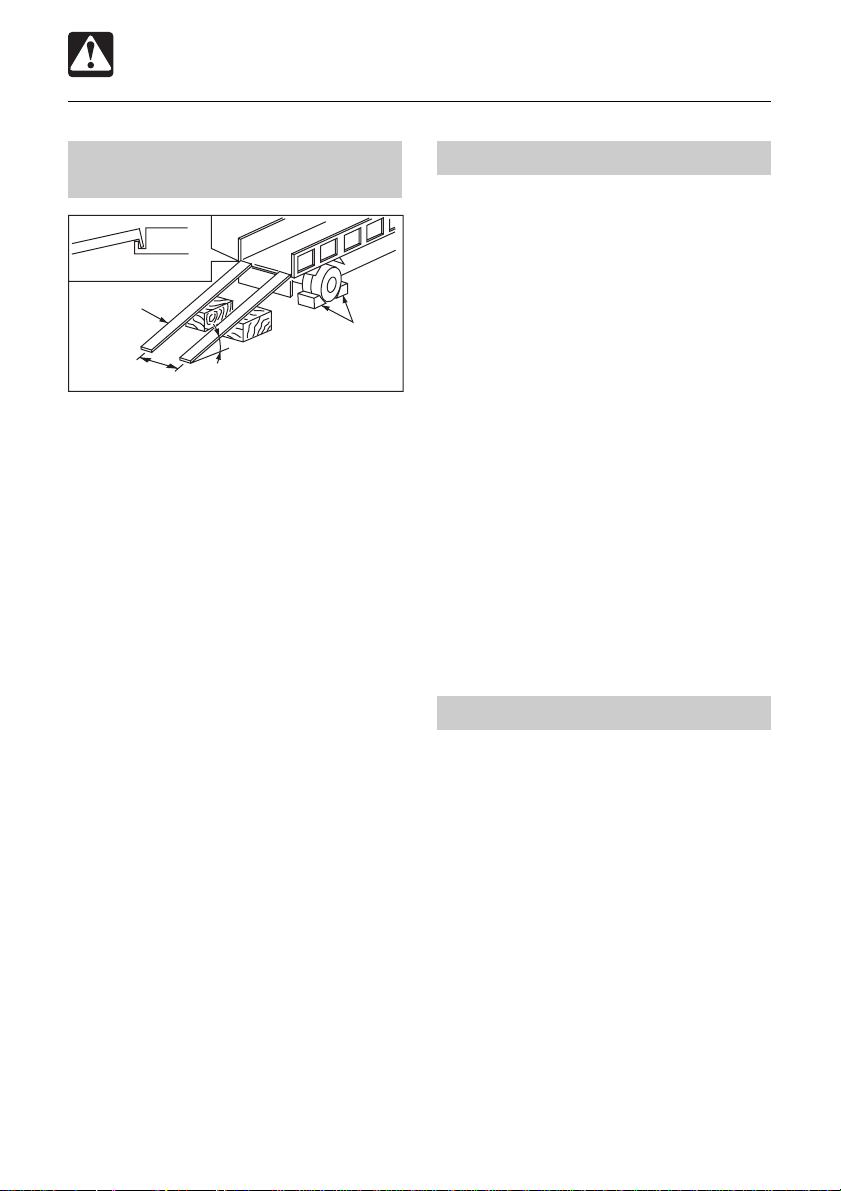

Be sure to lock the safety lock lever before leaving the operator’s seat

¡ Before leaving the operator’s seat, raise

the safety lock lever to engage the lock

and stop the engine. If any controls should

be touched accidentally when the safety

lock lever is lowered, the machine will

move suddenly, and cause serious injury

or death.

¡ < TB153FR > : Note that the dozer blade

control is not locked, even when the safety

lock lever is set to the lock position. Do

not touch this control accidentally.

¡ Before leaving the operator’s seat, lower

the working equipment, raise the safety

lock lever to engage the lock and stop the

engine. Also, be sure to remove the key

and take it with you.

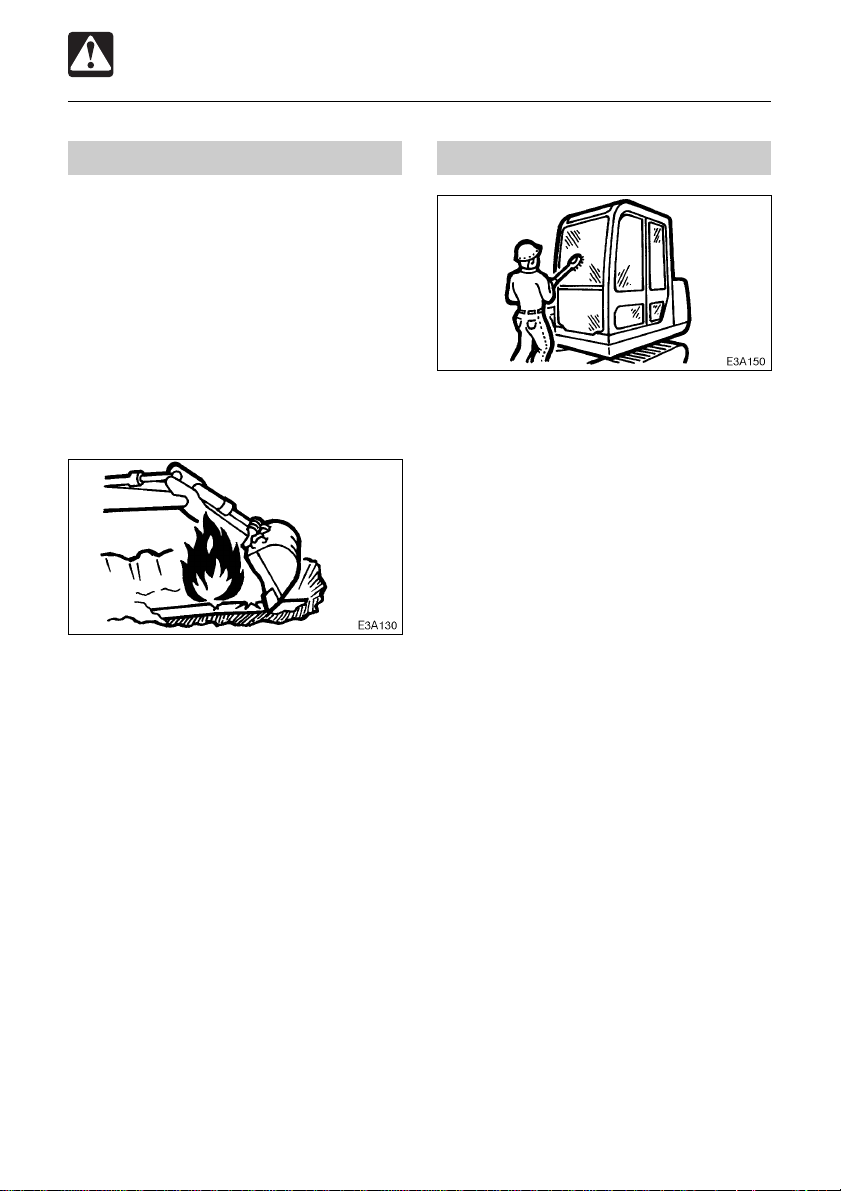

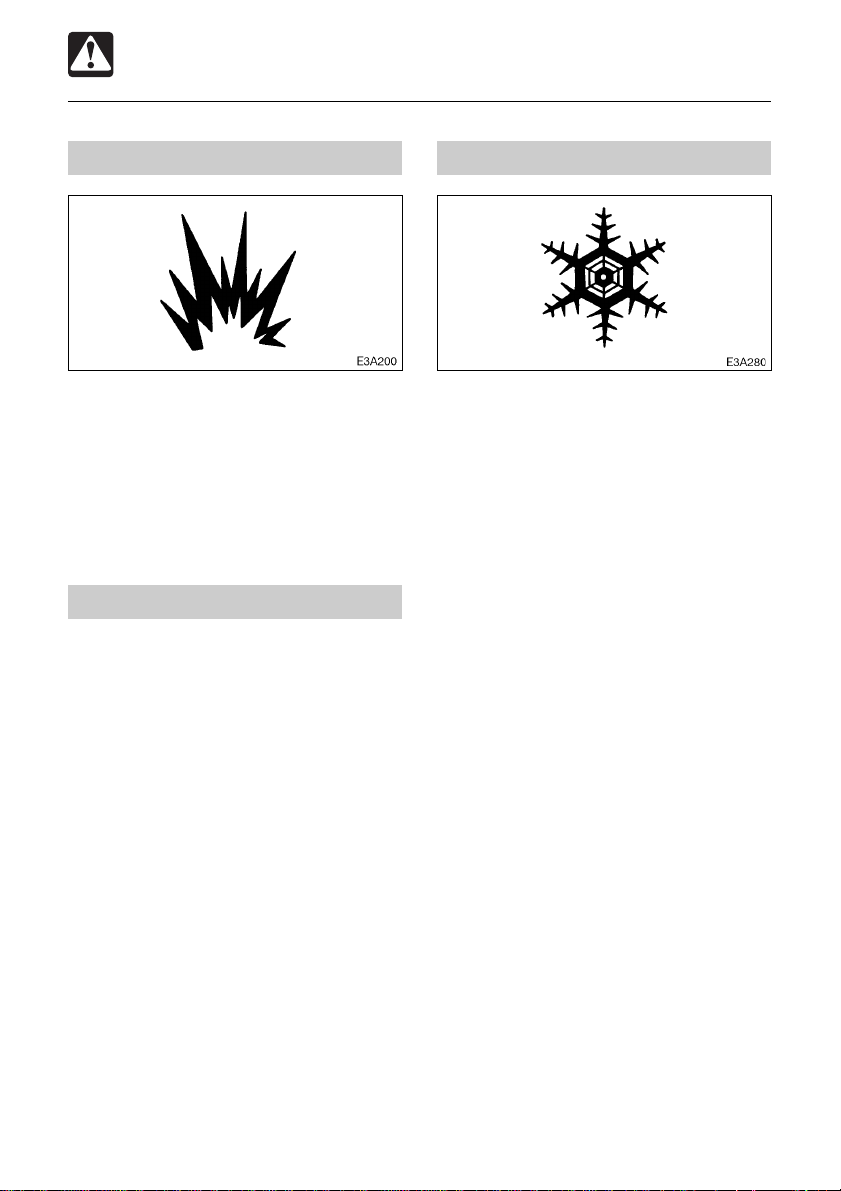

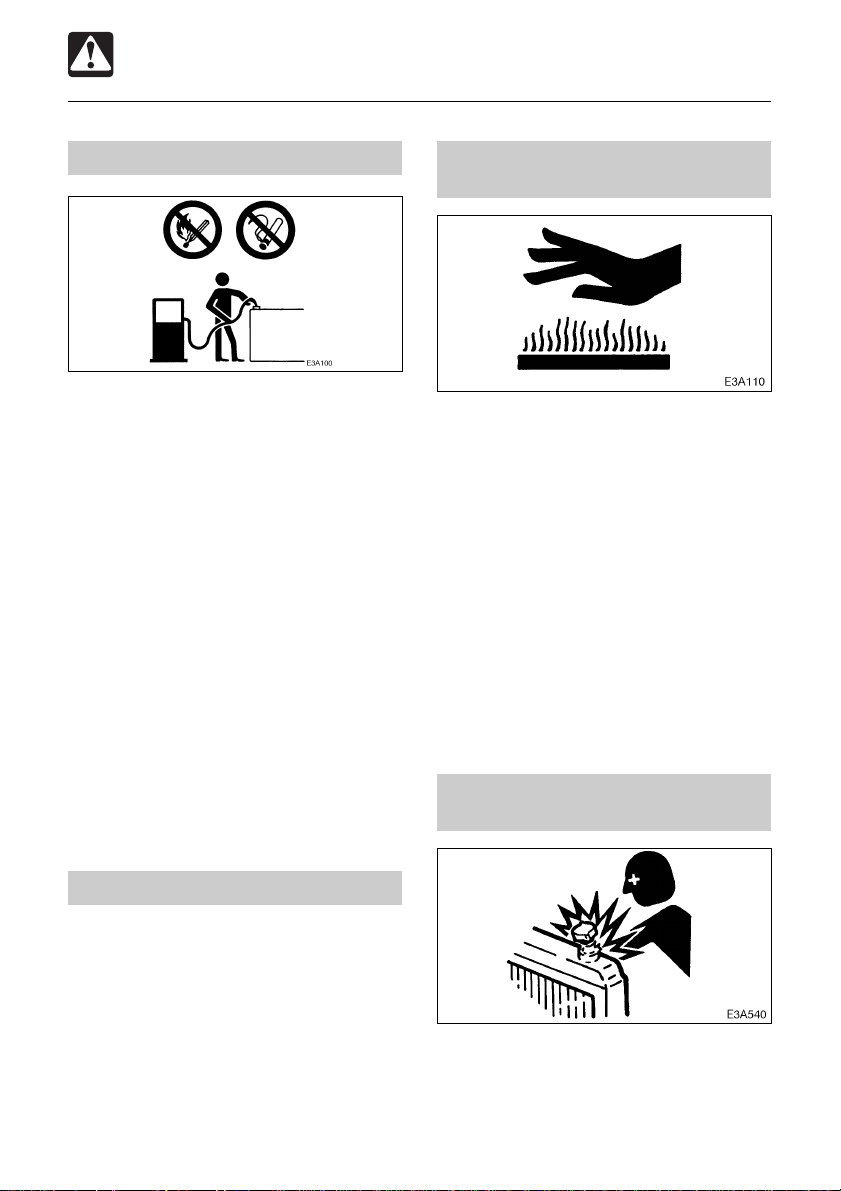

Avoid fire and explosion hazards

Keep flames away from fuel, hydraulic fluid,

oil, grease and antifreeze. Fuel is particularly

flammable and dangerous.

¡ When handling these combustible

materials, keep lit cigarettes, matches,

lighters and other flames or sources of

flames away.

¡ Do not smoke or permit open flames while

fueling or near fueling operations.

¡ Never remove the fuel cap or refuel with

the engine running or hot. Never allow fuel

to spill on hot machine components.

¡ Clean up spilled fuel, oil or other

flammable fluids immediately.

¡ Check for fuel, oil or hydraulic fluid leaks.

Stop all leaks and clean the machine

before operating.

¡ Do not cut or weld on pipes or tubes that

contain flammable fluids. Clean thoroughly

with nonflammable solvent before cutting

or welding.

¡ Remove all trash or debris from the

machine. Make sure that oily rags or other

flammable material are not stored on the

machine.

¡ Handle all solvents and dry chemicals

according to procedures identified on

manufacturers’ containers. Work in a wellventilated area.

¡ Never use fuel for cleaning purposes.

Always use a nonflammable solvent.

¡ Store all flammable fluids and materials

in a safe and well-ventilated place.

10

Page 13

SAFETY

General Precautions

Exhaust fumes from the engine can kill

¡ Do not operate the engine in an enclosed

area without adequate ventilation.

¡ If natural ventilation is poor, install

ventilators, fans, exhaust extension pipes

or other artificial venting devices.

Handling asbestos dust

Inhaling asbestos dust has been linked to

lung cancer. When handling materials which

may contain asbestos, take the following

precautions:

¡ Never use compressed air for cleaning.

¡ Avoid brushing or grinding of the materials.

¡ For clean up, use wet methods or a

vacuum equipped with a high efficiency

particulate air (HEP A) filter.

¡ Wear an approved respirator if there is no

other way to control the dust. When

working indoors, install a ventilation

system with a macro molecular filter.

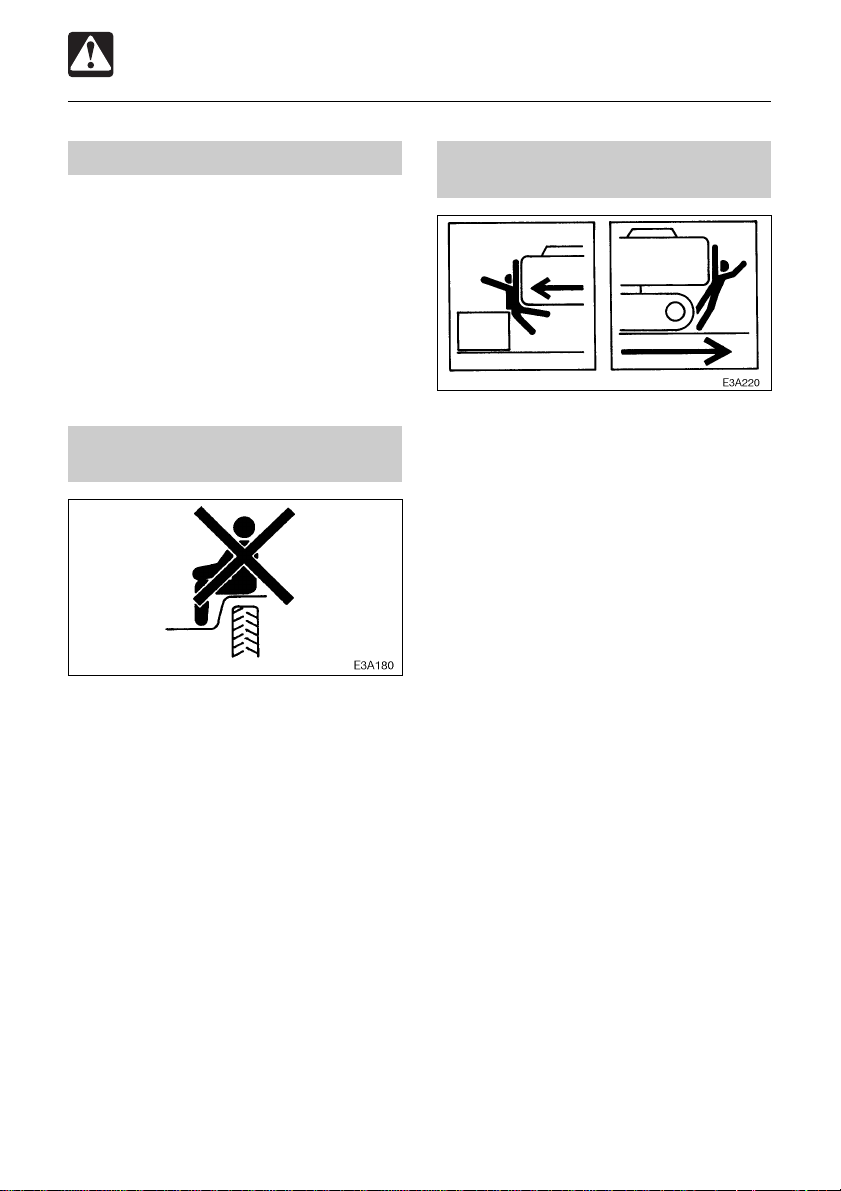

Be careful not to get crushed or cut

Never put your hands, feet or other parts of

your body between the upperstructure and

the undercarriage or tracks, between the

machine body and working equipment, or

between a cylinder and moving part. The size

of these gaps change when the machine

moves and if caught a person can suffer

severe injury or death.

Using optional products

¡ Consult with a Takeuchi dealer before in-

stalling optional attachments.

¡ Do not use attachments that have not

been approved by T akeuchi or a Takeuchi

dealer. Doing so may compromise safety

or adversely affect the machine’s

operation or service life.

¡ Takeuchi will not be held responsible for

any injuries, accidents or damage to its

products caused by the use of a nonapproved attachment.

Never modify the machine

Unauthorized modifications to this machine

can cause injury or death. Never make

unauthorized modifications to any part of this

machine.

11

Page 14

SAFETY

Preparing Precautions

Know the working area

Before starting operation, know the working

area to ensure safety.

¡ Check the topography and ground

condition of the working area, or the

structure of the building when working

indoors, and take the necessary safety

measures in dangerous spots.

¡ Note and avoid all hazards and

obstructions such as ditches, underground

lines, trees, cliffs, overhead electrical wires

or areas where there is danger of a slide.

¡ Check with the local utilities for the

locations of buried gas and water pipes

and buried power cables. Determine jointly

what specific precautions must be taken

to insure safety.

¡ When working on roads, be sure to take

into account the safety of pedestrians and

vehicles.

• Use a flagman an / or signals.

• Fence off the working area and prohibit

entry to unauthorized persons.

¡ When working in water or crossing shallow

streams or creeks, check the depth of the

water, the solidity of the ground, and the

speed of the current beforehand. Make

sure the water is not deeper than the

allowable depth.

Refer to the section titled “Cautions on

Operating” for further instructions.

Alway keep the machine clean

¡ Clean windows, mirrors and lights to

ensure good visibility .

¡ Wipe off any oil, grease, mud, snow or

ice, to prevent accidents due to slipping.

¡ Remove all loose objects stored in the

machine and all objects which do not

belong in or on the machine and its

equipment.

¡ Remove any dirt, oil or grease from the

engine area, to prevent fires.

¡ Clean the area around the operator’s seat,

removing any potential obstacles.

12

Page 15

SAFETY

Preparing Precautions

Perform inspection and maintenance daily

Failure to notice or repair machine

irregularities or damage can lead to

accidents.

¡ Before operating, perform the prescribed

inspections and make repairs immediately

should any irregularities be found.

¡ If a failure that causes loss of control such

as steering, service brakes or engine

occurs, stop the machine motion as

quickly as possible, follow the shutdown

procedure, and keep machine securely

parked until the malfunction is corrected.

13

Page 16

SAFETY

Starting Precautions

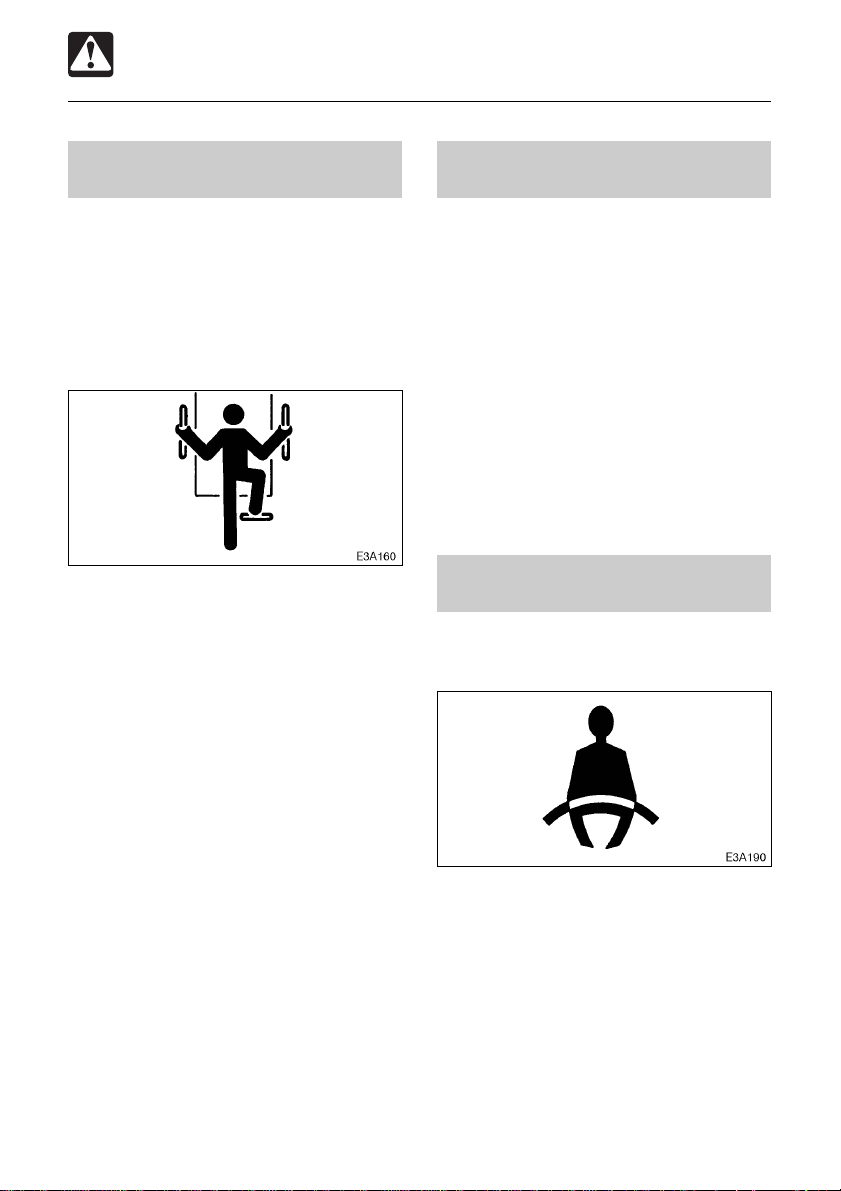

Maintain three point contact when mounting and dismounting

¡ Do not jump on or off the machine. Never

attempt to mount or dismount a moving

machine.

¡ When mounting and dismounting the cab,

first open the door fully to the locked

position and check that it does not move.

(For machines with cabs)

¡ Always face the access system and

maintain a three point contact with the

recommended handrails and steps while

getting on and off the machine. Keep steps

and platform clean.

¡ Never use the safety lock lever or control

levers as hand holds.

Clear the area of other persons before starting the machine

Do not start the engine until you are sure it is

safe. Before starting, check or perform the

following.

¡ Walk around the machine and warn all

personnel who may be servicing the

machine or are in the machine path. Do

not start until all personnel are clearly away

from the machine.

¡ Check for any “DO NOT OPERATE” tags

or similar warning notices on the cab door,

controls or starter switch.

¡ Sound horn to alert everyone around the

machine.

Start the engine from the operator’s seat

¡ Adjust, secure and latch the operator’s

seat.

¡ Fasten the seat belt.

¡ Check that the parking device is applied

and place all controls in the neutral

position.

¡ Check that the safety lock lever is in the

lock position.

¡ Clear the area of all persons.

¡ Start and operate the engine from the

operator’s seat only.

¡ Never attempt to start the engine by

shorting across the starter terminals.

14

Page 17

SAFETY

Starting Precautions

Starting with jumper cables

Use jumper cables only in the recommended

manner. Improper use of jumper cables can

result in battery explosion or unexpected

machine motion.

Refer to the section titled “If the Battery

Goes Dead” for proper instructions.

After starting the engine

After starting the engine, perform the

following operations and checks in a safe

place with no persons or obstacles in the

area. If any malfunctions are found, follow

the shutdown procedure and report the

malfunction.

¡ Warm up the engine and hydraulic fluid.

¡ Observe all gauges or warning

instruments for proper operation.

¡ Listen for unusual noises.

¡ Test engine speed control.

¡ Operate each control to insure proper

operation.

In cold weather

¡ Be careful of slippery conditions on

freezing ground, steps and hand holds.

¡ In severe cold weather, do not touch any

metal parts of the machine with exposed

flesh, as flesh can freeze to the metal and

Cause injury.

¡ Do not use ether or starting fluids on this

engine. These starting aids can cause

explosion and serious injury or death.

¡ Warm up the engine and hydraulic fluid

before operating.

15

Page 18

SAFETY

Operating Precautions

Ensure good visibility

¡ When working in dark places, turn on the

machine’s working lights and headlights

and/or provide extra stationary lighting if

necessary.

¡ When visibility is poor due to severe

weather (fog, snow or rain), stop operating

the machine and wait until conditions

improves.

Do not permit riders on the machine

¡ Do not allow anyone to ride on any part of

the machine at any time while traveling.

¡ Do not allow anyone to be on any part of

the machine while operating.

Check for safety in the surrounding area before starting

¡ Understand the machine limitations.

¡ Use a signal person where clearances are

close or your vision is obstructed.

¡ Never allow anyone to enter the slewing

(swing) radius and machine path.

¡ Signal your intention to move by sounding

the horn.

¡ There are blind spots to the rear of the

machine.

If necessary, swing the cab around before

backing up to check that the area is safe

and clear.

16

Page 19

SAFETY

Operating Precautions

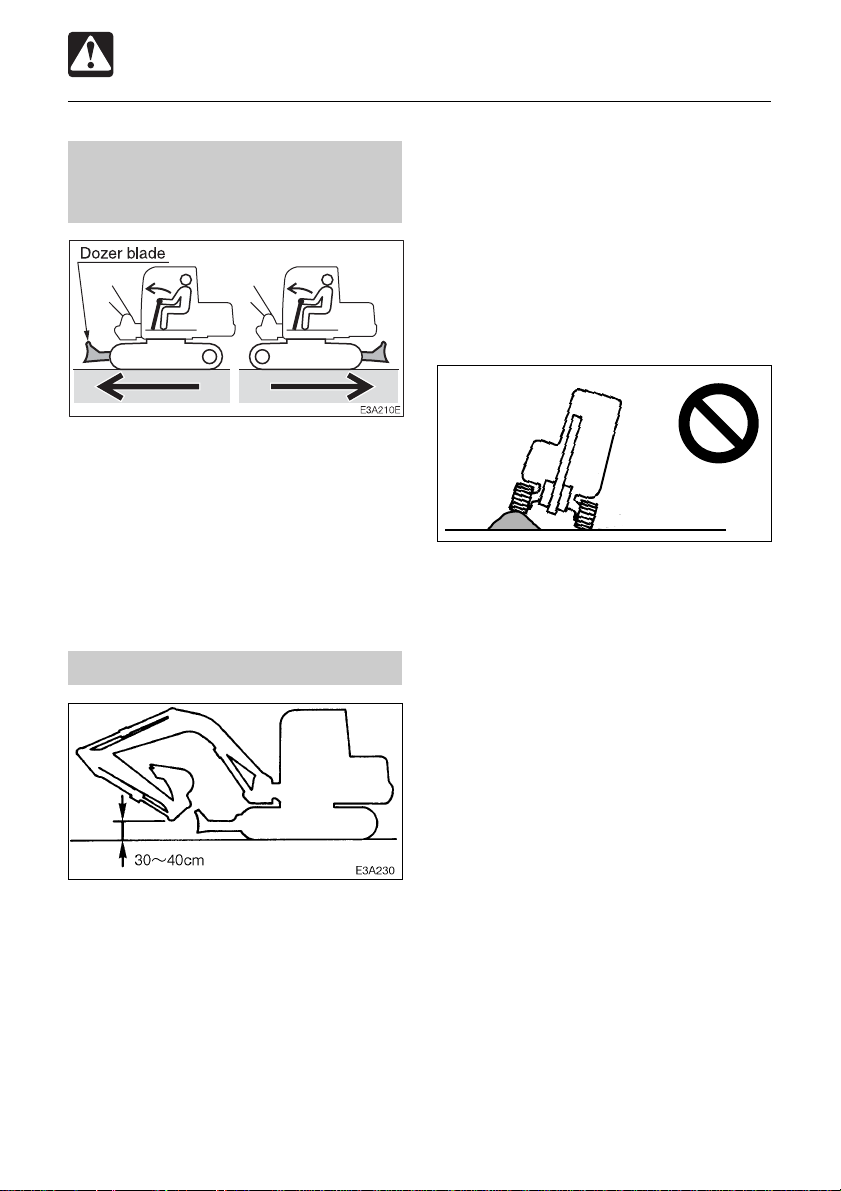

Check the position of the undercarriage (tracks) before traveling

Before operating the travel levers, check to

make sure that the dozer blade is to the front

of the operator’s seat. BE A WARE that when

the dozer blade is to the rear of the operator’s

seat, the travel levers operate in the opposite

direction to when the dozer blade is in the

front.

Travel safety

(12 to 16 in.)

¡ When a load greater than a set value is

applied during 2nd speed (high speed)

travel, the speed will automatically slow

down by switching to 1st speed (low

speed). Thereafter, when the load

becomes lighter, the speed will increase

by returning to 2nd speed (high speed).

Exercise due caution since the travel

speed changes automatically.

E4A040

¡ Avoid crossing over obstacles whenever

possible. If you must do so, keep the hoe

attachment close to the ground and travel

slowly. Never cross obstacles if they will

seriously tilt the machine (to an angle of

10° or greater).

¡ On uneven ground, travel at low speed

and avoid accelerating, stopping or

changing directions abruptly.

¡ When roading a machine, know and use

the signaling devices required on the

machine. Provide an escort for road travel

when required.

¡ Travel with the dozer blade up, the hoe

attachment folded as shown on the

diagram, and the bucket raised 30 to 40

cm (12 to 16 in.) from the ground.

¡ Do not slew (swing) while traveling. If you

must operate the hoe attachment while

traveling, operate at speeds slow enough

so you have complete control at all times.

17

Page 20

SAFETY

Operating Precautions

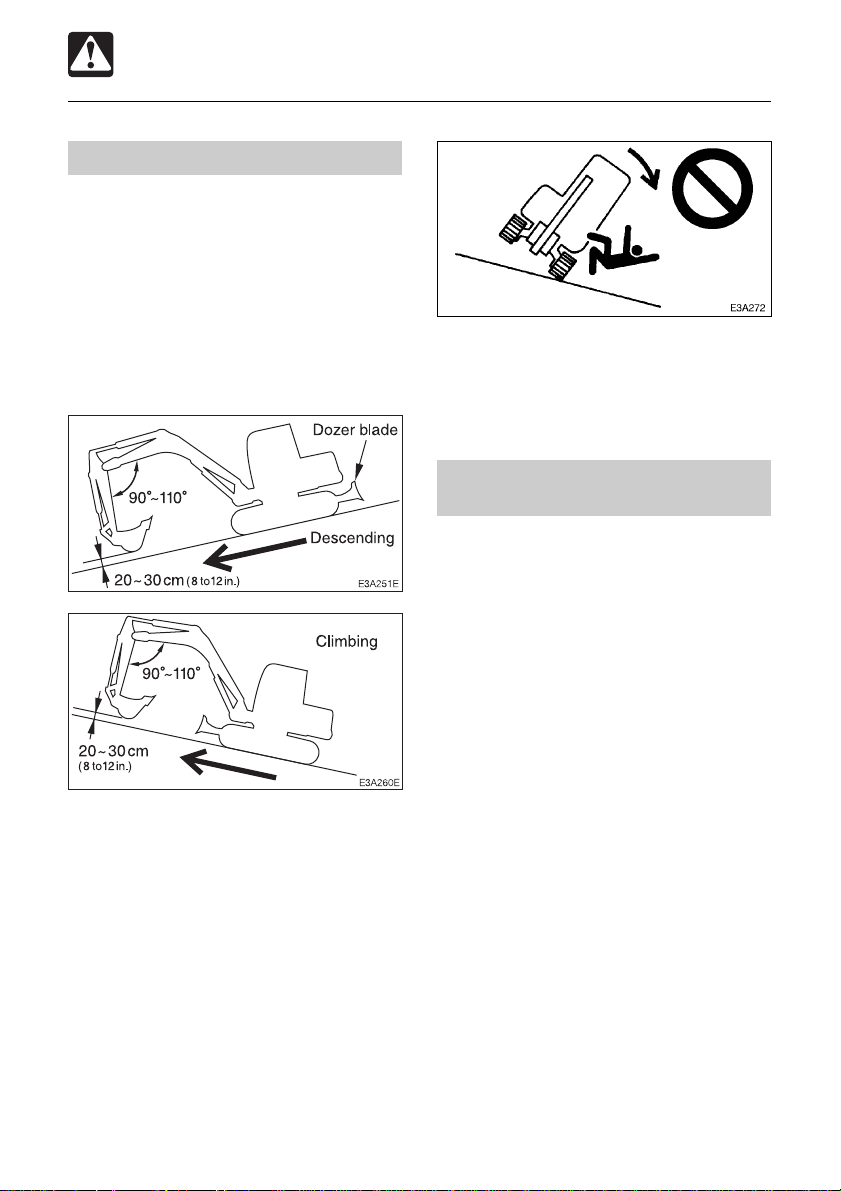

Cautions on traveling on slopes

When traveling on slopes or grades, be

careful that the machine does not tip (roll)

over or slide.

¡ Never exceed the machine’s stability

capabilities (maximum gradeability - 30°,

lateral tipping angle - 15°). Also note that

when actual working area conditions are

poor the machine’s stability capabilities

may be lower.

¡ Do not change directions or cross slopes

sideways. First return to a flat surface then

redirect the machine.

Operate on snow or ice with extra care

¡ When traveling on snow or frozen

surfaces, keep the machine travel speed

down and avoid accelerating, stopping or

changing directions abruptly .

¡ Remember that the road shoulder , fences,

etc., may be buried in the snow and not

visible.

¡ Lower the dozer blade when parked on

unsure ground conditions.

¡ When traveling on slopes or grades, lower

the bucket to a height of 20 to 30 cm (8 to

12 in.) off the ground. In emergencies,

lower the bucket to the ground and stop

the machine.

¡ When traveling on slopes or grades, move

slowly in first gear (low speed).

¡ Do not travel down slopes in reverse.

¡ On grass, dead leaves, wet metal or frozen

surfaces, the machine may slide sideways

even on very gentle slopes. Make sure

the machine never faces sideways with

respect to the slope.

18

Page 21

SAFETY

Operating Precautions

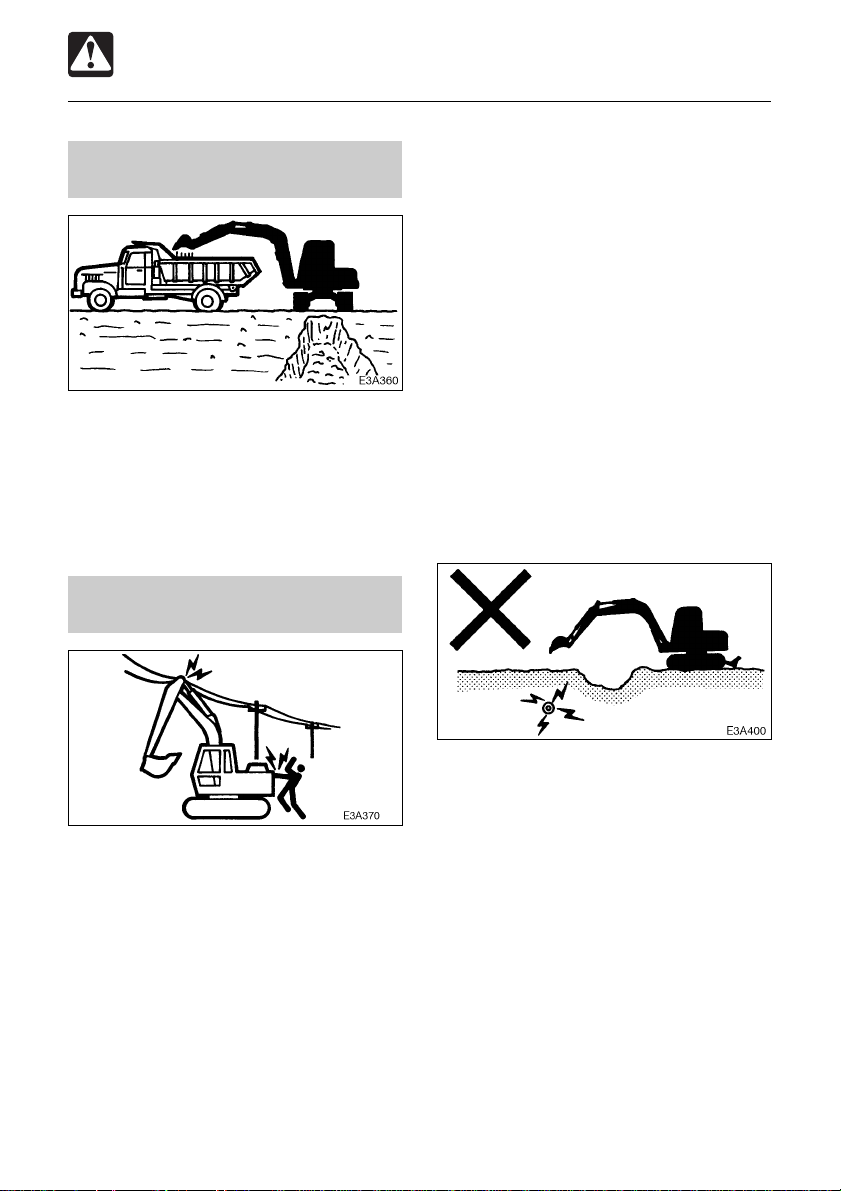

Insure driver safety before loading trucks

Do not load a truck unless the driver is in a

safe place.

¡ Never swing or position the bucket over

personnel or truck cabs.

¡ Load the truck from the rear.

Keep a safe distance from electrical power lines

¡ Always contact the nearest electric utility

and determine jointly what specific

precautions must be taken to insure safety.

¡ Consider all lines to be power lines and

treat all power lines as energized even

though it is known or believed that the

power is shut off and the line is visibly

grounded.

¡ Use a signal person to observe the

approach of any part of the machine or

load to the power line.

¡ Caution all ground personnel to stand

clear of the machine and the load at all

times.

¡ If the machine should come in contact with

a live electrical source, do not leave the

operator’s seat. Do not allow anyone to

approach or touch the machine.

Never approach power lines with any part of

the machine and its load unless all local and

national required safety precautions have

been taken. Electrocution and death can

result from arcing, touching or even being

close to a machine that is in contact with or

near an electrical source.

¡ Maintain the maximum possible distance

from power lines and never violate the

minimum clearance.

¡ Be especially careful of buried high voltage

power lines.

19

Page 22

SAFETY

Operating Precautions

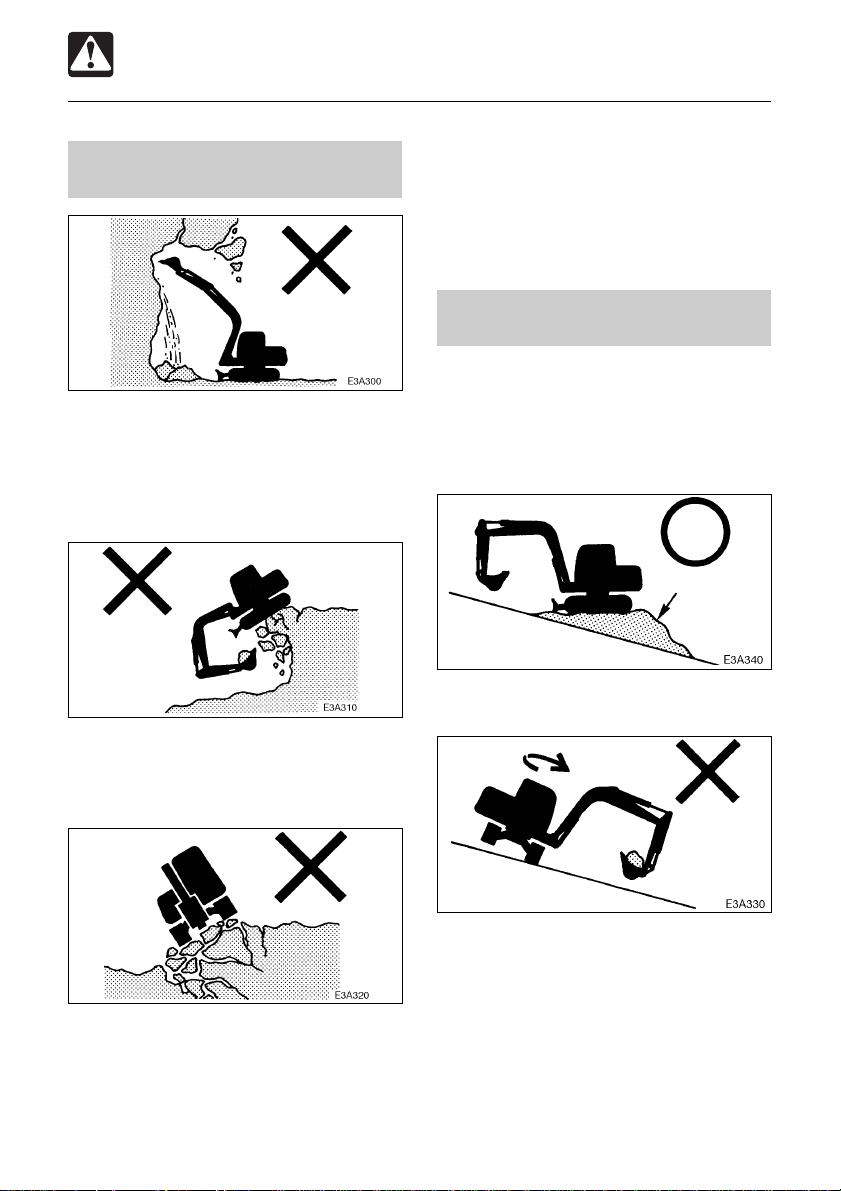

Watch out for hazardous working conditions

¡ Never undercut a high bank. Be

particularly alert for the possibility of a

cave-in.

¡ Do not operate in places where there is a

danger of falling rocks.

• The ground is weak after rain or

explosions.

• The ground is also unstable on banks

and near dugout trenches.

Operating on slopes is dangerous

When operating on slopes or grades, slewing

(swinging) or operating working equipment

may cause the machine to lose stability and

tip over. Avoid operating on slopes whenever

possible.

Fill

¡ Level off the work area.

¡ Keep machine well back from the edge of

an excavation. Avoid undercutting the

machine.

¡ Do not approach unstable surfaces (cliffs,

road shoulders, deep trenches, etc.). The

ground may give way under the machine’s

weight or vibrations, causing the machine

to tip over.

¡ Avoid swinging the loaded bucket in a

downhill direction. This will reduce the

stability of the machine.

20

Page 23

SAFETY

Operating Precautions

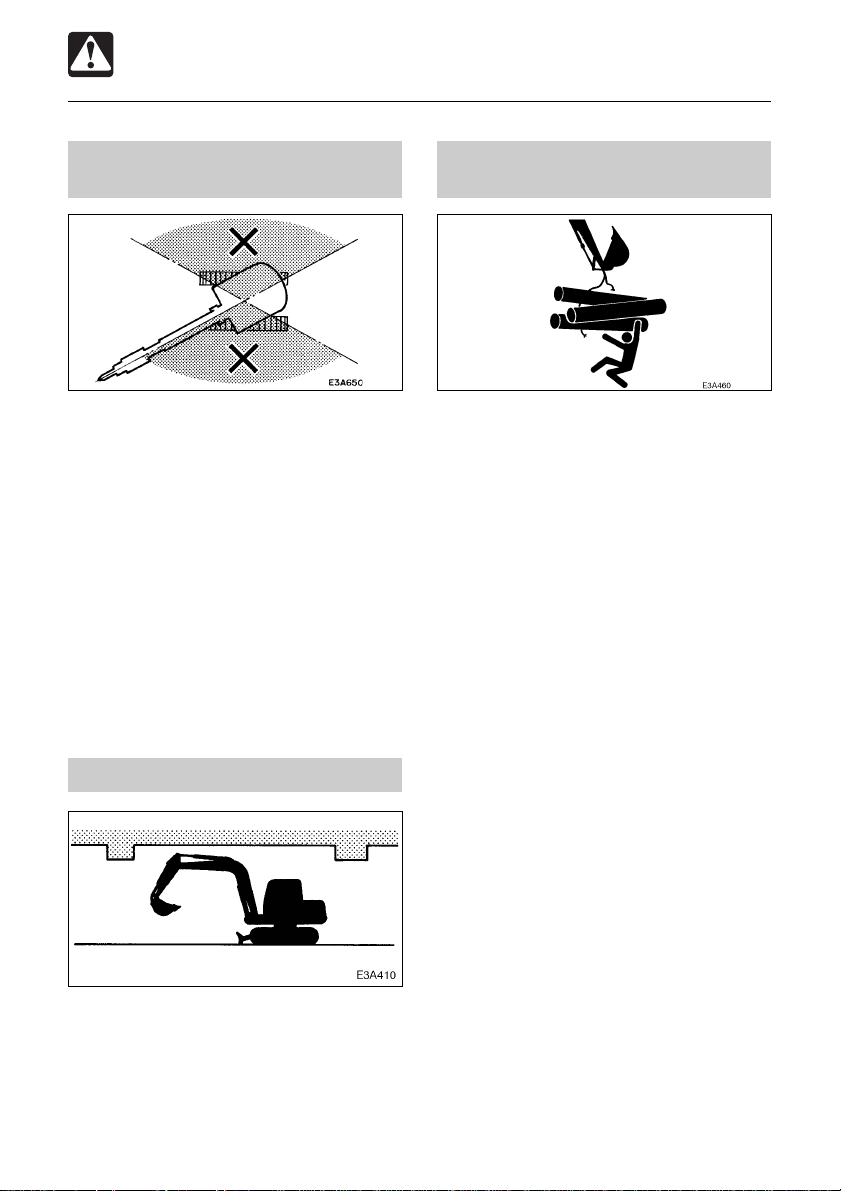

Never slew (swing) sideways with excessive weights

The machine can tip over more easily in the

lateral direction than in the longitudinal

direction.

¡ Do not slew (swing) sideways with

excessive weight at the front.

In particular do not slew sideways on

slopes.

¡ The front is heavier for machines equipped

with breakers, crushers or telescopic arms

than for machines equipped with the

standard bucket. Do not operate such

machines sideways especially with the

digging arm (boom) downhill.

Watch boom clearance

When operating under bridges, in tunnels,

near power lines or indoors, be careful not

to hit the boom or arm against overhead

objects.

Excavators are not designed for lifting loads

The machine is specifically designed for

excavation work and has no safety devices

for crane operation. Extreme caution should

be used if the excavator is used for lifting.

¡ Never lift loads in excess of capacity.

Overload will cause the machine to roll and

can result in serious injury or death.

¡ All rated lift capacities are based on the

machine being level and on a firm

supporting surface. For safe working

loads, the user is expected to make due

allowance for the particular job conditions

such as soft or uneven ground, non-level

condition, side loads, dynamic or jerked

loads, hazardous conditions, experience

of personnel, etc. The operator and other

personnel should fully acquaint

themselves with the operator’s manual

before operating this machine, and rules

for safe operation of equipment shall be

adhered to at all times.

¡ Failure of the bucket linkage or slings

could result if chains or slings are

incorrectly attached, resulting in serious

injury or death.

¡ Do not attempt to pull stumps out of the

ground while using the machine as a

crane. The loads imposed on the machine

under this use are completely unknown.

¡ Never allow any personnel to stand on or

under lifted loads or even within the

maneuvering area.

21

Page 24

SAFETY

Operating Precautions

Danger of flying objects

This machine is not equipped with protective

guards to protect the operator from flying

objects. Do not use the machine in places

where there are risks of the operator being

hit by flying objects.

Cautions on towing

N0A006

When towing, selecting the wrong wire rope,

inspecting improperly, or towing in the wrong

way could lead to accidents resulting in

serious injury or death.

¡ The wire rope breaking or coming

detached could be extremely dangerous.

Use a wire rope suited for the required

towing force.

¡ Do not use a wire rope that is kinked,

twisted or otherwise damaged.

¡ Do not apply strong loads abruptly to the

wire rope.

¡ Use safety gloves when handling the wire

rope.

¡ Make sure there is an operator on the

machine being towed as well as on the

machine that is towing.

¡ Never tow on slopes.

¡ Do not let anyone near the wire rope while

towing.

22

Page 25

SAFETY

Stopping Precautions

Park safely

E3A4901

¡ Park the machine on firm, level ground and

apply the parking device.

¡ When parking on streets, use barriers,

caution signs, lights, etc., so that the

machine can easily be seen even at night

to avoid collision with other vehicles.

¡ Before leaving the machine, do the

following:

1. Lower the bucket and dozer blade to

the ground.

2. Raise the safety lock lever to engage

the lock.

3. Stop the engine and remove the key.

4. Lock the cab and covers.

23

Page 26

SAFETY

Transporting Precautions

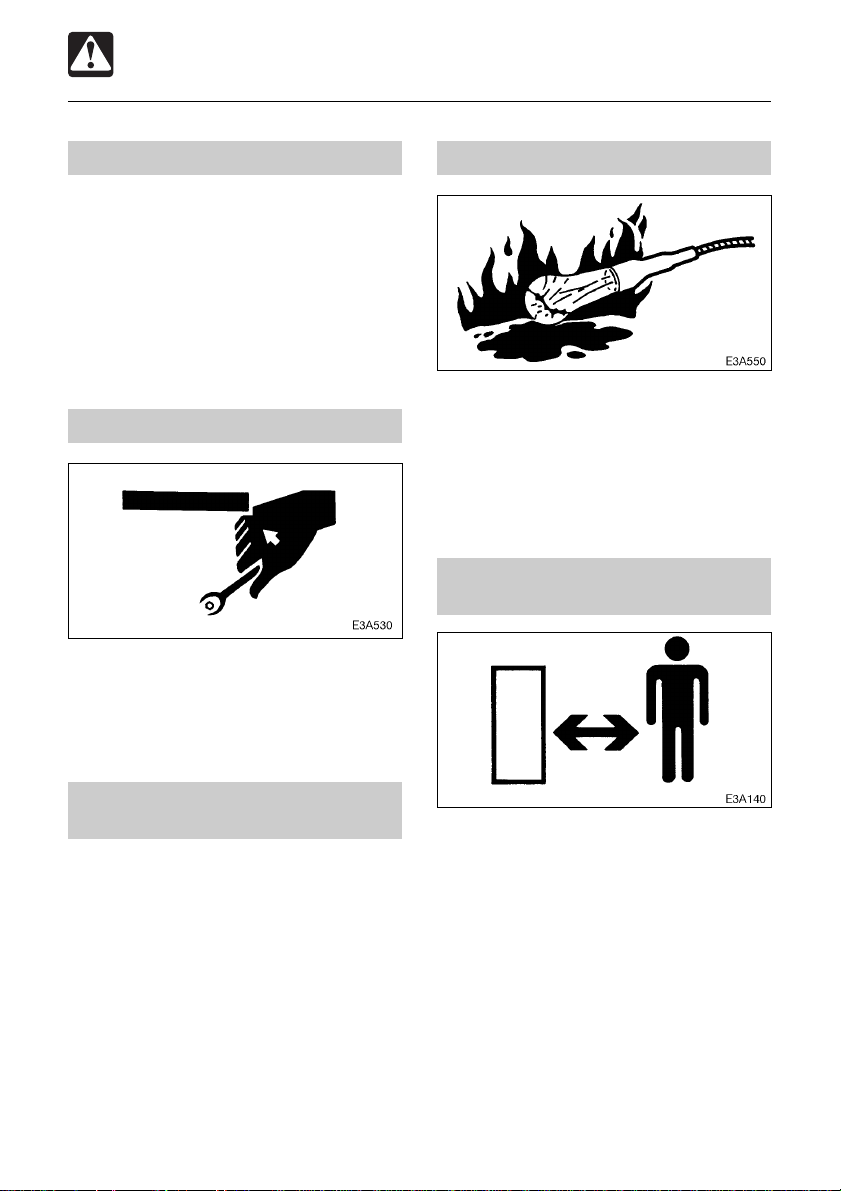

Load and unload the machine safely

Fasten to the suspension fitting

Ramp

Stopper

Distance between ramps

The machine may roll or tip over or fall while

loading or unloading it. Take the following

precautions:

¡ Select a firm, level surface and keep

sufficient distance from road shoulders.

¡ Use loading ramps of adequate strength

and size. Maintain the slope of loading

ramps within 15 degrees.

¡ Secure the ramps to the truck bed.

¡ Keep the truck bed and loading ramps

clean of oil, clay, ice, snow, and other

materials which can become slippery.

Clean the tracks.

¡ Block the transport vehicle so it can not

move.

¡ Use a signal person when loading and

unloading the machine, and travel slowly

in first gear (low speed).

¡ Never change course on the ramp.

¡ Do not slew (swing) on ramps. The

machine may tip over.

¡ When slewing (swinging) on the truck bed,

do so slowly as the footing can be

unstable.

¡ Engage the slew (swing) lock after loading.

¡ Block both tracks and secure the machine

to the truck bed with load binders.

15° or less

E4F001

Hoist the machine safely

¡ Know and use correct crane signals.

¡ Inspect the hoisting equipment daily for

damaged or missing parts.

¡ When hoisting, use a wire rope with

sufficient strength with respect to the

machine’s weight.

¡ Do not hoist with the machine in a posture

other than the one described in the

procedure below. Doing so is dangerous

as it may result in the machine losing its

balance.

Refer to the section titled “Hoisting the

Machine” for further instructions.

¡ Do not hoist the machine with an operator

(s) on it.

¡ When hoisting, hoist slowly so that the

machine does not tip.

¡ Keep all other persons out of the area

when hoisting. Do not move the machine

over the heads of the persons.

Transport the machine safely

¡ Know and follow the safety rules, vehicle

code and traffic laws when transporting

the machine.

¡ Consider the length, width, height and

weight of the truck with the machine

loaded on it when determining the best

route.

24

Page 27

SAFETY

Maintenance Precautions

Attach a “DO NOT OPERA TE” tag

Severe injury could result if an unauthorized

person should start the engine or touch

controls during inspection or maintenance.

¡ Stop the engine and remove the key

before performing maintenance.

¡ Attach a “DO NOT OPERATE” tag to the

starter switch or control lever.

Use the correct tools

Do not use damaged or weakened tools or

tools designed for other purposes. Use tools

suited for the operation at hand.

Anti-explosive lighting

Use anti-explosive electrical fixtures and

lights when inspecting fuel, oil, coolant,

battery fluid, etc. If lighting that is not antiexplosive should break, the substance could

ignite, resulting in serious injury or death.

Do not allow unauthorized personnel in the work area

Replace important safety parts periodically

¡ Replace fuel hoses periodically. Fuel

hoses become weaker over time, even if

they appear to be in good shape.

¡ Replace important safety parts whenever

an irregularity is found, even if it is before

the normal time for replacement.

Refer to the section titled “Important Parts”

for further details.

Do not allow unauthorized personnel in the

work area. Chips or other debris can fly off

machine parts when grinding, welding or

using a hammer.

25

Page 28

SAFETY

Maintenance Precautions

Prepare the work area

¡ Select a firm, level work area. Make sure

there is adequate light and, if indoors,

ventilation.

¡ Clear obstacles and dangerous objects.

Eliminate slippery areas.

Always clean the machine

Stop the engine before performing maintenance

¡ Avoid lubrication or mechanical

adjustments with the machine in motion

or with the engine running while stationary.

¡ If maintenance must be performed with

the engine running, always work as a two

person team with one person sitting in the

operator’s seat while the other works on

the machine.

• When performing maintenance, be sure

to keep your body and clothing away

from moving parts.

Stay clear of moving parts

¡ Clean the machine before performing

maintenance.

¡ Stop the engine and cover electrical parts

when washing the machine. Water on

electrical parts could cause short-circuits

or malfunctions.

Do not use water or steam to wash the

battery, sensors, connectors or the

operator’s seat area.

¡ Stay clear of all rotating and moving parts.

Wrapping or entanglement may result in

serious injury or death.

¡ Keep hands, clothing and tools away from

the rotating fan and running fan belts.

26

Page 29

SAFETY

Maintenance Precautions

Securely block the machine or any component that may fall

¡ Before performing maintenance or repairs

under the machine, set all working

equipment against the ground or in the

lowermost position.

¡ Securely block the tracks.

¡ If you must work beneath the raised

machine or equipment, always use wood

blocks, jack-stands or other rigid and

stable supports. Never get under the

machine or working equipment if they are

not sufficiently supported. This procedure

is especially important when working on

hydraulic cylinders.

Secure the engine hood or cover when opened

Be sure to secure the engine hood or cover

when opening it. Do not open the engine

hood or cover on slopes or in strong wind.

Cautions on tilting up the platform

¡ Raising or lowering the platform while the

engine is running may cause the machine

to move, and cause serious injury or

death. Lower the working equipment to the

ground and stop the engine before raising

or lowering the platform.

¡ When the floor is tilted up, support it firmly

with the stopper to prevent it from falling.

Place heavy objects in a stable position

Securely block the working equipment

To prevent unexpected movement, securely

block the working equipment when repairing

or replacing the cutting edges or bucket teeth.

When removing or installing the hoe

attachment, place it in a stable position so

that it does not tip over.

27

Page 30

SAFETY

Maintenance Precautions

Use caution when fueling

¡ Do not smoke or permit open flames while

fueling or near fueling operations.

¡ Never remove the fuel cap or refuel with

the engine running or hot. Never allow fuel

to spill on hot machine components.

¡ Maintain control of the fuel filler nozzle

when filling the tank.

¡ Do not fill the fuel tank to capacity. Allow

room for expansion.

¡ Clean up spilled fuel immediately.

¡ Tighten the fuel tank cap securely. Should

the fuel cap be lost, replace it only with

the original manufacturer’s approved cap.

Use of a non-approved cap without proper

venting may result in pressurization of the

tank.

¡ Never use fuel for cleaning purposes.

¡ Use the correct fuel grade for the operating

season.

Be careful with hot and pressurized components

Stop the engine and allow the machine to

cool down before performing inspection and

maintenance.

¡ The engine, muffler, radiator, hydraulic

lines, sliding parts and many other parts

of the machine are hot directly after the

engine is stopped. Touching these parts

will cause burns.

¡ The engine coolant, oil and hydraulic fluid

are also hot and under high pressure.

Be careful when loosening caps and

plugs. Working on the machine under

these conditions could result in burns or

injuries due to the hot oil spurting out.

Be careful with hot cooling systems

Handling of hoses

Fuel, oil or hydraulic fluid leaks can cause a

fire.

¡ Do not twist, bend or hit the hoses.

¡ Never use twisted, bent or cracked hoses,

tubes and pipes. They may burst.

¡ Retighten loose connections.

Do not remove the radiator cap or drain plugs

when the coolant is hot. Stop the engine, let

the engine and radiator cool and loosen the

radiator cap or drain plugs slowly.

28

Page 31

SAFETY

Maintenance Precautions

Be careful with fluids under pressure

Pressure can be maintained in the hydraulic

circuit long after the engine has been shut

down.

¡ Release all pressure before working on

the hydraulic system.

¡ Hydraulic fluid under pressure can

penetrate the skin or eyes and cause

injury , blindness or death. Fluid escaping

from a small hole can be almost invisible.

Wear a safety goggles and heavy gloves

and use a piece of cardboard or wood to

search for suspected leaks.

If fluid is injected into the skin, it must be

removed within a few hours by a doctor

familiar with this type of injury .

Release all pressure before working on the hydraulic system

Oil may spurt out if caps or filters are removed

or pipes disconnected before releasing the

pressure in the hydraulic system.

¡ Gradually press the air breather button to

relieve tank pressure.

¡ Move all the control levers and pedals

several times in all directions to release

the pressure from the working equipment

circuitry. (When equipped with accumulator)

¡ When removing plugs or screws or

disconnecting hoses, stand to the side and

loosen slowly to gradually release the

internal pressure before removing.

Handling of the accumulator

High pressure nitrogen gas is enclosed in

the accumulator and incorrect handling could

possibly bring about serious personal injury

due to explosion. The following matters

should be strictly observed :

¡ Do not disassemble.

¡ Do not bring close to fire or throw into a

fire.

¡ Do not make hole, weld, or fuse.

¡ Do not subject to shock such as hitting or

rolling.

¡ At time of disposal, it will be necessary to

release the enclosed gas. Please contact

a Takeuchi sales or service outlet.

29

N0A0051

Page 32

SAFETY

Maintenance Precautions

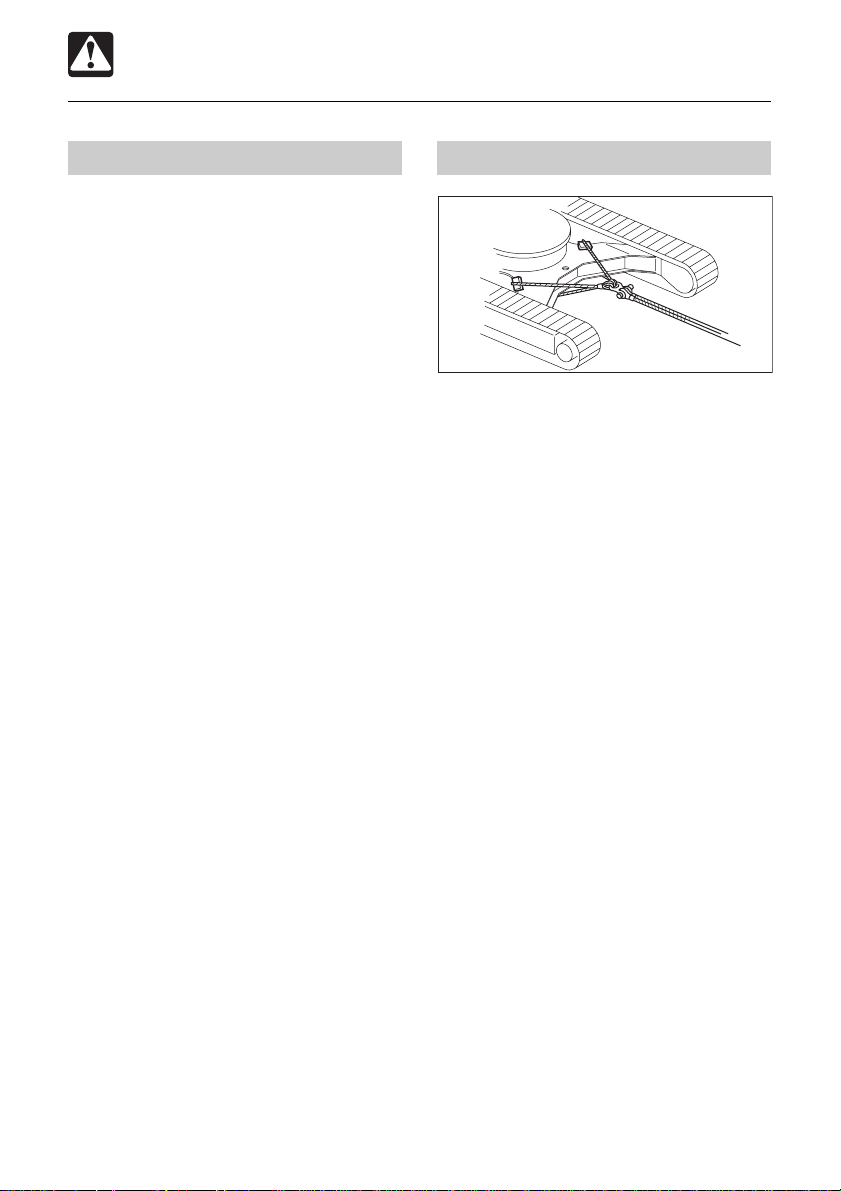

Be careful with grease under pressure < TB153FR >

E3A6201

The track adjuster contains highly

pressurized grease. If the tension is adjusted

without following the prescribed procedure,

the grease discharge valve may fly off,

resulting in injury.

¡ Do not loosen the grease nipple.

¡ Loosen the grease discharge valve slowly .

¡ Do not put your face, arms, legs or body

in front of the grease discharge valve.

¡ If no grease is expelled when grease

discharge valve is loosened, there is a

problem. Contact your nearest service

outlet for repairs. DO NOT disassemble,

as this is very dangerous.

Disconnect the battery

Disconnect the battery before working on the

electrical system or doing any welding.

Remove the negative (–) battery cable first.

When reconnecting the battery, connect the

negative (–) battery cable last.

Avoid battery hazards

¡ Batteries contain sulfuric acid which will

damage eyes or skin on contact.

• If acid contacts eyes, flush immediately

with clean water and get prompt medical

attention.

• If acid is accidentally swallowed, drink

large quantities of water or milk and call

a physician immediately.

• If acid contacts skin or clothing, wash

off immediately with clean water.

¡ Wear safety glasses and gloves when

working with batteries.

¡ Batteries generate flammable and

explosive gases. Keep arcs, sparks,

flames and lighted tobacco away.

¡ Use a flashlight to check battery electrolyte

level.

¡ Stop the engine and shut off electrical

equipment while inspecting or handling the

battery .

¡ Do not short circuit the battery posts with

metal items.

¡ Always unfasten the negative (–) battery

cable first when disconnecting the battery

cable. Always connect the negative (–)

battery cable last when fastening the

battery cable.

¡ Loose battery terminals may result in

sparks. Be sure to fasten terminals tightly.

¡ Make sure the vent caps are tightened

securely.

¡ Do not charge a battery or jump-start the

engine if the battery is frozen. Warm to

15°C (60°F) or the battery may explode.

¡ Do not use the battery when the fluid level

is below the lower level. Doing so will

hasten the deterioration of the internal

portions of the battery and shorten the

battery life, and can also cause rupturing

(or an explosion).

¡ Do not fill the battery above the upper

level. Doing so could cause the fluid to

leak, contact and damage the skin, or

cause parts to corrode.

30

Page 33

SAFETY

Maintenance Precautions

Have a T akeuchi service agent repair welding cracks or other damage

Ask a Takeuchi service agent to repair any

welding problems which are detected. If not

feasible, make sure the welding is done by a

qualified person in a properly equipped

workplace.

Vibrations to which the operator is subjected

According to the results of the tests carried

out to determine the vibrations transmitted

to the operator by the machine, the upper

limbs are subjected to vibrations lower than

2.5 m (8.2 ft) / sq.sec. while the seated part

of the body is subjected to vibrations lower

than 0.5 m (1.64ft) / sq.sec.

Checks after maintenance

Disposing of wastes

¡ Funnel spent fluids from the machine into

containers. Disposing of fluids improperly

destroys the environment.

¡ Follow the prescribed regulations when

disposing of oil, fuel, engine coolant,

refrigerant, solvents, filters, batteries or

other harmful substances.

¡ Gradually raise the engine speed from a

low idle to maximum speed and check that

no oil or water is leaking from serviced

parts.

¡ Move the controls and check that the

machine is operating properly.

31

Page 34

SAFETY

Safety Signs (Decals)

The following safety signs (decals) have been placed on your machine in the areas indicated.

They are intended for the personal safety of you, and those working with you. Please take

this manual, walk around your machine and note the content and location of these safety

signs. Review these signs and the operating instructions in this manual with your machine

operators.

¡ Keep the signs legible. If they are not, obtain replacements from your Service outlet.

32

Page 35

SAFETY

Safety Signs (Decals)

1. No.08810-31556

Warning

Read and understand this

manual before performing any

operation, inspection or

maintenance on this machine.

08810-31556

2. No.08810-31557

Hazard from falling window.

After raising window, be sure to lock it in

place with lock pins.

08810-31557

3. No.05793-00045

Hazard at lifting or lowering window

When the front window is opened or

closed, it will come close to the head.

Be careful that the window does not

strike the head.

05793-00045

4. No.05793-00052 <TB153FR >

Hazard of a flying plug from track adjuster

Read manual before adjusting track for

safe and proper handling.

5. No.05793-00011

Safety Distance

Do not get near or stand within the

machine working area.

05793-00011

6. No.05793-00049

Safety Distance

Hazard of being hit by

the working device of the

machine.

Keep away from machine

during operation.

05793-00049

7. No.05693-52506

Handling the interference prevention system

To ensure operator safety, this excavator is equipped

with a system which autmatically stops boom or bucket

when it approaches the cab to prevent it from hitting the cab

CAUTIONS ON USE

*Donot disassemble or damage the sensors installed

on the boom and main body.

In addition, do not install attachments other than

those designated by Takeuchi. The interference

prevention system may not function properly if other

attachments are installed.

Operation when the boom has stopped automatically

1

If theboom has stopped while rising:

Operate the boom downward.

2

If the boom has stopped while

offsetting to the left:

1.Operate theboom downwardto mov

it outsidethe automaticstop range.

2. Offsetto the left.

*Offsetting to the right is possibl

regardiess ofthe boom’spostuer.

Preliminary Inspection

Perform theinspection poeration operationsdescribed below andcheck

that the bucket,arm and boom do nottouch the cab when the boo

or bucketis moved near thecab and stopsautomatically.

WARNING

e

1

1

2

e

2

3

05793-00052

1

Upper part of cab

Offset the boom to the fornt of the poerator’s seat

and movethe boom near the cab.

Offset the boom to the right and move the bucket near the cab.

2

Offset

Offset the boom fully to the right and check thant it

can be set to the maximum rear inclination.

3

Offset to the left in the posture in above.

33

05693-52506

エ

2

Page 36

SAFETY

Safety Signs (Decals)

8. No.03593-13700

WARNING

1 -

This machine,if improperly operated or

maintained can cause bodily harm,or even

DEATH.

Read and understand the owners manual

2 -

supplied with this machine before operating.

Keep all safety devices in place and

3 -

functional.

Do not operate the machine unless the seat

4 -

belt is properly fastened around you.

Follow the instructions in the Operator’s

5 -

Manual when hoisting the machine or

fastening it to the transport vehicle.

9. No.03793-37300

WARNING

If the platform is raised or lowered while the

engine is running, the machine may start

moving.Be sure to stop the engine first.

If you need to run the engine while the

platform is raised, follow the instructions

below.

(Refer to the Instruction Manual.)

1. Place the machine on a stable, level

surface, and stop the engine.

2. Lock the operating lever.

3. Tilt-up the platform.

4. Insert the stopper to prevent platform from

dropping.

5. Make sure that all levers and pedals are in

neutral positions.

6. Push the throttle lever fully forward.

(Low idling)

7. Start the engine.

8. After inspection and maintenance is

compiete, stop the engine,

10. No.03593-07400

CAUTION

STOP ENGINE

BEFORE OPENING

11. No.03593-47010

WARNING

THIS EXCAVATOR

MUST NOT BE USED

AS A CRANE

12. No.03393-68100

WARNING

WHEN BUCKETS WIDER THAN STANDARD

ARE FITTED TO THIS MACHINE,

CAB(CANOPY)DAMAGE MAY OCCUR WHEN

FULL RIGHT HAND BOOM OFFSET IS USED.

03793-37300

03593-07400

03593-47010

03393-68100

03593-13700

13. No.03393-75040

CAUTION

DO NOT USE ETHER

USAGE OF ETHER FOR STARTING

PURPOSES MAY CAUSE INTERNAL

ENGINE DAMAGE.

03393-75040

14. No.03393-75050

CAUTION

HYDRAULIC TANK MUST REMAIN

PRESSURIZED TO AVOID DAMAGE

TO PUMPS.

03393-75050

15. No.05693-21980

WARNING

18. No.05693-53810

CAUTION

Setting this switch to the “OFF”

position will shut down all of

the electrical circuits and the

memory of the radio preset

tuning buttons will be deleted.

05693-53810

19. No.03593-06600

Diesel Fuel

D

Diesel Fuel Only

03593-06600

20. No.03593-06700

Hydraulic oil

Engine may be HOT

05693-21980

16. No.03993-52302

WARNING

DO NOT ENTER

INTO PINCH AREA.

03993-52302

21. No.08810-31549

Tie down point

for USA

17. No.03993-52303

22. No.03993-00500

WARNING

Failure to properly set the Attachment

Interference Switch can result in

equipment damage, bodily harm, or death.

03993-52303

Position of Hoisting

for USA

23. Noise Outside the Cab / for EU

This value indicates the noise level outside the machine

and refers to the noise perceived by the persons who are in

the vicinity of the work area.

< TB153FR >

No.03393-41031

< TB180FR >

No.05693-49035

34

Page 37

CONTROLS

Names of Components ..............................36

Doors and Covers ......................................38

Seat and Seat Belt......................................44

Instrument Cluster .....................................46

Switches .....................................................48

Levers and Pedals ..................................... 53

Accessories ...............................................56

35

Page 38

CONTROLS

Names of Components

Upperstructure

1. Cab

2. Seat

3. Engine hood

4. Fuel tank

5. Hydraulic tank

Undercarriage

6. Crawler belt

7. Idler

8. Track roller

9. Carrier roller

10. Travel motor

36

Working equipment

11. Bucket

12. Bucket cylinder

13. Arm

14. Arm cylinder

15. Boom

16. Boom cylinder

17. Boom bracket

18. Offset cylinder

19. Right link arm

20. Auxiliary hydraulic lines

21. Dozer blade

22. Blade cylinder

Page 39

CONTROLS

Names of Components

1. Instrument cluster

2. Starter switch

3. Light switch

4. Horn button

5. Travel speed switch

6. Wiper switch (Cab)

7. Safety lock lever

8. Attachment Interference switch

9. Throttle controller < TB180FR >

10. Left operating lever

11. Right operating lever

12. Travel levers

13. First Auxiliary hydraulic switches

14. Blade lever

15. Offset pedal

16. Decel. button

17. Heater & AC control panel

18. Automatic decel. button < TB180FR >

19. Cigarette lighter

20. Overload warning switch (Option)

21. Selector button (2nd or 4th Aux.) (Option)

< TB180FR >

22. Second / fourth auxiliary hydraulic switch

(Option)

23. Second auxiliary hydraulics operation

indicator lamp (Option) < TB180FR >

24. Third auxiliary hydraulic button (Option)

25. Third auxiliary hydraulic switch (Option)

26. Third auxiliary hydraulics warning lamp

(Option)

27. Throttle lever < TB153FR >

37

Page 40

CONTROLS

Doors and Covers

Starter Key

E4B003

The starter key is used not only to start and

stop the engine, but also to lock and unlock

the following places :

¡ Cab door

¡ Fuel filler cap

¡ Rear cover

¡ Rear cover

¡ Tool box

¡ Manual storage compartment (Canopy)

Cab Door

WARNING

Lock and unlock

2

1

C4C001

1. Insert and turn the starter key.

Opening

1. Pull the knob (1) towards you and open

the door.

To open the door from inside the cab, push

the lever (2) to the front.

2. Open the door fully and press it against

the cab to lock it in place.

Closing

4

3

When mounting and dismounting the

cab, first open the door fully to the locked

position and check that it does not move.

Open the door fully and press it against the

catch at the back of the door to lock it in place.

Always lock the door when mounting and

dismounting and when operating the

machine.

C4C002

1. Either push release lever (3) to the front

or lower release lever (4).

2. Close the released door.

38

Page 41

CONTROLS

Doors and Covers

Front Window (Cab)

WARNING

¡¡

¡ Grasp the handles firmly with both

¡¡

hands when opening and closing the

front window. Y our head or hands may

get caught if they slip.

¡¡

¡ When the front window is opened or

¡¡

closed, it will come close to the head.

Be careful that the window dose not

strike the head.

¡¡

¡ If you open the front window , be sure to

¡¡

lock it in place with the knobs (latch) (2)

on the left and right sides. The window

may fall if it is not locked in place.

Opening

Closing

WARNING

When closing the front window, lower the

window slowly so as not to hit your head.

Lowering the window abruptly may result

in injury or damage the front window.

1. Grasp the left and right handles (1) and

press the knobs (2) with your thumb to

release the lock.

2. Pull down the front window and while

doing so, slide it to the front and slowly

lower it.

1. Grasp the left and right handles (1) and

press the knobs (2) with your thumb to

release the lock.

2. Pull the front window toward you and lift

while doing so.

3. Lift the front window fully and then release

your thumb from the knobs (2) and lock

the front window.

3. Lower the front window fully and then

release your thumb from the knobs (2) and

lock the front window.

39

Page 42

CONTROLS

Doors and Covers

Lower Front Window (Cab)

Removing

4 4

N0B008

1. Open the front window and stow it in the

ceiling.

2. Grasp the protruding parts (4) on the left

and right with your fingers and slowly lift

the lower front window off.

4

5

6 6

3. Hold the glass firmly, place the lower front

window through the guides (5) at the rear,

then set it on the supports (6) and fasten

it in place.

4

5

C4C006

Side Window (Cab)

7

N0B023

1. Grasp the catch (7), unlock it and open

the side window.

2. To close the side window, close it until a

click is heard.

Tool Case

Lock and unlock

1. Insert and turn the starter key

counterclockwise (clockwise) to unlock

(lock).

40

Page 43

CONTROLS

Doors and Covers

Rear Cover

CAUTION

¡¡

¡ When opening the rear cover, open it

¡¡

firmly to the locked position.

¡¡

¡ When opening and closing the rear

¡¡

cover, be careful not to get your hands

or other parts of your body caught.

Opening

1. Insert the starter key and turn it clockwise

to unlock the rear cover (1).

2. Open the rear cover (1) fully until it stops.

(It locks automatically)

3. Check that the rear cover (1) is securely

locked in place.

Engine hood unlock knob (3) is located

behind the rear cover (1).

Engine Hood

WARNING

Before opening the engine hood, be sure

to stop the engine. If your hands or tools

should get caught in the fan or fan belt

while the engine is running they may be

severed.

Opening

1. Open the rear cover and pull the unlock

knob (3).

Refer to “Rear Cover”.

2. Lift the engine hood (1) fully.

Closing

1. Close the engine hood and press it down

until a click is heard at the front.

Closing

1. Raise the stay (2) to unlock the rear cover

(1).

2. Close the rear cover (1) and press it inside

until a click is heard at the front.

41

Page 44

CONTROLS

Doors and Covers

Fuel Filler Cap

WARNING

¡¡

¡ Do not smoke or permit open flames

¡¡

while fueling or near fueling

operations.

¡¡

¡ Supply fuel in a well ventilated place

¡¡

and with the engine stopped.

¡¡

¡ Clean up spilled fuel immediately.

¡¡

¡¡

¡ Do not fill the fuel tank to capacity.

¡¡

Allow room for expansion.

¡¡

¡ Tighten the fuel filler cap securely.

¡¡

Opening

1. Open the key cover, insert and turn the

key counterclockwise to unlock the fuel

cap.

2. Turn the fuel cap counterclockwise and

remove it.

Closing

1. Set the fuel cap in place and turn it

clockwise.

2. Turn the key clockwise to lock the fuel cap,

then remove the key.

42

Page 45

MEMO

43

Page 46

CONTROLS

Seat and Seat Belt

Seat

WARNING

Adjust, secure and latch the operator’s

seat.

(A) Back angle adjustment

WARNING

¡¡

¡ Do not set the seat back to its

¡¡

maximum reclining position and slide

the seat backwards at the same time.

Doing so may break the rear window

glass, resulting in injury.

¡¡

¡ Be careful not to allow the force of the

¡¡

spring to bring the seat back sharply

forward.

1. Raising your torso, sitting down firmly in

the seat.

2. Pulling lever (1) allows you to use the

pressure of the springs in the seat pressing

against your back to adjust the reclining

angle of the seat back. Release the lever

(1) at the desired angle and the seat back

will be locked in that position.

(B) Fore-and-aft adjustment

1. Pull on lever (2) and slide the seat backward

or forward to bring it to the optimum position

for operating the machine.

2. Release the lever (2) at the desired position

and the seat will be locked there.

Adjustment stroke: 15 steps,150 mm (5.9 in.)

(C) Weight adjustment

1. Turn handle (3) until the indicator (4) will

show the operator’s weight.

May be set to any value from 10 kg steps,

50 to 130 kg (1 10 to 287 lbs.)

(D) Adjusting the height of the seat

Upward

1. Lift the seat to first or second position clickstop.

Downward

1. First lift the seat to highest position, then

the seat can be lowered to lowest position.

(E) Headrest adjustment (Option)

The position of the headrest can be adjusted

in the vertical and front/back directions.

1. To adjust in the vertical direction, grasp

the headrest with both hands and move it

upwards or downwards.

2. T o adjust in the front/back direction, grasp

the headrest with hands and move it

forwards or backwards.

44

Page 47

CONTROLS

Seat and Seat Belt

Seat Belt

CAUTION

Always fasten the seat belt securely

before starting the engine.

Fastening the seat belt

1. Adjust the seat to the optimum position

for operating, raise your torso, and sit back

firmly into the seat.

2. Pull the seat belt to the desired length.

A

B

E4B023

3. Make sure that the belt is not twisted and

then insert the tongue plate (A) into the

buckle (B) of the seat belt until you hear a

clicking sound as it locks in place.

Releasing the seat belt

C

E4B024

1. T o remove the seat belt, simply press the

button (C) located on the buckle.

The seat belt is automatically stowed

away .

45

Page 48

CONTROLS

C4B030

G4B010

Instrument Cluster

Warning Lamps

IMPORT ANT: If a warning lamp flashes

and an alarm is sounded, stop all

operations immediately and inspect and

maintain the appropriate part.

Refer to page 169 “Troubleshooting”.

1. Engine Emergency Lamp

This lamp flashes and an

alarm is sounded if the

engine oil pressure or the

G4B009

coolant level in the radiator

drops or the coolant temperature rises

abnormally while the engine is running. After

approximately 5 seconds, the engine stops

or low idling automatically.

2. Engine Oil Pressure / Coolant Level

Warning Lamp

This lamp flashes and an

alarm is sounded if the

lubricant oil pressure or

L3B036

coolant level in the radiator

drops abnormally while the engine is running.

3. Coolant Temperature W arning Lamp

This lamp flashes and an

alarm is sounded if the

engine coolant temperature

C4B012

rises abnormally while the

engine is running.

4. Battery Charge Warning Lamp

This lamp flashes and an

alarm is sounded if a

problem arises in the

charging system while the

engine is running.

5. Air Cleaner Warning Lamp

This lamp flashes and an

alarm is sounded if the air

cleaner filter is clogged while

the engine is running.

46

Page 49

CONTROLS

Instrument Cluster

Indicators

6. Glow Lamp

This lamp turns off when

engine preheating is

completed.

C4B013

7. Travel Speed Lamp

This lamp lights when the

travel speed is set to 2nd

(high speed).

C4B014

8. Decel. Lamp

This lamp lights when decel.

switch pressed, the engine

speed decreases.

G4B011

Meters

9. Hour Meter

This displays the total

engine running time in

hours.

G4B012

The rightmost digit indicates

tenths of hours (6 minutes).

Set the inspection and maintenance intervals

according to the time displayed on the hour

meter.

10. Water Temperature Gauge

This gauge indicates the

temperature of the engine

coolant water.

G4B013

The needle should be within

the green range during machine operation.

The red range indicates overheating.

11. Fuel Gauge

This gauge indicates the

amount of fuel in the tank.

Be sure to top off the tank

G4B014

before running out of fuel.

47

Page 50

CONTROLS

Switches

Starter Switch

PREHEAT

IMPORTANT: Do not repeatedly switch

the key from OFF to ON and ON to OFF

over a short period. Doing so will cause

engine breakdown.

PREHEA T.....Position for preheating the

OFF ..............Position for stopping the

ON................ Position in which the engine

START ..........Position for starting the

OFF

ON

START

E4B010

engine.

engine and inserting or

removing the key.

is running. At this position, all

the electrical equipment is

functional.

engine. When the key is

released, the switch

automatically returns to the

ON position.

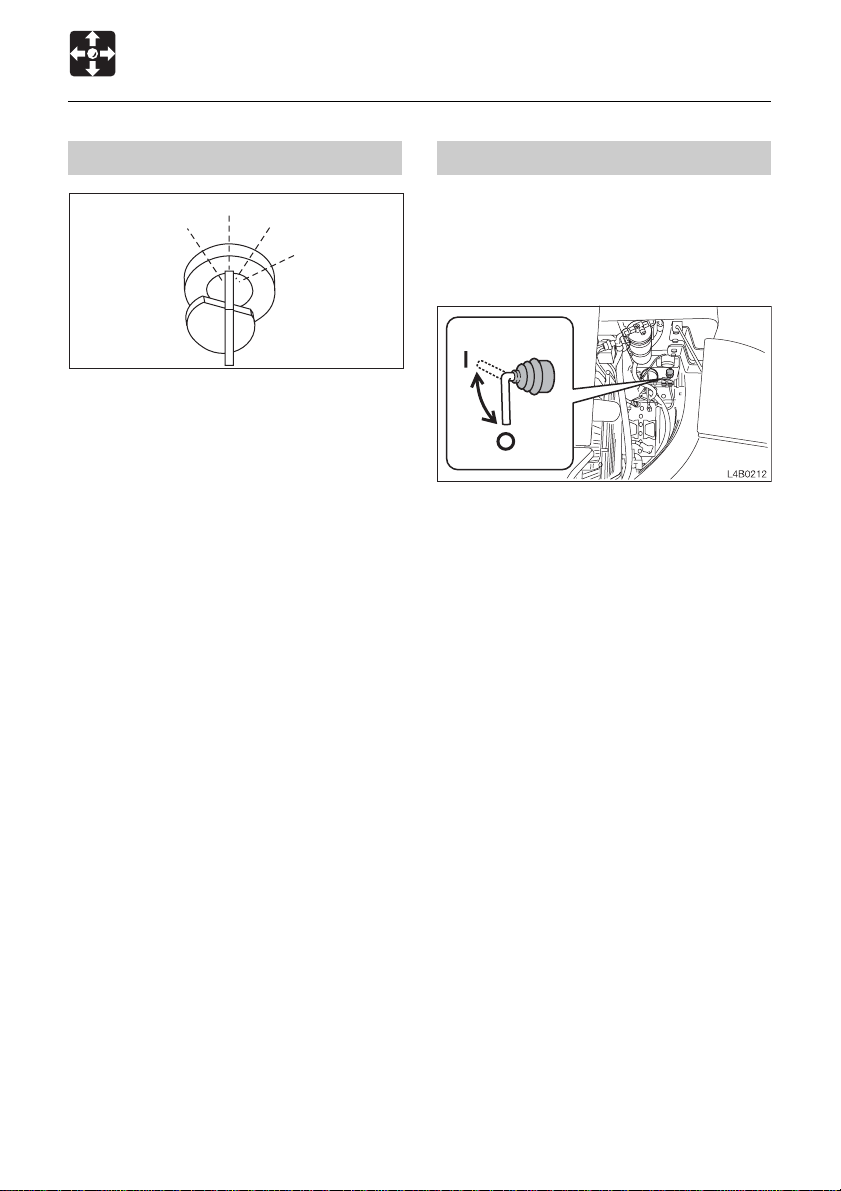

Battery Switch

IMPORTANT: Never set this switch to the

OFF (O) position while the engine is

running. Doing so might cause damage

to the electrical system.

1. Open the rear cover.

OFF (O) .... Switches off the electrical

circuit.Be sure to set this switch

to the OFF (O) position when

storing the machine for a long

period, or when performing

maintenance of the electrical

system.

ON ( I )...... Connects the electrical system.

Check that this switch is in the

ON ( I ) position before starting

the engine.

Supplement: Setting this switch to the OFF

(O) position will shut down all of the electrical

circuits and the memory of the radio preset

tuning buttons will be deleted.

48

Page 51

CONTROLS

Switches

Horn Button

Press the button on the right operating lever

to blow the horn.

Decel. Button

WARNING

Set the operating and travel levers to

neutral before operating the decel. button.

The machine’s operating speed will

change abruptly if the switch is operated

while the levers are engaged.

Automatic Decel. Button < TB180FR >

N0B019

Pressing this button to the ON position will

cause the lamp to light and will activate the

deceleration function. Use of the deceleration

button will not be possible at this time. After

about 4 seconds with the control levers set

to neutral, the engine speed will automatically

drop to Low idling to reduce fuel

consumption. Moving the control levers will

cause the speed to return to the original

engine speed.

Throttle Controller < TB180FR >

Press the button on the right operating lever

to lower the engine speed to low idling.

Press the button again to return to the engine

speed set with the throttle controler.

Supplement: The one-touch decelerator is

a device for lowering the engine speed and

reducing fuel consumption when little engine

output is required, for example when the

operating and travel levers are in neutral.

This controls the engine speed.

(A) .... Low idling

(B) .... Middle speed

(C) .... Maximum speed

49

Page 52

CONTROLS

Switches

Attachment Interference Switch

WARNING

¡¡

¡Failure to properly set the Attachment

¡¡

Interference Switch can result in

equipment damage, serious injury, or

death.

¡¡

¡Ensure that all buckets used in the

¡¡

standard position are no longer than a

standard bucket when measured from

pin to tooth.

The Attachment Interference Switch (AIS) is

automatically set to the M mode by the

interference Prevention System (IPS) when

the engine is started.

To use the minimal front radius feature, reset

the AIS to the M position then select the

appropriate attachment width (S.L or M).

< TB153FR >

S

Modes of Operation

< TB153FR >

S....... Standard bucket attachment less

than 635mm (24 inches) wide

L ....... Bucket attachment more than

635mm (24 inches) and less than

800mm (31 inches) wide

M ...... Bucket attachment more than

800mm (31 inches) wide or any other

approved attachment

< TB180FR >

S....... Standard bucket attachment less

than 750mm (30 inches) wide

L ....... Bucket attachment more than

750mm (30 inches) and less than

1000mm (40 inches) wide

M ...... Bucket attachment more than

1000mm (40 inches) wide or any

other approved attachment

Refer to page 82 “Attachment Interference

Switch / Interference Prevention System”.

L

M

J1B017

< TB180FR >

50

Page 53

CONTROLS

Switches

Travel Speed Switch

WARNING

When a load greater than a set value is

applied during 2nd speed (high speed)

travel, the speed will automatically slow

down by switching to 1st speed (low

speed). Thereafter, when the load

becomes lighter, the speed will increase

by returning to 2nd speed (high speed).

Exercise due caution since the travel

speed changes automatically.

Press this switch to set the travel speed to

2nd speed (high speed). Press again to

return to 1st speed (low speed).

First Auxiliary Hydraulic Switches

Slider Switch

(Proportional control)

Proportional control allows for slow-to-fast

movement of auxiliary functions.

Example: If you move the slider switch half

way, the auxiliary function will move at

approximately one-half speed.

Move this switch to control the flow of the oil

in the first auxiliary hydraulic lines.

Auxiliary Hydraulic Buttons

Press those buttons to control the flow of the

oil in the first auxiliary hydraulic lines.

¡Proportional control of the auxiliary

hydraulic circuit is not possible.

(A) .... Hydraulic oil flows to left auxiliary

line(a)

(B) .... Hydraulic oil flows to right auxiliary

line(b)

51

Page 54

CONTROLS

Switches

Light Switch

L3B028

When this switch is turned while the starter

switch is at ON, the lights turn on as follows :

O ...... Off

I ....... Meter light, front light and boom light

turn on.

Wiper Switch (Cab)

IMPORTANT: If no washer fluid is

discharged, do not operate the washer.

Doing so may damage the pump.

IMPORTANT: Operating the wiper with no

moisture on the windshield will scratch

the glass. Apply water or washer fluid

when operating the wiper.

IMPORTANT: In cold seasons, the wiper

blade may freeze to the glass. Operating

the wiper forcibly may damage the wiper

motor.

PUSH

L3B029

O ............ Off

I ............. Wiper operates.

PUSH ..... Washer fluid is squirted from the

nozzle while pressed, and stops

when released.

52

Page 55

CONTROLS

Levers and Pedals

Safety Lock Lever

WARNING

¡¡

¡Before leaving the operator’s seat,

¡¡

raise the safety lock lever to engage

the lock and stop the engine. If any

controls should be touched

accidentally when the safety lock lever

is lowered, the machine will move

suddenly, and cause serious injury or

death.

¡¡

¡< TB153FR > : Note that the dozer blade

¡¡

control is not locked, even when the

safety lock lever is set to the lock

position. Do not touch this control

accidentally .

¡¡

¡Be careful not to touch the operating

¡¡

levers when raising and lowering the

safety lock lever.

Operating Levers

WARNING

¡¡

¡Be careful to check which pattern of

¡¡

lever control arrangement you are

operating with before beginning

operations.

¡¡

¡The explanations in this manual are for

¡¡

the ISO pattern.

Use these levers to operate the boom, arm,

bucket and upperstructure (slew).

Refer to page 74 “Lever Pattern”.

Refer to page 84 “Operating the Working

Equipment”.

S2B015

This device is for locking the working

equipment, auxiliary hydraulic control,

slewing and traveling.

When the lever is raised, the lever stand

springs up and the lever is locked.

¡< TB153FR > : Note that the dozer blade

control is not locked, even when the safety

lock lever is set to the lock position. Do

not touch this control accidentally.

53

Page 56

CONTROLS

Levers and Pedals

Throttle Lever < TB153FR >

A

This controls the engine speed.

(A) .... Low idling

(B) .... Maximum speed

B

Blade Lever

D5B021E

Travel Levers

WARNING

Before operating the travel levers, check

to make sure that the dozer blade is to

the front of the operator’s seat. BE

AWARE that when the dozer blade is to

the rear of the operator’s seat, the travel

levers operate in the opposite direction

to when the dozer blade is in the front.

Use these to move forward and backward

and to change directions.

Refer to page 79 “Operating the Travel

Levers”.

Use this lever to operate the dozer blade.

(A) .... Blade up

(B) .... Blade down

Refer to page 85 “Operating the Dozer

Blade”.

54

Page 57

CONTROLS

Levers and Pedals

Offset Pedal

Use this pedal to operate the boom offset.

(A) .... Boom offset right

(B) .... Boom offset left

Refer to page 85 “Operating the Boom

Offset”.

Pedal Lock

WARNING

When not using the pedal, set the pedal

lock to the locked position. Stepping on

a pedal accidentally when it is not locked

may lead to unexpected accidents.

This device is for locking the offset pedal.

Set the pedal lock over the pedal to lock it.

55

Page 58

CONTROLS

Accessories

Heater (Cab)

WARNING

¡¡

¡Always be sure to allow sufficient

¡¡

ventilation.

¡¡

¡Do not place combustible or explosive

¡¡

objects near the air outlets.

Control panel

Fan Switch (1)

Use this switch to adjust the fan speed in

three steps.

OFF ........ Fan off

............ Low

............ Medium

............ High

Temperature Control Dial (2)

Use this dial to adjust the air temperature.

Counterclockwise

.......................... To lower the temperature

Clockwise ..... To increase the temperature

Supplement: No warm air is emitted if the

temperature of the engine coolant is low.

Airflow mode control dial (3)