Takagi T-K3 Service Manual

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Instantaneous Water Heater

Service Manual

TAKAGI Ind ustrial Co. USA Inc.

5 Whatney

Irvine, CA 92618

Toll Free: (888) 882-5244 USA

Toll Free: (877) 877-4953 CANADA

1

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

Table of Contents

1. Specifications of the T-K3, T-K3-OS, and T-K3-SP……………..………………………… 3

2. Exterior view ……………………...…….…………………………………………………….. 4

3. Interior view …………………………….…………………………………………………….. 5

4. List of main components in the interior view …….………………………………………… 6

5. Schematic diagram………………………………………………………………………….. 7

6. Wiring diagram………………………………………………………………………………. 8

7. Wiring diagram checkpoints f or diagnosis………………………..………………….….… 9

8. Resistance values of the temperature thermistors…………..…………………………… 10

9. Operational flow chart……………………………………………………………………… 11

Compo nent specifications………………...………………………………………………… 12

10.

Fault Analysis & Specifications……………………………………………………………... 32

11.

Controls and sett ings………………………………………………………………………… 40

12.

13. Compo nents diagrams……………………………………………………………….......... 65

14. Parts list……………………………………………………………………………………….. 68

15. Revisions……………………………………………………...…………………………….. 70

2

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

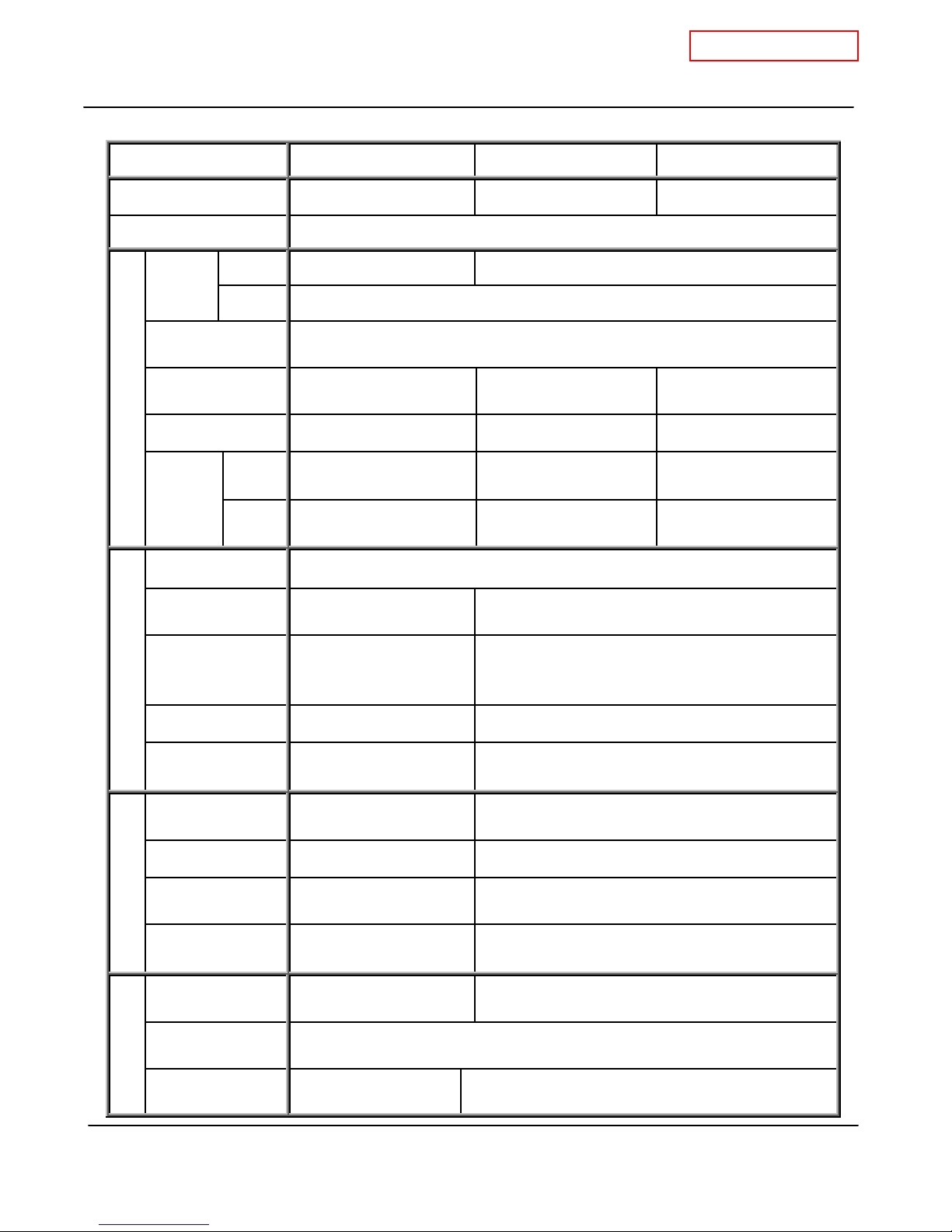

1. Specifications of the T-K3, T-K3-OS, and T-K3-SP

Mod el T-K3 T-K3-OS T-K3-SP

Dimensions H20.5"×W13.8"×D8.5" H20.5"×W13.8"×D8.5" H20.5"×W13.8"×D8.5"

Weight 40lbs.

INPUT

BTU/h

Combustion

Max 199,000 190,000

Min 11,000

Pow er vent

System

Ins ta lla tio n

Fan motor PWM turbo fan PWM fan PWM turbo fan

Combustion

Max

Man if old

Pressure

Min

Indo or, Outdoor,

& Direct-vent

LP 4.4” WC

Natural 2.5” W. C

LP 0.7” WC

Natural 0.4” W C

Outdoor Indo or & Outdoor

LP 3.1” WC

Natural 2.8” W. C

LP 0.8” WC

Natural 0.4” W C

LP 4.1” WC

Natural 2.4” W C

LP 0.8” WC

Natural 0.4” W C

Flow rate 0.5 GPM to 7.0 GPM

Available set

temp eratures

Temperature

dipsw itch settings

Water control

Bypass valve Yes N / A

99ºF ~ 185ºF

default: 122ºF

104ºF, 113ºF, 122ºF,

131ºF, 140ºF, 158ºF,

176ºF, 185ºF

99ºF ~ 167ºF

Default: 122ºF

113ºF, 122ºF, 140ºF, 167ºF

Thermisters

Remote controller

mod el

3 thermisters

(In,Out,Mixing)

TM-RE10

TM-RE30

2 thermisters (In,Out)

TK- RE02

PCB model T-K3 T-K3 OS/S P

Ind ic ator s

Operation

Pow er supply

control

Freeze protection

Self-combustion

“Burning” L ED &

7-SEG LED

GFI ( Including surge

absorber)

Cera mic heat ers and

Auto-firing system

Air-Fuel Ratio Det ection System

Surge absorber & Pow er switch

“Burning” L ED

Cera mic heat ers

improvement

Features

Easy-Link system Yes N / A

3

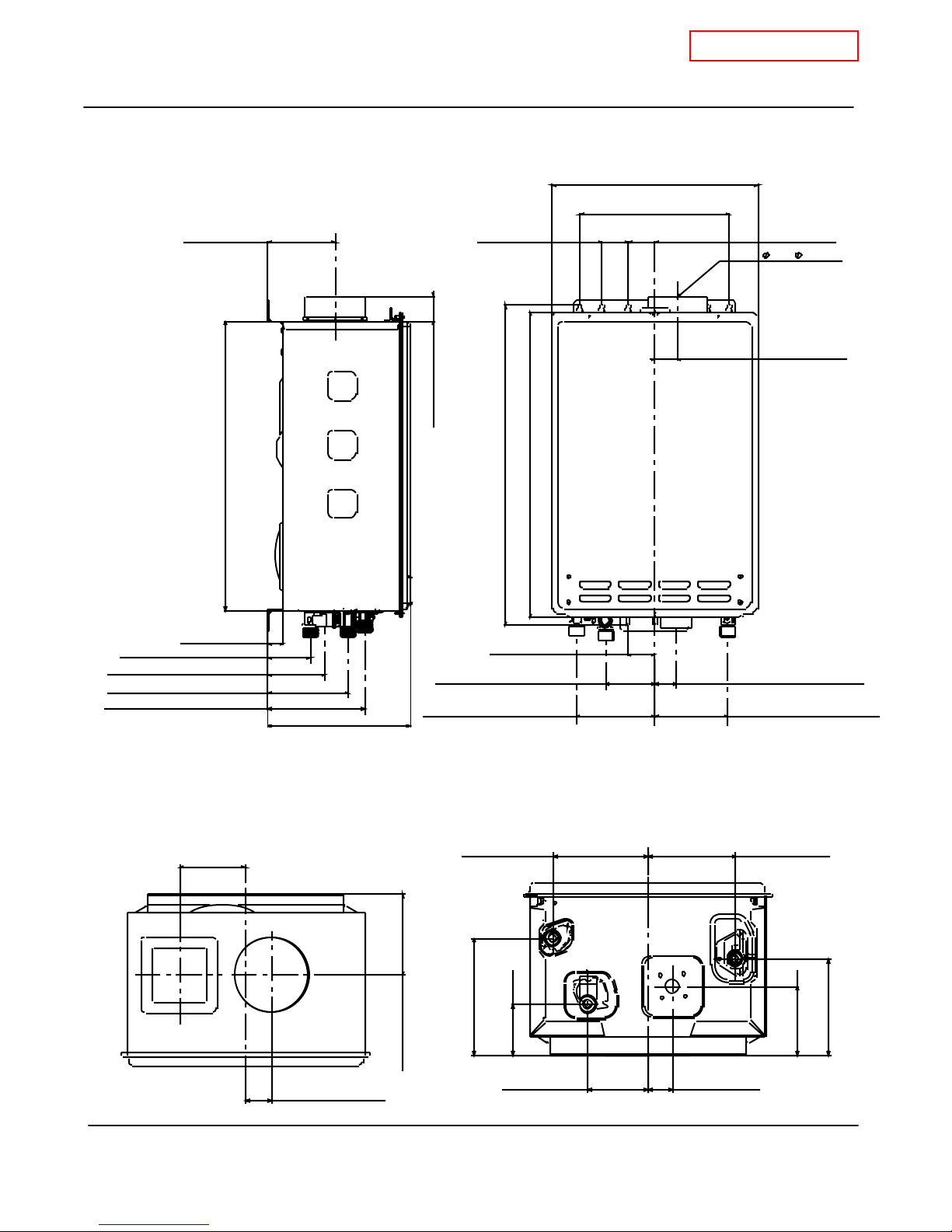

2. Exterior view

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

4-1/2"(11 4.2mm)

Side view

Front view

13-3/4"(350mm)

10"(2 54mm)

1-3/4(45mm)1-3/4"(45m m)

4"( 101.6mm)

1-1/2"(37.8mm)

1-5/8"(42.5mm)

20-1/4"(520mm)

19-3/8"(492.7mm)

21-3/8"(544mm)

2-3/4"(72mm) COLD

3-3/4"(9 6.5mm) 120V

5-3/8"(1 36.1mm) GAS

6-1/2"(164.4mm) HO T

1"(26.3mm)

3-5/ 8"(93.3mm)

1-7/8"(47mm)

3-1/4"(8 4mm) COLD

9-1/2"(241.3mm)

5-1/4"(132.9mm) HOT

Top view Bottom view

5-1/4"(132.9mm) 4-7/ 8"(124 .3mm)

6-1/2 "(164.4mm)

2 -3/4"( 72mm)

4- 1/2"( 114.2m m)

1-1/ 2"(37.8mm)

3-1 /4"(84 mm)

1-3/8"(36mm)

1-3/8"(36mm) 120V

4-7/8"(124.3mm) GAS

5-3/ 8"(13 6.1mm)

3-3 /4"(96 .5mm)

4

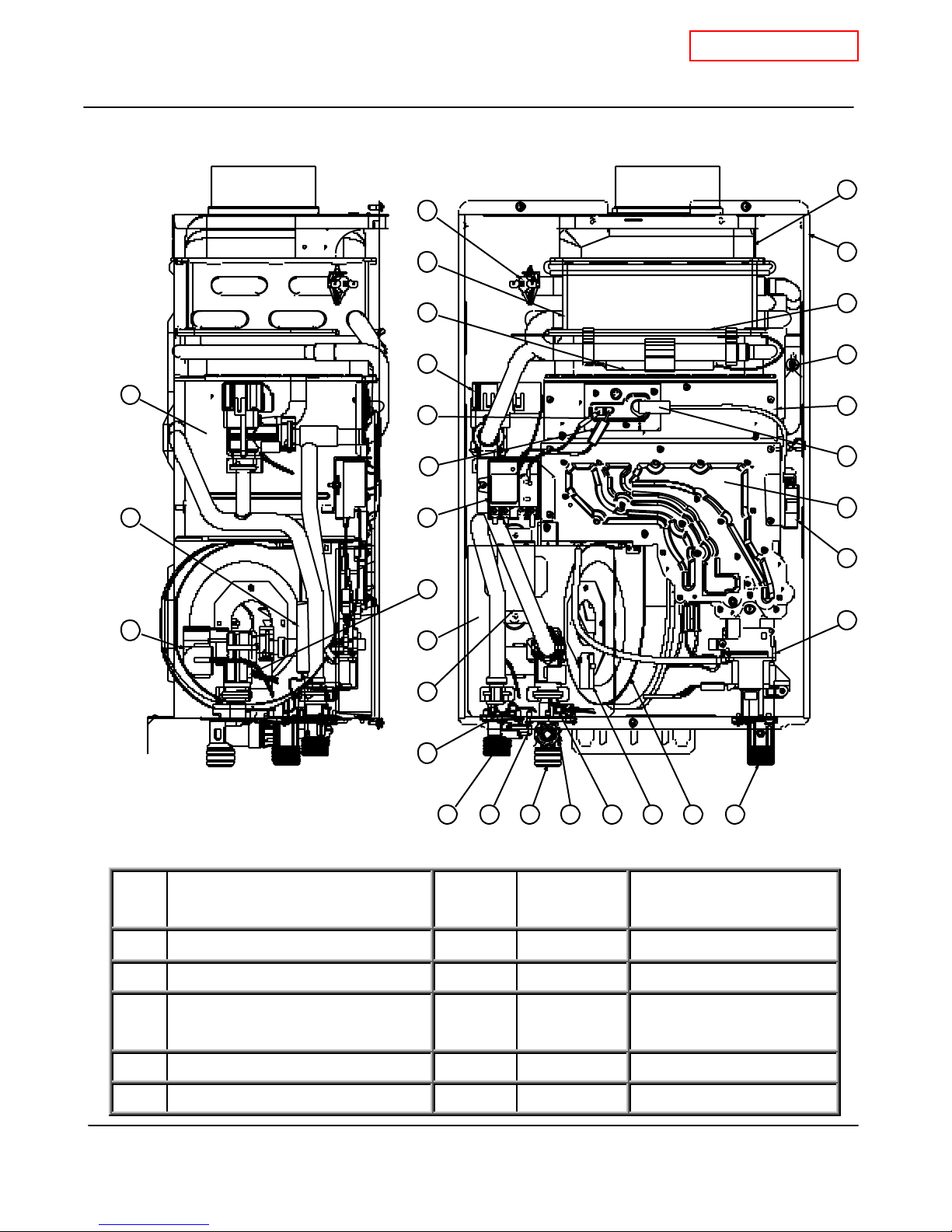

3. Interior view

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

14

18

21

29

20

1

12

11

2

27

13

26

28

21

23

24

5

17

22

4

3

6

9

78

25

10

30

1516

19

4. List of main components in the interior view

No. De s cr ipt ion

T- K 3

Pa r t#

1 Case assembly 001 EKK1D S P

2 Combustion cha mber 102 EKK1Y SP

Gas valve w ith Proportional

3

105 EKK1W OS, SP

valve

4 Compu ter board 701 EKK1L

5 Ign iter 704 EKN74 TKJr, TK1S, TH1, OS, SP

Ta k a g i

Par t #

Common parts

For other units

5

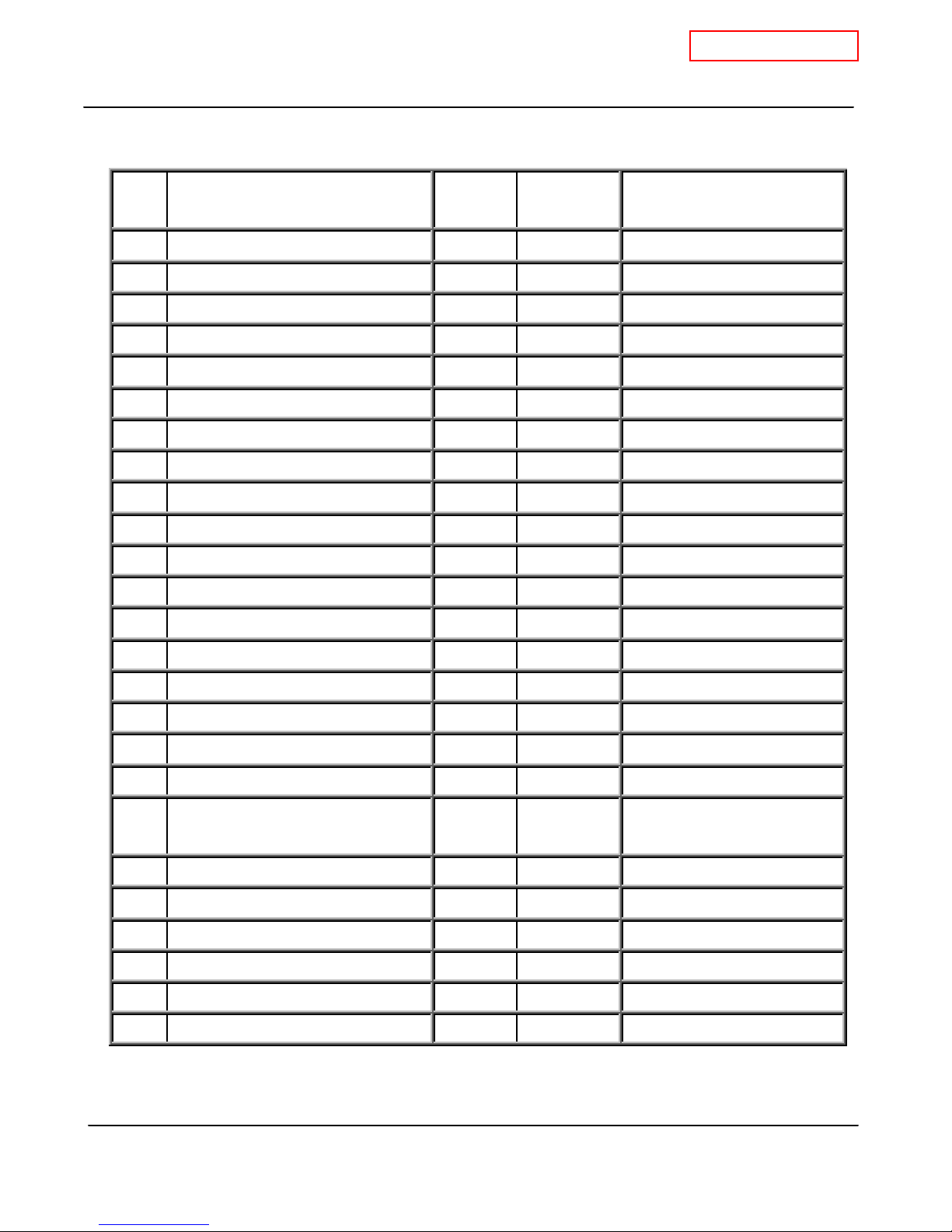

4. List of main components in the internal view (cont’d)

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

No. De s cr ipt ion

T- K 3

Pa r t#

6 Transf ormer 702 EKH09 TH1, OS, SP

7 Water inlet 404 EKK1U OS, SP

8 Water outlet 405 EKK1V OS, SP

9 Mixing ther mistor 408 EKK1A

10 In let ther mistor 406 EKK38

11 Outlet ther mistor 407 EKK2 T

12 Overheat cut-off fuse 411 EKK0S

13 Burner assembly (Burners) 101 EKK1N OS, SP

14 Hi-limit sw itch 409 EKN34 TKJr, TK1S, TH1, OS, SP

15 Fan motor 104 EKK25 S P

16 Freeze protection ther mostat 705 EKJ59 TK2, TK1S, OS, SP

17 Flow sensor 402 EKK0T

18 Heat exchanger 401 EKK1X SP

Ta k a g i

Par t #

Common parts

with other models

19 Gas inlet 108 EKK1E OS, SP

20 Exhaust 401 EKK1X

21 Heater 412 EKK2R OS, SP

22 Flow adjustment valve 402 EKK0T

23 GFI 703 EKN73 TK1S, TKJr, TH1

24 Man ifold 103

25 Outlet drain plug 419 EKK2E OS, SP

26 Air-fuel ratio rod (AFR rod) 716 EKK0E OS, S P

27 Flame rod 716 EKK0E OS, SP

28 Ign iter rod 107 EKK0F OS, SP

29 Bypass valve 403 EKK0 U

30 In let drain plug 416 EKK2B OS, SP

EKK1T(NA)

OS, SP

EKK1S(LP)

6

5. Schematic diagram

Hi-limit SW

Outlet

Thermistor

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

O.H.C.F

Air-fuel ratio rod

Flame rod

Bypass valve

Fan motor

Flow adjustment valve

w/ Flow sensor

Heater

Mixing

Thermi stor

Drain plug

Inlet

Thermistor

H

O

T

Inlet drain

plug f ilter

Ignite r rod

Igniter

Gas solenoid valve 3

PCB

G

A

C

O

L

D

Transformer

S

Gas proportional valve

Gas solnoid valve 1

Gas solenoid valve 2

Main gas valve

1. When a hot w ater tap is opened, cold w ater enters the T-K3 w ater heater.

The w ater flow sensor detects this w ater flow and sends this information to co mputer.

2.

The computer initiates fan motor and sends signal to igniter to create ignition spark.

3.

The main, proportional, and solenoid gas valves open to allow gas input.

4.

The gas ignites and f lames appe ar inside the burner chamber.

5.

Water circulates through the heat exchanger and is heated up to the set te mperature.

6.

Using ther mistors to measure temperatures, the computer modulates the gas and w ater

7.

valves to ensure proper output w ater temperatures.

When the tap is closed, the T-K3 w ater heater shuts dow n.

8.

7

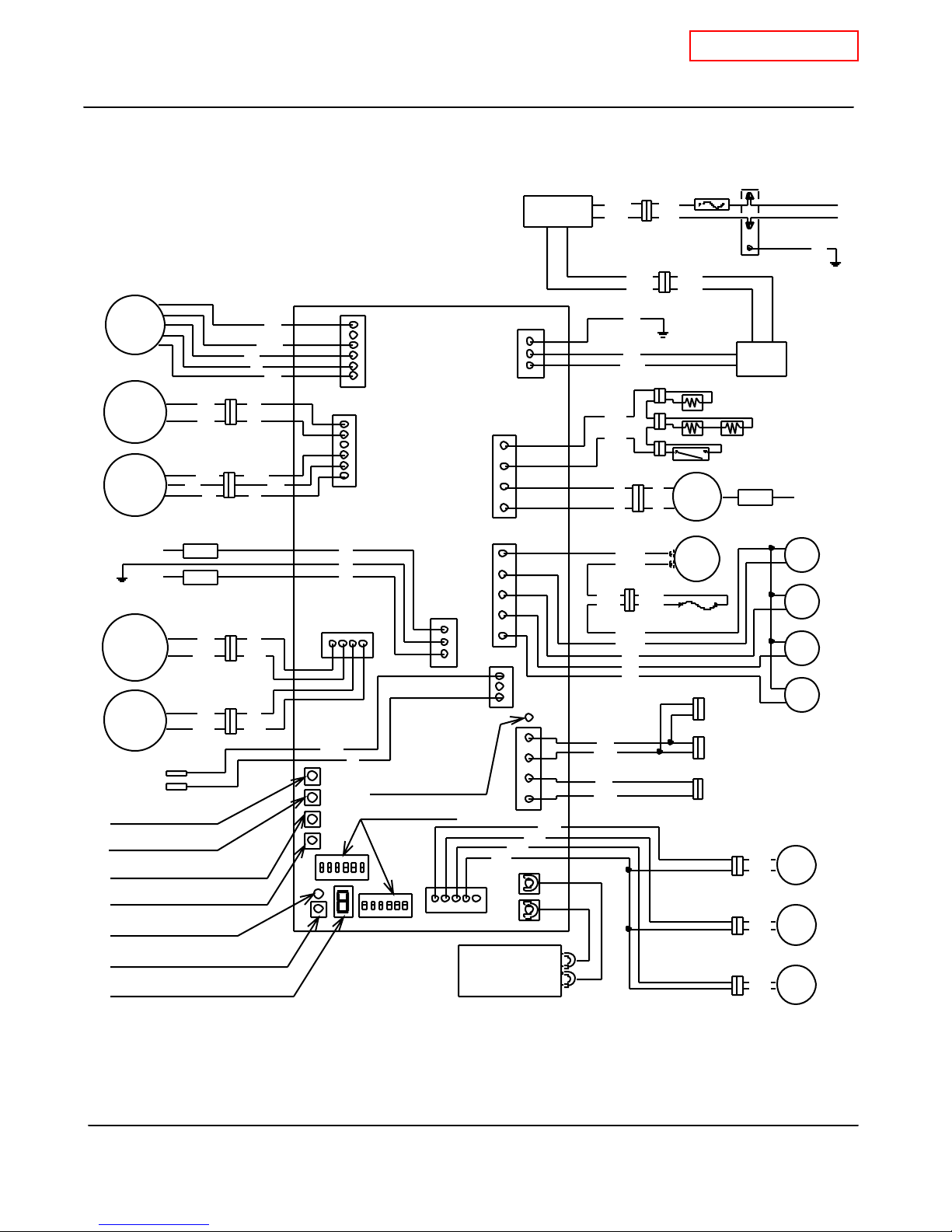

6. Wiring diagram

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

W W hite

R R ed

BK Black

P P urple

LB Lig ht blue

F

M

Proportional

Valve

Flow

Senso r

Groun d

Flow

Adjust

ment

Valve

Bypass

Valve

Pump

MAX button

MIN button

Increase bu tton

Decrease bu tton

Burning lam p

Error call button

7 Seg LED

W

R

K

B

W

R

AFR r od

Flame r od

R

B

K

R

B

K

K

BK

BK

A2

K

B

W

A1

R

B

B

R

G

W

BK

BL Blue

G G reen

Y Y ellow

O O range

BR Brown

R

B

L

Y

O

W

W

R

G

H1

33

Transformer

A

B1

B

K

W

R

R

J1

K

B

R

J2

K

B

OFF

Y

G

O

BK

W

123456

H2

I

Multi-system

On line lamp

Dip switch

654321

OFF

7

B2

7

3

9

C

53

73

D1

D2

BK

Remote

Contro ller

BK

BK

BK

F

C2

C1

BL

BL BL

W

BK

W

BK

P

P

P

P

BL

BL

BL

BL

LB

G

O

R

3A

B

K

W

B

R

B

R

Ground

Heater

Freez e

prote ction

therm ostat

IG

Hilimit

switch

O.H.C. F

SLAVE IN

SLAVE OUT

MASTER

Mixin g

therm istor

E1

Outlet

thermi stor

E2

Inlet

therm istor

E3

AC120V

Ground

G

GFI

Heate r

Elect rod

MV

SV1

SV2

SV3

BK

BK

BK

8

7. Wiring diagram check points for diagnosis

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

Check-

Part and Description Color of wires Normal range

point

Brown – Brown (A1)

A, A1 100V Power supply

AC 90~11 0 V

White – Black (A)

A2 120V Power supply Black - White AC 108~132V

B1 Heater Black - Black AC 90~11 0 V

B2 Ig niter Purple - Pu rpl e AC 9 0~11 0 V

Light blue - blue at COM

Green - blue at COM

DC 78~100V(in operation) / 0.9~1.3kΩ

DC 78~100V(in operation) / 1.3~1.9kΩ

C Gas val ves

Orange - blue at COM

Red - blue at COM

C Proportional Valve White - red at COM

DC 78~100V(in operation) / 1.3~1.9kΩ

DC 78~100V(in operation) / 0.9~1.7kΩ

DC 1~10V(in operation) / 30~51Ω

C1 Hi-limit switch Blue - Blue Less than DC 1V and less than 1.3Ω

C2 Overheat cutoff fuse Blue - Blue Less than DC 1V and less than 1.3Ω

D1 Black - White DC 15V (during Easy-Link operation)

Easy link connectors

D2

Black - White DC 15V

E1 Mixing thermistor Black - Black

E2 Outlet thermistor Black - Black

See table on p. 10

E3 Inlet thermistor Black - Black

F Remote controller * DC 11~25V

Red - Blue DC 110 ~160V

G Fan motor

Yellow - Blue DC 13~17V

Orange - Blue DC 2~6.5V

White - Blue See the “A

H1 Gas proportional valve White - red DC 1~10V and 30~50Ω

Red - Black DC 4~5.5V

H2 Flow sensor

Whi te - Bla ck DC 1~4V (1080pulse / min)

Air-fuel ratio flame rod Yellow - AFR rod More than 1μA (during burning)

I

Flame rod Orange - Flame rod More than 1μA (during burning)

J1 Flow adjustment valve Red - Black DC 7~16V and 0.09~0.2kΩ

J2 Bypass valve Red - Black DC 7~16V and 0.09~0.2kΩ

K Pump connector port White - Black Less than 1.3Ω

9

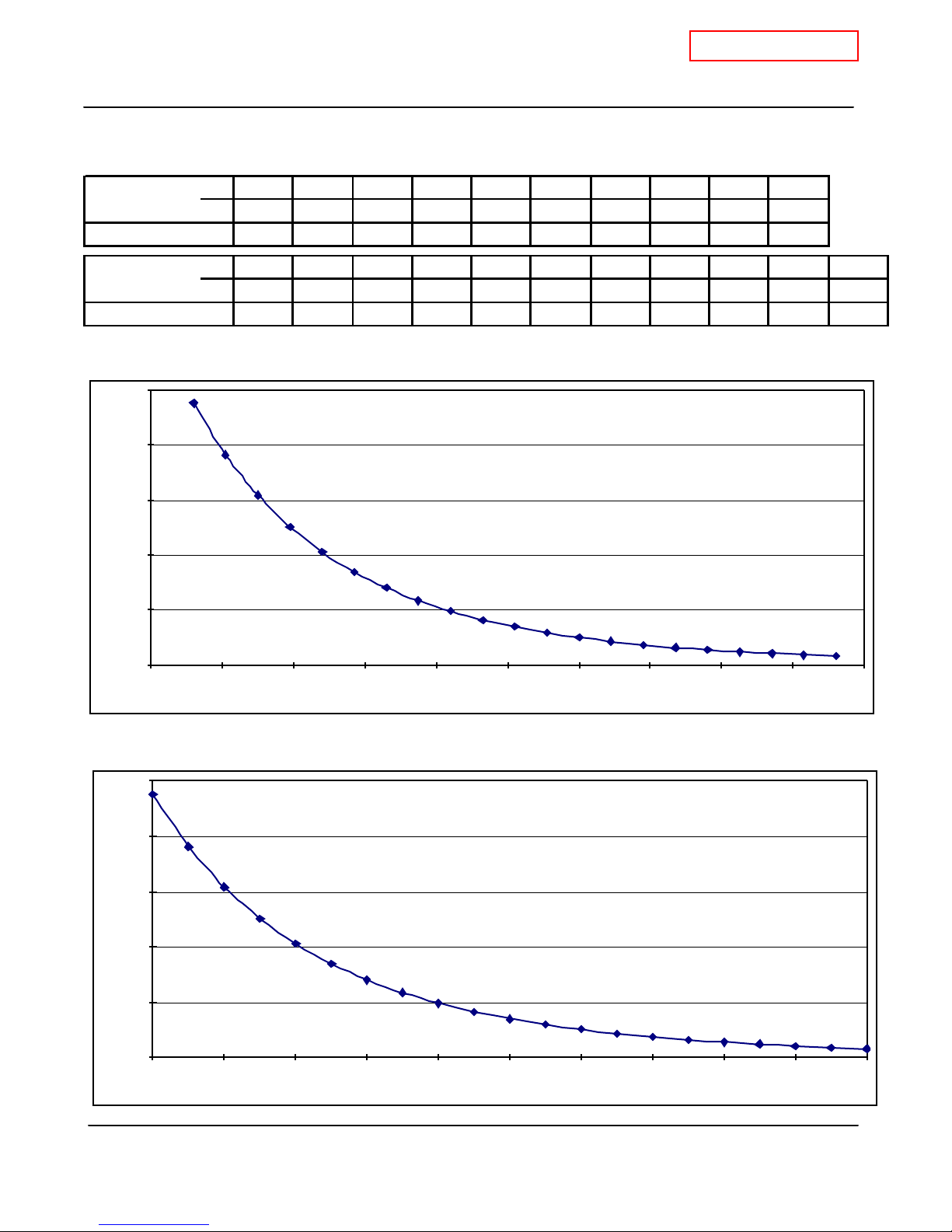

8. Resistance values of the temperature thermistors

Resis tance values at different temperatures

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

Temperature

ºF 32 41 50 59 68 77 86 95 104 113

ºC 0 5 10 15 20 25 30 35 40 45

Resistance kΩ 23.76 19.08 15.43 12.56 10.28 8.47 7.02 5.85 4.90 4.12

Temperature ºF 122 131 140 149 158 167 176 185 194 203 212

ºC 50 55 60 65 70 75 80 85 90 95 100

Resistance kΩ 3.49 2.96 2.53 2.16 1.86 1.60 1.39 1.21 1.05 0.92 0.81

Temperature(ºF) vs. Resistance(kΩ)

25.00

20.00

15.00

10.00

Resisitance (kΩ)

5.00

0.00

20 40 60 80 100 120 140 1 60 180 200 220

Temperature(

25.00

20.00

15.00

10.00

Resisitance (kΩ)

5.00

0.00

0 102030405060708090100

℃)

vs. Resistance(kΩ )

Temperature (ºF)

Temperature (ºC)

10

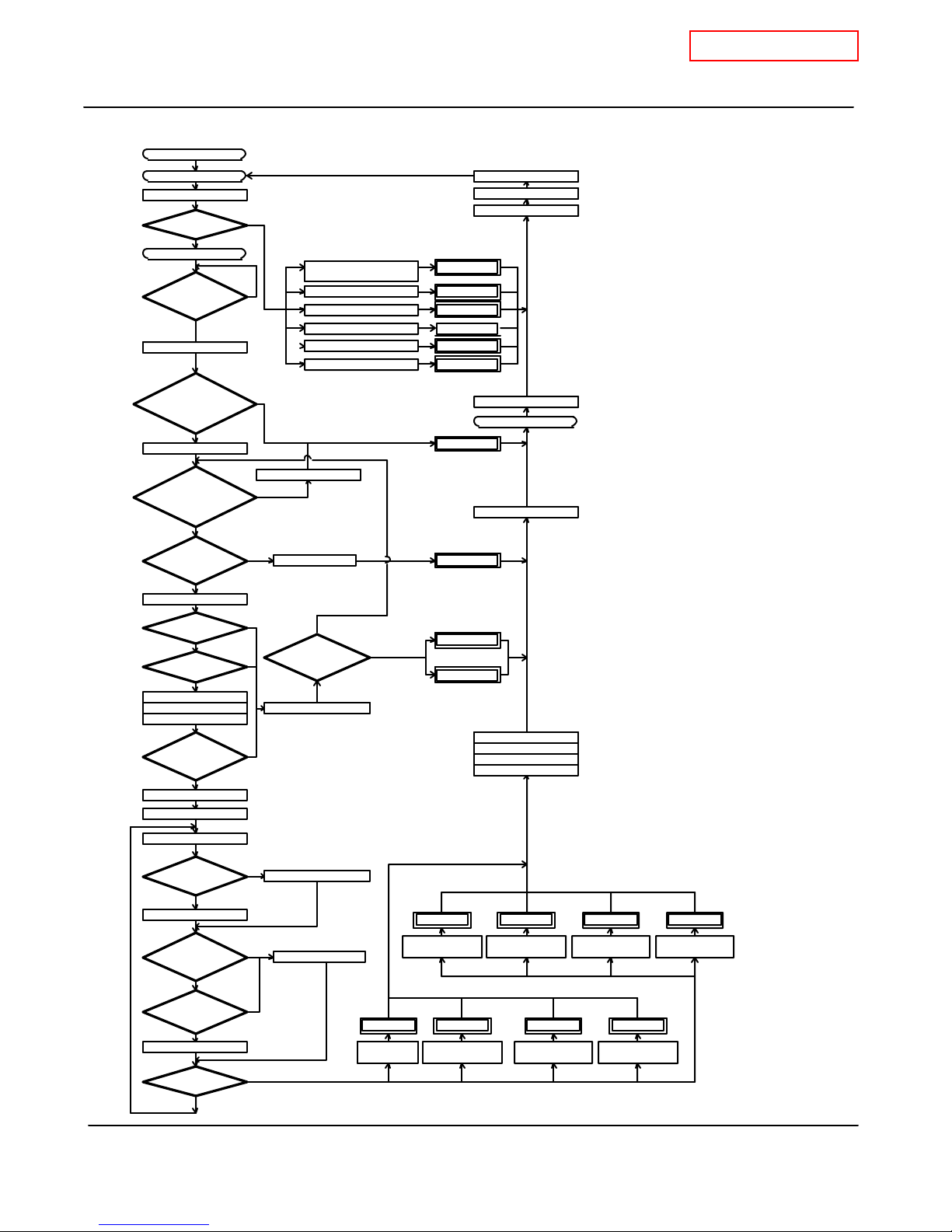

9. Operational flow chart

Power supply ON

Opeartion SW ON

OPEN FAV BV

YES

YES

NO

Miss select

NO

gas type

InTH failure

OuTH failure 311 blink

MiTH failure 331 blink

PCB failure

SV circuit failure

Pre-check

NORMAL?

OPEN the tap

Flow Sensor

Above 0.5GPM?

BV action

Remove cause

Opeartion lamp OFF

OPEARTION OFF

031 blink

321 blink

701 blink

511 blink

CONFIDENTI AL

T-K3 Service Manual

FAV ; Flow Adjustment Valve

B V ; Bypass Valve

F M ; Fan Motor

OHCF; Over Heat Cut-off Fuse

M V ; Main gas Valve

SV1 ; Solenoid Valve 1

SV2 ; Solenoid Valve 2

SV3 ; Solenoid Valve 3

GPV ; Gas Proportional Valve

InTH; Inlet thermistor

OuTH; Outlet thermistor

MiTH; Mixing thermistor

PCB ; Print Circuit board

(Computer board)

AFR ; Air Fuel Ratio

Ver. 1.05

YES

YES

A?

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

(5sec later)

FM speed

(Below

1,000rpm?)

Start FM

FM speed

(Above

1,000rpm?)

Pseudo-flame

Below

ƒÊ

DC0.15

Iginiter ON

Hi-limit

Normal?

OHCF

Normal?

MV ON

SV1 ON

GPV ON

Detect Flame

Above

DC1.0uA?

Burning lamp ON

Iginiter OFF

Proportional control

(3sec later)

Stop FM

(20sec later)

Retry ignite

Success?

Igniter OFF

YES

Flow sensor OFF

CLOSE the tap

611 blink

STOP FM

721 blinkPeseudo-flame

NO

111 blink

121 blink

SV1, SV2, SV3 OFF

MV OFF

SV1 OFF

GPV OFF

YES

YES

YES

NO

NO

NO

NO

YES

SV2 SV3 OFF

FAV close

Change over

point?

SV2 SV3 ON

Above water

heat capability?

Above

Max flow rate

ristriction?

FAV OPEN

Safety devise

work?

OuTH OPEN

or SH ORT

AFR rod failure

32 1 blink

‡F

InT H OPEN

or SHORT

(20sec later)

11

Abnorm al

AFR

331 blink

MiTH OPE N

or SHORT

Melt OHCF

Above 363

‹

F

6 11 blink311 blink

A bnormal

F M Speed

121 blink121 blin k991 blink391 blink

Flame rod

failure

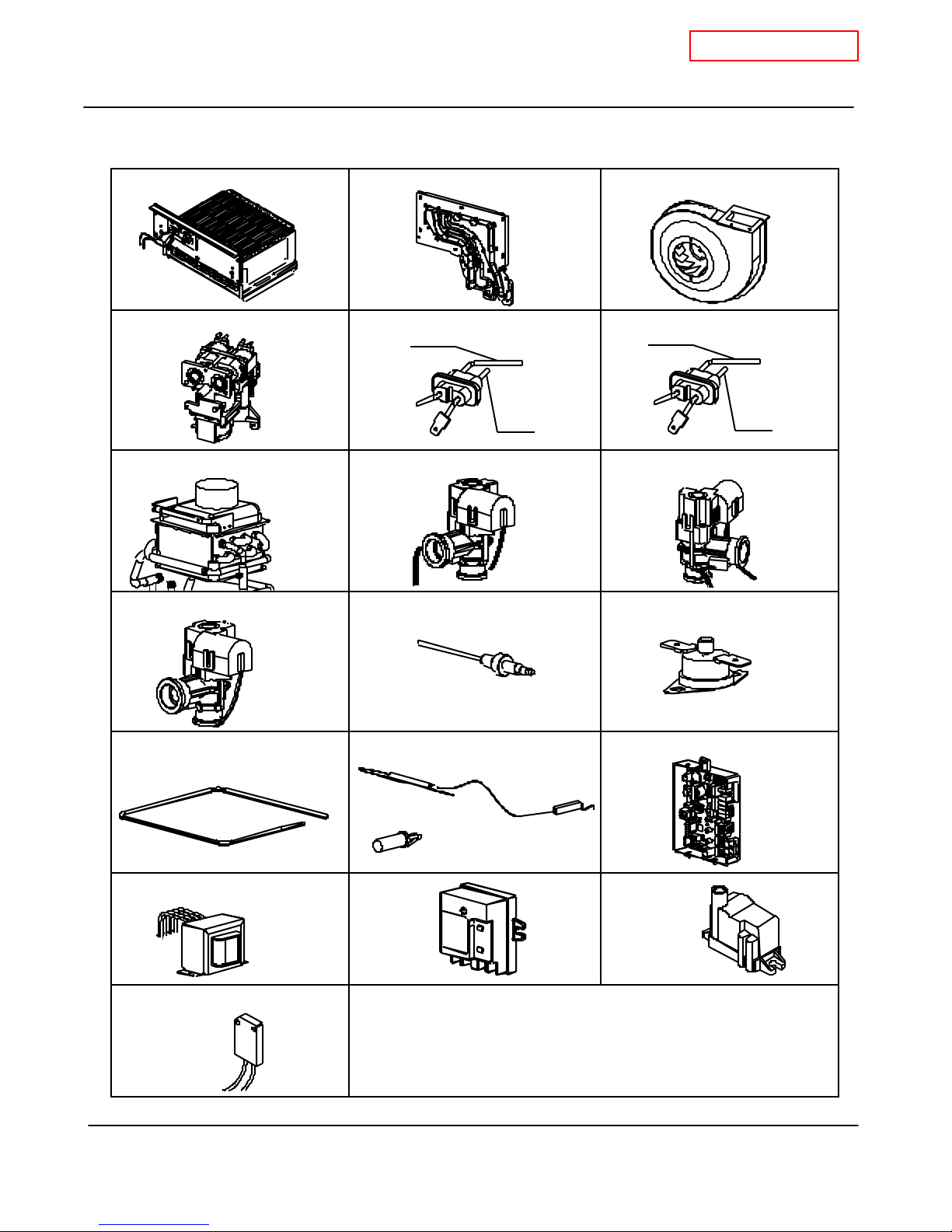

10. Component specifications

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

1. Burners

4. G a s va l ve a sse m b l y

7. Heat exchanger

10. Bypass valve

P.13

P.16

P.19

2. Manifold

5. Flame rod

Flame rod

AFR Rod

8. Flow adjustment valve

11. Thermistors

P.14

P.17

P.20

3. Fan motor

P.15

6. AFR rod

Flame rod

AFR Rod

P.18

9. Flow sensor

P.21

12. Hi-limit switch

P.22

13. Overheat cutoff fuse

P.25

16. Transformer

P.28

19. Freeze protection

thermostat

P.31

14. Heaters

17. GFI

P.23

P.26

P.29

P.24

15. Computer board

P.27

18. Igniter

P.30

12

CONFIDENTI AL

T-K3 Service Manual

10-1 . Burners

T-K3 Part # #101 Takagi Part # EKK1N C heckpoint N/A

There are 2 types of burners in the T-K3: th e gas-r ich burner stabilizes the flames

Function

F ailure even t s

within the combustion chamber and the air-rich burner produces more heat in the

combustion chamb er. The burner s facilitate the air/g as mixture necessa ry to

pr oduce th e p ro pe r he at durin g the com bu stion react ion .

1. Unable to initialize/sustain combustion

2. Dust or soot deposit on the burner surface.

3. Cracks on the burners. 4. Gas leakage from burners

Ver. 1.05

Effects on the T-K3

if burners fails

Error codes when the

burners fail

D iag nostic

Color/Number of

wires

Sixt ee n T- K3 B urne rs

1. An un expect ed co mbus tion.

2. Unsta bl e f lam e condition s an d/ o r flam e loss.

3. Ignition failure.

111 121

Visual inspection: excessive dust deposit on the burner surface and/or unstable

flam e cond itions du ring o pe rat io n.

N/A

6-3/4" (170mm)

3-1/8" (80mm)

5-5/8" (143.2mm)

3/8" (11.0mm)

T-K3 B urne r

13

10-2. Gas manifold

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Part # #103 Takagi Part # EKK1F Checkpoint

1. The manifold distributes gas from the gas valves to the burners. The manifold

Function

has t wo t ypes of the nozzles: one type f o r ga s-rich burners (16 noz zles) a nd th e

other f or air -ri ch burners (15 nozzles)

2. There are 3 zones within the manifold, to ensure efficient combustion operation.

Failure events

1. Dust deposit on the manifold. 2. Gas leakage from a failed manifold.

3. Ignition failure. 4. Imperfect combustion.

1. The burner s cannot re ceive proper gas flow from t h e ma nif o ld, which can ca use

Effects on the T-K3

if the manifold fails.

poor combustion in the combustion ch amber. In this case, the AFR rod will detect

an improper flame condition and computer will take safety measures.

2. Gas le akage fr om th e ma nifo ld.

Error codes when

the manifold fails.

111 121

1. Visual inspection: Excessive dust deposit around the nozzles or cracks on the

D iag no stic

manifold.

2. Check voltages and resistance: proper range of values shown below.

Color/Number of

wires

Blue -Red DC 78~100V / 0.9~1.7kΩ

Nozzles for gas-rich burners

N/A

Nozzles for air-rich burners

9-1/ 8" (23 2mm)

6-7/8" (175mm)

14

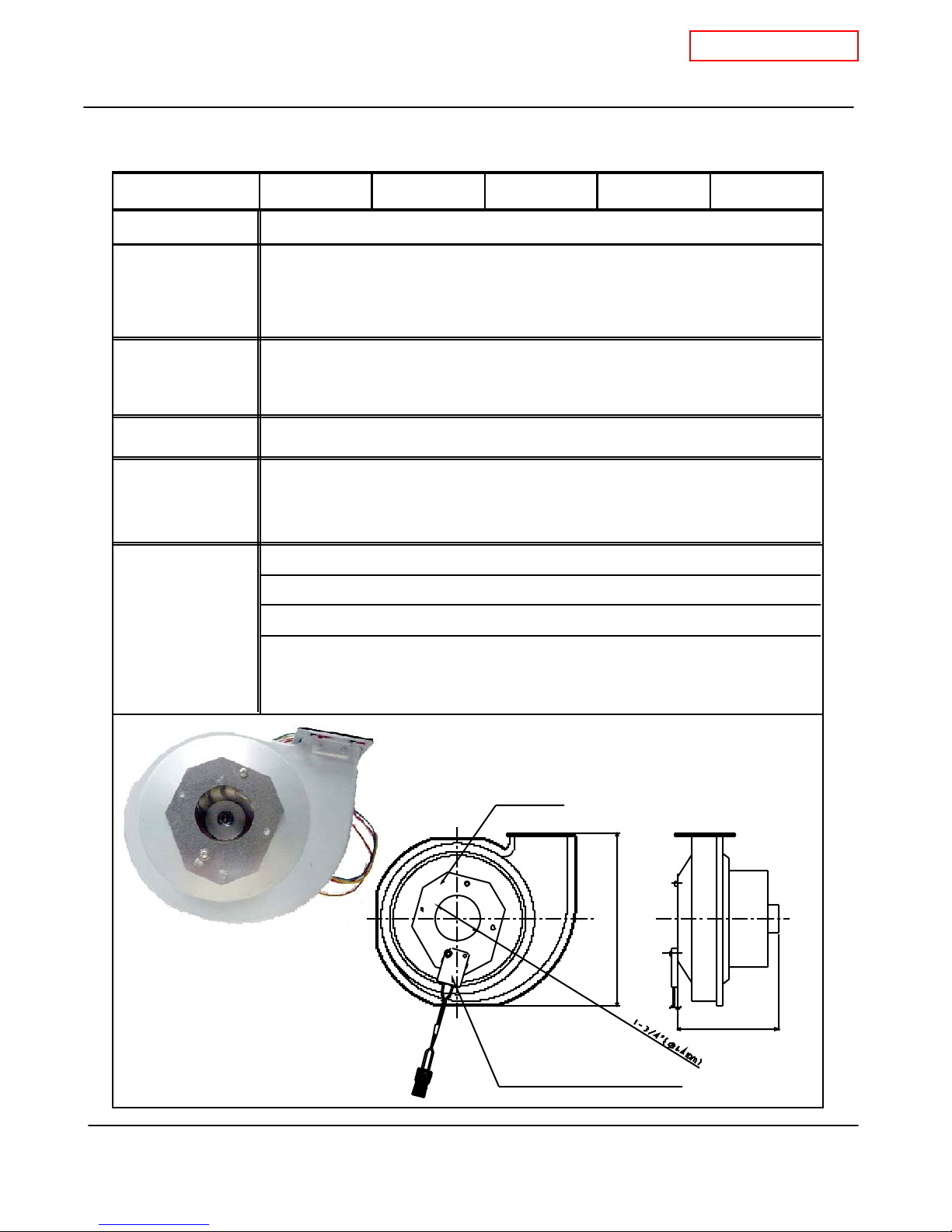

10-3. Fan motor

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Part # #1 04 Takagi Part # EKK25 C heckpo int

Function

To pro vid e combustion air into t h e bu rn er chamber a nd t o exhau st flue gas.

1. Fan sp ee d f ail ure, causing ab no rmal so un ds wit h o r without combust io n in th e

F ailure even t s

operation.

2. Unexpected working caused by the connectors of the fan motor getting wet.

3. Drops out from the bottom of the combustion chamber

Effects on the T-K3

if fan motor fails

Error codes when

the fan motor fails.

1. T-K3 does not function properly

2. Failure to ignite or abnormal ignition

3. Unstable combustion conditions

611

1. Visual inspection: connection/breakage of wires or dust (causing electrical

D iag nostic

sh orta ge )

2. Voltage check: proper range of voltages shown below.

DC 110~160V (Input)

D C 13 ~1 7V (Input)

DC 2.0~6.5V (Input)

Color/Number of

Red- Blue

Yellow-Blue

Orange-Blue

wires

Verify the fan motor speed using the Diagnostics Mode of the

White-Blue

TM-RE10 temperature remote controller. See Section 12-1 for

details.

G

Fan da mper

A

S

A

H

I

Freez e protection thermo stat

6-1/2" (165.5mm)

3-3/ 4"(95.75mm)

15

10-4. Gas valve assembly

)

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Part # #105 Tak agi Part # EKK1W Checkpoint

Opens and closes the gas pathways of the T-K3 (main and solenoid gas valves)

Function

Modulates the gas flow from the gas inlet (proportional gas valve)

1. Gas leak from the valves.

F ailure even t s

2. Unable to open/clo se (mai n an d solenoid gas valves)

3. Unable to modulate the gas flow (proportional gas valve)

1. Gas leak from the unit.

Effects on the T-K3

if valves fails.

2. Excess carbon monoxide emissions.

3. Lack of wate r t em pe ra t ure control .

4. No flames

Error codes when

the valves fail.

111 121 510 701 711

1. Visual inspection: connection/breakage of wires.

D iag nostic

2. Listen for "clunk" sounds from the gas valves opening right after fan motor

initi ates.

3. Check vo ltage s and resistance of c oils; proper r an ge of values shown below.

Color/Number of

wires

Blue -Red

Blue -light blue

Blue -Orange

Blue -Green

DC 78~100V / 0.9~1.7K

DC 78~100V / 0.9~1.3KΩ

DC 78~100V / 1.3~1.9K

DC 78~100V / 1.3~1.9K

Ω

Ω

Ω

C,H1

White - Red (Proportional Valve

Proportional Valve

Main g as val ve

2-5/8" (67mm)

1-3 /8 " (34mm)

D C 1~ 15 V / 20~40Ω

Solenoid valve

3-5/ 8" (91 .5mm)

4-1/4" (10 8mm) 7/8" (22.2mm)

Gas

valve

Proportional valve

4-5/8" (119 mm)

16

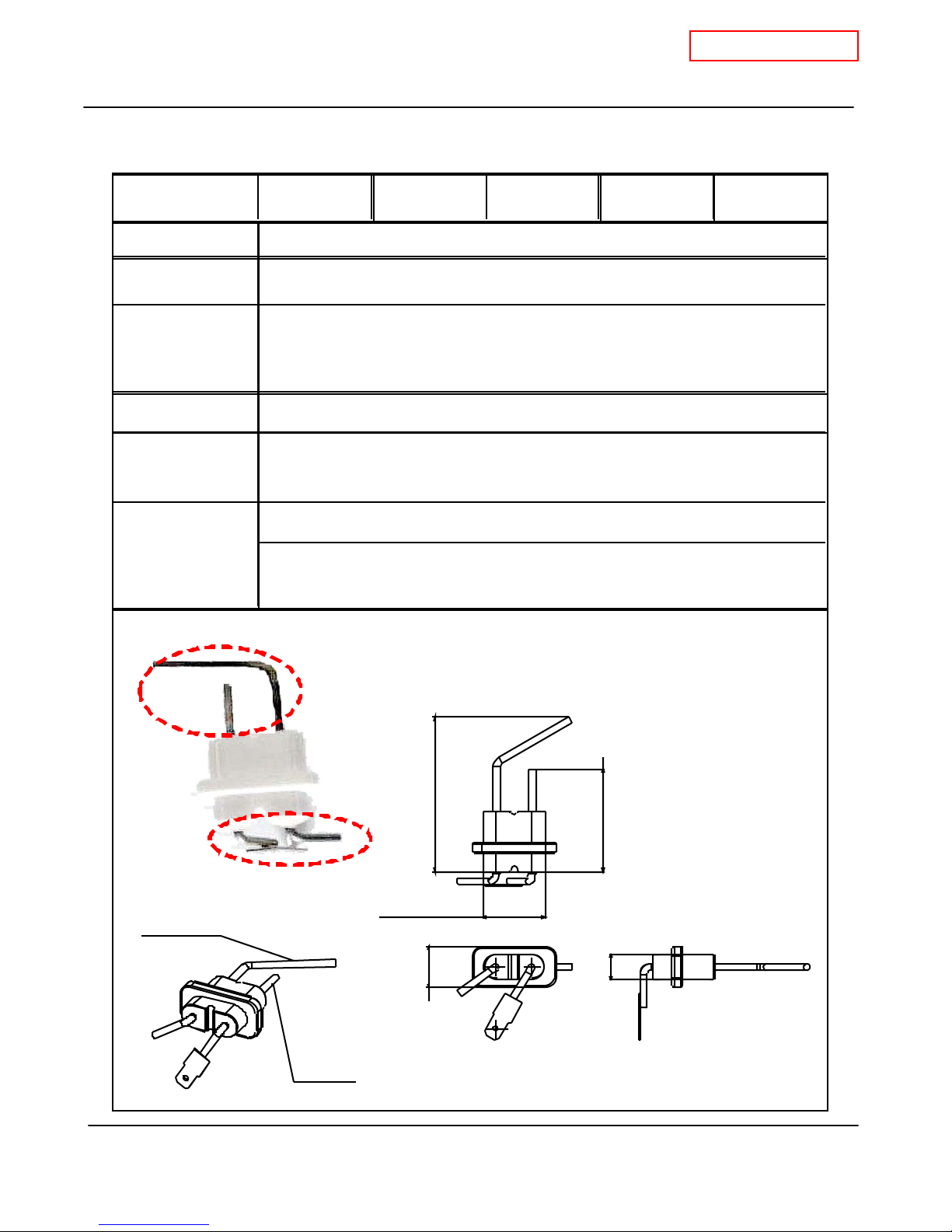

10-5. Flame rod

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Part # #716 Takagi Part # EKK0E Checkpoint

Function

Failure event

Effects on the T-K3

if flame rod fails

Error codes when

the flame rod fails.

D iag nostic

Color/Number of

wires

To detect fla me s whil e unit i s in oper ation.

1 Unable to detect flames when flames actually do occur

2. Detecting a false f lam e wh en n o f la mes act ua lly occu r

1. The T-K3 stops operating. The "111" and/or "121" error code(s) will display

2. The T-K3 wi ll not initiate the ignitio n proc ess. T he "721" error code will display

111 121 721

1. Visual inspection: connection/breakage of wires or soot buildup on rod.

2. Check amperes: proper range of values shown below.

Orange(17) - Green(18)

Orange(17) - Flam e r od

between the f la me r od an d the

(during combustion) 40KHz~60KHz

(during combustion) 1μA or more

co mput e r bo ar d

The flame rod is assembled with the AFR rod.

I

Flame r od

Detecting elements (flame a nd AFR

Leads to computer board

AFR Ro d

3-1/2" (88.6mm)

1-3/8" ( 35mm)

7/8" (24mm)

2-1/4" (58.6mm)

5/8" (15mm)

17

10-6 . AFR rod

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Part # #716 Ta kagi Part # EKK0E Checkpoint

-Checks flame conditions during combustion.

Functions

- Wh en AFR rod detects un exp ected flam e con ditio ns, the T-K3's computer mak es

adjustments in the fan motor speed to compensate.

Failure event

1. Unable to detect flames when flames actually do occur

2. Detecting a false fl am e when no flames actua lly occu r

1. The T- K3 stops oper ating. The "111 " a nd /or "1 21" er ro r code(s) will disp lay

Effects on the T-K3

if the AFR rod fails

2. The T-K3 will not initiate the ignition process. The "721" error code will display

3. The fan motor spe ed can not be mo du lat ed pro perly under abnorma l f lam e

conditions, which can result in excessive CO em ission.

Error codes when

the AFR rod fails.

D iag no stic

Color/Number of

wires

101 991 391

1. Visual inspection: connection/braking of wires, soot on it.

2. Check voltages: proper range of values are shown below.

Yellow (8) - Green (18)

Yellow (8) - AFR rod:

between the A FR rod and the

(during operation) 40KHz~60KHz

(during operation) 1μA or more

co mput er boa rd

I

The AFR rod is assembled with the flame rod.

Detecting elements (AFR and flame rods)

3-1/2" (88.6mm)

Leads to computer board

Flame rod

AFR Rod

1-3/8" (35mm )

7/8" (24mm)

2-1/4" (58.6mm)

5/8" (15mm)

18

CONFIDENTI AL

T-K3 Service Manual

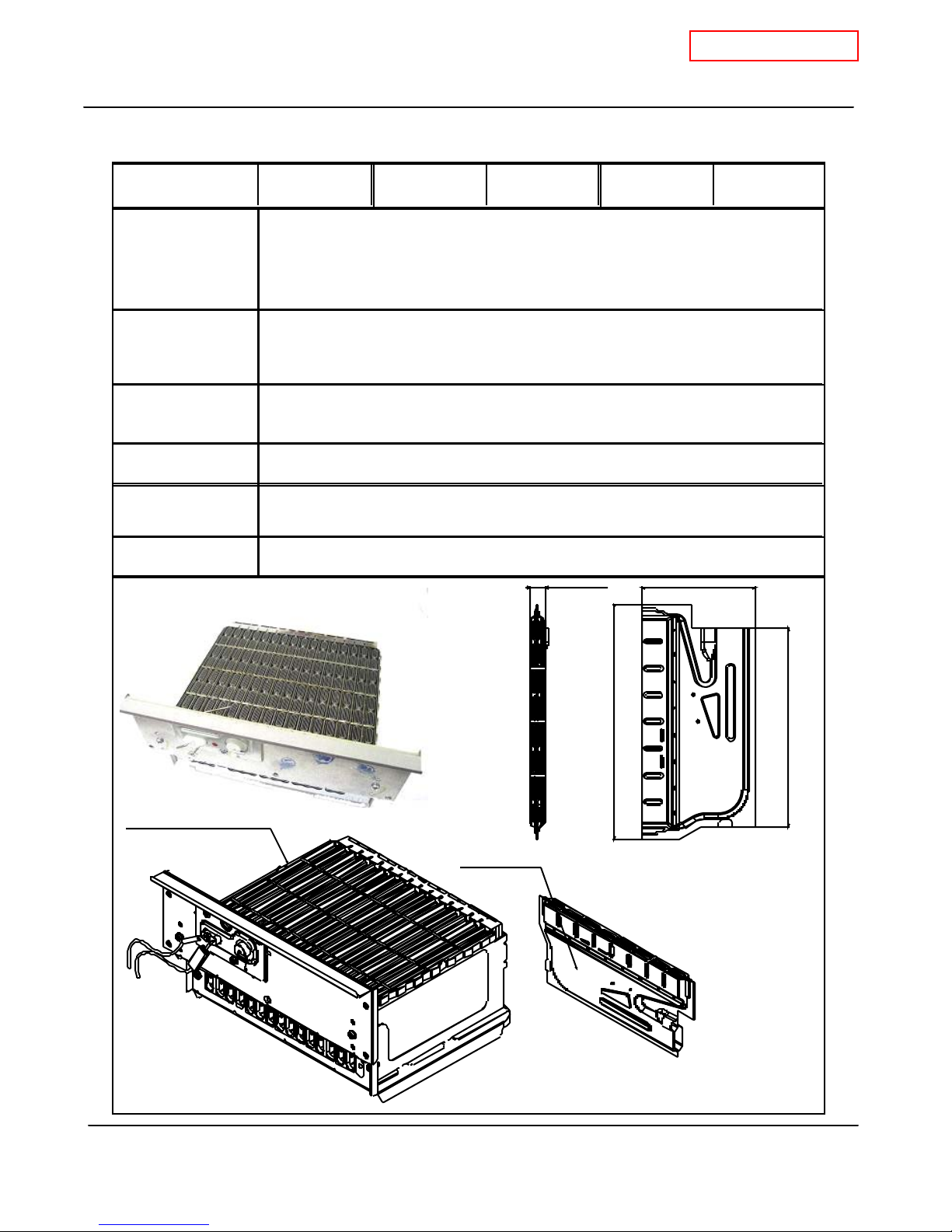

10-7. Heat exchanger

T-K3 Part # #401 Takagi Part # EKK1X Checkpoint N/A

Ver. 1.05

Function

Failure event

Effects on the T -K3

i f the heat

exchanger fails .

Error codes when the

heat exchanger fails.

D iag nostic

Color/Number of wires

Absorb heat from combustion and transfer it to water through the heat

exchanger pipes.

1. Clogged heat exchanger fins and/or cracks on the heat exchanger walls.

2. Leaking exhaust gas.

3. Improper heat transfer can cause the water in heat exchanger to boil.

1. Water leakage from the heat exchanger

2. Exhaust gas leakage (if this occurs, an overheat cutoff fuse is in place to

detect this event and immediately stop the T-K3 from operating)

3. Abnormal sounds during combustion

N/A

1. Visua l inspe ction: soot de po sits, cr ac k s o n t he heat exchanger walls , and/o r

water leakage from the heat exchanger.

2. In t he eve nt of abnormal so un ds during combustion :

A. Inspect for soot buildup inside the heat exchanger.

B . Ins pe ct fo r scale bu ildup i nside the he at exchanger pipes. Scal e bu ildup

obstructs proper heat transfer to the water, thereby overheating the heat

exchanger and causing damage.

N/A

Exhaust chamber

Heat exchanger

Water pipes

14-1/4" (361.3mm)

20-5/8" (522.5mm)

11-3/4" (297.2mm)

19

CONFIDENTI AL

T-K3 Service Manual

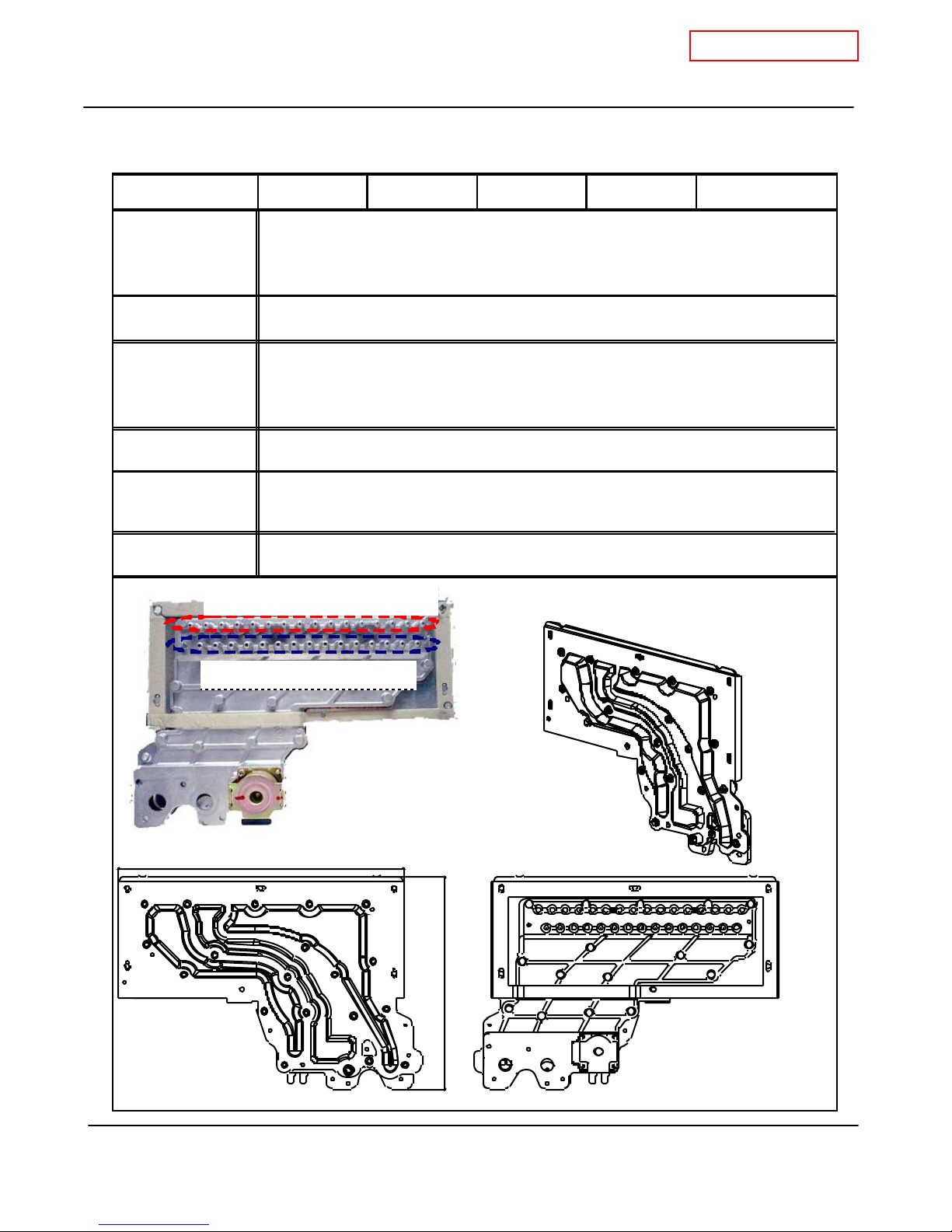

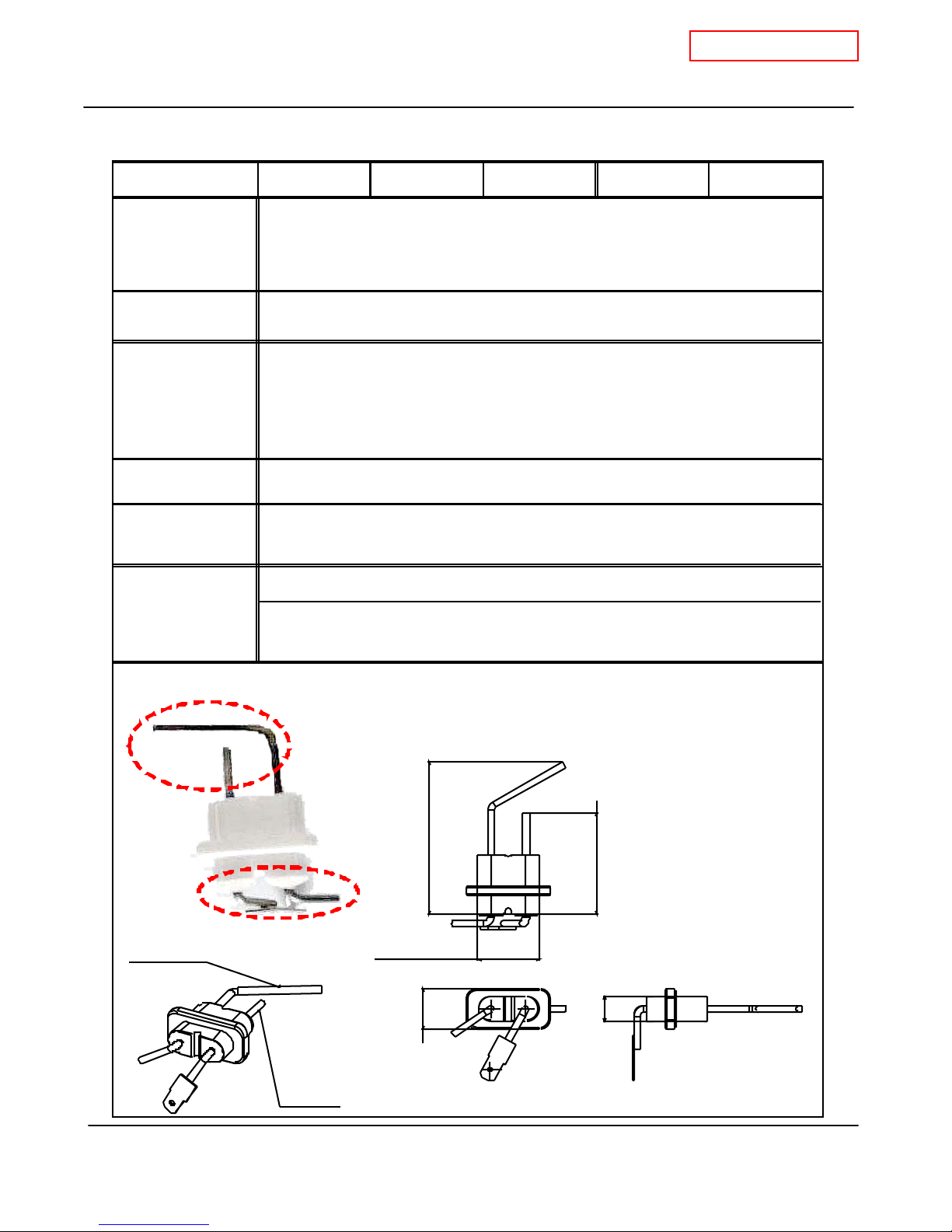

10-8. Flow adjustment valve

T-K3 Part # #402 Tak agi Part # EKK0T Checkpoint J1

Ver. 1.05

Function

F ailure even t

Effects on the T-K3

if flow adjustment

valve

fails

Controls water flow to properly control the output hot water temperaturet.

1. Water leakage from valve.

2. The valve cannot modulate or make open/close positions.

1. Wate r leaka ge from f a iled v al ve can da ma ge other T-K 3 co mp on en ts.

2. Temp er atur e fluctu atio ns in the hot wat e r ou tput.

3. Within a multi-unit Easy-Link system, the "651" error code can occur.

Error codes when

F low Adjust me nt

651 (only within multi-unit Easy-Link systems)

Va lve fail s.

1. Visual inspection: connection/breakage of wires, motor drive locked due to

D iag nostic

scal e bu ildup, a nd/ or water leak age.

2. Check vo ltage s and resistance ; prop er ran g e of val ues sh ow n below .

Color/Number of

wires

Black-Red

DC7~1 6V and 0.09~ 0 .2kΩ

The flow adjustment valve is assembled with the flow sensor.

Flow

adjustment

valve

Flow

adjustment

valve

Flow adjustment

val ve

IN

Flow sensor

Flow

adju stment

valv e

IN

Flow sensor

OUT

No.

3

No. 2

No.

1

(Bl ack)

1

M

(Re d)

3

Close

Open

132

-+

+ -

OUT

2- 5/8" (6 7.5mm )

>PPE-GF<

3-3/8" (84.4mm)

1-7/8" (47mm)

20

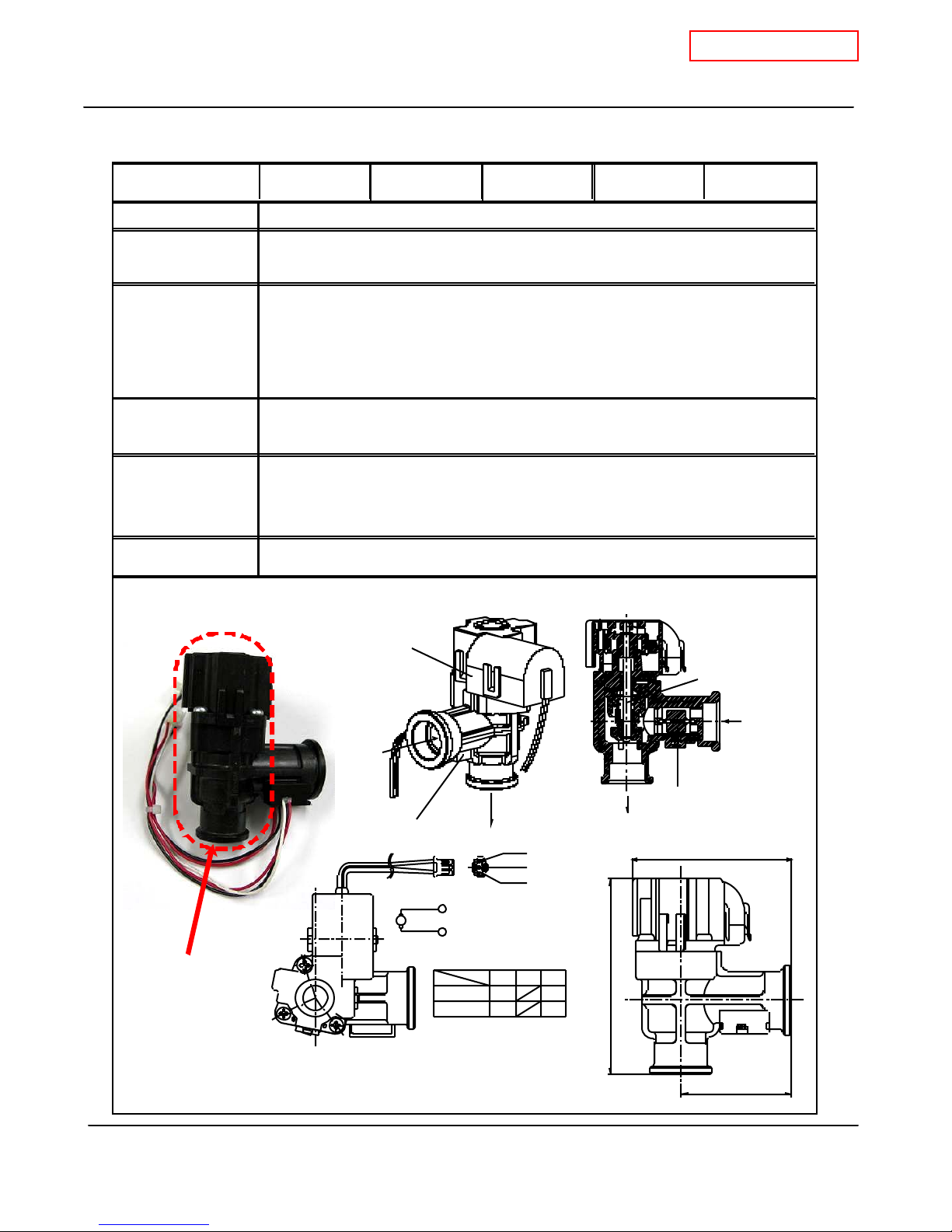

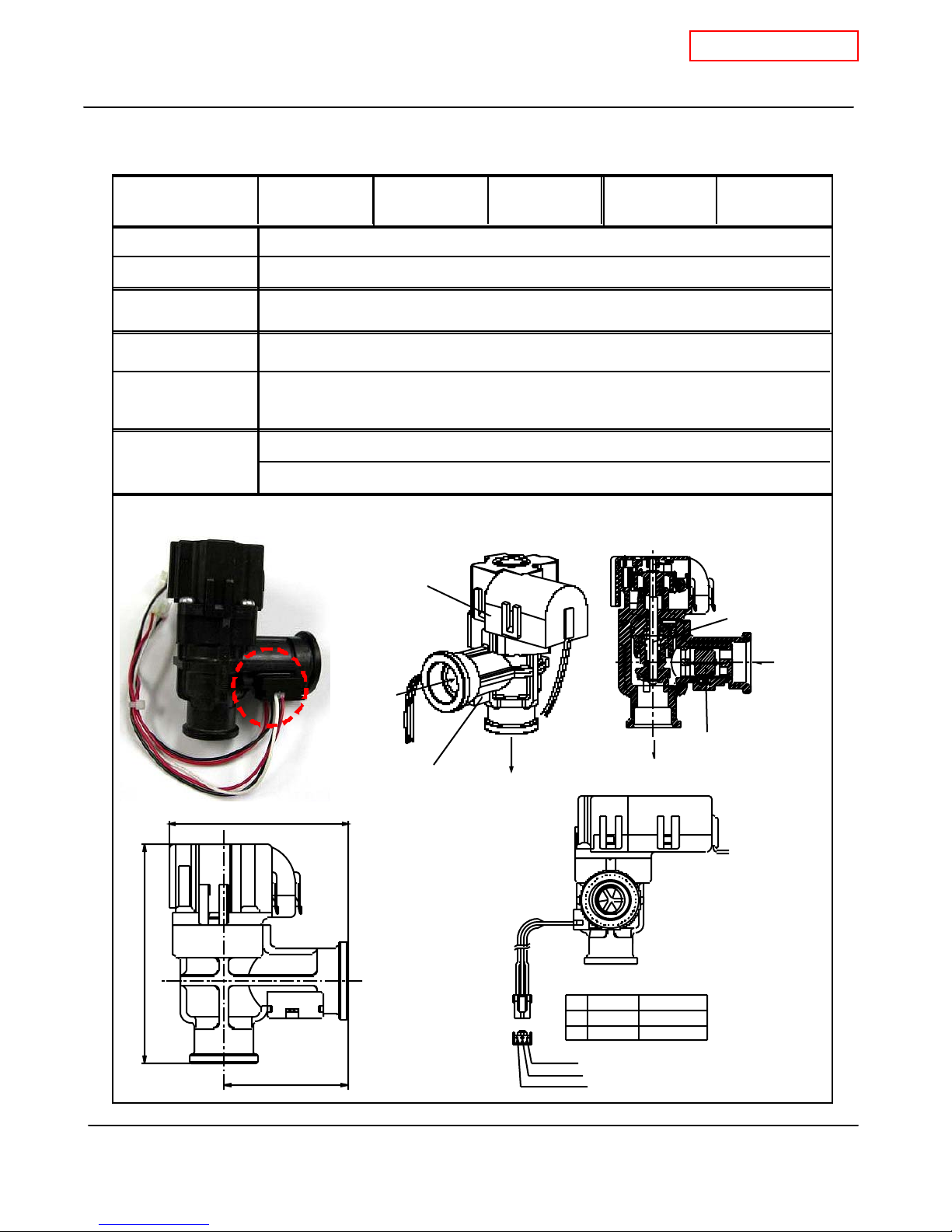

10-9 . Flow se nsor

u

CONFIDENTI AL

T-K3 Service Manual

Ver. 1.05

T-K3 Part # #402 Takagi Part # EKK0T Checkpoint

Function

Failure event

Effects on the T-K3

if flow sensor fails

Error codes when

the flow sensor fails.

D iag nostic

Color/Number of

wires

Detects and measures water flow rate using a spinning impeller and magnetic pick-

Unable to detect or measure any water flow rate.

Ignition sequence does not start (T-K3 will not initiate any operation)

441 (only within multi-unit Easy-Link systems)

1. Visual inspection: connection/breakage of wires and/or debris on impeller

2. Check voltages: proper range of values shown below.

Red-Black

W hite( 85) -Bla ck

DC 4~5.5V (Input)

DC 1~4 V (p ulse) 1,080 pu lse/m in (m ore tha n 1 8Hz)

The flow sensor is asse mbled with the flow adjus tment valve.

Flow

adjustm ent

valve

Flow sensor

H2

Flow

adjus tment

valve

2-5/8" (67.5mm)

3-3/8" (84.4mm)

>PPE-GF<

1-7/8" (47mm)

IN

Flow sen sor

OUT

Flow sensor

11

22

33

No.1

No.2

No.3

Red

White

Black

IN

Flow s ensor

OUT

VCC

OUTPUT

GND

21

Loading...

Loading...