Page 1

M800 SL2 CI

Part C T854 Transmitter

This part of the manual is divided into six sections, as listed below. There is a detailed

table of contents at the start of each section.

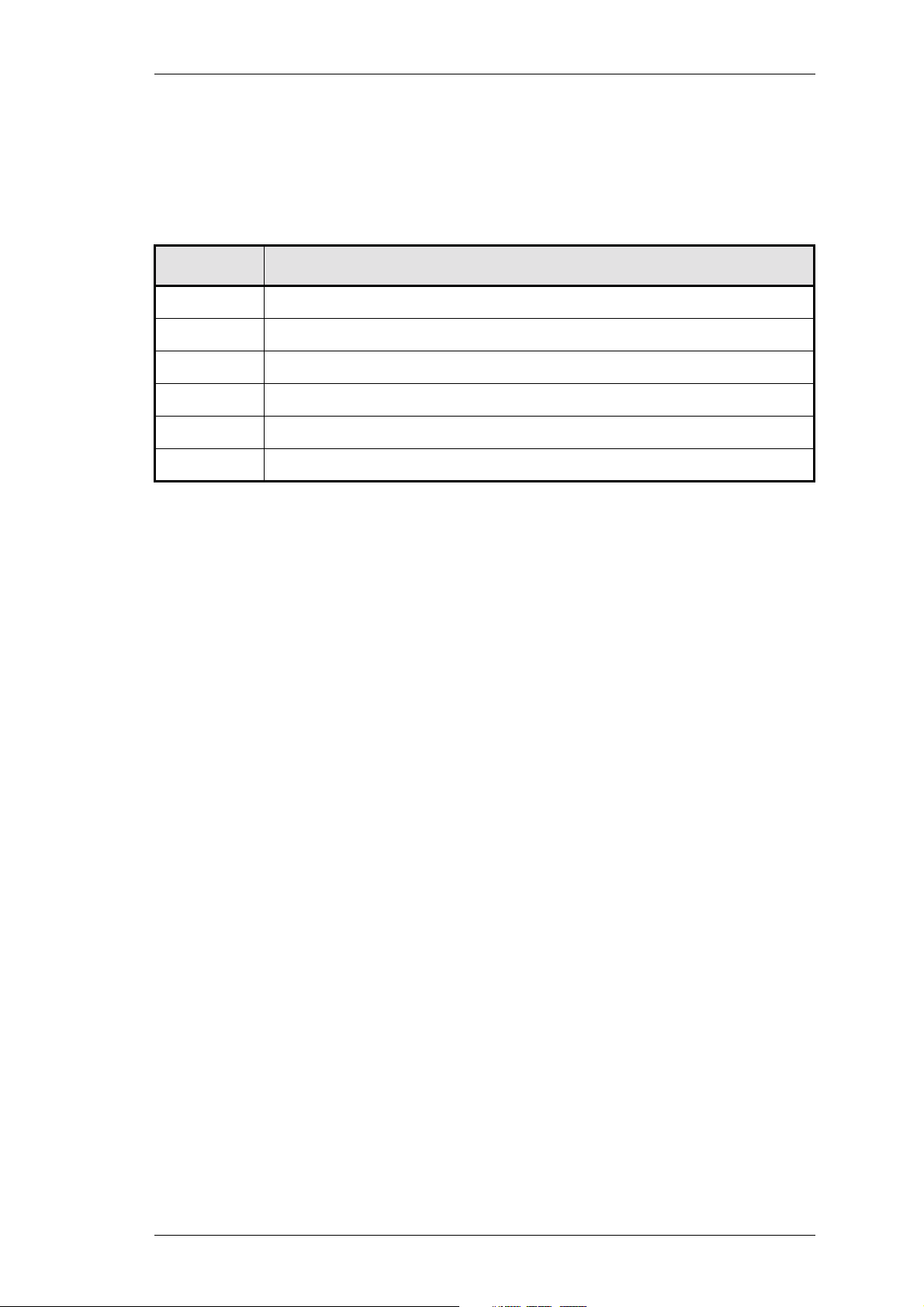

Section Title

1 General Information

2 Circuit Operation

3 Initial Tuning & Adjustment

4 Functional Testing

5 Fault Finding

6 PCB Information

Copyright TEL 01/03/02

Page 2

CII M800 SL2

01/03/02 Copyright TEL

Page 3

M800 SL2 T854 General Information C1.1

1 T854 General Information

This section provides a brief description of the T854 transmitter, along with detailed

specifications and a list of types available.

The following topics are covered in this section.

Section Title Page

1.1 Introduction 1.7

1.2

1.2.1

1.2.2

1.2.3

1.2.4

1.2.4.1

1.2.4.2

1.2.4.3

1.2.5

1.2.6

1.2.6.1

1.2.6.2

1.2.6.3

1.3 Product Codes 1.13

1.4 T854 Standard Product Range 1.14

Specifications

Introduction

General

RF Section

Audio Processor

Inputs

Modulation Characteristics

CTCSS

Microcontroller

Test Standards

European Telecommunication Standard

DTI CEPT Recommendation T/R-24-01

Telecommunications Industry Association

1.8

1.8

1.8

1.9

1.10

1.10

1.11

1.11

1.11

1.12

1.12

1.12

1.12

Figure Title Page

1.1 T854 Main Circuit Block Identification 1.4

1.2 T854 Front Panel Controls 1.4

Copyright TEL 01/03/02

Page 4

C1.2 T854 General Information M800 SL2

01/03/02 Copyright TEL

Page 5

M800 SL2 T854 General Information C1.3

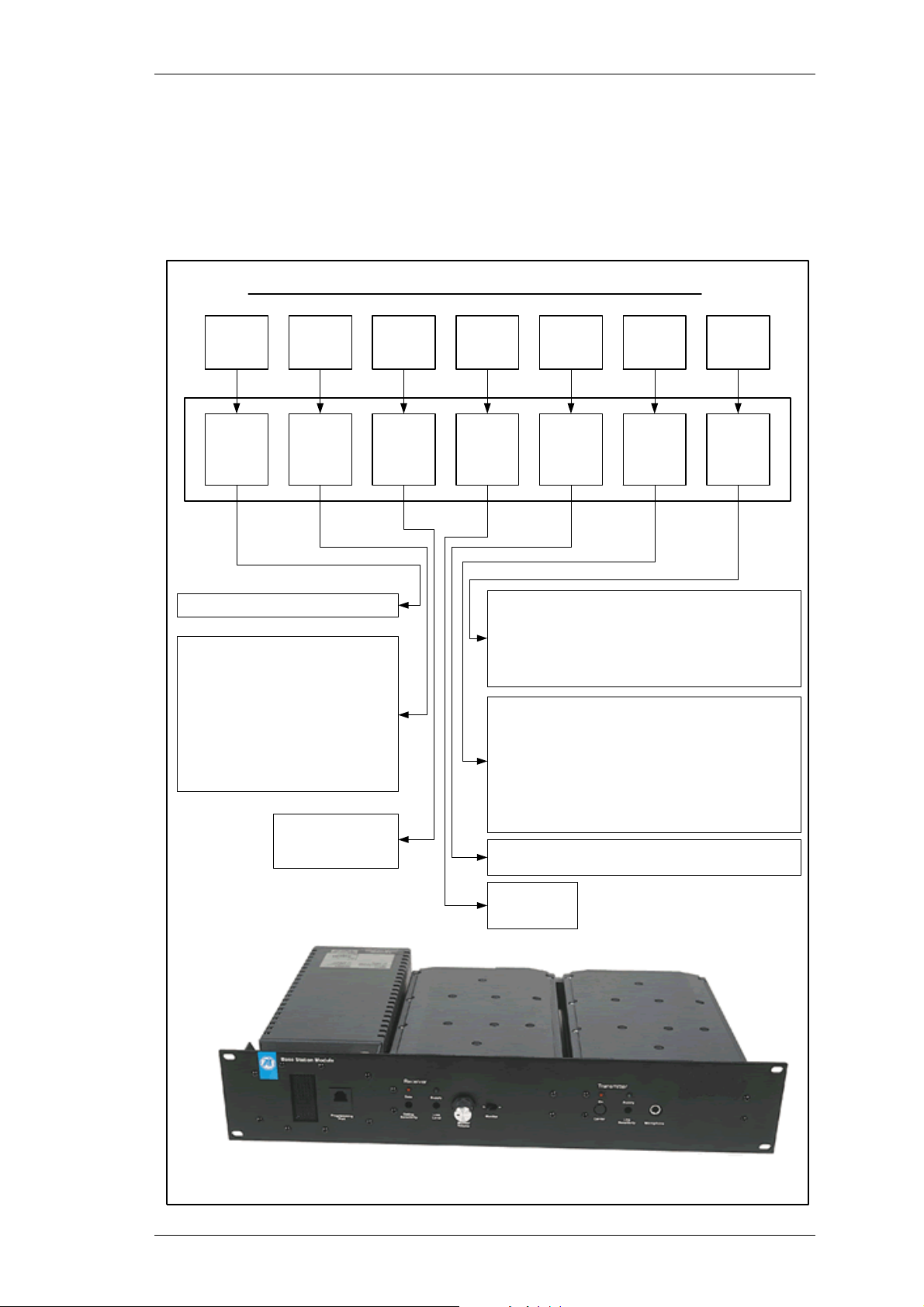

Figure 1.1 T854 Main Circuit Block Identification

replace this page with A3

8500C1xx.fm

Copyright TEL 01/03/02

Page 6

C1.4 T854 General Information M800 SL2

Figure 1.2 T854 Front Panel Controls

replace this page with A3

8500C1xx.fm

01/03/02 Copyright TEL

Page 7

M800 SL2 T854 General Information C1.5

1.1 Introduction

The T854 is a synthesised, microprocessor controlled FM base station transmitter

designed for single or multichannel operation in the 400 to 520MHz frequency range

with a standard power output of 25W. The RF section of the transmitter comprises a frequency synthesiser which provides 100mW of frequency modulated RF drive to a two

stage, wide band output driver followed by a 25W power supply. A thermal shutdown

feature is provided in the T854 in case operating temperatures exceed acceptable levels.

The T854 is rated for continuous operation.

The T854 is rated for a continuous output power of 25W at +60°C. This is achieved via a

high capacity heatsink, electric fan and shroud. The fan draws air across the heatsink to

dissipate the heat. The heatsink replaces one of the usual T800 covers.

A wide selection of audio characteristics may be obtained from the audio processor.

Optional circuit blocks are an audio compressor and a pre-emphasis stage. They can be

bypassed or linked to one or both audio inputs, and then back into the remaining audio

circuitry in almost any combination. All audio processor options are link selectable.

The synthesiser frequency is programmed via the serial communications port. Eight

channel select lines are accessible via an optional D-range connector (D-range 2 T800-03-0000) at the rear of the set.

All components except those of the VCO are mounted on a single PCB. This is secured

to a die-cast chassis which is divided into compartments to individually shield each section of circuitry. Access to the PCB is primarily through the top cover of the radio, as all

components are mounted on the top side of the PCB. There is provision within the chassis to mount small option PCBs.

1

The front panel controls include line sensitivity, microphone socket and carrier switch.

This switch turns on the carrier (unmodulated) as an aid to servicing.

The T854 is designed to be part of the slimline frame.

1. Although capable of operating over the 400-520MHz frequency range, the T854 and

T857 have an 8MHz switching range (see Section 1.2.3 and Section 3.1).

Copyright TEL 01/03/02

Page 8

C1.6 T854 General Information M800 SL2

1.2 Specifications

1.2.1 Introduction

The performance figures given are minimum figures, unless otherwise indicated, for

equipment tuned with the maximum switching range and operating at standard room

temperature (+22°C to +28°C) and standard test voltage (13.8V DC).

Where applicable, the test methods used to obtain the following performance figures

are those described in the EIA and ETS specifications. However, there are several

parameters for which performance according to the CEPT specification is given. Refer

to Section 1.2.6 for details of test standards.

Details of test methods and the conditions which apply for Type Approval testing in all

countries can be obtained from Tait Electronics Ltd.

The terms "wide bandwidth", "mid bandwidth" and "narrow bandwidth" used in this

and following sections are defined in the following table.

Channel Spacing

Wide Bandwidth 25kHz ±5.0kHz 15.0kHz

Mid Bandwidth 20kHz ±4.0kHz 12.0kHz

Narrow Bandwidth 12.5kHz ±2.5kHz 7.5kHz

Modulation

100% Deviation

Receiver

IF Bandwidth

1.2.2 General

Number Of Channels .. 128 (standard)

Supply Voltage:

Operating Voltage .. 10.8 to 16V DC

Standard Test Voltage .. 13.8V DC

Polarity .. negative earth only

Polarity Protection .. crowbar diode

Line Keying Supply (if required) .. -50V DC

Supply Current:

1

Transmit - T854 .. 5.5A (typical)

Standby - T854 .. 165mA (typical)

Operating Temperature Range .. -20°C to +60°C

1. Additional channels may be factory programmed. Contact your nearest Tait Dealer or

Customer Service Organisation.

01/03/02 Copyright TEL

Page 9

M800 SL2 T854 General Information C1.7

Overall Dimensions:

Height .. 132mm

Width .. 480mm

Depth .. 335mm

Weight with Tone Remote .. 16kg

Weight without Tone Remote .. 13kg

Time-Out Timer (optional) .. 0 to 5 minutes

1

adjustable in 10 sec-

ond steps

Tail Timer .. 0 to 5 seconds adjustable in 100ms

2

steps

Transmit Key Time .. <30ms

Transmit Lockout Timer .. 0 to 1 minute adjustable in 10 second

steps

1.2.3 RF Section

Frequency Range .. 400-520MHz (refer to Section 1.4 and

Section 1.5)

Modulation Type .. FM

Frequency Increment .. 5 or 6.25kHz

Switching Range .. 8MHz (i.e. ±4MHz from the centre

frequency)

Load Impedance .. 50 ohms

Frequency Stability .. ±1ppm, -20°C to +60°C

(see also Section 1.4 and Section 1.5)

Adjacent Channel Power (full deviation):

Wide Bandwidth (WB) .. -75dBc

(±25kHz/15kHz B/W)

Mid Bandwidth (MB) .. -70dBc

(±20kHz/12kHz B/W)

Narrow Bandwidth (NB) .. -65dBc

(±12.5kHz/7.5kHz B/W)

Transmitter Switching .. complies with ETS 300 113

1. Adjustable from 0 to 10 minutes in PGM800Win version 2.12 and later.

2. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

Copyright TEL 01/03/02

Page 10

C1.8 T854 General Information M800 SL2

Transmitter Side Band Noise:

(no modulation, 15kHz bandwidth)

At ±25kHz .. -95dBc

At ±1MHz .. -105dBc

Intermodulation .. -40dBc with interfering signal of

-30dBc

.. -70dBc with 25dB isolation

& interfering signal of -30dBc

(PA with output isolator)

T854 Mismatch Capability:

Ruggedness .. refer to your nearest Tait Dealer or

Customer Service Organisation

Stability .. 3:1 VSWR (all phase angles)

Radiated Spurious Emissions:

Transmit .. -36dBm to 1GHz

-30dBm 1GHz to 4GHz

Standby .. -57dBm to 1GHz

-47dBm 1GHz to 4GHz

Conducted Spurious Emissions: (T854 Only)

Transmit .. -36dBm to 1GHz

-30dBm 1GHz to 4GHz

Standby .. -57dBm to 1GHz

-47dBm 1GHz to 4GHz

Power Output:

T854 - Rated Power .. 25W (see Duty Cycle)

- Range Of Adjustment .. 5-25W

Duty Cycle.. 100% @ 25W at +60°C

1.2.4 Audio Processor

1.2.4.1 Inputs

Inputs Available .. line, microphone and CTCSS

Line Input:

Impedance .. 600 ohms (balanced)

Sensitivity (60% modulation @ 1kHz)-

With Compressor .. -50dBm

Without Compressor .. -30dBm

Microphone Input:

Impedance .. 600 ohms

01/03/02 Copyright TEL

Page 11

M800 SL2 T854 General Information C1.9

Sensitivity (60% modulation @ 1kHz)-

With Compressor .. -70dBm

Without Compressor .. -50dBm

1.2.4.2 Modulation Characteristics

Frequency Response .. flat or pre-emphasised (optional)

(below limiting)

Line And Microphone Inputs:

Pre-emphasised Response-

Bandwidth .. 300Hz to 3kHz (WB & MB)

.. 300Hz to 2.55kHz (NB)

Below Limiting .. within +1, -3dB of a 6dB/octave

pre-emphasis characteristic

Flat Response .. within +1, -2dB of output at 1kHz

Above Limiting Response .. within +1, -2dB of a flat response

(ref. 1kHz)

Distortion .. 2% max.

Hum And Noise:

Wide Bandwidth .. -55dB (300Hz to 3kHz [EIA]) typical

Mid Bandwidth .. -54dB (CEPT)

Narrow Bandwidth .. -50dB (CEPT)

Compressor (optional):

Attack Time .. 10ms

Decay Time .. 800ms

Range .. 50dB

1.2.4.3 CTCSS

Standard Tones .. all 37 EIA group A, B and C tones

plus 13 commonly used tones

Frequency Error .. 0.08% max.

(from EIA tones)

Generated Tone Distortion .. 1.2% max.

Generated Tone Flatness .. flat across 67 to 250.3Hz to within 1dB

Modulation Level .. adjustable

Modulated Distortion .. <5%

Copyright TEL 01/03/02

Page 12

C1.10 T854 General Information M800 SL2

1.2.5 Microcontroller

Auxiliary Ports:

Open Drain Type .. capable of sinking 2.25mA via 2k2Ω

max. .. 5V

V

ds

1.2.6 Test Standards

Where applicable, this equipment is tested in accordance with the following standards.

1.2.6.1 European Telecommunication Standard

ETS 300 086 January 1991

Radio equipment and systems; land mobile service; technical characteristics and test

conditions for radio equipment with an internal or external RF connector intended primarily for analogue speech.

ETS 300 113 March 1996

Radio equipment and systems; land mobile service; technical characteristics and test

conditions for radio equipment intended for the transmission of data (and speech) and

having an antenna connector.

ETS 300 219 October 1993

Radio equipment and systems; land mobile service; technical characteristics and test

conditions for radio equipment transmitting signals to initiate a specific response in the

receiver.

ETS 300 279 February 1996

Radio equipment and systems; electromagnetic compatibility (EMC) standard for private land mobile radio (PMR) and ancillary equipment (speech and/or non-speech).

1.2.6.2 DTI CEPT Recommendation T/R-24-01

Annex I: 1988

Technical characteristics and test conditions for radio equipment in the land mobile

service intended primarily for analogue speech.

Annex II: 1988

Technical characteristics of radio equipment in the land mobile service with regard to

quality and stability of transmission.

1.2.6.3 Telecommunications Industry Association

ANSI/TIA/EIA-603-1992

Land mobile FM or PM communications equipment measurement and performance

standards.

01/03/02 Copyright TEL

Page 13

M800 SL2 T854 General Information C1.11

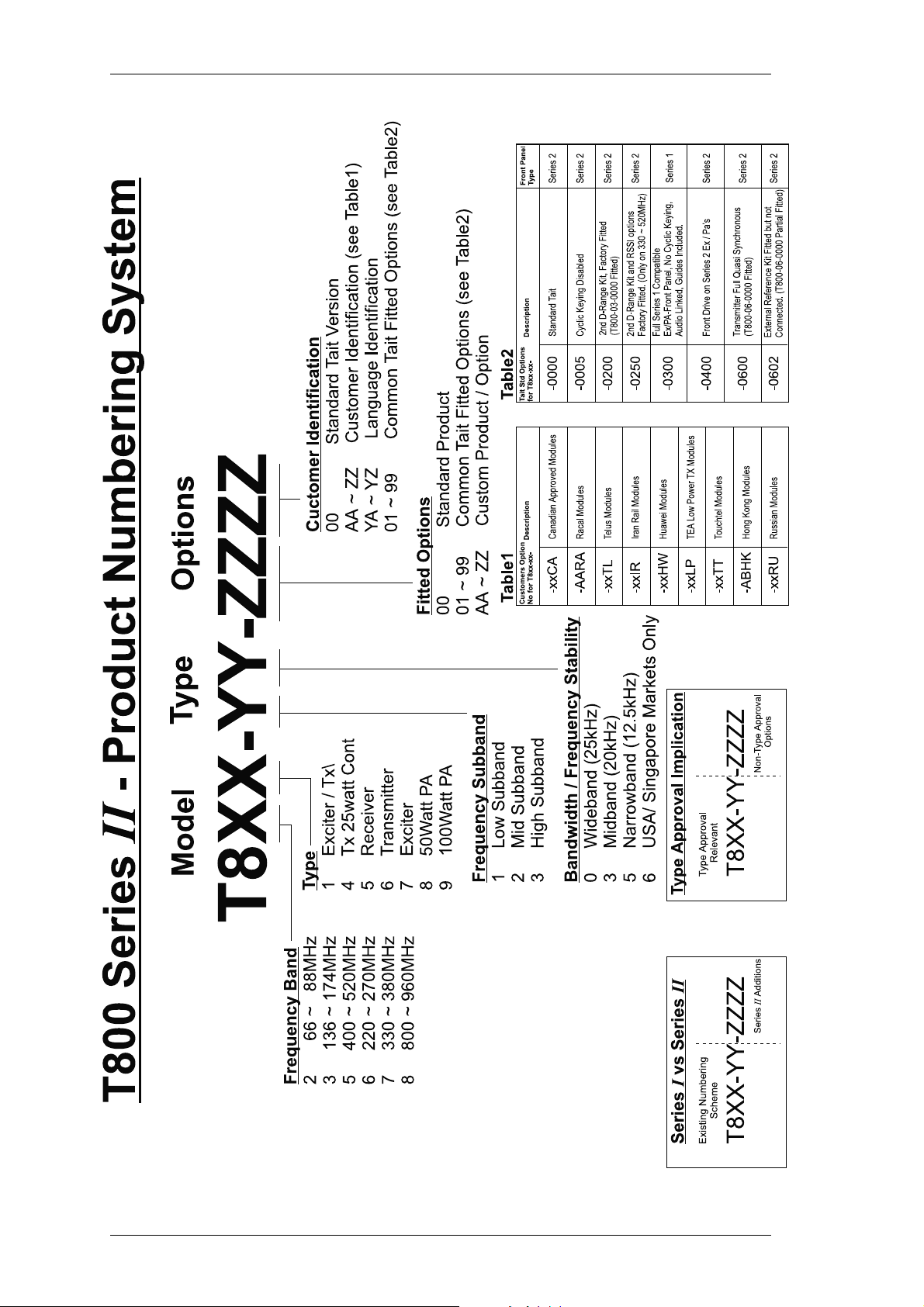

1.3 Product Codes

The three groups of digits in the T850 Series II product code provide information about

the model, type and options fitted, according to the conventions described below. Consult your nearest Tait Dealer or Customer Service Organisation for more information

regarding the availability of specific models, types and options.

Copyright TEL 01/03/02

Page 14

C1.12 T854 General Information M800 SL2

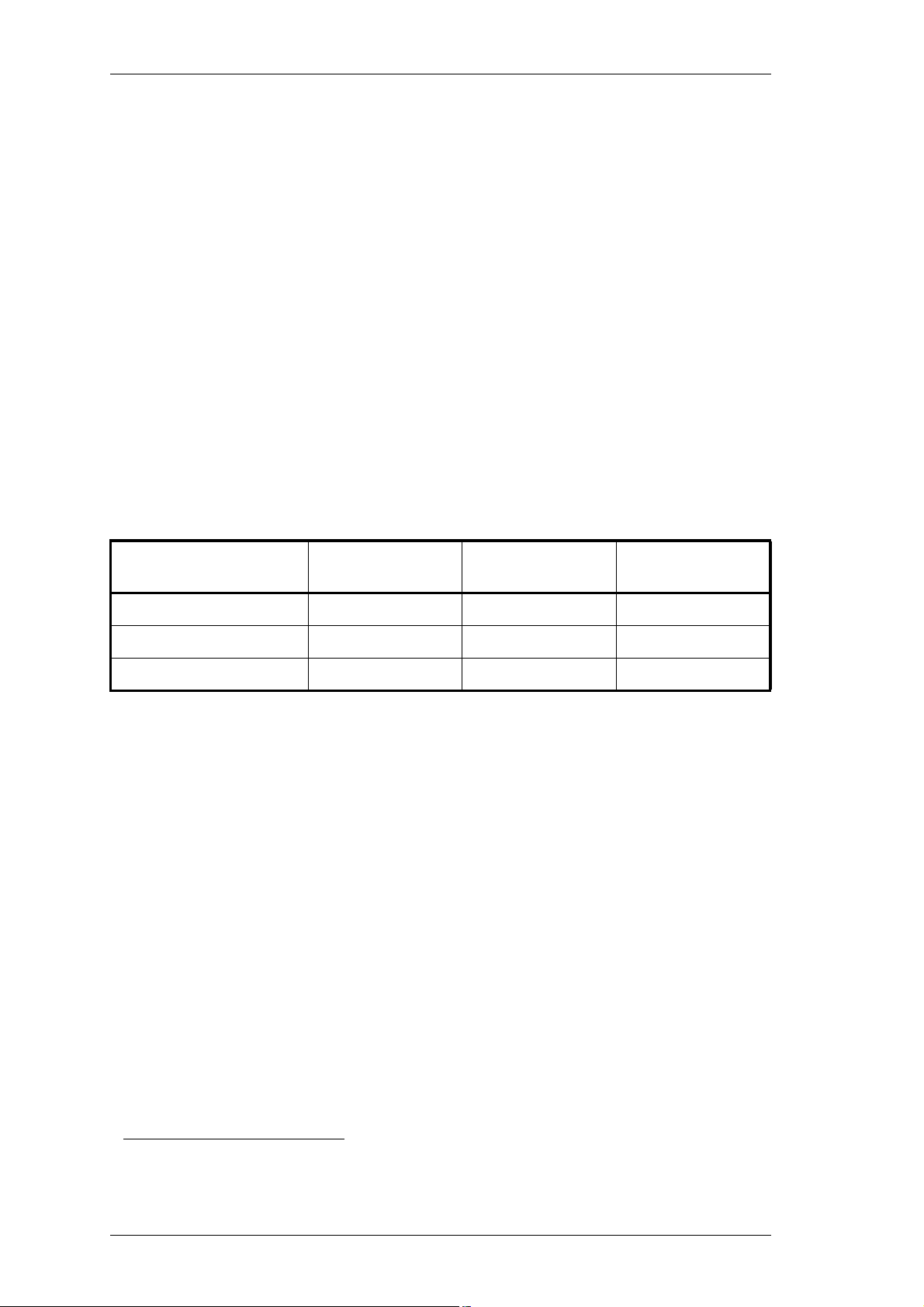

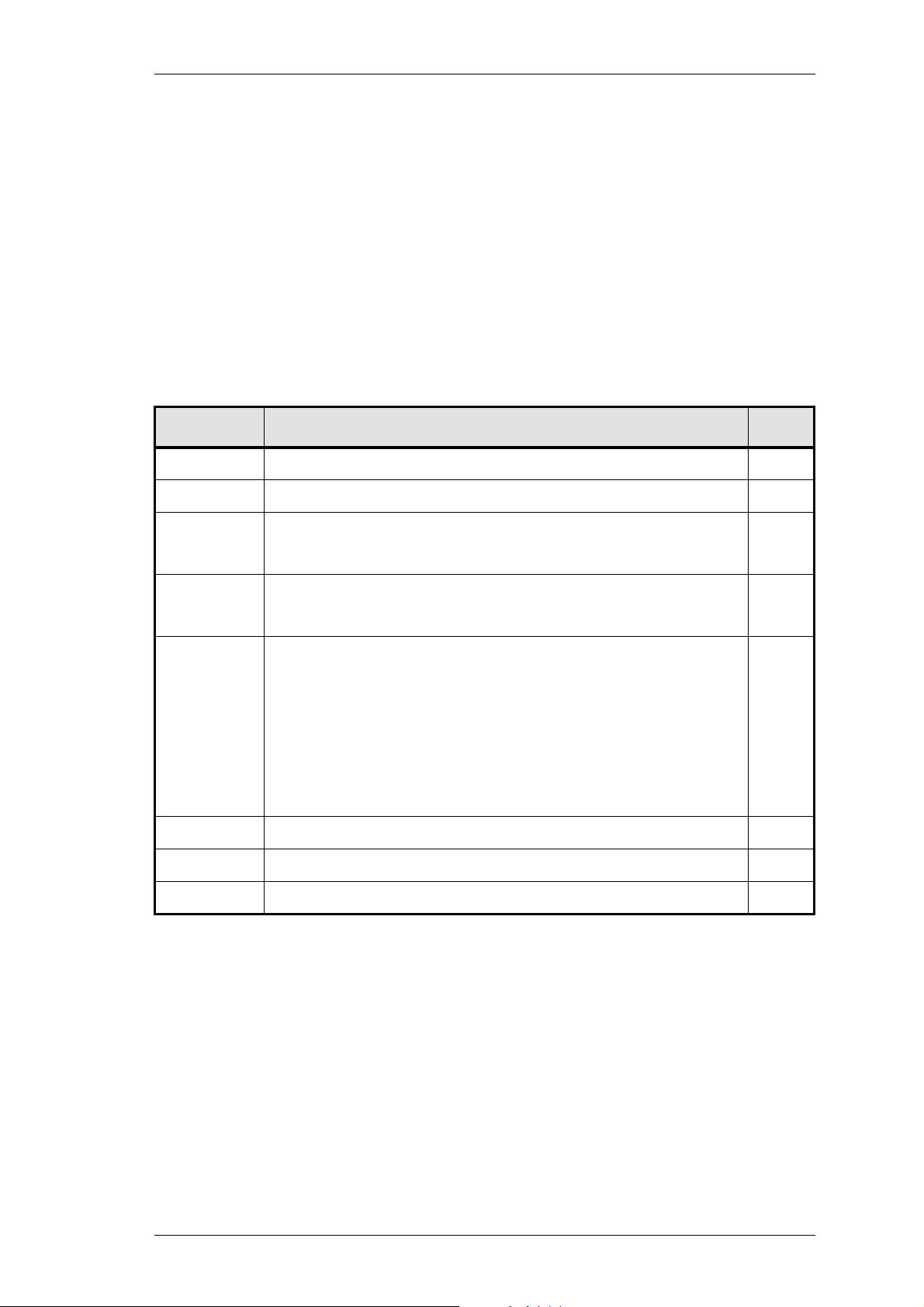

1.4 T854 Standard Product Range

The following table lists the range of standard T854 types (i.e. no options fitted) available at the time this manual was published. Consult your nearest Tait Dealer or Customer Service Organisation for more information.

Frequency Range (MHz) 400-440

Deviation (kHz) 2.5 2.5 4 5

TCXO ±1ppm -20°C to +60°C

Transmitter Type: T854- 16-0000

Frequency Range (MHz) 440-480

Deviation (kHz) 2.5 2.5 4 5

TCXO ±1ppm -20°C to +60°C

Transmitter Type: T854- 26-0000

Frequency Range (MHz) 480-520

Deviation 2.5 2.5 5

TXCO ±1ppm -20° to +60°C

Transmitter Type: T854- 36-0000

a. United States market only.

••••

a

15-0000 13-0000 10-0000

••••

a

25-0000 23-0000 20-0000

•••

a

35-0000 30-0000

Caution: T854-1X-XXXX Product Types

The 406 to 406.1MHz frequency range is reserved worldwide for use by

Distress Beacons. Do

not program transmitters to operate in this fre-

quency range.

You can identify the transmitter type by checking the product code printed on a label on

the rear of the chassis (Figure 1.1 in Part A shows typical labels). You can further verify

the transmitter type by checking the placement of an SMD resistor in the table that is

screen printed onto the PCB (refer to Section 6.1 for more details).

01/03/02 Copyright TEL

Page 15

M800 SL2 T854 General Information C1.13

T800 SL BSM Conventional Ordering Number System

System

Type

L A 1 W B 0 0

L = T800 SL BSM (T800-56-X0XX)

A =

66 - 88

B =

136 - 156

C =

148 - 174

D =

400 - 440

E =

440 - 480

F =

480 - 560

P =

800 - 870

Q =

860 - 910

*

R =

890 - 960

= Not Available for US Market

*

1

Frequency

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

Band

2

(T82x-xx-02xx)

(T83x-1x-02xx)

(T83x-2x-02xx)

(T85x-1x-02xx)

(T85x-2x-02xx)

(T85x-3x-02xx)

(T88x-1x-02xx)

(T88x-2x-02xx)

(T88x-3x-02xx)

RF Output

Power

1

2

Channel

Spacing

3

4

0 =

4 =

7

6 =

7 =

8 =

9 =

0 =

1 =

2 =

If Duplexer item code is set to (1), then Base/Repeater/

6

Slimline Requirement sheet must be completed. This is

required so correct Duplexer Frequency and Spacing can be

calculated.

Power

Supply

No Ancillary Option

Multi-Channel Option (10 CH)

Cabinet Desktop 3U (Blk)

Cabinet Desktop 4U (Blk)

Cabinet Transportable 6U (Blk)

Tone Remote Module

No Duplexer Fitted

50 Watt Duplexer Kit (T991-09-0001)+(T993-XX)

Coaxial Relay Kit (T800-09-0002)

Coaxial

Relay /

Duplexer

5

3/13/02

Ancillary

Options

67

(T992-03-0002)

(T992-04-0002)

(T992-06-0002)

(T803-00-0000)

1 =

25 Watts

4 =

5 Watts

*5 =

25 Watts (Cont)

* Only Available in Frequency

Bands

400-560Mhz

3

T991-09-0001 is a 1U 19" Tray for Duplexer fitting.

B =

5

4

BSM Kit with Power Supply

D =

BSM Kit with External DC

N =

12.5 kHz

M =

20 kHz

W =

25 kHz

(T800-56-X0X2)

(T800-56-X0X4)

Copyright TEL 01/03/02

Page 16

C1.14 T854 General Information M800 SL2

01/03/02 Copyright TEL

Page 17

M800 SL2 T854 General Information C1.15

Copyright TEL 01/03/02

Page 18

C1.16 T854 General Information M800 SL2

01/03/02 Copyright TEL

Page 19

M800 SL2 T854 Circuit Operation C2.1

2 T854 Circuit Operation

This section provides a basic description of the circuit operation of the T854 transmitter.

Note: Unless otherwise specified, the term "PGM800Win" used in this and follow-

ing sections refers to version 3.00 and later of the software.

Refer to Section 6 where the parts lists, grid reference index and diagrams will provide

detailed information on identifying and locating components and test points on the

main PCB. The parts list and diagrams for the VCO PCB are in Part E.

The following topics are covered in this section.

Section Title Page

2.1 Introduction 2.3

2.2 Microcontroller 2.4

2.3

2.3.1

2.4

2.4.1

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.6 Power Supply & Regulator Circuits 2.10

2.7 Transmit Timers 2.11

2.8 T854 Drive Amplifier & PA 2.12

Synthesised Local Oscillator

Two Point Modulation

VCO

VCO Supply

Audio Processor

General

Audio Inputs

Keying Inputs

Compressor (Automatic Level Control (ALC))

Outputs To Modulators

2.5

2.6

2.7

2.7

2.8

2.8

2.8

2.9

2.9

2.9

Copyright TEL 01/03/02

Page 20

C2.2 T854 Circuit Operation M800 SL2

Figure Title Page

2.1

2.3

2.4

2.5

2.6

2.7

2.8

T854 High Level Block Diagram

T854 Microcontroller Block Diagram

T854 Synthesiser Block Diagram

T854 Two Point Modulation

T854 Audio Processor Block Diagram

T854 Power Supply & Regulators Block Diagram

T854 Transmit Timers

2.3

2.4

2.5

2.6

2.8

2.10

2.11

01/03/02 Copyright TEL

Page 21

M800 SL2 T854 Circuit Operation C2.3

2.1 Introduction

The individual circuit blocks which make up the T854 are:

• synthesiser

• VCO

• audio processor

• drive amplifier

• voltage regulators.

Each of these circuit blocks is set in its own shielded compartment, formed as an integral part of the main chassis.

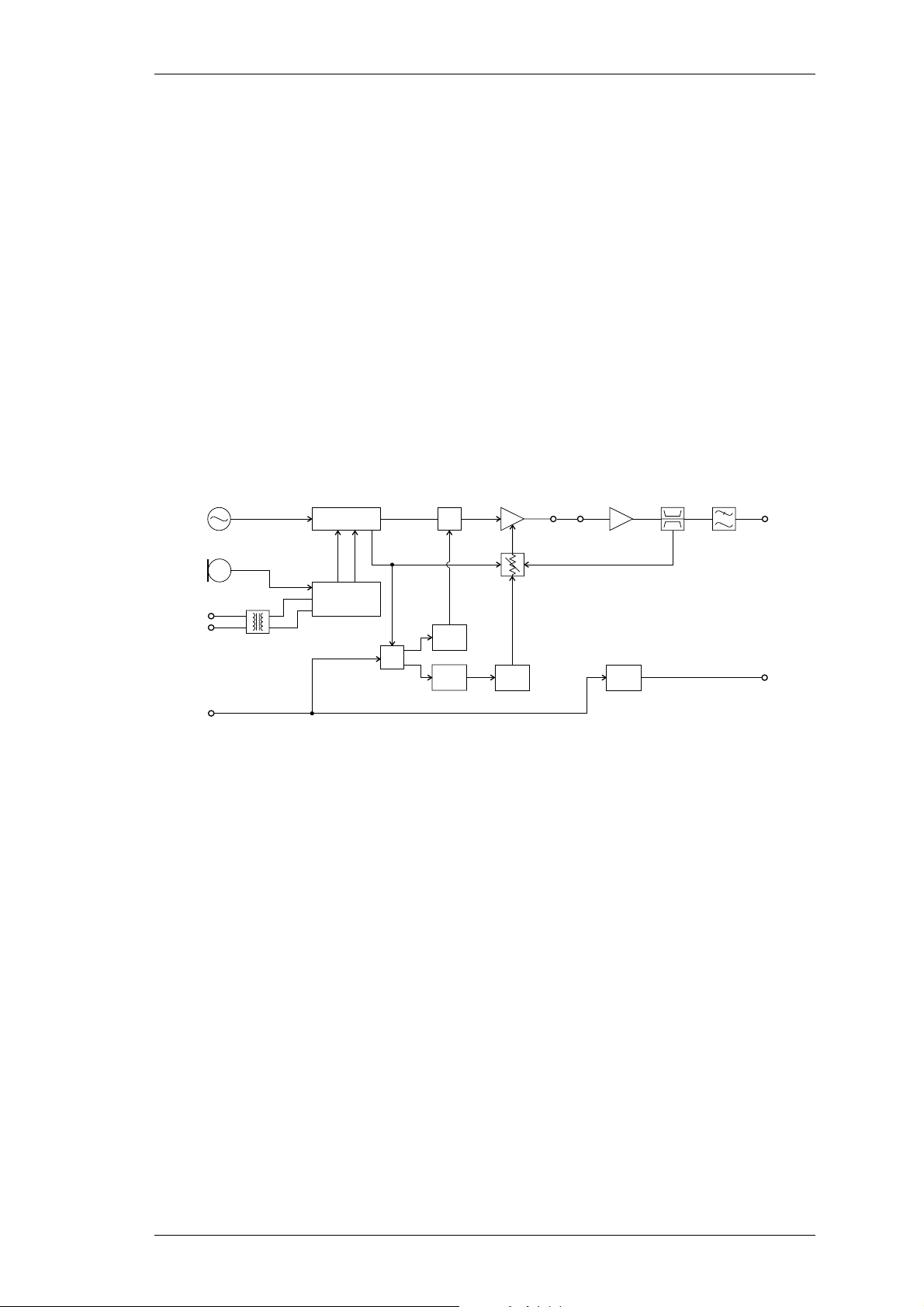

The configuration of the circuit blocks may be seen on a functional level in Figure 2.1 .

Refer to the circuit diagrams in Section 6.2 for more detail.

Exciter

Reference

Oscillator

12.8MHz

Microphone

Line

Transformer

Synthesiser

Audio

Processor

+22dBm

Lock

Detect

&

Gate

PIN

Switch

Time

Delay

Time

Delay

Power

Control

Drive

Amp.

Ramp

Gen.

Output

(+30dBm to

+33dBm)

PA

Time

Delay

Directional

Coupler

Low Pass

Filter

Transmitter

Output

(25W)

VCO

Tx Reg

Figure 2.1 T854 High Level Block Diagram

Copyright TEL 01/03/02

Page 22

C2.4 T854 Circuit Operation M800 SL2

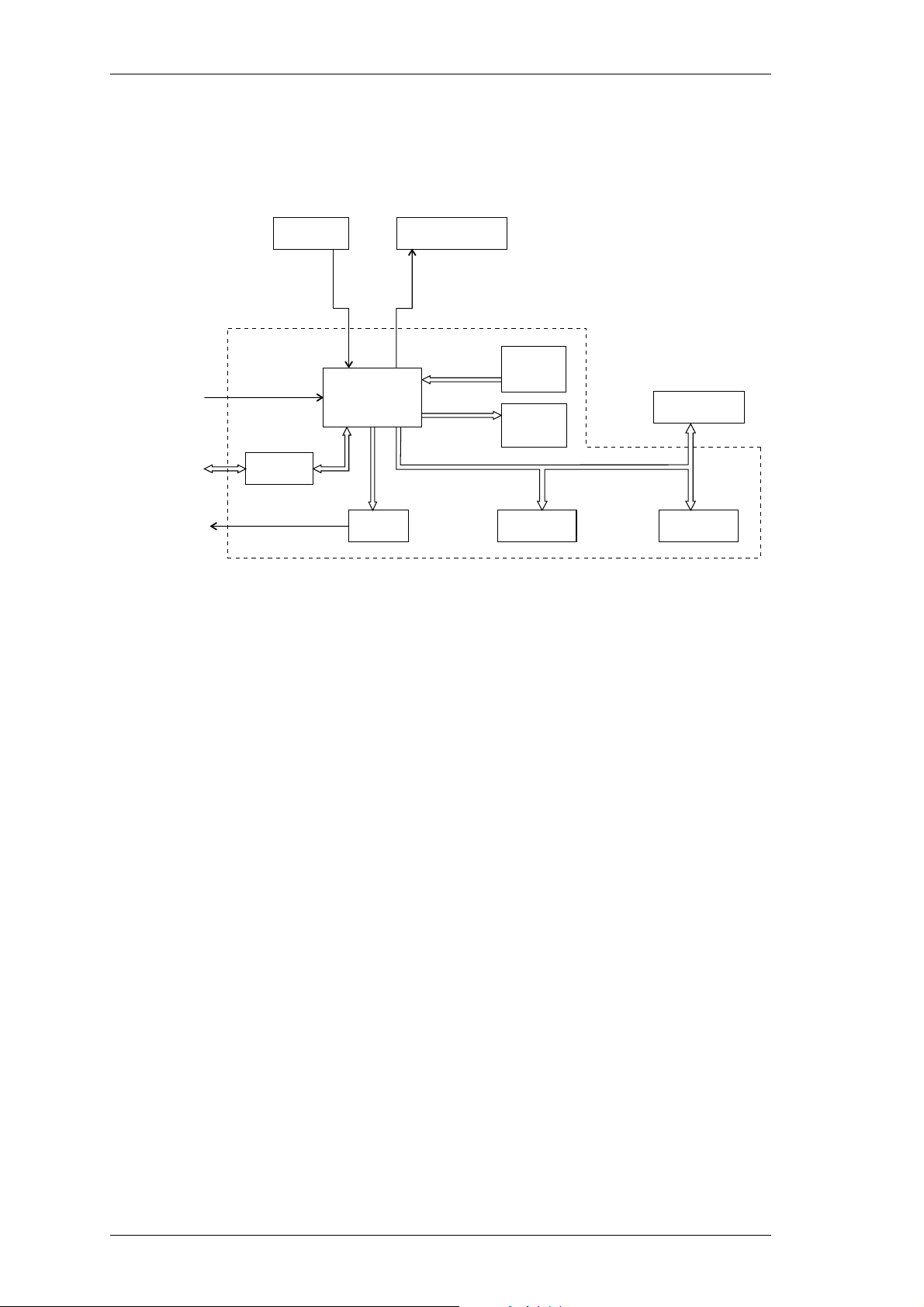

2.2 Microcontroller

(Refer to the microcontroller circuit diagram (sheet 8) in Section 6.2 or 6.3.)

Watchdog

Reset

Microcontroller Cavity

Channel

Auxiliary

Output

EEPROM

Select

Port

Dual Digital

Potentiometer

Port

Synthesiser

12.8MHz

Clock

External

Serial

Port

CTCSS Tone

5V Digital

Regulator

5V Reset

Microcontroller

Converter

CTCSS

Encoder

Figure 2.2 T854 Microcontroller Block Diagram

Overall system control of the T854 is accomplished by the use of a member of the 80C51

family of microcontrollers (IC810). It runs from internal ROM and RAM, thus leaving

all four ports free for input/output functions.

Non-volatile data storage is achieved by serial communication with a 16kBit EEPROM

(IC820). This serial bus is also used by the microcontroller to program the synthesiser

(IC740) and deviation control EPOTS (IC220).

The main tasks of the microcontroller are as follows:

• program the synthesiser and EPOT;

• interface with the PGM800Win programming software at 9600 baud via the

serial communication lines on D-range 1 (PL100) & D-range 2;

• monitor channel change inputs from D-range 2;

• generate timing waveforms for CTCSS encoding;

• coordinate and implement timing control of the exciter/transmitter.

• control the front panel "Supply" LED (refer to Section 5.3).

01/03/02 Copyright TEL

Page 23

M800 SL2 T854 Circuit Operation C2.5

m

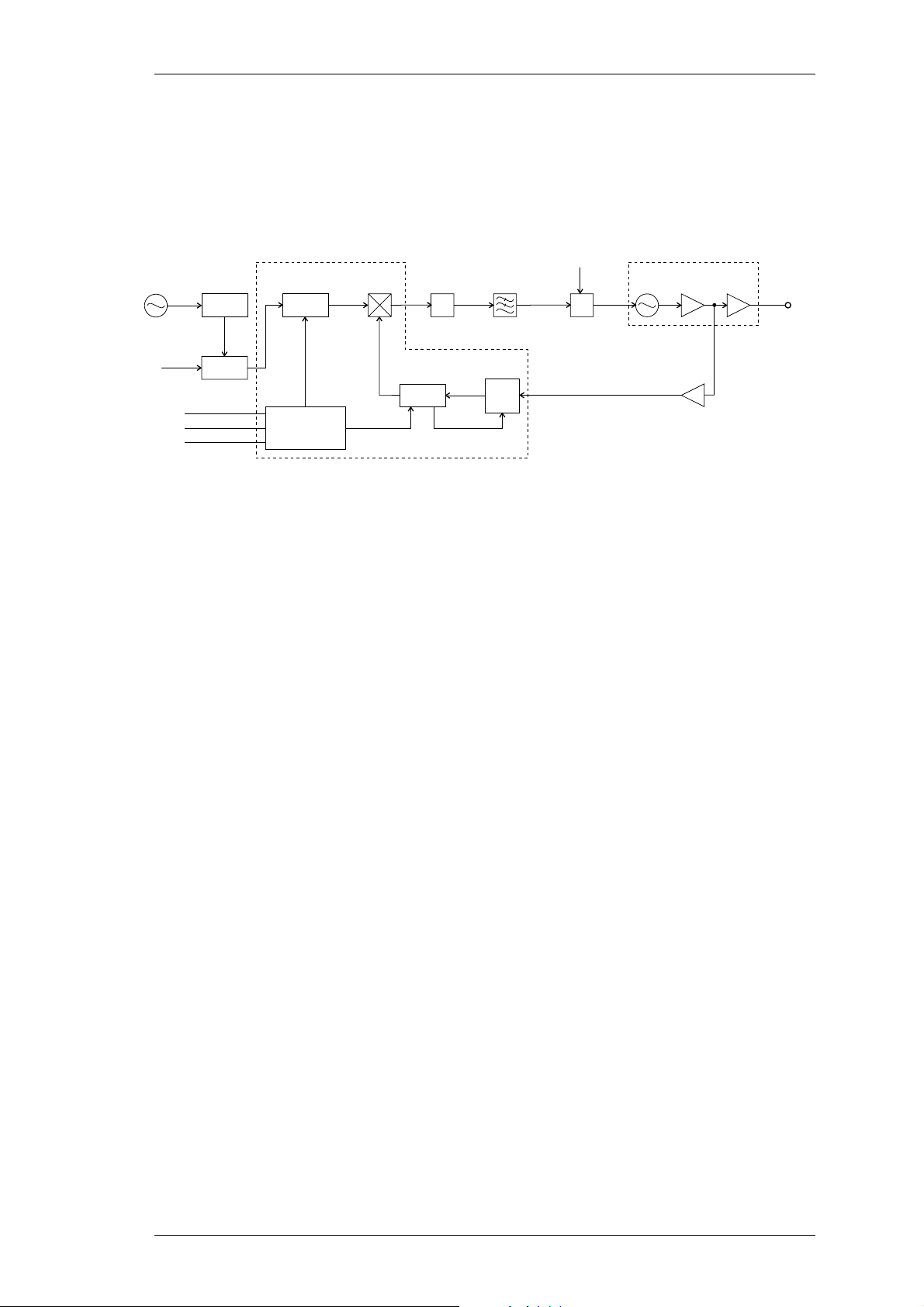

2.3 Synthesised Local Oscillator

(Refer to the synthesiser circuit diagram (sheet 7) in Section 6.2 or 6.3 and the VCO circuit diagram in Part E.)

12.8MHz

Reference

Oscillator

Ref

Mod

Serial

Bus

Clk

Data

En

Fixed

Divider

/64

Phase

Modulator

FREQUENCY SYNTHESISER IC

Reference

f

ref

Controller

Divider

/R

Phase

Detector

Programmable

Divider

/N

Charge

Pump

Loop

Filter

Prescaler

64/65

Modulation

f

in

VCO

Σ

VCO Buffer

Divider Buffer

VCO PCB

Output

Buffer

Figure 2.3 T854 Synthesiser Block Diagram

The synthesiser (IC740) employs a phase-locked loop (PLL) to lock a voltage controlled

oscillator (VCO) to a given reference frequency. The synthesiser receives the divider

information from the control microprocessor via a 3 wire serial bus (clock, data, enable).

When the data has been latched in, the synthesiser processes the incoming signals from

the VCO buffer (f

) and the phase modulator (f

in

ref

).

A reference oscillator at 12.8MHz (=IC700) is buffered (IC710 pins 3 & 4) and divided

down to 200kHz (IC730). This 200kHz square wave is then summed with the modulating audio and passed to an integrator (IC720 pins 9 & 8, Q710, Q720). This produces a

ramping waveform which is centred around a DC level determined by the incoming

audio. IC720 pins 5 & 6 perform as a comparator, ultimately producing a phase-modulated 200kHz square wave. This is followed by another phase shifting stage (IC720 pins

3 & 4, Q730, Q740), before being divided down to 6.25kHz or 5kHz within the synthesiser IC (IC740).

+22dB

L.O.

A buffered output of the VCO (Q795) is divided with a prescaler and programmable

divider which is incorporated into the synthesiser chip (IC740). This signal is compared

with the phase modulated reference signal at the phase detector (also part of the synthesiser chip). The phase detector outputs drive a balanced charge pump circuit (Q760,

Q770, Q775, Q780, Q785) and active loop filter (IC750 pins 5, 6 & 7, Q790) which produces a DC voltage between 0V and 20V to tune the VCO. This VCO control line is further filtered to attenuate noise and other spurious signals. Note that the VCO frequency

increases with increasing control voltage.

If the synthesiser loop loses lock, a pulsed signal appears at LD (pin 2) of IC740. This

signal is filtered and buffered by IC750 pins 1, 2 & 3, producing the Lock-Detect signal

used to shut off the power supply to the drive amplifier. IC750 pin 1 is at 20V when the

synthesiser is out of lock.

Copyright TEL 01/03/02

Page 24

C2.6 T854 Circuit Operation M800 SL2

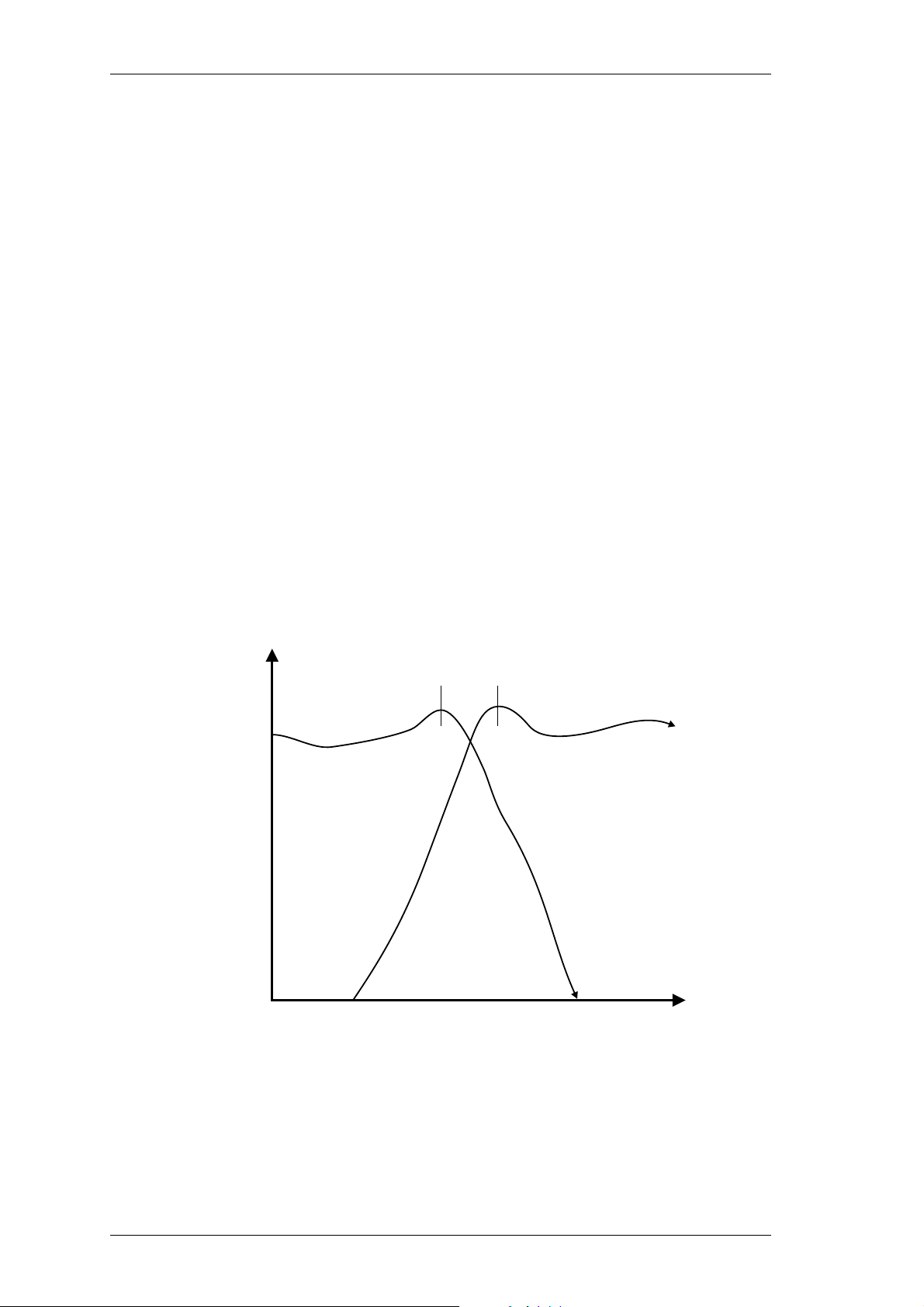

2.3.1 Two Point Modulation

Frequency modulation occurs by modulating both the VCO input and the synthesiser

reference input. This process is called two point modulation and ensures a flat modulation response from 67Hz to 3kHz (2.55kHz for narrow bandwidth).

The PLL has a fast response time, allowing a Tx key-up time of <30ms. Because of this

fast response time the PLL sees lower modulation frequencies superimposed on the

VCO as an error and corrects for it, resulting in no modulation on the carrier. At modulation frequencies greater than 300Hz the loop cannot correct fast enough and modulation is seen on the carrier. The response of the loop to VCO modulation is shown by f

in Figure 2.4 below.

To achieve low frequency modulation, the reference oscillator is also modulated so that

the phase detector of IC740 detects no frequency error under modulation. Thus, the

synthesiser loop will not attempt to correct for modulation and the audio frequency

response of the transmitter remains unaffected. The response of the loop to reference

frequency modulation is shown by f

The reference modulation is controlled by a 256-step 10k electronic potentiometer

(EPOT) which is adjustable via PGM800Win. The EPOT is made up of 256 resistive sections (representing approximately 39Ω each) which can be individually addressed by

the microcontroller. Each section can be switched in or out of circuit to achieve the

required total resistance, thus giving control of the reference modulation.

in Figure 2.4.

1

2

Deviation

ff

12

TCXO VCO

Frequency

Figure 2.4 T854 Two Point Modulation

01/03/02 Copyright TEL

Page 25

M800 SL2 T854 Circuit Operation C2.7

2.4 VCO

(Refer to the VCO circuit diagram in Part E.)

The VCO transistor (Q1) operates in a common emitter configuration, with an LC tank

circuit coupled between its gate and drain to provide the feedback necessary for oscillation. The VCO control voltage from the loop filter (IC750) is applied to the varicaps

(D1-D2) to facilitate tuning within an 8MHz band of frequencies. A trimcap (C6) is used

for coarse tuning of the VCO. The output from the oscillator circuit drives a cascode

amplifier stage (Q2, Q3) which supplies +10dBm (typically) to a further stage of amplification, Q5. This is the final amplifier on the VCO PCB, and delivers +20dBm (typically)

to the exciter drive amplifier.

A low level "sniff" is taken from the input to Q5 and used to drive the divider buffer for

the synthesiser (IC740).

The VCO operates at the actual output frequency of the exciter, i.e. there are no multiplier stages. It is modulated by superimposing the audio signal onto the control voltage

and by phase modulating the reference signal.

2.4.1 VCO Supply

The VCO is supplied from two switched +9V supplies under the control of the Tx-Reg.

supply.

The VCO and buffer amplifier are supplied from one +9V switched supply by Q540 via

the C multiplier (Q550, C530 on the T854 and C550 on the T857).

The output amplifier is supplied from the other +9V supply by Q520, Q530, and Q510.

A delay circuit holds the VCO on for a short time after the Tx-Reg. supply has been

switched off. This is to allow the RF power circuits (both exciter and PA) to ramp down

in the correct manner before the VCO is switched off.

Copyright TEL 01/03/02

Page 26

C2.8 T854 Circuit Operation M800 SL2

2.5 Audio Processor

(Refer to the audio processor circuit diagram (sheet 2) in Section 6.2 or 6.3.)

Carrier

Opto-Key

Tx Key

PTT

Microphone

Input

Line Input

+

_

Constant Current Sink

Opto-coupler

Microphone

Pre-amp.

Audio 1 Audio 2

Link

34

5

PL205

Compressor

5

N

3

M

12

L

emphasis

B

6

C

mic.

Inputs

line

Multiplexer

Output

Inhibit

utput

O

6

4

Link

PL210

Figure 2.5 T854 Audio Processor Block Diagram

Pre-

Tx Enable

Link

3

4

H

5

6

I

7

8

J

PL215

Link

34

E

2

1

D

PL220

Buffer

Output

To VCO

Limiter

Set Deviation

Digital Pot. (EPOT)

Σ

Low Pass

Filter

Ref. Mod. Adjust

Digital Pot. (EPOT)

Integrator

Ref.

Mod.

CTCSS

2.5.1 General

The audio processor comprises several link selectable circuit blocks which may be configured in a variety of combinations to suit individual requirements. The pre-emphasis

network and compressor may be linked individually or cascaded between either or both

audio inputs and the limiter.

Refer to Section 3.5.1 for linking details.

2.5.2 Audio Inputs

Two audio inputs are available: one from a 600 ohm balanced (or unbalanced) line, and

the other from a local microphone. The microphone signal is passed first to a pre-amplifier (Q210) and ultimately to a multiplexer (IC240), but in between may pass through

the compressor (depending on the linking details). The line transformer is also connected to the multiplexer and is disabled by the microphone PTT switch.

A third input for external CTCSS tones is also provided.

01/03/02 Copyright TEL

Page 27

M800 SL2 T854 Circuit Operation C2.9

2.5.3 Keying Inputs

There are four ways to key the exciter:

• pulling the Tx-Key line low (pin 13 on D-range 1 [PL100]) at the rear of the set);

• pushing the "Carrier" button on the front panel - this will inhibit all audio;

• using the PTT button on the local microphone, disabling audio from the line;

• via the opto-key inputs (pins 11 and 12 on D-range 1 [PL100]) when electrical

isolation is required. This features a constant current sink (Q270) to ensure reliable activation of the opto-coupler (IC250) at low keying voltages.

2.5.4 Compressor (Automatic Level Control (ALC))

The input signal is fed via a current controlled attenuator (Q230, Q220) to a high gain

stage (IC230) from which the output signal is taken. This signal is passed to a comparator (IC230) which toggles whenever the audio signal exceeds a DC threshold determined by RV220. Thus, the comparator produces a square wave whose mark-space

ratio is determined by the amplitude of the audio signal. This square wave pumps up

the reservoir capacitor (C233) which controls the attenuator (Q230, Q220), thus completing the feedback loop.

The compression level is set by adjustment of the comparator threshold (RV220).

Note: Although the high dynamic range of the compressor allows the use of very

low audio signal levels, such conditions will be accompanied by a degradation of the signal-to-noise ratio. Very low audio input levels should therefore be avoided where possible.

2.5.5 Outputs To Modulators

The output signal from the limiter (IC210, IC230) is summed with a CTCSS tone at a

summing amplifier (IC260). The signal is then low pass filtered (IC260) and split to supply the two modulators.

Since the VCO modulator is a true frequency modulator, its audio is simply buffered

(IC260). The reference modulator, however, is a phase modulator and its audio must

first be integrated (IC210).

It is vital that the audio levels to the modulators are accurately set,

other. Hence the inclusion of level adjustment in the reference modulator path. Once

set, adjustments to absolute deviation may be made only by IC220, a 256-step 10k electronic potentiometer (EPOT), which is controlled via PGM800Win. The EPOT is made

up of 256 resistive sections (representing approximately 39Ω each) which can be individually addressed by the microcontroller. Each section can be switched in or out of circuit to achieve the required total resistance, thus adjusting the absolute deviation level.

relative to each

Copyright TEL 01/03/02

Page 28

C2.10 T854 Circuit Operation M800 SL2

2.6 Power Supply & Regulator Circuits

(Refer to the regulators circuit diagram (sheet 6) in Section 6.2 or 6.3.)

Figure 2.6 T854 Power Supply & Regulators Block Diagram

+9V

Buffer

PS

Power

Switch

5V Dig

Reg

Tx Reg.

Watchdog

Timer

LVI

µP

µP

Reset

13.8V Nom.

From Rear

D-Range

Crowbar

Diode

Tx Enable

IC 370

9v Reg

5V

Reg

9v Ex

Micro-

controller

DC

Amp

Switching

13.8V

Nom.

5V 5V Dig9V 20V

The T854 are designed to operate from a 10.8-16V DC supply (13.8V nominal). A 5.3V

regulator (IC630) runs directly from the 13.8V rail, driving much of the synthesiser circuitry. It is also used as the reference for a DC amplifier (IC640, Q630, Q620) which provides a medium current capability 9V supply. The T854 has a regulator (IC370) which

produces 9V for use in the exciter and audio circuits.

A switching power supply (Q660, Q670) runs from the 9V supply and provides a low

current capability +20V supply. This is used to drive the synthesiser loop filter (IC750),

giving a VCO control voltage range of up to 20V.

Ultimate control of the transmitter is via the Tx-Reg. supply, switched from 9V by Q610.

This is enabled via the Tx-Enable signal from the audio processor, and microprocessor.

A crowbar diode is fitted for protection against connection to a power supply of incorrect polarity. It also provides transient overvoltage protection.

Note: A fuse must be fitted in the power supply line for the diode to provide effec-

tive protection.

01/03/02 Copyright TEL

Page 29

M800 SL2 T854 Circuit Operation C2.11

2.7 Transmit Timers

The transmit tail timer, transmit timeout timer and transmit lockout timer can all be set

from PGM800Win. The fields for setting these are found on the system information

page. These three timers operate as follows (refer also to Figure 2.7):

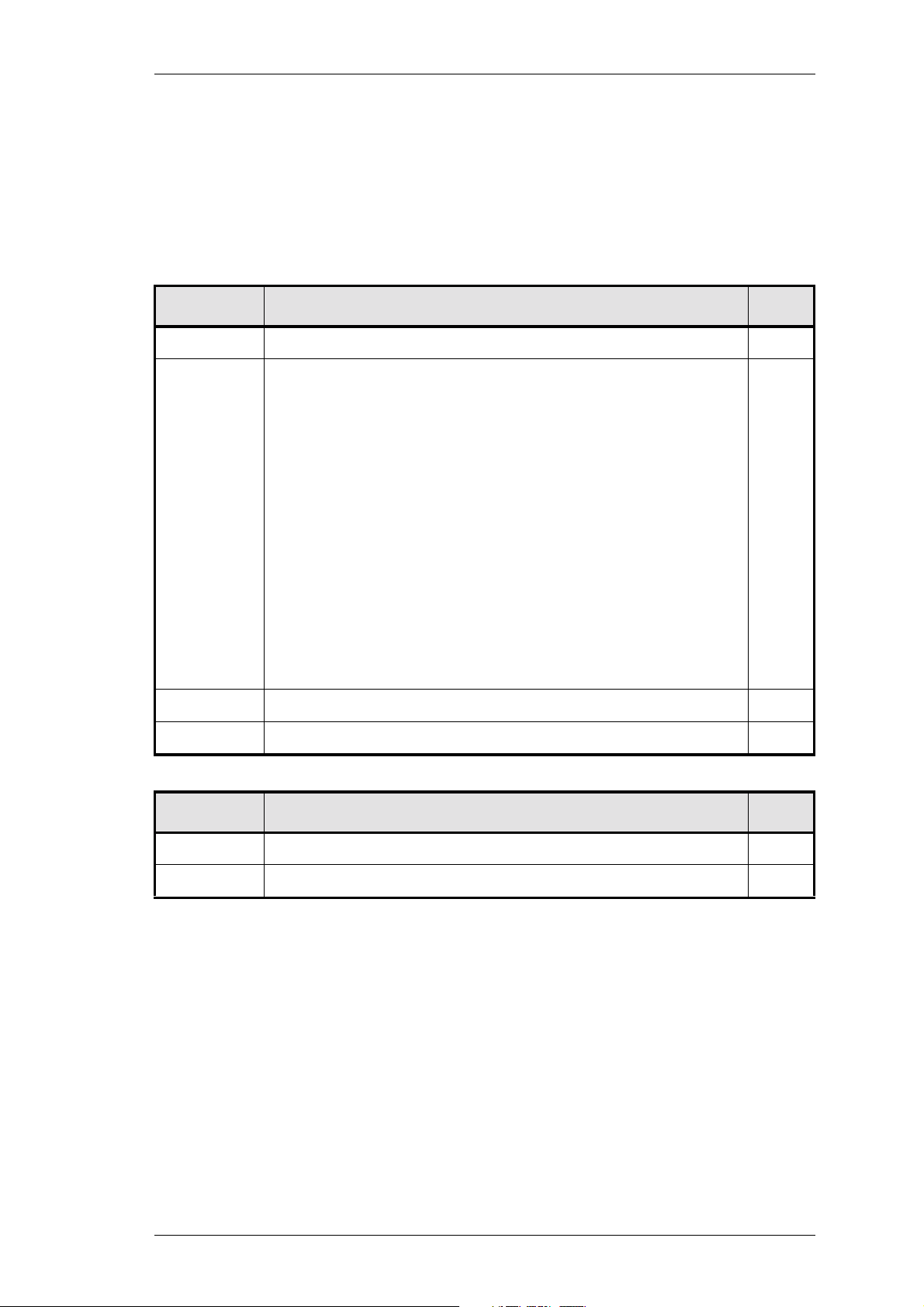

Timer Function Adjustment

Transmit Tail Sets the tail time during which the

transmitter stays keyed after the external key source has been removed.

Transmit Timeout Sets the maximum continuous trans-

mission time. Once the timer has

timed out, the transmitter must be

keyed again, unless prevented by the

transmit lockout timer.

Transmit Lockout Sets the period of time that must

elapse after a timeout before the transmitter can re-transmit. Once the timer

has timed out, the transmitter can be

keyed again.

a. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

b. Adjustable from 0 to 600 seconds in PGM800Win version 2.12 and later.

Tx-Enable

On

Tx-Enable

Tx-Reg.

0-5 seconds in 100ms

a

steps

0-300 seconds

b

in 10

second steps

0-60 seconds in 10

second steps

Tail Time

On

Tx-Reg.

Lockout Time

Timeout

Time

Figure 2.7 T854 Transmit Timers

Copyright TEL 01/03/02

Page 30

C2.12 T854 Circuit Operation M800 SL2

2.8 T854 Drive Amplifier & PA

(Refer to Figure 2.1 and the exciter and PA circuit diagrams (sheets 3 & 4) in Section 6.2.)

The output power of the PA is maintained at a constant level via a power control loop

applied to the two-stage, wide band exciter amplifier (Q337, Q336). The forward and

reverse RF power levels are sensed via a dual directional coupler and detector diodes

(D440, D420 in the PA cavity). The detected DC signals are buffered (IC330 pins 3 & 5)

and then summed with the ’power control’ level and fed to the control integrator (IC350

pin 6).

Note: Forward and reflected power signals are summed so that, under high

VSWR, the power control will turn the output RF level down.

To reduce the spurious output level when the synthesiser is out-of-lock, the Tx-Reg. and

Lock-Detect signals are gated to inhibit the PA control circuit and to switch off the RF

signal at the input to the drive amplifier. This is achieved by a PIN switch attenuator

(D340, D380, D360).

Cyclic keying control is provided by additional circuitry consisting of several time

delay, ramp and gate stages:

• Q330, IC350 power ramping

• Q326, Q325 Tx-Reg. and Lock-Detect

• Q335, Q340, Q345 delay and PIN switch drive.

This is to allow the RF power circuits (both exciter and PA) to ramp up and down in a

controlled manner so that minimal adjacent channel interference is generated during

the transition.

The output of the wide band amplifier is approximately 1W (+30dBm) for an input of

100mW (+20dBm) from the VCO, when the power control is set to maximum.

A temperature sensor (R481) is provided so that the RF output power can be reduced to

a preset level when a set temperature is exceeded. This is a protection circuit (IC350 pin

1, Q320) to prevent overheating.

#R517, #R518 and #R519 form an attenuator to provide good VCO/exciter isolation as

well as the correct exciter drive level.

The attenuator (#R395, #R396 and #R397) aids in producing the correct exciter drive

level to the PA over the three frequency ranges.

gate

The RF output from the exciter is fed to the driver stage (Q410) and then to the final

(Q420). DC is fed to the final via a low pass filter with special low frequency decoupling. CV475 tunes the output matching across the entire band.

01/03/02 Copyright TEL

Page 31

M800 SL2 T854 Circuit Operation C2.13

Copyright TEL 01/03/02

Page 32

C2.14 T854 Circuit Operation M800 SL2

01/03/02 Copyright TEL

Page 33

M800 SL2 T854 Initial Tuning & Adjustment C3.1

3 T854 Initial Tuning & Adjustment

Caution: This equipment contains CMOS devices which are susceptible to dam-

age from static charges. Refer to Section 1.2 in Part A for more information on anti-static procedures when handling these devices.

The following section describes both short and full tuning and adjustment procedures

and provides information on:

• channel programming

• selecting required audio links

• synthesiser alignment

• PA alig nment

• modulator adjustment

• limiter adjustment

• setting line level

• compressor adjustment

• timer adjustment.

Note: Unless otherwise specified, the term "PGM800Win" used in this and follow-

ing sections refers to version 3.00 and later of the software.

Refer to Figure 4.4 and Figure 4.5 which show the location of the main tuning and

adjustment controls. Refer also to Section 6 where the parts lists, grid reference index

and diagrams will provide detailed information on identifying and locating components and test points on the main PCB. The parts list and diagrams for the VCO PCB are

in Part E.

Section Title Page

3.1 Introduction 3.3

3.2 Channel Programming 3.3

3.3 Test Equipment Required 3.4

3.4

Short Tuning Procedure

3.5

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

Copyright TEL 01/03/02

Introduction

Synthesiser Alignment

Output Power Adjustment

Two Point Modulation Adjustment

CTCSS Encoder (If Used)

FM Deviation (Limiter) Adjustment

Line-in Level Adjustment

3.5

3.5

3.5

3.6

3.7

3.7

3.7

Page 34

C3.2 T854 Initial Tuning & Adjustment M800 SL2

Section Title Page

3.5

3.5.1

3.5.2

3.6 Synthesiser Alignment 3.9

3.7 PA Alignment 3.10

3.8 Thermal Shutdown 3.10

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

3.9.6

3.9.6.1

3.9.6.2

3.9.6.3

Audio Processor Links

Link Details

Typical Options

Audio Processor & CTCSS

Two Point Modulation

Modulator Adjustment

CTCSS Encoder (If Used)

Limiter Adjustment

Line Level Without Compressor

Compressor

Compressor On Line Input Only

Compressor On Microphone Input Only

Compressor On Both Line & Microphone Inputs

3.8

3.8

3.8

3.11

3.11

3.11

3.12

3.12

3.13

3.13

3.13

3.13

3.14

Figure Title Page

3.1

3.2

T854 Test Equipment Set-up With T800-01-0010

T854 Test Equipment Set-up Without T800-01-0010

3.4

3.4

01/03/02 Copyright TEL

Page 35

M800 SL2 T854 Initial Tuning & Adjustment C3.3

3.1 Introduction

When you receive your T854 transmitter it will be run up and working on a particular

frequency (the "default channel")

the 8MHz switching range (i.e. ±4MHz from the factory programmed frequency), you

should only need to reprogram the transmitter/exciter with the PGM800Win software

(refer to the PGM800Win programming kit and Section 3.2 below).

However, if you want to switch to a frequency outside the 8MHz switching range, you

will have to reprogram and re-tune the transmitter/exciter to ensure correct operation.

In this case you should carry out the short tuning procedure described in Section 3.4.

If you have carried out repairs or other major adjustments, you must carry out the full

tuning and adjustment procedure described in this section (except for Section 3.4).

1

. If you want to switch to a frequency that is within

3.2 Channel Programming

You can program up to 128 channel frequencies into the transmitter/exciter’s EEPROM

memory (IC820) by using the PGM800Win software package and an IBM

also use PGM800Win to select the transmitter/exciter’s current operating frequency (or

"default channel").

PC. You can

If the transmitter/exciter is installed in a rack frame, you can program it via the programming port in the speaker panel. However, you can also program the transmitter/

exciter before it is installed in a rack frame as follows:

• by using a T800-01-0010 calibration test unit;

• via D-range 1;

• via D-range 2 (standard T800-03-0000 auxiliary D-range only);

• via SK805 (internal Micromatch connector).

If you do not use the T800-01-0010, you will have to connect the PC to the transmitter/

exciter via a module programming interface (such as the T800-01-0004).

For a full description of the channel programming procedure, refer to the PGM800Win

programming software user’s manual.

Note: When an auxiliary D-range kit (D-range 2 - T800-03-0000) is fitted, you can

also select a channel with an external switch, such as the DIP switch on the

rack frame backplane PCB. Refer to Part C in the T800 Series Ancillary

Equipment Service Manual (M800-00-101 or later issue) or consult your

nearest Tait Dealer or Customer Service Organisation for further details.

1. Use the "Read Module" function in PGM800Win to find out what the default channel is.

Copyright TEL 01/03/02

Page 36

C3.4 T854 Initial Tuning & Adjustment M800 SL2

800

800

3.3 Test Equipment Required

You will need the following test equipment:

• computer with PGM800Win installed

• T800 programming kit

• module programming interface (e.g. T800-01-0004 - optional)

• 13.8V power supply

• digital multimeter

• audio signal generator

• RF power meter

• audio voltmeter x 2

or RF test set (optional)

• modulation meter

• oscilloscope (digital preferred)

• 20dB or 40dB pad

• T800-01-0010 calibration test unit (optional)

Figure 3.1 and Figure 3.2 show typical test equipment set-ups.

PSU

Audio

Generator

PGM

Voltmeter

Win

Audio

+13.8V

-Ve

Ω600

Line I/P

CTCSS I/P

T800

Calibration

Test Unit

Exciter/

Transmitter

Figure 3.1 T854 Test Equipment Set-up With T800-01-0010

20dB pad: exciter

40dB pad: transmitter

RF O/P

RF Power

Meter

Audio

Voltmeter

Frequency

Counter

AF O/P

Modulation

Meter

Oscilloscope

PSU

Audio

Generator

PGM

Voltmeter

Win

+13.8V

-Ve

Ω600

Audio

Line I/P

CTCSS I/P

Exciter/

Transmitter

Serial

via module programming interface

(e.g. T800-01-0004)

Com

RF O/P

Key

20dB pad: exciter

40dB pad: transmitter

RF Power

Meter

Audio

Voltmeter

Frequency

Counter

AF O/P

Modulation

Meter

Oscilloscope

Figure 3.2 T854 Test Equipment Set-up Without T800-01-0010

01/03/02 Copyright TEL

Page 37

M800 SL2 T854 Initial Tuning & Adjustment C3.5

3.4 Short Tuning Procedure

Use this procedure only if you want to reprogram the T854 to a frequency outside the

8MHz switching range and do not intend to carry out any other major adjustments or

repairs.

3.4.1 Introduction

Reprogram the operating frequency as described in the PGM800Win programming kit (refer to Section 3.2).

Remove the top cover (nearest the handle).

Set up the test equipment as described in Section 3.3.

Set the links in the audio processor section as required (refer to Section 3.5).

3.4.2 Synthesiser Alignment

• Connect a high impedance voltmeter to the long lead of L1 in the VCO (this measures the synthesiser loop voltage).

• Key the transmitter by earthing the Tx-Key line.

• Single Channel Tune VCO trimmer C6 for a synthesiser loop voltage of

10V.

Multichannel Tune VCO trimmer C6 for a synthesiser loop voltage of

10V on the middle channel.

If there is no middle channel, tune C6 so that the channels

are symmetrically placed around a loop voltage of 10V.

All channels should lie within the upper and lower limits

of 16V and 3V respectively.

Do not attempt to program channels with a greater fre-

quency separation than the specified switching range of

8MHz.

3.4.3 Output Power Adjustment

Connect an RF power meter with suitable attenuation to the output socket and

key the transmitter.

Turn RV310 (power control) fully clockwise.

Tune #CV475 (output power trim) for maximum output power and check that this

is >30W.

Adjust RV310 for the required output power (between 5 and 25W).

Readjust #CV475 to reduce the supply current by up to 0.5A.

Copyright TEL 01/03/02

Page 38

C3.6 T854 Initial Tuning & Adjustment M800 SL2

3.4.4 Two Point Modulation Adjustment

Note 1: In this and following sections deviation settings are given first for wide

bandwidth sets, followed by settings in brackets for mid bandwidth sets ( )

and narrow bandwidth sets [ ].

Note 2: The reference modulation and limiter adjustments are controlled by 256-

step electronic potentiometers (EPOTs), which are adjusted via the “Refer-

ence Modulation” and “Deviation” settings in PGM800Win. This allows the

two point modulation and deviation settings to be adjusted for each channel.

Note 3: To optimise the modulation response across the switching range, repeat

steps 1-4 below for each channel that will be used (usually needed only for

data applications). In applications where the modulation response is less

critical (e.g. voice use only), carry out steps 1-4 below on the middle channel

and use the “EPOT Fill” option

other channels.

Note 4: If you are using an RF test set, turn the low pass filter off and set the high

pass filter to 15kHz

before beginning this procedure.

1

in PGM800Win to copy the value to the

1. Inject an audio signal of 300Hz 1.5V rms (+5dBm) into the CTCSS input (D-range

1 (PL100) pin 8).

Key the transmitter by earthing the Tx-Key line.

2. Adjust the output from the audio generator to obtain ±3kHz (±2.4kHz) [±1.5kHz]

deviation at 300Hz.

3. Change the input frequency to 100Hz and, using PGM800Win, adjust the value of

the “Reference Modulation” EPOT setting for the current channel to obtain ±3kHz

(±2.4kHz) [±1.5kHz] deviation (you can use either the mouse or up and down

arrow keys).

4. Change the input frequency back to 300Hz.

Repeat steps 2 and 3 above until the deviations achieved at the two input frequen-

cies are within 0.2dB of each other. You will need to do this at least four times.

5. Sweep the audio between 50 and 300Hz for peaks.

Note: A peak between 50 and 300Hz will indicate a fault condition, i.e:

- incorrect set-up

or - modulation circuitry fault.

The specification window is ±1dB relative to 150Hz from 67 to 260Hz.

1. Use the “EDIT FILL” button on the tool bar or go to “Edit”, “Fill”, “Epot Settings” on

the menu bar.

01/03/02 Copyright TEL

Page 39

M800 SL2 T854 Initial Tuning & Adjustment C3.7

3.4.5 CTCSS Encoder (If Used)

Program a CTCSS tone on the default channel using PGM800Win.

If you are using an RF test set, turn off the 300Hz high pass filter.

Key the T854 with the front panel "Carrier" switch.

Adjust RV805 (CTCSS level adjust) to give ±500Hz (±350Hz) [±250Hz] deviation.

Set the maximum deviation as per Section 3.4.6.

3.4.6 FM Deviation (Limiter) Adjustment

Note: If the T854 will be used over the whole 8MHz switching range, you must set

the deviation for each channel. However, if the module will be used on frequencies that cover only a 1MHz (or less) switching range, you can set the

deviation on the middle channel and use this value for all other channels

with the “EPOT Fill” option in PGM800Win.

Inject 1kHz at -10dBm into the line input (D-range 1 (PL100) pins 1 & 4; pins 2 & 3

shorted; refer to Section 2.2 of Part F).

Adjust RV210 (line sensitivity) fully clockwise and key the transmitter by earthing

the Tx-Key line. Using PGM800Win, adjust the value of the “Deviation” EPOT

setting for the current channel to obtain a deviation limit of ±4.7kHz (±3.8kHz)

[±2.3kHz] (you can use either the mouse or up and down arrow keys).

Sweep the audio frequency from 100Hz to 4kHz and ensure that the maximum

deviation does not exceed ±4.7kHz (±3.8kHz) [±2.3kHz]. Readjust “Deviation” if

necessary via PGM800Win.

3.4.7 Line-in Level Adjustment

Remove the CTCSS signal (if used).

Set the injected signal at the line input to the required line level (typically -10 to

-20dBm).

Adjust RV210 (line sensitivity) to provide ±3kHz (±2.4kHz) [±1.5kHz] deviation.

Reapply the CTCSS signal (if required).

Copyright TEL 01/03/02

Page 40

C3.8 T854 Initial Tuning & Adjustment M800 SL2

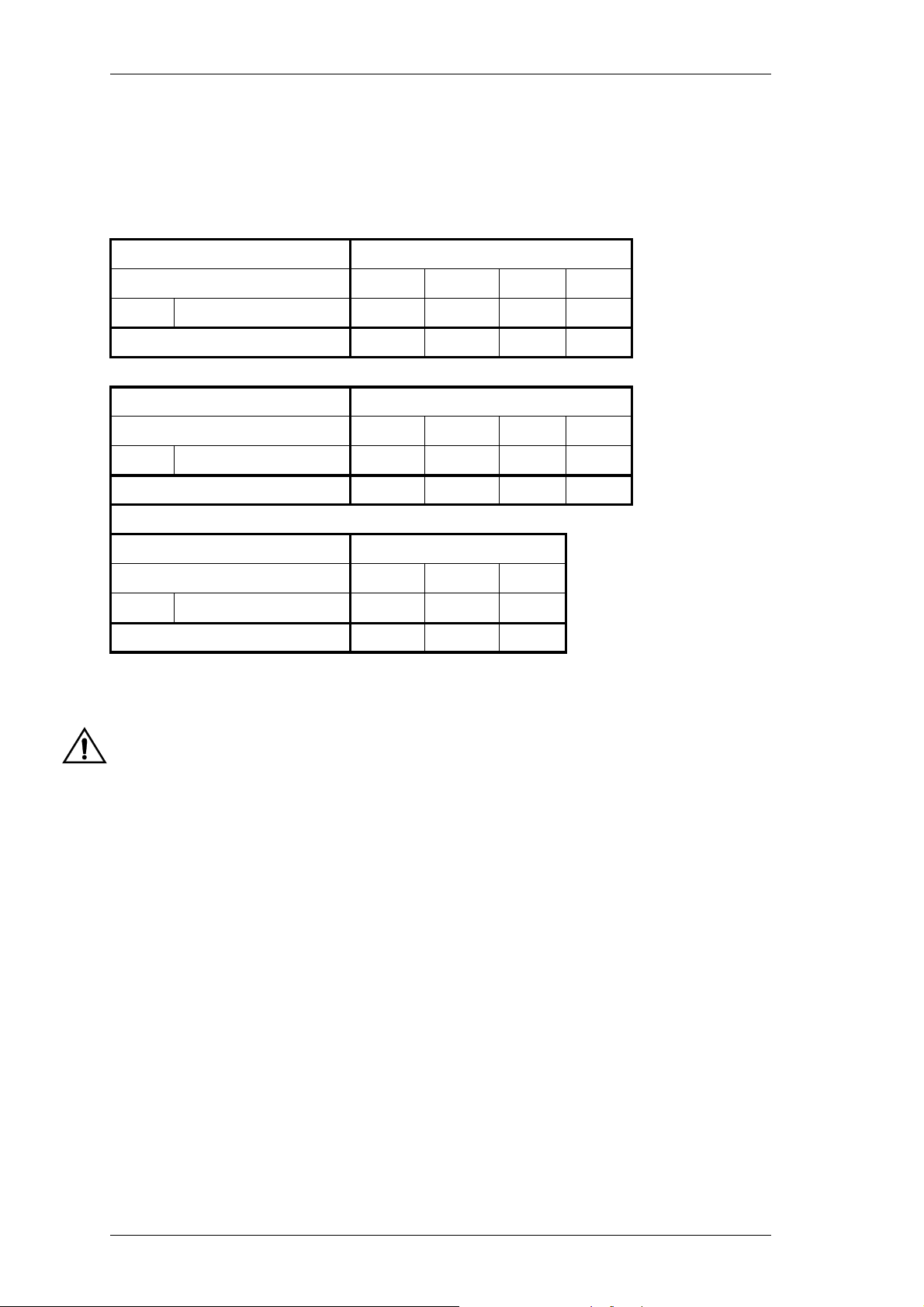

3.5 Audio Processor Links

3.5.1 Link Details

Use the following table to set up the audio processor to the configuration you require.

You should set the audio processor links before carrying out any of the tuning and

adjustment procedures. The factory settings are shown in brackets [ ].

Plug Link

1-2

PL205

PL210

PL215

PL220

a. The letters in this column and in the table in Section 3.5.2 below refer to the identification

letters screen printed onto the PCB beside each pair of pins.

[3-4]

5-6

[1-2]

3-4

5-6

1-2

[3-4]

5-6

7-8

9-10

1-2

[3-4]

5-6

a

A

B

C

L

M

N

G

H

K

D

E

F

not connected

microphone pre-amp. output to compressor input

microphone pre-amp. output to multiplexer input

multiplexer output to pre-emphasis input

multiplexer output to limiter input

multiplexer output to compressor input

not connected

compressor output to multiplexer input

compressor output to limiter input

I

compressor output to pre-emphasis input

J

not connected

pre-emphasis output to multiplexer input

pre-emphasis output to limiter input

not connected

Function

3.5.2 Typical Options

PL205 PL210 PL215 PL220

microphone pre-amp. compressed

and pre-emphasised;

line input pre-emphasised

(standard set-up)

microphone pre-amp. compressed

and pre-emphasised;

line input unprocessed

line and microphone compressed

and pre-emphasised

microphone pre-amp. compressed;

line and microphone flat response

01/03/02 Copyright TEL

[3-4]

B

3-4

B

5-6

C

3-4

B

[1-2]

L

3-4

M

5-6

N

3-4

M

[3-4]

H

7-8

J

7-8

J

3-4

H

[3-4]

E

1-2

D

3-4

E

5-6

F

Page 41

M800 SL2 T854 Initial Tuning & Adjustment C3.9

3.6 Synthesiser Alignment

• Ensure that the T854 has been programmed with the required frequencies using

PGM800Win software.

• Single Channel Select a channel using PGM800Win.

Multichannel Select the middle channel via PGM800Win.

• Connect a high impedance voltmeter to the long lead of L1 in the VCO (this measures the synthesiser loop voltage).

• Key the transmitter by earthing the Tx-Key line.

Single Channel Tune VCO trimmer C6 for a synthesiser loop voltage of

10V.

Multichannel Tune VCO trimmer C6 for a synthesiser loop voltage of

10V on the middle channel.

If there is no middle channel, tune C6 so that the channels

are symmetrically placed around a loop voltage of 10V.

All channels should lie within the upper and lower limits

of 16V and 3V respectively.

Do not attempt to program channels with a greater fre-

quency separation than the specified switching range

(8MHz).

• Measure the exciter output frequency and adjust the TCXO (=IC700) trimmer if

required.

Caution: This trimmer is susceptible to physical damage. Do not exert a down-

ward force of more than 500g (1lb) when adjusting.

Copyright TEL 01/03/02

Page 42

C3.10 T854 Initial Tuning & Adjustment M800 SL2

3.7 PA Alignment

Check that the exciter is connected to the PA with the coaxial link.

Connect an RF power meter to the PA output (use an appropriate attenuator as

necessary).

Turn RV310 (power control) fully clockwise.

Key the transmitter by earthing the Tx-Key line.

Tune #CV475 until maximum power is obtained. Check that the power exceeds

30W.

Adjust RV310 (power control) to 25W.

Readjust #CV475 to reduce the supply current by up to 0.5A.

3.8 Thermal Shutdown

Key the transmitter by earthing the Tx-Key line and set the output power to 25W

as described in Section 3.7.

Short L481 to ground.

Set RV330 (shutdown power level) for an output power of 5W.

01/03/02 Copyright TEL

Page 43

M800 SL2 T854 Initial Tuning & Adjustment C3.11

3.9 Audio Processor & CTCSS

3.9.1 Two Point Modulation

The T854 utilise two point modulation to obtain a wide audio bandwidth independent

of the synthesiser loop filter response. This is achieved by simultaneously frequency

modulating the VCO and phase modulating the synthesiser reference frequency. The

relative signal levels fed to the two modulators are quite critical and cause interaction

when setting up.

Both modulating signals require readjustment when the exciter is shifted in frequency

greater than the switching range (i.e.

Note 1: In this and following sections deviation settings are given first for wide

bandwidth sets, followed by settings in brackets for mid bandwidth sets ( )

and narrow bandwidth sets [ ].

Note 2: The reference modulation and limiter adjustments are controlled by 256-

step electronic potentiometers (EPOTs), which are adjusted via the “Refer-

ence Modulation” and “Deviation” settings in PGM800Win. This allows the

two point modulation and deviation settings to be adjusted for each channel.

∆F>±4MHz).

Note 3: To optimise the modulation response across the switching range, repeat

steps 1-4 below for each channel that will be used (usually needed only for

data applications). In applications where the modulation response is less

critical (e.g. voice use only), carry out steps 1-4 below on the middle channel

and use the “EPOT Fill” option

other channels.

Note 4: If you are using an RF test set, turn the low pass filter off and set the high

pass filter to 15kHz

before beginning this procedure.

1

in PGM800Win to copy the value to the

3.9.2 Modulator Adjustment

1. Inject an audio signal of 300Hz 1.5V rms (+5dBm) into the CTCSS input (D-range

1 (PL100) pin 8).

Key the transmitter by earthing the Tx-Key line.

2. Adjust the output from the audio generator to obtain ±3kHz (±2.4kHz) [±1.5kHz]

deviation at 300Hz.

3. Change the input frequency to 100Hz and, using PGM800Win, adjust the value of

the “Reference Modulation” EPOT setting for the current channel to obtain ±3kHz

(±2.4kHz) [±1.5kHz] deviation (you can use either the mouse or up and down

arrow keys).

1. Use the “EDIT FILL” button on the tool bar or go to “Edit”, “Fill”, “Epot Settings” on

the menu bar.

Copyright TEL 01/03/02

Page 44

C3.12 T854 Initial Tuning & Adjustment M800 SL2

4. Change the input frequency back to 300Hz.

Repeat steps 2 and 3 above until the deviations achieved at the two input frequen-

cies are within 0.2dB of each other. You will need to do this at least four times.

5. Sweep the audio between 50 and 300Hz for peaks.

Note: A peak between 50 and 300Hz will indicate a fault condition, i.e:

- incorrect set-up

or - modulation circuitry fault.

The specification window is ±1dB relative to 150Hz from 67 to 260Hz.

3.9.3 CTCSS Encoder (If Used)

Program a CTCSS tone on the default channel using PGM800Win.

If you are using an RF test set, turn off the 300Hz high pass filter.

Key the T854 with the front panel "Carrier" switch.

Adjust RV805 (CTCSS level adjust) to give ±500Hz (±350Hz) [±250Hz] deviation.

Set the maximum deviation as per Section 3.9.4.

3.9.4 Limiter Adjustment

Note: If the T854 will be used over the whole 8MHz switching range, you must set

the deviation for each channel. However, if the module will be used on frequencies that cover only a 1MHz (or less) switching range, you can set the

deviation on the middle channel and use this value for all other channels

with the “EPOT Fill” option in PGM800Win.

Set the links in the audio processor section as required (refer to Section 3.5).

Inject 1kHz at -10dBm into the line input (D-range 1 (PL100) pins 1 & 4; and pins 2

& 3 shorted; refer to Section 2.2 of Part F).

Adjust RV210 (line sensitivity) fully clockwise and key the transmitter by earthing

the Tx-Key line. Using PGM800Win, adjust the value of the “Deviation” EPOT

setting for the current channel to obtain a deviation limit of ±4.7kHz (±3.8kHz)

[±2.3kHz] (you can use either the mouse or up and down arrow keys).

Sweep the audio frequency from 100Hz to 4kHz and ensure that the maximum

deviation does not exceed ±4.7kHz (±3.8kHz) [±2.3kHz]. Readjust “Deviation” if

necessary via PGM800Win.

01/03/02 Copyright TEL

Page 45

M800 SL2 T854 Initial Tuning & Adjustment C3.13

3.9.5 Line Level Without Compressor

This section assumes that the compressor is not used. If the compressor is required,

refer to Section 3.9.6.

Remove the CTCSS signal (if used).

Adjust the line sensitivity as follows:

• set the injected signal at the line input to the required line level (typically -10 to

-20dBm);

• adjust RV210 (line sensitivity) to provide ±3kHz (±2.4kHz) [±1.5kHz] deviation.

Reapply the CTCSS signal (if required).

3.9.6 Compressor

The compressor may be used on the line input only, the microphone input only, or on

both the line and microphone inputs. If the compressor is used, refer to one of the following sections as appropriate.

3.9.6.1 Compressor On Line Input Only

Set RV210 (line sensitivity) fully clockwise and key the transmitter by earthing the

Tx-Key line.

Reduce the line level to -50dBm at 1kHz and set RV220 (compression level) fully

clockwise.

Check that ±3kHz deviation (±2.4kHz) [±1.5kHz] is still available.

Slowly increase the audio input level until the demodulated waveform shows significant signs of clipping (approximately ±4.5kHz (±3.6kHz) [±2.3kHz] deviation).

Adjust RV220 anticlockwise until the demodulated waveform is just clipping

(approximately ±4kHz (±3.2kHz) [±2kHz] deviation).

Increase the input level to -10dBm and check that the test tone is still held just into

clipping. The input line level should be typically -10 to -20dBm.

3.9.6.2 Compressor On Microphone Input Only

Key the transmitter by earthing the Tx-Key line and plug a microphone jack into

the front panel socket.

Adjust RV220 (compression level) fully clockwise.

Acoustically couple the microphone to a tone box (1kHz) and close the PTT

switch.

Copyright TEL 01/03/02

Page 46

C3.14 T854 Initial Tuning & Adjustment M800 SL2

Increase the audio level until the demodulated waveform shows significant signs

of clipping (approximately ±4.5kHz (±3.6kHz) [±2.3kHz] deviation).

Adjust RV220 anticlockwise until the demodulated waveform is just clipping

(approximately ±4kHz (±3.2khz) [±2kHz] deviation).

Increase the audio level by 10dB and verify that the test tone is held just into clipping.

Whistle steadily into the microphone, checking that approximately ±4kHz

(±3.2khz) [±2kHz] deviation is produced. The modulated waveform should be

basically sinusoidal.

Speak into the microphone, checking that the modulation peaks reach about

±5kHz (±4kHz) [±2.5kHz] deviation.

As the line is to be used without compression, set RV210 (line sensitivity) as

described in Section 3.9.5.

3.9.6.3 Compressor On Both Line & Microphone Inputs

Set up as described in Section 3.9.6.1.

01/03/02 Copyright TEL

Page 47

M800 SL2 T854 Functional Testing C4.1

4 T854 Functional Testing

Caution: This equipment contains CMOS devices which are susceptible to dam-

age from static charges. Refer to Section 1.2 in Part A for more information on anti-static procedures when handling these devices.

The following test procedures will confirm that the T854 has been tuned and adjusted

correctly and is fully operational.

Note 1: In this and following sections deviation settings are given first for wide

bandwidth sets, followed by settings in brackets for mid bandwidth sets ( )

and narrow bandwidth sets [ ].

Note 2: Unless otherwise specified, the term "PGM800Win" used in this and follow-

ing sections refers to version 3.00 and later of the software.

Refer to Figure 4.4 and Figure 4.5 for the location of the main tuning and adjustment

controls, and to Section 3.3 for the test equipment set-up. Refer also to Section 6 where

the parts lists, grid reference index and diagrams will provide detailed information on

identifying and locating components and test points on the main PCB. The parts list

and diagrams for the VCO PCB are in Part E.

The following topics are covered in this section.

Section Title Page

4.1 Current Consumption 4.3

4.2 Output Power 4.3

4.3 Output Frequency 4.3

4.4 Timers 4.3

4.5 Frequency Response 4.4

4.6 Audio Level Input Sensitivity 4.7

Figure Title Page

4.1

4.2

4.3

T854 Transmit Timers

T854 Pre-emphasis Response

T854 Limiting Response

4.4

4.5

4.6

4.4

4.5

Copyright TEL 01/03/02

T854 Main Tuning & Adjustment Controls

T857 Main Tuning & Adjustment Controls

4.9

4.11

Page 48

C4.2 T854 Functional Testing M800 SL2

01/03/02 Copyright TEL

Page 49

M800 SL2 T854 Functional Testing C4.3

4.1 Current Consumption

Connect the T854 to a 13.8V power supply.

Connect an RF power meter to the T854 output socket.

Check that the current in the 13.8V power cable is less than 150mA.

Key the T854 by earthing the Tx-Key line (the carrier "On" LED should light).

T854 Only: Adjust RV310 (power control) to obtain 25W output power.

Check that the current is as follows:

T854 <5.5A

4.2 Output Power

Connect an RF power meter with suitable attenuation to the T854 output socket.

Key the T854 by earthing the Tx-Key line.

Check that:

T854 the output power adjusts to ≥25W with RV310 (power control)

turned fully clockwise

4.3 Output Frequency

Connect the T854 output to a frequency counter via an attenuator pad:

T854 40dB pad

T857 20dB pad.

Measure the output frequency and, if necessary, adjust the TCXO (=IC700) to trim

to the nominal frequency (±100Hz).

4.4 Timers

The transmit tail timer, transmit timeout timer and transmit lockout timer can all

be set from PGM800Win. The fields for setting these are found on the system

information page. These three timers operate as follows (refer also to Figure 4.1):

Timer Function Adjustment

Copyright TEL 01/03/02

Page 50

C4.4 T854 Functional Testing M800 SL2

Transmit Tail Sets the tail time during which the

transmitter stays keyed after the external key source has been removed.

Transmit Timeout Sets the maximum continuous trans-

mission time. Once the timer has

timed out, the transmitter must be

keyed again, unless prevented by the

transmit lockout timer.

Transmit Lockout Sets the period of time that must

elapse after a timeout before the transmitter can re-transmit. Once the timer

has timed out, the transmitter can be

keyed again.

a. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

b. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

Tx-Enable

On

Tx-Enable

Tx-Reg.

0-5 seconds in 100ms

a

steps

0-300 seconds

b

in 10

second steps

0-60 seconds in 10

second steps

Tail Time

On

Tx-Reg.

Lockout Time

Timeout

Time

Figure 4.1 T854 Transmit Timers

4.5 Frequency Response

If the T854 has been correctly adjusted, the pre-emphasis and limiting responses should

closely match those shown in Figure 4.2 and Figure 4.3 respectively.

Note: The limits shown on these graphs should not be exceeded.

• If you are using an RF test set, turn off all filters.

• Measure the pre-emphasis response as follows:

Reduce the line level to give ±1kHz (±0.8kHz) [±0.5kHz] deviation at 1kHz.

Sweep the modulation frequency.

The response should closely match that shown in Figure 4.2.

• Measure the limiting response as follows:

Set the line level to give ±3kHz (±2.4kHz) [±1.5kHz] deviation at 1kHz.

Increase the line level 20dB and sweep the modulation frequency.

01/03/02 Copyright TEL

Page 51

M800 SL2 T854 Functional Testing C4.5

The response should closely match that shown in Figure 4.3.

Wide Bandwidth

Peak + max. dev. = +1.0kHz @ 1000Hz

+10

+8

+6

+4

+2

1kHz)

+0

. @

-2

-4

-6

-8

-10

-12

-14

odulation Level (dB ref. to dev

-16

M

-18

-20

-22

Peak - max. dev. = -1.0kHz @ 1000Hz

100 200 300 500 1k 2k 3k 5k 10k

Frequency (Hz)

Mid Bandwidth

The mid bandwidth graph is the same shape as the wide bandwidth graph. The deviation figures are as follows:

peak + max. deviation = +0.8kHz

peak - max. deviation = -0.8kHz.

Narrow Bandwidth

Peak + max. dev. = +0.5kHz @ 1000Hz

+10

+8

+6

+4

+2

1kHz)

+0

. @

-2

-4

-6

-8

-10

-12

-14

odulation Level (dB ref. to dev

-16

M

-18

-20

-22

Peak - max. dev. = -0.5kHz @ 1000Hz

100 200 300 500 1k 2k 3k 5k 10k

Frequency (Hz)

Figure 4.2 T854 Pre-emphasis Response

Copyright TEL 01/03/02

Page 52

C4.6 T854 Functional Testing M800 SL2

Wide Bandwidth

Peak + max. dev. = +4.9kHz @ 1500Hz

+10

+8

+6

+4

.)

+2

+0

ax. dev

-2

-4

-6

-8

-10

-12

-14

odulation Level (dB ref. to m

M

-16

-18

-20

-22

Peak - max. dev. = -4.4kHz @ 2500Hz

Above limiting (steady-state)

10 20 30 200 1k 2k 3k 10k

100 500300 5k50

Frequency (Hz)

Mid Bandwidth

The mid bandwidth graph is the same shape as the wide bandwidth graph. The deviation figures are as follows:

peak + max. deviation = +4kHz

peak - max. deviation = -4kHz.

Narrow Bandwidth

Peak + max. dev. = +2.4kHz @ 2000Hz

+10

+8

+6

+4

.)

+2

+0

ax. dev

-2

-4

-6

-8

-10

-12

-14

odulation Level (dB ref. to m

M

-16

-18

-20

-22

Peak - max. dev. = -2.5kHz @ 2000Hz

Above limiting (steady-state)

10 20 30 200 1k 2k 3k 10k

100 500300 5k50

Frequency (Hz)

Figure 4.3 T854 Limiting Response

01/03/02 Copyright TEL

Page 53

M800 SL2 T854 Functional Testing C4.7

4.6 Audio Level Input Sensitivity

• Adjust RV210 (line sensitivity) fully clockwise.

• Check that the input sensitivities are better than those specified below:

Line Input 600 ohms, ±3kHz (±2.4kHz) [±1.5kHz] deviation at

1kHz:

with compressor -50dBm

without compressor -30dBm

Microphone Input 600 ohms, ±3kHz (±2.4kHz) [±1.5kHz] deviation at

1kHz:

with compressor -75dBm

without compressor -55dBm

CTCSS Input 1kHz deviation at 150Hz 500mV rms

Note: A degraded signal to noise ratio can be expected with the compressor

selected. The extent of the degradation is dependent on the audio input

level.

Copyright TEL 01/03/02

Page 54

C4.8 T854 Functional Testing M800 SL2

#CV475

L1

RV805

CTCSS

level adjust

SK805

=IC700

TCXO

R481

L481

C6

RV330

shutdown

power level

RV320

shutdown

temperature

RV310

power control

SW230

carrier

01/03/02 Copyright TEL

RV210

line sensitivity

RV220

compression level

PL205 PL220 PL215 PL210

Page 55

M800 SL2 T854 Fault Finding C5.1

5 T854 Fault Finding

Caution: This equipment contains CMOS devices which are susceptible to dam-

age from static charges. Refer to Section 1.2 in Part A for more information on anti-static procedures when handling these devices.

The following test procedures and fault finding flow charts may be used to help locate a

hardware problem, however they are by no means a complete fault finding procedure.

If you still cannot trace the fault after progressing through them in a logical manner,

contact your nearest Tait Dealer or Customer Service Organisation. If necessary, you

can get additional technical help from Customer Support, Radio Systems Division, Tait

Electronics Ltd, Christchurch, New Zealand (full contact details are on page 2).

Note 1: In this and following sections deviation settings are given first for wide

bandwidth sets, followed by settings in brackets for mid bandwidth sets ( )

and narrow bandwidth sets [ ].

Note 2: Unless otherwise specified, the term "PGM800Win" used in this and follow-

ing sections refers to version 3.00 and later of the software.

Refer to Section 6 where the parts lists, grid reference index and diagrams will provide

detailed information on identifying and locating components and test points on the

main PCB. The parts list and diagrams for the VCO PCB are in Part E.

The following topics are covered in this section

Section Title Page

5.1 Visual Checks 5.3

5.2 Component Checks 5.3

5.3 Front Panel LED Indicator 5.3

5.4

5.4.1

5.4.2

5.5

DC Checks

Power Rails

VCO Locking

RF Checks

5.4

5.4

5.4

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.6 PGM800Win Generated Errors 5.7

Copyright TEL 01/03/02

T854 Drive Power

T854 PA Output Power

T857 Output Power

Audio And Modulation

5.5

5.5

5.5

5.6

Page 56

C5.2 T854 Fault Finding M800 SL2

Section Title Page

5.7

5.7.1

5.7.1.1

5.7.1.2

5.7.1.3

5.7.2

5.7.3

5.7.4

5.7.5

5.7.7

5.8 To Replace The T854 PA Transistors (Q410 & Q420) 5.19

Fault Finding Charts

Microcontroller

Basic Checks

Serial Communications

CTCSS Encode

Regulator

Synthesiser

T854 Drive Amplifier

T854 PA & Power Control

Audio Processor

5.8

5.8

5.8

5.9

5.10

5.11

5.12

5.15

5.16

5.18

Figure Title Page

5.1

5.2

RF Diode Probe Circuit

Typical Transistor/Capacitor Spacing (Not To Scale)

5.5

5.19

01/03/02 Copyright TEL

Page 57

M800 SL2 T854 Fault Finding C5.3

5.1 Visual Checks

Remove the top cover from the T854 and inspect the PCB for damaged or broken components, paying particular attention to the surface mounted devices (SMD's).

Check for defective solder joints. If repair or replacement is considered necessary, refer

to Section 3 of Part A.

5.2 Component Checks

If you suspect a transistor is faulty, you can assess its performance by measuring the forward and reverse resistance of the junctions. Unless the device is completely desoldered, first make sure that the transistor is not shunted by some circuit resistance. Use a

good quality EVM (e.g. Fluke 75) for taking the measurements (or a 20k ohm/V or better multimeter, using only the medium or low resistance ranges).

The collector current drawn by multi-junction transistors is a further guide to their performance.

If an IC is suspect, the most reliable check is to measure the DC operating voltages. Due

to the catastrophic nature of most IC failures, the pin voltages will usually be markedly

different from the recommended values in the presence of a fault. The recommended

values can be obtained from either the circuit diagram or the component data catalogue.

5.3 Front Panel LED Indicator

The green "Supply" LED on the T854 front panel will flash according to the conditions

described in the following table:

Flash Rate Condition

fast (a sec. on/a sec. off

approx.)

unequal (a sec. on/1 sec. off

approx.)

T854 is linked with PGM800Win

microcontroller has detected an

internal communications error -

refer to Section 5.7.1

Where two or more conditions occur at the same time, the precedence is in the order

shown above (i.e. T854 linked has the highest priority, followed by internal error).

Copyright TEL 01/03/02

Page 58

C5.4 T854 Fault Finding M800 SL2

5.4 DC Checks

5.4.1 Power Rails

Refer to the test points and options diagrams in Section 6 for test point locations, and to

the regulator fault finding chart (Section 5.7.2) for fault diagnosis.

Check the 13.8V (TP601) and 9V (TP602) supplies at their test points in the regulator compartment with a DMM.

Check the 5V (TP604) and 20V (TP603) rails at their respective test points in the

regulator compartment.

Check that Tx-Reg. (TP305 in the exciter compartment) comes up to 8.8V when the

exciter is keyed.

Check the +5V digital regulator output (TP607 in the regulator compartment).

T854 Only: Check the 9V supply (IC370 pin 1) with a DMM.

Check for short circuits.

5.4.2 VCO Locking

Key the exciter.

Using a DMM, monitor the VCO control voltage between between L1 and PL14

pin1 on the VCO PCB.

If the synthesiser is locked and the VCO aligned, the voltage at this point should

be between 3 and 16V.

If the VCO is not locked, refer to the synthesiser fault finding chart (Section 5.7.3).

01/03/02 Copyright TEL

Page 59

M800 SL2 T854 Fault Finding C5.5

5.5 RF Checks

In-circuit RF levels may be measured with an RF probe on which the earth lead has been