Page 1

M830P-00 1

T830 Series II Paging

Base Station Equipment

148-174MHz

Initial Adjustment Manual

July 2000

M830P-00-1A0

Copyright TEL 01/07/00

Page 2

2 M830P-00

T800

T800

Head Office

New Zealand

Tait Electronics Ltd

558 Wairakei Road

P.O. Box 1645

Christchurch

New Zealand

Phone: 64 3 358-3399

Fax: 64 3 358-3636

Radio Systems Division

535 Wairakei Road

P.O. Box 1645

Christchurch

New Zealand

Phone: 64 3 358-3399

Fax: 64 3 358-2825

Australia

Tait Electronics (Aust) Pty Ltd

186 Granite Street

Geebung

Queensland 4034

P. O . B o x 67 9

Virginia

Queensland 4014

Australia

Phone: 61 7 3865-7799

Toll Free: 1800 077-112

Fax: 61 7 3865-7990

Beijing

Tait Mobile Radio (HK) Ltd

Beijing Representative Office

Room 812, Tower A

Beijing Bright China

Chang An Building

No. 7 Jianguomennei Dai Jei

Dongcheng District

Beijing

China 100005

Canada

Tait Mobile Radio Inc.

Unit 5, 158 Anderson Avenue

Markham

Ontario L6E1A9

Canada

Phone: 1 905 472-1100

Toll Free: 1 800 890-8248

Fax: 1 905 472-5300

France

Tai t F r an c e S a rl

2 Avenue de la Cristallerie

92 316 Sèvres, Cedex

France

Phone: 33 1 41 14-05-50

Fax: 33 1 41 14-05-55

Germany

Tait Mobilfunk GmbH

Willstätterstraße 50

D-90449 Nürnberg 60

Germany

Phone: 49 911 96 746-0

Fax: 49 911 96 746-79

Hong Kong

Tait Mobile Radio (HK) Ltd

Unit 2216, North Tower

Concordia Plaza

1, Science Museum Road

Tsim Sha Tsui East

Kowloon

Phone: 852 2369-3040

Fax: 852 2369-3009

New Zealand

Tait Communications Ltd

Unit 4, 75 Blenheim Road

P. O. Bo x 1 1 8 5

Christchurch

Phone: 64 3 348-3301

Fax: 64 3 343-0558

Singapore

Tait Electronics (Far East) Pte

Ltd

4 Leng Kee Road

SIS Building #05-11A

Singapore 159088

Phone: 65 471-2688

Fax: 65 479-7778

Ta i w a n

Tait Mobile (Taiwan) Ltd

1104, No. 142 Chung Hsiao E. Rd

Sec. 4

Ta ip e i

Ta iw a n

Phone: 886 2 2731-1290

Fax: 886 2 2711-6351

Thailand

Tait Mobile Radio Ltd

14/1 Suwan Tower

Third Floor

Soi Saladaeng 1

North Sathorn Road

Bangrak

Bangkok 10500

Thailand

Phone: 662 267-6290

Fax: 662 267-6293

United Kingdom

Tait Europe Ltd

Ermine Business Park

Ermine Road

Huntingdon

Cambridgeshire PE18 6YA

United Kingdom

Phone: 44 1480-52255

Fax: 44 1480-411996

USA

Tait Electronics (USA) Inc.

9434 Old Katy Road

Suite 110

Houston

Texas 77055

USA

Phone: 1 713 984-8684

Toll Free: 1 800 222-1255

Fax: 1 713 468-6944

Internet

http://www.taitworld.com

01/07/00 Copyright TEL

Page 3

M830P-00 3

About This Manual

Scope This manual contains general, technical, tuning and adjustment

information on T830 Series II 50W and 100W paging base stations which comprise the following equipment:

50W base station T837 paging exciter

T838 50W power amplifier

100W base station T837 paging exciter

T839 100W power amplifier

PCB Information PCB information is provided for all current issue PCBs, as well

as all previous issue PCBs manufactured in production quantities, and is grouped according to PCB. Thus, you will find the

parts list, grid reference index (if necessary), PCB layouts and

circuit diagram(s) for each individual PCB grouped together.

Errors If you find an error in this manual, or have a suggestion on how

it might be improved, please do not hesitate to contact Customer

Support, Tait Electronics Ltd, Christchurch, New Zealand (full

contact details are on page 2).

Updating Equipment And Manuals

In the interests of improving performance, reliability or servicing, Tait Electronics Ltd

reserve the right to update their equipment and/or manuals without prior notice.

Copyright

All information contained in this manual is the property of Tait Electronics Ltd. All

rights are reserved. This manual may not, in whole or part, be copied, photocopied,

reproduced, translated stored or reduced to any electronic medium or machine readable

form without prior written permission from Tait Electronics Ltd.

Ordering Tait Service Manuals

You can order additional copies of this manual from your nearest Tait Dealer or Customer Service Organisation. When ordering, make sure you quote the correct Tait product code ("M" number). Note that only the latest issue of the manual will be available

for order.

Copyright TEL 01/07/00

Page 4

4 M830P-00

Table O f C ontents

This manual is divided into eight parts as listed below, with each part being further subdivided into sections. There is a detailed table of contents at the start of each part and/

or section.

Part Title

A Introduction To Servicing

B T835 Receiver - not used in this manual

C T837 Paging Exciter

D T838 & T839 Power Amplifiers

E T830 VCO PCB Information

F Installation

G T800-28-0X00 Paging Rack Frame

H T800 Ancillary Equipment

1

01/07/00 Copyright TEL

Page 5

M830P-00 AI

Part A Introduction To Servicing

This part of the manual is divided into the sections listed below. These sections provide

some general and advisory information on servicing procedures, and a brief history of

PGM800Win programming software.

Section Title Page

1

1.1

1.2

1.3

1.4

2

2.1

2.2

2.3

2.3.1

2.3.2

2.4

2.5

3

3.1

3.1.1

3.1.2

General

Additional Technical Information

Caution: CMOS Devices

Caution: Aerial Load

Caution: Beryllium Oxide & Power Transistors

Mechanical

Torx Recess Head Screws

Pozidriv & Philips Recess Head Screws

Disassembly/Reassembly

Exciters

Power Amplifiers

Cover Screw Torques

Chassis & Cover Compatibility

Component Replacement

Leaded Components

Desoldering Iron Method

Component Cutting Method

1.1

1.1

1.1

1.2

1.2

2.1

2.1

2.2

2.3

2.3

2.3

2.3

2.4

3.1

3.1

3.1

3.1

3.2

3.3

4

4.1

4.2

Surface Mount Devices

Cased Mica Capacitors

Software History

PGM800Win V1.0

PGM800Win V2.00

Figure Title Page

1.1

1.2

2.1

2.2

2.3

Typical Product Code & Serial Number Labels

Typical Anti-static Bench Set-up

Torx Screw Identification

Pozidriv & Philips Screw & Screwdriver Identification

Identification Of New-Design Chassis & Covers

3.2

3.2

4.1

4.1

4.1

1.1

1.2

2.1

2.2

2.4

Copyright TEL 01/07/00

Page 6

AII M830P-00

01/07/00 Copyright TEL

Page 7

M830P-00 General A1.1

1 General

1.1 Additional Technical Information

If you have any questions about this manual or the equipment it describes, please contact your nearest Tait Dealer or Customer Service Organisation. If necessary, you can get

additional technical help from Customer Support, Tait Electronics Ltd, Christchurch,

New Zealand (full contact details are on page 2).

When requesting information, please quote either the manual product code (e.g.

M830P-00-1TA), or the equipment product code and serial number which are printed on

a label on the back of the product (as shown in Figure 1.1).

this area used for regional

Type Approval information

T838-10-0000

Rev 1

900000

Tait Electronics Limited

Made in New Zealand

Figure 1.1 Typical Product Code & Serial Number Labels

product code

serial number

T835-10-0000 Rev 1

Tait Electronics Limited

Made in New Zealand

900000

If you require information about a particular PCB, please quote the full PCB internal

part number (IPN) which is screen printed onto the top side of the board (refer to the

appropriate PCB Information section in this manual for more details).

1.2 Caution: CMOS Devices

This equipment contains CMOS Devices which are susceptible to damage from static

charges. Care when handling these devices is essential. For correct handling procedures refer to the manufacturers' data books, e.g. Philips data books covering CMOS

devices, or Motorola CMOS data books, Section 5 'Handling', etc.

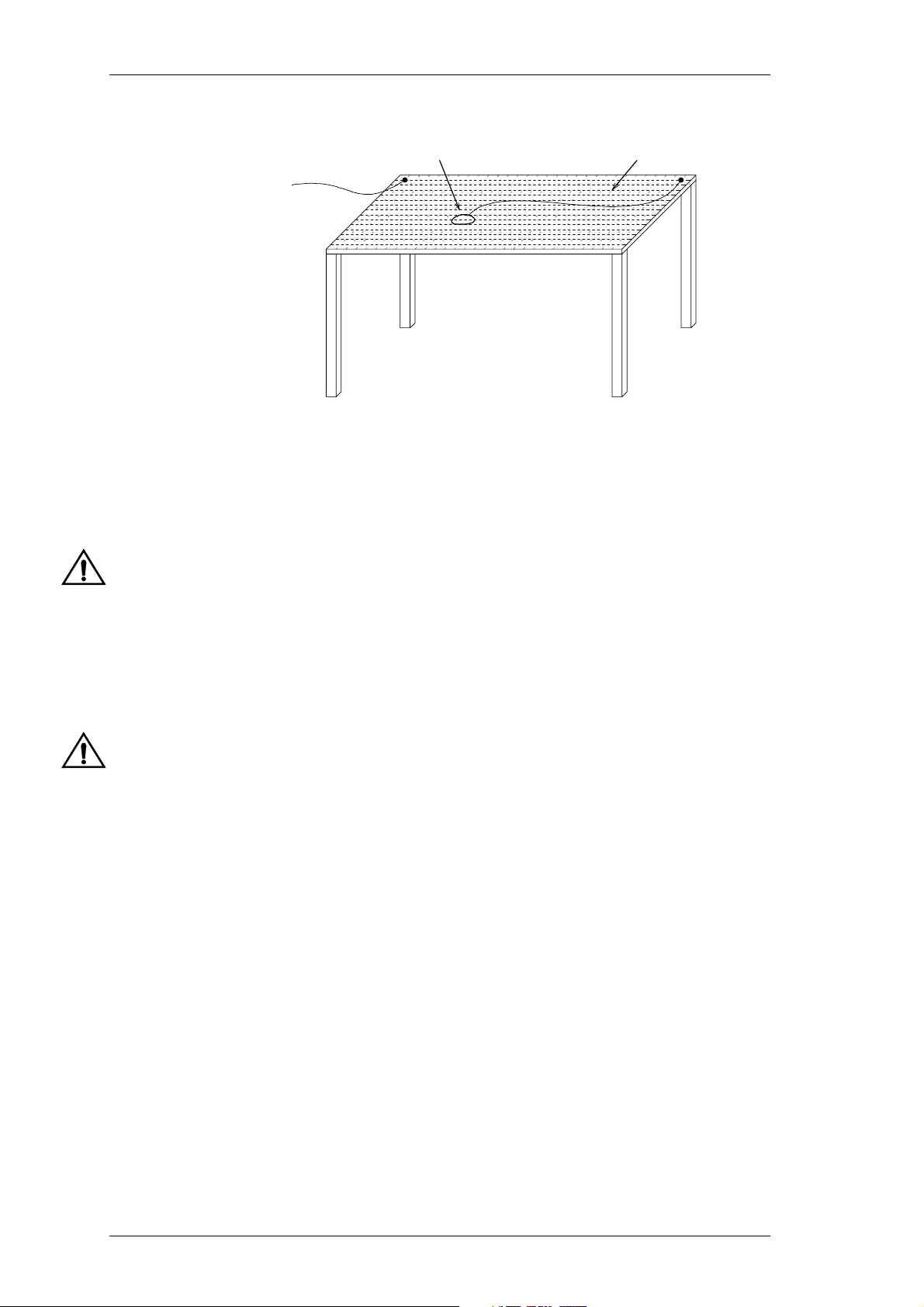

An anti-static bench kit (refer to Figure 1.2) is available from Tait Electronics Ltd under

the following product codes:

• KS0001 - 1 conductive rubber bench mat

- 1 earth lead to connect the mat to ground

• KS0004 - 1 wrist strap.

Copyright TEL 01/07/00

Page 8

A1.2 General M830P-00

conductive

wrist strap

to building earth

(not mains earth)

Figure 1.2 Typical Anti-static Bench Set-up

1.3 Caution: Aerial Load

conductive rubber

bench mat

The equipment has been designed to operate safely under a wide range of aerial loading

conditions. However, we strongly recommend that the transmitter should always be

operated with a suitable load to prevent damage to the transmitter output power stage.

1.4 Caution: Beryllium Oxide & Power Transistors

The RF power transistors in current use all contain some beryllium oxide. This substance, while perfectly harmless in its normal solid form, can become a severe health

hazard when it has been reduced to dust. For this reason the RF power transistors

should not be broken open, mutilated, filed, machined, or physically damaged in any

way that can produce dust particles.

01/07/00 Copyright TEL

Page 9

M830P-00 Mechanical A2.1

2 Mechanical

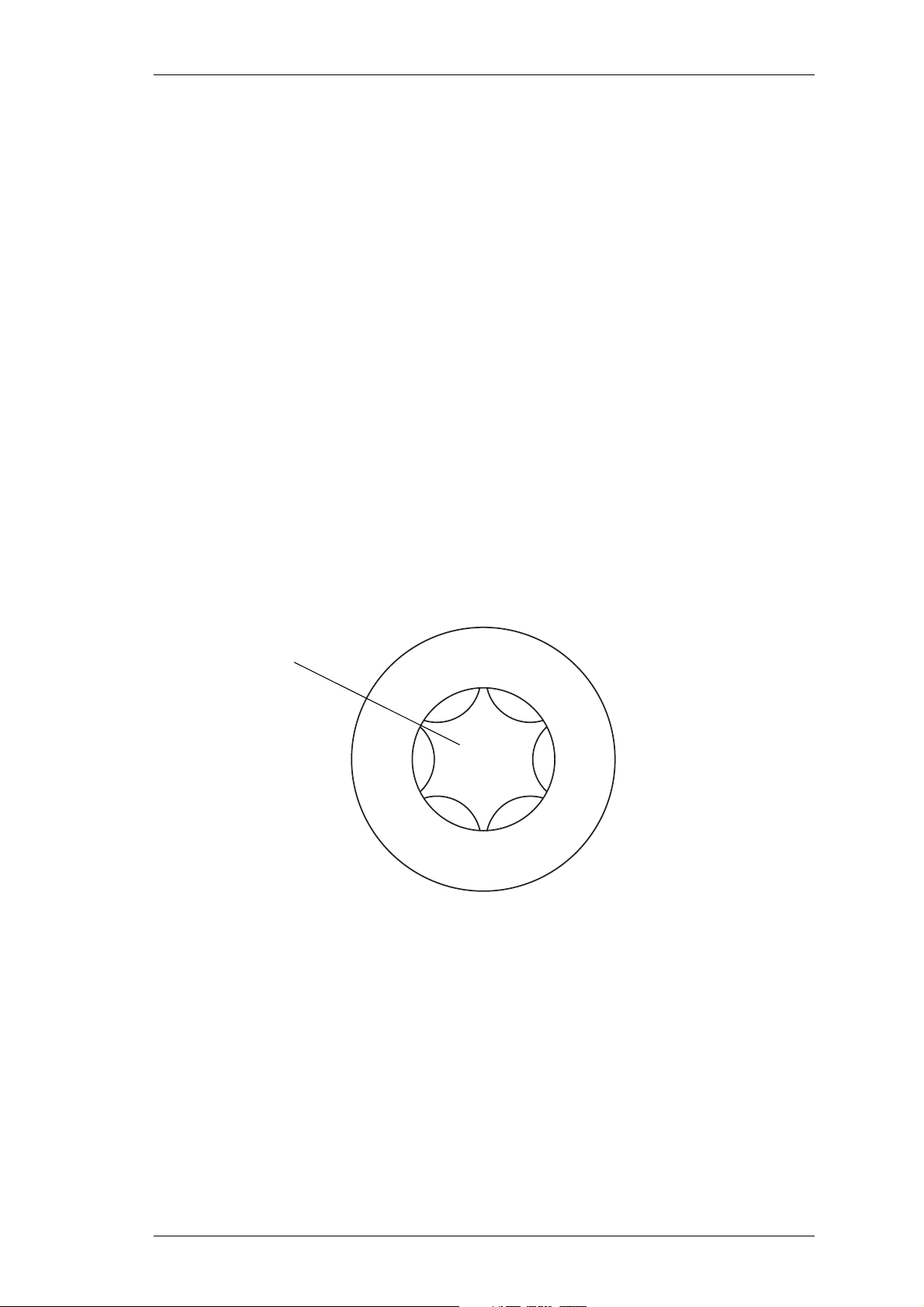

2.1 Torx Recess Head Screws

Torx recess head screws are becoming the standard screw head type in all T800 Series II

equipment, with Pozidriv and Philips recess head screws being used in fewer applications.

The Torx recess head has the advantage of improved screwdriver tip location, reducing

the chances of screw head damage caused by the driver tip rotating within the recess. In

addition, using a ball-tip Torx screwdriver allows you to drive a Torx head screw with

the driver on a slight angle, which can be useful in situations where access is restricted.

It is important that you use the correct Torx screwdriver tip:

M3 screws - T10

M4 screws - T20.

Figure 2.1 below shows a typical Torx recess head screw (actual hardware may differ

slightly from this illustration due to variations in manufacturing techniques).

"star" shaped recess with

six internal notches

Figure 2.1 Torx Screw Identification

Copyright TEL 01/07/00

Page 10

A2.2 Mechanical M830P-00

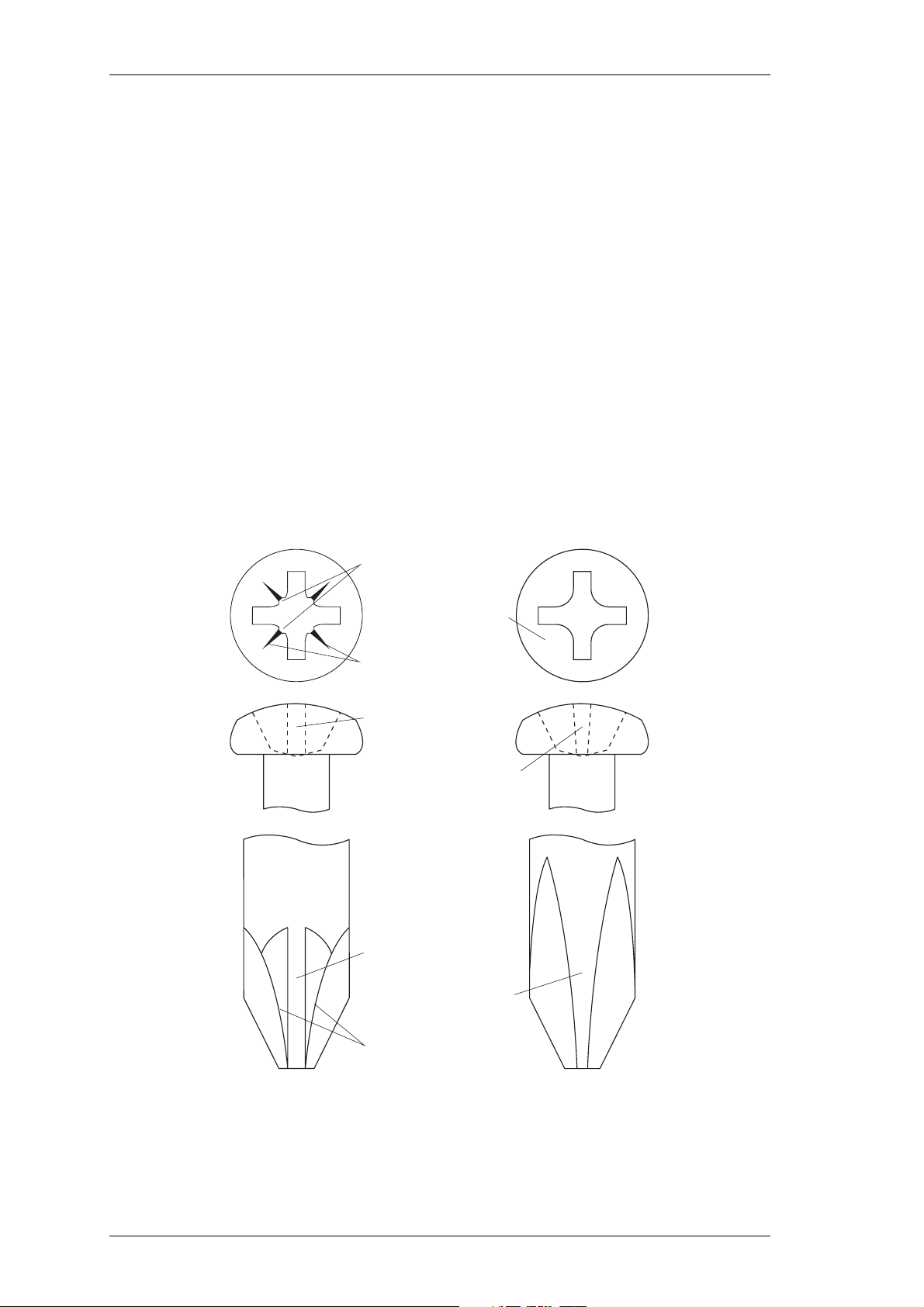

2.2 Pozidriv & Philips Recess Head Screws

Pozidriv and Philips recess head screws will continue to be used in T800 Series II equipment in a few special applications. It is important that you use the correct type and size

screwdriver for each screw type to avoid damaging the screw head.

It is particularly important that you do not use Philips screwdrivers on Pozidriv screw

heads as the tapered driving flutes of the Philips screwdriver do not engage correctly

with the parallel-sided slots in the Pozidriv screw head. This can result in considerable

damage to the screw head if the screwdriver tip turns inside the recess.

Note:

If you find you need excessive downwards pressure to keep the screwdriver

tip in the Pozidriv screw head, you are probably using the wrong type and/

or size screwdriver.

Figure 2.2 below shows the main differences between typical Pozidriv and Philips screw

heads and screwdriver tips (actual hardware may differ slightly from these illustrations

due to variations in manufacturing techniques).

Pozidriv Philips

internal notches

no special markings

"star" markings

between slots

slots with parallel sides

slots with tapered sides

driving flutes with

parallel sides

driving flutes with

tapered sides

ridges between

driving flutes

Figure 2.2 Pozidriv & Philips Screw & Screwdriver Identification

01/07/00 Copyright TEL

Page 11

M830P-00 Mechanical A2.3

2.3 Disassembly/Reassembly

2.3.1 Exciters

To carry out alignment or change option links, you need to remove only the top cover,

i.e. the one adjacent to the front panel handle and on the opposite side to the main

D-range connector (D-range 1/PL100).

You need to remove the bottom cover to access:

•Q370

• solder link SL501 (fast key option).

2.3.2 Power Amplifiers

You should carry out the tuning and power output level setting procedures with the

cover on.

2.4 Cover Screw Torques

Exciters .. 1.36Nm/12in.lbf.

Power Amplifiers .. 0.9Nm/in.lbf.

Copyright TEL 01/07/00

Page 12

A2.4 Mechanical M830P-00

2.5 Chassis & Cover Compatibility

The chassis and covers used in T800 Series II modules incorporate a number of design

changes to improve Electro-Magnetic Compatibility (EMC) performance. It is important that only the new-design covers are fitted to the new chassis to ensure correct

mechanical fit and continued compliance with appropriate EMC Type Approval regulations.

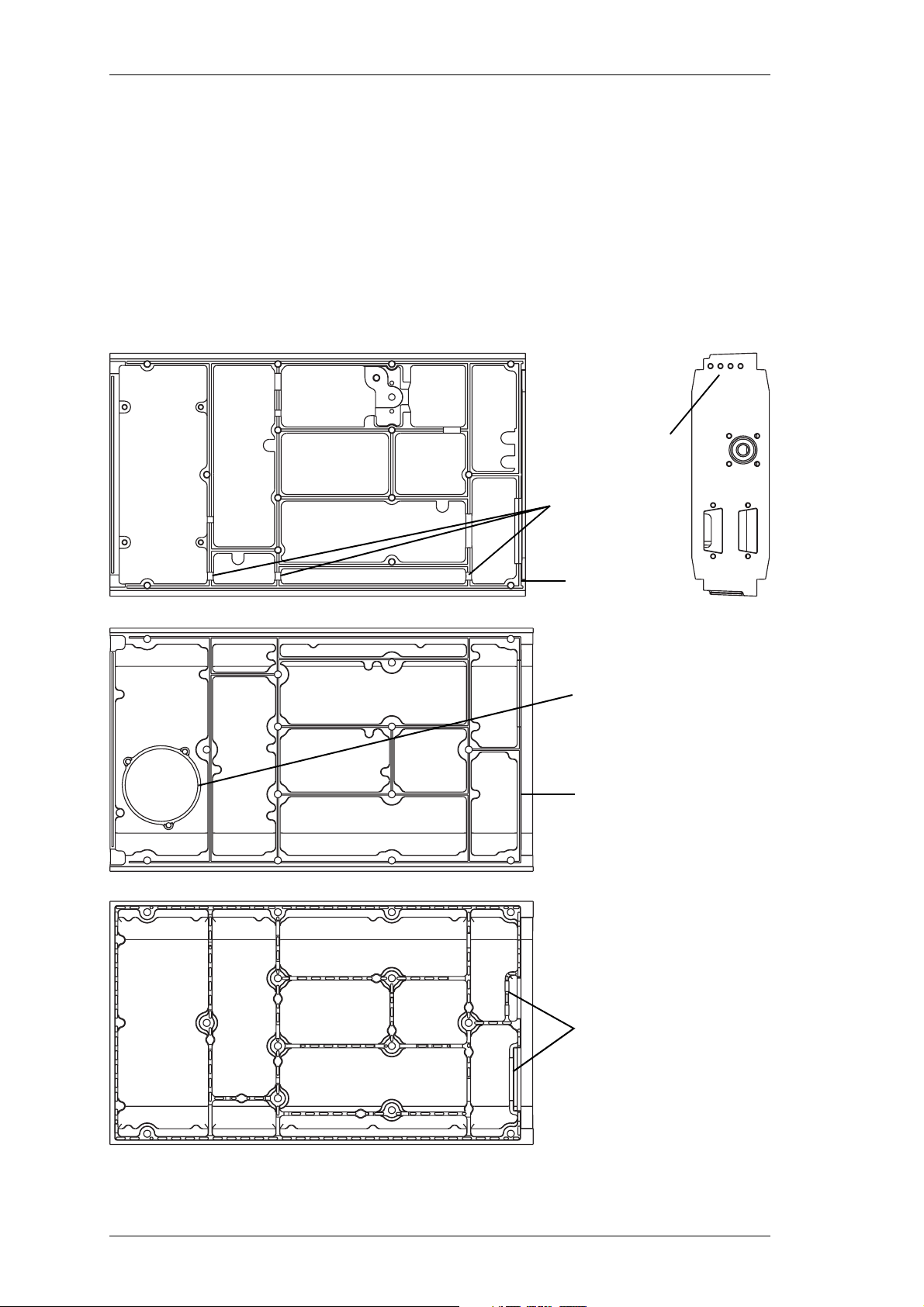

Figure 2.3 below shows some of the main features which can be used to identify the

new-design chassis and covers.

Chassis

←Top View

loom channel in

top of walls

Rear View

4 holes in

rear panel

→

groove in top

of rear wall

Top Cover

provision for mounting speaker

(future development)

ridge on top

of rear wall

Bottom Cover

additional walls

Figure 2.3 Identification Of New-Design Chassis & Covers

01/07/00 Copyright TEL

Page 13

M830P-00 Component Replacement A3.1

3 Component Replacement

3.1 Leaded Components

Whenever you are doing any work on the PCB that involves removing or fitting components, you must take care not to damage the copper tracks. The two satisfactory methods of removing components from plated-through hole (PTH) PCBs are detailed below.

Note:

The first method requires the use of a desoldering station, e.g. Philips SBC

314 or Pace MBT-100E.

3.1.1 Desoldering Iron Method

Place the tip over the lead and, as the solder starts to melt, move the tip in a circular motion.

Start the suction and continue the movement until 3 or 4 circles have been completed.

Remove the tip while continuing suction to ensure that all solder is removed from

the joint, then stop the suction.

Before pulling the lead out, ensure it is not stuck to the plating.

If the lead is still not free, resolder the joint and try again.

Note:

The desoldering iron does not usually have enough heat to desolder leads

from the ground plane. Additional heat may be applied by holding a soldering iron on the tip of the desoldering iron (this may require some additional help).

3.1.2 Component Cutting Method

Cut the leads on the component side of the PCB.

Heat the solder joint

out from the component side: do

Fill the hole with solder and then clear with solderwick.

Copyright TEL 01/07/00

sufficiently

to allow

not

easy

use undue force.

removal of the lead by drawing it

Page 14

A3.2 Component Replacement M830P-00

3.2 Surface Mount Devices

Caution: Surface mount devices (SMDs) require special storage, handling,

removal and replacement techniques. This equipment should be serviced only by an approved Tait Dealer or Customer Service Organisation equipped with the necessary facilities. Repairs attempted with

incorrect equipment or by untrained personnel may result in permanent damage. If in doubt, contact your nearest Tait Dealer or Customer

Service Organisation.

3.3 Cased Mica Capacitors

Cased mica capacitors can be removed by heating the top with a heavy-duty soldering

iron and gently lifting the capacitor off the PCB with a solder-resistant spike or equivalent.

01/07/00 Copyright TEL

Page 15

M830P-00 Software History A4.1

4 Software History

28/06/96 PGM800Win Version 1.0

18/08/97 PGM800Win Version 2.00

4.1 PGM800Win V1.0

PGM800Win V1.0 is different in concept from DOS versions of PGM800 in that it is Win-

1

dows

PGM800.

The major changes are outlined below:

based. It also includes many new and improved features over DOS versions of

• The Windows

• PGM800Win includes several new radio models which are not programmable

with DOS versions of PGM800.

• Out of range frequencies will result in warning messages and will not be accepted

for entry into the standard library module. User defined modules can be created,

however, allowing variation from the standard library module.

• Channel numbers default to 0-127 to match the EPROM memory locations. However, the user can change this setting so that the channel numbers run from 1-128

to suit his/her particular needs.

Note:

The data files produced by BASEPROG V1.0 and all DOS versions of

PGM800 are still compatible with PGM800Win V1.0.

environment makes data entry and editing significantly easier.

4.2 PGM800Win V2.00

PGM800Win V2.00 is an upgraded and expanded version of PGM800Win V1.0. It has

been developed specifically for T800 Series II base stations, but retains the ability to program Series I equipment.

The major changes are outlined below:

• PGM800Win V2.0 will program T800 Series II base station modules via serial communications.

• Deviation and reference modulation settings are written automatically to the

radio.

1. Windows is a registered trademark of the Microsoft Corporation.

Copyright TEL 01/07/00

Page 16

A4.2 Software History M830P-00

• Extra information that is not stored in the radio (but which is still relevant to the

radio) can be saved to a file on disk (e.g. note field, auxiliary pin names, etc.).

Note:

The data files produced by BASEPROG V1.0, all DOS versions of PGM800,

and PGM800Win V1.0 are still compatible with PGM800Win V2.00.

01/07/00 Copyright TEL

Page 17

M830P-00 BI

Part B T835 Receiver

The T835 receiver is not covered in this manual. Refer to M830-00-201 (or later issue) for

servicing information on the T835.

Copyright TEL 01/07/00

Page 18

BII M830P-00

01/07/00 Copyright TEL

Page 19

M830P-00 CI

Part C T837 Paging Exciter

This part of the manual is divided into six sections, as listed below. There is a detailed

table of contents at the start of each section.

Section Title

1 General Information

2 Circuit Operation

3 Initial Tuning & Adjustment

4 Functional Testing

5 Fault Finding

6 PCB Information

Copyright TEL 01/07/00

Page 20

CII M830P-00

01/07/00 Copyright TEL

Page 21

M830P-00 T837 General Information C1.1

1 T837 General Information

This section provides a brief description of the T837 paging exciter, along with detailed

specifications and a list of types available.

The following topics are covered in this section.

Section Title Page

1.1 Introduction 1.5

1.2

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

1.2.6.1

1.2.6.2

1.2.6.3

1.3 Product Codes 1.10

1.5 T837 Paging Product Range 1.11

Specifications

Introduction

General

RF Section

Low Speed Paging Modulator

Microcontroller

Tes t S ta nd a r ds

European Telecommunication Standard

Telecommunications Industry Association

Chinese Radio Regulatory Commission

1.6

1.6

1.6

1.7

1.8

1.8

1.8

1.8

1.8

1.9

Figure Title Page

1.1 T837 Main Circuit Block Identification 1.4

1.2 T837 Front Panel Controls 1.4

Copyright TEL 01/07/00

Page 22

C1.2 T837 General Information M830P-00

01/07/00 Copyright TEL

Page 23

M830P-00 T837 General Information C1.3

replace A4 pages C1.3/C1.4 with A3 pages C1.3/C1.4

Copyright TEL 01/07/00

Page 24

C1.4 T837 General Information M830P-00

replace A4 pages C1.3/C1.4 with A3 pages C1.3/C1.4

01/07/00 Copyright TEL

Page 25

M830P-00 T837 General Information C1.5

1.1 Introduction

The T837 is a synthesised, microprocessor controlled, DFSK low speed paging exciter

designed for single or multichannel

1

operation in the 148 to 174MHz frequency range2.

With a standard power output of only 800mW, the exciter is designed for use with the

T839 100W power amplifier. The RF section of the exciter comprises a frequency synthesiser which provides 170mW of frequency modulated RF drive to a two stage, wide

band output amplifier. The synthesiser frequency is programmed via the serial communications port.

The low speed paging modulator section provides DFSK modulation. It incorporates a

TCXO frequency reference and uses two point modulation to achieve modulation of

data rates from 2400bps down to DC.

All components except those of the VCO are mounted on a single PCB. This is secured

to a die-cast chassis which is divided into compartments to individually shield each section of circuitry. Access to both sides of the main circuit board is obtained by removing

each of the chassis lids. There is provision within the chassis to mount small option

PCBs.

The front panel has two indicator LEDs to show when the transmit carrier is on (red)

and when the DC supply is connected (green). The T837 is 60mm wide and occupies a

single space in a Tait rack frame, which has the ability to accommodate up to seven

standard modules.

1. Although you can program the microcontroller with up to 128 channels, you must

carry out the modulation adjustment procedure if you change frequency (see Section

3.5).

2. Although capable of operating over the 148-174MHz frequency range, the T837 has an

8MHz VCO switching range (see Section 1.2.3 and Section 3.1).

Copyright TEL 01/07/00

Page 26

C1.6 T837 General Information M830P-00

1.2 Specifications

1.2.1 Introduction

The performance figures given are minimum figures, unless otherwise indicated, for

equipment tuned with the maximum switching range and operating at standard room

temperature (+22°C to +28°C) and standard test voltage (13.8V DC).

Where applicable, the test methods used to obtain the following performance figures are

those described in the EIA and ETS specifications. However, there are several parameters for which performance according to the Chinese specification GB/T 15938 is given.

Refer to Section 1.2.6 for details of test standards.

Details of test methods and the conditions which apply for Type Approval testing in all

countries can be obtained from Tait Electronics Ltd.

1.2.2 General

Number Of Channels .. 128 (standard)

Supply Voltage:

Operating Voltage .. 10.8 to 16V DC

Standard Test Voltage .. 13.8V DC

Polarity .. negative earth only

Polarity Protection .. crowbar diode

Line Keying Supply (if required) .. -50V DC

Supply Current:

Tr an s mi t . . < 6 50 m A

Standby - T837-2X-1020 .. <150mA

- T837-2X-1021 .. <200mA

Operating Temperature Range .. -30°C to +60°C

Dimensions:

Height .. 183mm

Width .. 60mm

Length .. 320mm

1

Weight .. 2.1kg

Time-Out Timer (optional) .. 0 to 5 minutes

ond steps

1. Additional channels may be factory programmed. Contact your nearest Tait Dealer or

Customer Service Organisation.

2. Adjustable from 0 to 10 minutes in PGM800Win version 2.12 and later.

01/07/00 Copyright TEL

2

adjustable in 10 sec-

Page 27

M830P-00 T837 General Information C1.7

Tail Timer .. 0 to 5 seconds adjustable in 100ms1

steps

Tra ns mi t K ey Tim e:

T837-20-102X .. <100ms

T837-26-102X .. <30ms

Transmit Lockout Timer .. 0 to 1 minute adjustable in 10 second

steps

1.2.3 RF Section

Frequency Range .. 148-174MHz

Modulation Type .. DFSK

Frequency Increment:

T837-20-102X .. 5 or 6.25kHz

T837-26-102X .. 2.5 or 3.125kHz

VCO Switching Range .. 8MHz

Load Impedance .. 50 ohms

Frequency Stability:

T837-2X-1020 .. ±1.0ppm, -20°C to +70°C

±2.0ppm, -30°C to +70°C

T837-2X-1021 .. ±1.5ppm, -30°C to +70°C

External Reference Frequency .. 100kHz to 25.6MHz in 100kHz steps

(T837-2X-1021)

External Reference Amplitude .. 0 to +10dBm into 50Ω

Adjacent Channel Power .. -75dBc (ETS)

(4.5kHz deviation) -70dBc (GB/T 15938)

Transmitter Side Band Noise:

(no modulation, 15kHz bandwidth)

At ±25kHz .. -95dBc

At ±1MHz .. -105dBc

Radiated Spurious Emissions:

Transmit .. -36dBm to 1GHz

-30dBm to 4GHz

Standby .. -57dBm to 1GHz

-47dBm to 4GHz

1. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

Copyright TEL 01/07/00

Page 28

C1.8 T837 General Information M830P-00

Power Output .. 800mW ±200mW

Transmit Keying Noise .. -70dBc (GB/T 15938)

1.2.4 Low Speed Paging Modulator

Accepted Protocols/Speeds:

T837-20-102X .. POCSAG 512/1200 and FLEX 1600

T837-26-102X .. POCSAG 512/1200/2400 and

FLEX 1600

Input Data Levels .. TTL

Data Rise Time (10% - 90%):

T837-20-102X .. <150µs (GB/T 15938)

T837-26-102X .. <115µs

1.2.5 Microcontroller

Auxiliary Ports:

Open Drain Type .. capable of sinking 2.25mA via 2k2Ω

max. .. 5V

V

ds

1.2.6 Test Standards

Where applicable, this equipment is tested in accordance with the following standards.

1.2.6.1 European Telecommunication Standard

ETS 300 113 March 1996

Radio equipment and systems; land mobile service; technical characteristics and test

conditions for radio equipment intended for the transmission of data (and speech) and

having an antenna connector.

1.2.6.2 Telecommunications Industry Association

ANSI/TIA/EIA-603-1992

Land mobile FM or PM communications equipment measurement and performance

standards.

01/07/00 Copyright TEL

Page 29

M830P-00 T837 General Information C1.9

1.2.6.3 Chinese Radio Regulatory Commission

GB/T 15938 - 1995

General specification for equipment of radio paging systems.

Copyright TEL 01/07/00

Page 30

C1.10 T837 General Information M830P-00

1.3 Product Codes

The three groups of digits in the T830 Series II product code provide information about

the model, type and options fitted, according to the conventions described below.

The following explanation of T830 Series II product codes is not intended to suggest that

any combination of features is necessarily available in any one product. Consult your

nearest Tait Dealer or Customer Service Organisation for more information regarding

the availability of specific models, types and options.

Model

The Model group indicates the basic function of the product, as follows:

T83X

-XX-XXXX T837 exciter

T838 50W power amplifier

T839 100W power amplifier

Type

The Type group uses two digits to indicate the basic RF configuration of the product.

The first digit in the Type group designates the frequency range:

T83X-X

The second digit in the Type group indicates the channel spacing:

T83X-XX

X-XXXX ’2’ for 148-174MHz

-XXXX ’0’ for wide bandwidth (25kHz) - standard

’6’ for wide bandwidth (25kHz) - USA

Options

T83X-XX-XXXX The Options group uses four digits and/or letters to indicate

any options that may be fitted to the product. This includes

standard options and special options for specific customers.

’0000’ indicates a standard Tait product with no options fitted.

The large number of options precludes listing them here.

01/07/00 Copyright TEL

Page 31

M830P-00 T837 General Information C1.11

1.4 T837 Paging Product Range

The following table lists the range of T837 paging product types available at the time

this manual was published. Consult your nearest Tait Dealer or Customer Service

Organisation for more information.

Frequency Range (MHz) 148-174

Deviation (kHz) 5

Baud Rate (bps) 1200 1200 2400 2400

Frequency Increments (kHz) 5/6.25 5/6.25 2.5/3.125 2.5/3.125

±1.0ppm -20°C to +70°C

TCXO

Exciter Type: T837- 20-1020 20-1021 26-1020 26-1021

±2.0ppm -30°C to +70°C

±1.5ppm -20°C to +70°C

••

••

You can identify the exciter type by checking the product code printed on a label on the

rear of the chassis (Figure 1.1 in Part A shows typical labels). You can further verify the

exciter type by checking the placement of an SMD resistor in the table that is screen

printed onto the PCB (refer to Section 6.1 for more details).

Copyright TEL 01/07/00

Page 32

C1.12 T837 General Information M830P-00

01/07/00 Copyright TEL

Page 33

M830P-00 T837 Circuit Operation C2.1

2 T837 Circuit Operation

This section provides a basic description of the circuit operation of the T837 paging

exciter.

Note:

Refer to Section 6 where the parts lists, grid reference index and diagrams will provide

detailed information on identifying and locating components and test points on the

main PCB. The parts list and diagrams for the VCO PCB are in Part E.

The following topics are covered in this section.

Unless otherwise specified, the term "PGM800Win" used in this and following sections refers to version 2.00 and later of the software.

Section Title Page

2.1 Introduction 2.3

2.2 Microcontroller 2.4

2.3

2.3.1

2.4

2.4.1

2.5

Synthesised Local Oscillator

Two Point Modulation

VCO

VCO Supply

Low Speed Paging Modulator

2.5

2.6

2.7

2.7

2.8

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.5.6

2.6 Power Supply & Regulator Circuits 2.11

2.7 Transmit Timers 2.12

2.8 Exciter Drive Amplifier 2.13

General

AFC/PLL Operation

Data Path

External Reference Frequency (T837-2X-1021 Only)

Keying Inputs

Paging Modulator Links

2.8

2.8

2.9

2.9

2.10

2.10

Copyright TEL 01/07/00

Page 34

C2.2 T837 Circuit Operation M830P-00

Figure Title Page

2.1

2.2

2.3

2.4

2.5

2.6

T837 High Level Block Diagram

T837 Microcontroller Block Diagram

T837 Synthesiser Block Diagram

T837 AFC Block Diagram

T837 Power Supply & Regulators Block Diagram

T837 Transmit Timers

2.3

2.4

2.5

2.8

2.11

2.12

01/07/00 Copyright TEL

Page 35

M830P-00 T837 Circuit Operation C2.3

2.1 Introduction

The individual circuit blocks which make up the T837 are:

• synthesiser

•VCO

•paging modulator

•drive amplifier

• voltage regulators.

Each of these circuit blocks is set in its own shielded compartment, formed as an integral part of the main chassis.

The configuration of the circuit blocks may be seen on a functional level in Figure 2.1.

Refer to the circuit diagrams in Section 6.2 for more detail.

Reference

Oscillator

12.8MHz

Data

Tx Reg

Drive

Amp.

Ramp

Gen.

Synthesiser

Paging

Modulator

+22dBm

Lock

Detect

&

Gate

PIN

Switch

Time

Delay

Time

Delay

Figure 2.1 T837 High Level Block Diagram

Switching

Control

Low Pass

Filter

Exciter

Output

(800mW)

PA Control Signal

(via exciter RF coax)

VCO

Copyright TEL 01/07/00

Page 36

C2.4 T837 Circuit Operation M830P-00

2.2 Microcontroller

(Refer to the microcontroller circuit diagram (sheet 8) in Section 6.2.)

Watchdog

Reset

Microcontroller Cavity

Channel

Auxiliary

Output

EEPROM

Select

Port

Port

Synthesiser

12.8MHz

Clock

External

Serial

Port

5V Digital

Regulator

5V Reset

Microcontroller

Converter

Figure 2.2 T837 Microcontroller Block Diagram

Overall system control of the T837 is accomplished by the use of a member of the 80C51

family of microcontrollers (IC810). It runs from internal ROM and RAM, thus leaving

all four ports free for input/output functions.

Non-volatile data storage is achieved by serial communication with a 16kBit EEPROM

(IC820). This serial bus is also used by the microcontroller to program the synthesiser

(IC740).

The main tasks of the microcontroller are as follows:

• program the synthesiser;

• interface with the PGM800Win programming software at 9600 baud via the

serial communication lines on D-range 1 (PL100);

• coordinate and implement timing control of the exciter;

• control the front panel "Supply" LED (refer to Section 5.3).

01/07/00 Copyright TEL

Page 37

M830P-00 T837 Circuit Operation C2.5

m

2.3 Synthesised Local Oscillator

(Refer to the synthesiser circuit diagram (sheet 7) in Section 6.2 and the VCO circuit diagram in Part E.)

12.8MHz

Reference

Oscillator

Ref

Mod

Serial

Bus

Paging

Modulator

Clk

Data

En

FREQUENCY SYNTHESISER IC

Reference

12.8MHz

f

ref

Divider

/R

Controller

Phase

Detector

Charge

Pump

Programmable

Divider

/N

Loop

Filter

Prescaler

64/65

Modulation

f

in

VCO

VCO Buffer

Σ

Divider Buffer

Figure 2.3 T837 Synthesiser Block Diagram

The synthesiser (IC740) employs a phase-locked loop (PLL) to lock a voltage controlled

oscillator (VCO) to a given reference frequency. The synthesiser receives the divider

information from the control microprocessor via a 3 wire serial bus (clock, data, enable).

When the data has been latched in, the synthesiser processes the incoming signals from

the VCO buffer (f

) and the phase modulator (f

in

ref

).

A 12.8MHz reference frequency is fed from the paging modulator section to the frequency synthesiser Ref

(IC740 pin 20). This reference frequency is derived from the

in

VCXO (X101), which is locked to the internal frequency standard provided by the TCXO

(X100). The reference frequency has been modulated in the VCXO by the incoming data

to allow the synthesiser loop to modulate down to DC. This 12.8MHz reference frequency is divided down to 6.25kHz or 5.0kHz in the synthesiser IC (IC740).

VCO PCB

Output

Buffer

+22dB

L.O.

A buffered output of the VCO (Q795) is divided with a prescaler and programmable

divider which is incorporated into the synthesiser chip (IC740). This signal is compared

with the phase modulated reference signal at the phase detector (also part of the synthesiser chip). The phase detector outputs drive a balanced charge pump circuit (Q760,

Q770, Q775, Q780, Q785) and active loop filter (IC750 pins 5, 6 & 7) which produces a

DC voltage between 0V and 20V to tune the VCO. This VCO control line is further filtered to attenuate noise and other spurious signals. Note that the VCO frequency

increases with increasing control voltage.

If the synthesiser loop loses lock, a pulsed signal appears at LD (pin 2) of IC740. This

signal is filtered and buffered by IC750 pins 1, 2 & 3, producing the Lock-Detect signal

used to shut off the power supply to the drive amplifier. IC750 pin 1 is at 20V when the

synthesiser is out of lock.

Copyright TEL 01/07/00

Page 38

C2.6 T837 Circuit Operation M830P-00

2.3.1 Two Point Modulation

Frequency modulation occurs by modulating both the VCO input and the synthesiser

reference input. This process is called two point modulation and ensures a flat modulation response from 0 to 2400bps.

The PLL has a fast response time, allowing a Tx key-up time of <30ms. Because of this

fast response time the PLL sees lower modulation frequencies superimposed on the

VCO as an error and corrects for it, resulting in no modulation on the carrier. At modulation frequencies greater than 300Hz the loop cannot correct fast enough and modulation is seen on the carrier.

To achieve low frequency modulation, the reference oscillator is also modulated so that

the phase detector of IC740 detects no frequency error under modulation. Thus, the

synthesiser loop will not attempt to correct for modulation and the data frequency

response of the transmitter remains unaffected.

01/07/00 Copyright TEL

Page 39

M830P-00 T837 Circuit Operation C2.7

2.4 VCO

(Refer to the VCO circuit diagram in Part E.)

The VCO transistor (Q1) operates in a common source configuration, with an LC tank

circuit coupled between its gate and drain to provide the feedback necessary for oscillation. The VCO control voltage from the loop filter (IC750 pin 7) is applied to the varicaps (D1-D4) to facilitate tuning within an 8MHz band of frequencies. A trimcap (CV1)

is used for coarse tuning of the VCO. The output from the oscillator circuit drives a cascode amplifier stage (Q2, Q3) which supplies +10dBm (typically) to a further stage of

amplification, Q5. This is the final amplifier on the VCO PCB, and delivers +22dBm

(typically) to the exciter drive amplifier.

A low level "sniff" is taken from the output of Q3 and used to drive the divider buffer

(Q795) for the synthesiser (IC740).

The VCO operates at the actual output frequency of the exciter, i.e. there are no multiplier stages. The VCO is modulated by superimposing the data signal onto the control

voltage and by frequency modulating the reference signal.

2.4.1 VCO Supply

The VCO is supplied from two switched +9V supplies under the control of the Tx-Reg.

supply.

The VCO (Q1) and buffer amplifier (Q2 & Q3) are supplied from one +9V switched supply by Q540 via the capacitor multiplier (Q550, C550).

The output amplifier is supplied from the other +9V supply by Q520, Q530, and Q510.

A delay circuit holds the VCO on for a short time after the Tx-Reg. supply has been

switched off. This is to allow the RF power circuits (both exciter and PA) to ramp down

in the correct manner before the VCO is switched off.

Copyright TEL 01/07/00

Page 40

C2.8 T837 Circuit Operation M830P-00

2.5 Low Speed Paging Modulator

(Refer to the low speed paging modulator circuit diagram (sheet 2) in Section 6.2.)

2.5.1 General

The T837-2X-102X is a dedicated paging exciter. The low speed paging modulator section of the exciter accepts TTL data at the D-range input and modulates the synthesiser

using a two point modulation method that provides modulation of data input frequencies of 2400bps down to DC (all 1’s or all 0’s).

The paging modulator section incorporates a TCXO frequency reference and a modulatable VCXO which is locked to the reference frequency from the TCXO.

The paging modulator also has provision for fitting an optional FFSK modem PCB.

2.5.2 AFC/PLL Operation

-1

+

Data Line

Summing

Amp.

Modulated

Reference

Figure 2.4 T837 AFC Block Diagram

The TCXO is the default frequency standard. In PLL mode, the slave 12.8MHz VCXO is

phase locked to the TCXO. Both the TCXO and the VCXO outputs are clipped in IC100

and IC102 and then frequency divided by 4 in the twisted ring counters, IC105 (TCXO)

and IC110 (VCXO). The slave VCXO is also fed to the synthesiser reference input.

VCXO AFC

Loop Filter

12.8MHz

TCXO

Each twisted ring counter provides four divide-by-four outputs, the Q and not Q having

the relative phases 0°, 90°, 180° and 270°. These two signals are combined in the two

XOR gate phase discriminators in IC115 to provide two beat frequencies that are in

phase quadrature. Both these outputs are filtered to pass the low frequency beat signal,

which is a 5Vpp triangle wave.

The output from pin 8 of IC115 is then differentiated to provide a further 90° phase

shifted square wave output on pin 14 of IC120. The amplitude of the output is proportional to the frequency difference between the TXCO and the VCXO. The square wave

is then rectified by gating the signal with an inverted version of itself through a CMOS

01/07/00 Copyright TEL

Page 41

M830P-00 T837 Circuit Operation C2.9

switch. The switch is controlled by a square wave derived from the triangle wave on

pin 7 of IC120. This square wave will either be in-phase or inverted with respect to the

output on pin 14 of IC120, depending on whether the VCXO frequency is higher or

lower than the TCXO frequency.

The output from the CMOS switch (pin 14 of IC150) is a direct voltage which has amplitude and sense that is relative to the beat frequency. This signal is used as the control

voltage for the VCXO. The rectified signal is then summed with an inverted version of

the data, which cancels the effect of the data on the loop filter but still allows the VCXO

to follow the TCXO frequency. Although the VCXO and TCXO are not on the same frequency when data is being applied, the VCXO frequency will not drift with respect to

the TCXO.

2.5.3 Data Path

The input data enters the radio via pin 12 of D-range 1 (PL100). The data is fed into the

paging modulator at I/O pad P101, which is buffered by Q100, and then through an

XOR gate (IC115 pins 2 & 3) which gives the option of inverting the data.

IC140 pins 5 & 6 translate the level of the signal to 9Vpp, and then the data passes

through an attenuator and data filter. The data path is switched at the output of the filter by IC150 pins 1, 2 & 15, which allows the data to be removed from the AFC loop for

testing purposes.

From the switch the data travels three paths:

• The first path is via RV100 to the LOOP-MOD output to modulate the VCO.

• The second path is through RV101 to the summing amp. This data modulates

the control line of the VCXO, which produces the modulated reference.

• The third data path, which originates at the switch, is the feedforward data

path. The data is inverted, attenuated by RV102 and then summed with the

output of the AFC. The effect of this data path is to stop the loop filter from

correcting the VCXO frequency deviation caused by the data on the data line.

2.5.4 External Reference Frequency (T837-2X-1021 Only)

The paging modulator section of the T837-2X-1021 exciter incorporates an additional

synthesiser (*IC200) which can be configured to provide a 12.8MHz reference frequency

from an external frequency standard. This external frequency can be from 100kHz up to

25.6MHz in 100kHz steps.

When using an external reference, you must set the onboard synthesiser’s reference frequency according to the frequency of the external reference. This is achieved by placing

resistors *%R240 - *%R247 in a pattern corresponding to a binary number which represents the reference divider ratio (see Section 3.6).

The internal TCXO (%X100) is used as the standard reference frequency, but is phaselocked to the external frequency when this is applied.

Copyright TEL 01/07/00

Page 42

C2.10 T837 Circuit Operation M830P-00

When there is no external reference frequency present, *Q104 is turned off and *IC160

switches 2.5V DC to the AFC input of the internal TCXO. The reference frequency can

be adjusted by the trimmer on the TCXO itself.

When an external reference frequency is present, *Q104 switches on and *IC160 switches

the synthesiser phase detector output voltage to the AFC input of the internal TCXO. A

buffered 12.8MHz output of the internal TCXO is fed back to the synthesiser oscillator

input and compared with the external reference frequency, thus ensuring that the internal TCXO is phase-locked to the external reference frequency.

The synthesiser Lock-Detect signal drives an LED *D116 on the main PCB which is lit

when the synthesiser is locked to the external reference frequency. The Lock-Detect signal is also fed to pin 8 of D-range 1 (PL100) for external monitoring purposes. The output is low when the synthesiser is locked.

2.5.5 Keying Inputs

There are two ways to key the exciter:

• pulling the Tx-Key line low (pin 13 on D-range 1 [PL100]) at the rear of the set);

• via the modem carrier detect line when the optional modem PCB is fitted.

Note:

Link S100 must be connected when using the Tx-Key line input.

2.5.6 Paging Modulator Links

Three solder links are provided in the paging modulator circuit. Their functions are

described in the following table:

Standard

Link Function

S100 Tx-Key linked ties the Tx-Key line to +5V for earthed Tx-Key

S101 invert data not linked inverts the incoming data

S102 invert key not linked inverts the key line (connected when using

Setting Description

line operation

modem carrier detect)

01/07/00 Copyright TEL

Page 43

M830P-00 T837 Circuit Operation C2.11

2.6 Power Supply & Regulator Circuits

(Refer to the regulators circuit diagram (sheet 6) in Section 6.2.)

+9V

Buffer

Tx Enable

Micro-

controller

Power

Switch

Tx Reg.

13.8V Nom.

From Rear

D-Range

Crowbar

Diode

13.8V

Nom.

5V

Reg

DC

Amp

5V 5V Dig9V 20V

Switching

PS

5V Dig

Reg

Watchdog

Timer

LVI

Figure 2.5 T837 Power Supply & Regulators Block Diagram

The T837 is designed to operate from a 10.8-16V DC supply (13.8V nominal). A 5.3V

regulator (IC630) runs directly from the 13.8V rail, driving much of the synthesiser circuitry. It is also used as the reference for a DC amplifier (IC640, Q630, Q620) which provides a medium current capability 9V supply.

A switching power supply (Q660, Q670) runs from the 9V supply and provides a low

current capability +20V supply. This is used to drive the synthesiser loop filter (IC750),

giving a VCO control voltage range of up to 20V, and the Lock-Detect amplifiers.

Ultimate control of the transmitter is via the Tx-Reg. supply, switched from 9V by Q610.

This is enabled via the Tx-Enable signal from the modulator, and microprocessor.

µP

µP

Reset

A crowbar diode is fitted for protection against connection to a power supply of incorrect polarity. It also provides transient overvoltage protection.

Note:

A fuse must be fitted in the power supply line for the diode to provide effective protection.

Copyright TEL 01/07/00

Page 44

C2.12 T837 Circuit Operation M830P-00

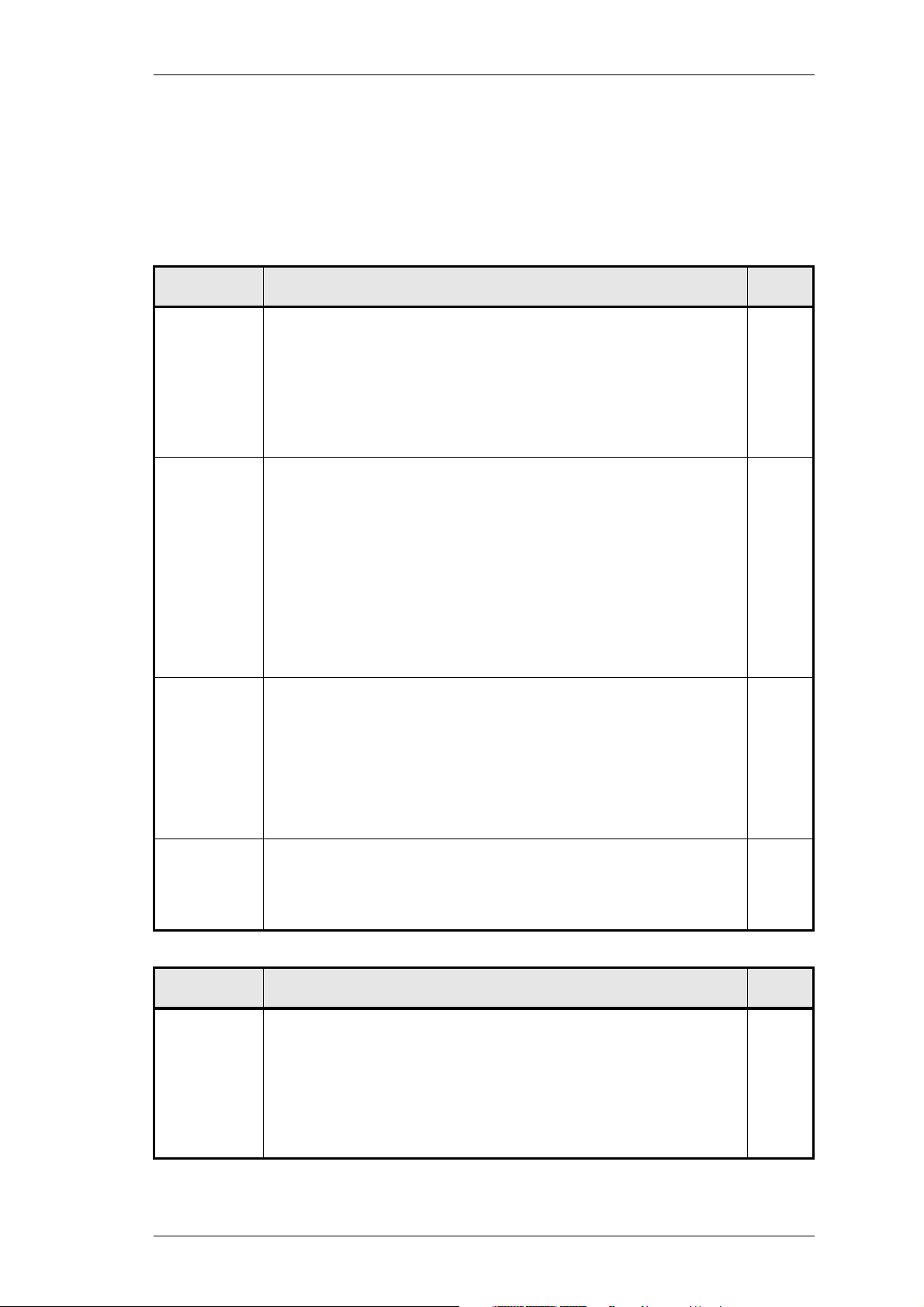

2.7 Transmit Timers

The transmit tail timer, transmit timeout timer and transmit lockout timer can all be set

from PGM800Win. The fields for setting these are found on the system information

page. These three timers operate as follows (refer also to Figure 2.6):

Timer Function Adjustment

Transmit Tail Sets the tail time during which the

transmitter stays keyed after the external key source has been removed.

Transmit Timeout Sets the maximum continuous trans-

mission time. Once the timer has

timed out, the transmitter must be

keyed again, unless prevented by the

transmit lockout timer.

Transmit Lockout Sets the period of time that must

elapse after a timeout before the transmitter can re-transmit. Once the timer

has timed out, the transmitter can be

keyed again.

a. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

b. Adjustable from 0 to 600 seconds in PGM800Win version 2.12 and later.

Tx-Enable

On

Tx-Enable

Tx-Reg.

0-5 seconds in 100ms

a

steps

0-300 secondsb in 10

second steps

0-60 seconds in 10

second steps

Tail Time

On

Tx-Reg.

Lockout Time

Timeout

Time

Figure 2.6 T837 Transmit Timers

01/07/00 Copyright TEL

Page 45

M830P-00 T837 Circuit Operation C2.13

2.8 Exciter Drive Amplifier

(Refer to Figure 2.1 and the exciter circuit diagram (sheet 3) in Section 6.2.)

A two-stage, wide band amplifier (Q365, Q370) provides an output level of approximately 800mW (+29dBm) for an input of 170mW (+22dBm) from the VCO. IC330 pins

5, 6 & 7, Q310, and Q315 provide a 10.5V regulated supply for the exciter.

To reduce the spurious output level when the synthesiser is out-of-lock, the Tx-Reg. and

Lock-Detect signals are gated to inhibit the exciter control circuit and to switch off the

RF signal at the input to the drive amplifier. This is achieved by a PIN switch attenuator

(D340, D350, D360).

Cyclic keying control is provided by additional circuitry consisting of several time

delay, ramp and gate stages:

• Q305, IC330 pins 5, 6 & 7 power ramping

• Q340, Q345 Tx-Reg. and Lock-Detect

• Q320, Q325, Q330, Q335 delay and PIN switch drive.

This is to allow the RF power circuits (both exciter and PA) to ramp up and down in a

controlled manner so that minimal adjacent channel interference is generated during

the transition.

R359, R342 and R344 form a 6dB attenuator to provide good VCO/drive amplifier isolation.

The output attenuator (R360, R362, R364, R366) assists in reducing exciter/PA interaction while also ensuring a good match for Q370.

Note:

The exciter provides a DC control signal to the PA via the RF coax. This is

injected via L390.

gate

Copyright TEL 01/07/00

Page 46

C2.14 T837 Circuit Operation M830P-00

01/07/00 Copyright TEL

Page 47

M830P-00 T837 Initial Tuning & Adjustment C3.1

3 T837 Initial Tuning & Adjustment

Caution: This equipment contains CMOS devices which are susceptible to dam-

age from static charges. Refer to Section 1.2 in Part A for more information on anti-static procedures when handling these devices.

The following section describes the full tuning and adjustment procedure and provides

information on:

• channel programming

• synthesiser alignment

• modulator adjustment

• external reference frequency configuration (T837-2X-1021 only).

Note:

Refer to Section 6 where the parts lists, grid reference index and diagrams will provide

detailed information on identifying and locating components and test points on the

main PCB. The parts list and diagrams for the VCO PCB are in Part E.

Unless otherwise specified, the term "PGM800Win" used in this and following sections refers to version 2.00 and later of the software.

Section Title Page

3.1 Introduction 3.3

3.2 Channel Programming 3.3

3.3 Test Equipment Required 3.4

3.4 Synthesiser Alignment 3.5

3.5 Modulator Adjustment 3.6

3.6 External Reference Frequency Configuration

(T837-2X-1021 Only)

3.7

Figure Title Page

3.1

3.2

Copyright TEL 01/07/00

T837 Test Equipment Set-up

T837 100Hz VCO Control Line Wave Form

3.4

3.6

Page 48

C3.2 T837 Initial Tuning & Adjustment M830P-00

01/07/00 Copyright TEL

Page 49

M830P-00 T837 Initial Tuning & Adjustment C3.3

3.1 Introduction

When you receive your T837 exciter it will be run up and working on a particular frequency (the "default channel")

8MHz VCO switching range (i.e. ±4MHz from the factory programmed frequency), you

will need to:

• reprogram the exciter with the PGM800Win software (refer to the PGM800Win

programming kit and Section 3.2 below);

• carry out the modulator adjustment procedure described in Section 3.5.

However, if you want to switch to a frequency outside the 8MHz VCO switching range,

you will have to:

• reprogram the exciter with the PGM800Win software;

• carry out the synthesiser alignment procedure described in Section 3.4;

• carry out the modulator adjustment procedure described in Section 3.5.

1

. If you want to switch to a frequency that is within the

3.2 Channel Programming

You can program up to 128 channel frequencies into the exciter’s EEPROM memory

(IC820) by using the PGM800Win software package and an IBM

PGM800Win to select the exciter’s current operating frequency (or "default channel").

PC. You can also use

If the exciter is installed in a rack frame, you can program it via the programming port

in the speaker panel. However, you can also program the exciter before it is installed in

a rack frame as follows:

• by using a T800-01-0010 calibration test unit;

•via D-range 1.

If you do not use the T800-01-0010, you will have to connect the PC to the exciter via a

module programming interface (such as the T800-01-0004).

For a full description of the channel programming procedure, refer to the PGM800Win

programming software user’s manual.

1. Use the "Read Module" function in PGM800Win to find out what the default channel is.

Copyright TEL 01/07/00

Page 50

C3.4 T837 Initial Tuning & Adjustment M830P-00

800

3.3 Test Equipment Required

You will need the following test equipment:

• computer with PGM800Win installed

• T800 programming kit

• module programming interface (e.g. T800-01-0004 - optional)

• 13.8V power supply

• digital multimeter

• function generator

•RF power meter

•frequency counter

or modulation analyser

•modulation meter

• oscilloscope (digital preferred)

• 20dB pad

Figure 3.1 shows a typical test equipment set-up.

+13.8V

PSU

-Ve

+5V

Function

Generator

TTL

Centre I/P

Data I/P

Exciter

Serial

via module programming interface

(e.g. T800-01-0004)

Com

20dB pad

Key

RF O/P

RF Power

Meter

Frequency

Counter

Modulation

Meter

AF O/P

Oscilloscope

PGM

Win

Figure 3.1 T837 Test Equipment Set-up

Note:

Although the T800-01-0010 calibration test unit can be used to program the

T837 paging exciter, it is not suitable for tuning and adjustment procedures

because of the different pin allocations of D-range 1 (PL100).

01/07/00 Copyright TEL

Page 51

M830P-00 T837 Initial Tuning & Adjustment C3.5

3.4 Synthesiser Alignment

Ensure that the T837 has been programmed with the required frequencies using

PGM800Win software.

Select a channel using PGM800Win.

Connect a high impedance voltmeter to PL4-1 or the junction of L1 and R1 in the

VCO (this measures the synthesiser loop voltage).

Key the transmitter by earthing the Tx-Key line.

Tune VCO trimmer CV1 for a synthesiser loop voltage of 9V.

Check that the exciter output power is 800mW ±200mW (measured at the rear

panel N-type connector).

If required, measure and adjust the exciter output frequency as follows:

• apply +5V DC to pin 11 of D-range 1 (PL100) - this changes the mode of

operation to PLL so that the carrier frequency can be observed - and measure the output frequency at the rear panel N-type connector;

• adjust the trimmer on the TCXO (%X100) if required;

• remove the +5V DC from pin 11.

Caution: This trimmer is susceptible to physical damage. Do not exert a down-

ward force of more than 500g (1lb) when adjusting.

Copyright TEL 01/07/00

Page 52

C3.6 T837 Initial Tuning & Adjustment M830P-00

3.5 Modulator Adjustment

Apply +5V DC to pin 12 (DATA input) of D-range 1.

Monitor the exciter output frequency and adjust RV102 (DC frequency offset) to

give an output frequency of F

Remove the +5V DC from pin 12 and apply a 100Hz 5Vp-p square wave to pin 12.

Monitor the signal at TP100 with an AC coupled oscilloscope set to 50mV/div.

and adjust RV101 (reference modulation) until the triangle wave amplitude is

minimised.

Change the frequency of the square wave to 600Hz.

Monitor the frequency deviation on the exciter output with a modulation meter

and adjust RV100 (VCO modulation) to obtain ±4.5kHz deviation.

Monitor the VCO control line at PL4-1 or the junction of L1 and R1 in the VCO

using an AC coupled oscilloscope set to at least 20mV/div.

carrier

+ 4.5kHz.

Change the frequency of the square wave back to 100Hz and check that the control

line still has a good trapezoidal wave form with flat top and bottom.

Note 1:

Note 2:

You may have to readjust RV101 & RV100 alternately to achieve a square

wave on the VCO control line at both 600Hz and 100Hz with a deviation of

±4.5kHz. Figure 3.2 shows a typical 100Hz VCO control line wave form

with RV101 and RV100 set correctly.

Figure 3.2

If the lower cut off frequency of an AC coupled oscilloscope is too high,

excessive distortion may be introduced which will result in ‘sag’ on the

square wave displayed. Determine if this is a problem by directly monitoring the original square wave source and observe any sag. If there is sag,

switch the oscilloscope to DC and use a 10µF capacitor in series with the

oscilloscope probe (observing the correct polarity) to directly monitor the

VCO control line. Note that the trace settling time will be approximately

one minute.

T837 100Hz VCO Control Line Wave Form

01/07/00 Copyright TEL

Page 53

M830P-00 T837 Initial Tuning & Adjustment C3.7

3.6 External Reference Frequency Configuration

(T837-2X-1021 Only)

When using an external reference frequency, you must set the onboard synthesiser’s reference frequency according to the frequency of the external reference. This is achieved

by placing resistors *%R240 - *%R247 in a pattern corresponding to a binary number

which represents the reference divider ratio.

If you are using a 10MHz external reference frequency, you need only carry out steps 4

and 5 in this section. You do not need to carry out steps 1, 2 and 3 because the T837 has

already been configured at the factory for a 10MHz external reference.

However, if you are using an external reference frequency other than 10MHz, you must

configure the internal synthesiser as described in steps 1, 2 and 3 before proceeding to

steps 4 and 5.

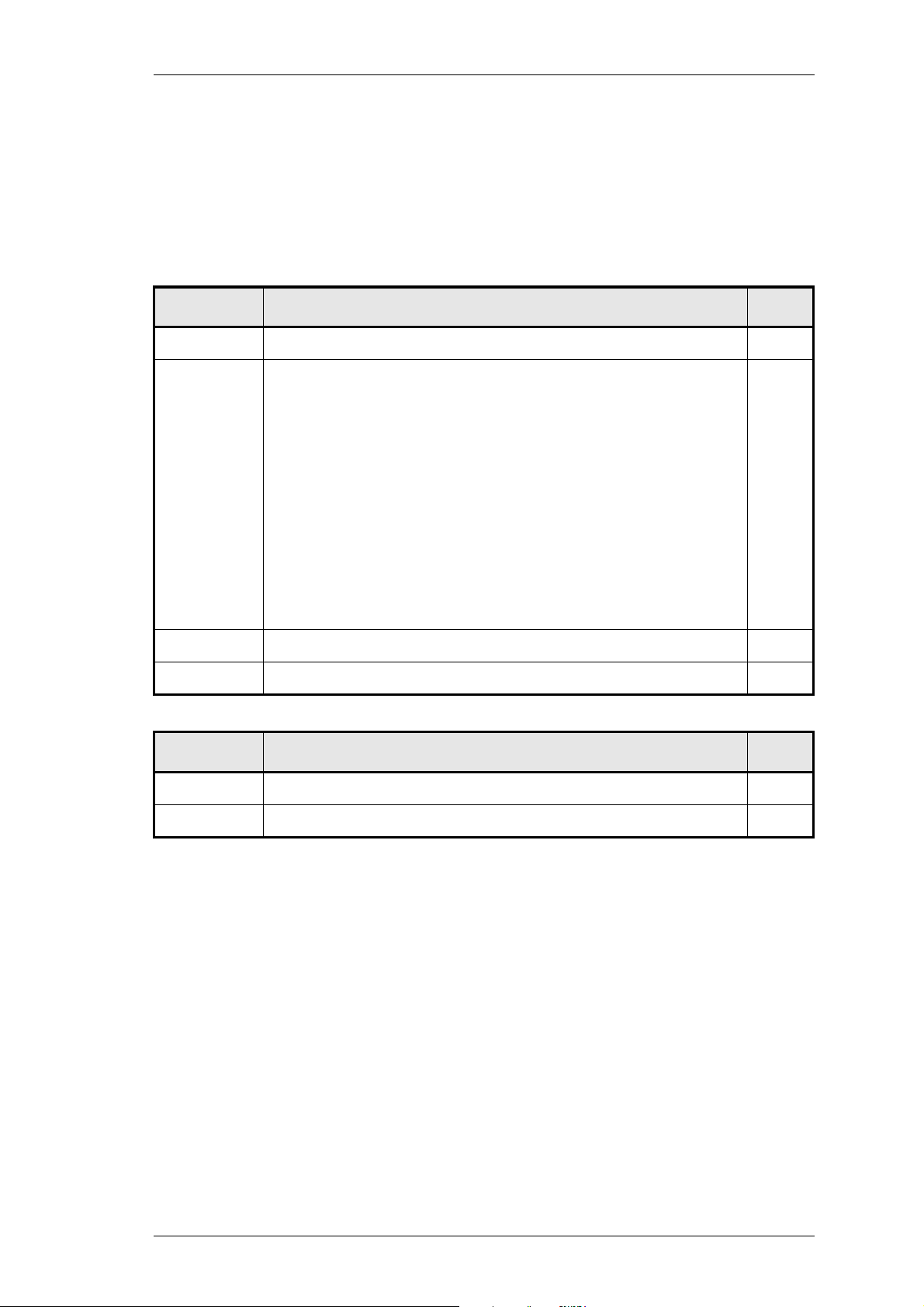

1. Divide the external oscillator frequency by 100kHz.

2. Convert the result to binary. You can use the following table to do this: select the

binary values in row three which add up to the result obtained in step 1, then

place a “1” in these positions and a “0” in the others.

MSB LSB

N7 N6 N5 N4 N3 N2 N1 N0

128

10

64

10

32

10

16

10

8

10

4

10

2

10

1

10

*%R240 *%R241 *%R242 *%R243 *%R244 *%R245 *%R246 *%R247

3. Where there is a “0” in the binary number, place a zero ohm resistor in the corresponding component location shown in the table. Where there is a “1”, leave an

open link.

Example:

The following example shows the resistor pattern for a 10MHz external reference frequency is calculated.

10MHz

100kHz

=100

100 = 64 + 32 + 4

therefore place resistors *%R240, *%R243, *%R244, *%R246

and *%R247 and leave all other links open

MSB LSB

N7 N6 N5 N4 N3 N2 N1 N0

128

10

64

10

32

10

16

10

8

10

4

10

2

10

1

10

0 1 100100

*%R240

Copyright TEL 01/07/00

*%R241 *%R242 *%R243 *%R244 *%R245 *%R246 *%R247

Page 54

C3.8 T837 Initial Tuning & Adjustment M830P-00

4. Connect the external reference frequency at a level of 0dBm to +10dBm/50Ω into

the external reference input and check that green LED *D116 lights.

5. Measure the TCXO (%X100) AFC voltage at %IC160 pin 4 with a high impedance

voltmeter and adjust the TXCO trimmer (if necessary) to obtain 2.5V DC ±0.2V.

01/07/00 Copyright TEL

Page 55

M830P-00 T837 Functional Testing C4.1

4 T837 Functional Testing

Caution: This equipment contains CMOS devices which are susceptible to dam-

age from static charges. Refer to Section 1.2 in Part A for more information on anti-static procedures when handling these devices.

The following test procedures will confirm that the T837 has been tuned and adjusted

correctly and is fully operational.

Note:

Refer to Figure 4.2 for the location of the main tuning and adjustment controls, and to

Section 3.3 for the test equipment set-up. Refer also to Section 6 where the parts lists,

grid reference index and diagrams will provide detailed information on identifying and

locating components and test points on the main PCB. The parts list and diagrams for

the VCO PCB are in Part E.

The following topics are covered in this section.

Unless otherwise specified, the term "PGM800Win" used in this and following sections refers to version 2.00 and later of the software.

Section Title Page

4.1 Current Consumption 4.3

4.2 Output Power 4.3

4.3 Output Frequency 4.3

4.4 External Reference Frequency (T837-2X-1021 Only) 4.3

4.5 Timers 4.4

Figure Title Page

4.1

4.2

Copyright TEL 01/07/00

T837 Transmit Timers

T837 Main Tuning & Adjustment Controls

4.4

4.5

Page 56

C4.2 T837 Functional Testing M830P-00

01/07/00 Copyright TEL

Page 57

M830P-00 T837 Functional Testing C4.3

4.1 Current Consumption

Connect the T837 to a 13.8V power supply.

Connect an RF power meter to the T837 output socket.

Check that the current in the 13.8V power cable is less than:

T837-2X-1020 - 150mA

T837-2X-1021 - 200mA.

Key the T837 by earthing the Tx-Key line (the carrier "On" LED should light).

Check that the current is less than 650mA.

4.2 Output Power

Connect an RF power meter to the T837 output socket.

Key the T837 by earthing the Tx-Key line.

Check that the output power is 800mW ±200mW.

4.3 Output Frequency

Connect the T837 output to a frequency counter via a 20dB attenuator pad.

Apply +5V DC to pin 11 of D-range 1 (PL100) - this changes the mode of operation

to PLL so that the carrier frequency can be observed - and measure the output frequency.

Adjust the TCXO (X100) (if required) to trim to the nominal frequency (±100Hz).

4.4 External Reference Frequency (T837-2X-1021 Only)

Connect the external reference frequency at a level of 0dBm to +10dBm/50Ω into

the external reference input and check that green LED *D116 lights.

Note:

Copyright TEL 01/07/00

Ensure that the onboard synthesiser’s reference frequency has been set

according to the frequency of the external reference (see Section 3.6).

Check the Lock-Detect signal level on pin 8 of D-range 1 (PL100) is as follows:

external reference frequency applied - 0V (approx.)

no external reference frequency applied - 4.5V (approx.).

Page 58

C4.4 T837 Functional Testing M830P-00

4.5 Timers

The transmit tail timer, transmit timeout timer and transmit lockout timer can all be set

from PGM800Win. The fields for setting these are found on the system information

page. These three timers operate as follows (refer also to Figure 4.1):

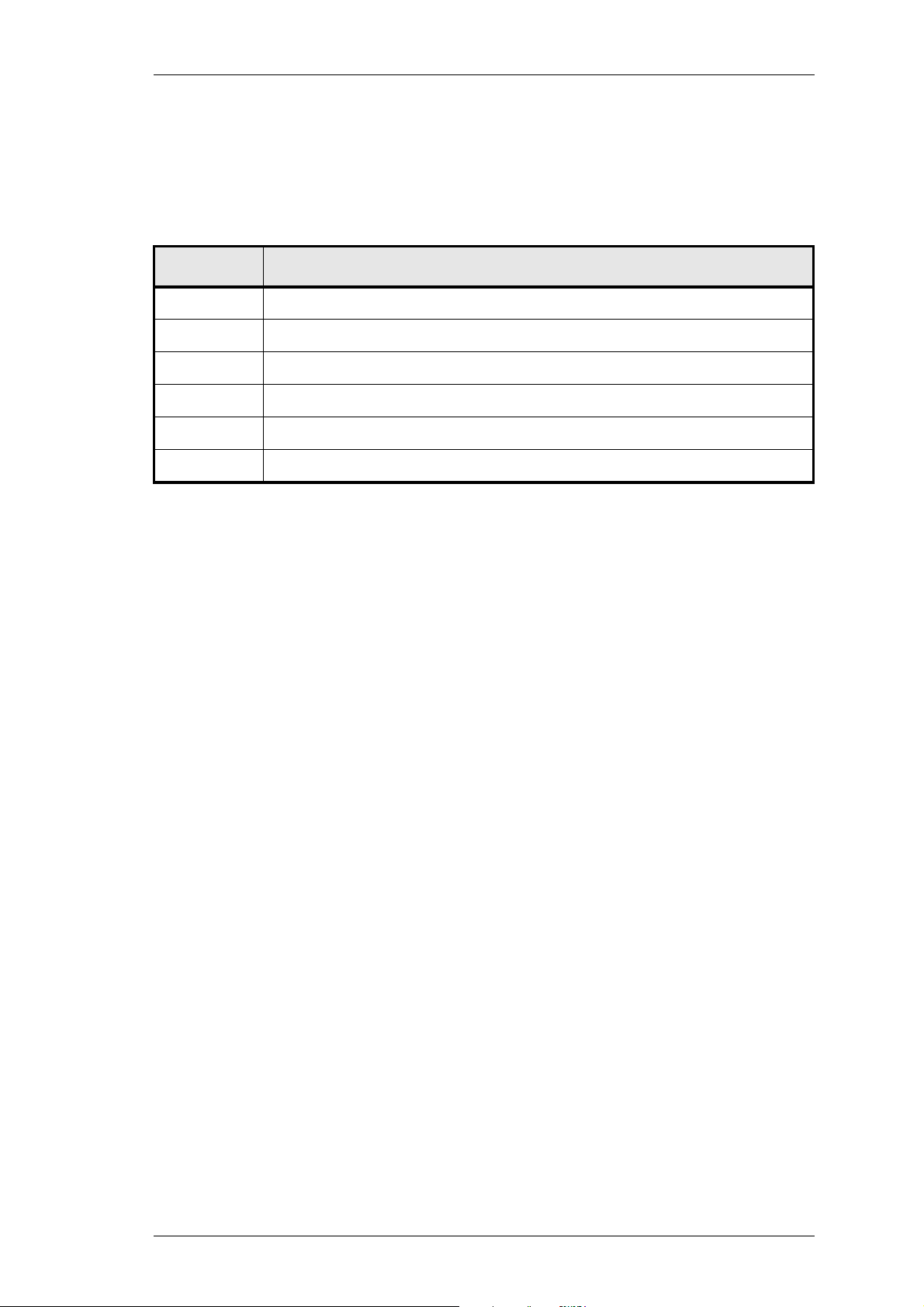

Timer Function Adjustment

Transmit Tail Sets the tail time during which the

transmitter stays keyed after the exter-

0-5 seconds in 100ms

steps

nal key source has been removed.

Transmit Timeout Sets the maximum continuous trans-

mission time. Once the timer has

0-300 seconds

second steps

timed out, the transmitter must be

keyed again, unless prevented by the

transmit lockout timer.

Transmit Lockout Sets the period of time that must

elapse after a timeout before the trans-

0-60 seconds in 10

second steps

mitter can re-transmit. Once the timer

has timed out, the transmitter can be

keyed again.

a. Adjustable in 20ms steps in PGM800Win version 2.12 and later.

b. Adjustable from 0 to 600 seconds in PGM800Win version 2.12 and later.

Tx-Enable

On

Tx-Enable

Tx-Reg.

a

b

in 10

Tx-Reg.

Tail Time

On

Lockout Time

Timeout

Time

Figure 4.1 T837 Transmit Timers

01/07/00 Copyright TEL

Page 59

M830P-00 T837 Fault Finding C5.1

5 T837 Fault Finding

Caution: This equipment contains CMOS devices which are susceptible to dam-

age from static charges. Refer to Section 1.2 in Part A for more information on anti-static procedures when handling these devices.

The following test procedures and fault finding flow charts may be used to help locate a

hardware problem, however they are by no means a complete fault finding procedure.

If you still cannot trace the fault after progressing through them in a logical manner,

contact your nearest Tait Dealer or Customer Service Organisation. If necessary, you

can get additional technical help from Customer Support, Radio Systems Division, Tait

Electronics Ltd, Christchurch, New Zealand (full contact details are on page 2).

Note:

Refer to Section 6 where the parts lists, grid reference index and diagrams will provide

detailed information on identifying and locating components and test points on the

main PCB. The parts list and diagrams for the VCO PCB are in Part E.

The following topics are covered in this section:

Unless otherwise specified, the term "PGM800Win" used in this and following sections refers to version 2.00 and later of the software.

Section Title Page

5.1 Visual Checks 5.3

5.2 Component Checks 5.3

5.3 Front Panel LED Indicator 5.3

5.4

5.4.1

5.4.2

5.5

DC Checks

Power Rails

VCO Locking

RF Checks

5.4

5.4

5.4

5.5

5.5.1

5.6 PGM800Win Generated Errors 5.6

5.7

5.7.1

5.7.1.1

5.7.1.2

5.7.2

5.7.3

5.7.4

Copyright TEL 01/07/00

Output Power

Fault Finding Charts

Microcontroller

Basic Checks

Serial Communications

Regulator

Synthesiser

Exciter Drive Amplifier

5.5

5.7

5.7

5.7

5.8

5.9

5.10

5.13

Page 60

C5.2 T837 Fault Finding M830P-00

Figure Title Page

5.1 RF Diode Probe Circuit 5.5

01/07/00 Copyright TEL

Page 61

M830P-00 T837 Fault Finding C5.3

5.1 Visual Checks

Remove the covers from the T837 and inspect the PCB for damaged or broken components, paying particular attention to the surface mounted devices (SMD's).

Check for defective solder joints. If repair or replacement is considered necessary, refer

to Section 3 of Part A.

5.2 Component Checks

If you suspect a transistor is faulty, you can assess its performance by measuring the forward and reverse resistance of the junctions. Unless the device is completely desoldered, first make sure that the transistor is not shunted by some circuit resistance. Use a

good quality EVM (e.g. Fluke 75) for taking the measurements (or a 20k ohm/V or better multimeter, using only the medium or low resistance ranges).

The collector current drawn by multi-junction transistors is a further guide to their performance.

If an IC is suspect, the most reliable check is to measure the DC operating voltages. Due

to the catastrophic nature of most IC failures, the pin voltages will usually be markedly

different from the recommended values in the presence of a fault. The recommended

values can be obtained from either the circuit diagram or the component data catalogue.

5.3 Front Panel LED Indicator

The green "Supply" LED on the T837 front panel will flash according to the conditions

described in the following table:

Flash Rate Condition

fast (D sec. on/D sec. off

approx.)

unequal (D sec. on/1 sec. off

approx.)

T837 is linked with PGM800Win

microcontroller has detected an

internal communications error -

refer to Section 5.7.1

Where two or more conditions occur at the same time, the precedence is in the order

shown above (i.e. T837 linked has the highest priority, followed by internal error).

Copyright TEL 01/07/00

Page 62

C5.4 T837 Fault Finding M830P-00

5.4 DC Checks

5.4.1 Power Rails

Refer to the top side PCB layout diagram in Section 6 or Figure 4.2 for test point locations, and to the regulator fault finding chart (Section 5.7.2) for fault diagnosis.

Check the 13.8V (TP601) and 9V (TP602) supplies at their test points in the regulator compartment with a DMM.

Check the 5V (TP604) and 20V (TP603) rails at their respective test points in the

regulator compartment.

Check that Tx-Reg. (TP310 in the paging modulator compartment) comes up to

8.8V when the exciter is keyed.

Check the +5V digital regulator output (TP607 in the regulator compartment).

Check for short circuits.

5.4.2 VCO Locking

Key the exciter.

Using a DMM, monitor the VCO control voltage at PL4-1 or the junction of L1 and

R1 on the VCO PCB.

If the synthesiser is locked and the VCO aligned, the voltage at this point should

be between 5 and 13V.

If the VCO is not locked, refer to the synthesiser fault finding chart (Section 5.7.3).

01/07/00 Copyright TEL

Page 63

M830P-00 T837 Fault Finding C5.5

5.5 RF Checks

In-circuit RF levels may be measured with an RF probe on which the earth lead has been

shortened to a minimum (i.e. 13mm). Refer to the circuit diagrams for typical levels.

Figure 5.1 shows a suitable RF probe circuit.

Probe

Earthing Clip

1n

This unit is not suitable for use on high power RF circuits.

10k

1N6263

Figure 5.1 RF Diode Probe Circuit

1n

100k

Coax

5.5.1 Output Power

Refer to the exciter drive amplifier fault finding chart (Section 5.7.4).

Ensure that the VCO locks (refer to Section 5.4.2).

Connect the exciter output to a power meter and key the exciter.

Check that the output power is between 600 and 1000mW.

DC to DVM or

Oscilloscope

Note:

If the synthesiser is out of lock, the lock detector (synthesiser IC740 and

comparator IC750) will prevent the RF signal from reaching the PA by

switching the supply to the exciter amplifier (Q340, Q345).

Copyright TEL 01/07/00

Page 64

C5.6 T837 Fault Finding M830P-00

5.6 PGM800Win Generated Errors

The following errors are those most likely to occur using PGM800Win. Refer to the

PGM800Win software user’s manual for a complete list of error messages.

Channel Switch Set

The programmed default channel change was not accepted by the base station because a

channel is selected externally. Try turning the external channel switch off to change the

default channel in PGM800Win.

Synth Out Of Lock

The synthesiser received incorrect data, or the data was corrupted. Enter a frequency

within the VCO switching range, or tune the VCO.

Internal Error

Data could not be read from the base station due to an internal error. Check for shorts

or open circuits on the SDA, SCK, SYNTH and EPOT lines. The SDA, SCK and SYNTH

are normally high.

Write/Read To An Unlinked Module

The link to the module does not exist. Undefined error.

01/07/00 Copyright TEL

Page 65

M830P-00 T837 Fault Finding C5.7

5.7 Fault Finding Charts

Note:

The standard test point designations used in this section are as follows:

TP601 13.8V

TP602 9V

TP603 20V

TP604 5V

5.7.1 Microcontroller (IC810)

5.7.1.1 Basic Checks

Is the 12.8MHz clock

present on IC810 pin 21

(microcontroller)?

N Pulsing

Replace

IC810.

Is pin 30

pulsing?

Y

Y

Check the

state of

pin 10.

Low

N

High or open circuit

Check IC740

(synthesiser).

Use a DSO* to check

operation of IC650

(i.e. active high

pulse at power up).

*digital storage oscilloscope

Replace

IC650.

Check state of

pins 36 to 43.

Static high/low

Replace IC810.

Pulsing

Check state

of pin 35.

Correct the fault causing

pin 35 to be low/floating.

High

Low/floating

Replace

IC810.

Copyright TEL 01/07/00

Page 66

C5.8 T837 Fault Finding M830P-00

5.7.1.2 Serial Communication

Disconnect the

programming lead.

Is IC810 pin 11 high?

(microcontroller)

Y

Connect the programming

lead and use PGM800Win

to read the rack/radio.

Check I/O pad P810

with a DSO*.

Does it swing from

0 to 5V?

Y*digital storage

oscilloscope

Use PGM800Win

to send a POLL

command to the

radio.

N

N

Check pin state.

Noise

on pin

Check the SERIAL-COM

and AUDIO-1/2 links.

Check the transistor

interface circuitry

and/or replace the

programming lead.

Low/floating

Check the transistor

interface circuitry.

Check IC810 pin 13

with a DSO. Is there

a response from IC810 after

a poll command is sent?

Y

Check the transistor

interface circuitry

and/or replace the

programming lead.

N

Replace

IC810.

01/07/00 Copyright TEL

Page 67

M830P-00 T837 Fault Finding C5.9

5.7.2 Regulator

Check for

overheating

components &

short circuits.

13.8V present on

IC630 pin 3?

Y

5.3V present on

IC630 pin 1?

Y

9.0V present

on TP602?

Y

20V present

on TP603?

Y

+5V present on

IC610 pin 2?

Y

Key Tx.

N

N

N

N

N

Check continuity

from pin 9 of

D-range 1.

Replace IC630.

Check Q630,

Q620 & IC640.

Check Q660 is

switching at

approx. 150kHz.

Check R615.

Replace IC610.

8.8V present

on Tx reg. TP305?

N

0V present

on Q860 collector?

N

0.6V present on

Q860 base?

N

Regulators OK.

Check microcontroller

section.

Y

Y

Y

Regulators OK.

Replace Q610.

Check Q860 and

associated circuitry.

Copyright TEL 01/07/00

Page 68

C5.10 T837 Fault Finding M830P-00

5.7.3 Synthesiser

Refer to the synthesiser circuit diagram (sheet 7) in Section 6 and the VCO circuit diagram in Part E.

A B

No VCO RF output.

9V present at

VCO Q4/Q5?

Y

DC V present

at Q4 & Q5?

Y

8.3V present

at VCO?

Y

DC V present at

VCO, Q1, Q2 & Q3?

Y

Capacitors OK?

Check for cracks,

shorts, etc.

Y

VCO out of lock.

N

N

N

N

N

Check Tx reg.,

Q610 & 9V reg.

Check biasing

resistors, Q4 & Q5.

Check Q5 C

multiplier

(synth).

Check biasing