Page 1

DRAFT 1

5Installation

This chapter provides information on the site requirements for your

TB9300 equipment and also describes how to install the base station in a

standard 19 inch rack or cabinet.

If this is your first time installing a TB9300 base station, we recommend

that you read the entire chapter before beginning the actual installation.

TB9300 Installation and Operation Manual Installation 63

© Tait Limited May 2013

Page 2

DRAFT 1

5.1 Before You Begin

5.1.1 Equipment Security

The security of your base station equipment is a high priority. If the site is

not fully secure, the base station should at least be locked in a secure

cabinet to prevent unauthorized access.

5.1.2 Grounding and Lightning Protection

Electrical Ground The base station modules are grounded by physical contact between the

module case and the subrack. To ensure a good ground connection you

must tighten each module retaining clamp securely (refer to “Final

Reassembly” on page 106 for the correct torque).

A threaded grounding connector is provided on the rear of the subrack for

connection to the site ground point (refer to “Connecting Up the Base

Station” on page 82 for more details).

Lightning Ground It is extremely important for the security of the site and its equipment that

you take adequate precautions against lightning strike. Because it is outside

the scope of this manual to provide comprehensive information on this

subject, we recommend that you conform to your country’s standards

organization or regulatory body.

5.1.3 Equipment Ventilation

Always ensure there is adequate ventilation around the base station.

Notice Do not operate it in a sealed cabinet. You must keep the

ambient temperature within the specified range, and we strongly recommended that you ensure that the cooling airflow is not restricted.

Notice The cooling fans are mounted on the front panel and will only

operate when the panel is fitted correctly to the front of the subrack. To

ensure adequate airflow through the base station, do not operate it for

more than a few minutes with the front panel removed (e.g. for servicing

purposes).

5.1.4 Ambient Temperature Sensor

The ambient temperature reading for the base station is provided by the

temperature sensor located on the front panel circuit board.

64 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 3

DRAFT 1

5.1.5 Cabinet and Rack Ventilation

The cooling airflow for the base station enters through the front panel and

exits at the rear of the subrack. For optimum thermal performance, the

heated air that has passed through a base station must not be allowed to reenter the air intakes on the front panel. Any space at the front of the cabinet

not occupied by equipment should be covered by a blanking panel. Refer

to Figure 5.1 on page 66.

To allow enough cooling airflow through a cabinet-mounted base station,

we recommend the following:

■ an area of at least 23in

holes in front of the air intakes for the fans for each subrack; for

example, thirty 0.25x3.3in (6x85mm) slots will allow the

recommended airflow

■ a vent in the top of the cabinet with an area of approximately 23in

(150cm

rear of the cabinet behind each subrack

■ a 2U gap at the top of the cabinet.

2

) per subrack, or a similar area of ventilation per subrack at the

2

(150cm2) of unrestricted ventilation slots or

2

Auxiliary Extractor

Fans

Notice The ventilation opening must be unrestricted. If the slots or

holes are covered with a filter, mesh or grille, the open area must be

increased to allow the same airflow as an unrestricted opening.

The maximum ambient temperature entering the cabinet must not exceed

+140°F (+60°C).

If you are installing multiple subracks in a cabinet, ensure that there will be

enough cooling airflow through the cabinet after the equipment has been

installed. For example, the recommended maximum number of subracks in

a 38U cabinet is five, as shown in Figure 5.1 on page 66.

If the base station is installed in a rack or cabinet with other equipment with

different ventilation requirements, we recommend that the base station be

positioned below this equipment.

The base station does not require auxiliary extractor fans mounted in the

top of the cabinet. If your cabinet is already fitted with fans, the following

procedures apply:

■ if there are six or more 4.75in (12cm) fans, each capable of extracting

■ if there are fewer than six fans, you must remove them and ensure the

3

94.2 ft

per minute (160m3 per hour), they must run continuously

vent in the top of the cabinet has an area of approximately 23in

(150cm

2

) per subrack.

2

If you have any other configuration, the performance of your system will

depend on how closely you comply with the base station airflow

requirements described above.

TB9300 Installation and Operation Manual Installation 65

© Tait Limited May 2013

Page 4

DRAFT 1

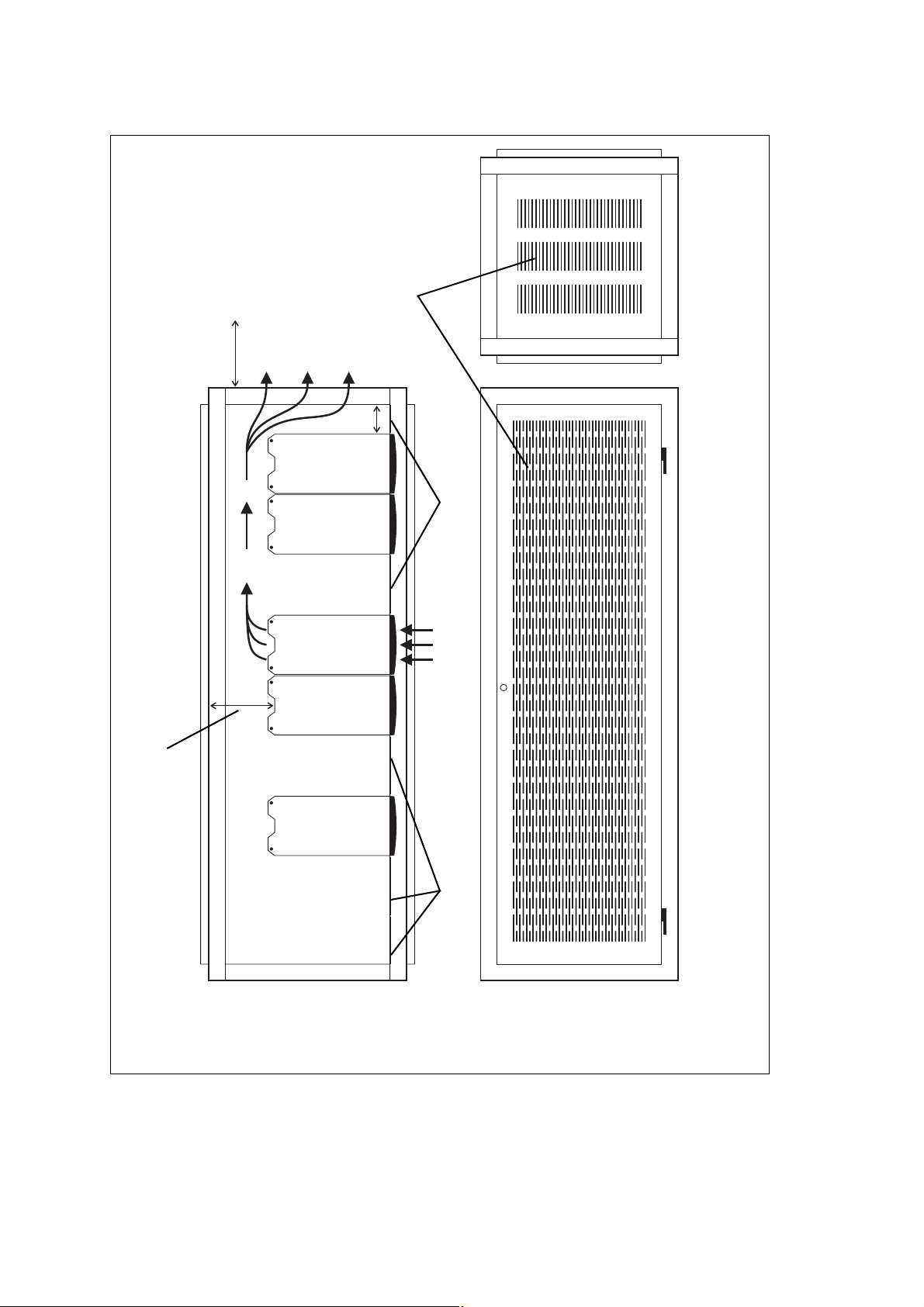

Figure 5.1 Typical cabinet ventilation requirements

b

8in

(20cm)

side view front view

2U

c

top view

≥7in

(≥17.5cm)

e

d

c

ventilation slots

b

blanking panels

c

66 Installation TB9300 Installation and Operation Manual

airflow entry

d

airflow exit path

e

© Tait Limited May 2013

Page 5

DRAFT 1

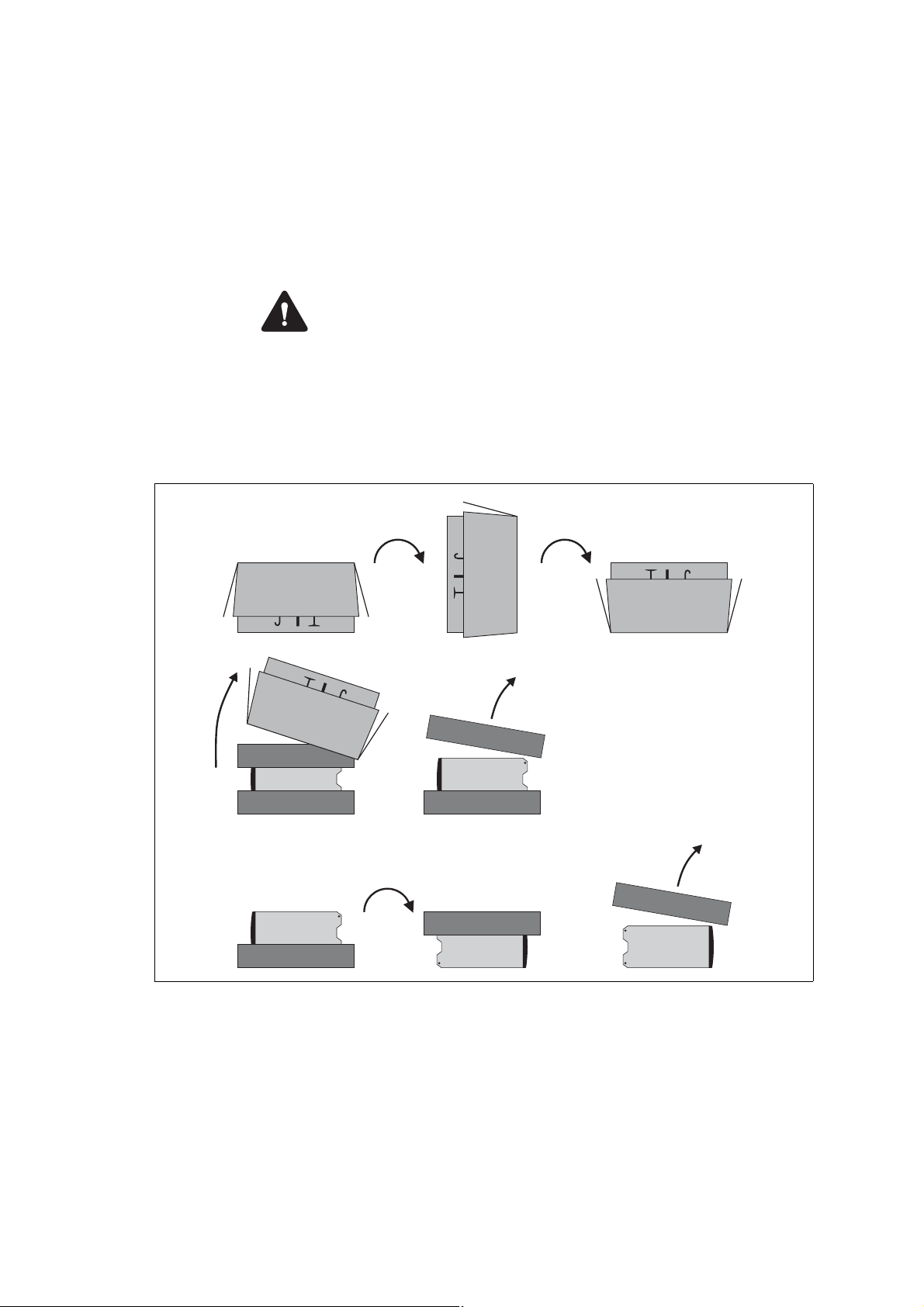

5.2 Unpacking and Moving the Subrack

The subrack is packed in a strong corrugated cardboard carton with top and

bottom foam cushions. To prevent personal injury and damage to the

equipment, we recommend that two people unpack and move the subrack.

To remove the subrack from the carton, follow the procedure illustrated in

Figure 5.2.

Caution A subrack complete with modules can weigh up to 62lb

(28kg), or up to 66lb (30kg) complete with packaging. We recommend

that you have another person help you unpack and move the equipment.

The TBAA03-16 carrying handles will make it easier to move the

equipment once it has been unpacked. If necessary, remove the modules

from the subrack before moving it (refer to “Replacing Modules” on

page 95). In all cases follow safe lifting practices.

Figure 5.2 Unpacking the subrack

b

e

g

1. Cut the tape securing the flaps at the top of the carton and fold them

flat against the sides

2. Rotate the carton carefully onto its side

ensuring that none of the flaps is trapped underneath.

cd

f

hi

b.

c and then onto its top d,

TB9300 Installation and Operation Manual Installation 67

© Tait Limited May 2013

Page 6

DRAFT 1

3. Slide the carton upwards over the foam cushions and lift it away e.

4. Rotate the subrack and cushion carefully over the rear of the subrack

Remove the cushion from the bottom of the subrack

f.

g so that it is the right way up with the cushion on top h. Remove

the cushion from the top of the subrack

i.

Disposal of

Packaging

If you do not need to keep the packaging, we recommend that you recycle

it according to your local recycling methods. The foam cushions are CFCand HCFC-free and may be burnt in a suitable waste-to-energy combustion

facility, or compacted in landfill.

68 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 7

DRAFT 1

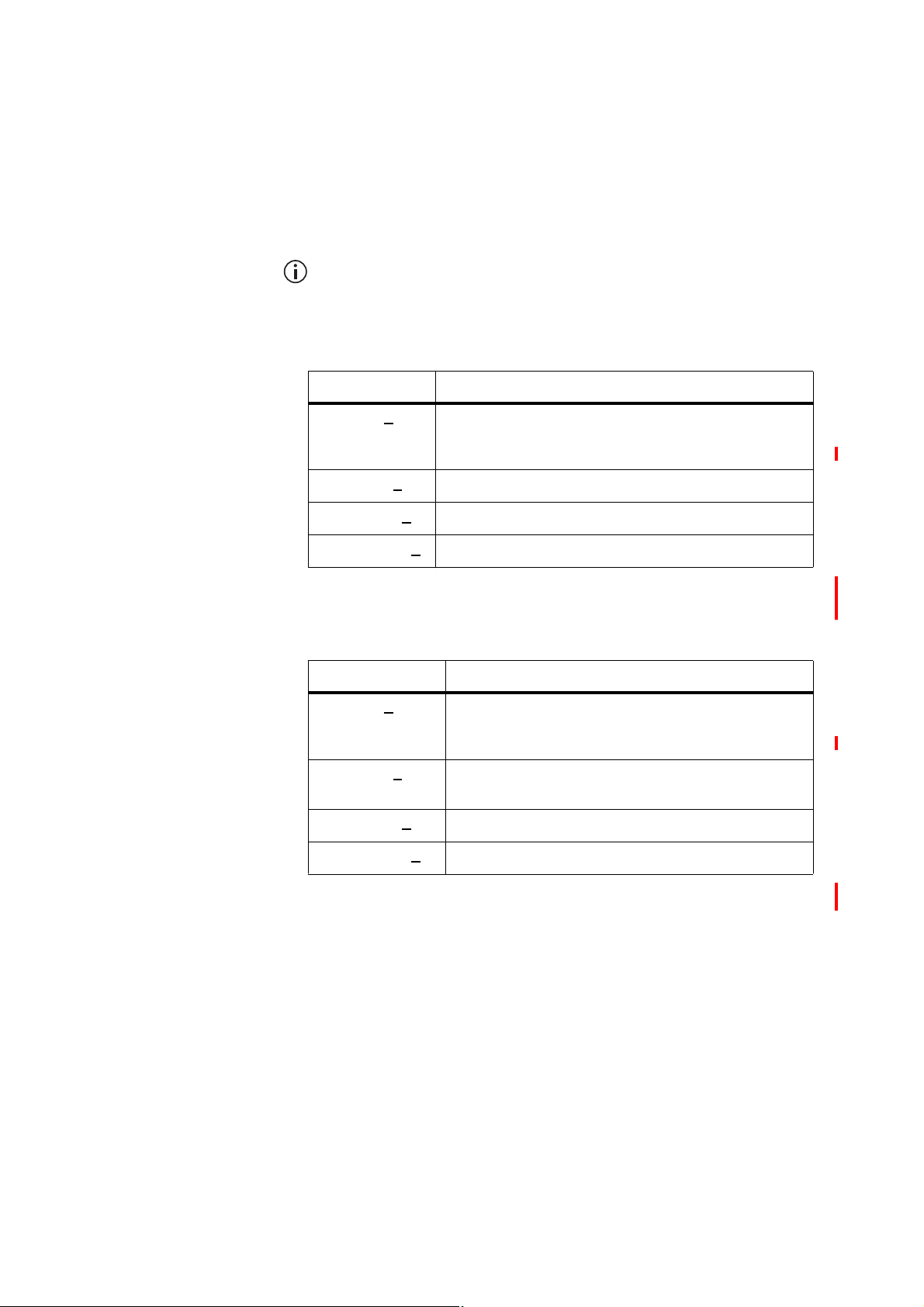

5.3 Identifying the Equipment

You can identify the model and hardware configuration of the TB9300

modules by referring to the product code printed on labels at the rear of

each module. The meaning of each character in the product code is

explained in the tables below.

This explanation of product codes is not intended to suggest that any

combination of features is necessarily available in any one product.

Consult your regional Tait office for more information regarding the

availability of specific models and options.

Reciter Product

Codes

PA Product Codes

Product Code Description

T01-01105-X

T01-01105-XXXX A = standard

T01-01105-XXX

T01-01105-XXXX

a. The actual frequency coverage in this band is:

Product Code Description

T01-01136-X

T01-01136-XXXX A = 50W

T01-01136-XXX

XXX Frequency Band and Sub-band

D = 148MHz to 174MHz (B3)

N = 762MHz to 870MHz

X A = default

A = default

Transmit: 762MHz to 776MHz and 850MHz to 870MHz

Receive: 792MHz to 824MHz

XXX Frequency Band

C = 136MHz to 174MHz (B band)

N = 762MHz to 870MHz

B = 100W

X A = default

a

(K4)

a

(K2)

T01-01136-XXXX

a. The actual frequency coverage in this band when used with a K-band TB9300 re-

citer is 762MHz to 776MHz and 850MHZ to 870MHz.

TB9300 Installation and Operation Manual Installation 69

© Tait Limited May 2013

A = default

Page 8

DRAFT 1

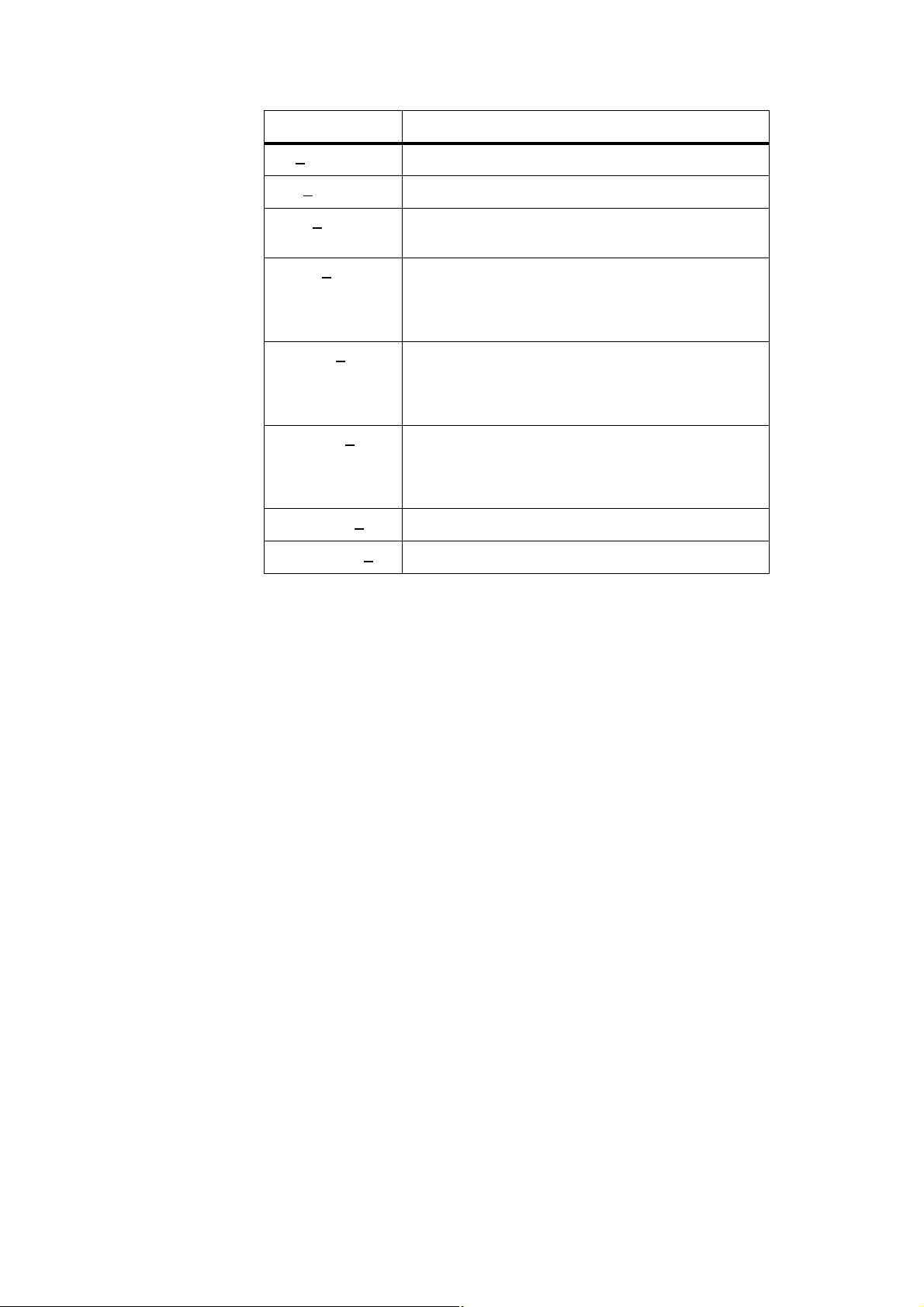

PMU Product

Codes

Product Code Description

TBAX

XXX-XXXX 3 = PMU

TBA3X

XX-XXXX 0 = default

TBA3XX

TBA3XXX

TBA3XXX-X

TBA3XXX-XX

TBA3XXX-XXX

TBA3XXX-XXXX

X-XXXX 0 = AC module not fitted

A = AC module fitted

-XXXX 0 = DC module not fitted

1 = 12V DC module fitted

2 = 24V DC module fitted

4 = 48V DC module fitted

XXX 0 = standby power supply card not fitted

1 = 12VDC standby power supply card fitted

2 = 24VDC standby power supply card fitted

4 = 48VDC standby power supply card fitted

XX 0 = auxiliary power supply board not fitted

1 = 12VDC auxiliary power supply board fitted

2 = 24VDC auxiliary power supply board fitted

4 = 48VDC auxiliary power supply board fitted

X 0 = default

0 = default

70 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 9

DRAFT 1

5.4 Initial Setting Up

Before putting the base station into service, you may want to carry out

some basic functional testing, configuration, and tuning (if required). This

section provides an overview of these procedures:

■ checking that the base station powers up correctly

■ checking the basic functionality of the base station by using the tests

available in the web interface

■ customizing the configuration for the intended installation and

verifying that the configuration is correct

■ changing the root password

■ tuning the base station (if required).

5.4.1 Confirming Operation

Notice Make sure that the RF output is connected to a suitable atten-

uator or dummy load. Do not remove the load while the PA is transmitting as this may damage the PA output stage.

Applying Power 1. Apply power by turning on the PMU.

2. Check that the base station powers up correctly:

■ The front panel display will show “Please wait...” while the base

station starts up (this may take up to two minutes). When the

startup process is complete, the display will show the home

screen.

■ The cooling fans in the front panel will run at full speed for a few

seconds, then run at low speed while the base station starts up,

and then assume standard operation. One or more fans may

operate, depending on the temperature of the modules.

TB9300 Installation and Operation Manual Installation 71

© Tait Limited May 2013

Page 10

DRAFT 1

Functional Tests

The following table provides an overview of the tests available using the

web interface. Refer to the Help for full details of these tests.

Test Notes Menu

receiver operation requires a suitable RF source Diagnose > RF Interface > Receiver

transmitter operation requires connection to the

network

ping checks the IP connection to

another device with an IP address

NTP query checks if the NTP-based time

synchronization is working

PMU mains failure requires a DC backup supply Diagnose > Subsystems > PMU Control

fan operation checks the operation of each fan

individually

Diagnose > RF Interface > Transmitter

Diagnose > Connection > Network

Tests

Diagnose > Subsystems > Fan Tests

72 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 11

DRAFT 1

5.4.2 Customizing the Configuration

The following steps provide an overview of the process used to configure

the base station with the settings it needs. Refer to the Help for detailed

information.

1. Log in to the base station (refer to “Connecting Your PC to the Base

Station” on page 48 for more details).

2. Select Configure. The base station has many different settings that

can be configured before it is put into operation, such as:

■ channel configurations

■ alarm control and SNMP agent

■ network interfaces

■ quality of service

■ CWID

■ miscellaneous items such as minimum battery voltages, fan

control, NTP and package servers.

3. Make the changes needed in each form and click Save.

We recommend that you save the configuration to your PC or network.

First make a backup copy of the configuration (which is stored in the base

station as a file), then save this file to a folder on your PC or network. This

provides a backup which can be restored to the base station if the

configuration information becomes lost or corrupted.

5.4.3 Restricted Port Numbers

Text already updated for

TB9400 manual.

Certain configuration settings in the base station’s web interface require

you to enter a port number (for example, the trunking interface).

Two ranges of port numbers are unavailable for use with the base station.

The web interface will prevent you from entering a number from these

ranges, as explained below.

Restricted Port Numbers Details

0 – 1023 The “well-known ports”, commonly used by other

devices in a network. Using a port number in this

range could cause compatibility problems with other

devices.

12000 – 14999 Reserved for internal use in the base station. Using a

port number in this range could cause the base

station to malfunction.

TB9300 Installation and Operation Manual Installation 73

© Tait Limited May 2013

Page 12

DRAFT 1

5.4.4 Changing the Root Password

The root password to the Linux operating system of the reciter is a possible

security risk. The equipment is delivered with a default password that is

well known. Knowledge of the password could be used to render the

equipment inoperable, for example by deleting files. If you are concerned

about the security risk that this poses, change the password. If Tait provides

support services, it may need to know the password.

Notice If you change the password and then lose it, the equipment

must be returned to Tait. Make sure that you store the password securely

and do not lose it.

To change the root password, follow these steps.

1. Log in from your PC to the base station using SSH client software

such as PuTTY. The username is “root” and the default password is

“k1w1”.

2. At the # prompt, enter the command “passwd”.

3. Follow the on-screen instructions.

4. Record the password in a secure location.

74 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 13

DRAFT 1

5.4.5 Tuning the Reciter

B3-Band Reciter Before the base station is installed on site, you may need to tune the

receiver front end. The receiver front end requires tuning if the receive

frequency is shifted more than 2MHz away from the previously set

frequency, or the RSSI level of the new frequency is more than 1dB lower

than the RSSI level of the previously set frequency.

The receiver in the B3-band VHF reciter covers the 148 to 174MHz

frequency band. This is split into two sub-bands: 148 to 159MHz and

159 to 174MHz. Each sub-band has its own helical filter (shown in

Figure 5.3 below) which is electronically switched in or out of circuit

depending on the frequency programmed into the reciter. The bandwidth of

these helical filters is approximately ±1.5MHz.

Figure 5.3 Identifying the receiver front end helical filters

159 to 174MHz

148 to 159MHz

To check the RSSI level and tune the receiver front end (if required), follow

these steps.

1. Remove the reciter from the subrack and reconnect the system

control bus cable to power up the reciter.

2. Log in to the reciter and select Monitor > Interfaces > RF Interface.

For information on connecting directly to the reciter, refer to

“Connecting a Networked PC to a Base Station” on page 52.

3. Feed a signal at the currently tuned receive frequency and at a level

of –80dBm into the reciter’s RF input. Check that the RSSI reading

on the RF Interface page is –80dBm ±1dB. Note this reading.

4. Set the reciter to the new receive frequency.

TB9300 Installation and Operation Manual Installation 75

© Tait Limited May 2013

Page 14

DRAFT 1

5. Change the RF input signal to the new receive frequency at

–80dBm. Check that the RSSI reading is –80 dBm ±1dB. If it is, the

receiver front end does not require tuning. If it is not, go to the next

step.

6. Using the Johanson tuning tool

the new frequency (as shown in Figure 5.3) to obtain a peak RSSI

reading. This reading should be within 1dB of the reading at the

previous frequency.

Adjust the center resonator of the filter first, followed by the two

outer resonators (in any order). Each resonator should require

approximately the same amount of adjustment when tuning.

A change in frequency of 5MHz requires approximately one turn of the

tuning slug. If tuning to a lower frequency, adjust the slug in (clockwise); for a higher frequency, adjust the slug out (counterclockwise).

7. Change the RF input signal and the reciter’s receive frequency to

0.5MHz above and below the required frequency and check that the

RSSI reading does not drop by more than 0.5dB from the reading at

the required frequency.

8. Recalibrate the RSSI at the new frequency (Calibrate > Reciter >

RSSI).

If you wish to confirm the accuracy of the tuning procedure, carry out a

sensitivity measurement at the new frequency.

1

, adjust the correct helical filter for

K-Band Reciter The K-band reciter does not require tuning.

1. Included in the TBA0ST2 tool kit. Also available separately as part number 937-00013-00.

76 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 15

DRAFT 1

5.5 Installing the Base Station on Site

5.5.1 Base Stations for Trunked Systems

When installing base stations that are part of a trunked system, it is very

important to observe good site engineering rules. This is especially true

when the channels are combined into a single antenna.

If at all possible, the RF planner should avoid frequency plans in which the

Rx to Tx spacing is an exact multiple of the trunked channel spacing, thus

forcing Tx intermodulation products to fall outside the Rx channels.

Cables and antennas should be of high quality construction. Solid shield

heliax type cables are best, but if braided shield cables must be used for

short distances, their braids must be silver-plated. Isolators should be used

at all transmitter outputs.

When the outputs of more than one transmitter are combined, their voltages

add, and the resulting peak envelope power is not simply the sum of their

powers, but is equal to the power of one of them multiplied by the square

of the number of sources. Cables, components, and hardware must be rated

to withstand the peak envelope power.

During the commissioning process, all transmitters should be activated

together using a diagnostic test tone, while the receiver RSSI is monitored.

There should be no perceptible increase in RSSI while the transmitters are

active.

5.5.2 Equipment Required

It is beyond the scope of this manual to list every piece of equipment that

an installation technician should carry. However, the following tools are

specifically required for installing the base station:

■ Pozidriv PZ3 screwdriver for the M6 screws used in the DC input

terminals on the PMU; M6 (0.25in) screws are also used to secure the

subrack to the cabinet in factory-assembled systems

■ Pozidriv PZ2 screwdriver for the M4 screws used to secure the module

retaining clamps, and for the fasteners used to secure the front panel to

the subrack

■ 8mm AF spanner for the SMA connectors, and the subrack ground

connector.

You can also obtain the TBA0ST2 tool kit from your regional Tait office.

It contains the basic tools needed to install, tune, and service the base

station.

TB9300 Installation and Operation Manual Installation 77

© Tait Limited May 2013

Page 16

DRAFT 1

5.5.3 Mounting the Subrack

Caution A subrack complete with modules can weigh up to 62lb

(28kg), or up to 66lb (30kg) complete with packaging. We recommend

that you have another person help you unpack and move the equipment.

The TBAA03-16 carrying handles will make it easier to move the

equipment once it has been unpacked. If necessary, remove the modules

from the subrack before moving it (refer to “Replacing Modules” on

page 95). In all cases follow safe lifting practices.

Figure 5.4 Subrack mounting points

front view

b

rear view

c

b main mounting holes - front c auxiliary mounting holes - rear

1. Remove the front panel, as described in “Preliminary Disassembly”

on page 97.

2. Fit the subrack into the cabinet or rack and secure it firmly with an

M6 (0.25in) screw, flat and spring washer in each of the four main

mounting holes

b, as shown in Figure 5.4.

If you need extra mounting security, additional mounting holes

provided at the rear of the subrack for auxiliary support brackets.

78 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

c are

Page 17

DRAFT 1

Figure 5.5 below gives the dimensions of the subrack and its mounting

holes.

Figure 5.5 Subrack dimensions

14.8 in

(375.5 mm)

17 in (432 mm)

6.96 in

(176.8 mm)

4 in

(101.6 mm)

19 in (482.6 mm)

18.3 in (465.1 mm)

0.42 in

(10.6 mm)

0.26 in

(6.6 mm)

14.7 in (373.5 mm)

14.37 in (365 mm)

5.25 in

(133.4 mm)

TB9300 Installation and Operation Manual Installation 79

© Tait Limited May 2013

Page 18

DRAFT 1

Auxiliary Support

Bracket

TBAA03-13 auxiliary support brackets can be fitted to the rear of the

subrack to provide additional mounting security. Figure 5.6 shows a

standard TBAA03-13 bracket

are not using the Tait cabinet, you may have to make your own brackets to

suit your installation.

Figure 5.6 Auxiliary support bracket

b fitted in a typical Tait cabinet c. If you

b

c

Notice Yo u must fit the auxiliary support brackets if you intend to

transport a cabinet fitted with a fully built-up base station.

We also recommend that you fit the brackets under the following

conditions:

■ when the installation is in an area prone to earthquakes

■ when third party equipment is installed hard up underneath the base

station subrack.

General Cabling We recommend that you try to route all cables to and from the base station

along the side of the cabinet so the cooling airflow is not restricted.

80 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 19

DRAFT 1

DC Power Cabling

DC power cables should be well supported so that the terminals on the

PMU and on the ends of the cables do not have to support the full weight

of the cables.

Figure 5.7 shows two recommended methods of securing these cables to

prevent straining either set of terminals.

We recommend that you fit the supplied covers to the DC terminals to

protect against accidental shorts.

Figure 5.7 DC power cabling

secure the cables to the

cabinet to support their

weight

TB9300 Installation and Operation Manual Installation 81

© Tait Limited May 2013

Page 20

DRAFT 1

5.6 Connecting Up the Base Station

This section provides information relevant to the task of connecting up the

various inputs and outputs of the base station.

5.6.1 Connection Overview

The connections at the rear of a dual 50W base station are identified in

Figure 5.8. External connections are all located at the rear of the subrack.

Figure 5.8 50W base station inputs and outputs

bcd

e

f

gh

1@

Reciter 1 PMU

b serial RS-232 connector

c 1 PPS input i auxiliary DC output

d external reference frequency input j AC mains input

e RF input 1) Ethernet interface connector

f RF output 1! subrack ground connector

g – VDC input 1@ system interface connector

Reciter 2

a

PA 1

PA 2

h + VDC input

ij1)1!

a. Factory use only.

82 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 21

DRAFT 1

5.6.2 Connecting AC Power

The PMU is designed to accept a mains input of 88 to 264VAC at 45 to

65Hz. A standard 3-wire grounded socket outlet must be used to supply the

AC power. The socket outlet must be installed near the equipment and must

be easily accessible. This outlet should be connected to an AC power

supply capable of providing at least 600W. The requirements of two typical

AC supplies are given in the following table.

Nominal Supply Current Requirement

115 VAC 8 A 10 A

230VAC 4A 6A

a. The actual current consumption of the base station will be lower than these re-

quirements (refer to the Specifications Manual for more information).

Your base station should come supplied

with a power supply cord to connect the

male IEC connector on the PMU to the

local AC supply. The pins of the IEC

connector on the PMU are identified at

right.

Circuit Breaker/Fuse

a

Rating

a

phase

ground

neutral

rear view

TB9300 Installation and Operation Manual Installation 83

© Tait Limited May 2013

Page 22

DRAFT 1

5.6.3 Connecting DC Power

The PMU is designed to accept a nominal 12VDC, 24VDC or 48VDC

input (depending on the model) with negative or positive ground. There is

a minimum DC startup threshold to prevent damaging a battery which has

little capacity left.

You must connect the DC supply from the battery to the PMU via a fuse or

DC-rated circuit breaker with a contact separation of 3mm, and with the

appropriate rating, as shown in the table below. The DC input leads should

be of a suitable gauge to ensure less than 0.2V drop at maximum load over

the required length of lead.

Nominal Supply

Voltage

12VDC 10VDC to 16.8VDC 60A 2AWG / 35mm

24VDC 20VDC to 33.6VDC 30A 5AWG / 16mm

48VDC 40VDC to 60VDC 15A 8AWG / 8mm

a. The actual current consumption of the base station will be lower than these re-

quirements (refer to the Specifications Manual for more information).

b. For a length of 5ft to 6.5ft (1.5 m to 2m) (typical).

Input Voltage

Range

Circuit Breaker/

Fuse Rating

a

Recommended

Wire Gauge

b

2

2

2

Terminate and insulate the DC input leads to protect them from

accidentally shorting to the subrack if the PMU is removed before the leads

are disconnected. Protective covers for the DC terminals are supplied with

each PMU.

Figure 5.9 Recommended DC power connection

Circuit Breaker

or Fuse

PMU

Battery

We recommend a screw torque of 18– 20 lbf · in (2 – 2.25 N · m).

84 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 23

DRAFT 1

5.6.4 Connecting the Auxiliary DC Power Output

The PMU can provide an auxiliary DC output from the auxiliary power

supply board. This board is available with an output of 13.65VDC,

27.3VDC, or 54.6VDC (depending on the model), and is current limited to

3A, 1.5A or 750mA respectively. This power supply is permanently on as

soon as the base station has finished powering up, and is available on the

auxiliary output connector on the rear panel.

You can connect multiple auxiliary power supply boards in parallel for

redundancy purposes, or to provide an output greater than 40W. Although

no active current sharing is used, auxiliary boards connected in parallel will

current-share before reaching their power limit. The failure (or switching

off) of one auxiliary board will not load any other paralleled auxiliary

boards in the circuit.

Auxiliary DC Power

Output Cabling

Network elements are supplied with a connector, as shown in Figure 5.10.

You can use this to connect the PMU’s auxiliary DC power output to

another device (refer to “PMU Auxiliary DC Output” on page 109 for the

pin allocations).

Contact your regional Tait office for details on the full range of wiring kits

available.

Figure 5.10 Auxiliary DC power connector

Phoenix MVSTBR2.5HC/2-ST/5.08 female

TB9300 Installation and Operation Manual Installation 85

© Tait Limited May 2013

Page 24

DRAFT 1

5.6.5 Connecting RF

Notice Do not remove the load from the PA while it is transmitting

as this may damage the PA output stage.

The RF input to the base station is via the marked BNC connector on the

rear panel of the reciter. The RF output is via the N-type connector on the

rear panel of the PA (refer to Figure 5.8 on page 82).

Cables and antennas should be of high quality construction. Solid shield

heliax type cables are best, but if braided shield cables must be used for

short distances, their braids must be silver-plated.

Recommendations

for Installing the PA

We recommend the following installation procedures, which should protect

the PA from damage under all but the most extreme operating conditions.

1. Do not connect the PA directly to the antenna. Fit an isolator or

duplexer between the PA and the load. Fit the isolator as close as possible to the RF output connector on the PA. Do not connect any

switching equipment between the isolator and the PA, unless the

switch cannot operate while there is RF present (i.e. the base station

is transmitting).

2. Fit a surge suppressor to the antenna cabling where it enters the

building.

3. Inspect all cables and equipment connected to the base station for

defects.

Ice on the antenna, or a broken antenna, is unlikely to cause damage to the

PA .

Explanation The circuit design of the PA protects the circuitry from high VSWR. This

makes it difficult to damage the RF power device by keying the PA into a

mismatched load, or if the load deteriorates over even a short period of time

(milliseconds).

However, it is possible to damage the device if all the following conditions

happen at the same time:

■ there is a step change in the PA load (for example, the load is removed)

■ the PA is transmitting

■ the feed line loss between the PA and the mismatch is <1dB.

The effect of such conditions is variable: some devices will not be

destroyed, and some may fail after repeated load interruptions.

86 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 25

DRAFT 1

5.6.6 Connecting an External Frequency Reference

An external reference frequency is not normally required for B3 band.

However, an external reference can be used when you need to maximize

the range of the base station. For K4 Band, the internal frequency reference

accuracy is inadequate, and an external reference must be used. The

external reference frequency can be 10MHz or 12.8MHz, with an input

level of 300mV

than 50 parts per billion. The reciter automatically detects the frequency of

the external reference and configures itself accordingly.

If an external reference is required, enable the external reference “Absent”

alarm (Configure > Alarms > Control).

Use a 50Ω coaxial cable (RG58 or RG223) to connect the external

reference to the base station’s external reference frequency input. You can

daisy-chain up to eight base stations using F-junctions. The maximum

overall cable length is 30m. Terminate the last connection with a 50Ω load.

Figure 5.11 Daisy-chaining an external frequency reference input

to 5Vpp. The stability of this reference should be better

pp

maximum overall cable

length is 30m

maximum of eight base

station loads on one

frequency reference output

50Ω termination

TB9300 Installation and Operation Manual Installation 87

© Tait Limited May 2013

Page 26

DRAFT 1

5.6.7 Ethernet Connection

The RJ-45 socket on the reciter’s rear panel provides the 10BASE-T or

100BASE-T Ethernet connection to the other devices in the network. Use

Cat-5 cable to connect this socket to the Tait DMR Network via a router or

switch.

If necessary, refer to “Ethernet Connector” on page 109 for a list of

Ethernet connection pin allocations.

88 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Page 27

DRAFT 1

5.6.8 Connecting General Purpose Inputs and Outputs

The base station has a number of general purpose inputs and outputs. These

are connected via the 25-way D-range on the rear panel.

The pin allocations for the D-range connector are given in the following

table. Not all pins are used in this release of the base station.

Pin Signal Name Signal Type Notes

1

2

3

4

5

not used reserved for future use

6

B

1$

C

1%

D

1^

E

1&

F

1*

G

1(

H

2)

I

2!

J

2@

1)

2#

1!

2$

1@

2%

1#

external view

7

8

9

10

11 digital in 1

12 digital in 2

13 + 5.2 VDC output power output maximum current 200mA

14 digital in 3

15 digital in 4

16 digital in 5

17 digital in 6

18 digital in 7

19 digital in 8

20 digital in 9

21 digital in 10

22 digital in 11

23 digital in 11

24 not used reserved for future use

25 ground ground

input

input

5V TTL logic

active low

5V TTL logic

active low

TB9300 Installation and Operation Manual Installation 89

© Tait Limited May 2013

Page 28

DRAFT 1

90 Installation TB9300 Installation and Operation Manual

© Tait Limited May 2013

Loading...

Loading...