Taema Monnal D2 Service manual

MONNAL D2

MONNAL D2

Maintenance

Manual

YM002100 - Rev 3 - December 1999

1

MONNAL D2

CONTENTS

GENERAL SAFETY INSTRUCTIONS................................................................................4

1 - GENERAL ...........................................................................................................................6

1.1 Introduction............................................................................................................6

1.2 Descriptions and Settings......................................................................................7

1.3 Specifications..........................................................................................................9

1.4 Symbols.................................................................................................................11

2 - OPERATION.....................................................................................................................12

2.1 Operating principle .............................................................................................12

2.2 Operational diagrams..........................................................................................14

2.2.1 Inspiratory phase ..............................................................................14

2.2.2 Expiratory phase ..............................................................................15

2.3 Troubleshooting...................................................................................................16

2.3.1 Ventilation problems ..........................................................................16

2.2.2 Problems originating in solenoid valve unit.......................................18

3 - DESCRIPTION .................................................................................................................19

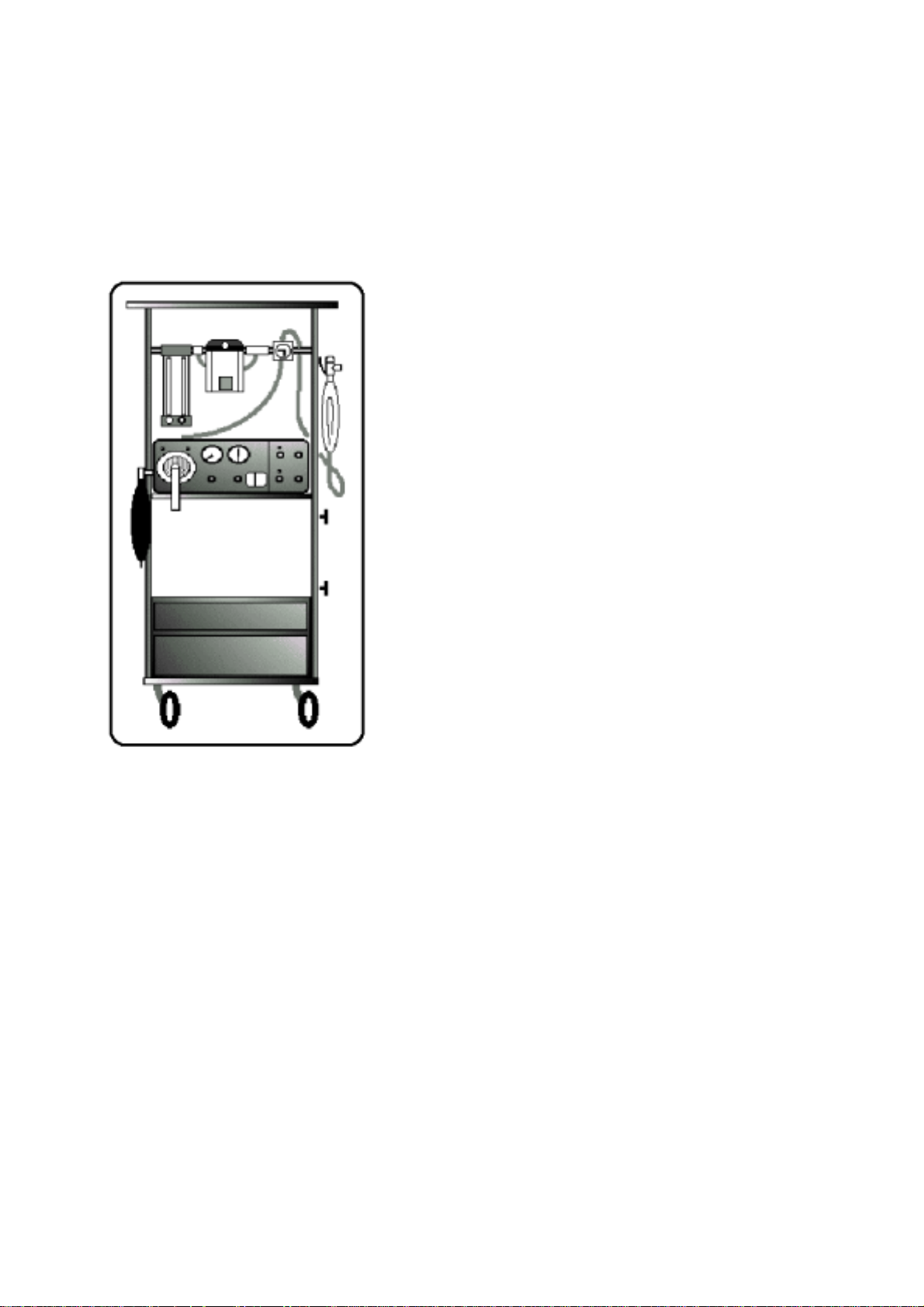

3.1 Overall views........................................................................................................19

3.2 Compressor assembly..........................................................................................20

3.3 Compressor outlet filter box assembly ..............................................................21

3.4 Compressor valve assembly(DC1)......................................................................21

3.5 Ventilation tap assembly.....................................................................................22

3.6 Distributor assembly ...........................................................................................22

3.7 Collectors assembly..............................................................................................23

3.8 Port filter with valve assembly ...........................................................................24

3.9 Safety valve assembly..........................................................................................24

3.10 Non-return valve assembly .................................................................................25

3.11 Reservoir bag connector assembly.....................................................................25

3.12 Pneumatic connector for pressure sensor assembly........................................26

YM002100 - Rev 3 - December 1999

MONNAL D2

4 - MAINTENANCE ..............................................................................................................27

4.1 Maintenance recommendation ...........................................................................27

4.1.1 Routine maintenance...........................................................................27

4.1.2 Maintenance by technician .................................................................28

4.2 Checking procedures...........................................................................................29

4.2.1 Compressor flow.................................................................................29

4.2.2 Compressor valve (DC1) ....................................................................29

4.2.3 Bag valve ............................................................................................30

4.2.4 Safety valve.........................................................................................30

4.2.5 O2 non-return valve seal.....................................................................31

4.2.6 Distibutor ........................................................................................... 31

4.2.7 Patient flow.........................................................................................32

4.2.8 Ventilation frequency..........................................................................33

4.2.9 I/E ratio...............................................................................................33

4.2.10 Trigger threshold (SD)........................................................................33

4.2.11 Pmin disconnection alarm...................................................................34

4.3 Special tools and equipment ...............................................................................35

4.3.1 Tools ...................................................................................................35

4.3.2 Measurement.......................................................................................35

5 - DIAGRAMS.......................................................................................................................36

5.1 Pneumatic circuit diagrams................................................................................36

5.1.1 Pneumatic circuit for n° ≥ 1300..........................................................36

5.1.2 Pneumatic circuit for551 ≤ n° < 1300.................................................37

5.1.3 Pneumatic circuit for n° < 551............................................................38

5.2 Pneumatic circuit of autonomous anaesthesia system......................................39

5.3 Electrical circuit diagrams..................................................................................40

5.3.1 Electrical circuit n° ≥ 1300 .................................................................40

5.3.2 Electrical circuit 650 ≤ n° < 1300.......................................................41

5.3.3 Electrical circuit n° < 650...................................................................42

5.4 Skeleton diagrams of motherboards..................................................................43

5.4.1 Motherboard n° ≥ 1300.......................................................................43

5.4.2 Motherboard 650 ≤ n° < 1300.............................................................44

5.4.3 Motherboard n° < 650.........................................................................45

5.5 Skeleton diagram of Pmin card for n° ≥≥≥≥ 1300...................................................46

5.6 Layout diagram of components on motherboard for n° ≥≥≥≥ 1300......................47

5.7 Layout diagram of components of Pmin card for n° ≥≥≥≥ 1300............................48

6 - PARTS LIST......................................................................................................................49

7 - APPENDICES ...................................................................................................................54

YM002100 - Rev 3 - December 1999

GENERAL SAFETY INSTRUCTIONS

Use of oxygen

Keep to the safety rules for the use of oxygen:

Do not smoke,

Do not use in the vicinity of a source of sparks or incandescent objects,

Do not lubricate operating equipment

Use and servicing of the machine

Compliant with NF C 74010 (§ 1.3):

"The manufacturer, assembler, installer or the importer are not considered responsible for

the safety, reliability and the characteristics of a machine unless:

MONNAL D2

- Assembly, extensions, settings, modifications or repairs have been carried out by

persons authorised by them, and

- The electrical wiring of the relevant premises complies with IEC regulations,

- The machine is used in accordance with the instructions for use."

If the replacement parts used for the periodic servicing do not comply with the manufacturer's

specifications, the latter is absolved from all responsibility in the event of an accident.

- Do not open the machine while it is switched on.

- Do not use ether type solvents.

- Do not use pipes or tubes which are anti-static or conductors of electricity.

- Do not use in a specifically magnetic environment (MRI,etc.).

- The MONNAL D2 pulmonary ventilator must not be used with inflammable anaesthetic

materials or explosive products.

4YM002100 - Rev 3 - December 1999

GENERAL SAFETY INSTRUCTIONS

Electromagnetic compatibility

The MONNAL D2 ventilator is a medical device compliant with the protection requirements

of directive 93/42/CEE.

Its operation may be affected by the use in its vicinity of machines such as diathermy machines, high frequency electrosurgery machines, defibrillators, short-wave therapy machines or mobile telephones, and more generally by electromagnetic interference exceeding

the levels specified by standard EN 60 601-1-2 (1993 edition).

The MONNAL D2 ventilator must be associated with the necessary complementary

monitoring (O

It is recommended that a manual ventilation system (Taema type IM5 ) and an

emergency medical oxygen tank equipped with a low pressure pressure reducing

valve be kept nearby.

, flow measurement, etc.) in compliance with the regulations in force.

2

MONNAL D2

The MONNAL D2 must be used in association with a patient airways monitoring system

(Taema Pmax UNIT type).

5YM002100 - Rev 3 - December 1999

1 - GENERAL

1 . 1 Introduction

MONNAL D2

The

MONNAL D2

designed to meet the needs of anaesthetist-reanimators

who wish to use a flexible and multi-purpose ventilator:

- in the recovery room and in post-operative situations

- in anaesthesia (open-circuit)

ventilator is a machine specially

MONNAL D2

The

gas or mixture of gases (in the presence of a halogenated

agent or not).

T o constitute an

with O2 and N2O from a source of O2 gas under pressure

(or from an oxygen concentrator) and from a source of

N2O gas under pressure (and with air from the ventilator).

MONNAL D2

The

- a halogenated agent evaporator,

- a safety O

- a manual induction circuit,

- an anaesthesia table.

ventilator can ventilate a patient with a

anaesthesia system

ventilator is generally associated with:

O mixer,

2/N2

, it can be supplied

6YM002100 - Rev 3 - December 1999

1 - GENERAL

MONNAL D2

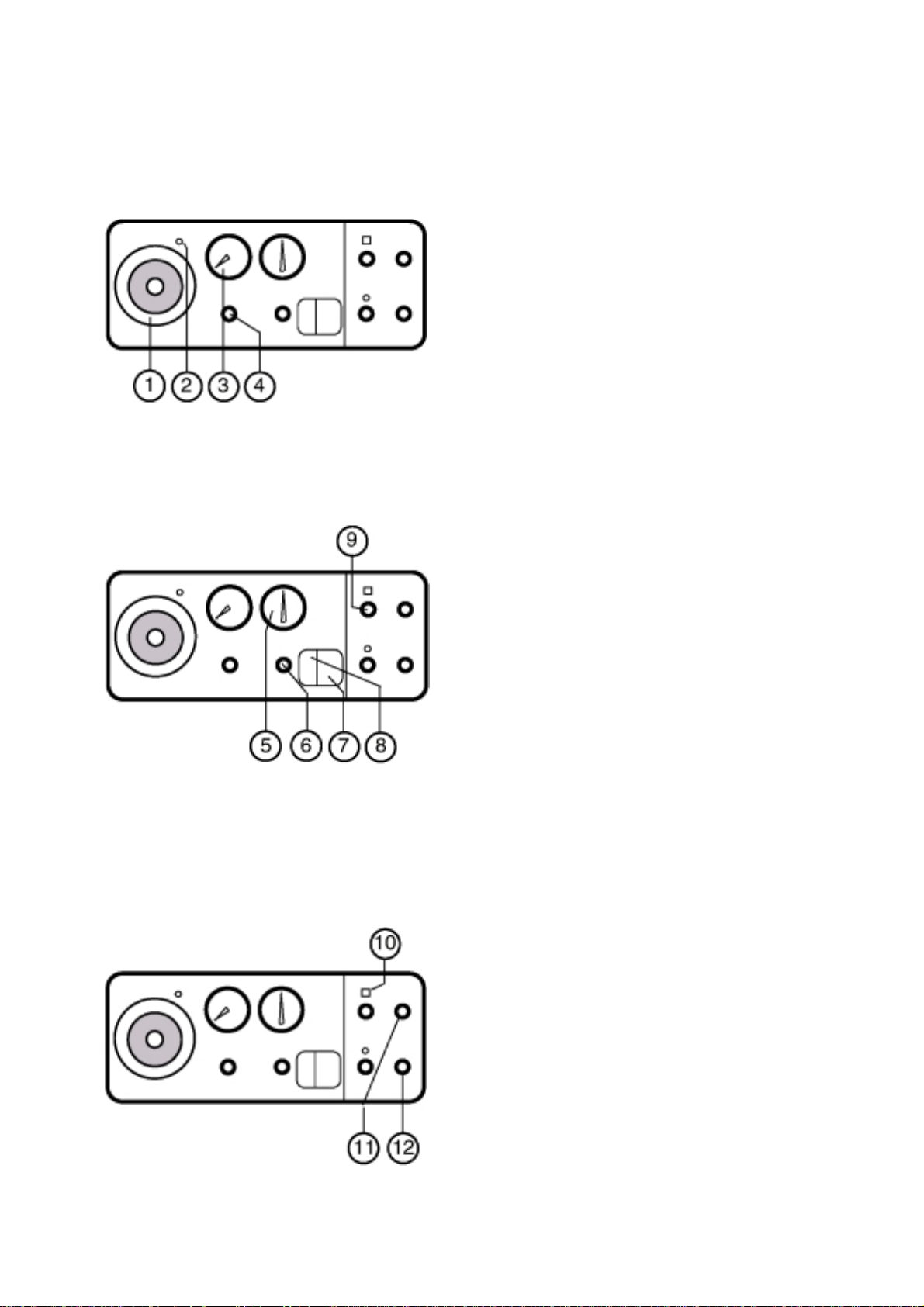

1 . 2 Descriptions and settings

FRONT PANEL

1- Bacteriological filter cover

2- Collector nozzle

Controls expiratory valve operation

3- Flowmeter for ambient air provided by

compressor

4- Air flow adjustment

5- Insufflation pressure manometer

6- Safety pressure adjustment (Pmax).

To adjust, it is necessary to:

-Block the patient circuit patient at the Y

piece

-Read off P max as it appears on the

manometer during insufflation

-adjust the setting by turning towards +/-

Note: The user may keep the P max value constant by removing the removable button

7- Green illuminated On/Off button

8- Yellow illuminated compressor start button (on

the rear panel on old models).

When the switch is in the on position, the

MONNAL D2

ambient air. Otherwise only the mixture from the

anaesthesia rack is used.

9- Pmin alarm setting

Setting by potentiometer .

10- Red LED and disabling button of Pmax.

audible alarm

When the audible and visible alarm is triggered,

pressing on the button disables the audible alarm

for 2 minutes but the red flashing LED continues

to operate.

11- I/E ratio setting

From1/3 to 1/1.

12- Frequency setting

ventilator delivers compressed

Minimum controlled cycle frequency setting.from

8 to 40 bpm.

13- Trigger sensitivity adjustment (SD/TS)

7YM002100 - Rev 3 - December 1999

1 - GENERAL

MONNAL D2

T rigger sensitivity allows Controlled Assisted Ventilation (CAV). The detection of a call sets off a

controlled cycle. If no call is detected a controlled

cycle is supplied by the machine to guarantee the

minimum set frequency

The standard SD/TS settings for CAV are

from - 1 to - 5 mbar.To move into Controlled V entilation mode (VC), set trigger sensitivity at - 20

mbar.

14- Inspiratory effort trigger

REAR PANEL

15- Hour counter

16- Water trap

17- Abacus: air and oxygen mixtures

18- Aeration

19- Mains socket

20- Fuse

2 supply protection fuses.

21- Compressed ambient air outlet nozzle

Outlet used for autonomous anaesthesia

system connection

22- Fresh gas inlet nozzle

23- Manufacturer's label

UPPER COVER CONTROL

21a - Compressed ambient air outlet control

Compressor to outlet air duct control (21) used

for autonomous anaesthesia connection.

The AIR DIRECT position corresponds to standard operation; the AIR INDIRECT position corresponds to the autonomous system

configuration.

8YM002100 - Rev 3 - December 1999

1 - GENERAL

1.3 Specifications

PHYSICAL

- Dimensions: L x D x H = 470 x 308 x 150 mm.

- Mass: 14 kg.

ELECTRICAL

- Electrical supply: 220 V~ 50 Hz

Own electrical consumption: 160 VA

Class I machine

Type B machine

MONNAL D2

- Protection at maximum current:

General supply protection: 2 F 1A fuses (rear panel),

Electronic card protection: 1 100 mAT internal fuse.

- Power failure protection:

Audible alarm (duration of discharge: 10 minutes).

ENVIRONMENT

- Minimum and maximum storage temperatures: From -40°C to +70°C.

- Minimum and maximum operating temperatures: From +10°C to +40°C.

- Atmospheric pressure (use): From 700 to 1060 mbar.

- Relative humidity (storage and use): From 30 to 75%.

- Protection index: IP20 (protected against solid bodies greater than 12 mm and non-

protected against penetration by liquids).

9YM002100 - Rev 3 - December 1999

1 - GENERAL

PERFORMANCE

- Breathing rate: From 8 to 40 bpm

- I/E ratio: From 1/1 to 1/3.

- Mean flow (insufflated per minute): From 0 to 20 l/min.

- Pmin pressure sensitivity: From 0 to 60 hPa.

- Trigger sensitivity (CAV): From 0 to -20 hP a.

- Instantaneous pressure display: From -20 to 100 hPa.

MATERIALS IN CONTACT WITH THE PATIENT AND GASES BREATHED

Silicone (autoclavable patient circuit),

Latex (accumulation bag),

MONNAL D2

PVC,

Aluminium.

STANDARDS/DIRECTIVES

NF C 74350: Artificial respiration treatment machines

NF S 90-118: Medical use ventilators

NF EN 601-1: Electromedical machine safety

NF EN 60-601-1-2: Electromagnetic compatibility of electromedical machines.

European directive 93/42/CEE concerning medical devices.

10YM002100 - Rev 3 - December 1999

1 - GENERAL

1.4 Symbols

/ T rigger Trigger sensitivity

MONNAL D2

Stop (power off)

Start (power on)

Pmin audible alarm disable

Ratio of inspiration phase to expiratory phase

Breathing rate (frequency)

organisation n° 0459).

(

MONNAL D2

Protection earth

Equipotential

Attention: Refer to accompanying documents

Type B machine

Compliance with directive 93/42/CEE (established by notified

units are systematically marked starting from serial number 1770)

11YM002100 - Rev 3 - December 1999

2 - OPERATION

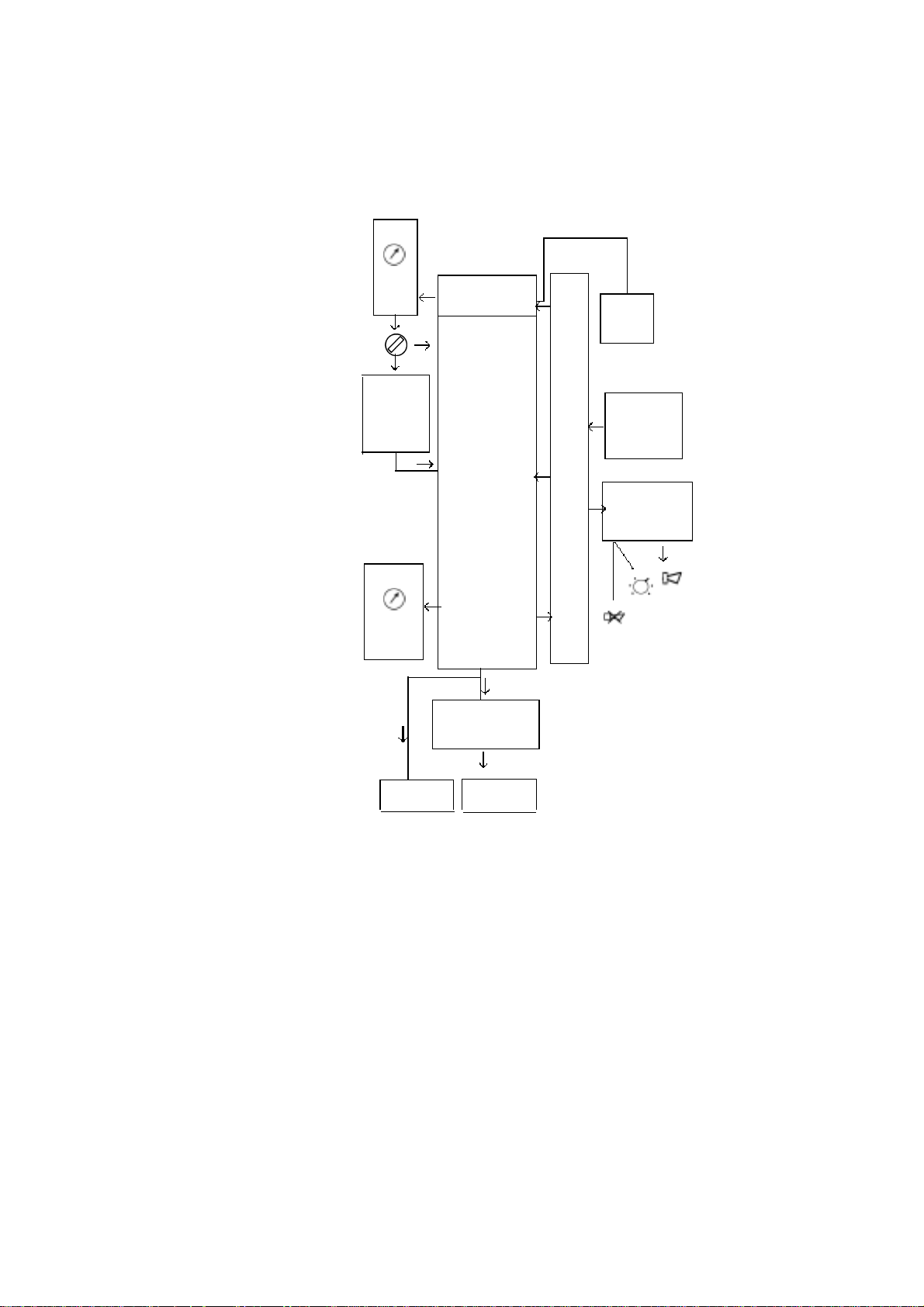

2.1 Operating principle

MONNAL D2

l/min

0 20

V

Anaesthetic

mixture or

O

2

mbar

-2 100

pressure

Compressor

Collector

block

Solenoid valves

Reservoir

bag

Safety

valve

Bacteriological

filter

unit

Electronic

0/1

compr.

f, I/E,

Pmin, TS

Settings

Pmin, mains

Alarms

Collector Patient

Operating diagram

The collector/solenoid block is supplied with air, and/or with a gas mixture (or with pure

oxygen), by means of a compressor.

Air ventilation (V) is displayed on a flowmeter and controlled by a tap.

The collector block including diaphragms associated with solenoid valves, controlled by the

electronic unit, distributes the continuous flow

- on one hand, towards the reservoir bag during the expiratory phase,

- on the other hand, with the addition of gas stored by the bag, towards the patient

through a bacteriological filter during the inspiratory phase.

The insufflation pressure is displayed on a manometer and can be limited by adjusting a

safety valve.

By means of the electronic unit the rate, the I/E ratio, the trigger sensitivity SD/TS (in CAV

mode) and Pmin sensitivity can be set. It also enables visual indication of the trigger sensitivity

SD/TS, audible and visual indication of Pmin, and audible indication of a mains power cut.

12YM002100 - Rev 3 - December 1999

2 - OPERATION

DESCRIPTION OF VENTILATION PHASES

Inspiratory phase

The patient receives the continuous flow from the compressor or from the fresh gas inlet

nozzle to which are added, by the Venturi effect, the gases which have accumulated in the

reservoir bag during the inspiratory phase.

The reservoir bag deflates.

If resistance is felt, the pressure in the patient circuit reaches the Venturi discharge pres-

sure, in which case the bag's non-return valve shuts, and this allows the compressor to

increase the insufflation pressure if necessary. This pressure is, however, limited to the

value of the patient safety valve setting.

Expiratory phase

The patient circuit is isolated from the machine, and the patient breathes out freely towards

the outside, through the expiratory valve.

MONNAL D2

Meanwhile the circuit towards the reservoir bag opens and the bag inflates.

The pressure in the bag is in any case limited to the opening pressure of the overpressure

valve.

AIR AND OXYGEN MIXTURE

If an additional supply of 100% oxygen is insufflated to the patient when the compressor is

operating, this oxygen flow is added to the air flow set on the manometer on the front panel.

O

l/min

2

13YM002100 - Rev 3 - December 1999

Pmini

I/E

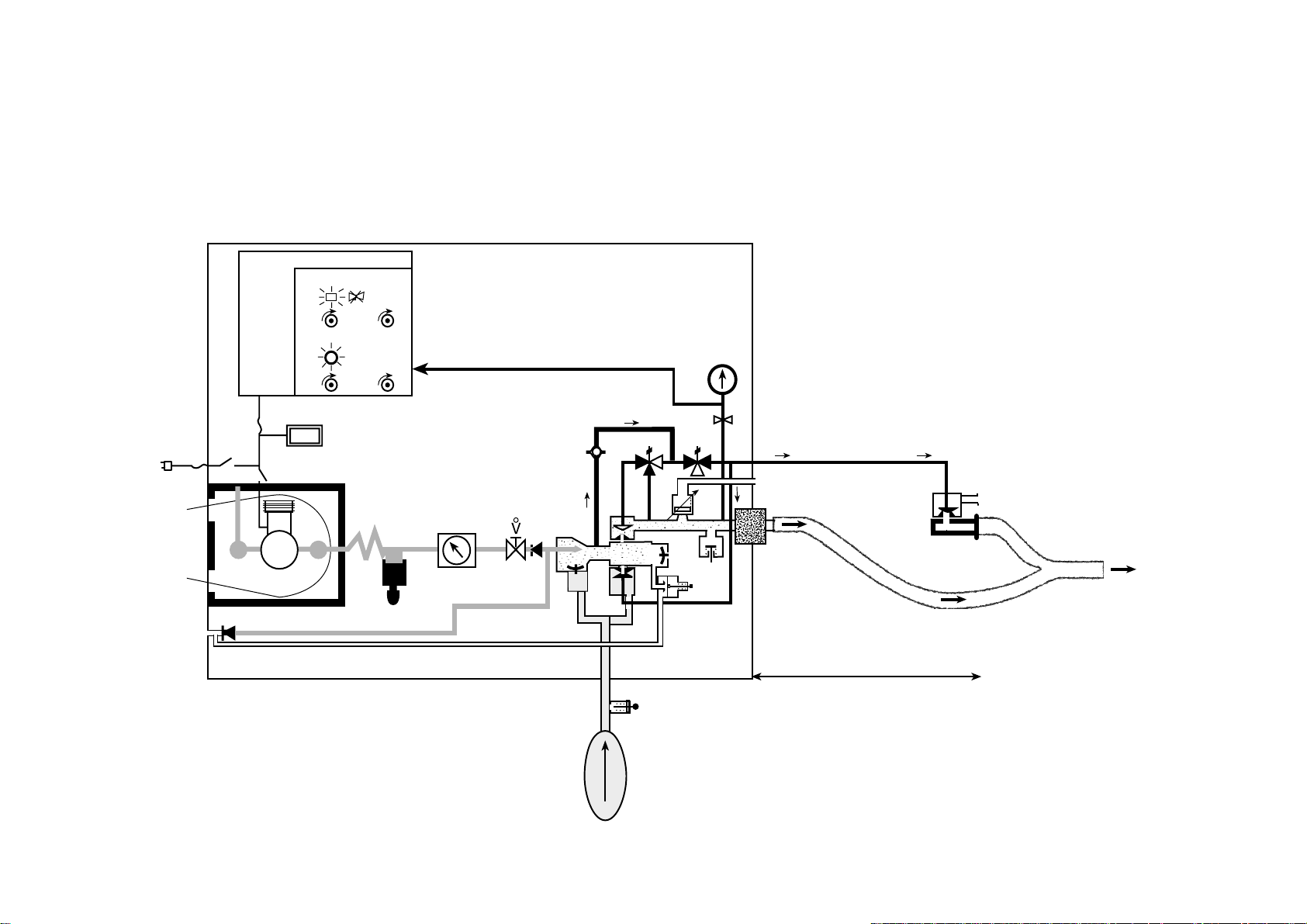

2.2.1 Inspiratory phase

2.2 Operating diagrams

2 - OPERATION

220 V

Fresh

gas

Hour counter

Compressor

SD

F

0-20 l/min

550 mbar

Filter

0 +80

mbar

110 mbar

-20 + 100

mbar

-

-20 mbar

170 mbar

+

PATIENT

MONNAL D2

PATIENTCIRCUIT

14YM002100 - Rev 3 - December 1999

Pmini

2 - OPERATION

2.2.2 Expiratory phase

I/E

220 V

Fresh

gas

Hour counter

Compressor

SD

F

0-20 l/min

550 mbar

Filter

0 +80

mbar

110 mbar

-20 + 100

mbar

-

-20 mbar

170 mbar

+

PATIENT

MONNAL D2

PATIENT CIRCUIT

15YM002100 - Rev 3 - December 1999

2 - OPERATION

2.3 Troubleshooting

2.3.1 Ventilation problems

MONNAL D2

OBSERVATIONS

No ventilation

The compressor does not

operate, the clock is not

working and there is no

“mains power fault” alarm.

The compressor does not

operate, the clock is not

working, but the “mains

power fault” alarm trips.

The compressor does not

operate, but the clock is

working.

SYMPTOMS

- On/Off button not pressed

in.

- Defective electronic unit.

- No electrical supply.

- Defective machine supply

fuse(s).

- Compressor on/off switch

not engaged

- Compressor overheating

(internal thermal circuit

breaker tripped).

REMEDIES

- Press the on/off button.

- Replace the unit.

- Check that the machine is

properly plugged in.

- Replace the F1A fuse(s).

- Switch on the compressor

(switch on rear panel on old

models).

- Check the air vents

- Recondition or replace the

compressor.

The compressor operates,

but the reservoir bag does

not inflate and the Pmin

alarm trips.

The compressor operates,

the reservoir bag inflates

and deflates, but the Pmin

alarm trips.

The compressor operates

but the clock is not

working and the “mains

power fault” alarm trips.

- Ventilation button is in off

position (flowmeter shows 0)

and the fresh gas supply is

zero.

- Automatic triggering at

wrong time.

- Expiratory valve

malfunction.

- Defective patient circuit.

- Defective fuse.

- Defective electronic unit.

- Open the ventilation tap

and/or supply the MONNAL

D2 with fresh gas.

- Press the SD (TS) button

(trigger sensitivity).

- Check the expiratory

diaphragm and its tube.

- Check the patient circuit

very carefully.

- Replace the F100 mA fuse

- Replace the unit.

16YM002100 - Rev 3 - December 1999

2 - OPERATION

MONNAL D2

OBSERVATIONS

Insufficient ventilation

Failure of Controlled

Assisted Ventilation

The “TRIGGER” LED is

permanently lit up.

The “TRIGGER” LED

does not light up.

SYMPTOMS

- Leak on patient circuit.

- Bacteriological filter assembly

not airtight.

- Expiratory valve collector

wrongly connected.

- Automatic triggering.

- Trigger sensitivity set around 20 mbar.

- Electronic defect.

REMEDIES

- Check patient circuit

assembly.

- Disassemble and reassemble the assembly.

- Check the collector and

its membrane.

- Set the trigger sensitivity

correctly (SD/ TS).

- Set the trigger sensitivity

correctly .

- Check the power supply

to the LED and/or Replace

the electronic unit.

Failure of Controlled

Ventilation

The “TRIGGER” LED

lights up.

Failure of Pmin

disconnection alarm

The Pmin alarm is

permanently triggered.

The Pmin does not trigger.

No humidification

(models with humidifier

socket)

- Ventilatory parameters

wrongly set.

- Wrong setting.

- Leak on the pressure sensor

circuit.

- Electronic defect.

- Humidifier not connected.

- Humidifier socket fuse blown.

- Set the ventilatory

parameters correctly.

- Set the Pmin sensitivity

correctly.

- Check that there are no

internal leeks.

- Replace the Pmin card.

- Plug in the humidifier

card.

- Replace the fuse.

17YM002100 - Rev 3 - December 1999

Loading...

Loading...