Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SPCW8 8 Inch Dual Voltage Speaker

for Fire and General Signaling Systems

Ceiling Speaker: SPCW8 with listed enclosure

Intended for use with separately sold tile support bracket: SB-SPC8

PRODUCT SPECIFICATIONS

Standard Operating Temperature: 32°F to 120°F (0°C to 49°C)

Humidity Range: 10 to 93% Non-condensing

Nominal Voltage: 25 Volts or 70.7 Volts

Maximum Supervisory Voltage: 50 VDC

Speaker Frequency Range:

Power Settings: ⅛, ¼, ½,1,2, 4, 8 Watts

Input terminal wire gauge: 12 to 18 AWG (2.5 mm²)

DIMENSIONS FOR PRODUCTS AND ACCESSORIES

Ceiling Speaker Diameter Depth

SPCW8 Speaker with grill 12.8” 325.1mm 2.7” 68.6mm

SPCW8 Speaker with back can 12.8” 325.1mm 4.2” 106.7mm

Tile Support Bracket Length Width Diameter opening

SB-SPC8 23.75” 603.3mm 4.125” 104.8mm 10.75” 273.1mm

NOTICE: This manual shall be left with the owner/user of this equipment.

BEFORE INSTALLING

Please read the System Sensor Voice Evacuation

Application Guide, which provides detailed information on speaker notification devices, wiring

and special applications. Copies of this manual are

available from System Sensor. NFPA 72, CAN/ULC

S524 and NEMA guidelines should be observed.

Important: The notification appliance used must be

tested and maintained following NFPA 72 requirements.

GENERAL DESCRIPTION

System Sensor series of notification appliances offer

a wide range of audible and visible devices for life

safety notification. The SPCW8 speaker is designed

to be used at either 25 or 70.7 volts, with field selectable tap settings from ⅛ to 8 Watts. These products are designed for high efficiency sound output

with low total harmonic distortion to offer high fidelity sound output.

Its clear audibility is designed to meet life safety

needs from fire to emergency communication messages. With its wide frequency range it can also

be used for general signaling such as paging and

background music. The SPCW8 speaker is listed

1 I56-0005-000R

05-20

400 – 4000 Hz (Fire Alarm)

200Hz – 15KHz (General Signaling)

to ANSI/UL 1480, CAN/ULC S541 and CSA C22.2

No. 205 requirements for public mode and general

signaling applications as well as ANSI/UL 2043 plenum rated. Speaker is suitable for indoor and damp

installations.

FIRE ALARM SYSTEM CONSIDERATIONS

All wiring must be installed in compliance with the

National Electrical Code (NEC , Canadian Electrical Code) and applicable local codes. System Sensor

recommends installing fire alarm speakers in compliance with NFPA 72, ANSI/UL 1480 , CAN/ULC

S524 and NEC 760.

WIRING AND MOUNTING

All wiring must be installed in compliance with the

National Electric Code and the local codes as well as

the authority having jurisdiction. Wiring must not

be of such length or wire size which would cause

the notification appliance to operate outside of its

published specifications. Improper connections can

prevent the system from alerting occupants in the

event of an emergency.

Wire sizes up to 12 AWG (3.31 mm²) may be connected to the wiring terminals. The terminals are

pre-set to accommodate 12 AWG wiring.

3825 Ohio Avenue, St. Charles, Illinois 60174

800/736-7672, FAX: 630/377-6495

www.systemsensor.com

MOUNTING BOX OPTIONS

SPEAKERS

Supplied Enclosure

I56-0005-000R

Page 2

CAUTION

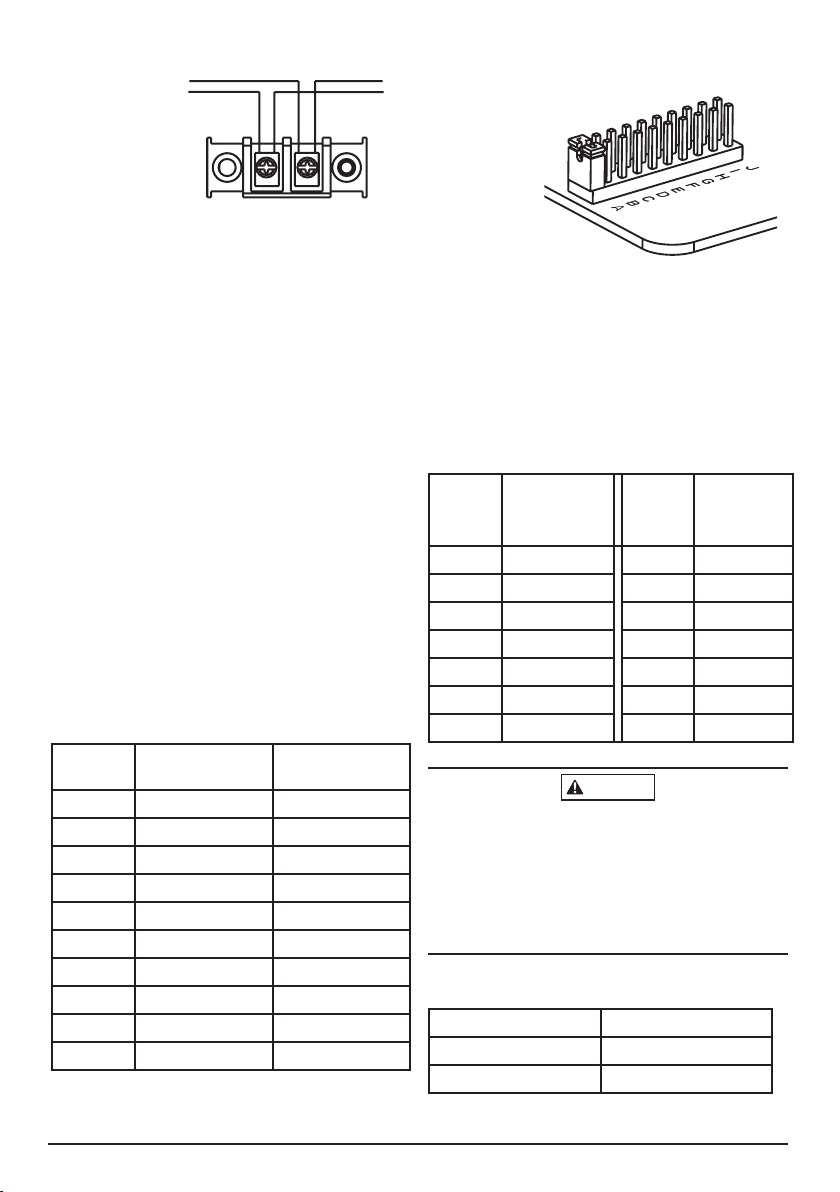

FIGURE 1. WIRING DIAGRAM

FROM PRECEDING

SPEAKER OR

FIRE ALARM

CONTROL PANEL

(FACP)

A0506-00

TO NEXT SPEAKER

OR END OF LINE

RESISTOR (EOLR)

FIGURE 2. JUMPER SETTINGS

FOR SPEAKER VOLUME

A0507-00

Make wire connections by stripping about 3/8” of

insulation from the end of the wire. Then slide the

bare end of the wire under the appropriate clamping plate and tighten the clamping plate screw.

1. Connect the speaker as shown in Figure 1.

2. Set speaker volume by selecting voltage input

jumpers as shown in Figure 2.

3. Mount according to instructions for the application’s appropriate configuration.

WIRING TERMINALS

1. Speaker Positive (+). Line in and out

2. Speaker Negative (COM). Line in and out.

NOTE: Do not loop electrical wiring under terminal

screws. Wires connecting the device to the control

panel must be broken at the device terminal connection in order to maintain electrical supervision.

SET SPEAKER VOLUME

In order to select the tap settings for given voltage

input (25V or 70.7V) select the jumper selections as

noted. Use the jumper connector to select tap setting for the desired speaker volume.

Jumper

Selection

Voltage Input

25V

Voltage Input

70V

A 8W

B 4W

C 2W

D 1W 8W

E ½W 4W

F ¼ W 2W

G ⅛W 1W

H ½W

I ¼ W

J ⅛W

AVAILABLE POWER SETTINGS

System Sensor offers a wide range of power settings

for your life safety needs, including ⅛,¼,½,1, 2, 4

and 8W.

Sound levels data per UL 1480 and CAN/ULC-S541

can be found in Table 1. Directional characteristics

can be found in Table 2.

TABLE 1. SOUND LEVELS FOR EACH TRANSFORMER POWER SETTING

Anechoic

Wattage

Setting

Reverberant

(dBA @ 10ft)

Wattage

Setting)

(dBA @

10ft)

⅛ W 75 ⅛ W 82

¼ W 78 ¼ W 85

½ W 81 ½ W 88

1 W 84 1 W 91

2 W 87 2 W 94

4 W 90 4 W 97

8W 93 8 W 10 0

Signal levels exceeding 130% rated signal voltage

can damage the speaker. Consequently, an incorrect

tap connection may cause speaker damage. This

means that if a 25V tap is selected when a 70.7V

amplifier is being used, speaker damage may result.

Therefore, be sure to select the proper taps for the

amplifier voltage/input power level combination

being used.

TABLE 2 DIRECTIONAL CHARACTERISTICS

Angle (degrees) Decibels

±30° -3dB

±60° -6dB

2 I56-0005-000R

05-20

Page 3

CAUTION

FIGURE 3 BACK CAN

KNOCKOUTS (5)

TIE-OFF TABS (4)

SCREW HOLES (8)

TIE-OFF SLOT (4)

HORSESHOE TAB (4)

FIGURE 4 REMOVING KNOCKOUTS

A0508-00

SUPPLIED BACK CAN

¾ inch knockouts are provided for conduit entry

way. Compatible with plenum rated cable and plenum whip flex conduit.

To remove the ¾ inch knockout, we recommend

you use a flat head screwdriver, place the blade of

the flat head screwdriver in the inner edge of the

knockout. Strike the screwdriver as you work your

way around as shown in Figure 4:

FLUSH MOUNTING INSTALLATION

1. Connect field wiring to terminals, as shown in

Figure 1.

2. Select the power tap settings using the jumper for

⅛, ¼, ½, 1, 2, 4, 8W.

3. Mount speaker to supplied back can using

mounting screws provided.

Factory finish should not be altered: Do not paint!

FIGURE 5 CEILING TILE WITH BACK CAN

A0509-00

CEILING TILE INSTALLATION (WITH BACK CAN)

1. Place ceiling tile with finished surface facing

up over a large garbage can (provides support and

saves clean up time).

2. Cut hole in the center of the ceiling tile using the

SB-SPC8 tile support opening as a template.

3. Flip the ceiling tile over and position the SB-SPC8

tile bridge on the unfinished side of the ceiling tile.

4. Punch out knockout in the supplied back can and

wire per the NEC. The back can is listed to accommodate plenum cable or plenum cable whip and

feed cable or whip through the knockout.

5. Install the SB-SPC8 tile bridge to the backcan

using the supplied clips and customer supplied

screws.

6. Connect field wiring to terminals, as shown in

Figure 1.

7. Select the power tap settings using the jumper for

⅛, ¼,½, 1, 2,4,8W.

8. Install the ceiling speaker using (4) 8-32 screws

provided with the ceiling speaker, sandwiching the

SB-SPC8 tile bridge and ceiling tile in between. The

screws anchor into the extruded threaded holes in

the SB-SPC8 tile bridge.

KNOCKOUTS (5)

SCREW HOLES (8)

HORSESHOE TAB (4)

A0510-00

3 I56-0005-000R

05-20

Page 4

Please refer to insert for the Limitations of Fire Alarm Systems

WARNING

THE LIMITATIONS OF SPEAKERS

Always make sure that the individual speakers

are tested after installation per NFPA regulations.

The speakers may not be heard. The loudness of

the speaker meets (or exceeds) current Underwriters

Laboratories’ standards. However, the speaker may

not alert a sound sleeper or one who has recently

used drugs or has been drinking alcoholic bever-

ages. The speaker may not be heard if it is placed

on a different floor from the person in hazard or

if placed too far away to be heard over the ambient noise such as traffic, air conditioners, machinery or music appliances that may prevent alert

persons from hearing the alarm. The speaker may

not be heard by persons who are hearing impaired.

Three-Year Limited Warranty

System Sensor warrants its enclosed product to be

free from defects in materials and workmanship under

normal use and service for a period of three years

from date of manufacture. System Sensor makes no

other express warranty for this product. No agent,

representative, dealer, or employee of the Company

has the authority to increase or alter the obligations

or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the replacement of any part of the product which is found to be

defective in materials or workmanship under normal

use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll free number 800-SENSOR2

(736-7672) for a Return Authorization number, send

defective units postage prepaid to: Honeywell, 12220

4 I56-0005-000R

©2016 System Sensor. 05-20

Rojas Drive, Suite 700, El Paso TX 79936, USA.

Please include a note describing the malfunction

and suspected cause of failure. The Company shall

not be obligated to replace units which are found to

be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date

of manufacture. In no case shall the Company be

liable for any consequential or incidental damages

for breach of this or any other Warranty expressed

or implied whatsoever, even if the loss or damage is

caused by the Company’s negligence or fault. Some

states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This

Warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Loading...

Loading...